Rinnai INFINITY 16, REU-V1616W, V1200, REU-V1620W, INFINITY 18 Service Manual

...

INFINITY 16 REU-V1616W

V1200 REU-V1620W

INFINITY 18 REU-V2018W

INFINITY 20 REU-V2020W

SERVICE MANUAL

Rinnai High Capacity Continuous Flow Gas Hot Water System

NOTE: This manual does not apply to models: REU-V1620WG, REU-V1620WB, REU-V2024WG, REU-V2024WE,

REU-V2426WB, REU-V2626WG, REU-VM2630WD, REU-VM2630WC, REU-V2632FFUG, REU-VM2632FFUC

All Rinnai products are certified by the

Distributed and serviced in Australia under a Quality

System certified as complying with ISO 9001 by

SAI Global

SAI Global

Australian Gas Association as compliant

to relevant Australian Standards.

Rinnai Australia Head Office is certified

as complying with ISO 9001 by SAI

Global.

Rinnai New Zealand has been certified to

ISO 9001 Quality Assurance by Telarc.

All Rinnai products are Certified to

WaterMark by SAI Global. WaterMark

certification is awarded to products and

fittings complying with safety and water

contamination standards.

© Copyright Rinnai Australia Pty Ltd ABN 74 005 138 769

All rights reserved

Produced by Technical Services Department

2005 - Issue 2.

No portion or part of this manual may be copied without prior permission from Rinnai

Australia.

Rinnai Australia takes no responsibility for the accuracy or otherwise of information

contained in

this manual, and reserves the right to make modifications and change specifications without

notice.

WARNING

Failure to comply with these instructions may result in serious personal

injury or damage to the appliance.

ALL WIRING INSIDE THIS APPLIANCE MAY BE AT 240 VOLTS POTENTIAL

ALL SERVICE WORK MUST BE CARRIED OUT BY AN AUTHORISED PERSON.

DO NOT TEST FOR GAS ESCAPES WITH AN OPEN FLAME

This manual has been published by Rinnai Australia Technical Services. We welcome

users of this manual to provide feedback and suggestions for improvement purposes.

SM REU-V1616W/

REU-V1620W/

REU-V2018W/

REU-V2020W

Issue N

o

2

Table of Contents

Glossary of Terms and Symbols ................................................................................ iv

1. Introduction ................................................................................................................ 1

2. Specifications ............................................................................................................. 2

3. Water Flow Rates and Pressures ................................................................................ 5

4. Dimensions ................................................................................................................ 8

5. Smartstart ................................................................................................................. 10

6. Cutaway Diagram .................................................................................................... 11

7. Operational Flow Chart ........................................................................................... 13

8. Operation Principles ................................................................................................ 14

9. Main Components .................................................................................................... 15

10. Remote Controls .................................................................................................... 16

11. Time Charts ............................................................................................................ 20

12. Wiring Diagram ..................................................................................................... 21

13. Dip Switch Settings ............................................................................................... 22

14. Fault Finding .......................................................................................................... 23

15. Component Circuit Value Table ............................................................................ 25

16. Component and Circuit Checks ............................................................................. 26

17. Maintenance Monitor / Error History .................................................................... 32

18. Gas Pressure Setting Procedure ............................................................................. 34

19. Gas Conversion Procedure ..................................................................................... 36

20. Dismantling for Service ......................................................................................... 37

21. Exploded Diagram ............................................................................... .................. 42

22. Parts List ................................................................................................................ 46

REU-V1616W ...................................................................................................................47

REU-V1620W ...................................................................................................................50

REU-V2018W ...................................................................................................................53

REU-V2020W ...................................................................................................................56

SERVICE CONTACT POINTS ............................................................................... 60

Infinity REU-V1616W / REU-V1620W / REU-V2018W / REU-V2020W- iii - Issue 2 - 21/03/06 ©Rinnai

Glossary of Terms and Symbols

dB(A) - sound pressure level in decibels, “A” range

DC - direct current

AC - alternating current

WFCD - water flow control device

FB - feedback information

FF - feedforward information

Hz - Hertz

IC - integrated circuit

kPa - kilopascals

LED - light emitting diode

L/min - Litres per minute

mA - milliamps

MJ/h - megajoule per hour

mm - millimetres

OHS - overheat switch

PCB - printed circuit board

CPU - central processing unit

POT - potentiometer

rpm - revolutions per minute

SV - soleno i d valve

ø - diameter

o

C - temperature rise above ambient

∆

POV - modulating valve

TE - thermal efficiency

TH - thermistor

T

T

IN

OUT

- temperature of incoming water

- temperature of outgoing water

Infinity REU-V1616W / REU-V1620W / REU-V2018W / REU-V2020W- iv - Issue 2 - 21/03/06 ©Rinnai

1. Introduction

The Rinnai V-Series hot water units represents the latest technology in continuous flow, temperature

controlled hot water.

Features

• The Infinity 16, V1200, Infinity 18 and Infinity 20 NEVER RUNS OUT of hot water. Whilst

electricity, water and gas supplies are connected, hot water is available whenever hot water taps are

open.

• Built into the main micro-processor is the facility to LIMIT THE MAXIMUM TEMPERATURE of

the hot water supplied. The water temperature may be limited to various maximum temperatures. This

is particularly useful when the hot water unit is installed where young children or the infirm may be

using the hot water. The Infinity is delivered with a maximum preset temperature of 50°C or 55ºC. If

required, the temperature limits can be changed by a service technician. For further information, please

contact Rinnai.

• The Infinity is a power flued appliance. It is COMPACT, saving both floor and wall space.

• The temperature of outgoing hot water is CONSTANTLY MONITORED by a BUILT-IN SENSOR. If

the temperature of the outgoing hot water rises to more than 3ºC above the selected temperature shown

on the Digital Monitor (or the pre-set limit when Remote Controls are not fitted), the burner will

automatically go out. The burner will ignite again once the outgoing hot water temperature falls below

the temperature shown on the Digital Monitor (or the pre-set limit).

• The burner lights automatically when the hot water tap is opened, and goes out when the tap is closed.

IGNITION IS ELECTRONIC, therefore there is not pilot light. When the hot water tap is of f, no gas is

used.

• ‘Standard’ Remote Controllers are available as an optional extra. Depending on the models chosen,

these offer the following additional features :

- Localised Temperature Control for up to one kitchen and two bathroom controllers

• Temperatures selected at the controllers are retained in the SYSTEM MEMORY.

• Operating NOISE LEVEL IS VERY LOW.

• ERROR MESSAGES ARE DISPLAYED on the Remote Controllers, assisting with service.

Infinity REU-V1616W / REU-V1620W / REU-V2018W / REU-V2020W- 1 - Issue 2 - 21/03/06 ©Rinnai

2. Specifications

Type of appliance Temperature controlled continuous flow gas hot water system

Operation With / without remove controls, mounted in kitchen, bathroom etc

Exhaust system Forced Flue

Rinnai model number REU-V1616W / REU-V1620W

Installation Externally mounted

Dimensions Width - 350 mm

Height - 530 mm

Depth - 170 mm

Weight 16 kilograms

Gas consumption (Min. / Max.) Natural gas : 125 ~ 18 MJ/h

Propane gas : 125 ~ 18 MJ/h

Output (kW) (Min. / Max.) 27.9 / 4.0

Connections Gas connection - R3/4 (20A)

Cold water connection - R1/2 (15A)

Hot water connection - R 1/2 (15A)

Ignition system Direct electronic ignition

Electrical consumption Normal - 47 W

Standby - 6 W (with 1 remote control)

Anti-frost protection - 74 W

Hot water capacity (Raised 25°C) 2.3 to 16 L/min

Thermal efficiency 80%

NOXaf 35 ppm

Temperature range (with remote) Kitchen controller : 37 ~ 55°C

Bathroom controller: 37 ~ 50°C

Default temperature control

(without remote)

