Rinnai REH-311FT(B), REH-311FT(C), ULTIMA II REH-311FT, ULTIMA II REH-311FTB, ULTIMA II REH-311FTC Operation & Installation Manual

Page 1

This appliance shall be installed in accordance with:

• Manufacturer’s Installation Instructions

• Current AS/NZS 3000 and

AS/NZS 5601

• Local Regulations and Municipal Building Codes

This appliance must be installed, serviced and removed by an authorised person.

All Rinnaigas products

are A.G.A.certified.

Distributed and serviced in Australia under a Quality

System certified as complying with ISO 9001 by

SAI Global

ULTIMA II

Flued Space Heater

Operation / Installation Manual

MODEL REH-311FT(B) - Inbuilt

MODEL REH-311FT(C) - Console

Page 2

Rinnai Australia i Ultima II Operation Manual

INSTALLATION REQUIREMENTS

This heater must be installed by an authorised person. The insta llation must conform to local regulations.

The installation must also comply with the instructions supplied by Rinnai.

Service and removal must be carried out by an author i sed pe rso n .

The Rinnai REH311FT has been certified by the Australian Gas Association.

The AGA Certification Number is shown on the appliance dataplate.

No parts or functions should be modified or permanently removed from the heater.

Please keep these instructions in a safe place for future reference.

CERTIFICATION

Page 3

Rinnai Australia ii Ultima II Operation/Installation Manual

ABOUT YOUR ULTIMA II ...........................................................................................1

DESIGN LAYOUT......................................................................................................................... 1

NAVIGATING THE CONTROL PANEL........................................................................................ 1

FEATURES..................................................................................................................2

SAFETY.......................................................................................................................2

IMPORTANT POINTS .................................................................................................3

BASIC USER GUIDE...................................................................................................5

HOW TO OPERATE THE HEATER............................................................................6

TO TURN THE HEATER ON........................................................................................................ 6

TO ADJUST SET TEMPERATURE.............................................................................................. 6

TO TURN THE HEATER OFF...................................................................................................... 6

MODES TO DELIVER COMFORT AND ECONOMY....... ... ... .......................................... ... ... .... .. 7

GAS MODE ..................................................................................................................................7

GAS / ECON MODE (ECONOMY MODE) ................................................................................... 7

GAS / ECON / AUTO OFF MODE................................................................................................ 7

SELECTING MODES ................................................................................................................... 7

TIMER OPERATION....................................................................................................8

CLOCK AND DUAL TIMERS............... ... ... ... ... .... ... ... ... .......................................... .... ... ... ... ... .... .. 8

SETTING THE CLOCK....... .... ... ... .......................................... .......................................... ............8

PROGRAMMING TIMERS ........................................................................................................... 9

OPERATING TIMERS................................................................................................................10

PREHEAT................................................................................................................................... 10

LOCK AND OTHER SAFETY DEVICES...................................................................11

USING THE OVERRIDE FUNCTION ........................................................................................ 11

USING THE LOCK FUNCTION........... ... ... ... ... .... ... ... ... .... ... .......................................... ... ... .......11

SAFETY DEVICES................................................. ... ... .... ... ... ... .... ............................................. 11

CARE AND MAINTENANCE.....................................................................................12

CLEANING FILTERS, GRILLES AND LOUVRES...................................................................... 12

SERVICE.................................................................................................................................... 12

TROUBLE SHOOTING CHECKLIST ......................................................................................... 13

ERROR CODES......................................................................................................................... 13

INSTALLATION.........................................................................................................15

SPECIFICATIONS.....................................................................................................28

PRODUCT SPECIFICATIONS................................................................................................... 28

DIMENSIONS............................................................................................................................. 28

