Rinnai Rice Cooker RL94i ( REU-VB2735FFUD-US), R98LSi ( REU-VA3237FFU-US), R98LSi-ASME Installation Manual

Direct Vent Tankless Water Heater

Operation and Installation Manual

RL75i .................. REU-VB2528FFUD-US

RL94i .................. REU-VB2735FFUD-US

R98LSi ................ REU-VA3237FFU-US

R98LSi-ASME .... REU-VA3237FFU-ASME

FOR INDOOR APPLICATIONS ONLY

Table of Contents ..................... 2

The VB series (RL75i, and RL94i) are certified for

installation in manufactured (mobile) homes.

Register your product at www.rinnairegistration.com or

call 1-866-RINNAI1 (746-6241)

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

WARNING

result causing property damage, personal injury or death.

— Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in

your building.

• Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

ANS Z21.10.3

●

CSA 4.3

— Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

Consumer Safety Information ... 4

Operating Instructions ............... 6

Maintenance ........................... 11

Error Codes ............................ 12

Installation Instructions ........... 16

Consumer Support .................. 44

French Version ....................... 47

If the information in these instructions is not

followed exactly, a fire or explosion may

California Proposition 65 lists chemical substances known to the state to cause cancer, birth defects, death,

serious illness or other reproductive harm. This product may contain such substances, be their origin from fuel

combustion (gas, oil) or components of the product itself.

R

R98LSi-ASME

This model has been built in accordance with

the requirements of the ASME Boiler and

Pressure Vessel Code and has received the

Certificate of Authorization from the National

Board. The heat exchanger on this unit has

the NB and HLW stamps.

Table of Contents

Specifications ..................................................... 3

Consumer Safety Information

Safety Definitions ............................................. 4

Safety Behaviors and Practices ....................... 4

Safety Features................................................ 4

Description of Operation .................................... 4

Operating Instructions

Temperature Controller .................................... 5

Features Available on Temperature

Controllers ........................................................ 6

How to Set the Temperature ............................ 7

Temperature Controller Settings .................. 7, 8

Temperature Options Without

a Temperature Controller ................................. 8

Setting the Sound Volume (Voice Prompt) ...... 8

Using the Water Smart / Bath Fill Function ..... 9

Overview ..................................................... 9

Setting the Water Volume ........................... 9

Filling the Tub ............................................ 10

Setting Controller to Mute .............................. 10

Setting the Clock ............................................ 10

Maintenance

Cleaning .................................................... 11

Vent System .............................................. 11

Motors ....................................................... 11

Temperature Controller ............................. 11

Lime / Scale Build-up ................................ 11

Snow Accumulation ................................... 11

Visual Inspection of Flame ........................ 11

Error Codes

Error Code Table ...................................... 12,13

Trouble Shooting for Common Issues ........... 14

Accessing Operating Information................... 14

Water Quality ................................................. 14

Flushing the Heat Exchanger

(Error Code: LC or 00) ................................... 15

Installation Instructions ................................... 16

General Instructions ....................................... 16

Clearances from Appliance ............................ 17

Attachment of the Water Heater .................... 17

Electrical Connection ..................................... 18

Error Indication or Air Handler Control Switch ...

(RL75i, RL94i only) ........................................ 18

Gas Piping

General Instructions ................................ 18

Pipe Sizing Procedure - Example ............ 19

Water Piping

Isolation Valves and

Pressure Relief Valves ............................ 20

Piping Requirements ............................... 21

Pressure Relief Valve Requirements ...... 21

Freeze Protection .............................. 21, 22

Freeze Protection Piping ............................... 23

Recommended Piping for Basic Installation ..

Recommended Piping for

Circulation Systems ....................................... 25

Venting Instructions

Intake / Exhaust Guidelines ..................... 26

Condensate ............................................. 26

Maximum Vent Length ............................ 27

Vent Products .......................................... 28

Flue Terminal Clearances

(ANS Z21.10.3, CSA 4.3

Additional Clearances - Vent Terminal .......... 30

Flue Installation - Concentric Venting

(RL75i, RL94i) ................................................ 31

Flue Installation

(R98LSi, R98LSi-ASME).......................... 32, 33

Connecting Multiple Water Heaters ............... 34

High Altitude Installations ........................ 34, 35

Temperature Controller Installation

Location ................................................... 36

Configurations.......................................... 36

Cable Lengths and Size .......................... 36

Mounting the Controller ........................... 37

Operating Instructions ................................... 38

Technical Data

Pressure Drop Curve ..................................... 39

Outlet Flow Data ............................................ 39

Space Heating ............................................... 40

Dimensions .................................................... 41

Ladder Diagrams ..................................... 42, 43

Consumer Support

Warranty Information ..................................... 44

Limited Warranty ...................................... 44, 45

State Regulations .............................................. 46

French Version ............................................ 47-68

) .............................. 29

24

2 VB Series Indoor LS Manual

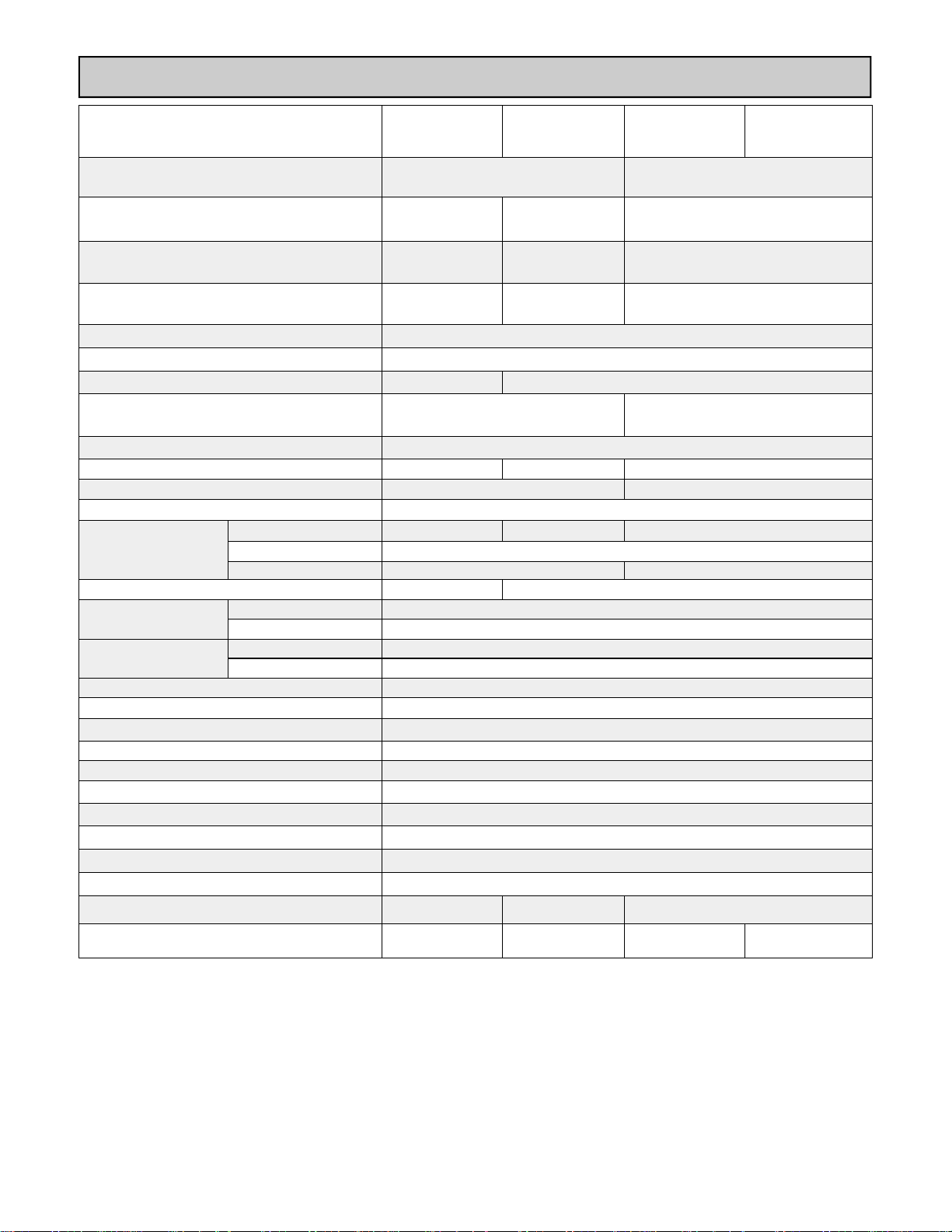

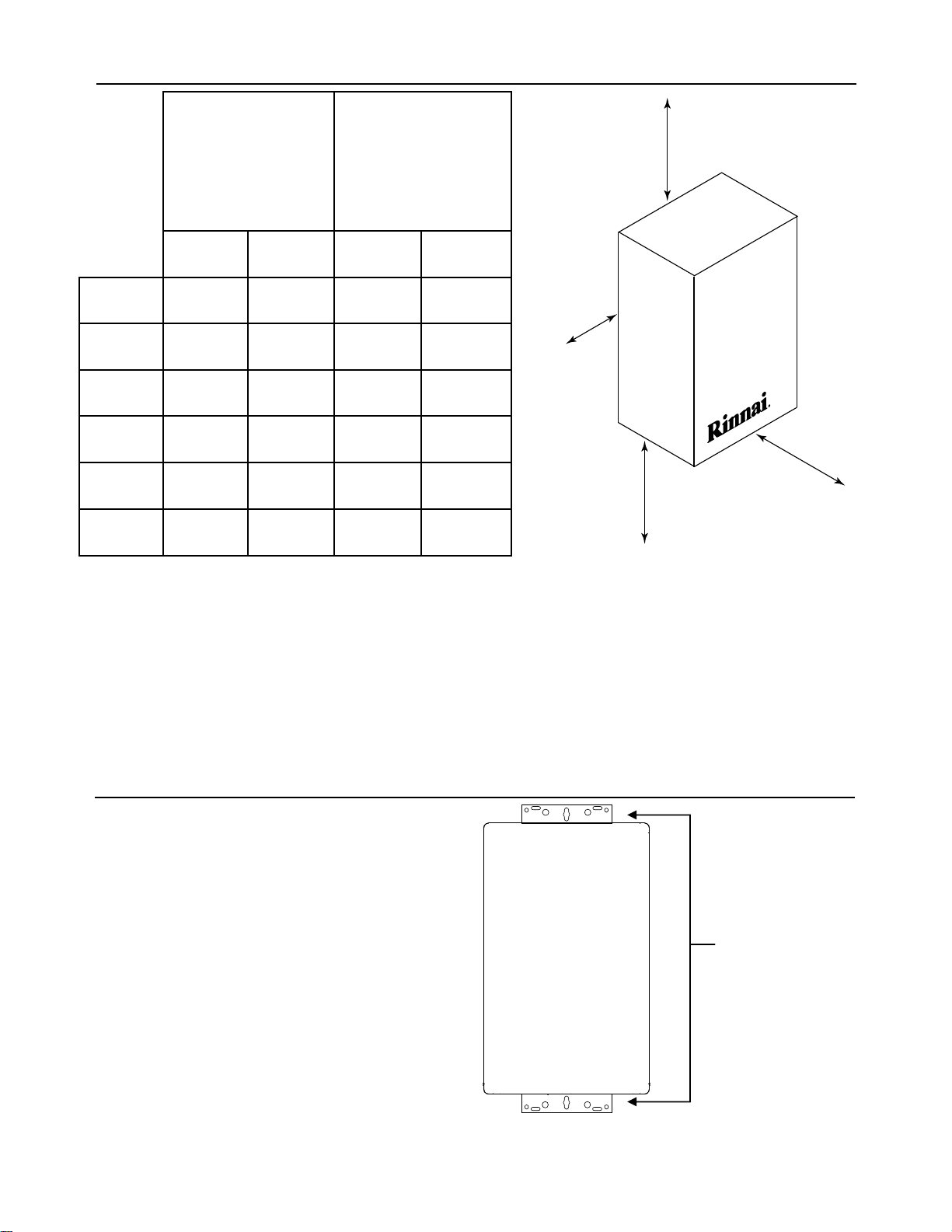

Specifications

Model

Minimum Gas Consumption Btu/h

Maximum Gas Consumption Btu/h 180,000

Hot water capacity (Min - Max) *

Hot water capacity (45°F rise)

Default Temperature Setting (no controller) 120º F (49º C)

Temperature Controller Default Setting 104º F (40º C)

Maximum Temp Setting (commercial **) 160º F (71º C) 185º F (85º C)

Maximum Temp Setting (residential)

see Temperature Ranges for more information

Minimum Temperature Setting 98º F (37º C)

Weight 51 lb (23 kg) 53 lb (24 kg) 55 lb (25 kg)

Efficiency Thermal Efficiency: 84.0%

Noise level 49 dB

Normal 76 W 83 W 99 W

Electrical Consumption

By-Pass Control Fixed Electronic

Minimum Gas Supply

Pressure

Maximum Gas Supply

Pressure

Type of Appliance Direct Vent, Temperature controlled continuous flow gas hot water system.

Operation With or without remote controls, mounted in kitchen, bathroom, etc.

Approved Gas Type Natural Gas or Propane - Ensure unit matches gas type supplied at the installation

Connections Gas Supply: 3/4" MNPT, Cold Water Inlet: 3/4" MNPT, Hot Water Outlet: 3/4" MNPT

Ignition System Direct Electronic Ignition

Electric Connections Appliance: AC 120 Volts, 60Hz. Remote Control: DC 12 Volts (Digital)

Water Temperature Control Simulation Feedforward and Feedback.

Water Supply Pressure Minimum Water Pressure: 20 PSI (Recommended 30-80 PSI for maximum

Maximum Water Supply Pressure 150 PSI

Remote Control Cable Non-Polarized Two Core Cable (Minimum 22 AWG)

Energy Star Qualified Yes Yes No (not applicable)

Certified for installation in manufactured (mobile)

homes

Standby 2 W

Anti-frost Protection

Natural Gas 5.0 inch W.C.

Propane 8.0 inch W.C.

Natural Gas 10.5 inch W.C.

Propane 13.5 inch W.C.

RL75i

9,900 (NG)

10,300 (LPG)

0.4 - 7.5 GPM

(1.5 - 28.5 L/min)

6.6 GPM

(25.0 L/min)

Selectable at 120º F (49º C) or at 140º F

(60º C)

Energy Factor: 0.82

184 W 116 W

Yes Yes No No

RL94i

199,000 (NG)

190,000 (LP)

0.4 - 9.4 GPM

(1.5 - 35.5 L/min)

7.1 GPM

(27.0 L/min)

R98LSi

237,000

0.6 - 9.8 GPM

(2.4 - 37 L/min)

8.5 GPM

(32.2 L/min)

140º F (60º C)

R98LSi-ASME

19,000

* Minimum flow may vary slightly depending on the temperature setting and the inlet water temperature.

** for commercial and hydronic applications requiring higher temperatures

Rinnai is continually updating and improving products. Therefore, specifications are subject to change without

prior notice.

The maximum inlet gas pressure must not exceed the value specified by the manufacturer. The minimum value

listed is for the purpose of input adjustment.

VB Series Indoor LS Manual 3

Consumer Safety Information

Safety Definitions

This is the safety alert symbol. This symbol alerts you to potential hazards that can kill or hurt you and

others.

DANGER

WARNING

CAUTION

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in minor or

moderate injury. It may also be used to alert against unsafe practices.

Safety Behaviors and Practices

WARNING

• Keep the area around the appliance clear and free

from combustible materials, gasoline, and other

flammable vapors and liquids.

• Any alteration to the appliance or its controls can be

dangerous and will void the warranty.

• Always check the water temperature before entering

a shower or bath.

Safety Features

• Overheat: The appliance will automatically shut

down when the appliance exceeds a predetermined

temperature.

