Rinnai Infinity V26 series, Infinity Heavy Duty 26 series, REU-V2626W series, REU-V2632W series Installation Information

Local regulations and / or the requirements of AS/NZS 3500.4 must be

considered regarding the temperature limitations of hot water supplied to

areas used primarily for personal hygiene. The temperature of water to

these areas may be limited to 50º C or less. To ensure these regulations

and / or requirements are met the system MUST be installed in

accordance with the 'Water Heater and Controller Installation

Configurations' Section of this document.

The appliance weighs 21 kg and the wall or structure on which it is to be

mounted must be capable of supporting the weight of the appliance and

associated pipe-work.

Ensure that suitable fixing screws or bolts are used to secure the Infinity

to the wall. Bracket and fixing hole locations are shown overleaf.

The top bracket has a keyhole slot so that the appliance can be

positioned by hanging it on one screw, then the other screws can be

secured.

After determining the most suitable position, fix the Infinity to the wall.

Positions of the cold water inlet, hot water outlet and gas connections are

shown overleaf. All connections are R ¾ (20mm). This is NOT an

indication of the pipe sizes required.

An Approved isolation valve and disconnection union MUST be fitted to

the cold water inlet. A non return valve is not required unless dictated by

local regulations.

GENERAL INSTALLATION INFORMATION

REU-V2626W SERIES / REU-V2632W SERIES

AG601/AS5601 - Gas Installations

AS/NZS 3500 - National Plumbing and Drainage

AS/NZS 3000 - Wiring Rules

Building Codes of Australia

The appliance should be placed as close as practicable to the most

frequently used hot water outlet point or points to minimise the delay

time for hot water delivery. For installations where the distance between

the unit and hot water outlet points is considerable, the appliance can

also be fitted in a 'flow and return system' which minimises the waiting

time for hot water delivery. Alternatively, multiple appliances can be

strategically placed to service outlet points with minimal delay time.

Contact Rinnai Australia for further information.

Location of the appliance flue terminal must be in accordance with the

clearances shown in Figure 5.3 of AG601/AS5601-2002 which is

reproduced right side. Ensure that the flue terminal and hot water outlet

connection cannot be touched by children. The appliance must be clear

of obstructions and shrubbery.

The appliance must be in an accessible location. Sufficient clearances

shall allow access to, and removal of, all serviceable components. The

appliance should not be mounted higher than 3.5 metres from the

ground or floor level unless the customer can arrange permanent and

safe access or can arrange another means of access, for example, by

means of scissor or boom lifts.

AC 240V, 10A weatherproof external earthed power point shall be

provided adjacent to the appliance. It must be clear of the gas and water

connections to the appliance, flue exhaust and water pressure relief

valve. The power cord of the appliance is 1500 mm long.

Note that AG601/AS5601-2002 was current at the time of printing but

may have been superseded. It is the installer's responsibility that the

current clearance requirements are met.

This appliance can use up to 199 MJ/h of gas. If the gas pipe sizing is

insufficient the customer will not get the full performance benefit. Gas

pipe sizing must consider the gas input to this appliance as well as all

the other gas appliances in the premises. The gas meter and regulator

must be specified for this gas rate. An approved sizing chart such as the

one in AG601 / AS5601 should be used.

Water pipe sizing and layout should be performed in accordance with

AS/NZS 3500. All hot water pipe-work should be insulated to optimise

maximum performance and energy efficiency.

Where the water supply pressure exceeds 1200 kPa, an approved

pressure limiting valve is required at the inlet of the appliance. To

achieve the rated flow a minimum water supply pressure of 140 kPa is

required at the appliance inlet. The unit will operate at lower supply

pressures but the rated flow will not be achieved. Contact Rinnai for

'gravity fed' or 'low pressure' hot water installations.

The water quality should be in accordance with the guidelines contained

in the 'How to use your Water Heater' booklet. Most Australian

Metropolitan water supplies will fall within these guidelines. If you are

unsure of your water quality, contact your local water authority. If sludge

or foreign matter is present in the water supply, a suitable filter should be

incorporated in the cold water supply pipe.

You must install this appliance in accordance with these Instructions and all

regulatory requirements which exist in your area. Applicable publications

may include:

•

•

•

•

THIS APPLIANCE IS DESIGNED FOR OUTDOOR INSTALLATION.

IT MUST BE MOUNTED ON A VERTICAL WALL OR STRUCTURE WITH

THE WATER AND GAS CONNECTIONS ON THE UNDERSIDE POINTING

TOWARDS THE GROUND.

THIS APPLIANCE MUST NOT BE USED AS A DOMESTIC SPA OR

SWIMMING POOL HEATER.

APPLIANCE LOCATION

PIPE SIZING

WATER SUPPLY

*Contact Rinnai for exemptions for the above clearances which may have

been granted since printing of this document.

HOT WATER DELIVERY TEMPERATURE

MOUNTING THE APPLIANCE

SERVICE CONNECTION POINTS

Min. clearances

(mm)

Ref.

