Rinnai Rice Cooker 37AHB Installation Manual

37AHB SERIES

HYDRONIC FURNACE

SIZES 045 THRU 090

Installation, Operation, and Maintenance Manual

Consumer Safety Information ................................ 2

Overview of the Rinnai Hydronic Furnace ............ 3

Model Number Nomenclature ................................ 3

Physical Data ......................................................... 4

Receiving & Checking Equipment ......................... 5

Installation

Clearances ..................................................... 5

Locating and Mounting ............................... 6-9

Plumbing ................................................. 10-13

Electrical Connections ............................ 14-16

Dip Switch Options ....................................... 17

Thermostat Installation............................ 17-18

Start-Up Procedure ...................................... 19

Troubleshooting ...................................... 20-23

Sequence of Operation ................................... 24-26

Maintenance................................................... 26, 27

Selection Guide .............................................. 27, 28

Air Distribution Guide ..................................... 28, 29

Quick Reference Duct Sizing Chart .................... 30

Hydronic Furnace’s Specifications ....................... 31

Air Delivery and Performance Data ................ 32-51

Accessories .......................................................... 59

Wiring Diagrams ............................................. 60-62

Parts List ......................................................... 63-64

Limited Warranty ............................................. 65-66

To register your hydronic furnace or tankless water heater,

please visit www.rinnairegistration.com

.

Quality Assurance

This product is manufactured in a

facility registered by UL to ISO 9001.

2100-536 Rev A

Consumer Safety Information

SAFETY DEFINITIONS

Indicates safety alerts. When this symbol is seen on the Hydronic Furnace and in all instructions and/or

manuals, be alert to the potential for personal injury. Recognize signal words DANGER, WARNING,

and CAUTION. These words are used with the safety alert symbol.

DANGER

WARNING

CAUTION

NOTICE

SAFETY CONSIDERATIONS

Before any work is undertaken, it is imperative to

observe all precautions as stated in this manual, on

tags, and/or labels, together with any other safety

measures that may apply.

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in minor or

moderate injury. It may also be used to alert against unsafe practices.

This is used to highlight important information which will aid in installation, improve

reliability or enhance operation.

• Wear safety glasses and work gloves.

• When practical, objects to be brazed shall be

moved to a designated safe location or, if the

objects to be brazed cannot be readily moved, all

movable fire hazards in the vicinity shall be taken

to a safe place, or otherwise protected.

• Use quenching cloth for all brazing and un-brazing

operations.

• Suitable fire extinguishing equipment shall be

immediately available in the work area and shall

be maintained in a state of readiness for instant

use.

WARNING

Before installing or servicing the Hydronic Furnace,

always turn off all power to unit. There may be more

than 1 disconnect switch. Electrical shock can cause

personal injury or death.

CAUTION

Failure to follow this caution may result in personal

injury. Sheet metal parts may have sharp edges or

burrs. Use care and wear appropriate protective

clothing.

Read these installation instructions carefully and

adhere to all WARNINGS and CAUTIONS. Consult

local building codes, Occupational Safety & Health

Administration (OSHA) and National Electrical Code

(NEC) for special requirements.

Improper installation, modification, service,

maintenance, or use of Hydronic systems can cause

electrical shock, burns or other conditions which may

cause personal injury or property damage. Consult a

qualified installer, service agency, or your distributor

for information or support. The qualified installer or

agent must use factory authorized kits and/or

accessories when installing this product. Refer to the

appropriate Rinnai® literature for listing.

Read the entire instruction manual before starting the installation.

2

Rinnai Corporation Hydronic Furnace (37AHB) Manual

NOTICE

Application of this Hydronic Furnace should be

indoors. Special attention should be given to unit

sizing and piping, filling, and purging.

Overview of the Rinnai Hydronic Furnace (RHF)

INTRODUCTION:

The optimum in hydronic technology: the updated

Rinnai® multi-position Hydronic Furnaces offer a

unique solution for a wide variety of small and medium

sized residential and light commercial applications.

They are compact and ready to fit in tight spaces

which may include, but not limited to, attics,

basements, closets, crawlspaces, and utility rooms.

The 37AHB units are equipped with an intelligent

microprocessor control that allows for domestic hot

water priority and adapts to available hot water flow for

space heating by automatically regulating the pump

and blower sequence to maximize comfort.

These unique Hydronic Furnaces are designed to

work in combination with our line of Rinnai® tankless

products to deliver a wide variety of heating capacities

that cover the entire residential and light commercial

heating spectrum.

Because our units are designed specifically to the

Rinnai® tankless products, our stated capacities are

fine tuned and are based on the “Hydronic Furnace /

Tankless Water Heater” match set and NOT a given

water flow rate.

CODES AND STANDARDS:

It is the responsibility of the installer to follow all

national codes, standards and local ordinances, in

addition to instructions laid out in this manual. The

installation must comply with regulations of the local

building, heating, plumbing, and other codes. Where

local codes are not applicable, the installation must

comply with the national codes and any and all

authorities having jurisdiction.

The following is a suggested list of codes and

standards for the United States and Canada:

General Installation

Installation of Air Conditioning and Ventilating Systems

NFPA 91 (latest edition)

Duct Systems

Sheet Metal and Air Conditioning Contractors National

Association (SMACNA)

American Society of Heating, Refrigeration, and Air

Conditioning Engineers (ASHRAE)

2001 Fundamentals Handbook Chapter 34 or 2000

HVAC Systems and Equipment Handbook Chapters 9

and 16

US and CANADA: Air Conditioning Contractors

Association (ACCA) Manual D

Acoustical Lining and Fibrous Glass Duct

US and CANADA: current edition of SMACNA; NFPA

90B as tested by UL Standard 181 for Class I Rigid Air

Ducts

Electrical Connections

US: National Electrical Code (NEC) ANSI/NFPA 70

(latest edition)

CANADA: Canadian Electrical Code CSA C22.1

(latest edition)

Plumbing Systems:

US and CANADA: ICC International Plumbing Code

(IPC); Uniform Mechanical Code (UMC); Uniform

Plumbing Code (UPC)

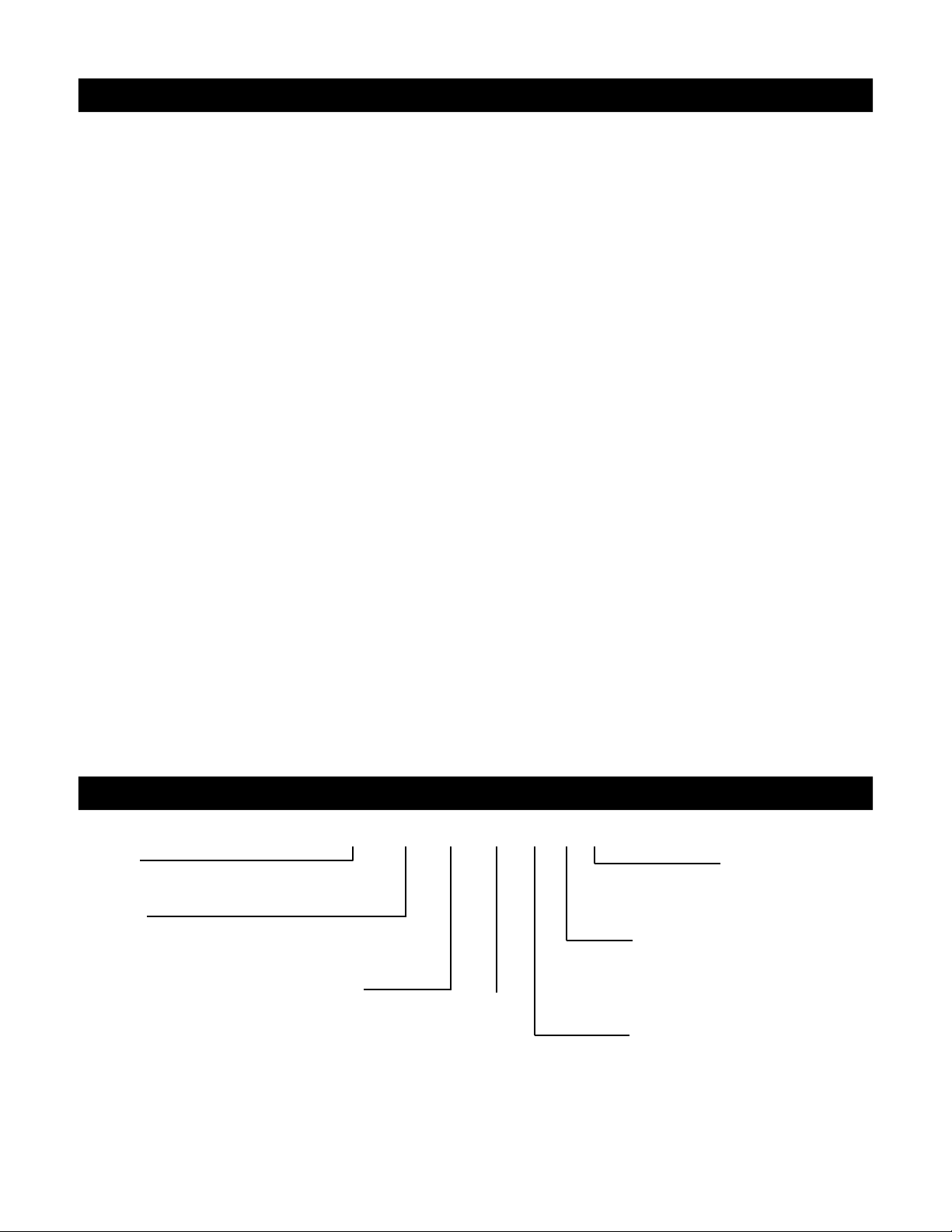

Model Number Nomenclature

37AH B 045 08 K A 5

Model

37AH - Multi-Speed Hydronic Furnace

Series

A - Unit with PSC Motor

B - Unit with ECM Technology

Nominal Heating

Capacity (BTU/h)

045 = 45,000

060 = 60,000

075 = 75,000

090 = 90,000

Cooling / Heating Air Flow Range (CFM)

08 = 800 (650-800)

12 = 1200 (650-1200)

14 = 1400 (1000-1600)

16 = 1600 (1200-1750)

Rinnai Corporation Hydronic Furnace (37AHB) Manual 3

Multi-position

5 = Yes

2 = No

Engineering Digit

Denotes minor change

(not present in sales or service

literature)

Voltage Code (V-Ph-HZ)

K = 115 - 1 - 60

L = 240 - 1 - 50 (export models)

