Page 1

Operation / Installation

Manual

RINNAI ‘PRESTIGE’® and

RINNAI ‘SUNMASTER’

®

Solar Split Systems

NOTE

WARNING

All Rinnai gas products

are A.G.A. certified.

Distributed and serviced in Australia under a Quality

System certified as complying with ISO 9001 by

SAI Global

AS 2712

Lic No.1849

SAI Global

W169

SAI Global

The appliance must be installed, commissioned and serviced by an

authorised person in accordance with all applicable local rules and

regulations.

The collector flow and return pipes should be 15mm copper tube or

alternative tube supplied by Rinnai.

Plastic pipe must not be used. Plastic pipe is not suited to the high

water temperatures and pressures that may occur in the collector

flow and return system.

NOT SUITABLE AS A POOL OR SPA HEATER

15401021

Page 2

IMPORTANT INFORMATION

Page 3

Rinnai Australia - 1 - Solar Split Systems Operating / Installation Manual Version 8 - 18/10/10

IMPORTANT INFORMATION & WARNINGS ....................................................................................... 2

SAFETY & REGULATORY INFORMATION...............................................................................................................................2

SCALDS HAZARDS ..................................................................................................................................................................3

OPERATION PRINCIPLE..........................................................................................................................................................4

SAFETY DEVICES.....................................................................................................................................................................5

EXCESSIVE DISCHARGE FROM SAFETY DEVICES.............................................................................................................5

WATER TEMPERATURE...........................................................................................................................................................6

TURNING ‘OFF’ THE WATER HEATING SYSTEM..................................................................................................................6

TURNING ‘ON’ THE WATER HEATING SYSTEM.....................................................................................................................6

WATER QUALITY ......................................................................................................................................................................7

DRAINING AND FILLING THE WATER HEATING SYSTEM....................................................................................................7

MAINTENANCE AND REGULAR CARE...................................................................................................................................7

SERVICING AND REPAIR.........................................................................................................................................................7

SAVE A SERVICE CALL....................................................................................................................... 8

SPECIFICATIONS FOR SYSTEMS..................................................................................................... 10

GENERAL................................................................................................................................................................................10

SYSTEM SPECIFICATIONS AND DIMENSIONS...................................................................................................................10

FLOW CONTROL VALVE........................................................................................................................................................10

DIFFERENTIAL TEMPERATURE CONTROLLER..................................................................................................................10

SPECIFICATIONS FOR SOLAR COLLECTORS................................................................................ 11

SPECIFICATIONS FOR STORAGE CYLINDERS .............................................................................. 12

SPECIFICATIONS FOR GAS BOOSTERS......................................................................................... 16

INSTALLATION & MAINTENANCE - ALL SYSTEMS........................................................................ 17

REGULATIONS AND OCCUPATIONAL HEALTH AND SAFETY (OH&S)..............................................................................17

LOCATION - GENERAL INFORMATION.................................................................................................................................17

STORAGE CYLINDER LOCATION.........................................................................................................................................17

GAS BOOSTER LOCATION AND MOUNTING (where applicable)........................................................................................18

WATER PIPES.........................................................................................................................................................................18

WATER SUPPLY......................................................................................................................................................................18

HOT WATER DELIVERY TEMPERATURE..............................................................................................................................18

FROST PROTECTION MODE ON SOLAR CONTROLLER....................................................................................................19

VALVES & FITTINGS...............................................................................................................................................................20

REGULATIONS AND OCCUPATIONAL HEALTH AND SAFETY (OH&S)..............................................................................21

SYSTEM ORIENTATION AND INCLINATION............................... ..........................................................................................21

SOLAR COLLECTOR ROOF MOUNTING OPTIONS.............................................................................................................22

SOLAR COLLECTOR INSTALLATION COMPONENTS .........................................................................................................23

STANDARD INSTALLATION....................................................................................................................................................24

FRAMED INSTALLATIONS - FLAT, REVERSE & SIDE PITCH...............................................................................................27

COLLECTOR FITTINGS INSTALLATIONS..............................................................................................................................28

INSTALLATION OF SOLAR GAS BOOSTED SYSTEMS.................................................................. 30

OVERVIEW OF SYSTEM COMPONENTS .............................................................................................................................30

GAS BOOSTER LOCATION....................................................................................................................................................30

GAS SUPPLY...........................................................................................................................................................................30

HOT WATER DELIVERY TEMPERATURE..............................................................................................................................30

CLEARANCES.........................................................................................................................................................................44

INSTALLATION PROCEDURE................................................................................................................................................44

FILLING THE SYSTEM........................ ..................... ..................... ..................... ..................... ................................................45

CHECKING SOLAR PUMP OPERATION................................................................................................................................45

ADJUSTING FLOW CONTROL VALVE...................................................................................................................................45

PRE SOLAR HEATING CHECKS............................................................................................................................................46

SOLAR HEATING....................................................................................................................................................................47

FINISHING THE INSTALLATION.............................................................................................................................................47

DRAINING INSTRUCTIONS....................................................................................................................................................48

INSTALLATION & MAINTENANCE - ELECTRIC BOOSTED SYSTEMS.......................................... 49

OVERVIEW OF SYSTEM COMPONENTS .............................................................................................................................49

ELECTRIC SUPPLY.................................................................................................................................................................49

HOT WATER STORAGE AND DELIVERY TEMPERATURES................................................................................................49

INSTALLATION PROCEDURE................................................................................................................................................54

FILLING THE SYSTEM........................ ..................... ..................... ..................... ..................... ................................................57

CHECKING SOLAR PUMP OPERATION................................................................................................................................57

ADJUSTING FLOW CONTROL VALVE...................................................................................................................................57

PRE SOLAR HEATING CHECKS............................................................................................................................................58

SOLAR HEATING....................................................................................................................................................................58

FINISHING THE INSTALLATION.............................................................................................................................................58

DRAINING INSTRUCTIONS....................................................................................................................................................59

CONTACT INFORMATION.................................................................................................................. 61

TABLE OF CONTENTS

Page 4

Rinnai Australia 2 Solar Split Systems Operating / Installation Manual - Version 8 18/10/10

IMPORTANT INFORMATION & WARNINGS

SAFETY & REGULATORY INFORMATION

DO NOT operate this system before reading the manufacturers instructions.

This appliance must be installed, commissioned and serviced by an authorised person in

accordance with all applicable local rules and regulations.

Access covers of water heating system components will expose 240V wiring and MUST be

removed by an authorised person.

This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of exper ience and knowle dge, unless t hey have been given

supervision or instruction concerning use of the applianc e by a person responsible for their safety.

For continued safety of this appliance it must be insta lled, operated and maintained in accordance

with the manufacturers instructions.

Children should be supervised to ensure they DO NOT play with the appliance.

Any power leads from the water heater system components MUST BE plugged into an external

weatherproof electrical outlet. If the power supply cord of any water heating components is

damaged, it MUST BE replaced by an authorised person in ord er to av oid a ha za rd, using g enuine

replacement parts available from Rinnai. Take care not to touch the power plugs wit h wet hands.

Care should be taken not to touch the pipe work as it may be HOT! The pipes between the solar

collectors and storage cylinder MUST BE copper, or alternative material pipes that may be

supplied by Rinnai. Plastic pipe is NOT suited to t he water temperatures and pressures th at may

occur in the system.

DO NOT place articles on or against this appliance.

DO NOT store chemicals or flammable materials near this appliance.

DO NOT operate with collectors or covers removed from this appliance.

DO NOT activate pump unless cylinder is full of water.

NEVER use a flammable spray such as hai r spray, lacquer, paint, etc near this unit as this may

cause a fire.

NOTICE TO VICTORIAN CONSUMERS

This appliance must be installed by a person licensed with the Plumbing Industry Commission.

Only a licensed person will have insurance protecting their workmanship.

So make sure you use a licensed person to install this appliance and ask for your Compliance Certificate.

For Further information contact the Plumbing Industry Commission on 1800 015 129.

WARNING

Page 5

Rinnai Australia 3 Solar Split Systems Operating / Installation Manual Version 8 - 18/10/10

IMPORTANT INFORMATION & WARNINGS

SCALDS HAZARDS

HOT WATER CAN CAUSE SCALDS.

CHILDREN, DISABLED, ELDERLY AND THE INFIRM ARE AT THE HIGHEST RISK OF

BEING SCALDED.

FEEL WATER TEMPERATURE BEFORE BATHING OR SHOWERING.

SCALDS FROM HOT WATER TAPS CAN RESULT IN SEVERE INJURIES TO YOUNG

CHILDREN.