Item

Fan assisted

Below eaves, balconies and other projections:

•

Appliances up to 50 MJ/h input

200

a

•

Appliances over 50 MJ/h input

300

b

From the ground, above a balcony or other surface †

300

c

From a return wall or external corner †

300

d

From a gas meter (M) (see 4.7.11 for vent terminal location of

regulator)

1000

e

From an electricity meter or fuse box (P)

500

f

From a drain pipe or soil pipe

75

g

Horizontally from any building structure = or obstruction facing a

terminal

500

h

From any other flue terminal, cowl, or combustion air intake†*

300

Horizontally from an openable window, door, non-mechanical air inlet, or any other opening

into a building with the exception of sub-floor ventilation:

•

Appliances up to 150 MJ/h input

300

•

Appliances over 150 MJ/h input up to 200 MJ/h input

500

•

Appliances over 200 MJ/h input

1500

j

•

All fan-assisted flue appliances, in the direction of disc harge

1500

k

From a mechanic al air inlet, including a spa blower

1000

Vertically below an openable window, non-mechanic al air inlet, or any other opening into a

building with the exception of sub-floor ventilation:

•

Space heaters up to 50 MJ/h input

150

•

Other appliances up to 50 MJ/h input

500

•

Appliances over 50 MJ/h input and up to 150 MJ/h input

1000

n

•

Appliances over 150 MJ/h input

1500

†

- unless appliance is approved for closer installation

NOTES:

1 All distances are measured to the nearest part of the terminal.

2 Prohibited area below electricity meter or fuse box extends to ground level.

3 See Clause 5.13.6.6 for restrictions on a flue terminal under a covered area.

4 See Appendix J, Figures J2(a) and J3(a), for clearances required from a flue terminal to an LP Gas

cylinder. A flue terminal is considered to be a source of ignition.

5 For appliances not addressed above, approval shall be obtained from the Authority.

g

openable

window

door

M

P

g

See note 3

T

b

d

d

e

e

See note 2

h

h

a

h

j

j

j

n

k

k

c

c

f

T = Flue terminal

I

= Mechanical air inlet

areas for flue terminals

T

T

I

Shading indicates prohibited

M = Gas meter

P = Electricity meter or fuse box

Fig 5.3

1

An Approved isolation valve and disconnection unit MUST be fitted to

the gas inlet.

Isolation Valves must not be fitted directly to the appliance.

It may be necessary to fit a temperature limiting device for delivery to

areas used primarily for the purposes of personal hygiene. Refer to the

'Water Heater and Controller Installation Configurations' Section of this

document.

Purge gas and cold water supply lines to remove air and swarf before

final connection of the appliance. Swarf in either the gas or water

supplies may cause damage.

Recess Box: The appliance can be 'recessed' into the wall for flush

fitting reducing even further the space required. A custom made Rinnai

Infinity Recess Box must be used for this purpose.

Pipe Cover: The pipe-work underneath the appliance can be covered

using a custom made Rinnai pipe cover.

Security Cage: A Security Cage can be fitted around the appliance.

Contact Rinnai for further details.

Remote Controllers are an optional extra. 'Standard' and 'Deluxe'

controls can be fitted. Standard controls allow temperature selection

only. Deluxe controls have temperature selection, bath-fill and voice

prompting functions. For detailed information regarding controller

operation refer to the 'How to use your water heater' booklet supplied

with the appliance. Other manufacturers' controllers are NOT compatible

with this appliance.

Up to 4 Standard Controls can be fitted to the appliance. They are

normally installed in the areas where the majority of hot water is used,

for example, the kitchen, bathroom, ensuite and laundry.

Deluxe controllers have 'kitchen' (MC-70-2A) and 'bathroom' (BC-70-2A)

versions. 'Kitchen' controls are intended for the kitchen or other

convenient area where the majority of hot water is used. Bathroom

controllers are intended to be fitted in the bathroom or ensuite and allow

the user to have a bath filled to the required level and temperature

automatically.

Up to three 'deluxe' controllers can be connected as follows:

If a fourth controller is required, a Standard controller can be included as

follows:

Controllers must be installed in shaded and clean locations. They should

be fitted out of reach of children (suggested height from floor at least

1500mm). Controllers are water resistant, however, durability is

improved when positioned outside the shower recess or at least 400mm

above the highest part of a sink, basin or bath.

NEAR A HEAT SOURCE, SUCH AS A COOK TOP, STOVE OR OVEN.

HEAT, STEAM, SMOKE AND HOT OIL MAY CAUSE DAMAGE.

IN DIRECT SUNLIGHT.

OUTDOORS UNLESS AN ENCLOSURE IS PROVIDED WHICH

PROTECTS THE CONTROLLER AGAINST SUNLIGHT AND DUST

INGRESS.

AGAINST A METAL WALL UNLESS THE WALL IS EARTHED IN

ACCORDANCE WITH AS/NZS 3000.