• Do not use this appliance if any part has been under

water. Immediately call a qualified service

technician to inspect the appliance and to replace

any part of the control system and any gas control

which has been under water.

• Power Surge Fuse: A glass fuse protects against

overcurrent. If the fuse blows then all indicator

lamps will be off.

• Flame Failure: The appliance will automatically

shut down if the burner flame is not adequate.

• Power Failure: The appliance will cut off the gas if

it loses electrical power.

• Fusible Link: In case the overheat feature does

not prevent the temperature from rising then the

fusible link will break shutting off the appliance.

Description of Operation

The Rinnai water heater is one of the most advanced

water heaters available. It provides a continuous

supply of hot water at a preset temperature. This

appliance is direct vent where air is brought in from the

outside and combustion gases are exhausted to the

outside.

While electricity, water, and gas supplies are

connected, the Rinnai water heater produces hot water

whenever a hot water tap is open.

Ignition is electronic. There is no pilot light consuming

gas while the water heater is not being used. The gas

burner lights automatically when the hot water tap is

opened and goes out when the tap is closed.

4 VB Series Indoor LS Manual

Installation of the temperature controller is highly

recommended. The temperature controller can set the

temperature within a specific range and can provide

error codes to diagnose any problems.

The temperature of the outgoing hot water is constantly

monitored. The Rinnai water heater may adjust the

water flow in order to maintain the temperature setting.

The water flow may vary from summer to winter due to

the difference in ground water temperature.

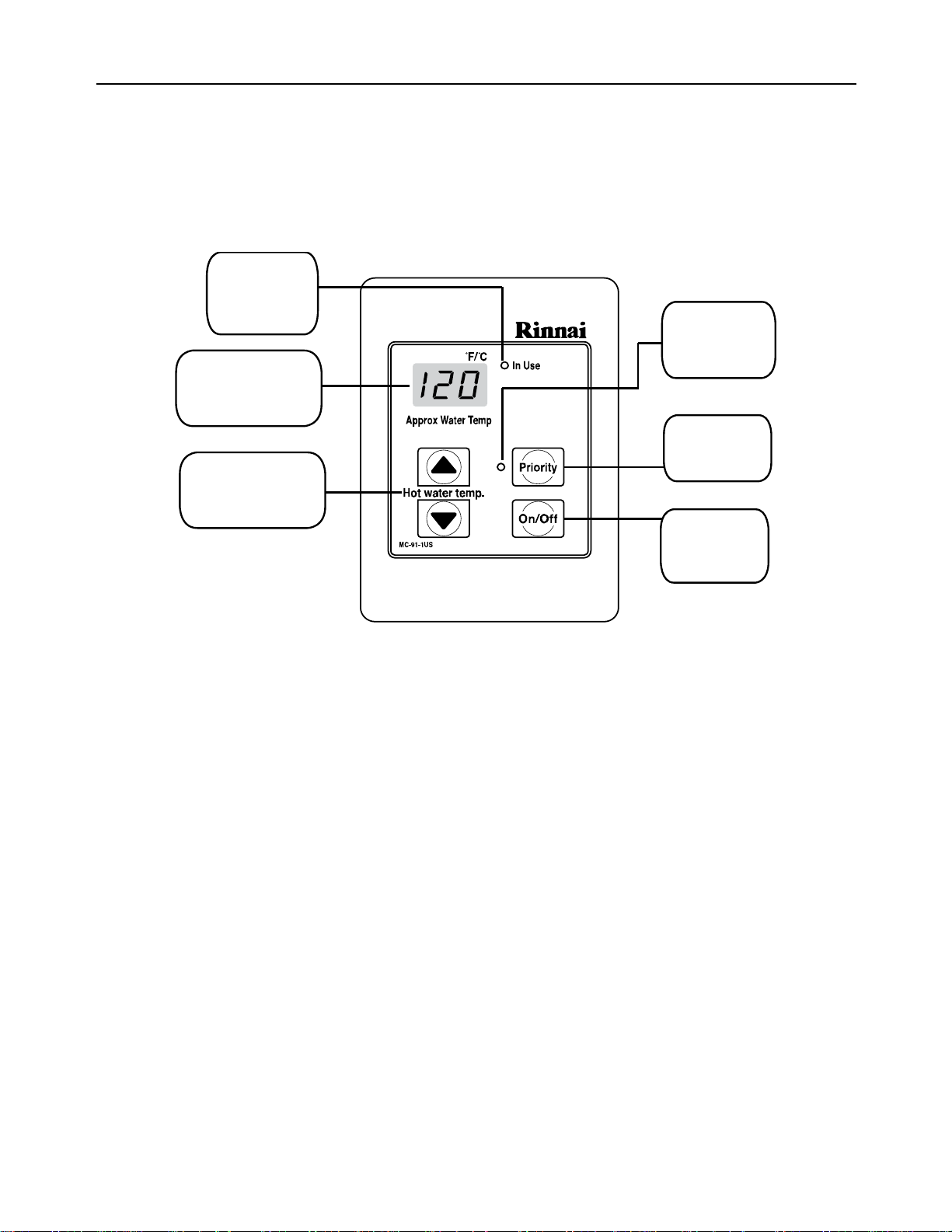

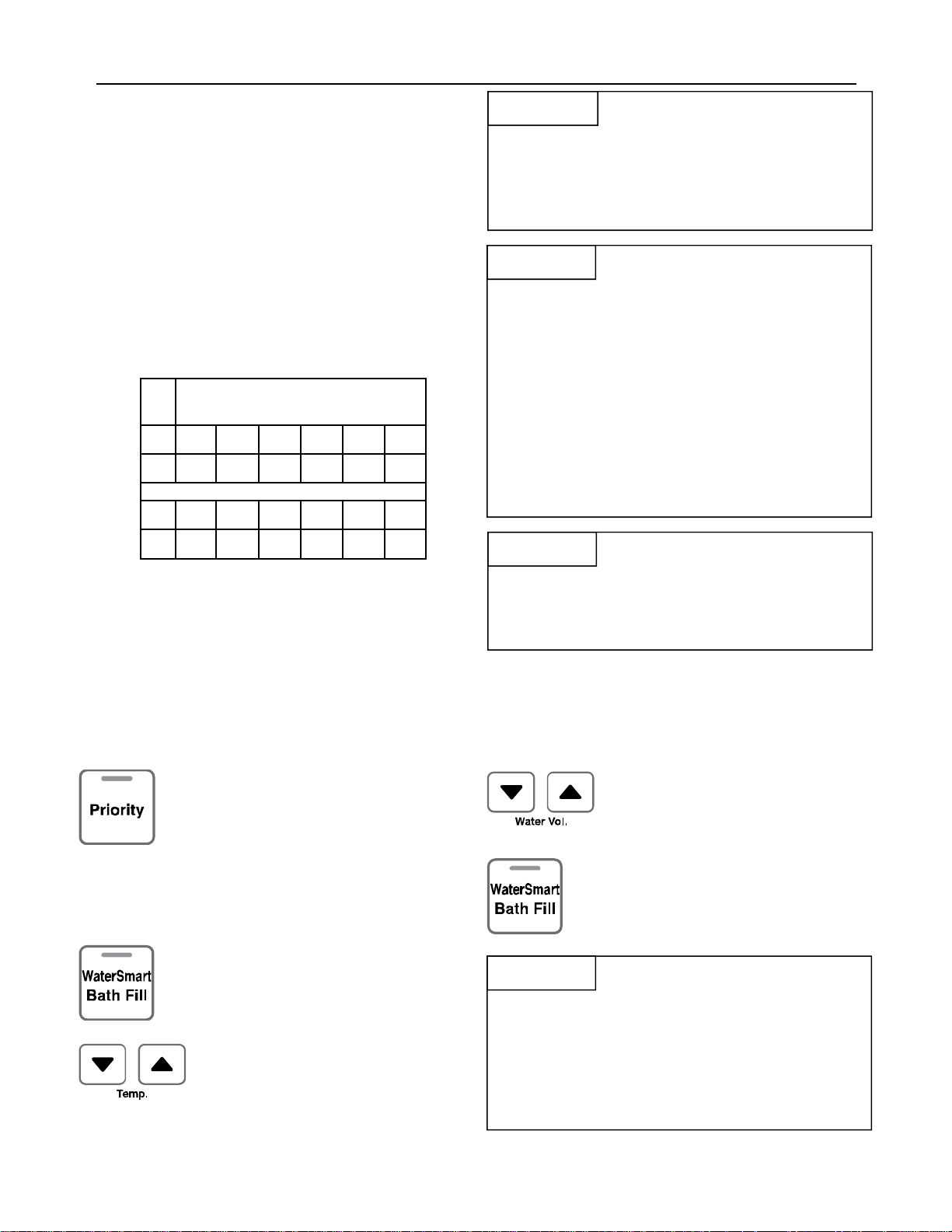

Temperature Controller

MC-91-1US & MCC-91-1US

Dimensions (inches): 3.5 W x 4.75 H x 0.75 D

The MC-91 controller is the standard temperature controller that is supplied with the water heater. On indoor

models it is integrated into the front panel. The MCC-91 controller is for commercial and hydronic applications

requiring higher temperatures. When the MCC-91 controller is connected, these higher temperatures are

available on all controller models in the system. Refer to the section on temperature ranges.

In Use

Indicator

Priority

Indicator

Temperature

Display

Priority

Temperature

Selection

Button

ON/OFF

Button

VB Series Indoor LS Manual 5

Operating Instructions

The MC-91 temperature controller is supplied with the RL75, RL94, and R98LS models. Additional functions are

available through the use of optional controllers.

There are several models of temperature controllers that can be purchased separately. Their description,

operation, and installation is provided in this manual in case additional temperature controllers are purchased and

installed.

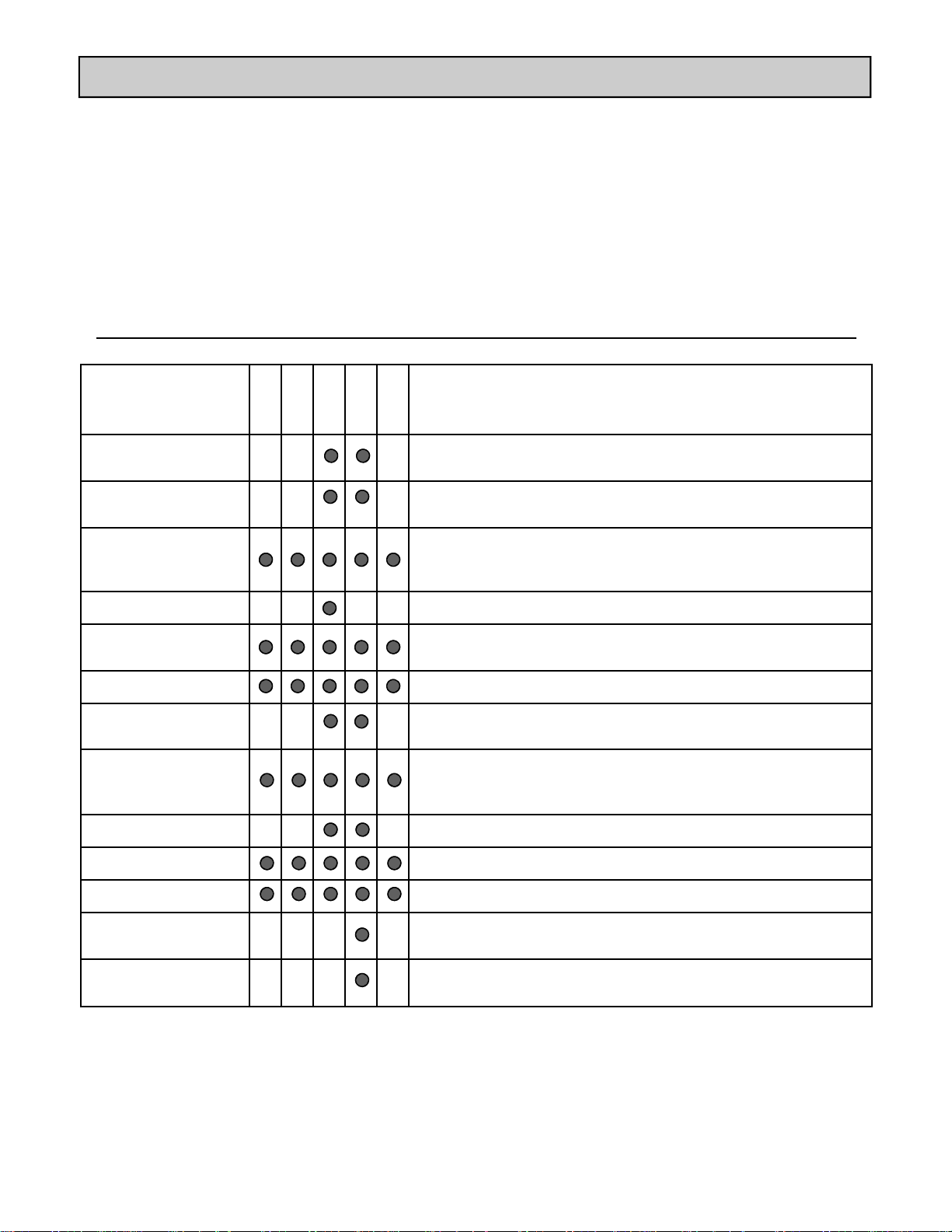

Features Available on Temperature Controllers

MC-91

MC-100

MCC-91

BC-100

Features

Sends a short series of beeps to all controllers in the system. It is

Call

Clock

Error Codes

Function

In Use Indicator

ON/OFF Button

Power Save

Priority Button /

Indicator

12 hour AM/PM clock. (The MC-100 must be installed for clock

When a fault is detected an error code flashes at the temperature

Used on this model to set the clock or sound volume.

Indicates that hot water is being supplied (i.e. a hot water tap is

Used to turn the water heater ON or OFF.

Indicates that this controller is setting the temperature . Priority

Allows the temperature controller to be in an energy saving

MC-502

Description

not an intercom.

to work on the BC-100.)

display on models MC-91, MCC-91, and MC-502; and flashes at

the clock display on models MC-100 and BC-100.

open).

mode.

can be switched to another controller by pressing its Priority

Button when no hot water is running.

Used to adjust the voice prompt volume.

Sound Volume

Temperature Display

Thermostat

Water Smart / Bath Fill

Button / Indicator

Water Volume

6 VB Series Indoor LS Manual

Shows the temperature setting.

Increases or decreases the temperature setting.

Used to select the Water Smart / Bath Fill Function to fill a bath

with a predetermined volume of water.

Used to select the water volume for the Water Smart / Bath Fill

Function.

