RISAFloor

Rapid Interactive Structural Analysis – Floor Systems

Version 5.0 – General Reference

26632 Towne Centre Drive, Suite 210

Foothill Ranch, California 92610

(949) 951-5815

(949) 951-5848 (FAX)

www.risatech.com

Copyright 2010 by RISA Technologies, LLC All rights reserved. No portion of the contents of this

publication may be reproduced or transmitted in any means without the express written permission of

RISA Technologies, LLC.

We have done our best to insure that the material found in this publication is both useful and accurate.

However, please be aware that errors may exist in this publication, and that RISA Technologies, LLC

makes no guarantees concerning accuracy of the information found here or in the use to which it may be

put.

Table of Contents

General Reference Manual

I

Table of Contents

Before You Begin ............................................... 1

Overview ........................................................... 1

Hardware Requirements .................................. 1

Program Limits ................................................. 2

License Agreement .......................................... 2

Maintenance ..................................................... 3

Installation ........................................................ 4

Application Interface ......................................... 5

Main Menu ........................................................ 5

Shortcut Menu .................................................. 8

Toolbars ............................................................ 8

Dynamic View Controls .................................... 11

Shortcut Keys and Hot Keys ............................ 12

Status Bar ......................................................... 13

Windows ........................................................... 14

Modes ............................................................... 14

Beams ................................................................. 16

Shear Results ................................................... 35

Bending Results ............................................... 35

Column Results ................................................ 36

Assumptions and Limitations ............................ 37

Special Messages ............................................ 38

Columns .............................................................. 39

Drawing Columns ............................................. 40

Modifying Column Properties ........................... 41

Modifying Column Design Parameters ............. 42

Column Stacks and Physical Columns ............. 43

Columns Spreadsheet ...................................... 44

Column Stacks Spreadsheet ............................ 47

Column Stack Manager .................................... 48

Columns – Results............................................. 51

Column Forces ................................................. 51

Concrete – Database ......................................... 55

Rebar Layout Database .................................... 55

Drawing Beams ................................................ 17

Drawing Infill Beams ......................................... 18

Modifying Beam Properties .............................. 20

Modifying Beam Design Parameters ................ 21

Beams – Primary Data ..................................... 22

Beams Spreadsheet – Detailing Data .............. 23

Beams – Results ................................................ 24

Beam Deflection Results .................................. 24

Beam End Reactions ........................................ 25

Beam Vibration Results .................................... 26

Cold Formed Steel – Databases ....................... 27

Custom vs. Manufacturer Shapes .................... 27

Cold Formed Shape Types .............................. 28

Cold Formed Steel – Design ............................. 30

Design Parameters ........................................... 30

Phi Factors ....................................................... 33

Design Results ................................................. 33

Concrete – Design ............................................. 60

Concrete Spans ................................................ 60

Concrete Design Parameters – Columns ......... 60

Concrete Design Parameters – Beams ............ 62

T-beam & L-beam Sections .............................. 64

Parabolic vs. Rectangular Stress Blocks .......... 64

Biaxial Bending of Columns .............................. 65

Limitations – General ........................................ 66

Limitations – ACI .............................................. 66

Limitations – Canadian Code ........................... 66

Limitations – Australian and NZ Codes ............ 66

Limitations – British .......................................... 67

Limitations – Euro ............................................. 67

Limitations – Indian ........................................... 67

Limitations – Saudi Code .................................. 67

Special Messages ............................................ 67

Concrete – Design Results ............................... 69

Code Checks .................................................... 34

Beam Results ................................................... 69

Table of Contents

II

RISAFloor v5.0

Column Results ................................................ 74

File Operations ................................................... 114

Concrete Detail Reports ................................... 76

Beam Detail Reports ........................................ 76

Column Detail Reports ..................................... 78

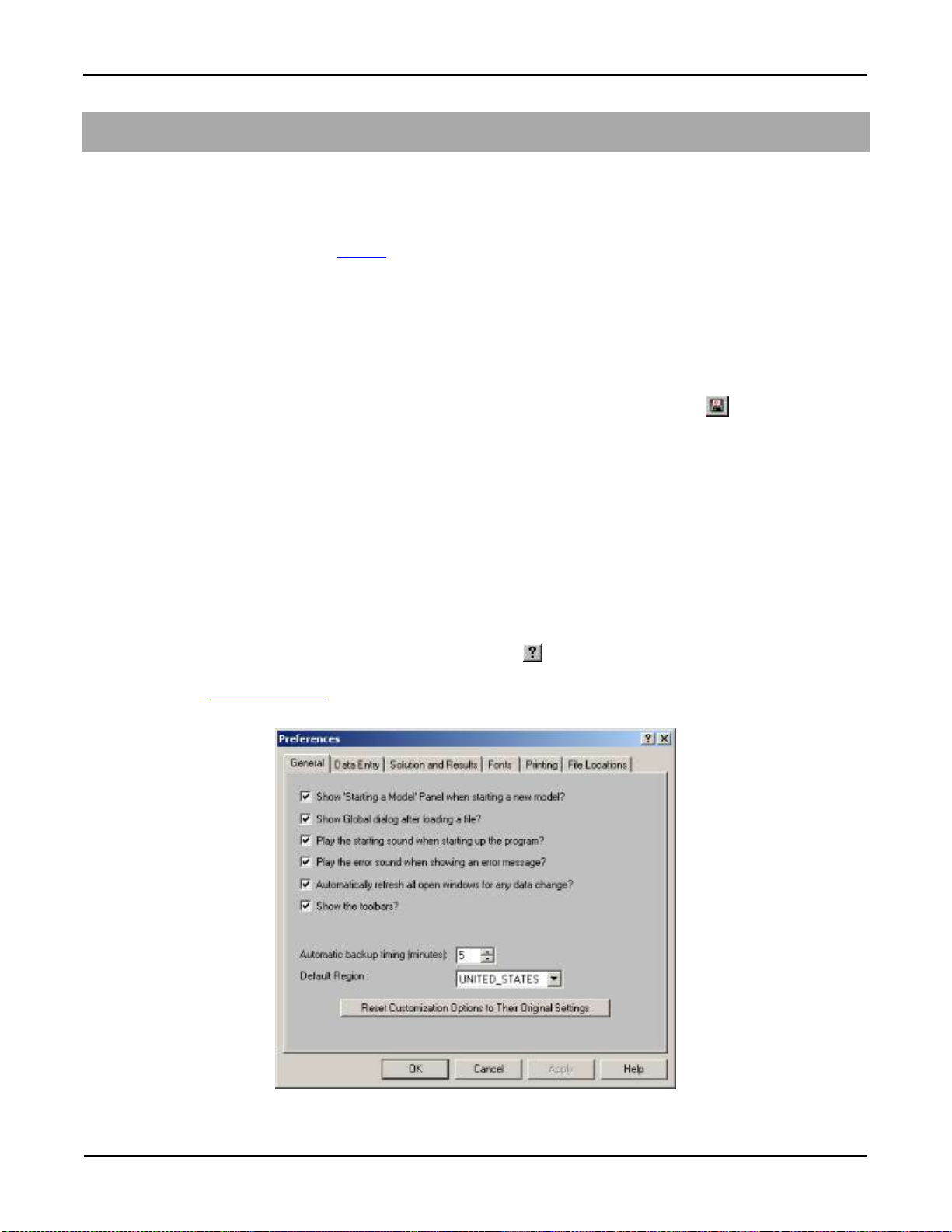

Customizing RISAFloor .................................... 81

Save as Defaults .............................................. 81

Preferences ...................................................... 81

Decks and Slabs ................................................ 86

Creating Slab Edges and Openings ................. 86

Modifying Slab Edges and Openings ............... 87

Assigning Slab and Deck Properties ................ 88

Deck Properties – General ............................... 89

Deck Properties – Composite ........................... 90

Deck Properties – Loads .................................. 92

Slab Edge and Opening Perimeters ................. 92

Design Optimization .......................................... 93

Design Lists ...................................................... 93

Design Rules – Size / U.C. ............................... 94

Starting Off........................................................ 114

Importing and Exporting Files ........................... 114

Automatic Backup ............................................. 114

Floors .................................................................. 116

Creating a New Floor ........................................ 116

Deleting a Floor ................................................ 116

Floors Spreadsheet .......................................... 117

Parent / Child .................................................... 118

Global Parameters ............................................. 119

Description ........................................................ 119

Solution ............................................................. 120

Codes ............................................................... 121

Composite ......................................................... 123

Wind .................................................................. 124

Seismic ............................................................. 125

Concrete ........................................................... 126

Graphic Display.................................................. 128

Design Rules – Deflection ................................ 95

Design Rules – Concrete Rebar....................... 96

Design Rules – Masonry Walls ........................ 97

Design Rules – Wood Wall (Studs) .................. 98

Design Rules – Wood Wall (Fasteners) ........... 99

Design Rules – Diaphragms ............................. 100

Member Redesign Dialog ................................. 100

Optimization Procedure – Walls ....................... 101

Diaphragms ........................................................ 102

Rigid Diaphragms ............................................. 102

Semi-Rigid Diaphragms ................................... 103

Flexible Diaphragms ......................................... 103

Diaphragms Spreadsheet ................................. 104

Diaphragm Modeling Tips ................................ 105

DXF Files ............................................................ 107

Importing DXF Files .......................................... 107

Exporting DXF Files ......................................... 109

Multiple Windows .............................................. 128

Controlling the Model View ............................... 129

Viewing Part of the Model ................................. 131

Saving and Retrieving Model Views ................. 131

Graphic Display – Plot Options ........................ 132

Beams/Columns/Walls ..................................... 132

