Page 1

English Italiano

DDTT AAMM GGrraaddee 3

HHiigghh CCeeiilliinngg MMoouunntt DDeetteeccttoorr

IInnssttaallllaattiioonn GGuuiiddee

3

Português

Françias Español

Nederlands

Page 2

Page 3

English

MMooddeell:: IInndd.. LLuuNNAARR 220000DDTTGG33

HHiigghh CCeeiilliinngg MMoouunntt DDeetteeccttoorr

IInnssttaallllaattiioonn GGuuiiddee

DDTT AAMM GGrraaddee 3

3

Page 4

General Description

The Industrial LuNAR DT AM Grade 3 (Ind. LuNAR 200DTG3) is a dual technology ceiling detector with

a mounting height of up to 8.6m (28ft) that incorporates RISCO Group’s Anti-Cloak™ Technology

(ACT™). The detector has an Intelligent Digital Signal Processing method that automatically adjusts the

alarm threshold and pulse count verification according to actual intruder crossing speed and

environmental factors, providing superior detection and false alarm immunity.

The Ind. LuNAR 200DTG3 can operate as a regular relay detector connected to any control panel, or as

an addressable BUS detector when connected to RISCO Group’s ProSYS control panel via the RS485

BUS.

Ind. LuNAR 200DTG3 Features

♦ PD6662, EN50131-1, TS50131-2-4 Grade 3

♦ Addressable Dual Technology detector with Anti-Cloak™ Technology

♦ Up to 8.6 m (28ft) mounting height

♦ 360

♦ 3 independent PIR channels for customized coverage

♦ Intelligent Digital Signal Processing – alarm verification and decision thresholds adjusted

♦ Built-in Triple EOL resistors, jumper selectable

♦ Active IR for Anti-Masking meeting TS50131 requirements

♦ Ceiling and cover tampers

♦ "Green Line" setting – for disabling the MW whe n the premises are occupied

♦ Opto–relays for low current consumption and long life

♦ Remote and Local Self Test

♦ Remote SET input

♦ Remote RC control input

♦ PIR coverage optimization by sliding the lenses

♦ Microwave Range Adjustment manually (analog trimmer) and remotely (digital setting)

♦ Trouble Indication (by LEDs or via communication)

♦ 3 Triple color LEDs for easy walk testing

♦ Advanced Remote control and diagnostics

♦ Reduced Power Consumption when connected to RISCO Group’s ProSYS

0

by 18m (60ft) diameter coverage pattern

according to actual intruder crossing speed

Ind. LuNAR 200DTG3 Installation Guide 2

Page 5

Remote Control and Diagnostic Features*

♦ Remote microwave adjustment enables one-man walk test.

♦ Diagnostic tools include detector input voltage reading and status of each PIR channel and

MW channel (signal voltage and noise levels), AM channel (signal voltage), SW version

verification.

♦ Remote display and control of detector settings: MW adjustment, ACT on/off, LEDs on/off.

♦ Remote trouble indication (Pass/Fail) for the PIR, MW and power supply input

♦ Control of MW bypass (during MW trouble) and MW disable during Disarm ("Green Line")

when connected to ProSYS.

*Via the optional Bi-Directional Infrared Remote Control, or the ProSYS Upload/Download

Software and Keypad.

Detection Method

The Ind. LuNAR 200DTG3 detection is based on:

♦ PIR (Passive Infra-Red) - which responds to changes in the IR radiation caused when an

intruder crosses the protected area.

♦ MW (Microwave) - which transmits signals and analyzes the frequency changes of the

reflected echo from an intruder using Doppler Effect.

ALARM is initiated only when both technologies trigger si multaneously (except for certain situations in

the ACT mode-see page 4 – “How ACT™ Works”), thus greatly reducing the possibility of false alarms.

English

Ind. LuNAR 200DTG3 Installation Guide 3

Page 6

How ACT™ Works

Anti-Cloak™ Technology (ACT™) provides the benefits of DT (Dual Technology) while avoiding its

drawbacks. This patent pending innovation has created a new standard for detectors.

Dual Technology, a combination of PIR +MW, was an important development for the security

industry...but, it has 2 major weaknesses:

IR emission blocking cloaks employed by intruders enable avoidance of detection.

PIR sensitivity is reduced when the protected area’s ambient temperature approaches body

temperature.

Responding to requests from its customer base to solve these pressing problems, RISCO Group

developed ACT™ -a revolutionary anti-cloak solution.

ACT™ prevents the alarm system from being bypassed, by neutralizing attempts to camouflage IR

radiation. Using unique pattern recognition algorithms, ACT™ distinguishes between the weak IR

signal of a moving intruder and the background noise and thermal interferences that may cause

false alarms.

Once the presence of an intruder is recognized, ACT™ switches the system automatically from dual

channel PIR/MW mode to single channel MW mode for a predetermined period of time, in order to

trigger an alarm utilizing the MW channel, and then returns to dual channel mode.

In the second case, when the ambient temperature approaches body temperature, the ACT™

switches to microwave-only detection.

Offering significantly higher detection capabilities as well as immunity from false alarms, ACT™

thwarts even the most sophisticated burglars.

4

Ind. LuNAR 200DTG3 Installation Guide

Page 7

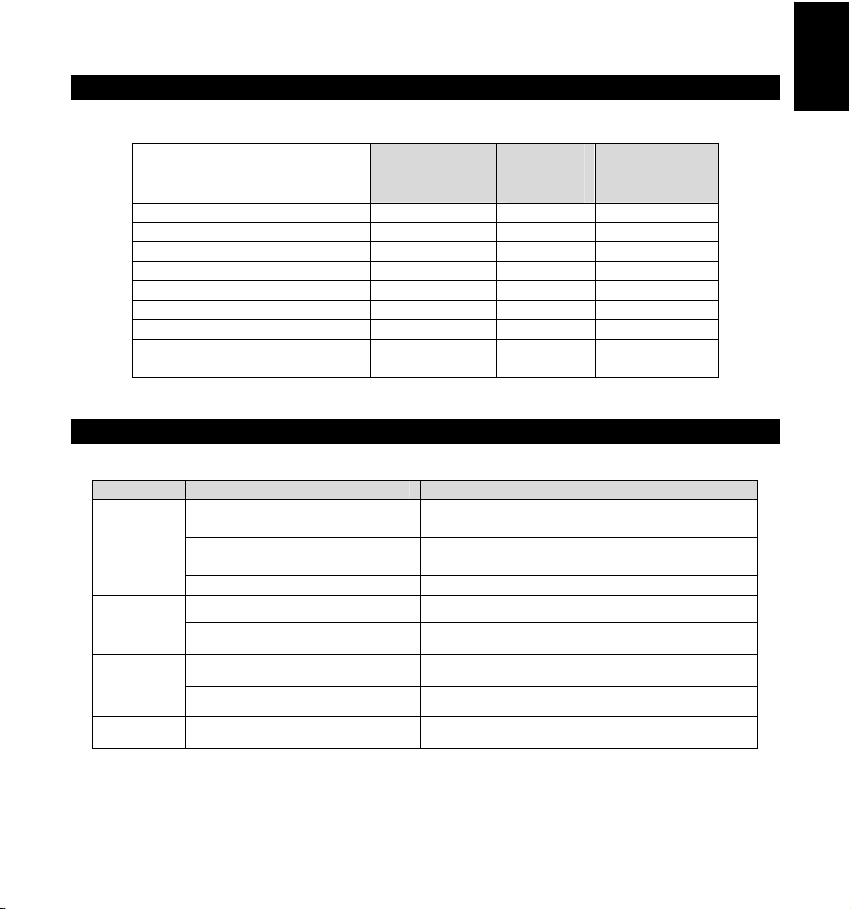

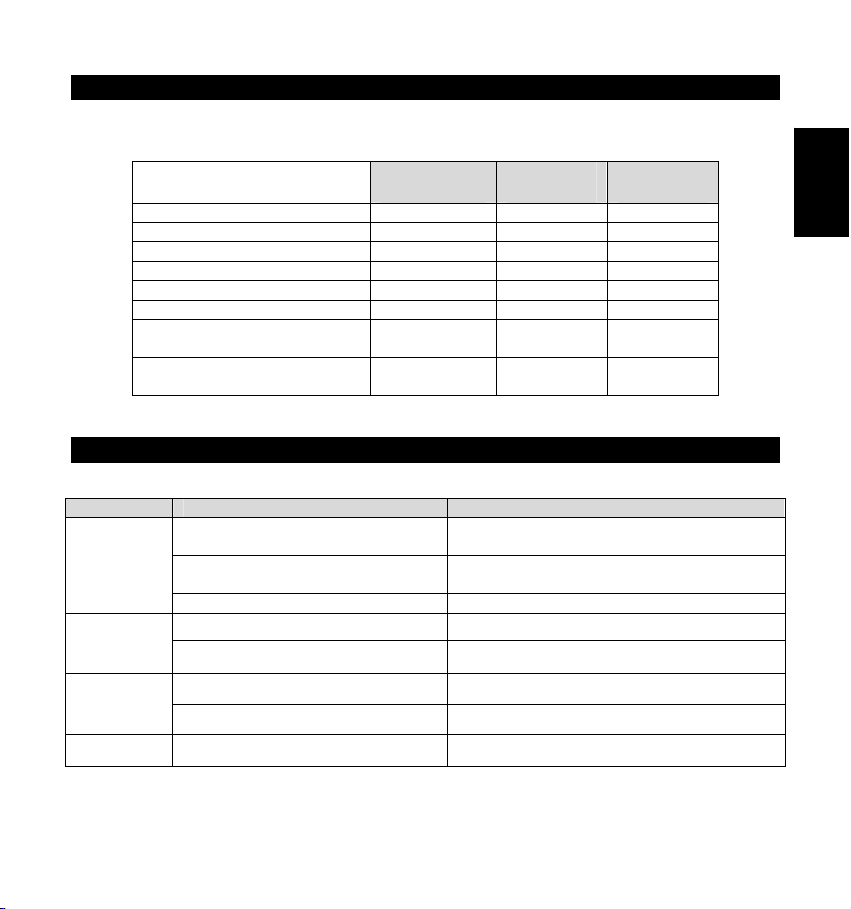

Ind. LuNAR 200DTG3 Configuration Options

The Ind. LuNAR 200DTG3 can be configured and/or diagnosed remotely via one of the options:

ACT Mode

LEDs

MW Sensitivity

Diagnostics

Status/Trouble/Info Reports

AM Diagnostics

MW Bypass

MW Disable on Disarm

("Green Line")

Manual

configuration

9 9 9

9 9 9

(by trimmer) 9 9

9

-

-

- -

- -

- -

Remote

Control

Device

9 9

9 9

ProSYS Bus

Control

9

9

9

LED Display

The three Tri color LEDs in the Ind. LuNAR 200DTG3, operate as herein described:

LED STATE MEANING

Steady

Red

Green

Orange

All LEDs

Flashing with low frequency

Flashing with high frequency AM detection

Steady Microwave detection

Flashing Trouble in the MW channel

Steady PIR detection

Flashing Trouble in the PIR channel

Flashing with change of color Upon power up

Detector alarm (simultaneous PIR and MW

detection)

Indicates malfunctioned communication

with ProSYS

English

Ind. LuNAR 200DTG3 Installation Guide 5

Page 8

INSTALLATION

Preliminary steps:

♦ Before installation, study the space to be protected carefully in order to choose the exact

location of the unit for the best possible coverage.

♦ Never install the Ind. LuNAR 200DTG3 in an environment that causes an alarm condition in

one technology.

♦ Avoid installations where rotating machines (e.g. fans) are normally in operation within the

coverage pattern. Point the unit away from glass exposed to the outdoors and objects that

may change temperature rapidly.

♦ Do not mount the detector in direct sunlight or near any heat sources. Detection sectors

should be pointed either towards a wall, floor but not towards windows or curtains. The

installation surface should be solid, smooth and vibration free

♦ Eliminate interference from nearby outside sources.

♦ For optimum detection, select a location likely to intercept an intruder moving across the

coverage pattern.

♦ Recommended mounting heights that allow 18m (60ft) detection, are from 3.7m to 8.6m.

♦ The detector must be mounted on the ceiling, preferably in the center of the room.