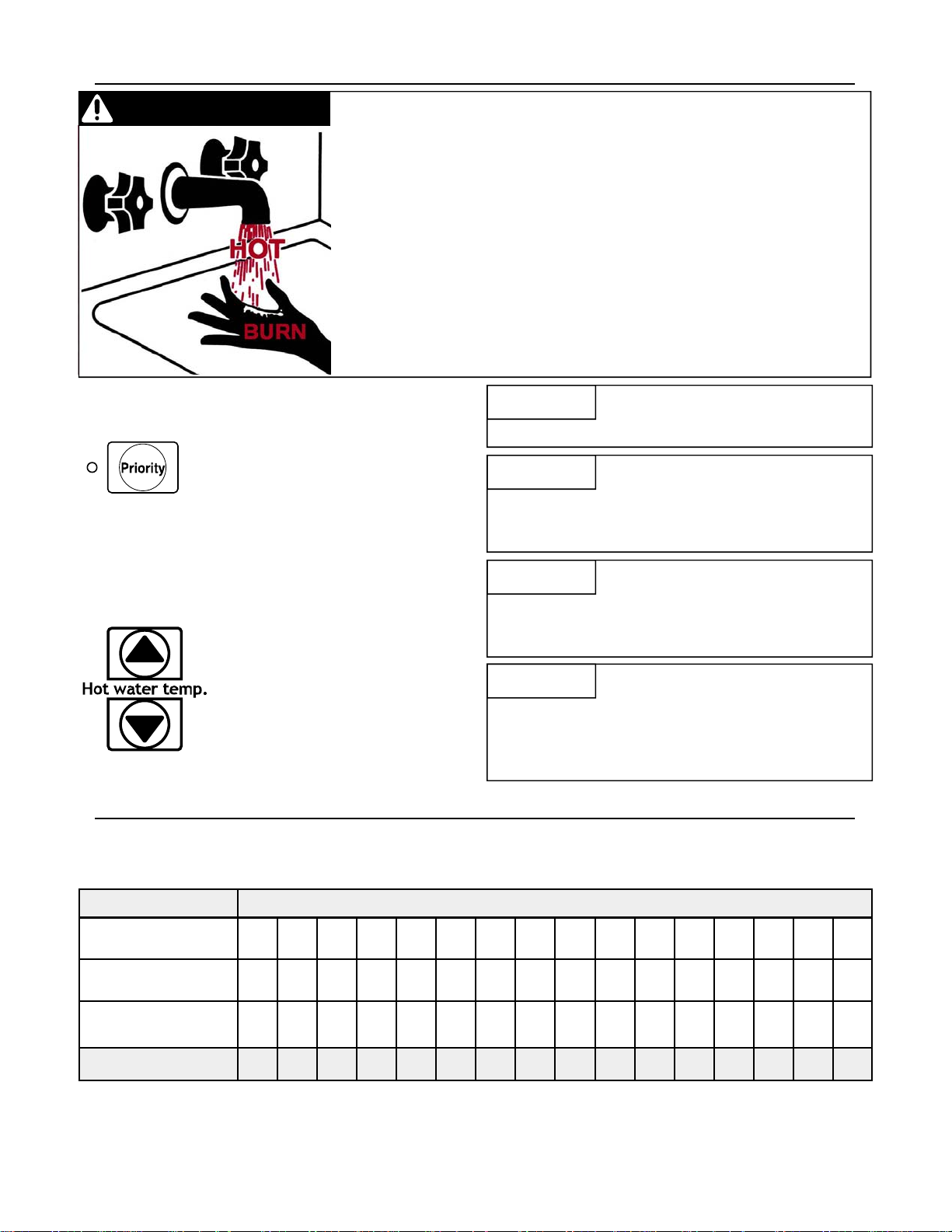

How to Set the Temperature

DANGER

1. If the water heater is off, press

the ON/OFF button to turn on.

2. Press the “Priority button” on the

temperature controller. The

green Priority light will glow

indicating that this controller is

controlling the temperature and

that the Rinnai water heater is

ready to supply hot water.

The priority can only be changed

while no hot water is running.

3. Press the ▲ or ▼ buttons to

obtain the desired temperature

setting.

All hot water sources are able to

provide water at this temperature

setting until it is changed again at

this or another temperature

controller.

Hot water can be dangerous, especially for infants or children, the elderly,

or infirm. There is hot water scald potential if the thermostat is set too high.

Water temperatures over 125º F (52º C) can cause severe burns or

scalding resulting in death.

Hot water can cause first degree burns with exposure for as little as:

3 seconds at 140º F (60º C)

20 seconds at 130º F (54º C)

8 minutes at 120º F (49º C)

Test the temperature of the water before placing a child in the bath or

shower.

Do not leave a child or an infirm person in the bath unsupervised.

NOTICE

NOTICE

NOTICE

NOTICE

While any hot water is being provided,

the temperature setting can only be

adjusted between 98º F and 110º F.

Check local codes for the maximum

water temperature setting allowed

when used in nursing homes, schools,

day care centers, and all other public

applications.

If a newly installed unit with a

controller has not been powered for at

least 6 hours then the temperature will

return to the default setting of 104º F

(40º C) if power is interrupted.

There may be a variation between the

temperature displayed on the

temperature controller and the

temperature at the tap due to weather

conditions or the length of pipe to the

water heater.

Temperature Controller Settings

This water heater will attempt to provide hot water at the temperature setting even when the water flow is varied

or when more than 1 tap is in use. The water heater can deliver water at only one temperature setting at a time.

The available temperatures for a given model are provided below.

Model

RL75i

RL94i

R98LSi

R98LSi-ASME

Temp in Celsius ºC 37 38 39 40 41 42 43 46 49

An older controller, MC-45, can be installed with the RL75i and RL94i by moving switch No. 6 in the bank of 6

switches to ON. Some of the temperature settings will be slightly different from the above table.

VB Series Indoor LS Manual 7

98 100 102 104 106 108 110 115 120

98 100 102 104 106 108 110 115 120

98 100 102 104 106 108 110 115 120 125 130 135 140

Temperature Settings Available (ºF)

125 * 130* 135* 140* 150

125* 130* 135* 140* 150

52 54 57 60 66 71 85

**

**

150

**

160

**

160

**

160

**

185

**

185

**

Temperature Controller Settings

* Re-setting the Maximum Temperature (RL75 and RL94 only)

Models RL75 and RL94 have a default maximum temperature of 120º F

(49º C) and an option to increase the maximum temperature to 140 ºF

(60 ºC). Temperature settings from 125-140 ºF (52-60 ºC) are available

by setting switch 6 to ON in the SW1 bank of 8 switches.

** MCC-91 Temperature Controller

These settings require the MCC-91 controller. When the MCC-91

controller is connected, these higher temperatures are available on all

controller models in the system. Use of an MCC-91 controller in a

residential dwelling will reduce the warranty coverage to that of a

commercial warranty application.

The MCC-91 controller is intended for commercial and hydronic

applications only. If an MCC-91 controller is used in a residential

dwelling for a hydronics application, a mixing valve must also be

installed to limit the potable hot water temperature to a safe

temperature. Water temperatures over 125º F (52º C) can cause severe

burns or scalding. Refer to the Danger Alert on water temperatures.

Rinnai shall not, in any event, be liable for damages resulting from such

misuse or misapplication.

Suggested temperatures are

• Kitchen 120 ºF (49º C)

• Shower 98 - 110 ºF (37 - 43 ºC)

• Bath Fill 102 - 110 ºF (39 - 43 ºC)

A temperature lower than 98º F (37º C) can be

obtained at the tap by mixing with cold water.

To change the temperature scale from Celsius to

Fahrenheit or vice versa, press and hold the “On/Off”

button for 5 seconds while the water heater is OFF.

These temperatures are suggestions only.

Maximum Temperature

120º F (49º C) 140 ºF (60 ºC)

Switch No.

ON

O

F

F

1

2

3

4

5

6

7

8

Switch No.

ON

O

F

F

1

2

3

4

5

6

7

8

WARNING

DO NOT adjust the other switches

unless specifically instructed to do

so.

Temperature Options Without a Temperature Controller

The default temperature setting for this appliance installed without a temperature controller is 120º F (49º C). If

desired, the temperature setting can be changed to 140º F (60º C) by adjustment of a switch.

In the SW1 bank of 8 switches, set switch 5 to ON to obtain 140º F water temperature setting. Set switch 5 to

OFF (default) to obtain 120º F water temperature setting.

If a temperature controller is installed, then switch 5 has no effect on temperature settings.

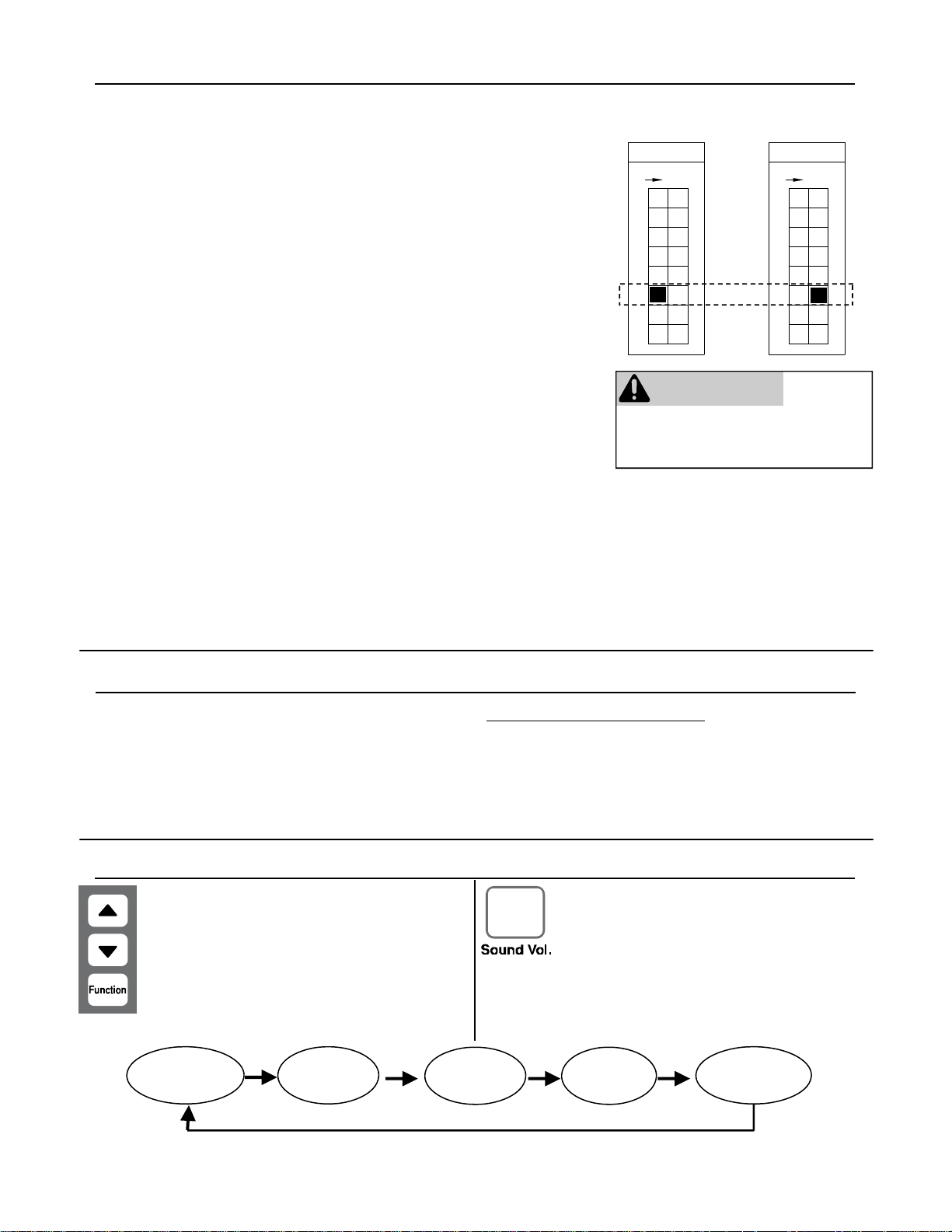

Setting the Sound Volume (Voice Prompt)

MC-100V Press the “Function” button to

adjust the voice prompt

volume. The default sound

volume is set to Medium.

Each subsequent press of the

▲ or ▼ button cycles through

the volume levels in the order

below.

Medium Volume

(default)

High Volume

Off Volume

(beep)

BC-100V Press the “Sound Vol.” button to

adjust the voice prompt volume.

The default sound volume is set

to Medium. Each subsequent

press of the button cycles

through the volume levels in the

order below.

Off Sound

(no beep)

Low Volume

8 VB Series Indoor LS Manual

Using the Water Smart / Bath Fill Function

Overview

This function is exclusive to the BC-100V temperature

controller. The bath fill function allows the consumer

to fill a tub with a preset volume of water at a preset

temperature. This is done by pressing the bath fill

button on the BC-100V controller while no hot water is

flowing and then opening only the hot water tap. The

water heater will stop the hot water flow when the

preset volume has been reached. The hot water tap

should then be closed and the bath fill button pressed.

The temperature settings for the bath fill function are

limited to those in the table below.

Bath Fill Temperature Settings

Available

ºF 98 100 102 104 106 108

ºC 37 38 39 40 41 42

ºF 110 112 114 116 118 120

ºC 43 44 46 47 48 49

NOTICE

Multiple

Water

Heaters

NOTICE

Power

Loss

NOTICE

Anti-scald

Fixtures

The bath fill function will not work

properly if it is connected to multiple

water heaters. The tub will overfill

because the bath fill function is not

able to measure the water volume

when connected to multiple water

heaters.

If power is lost during the bath fill

function, the water heater will shut

down but the water will continue to

flow. When power returns, the water

shuts off and Error Code 03 appears

on the controller.

If power is lost after the bath has filled

but before the bath fill function button

is de-selected, then the water will not

flow during the power loss or after the

power is returned. Once power

returns, close the hot water tap and

de-select the bath fill function. No

error code appears.

Do not use with single handle fixtures

that have anti-scald features built into

them. These fixtures allow a

predetermined amount of cold water

which is not taken into account by the

bath fill function.

Setting the Water Volume

The default volume is set to 25 gallons. The volume

can be set between 10 and 120 gallons.

1. Press the “Priority” button on the

temperature controller. The green

Priority light will glow indicating

that this controller is controlling

the temperature and that the

Rinnai water heater is ready to

supply hot water.

2. Press the “Water Smart Bath Fill”

button to set the water volume

and temperature.

3. Press the “Temp” ▲ or ▼ buttons

to obtain the desired temperature

setting.

NOTICE

To Prevent

Over Filling

4. Press the “Water Vol.”▲ or ▼

buttons to obtain the desired

water volume in gallons.

5. Press the “Water Smart Bath Fill”

button.

Be careful not to overfill the bath. An

average bath volume is 60 gallons.

When filling the bath using this

function for the first time:

•Monitor and remain by the bath while

the water is running.

•Use a low bath fill volume less than

25 gallons

VB Series Indoor LS Manual 9

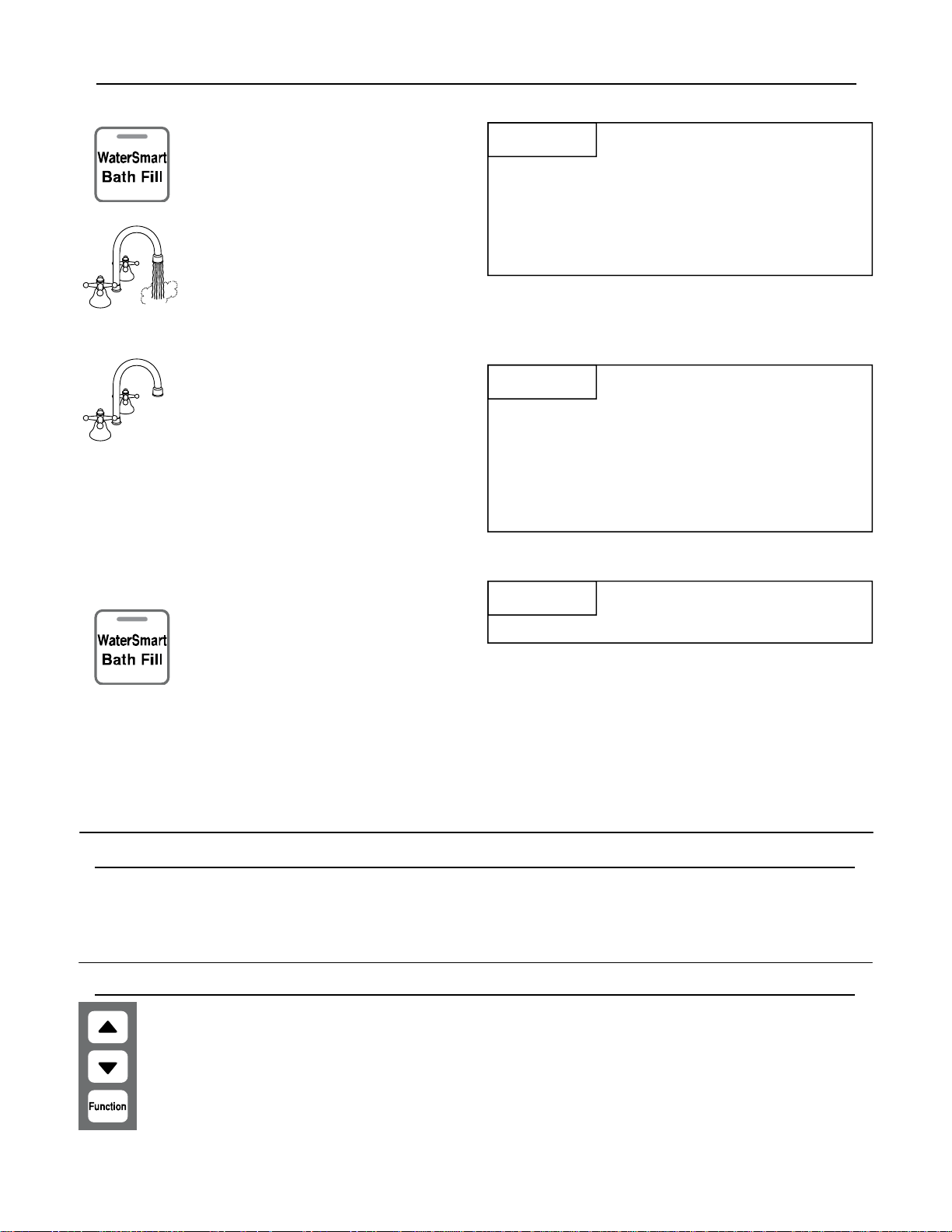

Using the Water Smart / Bath Fill Function

Filling the Tub

ON!