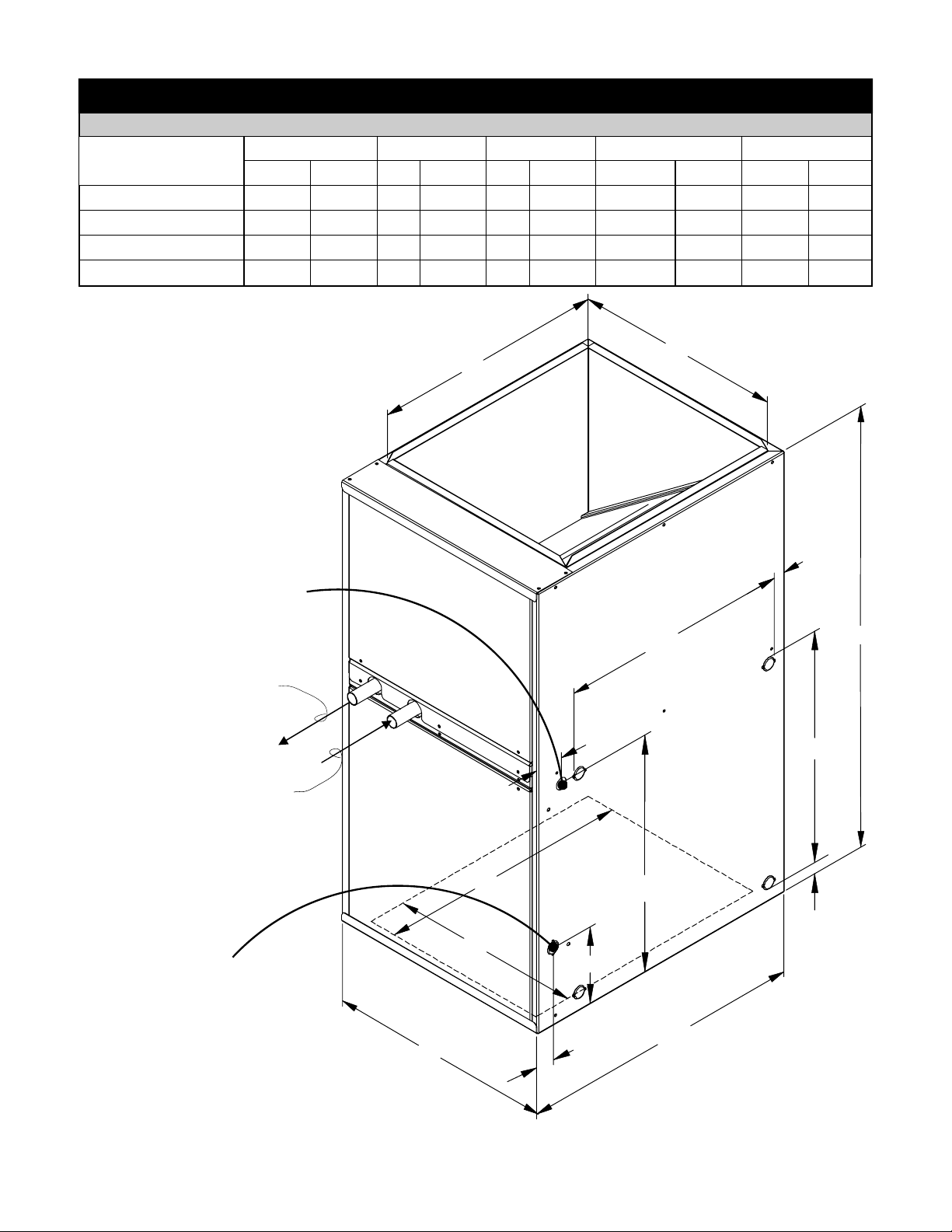

Table 1 - Physical Data

DIMENSIONS

UNIT SIZE

37AHB04508KA5 14 355.6 18 457.2 12 304.8 10 - 1/2 266.7 19 482.6

37AHB06012KA5 17 -1/2 444.5 18 457.2 16 406.4 16 - 11/16 423.9 19 - 1/4 489.0

37AHB07514KA5 21 533.4 18 457.2 20 508 18 - 11/16 474.7 19 - 1/2 495.3

37AHB09016KA5 24 - 1/2 622.3 18 457.2 24 609.6 21 - 1/8 536.6 19 482.6

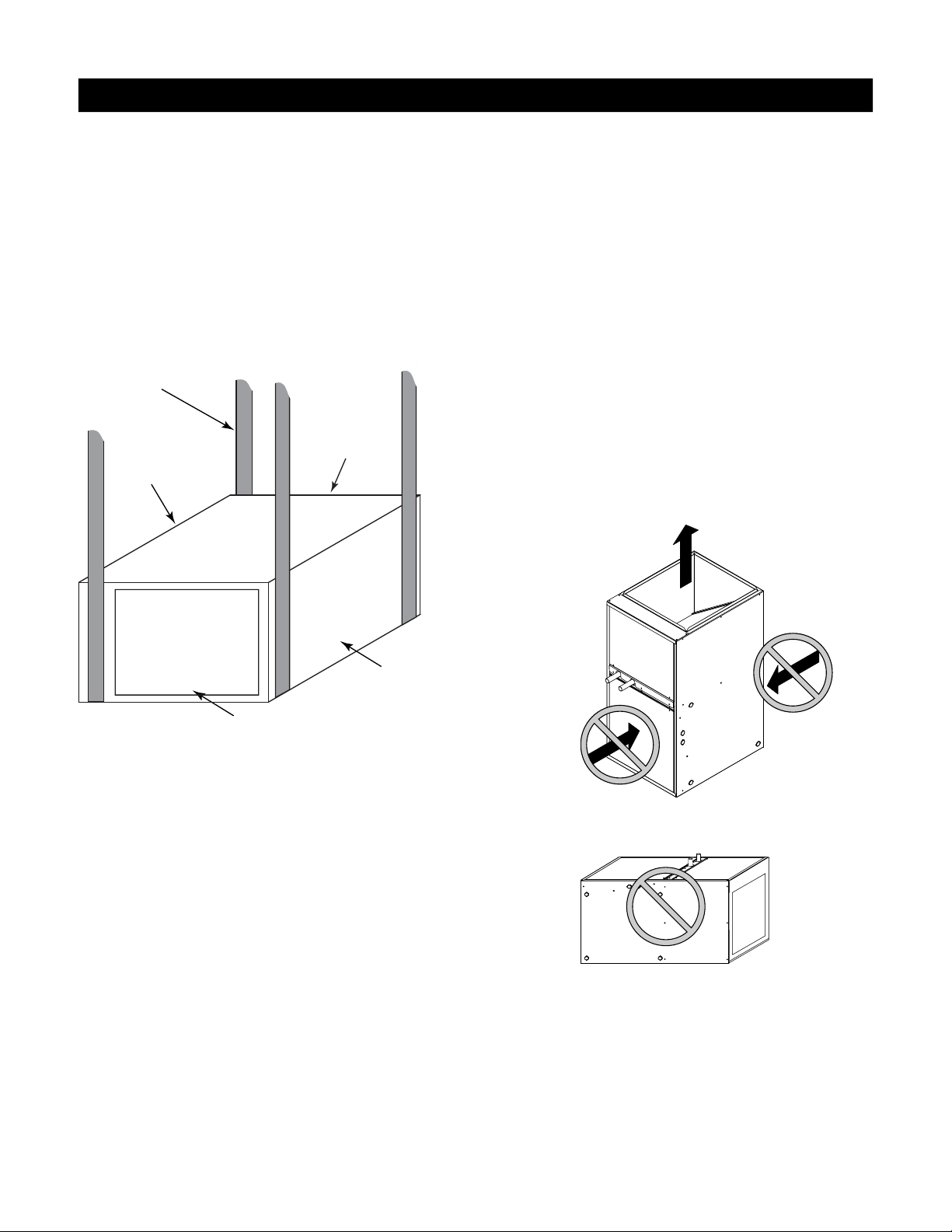

A B C D E

in. mm in. mm in. mm in. mm in. mm

C

B

7/8” Dia. KO Thermostat Wire

Entry (Typ. for both sides)

Water Out

Water In

7/8” Dia. KO Supply

Power Wire Entry

(Typ. for both sides)

1"

17 13/16"

34"

21/8"

17 13/16"

E

18 5/16"

1"

D

6"

4

A

13/8"

22"

Figure 1

Rinnai Corporation Hydronic Furnace (37AHB) Manual

Receiving and Checking Equipment

IDENTIFY UNIT

The unit model number and serial number are stamped

on the unit identification / name plate (located on the

top right side of unit). Check this information against

shipping papers and job requirements.

INSPECT SHIPMENT

Upon receipt of a 37 Series Hydronic Furnace the

packaging should be checked for peripheral signs of

transportation damage while unit is still in the shipping

package. If unit appears to be damaged or is torn

loose from its anchorage, the unit shall be immediately

examined by the receiving party before removal. If

Installation

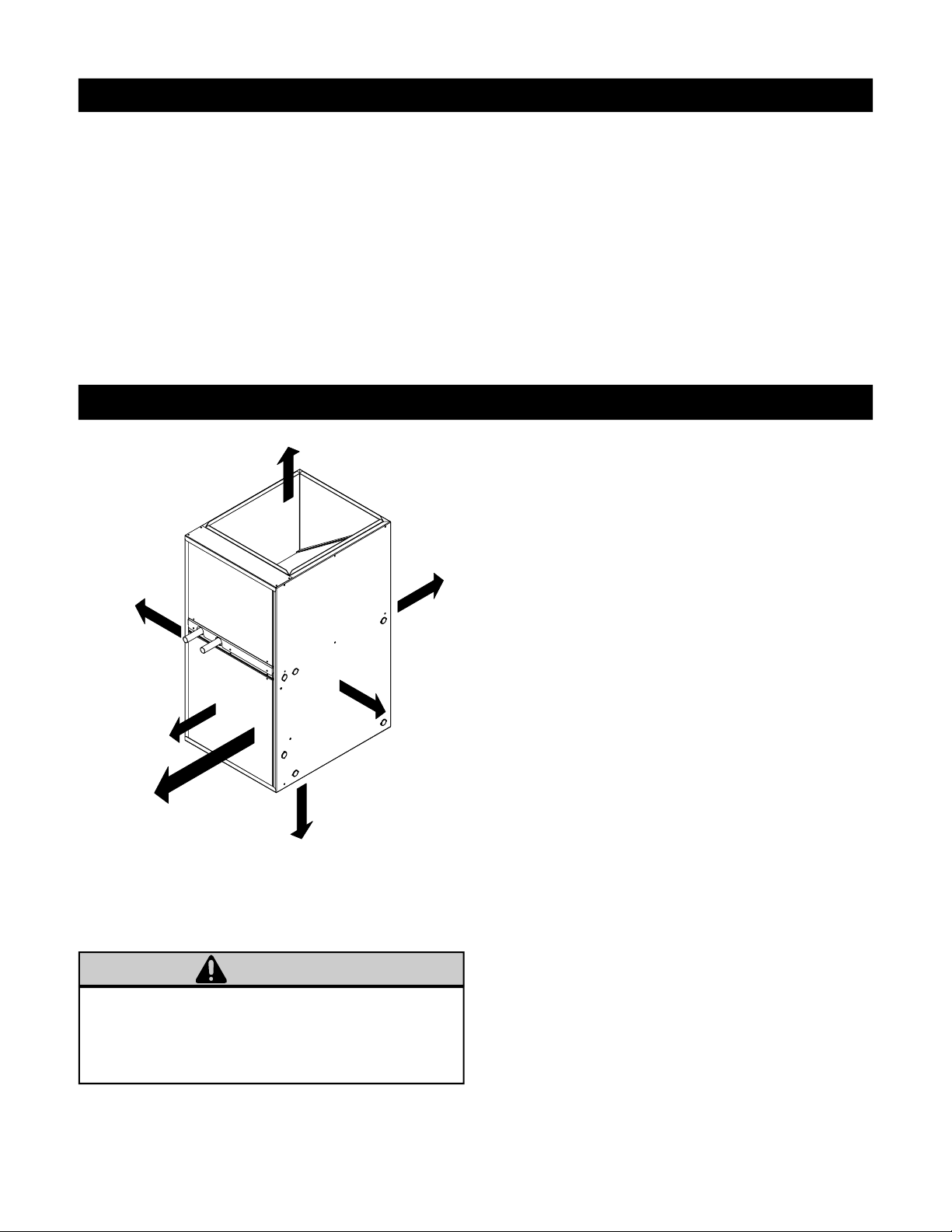

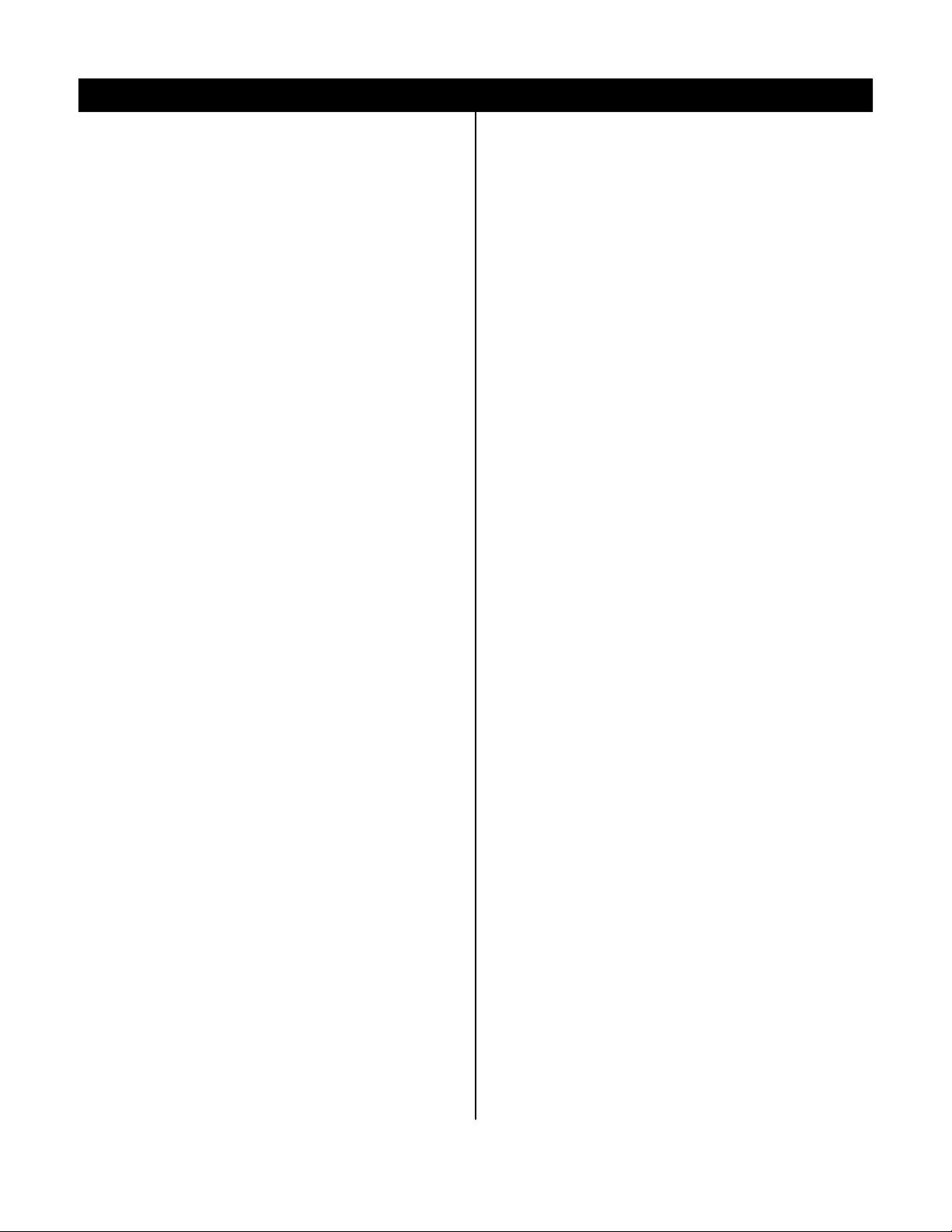

TOP/PLENUM

zero

BACK

SIDE

zero

zero

damage is found, the receiving party must sign the

driver’s delivery receipt noting all damage (i.e. carton

damage and/or product damage) as well as contact the

last carrier immediately, preferably in writing,

requesting inspection by the carrier’s agent. All claim

papers MUST be forwarded to Rinnai® America

Corporation for processing. In general, upon receipt of

product, be sure to check all items against shipping list;

if items are found to be missing, it should be noted as

such on the driver’s delivery receipt; and the receiving

party shall also immediately notify the area

distributor. To prevent loss or damage, leave all parts

in original packages until installation.

The 37AHB Series Hydronic Furnace needs to be

installed and commissioned by a knowledgeable

qualified professional.

NOTES:

1. This Furnace is approved for up-flow, down-flow,

and horizontal configurations.

2. Clearance arrows do not change with Hydronic

Furnace orientation.

FRONT

zero

SERVICING

24” (610 mm)

BOTTOM

zero

SIDE

zero

Figure 2: Minimum Clearance to Combustible

Construction

WARNING

Do not install this unit if the unit is damaged.

Do not install this unit if any part or all of unit has been

under water. Refer to the Receiving and Checking

Equipment section.

3. This Hydronic Furnace is for indoor

installation only.

4. Unit(s) shall be installed in such a way as to

ensure that the electrical components are

protected from any contact with water.

5. Unit(s) shall not be installed directly on any

combustible material other than wood flooring.

6. This unit is designed to be used with an air

distribution system (ductwork). Refer to section

the Air Distribution.

7. The installer shall provide ample space for

servicing and cleaning. Always comply with

minimum clearances as shown in Figure 2.

8. The 37AHB units are designed to be installed

vertically or horizontally on the floor; units may

also be hung from the ceiling or wall. Be sure to

allow appropriate clearances for wiring, piping,

and servicing.