SCALDS OCCUR WHEN CHILDREN ARE EXPOSED DIRECTLY TO HOT WATER WHEN

THEY ARE PLACED INTO A BATH WHICH IS TOO HOT.

ALWAYS......

Test the temperature of the water with your elbow before placing your child in the bath, also carefully feel

water before bathing or showering yourself.

Supervise children whenever they are in the bathroom.

Make sure that the hot water tap is turned off tightly.

CONSIDER.....

Installing child proof tap covers or child resistant taps (both approaches will prevent a small hand being

able to turn on the tap).

Installing tempering valves or thermostatic mixing valves which reduce the hot water temperature

delivered to the taps. Your local plumbing authorit y may already require that these be fitted. Contact your

installer or local plumbing authority if in doubt.

NEVER….

Leave a toddler in the care of another child. They may not understand the need to have the water

temperature set at a safe level.

Page 6

Rinnai Australia 4 Solar Split Systems Operating / Installation Manual - Version 8 18/10/10

IMPORTANT INFORMATION & WARNINGS

OPERATION PRINCIPLE

This system is designed to have the solar collectors on the roof and the storage cylinder installed at ground or floor

level.Electric and Gas boosted models are available. The system comprises a hot water storage cylinder, solar

collectors, pump circulation system solar control unit and temperature sensors. The solar control unit ensures

water circulates between the solar collectors and the storage cylinder to transfer heat from the solar collectors to

the water in the cylinder if enough heat is available from the sun.

Supplementary heating is provided if insufficient heat is available from sun (such as during cloudy or rainy weather

or during winter months) either via an electr ic heating e l ement(s) located inside the stora ge cylinder or via a on inline Gas booster located external to the storage cylinder. The following diagrams illustrates the Split Solar Hot

Water System set up for both the Electric and Gas boost.

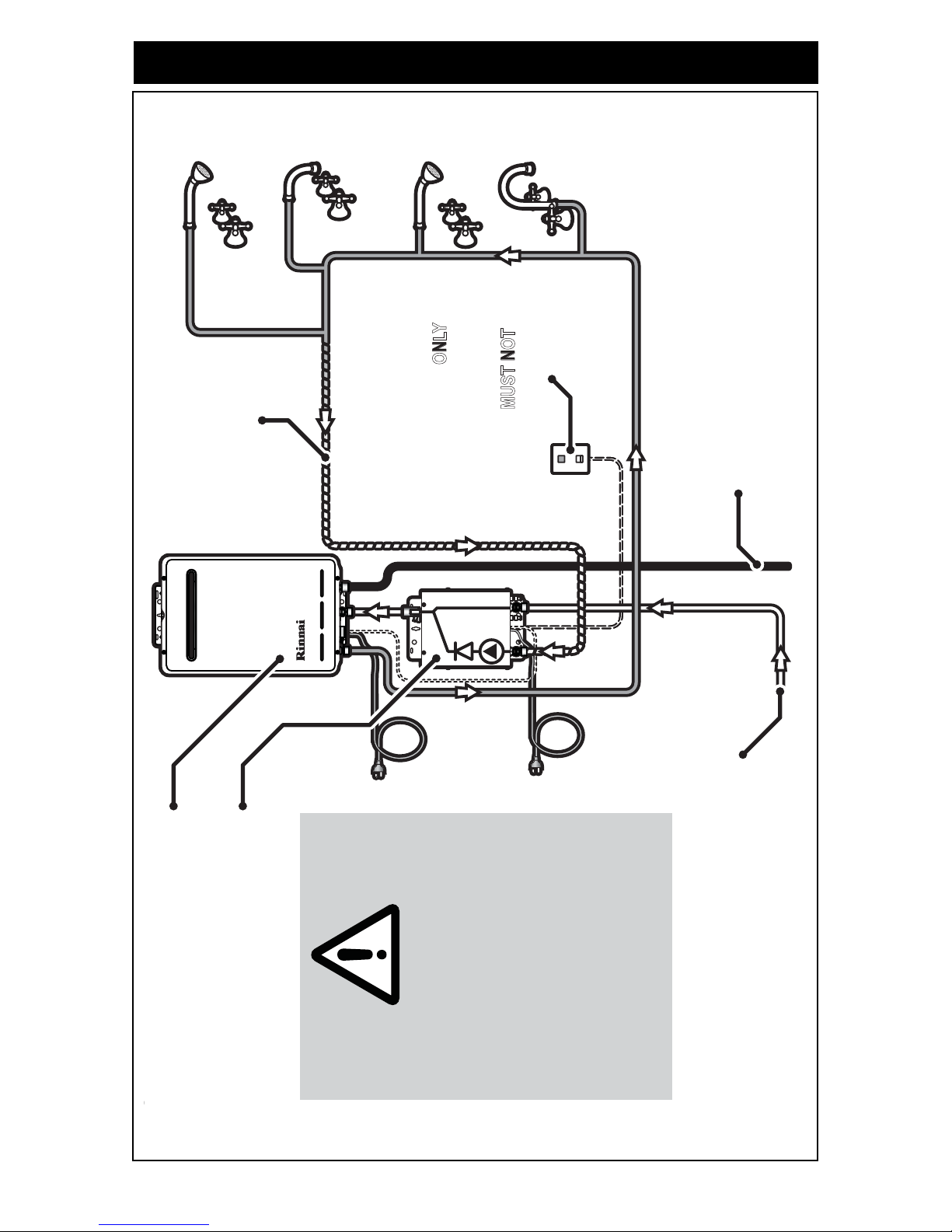

Figure 1. Sunmaster Gas Boosted Hot Water Systems Figure 2. Sunmaster Electric Hot Water Systems

Figure 3. Prestige Gas Hot Water Systems Figure 4. Prestige Electric Hot Water Systems

PUMP & SOLAR

CONTROL MODULE

COLD WATER

SUPPLY

TO HOT WATER

OUTLETS

GAS SUPPLY

TO HOT WATER

OUTLETS

PUMP & SOLAR

CONTROL MODULE

COLD WATER

SUPPLY

ELECTRIC ELEMENT

GAS SUPPLY

TO HOT WATER

OUTLETS

PUMP & SOLAR

CONTROL MODULE

COLD WATER

SUPPLY

PUMP & SOLAR

CONTROL MODULE

ELECTRIC ELEMENT

COLD WATER

SUPPLY

TO HOT WATER

OUTLETS

Page 7

Rinnai Australia 5 Solar Split Systems Operating / Installation Manual Version 8 - 18/10/10

IMPORTANT INFORMATION & WARNINGS

SAFETY DEVICES

The water heating system is supplied with various safety devices including temperature sensors, overheat sensors

and switches and a Pressure & Temperature Relief (PTR) valve. These devices must not be tampered with or

removed. The water heating system must not be operated unless each of these devices is fitted and is in working

order.

EXCESSIVE DISCHARGE FROM SAFETY DEVICES

Pressure & Temperature Relief (PTR) Valve

It is normal and desirable that this valve allows a small qua ntity of water to be discharged during the heating cycle.

If it discharges more than a bucket of water during a 24 hour period or discharges continuously there may be

another problem.

If the valve dribbles continuously, try easing the valve gear for a few seconds as described above. This may

dislodge any foreign matter and alleviate the problem.

If the valve discharges at high flows, especially at night, it may be as a result of the water pressure exceeding the

design pressure of the water heater. Ask your installer to fit a Pressure Limiting Valve (PLV).

Expansion Control Valve (ECV) - if fitted

It is normal and desirable that this valve allows a small qua ntity of water to be discharged during the heating cycle.

If it discharges more than a bucket of water during a 24 hour period or discharges continuously there may be

another problem.

If the valve leaks continuously, try easing the valve gear for a few seconds. This may dislodge any foreign matter

and alleviate the problem. If this does not alleviate the problem contact Rinnai.

Operate the easing gear regularly to remove any lime deposits and to verify that it is not blocked.

DO NOT tamper with or remove safety devices.

DO NOT operate the water heater unless all safety devices are fitted and in working order.

DO NOT block or seal the PTR Valve and drain pipe.

Pressure & Temperature Relief (PTR) Valve

This valve is located near the top of the water heater

and is essential for safe operation. It is normal for the

valve to release a small quantity of water through the

drain line during heating.

However, continuous leakage of water from the

valve and its drain line may indicate a problem with

the water heater.

Never block the outlet of the PTR valve or it’s drain line for any reason. The easing gear must be

operated at least every 6 months to remove lime dep osits a nd v erify that it is not bloc ked . Failure

to do this may result in the water heater failing.

If the valve does not discharge water when the easing gear lever is opened, o r does not se al again

when the easing gear is closed, attendance by an authorised person must be arranged without

delay. The PTR valve is not serviceable.