Remote controls operate at extra low voltage (12 Volts DC) which is

supplied from the appliance. Controllers are supplied with 15 m of

electrical cable. The cable wires for connection to the appliance are

fitted with spade terminals. Extension cables are available from Rinnai.

Alternatively, a two core sheathed (double insulated) flex with minimum

cross-sectional area of 0.5 mm² can be used. Maximum cable length is

50 m. For connection refer to the “CONNECTING REMOTE CONTROL

CABLES” section.

Determine the most suitable position for the Remote Control.

Determine the most suitable position for the Remote Control.

ACCESSORIES

REMOTE CONTROLLERS

STANDARD CONTROLLER (MODEL MC-91-1A)

DELUXE CONTROLLERS (MODELS MC-70-2A AND BC-70-2A)

POSITIONING OF CONTROLLERS

DO NOT INSTALL THE CONTROLLERS:

•

•

•

•

REMOTE CONTROL CABLES

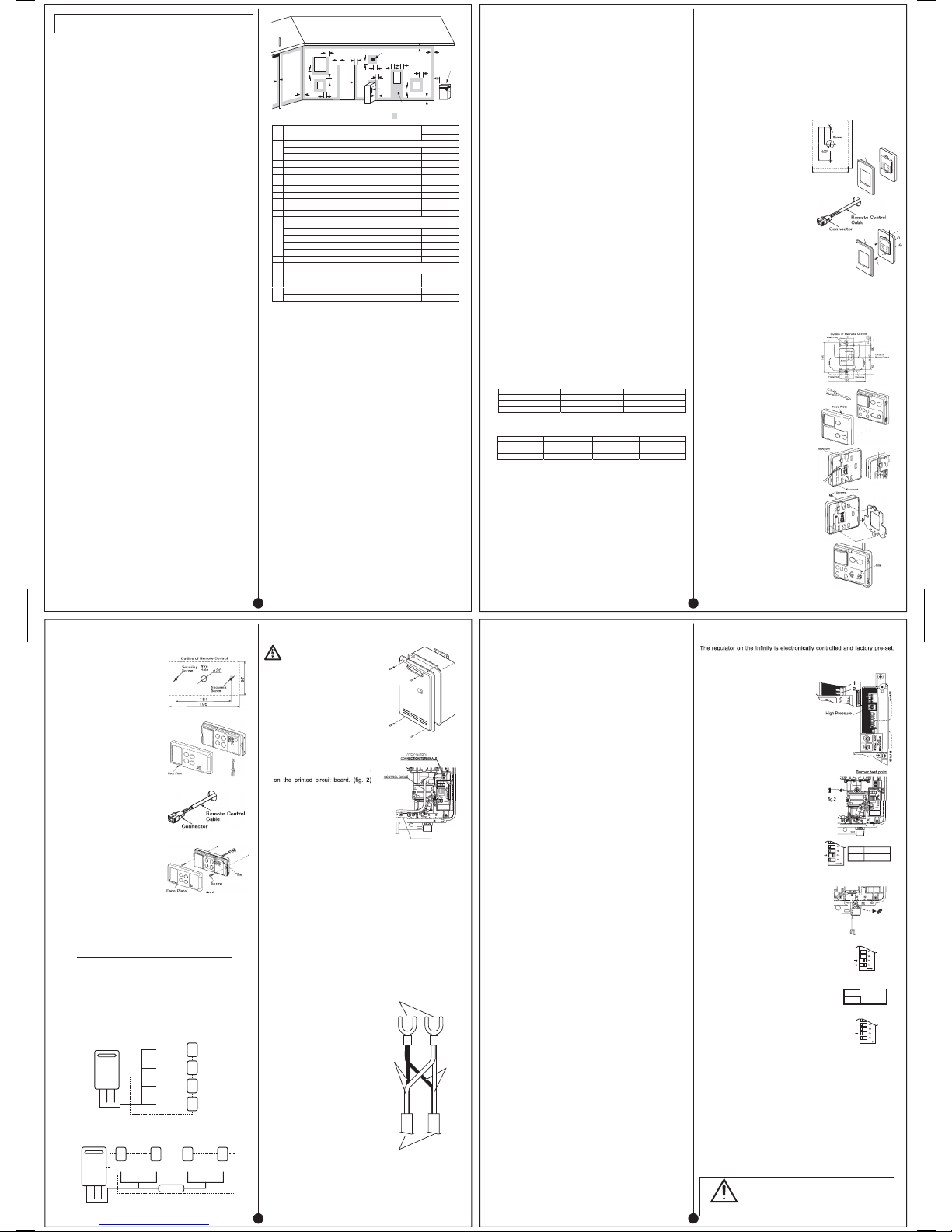

FITTING THE 'STANDARD' REMOTE CONTROLLERS (MC-91-1A)

1.

2.

3.

4.

5.

6.

7.

8.

Note: For details on how to program the MC-91-1A remote control see

Appendix 1. MC-91-1A CONTROLLER PROGRAMMING.