HOT

ON!

HOT

COLD

COLD

1. Press the “Water Smart / Bath Fill”

button once. The button will

illuminate, and a tone will sound.

2. The voice prompt will announce

“The hot water system is ready.

Open the hot water tap.”

Make sure the water volume is set.

Refer to “Setting the Water

Volume” on the previous page.

Open the hot water tap. The “In

Use” indicator will illuminate on

MC-100V and BC-100V controllers.

The hot water will begin to flow.

3. When the preset volume of water

has been produced then

•the water flow will cease

•the “Water Smart / Bath Fill”

button will flash

•a tone will sound

•the voice prompt will announce,

“Bath fill is complete. Turn

off the bath hot water tap and

push the Bath Fill button.”

4. Turn off the bath hot water tap and

push the Bath Fill button. The

water heater will not allow hot

water to flow from any source until

the “Water Smart / Bath Fill” button

is pushed.

The button light will go out.

NOTICE

To Stop the

Bath Fill

Before it

Finishes

NOTICE

When

Other Taps

Are Open

NOTICE

To stop the water flow during the Bath

Fill function, press the “Water Smart /

Bath Fill” button. The button will flash

and the voice prompt will announce,

“Hot water is not available. Turn off

all hot water taps and push the Bath

Fill button.” Follow the voice prompt

instructions.

During the bath fill function, any hot

water flowing at other locations,

subtracts from the total amount of

water for the bath. For example if the

bath fill function is set for 50 gallons

and 5 gallons of hot water are used at

other locations during the fill period

then the bath will only fill with 45

gallons.

During the operation of the bath fill

function, the MC-91 “In Use” indicator

does not light up.

Setting Controller to Mute

Models MC-91 and MCC-91

To eliminate the beeps when keys are pressed or to turn the beeps back on, press and hold both the ▲and ▼

buttons until a beep is heard (approximately 5 seconds).

Setting the Clock

MC-100V Press the “Function” button twice within 10 seconds to set the clock. Press the ▲ or

▼ button to reach the desired time. The clock on the BC-100V automatically shows

the time which has been set on the MC-100V.

10 VB Series Indoor LS Manual

Maintenance

WARNING

Turn off the electrical power supply, the manual gas

valve and the manual water control valve whenever

servicing the unit.

Repairs and maintenance should be performed by a

qualified service technician. The appliance should be

inspected annually by a qualified service technician.

Verify proper operation after servicing.

Cleaning

It is imperative that control compartments, burners,

and circulating air passageways of the appliance be

kept clean.

Clean as follows:

1. Turn off and disconnect electrical power. Allow to

cool.

2. Close the water shut off valves. Remove and clean

the water inlet filter.

3. Remove the front panel by removing 4 screws.

4. Use pressurized air to remove dust from the main

burner, heat exchanger, and fan blades. Do not

use a wet cloth or spray cleaners on the burner.

Do not use volatile substances such as benzene

and thinners. They may ignite or fade the paint.

Snow Accumulation

Keep the area around flue terminal free of snow and

ice. The appliance will not function properly if the

intake air or exhaust is impeded (blocked or partially

blocked) by obstructions.

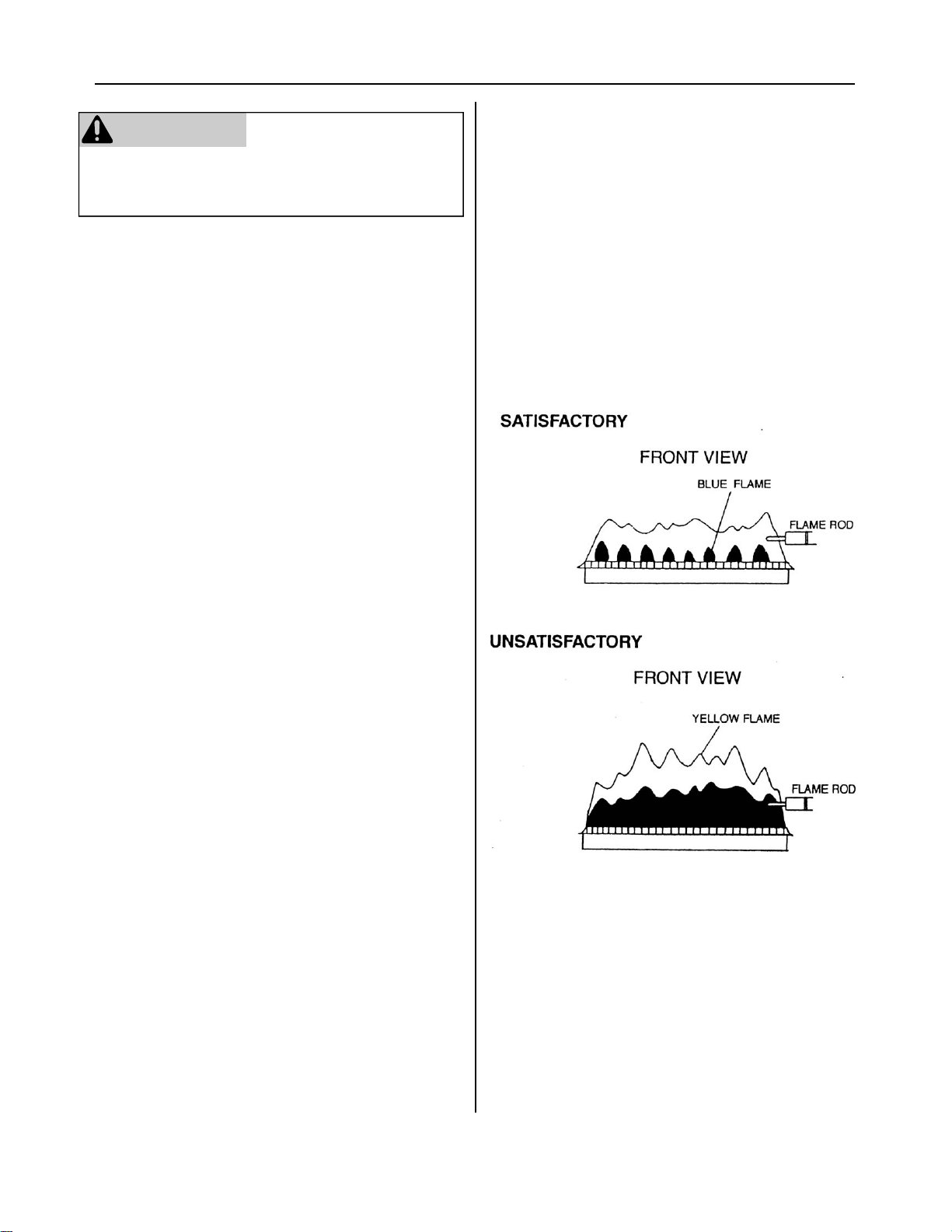

Visual Inspection of Flame

The burner must flame evenly over the entire surface

when operating correctly. The flame must burn with a

clear, blue, stable flame. See the parts breakdown of

the burner for the location of the view ports.

The flame pattern should be as shown in the figures

below.

5. Use soft dry cloth to wipe cabinet.

Vent System

The vent system should be inspected at least annually

for blockages or damage.

Motors

Motors are permanently lubricated and do not need

periodic lubrication. Keep fan and motor free of dust

and dirt by cleaning annually.

Temperature Controller

Use a soft damp cloth to clean the temperature

controller. Do not use solvents.

Lime / Scale Build-up

If you receive Error Code “LC”, refer to the procedure,

Flushing the Heat Exchanger. Refer to the section on

Water Quality to see if your water needs to be treated

or conditioned. (When checking maintenance code

history, “00” is substituted for “LC”.)

VB Series Indoor LS Manual 11

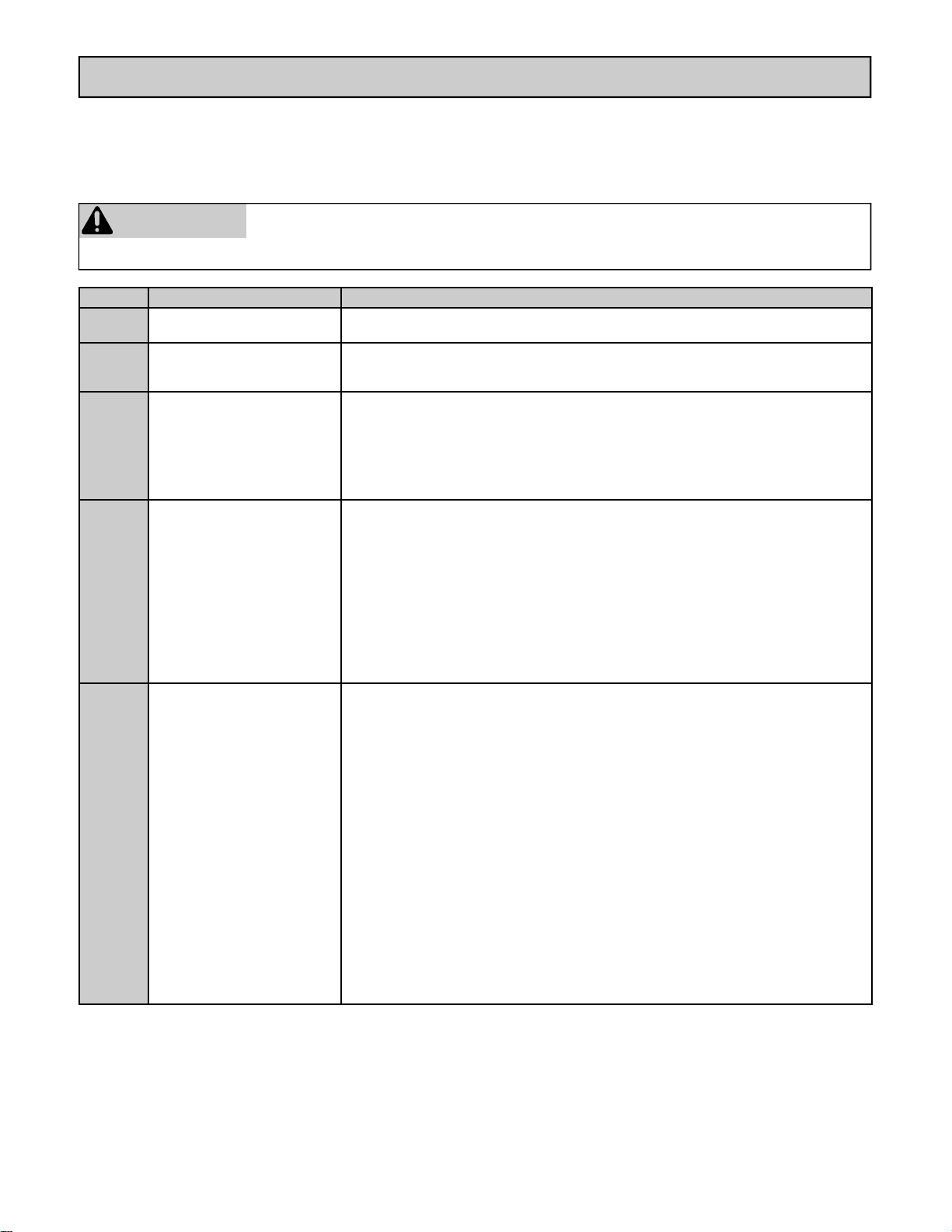

Error Codes

The Rinnai water heater has the ability to check its own operation continuously. If a fault occurs, an error code

will flash on the display of the temperature controller. This assists with diagnosing the fault and may enable you

to overcome a problem without a service call. Please identify the code displayed when inquiring about service.

WARNING

Some of the checks below may need to be done by a qualified service technician. Call a

service technician for any remedy that involves gas or electricity. Call a service

technician if you have any doubt or reservation about performing the remedy yourself.

Code Fault Remedy

02

03

10

11

12

No burner operation during

freeze protection mode

Power interruption during

Bath Fill (Water will not flow

when power returns).

Air Supply or Exhaust

Blockage

No Ignition Check that the gas is turned on at the water heater, gas meter, or cylinder.

Flame Failure Check that the gas is turned on at the water heater and gas meter. Check for

Service Call

Turn off all hot water taps. Press ON/OFF twice.

Ensure Rinnai approved venting materials are being used.

Check that nothing is blocking the flue inlet or exhaust.

Check all vent components for proper connections.

Ensure vent length is within limits.

Ensure condensation collar was installed correctly.

Verify dip switches are set properly.

Check fan for blockage.

Ensure gas type and pressure is correct.

Ensure gas line, meter, and/or regulator is sized properly.

Bleed all air from gas lines.

Verify dip switches are set properly.

Ensure appliance is properly grounded.

Disconnect EZConnect™ or MSA controls to isolate the problem.

Ensure igniter is operational.

Check igniter wiring harness for damage.

Check gas solenoid valves for open or short circuits.

Remove burner cover and ensure all burners are properly seated.

Remove burner plate and inspect burner surface for condensation or debris.

obstructions in the flue outlet.

Ensure gas line, meter, and/or regulator is sized properly.

Ensure gas type and pressure is correct.

Bleed all air from gas lines.

Ensure proper Rinnai venting material was installed.

Ensure condensation collar was installed properly.

Ensure vent length is within limits.

Verify dip switches are set properly.

Ensure appliance is properly grounded.

Disconnect keypad.

Disconnect EZConnect™ or MSA controls to isolate the problem.

Check power supply for loose connections.

Check power supply for proper voltage and voltage drops.

Ensure flame rod wire is connected.

Check flame rod for carbon build-up.

Disconnect and reconnect all wiring harnesses on unit and PC board.

Check for DC shorts at components.

Check gas solenoid valves for open or short circuits.

Remove burner plate and inspect burner surface for condensation or debris.

Check the ground wire for the PC board.

12 VB Series Indoor LS Manual

Code Fault Remedy

Error Codes

14

16

31

32

33

34

52

61

65

71

72

73

LC

No

code

Thermal Fuse Check gas type of unit and ensure it matches gas type being used.

Over Temperature

Warning

Burner Sensor Error Measure resistance of sensor.