Water Temperature control Simulation feedforward and feedback

Water flow control Water flow sensor, Electronic water flow control device

Minimum operating water pressure 10 kPa

Nominal operating water pressure 100 kPa ~ 830 kPa

Minimum operating water flow 2.4 L/min

Maximum operating water flow 16 L/min (REU-V1616W) / 20 L/min (REU-V162 0W)

Power supply Appliance - AC 240 Volts 50 Hz

Safety device Flame failure - flame rod

Deluxe remote control (optional) Kitchen control - MC-91Q-2A - MC70-2A

Cable (optional) Non-polarized two core cable

40°C, 43°C, 50°C, 55°C (factory setting), 65°C, 75°C

(set by combination of dip switches on PCB)

Remote control - DC 12 Volts (Digital)

Boil dry - water flow sensor

Remaining flame (OHS) - 97°C bi-metal switch

Over temperature - 95°C lockout thermistor

Fusible link - 129°C Thermal fuse

Pressure relef valve - Opens 2060 kPa, Closes: 1470 kPa

Combustion fan rpm check - Integrated circuit system

Over current - Glass fuse (3 Amp)

Bathroom control - MC91Q-2A - BC70-2A

Second bathroom control - MC91Q-2A

Note 1: The default factory setting is 50°C or 55º C for REU-V1616W / REU-V1620W. The unit can be ordered from

Rinnai to be pre-set to any of the other temperatures listed. The unit can be pre-set to any of the temperatures

listed by a suitably qualified person. Controllers are available with default temperatures up to 75º C. When

fitted with controllers, only temperatures not exceeding the default temperatures can be selected. When fitted

without controllers, the unit will deliver water at the default temperature.

Infinity REU-V1616W / REU-V1620W / REU-V2018W / REU-V2020W- 2 - Issue 2 - 19/04/06 ©Rinnai

REU-V2018W / REU-V2020W

Type of appliance Temperature controlled continuous flow gas hot water system

Operation With / without remove controls, mounted in kitchen, bathroom etc

Exhaust system Forced Flue

Rinnai model number REU-V2020W (Infinity 20)

REU-V2018W (Infinity 18)

Installation Externally mounted

Dimensions Width - 350 mm

Height - 530 mm

Depth - 170 mm

Weight 15.5 kilograms

Gas consumption (Min. / Max.) Natural gas : 160 ~ 20 MJ/h

Propane gas : 160 ~ 21 MJ/h

Output (kW) (Min. / Max.) 36.3 / 4.5

Connections Gas connection - R3/4 (20A)

Cold water connection - R1/2 (15A)

Hot water connection - R 1/2 (15A)

Ignition system Direct electronic ignition

Electrical consumption Normal - 55 W

Standby - 6 W (with 1 remote control)

Anti-frost protection - 74 W

Hot water capacity (Raised 25°C) 2.5 to 20 L/min

Thermal efficiency 80%

NOXaf 37 ppm

Temperature range (with remote) Kitchen controller : 37 ~ 55°C

Bathroom controller: 37 ~ 50°C

Default temperature control

(without remote)

Water Temperature control Simulation feedforward and feedback

Water flow control Water flow sensor, Electronic water flow control device

Minimum operating water pressure 10 kPa

Nominal operating water pressure 150 kPa ~ 830 kPa

Minimum operating water flow 2.4 L/min

Maximum operating water flow 20 L/min (REU-V2020W) / 18 L/min (REU-V201 8W)

Power supply Appliance - AC 240 Volts 50 Hz

Safety device Flame failure - flame rod

Deluxe remote control (optional) Kitchen control - MC-91Q-2A - MC70-2A

Cable (optional) Non-polarized two core cable

40°C, 43°C, 50°C, 55°C (factory setting), 65°C, 75°C

(set by combination of dip switches on PCB)

Remote control - DC 12 Volts (Digital)

Boil dry - water flow sensor

Remaining flame (OHS) - 97°C bi-metal switch

Over temperature - 95°C lockout thermistor

Fusible link - 129°C Thermal fuse

Pressure relef valve - Opens 2060 kPa, Closes: 1470 kPa

Combustion fan rpm check - Integrated circuit system

Over current - Glass fuse (3 Amp)

Bathroom control - MC91Q-2A - BC70-2A

Second bathroom control - MC91Q-2A

Note 1: The default factory setting is 50º C or 55°C for REU-V2018W / REU-V2020W.

The unit can be ordered from Rinnai to be pre-set to any of the other temperatures listed. The unit can be pre-set

to any of the temperatures listed by a suitably qualified person.

Controllers are available with default temperatures up to 75º C. When fitted with controllers, only temperatures

not exceeding the default temperatures can be selected. When fitted without controllers, the units will deliver

water at the default temperature.

Infinity REU-V1616W / REU-V1620W / REU-V2018W / REU-V2020W- 3 - Issue 2 - 19/04/06 ©Rinnai

Sensors and Safety Devices

• Heat Exchanger Thermistor: Measures hot water temperature at heat exchanger outlet. If water

temperature reaches a predetermined limit, gas supply is stopped.

• Hot Water Delivery Thermistor: Measures hot water temperature at the outlet valve (i.e. the ‘mixed’

temperature).

• Flame Rod: Monitors combustion characteristics inside the combustion chamber. If the flame fails, gas supply is

stopped.

• Overheat Switch: Situated on the heat exchanger, gas supply is stopped when water temperature reaches 97°C for

a number of seconds.

• Fusible Link: Situated on the heat exchanger, electrical power supply is stopped if the temperature exceeds

129°C.

• Water Pressure Relief Valve: Safeguards the water circuit against excessive inlet pressure. Opens at 2060 kPa,

closes at 1470 kPa.

• Electrical Fuse: (3A glass fuse) prevents against over-current.

Surge Protector: prevents against over-current.

• Boil Dry Prevention: If water flow sensor detects no flow, gas supply is stopped.

• Combustion Fan Speed Sensor: In case of combustion fan defect (no rotation of fan) gas supply is stopped.

• Temperature Cutout: If the delivered hot water temperature rises above the required delivery

temperature for a number of seconds, the gas supply is stopped.