FITTING THE 'DELUXE' REMOTE CONTROLLERS (MC-70-2A)

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Kitchen

Bathroom

Ensuite

MC-70-2A

MC-70-2A BC-70-2A

MC-70-2A

BC-70-2A BC-70-2A

Drill 3 holes in the wall, as shown in

fig.1, one for the cable and two for

the securing screws. Ensure holes

are drilled. Fit wall plugs if required.

Run the cable through the hole in the

wall-ensuring that the end fitted with

the connector is near the controller.

(fig.3)

Remove the face plate from the Remote

Control, using a screw driver.(

fig.2)

Connect the cable to the remote

controller.

Fix the remote controller to the wall

and fasten with phillips head screws

supplied as shown in fig.4.

Remove the protective plastic film from

the controller face as show in fig.4

Replace the face plate.

Drill 3 holes in the wall, as shown in

fig.1, one for the cable and two for

the securing screws. Ensure holes

are drilled. Fit wall plugs if required.

Fix the mounting bracket to the wall

using the screws provided.

Run the cable through the hole in the

wall.

Remove the face plate from the

Remote Control, using a screw driver.

(fig.2)

Connect the cable to the kitchen

remote control as shown in fig.3.

Connect cables from bathroom

controllers (if fitted) to the kitchen

remote control also (if required).

Polarity is not important; either colour

wire can be connected to either

terminal.

Fix the kitchen controller to the wall

bracket and fasten with phillips head

screws supplied (M4 x 12) as shown

in fig.4.

Remove the protective plastic film

from the controller face as shown in

fig.5.

Replace the face plate.

Close the flip panel.

Note: If the cable cannot be run in the

wall cavity, remove the plastic 'knockout'

lugs as shown in fig.3.

Kitchen Bathroom

Ensuite Laundry

MC-70-2A

MC-70-2A BC-70-2A

MC-70-2A BC-70-2A BC-70-2A MC-91-1A

Outline of Remote Control

90

Securing

Wire

fig.1

fig.3

fig.5

fig.4

fig.3

fig.2

fig.1

fig.2

Face Plate

fig.4

Face Plate

Screw

2

Drill 3 holes in the wall, as shown in

fig.1, one for the cable and two for

the securing screws. Drill holes to

ensure controller position will be level

when installed. Fit wall plugs if

required.

Run the cable through the hole in the

wall - ensuring that the end fitted with

the connector is near the controller.

(fig.3)

Remove the face plate from the

Remote Control, using a screw driver.

(fig.2)

Connect the cable to the bathroom

remote controller.

Fix the bathroom controller to the wall

and fasten with phillips head screws

supplied as shown in fig.4.

Remove the protective plastic film

from the controller face as shown in

fig.4.

Replace the face plate.

Close the flip panel.

Determine the most suitable position for the Remote Control.

If the front cover of the appliance contains the following text install it in

accordance with Diagram 1 below.

" THIS APPLIANCE DELIVERS WATER

NOT EXCEEDING 50ºC IN ACCORDANCE WITH AS 3498 "

If the front cover of the appliance does NOT contain the above text install

it in accordance with Diagram 2 below.

IMPORTANT: If the appliance is to deliver water primarily for the

purposes of personal hygiene in an early childhood centre, primary or

secondary school, nursing home or similar facility for young, aged, sick

or disabled persons as defined in AS/NZS 3500.4 a Temperature Limiting

Device (TLD), such as a Tempering Valve, may be required even if the

appliance is set to 50º C or less.

For these types of applications contact Rinnai.

Diagram 1 - 50ºC Appliance.

Diagram 2 - Not a 50ºC Appliance.

Note: TLD = Temperature Limiting Device.

Isolate the power supply.

Remove the front cover from the Appliance (4 screws) fig. 1.

Cut the spade connectors from 2 of the controller cables to be

connected to the appliance (4 spade connectors should be cut off) and

discard. Connect the wires from these two cables and terminate into

two new spade connectors as shown in fig.3. Spade connectors are

available from your local electrical component retailer.

Thread the 3 cables through the cable access hole at the base of the

appliance. Connect the 4 spade connectors to the terminals marked

"Remote Control" on the printed circuit board. (fig. 2) Polarity is not

important. Either wire colour can be connected to either terminal.

Replace cover of the Appliance. Ensure that the screw with the star

washer is placed at the bottom right hand corner for earthing purposes.

Replace cover of the Appliance. Ensure that the screw with the star

washer is placed at the bottom right hand corner for earthing purposes.

FITTING THE 'DELUXE' REMOTE CONTROLLERS (BC-70-2A)

1.

2.

3.

4.

5.

6.

7.

8.

9.

WATER HEATER & CONTROLLER INSTALLATION CONFIGURATIONS

CONNECTING REMOTE CONTROL CABLES

RISK OF ELECTRICAL SHOCK !

Connecting One or Two Controllers

2.3.4.

5.

Connecting Three Controllers

1.

3.

4.

5.