Ind. LuNAR 200DTG3 Installation Guide 6

Page 9

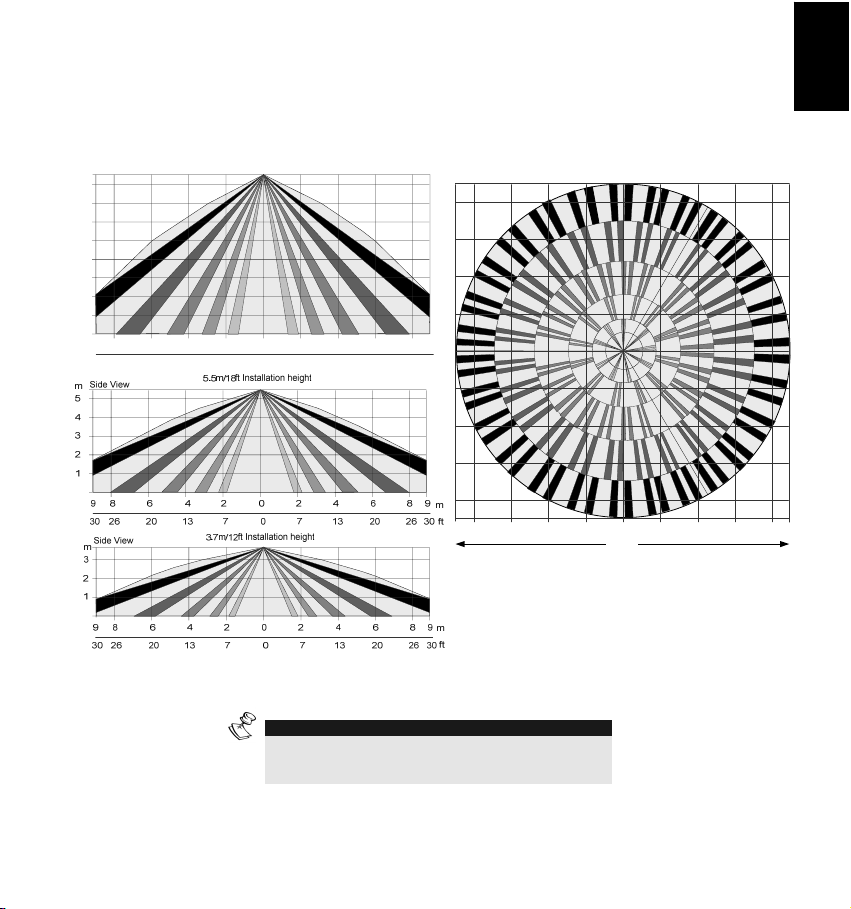

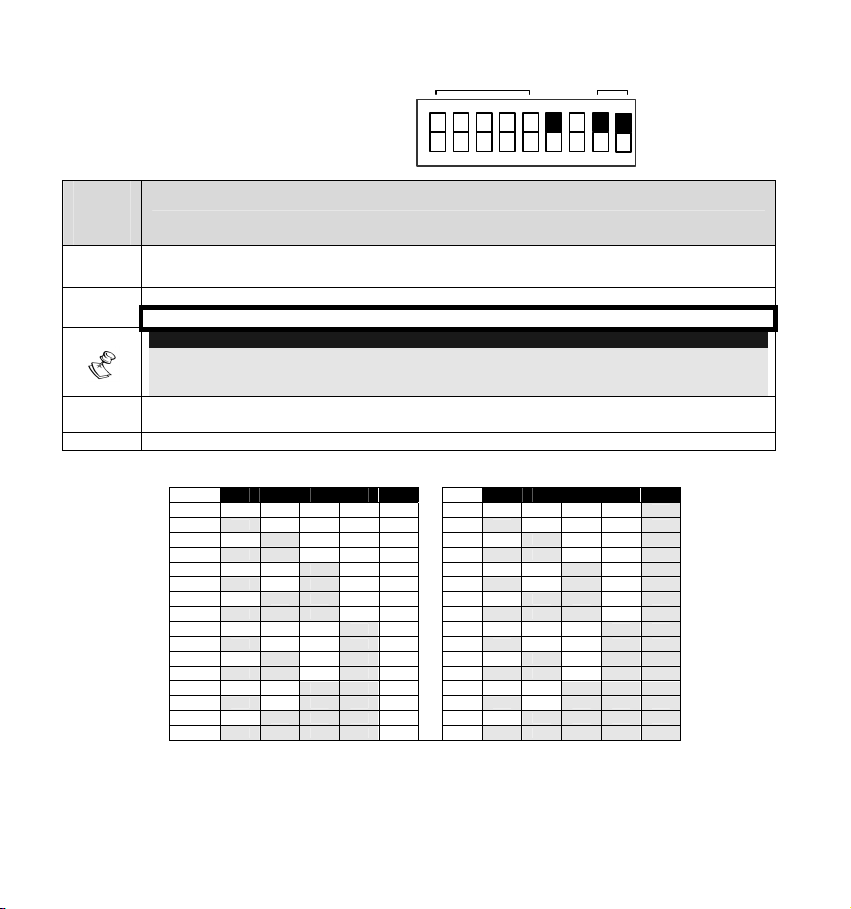

Typical Ind. LuNAR 200DTG3 detection coverage and installation height, are illustrated below:

m

8

7

6

5

4

3

2

1

Side View

8.6m/28ft Installation height

02468998 6 4 2

0 7 13 20 26 3030 26 20 13 7

m

ft

Top View

0 7 13 20 26 3030 26 20 13 7

English

ft

02468998642

18m/60"

NOTE:

When installing the Ind. LuNAR 200DTG3 detector in a

room occupied with high volume interfering elements,

Ind. LuNAR 200DTG3 Installation Guide 7

MW detection may be affected.

m

Page 10

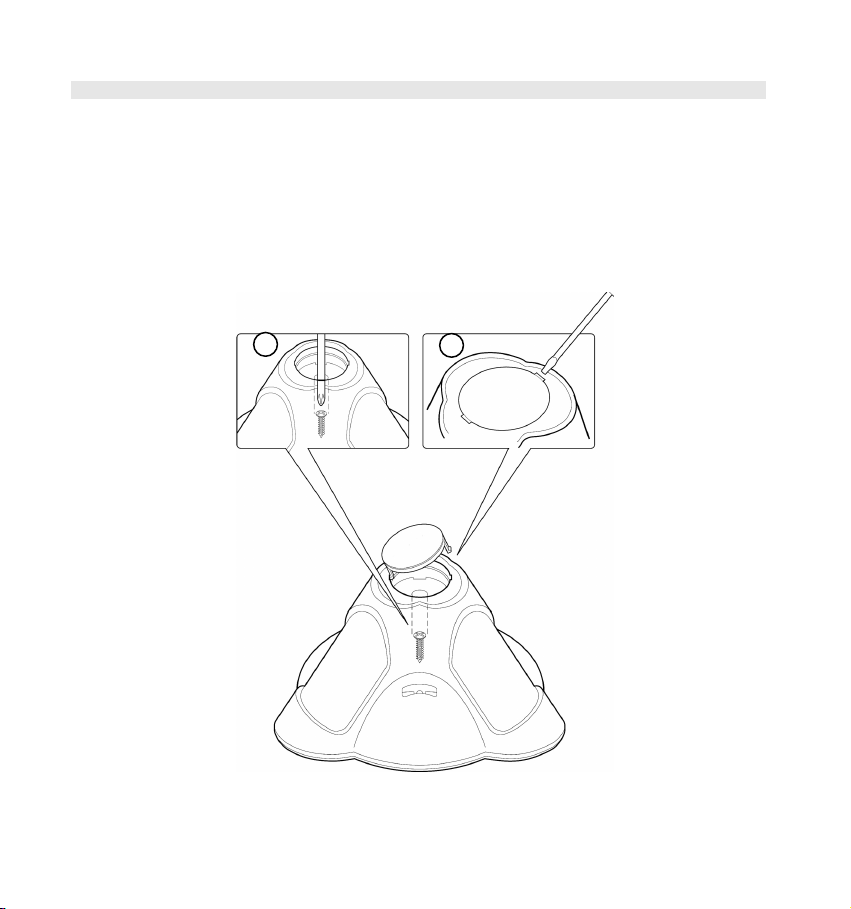

Installation Process:

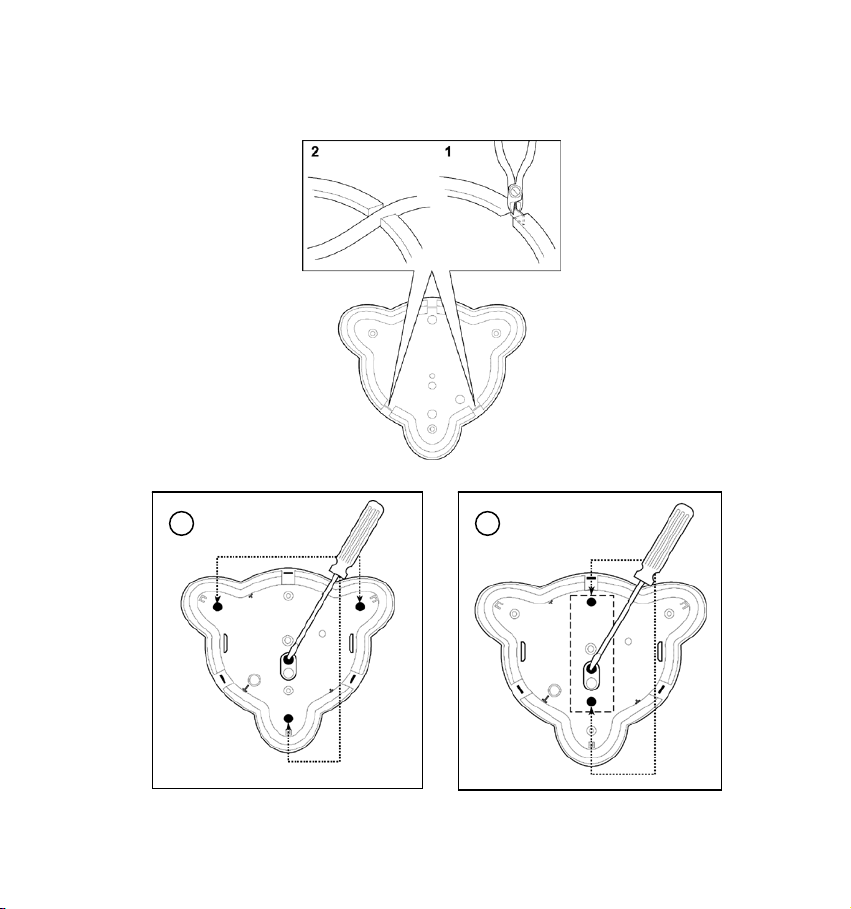

To open the detector (Figure 1), remove the cover by inserting a screwdriver (1) in the recess

between the detector’s protection cap and the cover. The cover will remain attached to the base of

the detector.

Using a Philips screwdriver, release the upper cover screw (2) and gently pull upward the detector’s

upper cover.

2

FIGURE 1

1

Ind. LuNAR 200DTG3 Installation Guide 8

Page 11

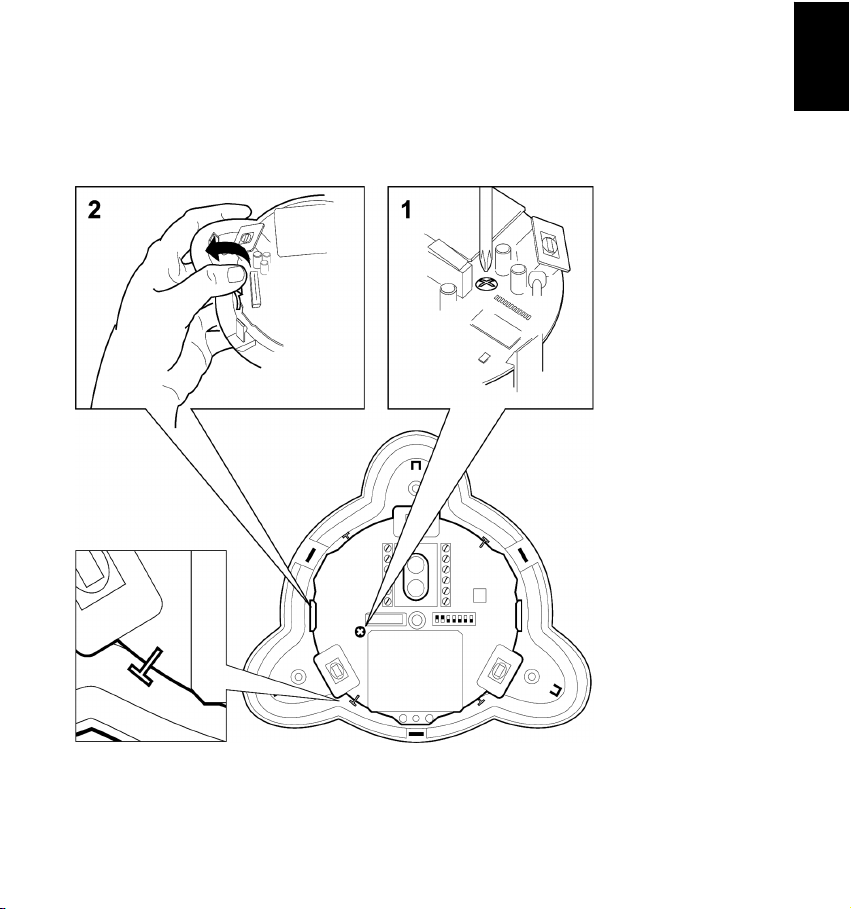

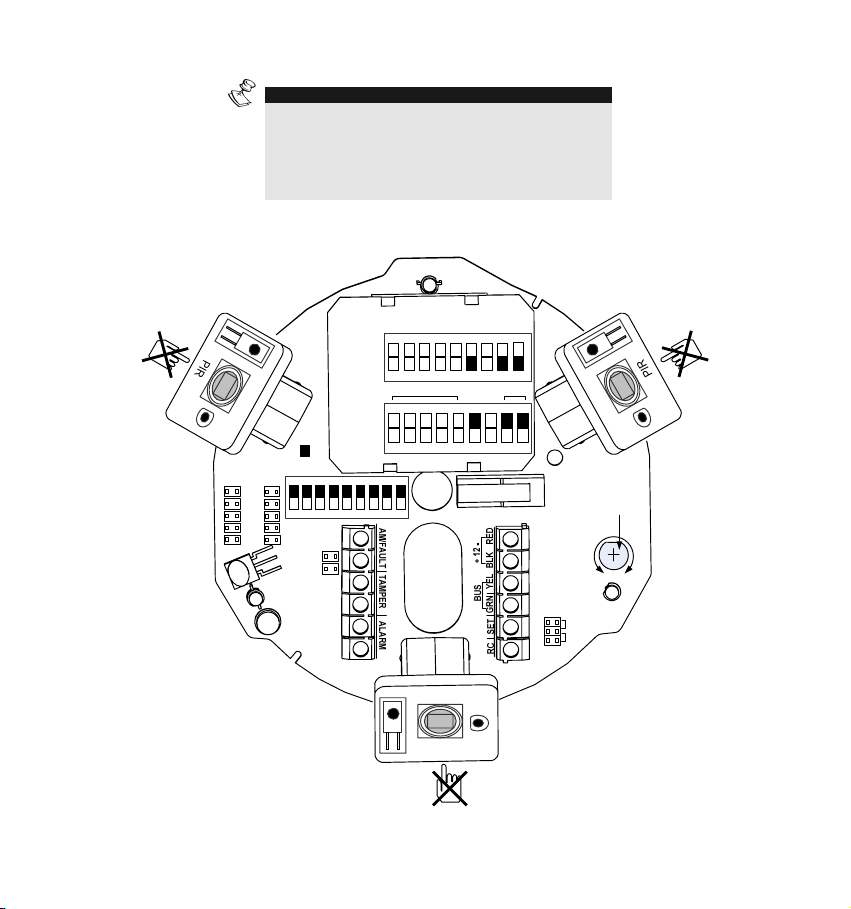

Release the PCB holding screw (Figure 2) located on the right hand side of the PCB (1), pull gently

the two release clips (2) outward and remove the PCB.

English

Do not touch

the PIR

FIGURE 2

sensors!

Ind. LuNAR 200DTG3 Installation Guide 9

Page 12

If required, open (Figure 3) the wiring channels knockout using a cutter (1, 2) and knockout holes in

the rear cover (3, 4) using a screwdriver.

FIGURE 3

3 4

Ind. LuNAR 200DTG3 Installation Guide 10

Page 13

Insert the cable via the cable opening (Figure 4) and connect the desired wires as described in

“Step 4- Wiring”.