NEVER replace the PTR valve with one which has a higher pressure rating than is specified for your

water heater.

WARNING

Twist cap until water

flows from drain line

Lift lever until water

flows from drain line

(Lower lever gently!)

WARNING

WARNING

Page 8

Rinnai Australia 6 Solar Split Systems Operating / Installation Manual - Version 8 18/10/10

IMPORTANT INFORMATION & WARNINGS

Gas boosted models

• Do not touch the flue outlet or do not insert any objects into the flue outlet.

• Keep flammable materials, spray cans, fuel containers, trees, shrubs and pool

chemicals etc. well clear of the flue outlet.

• Do not use the gas types other than those designated on the data plate. For

example, do not use Propane/Butane gas mixtures on appliances marked Propane

Gas.

• Do not use Propane gas on appliances marked as Natural gas and vice versa.

Hydrogen Gas

In the case of systems using a vitreous enamelled lined cylinder, if the hot water unit is not used for two weeks or

more, a quantity of hydrogen gas, which is highly flammable, may accumul ate in the water heater. To dissipate this

safety, it is recommended that a non electrically operated hot tap be turned on for two minutes at a sink, basin, or

bath, but not a dishwasher or other appliance. during this proced ure there must be no smoking, open flame or any

electrical appliance operating nearby. If hydrogen is discharged through the tap, it will probably make a sound like

air escaping.

WATER TEMPERATURE

The solar control unit and pump ensure water circulates be tween the solar co llectors and storage cylin der until the

water at the base of the cylinder reaches approximately 65°C. Under these conditions water at the hot outlet may

exceed 85°C. During periods of low solar gain supplementary heating occurs to a minimum of 60°C as required.

TURNING ‘OFF’ THE WATER HEATING SYSTEM

If you plan to be away for only a few nights, we suggest you leave the water heating system switched on. If it is

necessary to switch off the water heater, do so as outlined below:

Electric Boosted systems

• Switch off the electric supply to the supplementary hea ting element. The switch is usually marked and

located in the electricity meter box of the dwelling.

• Switch off the electric supply to the solar controller and pump.

Gas Boosted systems

• Switch off the electric supply to the gas booster.

• Switch off the electric supply to the solar controller and pump.

TURNING ‘ON’ THE WATER HEATING SYSTEM

Electric Boosted system

• Switch on the electric supply to the suppleme ntary heating element(s). The switch is usu ally marked and

located in the electricity meter box of the dwelling.

• Switch on the electric supply to the solar controller pump. Electric and solar water heating will now occur as

required. It may take a number of hours before hot water is available.

Gas Boosted systems

• Switch on the electric supply to the gas booster.

• Switch on the electric supply to the solar controller and pump. Solar water heating will now occur. Hot

water is available immediately from the gas booster when hot water tap is opened, irrespective of solar

heat gain.

To meet Australian regulatory requirements, supplementary heating temperature settings

must be at least 60°C.

HOT!

IMPORTANT

Page 9

Rinnai Australia 7 Solar Split Systems Operating / Installation Manual Version 8 - 18/10/10

WATER QUALITY

The water quality of most public supplies is suitable for the water hea ting system. The water quality from bore wells

is generally unsuitable for the water heating system. Refer to separate 'Warranty Terms and Conditions' document

for water quality parameters and how they affect the warranty conditions. If in doubt about the water quality, have

it checked against the parameters listed in the warranty conditions. The system is not suitable as a pool or spa

heater.

DRAINING AND FILLING THE WATER HEATING SYSTEM

• Draining or filling normally occur only during installation or servicing and must be carried out by an

authorised person.

MAINTENANCE AND REGULAR CARE

Operate the easing gear of the PTR as described under “SAFETY DEVICES” on page 5.

The overflow tray (supplied by installer) and drain underneath the storage cylinder (if fitted) should be periodically

checked to ensure there are no blockages.

SERVICING AND REPAIR

Our Servicing network personnel are fully trained and equipped to give the best service on your appliance. If your

appliance needs service, ring one of the service contact numbers on the back of this booklet.

It is recommended that the system be serviced at least every 5 years.

The pressure and temperature relief valve and expansion control valve must be checked for performance or

replaced by an authorised person at intervals not exceeding 5 years or more frequently in areas where the water

is classified as scaling water (refer to ‘Warranty Terms and Conditions’ document - ‘Water Quality’).

It is recommended that the sacrificial anode fitted to Sunmaster cylinders be inspected very 5 years or more

frequently in areas where there is a high incidence of water deposits. This does not apply to Rinnai Prestige

cylinders. Anodes suited to hard and soft water, are available from Rinnai.

If the electric conduit, power supply cord or plug to the water heater is damaged, they must be replaced by an

authorised person in order to avoid a hazard. The power supply cord and plug (if fitted) must be replaced by a

genuine replacement part available from Rinnai.

IMPORTANT INFORMATION & WARNINGS

Page 10

Rinnai Australia 8 Solar Split Systems Operating / Installation Manual - Version 8 18/10/10

SAVE A SERVICE CALL

Before calling Rinnai for service, perform the fault finding steps in the Table 1. If the problem persists, contact

Rinnai.

Service calls attending to any condition or fault that is not related to the Rinnai product and components may

be chargeable.

Table 1 - Troubleshooting

Problem Cause Remedy

Insufficient or no hot Water Booster heating not operating

Or

Insufficient gas supply for gas boosted heating

system

Electric boosted Systems:

Check to ensure the electric isolating switch(es) at the switchboard (usua lly marked

"Hot water" or "water heater") is switched 'ON'.

Check to ensure that the electric fuses for hot water at the switchboard are intact.

Gas Boosted Systems:

Check to ensure the power cord of the gas booster is plugge d in and the power point

switched 'ON'.

Check gas is available and turned ON'.

Close the hot tap and wait for 10 seconds and open it again. The hot tap must be

opened enough to ensure that the flow rate is not less than 2.4

L/min. gas the gas booster burners will not light if it is less than 2.4 L/min. Check t he

isolation valve in the gas line is opened.

If there is gas supply to other appliances in the rest of the house, t ry lighting anoth er

gas appliance.

Refer to your plumber to ensure the gas line has been purged of air after ins tallation.

Excessive hot water

consumption

Electric Boosted Systems:

If the water goes cold, are you using more hot water than you think? Often end

users are surprised at the amount of hot water used, especially when showering. If

the amount of hot water used during the day exceeds the storage capacity of the

cylinder, it is likely that there will be insufficient hot water. Has your plumber install

water saving fixtures and/or flow control or pressure limiting valves to reduce

consumption.

Gas Boosted Systems:

Insufficient flow may occur if multiple outlets are in use at the same time and exceed

the rated flow capacity of the gas boost er. If so, reduce the number of outlets in use.

Have your plumber install water saving fixtures and/or flow control or pressure

limiting valves to reduce consumption.

Check correct size gas booster is fitted.

Incorrect Solar system size Do you have the correct system size and configuration for your requirements? Refer

to Rinnai literature for information.

Temperature and pressure relief valve /

Expansion Control valve

discharging water continuously

Pressure and Temperature Relief (PTR) valve

It is normal and desirable that this valve allows a small quantity of water to be

discharged during the heating cycle. If it discharges more than a bucket of water

during a 24 hour period or discharges continuously t here may be another problem.

If the valve dribbles continuously, try easing the valve gear for a few seconds as

described under 'Regular Care'. This may dislodge any foreign matter and alleviate

the problem.

If the valve discharges at high flows, especially at night, it may be as a result of the

water pressure exceeding the design pressure of the water heater. Ask your installer

to fit a Pressure Limiting Valve (PLV).

• Never replace the PTR valve with one which has a higher pressure rating than is specified for your water heater.

• If the valve discharges hot water at high flows, (dumps) there may be a serious problem. Switch off the power

supply in the meter box (the switch marked ‘WATER HEATER’ or ‘HOT WATER’) or the isolating switch installed

near the water heater and contact Rinnai.

Insufficient or no hot Water

Continued

Expansion Control Valve (ECV) - if fitted

It is normal and desirable that this valve allows a small quantity of water to be

discharged during the heating cycle. If it discharges more than a bucket of water

during a 24 hour period or discharges continuously t here may be another problem.

If the valve leaks continuously, try easing the valve gear for a few seconds as

described under 'Regular Care'. This may dislodge any foreign matter and alleviate

the problem. If this does not alleviate the problem contact Rinnai.

WARNING

SAVE A SERVICE CALL

Page 11

Rinnai Australia 9 Solar Split Systems Operating / Installation Manual Version 8 - 18/10/10

Problem Cause Remedy

Insufficient or no hot Water

continued

Booster element Thermostat Settings Electric Boosted Systems:

The end user can check the temperature of hot water delivered with a

thermometer placed under the closest non tempered outlet (usually the kitchen

sink).