Points/Decks/Slabs ........................................... 133

Loads ................................................................ 134

Miscellaneous ................................................... 135

Graphic Editing .................................................. 137

Drawing and Modification Features .................. 137

Undo Operations .............................................. 138

Redo Operations .............................................. 138

Project Grid ....................................................... 138

Drawing Grid ..................................................... 140

Snap Points ...................................................... 143

Deleting Elements ............................................ 144

DXF Element Numbers .................................... 111

DXF File Format ............................................... 111

Graphic Selection .............................................. 146

Selection Modes ............................................... 146

Table of Contents

General Reference Manual

III

Inverting Selections .......................................... 147

Effective Width Calculation ............................... 169

Criteria Selections ............................................ 147

Locking Selections ........................................... 151

Graphic Selection from Spreadsheets ............. 151

Saving Selections ............................................. 152

Help Options ...................................................... 153

Electronic Help File .......................................... 153

Context Sensitive Help ..................................... 153

RISA Technologies Online ............................... 153

Tool-tips ............................................................ 153

Tutorial .............................................................. 153

Hot Rolled Steel – Databases ........................... 154

Hot Rolled Steel – Design ................................. 157

Design Parameters Spreadsheet ..................... 157

Member Design Parameters – General ........... 158

Member Design Parameters – AISC Codes .... 160

Hot Rolled Design Parameters – Canadian ..... 161

Hot Rolled Design Parameters – British ........... 161

General Limitations ........................................... 170

Limits / Assumptions for Canadian Comp ........ 170

Troubleshooting Composite Design ................. 171

Detail Reports for Composite Design ............... 171

Hot Rolled Steel – Design Results ................... 173

Design Results.................................................. 173

Code Checks .................................................... 174

Shear Results ................................................... 175

Bending Results ............................................... 175

Column Results ................................................ 176

Loads .................................................................. 178

Self Weight (Gravity Load) ............................... 178

Load Cases....................................................... 178

Load Categories ............................................... 179

Modifying Loads ............................................... 180

Deleting Loads .................................................. 180

Load Direction................................................... 180

Hot Rolled Design Parameters – EuroCode .... 162

Hot Rolled Design Parameters – Indian ........... 162

General Limitations .......................................... 163

Limitations – AISC ............................................ 163

Limitations – Canadian ..................................... 164

Limitations – British .......................................... 164

Limitations – EuroCode .................................... 164

Limitations – Indian .......................................... 165

Limitations – New Zealand and Australia ......... 165

Special Messages – AISC ................................ 165

Special Messages – Canadian ......................... 166

Special Messages – Eurocode ......................... 166

Hot Rolled Steel – Composite Beam Design .. 167

Pre-Composite Design ..................................... 167

Post-Composite Design – ASD (AISC 9th Ed) . 167

Post-Composite Design – LRFD ...................... 168

Deflection Design ............................................. 168

Loads – Load Types .......................................... 182

Area Loads ....................................................... 182

Tapered Area Loads ......................................... 185

Deck Loads ....................................................... 185

Line Loads ........................................................ 185

Point Loads ....................................................... 187

Loads – Live Load Reduction ........................... 190

Overview ........................................................... 190

Reducible Load Types ...................................... 190

Special Live Loads ........................................... 190

Area Calculations ............................................. 190

Limitations ......................................................... 190

Loads – Load Attribution .................................. 191

One Way Deck.................................................. 191

Two Way Deck.................................................. 192

Loads – Load Combinations ............................. 193

Load Combinations Spreadsheet ..................... 193

Studs and Stud Distribution .............................. 168

Deck Ranking ................................................... 169

Transient Load Combinations........................... 194

Timber Design Load Duration Factor ............... 195

Table of Contents

IV

RISAFloor v5.0

Generating Building Code Combinations ......... 195

Results Spreadsheets ...................................... 229

Load Generation – Notional Loads .................. 199

Vertical Load used for Notional Force Calcs .... 199

Notional Load Generation Dialog ..................... 199

Notional Load Results ...................................... 200

Load Generation – Seismic Loads ................... 201

Seismic Weight ................................................. 201

Seismic Design Parameters ............................. 202

Seismic Load Results ....................................... 203

Load Generation – Wind Loads ........................ 205

Wind Load Parameters ..................................... 205

Wind Load Results ........................................... 206

Sloped Roof Wind Loads .................................. 208

Wind Load Limitations ...................................... 209

Material Properties ............................................ 210

Material Properties Spreadsheet ...................... 210

Material Take-Off ................................................ 212

Cardinal Points .................................................. 213

Graphic Results ................................................ 230

Clearing Results ............................................... 230

Member Detail Report ...................................... 230

Concrete Member Detail Reports ..................... 231

RISAFloor and RISA-3D Integration ................. 232

Lateral System Model Generation .................... 232

Diaphragms ...................................................... 233

Gravity Loads.................................................... 233

Wind Loads ....................................................... 233

Seismic Loads .................................................. 233

RISAFoundation Interaction ............................. 234

RISAFoundation Interaction with RISA-3D ....... 234

RISAFoundation Interaction with RISAFloor .... 236

Limitations ......................................................... 236

Shape Databases ............................................... 238

Database Shape Types .................................... 238

Hot Rolled Shapes ............................................ 238

Overview ........................................................... 213

Detailing Input and Modification: ...................... 214

Visualization of the Detailing Layer .................. 217

File I/O .............................................................. 219

Modeling Tips ..................................................... 220

Dummy Members ............................................. 220

Stranded Columns ............................................ 220

Stranded Walls ................................................. 221

Modeling Hangers ............................................ 222

P-Delta – Analysis.............................................. 223

Leaning Column Effect ..................................... 223

Points .................................................................. 224

Point Locations Spreadsheet ........................... 224

Printing ............................................................... 226

Printing Reports ................................................ 226

Printing to a File................................................ 227

