Page 1

Flame Fire ETR

Electronic Timer and Remote

Operating and Installation Instructions

Timberflame IB35 ETR - New Zealand

Table of Contents

Customer Instructions

Control Panel Layout 3

Operation 4

Setting the Clock 6

Operating the Timers 7

Error Codes 8

Safety Points 9

Troubleshooting 10

Installation Instructions

Location 11

Flueing 12

Gas Connection 14

Log Installation 15

Testing & Commissioning 16

Technical Data 17

Service Contact Points 17

Wiring Diagram 18

Installation Checklist 20

Installer Details 20

IMPORTANT

This appliance shall be installed in accordance with:

•

Manufacturers Installation Instructions.

• Local Gas fitting regulations.

• Municipal Building codes.

• AGA Gas Installation Code AG601 - NZ 5261.

• Any other relevant statutory regulation.

• Rinnai strongly recommend that this product be installed with an

appproved flue system for optimum product performance.

• This appliance must only be installed, serviced and removed by an

authorised person.

Page 2

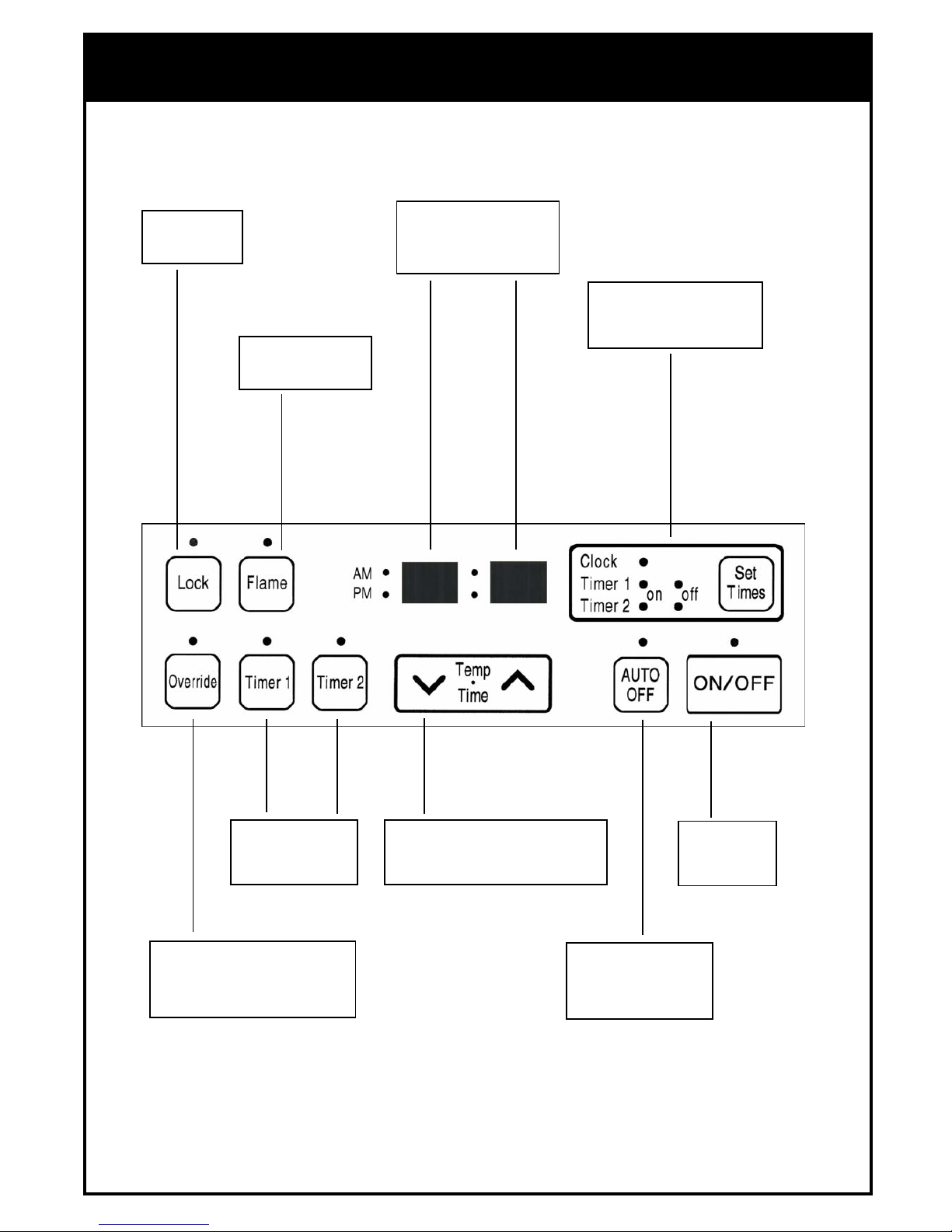

LOCK Button

Indicates lock

function

TIMER Indicator

Indicates that TIMER 1

or TIMER 2 has been

selected to operate.

TIME / TEMP. Adjustment

Increases or decreases the temperature

setting as well as changing

hours or minutes.

ON/OFF Button

Main Switch for

turning ON/OFF.

TIME/TEMP. Display

Shows either the time of day,

temperatures or coded error

messages.

CLOCK ADJUSTMENT AND

TIMER INDICATORS

Indicates that clock or dual timer

programme is being set.

OVERRIDE

Temporarily changes operation from

ON to OFF or OFF to ON, until next

programmed setting is reached.

AUTO OFF

When ON, Thermostat

turns heat down to OFF.

When OFF, Thermostat

turns heat down to LOW.

Flame Function

Med. High heat setting

and overides thermostat

CONTROL PANEL LAYOUT

3

Page 3

• TO OPEN THE CONTROL PANEL

Lift lightly in the centre of the lid where there is a catch. The control panel lid will then open backward to

an angle.

• TURNING ON

Press the ON/OFF button to operate the heater. The ON indicator will glow green. The spark generator will

be heard before the burner ignites and the ON indicator glows red, indicating that the burner is alight.

Warm air can be felt coming from the louvres. The fan will come on automatically after 4 minutes.

• TURNING OFF

Simply press the ON/OFF button to switch off the heater. The ON indicator will go out. The convection fan will