Rinnai Corporation Hydronic Furnace (37AHB) Manual 5

Installation

LOCATING AND MOUNTING THE HYDRONIC

FURNACE

General

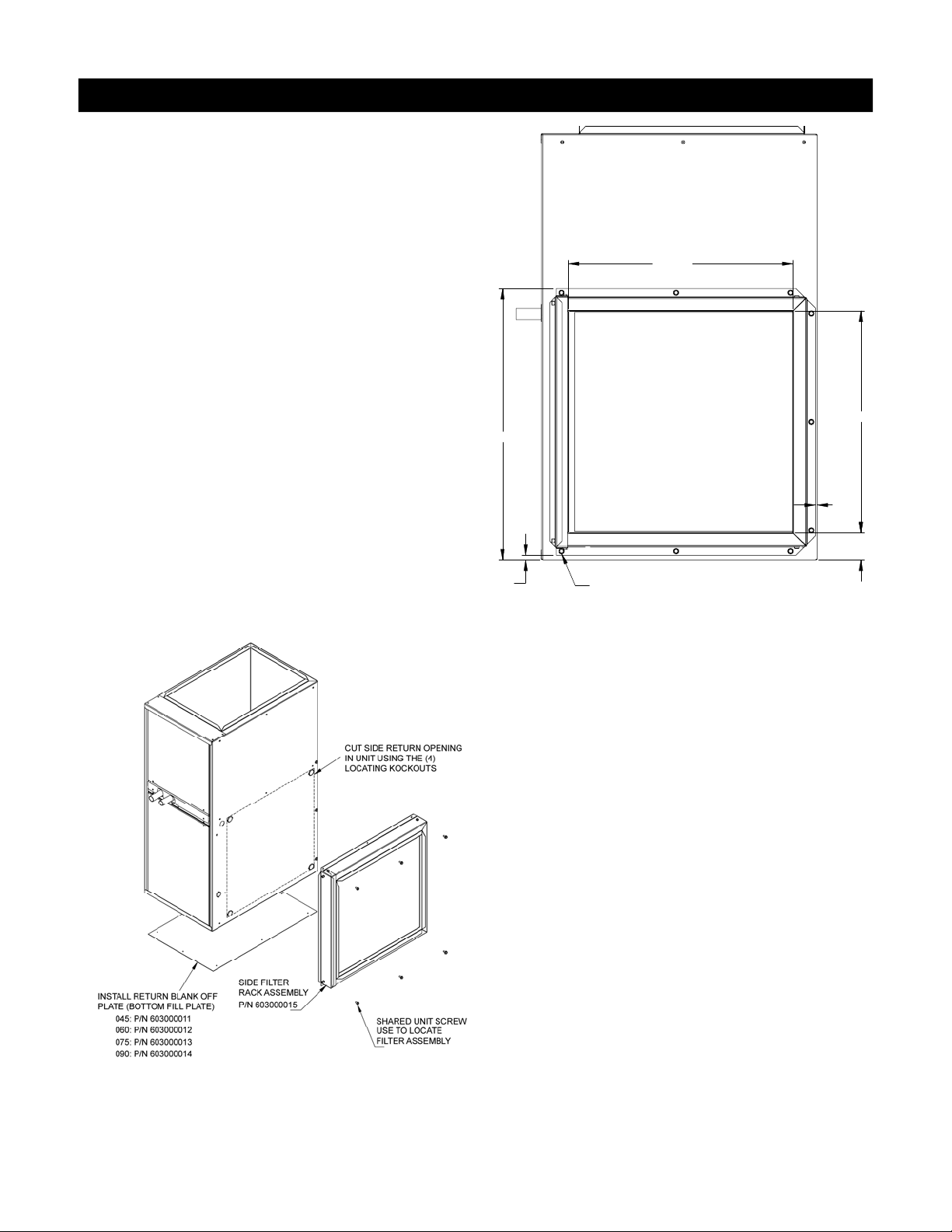

The multi-position 37AHB Series Hydronic Furnaces

are shipped in packaged configuration. This means

that the units may be installed without assembly and/

or modifications when configured for bottom return air

inlet application; however, some modifications and

assembly are necessary if units are to be installed in

an application that requires side return air inlet

arrangement. For instructions on required

modifications and assembly refer to Figures 3 and 4.

17 15/16"

NOTE: For side return application, obtain Side Filter

Rack” and “Bottom Fill Plate from your area

authorized Rinnai® distributor.

21 11/16"

3/8"

USE EXISTING SCREW HOLE

TO LOCATE FILTER RACK

Figure 4: Side Filter Rack Installation

17 3/4"

1/8"

23/16"

Figure 3: Modification of Unit to Accommodate

Side Filter Rack Installation

6

Rinnai Corporation Hydronic Furnace (37AHB) Manual

Installation

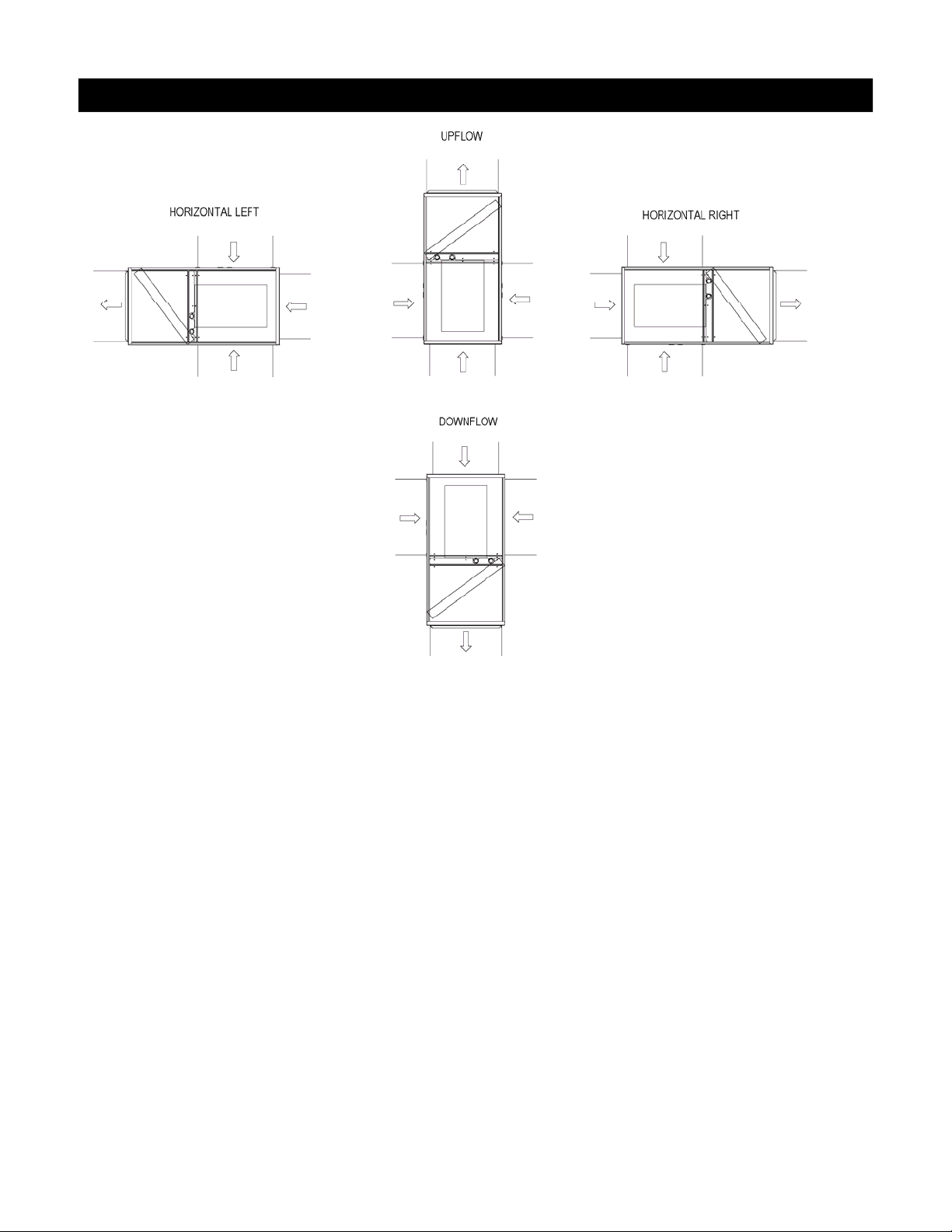

Blower located below coil

section. Conditioned air is

discharged upward.

Blower located to the right of

coil section. Conditioned air is

discharged to the left.

Figure 5: Multi-Position Orientation

Upflow Installations

The 37AHB Hydronic Furnace is ready to install in the

up-flow position without modifications.

The unit MUST be supported on the bottom ONLY and

set on a field supplied supporting frame or plenum.

Supporting frame or plenum must be anchored to the

unit and to the floor or wall.

Blower located to the left of coil

section. Conditioned air is

discharged to the right.

Blower located above coil

section. Conditioned air is

discharged downward.

Downflow Installation

The 37AHB Hydronic Furnace is ready to install in the

down-flow position without assembly or modifications

when configured for bottom return air inlet installation.

If side return air inlet installation is desired refer to

Figures 3 and 4.

Horizontal Left and Right Installations

The 37AHB Furnaces are shipped without a bottom fill

plate. If side return installation is desired, the return

opening (Bottom) must be blanked off. If a bottom fill

plate is required, install only a factory authorized

bottom fill plate. Refer to the Rinnai Accessory list for

details. For side filter rack installation instructions

refer to Figures 3 and 4.

Rinnai Corporation Hydronic Furnace (37AHB) Manual 7

Without Cased Coil:

If a cased coil is NOT being installed, the cabinet can

be placed on either side for horizontal airflow as

shipped, when configured for bottom return air inlet

installation. If side return air inlet installation is desired

refer to Figures 3 and 4.

With Cased Coil (Field Supplied):

Refer to the manufacturer’s Cased Coil installation

instructions for details.

Installation

CLOSET INSTALLATION (RETURN AIR THRU

OPENING OR GRILL)

The 37AHB Hydronic Furnace can be installed in a

closet on a supporting stand or be mounted from the

closet wall using the closet as the return air plenum.

Unit should be high enough from the floor to provide

unimpeded return air flow into the bottom of the

cabinet.

Closet return air opening can be on the front (in closet

door), side (thru the wall) or a combination of both,

providing there is clearance on the sides between

unit’s cabinet and closet. Refer to ACCA Manual D or

SMACNA for sizing and free area recommendations.

NOTE: Local codes may limit application of systems

without a ducted return to single story dwellings.

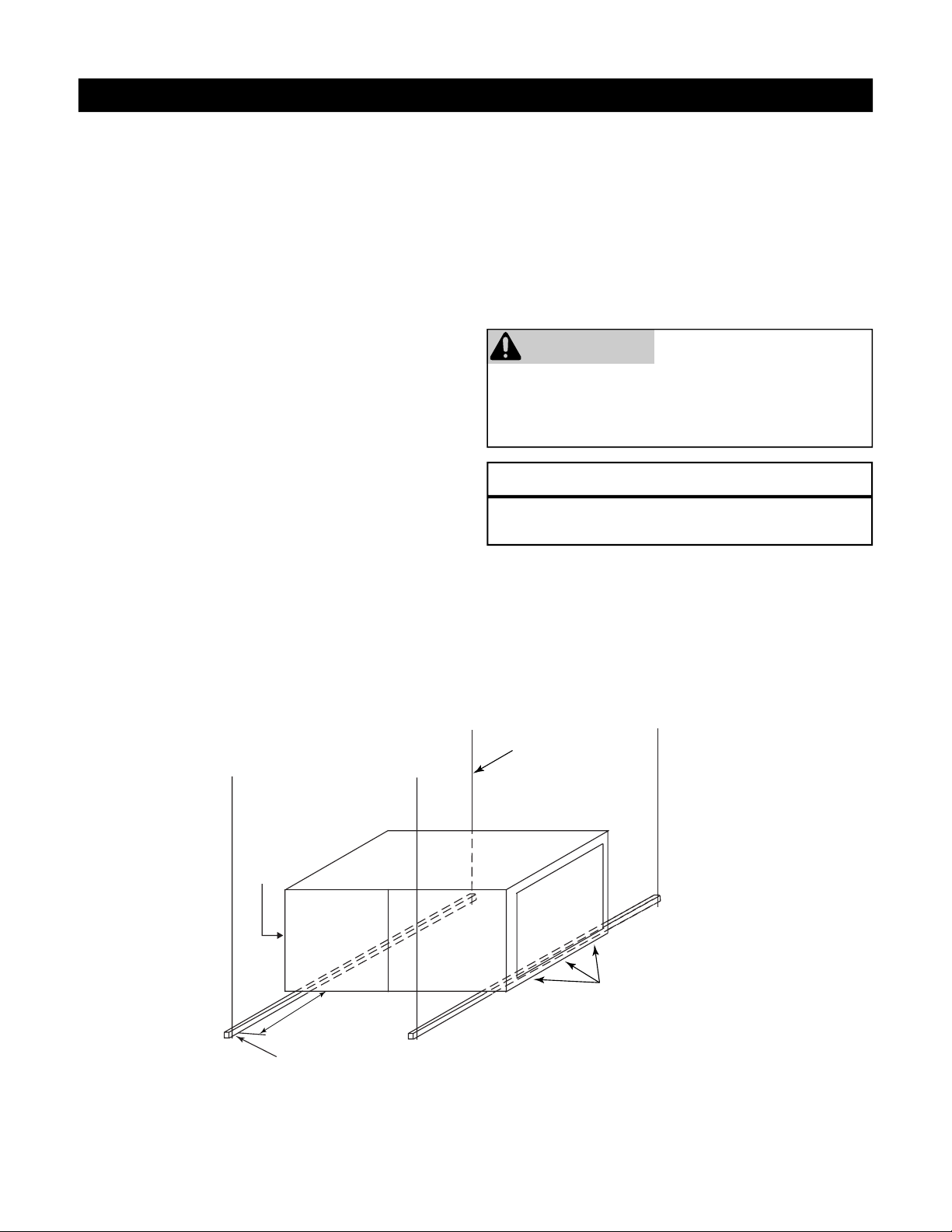

SUSPENDED CABINET INSTALLATION

If the cabinet cannot be supported on a frame or

supported from the wall, it may be suspended.

Use metal strapping or threaded rod with angle iron

under cabinet for support. These supports MUST run

parallel with the length of the cabinet (see Figures 6

and 7).

IMPORTANT: When a 37AHB unit is matched with an

evaporative type (cased coil/condensing unit) split

system for cooling application and the system is

installed above a finished ceiling and/or an occupied

space, building codes may call for a secondary

insulated condensate pan (by others) to be installed

under the entire unit. In other instances, some local

codes may allow the running of a separate, secondary

condensate line in lieu of the required drain pan. It is

the responsibility of the installer to consult local codes

for compliance.

WARNING

It is the installer’s responsibility to use an appropriate

hanging method capable of supporting the unit’s

weight. Refer to the specification section of this

document for the respective unit’s installed weights.

NOTICE

For seismic hanging requirements, refer to local

codes.

Ensure that there is adequate room to remove service

and access panels after installing supporting brackets.

If an auxiliary drain pan is required, the support is to

be placed under the drain pan. In such installations

the unit will need to be supported on vibration isolators

(rubber or Styrofoam blocks).

