Rinnai REU V2632FFUC, REU V2632FFU Installation Instruction

Flueing Installation Instructions for

Internally installed Water Heater

Models REU V2632FFU / REU V2632FFUC

This Flue shall be installed in accordance with: -

Manufacturer’s Installation Instructions

Local Gas Fitting Regulations

Municipal Building Codes

AGA Installation Code for Gas Burning Equipment

Any other relevant Statutory Regulation

This appliance and flue system must be installed,

serviced and removed by an Authorised Person.

UP

UP

UP

Distributed and Serviced in Australia under a Quality

system certified as complying with ISO 9002 by

Standards Australia Quality Assurance Services

.

Flueing Installation Instructions

Contents:

General...................................................................................................................2

Important Installation Notes ...................................................................................2

Flueing Options ......................................................................................................3

Installation Tips ......................................................................................................3

Direct Flueing With Wall Terminal..........................................................................4

Extended Horizontal Flueing With Wall Terminal ..................................................4

Vertical Straight Flueing With Roof Terminal.........................................................5

Combination Vertical / Horizontal Installations ......................................................6

Multiple Vertical / Horizontal Installations ..............................................................7

Cutting The Flue Components. ..............................................................................7

Condensate drain...................................................................................................8

Flue Dimensions & Part Numbers .........................................................................9

Minimum Flue Clearances .....................................................................................10

Contact Points........................................................................................................10

Installation

This flue must be installed by an authorised person, the Installation must conform to local

regulations. Installation must comply with the instructions supplied by Rinnai.

Service and removal must be carried out by an authorised person.

Approval

Approved by AGA as a suitable flueing system for Rinnai REU V2632FFU / REU V2632FFUC

Gas Internal Water Heaters.

General

1. These instructions only apply to Rinnai Infinity Flueing with white plastic outer pipe. These instructions do not

apply to Rinnai Infinity Flueing with the stainless steel single skin or stainless steel coaxial flue. If in doubt

contact the Rinnai Australia Technical Advice Helpline: 1300 366 388.

2. Before commencing installation, please read the 'Installation Instructions - General', located inside a pouch

behind the front cover of all Infinity models. The Internal Infinity Range of water heaters must only be installed

with Rinnai Infinity Fluing as referred to in these instructions.

3. The requirements of the current AS5601/AG601 and local authorities must be met, which is the installers

responsibility.

4. The Required clearances of the Internal Rinnai Infinity when installed as a single unit are shown in Fig.1A The

appliances are AGA certified to be installed side by side as shown on

between flues.

270mm between horizontal terminals.

160mm between vertical cowls.

5. The REU-V2632FFU/REU-V2632FFUC when correctly installed with the Rinnai approved flue components is a

room-sealed appliance. No internal ventilation is required.

6. The fan assisted flue clearance dimensions in Fig 5 should be used, as the REU2632FFU is a fan-assisted

appliance.

7. The outer plastic section of the coaxial flue complies with temperature hazard requirements and can be

installed with zero clearance to combustible material.

