Page 1

NEO

Installaon Manual

Appliance must be installed, commissioned and serviced by a licensed tradesperson in

accordance will all applicable local rules and regulations.

For installations into a combustible opening, a Rinnai zero clearance box and ue kit are

mandatory.

Before installation:

• Unpack the appliance and components and check for damage—DO NOT install any

damaged items

• Check all components have been supplied and that you have the correct gas type

• Read these instructions to get an overview of the steps required before starting the

installation

Failure to follow these instructions could cause a malfunction of the appliance. This could result

in serious injury and property damage.

RIB2310N

RIB2310L

Page 2

Contents

WARNING

Improper installaon, adjustment, alteraon, service or maintenance can cause

property damage, personal injury or loss of life.

For assistance or addional informaon contact Rinnai on 0800 RINNAI

(0800 746 624).

Checklist 3

Specication 4

Dimensions 5

Location 6

Enclosure dimensions 9

Gas supply 10

Flueing options and components 11

General ueing information 12

Masonry installations 14

Mock chimney installations 16

Freestanding installations 18

Log set installation 20

Granule pack installation 21

Test pressures 22

Checking the ame pattern 24

Fitting the frame assembly 25

Commissioning 26

Wiring diagram 27

Page 3

Rinnai New Zealand Limited Neo Installation Manual: 11906-B

02-11

3

Checklist

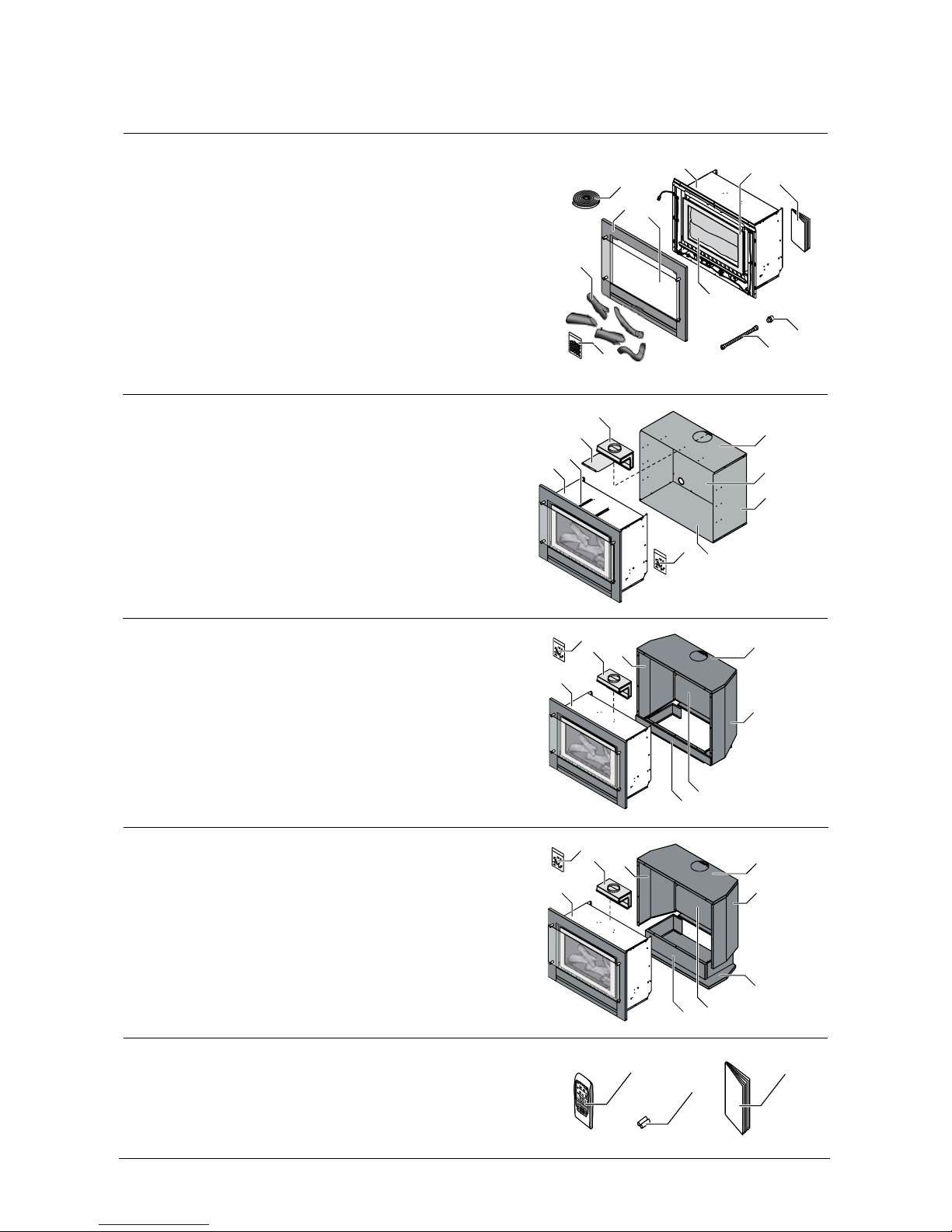

Engine - masonry installation:

1. Rinnai Neo heater (engine)

2. Outer (attached to heater with 2 x 8 g black screws)

3. Glass outer dress guard

4. Inner frame

5. Log set (inside appliance)

6. Packet of burner granules

7. Semi rigid stainless steel gas pipe with 5/8 " UNF are connection

8. Flared brass adaptor 5/8 " UNF - ½ " BSPT

9. Foam sealing strip

10. Operation and installation manual

7

8

6

5

9

2

3

1

4

5

10