CONTACT INFORMATION ......................................................................................29

INSTALLER: Go to page 15 for Installation Instructions

NOTE

OPERATION

Page 4

Rinnai Australia 1 Ultima II Operation Manual

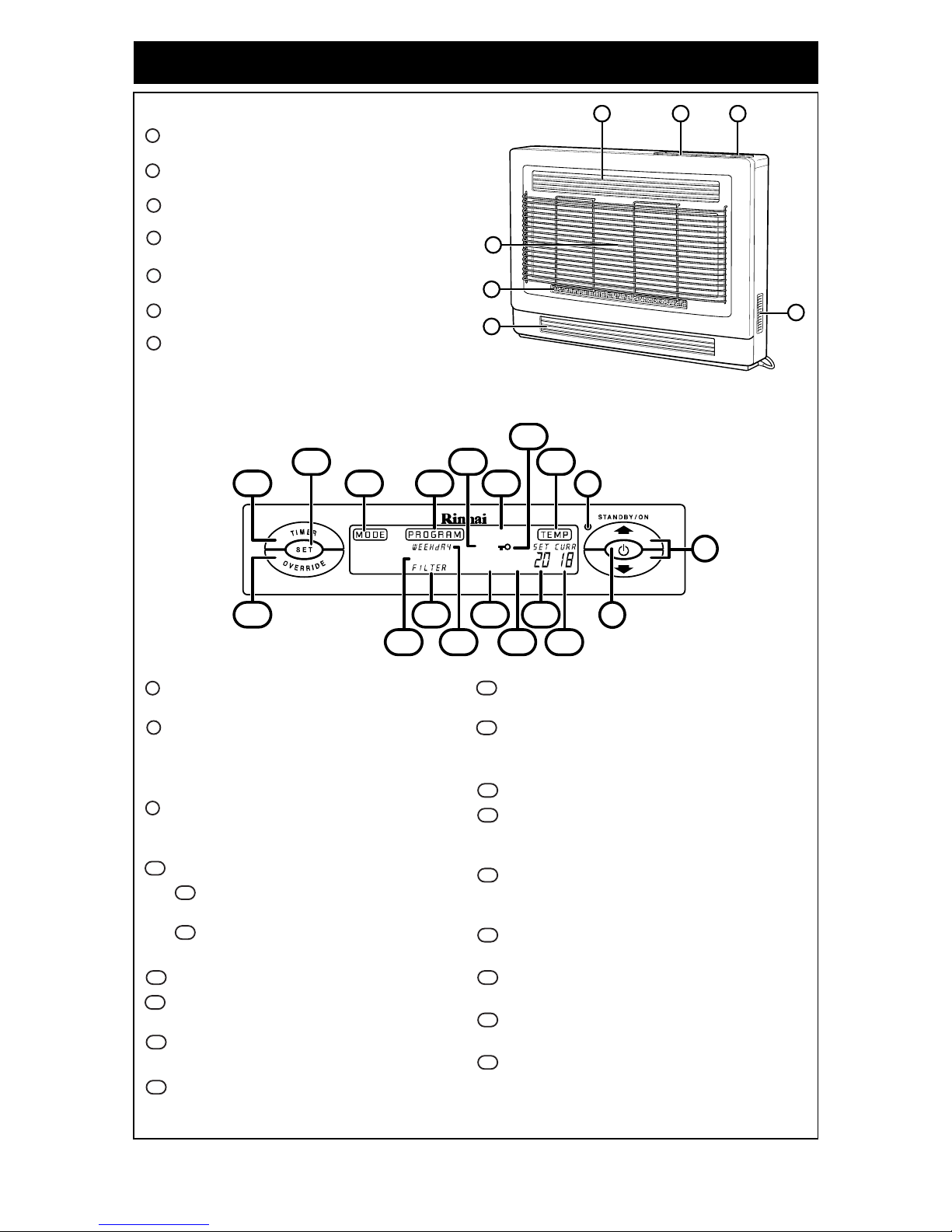

ABOUT YOUR ULTIMA II

DESIGN LAYOUT

Control panel

STANDBY/ON button

Burner filter

Air inlet louvre

Warm air discharge louvre

Thermistor grill cover

Dress guard

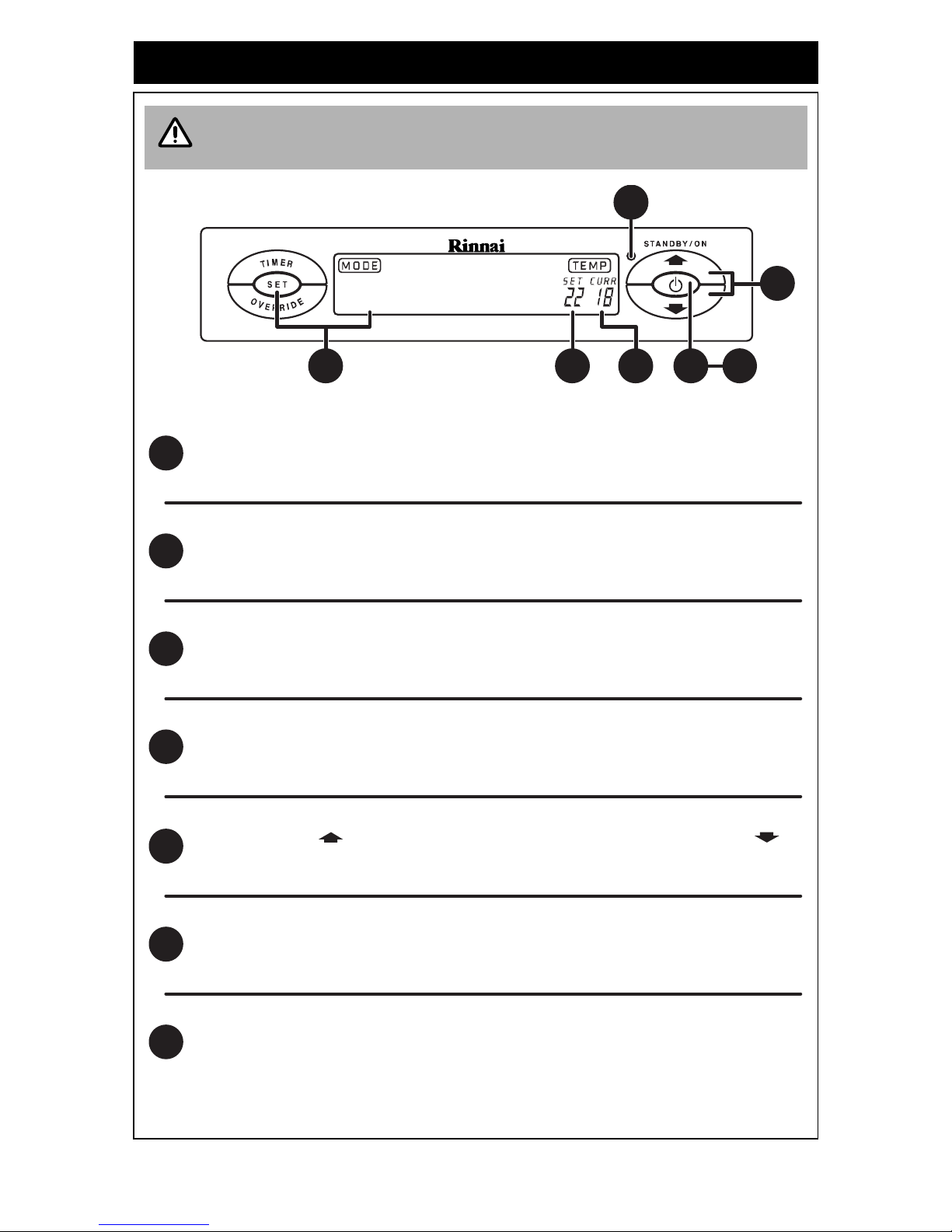

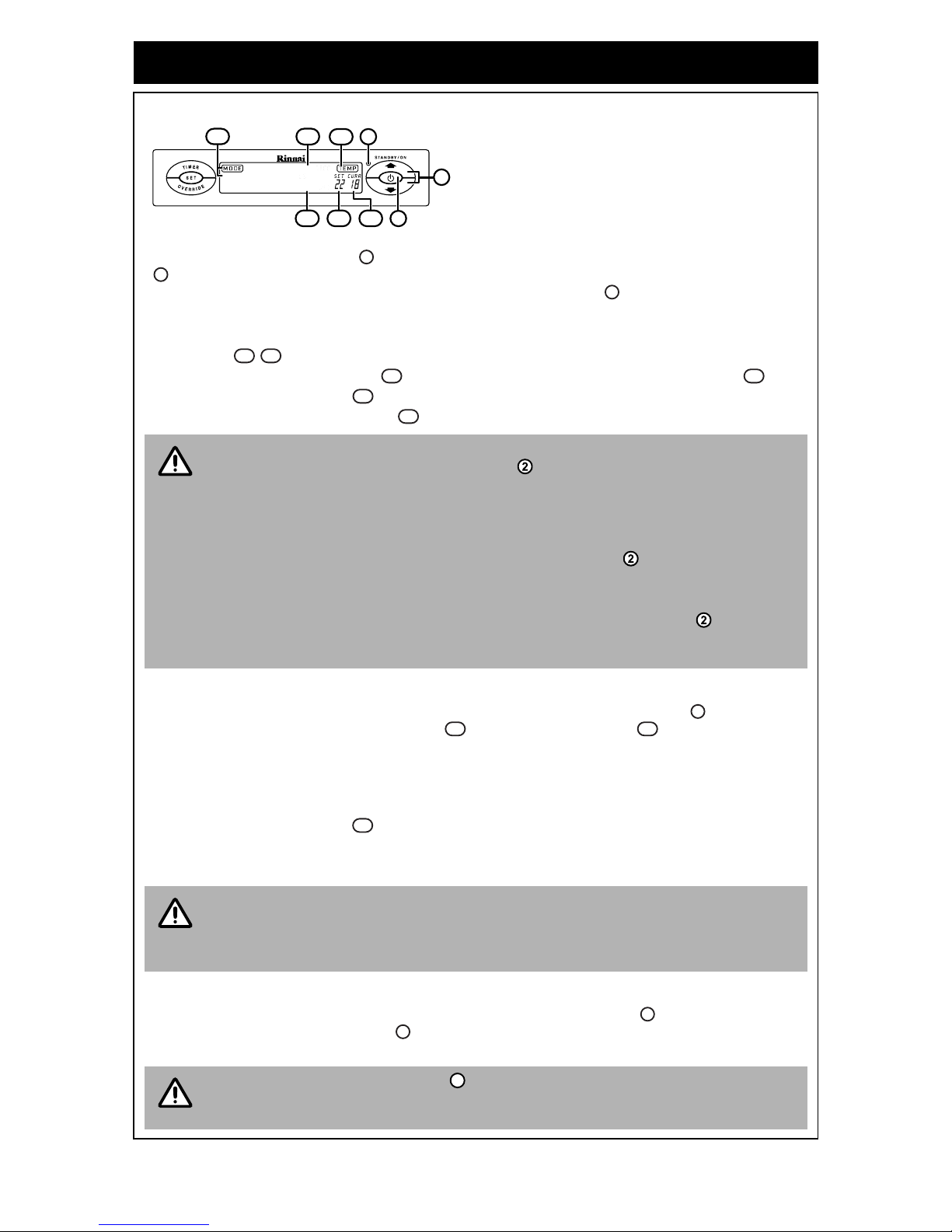

NAVIGATING THE CONTROL PANEL

STANDBY / ON button - used to operate and

stop the heater.

ON / Combustion indicator - when GREEN

appliance is in standby, when RED the burner

is operating and when flashing RED there is a

fault.

UP / DOWN button - used to adjust the SET

temperature, clock and timers and operate the

lock function.

TEMP display -

CURR - indicates the current room

temperature.

SET - indicates the desired room

temperature programmed by the user.

Clock display - displays current time.

MODE display - indicates which mode the

heater is operating in.

SET button - used to programme the heater

operation.

DAY display - displays the current day.

AM/PM indicator - indicates AM or PM of

clock or timer settings.

TIMER display - when the word ‘TIMER’ is

shown the display panel will be showing

current timer settings.

TIMER button - operates timer functions.

PROGRAM display - when the word

‘PROGRAM’ is shown the heater is in

programming mode.

WEEKDAY/WEEKEND display - Indicates

whether the weekday or weekend timers are

being programmed.

AM/PM display - indicates whether AM and/

or PM timer settings are being programmed .

OVERRIDE button - operates the manual

override function.

FILTER display - when shown the filter(s)

require cleaning.

LOCK display - when shown the lock function

is activated.

6

214

5

3

7

1

2

3

4

5

6

7

su

i0:30

am

timer

GAS ECON

AM PM

AUTO OFF

11

10

20 18

16

25

1419

23

15

17

2

9

8

121324

2122

2

8

9

10

11

121314

15

16

17

18

19

20

21

22

23

24

25

Page 5

Rinnai Australia 2 Ultima II Operation Manual

FEATURES

• The Rinnai Ultima II is one of the most efficient gas space heaters available in Australia.

This has been achieved by combining good design with the latest technology, making the heater

both highly efficient and easy to use.

• Downflow Convection operation and large capacity fan ensures effective heating to all parts of the

room and reduces stratification.

• 30 MJ/h input, large enough to suit most domestic applications.

• Ignition is fully automatic and the burner is continuously monitored by an electronic flame failure

system. If the flame is extinguished during operation, the gas supply is shut off immediately.

• Electronic temperature controls ensure that the room stays at the temperature you have selected.

• Electronic dual ON and OFF timers.

• Filters to protect the burner from dust and lint.

• Automatic fan switch to turn the fan on and off and match the fan speed to the heat input at all

times, increasing efficiency and comfort.

• Overheat switches avoid hazards should the appliance overheat.

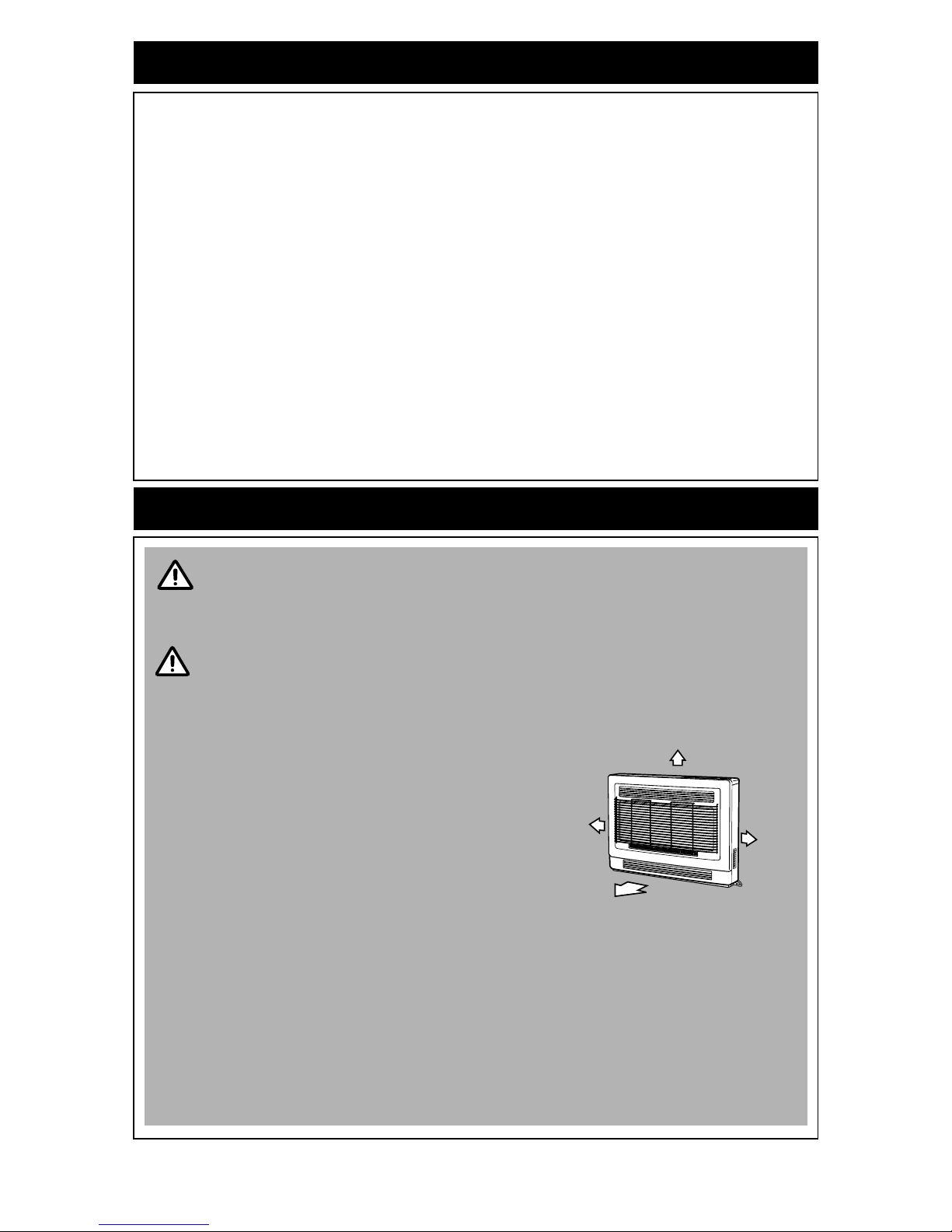

SAFETY

Failure to comply with these instructions could result in a fire or explosion, which

could cause serious injury, death or property damage.

Improper installation, adjustments, service or maintenance can cause serious injury,

death or property damage. Such work must be performed by an authorised person.