Graphics Printing .............................................. 227

Cold Formed Shapes ........................................ 238

Concrete Shapes .............................................. 238

Wood Shapes ................................................... 238

General Shapes ................................................ 238

Database Files .................................................. 241

Sloped Members ................................................ 242

Tips for Modeling on Sloped Floors .................. 244

Limitations ......................................................... 244

Solution ............................................................... 246

Solution Method ................................................ 246

Diff Between RISA-3D and RISAFloor ............. 246

Diff Between Analysis and Design Sizes .......... 246

Spreadsheet Operations ................................... 248

Moving and Scrolling ........................................ 248

Spreadsheet Keyboard Commands ................. 248

Selecting Spreadsheet Cells ............................ 249

Undoing Operations .......................................... 249

Results ................................................................ 229

Saving Results.................................................. 229

Redoing Operations .......................................... 249

Editing Spreadsheets ....................................... 249

Table of Contents

General Reference Manual

V

Moving and Copying Cell Contents .................. 251

Wood Wall – Design........................................... 295

Finding in Spreadsheets ................................... 252

Default Spreadsheet Data ................................ 252

Special Spreadsheet Functions ........................ 252

Steel Products (Joists and Joist Girders) ....... 253

Steel Products Database .................................. 253

Steel Products Design ...................................... 253

Design for Joists with Non-Uniform Loads ....... 254

Joist Girders ..................................................... 255

Design Results – Steel Products ...................... 255

Limitations ........................................................ 256

Units .................................................................... 257

Standard Imperial Units .................................... 257

Standard Metric Units ....................................... 257

Units Specifications .......................................... 257

Vibrations – Floor Framing ............................... 259

Vibrations Spreadsheet .................................... 259

Calculation of Vibration Loads and Def ............ 260

Limitations ........................................................ 260

Wall Panels ......................................................... 262

Drawing Wall Panels ........................................ 262

Modifying Wall Panels ...................................... 263

Wall Panel Spreadsheets ................................. 265

Wall Panel Editor .............................................. 266

Wall Panel Load Attribution and Load Trans .. 269

Wall Panel Load Attribution .............................. 269

Wall Panel Load Transfer ................................. 273

Wall Panels – Results ........................................ 278

Wall Panel Results ........................................... 279

Masonry Wall Panel – Design ........................... 283

Masonry Wall Input ........................................... 283

Masonry Wall Optimization ............................... 287

Masonry Wall Results........................................ 288

Masonry Wall Spreadsheet Results ................. 288

Concrete Reinforcing Spreadsheet Results ..... 288

Masonry Wall Detail Reports ............................ 288

Masonry Detail Reports – Lintels ..................... 292

Wood Wall Input ............................................... 295

General Requirements for Shear Walls ............ 297

General Program Functionality and Limits ....... 302

Wood Wall Results............................................. 307

Wood Wall Results Spreadsheets .................... 307

Wood Wall Self Weight ..................................... 307

Wood Wall Detail Reports ................................ 307

Warning Log ....................................................... 312

Wood – Database ............................................... 313

Custom Wood Sizes ......................................... 314

Wood – Design ................................................... 315

Glu-Lams .......................................................... 315

Custom Wood Materials & Structural Composite

Lumber .............................................................. 315

Wood Member Design Parameters .................. 316

Timber Design Adjustment Factors .................. 318

Beam Design Results ....................................... 320

Beam Code Checks .......................................... 321

Beam Shear Results ......................................... 322

Beam Bending Results ..................................... 322

Column Results ................................................ 323

Special Messages – Wood Design ................... 324

Limitations – Wood Design ............................... 325

Wood Products .................................................. 326

Wood Products Database ................................. 326

Wood Products Adjustment Factors ................. 327

Design Results – Wood Products ..................... 328

Wood Product Limitations ................................. 329

Appendix A – Redesign Lists ........................... 330

Appendix B – Error Messages .......................... 332

Appendix E – Interfacing w/ Other Programs . 333

Integration with other RISA programs .............. 333

Importing or Exporting DXF Files ..................... 333

Linking your Autodesk Revit Structure model with

RISAFloor ......................................................... 333

Appendix F – Wood Shear Wall Files............... 334

Hold Downs ...................................................... 334

Table of Contents

VI

RISAFloor v5.0

Panel Nailing Schedules .................................. 335

Diaphragm Nailing Schedules .......................... 337

Technical Support.............................................. 340

Before You Begin

General Reference Manual

1

Before You Begin

Welcome to the RISAFloor General Reference manual. Please read this topic prior to installing the program and pay

particular attention to the License Agreement. If you agree to the terms of the license then read the Installation section and

install the program. If you are a first time user of RISAFloor you should turn your attention to the User's Guide (a separate

document) which is designed to get you up and running as fast as possible while still exposing you to the important features

of the software.

The User's Guide is designed to be read in two ways. If you are already familiar with structural modeling in general you can

skip the supporting text and read only the underlined action items to quickly move through the tutorial. If you want more

thorough explanations of the modeling process you may read all or some of the supporting text as you see fit.

After you have gone through the User's Guide, use this General Reference for detailed information on any topic. The topics

are arranged in alphabetical order and are thoroughly indexed.

Overview

RISAFloor has been developed to make the definition, design and modification of floor systems as fast and easy as possible.

Analysis, up to and including calculation of maximum deflections and stresses, may be done on structures constructed of any

material or combination of materials. Furthermore, complete member design optimization is provided for hot rolled and cold

formed steel, NDS wood beams, concrete beams and columns, as well as steel or wood products.

RISAFloor has both graphical modeling and spreadsheet input capabilities. Not only can you draw your model, there are

exceptional generation tools that automatically layout floor elements. To modify your model input data directly, RISAFloor

employs a powerful, proprietary spreadsheet. The combination of these features makes modeling both intuitive and powerful.

The model can be rapidly edited, solved, viewed, modified, re-solved, etc. The truly interactive nature of RISAFloor is its

primary strength.

With RISAFloor, all model editing, model solution, and results browsing is accomplished through the same interface and

within the same program. The interactive approach offers several unique advantages such as the ability to do real time error

checking of your model data, the ability to do rapid model editing, solution, editing, and re-solution without jumping from

one program to another, and the need for the user to learn only one program interface.

You may access the features in RISAFloor by using the menu system, or the toolbars. The best way to learn RISAFloor is to

go through the User's Guide. The advantage to this is that you are exposed to the tools RISAFloor provides AND the ways

that you can take advantage of them.

