Rinnai REU-2018W, REU-2020W, REU-2422W, REU-2425W Service Manual

INFINITY

REU-2018W

REU-2020W

REU-2422W

REU-2425W

SERVICE MANUAL

Infinity Compact Continuous Flow Gas Hot Water System

All Rinnai products are certified by the

Australian Gas Association as compliant

to relevant Australian Standards.

Rinnai Australia Head Office is certified

as complying with ISO 9001 by SAI

Global.

SAI Global

Rinnai New Zealand has been certified to

ISO 9001 Quality Assurance by Telarc.

All Rinnai products are Certified to

WaterMark by SAI Global. WaterMark

certification is awarded to products and

fittings complying with safety and water

contamination standards.

© Copyright Rinnai Australia Pty Ltd

A.C.N. 005 138 769 A.B.N. 74 005 138 769

All rights reserved

Produced by Technical Services Department

2004 - Issue 2

No portion or part of this manual may be copied without prior permission from Rinnai Australia.

Rinnai Australia takes no responsibility for the accuracy or otherwise of information contained in

this manual, and reserves the right to make modifications and change specifications without notice.

Key to Warning Symbols

Failure to comply with the following instructions may result in serious

personal injuiry or damage to the appliance.

Be careful of possible electric shock. Wiring inside this appliance may

potentially be at 240 Volts.

Remove the plug from the source when carrying out any of the following

activities.

Read Fault Diagnosis and Wiring Diagram carefully to avoid incorrect wiring

Do not disassemble. Parts within cannot be exchanged or diagnosed faulty.

Please follow instructions carefully to ensure safe and appropriate service.

After completing the service and confirming that there no gas leaks or incorrect wiring,

test operation of unit according to the Customer Operating Instructions. After confirming

normal operation, explain what was serviced to the customer and operation principles if

necessary.

This manual has been compiled by Rinnai Australia Technical Services Department. While many

individuals have contributed to this publication, it will be successful only if you - the reader and

customer - find it useful. We would like to extend an invitation to users of this manual to make

contact with us, as your feedback and suggestions are valuable resources for us to include as

improvements. Rinnai are constantly working toward supplying improved appliances as well as

information, and specifications may be subject to alteration at any time.

SM Infinity REU-2425W

Issue N

o

2

Table of Contents

1. Introduction ................................................................................................... 3

2. Features ....................................................................................................... 4

3. Dimensions ................................................................................................... 5

4. Remote Controls .......................................................................................... 6

5. Safety Devices ............................................................................................. 9

6. Specification ............................................................................................... 10

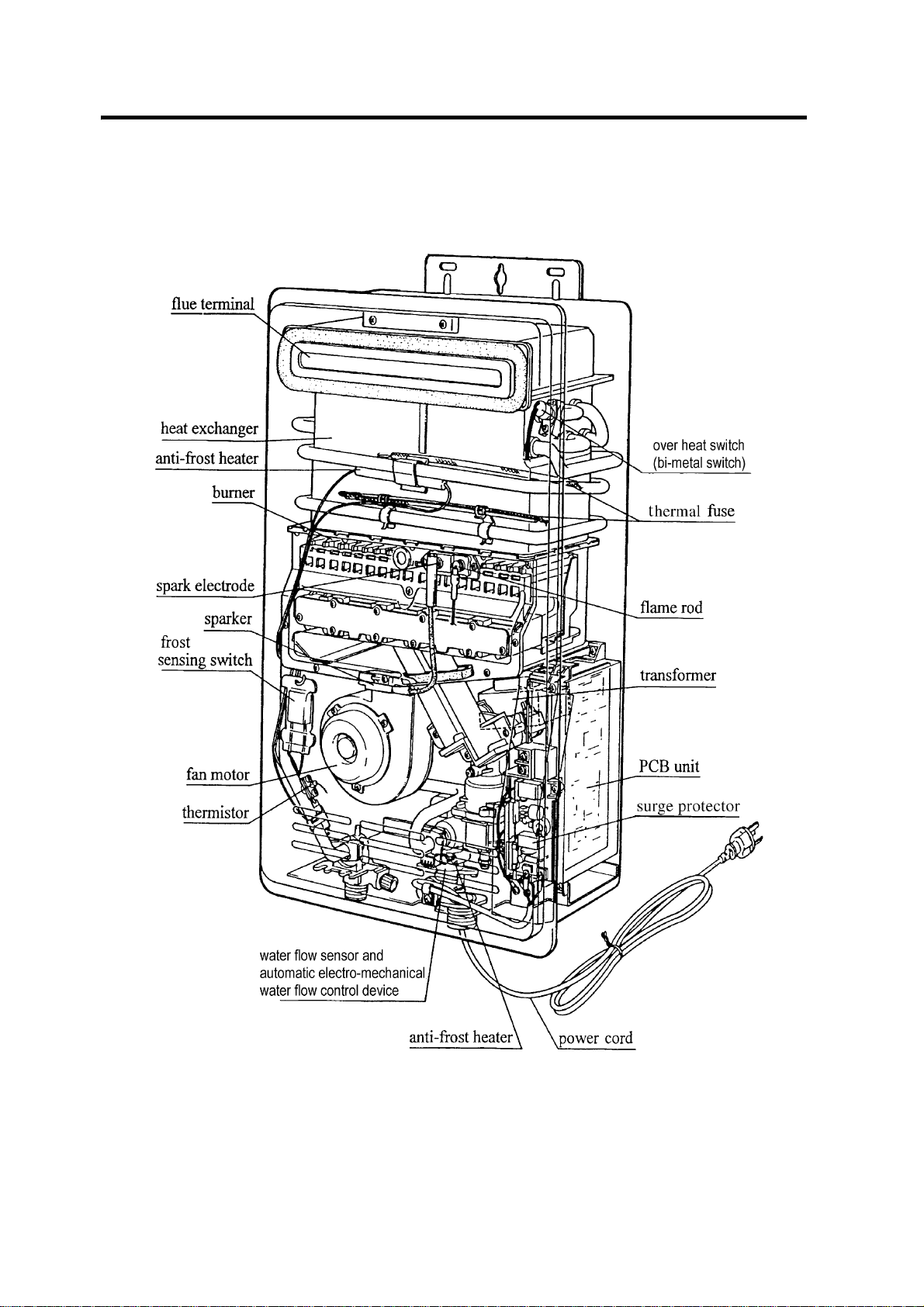

7. Cut-away Diagram ...................................................................................... 11

8. Schematic Diagram .................................................................................... 12

9. Combustion Specification ........................................................................... 13

10. Dip Switch Positions ................................................................................. 14

11. Water Flows ............................................................................................. 16

12. Main Components .................................................................................... 18

13. Time Charts .............................................................................................. 20

14. Operation Flow Principle .......................................................................... 21

15. Operation Principles ................................................................................. 23

16. Fault Finding ............................................................................................. 25

17. Fault Finding Table ................................................................................... 26

18. Maintenance Monitor / Error History ......................................................... 27

19. Component Circuit Value Table ............................................................... 29

20. Wiring Diagram ......................................................................................... 30

21. Fault Diagnosis ......................................................................................... 31

22. Electrical Component Analysis ................................................................. 40

23. Gas Conversion ........................................................................................ 43

24. Gas Pressure Setting Procedure .............................................................. 44

25. Dismantling for service ............................................................................. 45

26. Exploded Diagram .................................................................................... 51

27. Parts list .................................................................................................... 55

Infinity REU-2425W - 1 - Issue 2 - 5/07/04 ©Rinnai

Glossary of Terms and Symbols

This glossary of terms and symbols is provided to assist you in understanding some of the

language used throughout this manual.