continue to operate for several minutes after the burner has gone out in order to cool the appliance. Do not

unplug the appliance while the convection fan is running.

• ROOM TEMPERATURE ADJUSTMENT

Press the “▲“ button to increase the temperature setting or “▼“ button to decrease the temperature setting.

The temperatures can be preset to: a) [L] low (about 10°C)

b) [16°C] to [26°C] in 1°C steps

c) [H] (continuously high)

• LOCK

To operate the lock simply press the LOCK button. The function is activated immediately and the LOCK

indicator will glow. To deactivate the LOCK simply press the LOCK button for 3 seconds and the LOCK

indicator will go out. The LOCK can be deactivated at any time in this way.

If the heater does not ignite on initial use, this may be due to air remaining in the gas supply line. The

spark generator will only continue for 15 seconds. After this it will be necessary to press the ON/OFF

button OFF, then ON again.

DO NOT turn heater off by unplugging at the power point. The convection fan will continue to run

until the appliance cools.

The room temperature and pre-set temperatures can only be displayed and adjusted when the

heater is running.

If the heater does not ignite then the pre-set temperature may not be set to a setting which is higher

than the room temperature. The ON indicator will change colour from red to green when the heater

reaches the pre-set temperature and stops running.

The LOCK function will help to prevent accidental operation as well as small children from altering

the controls.

During normal operation the LOCK may be activated and all controls, other than the OFF switch, will

be locked. Deactivating the LOCK releases the controls. If the LOCK is activated whilst the heater is

turned OFF, then all functions will be locked. If the heater is turned OFF while the LOCK is activated,

it cannot be turned ON again until the LOCK is deactivated.

• FLAME

To operate the Flame function, simply press the FLAME button. This function will automatically override

the thermostat and set the heater to a default Medium High heat setting for full visual flame effect.

• AUTO OFF

To operate the Auto Off function, simply press the Auto Off button.

When the Auto Off function is ON, the indicator light will flash and the thermostat will turn the burners

down to the OFF heat setting.

When the Auto Off function is OFF, the indicator light will go Off and the thermostat will turn the burners

down to the LOW heat setting.