Hardware Requirements

Minimum

Any Windows compatible computer with a Pentium 3 or better processor

Windows 2000\XP\Vista\Windows 7

256 MB of RAM

200 MB of hard disk space

Two or three button mouse

USB port (required for Stand-Alone version or the Network Host computer)

Recommended

Windows XP\Vista\Windows 7

As much extended RAM as possible

As much free disk space as possible

Before You Begin

2

RISAFloor v5.0

Two button mouse with wheel

Note

The amount of space needed by RISAFloor to solve a particular structural model depends on the size of the

model. RISAFloor has been written such that it will use as much RAM as is available. If this isn't enough,

RISAFloorn will start using HD space until enough memory is obtained to solve the problem. Of course, if

RISAFloor is required to use HD space, the solution will be much slower. So, the more memory you have

available, the better. In general, 500 Megabytes (MB) of RAM is a good amount to solve most problems.

However, if you will be regularly solving large problems, more memory will save you a lot of time in the long

run.

Program Limits

200 Floors

1,000 Columns per Floor

3,000 Beams per Floor

500 Walls per Floor

2,000 Point Loads per Floor

2,000 Line Loads per Floor

200 Area Load Polygons per Floor

200 Tapered Area Loads per Floor

200 Deck Polygons per Floor

500 Materials

500 Custom Wood Species

5000 Load Combinations

Demonstration Version: While you can open and solve a larger model, the largest model that can be saved to disk with the

demonstration version is limited to a total of 4 walls and 3 Floors with a maximum of 30 members for each of the floors.

License Agreement

END-USER LICENSE AGREEMENT FOR RISA Technologies, LLC® SOFTWARE

The RISAFloor software product (SOFTWARE PRODUCT) includes computer software, the associated media, any printed

materials, and any electronic documentation. By installing, copying or otherwise using the SOFTWARE PRODUCT, you

agree to be bound by the terms of this agreement. If you do not agree with the terms of this agreement RISA Technologies,

LLC is unwilling to license the SOFTWARE PRODUCT to you. In such event you must delete any installations and destroy

any copies of the SOFTWARE PRODUCT and return the SOFTWARE PRODUCT to RISA Technologies, LLC within 60

days of purchase for a full refund.

Copyright 2010 by RISA Technologies, LLC. All rights reserved. The SOFTWARE PRODUCT is protected by United

States copyright laws and various international treaties. All rights not specifically granted under this agreement are reserved

by RISA TECHNOLOGIES.

1. SOFTWARE LICENSE. The SOFTWARE PRODUCT is licensed, not sold. All right, title and interest is and remains

vested in RISA Technologies, LLC. You may not rent, lease, or lend the SOFTWARE PRODUCT. You are specifically

granted a license to the use of this program on no more than one CPU at any given time. The Network Version of the

SOFTWARE PRODUCT is licensed for simultaneous use on a certain maximum number of network stations that varies on a

per license basis. As part of the license to use the SOFTWARE PRODUCT, the program user acknowledges the reading,

understanding and acceptance of all terms of this agreement. The SOFTWARE PRODUCT may not be reviewed, compared

Before You Begin

General Reference Manual

3

or evaluated in any manner in any publication without expressed written consent of RISA Technologies, LLC. You may not

disassemble, decompile, reverse engineer or modify in any way the SOFTWARE PRODUCT. If the SOFTWARE

PRODUCT was purchased at a discounted price for educational purposes it may in no event be used for professional design

purposes. The terms of this license agreement are binding in perpetuity.

2. DISCLAIMER. We intend that the information contained in the SOFTWARE PRODUCT be accurate and reliable, but it

is entirely the responsibility of the program user to verify the accuracy and applicability of any results obtained from the

SOFTWARE PRODUCT. The SOFTWARE PRODUCT is intended for use by professional engineers and architects who

possess an understanding of structural mechanics. In no event will RISA Technologies, LLC or its officers be liable to

anyone for any damages, including any lost profits, lost savings or lost data. In no event will RISA Technologies, LLC or its

officers be liable for incidental, special, punitive or consequential damages or professional malpractice arising out of or in

connection with the usage of the SOFTWARE PRODUCT, even if RISA Technologies, LLC or its officers have been

advised of or should be aware of the possibility of such damages. RISA TECHNOLOGIES' entire liability shall be limited to

the purchase price of the SOFTWARE PRODUCT.

3. LIMITED WARRANTY. RISA Technologies, LLC warrants that the SOFTWARE PRODUCT will operate but does not

warrant that the SOFTWARE PRODUCT will operate error free or without interruption. RISA Technologies sole obligation

and your exclusive remedy under this warranty will be to receive software support from RISA Technologies via telephone,

email or fax. RISA Technologies shall only be obligated to provide support for the most recent version of the SOFTWARE

PRODUCT. If your version of the SOFTWARE PRODUCT is not the most recent version RISA Technologies shall have no

obligation to provide support in any form. Except as stated above the SOFTWARE PRODUCT is provided without warranty,

express or implied, including without limitation the implied warranties of merchantability and fitness for a particular purpose.

4. PROTECTION DEVICE. In the event the SOFTWARE PRODUCT requires the use of a PROTECTION DEVICE to

operate, you are specifically prohibited from attempting to bypass the functionality of the PROTECTION DEVICE by any

means. If the PROTECTION DEVICE becomes broken or inoperable it should be returned to RISA TECHNOLOGIES for a

replacement. The replacement will not be provided if RISA TECHNOLOGIES can not affirm that the broken PROTECTION

DEVICE was originally provided by RISA TECHNOLOGIES for use with the SOFTWARE PRODUCT. A lost or stolen

PROTECTION DEVICE will not be replaced by RISA TECHNOLOGIES.

5. TERMINATION. RISA TECHNOLOGIES may terminate your right to use the SOFTWARE PRODUCT if you fail to

comply with the terms and conditions of this agreement. In such event you must delete any installations and destroy any

copies of the SOFTWARE PRODUCT and promptly return the SOFTWARE PRODUCT to RISA Technologies.

6. CHOICE OF LAW. By entering into this Agreement in accordance with Paragraph 1, above, you have agreed to the

exclusive jurisdiction of the State and Federal courts of the State of California, USA for resolution of any dispute you have

relating to the SOFTWARE PRODUCT or related goods and services provided by RISA Technologies. All disputes therefore

shall be resolved in accordance with the laws of the State of California, USA and all parties to this Agreement expressly

agree to exclusive jurisdiction within the State of California, USA. No choice of law rules of any jurisdiction apply.

"RISA" as applied to structural engineering software is a trademark of RISA Technologies.

"TJI" is a registered trademark of TJ International, Inc.

“Trus Joist” is a registered trademark of Weyerhaeuser Company Corporation.

"BCI" is a registered trademark of Boise Cascade Corporation.

"LPI" is a registered trademark of Louisiana-Pacific Corporation.

Maintenance

Program maintenance provides all upgrades to RISAFloor , and discounts on new products.

When your maintenance expires, you will be given the opportunity to continue program maintenance on an annual basis. You

are under no obligation to continue program maintenance, of course, but if you decide to discontinue maintenance you will

no longer receive RISAFloor program upgrades and technical support.

Complete program support is available to registered owners of RISAFloor and is included in the purchase price. This support

is provided for the life of the program. See Technical Support for a list of your support options.

Before You Begin

4

RISAFloor v5.0

The “life of the program” is defined as the time period for which that version of the program is the current version. In othe r

words, whenever a new version of RISAFloor is released, the life of the previous version is considered to be ended.

RISA Technologies will support only the current version of RISAFloor.

Installation

To install RISAFloor please follow these instructions:

1. Put the RISAFloor CD in your computer CD drive.

2. If the CD starts automatically go to step 4. If the CD does not start after 10 seconds click the Windows Start button

and select Run.

