Risco iWISE QuadSEQ Grade 3 Installation Instructions Manual

Page 1

iWISE QUADSEQ Grade 3

The iWISE QUADSEQ Grade 3 is designed to meet DD243 requirements for sequential

confirmation and also meet PD6662, EN 50131-1 and EN50131-2-2

Grade 3 requirements.

The iWISE QUADSEQ Grade 3 includes built - in Triple EOL resistors for installation

simplicity, and active IR anti-masking for reliable detection of masking attempts.

iWISE QUADSEQ Grade 3 Main Features

iWISE QUADSEQ Grade 3

Installation Instructions

x PD6662, EN50131-1, EN50131-2-2 Grade 3

x Two PIR Detectors in a single housing with separate alarm outputs

x Two non-overlapping coverage patterns

x Coverage 12m

x Active IR Anti-Mask (up to 15cm)

x Built-in Triple EOL resistors, jumper selectable

x Wall and Cover tampers

x Opto - relays for low current consumption and long life time

x Remote and Local Self Test

x LED control input

x LED control polarity Jumpers

x 3 LEDs for easy walk test

x True Temperature Compensation

x Wall tamper proof swivel (optional)

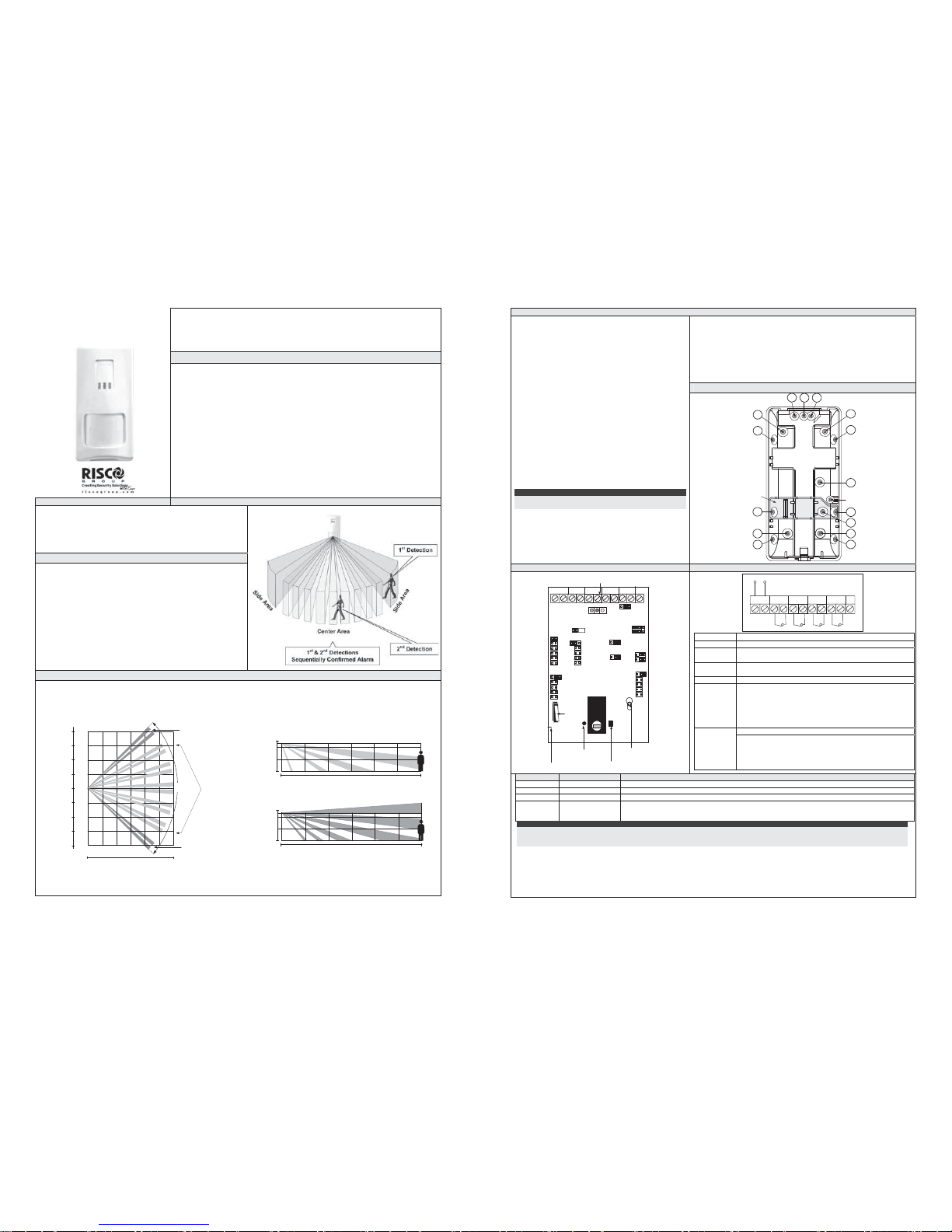

Principle of Operation 3D Image of the Application

The unit contains two independent detectors in a single housing. When

mounted in the corner of a room, one detector covers the two walls

(side area), while the second detector covers the center of the room.

When an intruder enters the room via a door or window, the side area

triggers. When the intruder then moves to the center of the room, the

second detector triggers, providing a sequentially confirmed alarm.

Installation Considerations

x Before installing, study the space to be protected carefully in order to

choose the exact location of the unit for the best possible coverage.

x Corner installation is recommended. The detection side areas

(which are two curtain zones at 80° to each other), should cover the

room walls, and therefore any vulnerable doors and windows.

x The additional internal PIR detector covers the center area of the

room. Recommended mounting height is 2.4m.

x Avoid installations where rotating machines (e.g. fans) are normally

in operation within the coverage pattern. Do not mount the detector

in direct sunlight or near any heat sources. Point the unit away from

glass exposed to the outdoors and objects that may change

temperature rapidly.

x The installation surface should be solid, smooth and vibration free.

Coverage

0m 2 4 6 8 10 12m

90

0

Top View

0m

2

4

6

8

2

4

6

8

Side Area

Center Area

Side Area

Side View - Center Area

0m 2 4 6 8 10 12m

0m

2

2.4m

Side View - Side Area

0m 2 4 6 8 10 12m

0m

2

2.4m

Page 2

Installation

8. Seal the remaining holes with a sealant compound.

9. Reinstall the PCB into its desired position.

10. Wire terminal (see Terminal Wiring section)

11. Set jumpers (see Jumper Settings section).

12. Install the front cover back to its place (in a reverse sequence of the

removal).

13. Reapply electrical power to the detector for correct AM calibration.

Recalibrate after every successive removal of cover.