CAUTION: Take care to avoid scalding. This test should be done early in

the morning after overnight electrical boosting before any hot water is

used. The temperature of the water delivered should be at least 55° C

(allowing for heat losses in pipe work).

If this is not the case or the temperature needs to be increased contact Rinnai.

The thermostat settings of the heatin g element thermo stat can also be co nfirmed

directly by a qualified person as described under 'hot water storage & delivery

temperature'. The settings can be increased if required. Contact Rinnai.

Gas Boosted Systems:

The delivery temperature of gas boosted systems is normally 60 or 65°C. Iff

temperatures are higher than this, the flow of water through the gas booster will

reduce and may result in insufficient flow rate.

The end user can check the temperature of hot water delivered with a

thermometer placed under the closest outlet (usually the kitchen sink).

CAUTION: Take care to avoid scalding. If the temperature is higher than

65°C the gas booster may be preset incorrectly. Contact Rinnai.

No Water from the hot tap Restriction in the hot tap or failure of the cold water

supply to the water heater.

Check for water flow at the other taps and that the cold water isolation is fully

open.

Gas Booster operating too

frequently

Insufficient Sunlight - Collectors shaded Ensure the trees or other objects are not shading onto the collecto r surface (Trim

the trees or relocate the solar collector if the obstruction is permanent).

Make sure the glass on the collector is not dirty.

High electricity or gas bill Excessive hot water consumption See entry under 'Insufficient hot water'.

Solar Control unit switched off If the solar control unit is switched off there will be no solar pre-heating of water

resulting in the water being heated entirely by electricity or gas' bo osting'. Check

the power outlet for the solar contr ol unit is switched on.

T emperature and pressure relief valve / Expansion

Control valve discharging water continuously

See entry under 'Insufficient hot water'.

Lack of solar gain Reduced sunlight:

Reduced sunlight due to overcast weather in summer or low solar contribution in

winter will result in an increased dependence on electricity or gas boosting.

Higher electricity or gas bills under these conditions, especially in winter, are

normal.

Collectors shaded:

If the solar collectors are shaded by trees or other objects, or the glass is dirty,

the effectiveness of the collectors is greatly reduced. Arrange for trimming of the

trees or relocation of the solar collectors if the obstruction is permanent. Arrang e

for cleaning of the collector glass.

Solar collectors incorrectly positioned

Check that positioning and alignment of solar collectors is in accordan ce with t he

section 'Location and alignment of solar collectors'.

WARNING: Persons working from elevated surfaces such as roofs must be

adequately trained an qualified in accordance with local OH&S requirements.

High Electricity Tariffs (electric boosted systems only) Electric Boosted Systems

The electricity tariff will determine the running costs of the system. It is important

the end user is aware of the applicable tariffs. Contact your electricity supplier to

confirm what these tariffs are.

Little or no water circulation in the solar 'flow and

return' loop

There are numerous causes of little or no circulation in the solar 'flow and return

circuit the circulation of water through the collectors. These causes must be

investigated by a qualified person. Contact Rinnai.

Water flow fluctuations One or more hot taps opened at the same time More than one or two hot taps in use at the same time may cause a decrease in

the hot water flow from the taps.

Is there more than one or two hot taps open, or are appliances such as a

dishwasher or washing machine, in use at the same time?

Ensure only one or two hot taps are on at one time.

Check the flow of the water from one tap, eg. the shower. The shower should be

adjusted so the hot tap is fully open.

Water Hammer Hot and cold water plumbing in the premises Have a plumber check clipping of hot and cold water pipework and install a

pressure limiting valve and water hammer arrestor as required.

SAVE A SERVICE CALL

Page 12

Rinnai Australia - 10 - Solar Split Systems Operating / Installation Manual - Version 8 - 18/10/10

SPECIFICATIONS FOR SYSTEMS

GENERAL

Split solar hot water systems are specified according to the grade of storage cylinder material, cylinder

capacity, number of solar collectors and boost type and capacity. Boost capacity for gas boosted

system depends on the gas booster model selected. Boost capacity for electrically boosted systems

depends on the power rating of electric heating elements and whether one or two electric heating

elements are fitted.

SYSTEM SPECIFICATIONS AND DIMENSIONS

Specifications and principal dimensions for the various systems and components are shown below.

FLOW CONTROL VALVE

A flow control valve is fitted to the pump and cont ro ller asse m bly .

It’s purpose is to allow the water flow rate through the collector collectors and storage cylinder to be

controlled to optimise the performance of the system.

DIFFERENTIAL TEMPERATURE CONTROLLER

The primary task of the differential temperature controller is to control the operation of the pump to

optimize solar energy collection. This task is performed by measuring the temperature differential

between the hot sensor and the cold sensor. When the differential exceeds 9°C the pump is activated

and water passes through the collectors collecting solar energy. When the d ifferentia l falls below 5°C

the pump is shut down.

A secondary task of the controller is to stop energy collection when the cylinder is full of hot water.

This is referred to as no load protection and the pump is shut down if the temperat ure of the water

going to the collectors exceeds 65°C. At such a temperature in the base of the cylinder, the

temperature of water in the top of the cylinder is expected to be about 85°C.

Table 2 - System Specifications

System Type

Rinnai ‘Sunmaster’

Systems

SG175, SG215,

SE160, SE200

Rinnai ‘Sunmaster’

Systems

SG270, SG340,

SE315

Rinnai ‘Prestige’

Systems

Connections:

Solar flow and return 1/2” 1/2” 1/2”

PTR Valve 1/2” 1/2” 3/4”

Cold Inlet 3/4” 3/4” 3/4”

Hot Outlet 3/4” 3/4” 3/4”

PTR Valve setting (kPa) 1000 850 850

Rating of PTR Valve supplied (kW) 10 10 10

Expansion Control V alve (ECV) setting

(kPa)

850 700 700

Max supply pressure with ECV (kPa) 680 550 560

Max supply pressure without ECV

(kPa)

800 680 700

Pressure limiting valve rating (kPa)

(supplied by installer if required)

500 500 500

Page 13

Rinnai Australia - 11 - Solar Split Systems Operating / Installation Manual - Version 8 - 18/10/10

Table 3 - Model Numbers and Specifications

CHARACTERISTICS

Enduro / Equinox

(SP200A) or

(SP200A FTC)

Excelsior

(EXT OR EXT FTC)

E-FROST

(HPFTC- 8-10)

TYPE

Flat plate Flat plate

Flat Plate /

Heat Pipe

- Waterways Copper Copper Copper

- Absorber Aluminium Copper Aluminium

- Selective Surface High Performance Sputtered Titanium Oxide High Performance

Maximum Operating

Pressure

Casing Material

Overall Dimensions

(L x W x H) (mm)

1940 x

1025 x

80

1964 x

1047 x

81

1940 x

1025 x

80

Weight empty

(STD/FTC) (kg).

33 / 35 35 / 38 34

Water volume (Litres) 1.3 1.5 0.6

Number risers

810

10

Potential Solar Output at

PTR relief conditions (kW)

- 1 Collector (mm) 1940 x 1025 1940 x 1047 1940 x 1025

- 2 Collectors (mm) 1940 x 2130 1940 x 2174 1940 x 2130

- 3 Collectors (mm) 1940 x 3235 1940 x 3301 1940 x 3235

Frost Protection to -12°C.

Power must be on at the

pump and the controller

must be in low temperature

mode

(refer page 19).