Outgoing Water

Temperature Sensor

Fault

Heat Exchanger

Outgoing Temperature

Sensor Fault

Combustion Air

Temperature Sensor

Fault

Modulating Solenoid

Valve Signal Abnormal

Combustion Fan Failure Ensure fan will turn freely.

Water Flow Control Fault The water flow control valve has failed to close during the bath fill function. Immediately turn

Solenoid Valve Circuit

Fault

Flame Sensing Device

Fault

Burner Sensor Circuit

Error

Scale Build-up in Heat

Exchanger (when

checking maintenance

code history, “00” is

substituted for “LC”)

Nothing happens when

water flow is activated.

Check for restrictions in air flow around unit and vent terminal.

Check for low water flow in a circulating system causing short-cycling.

Ensure dip switches are set to the proper position.

Check for foreign materials in combustion chamber and/or exhaust piping.

Check heat exchanger for cracks and/or separations.

Check heat exchanger surface for hot spots which indicate blockage due to scale build-up.

Refer to instructions in manual for flushing heat exchanger.

Measure resistance of safety circuit.

Ensure high fire and low fire manifold pressure is correct.

Check for improper conversion of product.

Check for restrictions in air flow around unit and vent terminal.

Check for low water flow in a circulating system causing short-cycling.

Check for foreign materials in combustion chamber and/or exhaust piping.

Check for clogged heat exchanger.

Replace sensor.

Check sensor wiring for damage.

Measure resistance of sensor.

Clean sensor of scale build-up.

Replace sensor.

Check sensor wiring for damage.

Measure resistance of sensor.

Clean sensor of scale build-up.

Replace sensor.

Check for restrictions in air flow around unit and vent terminal.

Check sensor wiring for damage.

Measure resistance of sensor.

Clean sensor of scale build-up.

Ensure fan blade is tight on motor shaft and is in good condition.

Replace sensor.

Check modulating gas solenoid valve wiring harness for loose or damaged terminals.

Measure resistance of valve coil.

Check wiring harness to motor for damaged and/or loose connections.

Measure resistance of motor winding.

off the water and discontinue the bath fill function. Contact a state qualified or licensed

contractor to service the appliance.

Replace the PC Board.

Ensure flame rod is touching flame when unit fires.

Check all wiring to flame rod for damage.

Remove flame rod and check for carbon build-up; clean with sand paper.

Check inside burner chamber for any foreign material blocking flame at flame rod.

Measure micro amp output of sensor circuit with flame present.

Replace flame rod.

Check sensor wiring and PC board for damage.

Replace sensor.

Flush heat exchanger. Refer to instructions in manual.

Replace heat exchanger.

NOTE: The LC code is the only error code that will allow the unit to keep running. The

display will alternate between the LC code and the temperature setting. The controller will

continue to beep. The LC code will reset if power is turned off and then on.

Clean inlet water supply filter.

On new installations ensure hot and cold water lines are not reversed.

Check for bleed over. Isolate unit from building by turning off cold water line to building.

Isolate the circulating system if present. Open your pressure relief valve; if water is

flowing, there is bleed over in your plumbing.

Ensure you have at least the minimum flow rate required to fire unit.

Ensure turbine spins freely.

Measure the resistance of the water flow control sensor.

Check for DC shorts at components.

VB Series Indoor LS Manual 13

Trouble Shooting for Common Issues

I don’t have any hot water when I open the tap.

Make sure there is gas, water, and electricity to the

Rinnai water heater (power is turned on and the gas is

turned on).

When I was using the hot water, the water got cold.

If you adjusted the flow from the tap to lessen it, you

may have gone below the minimum flow required. The

Rinnai water heater requires a minimum flow rate to

operate. (See the specification page for the flow rate

of your model.)

If you are experiencing issues with higher temperature

settings, then Rinnai recommends reducing the

temperature setting. Selecting a temperature closer to

that which is actually used at the faucet will increase

the amount of hot water being delivered to the faucet,

due to less cold water mixing at the fixture.

White smoke comes out of the exhaust.

During colder weather when the exhaust temperature

is much hotter than the outside air, the exhaust fumes

condense producing water vapor.

When I open a hot tap, I do not immediately get hot

water.

Hot water must travel through your plumbing from the

Rinnai water heater to the faucet. The time period for

hot water to reach your fixture is determined by the

amount of water in the plumbing system between the

water heater and the fixture, water pressure, and the

flow rate of the fixture.

After I turn off the hot water tap, the fan on the

Rinnai water heater continues to run.

The fan is designed to continue running for a short time

after the flow of water stops. This is to ensure constant

water temperatures during rapid starting and stopping,

as well as exhausting any residual gas flue products

from the unit.

Accessing Operating Information

Models MC-91 and MCC-91

To display the most recent error codes press and hold the “On/Off” button for 2 seconds. While holding the “On/

Off” button press the ▲ button. The last 9 error codes will flash one after the other. To exit this mode press the

“On/Off” and ▲ button as before.

To display the water flow through the water heater press and hold the ▲ button for 2 seconds and without

releasing the ▲ button press the “On/Off” button.

To display the outlet water temperature press and hold the ▼ button for 2 seconds and without releasing the ▼

button press the “On/Off” button.

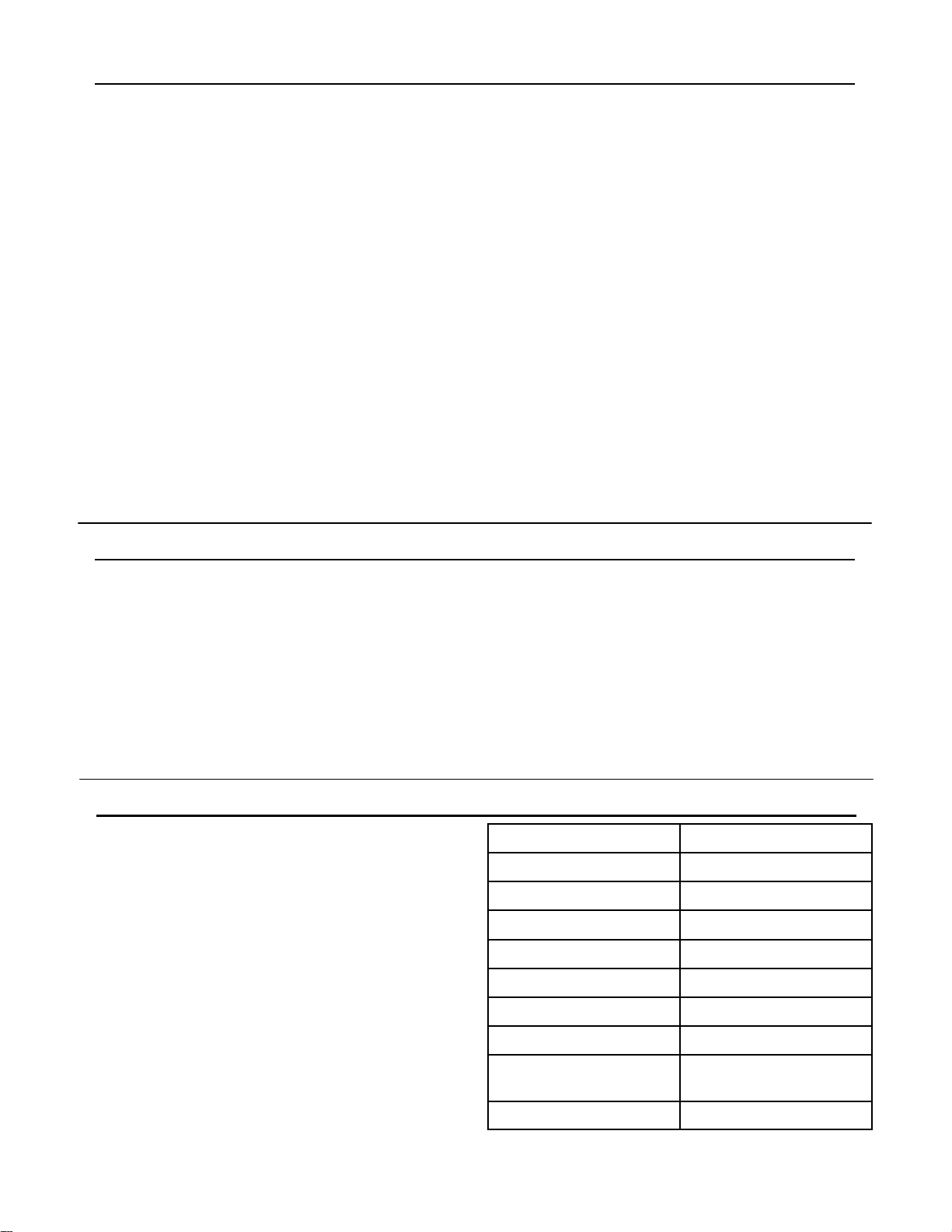

Water Quality

Consideration of care for your water heater should

include evaluation of water quality. If the water quality

exceeds the target levels provided in the table, you

may want to treat or condition the water.

* Source: Part 143 National Secondary Drinking Water

Regulations

Total Hardness Up to 200 mg / L

Aluminum * Up to 0.2 mg / L

Chlorides * Up to 250 mg / L

Copper * Up to 1.0 mg / L

Iron * Up to 0.3 mg / L

Manganese * Up to 0.05 mg / L

Maximum Level

pH * 6.5 to 8.5

TDS (Total Dissolved

Solids) *

Zinc * Up to 5 mg / L

14 VB Series Indoor LS Manual

Up to 500 mg / L

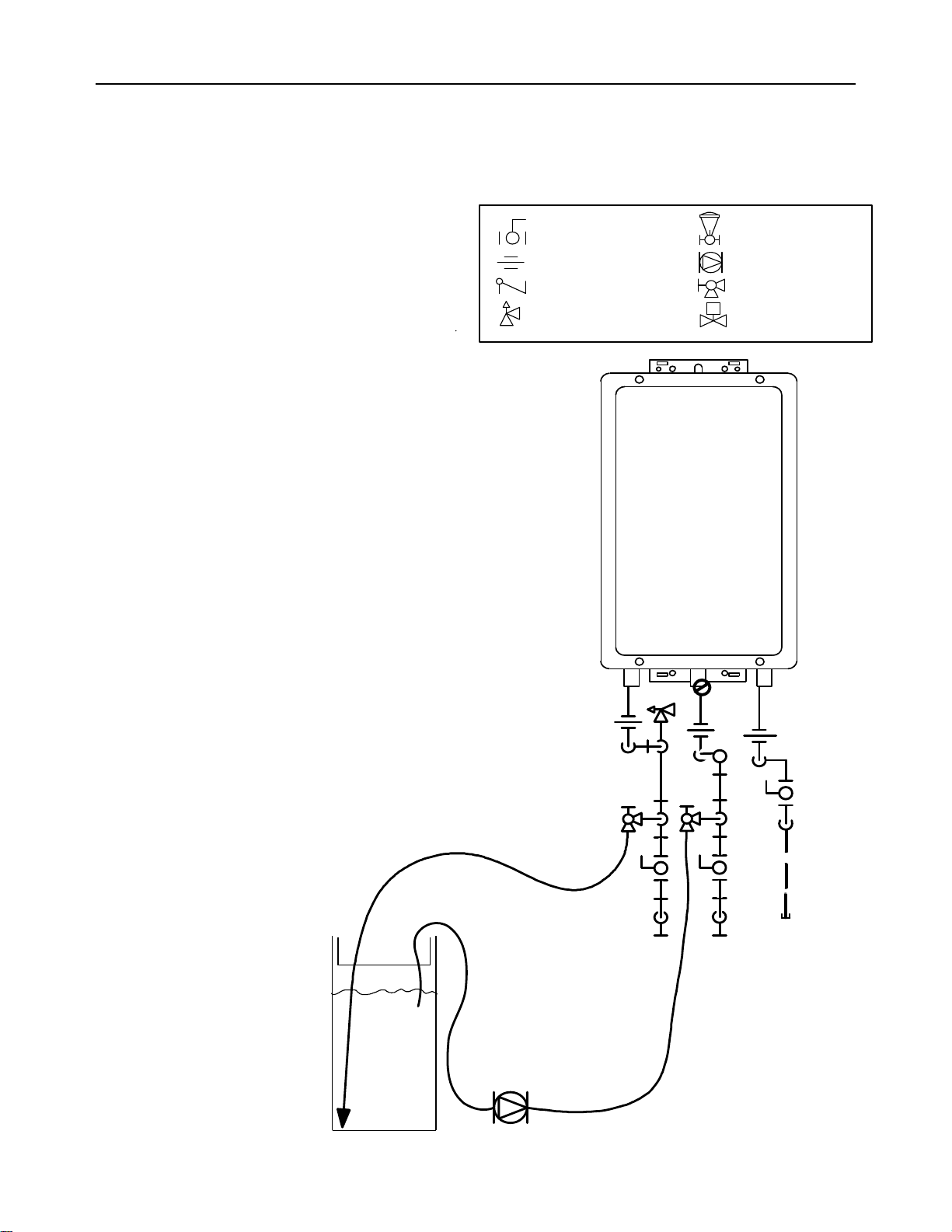

Flushing the Heat Exchanger (Error Code: LC or 00)

An “LC” or “00” error code indicates the unit is beginning to lime up and must be flushed. Failure to flush the

appliance will cause damage to the heat exchanger. Damage caused by lime build-up is not covered by the unit’s

warranty. After flushing, reset the LC fault code by turning off the power to the unit and turning the power back

on.

1. Disconnect electrical power to the water heater.

2. Close the shutoff valves on both the hot water and

cold water lines (V3 and V4).

3. Connect pump outlet hose (H1) to the cold water

line at service valve (V2).

4. Connect drain hose (H3) to service valve (V1).

5. Pour 4 gallons of undiluted virgin, food grade,

white vinegar into pail.

6. Place the drain hose (H3) and the hose (H2) to

the pump inlet into the cleaning solution.

7. Open both service valves (V1 and V2) on the hot

water and cold water lines.

8. Operate the pump and allow the cleaning solution

to circulate through the water heater for 1 hour at

a rate of 4 gallons per minute (15.1 liters per

minute).

9. Turn off the pump.

10. Rinse the cleaning solution from the water heater

as follows:

a. Remove the free end of the drain hose (H3)

from the pail.

b. Close service valve, (V2), and open shutoff

valve, (V4). Do not open shutoff valve, (V3).

c. Allow water to flow through the water heater for

5 minutes

d. Close service valve, (V1), and open shutoff

valve, (V3).

11. Disconnect all hoses.

12. With (V4) closed, remove the in-line filter at the

cold water inlet and clean out any residue. Place

filter back into unit and open (V4).

13. Restore electrical power to the water heater.

KEY

3/4" Ball Valve

3/4" Union

Check Valve

Pressure Relief Valve

Water Heater

V1

S

Rinnai

n

I

F

V2

Pressure Regulator

Circulating Pump

Boiler Drain Valve

Solenoid Valve

n

i

e

l

e

t

r

l

i

CLEAN THERMISTORS

Remove and clean thermistors

H3

V4

V3

with a soft cloth or sponge after

removing O-rings.

W

H

o

t

a

e

t

r

n

i

L

e

W

C

o

a

t

L

n

i

G

a

d

l

e

r

e

s

S

u

p

p

y

l

H2

Cleaning solution is 4 gallons of

undiluted virgin, food grade,

white vinegar.

Circulating Pump

VB Series Indoor LS Manual 15

H1

Installation Instructions

Only properly trained and qualified installers

should install this appliance. The warranty may

be voided due to improper installation or

installation by a non-qualified installer.

Rinnai highly recommends all installers attend a

product knowledge class.

For information on a Rinnai Training Course or

for questions on installation call 1-800-621-

9419.