Inbuilt mock chimney installation:

A Engine set (see above)

1. Spigot adaptor

2. Spigot guide panel

3. Spigot guide rails

4. Zero clearance box top panel

5. Zero clearance box rear panel

6. Zero clearance box left and right panels

7. Zero clearance box base panel

8. Hardware pack

A

3

7

2

1

8

5

6

4

Freestanding console installation:

A Engine set (refer masonry installation)

1. Spigot adaptor

2. Console top panel

3. Console right side panel

4. Console left side panel

5. Console rear panel

6. Console pillar

7. Hardware pack

1

A

3

2

7

4

5

6

Freestanding plinth installation:

A Engine set (refer masonry installation)

1. Spigot adaptor

2. Plinth top panel

3. Plinth right side panel

4. Plinth left side panel

5. Plinth rear panel

6. Plinth pillar

7. Plinth base

8. Hardware pack

1

A

3

2

4

5

6

7

8

Remote/thermostat - comes with all ETR models

1. RF combination remote/thermostatic control with wall mount

2. AA batteries (x2)

3. Operation manual

1

2

3

Page 4

Rinnai New Zealand Limited Neo Installation Manual: 11906-B

02-11

4

Specicaon

Description • Inbuilt gas space heater

• Burning log eect

• Glass front with glass dress guard

• Convection fan, top air discharge

Installation Inbuilt masonry, inbuilt mock chimney, and freestanding options

Combustion Method Bunsen type burner

Data Plate Inside appliance on the front left hand side

Flue - Masonry Rinnai strongly recommends the use of a Rinnai exiliner ue system (exi Ø 100 mm).

Failure to meet this criteria may result in an unsafe situation.

Installation without a exiliner ue is permissible as long as the chimney is checked for

soundness and ability to achieve a good draw. Terminal 240 mm x 45 mm rear discharge

(spigot).

Flue - Decorative

(mock chimney) and

Freestanding

Natural draft twin skin ue. An approved 100 mm cowl must be tted to all installations.

Decorative chimney installations require a Rinnai zero clearance box and zero clearance

ue kit.