OPERATION

4

Page 4

To operate the OVERRIDE simply press the OVERRIDE button. The OVERRIDE indicator will flash.

To manually deactivate the OVERRIDE simply press the OVERRIDE button again. The OVERRIDE indicator

will go out, and the heater will return to standby mode.

This function is intended to be used to manually override the current operation of the heater. For

example; If the heater is in standby mode (ie. between finishing time and starting time of a Timer),

and the OVERRIDE button is selected, then the heater will begin to operate and heat the room.

The heater will continue to operate on OVERRIDE until the OVERRIDE button is pressed again, or

one of the Timers takes over the operation of the appliance. This means that the OVERRIDE mode

will automatically drop out if a programmed starting time is reached. The appliance will then return to

operating at times programmed into the Timer(s).

• OVERRIDE

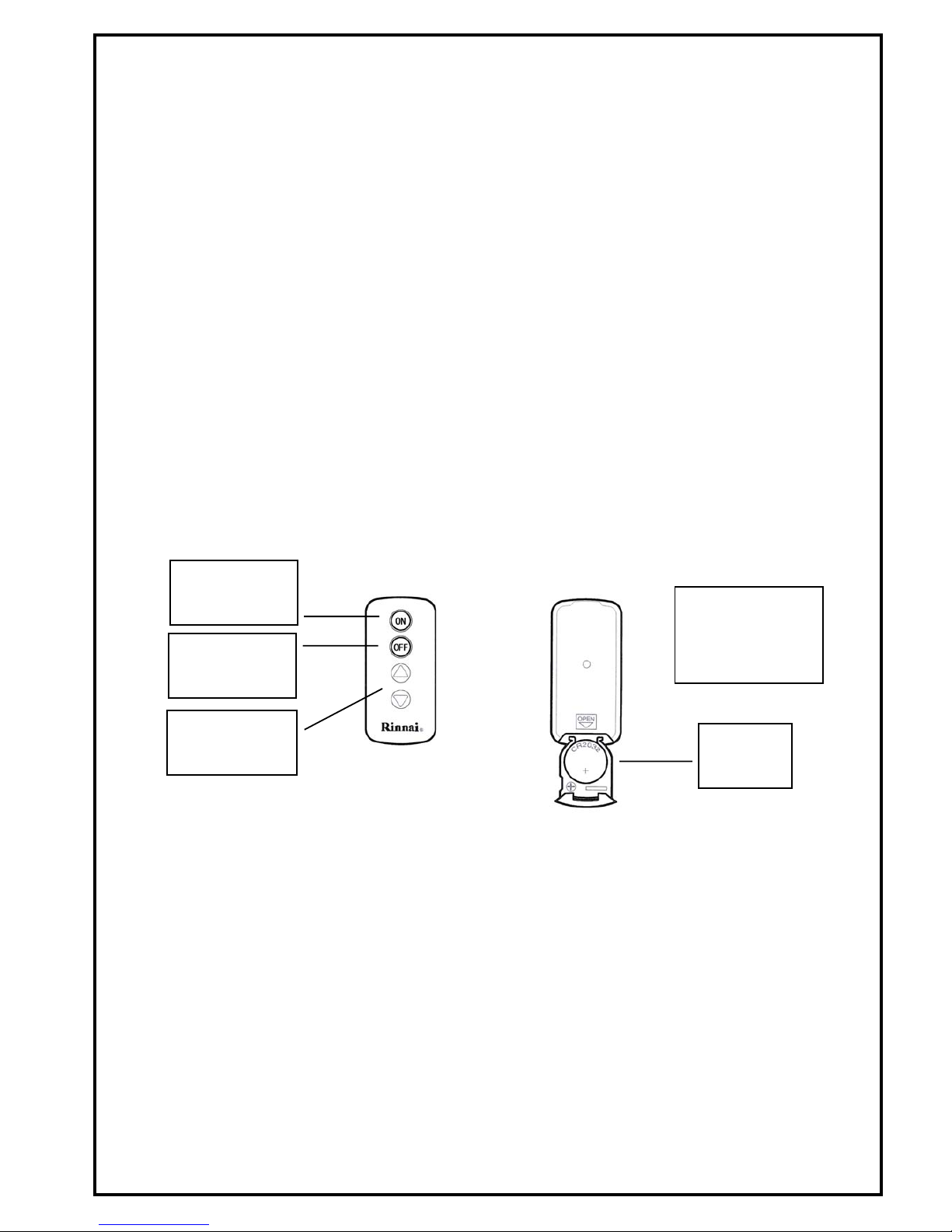

• REMOTE CONTROL

To manually operate when Timer(s) are not selected, simply press the ON or OFF button.