English

FIGURE 4

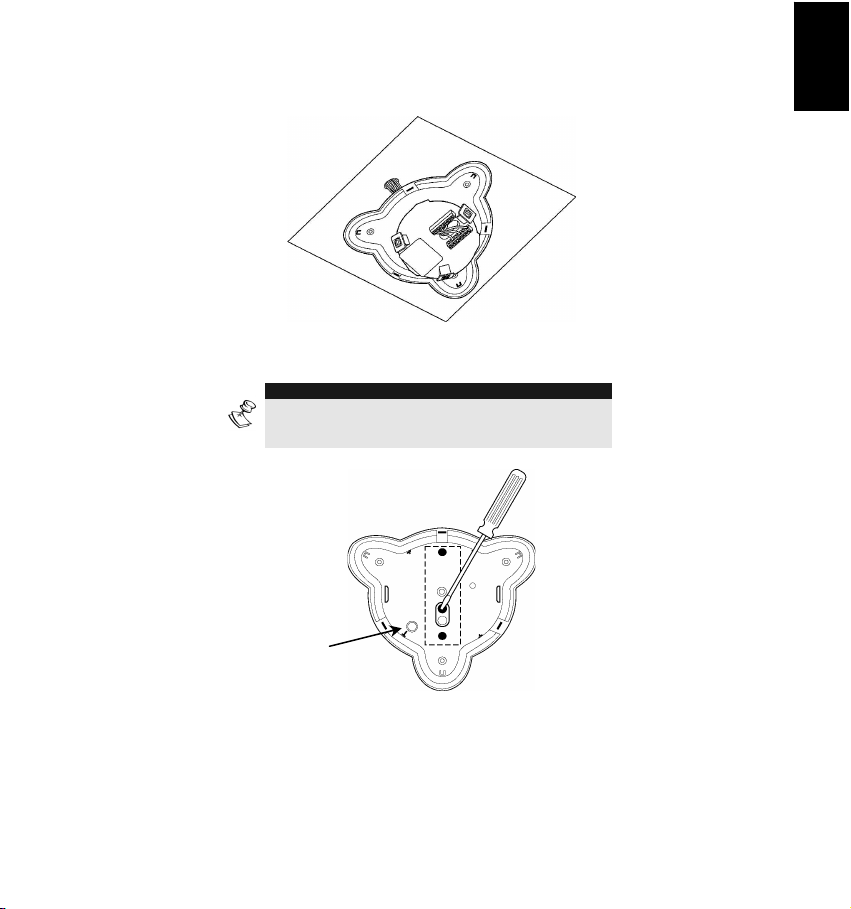

Mount the rear cover in its final location (Figure 5) using the 3 mounting screws and seal the

remaining open holes with sealant.

NOTE:

When a single gang box is used, use 2 additional

screws to mount the base to the single gang box.

The back tamper cannot be used in this case!

FIGURE 5

Back

Tamper

Hole

Return the PCB to its previous location and verify that it is well secured by the holding clips and the

screw.

Ind. LuNAR 200DTG3 Installation Guide 11

Page 14

Perform lens adjustment and DIP switch settings as described in “Lens Adjustment” on page 12

and on page 15.

Mount the top cover on the detector’s base.

Tighten the top cover’s central screw.

Replace the detector’s protection cap.

NOTE:

If ceiling tamper is desired, break and open the ceiling

tamper hole at the detector’s base!

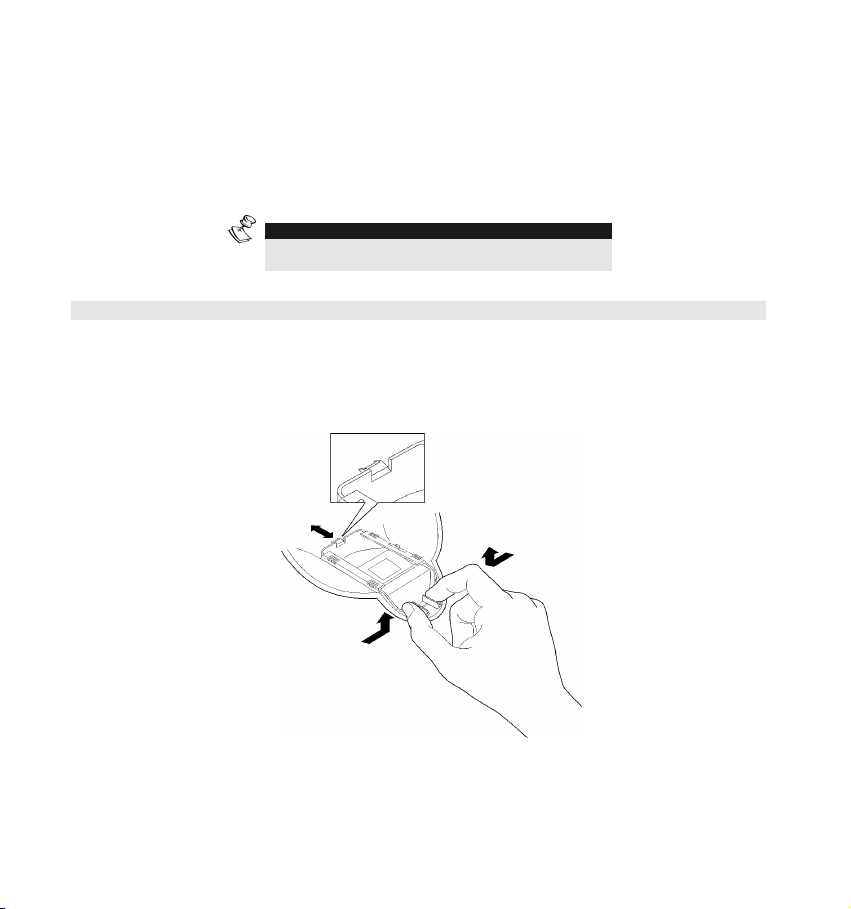

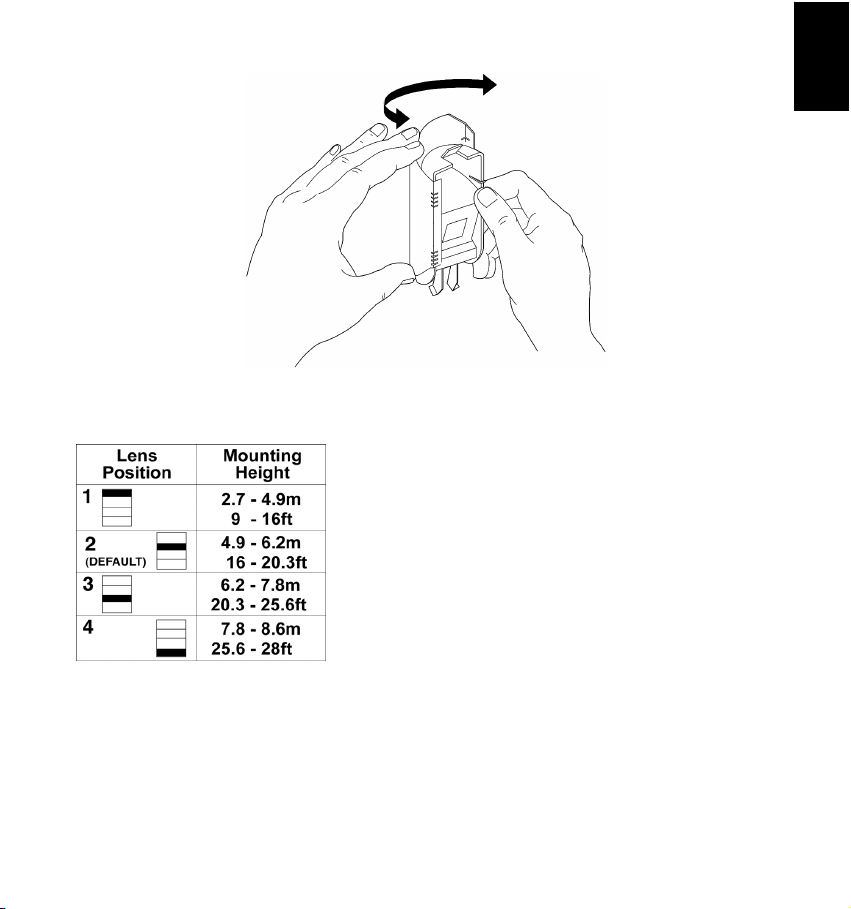

Lens Adjustment:

The Ind. LuNAR 200DTG3 has three - Fresnel lenses attached to the cover, located in sensor

protective sleeves. Adjust the position of the lenses based on the ceiling mounting height as follows:

Press the 2 clips attaching the sleeve (Figure 6) to the detector’s cover, and gently pull out the

sleeve.

FIGURE 6

Remove the lens from the sleeve (Figure 7) by gently lifting it from the holding pins that secure it to

the sides of the sleeve.

Ind. LuNAR 200DTG3 Installation Guide 12

Page 15

FIGURE 7

Place the two pins, which are located on both sides of the sleeve into the matching slots on the lens.

Use the following table to select the desired lens position.

English

Return the protective sleeve back into place on the detector front cover.

Repeat steps 1 to 5 for the remaining 2 lenses.

Ind. LuNAR 200DTG3 Installation Guide 13

Page 16

NOTES:

Below 3.7m mounting height, the coverage diameter

starts decreasing, and at 2.7m height coverage

diameter is 15m (50ft).

For customized coverage, it is possible to set the

position of each lens to a different height, according to

the installation conditions.

DO NOT TOUCH PIR

SENSORS

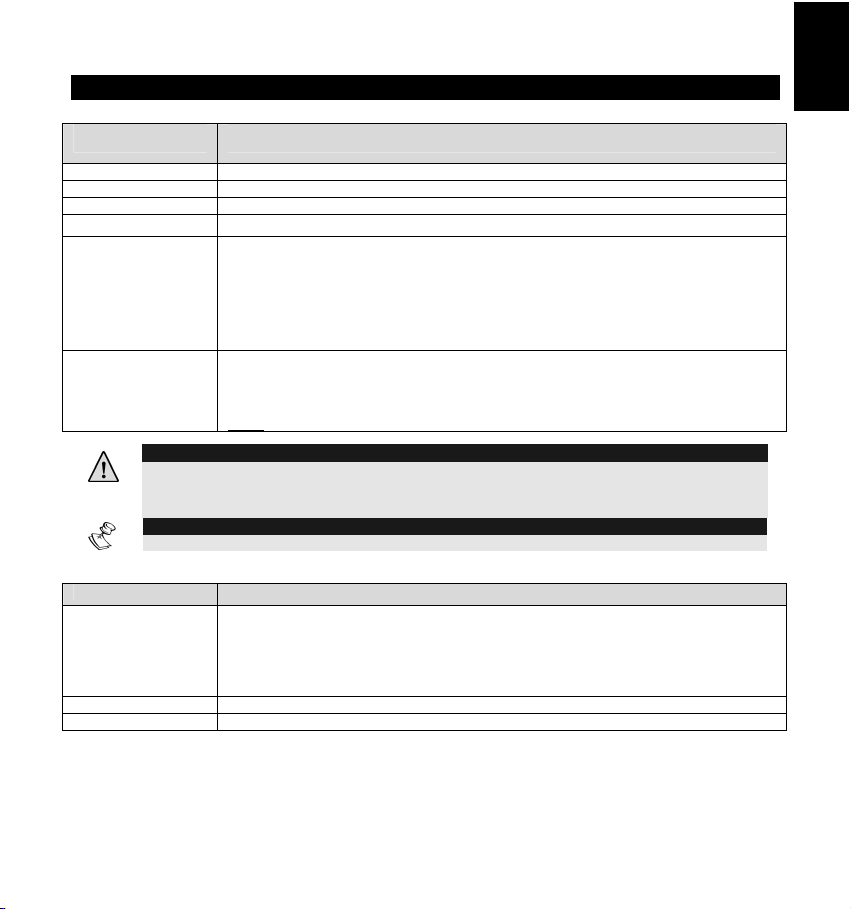

DIPswitch Settings

Green

Self

RELAY

REMOTE

AM

N/A N/A

MODE

CONTROL

9

8

TAMPER

BUS

N/A

MODE

9

8

MW

Potentiometer

MIN MAX

RC/SET INPUT

0V

12V

TAMPER EOL

J3

ALARM

ON

EOL

1K

2.2K

12345678

4.7K

5.6K

6.8K

J3

Relay Mode

Configuration

BUS Mode

Configuration

AM EOL

ACT LED

Line

Test

1234567

BUS ADDRESS

1234567

9

PIR

Ind. LuNAR 200DTG3 Installation Guide 14

Page 17

Selectors and Jumpers

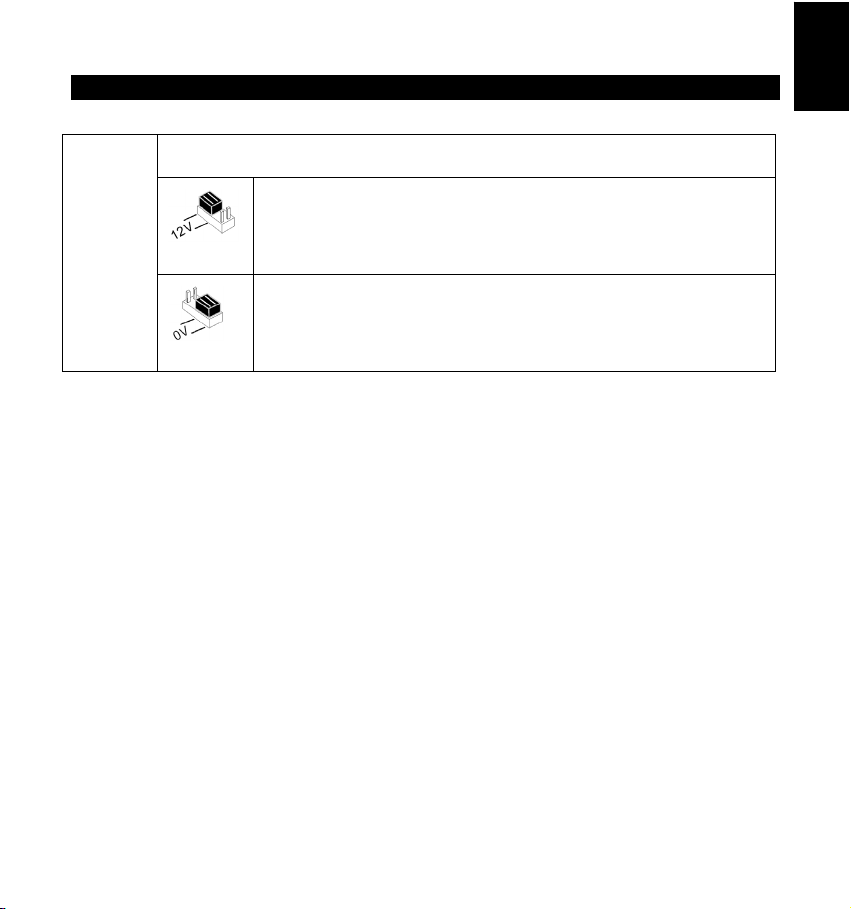

RC/SET

INPUT

Used to determine the polarity of the external inputs.

12V: 12v has to be connected in order activate the function.

GND or N.C. has no influence on the RC/SET status.

(see Relay mode DIP switches configuration)

English

0V: The GND has to be connected in order to activate the function.

12v or N.C. has no influence on the RC/SET status.