RL75i .................. REU-VB2528FFUD-US

RL94i .................. REU-VB2735FFUD-US

R98LSi ................ REU-VA3237FFU-US

R98LSi-ASME .... REU-VA3237FFU-ASME

The VB series (RL75i, and RL94i) are certified for installation in

manufactured (mobile) homes.

General Instructions

WARNING

Do not use substitute materials.

Use only parts certified with the appliance.

• This appliance must be installed by a state qualified

or licensed contractor. It is the responsibility of the

person having the water heater installed to ensure

the installing contractor has proper licenses and

permits for installing water heaters in your location.

Rinnai highly recommends that installers attend a

product knowledge class to ensure customer

satisfaction and warranty coverage. Failure to

comply with state and local codes pertaining to

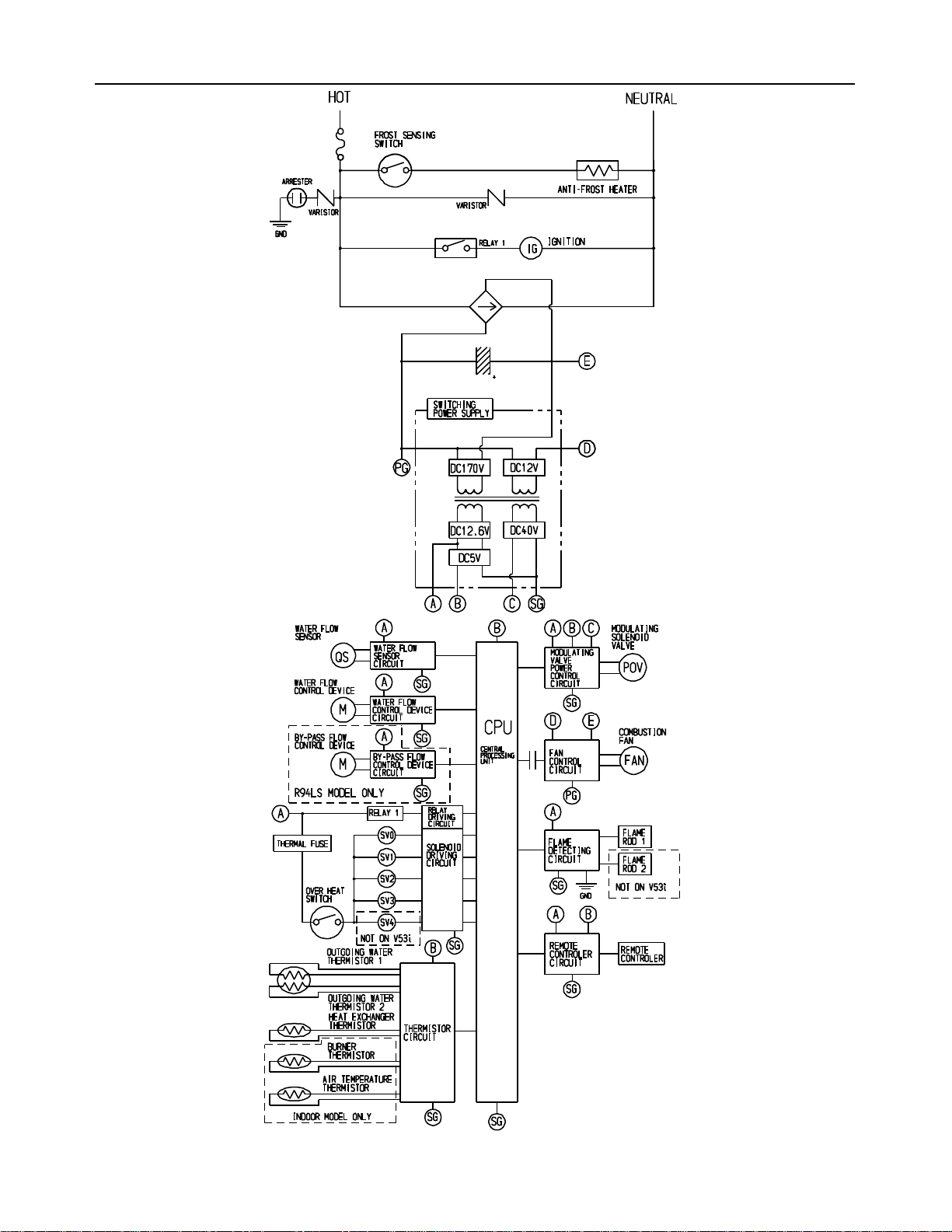

water heater installations may void the warranty.

• This appliance is not to be installed outdoors.

• A qualified installer or service technician should

install the appliance, inspect it, and leak test it

before use.

• The installation must conform with local codes or, in

the absence of local codes, with the National Fuel

Gas Code, ANSI Z223.1/NFPA 54, or the Natural

Gas and Propane Installation Code, CSA B149.1. If

installed in a manufactured home, the installation

must conform with the Manufactured Home

Construction and Safety Standard, Title 24 CFR,

Part 3280 and/or CAN/SCA Z240 MH Series, Mobile

Homes.

• The appliance, when installed, must be electrically

grounded in accordance with local codes or, in the

absence of local codes, with the National Electrical

Code, ANSI/NFPA 70, or the Canadian Electrical

Code, CSA C22.1.

• The appliance and its appliance main gas valve

must be disconnected from the gas supply piping

system during any pressure testing of that system at

test pressures in excess of 1/2 psi (3.5 kPa) (13.84

in W.C.).

• The appliance must be isolated from the gas supply

piping system by closing its individual manual

shutoff valve during any pressure testing of the gas

supply piping system at test pressures equal to or

less than 1/2 psi (3.5 kPa) (13.84 in W.C.).

• Follow the installation instructions and those in Care

and Maintenance for adequate combustion and

ventilation air.

• The appliance should be located in an area where

water leakage of the unit or connections will not

result in damage to the area adjacent to the

appliance or to lower floors of the structure. When

such locations cannot be avoided, it is

recommended that a suitable drain pan, adequately

drained, be installed under the appliance. The pan

must not restrict combustion air flow.

• The flow of combustion and ventilation air shall not

be obstructed. Combustion air shall not be supplied

from occupied spaces.

• This appliance is not suitable for use in an

application such as a pool or spa heater that uses

chemically treated water . (This appliance is

suitable for filling large or whirlpool bath tubs with

potable water.)

• If a water heater is installed in a closed water supply

system, such as one having a backflow preventer in

the cold water supply line, means shall be provided

to control thermal expansion. Contact the water

supplier or local plumbing inspector on how to

control thermal expansion.

• Should overheating occur or the gas supply fail to

shut off, turn off the manual gas control valve to the

appliance.

• Keep the air intake location free of chemicals such

as chlorine or bleach that produce fumes. These

fumes can damage components and reduce the life

of your appliance.

• For gas type conversion, contact Rinnai.

16 VB Series Indoor LS Manual

Clearances from Appliance

Top of

Heater

Back of

Heater

Front of

Heater

Sides of

Heater

Ground/

Bottom

Vent

to Combustibles

RL75i

RL94i

6 inches **

(152 mm)

0 (zero) 0 (zero) 0 (zero) 0 (zero)

6 inches

(152 mm)

2 inches

(51 mm)

12 inches

(305 mm)

0 (zero) 4 inches * 0 (zero) 0 (zero)

R98LSi

12 inches

(305 mm)

6 inches

(152 mm)

2 inches

(51 mm)

12 inches

(305 mm)

2 inches **

(51 mm)

6 inches

(152 mm)

1/2 inch

(13 mm)

12 inches

(305 mm)

to Non-

Combustibles

RL75i

RL94i

R98LSi

2 inches

(51 mm)

6 inches

(152 mm)

1/2 inch

(13 mm)

2 inches

(51 mm)

to top

to side

to front

to ground/bottom

* 4 inches (102 mm) for enclosed area; 1 inch (26 mm) for unenclosed area.

** 0 inches from vent components and condensate drain line.

The clearance for servicing is 24 inches in front of the water heater.

For closet installation: clearance is 6 inches (152 mm) from the front.

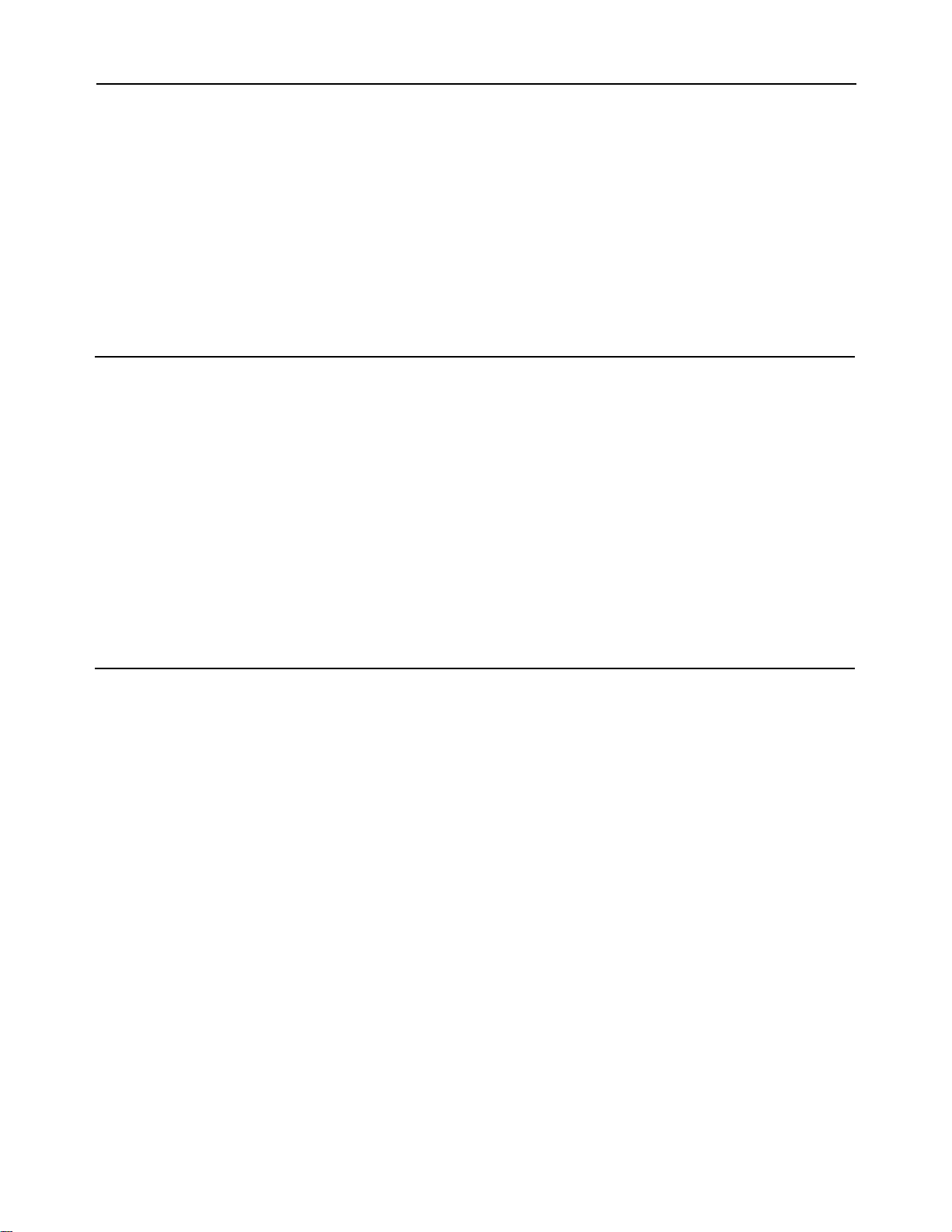

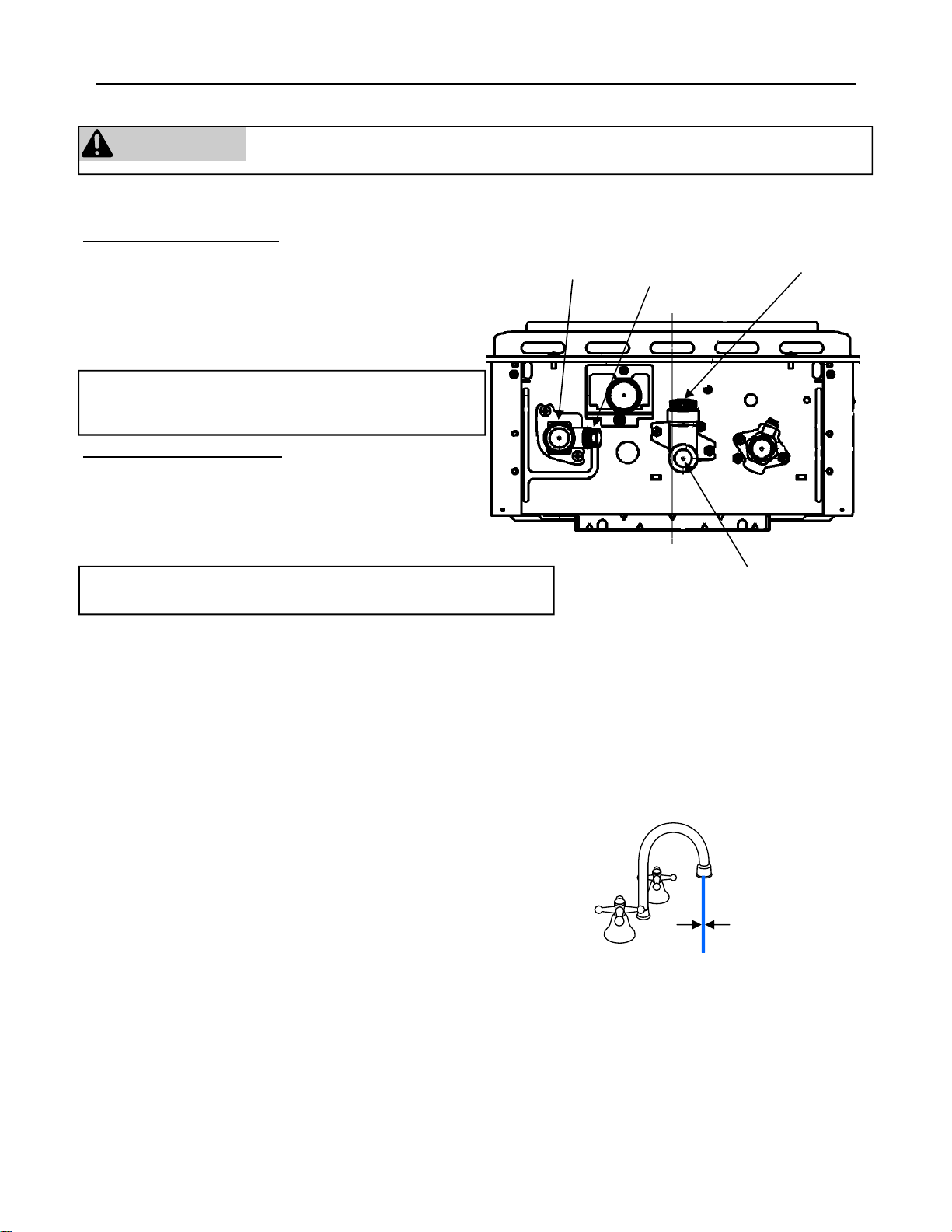

Attachment of the Water Heater

1. Identify the installation location and confirm that

the installation will meet all required clearances.

2. Securely attach the water heater to the wall using

any of the holes in the wall installation brackets

which are at the top and bottom of the water

heater. Ensure that the attachment strength is

sufficient to support the weight. Refer to the

weight of the water heater in the Specifications

section.

NOTE: Rinnai water heaters should be installed in an

upright position. Do not install upside down or on its

side.

wall installation

brackets

VB Series Indoor LS Manual 17

Electrical Connection

The water heater requires 120 VAC, 60 Hz power from a properly grounded circuit.