MODEL NUMBERS AND SPECIFICATIONS

CONSTRUCTION

850 kPa

Aluminium

1.25

Approximate Roof space Required: Length x Width

Frost Protection

* Standard version - no frost protection

FTC Version Frost Protection to -5°C

* FOR MORE INFORMATION ON FROST PROTECTION

REFER TO WARRANTY BOOKLET

SPECIFICATIONS FOR SOLAR COLLECTORS

Page 14

Rinnai Australia - 12 - Solar Split Systems Operating / Installation Manual - Version 8 - 18/10/10

SUNMASTER GAS - VITREOUS ENAMEL

Figure 5 - Dimensional Drawing - Rinnai Sunmaster Vitreous Enamel Storag e Cylinder -

Gas Boosted Split Systems

SG175 SG215 SG270 SG340

Cylinder Height 1530 1825 1265 1510

PTR / Solar Return 1310 1605 985 1200

Flow line to collectors 665 665 700 700

Cold Water Inlet 225 225 260 260

Gas Supply and Hot Water Outlet 940 1235 675 920

Gas Booster Flue Outlet 1400 1695 1135 1380

Diameter 515 515 685 685

Weight Empty (kg) 66 88 95 103

TEMPERATURE SENSOR

DRY WELL

P&TR / SOLAR RETURN

GAS SUPPLY AND

HOT WATER OUTLET

GAS BOOSTER FLUE OUTLET

COLD

WATER

INLET

CYLINDER HEIGHT

P&TR VALVE

SOLAR

RETURN

FLOW LINE TO COLLECTORS

SYSTEM DEPTH

CYLINDER DIAMETER

SPECIFICATIONS FOR STORAGE CYLINDERS

Page 15

Rinnai Australia - 13 - Solar Split Systems Operating / Installation Manual - Version 8 - 18/10/10

SUNMASTER - ELECTRIC - VITREOUS ENAMEL

Figure 6 - Dimensional Drawing - Rinnai Sunmaster Vitreous Enamel Storage Cylinder

- Electric Boosted Split Systems

SE160 SE200 SE315

PTR / Solar Return / Hot Water Outlet 1310 1605 1200

Flow line to Collectors 665 665 700

Cold Water Inlet 225 225 260

Cylinder Height 1530 1825 1510

Diameter 515 515 685

Weight Empty (kg) 71 83 100

PTR / SOLAR RETURN

COLD

WATER

INLET

CYLINDER DIAMETER

HOT WATER OUTLET

CYLINDER HEIGHT

P&TR VALVE

SOLAR

RETURN

FLOW LINE TO COLLECTORS

TEMPERATURE

SENSOR

DRY WELL

SPECIFICATIONS FOR STORAGE CYLINDERS

Page 16

Rinnai Australia - 14 - Solar Split Systems Operating / Installation Manual - Version 8 - 18/10/10

PRESTIGE GAS - STAINLESS STEEL

Figure 7 - Dimensional Drawing - Rinnai Prestige Stainless Steel Storage Cylinder

- Gas Boosted Split systems

250 315

Cylinder Height 1700 2090

PTR / Solar Return / Hot Water Outlet 1490 1880

Gas Supply and Hot Water Outlet 880 1270

Gas Booster Flue Outlet 1345 1735

Weight Empty (kg) 56 68

COLD WATER

INLET

P&TR VALVE

GAS SUPPY AND

HOT WATER OUTLET

GAS BOOSTER FLUE OUTLET

CYLINDER HEIGHT

210

795

300

600

650

SOLAR

RETURN

SPECIFICATIONS FOR SOLAR COLLECTORS

Page 17

Rinnai Australia - 15 - Solar Split Systems Operating / Installation Manual - Version 8 - 18/10/10

Figure 8 - Dimensional Drawing - Rinnai Prestige Stainless Steel Storage Cylinder

- Electric Boosted Split systems

PRESTIGE ELECTRIC - STAINLESS STEEL

160 250 315

PTR / Solar Return / Hot Water Outlet 995 1490 1880

Cylinder Height 1205 1700 2090

Weight Empty (kg) 44 56 68

P&TR VALVE & HOT WATER OUTLET

CYLINDER HEIGHT

COLD

WATER

INLET

SOLAR

RETURN

210

300

650

600

SPECIFICATIONS FOR SOLAR COLLECTORS

Page 18

Rinnai Australia - 16 - Solar Split Systems Operating / Installation Manual- Version 8 - 18/10/10

Table 4 - Specifications - Gas Boosters

Model Name: S20 S26

Boost Capacity:

- L/min. @ 20°C rise

- L/min @ 25°C rise

(L/min)

20

16

26

24

Maximum Rated Flow: (L/min) 20 26

Minimum Supply Pressure for Maximum rated flow:

(1)

(kPa) 120 200

Minimum Flow for Operation: (L/min) 2.4 2.4

Frost Protection: Yes Yes

Gas Consumption (Maximum / Minimum): (MJ/hr.) 125 - 18 188 - 23

Star Rating (AS 4552 - 1998): 5.5 5.0

Hot Water Delivery Temperature:

(2)

60°C 60°C

Dimensions: Height x Width x Depth: (mm) 530 x 350 x 194 530 x 350 x 194

Weight: (Kg) 15 21

(1) - Units will operate at lower pressures but the rated flow with not be achieved.

(2) - Gas boosters for Solar hot water applications should be preset to deliver a minimum temperature of 60°C.

Gas boosters factory pre set to 60°C or 65°C will be marked as such. If there are no temperature markings on the water

heater, on site conversion is required. This is a simple procedure, contact your Service Agent.

SPECIFICATIONS FOR GAS BOOSTERS

Page 19

Rinnai Australia - 17 - Solar Split Systems Operating / Installation Manual - Version 8 - 18/10/10

REGULATIONS AND OCCUPATIONAL HEALTH AND SAFETY (OH&S)

LOCATION - GENERAL INFORMATION

All system components must be in an accessible location. The storage cylinder must be accessible

without the use of a ladder or scaffold. Sufficient clearances shall allow access to, and removal of,

all serviceable parts. Ensure the PTR valve, pump kit, drain lines and thermostat and elements for

electric systems have sufficient clearances and are accessible for service and removal. The

information on any data plates must also be readable. In the case of vitreous enamel lined cylinder s,

leave a clearance of the height of one storage cylinder above the cylinder being installed so the

sacrificial anode can be inspected and replaced. This does not apply to stainless steel cylinders.

Select suitable areas of roof on which to install the solar collectors as close as practicable to the

cylinder. Ensure that the area is even and without cracked or damaged tiles. Collectors should be

positioned for optimum solar benefit. Refer to the section 'INSTALLATION OF SOLAR

COLLECTORS' for more information.

The solar pump kit and gas booster heater require an AC 240V power supply. A wea therproof 240V,

10A earthed power point must therefore be pr ovided a djacent to thes e. All electrically boosted solar

hot water heating elements must be connected to an independent, fused, AC 240V 50 Hz power

supply with an isolating switch installed at the switch board.

STORAGE CYLINDER LOCATION

The storage cylinder should be placed as close as pr acticable to the mo st frequently used ho t wate r

outlet point or points to minimise the delay time for hot water delivery. This will usually be the kitchen

tap.

The solar storage cylinders have an ingress protection rating of IPX4 making them suitable for

internal or external installation. Rinnai 'external' gas boosters are suitable for external installation

only.

Storage cylinders must be installed in freestanding mode on a level and stable base. For external

installations, storage cylinders should be mounted on a concrete base at least 50mm thick or on well

seasoned, evenly spread hardwood slats with a thickness of at least 25mm. Where prop erty damage

can occur, storage cylinders should be installed with an approved safe tray (overflow tray).

Ensure the cylinder does not stand on wet surfaces.

Installation and commissioning must be performed by authorised persons.

Solar systems must be installed in accordance with these instructions and all

regulatory requirements which exist in your area including those in relation to

manual lifting, working at heights and on roofs. Applicable publications and

regulations may include:

• AS 5601 Gas Installations

• AS/NZS 3500 National Plumbing and Drainage

• AS/NZS 3000 Wiring rules

• Building Codes of Australia (BCA)

• Local Occupational Health and Safety (OH&S) regulations

This appliance is not suitable for use as a domestic spa pool or swimming pool

heater.

Solar collectors are heavy and bulky items and are usually positioned on the

roofs of buildings. Australian State and Territories have a principal Occupationa l

Health and Safety (OH&S) Act which contains requirements relating to the

handling of large, bulky or awkward items and the prevention of falls from

elevated surfaces. Persons installing solar collectors must be aware of their

responsibilities and be adequately trained and qualified, in accordance with

local OH&S requirements.

WARNING

INSTALLATION & MAINTENANCE - ALL SYSTEMS

Page 20

Rinnai Australia - 18 - Solar Split Systems Operating / Installation Manual - Version 8 - 18/10/10

GAS BOOSTER LOCATION AND MOUNTING (where applicable)

The gas booster is designed for 'Outdoor' Installation only. As such, it must be located in an above

ground open air situation with natural ventilation, without stagnant areas, where gas leakage and

products of combustion are rapidly dispersed by wind and natural convection.

The maximum recommended combined lengths of the solar flow and return pipes are as follows:

WATER SUPPLY

The minimum and maximum water pressures for the various systems are listed in Table 2. Approved

pressure limiting valves may be required if the 'Maximum' rated water supply pressures are

exceeded. For gas boosted systems to achieve the rated flow through the outlet of the continuous

flow water heater, the minimum water supply pressures must be supplied. The systems will operate

at lower pressures but the rated flow will not be achieved.

Water chemistry and impurity limits are detailed in the separate Warranty document. Most

metropolitan water supplies fall within these requirements. If you are unsure about water quality,

contact your water authority. If sludge or foreign matter is present in the water supply, a suitable filter

should be incorporated in the water supply to the storage cylinder.