• The appliance must be installed in accordance with the local gas and electrical

authority regulations.

• This appliance must not be installed where curtains or ot her combust ible mat erials

could come into contact with it. In some cases curtains may need restraining.

• This appliance discharges a large volume of

warm air at low level to provided even heat

distribution.

• Some nylon carpets contain dyes which may

be affected by the warm air flow.

• Heat emanating from the front of this

appliance may over time affect the appear ance

of some materials used for flooring such as

carpet, vinyl, cork or timber. This effect may

be amplified if the air in the room contains

cooking vapours or cigarette smoke. To avoid

this possibility, it is recommended that a mat

be placed in front of the appliance, extending

at least 750 mm in front of it.

• The appliance is not intended for use by young children or infirm persons without

supervision.

• Young children should be supervised to ensure they do not play with the

appliance.

• If the supply cord is damaged or requires replacing, it must be replaced by the

manufacturer or the manufacturer's agent or similarly qualified person in order to

avoid a hazard.

CAUTION

IMPORTANT

150mm

1000mm

150mm

150mm

The above diagram shows the clearances required

around this heater whilst in operation

Page 6

Rinnai Australia 3 Ultima II Operation Manual

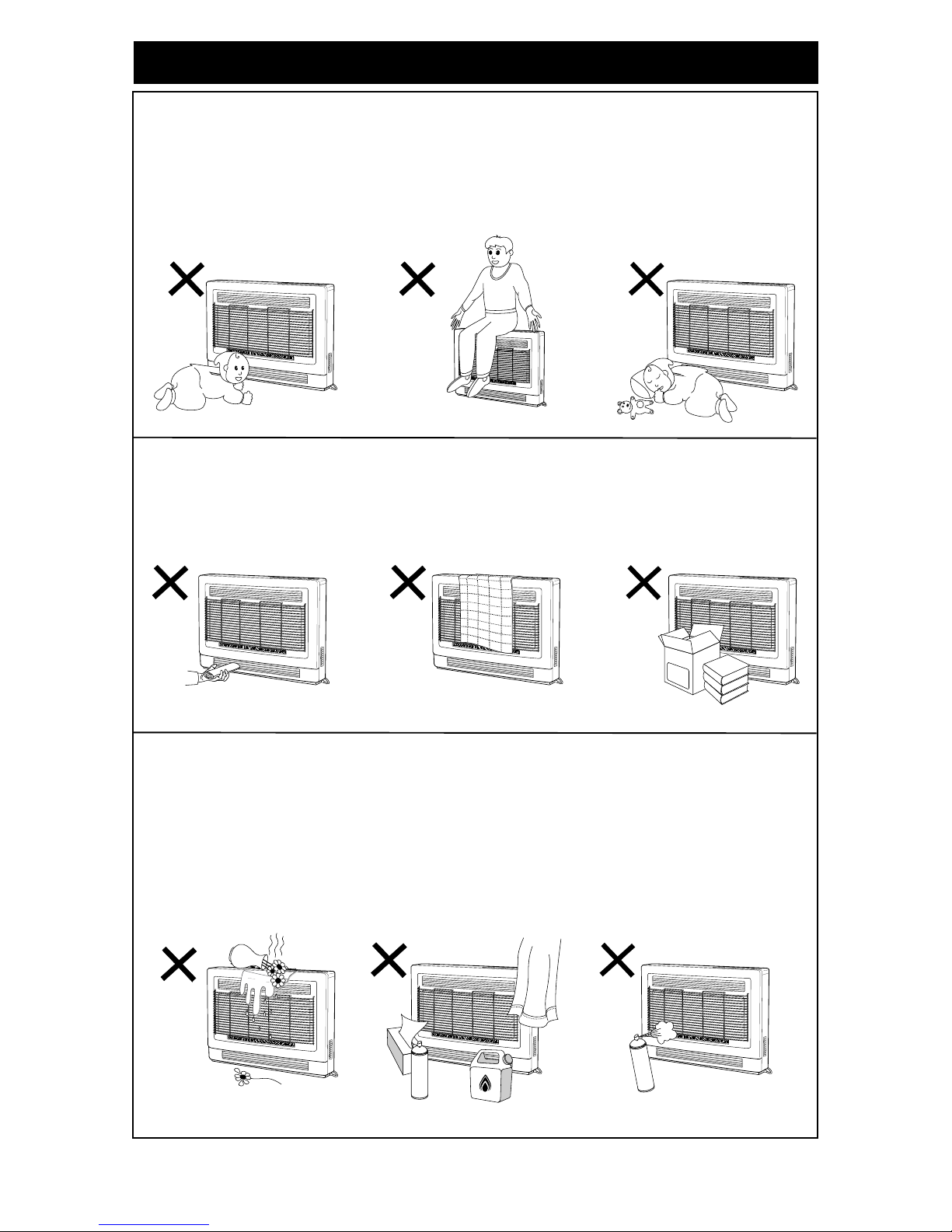

The appliance is not intended for use by young children or infirm persons without supervision.

Young children should always be supervised to ensure that they DO NOT play with the appliance.

DO NOT allow children or elderly persons to sleep in the warm air discharge from the heater.

DO NOT sit on this heater.

DO NOT post or allow children to post articles into the louvres of the heater.

DO NOT cover or place articles on this heater.

DO NOT place articles in front of the louvres

.

Keep heater away from flammable materials. Combustible materials must not be placed where the

heater could ignite them.

DO NOT place containers of liquid on top of the heater. Water spillage can cause extensive damage to

the appliance and create an electrocution hazard.

DO NOT spray aerosols near this heater while it is in use. Most aerosols contain butane gas which can

be a fire hazard if used near this heater when it is in use.

Use of aerosols, paint, polishes etc. whilst this heater is in use may also cause unpleasant smells.

IMPORTANT POINTS

Page 7

Rinnai Australia 4 Ultima II Operation Manual

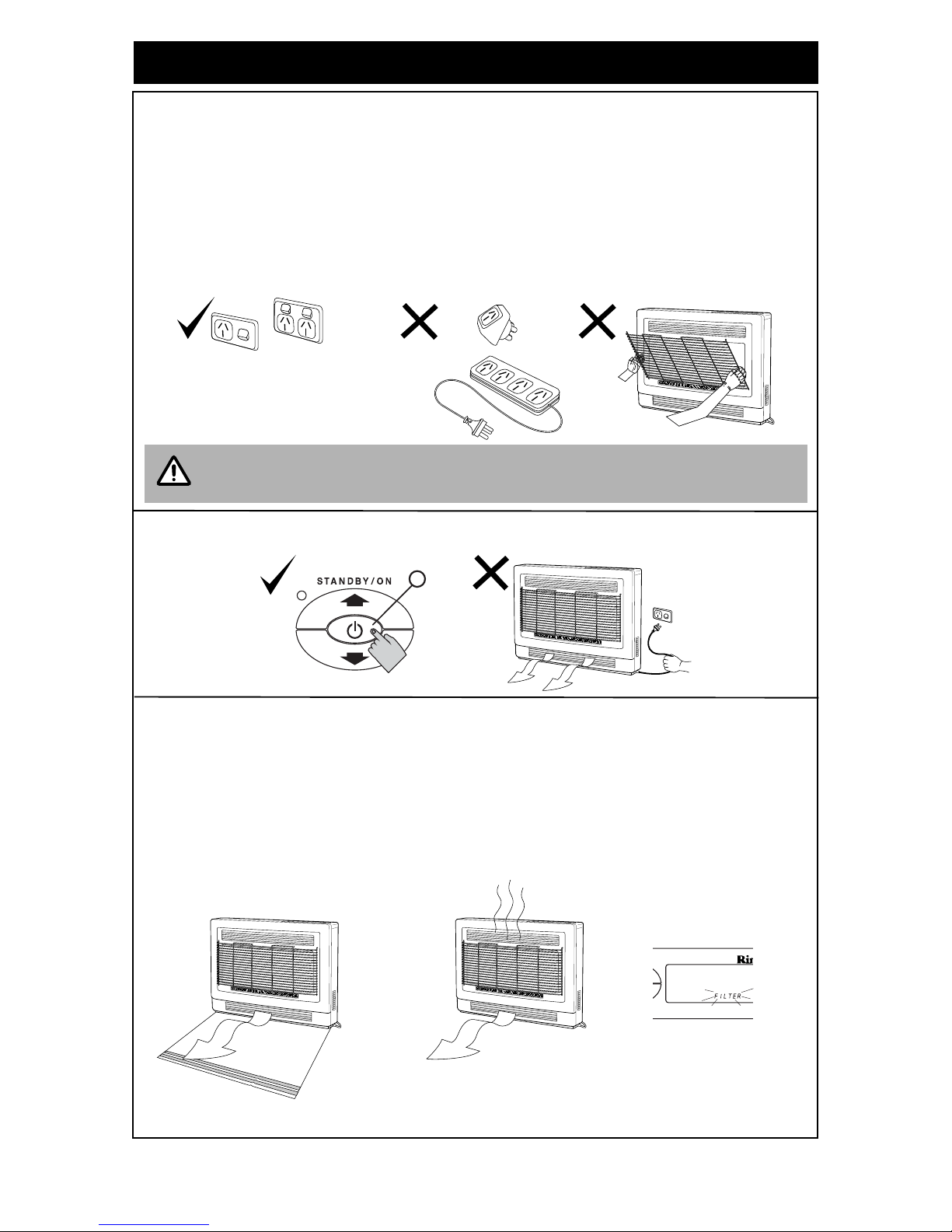

It is recommended that a dedicated 240V 10 Amp earthed power point be used with this appliance.

DO NOT use power boards or double adaptors to operate this appliance. Heater MUST NOT be

located below a power socket-outlet.

DO NOT remove the Dress Guard.

The dress guard is fitted to this appliance to reduce the risk of fire injury from burns and no part of it

should be permanently removed. It does not give full protection to young children or the infirm.

For protection of children or the infirm, a secondary guard is recommended.

Turn the heater to Standby after use. DO NOT unplug the heater while it is in operation or while the

fans are still cycling.

Heat emanating from the front of this appliance may over time affect the appearance of some materials

used for flooring such as carpet, vinyl, cor k or tim ber. This effect may be amplified if the air in the room

contains cooking vapours or cigarette smoke. To avoid this possibility, it is recommended that a mat be

placed in front of the appliance, extending at least 750 mm in front of it.

When the heater is operated for the first time or after long periods of non use a slight odour may be

emitted, this is normal. However if odours persist switch off the appliance and contact Rinnai.

During periods of frequent operation periods the filters should be cleaned weekly, however if the Filter

warning indicator illuminates, turn off the appliance immediately and clean filters before further use.