Flue dimensions:

• Outer - 150 mm

• Inner - 100 mm

Gas Connection

½ " BSPT, the gas supply terminates inside the heater at the front lower right hand side

of the appliance

Gas Type NG and General Product LPG

Convection Fan 2-speed centrifugal, double diameter 160 x 180 mm

Heating Area • Up to 107 m

2

(NG)

• Up to 93 m2 (ULPG)

Ignition Continuous spark electronic ignition

Input/Output

Input NG: 14-30 MJ/h

Input ULPG: 14-27 MJ/h

Output NG: 3.24-6.94 kW

Output ULPG: 2.98-6.04 kW

Noise Level 37-45 dB(A)

Power Consumption High 50 W

Standby <3 W

1500 mm cord is supplied with 3-pin plug on the rear left of the appliance

Safety Devices Overheat switch, electrical fuse, ame failure sensing system, and power failure

protection

Temperature Control

Manual models, manual control on unit

ETR models, thermostatic, temperature control range 7-32 °C

Thermal Eciency NG - 80.5%

ULPG - 80%

Eciency star rating: 4.10 stars

Weight 60 kg

Page 5

Rinnai New Zealand Limited Neo Installation Manual: 11906-B

02-11

5

A A

AA

E

E

E

E

BB FF

BB

G

G

G

C D

C D

C D

C D

FF

H H

H

H

II

I

I

J J

J

J

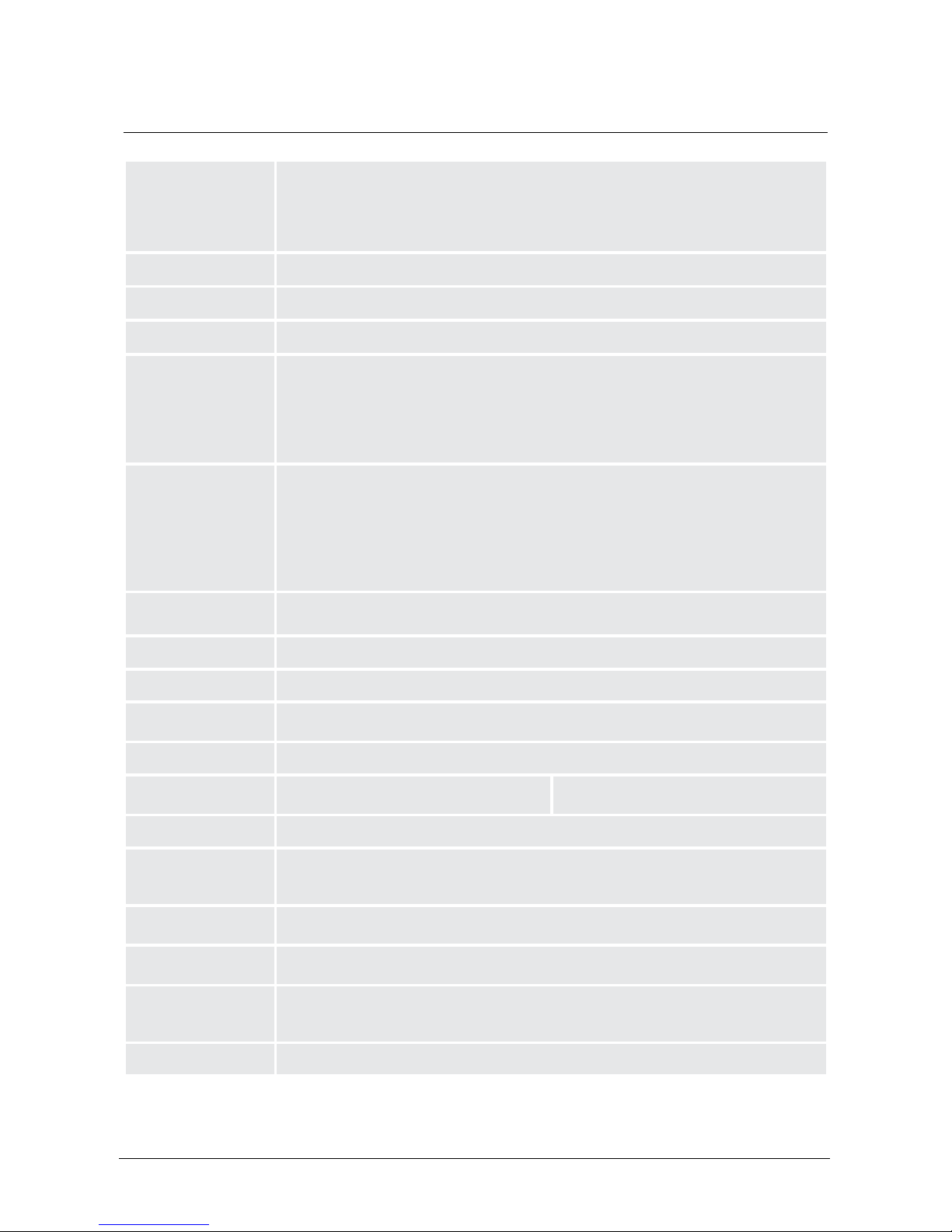

Inbuilt masonry Inbuilt mock chimney

Freestanding console Freestanding plinth

Dimensions (mm)

Model External dimensions Gas connection

A B C D E F G H I J

Inbuilt masonry 865 660 359 62 691 589 - 305 45 235

Inbuilt mock chimney 865 660 363 62 795 650 280 305 45 240

Freestanding console 865 760 363 62 865 760 280 305 140 235

Freestanding plinth 865 837 363 62 865 837 280 305 215 235

Page 6

Rinnai New Zealand Limited Neo Installation Manual: 11906-B

02-11

6

Locaon

The main points governing location are ueing and warm air distribution. The heater must not

be installed where curtains or other combustible materials could come into contact with the

appliance. In some cases curtains may need restraining. The Neo gas replace is not designed

to be built into bookcases.

Standard ued appliances draw the air for combustion from the room itself so there is a need

for xed ventilation. Fixed ventilation must be provided as per NZS 5261.