(see Relay mode DIP switches configuration)

Ind. LuNAR 200DTG3 Installation Guide 15

Page 18

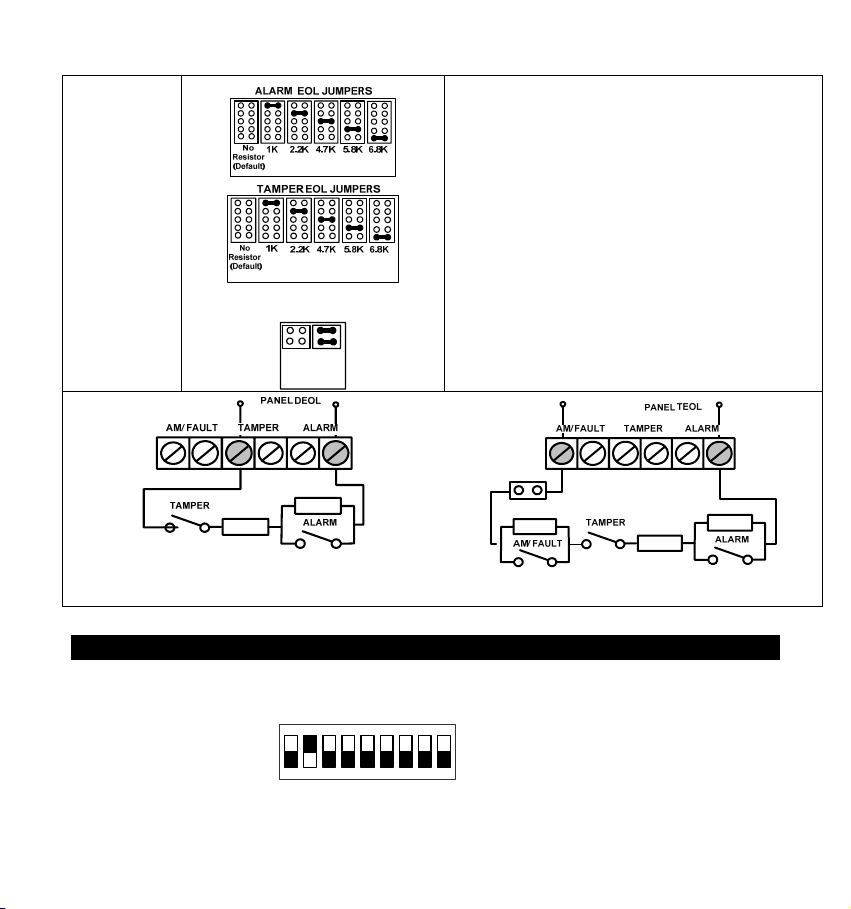

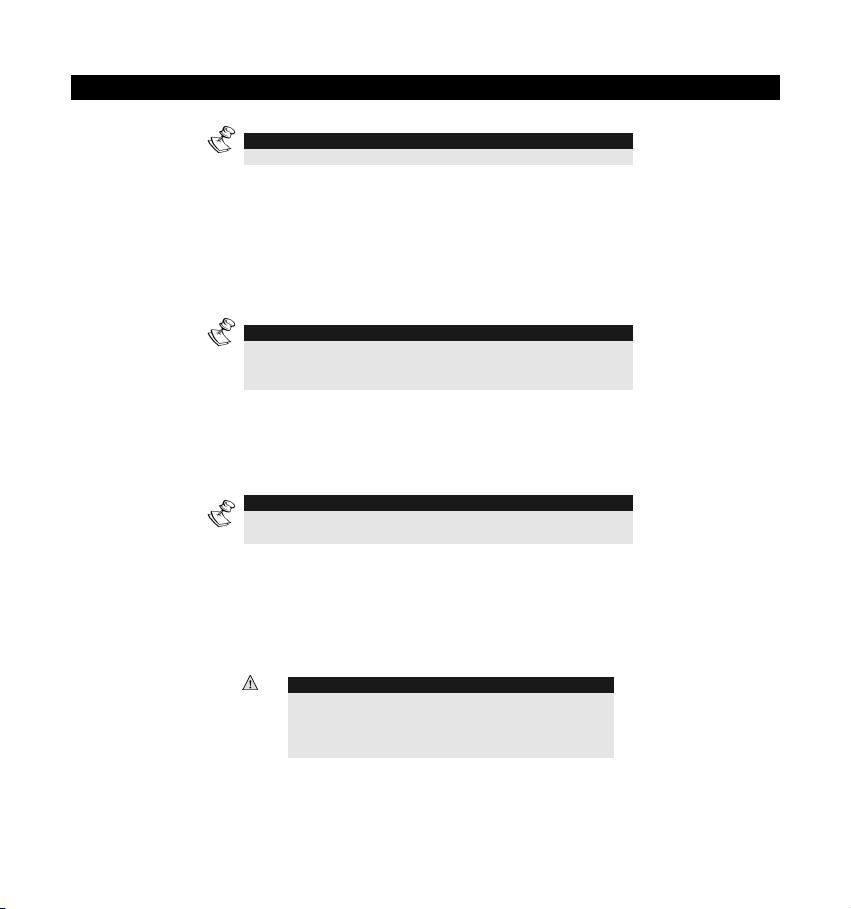

EOL

RESISTORS

JUMPERS

FAULT/AM EOL

JUMPERS

12K

No

Resistor

(Default)

The jumpers are used when connecting the

detector to a DEOL or TEOL Zone. The jumpers

allow the selection of TAMPER, ALARM E.O.L

resistors (1K, 2.2K, 4.7K, 5.6K or 6.8K), according

to the control panel settings. An additional double

jumper allows the connection of 12K FAULT/AM

E.O.L resistor (see EOL Resistors Schematic).

Follow the terminal block connection diagram

when connecting the detector to a Double/Triple

End Of Line (DEOL/TEOL) Zone.

Schematic of EOL Resistors

DIP Switch Settings

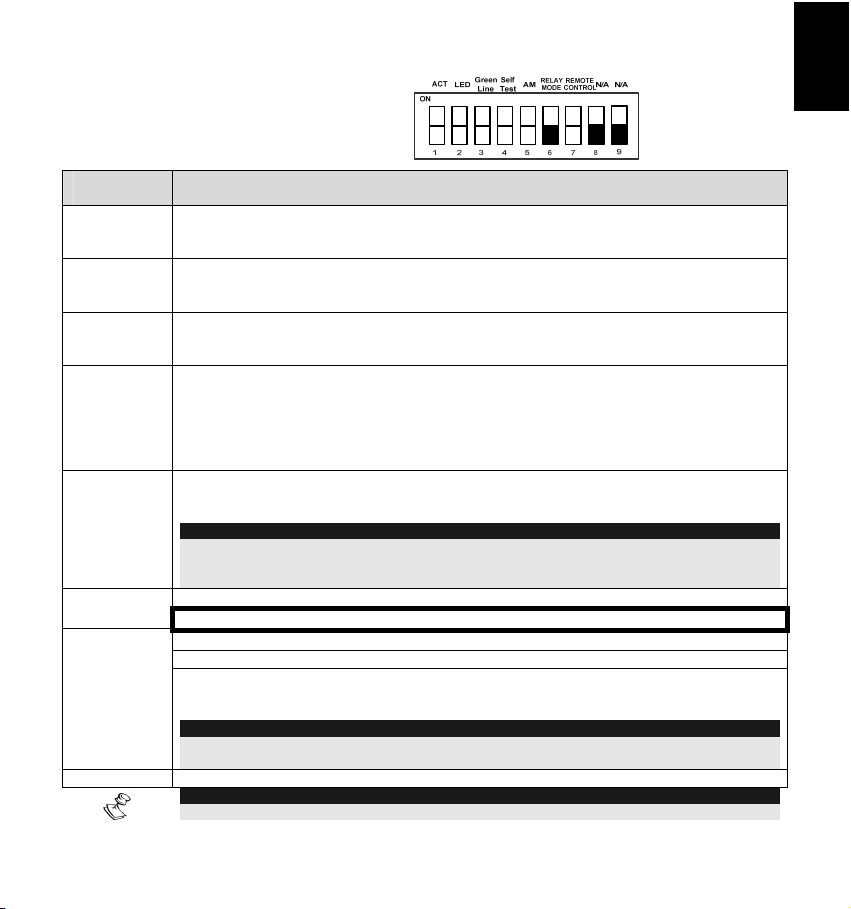

The Ind. LuNAR 200DTG3 has a 9 position DIP switch that changes functionality for use in Relay

mode or in BUS operation mode. Set the DIP switch according to the tables below:

Factory Default Settings:

Ind. LuNAR 200DTG3 Installation Guide 16

ON

123456789

Page 19

Relay Mode Configuration (DIP

switch 6=OFF)

:

English

DIP switch

Description

Number

1

Used to determine the operation of the ACT

DIP switch ON: ACT is enabled

DIP switch OFF: ACT is disabled (def ault factory)

2

Used to determine the operation of the detector’s LEDs

Dip switch ON: LEDs are enabled (default factory)

DIP switch OFF: LEDs are disabled

3

Used to determine the operation of the "Green Line" (See Note below)

DIP switch ON: "Green Line" is enabled

DIP switch OFF: "Green Line" is disabled (default factory)

4

Used to determine the type of Self Test (See Note below)

DIP switch ON: Local Self Test:

In case the local self test fails, the FAULT/AM Relay is activated for a period of 2.5 secs.

DIP switch OFF: Remote Self Test (default factory):

In case the remote self test passes, the Alarm Relays are activated for a period of 5 secs.

In case the test fails, FAULT/AM Relay is activated for a period of 2.5 seconds.

5

Used to determine whether Active IR Anti-Masking is active. (See Note below)

DIP switch ON: Enable

DIP switch OFF: Disable (default factory)

IMPORTANT:

If the AM is enabled via DIP Switch 5, the cover must be fitted within 1 minute from applying the

power. If the detector is already powered up and DIP Switch 5 is turned on, the unit must be

6

down powered to reset the AM calibration.

Used to determine the detector’s connection mode

DIP switch OFF: Relay mode

Used to determine if the Remote Control communication is enabled or disabled.

DIP switch ON: RC communication is always enabled.

DIP switch OFF: RC communication depends on the voltage applied to the terminal block

“RC”

7

(default factory)

When an activation signal is applied to the RC input of the terminal block, RC is enabled.

IMPORTANT:

Turn dipswitch 7 “OFF” after installation and when leaving the site for security reasons. This

will prevent unauthorized use of a remote control unit that may be used to disable the detector.

8-9 DIP switches OFF

NOTE:

See Set Terminal Blocks for activation details.

Ind. LuNAR 200DTG3 Installation Guide 17

Page 20

BUS Mode Configuration (DIP

switch 6=ON):

DIP

Description

switch

Number

1-5

Used to set the detector ID number. (See Table 1)

Set the ID number in the same way as for any other ProSYS accessory.

Used to determine the detector’s connection mode.

6

DIP switch ON: ProSYS connection – BUS configuration

NOTE:

Upon power up or normal operation, the Ind. LuNAR 200DTG3 waits 10 seconds for ProSYS

communication. Communication problem may occur due to bad wiring, wrong address, or ProSYS

not configured properly; RED LEDs will continuously flash until the problem is solved.

Not applicable (RC communication is automatically enabled when entering Walk Test mode in

7

8-9

the ProSYS and disabled othe rwise).

DIP Switch ON: in order to enable the dete ctor to report the tamper status to ProSYS.

Table 1: ID Settings for BUS connection

ID 1 2 3 4 5 ID 1 2 3 4 5

OFF OFF OFF OFF OFF

01

ON OFF OFF OFF OFF

02

OFF ON OFF OFF OFF

03

ON ON OFF OFF OFF

04

OFF OFF ON OFF OFF

05

ON OFF ON OFF OFF

06

OFF ON ON OFF OFF

07

ON ON ON OFF OFF

08

OFF OFF OFF ON OFF

09

ON OFF OFF ON OFF

10

OFF ON OFF ON OFF

11

ON ON OFF ON OFF

12

OFF OFF ON ON OFF

13

ON OFF ON ON OFF

14

OFF ON ON ON OFF

15

ON ON ON ON OFF

16

ON

1234

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

BUS ADDRESS

BUS

N/A

MODE

6

5

7

OFF OFF OFF OFF ON

ON OFF OFF OFF ON

OFF ON OFF OFF ON

ON ON OFF OFF ON

OFF OFF ON OFF ON

ON OFF ON OFF ON

OFF ON ON OFF ON

ON ON ON OFF ON

OFF OFF OFF ON ON

ON OFF OFF ON ON

OFF ON OFF ON ON

ON ON OFF ON ON

OFF OFF ON ON ON

ON OFF ON ON ON

OFF ON ON ON ON

ON ON ON ON ON

TAMPER

8

9

Ind. LuNAR 200DTG3 Installation Guide 18

Page 21

Terminal Blocks

TERMINAL BLOCK 1 DESCRIPTION

+12V (RED) Power supply positive (+) input voltage

- (BLK) Common to control panel power supply

BUS (GRN) Used for data communication with the ProSYS

BUS (YEL)

SET ∗

RC ∗

(REMOTE

CONTROL)

WARNING:

Turn DIP switch 7 “OFF” after installation and when leaving the site for security

reasons. This will prevent unauthorized use of a remote control unit that may be used

to disable the detector.

∗

Not relevant in BUS mode

TERMINAL BLOCK 2 DESCRIPTION

AM/FAULT Normally closed output

TAMPER Normally closed output

ALARM Normally closed output

Used for data communication with the ProSYS

Used to remotely SET/UNSET the detector.

When an activation signal (see RC/SET Activation jumper for settings) is applied to the

SET input of the terminal block:

AM will be disabled (if the AM DIP switch 5 was previously ON)

MW module is enabled (if the Green Line DIP switch 3 was previously ON).

Removing an activation signal will cause a Self Test (if the Remote Self Test DIP switch

4 was previously OFF).

Used to enable/disable the remote control communication, only when DIP switch 7 is

“OFF”.

When an activation signal (see RC/SET input jumper for settings) is applied to the RC

input of the terminal block, Remote Control will be enabled.

Note:

DIP switch 7 “ON” constantly enables RC communication.

The AM/FAULT output opens in the following events:

Detector is masked (ALARM also opens in this case)

Self Test failed

Input voltage is low (6VDC-8VDC)

English

Ind. LuNAR 200DTG3 Installation Guide

19

Page 22

Walk Test

NOTE:

To perform the walk test, first enable the LEDs.

Two minutes after applying power (warm-up period), walk test the detector over the entire protected

area to verify proper operation of the detector and observe the Tri - color LED. The edge of the

microwave pattern is determined by the first red LED activation (both PIR and MW LEDs are

triggered).

NOTE:

If the PIR/MW LEDs do not TURN ON, probably it means that

there is a problem with either the lens (PIR) position, or MW

Adjust the microwave sensitivity by turning the PCB potentiometer (using a screwdriver), or by using

the Remote Control device. Walk test the unit from all directions to determine all the detection

pattern boundaries.

When using the Remote Control device, it is recommended to perform the LuNAR Self Test; for

further instructions refer to the Remote Control Instructions.