HOT WATER DELIVERY TEMPERATURE

Local regulations and/or the requirements of AS/NZS3500.4 must be considered regarding the

temperature limitations of hot water supplied to areas used primarily for personal hygiene. The

temperature of water to these areas is limited to 45°C for early childhood centres, primary and

secondary schools and nursing homes or similar facilities for young, aged, sick or people with

disabilities and 50°C for all other buildings. To comply with these requirements, a temperature

limiting device, such as a thermostatic mixing or tempering valve, will be required on all solar hot

water systems as detailed in Figures 9 and 10.

WATER PIPES

All hot water pipework should be insulated with sealed Polyethylene foamed or equivalent insulation

to optimise performance and energy efficiency. Such insulation may also be mandatory under local

regulations. With the exception of solar collector flow and return pipes, water pipe sizing should be

performed in accordance with AS/NZS 3500.

The collector flow and return pipes should be a minimum of 15 mm copper tube.

Plastic pipe must not be used. Plastic pipe is not suited to the high water

temperatures and pressures that may occur in the collector flow and return

system.

Table 5 - Collector Flow and Return Pipe Sizing

Pipe Size 1 Collector 2 Collectors 3 Collectors

DN 15 (metres) 60 50 30

DN 20 (metres) Not recommended 60 40

Figure 9 - Tempered gas hot water systems Figure 10 - Tempered Electric hot water systems

WARNING

Kitchen Laundry BathroomEnsuite

TLD

Note:TLD = Temperature Limiting Device

Storage

cylinder

Coldwater supply

Solar cold water inlet

Hot water outlet

Gas supply

Cold Inlet

Solar hot water return

Heated water from storage cylinder

Gas boost

S

o

l

a

r

c

o

l

l

e

c

t

o

r

s

Rinnaigas continuous

flowwater heater for

solarapplications,

presetto deliver

hot water at a fixed

temperature of 60°C or higher

Kitchen Laundry BathroomEnsuite

TLD

Note: TLD = Temperature Limiting Device

Electrically

boosted

storage

cylinder

Solar cold water inlet

Solar hot water return

Heated water from storage cylinder

S

o

l

a

r

c

o

l

l

e

c

t

o

r

s

INSTALLATION & MAINTENANCE - ALL SYSTEMS

Page 21

Rinnai Australia - 19 - Solar Split Systems Operating / Installation Manual - Version 8 - 18/10/10

FROST PROTECTION MODE ON SOLAR CONTROLLER

• The Solar Controller has two different temperature modes. Low temperature mode and

standard operating mode.

• Systems installed with E-Frost Collectors MUST be set to low temperature mode for the

warranty on the collector be valid. Refer warranty booklet for more details.

• Systems with other types of collectors should be set to standard operating mode.

• The factory default is Low Temperature Mode.

Figure 11 - Frost Protection on Solar

Collector

Figure 12 - Dip Switches K1 & K2

Mode

Dip Switch K1 Dip Switch K2

Standard Operating Mode

SOM ‘ON’ CIR

Low temperature Mode

LTM ‘ON’ CIR

• Power MUST be turned OFF to the Controller before opening the controller

box.

• Power MUST be OFF when adjusting Dip Switches.

WARNING

INSTALLATION & MAINTENANCE - ALL SYSTEMS

Page 22

Rinnai Australia - 20 - Solar Split Systems Operating / Installation Manual - Version 8 - 18/10/10

VALVES & FITTINGS

The following valves and fittings are supplied with your solar hot water system:

• A combined pressure and temperature (PTR) relief valve, capacity 10 kW.

Relief valve pressure settings vary with models. This valve is fitted at the top of the storage

cylinder. The PT R valve is a safety de vice and it is ma ndatory that it is fitted by the inst aller in all

installations.

• A non return valve fitted on the solar pump outlet to prevent backflow through the pump from

the solar collectors. This valve is factory connected.

• For gas boosted systems, elbow connections for the hot, cold and gas suppl y are fitted at the

bottom of the gas booster.

• Fittings as shown in Figures 32 - 36 and 40 - 41.

The following valves & fittings are to be supplied by the installer:

• A cold water expansion control valve (ECV). An ECV must be fitted in Western Australia and

South Australia to the cold water supply to the storage cylinder to comply with local regulations.

An ECV is recommended in all other geographical areas where the water supply has a

tendency to cause scaling. This will reduce hot water discharge from the Pressure and

Temperature Relief (PTR) valve which minimises wear on this valve.

• A stop cock, non return valve and line strainer. Combination valves incorporating two or more

of these functions (such as 'Trio' valves) are suitable. These are fitted to the cold water supply

to the storage cylinder by the installer.

• Cold water supply and hot water discharge pipework to and from the storage cylinder.

• Solar collector flow and return pipes and storage cylinder connections.

• An isolating valve and connection union for the gas supply to the gas booster.

• A approved pressure limiting valve (supplied with some systems) is required if the maximum

rated water supply pressure in Table 2 is exceeded.

INSTALLATION & MAINTENANCE - ALL SYSTEMS

Page 23

Rinnai Australia - 21 - Solar Split Systems Operating / Installation Manual - Version 8 - 18/10/10

REGULATIONS AND OCCUPATIONAL HEALTH AND SAFETY (OH&S)

Installation and commissioning must be performed by authorised persons. Rinnai solar systems must be

installed in accordance with these Instructions and all regulatory requirements which exist in yo ur area

including those in relation to manual lifting, working at heights and on roofs. Applicable publications and

regulations may include:

• AS 5601 Gas Installations

• AS/NZS 3500 National Plumbing and Drainage

• AS/NZS 3000 Wiring rules

• Building Codes of Australia

• Local Occupational Health and Safety (OH&S) regulations

SYSTEM ORIENTATION AND INCLINATION

The performance of any solar hot water system is determined by the way that the system is installed.

In Australia, the solar collectors should face the equator (North) as shown below. Where this orientation

is not practical, collectors facing within 45 degrees from North (between North-East and North-We st) area

acceptable, with a reduction in efficiency of approximately 5%. If the bulk of hot water consumption occurs

before 2 pm face the collectors in a North - Easterly direction. If the bulk of hot water consumption occurs

after 2 pm face the collectors in a North Westerly direction.

Figure 13 - Orientation Angle of Collectors

The inclination of the solar collectors should ideally be the same as the latitude angle of the site.

Inclinations within 20 degrees of the latitude angle of the site are acceptable, with a reduction in efficiency

of approximately 5%.

Figure 14 - Inclination of Collector

• Solar collectors are heavy and bulky items and are usually positioned on the

roofs of buildings. Each Australian State and Territory has a principal

Occupational Health and Safety (OH&S) Act which contains requirements

relating to the handling of large, bulky or awkward items and the prevention of

falls from elevated surfaces. Persons installing solar collectors must be aware

of their responsibilities and be adequately trained and qualified, in accordance

with local OH&S requirements.

WARNING

45

o

45

o

South

East

North

(Ideal gives 3 hours either side of noon day sun

)

City Latitude +/- 20

o

N

orth

INSTALLATION OF SOLAR COLLECTORS

Page 24

Rinnai Australia - 22 - Solar Split Systems Operating / Installation Manual - Version 8 - 18/10/10

Table 6: Latitudes of Australian Cities

City Latitude City Latitude City Latitude City Latitude

Adelaide 35°S Cairns 17°S Hobart 42°S Port Hedland 20°S

Alice Springs 24°S Canberra 35°S Mildura 34°S Rockhampton 24°S

Brisbane 27°S Darwin 12°S Melbourne 38°S Sydney 34°S

Broken Hill 31°S Geraldton 28°S Perth 32°S Townsville 19°S

For all installations the collector bank must slope upwards approximately 8 mm per collector from inlet

to outlet as shown below:

A maximum of three collectors can be connected together in parallel. Inlet (Cold) and outlet (Hot)

connections are made at opposite corners of the collector array.

SOLAR COLLECTOR ROOF MOUNTING OPTIONS

For mounting options not shown in Figure 17, for example in areas where the cyclon e frame can no t be

used, consult your nearest Rinnai Branch or Rinnai Representative.

It is normal to mount the solar collectors down close to the gutter. Roof construction must be checke d to

ensure that the roof timbers are capable of supp orting the additiona l load. (Refer to AS3 500.4 Ap pendix

H).

For tiled roof installations. Check for cracked or damaged tiles in the area of proposed installation.

Replace any faulty tiles.

If spare tiles are not available, swap damaged tiles with good ones from along the gutter line.