dB(A) - sound pressure level in decibels, “A” range

DC - direct current

AC - alternating current

WFCD - water flow control device

FB - feedback information

Hz - Hertz

IC - integrated circuit

kcal/h - kilocalorie per hour

kPa - kilopascals

LED - light emitting diode

L/min - Litres per minute

mA - milliamps

MJ/h - megajoule per hour

mm - millimetres

mmH2O - millimetres of water (guage pressure)

NO

X

- oxides of nitrogen (NO & NO2)

OHS - overheat switch

PCB - printed circuit board

CPU - central processing unit

POT - potentiometer

rpm - revolutions per minute

SV - solenoid valve

ø - diameter

o

C - temperature rise above ambient

∆

POV - modulating valve

TE - thermal efficiency

TH - thermistor

T

IN

T

OUT

Infinity REU-2425W - 2 - Issue 2 - 5/07/04 ©Rinnai

- temperature of incoming water

- temperature of outgoing water

1. Introduction

The brand name Infinity refers to “Endless Hot Water”. The Infinity 24 has been developed in

response to the growing changes in the lifestyle of consumers, and the increasing diversification

and sophistication of demand in the marketplace.

The Infinity series offers reduced cost, advanced safety features, and an option to connect one,

two, or three remote control pads.

The Infinity 24 is delivered with the maximum hot water temperature of 50oC, with or without

remote controls connected.

About the Infinity

The front cover of each appliance in this series is formed from 0.6 mm coated steel, secured to

the main box assembly by 4 screws. Seals around the front cover and flue outlet prevent water

from entering the appliance.

Air inlets are situated in the front panel. The general layout of components is shown on the

cutaway diagram on

coated steel.

page 11. All components are supported within a box formed from 0.8 mm

The heat exchanger occupies the top section of the box, and the burner is situated in a chamber

formed from 0.8 mm aluminised steel attached to the bottom of the heat exchanger.

The air for combustion is supplied by a fan which is connected to the burner box by a duct at the

left hand side of the appliance.

Gas and water controls are situated at the bottom right of the appliance, directly under the

manifold. The products of combustion are expelled from the appliance through a flue outlet

situated on the front of the appliance, at the top.

The burner assembly is made up of 18 identical stainless steel bunsen burners, secured by an

aluminised steel framework. An aluminium manifold with 18 integrally moulded injectors supplies

gas to the burners, and is attached to the lower front cover of the burner box.

There is one thermistor, it is located on the outgoing hot water supply tube, near the outlet of the

heater.

Infinity REU-2425W - 3 - Issue 2 - 5/07/04 ©Rinnai

2. Features

Installation

The light-weight, slim, and compact form enable easier, improved appearance installations. The

remote controls (where fitted) are connected to the appliance by 2-core non-polar cable, ensuring

easy wiring and eliminating misconnection problems.

Low Noise Level

Low noise level design enables these appliances to be installed in units, flats, townhouses, and

other high density residential areas with little concern about noise disturbances.

Safety

Various safety devices controlled by a micro-computer ensure complete safety. Also, the antifrost device (where fitted), automatically prevents the water inside the appliance from freezing by

using small electrical ceramic heaters connected to the pipework at strategic locations.

Economy

Direct electronic ignition to the main burner eliminates wasteful pilot gas consumption. The

combustion fan rpm is proportionally controlled with gas consumption. This maintains high energy

efficiency as the gas consumption changes.

Water Supply Control

The water supply capacity varies proportionally from 2.7 L/min to 24 L/min. A suitable volume of

hot water can be supplied throughout all seasons by the water flow control device and water flow

servo mechanism. REU 2425W model will supply up to 24L/min, (maximum unmixed), controlled

by an automatic electro-mechanical water flow device. See

details on water flow.

“Water Flows” on page 16 for precise

Water Temperature Control

With a remote control connected, the hot water control range is between 37°C and 50°C (in 12

steps). With or without a remote control connected the outgoing hot water temperature is fixed to

50°C maximum with no remote. This means that the Infinity Series can be set to comply with

various State laws on temperature control in homes, child care centres, and elderly care centres.

The maximum temperature selectable on the bath remote control is 50°C (this is a safety feature).

Over Temperature Protection

All Infinity models incorporate a device to prevent the hot water temperature exceeding the preset temperature by more than 3°C.

Temperature Locks

With the remote control(s) connected, the pre-set water temperature can only be altered between

37°C and 43°C while the hot water is flowing. This helps to avoid inadvertently increasing the

temperature to a hazardous level whilst someone is in the shower. While the water is flowing, the

remote control(s) can be turned off, but not on again.