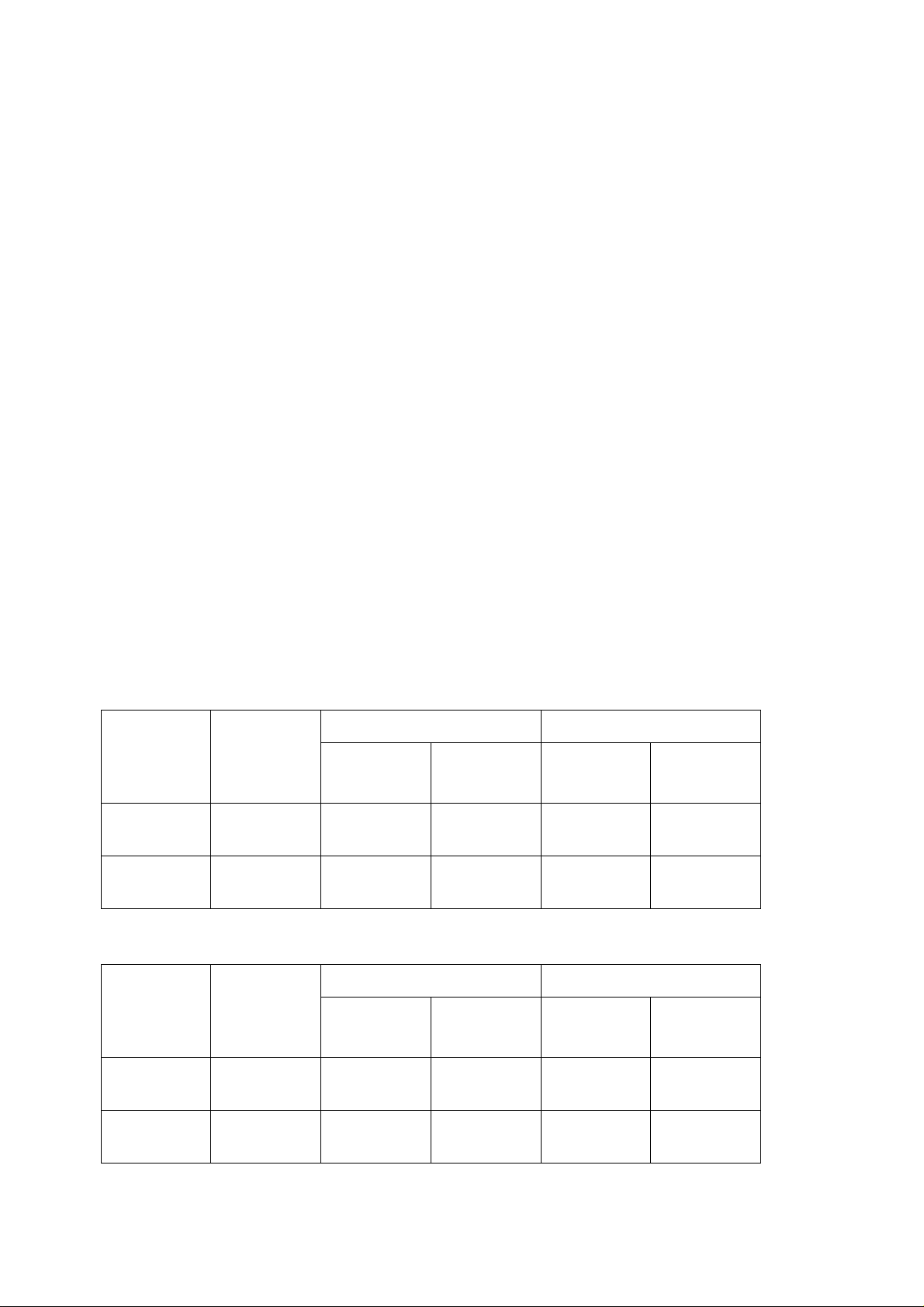

Combustion Specifications - REU-V1616W / REU-V1620W

Gas Type Injector

Size (mm)

Upper /

[Lower]

Natural ø 0.85

[ø 1.30]

Propane ø 0.7

[ø 1.05]

Nominal TPP (kPa) ** Gas Input (MJ/hr)

Low High Low High

0.181

2.05

0.178

2.75

0.883

1.13

0.814

2.75

18.8 125

18 125

Combustion Specifications - REU-V2018W / REU-V2020W

Gas Type Injector

Size (mm)

Upper /

[Lower]

Nominal TPP (kPa) ** Gas Input (MJ/hr)

Low High Low High

Natural ø 0.85

[ø 1.3]

Propane ø 0.7

[ø 1.05]

0.181

2.05

0.187

2.75

0.922

1.13

0.827

2.75

20 160

21 160

** The TPP is measured with the cover off the appliance at the regulator test point with supply pressures

of 1.13 kPa (NG) and 2.75 kPa (Propane).

Infinity REU-V1616W / REU-V1620W / REU-V2018W / REU-V2020W- 4 - Issue 2 - 21/03/06 ©Rinnai

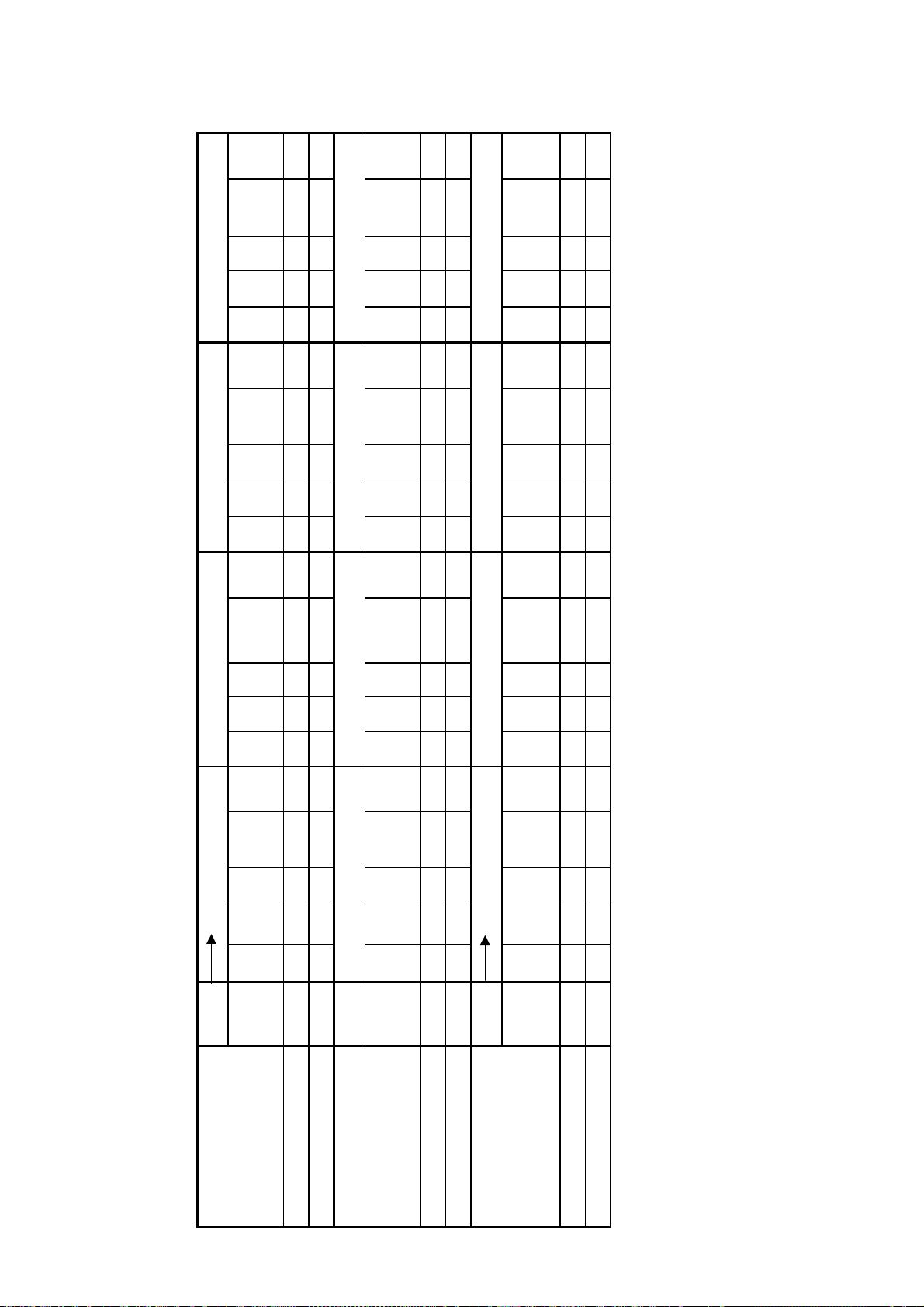

3. Water Flow Rates and Pressures

Water Flows

Table 1 shows unmixed and mixed water flow rates and approximate gas consumptions for various

temperature rises. The unmixed flow rates are the flow rates available at the given temperature rise directly

at the outlet of the water heater. The mixed water flow rates are available at the given temperature rise by

mixing hot water from the outlet of the water heater with cold water from the mains supply.

Water Flows can also be calculated by the following formula :

Q = Heat energy available in kW = 28 kW for the REU-V1616W / REU-V1620W

C = Specific heat of water = 4.2KJ/Kg °C. C does not change for the purpose of this calculation.

∆

T = Temperature rise required (°C)

Example:

What is the flow rate available with an incoming water temperature of 10°C and a required temperature of

20°C?

∆

T = 20 - 10 = 10°C

Q = 28

C = 4.2

M = 60 x ( 28 / (4.2 x 10) ) = 40 l/min. Since 40 is greater than 16 this flow rate is mixed. This result

corresponds with the value in Table 1.

REU-V2018W and REU-V2020W

Q = Heat energy available in kW = 36 kW for the REU-V2018W / REU-V2020W

C = Specific heat of water = 4.2 KJ/Kg °C. C does not change for the purpose of this calculation.