14. Perform a Walk test (see Walk Test section).

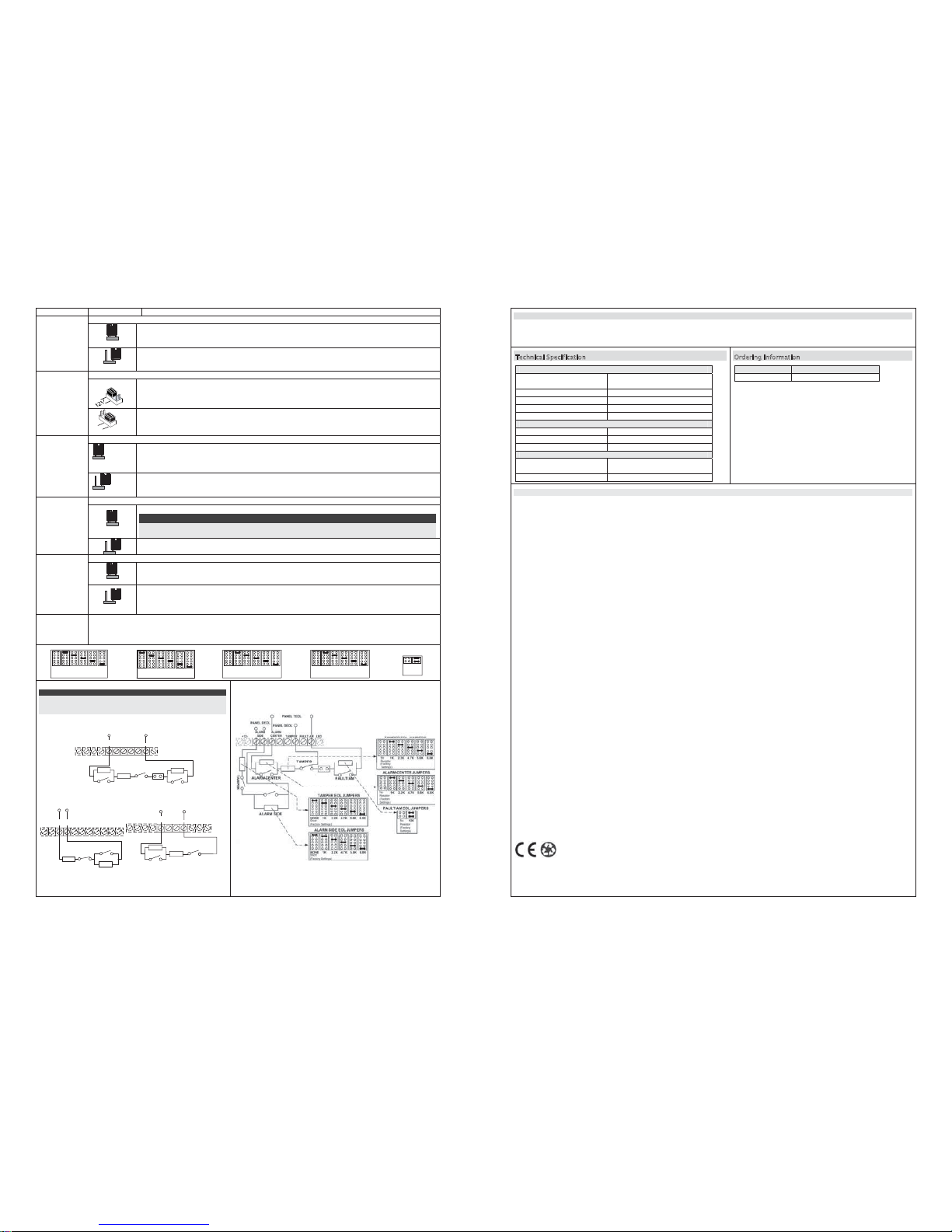

Back Plate Knockouts

1. To open the front cover:

x Turn the front cover locking screw counter-

clockwise.

x Insert a screwdriver through the dedicated slot/s to

open the detector's front cover.

2. Loosen the PCB holding screw, located on the right

hand side of the PCB and slide the PCB down until the

screw reaches the widened opening. Lift the PCB up to

remove.

3. Mounting - iWISE QUADSEQ Grade 3

can be mounted

either on a flat surface or on a wall corner (corner

mounting).

x Using a suitable tool, open the following

knockouts on the detector’s base.

x A1, A2 and A3: External cables knockouts (open

out at least one wiring knockout)

x A4, A6, A9, A12, and A15: Wall mounting

knockouts

x When using a swivel adapter use the A4, A6, and

A15 openings to connect the detector to the

swivel adapter.

x A5 and A10: Right corner mounting knockouts

x A11 and, A14: Left corner mounting knockouts

Note:

The A7, A8 AND A13 knockouts are not to be used in this

configuration.

4. Use the base as a template for marking the installation

holes (mark through the mounting holes).

5. Put the base in a safe place, drill the required holes in

the surface or in the corner, and insert anchors (if

necessary).

6. Insert external cables through the cable hole/holes.