Infinity REU-2425W - 4 - Issue 2 - 5/07/04 ©Rinnai

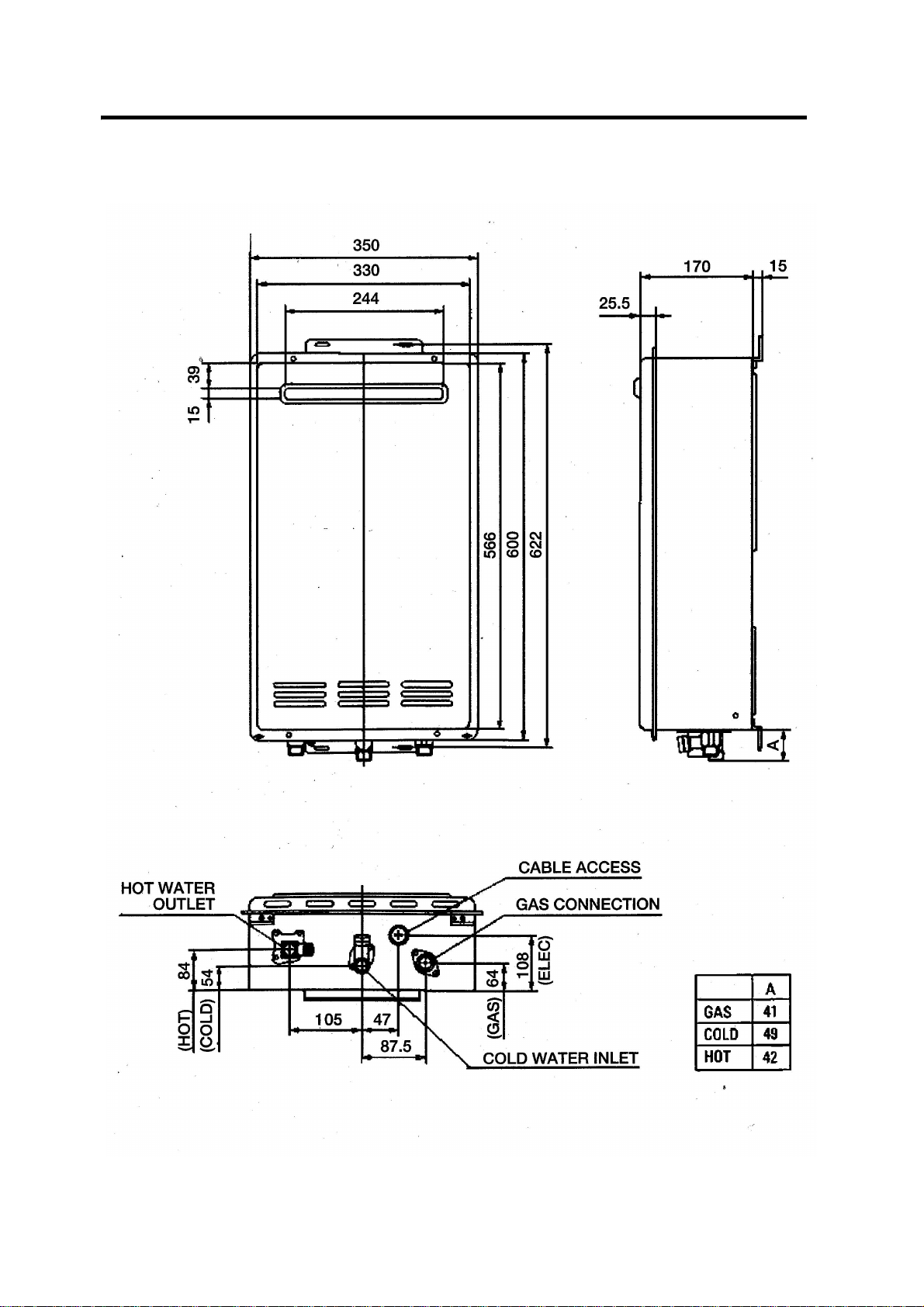

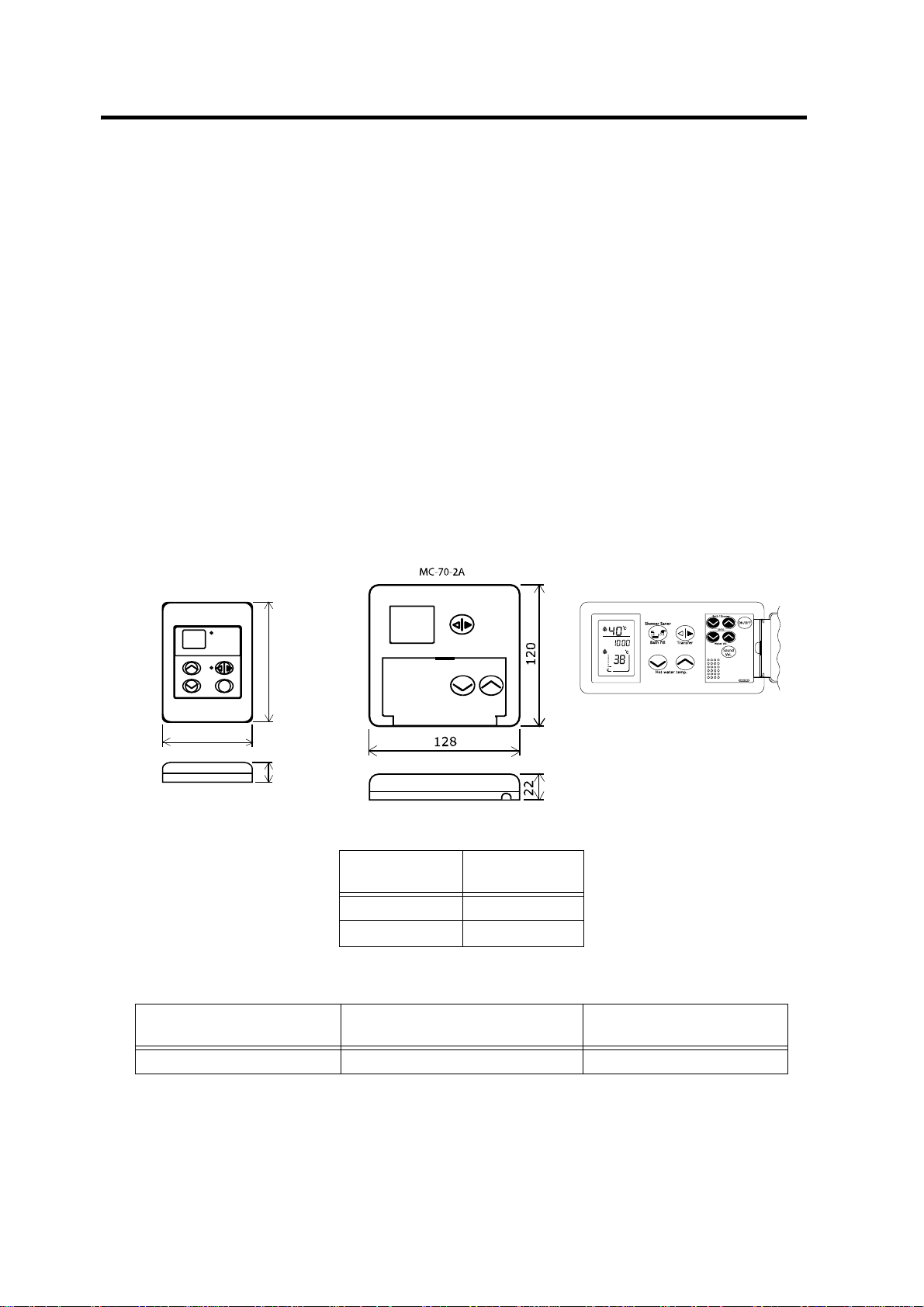

3. Dimensions

Note: All dimensions are in mm.

Infinity REU-2425W - 5 - Issue 2 - 5/07/04 ©Rinnai

4. Remote Controls

BC-70-2A

Remote Controls

Remote Controllers are an optional extra. 'Universal' and 'Deluxe' Controllers can be fitted.

Universal controllers allow temperature selection only. Deluxe controllers have temperature

selection, bath-fill and voice prompting functions. For detailed information regarding controller

operation refer to the 'How to use your water heater' booklet supplied with the appliance. Other

manufacturers' controllers are NOT compatible with this appliance.

Universal Controller (Model: MC-91-1A)

Up to 3 Universal Controllers can be fitted to the appliance. They are normally installed in the

areas where the majority of hot water is used, for example, the Kitchen, Bathroom, Ensuite and

Laundry.