If using the 6 foot long power cord, plug it into a standard 3 prong 120 VAC, 60 Hz properly grounded wall outlet.

The wiring diagram is located on the Technical Sheet attached to the inside of the front cover.

The water heater must be electrically grounded in accordance with local codes, or in the absence of local codes

with the National Electrical Code, ANSI/NFPA 70 and/or the CSA C22.1, Canadian Electrical Code.

Error Indication or Air Handler Control Switch (RL75i, and RL94i only)

When using the Rinnai water heater with an Error Indication Switch, switch No. 4 in the bank of 8 switches should

be in the off position. This is the default position.

To connect the water heater to the Rinnai Air Handler, the Control Switch is necessary to function as the electrical

connection. When the Control Switch is functioning as the electrical connection between the water heater and air

handler, switch No. 4 in the bank of 8 switches should be in the on position.

The Error Indication Switch and the Rinnai Air Handler Control Switch are optional products available from Rinnai.

Installation instructions are included with these products.

Gas Piping

General Instructions

• A manual gas control valve must be placed in the

gas supply line to the Rinnai water heater. A union

can be used on the connection above the shut off

valve for the future servicing or disconnection of the

unit.

• Check the type of gas and the gas inlet pressure

before connecting the Rinnai water heater. If the

Rinnai water heater is not of the gas type that the

building is supplied with, DO NOT connect the water

heater. Contact the dealer for the proper unit to

match the gas type.

• Check the gas supply pressure immediately

upstream at a location provided by the gas

company. Supplied gas pressure must be within the

limits shown in the Specifications section.

• Before placing the appliance in operation all joints

including the heater must be checked for gas

tightness by means of leak detector solution, soap

and water, or an equivalent nonflammable solution,

as applicable. (Since some leak test solutions,

including soap and water, may cause corrosion or

stress cracking, the piping shall be rinsed with water

after testing, unless it has been determined that the

leak test solution is non-corrosive.)

• Always use approved connectors to connect the unit

to the gas line. Always purge the gas line of any

debris before connection to the water heater.

• The gas supply line shall be gas tight, sized, and so

installed as to provide a supply of gas sufficient to

meet the maximum demand of the heater and all

other gas consuming appliances at the location

without loss of pressure.

• Any compound used on the threaded joint of the gas

piping shall be a type which resists the action of

liquefied petroleum gas (propane / LPG).

• Refer to an approved pipe sizing chart if in doubt

about the size of the gas line.

18 VB Series Indoor LS Manual

Gas Piping

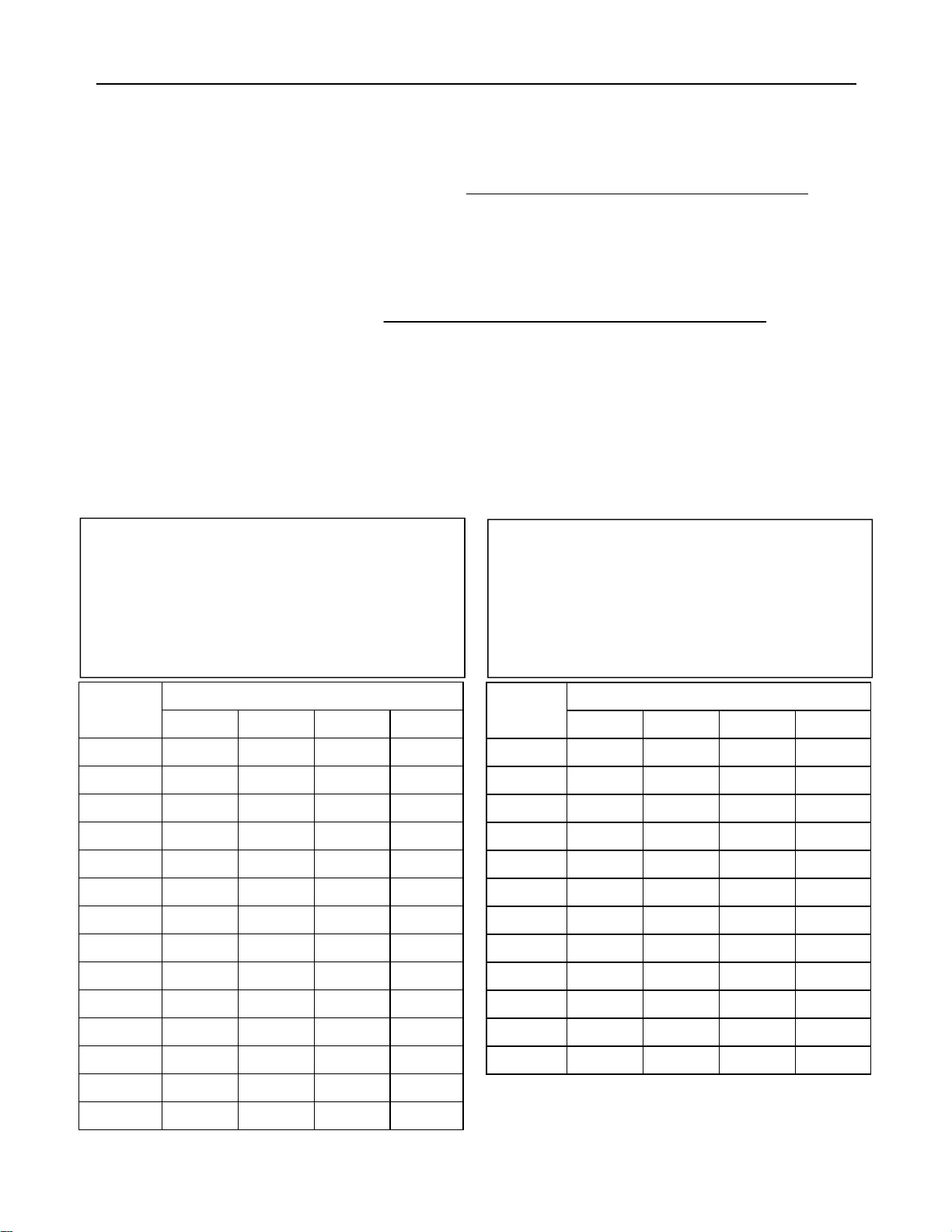

Pipe Sizing Procedure - Example

The gas supply must be capable of handling the entire gas load at the location. Gas line sizing is based on gas

type, the pressure drop in the system, the gas pressure supplied, and gas line type. For gas pipe sizing in the

United States, refer to the National Fuel Gas Code, NFPA 54. For Canadian gas pipe sizing, refer to the Natural

Gas and Propane Installation Code CAN/CSA B149.1. The below information is provided as an example. The

appropriate table from the applicable code must be used.

1. For some tables, you will need to determine the cubic feet per hour of gas required by dividing the gas input

by the heating value of the gas (available from the local gas company). The gas input needs to include all gas

products at the location and the maximum BTU usage at full load when all gas products are in use.

Gas Input of all gas products (BTU / HR)

Cubic Feet per Hour (CFH) =

Heating Value of Gas (BTU / FT 3 )

2. Use the table for your gas type and pipe type to find the pipe size required. The pipe size must be able to

provide the required cubic feet per hour of gas or the required BTU/hour.

Example: The heating value of natural gas for your location is 1000 BTU/FT

199,000 BTU/HR. Additional appliances at the location require 65,000 BTU/hr. Therefore the cubic

feet per hour = (199,000 + 65,000) / 1000 = 264 FT

pipe size is capable of supplying 264 FT

3

/HR of natural gas.

3

/HR. If the pipe length is 10 feet then the 3/4 inch

3

. The gas input of the RL94i is

Pipe Sizing Table - Natural Gas

Schedule 40 Metallic Pipe

Inlet Pressure: less than 2 psi (55 inches W.C.)

Pressure Drop: 0.3 inches W.C.

Specific Gravity: 0.60

Capacity in cubic feet per hour

Length

10

20

30

40

50

60

70

80

90

3/4 1 1 1/4 1 1/2

273 514 1060 1580

188 353 726 1090

151 284 583 873

129 243 499 747

114 215 442 662

104 195 400 600

95 179 368 552

89 167 343 514

83 157 322 482

Pipe Size (inches)

Pipe Sizing Table - Propane Gas

Schedule 40 Metallic Pipe

Inlet Pressure: 11.0 inches W.C.

Pressure Drop: 0.5 inches W.C.

Specific Gravity: 1.50

Capacity in Thousands of BTU per Hour

Length

10

20

30

40

50

60

80

100

125

1/2 3/4 1 1 1/4

291 608 1150 2350

200 418 787 1620

160 336 632 1300

137 287 541 1110

122 255 480 985

110 231 434 892

101 212 400 821

94 197 372 763

89 185 349 716

Pipe Size (inches)

100

125

150

175

200

VB Series Indoor LS Manual 19

79 148 304 455

70 131 269 403

63 119 244 366

58 109 224 336

54 102 209 313

150

175

200

84 175 330 677

74 155 292 600

67 140 265 543

Water Piping

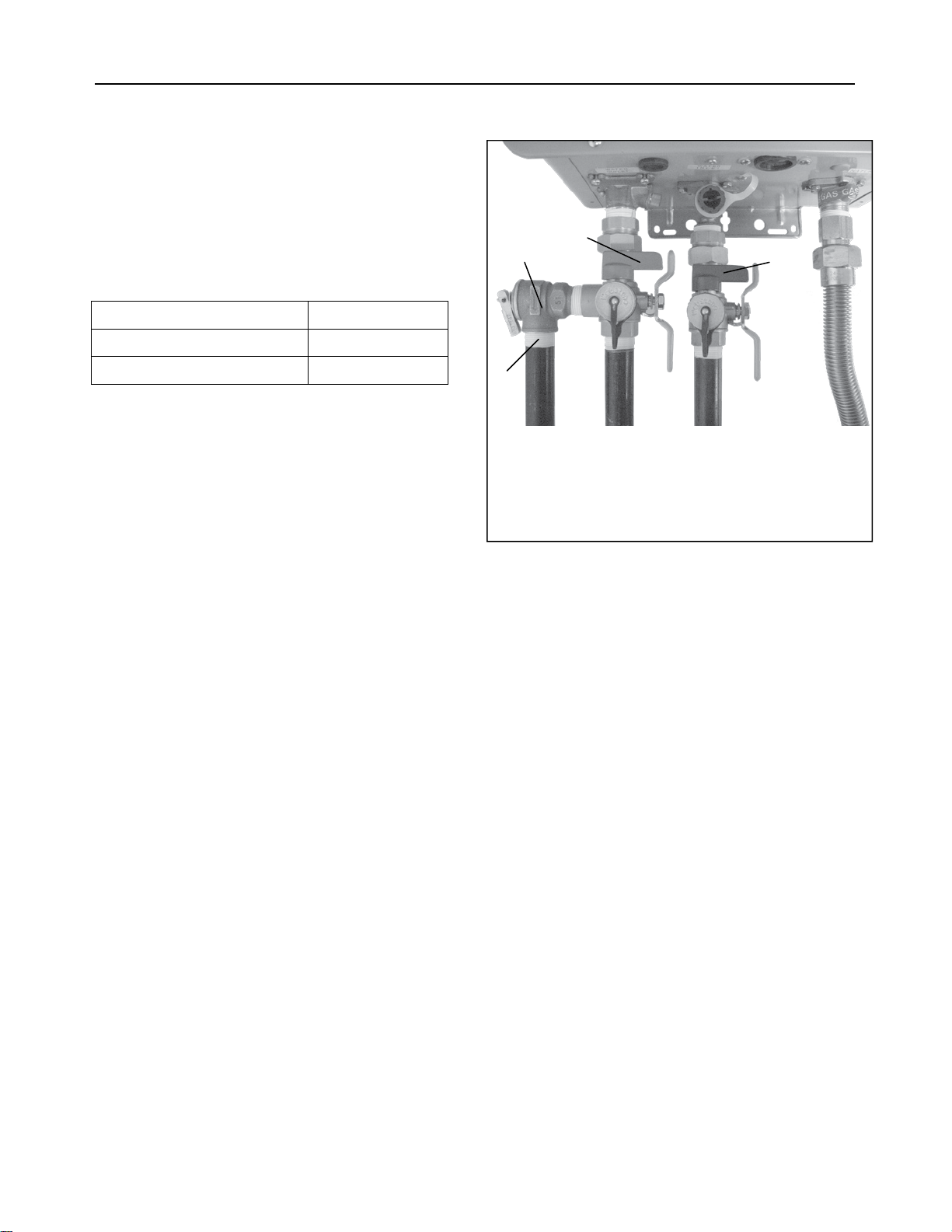

Isolation Valves and Pressure Relief Valve (RL75i and RL94i)

The isolation valves provide the ability to isolate the

water heater from the structure’s plumbing and allow

quick access to flush the heat exchanger. Check with

local codes to determine if a pressure and temperature

relief valve is required. The included valves meet

American National Standard (ANSI Z21.10.3) /

Canadian Standard (CSA 4.3) and are ANSI/NSF 61

approved for potable water.

A

C

D

Isolation Valve (Cold)

Isolation Valve (Hot)

Pressure Relief Valve (PRV)

Isolation Valves Installation Instructions:

1. Wrap the ends of the threaded water inlet & outlet

on the tankless water heater,as well as the

threaded end of the approved pressure relief valve

with a minimum of 5 wraps of Teflon® tape.

2. Screw the pressure relief valve into the 3/4”

threads opposite the wing handle on the HOT

water service valve. (RED drain handle) (see

Pressure Relief Valve Section for proper

installation requirements)

3. Loosen the 3/4” union nut on the HOT water valve

and connect to the HOT water outlet on the

tankless water heater. If nut is removed, ensure

that you realign the tailpiece accurately to the

valve and that the black washer is positioned such

that the raised metal edge of the valve is inside

the washer.

4. Align the direction of the HOT water drain to the

desired position.

5. Tighten the union assembly to the HOT water

valve using approximately 15 foot lbs of torque.

6. Repeat steps 3-5 for the COLD water valve.

(BLUE drain handle) for connection to the COLD

water inlet on the tankless water heater.

7. Connect the INLET on the COLD water valve to

the MAIN SOURCE of the water supply.

8. Connect the OUTLET on the HOT water valve to

the HOT WATER plumbing system.

9. Ensure that both drain valve lever handles are in

the closed position (perpendicular to the drain

portion of the body).

107000081

107000083

107000085

B

A Pressure Relief Valve (PRV)

B PRV Discharge Outlet

C Hot Ball Valve Drain Handle

D Cold Ball Valve Drain Handle

Pressure Relief Valve Installation Instructions:

The PRV must be connected by the threaded

connection opposite the wing handle on the hot water

valve (designated by the RED drain handle) or the

threaded connection on the side of the relocation

fitting above the hot water valve. Installation must

maintain a ¾” port size with no shut off valve or line

restriction in-between the appliance and the PRV. The

discharge line from the PRV should pitch downward

and terminate 6” above drains where discharge will be

clearly visible. The discharge end of the line shall be

plain (unthreaded) and a minimum of ¾” in diameter.

The discharge line material must be suitable for water

at least 180º Fahrenheit and can be no more than 30

feet in length and contain no more than 4 elbows or

bends. No valve of any type may be installed in the

discharge line of the pressure relief valve.

Pressure Relief Valve Maintenance:

For proper care of this approved pressure relief valve,

it is recommended that the valve is manually operated

once a year. In doing so, it will be necessary to

take precautions with regard to the discharge of

potentially scalding hot water under pressure. Ensure

discharge has a place to flow. Contact with your body

or other property may cause damage or harm.

Please note that only the PRV in this package is

certified by CSA International as an approved item.

20 VB Series Indoor LS Manual

Piping Requirements

• A manual water control valve must be placed in the

water inlet connection to the Rinnai water heater

before it is connected to the water line. Unions may

be used on both the hot and cold water lines for

future servicing and disconnection of the unit.