7. Mount the rear cover in its final location.

Range

Adjustment

Bolt Thread

A1 A2 A3

A6

A7

A8

A9

A10

A12

A11

A13

A4

A5

A15

A14

Back tamper

“Breakable” plate

PCB View Terminal Wiring/Outputs Activation

Tamper

Switch

Range

Adjustment

Screw

Terminal

Block

Active IR

Anti-Mask Receiver

FAULT/AM

TAMPER

-12 +

LED

ALARM

SIDE

LEDS

LONG

ALARM

Active IR

Anti-Mask Transmitter

Range Scale

Mark

ALARM

CENTER

TAMPER EOL

LED

INPUT

2.2K

1K

4.7K

5.6K

6.8K

LEDS

SIDE

FAULT/AM

CENTER

ALARM CENTER

ON

SENSITIVITY

HIGH LOW

0V

12K

SHORT

AM E.O.L

SELF TEST

LOC REM

INT EXT

CONF

12V

2.2K

1K

4.7K

5.6K

6.8K

2.2K

1K

4.7K

5.6K

6.8K

NONE

OFF

SIDE

TAMPER

(upper) EOL

FAULT/AMTAMPER

12VDC

LED

ALARM

SIDE

ALARM

CENTER

+ -

Terminal Description

- 12 +

12VDC Input

ALARM

SIDE

Normally closed output

ALARM

CENTER

Normally closed output

TAMPER

Normally closed output

FAULT/AM

Normally closed output

The FAULT/AM output opens in the following events:

x Detector is masked (Alarm Side and Alarm Center

also open in this case)

x Self test failed

x Input voltage is low (6VDC - 8VDC)

See LED INPUT jumper for settings

LED

When an activation signal is applied to the LED input of the

terminal block, LEDs will be disabled (see also Self Test in

Jumper Settings table).