DOOR

ASSEMBLY

8” MIN FOR

DOOR REMOVAL

(2) HEX NUTS, (2) WASHERS & (2)

LOCK WASHERS REQ. PER ROD

1/4” THREADED ROD

(4 REQUIRED)

SECURE ANGLE

IRON TO BOTTOM

OF CABINET WITH 3

#8 x 3/4” SCREWS

TYPCIAL FOR 2

SUPPORTS

USE 1” SQUARE, 1-1/4 x 1-1/4 x 1/4

ANGLE IRON OR EQUIVALENT

8

Figure 6: Horizontal Unit Suspension

Rinnai Corporation Hydronic Furnace (37AHB) Manual

Installation

Attachment Methods Using Straps

Method 1

Use (4) #8 x 3/4 sheet metal screws for each strap.

Straps to be vertical against the unit’s sides and not

allowed to be pulled away from the sides.

Method 2

Fold all straps under the furnace and secure with (4)

#8 x 3/4 sheet metal screws (2 screws at the side and

2 screws at the bottom. (Care must be taken not to

drive the screw through the coil.)

1 INCH x 22 GAUGE

GALVANIZED STRAPS

TYPICAL FOR 4 STRAPS

RETURN AIR

OPENING

DOOR

ASSEMBLY

AIR SYSTEM

Existing Ductwork

It is the responsibility of the installer to inspect all

previously installed air distribution systems to

determine its suitability for the new heating and/or

cooling system. Existing ductwork may have to be

modified and/or insulated to provide satisfactory air

distribution.

Ductwork Installation

Connect the supply-air duct over the outside of 3/4-in.

flange on the unit’s discharge side. Secure the duct to

the flange with proper fasteners for the type of duct

used. Support the duct independently.

Use flexible connectors (if desired between the

ductwork and the unit to prevent transmission of

vibration.

Use insulation with vapor barrier for ductwork passing

PROHIBITED INSTALLATIONS

COIL

INTERFACE

AREA

BACK OF UNIT

SUPPLY AIR OPENING

Figure 7: Horizontal Unit Suspension with Straps

DUCT CONNECTIONS

Supply Duct

The supply ductwork must be attached to the outside

of the flange on the air discharge end of unit. Flexible

connectors may be used if desired.

Return Duct

The return ductwork should be attached to the air

return side (bottom or side) of unit using sheet metal

screws or other fasteners.

For side return air inlet installation see the Figures 3

and 4.

FILTER INSTALLATION

Internal filter rack and a 1 inch disposable filter are

standard on all models. Refer to the Specifications

section for dimensions.

Back

Front

Figure 8:

The air inlet is not allowed to be at

the front or back of the furnace

Figure 9:

Do not position the furnace on its

back or with it face down.

NOTE:

Multiple Furnace configured for installation with a

single Rinnai Tankless Water Heater is prohibited.

Rinnai Corporation Hydronic Furnace (37AHB) Manual 9

Installation

PLUMBING

Codes:

Observe all local sanitary codes when installing water

lines. The water supply mating connection to the

37AHB Hydronic Air-Handling Units are made via the

two (3/4 in. Dia. X 2-1/2 in. Long) copper stubs to the

front-left of the unit labeled “WATER IN” and “WATER

OUT” (see Figure 1). Mating connectors to be two

field supplied 3/4 in. FNPT-sweat ends or two fieldsupplied 3/4 in. SharkBite type FNPT-push fitting ends

or equivalent.

All associated hydronic piping MUST comply with ICC,

UPC and any other local codes or ordinances having

jurisdiction. USE POTABLE GRADE COPPER OR

OTHER PIPING MATERIALS. MATERIALS TO BE

LEAD FREE APPURTENANCES ONLY.

NOTE: Recommended piping, fittings, valves and

other appurtenances (exclusive of those indicted as

accessories that are available through Rinnai

distribution) called for in piping schematics to be fieldsupplied.

Flow Sensor Installation:

(Required for Open Loop Systems)

Mechanical Joining of Tubing:

Where used, refer to the respective mechanical

system manufacturer’s installation instructions.

Tubing Insulation:

Any tube conveying fluid at a temperature greater than

that of the surrounding air releases heat.

Insulate all accessible hot water lines and associated

valves with material, such as expanded neoprene or

polyurethane 3/8-in. to 1⁄2-in. thick.

Match the pipe sleeve's inside diameter to the pipe’s

outside diameter for a snug fit. Place the pipe sleeve

so the seam will be face down on the pipe. Tape,

wire, or clamp insulation every foot or two to secure it

to the pipe. If taping is desired, use acrylic tape

instead of duct tape.

Copper Tubing Support:

Copper tubing must be properly supported to prevent

sagging or buckling. On horizontal runs with hard

temper tubing, the following maximum support spacing

is suggested:

• 1/2 in. to 3/4 in. tube: 5 feet maximum spacing

Care must be taken to ensure that the flow sensor is

not damaged due to excessive tightening. The torque

must not exceed the maximum limit stated below. The

installation should be checked to ensure that no

leaking is evident.

Mating connectors to be (2) 3/4” FNPT fittings (field

supplied).

Pipe-work/connector alignment is imperative (avoid

bending stress).

Polytetrafluoroethylene (PTFE) thread seal tape (teflon

tape), or equivalent, is recommended.

Tighten fittings to maximum torque of 15lb/ft (20Nm).

Soldering Copper Tubing:

The common method of joining copper tubing in

hydronic heating systems is soft soldering. Plumbing

codes do not allow solders containing lead to be used

for domestic water service. USE ONLY 95/5 tin/

antimony solder for all piping systems that incorporate

a domestic water supply.

Note: Precautions must be taken during soldering to

avoid debris or solder from lodging in piping

system.

• 1 in. to 1-1/4 in. tube: 6 feet maximum spacing

• 1-1/2 in. to 2 in. tube: 8 feet maximum spacing

The above suggested spacing does not account for

extra weight of piping components such as an

expansion tank, etc. When such components are

present the piping should be supported immediately

adjacent to the component.

On vertical runs, copper tubing should be supported at

each floor level or at a maximum of every 10 feet.

Thermal Expansion of Piping:

In all hydronic systems, piping undergoes temperature

swings as the system operates. This causes changes

in the length of the piping due to thermal expansion.

If the piping is rigidly mounted, this expansion can

cause annoying popping or squeaking sounds and in

extreme cases, the piping can even buckle.

To counter expansion movement, design piping

circuits with sufficient elbows, tees or expansion loops

(only used in large systems) or piping supports that

allow the tubing to expand and contract freely.

Another alternative is to install an expansion

compensator fitting capable of absorbing the

movement.

10

Rinnai Corporation Hydronic Furnace (37AHB) Manual

Installation

Hydraulic Resistance of Fittings, Valves, and Other

Devices:

Before the total hydraulic resistance of a piping circuit

can be found, the individual hydraulic resistances of all

fittings, valves, or other such components must be

determined. One approach is to consider each fitting,

valve, or other device as an equivalent length of

copper tube of the same pipe size (see Table 2).

By using the equivalent length of piping for all

components in the circuit, the circuit can be treated as

if it were a single piece of pipe having a length equal

to the sum of the actual pipe length, the total

equivalent lengths of all fittings, valves, or other

devices. Refer to Figure 10 and the associated

computation of equivalent lengths.

Pipe Sizing Considerations:

When selecting a pipe size for a given flow rate, the

resulting average flow velocity should be between 2

and 4 feet per second.

At water flow velocities of approximately 2 feet per

second, flowing water will carry air bubbles along a

vertical pipe. Average flow velocities of 2 feet per

second or higher can draw along air bubbles in a

downward flow. At the above stated velocities air

bubbles shall be routed to an air separator where they

can be collected and discharged from the system.

Use Taco 4900 series air separator, Model 49-075, or

equivalent (field supplied).

Average flow velocities higher than 4 feet per second

could cause flow noise and should be avoided.

Expansion Tanks:

All liquids used in hydronic heating systems expand

when heated. For all practical purposes, liquids are

incompressible. Any container completely filled with a

liquid and sealed from the atmosphere will experience

a rapid increase in pressure as the liquid is heated.

To prevent this from occurring, all modern hydronic

systems MUST be equipped with an expansion tank.

Refer to expansion tank manufacture’s instructions for

proper sizing and installation.

Rinnai Corporation Hydronic Furnace (37AHB) Manual 11

Installation

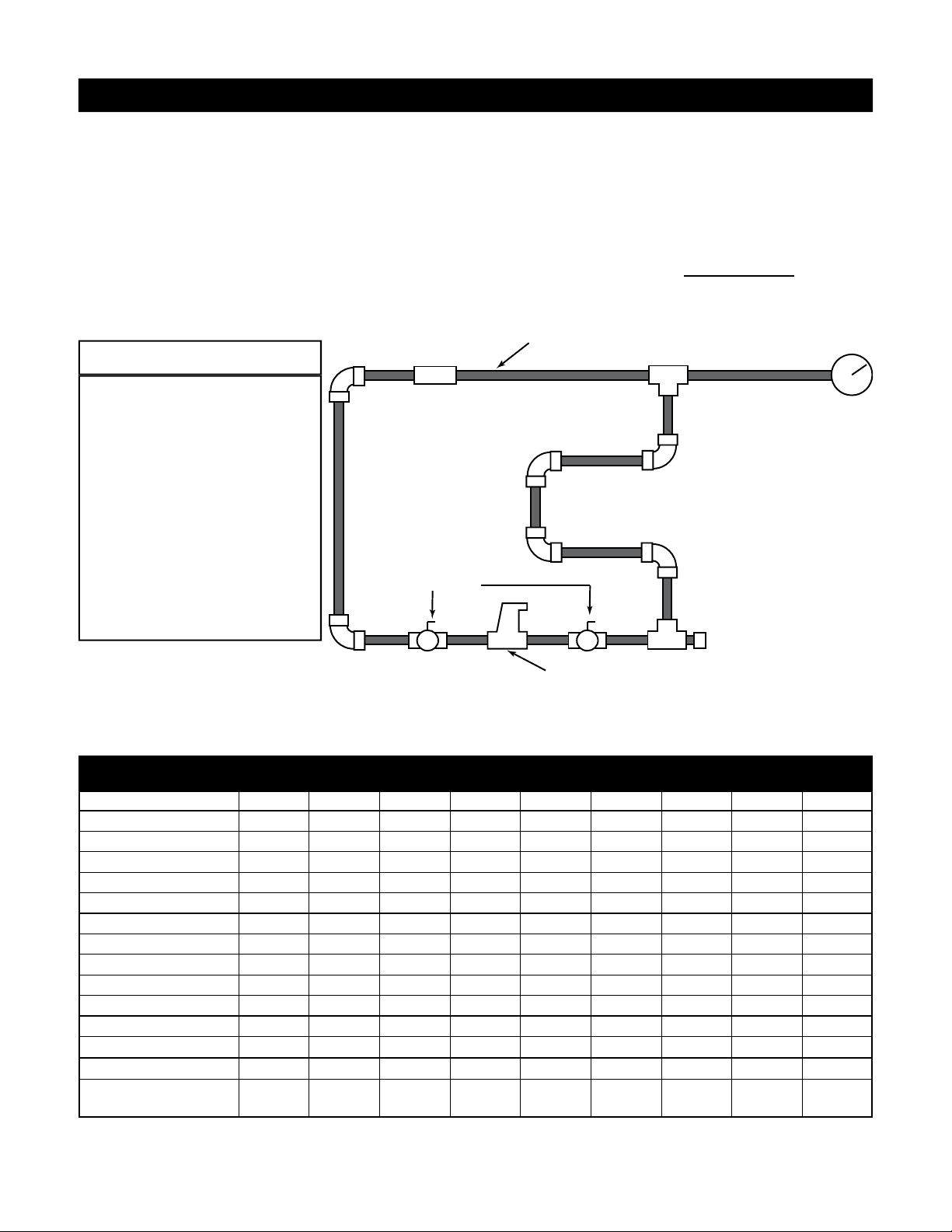

PROCEDURE FOR CALCULATING THE TOTAL

EQUIVALENT LENGTH OF PIPE

Given piping assembly as shown in Figure 10 below,

what is the total equivalent length of the system?

First determine the total straight pipe lengths; next

refer to table 2 to determine the equivalent straight

pipe length for each fitting shown. Add together the

equivalent lengths of piping and fittings.

Rinnai Flow Sensor

NOTICE

Where possible the length of pipe

4 ft

FS

should not exceed 150 feet total

equivalent length.

Any piping running through

unconditioned space MUST be

insulated to prevent heat loss,

and possible freezing of the line.

12 ft

Stickers indicating direction of

flow, (WATER IN, and WATER

OUT) are labeled on the outside

of the cabinet. DO NOT reverse

ball valves

these lines, as this will cause the

unit to malfunction.

¾” Tubing (total straight pipe length)....68 ft.

(6) ¾” 90 deg. Elbows….……..6(2) = 12 ft.

(2) ¾” Side port tee……….…..2(3) = 6.0 ft.

(1) ¾” Taco air separator….1(0.3) = 0.3 ft.

(1) ¾” Rinnai flow sensor.....1(3.2) = 3.2 ft.

(2) ¾” Ball valves….….….....2(2.2) = 4.4 ft.

Total Equivalent length……..……93.9 ft.