3. In the Run dialog box type “d:\launch” (where “d” is the label of your CD drive) and then click the OK button.

4. Follow the on-screen instructions.

Application Interface

General Reference Manual

5

Application Interface

The User's Guide (a separate document) contains a tutorial that leads you through the RISAFloor interface with an actual

model. Consider going through the tutorial if you have not done so already, as it is the fastest way to learn the program.

Although it requires some time up front, the tutorial will save you time and brainpower in the long run.

The features that are available to you in RISAFloor may be accessed through the main menu, shortcut menus, toolbars and

shortcut keystrokes. You may use any or all of these vehicles to interact with the software. The main menu has the advantage

of containing all of the program options and features and may initially be the simplest to use, letting you learn just one

system. The toolbars contain more common options and invoke with one click. The shortcut menus present options relevant

to the task at hand. The shortcut keys provide a fast way to access features should you use the program often enough to make

them familiar to you. All of these features are discussed in the sections below. There are many ways to access features and

the method that you will use will simply be a matter of personal preference. The good news is that you have the options.

The bar along the top of the screen is called the titlebar and contains the name of the file that is currently open. The three

buttons on the far right side of the title bar are used to control the main window. The left button will shrink the

main application window to a button on the taskbar. The middle button will shrink or maximize the window on your screen.

The right button will close the window, prompting you to save changes if necessary. You will also see these buttons in other

windows and they have basically the same functions there as well.

The actual work that you do will be in the main area on the screen, which is called the workspace. When you open a model

view, a spreadsheet or a dialog it will be opened in the workspace and listed in the Window menu. You may have as many

windows open as you like.

Main Menu

All of the program features may be accessed through the main menu system at the top of the screen beginning with File on

the far left and ending with Help or possibly Director on the far right. Clicking on each of these menus (listed below) will

display sub-menus that contain options that you may choose from. You may also select the main menus by using the ALT

key along with the underlined letter in the menu you wish to choose. You may then continue to use the keyboard to choose

from the menu options. In addition, some of the menu options will have hot key combinations listed to the right of the option.

These hot keys allow you to use the keyboard to access features without using the menu system.

File Menu

New will close the current file, prompting for saving if necessary, and will open a new file.

Open will close the current file, prompting for saving if necessary, and will open an existing file.

Save will save the current file, prompting for a name if necessary.

Save As will save the current file, prompting for a name.

Import DXF File will create a new floor using an existing DXF file.

Export will export the current file to a DXF, SDNF, or Pro-Steel exchange file.

For more information on the interaction between RISA and other programs refer to Appendix E.

Print will access RISAFloor printing options.

Page Setup will present page setup options for printing.

Recent Files The five most recent files will be listed at the bottom of the menu. Selecting one of these files will close the

current file, prompting for saving if necessary, and will open the selected file.

Exit will close RISAFloor, prompting for saving if necessary.

Application Interface

6

RISAFloor v5.0

Edit Menu

Undo will undo the last edit that was applied to the model whether it was made graphically or in the spreadsheets. You may

continue to apply Undo to remove up to 100 model edits.

Redo will reverse the last undo that was applied to the model. You may continue to apply Redo to remove up to 100 undo

operations.

Copy will copy the selected spreadsheet cells or model view from the active window to the clipboard.

Paste will paste data from the clipboard to the spreadsheet cells.

Insert Line will insert a new line in the spreadsheet beneath the current line.

Delete Line will delete the current spreadsheet line.

Repeat Line will insert a new line in the spreadsheet beneath the current line and copy the data from the current line.

Mark All Lines will select all of the lines in the spreadsheet.

Unmark Lines will unmark any currently marked lines.

Delete Marked Lines will delete the marked lines in the spreadsheet.

Find will locate an item on the spreadsheet by its label.

Fill Block will fill the marked block of cells with a valid entry.

Math on Block allows you to add, subtract, multiply or divide the values in the marked block of cells.

View Menu

New View will open a new model view window.

Save or Recall Views allows you to save a view or recall a view that has previously been saved.

Clone View makes a copy of the current view so you can modify one and maintain the other.

Refresh All will refresh all of the windows that are open in the workspace.

Select provides graphic select options that are also provided on the Selection Toolbar.

Unselect provides graphic unselect options that are also provided on the Selection Toolbar.

Save or Recall Selection States allows you to save a selection or recall a selection that has previously been saved.

Zoom provides options for zooming in and out of the current model view.

Rotate provides options to snap the model view to global planes or an isometric view.

Plot Options opens the Plot Options.

Render will turn rendering of the current model view on or off, depending on the current setting.

Drawing Grid will turn the display of the Drawing Grid on or off, depending on the current setting.

Project Grid will turn the display of the Project Grid on or off, depending on the current setting.

Axes will turn the display of the global axes in the model view on or off, depending on the current setting.

Loads will turn the display of the model loads on or off, depending on the current setting.

Point Labels will turn the display of the point labels on or off, depending on the current setting. A third setting is also

available where the points themselves are not shown at all.

Beam Labels will turn the display of the beam labels on or off, depending on the current setting. However, if rendering is

turned on, beam labels will not be visible in the model view.

Application Interface

General Reference Manual

7

Insert Menu

The Insert Menu will help you insert new items into the model. Most of the options will provide a graphical method of

insertion but some will open spreadsheets where appropriate. See Graphic Editing for specific information.

Modify Menu

The Modify Menu will help you modify existing items in the model. Most of the options will provide a graphical method of

modification but some will open spreadsheets where appropriate. The Delete Items Dialog may also be accessed via this

menu. See Graphic Editing for specific information.

Spreadsheets Menu

The Spreadsheets Menu provides access to any of the input spreadsheets. See Spreadsheet Operations to learn how to work

within the spreadsheets.

Solve Menu

Clicking on the Solve Menu will immediately begin a solution to the model. See Solution for more information.

Results Menu

The Results Menu provides access to any of the results spreadsheets. See Results Spreadsheets for more information.

Tools Menu

Delete All Unattached Points will delete any points that are not connected to beams, columns, decks, deck edges or loads.

RISA-3D Data will allow you delete selected portions of the RISA-3D model that automatically generated by Floor. It will

also allow your to "re-start" the optimization of member sizes based on the current RISAFloor sizes.

Preferences contain settings that let you customize the program. See Customizing RISA for more information.

Customize Toolbar... allows you to modify the model view toolbar by adding, subtracting and re-ordering buttons. See the

customizable toolbar section.

Reset All Program Defaults will reset all customized settings to the original factory settings.

Window Menu

In order to help you work with the model and the results, you are provided with many window arrangements to choose from.

You may access them from the Window Menu. The best way to understand just what these 'tilings' do is to try them.

Remember that once you choose a tiling you may adjust any of the windows as you wish.

Help Menu

Help Topics opens the RISAFloor Help File so that you may search the contents and the index. See Help Options to learn

about getting help.

Check for Updates runs an internal check for possible program updates. If your program is up to date, you will receive a

message saying you are up to date. If you are out of date, the check will offer you the option to email RISA Technologies for

upgrade information if you are out of date for a major update. If you are out of date just a minor update, then we will send

you to our website to upgrade.. This check is also offered during the installation process.

About provides RISAFloor version and hardware key information.

Director Menu

Application Interface

8

RISAFloor v5.0

If you are working from within the RISA Building System (RBS), use this menu to switch between RISAFloor, RISA-3D

and RISAFoundation. If you are not working within the RISA Building System, the Director Menu will not be shown. See

"RISAFloor and RISA-3D Integration" on page 232 for more information.