When the heater is unplugged the for an extended period the clock will stop and will

need to be reset. However programmed ON/OFF times will remain in the memory.

NOTE

2

weehen0

AM PM

AUTO OFF

IMPORTANT POINTS

Page 8

Rinnai Australia 5 Ultima II Operation Manual

BASIC USER GUIDE

Below is a guide to the basic operation of the Ultima II heater. For details on how to

use the advanced features of this appliance please read pa ges 6 to 1 1 of this man ual.

NOTE

1

2

When the heater has started to heat the room the On/Combustion indicator will

change from Green to Red (steady illumination) to confirm heater operation.

This number indicates the current (CURR) room temperature.

(The SET temperature must be higher than this temperature for the heater to start)

Use the up arrow to raise the room temperature and use the down arrow to

lower it .

This number indicates the selected (SET) room temperature.

(The available SET temperatures are: L = low, 16°C to 30°C in [ 1°C steps ], H = high)

4

3

5

To turn on the heater press the STANDBY/ON button, the On/Combustion indicator

will illuminate Green (steady illumination) until the heater starts.

6

Press the SET button until the desired mode(s) are shown in the display.

(For best comfort and economy press the SET button until GAS, ECON & AUTO OFF are

all shown. The last mode(s) sellected become the default the next time the heater is used)

7

To turn off the heater press the STANDBY/ON button, the On/Combustion indicator

will go out and the digital display will revert to a CLOCK display for 10 seconds and

then go blank.

(The fan will continue to cycle for several minutes to cool the heater down)

--:--

time

GAS ECON

weehen0

AM PM

AUTO OFF

1 7

5

2

436

Page 9

Rinnai Australia 6 Ultima II Operation Manual

HOW TO OPERATE THE HEATER

TO TURN THE HEATER ON

Before you begin ensure that the Gas and Power

have been connected and turned on.

The combustion chamber of this appliance r equires

purging before gas flows and the burner sequence

begins. As a result the combustion fan starts several

seconds before there are any signs of ignition.

Press the STANDBY/ON button once to begin the ignition sequence. The On/Combustio n indicator

will glow green and the combustion fan will cycle to purge the combustion chamber. Once purged

burner ignition will take 5 ~ 10 seconds. The ON/Combustion indicator will change to Red (steady)

after ignition has been achieved.

After ignition the appliance will begin to operate in the following factory preset manner:

• The TIME / will display - - : - -, to set the time see page 8.

• The temperature displays TEMP and will show the current room temperature CURR . The

default set temperature SET will be 22°C. See below on how to adjust set temperature.

• The default operating mode is GAS , see page 7 for modes of operation.

TO ADJUST SET TEMPERATURE

The set temperature may be raised or lowered by use of the Up and Down buttons . The selected

temperature will be displayed under the SET icon of the TEMP display .

The following set temperatures can be selected.

• 'L' for continuous combustion on the lowest burner setting, without thermostatic control.

• Thermostatic control between 16°C to 30°C in 1°C steps

• 'H' for continuous combustion on the highest burner setting, without thermostatic control.

The current room temperature will display temperatures between 1°C to 30°C.

Once the temperature is set it will be stored in the memory of the microcomputer. If the temperature

is not adjusted further it will be the default setting when the appliance is next used.

TO TURN THE HEATER OFF

To turn the heater off while it is in operation press the STANDBY/ON button located on the control

panel. The On/Combustion indicator w ill go out and the digital display will revert to the CLOCK

display.

To save energy, during standby the digital display will de-activate (go blank) after 10

seconds. Pressing the STANDBY/ON button overrides this feature and will initiate

the ignition sequence, pressing any other button once re-activat es the digital display.

When using the appliance for the first time or after long periods of non use, ignition

may not occur the first time it is operated as there may be air within the pipes. If

ignition does not occur after approximately 30 seconds the heater will cease oper ation

automatically. If this occurs press the STANDBY/ON button twice to restart.

This heater may make noises after ignition/extinction. This is due to expansion and

contraction of the heater components and is normal.

The heater will not immediately ignite if the STANDBY/ON button is pressed

straight after extinction. After approximately 20 seconds has passed, the heater will

automatically go into ignition mode.

Rooms may not arrive at the SET temperature due to the size and construction of the

room, location of the appliance or external temperatures.

If the appliance does not ignite then the actual room temperature may already be

higher than the pre-set temperature.

After the On/Combustion indicator has gone out, the appliance fan will continue to

cycle for several minutes. This is to lower the temperature within the appliance and is

normal. DO NOT disconnect the power during this time.

--:--

time

GAS ECON

weehen0

AM PM

AUTO OFF

11

10

14

2

9

8

1213

18

2

8

8

13

18

10

11

12

14

NOTE

9

12

18

11

NOTE

2

8

NOTE

8

Page 10

Rinnai Australia 7 Ultima II Operation Manual

HOW TO OPERATE THE HEATER

MODES TO DELIVER COMFORT AND ECONOMY

Your appliance has several MODE settings to choose from. The factory default mode is GAS. If the

mode is not adjusted this will be the default setting the next time the appliance is used.

As a room is warmed, the walls and ceilings are also warmed, making one feel a little warmer than

when the ceilings and walls were cold, even though the room temperature is the same. The economy

mode prevents discomfort from overheating and saves energy.

GAS MODE

Gas combustion in this mode is continuous and will adjust automatically to maintain the set

temperature. This is the factory default mode for the appliance.

GAS / ECON MODE (ECONOMY MODE)

In this mode, once the set temperature has been maintained for a period of 30 minutes, the comfort

control system will progressively lower the set temperature by 2°C over a period of 60 minutes. When

GAS / ECON mode is selected, gas combustion is continuous and will adjust automatically to maintain

the set temperature minus 2°C.

GAS / ECON / AUTO OFF MODE

In this mode, once the set temperature has been maintained for a period of 30 minutes, the comfort

control system will progressively lower the set temperature by 2°C over a period of 60 minutes. When

GAS / ECON / AUTO OFF mode is selected, gas combustion will start and stop automatically to

maintain the set temperature minus 2°C.

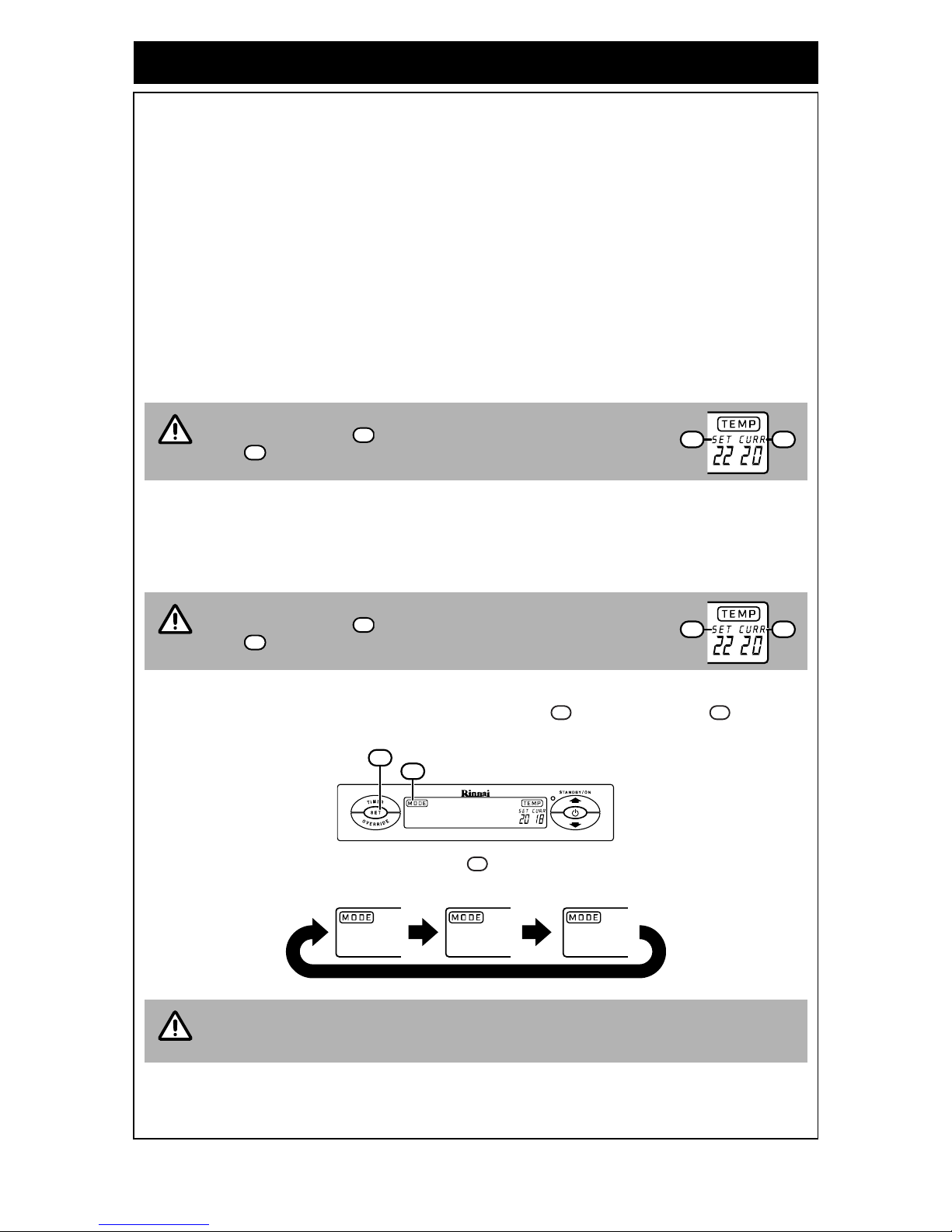

SELECTING MODES

The current operation mode is displayed on the digital display and the SET button is used to

select which mode the heater will use during operation.

The select a different mode press the SET button whilst the appliance is in operation, this will cycle

the heater through the available modes as follows:

During operation in GAS / ECON mode the current room

temperature (CURR ) may be lower than the set temperature

(SET ), however this is normal.

During operation in GAS / ECON / AUTO OFF mode the current room

temperature (CURR ) may be lower than the set temperature

(SET ), however this is normal.

The MODE selected will be stored in the memory of the microcomputer. if the MODE

is not changed further it will be available as the initial setting when the appliance is

next used.

NOTE

1112

11

12

NOTE

1112

11

12

14

15

su

--:--

am

timeroff

GAS ECON

weehen0

AM PM

AUTO OFF

14

15

15

GAS ECON

AUTO OFF

GAS ECON

AUTO OFF

GAS ECON

AUTO OFF

NOTE

Page 11

Rinnai Australia 8 Ultima II Operation Manual

TIMER OPERATION

CLOCK AND DUAL TIMERS

The setting of the Clock and programming of the Timers is done via the SET button . Each press

of this button will cycle the appliance through the available clock setting and timer programming

modes.