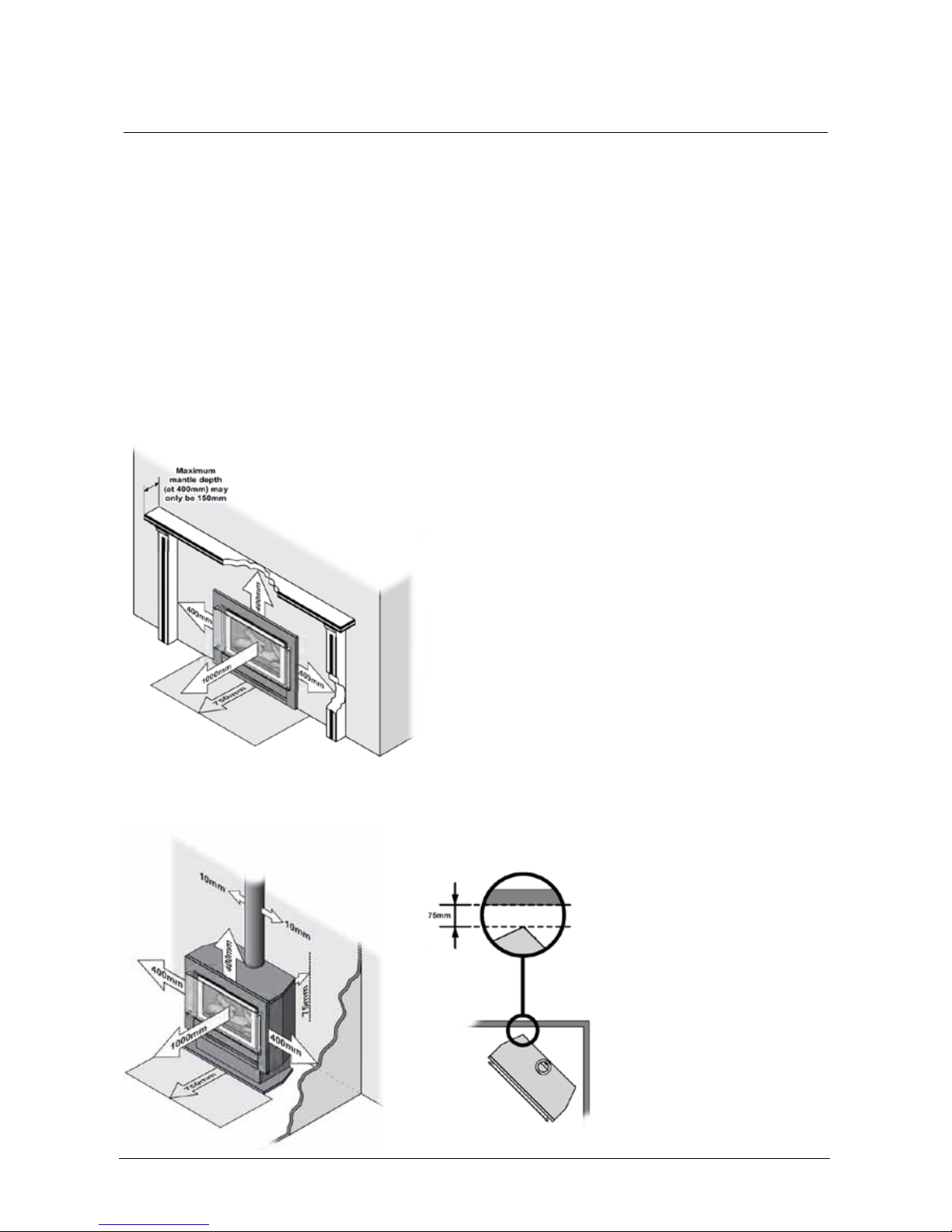

Clearances

The clearances listed below are minimum clearances unless otherwise stated.

Inbuilt models

Freestanding models (can be posioned directly on the oor)

Page 7

Rinnai New Zealand Limited Neo Installation Manual: 11906-B

02-11

7

Locaon

Mantels, surrounds, and hearths for inbuilt installaons

A mantel and surround are allowed providing they are outside the minimum clearances shown

on the previous page.

Minimum clearance

The minimum clearance from the top of the appliance is 400 mm. The depth of the mantel/

surround at this minimum clearance must not exceed 150 mm.

Additional mantel/surround depth

For every 50 mm of added mantel depth/surround, there must be an additional 100 mm of

clearance. For example; a 200 mm mantel depth will require a 500 mm clearance from the top

of the appliance.

Hearths

A hearth is not necessary but can be used for decorative purposes or protection of sensitive

ooring if required. It must not obscure the front of the re.