To alter the temperature at anytime while the heater is operating, simply press the “▲“ or “▼“ buttons.

Remote Control will not turn heater ON if Timer(s) have been selected.

ON BUTTON

Operates the heater

manually.

OFF BUTTON

Stops heater

manually.

TEMPERATURE

ADJUSTMENT

Increases or decreases

the temperature setting.

TO REPLACE

BATTERY

Simply open the back of

the remote control and

replace Lithium battery.

TYPE: CR 2032

BATTERY

Power source

for operating

remote control

Some fluorescent lights may interfere with the transmission of remote control signals, in this case changing

the position from which you are operating the remote control may help.

Avoid getting the remote control wet, or dropping it.

The remote control works within 5 metres and an angle of 40° to the receiver on the heater.

Only use the battery type specified. (CR2032).

Remove battery if control is not going to be used for a long period. This will help avoid damage from

leaking batteries.

If the Timer(s) have been selected, and the heater is in standby mode, and the OFF button on the

Remote Control is pressed, the Timer(s) will be deactivated.

5

Page 5

pTR

Press and hold the “▲“ button; the minutes will begin to change first, then the time will change by whole

hours.

Release the button when AM 10:00 shows on the Digital Display. Confirm that you have selected AM, a small

indicator on the left hand side of the Digital Display indicates the AM setting.

Press and hold the “▲“ button again, release the button when AM 10:35 shows. If you go past AM 10:35, then

the “▼“ button can be used to change the time settings in reverse.

Press the Timer Set button five times to lock in and complete setting the time. The Clock and Timer indicators

will go out. A small indicator on the Digital Display will flash to show that the clock is operating.

• SETTING THE CLOCK

When the appliance is first plugged in or after a power failure, the Digital Display will show --:--

As an example, let’s set the clock to 10:35 am:

Press the SET TIMES button once, the Clock indicator will flash.

As an example, let’s program Timer 1 to heat the room by 7:10am and finish at 9:00am.

Press the Set Times button twice. The Digital Display will show AM 6:00. Timer 1 indicator will flash.

Press the “▲“ button until AM 7:00 appears, release the button, then press it again until AM 7:10 appears.

(Press the “▼“ button if you go past AM 7:10.)

Press the Set Times button again, the Timer 1 OFF indicator will flash. Press the “▲“ button until AM 9:00

appears. (Press the “▼“ button if you go past AM 9:00.)

Press the Set Times button three times to lock in the program time. The Digital Display will show the current

time. A small indicator on the Digital Display will flash to show that the Display has returned to the clock.

Before programming the Timers you must ensure that the clock has been set to the correct time.

Timer 2 is programmed in the same way, remember to ensure that the Timer 2 indicator is flashing

when you program in the desired setting. The Timers can be programmed to operate for any two

periods in any 24 hours.

Turn to the next page to operate the dual timer. The programmed time must be selected and

locked-in within one minute of the On Timer indicators flashing otherwise the programmed times will

not be retained in the system memory.

• PROGRAMMING THE ON / OFF TIMERS

SETTING THE CLOCK

6

Page 6

To select the Timer(s) to commence heating.

Check the time shown on the Digital Display is correct.

Check the ON and OFF times, for both Timers if necessary.

Press the ON/OFF button to operate the heater. The ON indicator will glow green and the heater will begin to

operate.

Select the desired temperature setting.

Press the Timer 1 and/or Timer 2 button(s). The timer indicator(s) will glow and the heater will remain on

standby until one hour prior to the time programmed into the selected Timer(s) is reached. When this time is

reached, the Timer indicator will flash and the heater will operate. The ON indicator glows red when the

heater commences operation.