SETTING THE CLOCK

With the heater in the STANDBY condition press the

SET button once (if the digital display is blank

press the SET button twice) to enter the TIME

function. The factory default clock display is SU

12:00 AM. The day indicator will be flashing.

The following example will show how to set the clock

to Wednesday 8:53 pm.

Press up or down buttons to scroll to the desired

day of the week. For this example WE (Wednesday)

is selected.

After setting the day, press the SET button once.

The day indicator will cease flashing and the

hour digits will begin to flash.

Press up or down buttons to scroll the numbers

to set the hour. For this example 8 is selected.

After setting the hour, press the SET button

once. The hour digits will cease flashing and the

minute digits will begin to flash.

Press up or down buttons to scroll the numbers

to set minutes. For this example 53 is selected.

After setting minutes, press the SET button

once. The minute digits will cease flashing and

the AM/PM indicators will begin to flash.

Press up or down buttons to set AM or PM. For

this example PM is selected.

After setting AM or PM, press the SET button

once and then press the STANDBY/ON button

twice to save the new time setting. The Hour/Minute

delineator will begin to flash to show that the

clock is now in operation.

It is recommended that the electric power supply to the heater is disconnected

(unplugged) only if the heater is not going to be in use for an extended period. When

the appliance is unplugged for an extended period the clock will stop and will need to

be reset. However, timer programming will remain in the memory.

15

su

i2:00

am

timeroff

GAS ECON

weehen0

AM PM

AUTO OFF

15

16

1

15

15

16

WE

i2:00

am

timeroff

GAS ECON

weehen0

AM PM

AUTO OFF

16

9

2

9

WE

18:00

am

time

GAS ECON

weehen0

AM PM

AUTO OFF

13

9

15

3

15

16

13

9

WE

18:53

am

time

GAS ECON

weehen0

AM PM

AUTO OFF

13

9

15

4

15

13

13

9

WE

18:53

pm

time

GAS ECON

weehen0

AM PM

AUTO OFF

17

9

15

5

15

13

17

9

WE

18:53

pm

time

GAS ECON

weehen0

AM PM

AUTO OFF

13

2

6

9

2

13

NOTE

Page 12

Rinnai Australia 9 Ultima II Operation Manual

TIMER OPERATION

PROGRAMMING TIMERS

With the heater in the STANDBY condition press the

SET button until the PROGRAM indicator is

shown in the display and the hour digits are

flashing. The WEEKDAY AM timer is the

initial timer that is made available for programming.

TIMER ON - Hour. Press the up or down buttons

to scroll through and select the hour that the heater

timer program will start. Press the SET button

once to lock in the hour. The minute digits will

begin to flash.

TIMER ON - Minutes. Press the up or down buttons

to scroll through and select the minutes past the

hour that the heater timer program will start. Press

the SET button once to lock in the minutes. The

AM/PM digits will begin to flash.

TIMER ON - AM/PM. Press the up or down buttons

to select either AM or PM. Press the SET button

once to lock in the AM or PM setting. The hour

digits will begin to flash again.

TIMER OFF - Hour. Press the up or down buttons

to scroll through and select the hour that the heater

timer program will finish. Press the SET button

once to lock in the hour. The minute digits will

begin to flash.

TIMER OFF - Minutes. Press the up or down buttons

to scroll through and select the minutes past the

hour that the heater timer program will finish. Press

the SET button once to lock in the minutes. The

AM/PM digits will begin to flash.

TIMER OFF - AM/PM. Press the up or down buttons

to select either AM or PM. Press the SET button

once to lock in the AM or PM setting. The hour

digits will begin to flash again.

Repeat steps through above for the setting of the WEEKDAY PM, WEEKEND AM

and WEEKEND PM timer programs as required or press the STANDBY/ON button

twice to exit.

su

i2:00

am

timer on

GAS ECON

weehen0

AM PM

AUTO OFF

15

2122

13

20

1

15

20

13

21

22

16:00

am

timer on

GAS ECON

weehen0

AM PM

AUTO OFF

9

13

15

2

9

15

13

WE

16:53

am

timer on

GAS ECON

weehen0

AM PM

AUTO OFF

9

15

17

3

9

15

17

WE

10:00

am

timer0ff

GAS ECON

weehen0

AM PM

AUTO OFF

9

15

13

4

9

15

13

WE

19:00

am

timer0ff

GAS ECON

weehen0

AM PM

AUTO OFF

9

15

13

5

9

15

13

WE

18:53

Am

timer0ff

GAS ECON

weehen0

AM PM

AUTO OFF

9

15

17

6

9

15

17

su

i2:00

am

timer on

GAS ECON

weehen0

AM PM

AUTO OFF

15

9

2

13

7

9

15

13

NOTE

2

7

Page 13

Rinnai Australia 10 Ultima II Operation Manual

TIMER OPERATION

OPERATING TIMERS

Before a timer program can be used the heater must

be turned ON with the desired set temperature and

mode of operation selected. To scroll through the

available timers press the TIMER button . When

the heater is awaiting timer operations to begin the

Combustion indicator is illuminated Green.

To select the WEEKDAY Timer, press the TIMER

button until the WEEKDAY indicator is

shown. The programmed on and off times for the

timer will then appear briefly, before the display

reverts back to the clock.

To select the WEEKEND Timer, press the TIMER

button until the WEEKEND indicator is

shown. The programmed on and off times for the

timer will then appear briefly, before the display

reverts back to the clock.

To select both the WEEKDAY and WEEKEND

Timers, press the TIMER button until the

WEEKDAY-END indicator is shown. The

programmed on and off times for the timers will then

appear briefly, before the display reverts back to the

clock.

To return the appliance to the STANDBY conditio n,

press the TIMER button until no timer indicators

are displayed, the On/Combustion indicator will

be extinguished and the clock will be displayed to

confirm that the heater is now in the STANDBY

condition and that no timer programs are selected.

When the heater is operating under the control of a

timer program, the timer that is in use is

displayed and the relevant AM or PM ind icator

for the timer flashes. The clock is also displayed.

PREHEAT

This function operates automatically in conjunction with the Timers.

When a Timer is selected, the heater may operate anywhere within

an hour prior to the programmed starting time of a Timer.

This function is called Pre-heat since it ensures the room reaches

the desired temperature by the On Time programmed into the

Timer(s). The room temperature is sensed one hour before the

programmed On Time.

The actual room temperature one hour prior to the programmed

starting time of a timer combined with the data from previous

operation governs exactly how long before the programmed On

Time the micro-computer will ignite the burner.

The heater continues to operate under control of the timers until timers are cancelled.

If the STANDBY/ON button is pressed whilst under control of the timers the heater

will be turned off and the timer programs will not operate.

su

ii:2i

pm

timer on

GAS ECON

weehen0

AM PM

AUTO OFF

12

8

14

12

14

19

8

WE

ii:2i

pm

timer on

GAS ECON

weehen0

AM PM

AUTO OFF

21

19

1

19

21

WE

ii:2i

pm

timer on

GAS ECON

weehen0

AM PM

AUTO OFF

21

19

2

19

21

WE

ii:2i

pm

timer on

GAS ECON

weehen0

AM PM

AUTO OFF

21

19

3

19

21

WE

1ii:2i

pm

timer on

GAS ECON

AM PM

AUTO OFF

19

8

4

19

8

TH

1 9:42

pm

timer on

GAS ECON

AM PM

AUTO OFF

2122

2

5

21

22

NOTE

Page 14

Rinnai Australia 11 Ultima II Operation Manual

LOCK AND OTHER SAFETY DEVICES

USING THE OVERRIDE FUNCTION

This function is used to manually override the current

timer controlled operation of the heater.

For example:

If the heater is between the finishing and starting times of a tim er pr ogram an d the Overrid e b utton is

pressed the OVERRIDE indicator will illuminate (if the digital display is blank press the

Override button twice) and the heater will begin to operate and heat the room until the next timer

off operation is reached.

If the heater is between the starting and finishing times of a tim er pr ogr am an d the Over ride b utton is

pressed the OVERRIDE indicator will illuminate and the heater will stop heating the room until

the next timer on operation is reached.

To cancel override and to return to Timer operation press the Override button again. The Override

indicator will go out.

USING THE LOCK FUNCTION

The Lock function avoids accidental operation and

prevents small children from altering settings.

To Activate the Lock

To activate the Lock function press both the Up and Down buttons simultaneously for 3 seconds.

The function is activated immediately and the Lock indicator will be illuminated.

To Deactivate the Lock

To deactivate the Lock function press both the Up and Down buttons simultaneously for 3 seconds.

The Lock indicator will go out to show that the Lock function is no longer active. The Lock function

can be deactivated at any time in this manner.

SAFETY DEVICES

Overheat switches

If various critical components of the heater get too hot during operation these devices turn the gas off

automatically.

Electrical fuse

The electrical circuits are protected by a fu se.

Flame failure sensor

This device automatically cuts off the gas supply to the heater in the event of a gas failure.

Power failure

In the event of a power failure or power cut, the gas valves will automatically close.

If the STANDBY/ON button is pressed the heater will be turned off and the timer

programs will not operate.

If the Lock function is activated whilst the heater is in operation or in Timer mode, all

controls other than the ability to switch the appliance OFF with the STANDBY/ON

button will be locked until the Lock is deactivated. Timer operation will not be

affected.

If the lock function is activated whilst the appliance is in the off position, all controls

will be locked until the Lock function is de-activated.

If the appliance is switched off whilst the Lock function is activated, all controls will

be locked until the Lock function is de-activated.

Lock programming (activated or de-activated) is stored in the appliance memory.

Unplugging the appliance from the power supply has no effect on Lock prog ramming.

su

ii:22

pm

OUERI E

GAS ECON

AM PM

AUTO OFF

2

9

1218

8

23

23

18

23

23

18

23

18

NOTE

su

ii:2i

pm

timer on

GAS ECON

weehen0

AM PM

AUTO OFF

2

9

25

9

25

9

25

NOTE

Page 15

Rinnai Australia 12 Ultima II Operation Manual

CARE AND MAINTENANCE

Your heater needs very little maintenance, but the following information will help you to keep it looking

good and working efficiently.

CLEANING FILTERS, GRILLES AND LOUVRES

The burner filter , air inlet louvre , warm air discharge louvre and thermistor grill cover must

be kept clear of dust or other obstructions.

Dust contamination of these parts reduces the heating effectiveness of the appliance and may require

cleaning at least once a week during the heating season to prevent blockages.

SERVICE

Rinnai recommend that this appliance and installation be inspected and serviced every 2 years.