T = Temperature rise required (°C)

∆

Example:

What is the flow rate available with an incoming water temperature of 10°C and a required temperature of

20°C?

∆

T = 20 - 10 = 10°C

Q = 28

C = 4.2

M = 60 x ( 28 / (4.2 x 10) ) = 40 l/min. Si nce 40 is g rea ter than 20 (18) this fl ow rate is mixed. This result

corresponds with the value in Table 1.

Infinity REU-V1616W / REU-V1620W / REU-V2018W / REU-V2020W- 5 - Issue 2 - 21/03/06 ©Rinnai

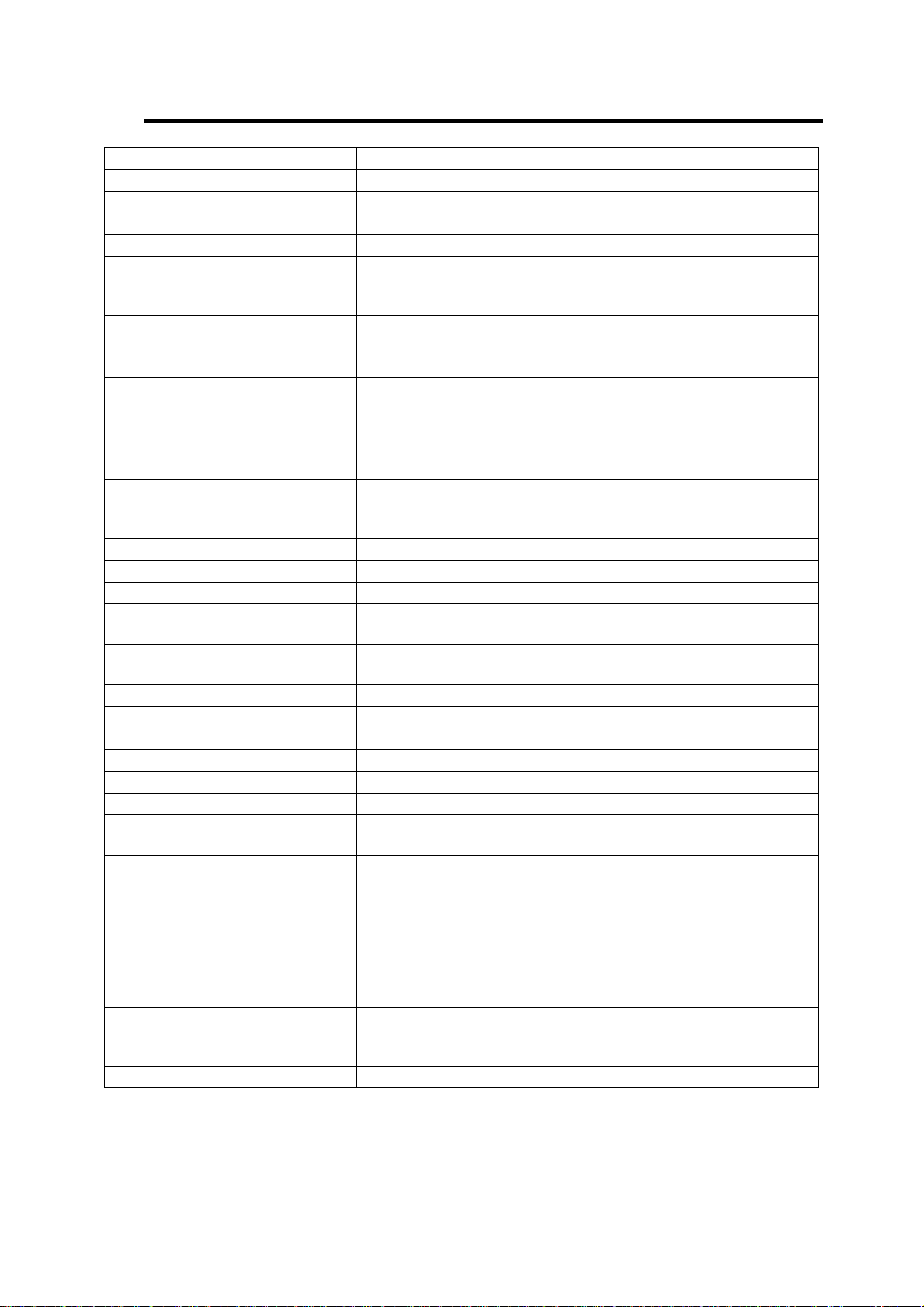

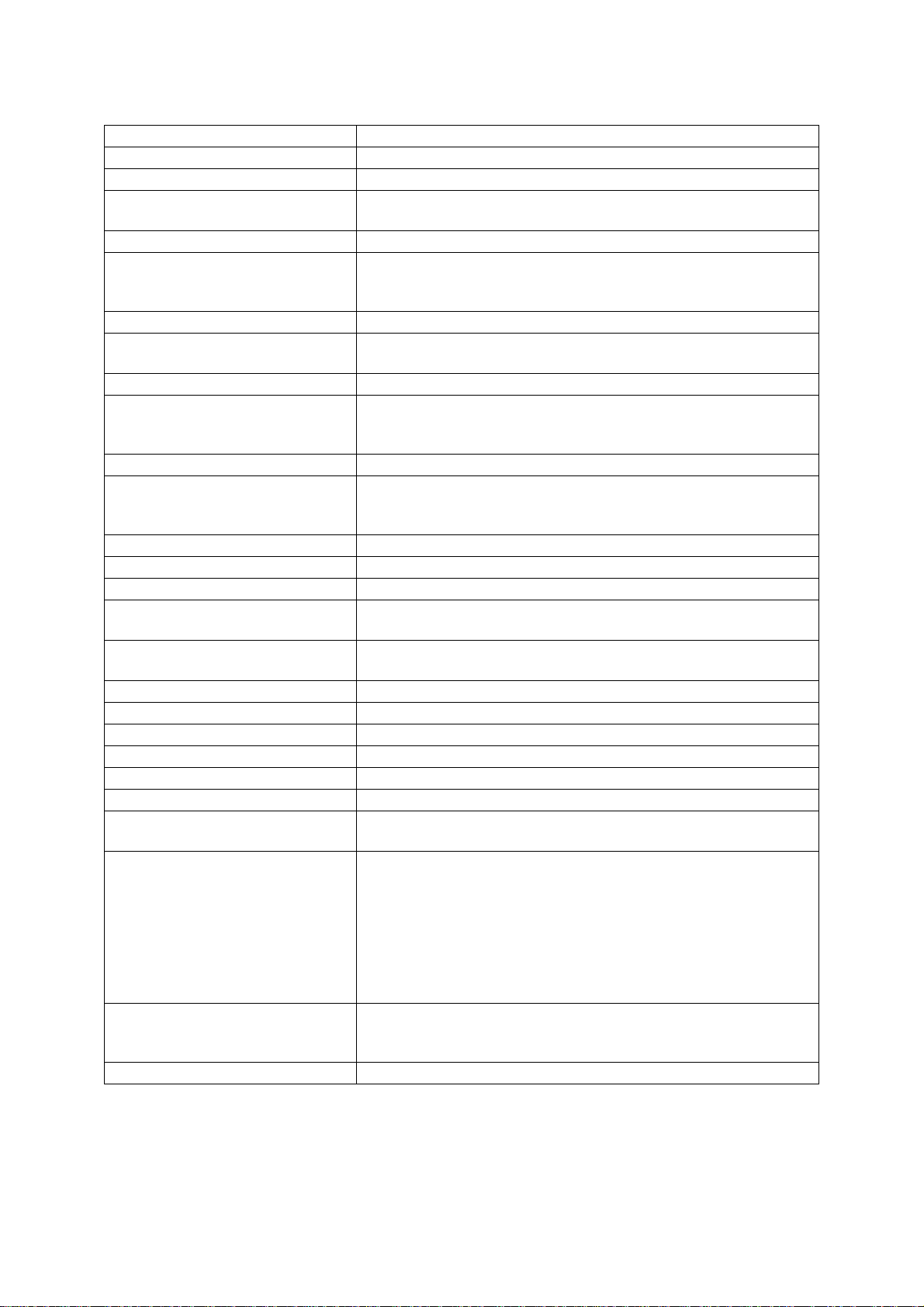

Table 1: Approximate Water Flows & Gas Usage - REU-V1616W/V1620W/V2020W

e

(

)

e

(

)

e

(

)

20

Gas

Cons.