• SET AND FORGET OPERATION

Your heater can be operated to alternate between Timers automatically during cold weather by selecting

Timer 1 and Timer 2 together. Both Timer indicators will glow. The appliance will remain on standby at intervals

between the programmed finishing and starting times of each Timer. While the heater is operating during

programmed intervals the Timer indicator will flash.

Before operating the Timer(s), the clock time must be correct and a starting time and finishing time

for the Timer(s) must be programmed. See page 5. The two Timers operate in the same way. This

heater does not commence operation at the programmed starting time. It will attempt to heat a room

by the programmed starting time. See Pre-heat page 6, for further explanation.

If there is a power failure, the system memory will retain the Timer programs, and the clock will stop

at the time the power goes off. The clock will start again when the power comes back on, but the time

will be slow by the duration of the power failure. To set the clock to the correct time after the power

has come back on, simply follow the instructions on page 5.

• PREHEAT

This function operates automatically in conjunction with either of the timers. When a timer is selected, the

heater may operate anywhere within an hour prior to the programmed starting time of the timer.

The preheat function will attempt to preheat the room by the programmed ON time.

This function is called pre-heat due to the way it operates. The room temperature is sensed one hour before

reaching the programmed time of either timer.

The temperature differential at the time of sensing the room governs how long before the program ON time

the microcomputer will operate the heater and ignite the burner.

OPERATING THE TIMERS

7

•

OPERATING THE TIMERS

Page 7

• ERROR CODE MESSAGE

The Flame Fire ETR has the ability to check its own operation continuously. If a fault occurs, an Error

Message will flash on the Digital Display of the control panel. This assists with diagnosing the fault, and may

enable you to overcome a problem without a service call. Please quote the code displayed when enquiring

about service.

Error Code Probable Cause

Comments

Ignition Failure

Check gas is turned on.

Service call if repeated.

Flame Failure

Check gas is turned on.

Service call if repeated.

1 2

1 4

Overheat

Service call.

1 6

Room Overheat

Lower room temperature

to less than 40ºc.

3 1

Room temperature

Sensor Faulty

Service call.

Overheat temperature

Sensor Faulty

3 2

Room temperature

Sensor Faulty

Service call.

3 3

Service call.

7 0

Faulty ON / OFF Switch

Service call.

7 1

Faulty Solenoids

Service call.

7 2

Faulty Flame Rod

Service call.

7 3

Communication error

Turn heater OFF,

then ON again.

9 9

Flue Block

Service call.

--:--

Power Failure

Turn heater OFF,

then ON again.

ERROR CODES

1 1

8

In all cases, you may be able to clear the Error Message simply by turning the heater OFF, then ON again. If

the Error Message still remains or returns on the next operation, please contact your nearest service contact

and arrange for a service call.

Page 8

Do not restrict the warm air discharge by

placing articles in front of the heater.

This appliance must not be used for any purpose other than heating.

Do not spray aerosols whilst the heater is

operating. Most aerosols contain butane gas,

and can be a fire hazard if used near the heater

when it is in use.

Young children should be supervised at

all times. Hand or body contact with the

louvres should be avoided.

Do not allow young children or the infirm to sleep

directly in front of the heater.

Do not allow anyone to sit on or lean

against the appliance.

Do not allow anyone to post articles

through the louvres.

Do not allow curtains or other flammable

or combustible materials to come into

contact with the heater.

SAFETY POINTS

DO NOT PLACE ARTICLES ON OR AGAINST THIS APPLIANCE.

DO NOT USE OR STORE FLAMMABLE MATERIALS NEAR THIS APPLIANCE.

DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE WHILST

IT IS IN OPERATION.

9

Page 9

• NOTE

If you have any other faults or problems, please refer to your Installer.

• OUTER CASE

The outer case of the heater should be cleaned with a soft, damp cloth.

Do not use aerosol polishes to clean the casing while the heater is in operation.

• CLEANING INSTRUCTIONS.

Before cleaning, ensure the power and gas are turned off and that the heater has cooled down.

Do not remove any internal wiring covers.

Use only non-abrasive cleaners.

Do not use solvent based cleaners.