If the power supply cord or any other component of the heater are damaged, they must be replaced

by Rinnai or a suitably qualified person.

Any service or repair work should only be carried out by an authorised person. Rinnai has service and

spare parts departments nationally see back cover for contact details.

Unplug before cleaning.

All parts of the heater can be cleaned using a soft, damp cloth.

DO NOT use solvents to clean any parts.

DO NOT spray aerosols in the vicinity of the heater whilst in operation.

DO NOT place articles on or against this heater.

DO NOT store flammable materials near this heater.

DO NOT wait for FILTER indicator to

illuminate on the display of the control panel

on before cleaning these areas.

DO NOT use the heater with the FILTER

indicator illuminated. This may cause

the appliance to overheat.

Service calls for general cleaning, maintenance and wear and tear are not necessarily

covered under the warranty. Service calls of this nature may be chargeable.

IMPORTANT

345

6

6

14

5

3

7

IMPORTANT

su

i0:30

am

timeroff

GAS ECON

weehen0

AM PM

AUTO OFF

24

24

1

24

NOTE

Page 16

Rinnai Australia 13 Ultima II Operation Manual

CARE AND MAINTENANCE

TROUBLE SHOOTING CHECKLIST

Use the following chart to help determine whether a service call is required, however if you are unsure

about the way your heater is operating, contact Rinnai or your local agent.

ERROR CODES

Your heater is also fitted with self diag nostic electronics that monitor the appliance

during start-up and operation. Should a fault occur the heater will shut down and

the cause fault will be indicated by a pair of flashing digits in the Digital display

and the On/Combustion indicator will also flash Red. Refer to the table below

for probable cause and the suggested remedy.

Fault

Condition

Probable

Cause

No Display

Burners fail to ignite

Filter Indicator

is illuminated

Combustion stops

during operation

Smell of gas

Takes a long time to

warm the room

Possible Remedy

Not plugged in or turned off. Plug in power cord and turn power on.

Mains power failure. Re-ignition, when power restored, page 5.

(Initial Install) Air in gas pipe. Installer to purge air from gas supply.

Dust on air filters. Clean the air filters (Weekly).

Room too large. Check with retailer.

Air filter blocked. Clean the air filters (Weekly).

Louvre obstructed. Remove obstruction

Gas supply turned off. Turn gas supply on at the meter or cylinder.

Gas escape. Isolate gas supply, call Rinnai service.

On Timer is set. Cancel timer by using the override page 11.

Lock set. Cancel Lock as described on page 11.

Code Probable Cause Suggested Remedy

-:- - Power Failure Press the ON/OFF button 2 twice to reset the heater.

00 Power Outage As above.

11 Ignition Failure

Check gas supply is turned on, turn the heater OFF and

then ON again. If the heater fails to ignite after 4 attempts

a Service Call will be required.

12 Flame Failure As above.

14 Overheat

Clean air inlet. If error continues a Service Call will be

required.

16 Room Overheat Lower room temperature to below 40°C.

31 Room temperature Sensor Faulty Service Call.

33 Overheat Temperature Sensor Faulty Service Call.

35 Flue Temperature Sensor Faulty Service Call.

53 Sparker Failure Service Call.

61 Combustion Fan Failure Service Call.

70 ON/OFF Switch Faulty Service Call.

71 Solenoids Faulty Service Call.

72 Flame Rod Faulty Service Call.

90

Flue Blockage / Exhaust temperature

high

Service Call.

8

11

11

8

Page 17

Rinnai Australia 14 Ultima II

NOTES

Page 18

Rinnai Australia 15 Ultima II Installation Manual

GENERAL - INSTALLATION ................ ... .... ... ... ... ... .... ... ... ... .......................................... .... ... ... .......... 16

MAIN POINTS GOVERNING HEATER LOCATION............................................................................................. 16

UNPACKING THE APPLIANCE ........................................................................................................................... 16

ELECTRICAL SUPPLY................. ... ..................................................................................................................... 16

INBUILT INSTALLATION, MASONRY FIRE PLACE ......................................................................... 17

CHECK FLUEWAY ............................................................................................................................................... 17

FIT FLUE SPIGOT................................................................................................................................................ 17

GAS INLET UNION............................................................................................................................................... 17

REMOVE GAS INLET UNION FROM HEATER................................................................................................... 18

GAS CONNECTION POSITION ........................................................................................................................... 18

RUN GAS SUPPLY............................................................................................................................................... 18

INSTALL THE HEATER........................................................................................................................................ 19

INSTALL RADIANTS .................................... .. ................................ .. ... ... .. ............................................................ 19

CHECK FOR GAS ESCAPES ..... .................................. .................................. ... ................................................. 19

CLOSE GAS SUPPLY COVER ........................................................................................................................... 19

INSTALL COWL ........................ ... ... .. ... .. .............................................................................................................. 19

TEST APPLIANCE ............................................................................................................................................... 19

INSTRUCT CUSTOMER ..................................................................................................................................... 19

CONSOLE INSTALLATION, CAVITY TWIN SKIN FLUE .................................................................. 20

CUT OPENING IN WALL...................... .. ................................... .................................. ......................................... 20

RUN GAS SUPPLY............................................................................................................................................... 20

CUT AWAY THE TOP PLATE AND ANY NOGGINS BETWEEN STUDS ........................................................... 20

LOWER TWIN SKIN FLUE DOWN CAVITY......................................................................................................... 20

INSTALL FLUE SUPPORT.......................................... ... ... .. ... .............................................................................. 20

FIT SEALING PLATE............................................................................................................................................ 20

FIT RECTANGULAR TO ROUND ADAPTOR...................................................................................................... 21

GAS INLET UNION............................................................................................................................................... 21

REMOVE GAS INLET UNION FROM HEATER .................................................................................................. 21

GAS CONNECTION POSITION .......................................................................................................................... 21

INSTALL HEATER .. ... .. ... .. ................................ ... .. ... .. ................................ ... .. ... .. ............................................... 22

INSTALL RADIANTS ... ........................................................................................................................................ 22

CHECK FOR GAS ESCAPES ..... .................................. .................................. ... ................................................. 22

CLOSE GAS SUPPLY COVER ........................................................................................................................... 22

TEST APPLIANCE ............................................................................................................................................... 22

INSTRUCT CUSTOMER ..................................................................................................................................... 22

CONSOLE INSTALLATION, MASONRY FIRE PLACE ..................................................................... 23

PREPARE FIREPLACE........................................................................................................................................ 23

INSTALL COWL......................... ... ... .. ... .. .............................................................................................................. 23

GAS INLET UNION............................................................................................................................................... 23

REMOVE GAS INLET UNION FROM HEATER................................................................................................... 24

GAS CONNECTION POSITION ........................................................................................................................... 24

RUN GAS SUPPLY............................................................................................................................................... 24

INSTALL HEATER............................................................................ ... ... .. ... ......................................................... 25

INSTALL RADIANTS .................................... .. ................................ .. ... ... .. ............................................................ 25

CHECK FOR GAS ESCAPES ..... .................................. .................................. ... ................................................. 25

CLOSE GAS SUPPLY COVER ........................................................................................................................... 25

TEST APPLIANCE ............................................................................................................................................... 25

INSTRUCT CUSTOMER ..................................................................................................................................... 25

INBUILT / CONSOLE COMMISSIONING ........................................................................................... 26

INBUILT / CONSOLE BURNER PRESSURE SETTING .................................................................... 27

PRODUCT SPECIFICATIONS ............................................................................................................................ 28

DIMENSIONS ...................................................................................................................................................... 28

CONTACT INFORMATION................................................................................................................. 29

INSTALLATION

Page 19

Rinnai Australia 16 Ultima II Installation Manual

GENERAL - INSTALLATION

The following pages contain information relating to Installati on and Service. Failure to

comply with these instructions could result in a fire or explosion, which could cause

serious injury, death or property damage.

Improper installation, adjustments, service or maintenance can cause serious injury,

death or property damage. Such work must be performed by an authorised person.

• The appliance must be installed in accordance with the local gas and electrical

authority regulations.

• This appliance must not be installed where curtains or other combustible materials

could come into contact with it. In some cases curtains may need restraining.

• This appliance discharges a large vo lu me of wa rm air

at low level to provided even heat distribution.

• Some nylon carpets contain dyes which may be

affected by the warm air flow.

• Heat emanating from the front of this appliance may

over time affect the appearance of some materials

used for flooring such as carpet, vinyl, cork or timber .

This effect may be amplified if the air in the room

contains cooking vapours or cigarette smoke. To

avoid this possibility, it is recommended that a ma t be

placed in front of the appliance, extending at least

750 mm in front of it.

• If the supply cord is damaged or requires replacing, it must be replaced by the

manufacturer or the manufacturer's agent or similarly qualified person in order to

avoid a hazard.

1. MAIN POINTS GOVERNING HEATER LOCATION

i. Suitable Installation Type

• Ultima II Inbuilt: Suitable for masonry fireplace installations ONLY!

• Ultima II Console: Suitable for a masonry fireplace installation, or against a wall using a twin skin flue

in the wall cavity.

Ultima II Console and Inbuilt models are NOT SUITABLE for ‘built in’ installations

other than a masonry fireplace as described in this manual. They are not suitable for

installation into non masonry or ‘false’ fireplaces, bookcases or shelves.

ii. Flue connection and cowl to comply with AS/NZS 5601.

iii. Warm air distribution.

iv. Ensure that the area in which the appliance is installed has adequate fixed ventilation, this fixed

ventilation must be provided in accordance with AS/NZS 5601.

2. UNPACKING THE APPLIANCE

• Undo straps.

• Lift carton off heater, never lift heater out of carton by top louvres.

• Check for damage. If the heater is damaged, contact your supplier for advice.

• Before installing this appliance, check it is labelled for the correct gas type (see label on rear of heater).

Refer to local gas authority for confirmation of gas type if you are in doubt.

• For the Ultima II Inbuilt model only, before installation, remove & discard the triangular packing bracket s

from rear top of the front casing.

The following additional items should be included in the carton:

• Radiants (2 packs of 3)

• Flue spigot and screws

• Foam sealing strip (Inbuilt only)

• Rear Cover and screws with wall brackets (Console only).

3. ELECTRICAL SUPPLY

The heater has a power cord with a three pin plug supplied.

Rinnai recommends that the heater be plugged into a 240V, 10A

earthed power point. The power point must be a minimum of

300mm to the side of the heater (it must not be above the heate r).

Alternatively - heater can be direct wir ed if the power supply is to be concealed. Consult a qualified

electrician if direct wiring is required as it must comply to AS/NZS 5601 and AS/NZS 3000.