Deluxe Controllers (Models: MC-70-2A) and (BC-70-2A)

Deluxe Controllers have 'Kitchen' (MC-70-2A) and 'Bathroom' (BC-70-2A) versions. 'Kitchen'

Controls are intended for the Kitchen or other convenient area where the majority of hot water is

used. 'Bathroom' Controllers are intended to be fitted in the Bathroom or ensuite and allow the

user to have a bath filled to the required level and temperature automatically.

MC-91-1A

120

90

20

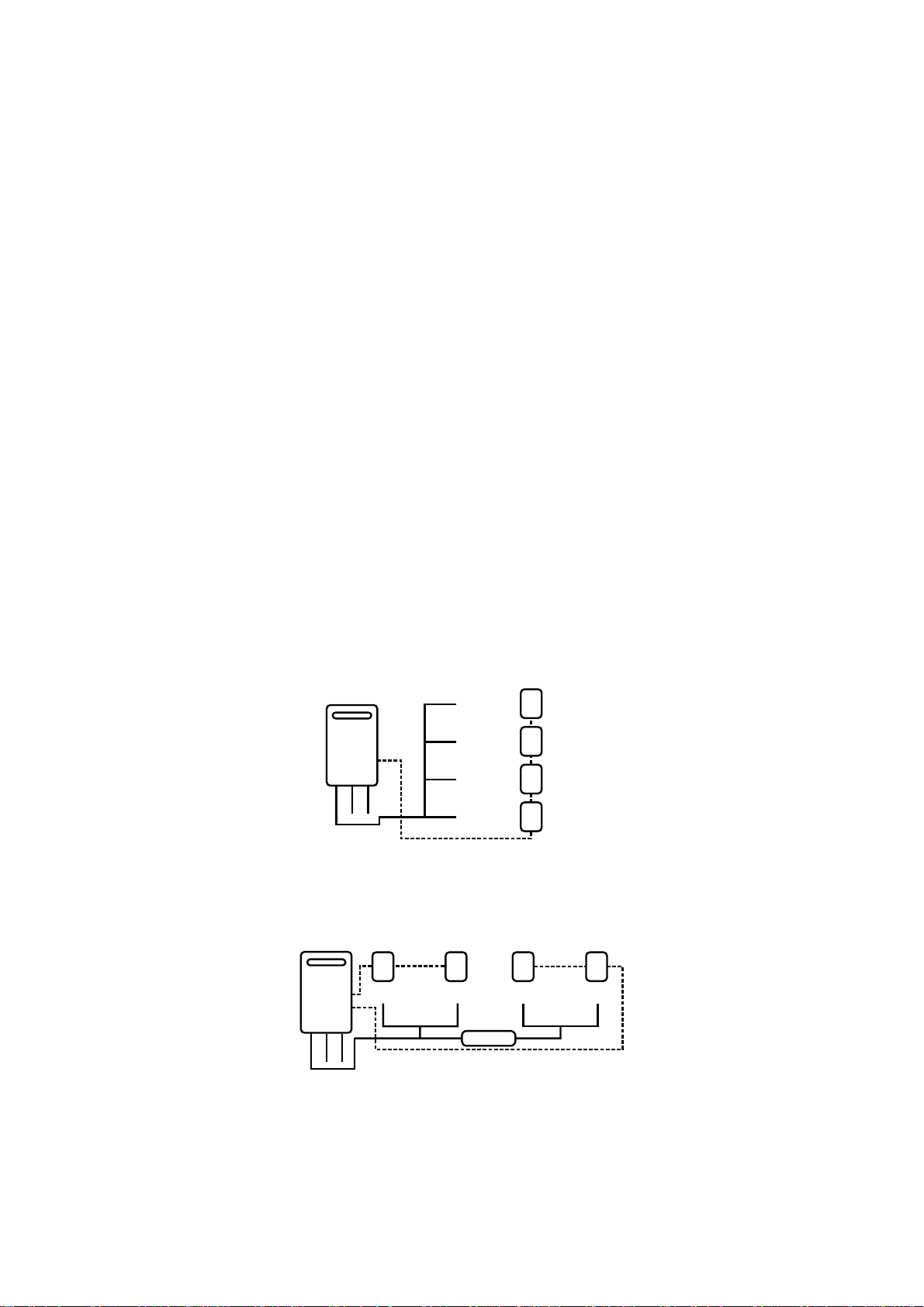

Up to two ‘Deluxe” controllers can be connected as follows:

Kitchen Bathroom

MC-70-2A

MC-70-2A BC-70-2A

If a Third controller is required, a ‘Unviersal’ controller can be included as follows:

Kitchen Bathroom Laundry

MC-70-2A BC-70-2A MC-91-1A

Positioning of Controllers

Controllers must be installed in shaded and clean locations. They should be fitted out of reach of

children (suggested height from floor at least 1500mm). Controllers are water resistant, however,

durability is improved when positioned outside the shower recess or at leat 400mm above the

highest part of a sink, basin or bath.

Infinity REU-2425W - 6 - Issue 2 - 5/07/04 ©Rinnai

DO NOT INSTALL THE CONTROLLERS

• NEAR A HEAT SOURCE, SUCH AS A COOK TOP, STOVE OR OVEN. HEAT, STEAM,

SMOKE AND HOT OIL MAY CAUSE DAMAGE.

• IN DIRECT SUNLIGHT.

• OUTDOORS UNLESS AN ENCLOSURE IS PROVIDED WHICH PROTECTS THE

CONTROLLER AGAINST SUNLIGHT AND DUST INGRESS.

• AGAINST A METAL WALL UNLESS THE WALL IS EARTHED IN ACCORDANCE WITH AS/

NZ3000.

Remote Controller Connection

Remote controls operate at extra low voltage (12 Volts DC) which is supplied from the appliance.

Controllers are supplied with 15 m of electrical cable. The cable wires for connection to the

appliance are fitted with spade terminals.

Extension cables are available from Rinnai. Alternatively, a two core sheathed (double insulated)

flex with minimum cross-sectional area of 0.5 mm² can be used. Maximum cable length is 50 m.

For connection refer to the “CONNECTING REMOTE CONTROL CABLES” section.

Water Heater and Controller installation configurations

If there is a label on the appliance casing that contains the text ”This appliance delivers water

not exceeding 50°C”, local regulations may permit it’s installation without a Temperature

Limiting Device. Installations without a Temperature Limiting Device are shown in Diagram 1.

If you are unsure about your local regulations contact your regulating authority or Rinnai.

If the appliance does not have this label, or your local regulations require installation with a

Temperature Limiting Device then install the appliance in accordance with Diagram 2.

Temperature

controller

(optional)

Temperature

controller

(optional)

Temperature

controller

(optional)

Temperature

controller

(optional)

H

O

T

50º C

C

O

L

D

G

A

S

Diagram 1. 50º C Appliance

KITCHEN

LAUNDRY

BATHROOM

ENSUITE

Temperature

controller

(optional)

KITCHEN

H

C

G

O

O

A

T

L

S

D

Diagram 2. Not a 50º C Appliance

Note: TLD = Temperature Limiting Device.