• GLASS CLEANING

After a period of use the glass panel may require cleaning. When your heater is cold, refer to Page 12 and

follow the initial log installation instructions to remove side panels and glass for cleaning purposes.

TROUBLESHOOTING

10

SYMPTOM CAUSE

SOLUTION

Burner will not light No power present

No gas present

Power cut

Air in gas pipe

Ignition Failure

Ensure power cord is plugged in

and turned on

Ensure gas supply is turned on

Re-ignite after power is restored

Purge air (installer)

Repeat lighting procedure

(refer page 3)

Smell of gas

Leaking gas Turn gas off at meter and

call installer

Fan not working

Heat switch not activated

Fan not turned on

Allow heater to run on HIGH

for 15 minutes minimum.

Ensure appliance fan switch

is in ON position

Severe soot deposit

forming on Glass or

Logs

Inadequate Flue System

Log Misalignment

Incorrect Gas Pressure

Condensation on Glass Normal operation

Allow heater to warm up

Streaky lines on Glass Normal operation

Remove and clean Glass

Call Rinnai Service Dept./Agent

Digital Error Message

on Control Panel

Electronic fault

detected

See Error Messages

Page 8

Small soot deposit

Normal operation

No action required

Page 10

LOCATION

When positioning the heater, the main points governing the location are:

1. Flueing.

2. Warm air distribution.

3. Adeqaute air supply.

4. The heater must not be installed where curtains or other combustible materials could come

into contact with it. In some cases, curtains may need restraining.

See below for minimum clearances required.

5. The heater is not designed to be built into bookcases or shelves or any combustible

opening. However, mantles are allowable providing outside the minimum clearance and

protrude no further than 150mm. from the wall.

6. Check that room ventilation complies with local regulations.

7. Check that an EARTHED power point is within 1500mm. of the right hand side of the

heater.

8. The heater must be mounted on a hearth no less than 50mm. high and the width and

depth of the heater.

9. Under no circumstances must combustible materials be present on the inside of the

fireplace recess or flueway. For combustible opening installations, a Rinnai Zero

Clearance Kit is available from your gas appliance retailer.

11

Page 11

Rinnai strongly recommends that this appliance be installed with an approved

flue liner system in all installations.

Installation without a flue liner is however permissible into masonry chimneys only after physical inspection

and testing of the chimney to set criteria. Installation of this appliance into a chimney that fails to meet this

criteria will not only void the product warranty, but is highly likely to impede product performance.

The following criteria must be met in all cases:-

Internal Criteria:

• Allow sufficient height above the firebox to enable the debris diverter (See page 8) to be fully operational

(ie. open 45°). Failure to do so will result in incomplete combustion and emissions discharged into the

room.

• All loose/broken bricks must be repaired ensuring the chimney is of sound construction and free from

leakage. Failure to do so may result in emission discharge into the room.

• The chimney must be free of soot and creosote accumulation resulting from previous slow combustion

wood fires. It must also be clear of all blockages and swept prior to installation.

• Any damper plate must be fixed in the open position or removed.

• Any underfloor air supply to the fireplace must be completely sealed off to prevent secondary air draw.

External Criteria:

• An approved chimney cap and cowl must be installed with this appliance. If there is an existing cap, it must

be free of defects/deterioration and repaired if found to be faulty.

• Inadequate chimney height can also effect product performance. Some applications may require the

chimney height to be extended to reduce possible down drafts.

• A flue draft smoke test must be carried out to confirm that an updraft occurs and the flue system is sound.

There must be no leakage of smoke through the structure of the chimney during or after the test. Inside,

upstairs and/or adjacent rooms should also be checked.

If any of the above criteria is not met, a Rinnai approved flue liner system

must be installed.

FLUEING

12

Page 12

•

CHECK DIMENSIONS OF FIREPLACE

Check dimensions of fireplace and if necessary

bring them to dimensions shown.

•

CHECK FLUEWAY

Check flueway is clear of obstructions.

Provide a firm, flat and sealed base for unit.

Sealed means no holes or openings in fireplace.