• The piping (including soldering materials) and

components connected to this appliance must be

approved for use in potable water systems.

• Purge the water line to remove all debris and air.

Debris will damage the Rinnai water heater.

Pressure Relief Valve Requirements

• An approved pressure relief valve is required by the

American National Standard (ANSI Z21.10.3) /

Canadian Standard (CSA 4.3) for all water heating

systems, and shall be accessible for servicing.

• The relief valve must comply with the standard for

Relief Valves and Automatic Gas Shutoff Devices

for Hot Water Supply Systems ANSI Z21.22 and /or

the standard Temperature, Pressure, Temperature

and Pressure Relief Valves and Vacuum Relief

Valves, CAN1-4.4.

• The relief valve must be rated up to 150 psi and to

at least the maximum BTU/hr of the appliance.

• The discharge from the pressure relief valve should

be piped to the ground or into a drain system to

prevent exposure or possible burn hazards to

humans or other plant or animal life. Follow local

codes. Water discharged from the relief valve could

cause severe burns instantly, scalds, or death.

• The pressure relief valve must be manually

operated once a year to check for correct operation.

• Toxic chemicals such as those used for boiler water

treatment are not to be introduced to the potable

water used for space heating.

• If the appliance will be used as a potable water

source, it must not be connected to a system that

was previously used with a nonpotable water

heating appliance.

• Ensure that the water filter on the Rinnai water

heater is clean and installed.

• The relief valve should be added to the hot water

outlet line and near the hot water outlet according to

the manufacturer’s instructions. DO NOT place any

other type valve or shut off device between the relief

valve and the water heater.

• Do not plug the relief valve and do not install any

reducing fittings or other restrictions in the relief line.

The relief line should allow for complete drainage of

the valve and the line.

• If a relief valve discharges periodically, this may be

due to thermal expansion in a closed water supply

system. Contact the water supplier or local

plumbing inspector on how to correct this situation.

Do not plug the relief valve.

• Neither Rinnai nor the American National Standard

(ANSI Z21.10.3) / Canadian Standard (CSA 4.3)

requires a combination temperature and pressure

relief valve for this appliance. However, local codes

may require a combination temperature and

pressure relief valve.

Freeze Protection

The freeze protection features include electrical

heating elements. Freeze protection may be disabled

if electricity is not supplied, or if there is an error

preventing the water heater from functioning. Loss of

freeze protection may result in water damage from a

burst heat exchanger or water lines.

The installation of auto drain down solenoid valves is

optional. However, Rinnai strongly recommends that

these valves be installed to prevent damage from

freezing in case the normal freeze protection should

become disabled. Any product damage due to

freezing will not be covered by the warranty.

In addition, the solenoid valves should be connected

electrically to a surge protector with terminals. This

allows the solenoid valves to operate if the water

heater is disabled due to an error code.

VB Series Indoor LS Manual 21

The solenoid valves and surge protector with terminals

are available for purchase at Rinnai.

The freeze protection features will not prevent the

external piping from freezing. Rinnai recommends

heat tracing and insulating hot and cold water pipes

connecting units. Pipe cover enclosures may be

packed with insulation for added freeze protection.

With electrical power supplied, Rinnai water heaters

will not freeze when the outside air temperature is as

cold as –22ºF (-30ºC) for indoor models or is as cold

as –4ºF (-20ºC) for outdoor models, when protected

from direct wind exposure. Because of the “wind-chill”

effect, any wind or circulation of the air on the unit will

reduce its ability to freeze protect.

Freeze Protection

Manual draining of the water heater

WARNING

If the water heater is not going to be used during a period of possible freezing weather, it is recommended that the

water inside the water heater be drained.

To manually drain the water:

1. Shut off cold water supply and gas supply.

2. Turn off the temperature controller.

3. Disconnect the power to the water heater.

4. Open hot water drain plug at the hot water outlet.

5. Remove water filter to drain the cold water.

If an isolation kit is installed, remove the drain caps on

both isolation valves and open both valves above the

caps (blue and red valve handles).

To resume normal operation:

1. Confirm that all water drain plugs are removed, that

the gas supply is turned off, and that all taps are

closed.

2. Screw in the hot water drain plug.

3. Screw in the water filter in the cold water inlet.

If the isolation kit was used to drain the unit, replace the drain caps

and close both isolation valves (blue and red valve handles).

To avoid burns, wait until the equipment cools down before draining the water. The

water in the appliance will remain hot after it is turned off.

Hot water

outlet

Hot water

drain plug *

Cold water

inlet

Water

filter

4. Open the cold water supply.

5. Open a tap and confirm that water flows, and then close.

6. Turn on the power.

7. After confirming that the temperature controller is off, turn on

the gas supply.

8. Turn on the temperature controller.

* Use a wrench or other

tool to unscrew the hot

water drain plug.

Running a low volume of water through the water heater to prevent freezing

If the temperature exceeds the ability of the water heater to freeze

protect itself, or if power is lost, the following steps may prevent the

water heater and external piping from freezing. (Units connected with

MSA or EZConnect should be drained to prevent freezing if not in use.)

1. Turn the water heater off.

2. Close the gas supply valve.

3. Reduce the flow to about 0.1 gal/min or to where the stream is about

0.2 inches thick.

ON!

HOT

COLD

0.1 gal/min or

about 0.2 inch

thick

When the water heater or external piping has frozen

1. Do not operate the water heater if it or the external piping is frozen.

2. Close the gas and water valves and turn off the power.

3. Wait until the water thaws. Check by opening the water supply valve.

4. Check the water heater and the piping for leaks.

22 VB Series Indoor LS Manual

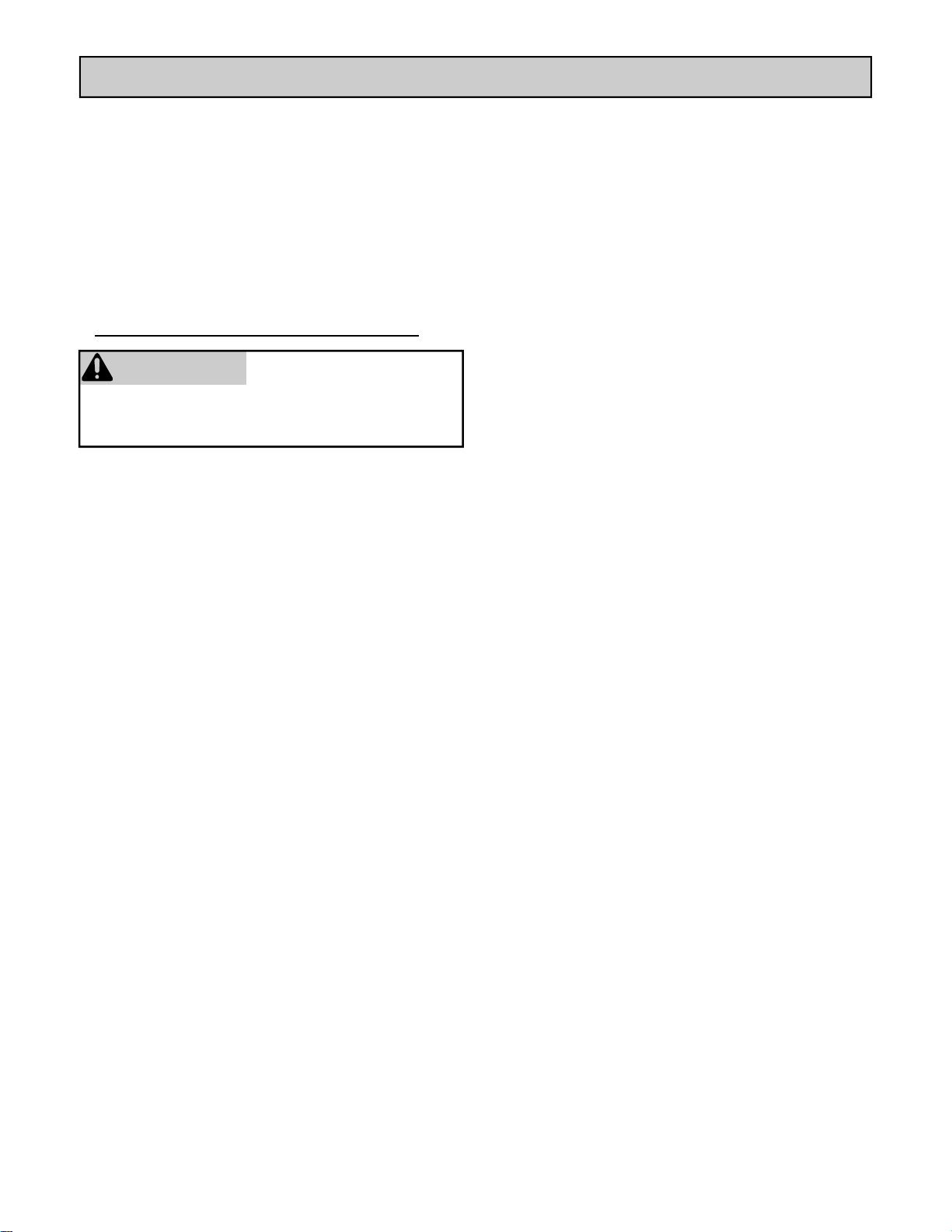

Freeze Protection Piping

NOTICE

Warranty does not cover damage due to freezing.

In the event of a power failure at temperatures below

freezing the water heater should be drained of all

water to prevent freezing damage.

The unit may be drained manually. However, Rinnai

highly recommends that drain down solenoid valves

be installed that will automatically drain the unit if

power is lost. Rinnai also recommends the installation

of a surge protector with terminals which allows the

solenoid valves to operate if the unit is disabled due to

an error code.

When the electrical power to the water heater fails, the

3/4” solenoid valve closes (stopping the flow of water

into the heater) and the 1/2” solenoid valve opens

(allowing the water heater and associated piping to

drain. Ensure that you run the drain for the solenoids

to the outside environment to prevent discharging

water inside the building causing water damage).

Rinnai

Water Heater

Vacuum

Breaker

NOTE:

Heat trace ALL water pipe and fittings located

outside home (attic, crawl space) or building

structure. (ALL water pipe and fittings shown

above the dashed line in the drawing.)

NOTE:

ALL pipe and fittings shown below dashed line

should be located inside home or building

structure.

The vacuum breaker line should be located

inside the building structure.

KEY

3/4" Ball Valve

3/4" Union

Check Valve

Pressure Relief Valve

Pressure Regulator

Circulating Pump

Boiler Drain Valve

S

Solenoid Valve

Minimum 3/4" Hot Water

Supply Line

1/2" Minimum

Normally Open

Solenoid Valve

This is not an engineered drawing. It is intended only as a guide and not

as a replacement for professionally engineered project drawings. This

drawing is not intended to describe a complete system. It is up to the

contractor/engineer to determine the necessary components and

configuration of the particular system being installed. This drawing does

not imply compliance with local building code requirements. It is the

responsibility of the contractor/engineer to ensure installation is in

accordance with all local building codes. Confer with local building

officials before installation.

G

S

3/4" Minimum

Normally Closed

Solenoid Valve

S

Route to Floor Drain

3

s

G

"

a

4

/

p

p

u

s

S

a

y

l

M

C

S

t

c

e

n

n

C

o

n

i

o

u

n

o

i

i

4

/

3

m

m

u

d

l

p

"

W

a

e

t

r

p

e

n

i

y

l

L

VB Series Indoor LS Manual 23

Recommended Piping for Basic Installation

Rinnai

Water Heater

Rinnai

Equipment List

Rinnai

Water Heaters

RIK-KIT (Optional)

(3/4" Fittings Include:

2 Unions, 2 Ball Valves,

2Drain Valves and

1 Pressure Relief Valve.)

3

4

G

/

"

a

s

C

o

c

n

o

i

n

t

e

n

QTY

1

1

3/4" Ball Valve

3/4" Union

Check Valve

Pressure Relief Valve

3/4" Hot Water Supply Line

For Building Fixtures

KEY

Pressure Regulator

Circulating Pump

Boiler Drain Valve

S

Solenoid Valve

G

a

s

S

u

p

p

y

l

3

4

C

/

"

o

d

a

W

l

e

t

r

S

u

p

p

y

l

L

n

i

e

This is not an engineered drawing. It is intended only as a guide and not

as a replacement for professionally engineered project drawings. This

drawing is not intended to describe a complete system. It is up to the

contractor/engineer to determine the necessary components and

configuration of the particular system being installed. This drawing does

not imply compliance with local building code requirements. It is the

responsibility of the contractor/engineer to ensure installation is in

accordance with all local building codes. Confer with local building

officials before installation.

24 VB Series Indoor LS Manual

t

t

Recommended Piping for Circulation Systems

NOTE:

NOTE:

For residential and commercial

For residential and commercial

applications, this piping arrangement

applications, this piping arrange-

maintains full warranty.

ment maintains full warranty.

Rinnai

Water Heater

For this application:

Pump should be controlled by an Aquastat, Timer or Combination Aquastat and

Timer.

Pump to be sized to maintain circulation

loop temperature.

The pump should be sized to overcome

he pressure loss through the tank water

heater, and supply and return plumbing.

Reference the Rinnai Hot Water System

Design Manual, Pump Sizing for Circula-

ion.

Pump to be of bronze or stainless

construction.

3

/

G

s

S

a

Minimum 3/4" Cold Water Supply Line

Tank Water Heater to be Sized for

Heat Loss of Circulation Loop.

Rinnai

Equipment List

Rinnai

Water Heaters

RIK-KIT (Optional)

(3/4" Fittings Include:

2 Unions, 2 Ball Valves,

2 Drain Valves and

1 Pressure Relief Valve.)

4

"

s

G

n

C

a

o

o

i

n

t

c

e

n

u

p

p

y

l

Building Supply

QTY

1

1

IMPORTANT: Connect the building

return line to the hot water supply line

as close as possible to the Rinnai Water

Heater.

KEY

3/4" Ball Valve

3/4" Union

Check Valve

Pressure Relief Valve

Pressure Regulator

Circulating Pump

Boiler Drain Valve

S

Solenoid Valve

This is not an engineered drawing. It is intended only as a guide and not

as a replacement for professionally engineered project drawings. This

drawing is not intended to describe a complete system. It is up to the

contractor/engineer to determine the necessary components and

configuration of the particular system being installed. This drawing does

not imply compliance with local building code requirements. It is the

responsibility of the contractor/engineer to ensure installation is in

accordance with all local building codes. Confer with local building

officials before installation.

Electric Water

Heater

Building

Fixtures

k

n

a

T

n

o

i

s

n

a

p

x

E

VB Series Indoor LS Manual 25

Venting Instructions

Intake / Exhaust Guidelines

• This water heater is a direct vent water heater and

therefore is certified and listed with the vent

system. You must use vent components that are

certified and listed with the water heater model.

• Do not combine vent components from different

manufacturers.

• The vent system must vent directly to the outside

of the building and use outside air for combustion.

• Venting should be as direct as possible with a

minimum number of pipe fittings.

• Avoid dips or sags in horizontal vent runs by

installing supports per the vent manufacturer’s

instructions.

• Support horizontal vent runs every four feet and all

vertical vent runs every six feet or in accordance

with local codes.

• Vent diameter must not be reduced.

• Do not connect the venting system with an existing

vent or chimney.

Refer to the specific instructions on your vent product for additional

installation requirements.

• Do not common vent with the vent pipe of any

other water heater or appliance.

• Vent connections must be firmly pressed together

so that the gaskets form an air tight seal.

• RL75i, RL94i: The vent piece connected to the

water heater must be secured with one self-tapping

screw.

• Refer to the instructions of the vent system

manufacturer for component assembly instructions.

• If the vent system is to be enclosed, it is suggested

that the design of the enclosure shall permit

inspection of the vent system. The design of such