Figure 17 - Solar Collector Roof Mounting Options

Figure 15 - Enduro, Equinox, Excelsior

Collectors

Figure 16 - E-Frost Collectors

BLANKED OFF

CONNECTION

HOT CONNECTION

BLANKED OFF

CONNECTION

COLD

CONNECTION

COLLECTOR BANK MUST SLOPE

UPWARDS APPROX 8 mm PER COLLECTOR

BLANKED OFF

CONNECTION

HOT CONNECTION

BLANKED OFF

CONNECTION

COLD

CONNECTION

COLLECTOR BANK MUST SLOPE

UPWARDS APPROX 8 mm PER COLLECTOR

COLD

CONNECTION

N

FLAT ROOF FRAME

SIDE PITCH FRAME

N

REVERSE PITCH FRAME

N

STANDARD

N

INSTALLATION OF SOLAR COLLECTORS

Page 25

Rinnai Australia - 23 - Solar Split Systems Operating / Installation Manual - Version 8 - 18/10/10

SOLAR COLLECTOR INSTALLATION COMPONENTS

Table 7 - Components for Installing Collectors

COLLECTOR MOUNTING COMPONENTS

(supplied in Collector Installation kit)

COLLECTOR CONNECTING COMPONENTS

(supplied in Collector Installation kit)

Number of

Collectors

Number of

Collectors

1 2 3 1 2 3

2 - -

Mounting Rail Small

14201196

- 2 -

Mounting Rail Medium

14201197

2 2 2

Stop End

(1 x plug ¾G (Kinco) + 1 x ¾ Kinco nut and olive)

(Not used with E-Frost Collector)

28801025

- - 2

Mounting Rail Large 14201198

- 2 4

Compression Union ¾ - ¾

(1 x Nipple G¾ (Kinco) + 2 x ¾ Kinco nut and olive)

(Half of these not used with E-Frost Collector)

32201709

2*

+2

#

4*6

*

Collector Mounting Strap

* supplied with collectors,

# supplied in collector installation kit

12401012

1 1 1

Compression Union ¾ - ½

(1 x Nipple G¾ (Kinco) + 1 x ¾ Kinco nut and olive

+ 1x ½ Kinco nut and olive )

32201711

4 4 4

M8 Bolt, Washer and Nut BOLT 22601052

(used to bolt collector mounting WASHER 17401072

strap to mounting rail) NUT 16801062

1 1 1

Air Bleed Valve 11007701

4 8 12

Collector Retainer 26601706

1 1 1

Hot Sensor Sheath 10204714

4 8 12

BOLT 22601073

M6 Bolt, Washer and Nut WASHER 17401073

(used with collector retainers) NUT 16801007

1 1 1

Hot Sensor Lead (20 m) 31002706

1 1 1

Kinco Nut ½ 16801012

INSTALLATION KITS PART NUMBERS

1 collector : R33202739

2 collectors : R33202740

3 collectors : R33202741

1 1 1

Kinco Olive ½ 33001012

INSTALLATION OF SOLAR COLLECTORS

Page 26

Rinnai Australia - 24 - Solar Split Systems Operating / Installation Manual - Version 8 - 18/10/10

STANDARD INSTALLATION

Collector Mounting Component Pre Assembly for a Standard Installation

• Assemble the collector rail components as shown in Figure 18 below.

• Only loosely attach the collector retainers to the rails.

Figure 18 - Collector Mounting Components

This installation is not suitable for us e in cyclonic areas. For furt her details, please

contact your local Rinnai Solar distributor.

NOTE

MOUNTING RAIL

COLLECTOR SUPPORT STRAPS

COLLECTOR SUPPORT STRAPS

COLLECTOR RETAINERS

M6 BOLT, NUT &WASHER

COLLECTOR RETAINERS

M6 BOLT, NUT &WASHER

MOUNTING RAIL

INSTALLATION OF SOLAR COLLECTORS

Page 27

Rinnai Australia - 25 - Solar Split Systems Operating / Installation Manual - Version 8 - 18/10/10

STANDARD INSTALLATION CONTINUED

Fastening (Collectors to a Tiled Ro o f)

This installation is not suitable for in cyclonic areas. For further details, please

contact your local Rinnai Solar distributor.

• Position the lower collector mounting rail

assembly so that the rail is angled to ensure

the collectors have an 8 mm / collector rise.

• For aesthetic reasons it is best to mount as

close as possible to the gutter.

• Attach the collector mounting straps to the

rafter or truss under the tiles as shown in

Figure 19.

Figure 19 - Mount Lower Collector Rail

• Place the co llector(s) onto the ro of above the

lower rail. If more than one collector is being

installed then join them together using the

compression fittings supplied.

• Push down on the collector retainers to clamp

the collector and tighten the nuts as shown in

Figure 20.

Figure 20 - Mount collector on Roof

• Position the upper collector rail above the

collectors. Push down on the retainers to

clamp the collector and tighten the nuts.

• Attach the collector mounting straps to the

rafter or truss under the tiles as shown in

Figure 21.

Figure 21 - Attach Mounting Straps

• Replace the tiles and ensure the collector is

secure as shown in Figure 22.

Figure 22 - Replace Tiles

NOTE

Nail strap to rafter

Tiles removed

Nail strap

to rafter

Tiles removed

INSTALLATION OF SOLAR COLLECTORS

Page 28

Rinnai Australia - 26 - Solar Split Systems Operating / Installation Manual - Version 8 - 18/10/10

STANDARD INSTALLATION CONTINUED

Fastening (Collectors to a Metal Roof)

This installation is not suitable for use in cyclonic areas. For further details, please

contact your local Rinnai Solar distributor.

• Position the lower collector mounting rail

assembly so that the rail is over the roof

purlin and the rail is angled ensure the

collectors have an 8 mm / collector rise. For

aesthetic reason it is best to mount as close

as possible to the gutter.

• Drill through the roof iron and purlin using the

holes in the rail as a guide. Apply some

silicone sealant down the holes to ensure no

water leakage.

• Bolt the rail to the roof purlin using a suitable

fastener as shown in Figure 23.

Figure 23 - Mount Lower Collector Rail

• Position the collector(s) onto the roof above

the lower rail. If more than one collector is

being installed, join them together using the

compression fittings supplied.

• Push down on the collector retainers to clamp

the collector and tighten the nuts.

• Place the upper collector mounting rail above

the collectors. Push down on the collector

retainers to clamp the collector and tighten

the nuts.

• Drill through the roof iron and purlin using the

upper mounting rail as a guide. Apply some

silicone sealant down the holes to ensure no

water leakage and secure with suitable

fasteners as shown in Figure 24.

Alternatively the rail can be attached to the

roof using the collector mounting straps.

Figure 24 - Mount Collector on Roof

Figure 25 - Attach Upper Rail

NOTE

Bolt lower

mounting rail

to roof purlin

using a suitable

fastener

Bolt upper mounting

rail to roof purlin using

a suitable fastener

INSTALLATION OF SOLAR COLLECTORS

Page 29

Rinnai Australia - 27 - Solar Split Systems Operating / Installation Manual - Version 8 - 18/10/10

The frames are not suitable use in cyclonic areas. For the correct frame for use

in cyclone areas, contact your local Rinnai Solar distributor.

FRAMED INSTALLATIONS - FLAT, REVERSE & SIDE PITCH

Table 8 - Framed Installations

Figure 26 - Flat Roof Frames

• For use on a flat roof or where the roof

pitch is too low.

• This frame allows the Collectors to be

installed at a suitable inclination.

• Installations instructions are provided in

the Rinnai Frame Installation Manual.

Figure 27 - Reverse Pitch Roof Frames

• These comprise of a split system flat roof

frame and a side/reverse pitch kit.

• They can be used when the Collectors

need to be installed in the reverse

direction to the direction the roof is facing.

• For example, using a reverse pitch frame

on a South facing roof enables the

system to be oriented to the North.

• Installations instructions are provided in

the Rinnai Frame Installation Manual.

Figure 28 - Side Pitch Roof Frames

• These comprise of a split system flat roof

frame and a side/reverse pitch kit.

• They can be used when the Collectors

need to be installed side on to the

direction the roof is facing.

• For example, using a side pitch frame on

an East or West facing roof to enables

the system to be oriented to the North.

• Installations instructions are provided in

the Rinnai Frame Installation Manual.