, allowing a Minimum distance

page 7

Rinnai Aust ralia Pty Lt d 20/08/2003 Page 2 of 10

Flueing Installation Instructions

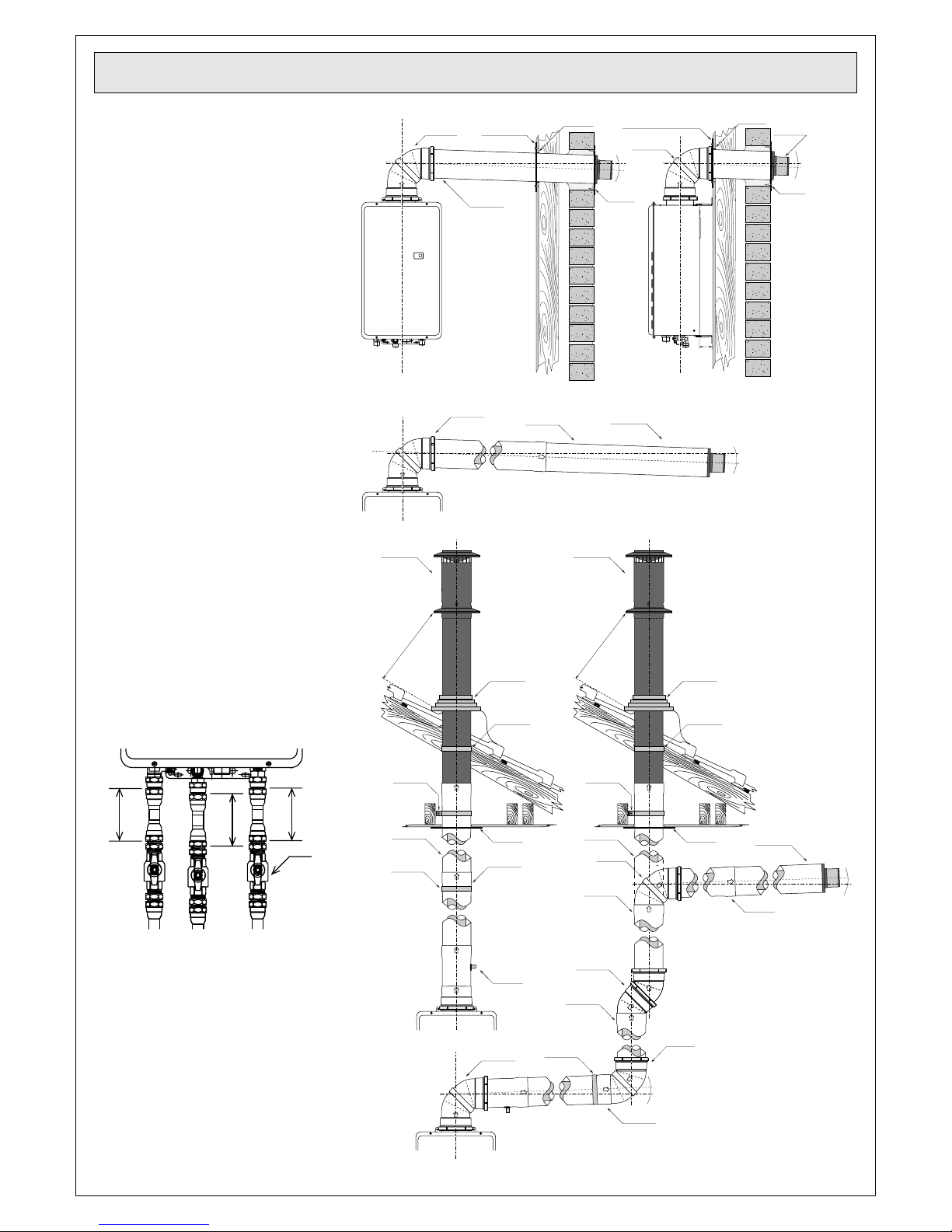

Flueing Options

Direct Flueing with Wall

1.

Terminal: (Fig.1)

Horizontal Extension Flueing

2.

with Wall Terminal: (Fig.2).

3. Vertical Flueing with Roof

Terminal (Fig.3)

4. Vertical / Horizontal Flueing with

Bends Wall and Terminal or

Roof Terminal (

Fig.4).

UP

FFBEND90BA

FFWPLATE or

FFWSEAL (Optional)

FFWALLTERM

127mm Hole

FFWPLATE or FFWSEAL (Optional)

FFBEND90BA

2° fall

to

terminal

FFWPLATE

UP

127mm Hole

2° fall

to

terminal

FFWPLATE

50

Fig.1

Installation Tips

1. The use of soft liquid soap on

the rubber seals will allow the

fittings to easily slide together.

(It is important to use soft soap,

2.

e.g.: Liquid hand soap, as hard

detergents may damage the

seals and PVC outer section).

3. Rinnai recommend 100 mm of

pipe (gas and water) section

between the isolating valves and

the appliance, which when

removed will allow the Infinity to

be lowered and disconnected

from the flue. (Fig. 5).

100

100

100

Valves

UP

FFROOFCOWL

FFBEND90BA

FFPIPE1000

U

P

FFROOFCOWL

FFWALLTERM

2° fall

to

terminal

Fig.2

Minimum

Clearance

500 mm

Flue pipe clip

supplied with

FFPIPE1000

Flue pipe clip

supplied with

FFPIPE1000

Decktite or lead

collar flushing

Flue pipe clip

supplied with

FFROOFCOWL

UP UP

UP

FFWSEAL FFWSEAL

FFPIPE1000

UP

Minimum

Clearance

500 mm

Flue pipe clip

supplied with

FFPIPE1000

FFPIPE1000

FFBEND90

FFPIPE1000

Decktite or lead

collar flushing

Flue pipe clip

supplied with

FFROOFCOWL

FFWALLTERM

U

U

P

UP

P

FFPIPE1000

2° fall

to trap

GasColdHot

Fig.5

4. When cutting any section of the

flue, remove all burrs and file a

slight bevel on the outer edge to

reduce any damage to the seal

when inserting into the

connecting fitting.

(See the section ‘Cutting the

Flue Components’ (Fig.9).

Rinnai Aust ralia Pty Lt d 20/08/2003 Page 3 of 10

Fig.3

UP

UP

UP

FFCONDK

FFBEND90BA

U

P

FFPIPE1000

Flue pipe clip

supplied with

FFPIPE1000

FFBEND45

(x2 = 90° Bend)

U

P

UP

UP

UPU

P

UP

U

P

FFPIPE1000

2° fall

to trap

FFBEND90

Fig.4

Loading...

Loading...