LEDs are enabled if nothing is connected (unless LED jumper

is OFF).

LED State Description

Yellow On Center Area PIR detection

Green On Side Area PIR detection

Red Flashing Fault / Anti Masking detection ***

All LEDs

Flashing

(One after another)

At Power - up, the LEDs will blink continuously, one after the other, until the end of the warm-up period (2-3 minutes).

At the end of power-up period the RED LED will continue to flash until the end of AM calibration.

Important: Always close the front cover prior to applying power, for correct AM calibration.

Notes:

* To enable LED indications, the LED jumper has to be in ON position and no signal is attached to the LED terminal.

** When an activation signal (see LED Activation jumper for settings) is applied to the LED input of the terminal block, LEDs will be disabled.

*** AM indication continues until masking is removed, and during power up AM calibration.

Page 3

Jumper Position Function

Used to determine the sensitivity of the center PIR area.

HighHigh Sensitivity selection

SENSITIVITY

(Default)

Low: Low Sensitivity selection

Used to determine the polarity of the external input.

(Default)

12V: 12v has to be connected in order to disable the LED’s.

GND or N.C. has no influence on the LED’s status. (see self test jumper configuration)

LED INPUT

0

V

0V: The GND has to be connected in order to disable the LED’s.

12v or N.C. has no influence on the LED’s status. (see self test jumper configuration)

Used to determine the relay’s activation logic.

INT: The detector’s alarm activation is determined by the detector’s internal logic. Intruder detection on

one of the PIR’S detection areas (side or center) activates the appropriate LED only.

If both PIR’S (side and center) are triggered within a time window of 2 minutes, then both side and

center relays are activated

CONF

(Default)

EXT: The security panel determines the detector’s alarm activation. Intruder detection on one of the

detection zones (side or center) activates the appropriate LED and Relay only.

Used to determine the operation of the detector’s LEDs

(Default)

ON: LEDs are enabled

Note:

When an activation signal (see LED Activation jumper for settings) is applied to the LED input of the

terminal block, LEDs will be disabled.

LED

OFF: LEDs are disabled

Used to test the PIR channels functionality

LOC (Local Self Test): If there is no alarm detection within 1 hour from previous detection, the detector

will self test both PIR channels.

In case the local self test fails, the FAULT/AM Relay is activated for a period of 2.5 seconds.

SELF TEST

(Default)

REM (Remote Self Test): Remote Self Test is activated when the LED terminal input is switched from

DISABLE to ENABLE mode (see LED Activation jumper for settings).

In case the remote self test passes, the Alarm Relays are activated for a period of 5 seconds.

In case the test fails, FAULT/AM Relay is activated for a period of 2.5 seconds.

EOL

RESISTORS

JUMPERS

The jumpers are used when connecting the detector to a DEOL or TEOL Zone. The jumpers allow the selection of

TAMPER, TAMPER (upper), ALARM CENTER and ALARM SIDE E.O.L resistors (1K, 2.2K, 4.7K, 5.6K or 6.8K),

according to the control panel. An additional double jumper allows the connection of 12K FAULT/AM E.O.L resistor (see

EOL Resistors Scheme).

TAMPER EOL JUMPERS

1K

No

Resistor

(Default)

2.2K 4.7K 5.6K 6.8K

TAMPER (upper) EOL JUMPERS

1K

Short

(Default)

2.2K 4.7K 5.6K 6.8KNONE

ALARM CENTER JUMPERS

1K

No

Resistor

(Default)

2.2K 4.7K 5.6K 6.8K

ALARM SIDE EOL JUMPERS

1K

No

Resistor

(Default)

2.2K 4.7K 5.6K 6 .8K

FAULT/AM EOL

JUMPERS

12K

No

Resistor

(Default)

EOL Resistors Scheme

Note:

Side & Center area can be connected to DEOL or

TEOL areas on the panel as illustrated below.