Connecting Four Controllers

1.

2.

3.

4.

5.

Isolate the power supply.

Remove the front cover from the

Appliance (4 screws) fig. 1.

Thread the cable(s) through the cable

access hole at the base of the

appliance.

Connect the spade connectors to the

terminals marked

‘

Remote Control

Polarity is not important. Either wire

colour can be connected to either

terminal.

Replace cover of the Appliance.

Ensure that the screw with the star

washer is placed at the bottom right

hand corner for earthing purposes.

Isolate the power supply.

Remove the front cover from the

Appliance (4 screws) fig.1.

Cut the spade connectors from all

four controller cables to be connected

to the appliance (8 spade connectors

should be cut off) and discard.

Connect the wires from two cables

and terminate into two new spade

connectors as shown in fig.3.

Repeat for the remaining two cables.

Spade connectors are available from

your local electrical component

retailer.

Thread the 4 cables through the

cable access hole at the base of the

appliance. Connect the 4 spade

connectors to the terminals marked

‘"Remote Control" on the printed

circuit board. (fig. 2) Polarity is not

important. Either wire colour can be

connected to either terminal.

fig. 2

Do not attempt to connect the

remote control cable terminals to

the appliance with the power on.

fig. 3

New spade connectors

Cable

wires

Cable

wires

Remote control cables

50º C

KITCHEN

Temperature

controller

(optional)

Temperature

controller

(optional)

Temperature

controller

(optional)

Temperature

controller

(optional)

LAUNDRY

BATHROOM

ENSUITE

H

O

T

C

O

L

D

G

A

S

KITCHEN

Temperature

controller

(optional)

Temperature

controller

(optional)

LAUNDRY BATHROOM

Temperature

controller

(optional)

Temperature

controller

(optional)