A rough base may affect the performance of this unit

CHIMNEY INSPECTION

A. Improper chimney height.

B. Chimney Cap deterioration.

C. Creosote stains.

D. Blockage within flue.

E. Clearance to combustibles.

F. Soot / Creosote accumulation.

G. Structural deterioration.

H. Loose or broken bricks.

I. Smoke Pellet test. (Leakage)

• SEALING THE INBUILT

INSTALLATION

Peel protective backing off the foam strips supplied

with the heater. Attach strips to rear of casing as

shown.

The strip is intended to form a seal between the

heater and fireplace. If an adequate seal cannot be

formed with this strip, another means of sealing must

be used (eg. non-combustible insulation), between

the fireplace and the heater body.

13

Page 13

• RUN GAS SUPPLY

For pipe sizing, refer to your local gas installation codes.

Copper supply should be run leaving the end of the pipe in a

suitable position to be able to attach to the stainless steel flexi- tube

and the 1/2” BSP male union provided.

(refer diagram)

PURGE SUPPLY OF AIR AND SWARF.

All foreign materials such as filings must be purged from the gas

supply, as they may cause the gas valve to malfunction.

• SLIDE HEATER INTO FIREPLACE

Slide the heater carefully into position, while feeding the stainless

steel flexi-tube through the supply access opening at right hand rear.

NOTE: A spring-loaded flue protector plate is fitted to

prevent the entry of foreign objects for a masonry

chimney installation.

The plate will fold down as the heater slides through the

fireplace opening.

IMPORTANT: Make sure that the flue protector plate is not

restricted and returns to its normal position when the heater

is installed.

If the fire has to be removed, the plate will pivot

backwards to allow the heater to slide clear.

When a flue liner or Zero Clearance Box is used,

the flue protector plate must be unscrewed and removed.

Secure the heater to the fireplace. There are pre-drilled holes in the

heater surround behind the doors. Drill additional holes if the

existing ones are not in suitable positions.

Refer to Page 9 for removal and replacement of logset.

Remove the front and middle burners by undoing the left hand end

screws, sliding the burners to the left, and lifting out.

Slide out and remove the bottom louvre rods which are

held in place by tension.

Carefully remove the screws from both ends of the front panel.

Remove the top and bottom screws from the centre louvre rod

retaining bracket.

Slide out the fan partition tray exposing the gas control and

flare connection.

Bend the flexi-tube and connect to the gas control valve.

Check for gas leaks.

Replace and refit all parts that have been removed in reverse order.

On completion of all work, check all connections for gas leaks.

14

GAS CONNECTION

Page 14

LOG INSTALLATION

The logset is packed inside the heater and the packaging must be removed prior to

installing the logset in its correct position.

• Open both side panels.

• Remove fastenings on both sides of the

top glass retainer.

Lift retainer away from heater.

• Loosen screws on bottom glass retainer.

Carefully lift glass out of bottom channel.

• Carefully remove log packaging.

The logset consists of a Main Log which has four pins on the top, for the location of the Top and Right Logs

and two holes underneath for location onto the pins inside the heater.

Place the logset into the heater ensuring that the locating pins enter the two locating holes on the

bottom face of the logset, if not already attached.

Carefully position the Top Log and the Right Log on the locating pins of the Main Log as shown.

Gently place loose ember bed material in front of the front log. Do not pour as dust particles from

the plastic bag may block the burner ports. Level it with a pencil or screwdriver and remove excess

material. Note: The ember bed material must be placed after the logs are fitted. If the logs are to be removed

for any reason, the ember bed material must be removed first and replaced after the logs are refitted. Any

material that prevents the logs sitting flat on the burner top can upset the burning pattern and performance

of the heater.

• Replace glass and top glass retainer, tighten bottom glass retainer screws.

• Note: Fit glass so that the join/gap in the glass seal is at the bottom.

• Take care not to damage seals.

• Reinstall side panels.

Top Log

Right Log

Main Log

Note: When first lighting the heater, the logs need to be burnt in, which may take approximately 2

hours. The flame colour may change after the initial burning in period.

vvvvv

15

Page 15

16

TESTING & COMMISSIONING

• TESTING PROCEDURE

Turn gas supply on and plug the unit into the power supply. (Caution 240V.)

• TO CHECK BURNER PRESSURE

• Refer to Data Plate.

• Remove the wiring cover panel.

• Remove test point screw and attach manometer to test point.