Upon completion of installation and testing stages, ensure that all switches are in their desired

positions.

adjustment!

NOTE:

Adjust the MW to the lowest possible setting that will still

provide enough coverage for the entire protected area!

IMPORTANT:

Turn DIP switch 7 “OFF” after installation and when

leaving the site for security reasons. This will

prevent unauthorized use of a remote control unit,

that may be used to disable the detector.

Ind. LuNAR 200DTG3 Installation Guide 20

Page 23

Troubleshooting

This section describes possible system problems and their solutions:

Always perform the following preliminary checks before referring to the troubleshooting table:

Perform a complete visual inspection of the Ind. LuNAR 200DTG3, for signs of mechanical damage,

loose connections or torn wires.

Check the connections of the incoming AC power source.

Trouble Meaning Response

ProSYS Configuration of

detectors fails/not accepted by

the system

Tamper indication while working

in the BUS mode

Tamper indication in the Relay

or BUS mode

Walk test cannot be initiated via

the ProSYS keypad

Green LED doesn’t operate

during Walk test - MW channel

does not function

ID configuration

problem

Tamper

connection

malfunction

Tamper probably

not closed

Wrong code Insert the appropriate code

Ind. LuNAR

200DTG3 is

configured (via

the ProSYS) to

the “MW disable

on DISARM”

during ProSYS’s

DISARM mode

Ind. LuNAR

200DTG3

operating in

Bypass mode

due to “Bypass

MW channel

mode”

Disconnect all power sources,

configure the desired IDs and

reconnect power again

Verify that both DIP 8 and 9 are in

ON position

Visually verify that ceiling tamper

and spring are correctly installed

Normal behavior

Reset the detector.

If MW channel trouble reoccurs,

replace the detector with a new one

English

Ind. LuNAR 200DTG3 Installation Guide 21

Page 24

Specifications

Coverage

Coverage pattern consists of 192 fingers (96 Fresnel facets)

divided into 3 lens sections.

Each lens section has 4 adjustable vertical positions for variable

mounting height and customized coverage.

360° by 18m (60ft) diameter. When mounting the detector under

3.7m, the coverage diameter starts to decrease up to 15m (50ft).

Variable Mounting Height From 2.7m to 8.6m (9’ to 28’), 4 lens positions according to

installation height

RFI immunity According to EN50130-4

Operating voltage 9 to 16VDC

Current consumption 20mA at 12VDC, 30mA at 16 VDC, Maximum 40mA with all

LEDs on.

Alarm and AM contacts Opto-relay NC, 100mA, 24 VDC

Tamper contacts NC, 500mA, 24 VDC

Alarm Time 2.2 seconds

Warm-up time 2 minutes

Optical Filtering for white

Pigmented Fresnel lens

light

protection

Operating temperature -20° C to 55° C (-4° F to 131° F)

Storage temperature -20° C to 60° C (-4° F to 140° F)

Dimensions (Height x

99mm x 194mm (3.9’’x 7.6’’)

Diameter)

The Ind. LuNAR 200DTG3 detector is suitable for use in installations complying with

PD6662, EN50131-1 and EN50131-2-4 Grade 3, Class II.

Ind. LuNAR 200DTG3 Installation Guide

22

Page 25

DDTT AAMM GGrraaddee 33

MMooddeelllloo:: IInndd.. LLuuNNAARR 220000DDTTGG33

RRiivveellaattoorree ddaa SSooffffiittttoo

MMaannuuaallee ddii IInnssttaallllaazziioon

nee

Italiano

Page 26

Descrizione Generale

Il LuNAR industriale DT AM Grado 3 (Ind. LuNAR 200DTG3) è un rivelatore doppia tecnologia da soffitto

che può essere installato fino ad una altezza di 8.6 metri e integra la rivoluzionaria tecnologia Anti-Cloak™

Technology (ACT™) di RISCO. Il rivelatore ha un’intelligente elaborazione digitale del segnale che

configura automaticamente le soglie di allarme e il conteggio degli impulsi in funzione del movimento

dell’intruso all’interno dell’area protetta rispetto ai fattori ambientali, garantendo la migliore rivelazione

possibile.

Il Ind. LuNAR 200DTG3 può funzionare sia come unità “stand alone”, collegabile a qualsiasi centrale d’allarme,

sia come Accessorio BUS, collegabile via BUS RS-485 ai sistemi d’allarme RISCO serie ProSYS.

Caratteristiche del Ind. LuNAR 200DTG3

♦ Conforme alle normative europee PD6662, EN50131-1, TS50131-2-4 Grado 3

♦ Rivelatore doppia tecnologia indirizzato con tecnologia Anti-Cloak™

♦ Installazione fino a 8.6 metri di altezza

♦ Copertura di 360

♦ 3 rivelatori PIR indipendenti per una copertura programmabile

♦ Elaborazione Digitale del Segnale – verifica dell’allarme e modifica delle soglie di

allarme in funzione del movimento dell’intruso all’ int er no dell’area protetta

♦ Resistenze di fine linea selezionabili tramite ponticelli

♦ IR attivo Anti-Mask conforme alle specifiche tecniche europee TS50131

♦ Interruttori antimanomissione contro l’apertura e la rimozione

♦ Configurazione "Green Line" per disabilitare le emissioni della sezione microonda

ad impianto disinserito

♦ Relè opto isolati a basso assorbimento di corrente e lunga durata

♦ Auto-test locale o remoto tramite comando remoto

♦ Ingresso di stato impianto inserito/disinserito (SET)

♦ Ingresso per l’abilitazione del dispositivo di controllo remoto (RC)

♦ Ottimizzazione della copertura PIR tramite lo spostamento delle Lenti

♦ Portata Microonda regolabile manualmente tramite potenziometro (regolazione

analogica) e in remoto (regolazione digitale)

♦ Indicazione di anomalia (tramite LED o in remoto)

♦ 3 LED con tricolore per effettuare agevolmente la prova di copertura

♦ Controllo e diagnostica remota avanzata

♦ Limitazione dell’assorbimen to in corrente se collegato ai sistemi d’allarme ProSYS

0

con 18 metri di diametro

Ind. LuNAR 200DTG3 - Guida all’installazione 2

Page 27

Caratteristiche di Controllo e Diagnostica Remota*

♦ Regolazione remota della microonda.

♦ Le utilità di diagnostica includono la lettura della tensione di alimentazione del

rivelatore, lo stato dei 3 canali PIR (Infrarosso) e del canale MW (microonda)

(tensione del segnale e livelli di rumore) e la verifica della versione del

firmware.

♦ Visualizzazione remota e controllo della configurazione dell’unità per quanto

riguarda la regolazione della microonda, l’ACT (on/off) e i LED (on/off).

♦ Indicazione remota di anomalia per la sezione PIR, MW e l’ingresso di

alimentazione.

♦ Controllo ed esclusione microonda MW (in caso di anomalia MW) e

disabilitazione microonda MW durante il periodo in cui l’impianto d’allarme è

disinserito (funzione “Green Line”), se collegato via bus ai sistemi d’allarme

ProSYS.

*Tramite il dispositivo bidirezionale di controllo all’infrarosso (opzionale) o il software di

teleassistenza se l’unità è collegata via BUS ad un sistema d’allarme ProSYS.

Sistema di Rilevazione

La rilevazione del Ind. LuNAR 200DTG3 si basa sulle seguenti tecnologie:

♦ PIR (Infrarosso Passivo) – rileva il cambiamento di temperatura che viene

generato da un intruso che attraversa l’area protetta dal sensore.

♦ MW (Microonda) – trasmette segnali e analizza la variazione di frequenza

degli stessi causata da un intruso che si muove all’interno dell’area protetta.

Questa tecnologia lavora con il principio dell’effetto Doppler.

L’ALLARME viene generato solo quando entrambe le tecnologie di rilevazione vengono attivate

simultaneamente (ad eccezione del funzionamento con ACT – consultare la pagina 4 – “Come

funziona l’ACT™”), riducendo drasticamente la percentuale di allarmi impropri.

Italiano

Ind. LuNAR 200DTG3 - Guida all’installazione 3

Page 28

Come funziona l’ACT™

Anti-Cloak™ (ACT™) è la prima vera innovazione della tecnologia di rivelazione volumetrica

antintrusione dall'introduzione della tecnologia ad Infrarosso Passivo. Offrendo i benefici di un

rivelatore a Doppia Tecnologia ma allo stesso tempo sopperendo ai suoi punti deboli, questa

innovazione, in attesa di brevetto, costituisce un nuovo standard nella tecnologia dei rivelatori

antintrusione.

I rivelatori a doppia tecnologia Microonda e Infrarosso Passivo sono stati un importante sviluppo per

l'industria della sicurezza per la loro capacità di riduzione degli allarmi impropri. Essi però hanno due

grandi punti deboli:

Gli intrusi possono evitare di essere rilevati dal canale IR bloccando le radiazioni infrarosse del

proprio corpo con un grosso ombrello, un cartone o altro.

La sensibilità del PIR si riduce notevolmente quando vengono protette aree in cui la temperatura

ambientale raggiunge quella del corpo umano.

In risposta alle richieste dei clienti di risolvere queste problematiche, RISCO ha sviluppato la

rivoluzionaria tecnologia chiamata ACT™.

ACT™ previene la neutralizzazione del sistema di allarme quando il canale all'infrarosso dei normali

rivelatori a doppia tecnologia viene messo in condizione di non rilevare un intruso. Utilizzando

algoritmi che analizzano la forma d'onda e la frequenza dei segnali infrarossi, ACT™ identifica il

segnale particolarmente basso di un intruso in movimento rispetto ad interferenze termiche che

potrebbero essere causa di allarmi impropri.

Una volta che la presenza di un intruso è stata rilevata, ACT™ commuta automaticamente il

rivelatore da doppia tecnologia al funzionamento in solo Microonda per un periodo di tempo

determinato al fine di attivare l'allarme con il solo canale Microonda.

Nel secondo caso, quando la temperatura dell'ambiente protetto si avvicina alla temperatura del

corpo umano, ACT™ commuta in microonda singola.

ACT™ garantisce rilevazione dell’intruso anche in condizioni critiche ed elevata immunità ai falsi

allarmi.

Ind. LuNAR 200DTG3 - Guida all’installazione 4

Page 29

Opzioni di Configurazione del Ind. LuNAR 200DTG3

Il Ind. LuNAR 200DTG3 può essere configurato e/o testato in remoto tramite le opzioni elencate

nella tabella che segue:

Modo ACT

Abilitazione LED

Sensibilità MW

Diagnostica

Stato/Anomalie/Informazioni

Diagnostica AM

Esclusione MW se in

anomalia

Disabilita MW in disinserito

(Funzione "Green Line")

Locale sul

rivelatore

9 9 9

9 9 9

(via trimmer) 9 9

9

-

-

- -

- -

- -

Dispositivo

Remoto

9 9

9 9

Da centrale

ProSYS

9

9

9

Indicatori LED

I tre LED tricolori del Ind. LuNAR 200DTG3, riportano le informazioni che seguono:

LED STATO SIGNIFICATO

Acceso

Rosso

Verde

Arancio

Tutti i LED

Lampeggiante lento

Lampeggiante veloce Rilevazione circuito Anti-Mask (AM)

Acceso Rilevazione canale Microonda (MW)

Lampeggiante Anomalia canale Microonda (MW)

Acceso

Lampeggiante Anomalia canale Infrarosso (PIR)

Lampeggianti con cambio di colore Alimentazione iniziale

Rivelatore in allarme (rilevazione

simultanea su canale PIR e MW)

Anomalia di comunicazione con la centrale

ProSYS

Rilevazione canale Infrarosso (PIR)

Ind. LuNAR 200DTG3 - Guida all’installazione 5

Italiano

Page 30

INSTALLAZIONE

Fase preliminare:

♦ Prima di procedure con l’installazione, studiare attentamente l’area da

proteggere al fine di trovare la corretta locazione del rivelatore per la migliore

copertura possibile.

♦ Non installare mai il LuNAR in un ambiente con un disturbo che causa una

condizione d’allarme persistente in una delle due tecnologie.

♦ Evitare installazioni in presenza oggetti in movimento (ad esempio ventole)

che operano normalmente nell’area coperta dal rivelatore. Puntare l’unità

lontano da vetrate che danno all’esterno o oggetti che possono cambiare

temperature rapidamente.

♦ Non installare il rivelatore in posizioni che possano essere colpite da raggi

solari diretti o vicino a sorgenti di calore. Le zone di rilevazione dovrebbero

essere posizionate davanti a pareti, pavimenti ma non di fronte a tendaggi. La

superficie di installazione deve essere solida, liscia ed esente da vibrazioni.

♦ Per un’ottima rilevazione scegliere la posizione di installazione in modo che

l’eventuale intruso si introduca nell’area protetta attraversando le zone sensibili

del rivelatore.

♦ L’altezza di installazione consigliata, per una copertura con un diametro di 18

metri, và da 3.7 a 8.6 metri. Installato a 2.7 metri di altezza il rivelatore ha una

copertura caratterizzata da un diametro di 15 metri.

♦ Il rivelatore và montato a soffitto, preferibilmente al centro dell’area da

proteggere.

Ind. LuNAR 200DTG3 - Guida all’installazione 6

Page 31

I diagrammi di copertura tipici e le relative altezze di installazione sono di seguito illustrate:

Italiano

NOTE:

Quando il rivelatore Ind. LuNAR 200DTG3 viene

installato in un ambiente ove sono presenti elementi

che causano interferenze, la MW potrebbe avere una

Ind. LuNAR 200DTG3 - Guida all’installazione 7

copertura ridotta o un funzionamento anomalo.

Page 32

Procedura di installazione:

1. Per aprire il rivelatore (Figura 1), inserire un cacciavite nella fessura tra il tappo di protezione

superiore e il coperchio. Il coperchio rimarrà agganciato alla base del sensore.

2. Con il cacciavite svitare la vite del coperchio e tirare a sé il coperchio.

2

FIGURA 1

1

Ind. LuNAR 200DTG3 - Guida all’installazione 8

Page 33

3. Allentare la vite di fissaggio della scheda elettronica (Figura 2) posizionata sul lato destro della

scheda (1), premere verso l’esterno le 2 clip di sblocco (2) e rimuovere la scheda elettronica.

Italiano

Non toccare

FIGURA 2

Ind. LuNAR 200DTG3 - Guida all’installazione 9

con le dita

l’elemento

piroelettrico !

Page 34

4. Se necessario, aprire con una tronchesina (Figura 3) le predisposizioni per il passaggio cavi

(1, 2) e con un cacciavite i fori a sfondare situati nella base del contenitore (3, 4).

FIGURA 3

3 4

Ind. LuNAR 200DTG3 - Guida all’installazione 10

Page 35

5. Inserire il cavo facendolo passare (Figura 4) tramite gli appositi passaggi ed effettuare i

collegamenti descritti nel paragrafo “Fase 4- Cablaggio”.