Approx

Pressure

Min Water

L/sec L/min L/hr

Gas

Cons.

Approx

Pressure

Min Water

L/sec L/min L/hr

Gas

Cons.

Approx

(MJ/h)

(kPa)

(MJ/h)

(kPa)

(MJ/h)

Gas

Cons.

Approx

Pressure

Min Water

L/sec L/min L/hr

Gas

Cons.

Approx

Pressure

Min Water

L/sec L/min L/hr

Gas

Cons.

Approx

(MJ/h)

(kPa)

(MJ/h)

(kPa)

(MJ/h)

605045

55

Gas

Cons.

Approx

Pressure

Min Water

L/sec L/min L/hr

Gas

Cons.

Approx

Pressure

Min Water

L/sec L/min L/hr

Gas

Cons.

Approx

(MJ/h)

(kPa)

(MJ/h)

(kPa)

(MJ/h)

(kPa)

Pressure

Min Water

L/sec L/min L/hr

Gas

Cons.

(MJ/h)

Approx

(kPa)

Pressure

Min Water

51015

0.27 16 960 72 25 0.27 16 960 72 50 0.27 16 960 72 75 0.27 16 960 72 100

L/sec L/min L/hr

º C

Input

18-125

Temp

Ris

/ Max Gas

Approx. Min

20-125

(MJ/hour)

Temp

Approx

25 30 35 40

º C

Approx. Min

Ris

Pressure

Min Water

L/sec L/min L/hr

Gas

Pressure

Min Water

L/sec L/min L/hr

/ Max Gas

(kPa)

Cons.

(MJ/h)

(kPa)

Input

(MJ/hour)

0.27 16 960 72 125 0.22 13.2 792 60 125 0.19 11.4 684 44 125 0.17 10.2 612 35 125

18-125

20-125

º C

Temp

Ris

Pressure

Min Water

L/sec L/min L/hr

Gas

Cons.

Approx

Pressure

Min Water

L/sec L/min L/hr

Approx.

Min / Max

Gas Input

(kPa)

(MJ/h)

(kPa)

18-125

(MJ/hour)

0.15 9 540 29 125 0.13 8 480 24 125 0.12 7.2 434 21 125 0.11 6.6 396 20 125

20-125

REU-V1616W

REU-V1616W - Ext.

REU-V2020W 21-160 0.33 20 1200 115 155 0.29 17.4 1044 87 160 0.25 15 900 64 160 0.22 13.2 792 50 160

REU-V2020W - Ext. 21-160 0.33 20 1200 115 31 0.33 20 1200 115 62 0.33 20 1200 115 93 0.33 20 1200 115 124

Models (All Pre-set Temperatures)

Infinity REU-V1616W / REU-V1620W / REU-V2018W / REU-V2020W- 6 - Issue 2 - 21/03/06 ©Rinnai

Models (All Pre-set Temperatures)

Models (All Pre-set Temperatures)

REU-V1616W

REU-V2020W 21-160 0.19 11.4 684 42 160 0.17 10.2 612 35 160 0.16 9.6 576 29 160 0.14 8.4 504 26 160

Water Pressure

As seen in the table below a minimum supply pressure of 80 kPa is required to operate at the rated flow of

16 L/min. In an actual installation, pressure losses in the plumbing system also need to be considered.

Infinity REU-V1616W / REU-V1620W / REU-V2018W / REU-V2020W- 7 - Issue 2 - 21/03/06 ©Rinnai

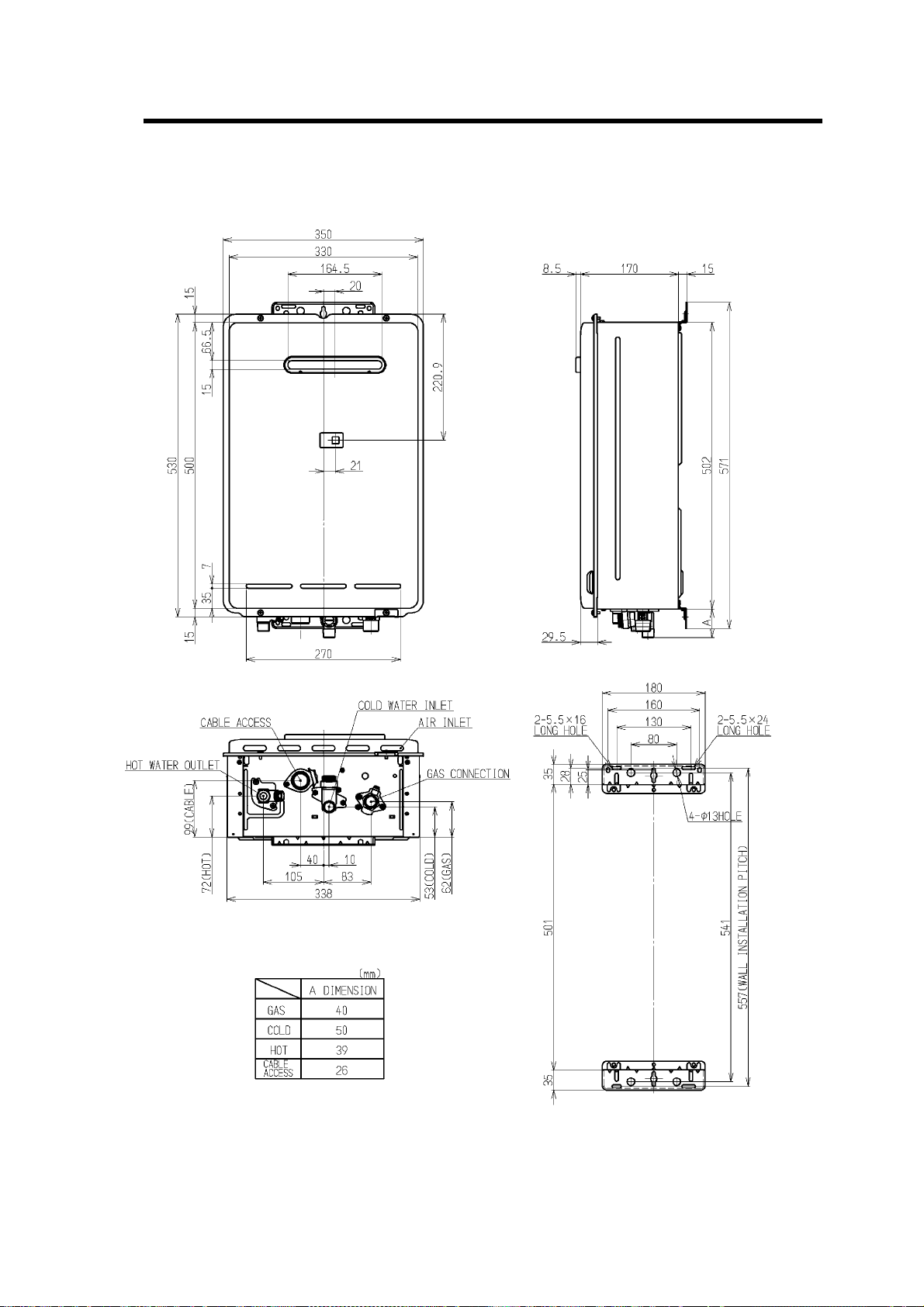

4. Dimensions

REU-V1616W / REU-V1620W

Infinity REU-V1616W / REU-V1620W / REU-V2018W / REU-V2020W- 8 - Issue 2 - 21/03/06 ©Rinnai