TAMPER

ALARM

CENTER

ALARM

SIDE

TAMPER+12- LED

FAULT/AM

TEOL ZONE

FAULT AM

ALARM

CENTER

+12- LED

ALARM SIDE

TAMPER FAULT AM

TAMPER

DEOL/TEOL

ZONE

ALARM SIDE

ALARM

CENTER

TAMPER

ALARM

CENTER

+12-

FAULT AM

LED

DEOL ZONE

ALARM

SIDE

TAMPER

ALARM

CENTER

Page 4

Walk Test

Two minutes after applying power (warm-up period), walk test the Detector over the entire protected area to verify proper operation of the

unit.

Important: Always close the front cover prior to applying power to the detector.]

7HFKQLFDO6SHFLILFDWLRQ

Electrical

Current consumption 12mA at 12VDC, 39mA at

12VDC (max. with all LEDs ON)

Voltage requirements 9 -16VDC

Alarm contacts 24VDC, 0.1A

Tamper contacts 24VDC, 0.1A

FAULT/AM contacts 24VDC, 0.1A

Environmental

RF immunity According to EN50130-4

Operating temperature -20°C to 55°C (-4°F to 130°F)

Storage temperature -20°C to 60°C (-4°F to 140°F)

Physical

Size 127.6 x 64.2 x 46.6 mm

(5 x 2.5 x 1.84 in.)

Weight 115 gr. (4 oz)

2UGHULQJ,QIRUPDWLRQ

Part Number Description

RK800QS0000A iWISE QUADSEQ Grade 3

RISCO Group Warranty

RISCO Group and its subsidiaries and affiliates ("Seller") warrants its products to be free from defects in materials and workmanship under normal use for 24

months from the date of production. Because Seller does not install or connect the product and because the product may be used in conjunction with products

not manufactured by the Seller, Seller cannot guarantee the performance of the security system which uses this product. Seller's obligation and liability under

this warranty is expressly limited to repairing and replacing, at Sellers option, within a reasonable time after the date of delivery, any product not meeting the

specifications. Seller makes no other warranty, expressed or implied, and makes no warranty of merchantability or of fitness for any particular purpose.

In no case shall seller be liable for any consequential or incidental damages for breach of this or any other warranty, expressed or implied, or upon any other

basis of liability whatsoever.

Seller's obligation under this warranty shall not include any transportation charges or costs of installation or any liability for direct, indirect, or consequential

damages or delay.

Seller does not represent that its product may not be compromised or circumvented; that the product will prevent any persona; injury or property loss by

burglary, robbery, fire or otherwise; or that the product will in all cases provide adequate warning or protection. Buyer understands that a properly installed and

maintained alarm may only reduce the risk of burglary, robbery or fire without warning, but is not assurance or a guarantee that such will not occur or that there

will be no personal injury or property loss as a result.

Consequently seller shall have no liability for any personal injury, property damage or loss based on a claim that the product fails to give warning. However, if

seller is held liable, whether directly or indirectly, for any loss or damage arising from under this limited warranty or otherwise, regardless of cause or origin,

sellers maximum liability shall not exceed the purchase price of the product, which shall be complete and exclusive remedy against seller. No employee or

representative of Seller is authorized to change this warranty in any way or grant any other warranty.

United Kingdom

Tel: +44-161-655-5500

technical@riscogroup.co.uk

Italy

Tel: +39-02-66590054

support@riscogroup.it

Spain

Tel: +34-91-490-2133

support-es@riscogroup.com

France

Tel: +33-164-73-28-50

support-fr@riscogroup.com

Belgium

Tel: +32-2522-7622

support-be@riscogroup.com

USA

Tel: +305-592-3820

support-usa@riscogroup.com

Brazil

Tel: +55-11-3661-8767

support-br@riscogroup.com

China

Tel: +86-21-52-39-0066

support-cn@riscogroup.com

Poland

Tel: +48-22-500-28-40

support-pl@riscogroup.com

Israel

Tel: +972-3-963-7777

support@riscogroup.com

PD6662, EN50131-1, EN50131-2-2 Grade 3 Class II

© RISCO Group 12/08 5IN800QS B

Loading...

Loading...