FIGURA 4

6. Installare la base del contenitore (Figura 5) nella posizione finale usando 3 viti di fissaggio e

sigillare i restanti fori aperti con del sigillante.

NOTA:

Se si utilizza una scatola elettrica per montare il

rivelatore, usare 2 viti aggiuntive per fissare la

base del rivelatore alla scatola.

In questo caso verificare che sia possibile

utilizzare il tamper antirimozione!

FIGURA 5

Foro del

Tamper

anti-

rimozione

Italiano

Ind. LuNAR 200DTG3 - Guida all’installazione 11

Page 36

7. Inserire la scheda elettronica nella posizione originale e verificare che sia bloccata dalle clip e

dalla vite di fissaggio.

8. Effettuare la regolazione delle lenti e la predisposizione dei microinterruttori come descritto nel

paragrafo “Regolazione delle Lenti” alla pagina 12 e “Configurazione Microinterruttori” alla

pagina 15.

9. Montare il coperchi del rivelatore sulla base.

10. Stringere il coperchio tramite l’apposita vite centrale.

11. Riposizionare il tappo di protezione del rivelatore.

NOTA:

Se si desidera utilizzare il tamper antirimozione, aprire

il foro corrispondente nella base del rivelatore !

Utilizzando il tamper antirimozione viene garantito il II°

livello di prestazione IMQ.

Regolazione delle Lenti:

Il Lunar ha tre lenti di Fresnel pigmentate integrate nel coperchio del rivelatore inserite all’interno di

una sezione plastica che protegge gli elementi piroelettrici. Regolare la posizione di queste tre lenti

in funzione dell’altezza di installazione come di seguito spiegato:

1. Premere le 2 clip di sblocco del supporto plastico (Figura 6) che mantiene la lente

tirandolo verso l’esterno.

FIGURA 6

Ind. LuNAR 200DTG3 - Guida all’installazione 12

Page 37

2. Rimuovere la lente sganciandola dai supporti laterali (Figura 7) che la fissano alla sua

FIGURA 7

Italiano

custodia plastica.

3. Posizionare i 2 supporti laterali posizionati ai lati della custodia plastica negli appositi fori

della scala verticale della lente facendo riferimento alla tabella seguente.

4. Riposizionare la custodia plastica della lente nel coperchio del Lunar.

5. Effettuare la stessa procedura per le altre 2 lenti.

Ind. LuNAR 200DTG3 - Guida all’installazione 13

Page 38

NOTE:

^д=Зб=лзннз=ЗЙб=PKT=гЙнкб=Зб=~днЙтт~=Зб=белн~дд~тбзеЙ=бд=

Зб~гЙнкз=Зб=ЕзйЙкнмк~=Зб=NU=гЙнкб=бебтб~=~=ЗбгбембкЙ=Сбез=

~З=~ккбо~кЙ=~=NR=гЙнкб=~З=ме~=~днЙтт~=Зб=белн~дд~тбзеЙ=Зб=

OKT=гЙнкбK=

mЙк=ме~=ЕзйЙкнмк~=йЙклзе~дбтт~н~=≠=йзллбДбдЙ=

йкЙЗблйзккЙ=д~=йзлбтбзеЙ=Зб=зЦеме~=ЗЙддЙ=P=дЙенб=~З=

~днЙттЙ=ЗбССЙкЙенб=бе=СметбзеЙ=ЗЙддЙ=ЕзеЗбтбзеб=Зб=

белн~дд~тбзеЙK==

P

I

R

TAMPER EOL

J3

ALARM

ON

EOL

1K

2.2K

123456789

4.7K

5.6K

6.8K

J3

AM EOL

NON TOCCARE

CON LE DITA

L'ELEMEN TO

PIR OELETTRICO

Configurazione Microinterruttori

ACT LED

Modo di

Collegamento

a Relè

1234567

INDIRIZZO ID RIVELATORE

Modo di

Collegamento

via BUS

ProSYS

1234 567

TA MP ERAM/FAULT AL A R M

Green

Auto

Modo

Disp.Ctrl

AM

Line

N/A N/A

Test

Relè

Remoto

8 9

TAMPER

MODO

N/A

BUS

9

8

+12 -

BLK R ED

BUS

RC/SET INPUT

GRN YEL

RC SET

Potenziometro

MW

MIN M AX

0V

12V

R

I

P

PIR

=

= fеЗK=iмk^o=OMMaqdP=J=dмбЗ~=~ддЫбелн~дд~тбзеЙ=

14

Page 39

Predisposizione Ponticelli

RC/SET

INPUT

Usati per impostare la polarità dei comandi di attivazione per gli ingressi RC e SET.

Posizionato sul lato 12V richiede come comando di attivazione una

tensione positiva. Fare riferimento alla sezione relativa il Cablaggio

Morsettiera, morsetti RC e SET.

Posizionato su 0V richiede come comando di attivazione un

riferimento negativo di alimentazione 0V. Fare riferimento alla sezione

relativa il Cablaggio Morsettiera, morsetti RC e SET.

Italiano

Ind. LuNAR 200DTG3 - Guida all’installazione 15

Page 40

PONTICELLI

PER

RESISTENZE

EOL

PONTICELLI EOL ALLARME

1K 2.2K 4.7K 5.6K 6.8K

Il "default" è nessuna resistenza

PONTICELLI EOL TAMPER

1K 2.2K 4.7K 5.6K 6.8K

Il "default" è nessuna resistenza

PONTICELLI EOL FAULT/AM

I ponticelli permettono la selezione dei valori

resistivi da assegnare ai circuiti di TAMPER e di

ALLARME (1K, 2.2K, 4.7K, 5.6K o 6.8K) in

funzione della centrale d’allarme utilizzata. Un

doppio ponticello aggiuntivo permette la selezione

di una resistenza da 12K per supervisionare il

circuito Anomalia/Anti-Mask (FAULT/AM) (vedere

lo schema di collegamento delle resistenze EOL).

Seguire lo schema di collegamento dei morsetti

se si vuole collegare il rivelatore ad una centrale

d’allarme usando il doppio o il triplo bilanciamento

resistivo (DEOL/TEOL).

CON DOPPIA

EOL

ALLARME

12K

ALARMAM / FAULT TAMPER

AM / FAULT

ALLA CENTRALE

CON TRIPLA EOL

AM / FAULT TAMPER

TAMPER

ALARM

ALLARME

Il "default" è nessuna resistenza

ALLA CENTRALE

TAMPER

Schema di collegamento delle resistenze EOL

Configurazione Microinterruttori

Ind. LuNAR 200DTG3 ha un banco di microinterruttori a 9 posizioni le cui funzioni cambiano a

seconda della modalità di funzionamento impostata, RELE’ o BUS.

Configurazione di fabbrica:

Ind. LuNAR 200DTG3 - Guida all’installazione 16

ON

123456789

Page 41

Modo Collegamento a Relé

(Microinterruttori 6, 8 e 9=OFF):

ON

ACT LE D

Green

Line

Auto

Test

DISP.

MODO

CTRL

AM

RELE'

REMOTO

N/A N/A

N. Micro -

1234567

Descrizione

9

8

interruttore

1

Usato per determinare lo stato del sistema ACT

Microinterruttore ON: l’ACT è abilitato

Microinterruttore OFF: l’ACT è disabilitato (impostazione di fabbrica)

2

Usato per determinare il funzionamento dei LED

Microinterruttore ON: I LED sono abilitati (impostazione di fabbrica).

Microinterruttore OFF: I LED sono disabilitati.

3

Usato per determinare il funzionamento della funzione "Green Line"

Microinterruttore ON: La funzione "Green Line" è abilitata.

Quando la funzione Green Line è attiva (Microonda spenta), il rivelatore si attiva usando

la sola sezione ad infrarossi (PIR).

NOTA: Per avere maggiori dettagli sull’attivazione della funzione fare riferimento al

morsetto SET nella sezione cablaggio morsettiere.

Microinterruttore OFF: La funzione “Green Line” è disabilitata. La sezione a

microonda (MW) è sempre accesa. (impostazione di fabbrica)

4

Usato per testare le tecnologie di rilevazione.

Microinterruttore ON (Auto-Test locale):

Se non viene rilevata alcuna attivazione del canale PIR per 1 ora, il rivelatore eseguirà

un auto-test. Se il test fallisce, l’uscita a relè FAULT/AM verrà attivata per 2,5 secondi.

Microinterruttore OFF (Auto-Test remoto) - (impostazione di fabbrica):

A conferma che l’auto-test remoto è stato superato l’uscita a relé di allarme si attiverà

per 5 secondi. Nel caso in cui l’auto-test sia fallito si attiverà l’uscita a relé FAULT/AM.

NOTA: Per avere maggiori dettagli sull’attivazione dell’ A uto-T e st remoto fare

riferimento al morsetto SET nella sezione cablaggio morsettiere.

5

Usato per determinare lo stato di funzionamento dell’Anti-Mask.

Microinterruttore ON: Il circuito di Anti-Mask è abilitato.

NOTA: Per avere maggiori dettagli sullo stato di funzionamento dell’Anti-Mask fare

riferimento al morsetto SET nella sezione cablaggio morsettiere.

Microinterruttore OFF: Il circuito di Anti-Mask è disabilitato.(impostazione di fabbrica)

IMPORTANTE:

Se l’Anti-Mask (AM) viene abilitato tramite il microinterruttore 5, il coperchio del rivelatore

deve essere chiuso correttamente entro 1 minuto da quando viene alimentato. Se il rivelatore

è già alimentato e il microinterruttore 5 viene spostato su ON, togliere e ridare alimentazione

al rivelatore per resettare correttamente la stabilizzazione del circuito di Anti-Mask.

6

Usato per stabilire il modo di collegamento del rivelatore

Microinterruttore OFF: Modo Relé

Ind. LuNAR 200DTG3 - Guida all’installazione 17

Italiano

Page 42

Usato per abilitare o disabilitare il dispositivo remoto.

Microinterruttore ON: Dispositivo remoto SEMPRE abilitato.

Microinterruttore OFF: Il dispositivo remoto viene abilitato solo se presente un segnale

7

di attivazione al morse tto RC del rivelatore (0V o 12V in funzione della polarità

configurata tramite il ponticello RC/SET INPUT). (impostazione di fabbrica).

IMPORTANTE:

Per la sicurezza del sistema, spostare il microinterruttore 7 in posizione OFF dopo

l’installazione. Questo eviterà che un male intenzionato, in possesso di un dispositivo di

controllo remoto, disabiliti le funzioni di rilevazione del sensore.

8-9 Microinterruttori su OFF

IMPORTANTE:

Scollegare l’alimentazione del rivelatore prima di configurare i Microinterruttori. Alimentare

nuovamente l’unità dopo aver completato la configurazione!

Ind. LuNAR 200DTG3 - Guida all’installazione 18

Page 43

Modo collegamento via BUS ProSYS

(Microinterruttore 6, 8 e 9=ON):

N. Microinterruttore Descrizione

1-5

6

Usati per impostare l’indirizzo ID del rivelatore. (Consultare la Tabella 1)

Imposta il modo di collegamento del rivelatore.

Microinterruttore ON: Modo di collegamento via BUS PROSYS

NOTA:

All’alimentazione, in modo normale di funzionamento, il LuNAR attende 10 secondi

per la comunicazione con la centrale ProSYS. Problemi di comunicazione possono

essere causati da cablaggio errato, indirizzo errato, o sistema ProSYS non

configurato correttamente; in queste condizioni tutti i LED del rivelatore

lampeggeranno fino alla soluzione del problema.

Non applicabile. Il dispositivo di controllo remoto RC viene automaticamente

7

abilitato entrando nel menù Test Sensor i della ce ntrale ProSYS e disabilitato

quando si esce dal menù.

8-9

ID 1 2 3 4 5 ID 1 2 3 4 5

Microinterruttore ON: Abilita il rivelatore a comunicare lo stato del tamper alla

centrale ProSYS.

Tabella 1: Predisposizione Indirizzi ID

OFF OFF OFF OFF OFF

01

ON OFF OFF OFF OFF

02

OFF ON OFF OFF OFF

03

ON ON OFF OFF OFF

04

OFF OFF ON OFF OFF

05

ON OFF ON OFF OFF

06

OFF ON ON OFF OFF

07

ON ON ON OFF OFF

08

OFF OFF OFF ON OFF

09

ON OFF OFF ON OFF

10

OFF ON OFF ON OFF

11

ON ON OFF ON OFF

12

OFF OFF ON ON OFF

13

ON OFF ON ON OFF

14

OFF ON ON ON OFF

15

ON ON ON ON OFF

16

INDIRIZZO ID RIVELATORE

ON

1234567

OFF OFF OFF OFF ON

17

ON OFF OFF OFF ON

18

OFF ON OFF OFF ON

19

ON ON OFF OFF ON

20

OFF OFF ON OFF ON

21

ON OFF ON OFF ON

22

OFF ON ON OFF ON

23

ON ON ON OFF ON

24

OFF OFF OFF ON ON

25

ON OFF OFF ON ON

26

OFF ON OFF ON ON

27

ON ON OFF ON ON

28

OFF OFF ON ON ON

29

ON OFF ON ON ON

30

OFF ON ON ON ON

31

ON ON ON ON ON

32

MODO

BUS

TAMPER

N/A

9

8

Italiano

Ind. LuNAR 200DTG3 - Guida all’installazione 19

Page 44

Cablaggio Morsettiere

MORSETTIERA 1 DESCRIZIONE

+12V (RED) Ingresso di alimentazione positiva (+)

- (BLK) Comune da collegare all’alimentatore della centrale

BUS (GRN)

BUS (YEL)

SET ∗

RC ∗

(Dispositivo di

Controllo Remoto

ad Infrarossi)

** Per Segnale di Attivazione si intende quanto segue:

- Viene applicata una tensione 12Vcc e il ponticello RC/SET INPUT è nella posizione 12V

- Viene applicato un riferimento di alimentazione 0V e il ponticello RC/SET INPUT è nella posizione 0V

IMPORTANTE:

Per garantire la sicurezza del sistema, spostare il microinterruttore 7 in posizione OFF dopo

l’installazione. Questo eviterà che un male intenzionato, in possesso di un dispositivo di controllo

remoto, possa disabilitare le funzioni di rilevazione del sensore.

∗

Non rilevante nella configurazione BUS ProSYS.

MORSETTIERA 2 DESCRIZIONE

AM/FAULT Uscita Normalmente Chiusa

TAMPER Uscita tamper Normalmente Chiusa

ALARM Uscita di allarme Normalmente Chiusa

Ind. LuNAR 200DTG3 - Guida all’installazione 20

Usato per la comunicazione dei dati con la ProSYS

Usato per la comunicazione dei dati con la ProSYS

Controllo remoto dello stato impianto.

Stato Inserito: Quando viene applicato un **”Segnale di Attivazione” a questo morsetto, il

circuito di Anti-Mask viene disabilitato (se il microinterruttore 5 è su ON).