ENSUITE

TLD

H

O

T

C

O

L

D

G

A

S

fig. 1

fig.3

CABLE CLAMP

REMOTE

REMO

fig.1

fig.2

fig.4

3

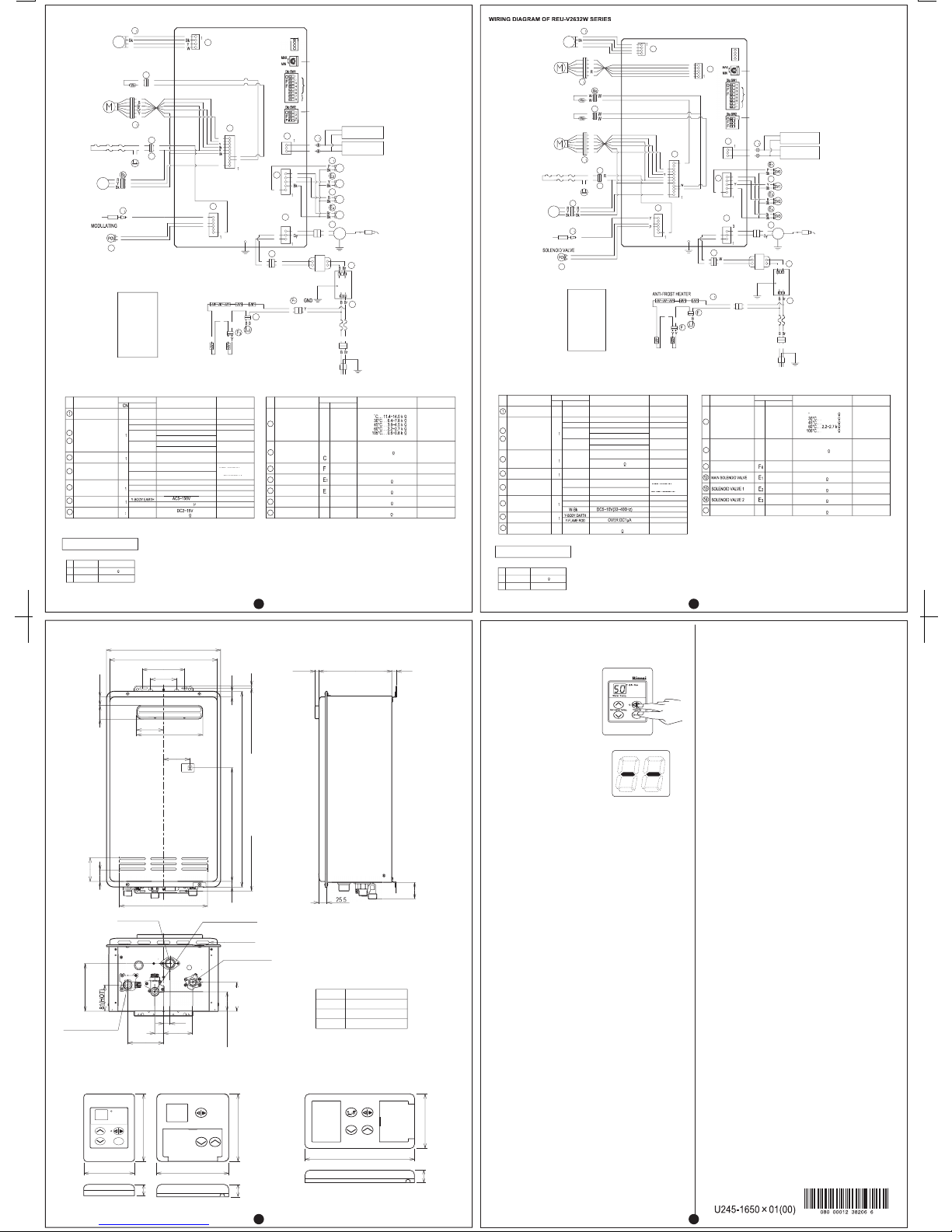

Regulator adjustment

screw access plug

TESTING AND COMMISSIONING

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

GAS PRESSURE SETTING

Under normal circumstances it does not require adjustment during

installation. Perform this procedure only if the unit is not operating correctly

and all other possible causes for incorrect operation have been eliminated.

1.

2.

3.

4.

Note: 'ON' towards front, 'OFF' towards rear.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

Before final connection of the water heater purge gas, hot and cold

water supply lines. Swarf in either the gas or water supplies may cause

damage.

Turn on gas and cold water supplies.

Test for water leaks and gas escapes near the unit.

Isolate gas supply. Remove test point screw located on the gas inlet

connection and attach pressure gauge.

Turn the power 'on' at the power point socket and turn on gas.

If remote controllers are fitted, turn the controller 'on', select the

maximum delivery temperature and open ALL available hot water taps

including the shower. If remote controllers are not fitted, simply open all

available hot water taps. (CAUTION: Ensure building occupants do not

have access to hot water outlets during this procedure.)

Operate ALL other gas appliances at their maximum gas rate, in

accordance with manufacturers instructions.

With all gas appliances in operation at maximum gas rate, the pressure

gauge at the incoming test point the Infinity should read 1.13 - 3.0 kPa

on Natural Gas. On LPG the pressure should be 2.75 - 3.0 kPa. If the

pressure is lower, the gas supply is inadequate and the Infinity unit will

not operate to specification. Check gas meter, regulator and pipework

for correct operation/sizing and rectify as required. Note that the gas

regulator on the Infinity is electronically controlled and factory pre-set.

Under normal circumstances it DOES NOT need adjustment during

installation.

Close hot water taps including the shower.

Inspect and clean the strainer located on the cold water inlet

connection. This procedure may need to be repeated to ensure the

strainer remains clear, especially on new installations.

If Temperature Controllers are fitted, it is necessary to test their

operation through the complete range of functions. (Refer to the 'How to

use your Water Heater' booklet.)

Confirm the hot water delivery temperature(s) using a thermometer.

If controllers are fitted, ensure temperatures exceeding 50º C cannot be

selected on bathroom or ensuite controllers.

After testing is completed, explain to the householder the functions and

operation of the water heater and temperature controllers (if fitted).

Ensure the 'Customer Record' section of the 'How to use your Water

Heater' booklet is filled in and that the booklet is handed to the

customer. Remind the customer to complete the Warranty Card and

forward to Rinnai.

Turn 'OFF' the gas supply.

Turn 'OFF' 240V power supply.

Remove the front cover from the

appliance.

Check gas type switches (fig. 1) are in

the correct position (dipswitch 1 of

SW2 'ON' = NG, 'OFF' = LPG).

Attach pressure gauge to burner test

point, located on the gas control.

(fig. 2)

Turn 'ON' the gas supply.

Turn 'ON' 240V power supply.

If remote controllers are fitted, turn the

unit 'ON' at the kitchen controller,

select the maximum delivery

temperature of 55°C and open a hot

water tap fully. (CAUTION: Ensure

building occupants do not have access

to hot water outlets during this

procedure.)

Set the Infinity to 'Forced Low'

combustion by setting No. 7 dipswitch

of the SW1 set of dip switches to 'ON'.

(fig. 3)

Check the burner test point pressure.

Remove rubber access plug and

adjust the regulator screw on the

modulating valve (fig. 4) as required to

the pressure. Table 1. Replace rubber

access plug.

Set the Infinity to 'Forced High'

combustion by setting both No. 7 and

No. 8 dipswitches of the bottom SW1

set to 'ON'. (fig. 5) Ensure maximum

water flow.

Check the burner test point pressure.

Adjust the high pressure Potentiometer

(POT) on the Printed Circuit Board

(PCB) as required to the pressure

shown Table 2. (fig.1).

IMPORTANT: Set dip switches No's 7 and 8 on the bottom (SW1) set

of switches to 'OFF' to return the appliance to 'Normal' combustion.

(fig. 6)

Close hot water tap.

Turn OFF the gas supply and 240V power supply.

Remove pressure gauge, and replace sealing screw.

Turn 'ON' the gas supply and 240V power supply.

Operate unit and check for gas leaks at test point.