The directory button is located at the far, far right hand side of the Main Menu Toolbar as shown in the image above.

Shortcut Menu

The Shortcut Menu is also referred to as the Right-Click Menu. This is because to access the shortcut menu you simply

click the RIGHT mouse button where you are working to see options that are relevant to what you are doing. For example if

you are working in a model view the right click menu will provide options to help you modify the view and edit the model

graphically. If you are working in a spreadsheet the menu will provide editing tools for that spreadsheet.

This menu will appear wherever you RIGHT click the mouse. This way you do not need to move away from where you are

working to select the features you want to use.

Toolbars

The Toolbars provide buttons to help you access common commands and popular options in the menu system discussed

above. There are different toolbars that will appear as you work to build your model and browse your results. If at any time

you are not sure what a particular button does, simply let your mouse hover over the button and a helpful tip will pop up and

explain the button.

RISA Toolbar

The first horizontal toolbar located just below the Main Menu is called the RISA Toolbar. The buttons on this bar facilitate

file and window access. You may use these buttons to open files and windows and also to analyze the model.

Window Toolbar

The Window Toolbar is the second horizontal toolbar located below the Main Menu. It gets its name because the buttons

change as you move from window to window in order to help you with what you are currently doing. When you are working

in a model view the buttons provide viewing tools, such as Rotate and Zoom, to assist you with that view. There are also

many other results and information display toggles, including some icons with the drop down arrow next to them. Clicking

the arrow will show you the different view options for that icon. Clicking the icon itself will bring you back to the default

view. Note that this model view toolbar is now fully customizable. See below for more information.

Other model view windows that are open will not be affected so that each may show different information. When you are

working in a spreadsheet, editing tools are provided that are appropriate to that particular spreadsheet. Note that not all tools

are available with all spreadsheets. In fact there are many tools that are provided for one spreadsheet only. See Spreadsheet

Operations for more information.

Customizable Model View Toolbar

The model view toolbar is fully customizable. By creating your personalized toolbar, you can quickly access your most

frequently used buttons. This can be done quickly and easily in just a few steps.

1. Go to Tools menu and select Customize Toolbar.

Application Interface

General Reference Manual

9

2. Select one of the toolbars by clicking in the box Available toolbar buttons, and click on Add to place them on the

current toolbar.

3. Once you‟ve moved the buttons to the Current Toolbar, you can rearrange them by clicking on Move Up or Move

Down.

4. Click Close and you will see your selections on the model view toolbar.

Note:

You must have a model view as the current view to see this toolbar.

If you add more buttons than will fit on the toolbar the buttons that are at the end of the "Current toolbar buttons" will

be cut off.

Application Interface

10

RISAFloor v5.0

The changes you have made will automatically be saved on a per-user (Windows User) basis, such that next time you

open the program the toolbar will be arranged per your preferences.

Selection Toolbar

The vertical toolbar on the left side of the screen is the Selection Toolbar. This toolbar will only be available when the active

window is a model view. The buttons on this toolbar help you select and unselect items in the model in order to help you

build and modify the model or view results. See Graphic Selection for more information.

Drawing Toolbar

Another toolbar that is available is the Drawing Toolbar. Unlike those mentioned above, this toolbar is located in the model

view windows rather than in the main application window. This way the drawing tools stay close to where you are working.

This toolbar controls modeling features that help you draw, load, and modify your model graphically. You may have more

than one view open and a Drawing Toolbar for each view. This way you can simultaneously draw columns in one window

and beams in another.

The Drawing Toolbar may be displayed in any model view window by clicking on the Window Toolbar while in the

model view window. Some of the buttons on the toolbar are for one-time applications such as modifying the drawing grid.

Other buttons place you in an editing mode, such as Draw Columns, that remains active until you cancel it. The current mode

is indicated by the mouse pointer and by the state of the button. While in an editing mode the button will stay down until you

click it again or choose another button. See Graphic Editing for more information.

This brings us to an important point. Some of the toolbar buttons remain down when you press them to indicate that you are

in a certain mode or that something is either on or off. For example the Box Zoom button will stay down to indicate that

you are currently in the zooming mode. The Show Drawing Toolbar button will remain down when you turn on this

toolbar for the active window. You may be in more than one mode at the same time as long as they are not mutually

exclusive.

Application Interface

General Reference Manual

11

Mouse Action

Model View Function

Rolling the Wheel

Forward

Zoom In

Rolling the Wheel

Backward

Zoom Out

Clicking and holding the

Wheel Button

Grab the image and pan in the direction of

mouse movement

Click and hold the Wheel

button while pressing the

Shift key

Dynamically rotate the structure in the

direction of mouse movement

The Data Entry Toolbar is the vertical toolbar on the right side of the application window. It contains buttons that facilitate

data entry through the spreadsheets. The buttons on this toolbar provide quick access to the spreadsheets that are also listed in

the Spreadsheets Menu. You may open and close the toolbar by clicking the button on the RISA Toolbar.

The Results Toolbar is the vertical toolbar on the right side of the application window that is placed over the Data Entry

Toolbar after the model has been solved. The buttons on this toolbar provide quick access to the results spreadsheets that are

also listed in the Results Menu. You may open and close the toolbar by clicking the button on the RISA Toolbar.

Dynamic View Controls

When your current window is a graphical model view, you can use the mouse wheel to dynamically zoom, pan, or rotate the

graphical image. These functions are only available to users who have a mouse with a wheel button and whose computers are

running the Windows XP operating system.

Dynamic Pan: Clicking and holding the mouse wheel button triggers the tool and allows the user to pan or drag the view to

the limit of scroll bars.

Dynamic Zoom: This tool uses the wheel button on the mouse. Rotating forward zooms in and rotating backward zooms out.

Dynamic Rotate: This tool is triggered by clicking and holding the mouse wheel button while holding the Shift key. The

rotational movement will be based on the how the user drags the mouse cursor over the screen and the projection of global

axis on the screen. For rotation about X axis, drag the cursor perpendicular to the projection of the global X axis. The same

logic applies for Y or Z axis rotations. When rotation is initiated, the system locks for rotation about that axis until the user

releases the middle mouse button.

Application Interface

12

RISAFloor v5.0

Zoom Previous/Next: Function keys F3 and F4 are associated with Zoom Previous and Zoom Next respectively. The system

Key Combination

Function

F1

Help on the active window

F5

Activates the Dynamic Distance Tool

Ctrl-F1

Main Help topics

Ctrl-F2

Create New view

F7, Ctrl-F7

Ctrl-C

Copy to the clipboard

Ctrl-V

Paste from clipboard

Ctrl-N

Start a new file

Ctrl-O

Open an existing file

Ctrl-S

Save the current file

Ctrl-P

Print

Ctrl-Z

Undo

Alt-

Access the menus by combining the Alt

key with the underlined letter in the menu

Key Combination

Model View Window

Spreadsheet

Ctrl-D

Open last graphic editing

dialog

Delete Marked Lines

Ctrl-G

Toggle Drawing Toolbar

Ctrl-A

Select All

Ctrl-U

Unselect all

Ctrl-F

Block Fill

Ctrl-M

Block Math

Ctrl-I

Invert Selection

Ctrl-L

Toggle Lock unselected

Unmark lines

Ctrl-Enter

Press cell button

holds a doubly linked list of zoom info. This list has 10 zoom-states in the list. The F3 or F4 keystroke moves the active

pointer forward or backward on the list. Each window has its own zoom list.