Temperature

controller

(optional)

LAUNDRY BATHROOM

TLD

Temperature

controller

(optional)

Temperature

controller

(optional)

ENSUITE

IMPORTANT: If the appliance is to deliver water primarily for the purposes of personal hygiene

in an early childhood centre, primary or secondary school, nursing home or similar facility for

young, aged, sick or disabled persons as defined in AS/NZ3500.4 a Temperature Limiting Device

(TLD), such as a Tempering Valve, may be required even if the appliance is set to 50º C or less.

For these types of applications contact Rinnai.

Infinity REU-2425W - 7 - Issue 2 - 5/07/04 ©Rinnai

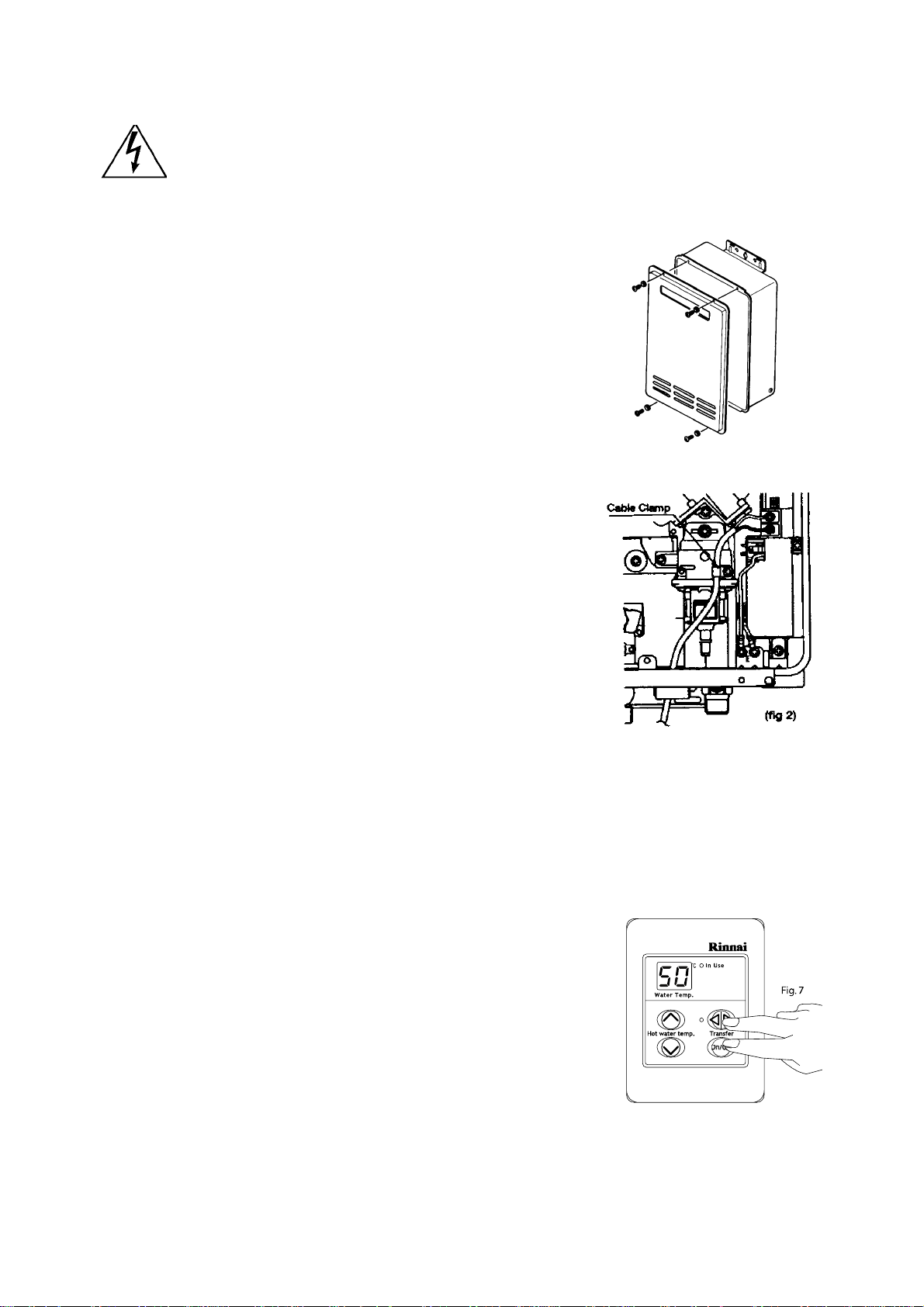

Connecting remote control cables

Do not attempt to connect the remote control cable terminals to the appliance with the

power on.

RISK OF ELECTRICAL SHOCK

Connecting One or Two Controllers

1. Isolate the power supply.

2. Remove the front cover from the Appliance (4 screws) fig. 1.

3. Thread the cable(s) through the cable access hole at the base of the appliance.

4. Locate the terminals for controls, the position of which is marked on

the Printed Circuit Board casing. Connect the space connectors to

the terminals on the P.C.B. (Fig. 2). Polarity is not important. Either

wire colour can be connected to either terminal.

5. Replace cover of the Appliance. Ensure that the special screw is placed at the bottom right hand corner for earthing purposes.

Connecting Three Controllers

1. Isolate the power supply.

2. Remove the front cover from the Appliance (4 screws) fig.1.

3. Cut the spade connectors from 2 of the controller cables to be

connected to the appliance (4 spade connectors should be cut off)

and discard. Connect the wires from these two cables and

terminate into two new spade connectors as shown in fig.3. Spade

connectors are available from your local electrical component

retailer.

4. Located the terminals for controls, the position of which is marked

on the Printed Circuit Board casing. Connect the 4 spade

connectors to the terminals on the P.C.B. (Fig. 2). Polarity is not

important. Either wire colour can be connected to either terminal.

5. Replace cover of the Appliance. Ensure that the special screw is placed at the bottom right hand corner for earthing purposes.

fig.1.