3/4 in. type M copper tubing

9 ft

3 ft

10 ft

5 ft

10 ft

3 ft

3 ft3 ft3 ft3 ft

15 ft

cap

gauge

TACO Model 49-075

Air Separator

Figure 10 Equivalent Length Calculation

Table 2: Equivalent Length of Straight Pipe for Valves and Fittings (ft)

Fitting or Valve 3/8" 1/2" 3/4" 1" 1 1/4" 1 1/2" 2" 2 1/2" 3"

90 deg. Elbow 0.5 1 2 2.5 3 4 5.5 7 9

45 deg. elbow 0.35 0.5 0.75 1 1.2 1.5 2 2.5 3.5

Straight thru tee 0.2 0.3 0.4 0.45 0.6 0.8 1 0.5 1

Side port tee 2.5 2 3 4.5 5.5 7 9 12 15

Reducer coupling 0.2 0.4 0.5 0.6 0.8 1 1.3 1 1.5

Gate valve 0.35 0.2 0.25 0.3 0.4 0.5 0.7 1 1.5

Globe valve 8.5 15 20 25 36 46 56 104 130

Angle valve 1.8 3.1 4.7 5.3 7.8 9.4 12.5 23 29

Ball valve 1.8 1.9 2.2 4.3 7 6.6 14 0.5 1

Swing check valve 0.95 2 3 4.5 5.5 6.5 9 11 13

Flow check valve NA NA 83 54 74 57 177 85 98

Butterfly valve NA 1.1 2 2.7 2 2.7 4.5 10 15.5

Rinnai Flow Sensor NA NA 3.2 NA NA NA NA NA NA

Taco 49-075 Air NA NA 0.3 NA NA NA NA NA NA

12

Rinnai Corporation Hydronic Furnace (37AHB) Manual

Installation

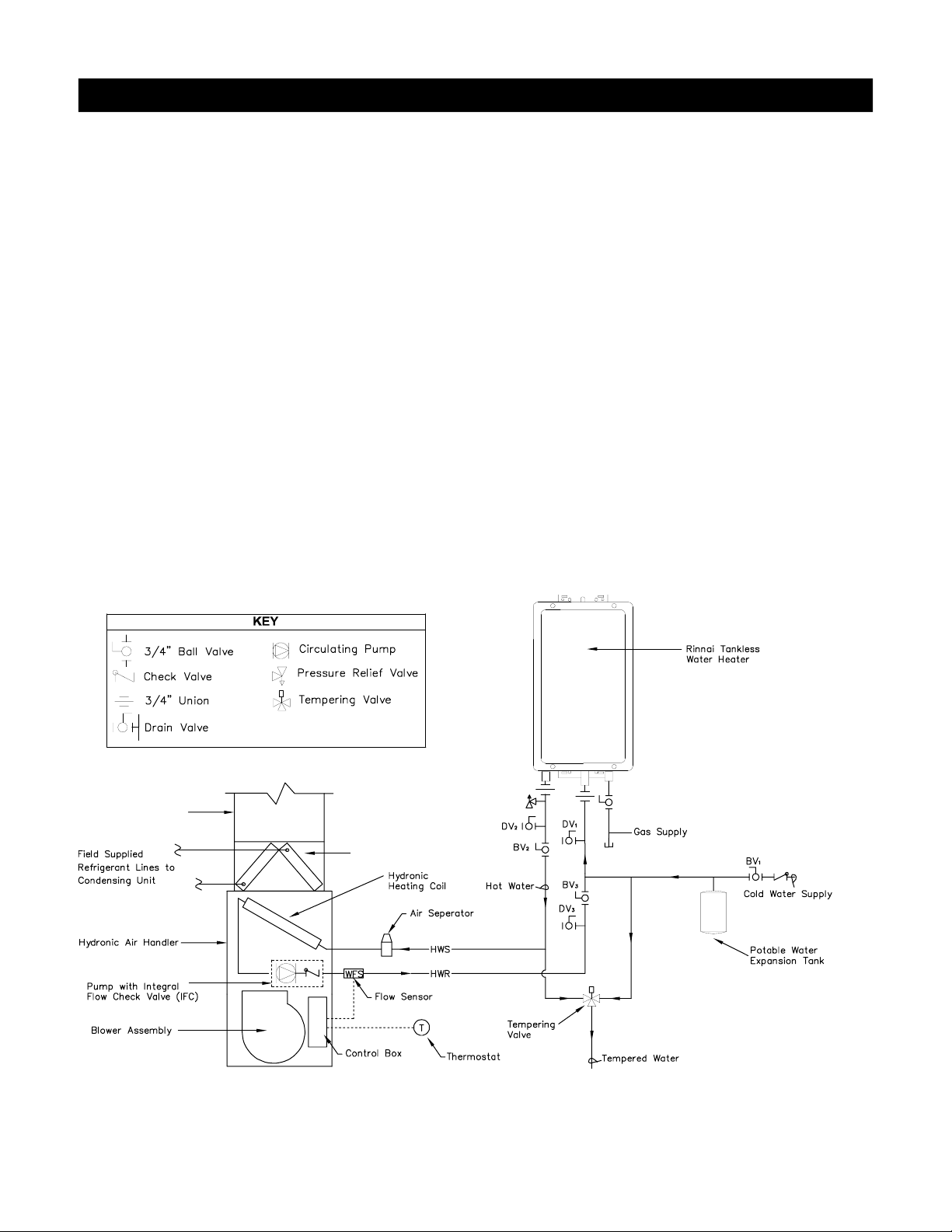

Piping Configuration

When employing a Tankless Water Heater in a

combination hydronic hot water heating system, the

system is considered an Open Loop System; i.e. the

system must be configured to simultaneously deliver

both domestic hot water and space heating. By

definition, if the circuit is sealed off from the

atmosphere at all locations (as is true for most modern

hydronic systems) it is called a closed loop system.

Conversely If the circuit is open to the atmosphere at

any point, it is called an open loop system. Current

Rinnai tankless products are not certified for closed

loop applications. Furnaces may be used in closed

loop application only with the new Rinnai Condensing

Boilers. Refer to Boiler Manuals for more details.

Open Loop System

If piping is done in accordance with the recommended

schematic diagram shown in Figure 11, the following

purge and priming procedure applies.

PURGING AND PRIMING THE SYSTEM:

The following procedure describes how the Rinnai®

system may be piped to eliminate the need for a

“purge cart” to fill the system and remove entrapped

air bubbles.

STEP 1: CLOSE the air separator venting valve.

STEP 2: CLOSE ball valve 3 (BV

STEP 3: OPEN drain valve 3 (DV

);

3

) to which a hose

3

MUST be connected and draining to a sink, drain or

outdoors.

STEP 4: CLOSE drain valves 1 & 2 (DV

and OPEN ball valve 2 (BV

2

).

and DV 2)

1

STEP 5: OPEN cold water supply main valve (ball

valve 1 - BV

). The system will begin the prime/purge

1

process using the street pressure. Entrapped air

bubbles being pushed out of the system will be evident

by a slight vibration of the discharge hose connected

to drain valve 3 (DV

). The hose will stop vibrating

3

when laminar flow is achieved.

STEP 6: CLOSE drain valve 3 (DV

STEP 7: OPEN ball valve 3 (BV

);

3

). The system is now

3

purged, primed and ready to go.

STEP 8: OPEN the air separator venting valve.

Note: For an open loop system, use expansion tank

approved for potable water use only.

(BV)

(DV)

Field Supplied Ducting

All piping to be 3/4 inch.

Field Supplied

Evaporator Coil

Figure 11 - Typical Piping Arrangement For Direct Space Heating and Domestic Water Supply with Tankless

Water Heater. Open Loop

Rinnai Corporation Hydronic Furnace (37AHB) Manual 13

Installation

ELECTRICAL CONNECTIONS

Line-Voltage Connections:

U.S. INSTALLATIONS: Make all electrical connections

in accordance with National Electrical Code (NEC)

ANSI/NFPA 70 and all local codes or ordinances

having jurisdiction.

CANADIAN INSTALLATIONS: Make all electrical

connections in accordance with Canadian Electrical

Code CSA C22.1 and all authorities having

jurisdiction.

Check all factory wiring per unit wiring diagram and

inspect factory wiring connections to be sure none

were loosened in transit.

WARNING

Before installing or servicing system, always turn off

all power to system. There may be more than 1

disconnect switch. Electrical shock can cause

personal injury or death.

CAUTION

If a disconnect switch is to be mounted on the unit,

select a location where a drill or fastener will not be in

contact with electrical or hydronic components.

Electrical shock can cause personal injury or death.

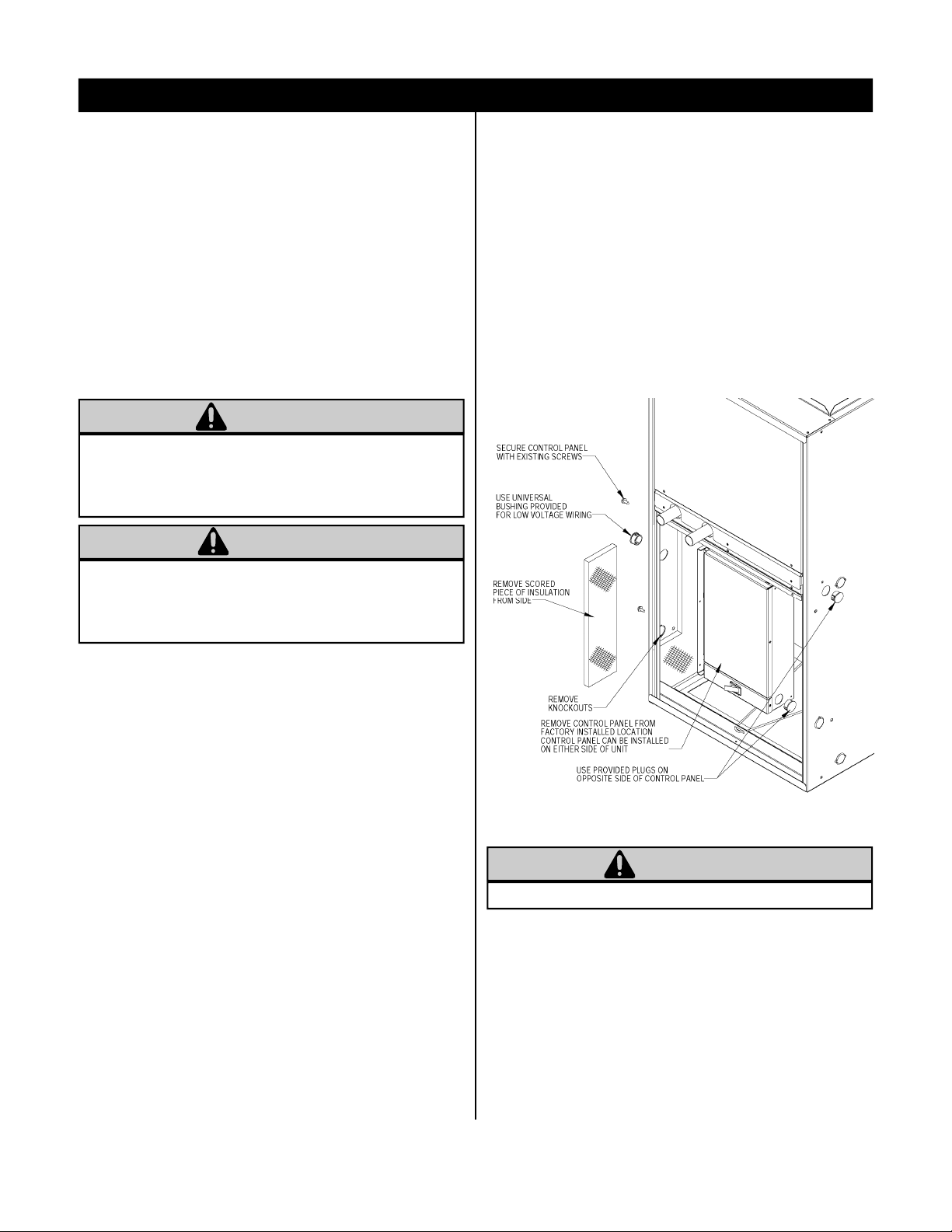

side) follow steps 1 thru 7 below:

1. Remove and keep one screw and cover from the

Control Box.

2. Remove and keep two screws holding Control Box

to casing of 37AHB unit (See Fig. 12.).

3. Remove wire tie from looped wires attached to

Control Box.

4. Before Control Box is reinstalled, remove the

scored piece of insulation from the desired side.

Remove two knockouts in the casing where the

Control Box is to be installed.

NOTE: Prior to making any electrical connections,

ensure that supply voltage, frequency, and phase are

as specified on unit rating plate.

Check to ensure that the existing electrical service is

adequate to handle the additional load imposed by the

Hydronic Furnace. Refer to unit wiring diagram for

proper electrical connections.

All electrical connections MUST comply with NEC and

any other local codes or ordinances having

jurisdiction. USE COPPER WIRE ONLY. Provide

separate branch electric circuit with field supplied

disconnect switch.

Location of disconnect switch to be in clear site,

accessible and in close proximity to the unit.

Correct polarity MUST be maintained for 115 V wiring.

If polarity is incorrect unit will NOT operate.

Control Box Relocation:

The Control Box is factory installed in the blower

compartment upper left corner (see Figure 12); if

factory location of Control Box is suitable, proceed to

next section. To relocate the Control Box to an

alternate location (blower compartment upper right

Figure 12: Control Box Relocation

WARNING

Do NOT remove ground screw inside control box.

5. Secure Control Box to casing with the two screws

removed and kept from Step 2.

6. Reinstall two plastic plugs (from spare parts bag)

where indicated in openings on adjacent side of

Control Box.

7. Route Control Box wiring within unit away from hot

surfaces, sharp edges and rotating parts.

14

Rinnai Corporation Hydronic Furnace (37AHB) Manual

Installation

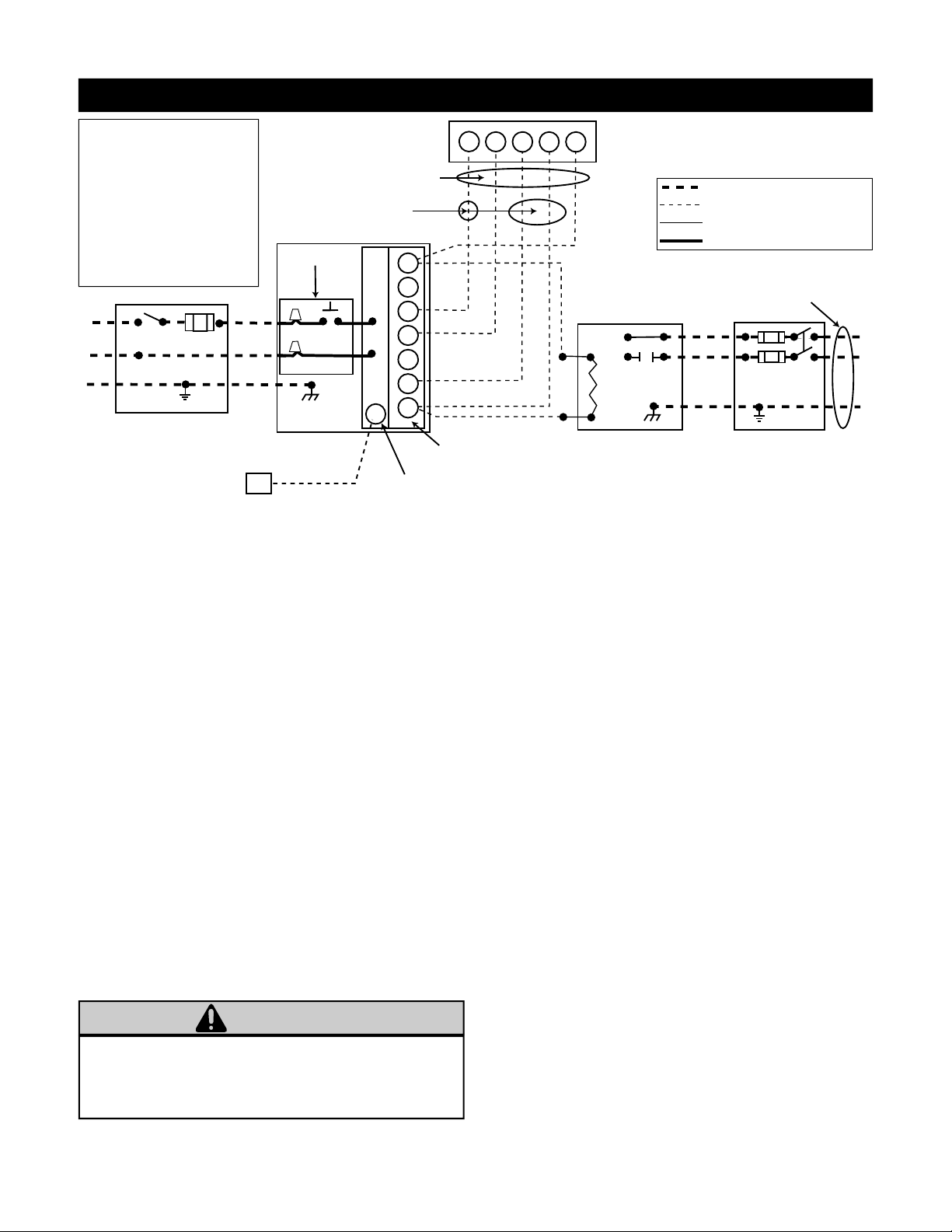

NOTES:

1. Connect Y1 terminal as

shown for proper operation.