The test point is on the left hand side of the gas valve.

• Light heater, turn to High heat setting and

check pressure.

• If adjustments are necessary, the regulator is situated on

the front of the gas control.

• After checking pressure, turn the unit off, remove manometer and replace test point screw.

• Turn the heater on and off a few times to check ignition.

• When you are satisfied that the heater is working correctly, reassemble panels.

• All burner aeration is factory preset and cannot be adjusted.

• If you are unable to get the unit to operate correctly, refer to Troubleshooting on Page 9,

before contacting your local service contact as listed on Page 14.

• It may take approximately 2 hours for the logs to achieve their full flame pattern and glow.

• During the initial burning in period, some smoke and smell may be experienced. The

heater should be run on the high position in a well ventilated room until these dissipate.

It is the responsiblility of the installer to check that under normal operating conditions of the

appliance, all flue gases are exhausted to the outside atmosphere and that there is no spillage of

combustion gases into the room. Please refer to NZS 5261: 1996

• INSTRUCT CUSTOMER ON USE OF UNIT

Explain to customer about use and care of unit. Make sure the customer understands the instructions.

• EXPLAIN

Ignition, Adjusting heat level, Fan Switch, Turning “OFF”.

• COMMISSIONING

• INSTALLATION AND COMMISSIONING CHECKLIST

Complete the installation / commissioning checklist and the installer / gasfitter details on page 12 and

make sure that this instruction book is left with the customer.

NOTE:

RINNAI RESERVES THE RIGHT TO CHANGE OR MODIFY SPECIFICATIONS WITHOUT NOTICE.

Page 16

Comple

IB35ETRN (NG) New Zealand

IB35ETRL (Propane) New Zealand

Rinnai Inbuilt Radiant/Convector, glass-fronted, ceramic log space heater

with forced convection and natural draught flue system.

33 MJ/h Natural Gas and Propane.

Rinnai Electronic Control Valve.

Ceramic Logs, Ember Bed and Heat Burner.

15mm. Copper Flare Connection.

Natural Gas 0.95 kPa; Propane 2.00 kPa.

Natural Draught.

An approved 100mm. cowl must be fitted

to all installations.

Electronic Spark.

230/240v. 50Hz unit is supplied with 3 pin

plug and supply lead, replace only with

Rinnai P/N 90179599(Aust.) 6765B(NZ).

Tangential 2 Speed, Watt Rating 90W.

Bottom R/H side of pillar.

Model:

Description:

Input:

Gas Control:

Burner:

Gas Inlet:

Test Point Pressure:

Flue:

Flue Termination:

Ignition:

Power Supply:

Fan:

Data Plate:

TECHNICAL DATA

17

SERVICE CONTACT POINTS

RINNAI NEW ZEALAND LTD.

691 Mt. Albert Rd. Royal Oak, Auckland, NZ.

PO Box 24-068 Tel. (09) 625 4285 Fax. (09) 624 3018

24 Hr. Service Tel. 0800 746624 (0800 Rinnai)

Internet: www.rinnai.co.nz

Email: service@rinnai.co.nz

Page 17

WIRING DIAGRAM

18

Page 18

20

INSTALLATION / COMMISSIONING CHECKLIST

(To be completed by certified Gas Installer)

Model: ____________________

1. Was a fireplace inspection carried out?

(ie. clearances, combustibles etc.)

2. Was chimney inspected?

3. Did chimney require flue liner system to be installed?

If NO, did chimney meet specified criteria as per manual?

4. Has specified gas pressure been set?

5. Are decorative logs located correctly on pins?

6. Have ember granules been placed and free of dust and powder?

7. Has appliance been sealed around the fireplace?

8. Has the appliance been commissioned?

9. Is the end-user fully aware of operating procedure?

NO

YES

INSTALLER / GASFITTER DETAILS

Company Name: ____________________________________________________________________

Gasfitters Name: ____________________________________________________________________

Address:____________________________________________________________________________

____________________________________________________________________________

Phone: __________________________

Mobile: ____________________________

Certificate of Compliance / Certification Number: ______________________________________

Signed: _________________________________ Date: ______________________________

Part Number 7082

Loading...

Loading...