Replace the front cover of the appliance.

ON

fig. 3

fig. 4

Table 1.

N.G.

0.14 kPa

0.22 kPa

Prop.G.

Pressure Setting Low

ON

fig. 6

ON

fig. 5

Table 2.

N.G.

0.79 kPa

1.15 kPa

Prop.G.

Pressure Setting High

DURING PRESSURE TESTING OF THE INSTALLATION

ENSURE GAS COCK SITUATED BEFORE UNIT IS SHUT-OFF.

FAILURE TO DO SO MAY RESULT IN SERIOUS

DAMAGE TO THE APPLIANCE AND POSSIBLE INJURY.

SW2

g

fig.1

SW1

SW1

WARNING

Potentiometer

4

DIAGNOSTIC POINTS OF REU-V2632W SERIES

WIRING DIAGRAM OF REU-V2626W SERIES

DIAGNOSTIC POINTS OF REU-V2626W SERIES

TRANSFORMER

VOLTAGES AND RESISTANCES

FLOW

CHART

No.

COMPONENT

MEASUREMENT POINT

WIRE COLOR

A NOTE

SURGE PROTECTOR

AC207~264V

DC11~13V

REMOTE CONTROL

3

DC11~13V

3

WATER FLOW SENSOR

5

C

DC4~7V(PULSE 17~460Hz)

DC6~45V

67~81

MODULATING

SOLENOID VALVE

WATER FLOW

CONTROL DEVICE

Gy-Br

Gy-Y

BELOW DC1V(LIMITER ON)

DC11~13V

DC4~6V(LIMITER OFF)

FULL OPEN POSITION

DC11~13V

Gy-Or

OPERATE ELECTRICITY

BELOW DC1V(LIMITER ON)

DC4~6V(LIMITER OFF)

ON2.7l/min (30Hz)

OVER 1800PULSE/min

()

(

GND

5

COMBUSTION FAN

6

OVER DC1

µ

AFTER IGNITION

FLAME ROD

C

OFF2.0l/min (20Hz)

BELOW 1200PULSE/min

()

(

15

NORMAL VALUE

CONTROL ELECTRICITY

FULL CLOSE POSITION

FLAME CONDITION

GND

DC11~13V

DC5~10V(33~400Hz)

()

Y-FLAME ROD

16~18

WIRE COLOR

CN

5

NORMAL VALUE

AC90~110V

FLOW

CHART

No.

COMPONENT

MEASUREMENT POINT

CN

WIRE COLOR

A NOTE

Gy-Gy

6

IGNITER

MAIN SOLENOID VALVE

THERMAL FUSE

AC90~110V

DC80~110V

BELOW 1

8

10

13

15

3

OUTGOING WATER

THERMISTOR

DC80~110V

DC80~110V

DC80~110V

SOLENOID VALVE 1

SOLENOID VALVE 2

SOLENOID VALVE 3

ON MANIFOLD

NORMAL VALUE

3

9

FLOW

CHART

No.

COMPONENT

MEASUREMENT POINT

CN

WIRE COLOR

A NOTE

SURGE PROTECTOR

AC207~264V

DC11~13V

REMOTE CONTROL

DC11~13V

3

WATER FLOW SENSOR

5

6

C

DC4~7V(PULSE 17~460Hz)

DC6~45V

67~81

DC2~15V

MODULATING

SOLENOID VALVE

WATER FLOW

CONTROL DEVICE

Gy-Br

Gy-Y

BELOW DC1V(LIMITER ON)

DC11~13V

DC4~6V(LIMITER OFF)

FULL OPEN POSITION

DC11~13V

Gy-Or

OPERATE ELECTRICITY

BELOW DC1V(LIMITER ON)

DC4~6V(LIMITER OFF)

ON2.7L/min (30Hz)

OVER 1800PULSE/min

()

(

GND

5

COMBUSTION FAN

AC5~150V

AFTER IGNITION

FLAME ROD

C

8

OFF2.0L/min (20Hz)

BELOW 1200PULSE/min

()

()

G

Or-W

DC2~6V

15~35

GND

3

16

BY-PASS FLOW

CONTROL DEVICE

NORMAL VALUE

CONTROL ELECTRICITY

FULL CLOSE POSITION

OPERATE CONDITION

FLAME CONDITION

TRANSFORMER

VOLTAGES AND RESISTANCES

16~18

WIRE COLOR

CN

5

NORMAL VALUE

GND

DC11~13V

AC90~110V

FLOW

CHART

No.