2. Rinnai thermostats require a

“C” terminal connection as

shown.

3. If any of the original wire, as

supplied, must be replaced,

use the same type or

equivalent wire.

BLK

WHT

GND

115 Volt Fuse Disconnect

(Field Supplied)

Flow Sensor

(Packaged with Unit)

BLK

WHT

FS

3 Wire Heating Only

HYDRONIC FURNACE

Junction Box

Control Box

Y1

Y2

L1

PCB

L2

P3

Figure 13: Field Wiring Diagram

W

G

R C

5 Wire

W

G

O

R

C

24 Volt Terminal Block

24 Volt FS / WH Connector

Single Stage

Thermostat

Y1

(Available Accessory)

Condensing Unit

(Field Supplied)

Field 115, 208 / 230 Volt Wiring

Field 24 Volt Wiring

Factory 24 Volt Wiring

Factory 115 Volt Wiring

208 / 230 Volt

Single Phase

GND

Disconnect

(Field Supplied)

Electrical Connection to Control Box

1. Route the furnace power wires through aligned

holes in casing and Control Box and make field

wire connections in Control Box. Use best

practices for wire bushings, strain relief, etc.

Field wiring to the unit must be grounded and

conform to the National Electrical Code C22.1 Part

1 - latest edition. Use only UL listed conduit and

conduit connectors to connect supply wires to the

unit and provide appropriate grounding.

Grounding may also be accomplished by

grounding the control box per appropriate local

codes. Electric wires that are field installed shall

conform to the temperature limitation for 63° F

(35° C) rise when installed in accordance with

instructions. Refer to Table 4 for specific furnace

electrical data.

2. Route and secure field ground wire to ground

screw on Control Box.

3. Connect line voltage leads as shown in Figure 13.

4. Reinstall cover to Control Box. Ensure that wires

are not pinched between cover and edge of

Control Box.

WARNING

Failure to follow this warning could result in a fire. Do

not use aluminum wire between the Hydronic Furnace

and the disconnect switch. USE COPPER WIRE

ONLY.

24V Control System Connections to Unit’s PrintedCircuit Board (PCB):

Refer to Figures 25 through 27 for factory wiring

details. For low voltage connections between the unit

and the thermostat, use No. 18 AWG color-coded,

insulated (63° F / 35°C minimum) wires. (Refer to

Figures 16 through 19.)

Low Voltage Connections:

These units use a grounded 24 volt AC low voltage

circuit and require at least a Single stage heating and

a Single stage cooling thermostat.

The “R” terminal is the hot terminal and the “C”

terminal is grounded.

“G” terminal is the fan input.

“Y1” terminal is the compressor Stage 1 input.

“Y2” terminal is the compressor Stage 2 input.

“O” terminal is the reversing valve input. The

reversing valve must be de-energized for heating

mode.

“R” terminal is 24 VAC hot.

“C” terminal is 24 VAC grounded.

“W” terminal is the heat input. This terminal also

energizes the emergency heat if configured for heat

pump.

Rinnai Corporation Hydronic Furnace (37AHB) Manual 15

Installation

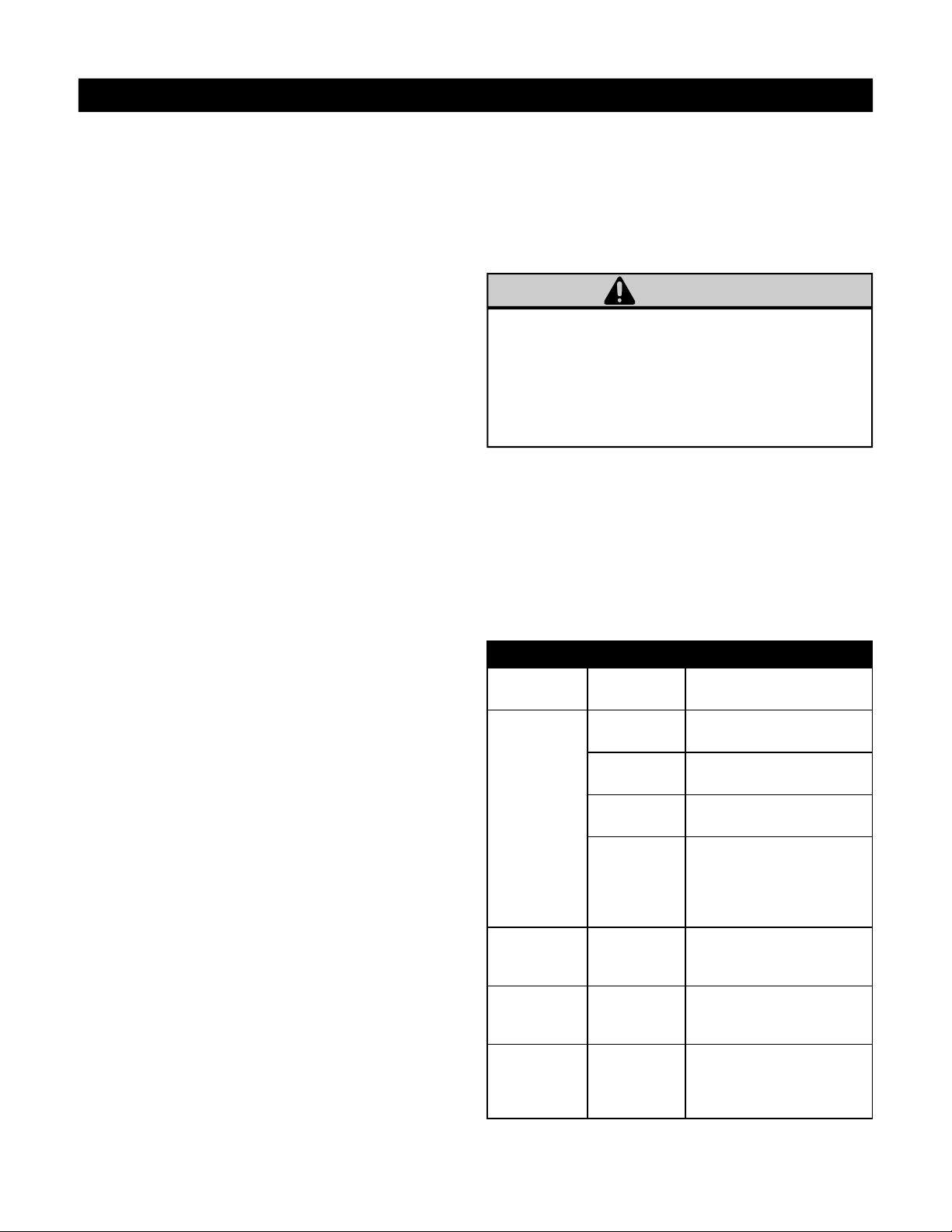

System Low Voltage Wiring Diagrams

NOTE: Local codes may require thermostat wiring to

be routed through conduit or raceways. In such

instances splices can be made inside the Hydronic

Furnace. All wiring must be NEC Class l and must be

separated from incoming power leads.

Provide field supplied disconnect. Refer to Table 4

(Specifications) for maximum fuse or circuit breaker

sizes.

Transformer is factory wired for 115v operation. (See

Figures 27 through 29.)

The secondary circuit of the transformer is protected

by a 3-amp fuse mounted on the printed-circuit board.

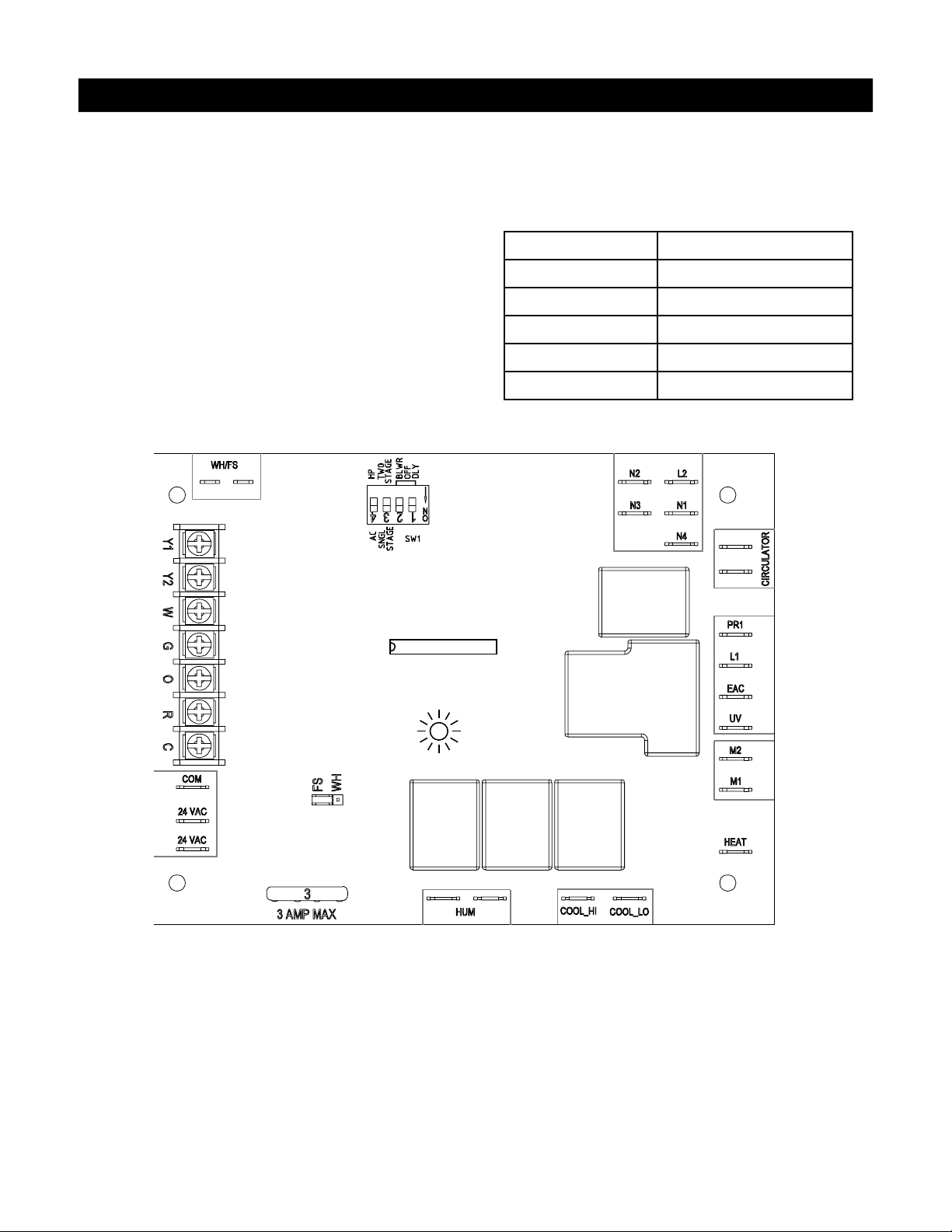

FLOW SENSOR

CONNECTIONS

P3

P7

SW1 SET-UP SWITCH

AND HEATING BLOW

OFF DELAY

IMPORTANT: Where possible, use a Rinnai factory

authorized thermostat with the 37AHB series Hydronic

Furnaces. If a thermostat other than specified is used,

refer to the manufacturer’s installation instructions for

further details.

Wire Gauge Maximum Distance (feet)

20 gauge 45

18 gauge 60

16 gauge 100

14 gauge 160

12 gauge 250

115 VAC (L2)

NEUTRAL

CONNECTIONS

PUMP

CONNECTIONS

FLASH UPGRADE

P4

24 V THERMOSTAT

TERMINALS

OPERATING MODE

JUMPER (SHUNT)

TRANSFORMER 24 V

CONNECTIONS

P1

3AMP FUSE

CONNECTION

(FACTORY ONLY)

STATUS LED LIGHT

AN1

HUMIDIFIER CONNECTIONS

(DRY CONTACT) 24 VAC OR

115 VAC

u1

115 VAC (L1) LINE

VOLTAGE

CONNECTION

FAN

PAR K

FAN

CONNECTION

HEATING

FAN

CONNECTION

COOLING

Figure 14: Hydronic Furnace Control Board

Notes:

1. For proper operation of an open loop system with the flow sensor refer to Figures 11 and 14; Note that the

jumper (shunt) position on the PCB “point P7” MUST be in the FS position.