NOTE

INSTALLATION OF SOLAR COLLECTORS

Page 30

Rinnai Australia - 28 - Solar Split Systems Operating / Installation Manual Version 8 - 18/10/10

COLLECTOR FITTINGS INSTALLATIONS

Connect the fittings to the collectors as shown in the diagrams below:

Figure 29 - Collector Fitting Details (Enduro, Equinox & Excelsior Collectors)

STOP END

COMPRESSION

UNION

1/2" TO 3/4"

UNION

COLD FLOW

PIPE SUPPLIED

BY INSTALLER

AIR BLEED

VALVE

HOT

SENSOR

LEAD

HOT SENSOR

SHEATH

1/2" NUT

1/2" OLIVE

RETURN PIPE

SUPPLIED BY

INSTALLER

COMPRESSION

UNION

STOP END

When connecting collectors to other

collectors or to other copper pipe

with compression unions, ensure

that the compression union is held

in two points as shown in the picture.

One side should be held still

while the other side is tightened.

Not doing this can cause damage

to the collector.

INSTALLATION OF SOLAR COLLECTORS

Page 31

Rinnai Australia - 29 - Solar Split Systems Operating / Installation Manual Version 8-18/10/10

Figure 30 - Collector Fitting Details (E-Frost Collectors)

AIR BLEED

VALVE

HOT

SENSOR

LEAD

HOT SENSOR

SHEATH

1/2" NUT

1/2" OLIVE

RETURN PIPE

SUPPLIED BY

INSTALLER

COMPRESSION

UNION

When connecting collectors to other

collectors or to other copper pipe

with compression unions, ensure

that the compression union is held

in two points as shown in the picture.

One side should be held still

while the other side is tightened.

Not doing this can cause damage

to the collector.

1/2" TO 3/4"

UNION

PIPE SUPPLIED

COLD FLOW

BY INSTALLER

HEADER PIPE MUST BE AT TOP TO

ENSURE COLLECTOR OPERATION

INSTALLATION OF SOLAR COLLECTORS

Page 32

Rinnai Australia - 30 - Solar Split Systems Operating / Installation Manual Version 8 - 18/10/10

OVERVIEW OF SYSTEM COMPONENTS

The range of gas boosted solar hot water systems include all the components shown in Figure 32

- 41 (refer to the appropriate Figure depending on cylinder type/size and kit on the following

pages).

The pump kit and associated plumbing connections are factory pre-assembled. All other

components and fittings will require connection on site. The gas booster and pump/controller kit may

be mounted to the front of the storage cylinder casing or in an alternative external location. In all

cases the heated outlet of the cylinder is connected to the cold water inlet of the gas booster.

GAS BOOSTER LOCATION

The gas booster is designed for ‘Outdoor” Installation only. As such, it must be located in an above

ground open air situation with natural ventilation, without stagnant areas, where gas leakage and

products of combustion are rapidly dispersed by wind and natural convection. The location must

comply with the clearances specified in AS5601.

The gas booster must be mounted on a vertical structure with the water and gas connections on the

underside pointing downwards. In most installations the gas booster is mounted directly on the

storage cylinder using two custom made mounting brackets. In all cases the heated outlet of the

cylinder is connected to cold water inlet of the gas booster.

GAS SUPPLY

The maximum gas consumption of the gas booster and the required ga s pressure are shown on the

appliance data plate. If the gas pipe sizing is insufficient the customer will not get the full

performance benefit. Gas pipe sizing must consider the gas input to the gas booster as well as all

the other gas appliances on the premises. The gas meter and regulator must be specified for this

gas rate. An approved sizing chart such as the one in AS 5601 should be used. An approved full

flow isolation valve and disconnection union must be fitted to the gas supply inlet of the gas booster.

Isolation valves must not be fitted directly.

HOT WATER DELIVERY TEMPERATURE

Gas boosters for use in solar hot water systems are preset to deliver a fixed temperature of 60°C in

accordance with plumbing regulations. In addition, they contain the warning stating "Rinnai Water

Controllers are NOT compatible with solar hot water insta llations and MU ST NOT BE USED" in the

vicinity of the temperature controller connections inside the appliance.

Gas Boosters other than models designated “S20”, “S26” or “Solar” must not be

used.

Gas Boosters marked with the text: "THIS APPLIANCE DELIVERS WATER NOT

EXCEEDING 50°C IN ACCORDANCE WITH AS 3498" are incompatible with solar hot

water systems and must not be used.

NOTE

INSTALLATION OF SOLAR GAS BOOSTED SYSTEMS

Page 33

Rinnai Australia - 31 - Solar Split Systems Operating / Installation Manual Version 8-18/10/10

f

f

Figure 31 - Smartstart® Schematic

Rinnai Smartstart Unit

Rinnai Continuous Flow Water

Heater - Gas Booster

Manual Activation

Switch ONLY

(not supplied)

Water controllers

MUST NOT

be used!

Gas Supply

Return Line

Outlets to Personal Hygiene areas

to be tempered to 50°C as per

AS3500.4

Refer to Rinnai manuals supplied

with appliances for important

installation information.

Installations MUST conform to local

regulataions.

Supply from solar storage cylinder

IMPORTANT

INSTALLATION OF SOLAR GAS BOOSTED SYSTEMS

Page 34

Rinnai Australia - 32 - Solar Split Systems Operating / Installation Manual Version 8 - 18/10/10

CLEARANCES

Figure 5.3 is reproduced below. Note that AS 5601-2004 was current at time of printing but may have

been superseded. It is the installer’s responsibility to ensure current requirements are met.

AS 5601 - Figure 5.3 ‘Clearances’ - Gas Booster Flue Terminal

INSTALLATION & MAINTENANCE - GAS BOOSTED SYSTEMS

Page 35

Rinnai Australia - 33 - Solar Split Systems Operating / Installation Manual Version 8 - 18/10/10

If the gas booster is not mounted on the storage cylinder, ensure that the wall or structure on which it is

to be mounted are capable of supporting the weight of the appliance and asso ci ated pipe wo rk. Refer to

Table 4 for individual gas booster weights. For gas boosters installed on elevated structures or under

floors specific requirements apply, refer to AS 5601 for details.

Location of gas booster flue terminal must be in accordance with Figure 5.3 of AS 5601.

Table 9 - GAS BOOSTER MOUNTING Sunmaster

Step 1. Mount upper moun ting bracket using template provided.

(SG175 - SG215 are factory mounted)

Step 2. Fix lower mounting bracket to Booster using screws provided.

Step 3. Hang booster on bracket and secure with screws provided.

Step 4. Secure lower mounting bracket to cylinder using screws provided.

INSTALLATION & MAINTENANCE - GAS BOOSTED SYSTEMS

Page 36

Rinnai Australia - 34 - Solar Split Systems Operating / Installation Manual - Version 8- 18/10/10

Figure 32 - Sunmaster Gas SG175 or SG215 with SGPKIT

Sunmaster - 3'OR3'WITHSGPKIT

33

3

16

16

6

9

5

8

7

10

1013

13

11

1114

14

15

12

1215

2

1

3

INSTALLATION & MAINTENANCE - GAS BOOSTED SYSTEMS

Page 37

Rinnai Australia - 35 - Solar Split Systems Operating / Installation Manual Version 8-18/10/10

Sunmaster SG175 or SG215 with SGPKIT

Items Supplied with Cylinder Items Supplied in SGPKIT (cont…)

1

1

PTR Valve 92501190

1

Adaptor R ¾ x Rp ½

3

3

Nipple R ¾

11

1

Pump & Controller Assembly 39001735

includes:

x 2 x ½” Kinco nut & olive

x flow control valve 11001033

x non return valve 27801711

x Temperature sensor lead 31002710

x Pump 30001703

x Control Box 31002703

12

1

Temperature Sensor with 2 m lead

Part of Pump and Controller Assembly

(39001735), but shown separately

for clarity in diagrams 31002710

16

2

Gas Booster Mounting Brackets

1 x tabs bent

26601098

1 x tabs unbent 26601096

Items Supplied in SGPKIT

13

2

Elbow ¾ Rp x ¾ G flexi 21201012

5

1

¾ Kinco Olive 33001011

14

2

Fibre Washer ¾ 17401008

6

1

¾ Kinco Nut 16801018

7

1

Copper Tee 11603936

15

1

Insulated Flexi Pipe 890 mm 11601070

8

2

½ Kinco Olive

33001012

(*1 not needed)

- 12

Screws 22601048

9

2

½ Kinco Nut 16801012

(*1 not needed)

- 3

Cable Ties 39601036

* 2

Nipples 17201003

10

1

Insulated Copper

Extension Pipe

11603348

-

1

Operation and

Installation Manual

15401030

-

1

Booster and Pump Mounting

Instruction Sheet

15401031

-

1 Warranty booklet

15401024

- 1

Saddle Clamp 27201015

-

1 RECS form

15401023 - 1 Standardsmark Sticker 15802091

INSTALLATION & MAINTENANCE - GAS BOOSTED SYSTEMS

Page 38