REU-V2018W / REU-V20202W

Convector 318H - 9 - ©Rinnai

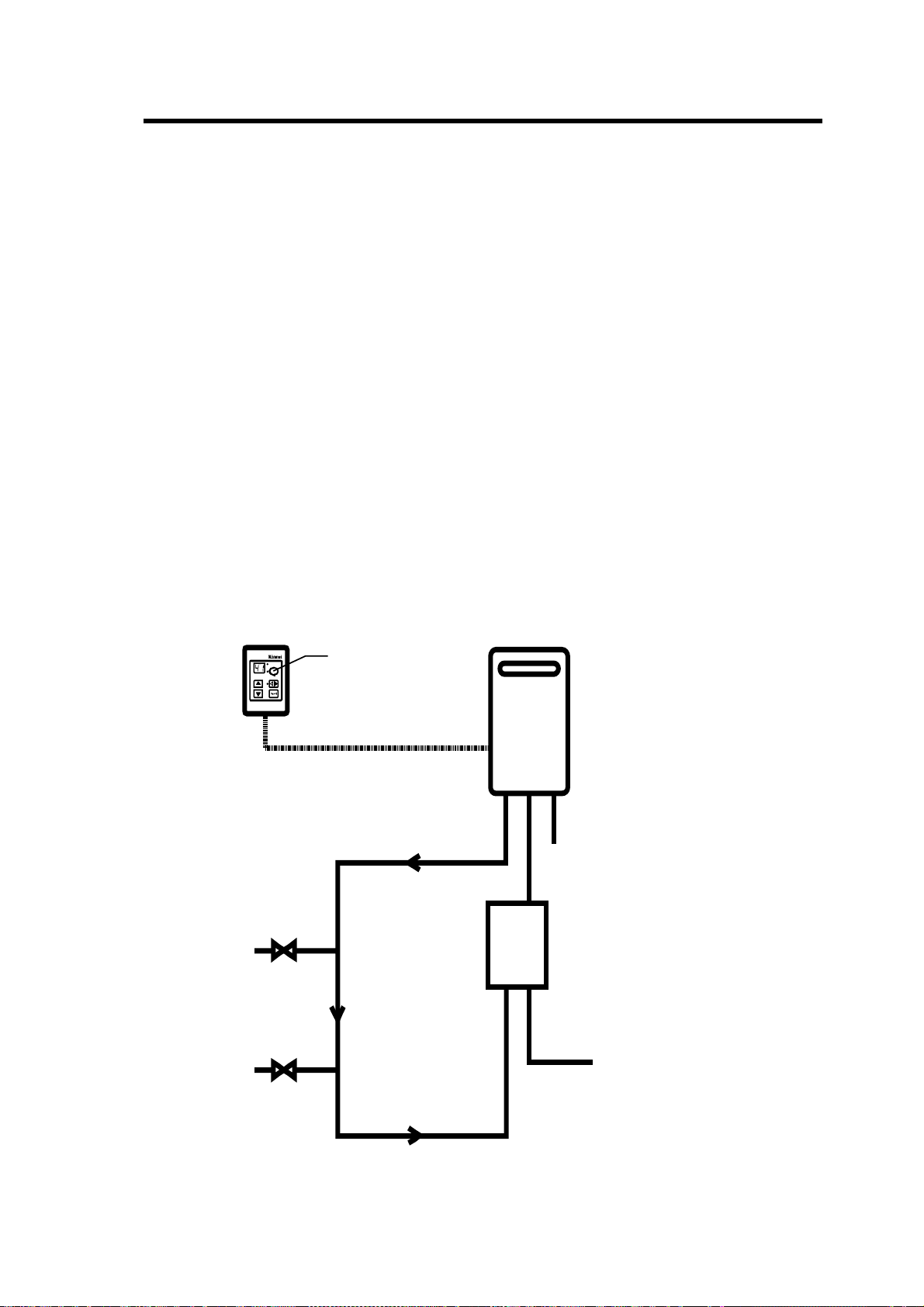

5. Smartstart

At least one temperature controller model MC-91Q must be used in conjunction with the water heater and

the Smartstart® system. Alternatively, if Temperature Controllers cannot be used a manual activation

switch is available. See separate service manual.

The installation of the water heater and temperature controllers must be performed in accordance with the

installation instructions supplied with the water heater.

The Smartstart® system is designed for domestic installations. However, it may be suitable for certain non

domestic installations. See separate service manual for more information.

Principle of operation (Fig.2)

The "Smartstart®" system heats the water in the pipework water connected between the water heater and

the hot water outlets before any outlets are opened using the 'flow and return' pipework principle. This

results in water savings and reduced waiting time for heated water delivery from the outlet when opened.

Traditional 'flow and return' systems usually keep the water in the pipework heated continuously. The

Smartstart® system however, only heats the water before the outlet is opened. This results in significant

energy savings because water is not heated unnecessarily whilst retaining the benefits of traditional flow

and return systems.

A schematic of the Smartstart® system installed in conjunction with a Rinnai continuous flow water heater

and temperature controller is shown in Fig.2 below.

One or more

MC-91Q

Controllers

Hot Water

Outlet

Hot Water

Outlet

Preheat Button

Heating Loop Flow

Rinnai Continuous

Flow Water Heater

H

C

O

T

G

O

A

L

S

D

Smartstart®

Module

Cold Inlet Mains

Heating Loop Return

Fig.2

Infinity REU-V1616W / REU-V1620W / REU-V2018W / REU-V2020W- 10 - Issue 2 - 21/03/06 ©Rinnai