Dynamic Distance Tool: This tool triggers by pressing the F5 key. The user has to pick up two points on the screen and the

system gives back the total and partial distance between points on the status bar.

Shortcut Keys and Hot Keys

Shortcut Keys and Hot Keys allow you to use the keyboard to quickly access features. The difference between the two is

simply that the shortcut keys are related to a specific window and will only work in that window while the hot keys will

perform at most any time.

General Hot Keys

Shortcut Keys available for Specific Windows

Application Interface

General Reference Manual

13

F2

Open Plot Options

Start/Stop Cell Edit

F3

Zoom Previous

Insert line

F4

Zoom Next

Delete Line

F5

Initiates the "Distance" tool

Find

F8

Repeat Current Line

F9 Sort

+

Zoom In

-

Zoom Out

PgUp PgDwn

Scrolling

Scrolling

Key Combination

Unsolved model

Solved Model

Ctrl-Alt-C

Point Coordinates

Column Results

Ctrl-Alt-D

Line Loads

Ctrl-Alt-E

Beams – Primary Data

Deflection Results

Ctrl-Alt-F

Bending Results

Ctrl-Alt-G

Global Parameters

Ctrl-Alt-H

Design Results

Ctrl-Alt-L

Load Combinations

Ctrl-Alt-M

Materials

Material Take Off

Ctrl-Alt-N

Concrete Reinforcing

Ctrl-Alt-P

Point Loads

Ctrl-Alt-R

Design Rules

End Reactions

Ctrl-Alt-S

Shear Results

Ctrl-Alt-U

Design Results

Solution Type

Unsolved

Solved

Static

Spreadsheet Hot Keys that open spreadsheets

Status Bar

The Status Bar passes useful information to you as you work. It is divided into four parts located along the very bottom of

the main application window, just beneath the workspace.

The left side of the status bar shows a solution flag to indicate the solved state of the model as follows:

After a solution has been performed and modifications are made to the model, the “S” icon changes to (yellow). This

indicates that the model has been solved but then modified

To the right of the solution flags there are three message boxes.

Application Interface

14

RISAFloor v5.0

The first and largest box lets you know what you are currently doing. If you are in a spreadsheet, this box will contain the

explanation of the current cell. If you are working in a model view and select a graphic editing option, look to this box for

information on how to use the feature.

The second box is used to pass you units of the current spreadsheet cell.

The third box indicates the coordinates of the mouse when a model view is active. The mouse coordinates that are displayed

are the coordinates of the grid point or joint that is nearest to the mouse.

Windows

Modeling the structure will take place within model views and spreadsheets, each in their own window that may be moved

around the workspace and sized as you wish. The ability to have multiple model views and multiple spreadsheets open at one

time is a powerful feature. The options in the Window Menu are provided to help you manage these windows.

These windows contain three buttons in the upper right corner to help you minimize, maximize and close the

window, respectively. There are also scroll boxes to help you view information that is outside of the window viewing area.

Click the scroll bar buttons or drag the scroll box to advance the display in one direction or another.

Model Views

Model View windows show a graphic view of the model. Open a new view with the button.

You may open as many model view windows as you like. This is especially helpful when working in close on large models.

You might have one overall view and a few views zoomed in and rotated to where you are currently working. You may also

have different information plotted in multiple views.

One thing to remember is that the toolbars that are displayed depends upon what window is active. The active window is the

one with the blue titlebar. For example, if you are looking for the zoom toolbar button and the active window is a spreadsheet

you need to select a model view first before you can access the zooming tools.

Spreadsheets

Spreadsheet windows are made up of rows and columns of data cells. If you wish to add or edit data in a spreadsheet cell

you click on the cell, making it the active cell, and then edit the cell. This active cell is simply the green cell that moves

around the spreadsheet as you hit the cursor keys (← , →), Page Up, Page Down, Home, End, etc. There is always one and

only one active cell, which is the cell that has the “attention” of the keyboard.

You may also select blocks of data to work on. You can select a block of data by clicking and holding the mouse button on

the first cell in the block and then dragging the mouse to the opposite corner of the block and releasing the mouse.

Dialogs

A Dialog is a third type of window and is used to access a specific function within the program. Another powerful feature is

that most of the dialogs may be left open while you edit the model, making it easy to make adjustments as you work. You

will find that dialogs are very easy to work with. There are Help buttons that will bring you directly to the relevant topic in

the help file.

Modes

There are three basic program modes (View, Select, and Edit) and a mode hierarchy to allow you to move between them

easily. While you are editing the model you may select items to edit. When you are finished selecting you will be returned to

editing. Likewise, while you are selecting items you can adjust the view and then be returned to selecting.

Different mouse cursors are used with each mode to make it clear what the current mode is.

View Mode is the upper level mode that allows you to adjust the view by zooming in and out, rotating and setting plot

options. This mode supersedes all other modes so that you may do these things at any time, and then be returned to the

Application Interface

General Reference Manual

15

previous mode. This mode does not cancel other modes so that when you are finished adjusting the view you are returned to

what you were doing. See Graphic Display for more information.

Select Mode is the middle level mode that allows you to make a graphic selection of joints, members and plates. This mode

supersedes the Edit Mode but not the View Mode. This means that you can make a selection while in the middle of editing

the view and when you are finished you are returned to the editing feature that you were using. It also means that you may

adjust the view while remaining in the same Select Mode. See Graphic Selection for more information.

Edit Mode is the lower level mode that allows you to graphically edit the model. You may make selections and adjust the

view while in the edit mode such that when you are finished selecting you will be returned to the Edit Mode. Some Edit

Mode features have options on how you apply the edit. See Graphic Editing for more information.

Note

The default mode is the mode you are in if you are not in any other mode and is indicated by the standard

mouse cursor. The default mode is a selection mode where you can select/unselect individual items by clicking

on them.

You may use the ESC key or the right mouse button to cancel a mode.

Beams

16

General Reference Manual

Beams

Designation

Shape Group

Hot Rolled

Wide Flange

Channel

Tube

Single Angle

Double Angle

Pipe

W_Tee

Cold Formed

CU CS

ZU ZS HU

Wood

Rectangular

Rectangular Double

Rectangular Triple

Round

Glulam Western

Glulam Southern Pine

Concrete

Rectangular

Rectangular MM

Steel Product

Steel Joist

Wood Product

Wood Joist

TJI Joist

LPI Joist

BCI Joist

One of RISAFloor‟s primary tasks is the modeling, loading, and design of beams. This includes automatic attribution of loads

from the deck system, live load reduction, and design optimization for the desired code and criteria. Loads modeled on the

deck are attributed to the beams and the beams transfer the loads through the floor framing to walls and columns and

ultimately down to the foundation. Automatic live load reductions may also be applied. With the use of beam end releases

you may define simply supported or fixed end / continuous beams.

The beams can function to resist only gravity loads, where they are analyzed and designed completely within RISAFloor, or

they can function as part of a lateral load resisting system. The lateral systems can be analyzed in RISA-3D for load cases

such as wind or seismic events and the beams are designed for combined gravity and lateral forces. See RISA-3D Integration

for more information.

Beam data may be viewed and edited in two ways: graphically in the Information Dialog or in the Beams Spreadsheet. See

Beams – Primary Data for descriptions of the beam data.

Beams can be specified as Hot Rolled Steel, Cold Formed Steel, Wood, Concrete, and Steel or Wood Products. Refer to the

specific sections for Steel Design, Wood Design, and Steel or Wood Product Selection for more info on the design or code

checking of beams. The shape groups available for each designation are listed below.