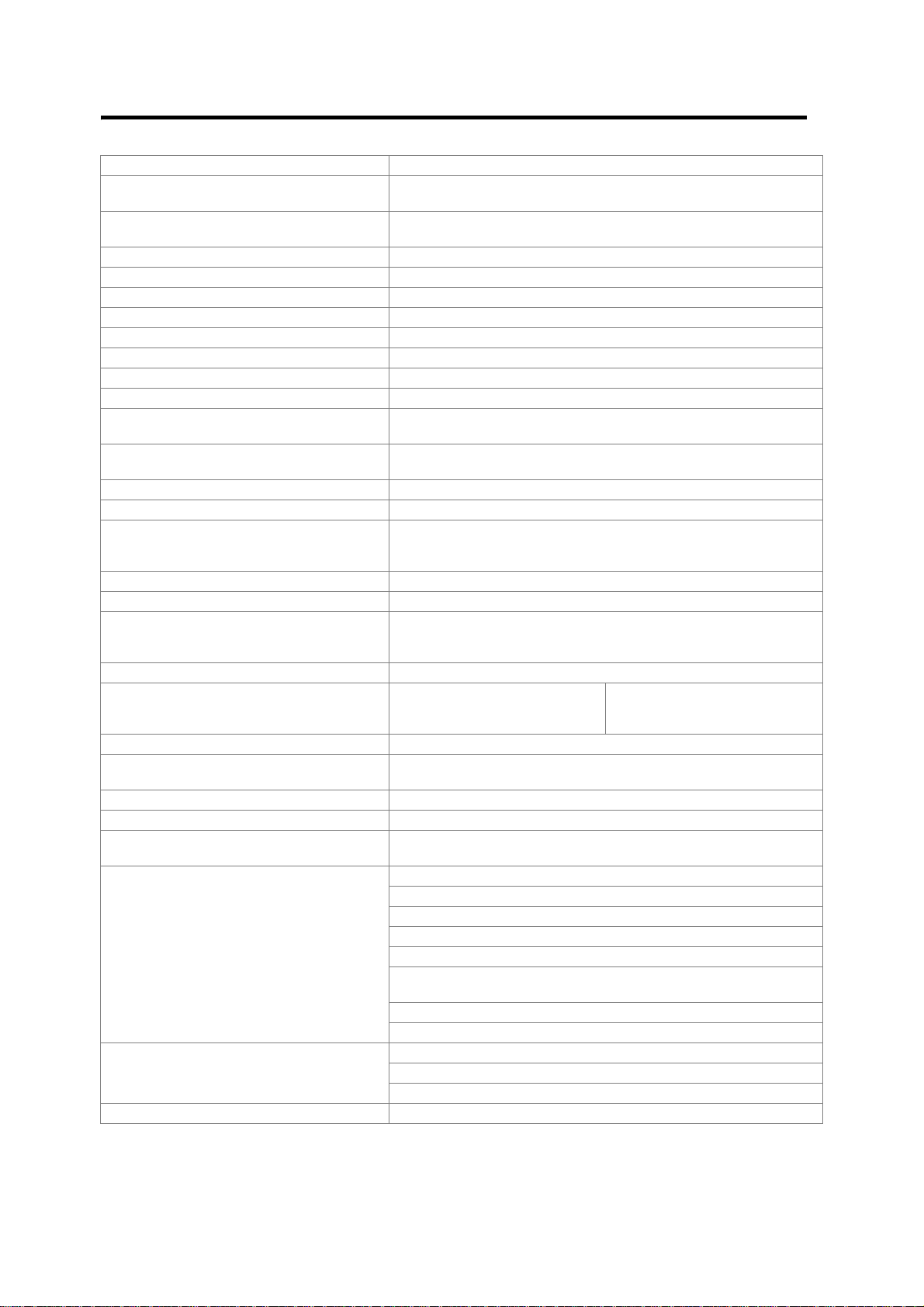

MC-91A Controller Programming

Is there a label on the appliance casing that contains the text.

“THIS APPLIANCE DELIVERS WATER NOT EXCEEDING 50° C

IF YES:No further action required.

IF NO: You will need to program Kitchen controller to enable selection of

temperatures higher than 50º C.

STEP 1:

For the controller in the KITCHEN only, press and hold the 'Transfer'

and 'On/Off' buttons simultaneously (see Fig 7.) until a 'beep' is heard

(approximately 5 seconds).

STEP 2:

When the controller fitted in the KITCHEN is switched on, it should be

possible to select temperatures higher than 50º C. If not, repeat Step 1.

Note:

• If the kitchen controller is replaced, repeat STEP 1 above for the replacement controller.

• If the kitchen controller is swapped with another controller (for example, the controller fitted in a

bathroom), repeat STEP 1 for the controller moved from the kitchen to the bathroom. Then perform

STEP 1 for the controller moved from the bathroom to the kitchen.

Infinity REU-2425W - 8 - Issue 2 - 5/07/04 ©Rinnai

5. Safety Devices

Flame Failure

Situated to the right of the burner at the front, the flame rod monitors combustion, preventing any

discharge of gas to the burner if there is no flame, by sending a signal to the PCB which in turn

isolates the gas.

Over Heat Protection Device

Also referred to as an Over Heat Switch. This device is fitted to a bend section at the inlet to the

heat exchanger. If the flame remains on the burner after the tap is closed, and the water

temperature inside the heat exchanger reaches 97°C, a DC 12 volt bi-metal cut-off switch isolates

the gas to the solenoids.

No Water

Should the incoming water flow become restricted or stop, then the water flow sensor will cease

to send a magnetic pulse signal to the PCB, in turn isolating the flow of gas to the burner.

Thermal Fuse

Wrapped around the entire surface of the heat exchanger, if the heat exchanger burns out, or the

temperature outside it reaches 129°C, the thermal fuse melts, breaking the electronic circuit.

Current to the gas solenoid valve circuit is cut, and combustion stops, shutting down the unit.

Pressure Relief Valve

This spring and seat type valve located on the hot water outlet will release the built up pressure

if the pressure inside the heat exchanger reaches 2100 kPa until 1500 kPa is maintained.

Combustion Fan Revolution Check

The combustion fan rpm is continually monitored by a magnetic pulse counter connected to the

PCB. If the fan revolutions deviate from the speed required for complete combustion, a signal is

sent to the PCB and the revolutions adjusted accordingly. (If not the unit shuts down)

Automatic Frost Protection

When the outdoor temperature drops and the temperature inside the appliance goes below 3.5°C,

the frost sensing device is activated, and the anti-frost heaters prevent the water in the appliance

from freezing. These anti-frost heaters remain ON until the temperature inside the appliance rises

to 11.5°C. There are 5 x 16 Watt anti-frost heaters located at various points in the main water flow

area of the appliance. The anti-frost protection device will prevent freezing down to -20°C in a no

wind situation, and -15°C in a windy situation.

3°C Over Temperature Cut-Off

The temperature of the outgoing hot water is constantly monitored by the water temperature

thermistor located near the outlet of the appliance. If the outgoing water temperature reaches 3°C

above the preset temperature, the burner will automatically go out. The burner will only ignite

again once the outgoing hot water temperature falls below the preset temperature.

Infinity REU-2425W - 9 - Issue 2 - 5/07/04 ©Rinnai

6. Specification

Rinnai Model No. REU-2425W

Type of appliance Temperature controlled continuous flow gas hot water

system.

Operation With or without remote controls, mounted in kitchen,

bathroom, or ensuite.

Exhaust system Forced combustion

Installation Externally mounted

Maximum gas rate 188 MJ/h

Minimum gas rate 21 MJ/h

Output (Kw) 41.7

Efficiency rating 80%

Hot water capacity, unmixed 2.7 to 24 L/min

Hot water capacity, mixed (25°C rise) 2.7 to 24 L/min

Default temperature (without remote)

(Set using switches on PCB)

Maximum temperature ceilings

(remote connected)

Temperature range (with remote) 37 to 50°C in 13 steps

Approved gas types Natural; Propane

Dimensions Width - 350 mm

Weight 18 kilograms.