Stato Disinserito: Se all’ingresso non viene collegato niente il circuito Anti-Mask viene

abilitato (se il microinterruttore 5 è su ON) e la sezione a microonda viene disabilitata

“funzione Green Line” (se il microinterruttore 3 è su ON). Rimuovendo un **”Segnale di

Attivazione” a questo morsetto, verrà anche attivato l’Auto-Test remoto (se il

microinterruttore 4 è su OFF).

Usato per abilitare/disabilitare il dispositivo ad infrarossi di Controllo Remoto (RC)

tramite una uscita della centrale d’allarme, solo quando il microinterruttore 7 è in

posizione “OFF”.

Quando viene applicato un **”Segnale di Attivazione” al morsetto RC, il Dispositivo di

Controllo Remoto (RC) verrà abilitato.

Nota:

: il microinterruttore 7 in posizione “ON” abilita co stantemente il dispositivo di

Controllo Remoto RC.

L’uscita AM/FAULT si attiva per i seguenti eventi:

Il rivelatore è mascherato (anche l’uscita di ALLARME viene attivata)

Auto-test del rivelatore è fallito

L’ingresso di alimentazione è sotto gli 8 V

Page 45

Prova di Movimento (Walk Test)

NOTE:

Per effettuare la prova di movimento ovvero la prova di

copertura del rivelatore, abilitare il funzionamento dei LED.

1. Dopo due minuti dalla alimentazione (periodo di riscaldamento), verificare la copertura del

rivelatore muovendosi all’interno dell’area da proteggere e osservare i LED a tre colori

dell’unità. L’accensione del LED rosso determina la corretta copertura del rivelatore (attivazione

PIR e MW).

NOTA:

Se il LED del PIR (Giallo) o della MW (Verde) non si Illumina

indica un problema di regolazione della Lente del PIR o del

potenziometro di sensibilità della MW. Effettuare le

regolazioni e riprovare.

2. Regolare la sensibilità della microonda (MW) ruotando con un cacciavite il potenziometro

posizionato sulla scheda elettronica del prodotto o tramite il dispositivo di comando remoto ad

infrarossi. Camminare in tutte le direzioni all’interno dell’area da proteggere per determinare

l’area coperta dal rivelatore.

NOTA:

Regolare la sensibilità della microonda al valore minimo

possibile per coprire l’area da proteggere !

3. Utilizzando il Dispositivo di Contr ollo Remoto a infrarossi, si raccomanda di effettuare l’Auto

Test del LuNAR. Per maggiori informazioni fare riferimento alle Istruzioni fornite con il

Dispositivo di Controllo Remoto.

Una volta terminata la fase di installazione e test dell’unità, assicurarsi che tutti i microinterruttori

siano posizionati correttamente per le funzioni richieste.

IMPORTANTE:

Per garantire la sicurezza del sistema, spostare il

microinterruttore 7 in posizione OFF dopo

l’installazione. Questo eviterà che un male

intenzionato, in possesso di un dispositivo di

controllo remoto, possa disabilitare le funzioni di

rilevazione del sensore.

Italiano

Ind. LuNAR 200DTG3 - Guida all’installazione 21

Page 46

Ricerca Guasti

Questo paragrafo descrive le possibili problematiche del prodotto e le rispettive soluzioni.

Ricordarsi di effettuare tutti i controlli preliminari descritti in questo manuale prima di fare riferimento

alla tabella Ricerca Guasti che segue.

Effettuare una ispezione preliminare del rivelatore per rilevare eventuali danni meccanici,

connessioni allentate, o cavi danneggiati.

Controllare le connessioni alla sorgente di alimentazione e verificare che ci sia la corretta

alimentazione al rivelatore.

Anomalia Spiegazione Soluzione

La configurazione dei rivelatori

non viene accettata dalla

centrale ProSYS

Segnalazione di Tamper

(manomissione) utilizzando il

modo di collegamento BUS

ProSYS

Segnalazione di Tamper

(manomissione) nel modo di

funzionamento Relé o BUS

La Procedura di Test Sensori

(Prova di Movimento) non

viene attivata dalla tastiera

della centrale ProSYS

Il LED verde non si accende

durante la prova di movimento

(test sensori). Il canale

Microonda (MW) non funziona

(nessuna rilevazione)

Problema di

configurazione

dell’indirizzo ID del

rivelatore

Connessione del

Tamper errata per il

funzionamento in modo

BUS ProSYS

L’interruttore del

Tamper è

probabilmente aperto

Il codice inserito è

errato.

1. LuNAR è

configurato (via

centrale ProSYS) per

disabilitare la sezione

microonda a sistema

disinserito

2. Il LuNAR sta

operando in modo

Esclusione Microonda a

causa di un’anomalia

del canale microonda

(MW)

Scollegare tutte le sorgenti di

alimentazione (rete elettrica e

batterie), verificare la

configurazione dell’indirizzo ID dei

rivelatori e ridare alimentazione.

Verificare che i microinterruttori 8 e

9 siano in posizione ON.

Verificare che la molla di chiusura

dell’interruttore del tamper del

contenitore sia posizionata

correttamente.

Inserire un codice abilitato ad

effettuare la procedura di test

sensori.

Il funzionamento è corretto, il LED

verde della microonda non deve

illuminarsi.

Togliere l’alimentazione al sensore

e darla nuovamente, se il problema

persiste, sostituire il rivelatore.

Ind. LuNAR 200DTG3 - Guida all’installazione 22

Page 47

Specifiche Tecniche

Copertura

Altezza di installazione variabile

Frequenza sezione MW

Tipo di segnale emesso MW

Potenza Max. irradiata MW

Immunità RFI `зеСзкгЙ=~дд~=езкг~нбо~=bkRMNPMJQ=

Alimentazione

Assorbimento di corrente

Contatti di allarme k`I=NMMã^I=OQ=s==

Contatti tamper k`I=RMMã^I=OQ=s==

Tempo di allarme OKO=лЙЕзеЗб=

Tempo di preriscaldamento O=гбемнб=

Filtro ottico per la protezione

contro le luci bianche

Temp. di funzionamento

Temp. di funzionamento

certificate

Temp. di stoccaggio

Livello di prestazione

Dimensioni (Altezza x Diametro)

Ind. LuNAR 200DTG3=≠=ЕзеСзкгЙ=~ддЙ=езкг~нбоЙ=ЙмкзйЙЙ=maSSSOI=bkRMNPNJN=Й=bkRMNPNJOJQ=

dк~Зз=PI=`д~ллЙ=ff=ЙЗ=≠=ЕЙкнбСбЕ~нз=fjn=ff=iбоЙддз=Зб=йкЙлн~тбзеЙK=

fд=Зб~Цк~гг~=Зб=ЕзйЙкнмк~=беЕдмЗЙ=NVO=ЙдЙгЙенб=лЙелбДбдб=

EVS=тзеЙF=лмЗЗбоблб=бе=P=зннбЕЬЙK=lЦеб=зннбЕ~=Ь~=Q=йзлбтбзеб=

йЙк=д~=кЙЦзд~тбзеЙ=оЙкнбЕ~дЙ=йЙк=~З~нн~клб=~ддЫ~днЙтт~=Зб=

белн~дд~тбзеЙ=з=~=ЕзйЙкнмкЙ=йЙклзе~дбтт~нЙK=

PSMш=Й=NUг=Зб=Зб~гЙнкзK=^д=Зб=лзннз=ЗЙб=PKT=гЙнкб=Зб=~днЙтт~=

Зб=белн~дд~тбзеЙ=бд=Зб~гЙнкз=Зб=ЕзйЙкнмк~=Зб=NU=гЙнкб=бебтб~=~=

ЗбгбембкЙ=Сбез=~З=~ккбо~кЙ=~=NR=гЙнкб=~З=ме~=~днЙтт~=Зб=

белн~дд~тбзеЙ=Зб=OKT=гЙнкбK=

a~=OKTг=~=UKSгI=Q=йзлбтбзеб=йЙк=зЦеб=зннбЕ~=бе=СметбзеЙ=

ЗЙддЫ~днЙтт~=Зб=белн~дд~тбзеЙ=

NMKRUT=deтK=

qбйз=ймдл~нз=

NPKR=З_г=Йкй=

a~=V=s==~=NS=s==

OMг^=~=NO=s

б=iba=~ЕЕЙлбK=

iЙенб=Зб=cкЙлеЙд=йбЦгЙен~нЙ=

a~=JOMø=`=~=RRø=`==

a~=Rø=`=~=QMø=`==

a~=JOMш=`=~=SMш=`==

ffш=iбоЙддз=fjn=

VVãã=ñ=NVQãã==

I=PMã^=~=NS=s=I=j~ллбгз=QMг^=Езе=нмннб=

Italiano

= fеЗK=iмk^o=OM MaqdP=J=dмбЗ~=~ддЫбелн~ дд~тбзеЙ= =

23

Page 48

Ind. LuNAR 200DTG3 - Guida all’installazione 24

Page 49

DDTT AAMM GGrraauu 3

MMooddeelloo:: IInndd.. LLuuNNAARR 220000DDTTGG33

3

DDeetteeccttoorr ppaarraa iinnssttaallaaççããoo eemm tteettooss aallttooss

GGuuiiaa ddee iinns

sttaallaaççããoo

Português

Page 50

Descrição Geral

O Industrial LuNAR DT AM Grau 3 (Ind. LuNAR 200DTG3) é um detector de teto de Dupla Tecnologia

com uma altura de montagem de até 8.6m (28 pés), que incorpora a Tecnologia (ACT™) Anti-Cloak™ do

RISCO Group. O detector possui um método de Processamento Inteligente do Sinal Digital que ajusta

automaticamente o limiar do alarme e a verificação do contador de pulsos, segundo a real velocidade de

passagem do intruso e fatores ambientais, proporcionando uma melhor detecção e imunidade a falsos

alarmes.

O Ind. LuNAR 200DTG3 pode funcionar como um detector convencional de relé conectado a qualquer

painel de controle, ou como um acessório direcionável do BUS quando conectado ao painel de controle

do ProSYS do RISCO Group, através do BUS RS485.

Características do Ind. LuNAR 200DTG3

♦ PD6662, EN50131-1, TS50131-2-4 Grau 3

♦ Detector com Dupla Tecnologia (Microondas + Infraverm elho Pa ssivo) com Tecnologia Anti-Cloak™

♦ Altura de montagem de até 8.6 m (28 pés)

♦ Padrão do diâmetro de cobertura de 360° por 18m (60 pés)

♦ 3 canais de Infravermelho Passivos para uma cobertura ajustável para cada necessidade

♦ Processamento Inteligente do Sinal Digital – verificação do alarme e limiares de decisão ajustados

segundo a atual velocidade de passagem do intruso

♦ Resistências de fim de linha triplas embutidas, selecionável através de jumper.

♦ Anti-Mascaramento através de Infravermelho Ativo, atendendo aos requisitos TS50131

♦ Tampers de teto e tampa

♦ Configuração “Green” – para desativar o Microondas quando o sistema estiver desarmado

♦ Opto-relés para baixo consumo de corrente e longo ciclo de vida

♦ Autoteste local e remoto

♦ Entrada de SET (ajuste) remoto

♦ Entrada para habilitar/desabilitar o controle remoto

♦ Ajuste das lentes para maior eficiência da cobertura do Infravermelho Passivo

♦ Ajuste do Alcance de Microondas manualmente (Através de Trímmer - Analógico) ou remotamente

(configuração digital)

♦ Indicação de Problemas (por LEDs ou via comunicação)

♦ 3 LEDs tricolores para um teste de caminhada fácil

♦ Avançado Controle Remoto e Diagnóstico

♦ Consumo de Corrente reduzido quando conectado ao ProSYS do RISCO Group

Ind. LuNAR 200DTG3 – Guia de Instalação 2

Page 51

Características de Controle Remoto e Diagnóstico*

♦ Ajuste remoto do canal de microondas permite habilitar o teste de caminhada por uma

pessoa.

♦ Ferramentas de diagnóstico incluem a leitura da voltagem de entrada ao detector e o

estado de cada canal de Infravermelho Passivo do canal de microondas (voltagem do

sinal e níveis de ruído), canal AM (voltagem do sinal), verificação da versão do Software.

♦ Apresentação remota e controle da configuração do detector: ajuste do microondas, ACT

Ativo / Inativo, LEDs Ativo / Inativo.

♦ Indicador remota de problemas (Passa / Falha) para o Infravermelho Passivo, o

microondas e a entrada de alimentação de energia

♦ Controle da anulação do canal de Microondas (durante problema de Microondas) e de

desabilitar o canal de Microondas durante o Desarme ("Green Line") quando conectado

ao ProSYS.

*Através do Controle Remoto Infravermelho Bidirecional opcional, ou do Software Upload/

Download do ProSYS e o teclado numérico.

Método de Detecção

A detecção do Ind. LuNAR 200DTG3 está baseada em:

♦ IVP (Infravermelho Passivo) – que responde as mudanças na radiação de Infravermelho

causadas quando um intruso cruza a área protegida.

♦ Microondas – que transmite sinais e analisa as mudanças de freqüência do eco refletido

de um intruso usando o Efeito Doppler.

Um ALARME é iniciado somente quando ambas as tecnologias são acionadas simultaneamente

(exceto em certas situações no modo ACT – ver página 4 – “Como Funciona o ACT™”), reduzindo

assim em grande escala a possibilidade de falsos alarmes.

Português

Ind. LuNAR 200DTG3 – Guia de Instalação 3

Page 52

Como Funciona o ACT™

A Tecnologia Anti-Cloak™ (ACT™) proporciona os benefícios de um detector DT (Dual

Technology – Dupla Tecnologia) enquanto evita as suas desvantagens. Esta inovação (Patente

Pendente) criou um novo padrão para os detectores.

A Dupla Tecnologia, uma combinação de Infravermelho Passivo + Microondas, foi um importante

crescimento para a indústria da segurança... Mas possui 2 grandes pontos fracos:

A emissão de Infravermelho dos intrusos pode ser bloqueada, evitando a detecção.

A sensibilidade do Infravermelho Passivo é reduzida quando a temperatura do ambiente da área

protegida se aproxima à temperatura do corpo.

Respondendo às solicitações de seus clientes para solucionar estes problemas urgentes, o RISCO

Group desenvolveu a ACT™ - uma revolucionária solução anti-camuflagem.

O ACT™ impede que o sistema de alarme seja anulado – neutralizando as tentativas de camuflar

a radiação de Infravermelho. Usando algoritmos de reconhecimento de padrão único, a ACT™

distingue entre o sinal fraco de Infravermelho de um intruso em movimento e o ruído de fundo e as

interferências térmicas que podem causar falsos alarmes.

Uma vez verificada a presença de um intruso, a ACT™ troca automaticamente o sistema do modo

de dupla tecnologia Infravermelho Passivo/Microondas para o modo de canal único de Microondas

por um período de tempo predeterminado, com a finalidade de ativar um alarme usando o canal

Microondas, e depois retorna ao modo de canal duplo.