WARNING

IMPORTANT

150mm

1000mm

150mm

150mm

The above diagram shows the clearances required

around this heater whilst in operation

IMPORTANT

Heater

1500mm

(300mm Min)

Power

Point

Wall

Page 20

Rinnai Australia 17 Ultima II Installation Manual

INBUILT INSTALLATION, MASONRY FIRE PLACE

1. CHECK DIMENSIONS OF FIREPLACE

Masonry Fireplace Dimensions

Width

710 mm minimum

805 mm maximum

Height

605 mm minimum

635 mm maximum

Depth

330 mm minimum

2. CHECK FLUEWAY

• Remove damper plate/baffle - Any damper plate or

baffle which has been installed in the chimney shall

be removed.

• Check flueway is clear of obstructions.

• Check dimensions of fireplace and if necessary

remove any protruding brickwork to give 75 mm

minimum clearance from flue spigot.

• Provide a firm, flat and sealed base for heater. A

rough base may cause rattles and affect

performance.

• Check that there are no unwanted holes or

openings in fireplace. If so these must be sealed.

• The chimney must be confirmed free of soot and

creosote that may have built up if previously used

for a solid fuel fire. Before installing the heater,

inspect the chimney, flue piping and/or solid fuel

burning fire place and remove any combustible

materials.

• A gas appliance must not be connected to a

chimney flue serving a separate solid-fuel burning

appliance.

• Peel protective backing off the foam strips supplied

with the heater.

• Attach strips supplied with the heater. The strip is

intended to form a seal between the heater and

fireplace. If an adequate seal cannot be formed

with this strip another means of sealing must be

used (e.g. fibreglass batts), between the fireplace

and the heater body.

3. FIT FLUE SPIGOT

• The flue spigot is packed separately in the carton.

• It must be fitted to all models, inbuilt and console.

4. GAS INLET UNION

• For ease of connection a combined gas inlet union/

copper elbow is provided with every heater. It is

situated at the bottom right hand side below the

control.

w

d

h

w

h

d

Page 21

Rinnai Australia 18 Ultima II Installation Manual

INBUILT INSTALLATION, MASONRY FIRE PLACE

5. REMOVE GAS INLET UNION FROM HEATER

• The inlet union/elbow should be fitted to the end of

the copper supply tube before installing the heater

in the fireplace opening.

For access to union:

• Remove bottom louvre panel, 2 screws in the lower

right and left hand corners of louvres.

• Remove upper front panel, 2 screws at the bottom

right and left hand edges of the panel.

• Lift panel to disengage top and remove from heater .

• Do not lift the panel by the dress guard or top

louvres.

• Remove union.

• Ensure that removal and replacement of the bottom

panel is not obstructed by carpet etc.

6. GAS CONNECTION POSITION

• Drawing is viewed from rear of heater .

• Actual connection is on right hand side when

viewed from front.

• Dimensions are to the centre of the flare fitting on

the inlet elbow/union. Flare fitting suits 15 mm

copper tube.

7. RUN GAS SUPPLY

• Refer to AS/NZS 5601 or other approved pipe

sizing chart if in doubt about size of gas line.

• Copper supply should be run leaving a flare

connection the position shown.

• Connect the union/elbow fitting to the copper

supply with the union nut facing upwards.

• Purge supply of air and swarf.

• All foreign materials such as filings must be purged

from the gas supply, as they could cause the gas

valve to malfunction.

Don’t forget to put flare nut on tube before flaring.

Gas pipe sizing must consider the gas input to this appliance as well as all other

gas appliances in the premises. The gas meter and regulator must be specified for

the total gas rate. Suitable sizing chart such as the one in AS/NZS 5601 should be

used.

NOTE

IMPORTANT

Page 22

Rinnai Australia 19 Ultima II Installation Manual

INBUILT INSTALLATION, MASONRY FIRE PLACE

8. INSTALL THE HEATER

• Feed the copper tube through the supply access

opening.

• Connect and tighten gas supply union.

• Secure heater to fireplace, there are pre-drilled

holes in the heater flanges.

• Drill additional holes if the existing ones are not in

suitable positions.

9. INSTALL RADIANTS

• Remove glass panel, install radiants as shown.

• Replace glass panel.

10. CHECK FOR GAS ESCAPES

• Use a manometer or soapy water.

•

DO NOT USE A NAKED FLAME.

11. CLOSE GAS SUPPLY COVER

• This seals the heater from the chimney and prevents

chimney draughts affecting the performance of the

heater, as well as preventing the entry of debris from

the chimney.

12. INSTALL COWL

• A cowl certified for gas appliances must be installed

on all chimneys.

• Clearances to conform with AS/NZS 5601. The

minimum clearance between top of chimney and

the lowest opening in the flue cowl is 200 mm as

shown.

• Size:100 mm.

13. TEST APPLIANCE

• See page 26.

14. INSTRUCT CUSTOMER

• Instruct customer on operation and servicing of the

appliance.

• Remind customer of dress guard requirements.

Page 23

Rinnai Australia 20 Ultima II Installation Manual

CONSOLE INSTALLATION, CAVITY TWIN SKIN FLUE

1. GENERAL

• Depth of cavity wall must be at least 75 mm.

• Select position of heater and locate studs. There

must be a minimum distance of 345 mm and a

maximum distance of 550 mm between studs.

• Ensure ceiling and roof structure will not obstruct

flue.

2. CUT OPENING IN WALL

• The wall box measures 330 mm x 100 mm but the

opening required is 335 mm x 160 mm. This is to

allow for ventilation around the wall box.

• Failure to cut the correct sized hole may lead to

excessively high wall temperatures.

3. RUN GAS SUPPLY

• The gas supply should be run before installing the

heater. The easies t way is to run the supp ly, leaving

the end of the copper flare as shown in the

diagrams, then attach the elbow / union to the

copper supply when the heater is installed.

• Refer to an approved pipe sizing chart such as the

one in AS/NZS 5601 ‘Gas Installations’ if in doubt

about size of supply pipe.

4. CUT AWAY THE TOP PLATE AND ANY NOGGINS BETWEEN STUDS

Fit flue housing into prepared opening:

• Tabs should be fitted tightly against the plaster

board.

• Drill through flanges at stud centres and fix to wall

with 4 screws.

• The housing must be secured to the studs to allow

the outlet to protrude back into the cavity, giving the

twin skin flue a minimum clearance from plaster

board of 10 mm, excluding spacers.

5. LOWER TWIN SKIN FLUE DOWN CAVITY

• Straighten tabs at bottom of twin skin flue assembly

and lower down wall cavity to housing.

• Insert tabs in slots in housing then bend tabs to

secure flue to housing.

6. INSTALL FLUE SUPPORT

• Drop top plate flue support over top of flue, position

centrally in space between studs and secure

support in position.

7. FIT SEALING PLATE

• If flue protrudes more than 65 mm above top plate,

adaptor supports must be screwed to the flue, and

positioned so that when the sealing plate is fitted it

is 50 mm from the top of the flue.

Page 24

Rinnai Australia 21 Ultima II Installation Manual

CONSOLE INSTALLATION, CAVITY TWIN SKIN FLUE

8. FIT RECTANGULAR TO ROUND ADAPTOR

• Fit adaptor to top of twin skin.

• Fit 100 mm flue and approved cowl.

• Flue termination above the roof must comply with

AS/NZS 5601.

• Locate the longer end inside the aluminium liner of

twin skin.

• Position elbow into housing.

• The flue must be supported independently of the

heater to comply with AS/NZS 5601.

• Attach loosely to housing with screw provided.

• Measure distance from floor to flue outlet.

• Adjust elbow to these dimensions, tighten screw.

• Fit right and left hand rear covers to Heater.

• Place top spacer (cover) in position temporarily for

wall marking.

• Remove front cover and inlet union.

9. GAS INLET UNION

• For ease of connection a combined gas inlet union/

copper elbow is provided with every heater. It is

situated at the bottom right hand side below the

control.

10. REMOVE GAS INLET UNION FROM HEATER

• The inlet union/elbow should be fitted to the end of

the copper supply tube fore installing the heater in

the fireplace opening.

For access to union:

• Remove bottom louvre panel, 2 screws in the lower

right and left hand corners of louvres.

• Remove upper front panel, 2 screws at the bottom

right and left hand edges of the panel.

• Lift panel to disengage top and remove from heater .

• Do not lift the panel by the dress guard or top

louvres.

• Remove union.

• Ensure that removal and replacement of the bottom

panel is not obstructed by carpet etc.

11. GAS CONNECTION POSITION

• Drawing is viewed from rear of heater .

• Actual connection is on right hand side when

viewed from front.

• Dimensions are to the centre of the flare fitting on

the inlet elbow/union. Flare fitting suits 15 mm

copper tube.

Page 25

Rinnai Australia 22 Ultima II Installation Manual

CONSOLE INSTALLATION, CAVITY TWIN SKIN FLUE

12. INSTALL HEATER

• Mark position of top of spacer on wall.

• Fit wall clips.

• Feed the copper tube through the supply access

opening.

• Install heater, ensure spigot is correctly engaged

into elbow.

• Replace top spacer, clipping the spacer into the

wall brackets at the same time as attaching it to the

heater.

• Secure top spacer with the four screws provided.

• The heater is now secured to the wall.

13. INSTALL RADIANTS

• Remove glass panel, install radiants as shown.

• Replace glass panel.

14. CHECK FOR GAS ESCAPES

• Use a manometer or soapy water.

•

DO NOT USE A NAKED FLAME.

15. CLOSE GAS SUPPLY COVER

• This seals the heater from the chimney and prevents

chimney draughts affecting the performance of the

heater, as well as preventing the entry of debris from

the chimney.

16. TEST APPLIANCE

• See page 26.

17. INSTRUCT CUSTOMER

• Instruct customer on operation and servicing of the

appliance.

• Remind customer of dress guard requirements.

Page 26

Rinnai Australia 23 Ultima II Installation Manual

CONSOLE INSTALLATION, MASONRY FIRE PLACE

1. GENERAL

• In this type of installation the fireplace is closed off

with fireproof material. The heater is placed against

the fireproof material and a hole is cut for

penetration of the flue spigot into the fireplace.

• The flue spigot must have an extension added to

extend beyond overhead brickwork.The extension

must be constructed so that it prevents falling

debris entering the flue spigot. Cutting the end of

the spigot at a 45 degree angle facing downwards

will achieve this.

• The spigot extension must not be extended so far

into the chimney as to cause an obstruction to the

discharge of flue gases. The minimum clearance

from the end of the spigot extension to any

obstruction is 75 mm.

• Do not install heater below a wooden shelf.

2. PREPARE FIREPLACE

• Remove any damper plates or baffles.

• Check flueway is clear of obstructions.

• Check fireplace dimensions and, if necessary,

remove any brickwork to provide 75mm clearance

between the end of the spigot extension and any

obstruction.