Noise level 49 dB(A)

Connections Gas supply- R: / 20mm

Ignition system Direct electronic ignition

Electrical consumption (Watts) Normal -

Water temperature control Simulation feedforward and feedback

Water flow control Water flow sensor & automatic electro-mechanical water

Minimum operating pressure 200 kPa

Nominal operating pressure 200 ~ 1200 kPa

Power supply Appliance- AC240 Volts 50 Hz.

Safety devices Flame failure- Flame rod.

Remote control MC-91-1A- Universal control

Remote control cable Non polarised two-core cable

50°C

(40,43,50,55,60,65,75°C)

50°C (set by combination of switches on PCB)

Other temp.settings than 50°C avail. from alternative PCB

Height - 600 mm

Depth- 170 mm

Cold water inlet- R: / 20mm

Hot water outlet- R: / 20mm

55

Standby Anti frost protection -

flow control device

Remote control- DC12 Volts (Digital)

Boiling protection- 105°C lockout thermistor (25 seconds)

Remaining flame [OHS]- 97°C bi-metal switch

Thermal fuse- 129°C

Pressure relief valve- Opens-2100kPa, closes-1500 kPa

Automatic frost protection- Bi-metal sensor & anti-frost

heaters

Combustion fan rpm check- Integrated circuit system

Over current- Glass fuse (5 Amp).

MC-70-2A- Kitchen control

BC-70-2A- Bathroom control

8

80

Infinity REU-2425W - 10 - Issue 2 - 5/07/04 ©Rinnai

7. Cut-away Diagram

Infinity REU-2425W - 11 - Issue 2 - 5/07/04 ©Rinnai

8. Schematic Diagram

Infinity REU-2425W - 12 - Issue 2 - 5/07/04 ©Rinnai

9. Combustion Specification

REU-2425W

Input NG/Propane

LPG #

Gas Consumption NG/Propane

LPG #

Integral Injector size (18) NG mm ø 1.7

Propane/LPG # ø 1.0

Damper (1 piece) NG NIL

Propane/LPG # A

Pressure NG HI kPa 0.90

Propane/LPG # HI kPA 2.26 (1.90)

Burner type NG/

Dip Switch positions Refer to page 14

HI MJ/h 188

LO 21

HI kW 52.3 (50)

LO 5.93

LO 0.08

LO 0.17 (0.15)

Propane Common

Note: LPG values specified in brackets are for New Zealand.

Infinity REU-2425W - 13 - Issue 2 - 5/07/04 ©Rinnai

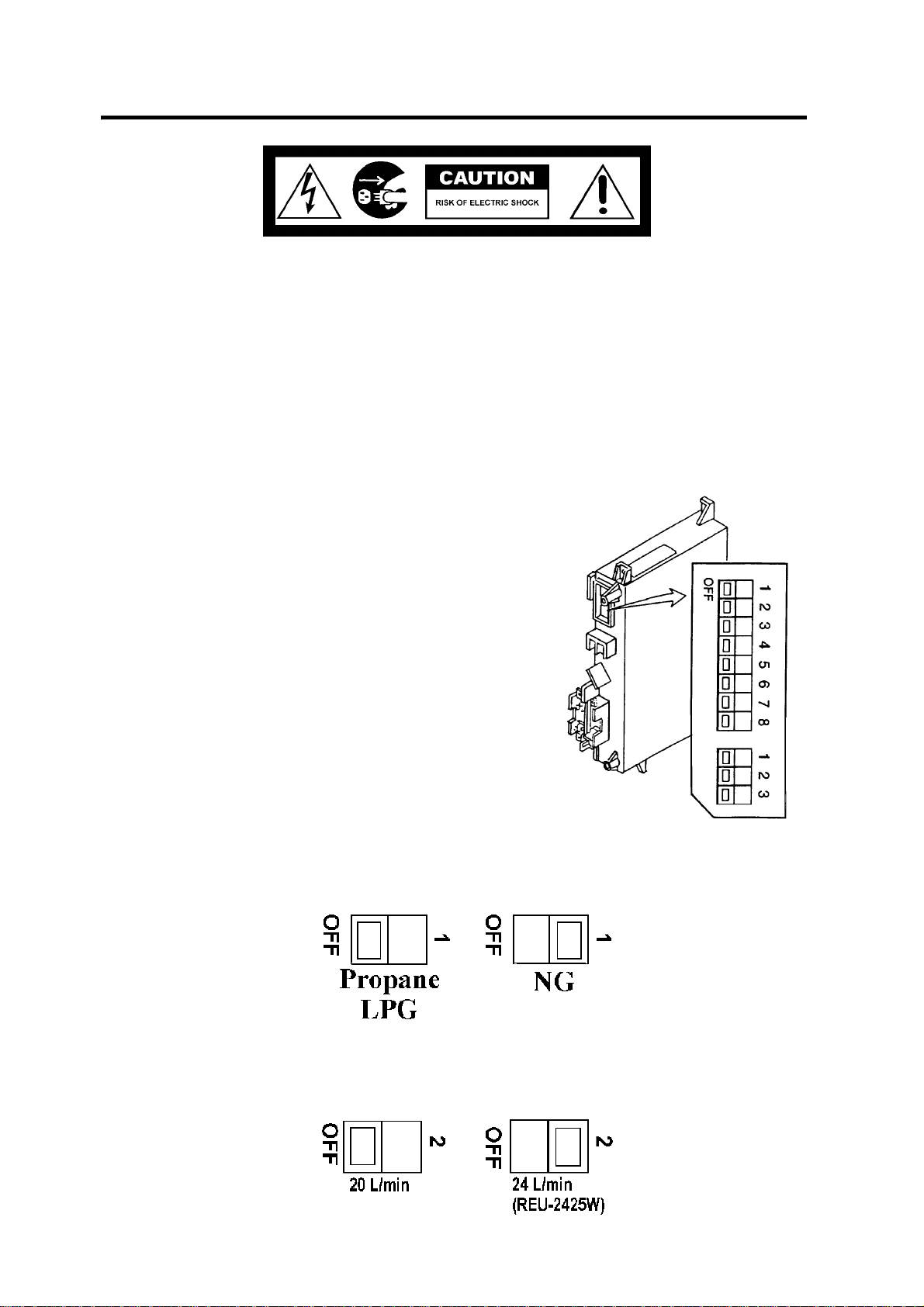

10. Dip Switch Positions

Please do not adjust the DIP Switch Positions before reading this information.

The dip switches are provided so that the water heater can be set to different operating

configurations. In some instances such as nursing homes or even domestic situations, it may be

necessary to limit the temperature of the hot water coming from the units.

The set-up configuration for the water heater differs depending on:

• Gas type

• Maximum water flow select

• Temperature limiting requirements

• Alternate type

DIP Switches explained

Top switch settings 1 ~ 8

1: Gas type (used only during conversion)

2: To select maximum water flow volume

4 to 8: To select the temperature with or without remote

connected.

Bottom switch settings 1 ~ 3

1: Factory use (To select the capacity of appliance)

2 & 3: Combustion control

The Infinity REU-2425W model delivers maximum hot

C, however alternative

water temperature limited to 50

PCB for the other maximum temperature of hot 40°C,

43°C, 50°C, 55°C, 60°C, 65°C, or 75°C available.