No segundo caso, quando a temperatura do ambiente se aproxima à temperatura do corpo, o

ACT™ passa a detecção somente por microondas.

Oferecendo uma capacidade de detecção excepcionalmente alta, assim como imunidade a falsos

alarmes, a ACT™ frustra até aos mais sofisticados intrusos.

Ind. LuNAR 200DTG3 – Guia de Instalação 4

Page 53

Opções de Configuração do Ind. LuNAR 200DTG3

O Ind. LuNAR 200DTG3 pode ser configurado e/ou diagnosticado remotamente através de uma

das seguintes opções:

Modo ACT

LEDs

Sensibilidade Microondas

Diagnóstico

Estado/Problema/Informes

Configuração

Manual

Controle

Remoto

9 9 9

9 9 9

(Através do

9

trimmer)

-

-

9 9

9 9

9 9

Controle Bus

ProSYS

de Informação

Diagnóstico Antimáscara

Anulação Microondas

Microondas Desativadas ao

Desarmar ("Green Line")

- -

- -

- -

9

9

9

Visualização dos LED’s

Os três LEDs tricolores no Ind. LuNAR 200DTG3, operam como descrito a seguir:

LED ESTADO SIGNIFICADO

Alarme do detector (detecção

Constante

Vermelho

Piscando em baixa freqüência

Infravermelha Passivo e Microondas

simultâneo)

Indica mau funcionamento da comunicação

com o ProSYS

Piscando em alta freqüência Detecção Anti-máscara

Verde

Laranja

Constante Detecção microondas

Piscando Problema no canal de Microondas

Constante Detecção Infravermelho Passivo

Piscando Problema no canal Infravermelho Passivo

Todos os

LEDs

Piscando com mudança de

cor

Ao ativar-se

Ind. LuNAR 200DTG3 – Guia de Instalação 5

Português

Page 54

INSTALAÇÃO

Passos preliminares:

♦ Antes de instalar, estude cuidadosamente o espaço a ser protegido para escolher a

localização exata da unidade para a melhor cobertura possível.

♦ Nunca instale o LuNAR num ambiente que cause uma condição de alarme em uma das

tecnologias.

♦ Evite as instalações onde máquinas rotativas (por exemplo, ventiladores) estejam

normalmente em operação dentro da área de cobertura. Aponte a unidade para longe de

vidros expostos ao exterior e a objetos que podem mudar rapidamente de temperatura.

♦ Não monte o detector com luz direta do sol nem perto de nenhuma fonte de calor. Os

setores de detecção devem apontar em direção a uma parede, ou a um assoalho mas

nunca em direção a janelas ou cortinas. A superfície de instalação deve ser sólida, lisa e

sem vibrações.

♦ Elimine a interferência de fontes exteriores próximas.

♦ Para uma ótima detecção, selecione uma localização propensa a interceptar um intruso

movendo-se através do padrão de cobertura.

♦ A altura de montagem recomendada, que permite um diâmetro de detecção de 18m (60

pés), é de 3.7m até 8.6m.

♦ O detector deve ser montado no teto, preferentemente no centro do recinto.

Ind. LuNAR 200DTG3 – Guia de Instalação 6

Page 55

A típica cobertura de detecção do Ind. LuNAR 200DTG3 e a altura de instalação são ilustradas

abaixo:

Português

Ind. LuNAR 200DTG3 – Guia de Instalação 7

NOTA:

Quando o detector Ind. LuNAR 200DTG3 é instalado

em um local que contenha uma quantidade de fatores

que causem interferência, a detecção por Microodas

pode ser afetada

Page 56

Processo de Instalação:

Para abrir o detector (Figura 1), retire a tapa inserindo uma chave de fenda (1) no encaixe entre a

tampa de proteção e a capa. A capa permanece unida à base do detector.

Usando uma chave de fenda Philips, libere o parafuso superior da tapa (2) e puxe suavemente

para cima a tapa superior do detector.

2

FIGURA 1

1

Ind. LuNAR 200DTG3 – Guia de Instalação 8

Page 57

Libere o parafuso que mantém o PCB (Figura 2) localizado no lado direito do PCB (1), puxe

suavemente os dois clipes de liberação (2) para fora e retire o PCB.

Não toque nos

sensores de

FIGURA 2

Infravermelho

Passivo!

Português

Se requerido, abra (Figura 3) o furo pré-marcado dos canais de fiação usando um alicate de corte

(1, 2) e os furos pré-marcados na tampa posterior (3, 4) usando uma chave de fenda.

Ind. LuNAR 200DTG3 – Guia de Instalação 9

Page 58

FIGURA 3

3 4

Introduza o cabo através da abertura do cabo (Figura 4) e conecte os cabos desejados como

descrito no “Passo 4- Fiação”.

Ind. LuNAR 200DTG3 – Guia de Instalação 10

Page 59

FIGURA 4

Monte a tampa posterior em sua localização final (Figura 5) usando os três parafusos de

montagem e sele os furos abertos remanescente com um material impermeabilizante.

NOTA:

Quando for utilizada uma única caixa de passagem,

use 2 parafusos adicionais para montar a base na

caixa.

O tamper posterior não pode ser usado neste caso!

FIGURA 5

Furo do

Tamper

Posterior

Retorne o PCB à sua localização anterior e verifique que tudo está bem assegurado pelos clipes

de sustentação e pelo parafuso.

Execute o ajuste da lente e a configuração dos Interruptores Dip como descrito em “Ajuste de

Lentes” nesta página e “Configuração dos Interruptores Dip” na página 15.

Monte a tampa superior na base do detector.

Aperte o parafuso central da tampa superior.

Ind. LuNAR 200DTG3 – Guia de Instalação 11

Português

Page 60

Recoloque a tampa de proteção do detector.

NOTA:

Se for requerido tamper de teto, rompa e abra o furo

do tamper do teto na base do detector!

Ajuste de Lentes:

O LuNAR tem três lentes Fresnel unidas à tampa, localizadas em mangas protetoras do sensor.

Ajuste a posição das lentes baseando-se na altura de montagem em teto como segue:

Pressione os 2 clipes que unem a manga (Figura 6) à tampa do detector, e retire suavemente a

manga.

FIGURA 6

Retire as lentes da manga (Figura 7) levantando-a suavemente dos pinos de sustentação que a

asseguram nos lados do protetor de elemento piroelétrico.

Ind. LuNAR 200DTG3 – Guia de Instalação 12

Page 61

FIGURA 7

Coloque os dois pinos, que estão localizados em ambos os lados do protetor de elemento

piroelétrico ranhuras apropriadas na lente. Use a seguinte tabela para selecionar a desejada

posição da lente.

Retorne o protetor de elemento piroelétrico a seu lugar na tampa dianteira do detector.

Repita os passos 1 a 5 para as 2 lentes remanescentes.

Ind. LuNAR 200DTG3 – Guia de Instalação 13

Português

Page 62

NOTAS:

Abaixo da altura de montagem de 3.7m, o diâmetro de

cobertura começa a diminuir, e na altura de 2.7m, o

diâmetro de cobertura é de 15m (50 pés).

Para uma cobertura personalizada, é possível fixar a

posição de cada lente numa altura diferente, segundo

as condições de instalação.

P

I

R

+ 12 -

TAMPERAM/FAULT ALARM

BLK RED

BUS

GRN YEL

RC SET

R

I

P

Ind. LuNAR 200DTG3 – Guia de Instalação 14

Page 63

Jumpers de controle

ENTRADA DE

CONTROLE

REMOTO/SET

Usado para determinar a polaridade das entradas externas.

12V: Para ativar o funcionamento é necessário aplicar 12V.

GND ou Desligado não tem influência no estado do Controle

remoto/SET.

(veja as configurações dos dipswitches no modo Relé)

0V: Para ativar o funcionamento é necessário aplicar GND.

12v ou Desligado não tem influência no estado do Controle

remoto/SET.

(veja as configurações dos dipswitches no modo Relé)

Ind. LuNAR 200DTG3 – Guia de Instalação 15

Português

Page 64

JUMPERS

RESISTÊNCIA

EOL

FAULT/AM EOL

JUMPERS

12K

No

Resistor

(Default)

Os jumpers são usados ao conectar-se o detector

a uma Zona DEOL ou TEOL. Os jumpers

permitem a seleção de resistências EOL de

TAMPER, ALARME (1K, 2.2K, 4.7K, 5.6K

ou6.8K), de acordo com as configurações do

painel de controle. Um jumper duplo adicional

permite a conexão de uma resistência EOL de

12K FALHA/AM (ver Diagrama de Resistências

EOL).

Siga o diagrama de conexão do bloco de

terminais ao conectar o detector a uma Zona de

Duplo/Triplo Fim-de-Linha (DEOL/TEOL).

Diagrama Esquemático das Resistências EOL

Configuração dos Interruptores DIP

O Ind. LuNAR 200DTG3 tem um interruptor DIP de 9 posições que muda de funcionalidade para

uso no modo de operação Relé ou BUS. Configure o interruptor DIP de acordo com as tabelas

abaixo:

Configuração Predeterminada em Fábrica:

Ind. LuNAR 200DTG3 – Guia de Instalação 16

ON

123456789

Page 65

Configuração do Modo Relé

(Interruptor DIP 6=OFF)

:

Número do

Interruptor DIP

1

2

3

4

5

6

7

Descrição

Usado para determinar a operação do ACT

Interruptor DIP ON: ACT está ativado

Interruptor DIP OFF: ACT está desativado (predeterminado em fábrica)

Usado para determinar a operação dos LEDs do detector

Interruptor DIP ON: LEDs estão ativados (predeterminado em fábrica)

Interruptor DIP OFF: LEDs estão desativados

Usado para determinar a função "Green Line" (veja nota abaixo)

Interruptor DIP ON: "Green Line" está ativada

Interruptor DIP OFF: "Green Line" está desativada (Ajuste de fábrica)

Usado para determinar o tipo de Autoteste (veja nota abaixo)

Interruptor DIP ON: Autoteste Local:

No caso de falhar o autoteste local, o Relé FALHA/AM é ativado por um período de

2.5 segundos.

Interruptor DIP OFF: Autoteste Remoto (predeterminado em fábrica):

No caso de o autoteste remoto ser bem sucedido, os Relés Alarme são ativados por

um período de 5 segundos. No caso de o teste falhar, o Relé FALHA/AM é ativado

por um período de 2.5 segundos.

Usado para determinar se o Anti-Mascaramento por Infravermelho Ativo está ativado.

(veja nota abaixo)

Interruptor DIP ON: Ativado

Interruptor DIP OFF: Desativado (predeterminado em fábrica)

IMPORTANTE:

Caso o Jumper do AM esteja habilitado através do Dipswitch 5, a tampa do detector deve

ser colocada dentro de 1 minuto após a ligação da alimentação elétrica. Caso o detector já

esteja alimentado eletricamente e o Dipswitch 5 esteja ligado, a unidade deve ter a sua

alimentação desligada e re-ligada, para re-iniciar a calibração do sistema de Anti-Máscara

(AM).

Usado para determinar o modo de conexão do detector

Interruptor DIP OFF: Modo Relé

Usado para determinar se a comunicação do Controle Remoto (RC) está ativada ou

desativada.

Interruptor DIP ON: A comunicação do RC está sempre ativada.

Português

Ind. LuNAR 200DTG3 – Guia de Instalação 17

Page 66

Interruptor DIP OFF: A comunicação do Controle Remoto depende da voltagem

aplicada ao bloco de terminais “RC” (Ajuste de fábrica)

Quando um sinal de ativação é aplicado à entrada do Controle Rem oto do blo co de

terminais, o controle remoto estará ativado.

IMPORTANTE:

Passe o interruptor 7 para “OFF” depois da instalação e quando sair do local por razões de

segurança. Isto evitará o uso não-autorizado de uma unidade de controle remoto que pode

ser utilizada para desativar o detector.

8-9

Não Aplicável – Dipswitches desligados

IMPORTANTE:

Desconecte todas as fontes de energia antes de configurar os interruptores DIP do Ind.

LuNAR 200DTG3. Ligue as fontes de energia ao completar a configuração!

NOTE:

Consulte os ajustes de do bloco de terminais para detalhes de ativação.

Configuração do Modo BUS

(Interruptor DIP 6=ON):

Número

do

Interruptor

Descrição

DIP

Usado para configurar o número de ID do detector. (Ver Tabela 1)

1-5

Configure o número de ID da mesma maneira como para qualquer outro acessório do

ProSYS.

6

Usado para determinar o modo de conexão do detector.

Interruptor DIP ON: Conexão ProSYS– Configuração BUS

NOTE:

Ao ser ativado ou em operação normal, o LuNAR espera 10 segundos para a comunicação

com o ProSYS. Pode ocorrer um problema de comunicação devido à má fiação, endereço

errado, ou se o ProSYS não foi devidamente configurado; todos os LEDs piscarão

continuamente até ser solucionado o problema.

7

8-9

Não aplicável (a comunicação RC é automaticamente ativada ao passar para o modo

teste de caminhada no ProSYS e desativada em caso contrário).

Interruptor DIP ON: A fim de habilitar o detector para informar o estado do tamper ao

ProSYS.

ON

1234

BUS ADDRESS

TAMPER

BUS

N/A

MODE

9

8

6

5

7

Ind. LuNAR 200DTG3 – Guia de Instalação 18

Page 67

Tabela 1: Configuração do ID para a conexão BUS

ID 1 2 3 4 5 ID 1 2 3 4 5

OFF OFF OFF OFF OFF

01

ON OFF OFF OFF OFF

02

OFF ON OFF OFF OFF

03

ON ON OFF OFF OFF

04

OFF OFF ON OFF OFF

05

ON OFF ON OFF OFF

06

OFF ON ON OFF OFF

07

ON ON ON OFF OFF

08

OFF OFF OFF ON OFF

09

ON OFF OFF ON OFF

10

OFF ON OFF ON OFF

11

ON ON OFF ON OFF

12

OFF OFF ON ON OFF

13

ON OFF ON ON OFF

14

OFF ON ON ON OFF

15

ON ON ON ON OFF

16

OFF OFF OFF OFF ON

17

ON OFF OFF OFF ON

18

OFF ON OFF OFF ON

19

ON ON OFF OFF ON

20

OFF OFF ON OFF ON

21

ON OFF ON OFF ON

22

OFF ON ON OFF ON

23

ON ON ON OFF ON

24

OFF OFF OFF ON ON

25

ON OFF OFF ON ON

26

OFF ON OFF ON ON

27

ON ON OFF ON ON

28

OFF OFF ON ON ON

29

ON OFF ON ON ON

30

OFF ON ON ON ON

31

ON ON ON ON ON

32

Português

Ind. LuNAR 200DTG3 – Guia de Instalação 19

Page 68

Blocos de Terminais