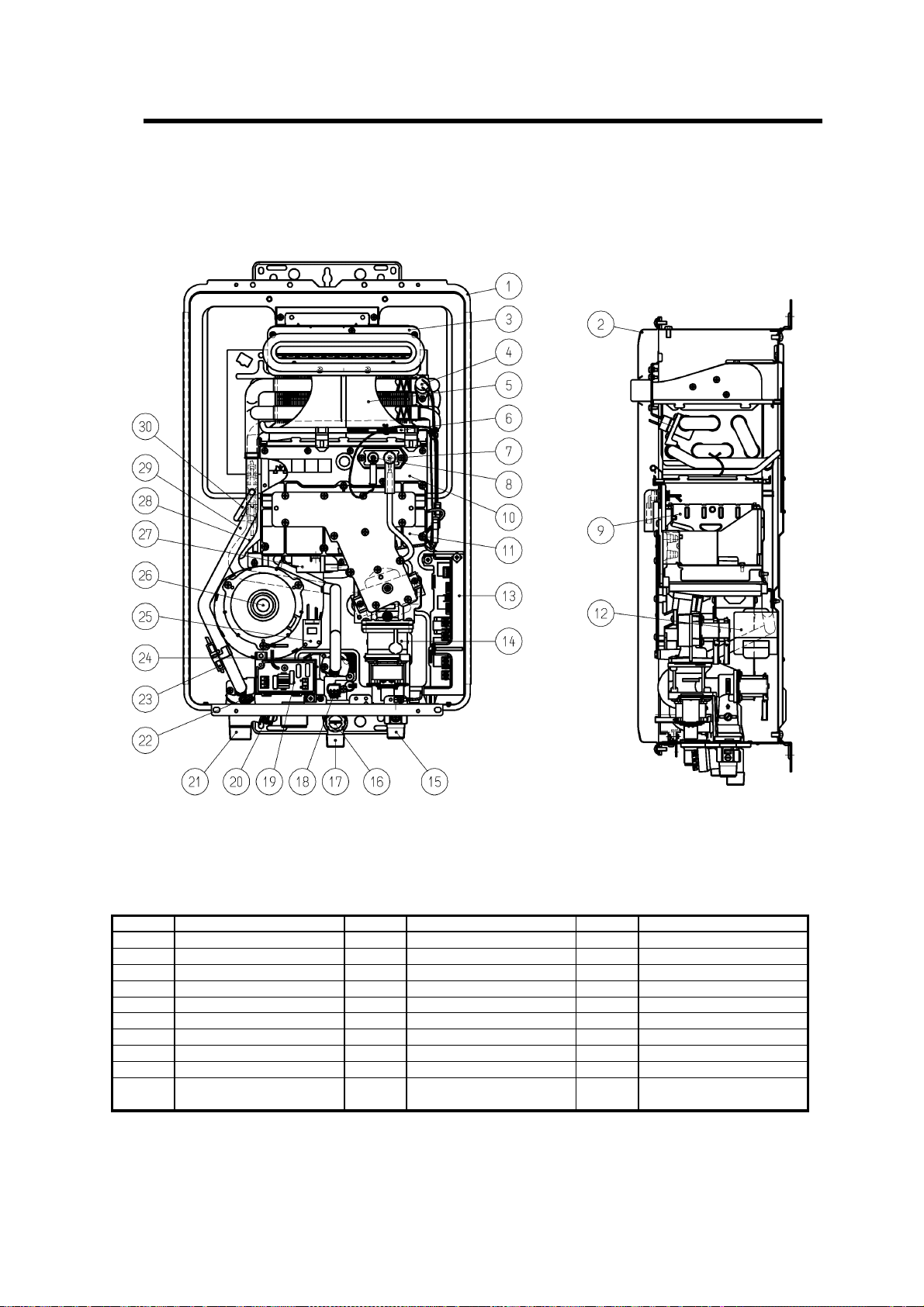

6. Cutaway Diagram

REU-V1616W / REU-V1620W

Part No. Description Part No. Description Part No. Description

1 Casing Assembly 11 Manifold Assembly 21 Hot Water Outlet

2 Front Panel Assembly 12 Transformer 22 Ongoing Water Thermistor

3 Flue Outlet 13 P.C.B. 23 Anti-Frost Heater

4 Overheat Switch 14 Gas Control Assembly 24 Water Flow Control Device

5 Heat Exchanger 15 Gas Connection 25 Frost Sensing Switch

6 Thermal Fuses 16 Water Filter Assembly 26 Combustion Fan

7 Electrode 17 Water Inlet 27 Igniter

8 Flame Rod 18 Water Flow Sensor 28 Water Connecting Pipe

9 Main Burner 19 Surge Protector 29 Hot Water Connecting Pipe

Combustion Chamber Front

10

Plate Assembly

Infinity REU-V1616W / REU-V1620W / REU-V2018W / REU-V2020W- 11 - Issue 2 - 21/03/06 ©Rinnai

20 Pressure Relief Valve

30

By-pass Pipe

REU-V2018W / REU-V2020W

Part No. Description Part No. Description Part No. Description

1 Casing Assembly 11 Manifold Assembly 21 Hot Water Outlet

2 Front Panel Assembly 12 Transformer 22 Ongoing Water Thermistor

3 Flue Outlet 13 P.C.B. 23 Anti-Frost Heater

4 Overheat Switch 14 Gas Control Assembly 24 Water Flow Control Device

5 Heat Exchanger 15 Gas Connection 25 Frost Sensing Switch

6 Thermal Fuses 16 Water Filter Assembly 26 Combustion Fan

7 Electrode 17 Water Inlet 27 Igniter

8 Flame Rod 18 Water Flow Sensor 28 Water Connecting Pipe

9 Main Burner 19 Surge Protector 29 Hot Water Connecting Pipe

Combustion Chamber Front

10

Plate Assembly

20 Pressure Relief Valve

30

By-pass Pipe

Infinity REU-V1616W / REU-V1620W / REU-V2018W / REU-V2020W- 12 - Issue 2 - 21/03/06 ©Rinnai

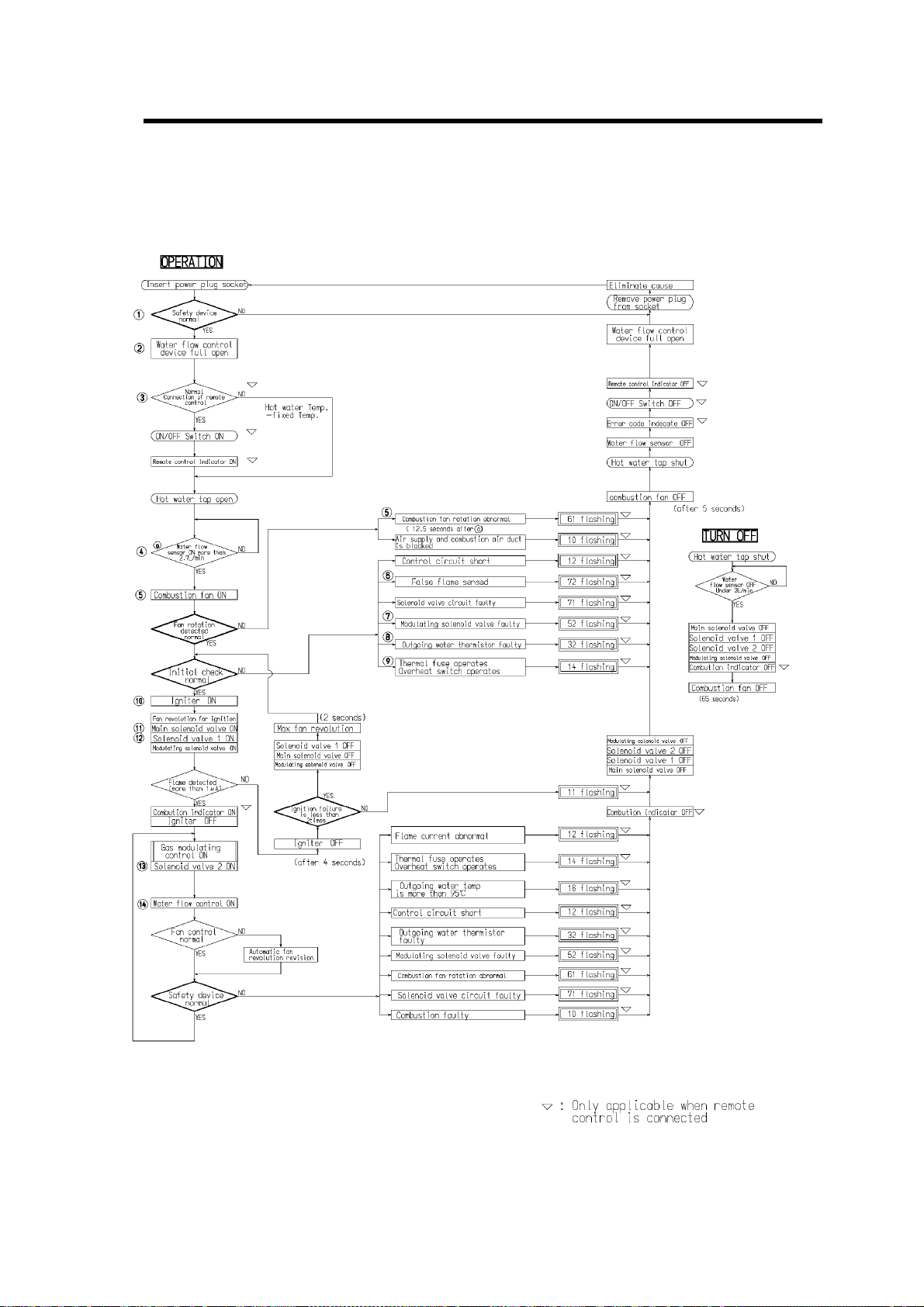

7. Operational Flow Chart

Infinity REU-V1616W / REU-V1620W / REU-V2018W / REU-V2020W- 13 - Issue 2 - 21/03/06 ©Rinnai