• Check there are no unwanted holes or openings in

the fireplace. If so these must be sealed, so that the

fireplace is in a sound condition.

• The chimney shall be confirmed free of soot and

creosote that may have built up if previously used

for a solid fuel fire. Remove combustible materials

or substances before installing the heater.

• A gas appliance must not be connected to a

chimney serving a separate solid fuel burning

appliance.

• Provide a firm, flat and sealed base for the heater.

A rough or uneven base may cause rattles and

affect performance.

• Close off the fireplace with a fireproof material and

cut hole for flue spigot as shown.

3. INSTALL COWL

• A cowl certified for gas appliances must be installed

on all chimneys.

• Clearances to conform with AS/NZS 5601. The

minimum clearance between top of chimney and

the lowest opening in the flue cowl is 200 mm as

shown.

• Size:100 mm.

4. GAS INLET UNION

• For ease of connection a combined gas inlet union/

copper elbow is provided with every heater. It is

situated at the bottom right hand side below the

control.

Page 27

Rinnai Australia 24 Ultima II Installation Manual

CONSOLE INSTALLATION, MASONRY FIRE PLACE

5. REMOVE GAS INLET UNION FROM HEATER

• The inlet union/elbow should be fitted to the end of

the copper supply tube fore installing the heater in

the fireplace opening.

For access to union:

• Remove bottom louvre panel, 2 screws in the lower

right and left hand corners of louvres.

• Remove upper front panel, 2 screws at the bottom

right and left hand edges of the panel.

• Lift panel to disengage top and remove from heater .

• Do not lift the panel by the dress guard or top

louvres.

• Remove union.

• Ensure that removal and replacement of the bottom

panel is not obstructed by carpet etc.

6. GAS CONNECTION POSITION

• Drawing is viewed from rear of heater .

• Actual connection is on right hand side when

viewed from front.

• Dimensions are to the centre of the flare fitting on

the inlet elbow/union. Flare fitting suits 15 mm

copper tube.

7. RUN GAS SUPPLY

• Refer to AS/NZS 5601 or other approved pipe

sizing chart if in doubt about size of gas line.

• Copper supply should be run leaving a flare

connection the position shown.

• Connect the union/elbow fitting to the copper

supply with the union nut facing upwards.

• Purge supply of air and swarf.

• All foreign materials such as filings must be purged

from the gas supply, as they could cause the gas

valve to malfunction.

Don’t forget to put flare nut on tube before flaring.

Gas pipe sizing must consider the gas input to this appliance as well as all other

gas appliances in the premises. The gas meter and regulator must be specified for

the total gas rate. Suitable sizing chart such as the one in AS/NZS 5601 should be

used.

NOTE

IMPORTANT

Page 28

Rinnai Australia 25 Ultima II Installation Manual

CONSOLE INSTALLATION, MASONRY FIRE PLACE

8. INSTALL HEATER

• Fit right and left rear covers to heater.

• Place top spacer (covers) in position temporarily for

wall marking.

• Attach flue spigot extension to heater.

• Feed the copper tube through the supply access

opening.

• Secure heater to the fireproof material using the

clips in the top spacer (covers).

• Connect and tighten the gas supply .

9. INSTALL RADIANTS

• Remove glass panel, install radiants as shown.

• Replace glass panel.

10. CHECK FOR GAS ESCAPES

• Use a manometer or soapy water.

•

DO NOT USE A NAKED FLAME.

11. CLOSE GAS SUPPLY COVER

• This seals the heater from the chimney and prevents

chimney draughts affecting the performance of the

heater, as well as preventing the entry of debris from

the chimney.

12. TEST APPLIANCE

• See page 26.

13. INSTRUCT CUSTOMER

• Instruct customer on operation and servicing of the

appliance.

• Remind customer of dress guard requirements.

Page 29

Rinnai Australia 26 Ultima II Installation Manual

INBUILT / CONSOLE COMMISSIONING

240V inside heater, risk of electrical shock.

Commissioning

1. After purgin g and clearing supply, connecting gas and testing for escapes, plug the heater into the

power point.

2. Remove test point screw, situated just above the barrel union on the inlet gas connection.

3. Attach manometer to test point.

4. Light the burner (See Customers Instructions page 6).

5. Check the appeara nce of the flame on high and low settings, there should be no flame lift or yellow

flames.

6. With the a ppliance operating on high confirm that incom ing pressure is a least 1.13 kPa for Natural

gas or 2.75 kPa for Propane Gas.

7. Turn the heater off.

8. Remove manometer to test point and replace test point screw.

9. Carefully check for gas escapes around the test point screw.

10.Re-assemble front panels.

11. It is the responsibility of the installer to check that under normal operating conditions of the

appliance, all flue gases are exhausted to the outside atmosphere and that there is no spillage of

combustion gases into the room. Please refer to AS/NZS 5601.

12.If you are unable to get the heater to work correctly, contact Rinnai o r your agent. Check “ERROR

CODES” on page 13.

13.Explain the operation and features of this applia n ce to the custo m er .

14.Explain the requirement to have the secondary guard fitted at all times to minimise the risk of injury

from burns.

15.Also explain that a secondary guard is recommended for addition al protection to the young or the

infirm.

16.Explain the requirement for regular cleaning of air filters and regular servicing by an authorised

person in accordance with these instructions.

CAUTION

Page 30

Rinnai Australia 27 Ultima II Installation Manual

INBUILT / CONSOLE BURNER PRESSURE SETTING

1. With the heater Turned OFF.

2. Remove test point screw , of the gas control .

3. Attach manometer to test point .

4. Opera te the appliance. (Start combustion).

5. Push red test butto n located on the top right hand side of

printed circuit board (PCB) three times. This will force the

burner to the maximum gas rate.

6. Display window should display "PH" (Forced High)

7. Check hig h burner pressure on manometer , for Natural Gas 0.98 kPa and for Propane Ga s 2.15

kPa.

8. If burner pressure requires adjustment, alter burner pressure by pressing the "UP" button on the

display panel to increase the gas pressure, or press the "DOWN" button on the control panel to

decrease the gas pressure.

9. Push the red test button on the PCB twice.

10.Burner will modulate down to a forced low pressure (Low setting mode. 'PL' will be indicated on

the display panel

11.Check low burner pressure on manometer, for Natural Gas 0.26 kPa and for Propane Gas 0.56

kPa.

12.If burner pressure requires adjustment, alter burner pressure by pressing the "UP" button on the

display panel to increase the gas pressure, or press the "DOWN" button on the control panel to

decrease the gas pressure.

13.After checking pressure, turn the heater OFF, remove manometer and replace test point screw.

14.Carefully check for gas escapes around the test point screw.

15.Re-assemble front panels.

16. It is the responsibility of the installer to check that under normal operating conditions of the

appliance, all flue gases are exhausted to the outside atmosphere and that there is no spillage of

combustion gases into the room. Please refer to AS/NZS 5601.

17.If you are unable to get the heater to work correctly, contact Rinna i or your agent. Check “ERROR

CODES” on page 13.

18.Explain the operation and features of this applia n ce to the custo m er .

19.Explain the requirement to have the secondary guard fitted at all times to minimise the risk of injury

from burns.

20.Also explain that a secondary guard is recommended for ad ditional pr otection to the young or th e

infirm.

21.Explain the requirement for regular cleaning of air filters and regular servicing by an authorised

person in accordance with these instructions.

240V inside heater, caution

must be taken to avoid the risk

of electrical shock.

The gas regulator is factory pre-set. Before

making any adjustments to the appliance

regulator, check the supply pressure.

Wait for 70 seconds before proceeding as this

will allow time for the combustion of the

appliance to stabilise.

CAUTION

IMPORTANT

B

A

C

B

A

C

IMPORTANT

Page 31

Rinnai Australia 28 Ultima II Installation Manual

SPECIFICATIONS

PRODUCT SPECIFICATIONS

Model: REH-311FTB INBUILT / REH-311FTC CONSOLE

Name: Ultima II INBUILT / CONSOLE

Rinnai reserves the right to change or modify specifications without notice.

DIMENSIONS

*The total installation depth includes the dress guard and where applicable the rear cover kit.

General description: Rinnai Ultima II

Radiant / Convector, Forced Exhaust, Fully Automatic Space Heater.

Gas input rate: Natural Gas Propane

High (MJ/hr): 30 30

Low (MJ/hr): 15 15

Gas control: Rinnai Electronic control with Rinnai Solenoid Valves

Burners Stainless Steel Ribbon Type

Gas Inlet: Barrel Union / Flare Fitting (15 mm flare connection)

Test Point Pressure: High (kPa) 0.98 2.15

Low (kPa) 0.26 0.56

Flue System: Forced exhaust, for twin skin flue or fireplace installation

Fan: Tangential 3 speed 32 Watt rating

Flue Termination: An approved 100 mm cowl must be fitted to all installations.

Combustion Fan: 2 - pole shaded pole induction motor (with revolution detection)

Sirocco fan (240 V)

Ignition system: Electronic automatic ignition

Power Supply: 240 V / 50 Hz. Heater is fitted with a supply lead and 3 pin plug.

Replace only with Rinnai Part Number 90192303.

Data Plate: Bottom left hand side, behind front panel.

Installation type: Console or Inbuilt

Weight: Console: 41 Kg. / Inbuilt: 38 Kg.

Legend

CONSOLE

A 910 mm C 265 mm E 13.6 mm G 600 mm I 114 mm

K

Total Installed Depth*

B 653 mm D 24 mm F 93 mm H 280 mm J 393 mm 404 mm

INBUILT

A 910 mm C 140 mm E 138.6 mm G 600 mm I 114 mm

K

Total Installed Depth*

B 653 mm D 24 mm F 93 mm H 280 mm J 393 mm 164 mm

AC

D

K

E

JG

H

F

B

CONSOLE

I

F

I

GJ

H

K

C

D

E

INBUILT

Page 32

29 Ultima II OPINST Manual, Issue No.4 / RA 05.013 1/10/12

Head Office

10-11 Walker Street,

Braeside, Victoria 3195

P.O. Box 460

Tel: (03) 9271 6625

Fax: (03) 9271 6622

National Help Line

Tel: 1300 555 545* Fax: 1300 555 655*

*Cost of a local call Higher from mobile or public phones.

Australia Pty. Ltd.

ABN 74 005 138 769

Internet: www.rinnai.com.au E-mail: enquiry@rinnai.com.au

Rinnai has a Service and Spare Parts network with personnel who are fully trained

and equipped to give the best service on your Rinnai appliance. If your appliance

requires service, please call Rinnai. Rinnai recommends that this appliance be

serviced every 3 years.

REH311-114x05 (00)

CONTACT INFORMATION

Loading...

Loading...