2. When changing the shunt position ensure that the unit’s power is turned off.

16

Rinnai Corporation Hydronic Furnace (37AHB) Manual

C

Installation

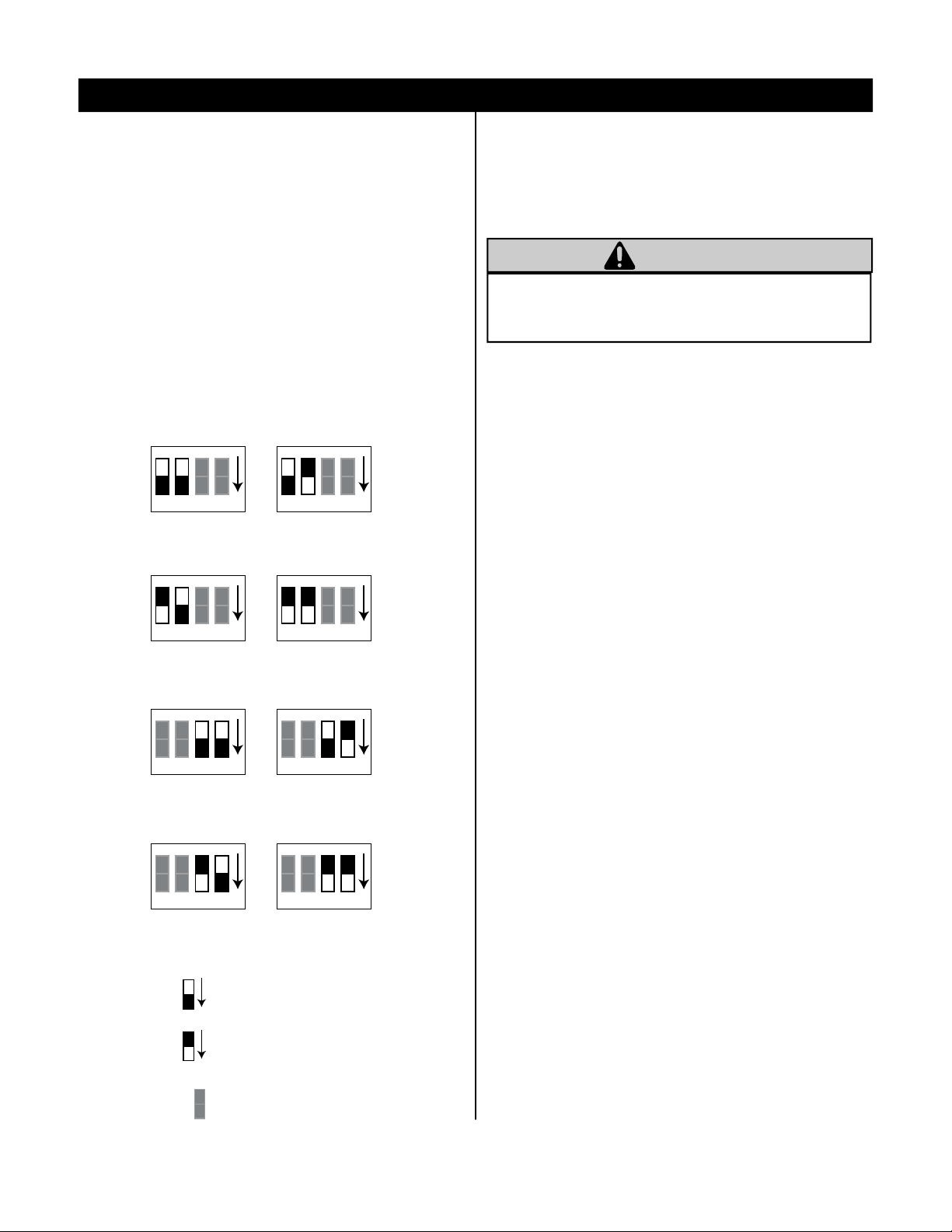

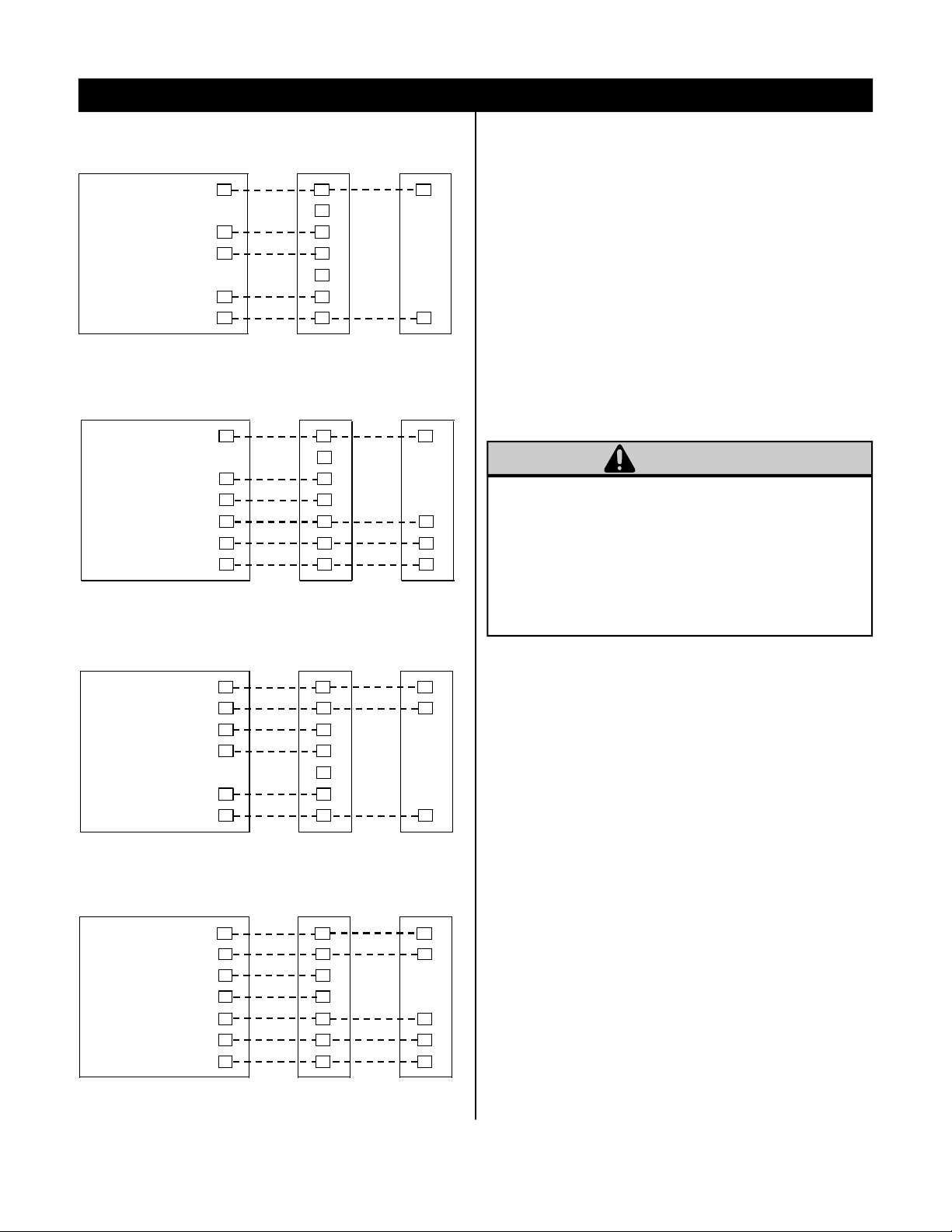

Dip Switch Options (Smart Operating System):

The Rinnai® exclusive Smart Operating System is a

feature of your 37AHB series Hydronic Furnace’s

control system that is designed to allow the installer

(via DIP Switch – SW1) to configure the unit for single

or two stage, A/C or Heat pump systems with

selectable heat bower off delay.

Refer to Figures 14 and 15 for the proper dip switch

setting to be used with the desired configuration.

When viewed with the Furnace in the upflow position,

the dip switch will be as shown below (upside down.

SINGLE-STAGE A/

CONFIGURATION

(DEFAULT)

1

2 3 41

SINGLE-STAGE HP

CONFIGURATION

1

2 3 41

30 SECONDS OFF

DELAY (DEFAULT)

1

2 3 41

90 SECONDS OFF

DELAY

1

2 3 41

TWO-STAGE A/C

CONFIGURATION

N

O

TWO-STAGE HP

CONFIGURATION

N

O

60 SECONDS OFF

N

O

120 SECONDS OFF

N

O

DELAY

DELAY

N

2 3 4

O

N

2 3 4

O

N

2 3 4

O

N

2 3 4

O

Figure 15: Dip Switch Positions

Key:

N

Switch is in the ON position.

1

O

N

Switch is in the OFF position.

1

O

Switch does not affect this setting.

THERMOSTAT INSTALLATION:

Safety Considerations:

All wiring must conform to local and national electrical

codes. Improper wiring or installation may damage

thermostat.

WARNING

Before installing thermostat, turn off all power to unit.

There may be more than one power disconnect.

Electrical shock can cause personal injury or death.

INSTALLATION CONSIDERATIONS:

Air Conditioner Model:

The Standard Model A/C thermostat may be wired

with or without connecting a common wire between

the indoor equipment and the thermostat. However, it

is recommended to use a common wire whenever

possible. Without a common wire this thermostat

becomes "power stealing." This means it will need to

steal a small amount of power from the equipment to

which it is connected. When "power stealing"

connection is used, the supplied 270 ohm resistor

must be connected at the indoor unit.

Heat Pump Model:

The Standard Model HP thermostat is not "power

stealing" and MUST have both ‘R’ and ‘C’ wires

connected to operate properly. This thermostat uses a

green LED to indicate auxiliary/emergency heat

operation.

Installation:

Thermostat should be mounted

• approximately 5 ft. (1.5 m) from floor

• close to or in a frequently used room, preferably on

an inside partitioning wall

• on a section of wall without pipes or duct work.

Thermostat should NOT be mounted

• close to a window, on an outside wall, or next to a

door leading to the outside.

• exposed to direct light and heat from a lamp, sun,

fireplace, or other heat-radiating object which may

cause a false reading.

• close to or in direct airflow from supply registers

and return-air grilles

• In areas with poor air circulation, such as behind a

door or in an alcove

Refer to Figures 16 through 19 for thermostat wiring

diagram and thermostat installation instructions for

further details.

Rinnai Corporation Hydronic Furnace (37AHB) Manual 17

A

C

Installation

THERMOSTAT WIRING DIAGRAMS

HEAT/COOL & CO OL ONLY

THERMOSTATS

FIRST STAGE HEAT/COO L

AUX HEATING

FAN

24VAC HOT

24 VAC COMM ON

Figure 16

FIRST STAGE HEAT/COO L

AUX HEATING

FAN

RVS COOLI NG

24VAC HOT

24 VAC COMMON

Figure 17

Single Stage Hydronic Furnace w/ Single Stage

HEAT PUMP THERMOSTATS

Single Stage Hydronic Furnace

w/ Single Stage Heat Pump

Y1

W

G

R

C

Y1

W

G

O

R

C

SINGLE STAGE

HYDRONIC FURNACE

Y1

Y2

W

G

O

R

C

SINGLE STAGE SINGLE STAGE

HYDRONIC FURNACE

Y1

Y2

W

G

O

R

C

SINGLE SPEED

CONDENSING

UNIT

Y1

C

HEAT PUMP

Y1

O

R

C

Shunt Jumper Options:

An additional feature of the 37AHB series is its

selectable operating sequence option; the 3-pin shunt

header (P7) allows the control to operate the proper

heating logic based on the following system

requirements:

The 37AHB unit in Open Loop configuration:

“FS” Shunt selection: The “FS” logic sequence will

configure the unit for operation with all Rinnai®

Tankless Water Heaters; this logic monitors the ratio

of available flow for space heating (via Flow Sensor);

this status is then communicated to the PCB whose

operating characteristics is primarily determined by the

status of the Flow Sensor input (sequence allows

domestic priority).

WARNING

Failure to follow this warning could result in an

electrical shock, fire, or death.

To minimize personal injury if an electrical fault should

occur, cabinet grounding MUST be an uninterrupted

ground and MUST comply with NEC, ANSI/NFPA 70

and all local codes having jurisdiction. The ground

may consist of electrical wire or metal conduit when

installed in accordance with existing electrical codes.

HEAT/COOL & COOL ONLY

THERMOSTATS

FIRST STAG E HEAT/COOL

SECOND STAGE HEAT/COO L

AUX HEATING

FAN

24VAC HOT

24 VAC COMM ON

Figure 18

FIRST STAGE HEAT/COO L

SECOND STAGE HEAT/COOL

AUX HEATING

FAN

RVS COOLI NG

24VAC HOT

24 VAC COMMON

Figure 19

Single Stage Hydronic Furnace w/ Two Stage A/

HEAT PUMP THERMOSTATS

Single Stage Hydronic Furnace

w/ Two Stage Heat Pump

18

SINGLE STAGE

HYDRONIC FURNACE

Y1

Y2

W

G

R

C

Y1

Y2

W

G

O

R

C

Y1

Y2

W

G

O

R

C

SINGLE STAGE TWO STAG E

HYDRONIC FURNACE

Y1

Y2

W

G

O

R

C

TWO STAGE

CONDENSING

UNIT

Y1

Y2

C

HEAT PUMP

Y1

Y2

O

R

C

Rinnai Corporation Hydronic Furnace (37AHB) Manual

Installation

START-UP PROCEDURE (HEATING ONLY):

The following conditions must be met prior to unit start

-up.

Debris from soldering and/or other installation

activities can cause equipment failure. Ensure that all

associated lines and appurtenances are free of debris.

Check to ensure that unit is secure.

Check that blower wheel rotates freely within the scroll

housing.

Check all wiring to ensure that connections are tight.

Check all ductwork and pipe connections to ensure

proper seal.

Check to ensure that all packaging wraps are removed

from equipment.

Ensure that front access doors are properly installed.

Check to ensure proper connections to the appropriate

blower speed tap (Heat /Cool – High and Low). Refer

to Air Delivery and Capacity Charts and/or the

appropriate wiring diagram in this manual.

Perform all safety and start-up checks for Tankless

Water Heater as per manufacturer’s instructions.

Having verified all preceding checks, the Furnace’s

Start-Up Procedure is as follows:

STEP 1: Purge and fill system; follow appropriate

purging procedure as laid out in this manual in section

titled “Purging and Priming the System”.

STEP 2: Turn on power supply to Furnace. Caution:

blower and/or circulator may start to operate if

thermostat is on and a call is present.

STEP 3: Turn thermostat on and switch system to the

heating mode. The thermostat shall be set higher than

the actual room temperature; this will cause the

circulator to energize and initiate the heating cycle. (If

the pump does not start, or the Furnace is not

producing heat, refer to the Troubleshooting Section in

this manual).

STEP 4: Program room thermostat as desired by

homeowner.

START-UP PROCEDURE (COOLING SYSTEM)

Refer to field supplied evaporator coil and outdoor unit

manufacturer’s Installation Instructions for system

hook-up, start-up instructions and refrigerant charging

method details.