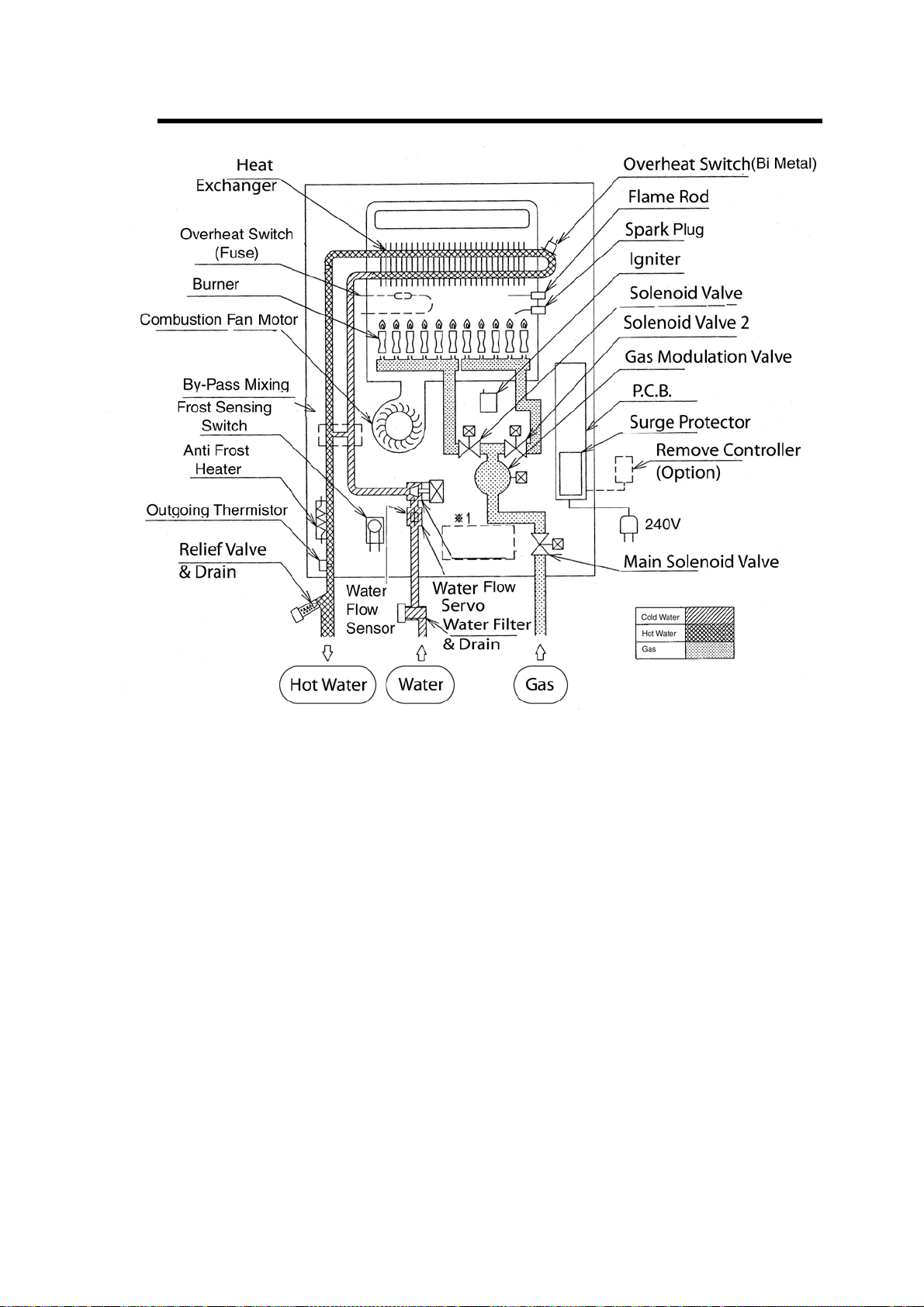

8. Operation Principles

Hot Water Operation

1. Ignition

• Activate controllers (if fitted) an d open the hot water tap (for full details regarding operation of controllers refer

to the ‘How To Use Your Water Heater’ booklet).

• When water flows through the unit, the water flow sensor rotates and sends an electrical ‘pulse’ signal to the

Printed Circuit Board (PCB). This signal is proportional to the water flow rate.

• The PCB sends electrical current to the combustion fan motor causing it to turn. The fan motor sends an electrical

pulse signal to the PCB. If fan rotation is OK, the main solenoid and changeover solenoid valves open as

required, the spark generator activates and the spark electrode ignites the burner.

2. Water Temperature / Flow Control / Volume Control

• The PCB will automatically control operation of the internal components to achieve the programmed

temperature. When a high temperature rise is required, the PCB may cause the Water Flow Servo to close

partially resulting in a lower flow rate to achieve the programmed temperature. This is a necessary operational

feature of the unit.

• When operating in ‘Bath Fill’ mode, t he signal from the water flow sensor is also used by the PCB to com pute

the volume of water that has been passed through the unit at any instant whilst the bath is filling.

3. Shut Down

• When operating in ‘Bath Fill’ mod e, the PCB causes the Water Flow Servo to close when the programmed Bath

Fill volume has passed through the unit. Alternatively, flow is stopped when the user closes the hot water tap.

• When water flow stops, the water flow sensor stops rotating and the pulse signal to the PCB stops. The PCB then

causes the main solenoid and solenoid valves to close and the burner is extinguished. The combustion fan will

continue to operate for some time to purge the combustion chamber.

Infinity REU-V1616W / REU-V1620W / REU-V2018W / REU-V2020W- 14 - Issue 2 - 21/03/06 ©Rinnai

9. Main Components

1) Printed Circuit Board

• The Printed Circuit Board controls all operational functions including Air Supply Control, Gas Control,

Water Flow Measurement, Water Flow Control, Combustion System and all sensors and safety devices.

2) Gas Flow Control

• During normal operation, the PCB keeps the main solenoid valve open whilst there is flow through the

unit and the burner needs to be lit.

• Gas flow rate is controlled by the modulating valve assembly and three changeover solenoid valves to

always ensure constant outlet water temperature, regardless of flow rate or incoming water temperature.

• The modulating valve is electronically controlled by the PCB using signals from the water flow sensor,

water flow control device, water temperature thermistors and combustion fan speed sensor. The

modulating valve directs gas to the three changeover solenoid valves.

• The three changeover solenoid valves direct gas to each of the two burner banks independently. Any one

or two or both of the solenoid valves may be open during operation.

• Gas flow is modulated between 18 and 125 MJ/hr for REU-V1616W/REU-V1620W and between 20

and 160 MJ/hr for REU-V2018W and REU-V2020W by a combination of the modulating valve and

changeover solenoid positions.

• The maximum gas rate is predetermined and the appliance cannot be overloaded when correctly

installed.

3) Water Flow Control

• Water flow is detected by a turbine coupled to a magnetic pulse generating device. The magnetic pulses

are detected and counted by the PCB. The PCB calculates the exact water flow from the frequency of

pulses generated by the turbine. A minimum flow rate of 2.4 L/min. is required for the burner to ignite.

• Water flow control is achieved through the use of servo driven water flow and fixed bypass. Servo

motor is controlled by the PCB. The ‘Water Flow Valve’ restricts the flow of water into the heat

exchanger assembly if the programmed temperature cannot be achieved. During normal operation, c old

water from the inlet valve is mixed with hot water from the heat exchanger outlet.

• The ‘Bypass’ mixes cold and hot water to ensure hot water delivery temperature over the available range

of flow rates.

4) Air Supply Control

• Air for combustion is supplied by a centrifugal fan driven by a variable speed DC motor. The voltage to

the motor is determined by the PCB based on water flow, delivered water temperature and programmed

water temperature. The actual fan speed is monitored by a magnetic pulse counter. This counter emits a

signal to the PCB. From the voltage supplied to the DC motor and the fan speed signal, the PCB

determines whether an error condition exists with the fan.

5) Combustion System

The combustion chamber is housed within the heat exchanger assembly and comprises:

• Aluminium alloy manifold with a total of 28 integral injectors. Gas flow to each chamber is controlled

by an electronic solenoid valve (refer ‘Gas Flow Control’ above).

• A burner assembly comprising fourteen identical modular stainless steel bunsen burners secured by an

aluminised steel framework. The manifold is attached to the front of the burner module. Each bunsen

burner is supplied by two injectors.

• A combustion chamber. Integrated into the combustion chamber front panel are the flame rod and two

ignition electrodes.

Infinity REU-V1616W / REU-V1620W / REU-V2018W / REU-V2020W- 15 - Issue 2 - 21/03/06 ©Rinnai

Loading...

Loading...