Any available material listed in the Materials spreadsheet can be assigned to a beam. See Material Properties for more

information. All beam shapes and material properties may be assigned graphically either as you draw or later as a

modification to the beams.

Beams

General Reference Manual

17

Drawing Beams

To create new beams you can draw from point to point, point to member, and member to member. Point to Point is when

you want to draw a beam between columns, points, or a combination of column and a point. Point to member is when you

draw a beam from a column or snap point to a member with an offset distance from the member end. Member to member is

when you draw a beam between members using an offset distance for both members. For member offsets click toward the

end of the member that you want the offset measured from. You can set all of the beam properties before drawing them or

you can modify these properties after you draw a beam. Graphically modifying properties is discussed in the next section.

See Beams– Primary Data for information on the beams and beam properties themselves.

To draw beams, click on the Drawing Toolbar to open the Draw Beams dialog. Enter the beam type, material, shape

group, redesign rules, span type, function, orientation, end releases, and drawing option, click Apply and draw beams

accordingly.

If the Keep Spans Continuous is not checked, each beam you draw will be divided up at each beam or column intersection

found along its length. The end conditions for each beam will be those specified in the End Releases field. If the Keep

Spans Continuous IS checked, the first point you click on is the start of the beam and gets the Start end release that is

specified in the End Releases field. The last point you click on gets the 'End' end release that is specified in the End Releases

field. For these continuous beams, all intermediate columns or beams that occur along its length will be fully fixed to the

continuous beam.

As you draw, the coordinates of the nearest grid point or snap point are shown in the status bar in the lower right corner. The

new beams will be shown on screen and will be recorded in the Beams spreadsheet. For help on an item, click and then

click the item.

Drawing Cantilevers

To draw cantilevers, select the Cantilevers tab from the Beams dialog. Enter the cantilever length and click Apply. Click

toward the end of the beam that you would like to add the cantilever to. The new cantilever will be shown on screen and will

be recorded in the Beams spreadsheet. For help on an item, click and then click the item.

Beams

18

RISAFloor v5.0

To Draw Beams

1. If there is not a model view already open then click on the RISA Toolbar to open a new view and click to

turn on the Drawing Toolbar if it is not already displayed.

2. If you do not already have existing columns or walls, you will need to create them first.

3. Click the button and set the beam properties. For help on an item, click and then click the item.

4. Click Apply to start drawing beams by clicking on columns, beams, or points with the left mouse button. For

member offsets click toward the end of the member that you want the offset measured from. The coordinates of the

closest grid point or snap point to your cursor are displayed in the lower right hand corner.

The first click will define the Start-end of the first beam. The second click and each click thereafter will define the

End-end of the first beam and also the Start-end of the next beam so that you may continue to draw as if your pencil is

down. To “pick up” the pencil, click the right mouse button. You may then start drawing somewhere else with the

left button.

5. To stop drawing altogether click the right mouse button, or press the Esc key.

Note

Press CTRL-D to quickly recall the last dialog and make changes.

Instead of clicking on multiple individual columns to draw beams you may also box a set of columns or a line of

columns.

You may also specify or edit beams in the Beams Spreadsheet.

You may undo any mistakes by clicking the Undo button.

Drawing Infill Beams

Because they tend to be evenly spaced and repetitive, you would not want to draw each and every one of your infill beams or

joists. RISAFloor provides special tools to generate large numbers of infill beams at one time. These tools will allow you to

draw an entire bay of new infill beams with a single click. You can set all of the infill beam properties up front or you can

Beams

General Reference Manual

19

modify these properties after you generate them. The procedure for graphically modifying infill beam properties is exactly

the same as discussed in the previous sections.

To draw infill beams, click on the Drawing Toolbar to open the Generate Infill Beams dialog. Enter the beam type,

material, shape group, redesign rules, orientation for bending, beam spacing, placement orientation, and the bay selection

option, click Apply and click the bay to be filled. You can also draw a polygon around multiple bays or simply drag a box

around the bays to be filled. If the placement orientation is referenced to a global angle then no other clicks are required, the

new beams will be shown on screen and will be recorded in the Beams spreadsheet. If the placement orientation is

referenced to a member you must then click the reference member and the new beams will be created. For help on an item,

click and then click the item.

To Draw Infill Beams

1. If there is not a model view already open then click on the RISA Toolbar to open a new view and click to

turn on the Drawing Toolbar if it is not already displayed.

2. If you do not already have existing framed bays, you will need to create them first.

3. Click the button and set the beam properties.

4. Click Apply to start generating beams by clicking on the bay opening or drawing a box around the bays in which you

want the beams generated. If the placement orientation is referenced to a member, you must then click the reference

member with the left mouse button. The coordinates of the closest grid point or snap point to your cursor are

displayed in the lower right hand corner.

5. To stop drawing click the right mouse button, or press the Esc key.

Note

Press CTRL-D to quickly recall the dialog and make changes.

You may also specify or edit beams in the Beams Spreadsheet.

You may undo any mistakes by clicking the Undo button.

Beams

20

RISAFloor v5.0

The items in the material and design rules are listed in the same order in which they appear in the Material and Design

Rules spreadsheets.

Modifying Beam Properties

There are two ways to modify beams. You may view and edit the beam data in the Beams Spreadsheet. Or, you can use the

Modify Beams tool of the Beams dialog to graphically modify a possibly large selection of beams. See Beams – Primary

Data for information on the beams and properties themselves.

The graphical Beam Modify tool discussed here lets you modify the properties of beams that already exist in your model. To

use this, you will typically specify parameters you want changed then select the beams that you want to modify. You can

modify beams one at a time by selecting the Click to Apply option and then click on the beams you wish to modify. You

may also modify entire selections of beams by selecting the beams first and then use the Apply to Selected option. See

Graphic Selection for more on selecting or unselecting portions of your model.

To Modify Beams

1. If there is not a model view already open then click on the RISA Toolbar to open a new view and click to

turn on the Drawing Toolbar if it is not already displayed.

2. Click the button and select the Modify Properties tab. Set the parameters for the changed beams. Check the

Use? Box for the items to apply. For help on an item, click and then click the item.

3. You may choose to modify a single beam at a time or an entire selection of beams.

To modify a few beams choose Apply Entries by Clicking Items Individually and click Apply. Click on the beams

with the left mouse button.

To modify a selection, choose Apply Entries to All Selected Items and click Apply.

Note

To modify more beams with different parameters, press CTRL-D to recall the Modify Beams settings.

You may also modify beams in the Beams Spreadsheet.

To relabel beams first sort the Beams spreadsheet into the desired order then select the Tools menu and choose

Relabel Beams.

You may undo any mistakes by clicking the Undo button.

The parameters shown are the same as those used to define new beams. For help on an item, click and then click the

item.

Beams

General Reference Manual

21

The Use? check boxes next to the data fields indicate whether the particular parameter will be used or not when the

modification is applied. If the box next to a field is checked, that parameter will be applied to any selected beams, if the box

is NOT checked, the parameter will NOT be applied, even if a value is entered in the field. This lets you easily change one or

two properties on beams without affecting all the rest of the properties. Note that if the field is blank and the corresponding

Use? box is checked, clicking Apply will have the effect of clearing the data for these fields.

Modifying Beam Design Parameters

You can graphically specify the AISC, AISI, NDS and composite design parameters such as unbraced lengths, K factors, and