COMPONENT

MEASUREMENT POINT

CN

WIRE COLOR

A NOTE

Gy-Gy

IGNITER

THERMAL FUSE

AC90~110V

DC80~100V

BELOW 1

9

15C11.4~14.0 k

6.4~7.8 k

3.6~4.5 k

0.6~0.8 k

OUTGOING WATER

THERMISTOR

5

DC80~100V

15

DC80~100V

DC80~100V

1.7~2.0k

HEAT EXCHANGER

OUTGOING THERMISTOR

SOLENOID VALVE 3

ON MANIFOLD

NORMAL VALUE

C

3

10

3

3

B

C

Gy

5

6

C

C

C

3

Gy

SV1

3

SV0

6

IG

SV2

Gy

Gy

TRANSFOMER

SURGE PROTECTOR

5

FUSE

(3A)

Gr/Y

Gr/Y

GND

ELECTRODE

SPARK

IGNITER

SV3

MAIN SOLENOID VALVE

SOLENOID VALVE 1

SOLENOID VALVE 2

SOLENOID VALVE 3

MODULATING VALVE

CURRENT ADJUSTING

Temperature control

Gas pressure

Gas type

OUTGOING WATER

THERMISTOR

WATER FLOW

CONTROL DEVICE

COMBUSTION FAN

THERMAL FUSE

OVERHEAT

SWITCH

QS

WATER FLOW

SENSOR

FLAME ROD

SOLENOID VALVE

BC-70-2A OR

MC-91-1A

COLOR CODING

W :White

Bk:Black

Br:Brown

R :Red

B :Blue

Y :Yellow

Or:Orange

Gr:Green

Gy:Grey

AC240V

Gr/Y

GND

ANTI-FROST HEATER

ANTI-FROST HEATER

FROST SENSING

SWITCH

MC-70-2A OR

MC-91-1A

10

3

C

Gy

Gy

5

3

6

3

C

C

C

3

Or

Gy

6

IG

Gy

TRANSFOMER

SURGE PROTECTOR

5

1

3

FUSE

(3A)

Gr/Y

GND

Gr/Y

GND

ELECTRODE

SPARK

IGNITER

MAIN SOLENOID VALVE

SOLENOID VALVE 1

SOLENOID VALVE 2

SOLENOID VALVE 3

MODULATING VALVE

CURRENT ADJUSTING

Temperature control

Gas pressure

Gas type

Or

OUTGOING WATER

THERMISTOR

HEAT EXCHANGER

THERMISTOR

BY-PASS FLOW

CONTROL DEVICE

WATER FLOW

CONTROL DEVICE

COMBUSTION FAN

THERMAL FUSE

OVERHEAT

SWITCH

QS

WATER FLOW

SENSOR

FLAME ROD

MODULATING

G

BC-70-2A OR

MC-91-1A

5

G

Or

RR

COLOR CODING

W :White

Bk:Black

Br:Brown

R :Red

B :Blue

Y :Yellow

Or:Orange

Gr:Green

Gy:Grey

AC240V

Gr/Y

GND

ANTI-FROST HEATER

3

FROST SENSING

SWITCH

MC-70-2A OR

MC-91-1A

5

WATER HEATER DIMENSIONS

REMOTE CONTROLLER DIMENSIONS

You will need to activate the fourth controller.

(You have 3 controllers or fewer), go to Question 2.

No further action required.

You will need to program the kitchen controller to enable

selection of temperatures higher than 50º C.

STEP 1:

For the controller in the KITCHEN only, press and hold the 'Transfer'

and 'On/Off' buttons simultaneously ( see fig.1 ) until a 'beep' is heard

(approximately 5 seconds).

STEP 2:

When the controller fitted in the KITCHEN is switched on, it should be

possible to select temperatures higher than 50º C. If not, repeat Step 1.

If the kitchen controller is replaced, repeat STEP 1 above for the

replacement controller.

If the kitchen controller is swapped with another controller (for

example, the controller fitted in a bathroom), repeat STEP 1 for the

controller moved from the kitchen to the bathroom. Then perform STEP

1 for the controller moved from the bathroom to the kitchen.

STEP 1:

For the controller in the KITCHEN

only, press and hold the 'Transfer'

and 'On/Off' buttons simultaneously

( see fig 1.) until a 'beep' is heard

(approximately 5 seconds).

STEP 2:

Check that the display on ALL FOUR

controllers is lit and displaying a

temperature when 'switched on'. If

any ONE of the controller displays

two dashes ( see fig 2. ) in the

display repeat STEP 1.

This completes the activation

procedure. Ignore question 2.

Appendix 1. MC-91-1A CONTROLLER PROGRAMMING

QUESTION 1: Are 4 controllers connected ?

IF YES:

IF NO:

QUESTION 2: Is your water heater labeled "THIS APPLIANCE

DELIVERS WATER NOT EXCEEDING 50º C IN

ACCORDANCE WITH AS 3498 " on the front cover ?

IF YES:

IF NO:

Note

·

·

fig 1.

fig 2.

195

22

97

120

120

12890

20

22

BC-70-2A

MC-70-2AMC-91-1A

89

20

HOT WATER OUTLET

GAS CONNECTION

COLD WATER INLET

CABLE ACCESS

350

330

A

270

81

82.5

203

80

Cold water inlet:20mm

Gas inlet :20mm

A Dimensions

GAS

COLD

40

50

6

87

Loading...

Loading...