°

1. Gas Type

Only alter gas type positions when converting. For conversion instructions refer to page 43.

2. Maximum Water Flow Select

Infinity REU-2425W - 14 - Issue 2 - 5/07/04 ©Rinnai

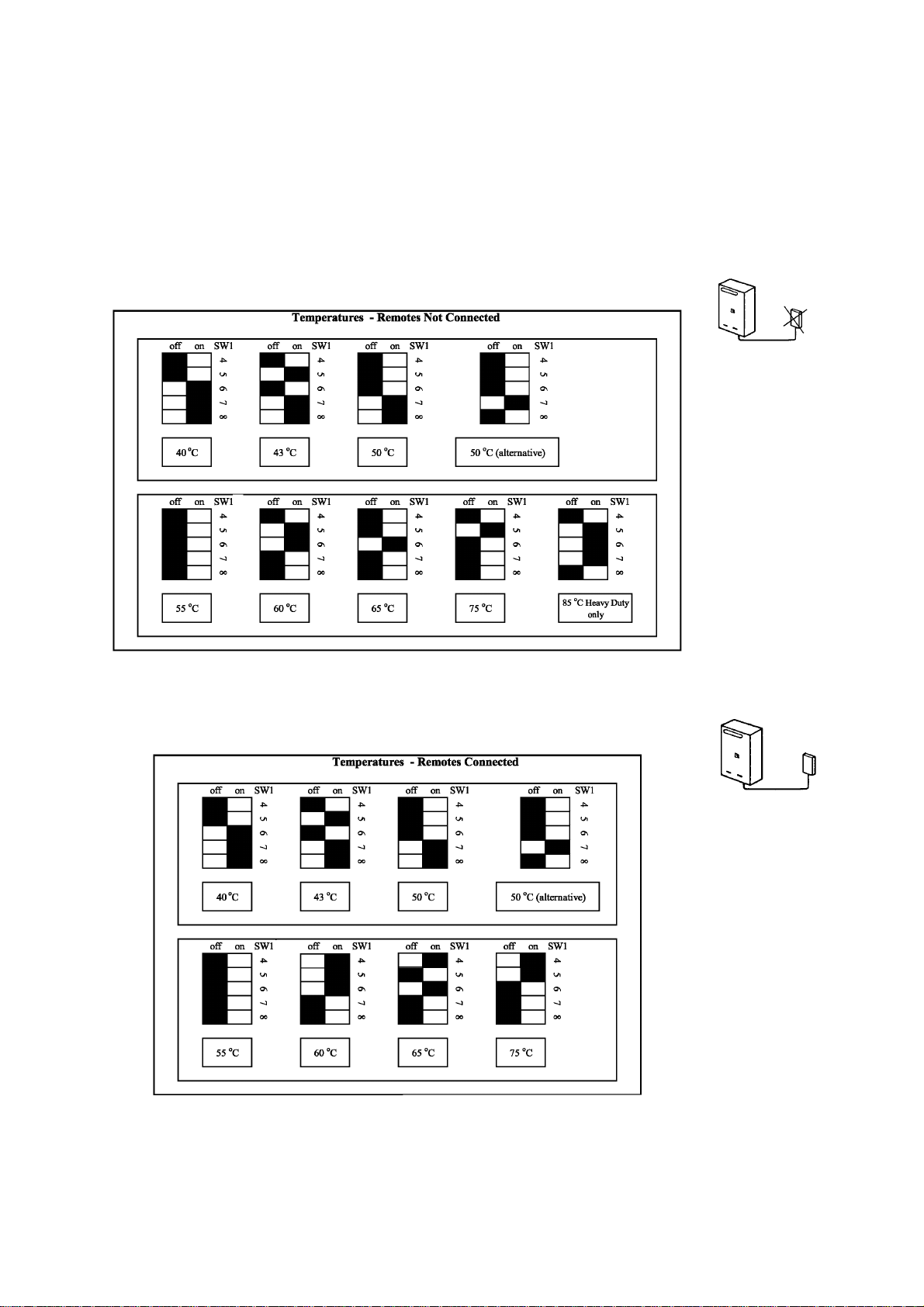

3. Temperature Limiting

There are different positions, depending on the temperature limit required and whether the

remote controls are connected or not.

Dip Switch Settings for Alternative PCB

a. Fixed hot water temperature ‘‘without’’ remote connected

Upper limit hot water temperature ‘‘with’’ remote connected

Note:

a) The black squares indicate the position of switches.

b) It will be noted that some dip switch configurations are the same for a given temperature

whether controllers are connected or not. These similarities are not mistakes.

Infinity REU-2425W - 15 - Issue 2 - 5/07/04 ©Rinnai

11. Water Flows

A simple calculation of the water flow rate, in litres per minute, can be made using the charts on

the next page, or simply using the formula provided below. The charts on the following pages

indicate the water flow from the Infinity at various combinations of incoming water temperatures,

and the selected temperature at the remote control.

How to read the charts:

The vertical plane indicates the selected temperature at the remote, and the horizontal plane

indicates the flow of water in litres per minute. Remote control range is between 50°C, therefore

the water flow charts only show the temperatures in that range. The temperature rise is the

difference between the temperature of the incoming water and the selected temperature at the

remote controls.

Select the appropriate chart depending on the incoming water temperature. Draw a horizontal line

across the graph from the selected temperature at the remote until it intersects the curve. At this

point draw the line in the vertical direction. The water flow is indicated where the line intersects

the bottom of the chart.

How to calculate water flows:

The following information is an outline of the formula required to measure accurately the flow rate

in litres per minute, as well as being the base for the charts on the next page. The most useful

way in which this formula can be utilised, is to calculate the water flow rate where there is

maximum gas input of 188MJ/h.

Formula: IN x TE = (TOUT -TIN) x 60 x Q

Where: T

# This is the maximum gas input converted from MJ/h into kilocalories. As 1 kilocalorie raises

* Thermal efficiency may be in the range of 78% to 90%, depending on the

Example Data Calculation

TIN =15°C

TOUT = 60°C

IN = 45000kcal/h

TE = 80%

Q = Water flow in Litres per minute

IN

T

OUT

IN = Gas input#.

TE = Thermal efficiency*.

Q = Water flow in litres per minute.

the temperature of 1 litre of water by 1 degree centigrade, the method of calculation is to

multiply the input in MJ/h by 239.

temperature rise and water flow. For the purpose of the following calculation we

have assumed an efficiency of 80%.

= Incoming water temperature.

= Outgoing water temperature as selected at the remote

IN x TE = (T

45000 x 0.8 = (60 - 15) x 60 x Q

36000 = 45 x 60 x Q

36000

-------------- -

= 60 x Q

45

800 = 60 x Q

800

-------- -

= Q

60

- T IN) x 60 x Q

OUT

13.3 L/min

Infinity REU-2425W - 16 - Issue 2 - 5/07/04 ©Rinnai

Loading...

Loading...