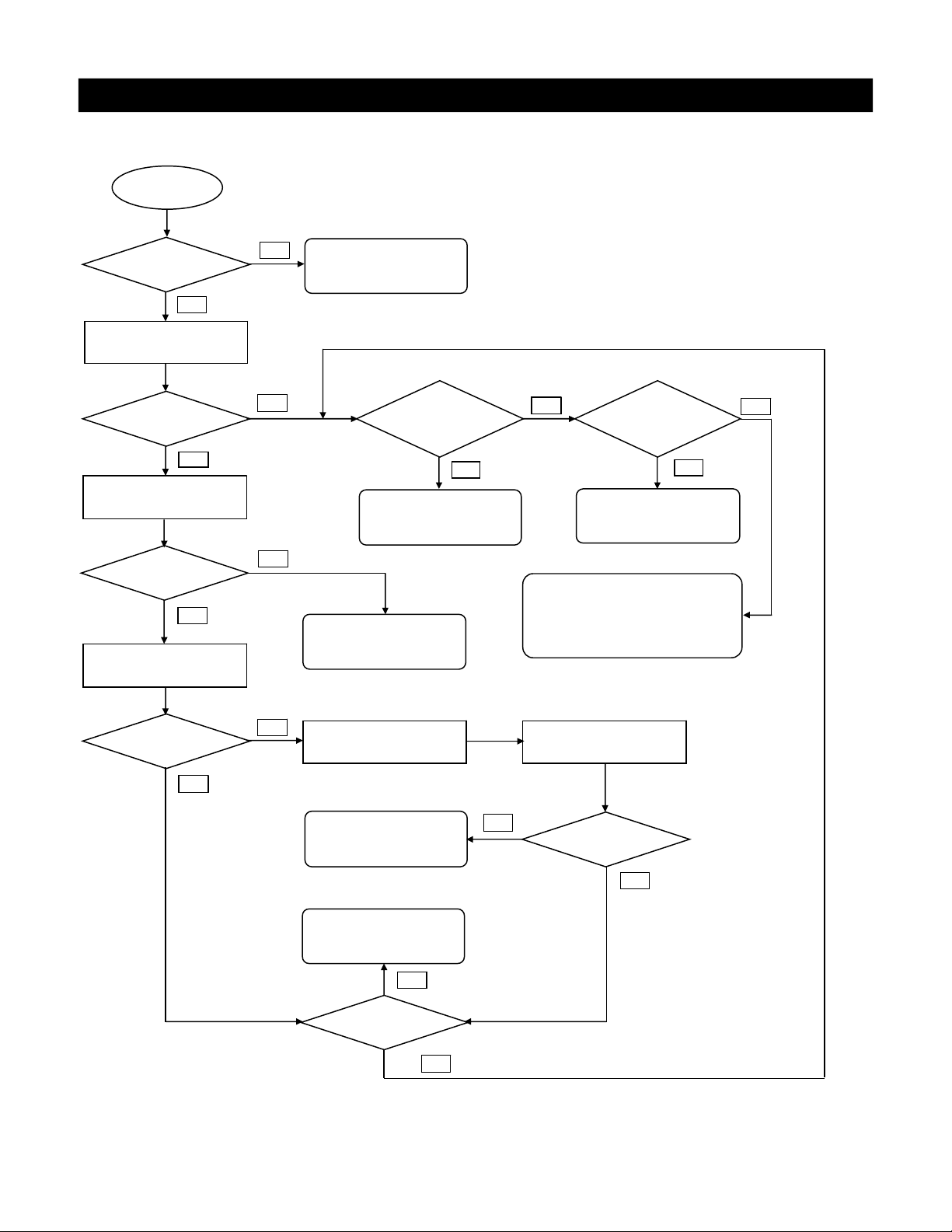

TROUBLESHOOTING BLOWER AND/OR PUMP

MOTOR AND CONTROLS

If blower and/or pump motor does not run:

Turn off power and check the following:

1. Check that door switch is in the CLOSED position.

2. Check 3 amp fuse on Printed Circuit Board (PCB).

CAUTION

High voltage is at all times present at motor.

Disconnect power to the Hydronic Furnace before

removing or replacing or servicing motor. Wait at

least 5 min after disconnecting power before opening

motor. Failure to follow this CAUTION could result in

minor personal injury or product and property

damage.

3. Check for 24 VAC between COM and 24 VAC on

PCB. If no voltage is present, check transformer.

4. Check all connections for kinks which could cause

loose connections. Ensure connections are secure.

5. Verify that approximately 120 VAC is present

across L1 and L2 (refer to wiring diagrams).

If system still fails to start, refer to Figures 20 through

23 for additional help.

TABLE 2.1: BLOWER MOTOR TROUBLESHOOTING

SYMPTOM

Motor fails to

start

Motor does

not come up

to full speed

Motor stalls

during

operation

Motor vibrates

or is

excessively

noisy

POSSIBLE

CAUSES

Blown fuse

Incorrect

voltage

Improper

connections

Blower wheel

obstruction

Not applied

properly

Overload

motor

Loose or

defective fan

CORRECTIVE ACTION

Turn off motor. Replace

fuse

Verify motor voltage

matches system voltage

Turn off motor. Verify

connections

Verify blower wheel is not in

contact with the blower

housing. Readjust blower

wheel position on motor

shaft.

Check speed taps as per

wiring diagram.

Check for duct blockage

and/or verify that ducting

system is not restrictive.

Turn off motor. Tighten fan

set screw or replace fan.

Rinnai Corporation Hydronic Furnace (37AHB) Manual 19

L

Installation

START

SYSTEM

PURGED

YES

WITH DOOR SWITCH CLOSED

(SET SYSTEM IN HEATING

MODE - CALL FOR HEAT)

NO

RETURN TO PURGE & PRIME

STEPS ‡

NOTES:

1 Pipe system between Tankless Water Heater and Hyronic Furnace ‡

2 Leak check piping system

3 Purge and prime plumbing system

4 Perform required electrical work

5 Check system operation with power to condensing unit off (if installed)

6 Control board is sometimes refered to as 'PCB'

7 Hyronic Furnace is sometimes refered to as 'RHF'

8 Typical for all check, ensure system is in the following operating mode:

AC / SINGLE STAGE

9 For Amp loads refer to specification sheet

10 Thermostat is sometimes refered to as 'T'STAT'

IS 'LED' ON

NO

CHECK BREAKER AND POWER

SUPPLY

IS POWER

SUPPLY OK

YES

CHECK VOLTAGE ACROSS'L1'

AND 'L2'

VAC = 115V +/-

YES

YES

NO

NO

IS 'LED'

RAPIDLY

FLASHING

STEADY 'LED' FLASH - NORMAL

OPERATION OR STAND-BY

MODE AWAITING

THERMOSTAT CAL

RECTIFY SUPPLY VOLTAGE

PROBLEM(S) AND RETURN TO

START

CHECK FOR LOOSE OR

BROKEN WIRE

CHECK DOOR SWITCH, IF

DEFECTIVE, REPLACESAME

AND RETURN TO START

NO

YES

INCONSISTENT RAPID FLASH (PULSATING

PUMP OPERATION)– WRONG SHUNT

POSITION - REFER TO FIG.14 HYDRONIC

FURNACE CONTROL BOARD, JUMPER

(SHUNT) POSITION'P7'TO BE IN 'FS'

CHECK SYSTEM WIRING

AGAINST WIRING DIAGRAM -

RECTIFY PROBLEM(S)

IS 'LED' RAPID

FLASH

CONSISTENT

DOMESTIC HOT WATER

DEMAND PRESENT –SYSTEM

ON HOLD- SEARCH MODE

MODE

NO

L1/L2 = 115V +/-

NO

YES

YES

GO TO24 VOLTS

TROUBLESHOOTING CHART

NO

IS 'LED' ON

YES

‡ Refer to plumbing section in this manual

Figure 20: Hydronic Furnace Start-Up and ‘LED’ Troubleshooting - Flow Sensor (FS Configuration)

20

Rinnai Corporation Hydronic Furnace (37AHB) Manual

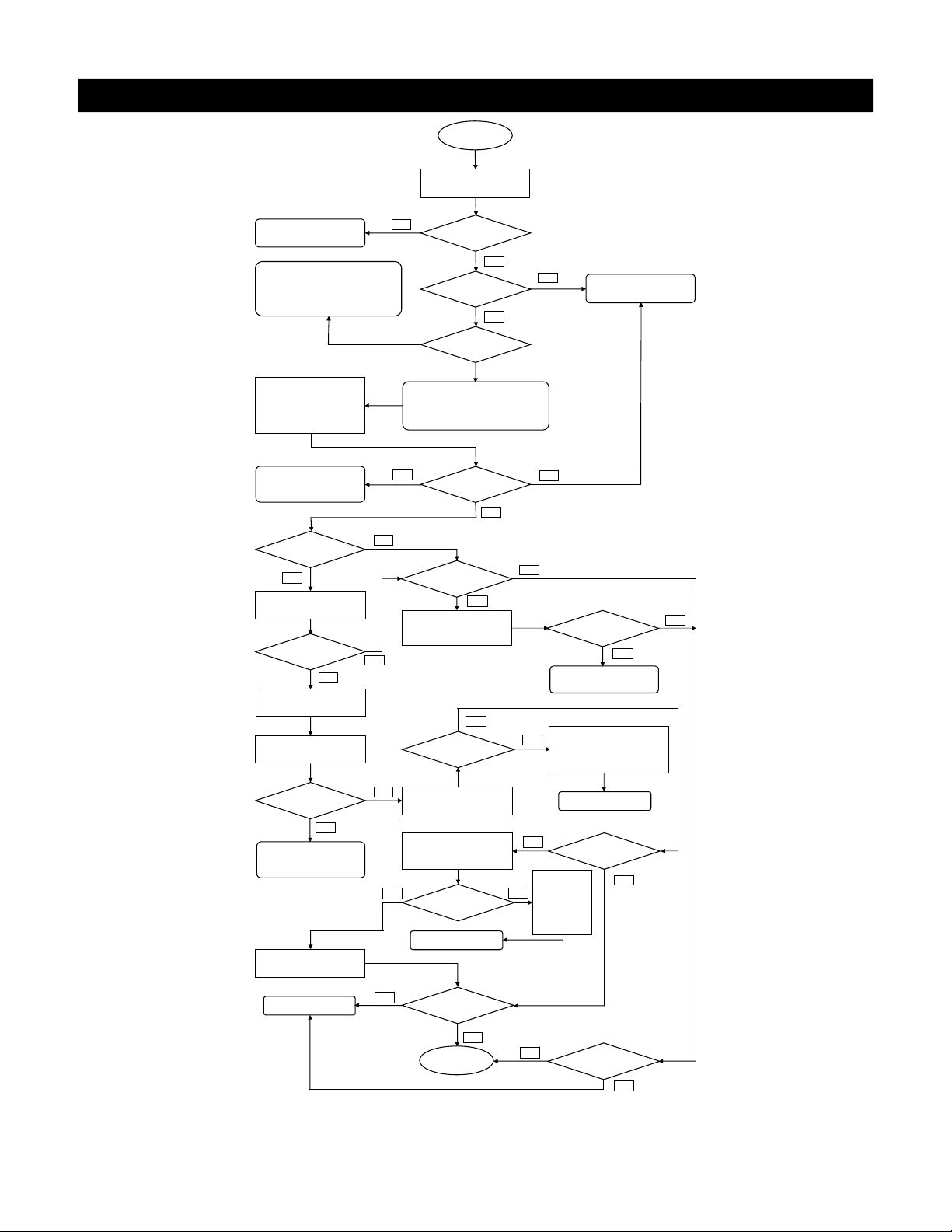

()

COMPO

Installation

START

WITH DO OR SWITCH CLOSE D

(SET SYSTEM IN HEA TING

MODE; CALL FOR HEAT )

GO TO RHF START-UP & 'LED'

TROUBLESHOOTING

PULSING FLASH WITH PUMP AND FAN

ENERGIZED (associated with contactor

clicking sound) - WRONG SHUNT POSITION

FOR OPERATING MODE - REFER TO

FIG.14; CHANGE SHUNT POSITI ON AND

TO ISOLATE CAUSE: ENSURE

THAT SYSTEM IS P URGED AND

ALL FAUCETS AND OTHER

WATER CONSUMING

EQUIPMENT IS OFF (FLOW TO

RHF SHOULD BE ≥ 1 GPM)

GO TO CIRCULAT ING PUMP

115 v TROUBLESHOOTING

FAN

ENERGIZED

YES

NO

ADJUST THERMOSTAT SET

TEMPERATURE HIGHER THAN

ROOM TEMPERATURE

FAN

ENERGIZED

YES

NO

CHECK FOR LOOSE OR BROKEN

WIRES

CHECK VOLTS ACROSS 'FAN'

CONNECTIONS ON PCB ('COOL-

HI' AND 'N4')

NO

IS 'LED' ON

YES

STEADY 'LED'

FLASH

NO

'LED' FLASH

CODE

RAPID FLASH - PUMP NOT ENERGIZED CAUSES:

1. SEARCH MO DE (INSUFFICIE NT FLOW);

2. NO POWER TO PUMP ;

3. NO POWER TO FLOW SENSOR

NO

STEADY 'LED'

FLASH

YES

FAN AMP DRAW

NORMAL

NO

CHECK CAPACIT OR; IF

DEFECTIVE, REPLACE

COMPONENT AND RE-CHECK

AMP DRAW

YES

FAN MOTOR

ENERGIZED

YES

YES

YES

FAN AMP DRAW

NORMAL

CHECK FAN MOTOR; IF

DEFECTIVE REPLACE

(1) RECTIFY WIRING PROBLEM(S)

NO

(2) CHECK MOTOR AND

CAPACITOR; IF DEFECTIVE,

REPLACE FAULTY COMPONENT(S)

NORMAL OPERATION OR

STAND-BY MODE (AWAITING

THERMOSTAT CALL)

YES

NO

NENT

YES

VAC = 115V +/-

NO

PROBLEM(S) WITH 24V TO PCB

- GO TO 24V

TROUBLESHOOTING CHART

RECONNECT WIRES AND

CONFIRM T HAT WIRING IS A S

PER WIRI NG DIAGRAMS

CONTACT TECH.

SUPPORT

CONNECT FAN DIRECTLY TO

115 VAC POWER SUPPLY

CHECK CAPACITOR; IF

DEFECTIVE REPLACE

COMPONENT AND RE-CHECK

YES

RETURN TO START

NO

AMP DRAW

FAN AMP DRAW

NORMAL

SYSTEM

WORKING

NO

NO

CHECK FAN

MOTOR; IF

DEFECTIVE

REPLACE

COMPONENT

AND RE-CHECK

AMP DRAW

RETURN TO START

FAN AMP DRAW

NORMAL

YES

YES

FINISH

YES

SYSTEM

WORKING

NO

Figure 21: Blower System 115V Troubleshooting - Flow Sensor (FS) Configuration

Rinnai Corporation Hydronic Furnace (37AHB) Manual 21

Loading...

Loading...