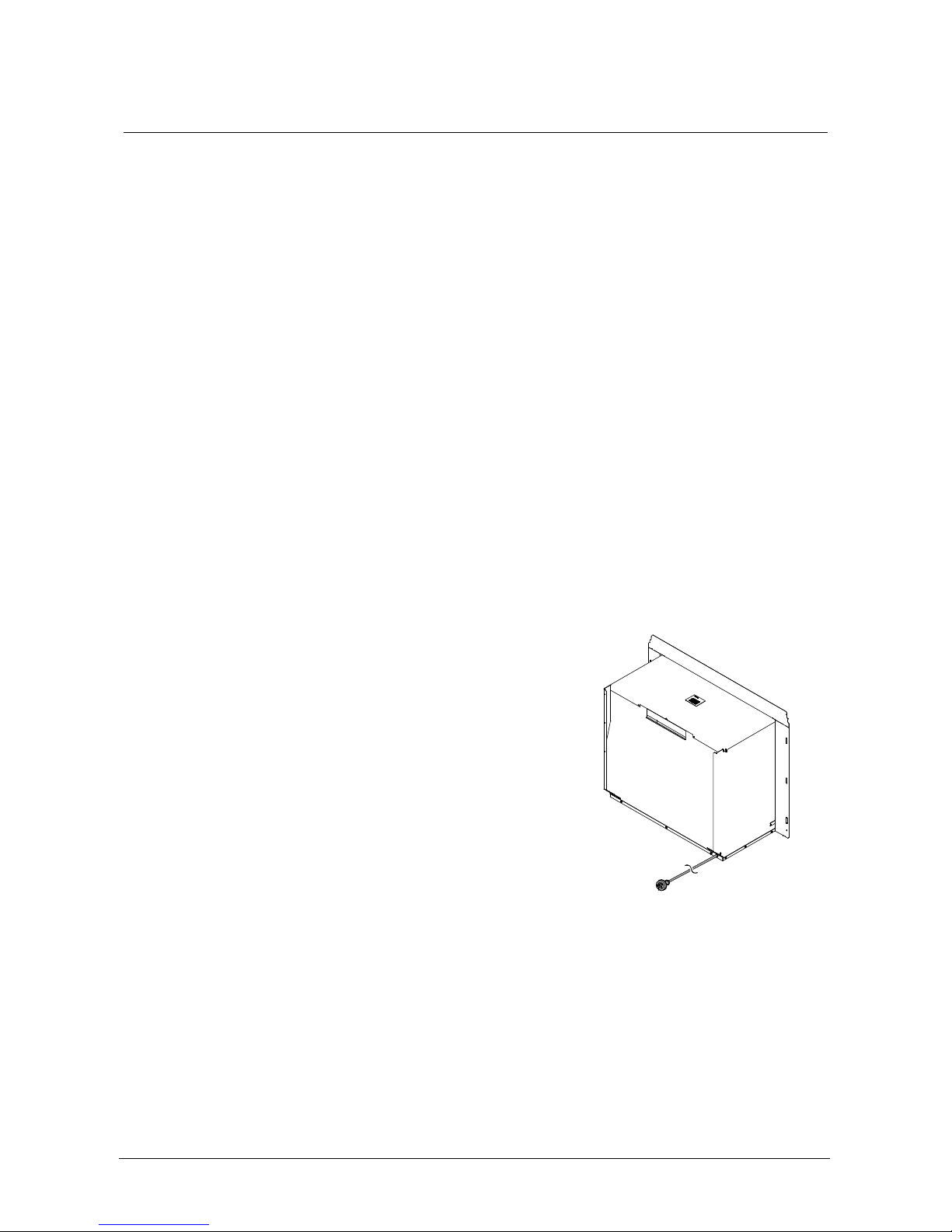

Electrical connecon

The Neo is supplied with a power cord (length 1500 mm)

and a 3-pin plug. The standard electrical connection passes

through the rear panel, but can also pass through the left

and right hand side of the unit by removing the knockout

tab from the bottom edge of the front panel. If changing

the electrical position use the rubber grommet from the

rear of the appliance for cable protection.

Rinnai recommend the heater is plugged into a dedicated

240 V, 10 A earthed power point. The power point must not

be located above the heater (potential re hazard). If the

supplied plug and power cord is to be used with an external

power point then the power cord will need to be tted with

the supplied grommet.

A suitable means of electric isolation must be provided which is adjacent to the appliance and

accessible with the appliance installed.

The electrical cord is not re rated and should not come into contact with the unit. If the

supply cord is damaged, it must be replaced by a licensed tradesperson. This must be a genuine

replacement part available from Rinnai—part number 6765B.

Page 8

Rinnai New Zealand Limited Neo Installation Manual: 11906-B

02-11

8

Locaon

TV installaon above a replace

If installing a at screen TV above the re the main issue is heat. Heat from the re and heat

from the ueing components that sit behind the TV, especially if recessed.

The Neo gas res have a fan that distributes warm air from the top of the appliance out into

the room. As warm air is dispersed outwards as opposed to directly upwards, installation of a

TV may be an option. The diagram below outlines recommended minimum clearances when

installing a TV directly above the Neo inbuilt models. All dimensions are in millimetres.

Mantel

400

TV

Rinnai

Neo Inbuilt

400

75

200

20

Flue

Flue

TV

Rinnai

Neo Inbuilt

The 400 mm dimension is the

minimum clearance required

to combustibles and to a

mantel.

For a TV mounted directly

above the Neo, the mantel

must be at least the depth

of the TV to deect the heat

away from the appliance.

It is up to the customer to check the TV installation instructions with the TV supplier to verify

clearances. Some TV manufacturers have warranty conditions that state a TV is not to be

installed above a replace.

Rinnai does not accept any responsibility for damage to a TV resulting from the use of this

information.

Page 9

Rinnai New Zealand Limited Neo Installation Manual: 11906-B

02-11

9

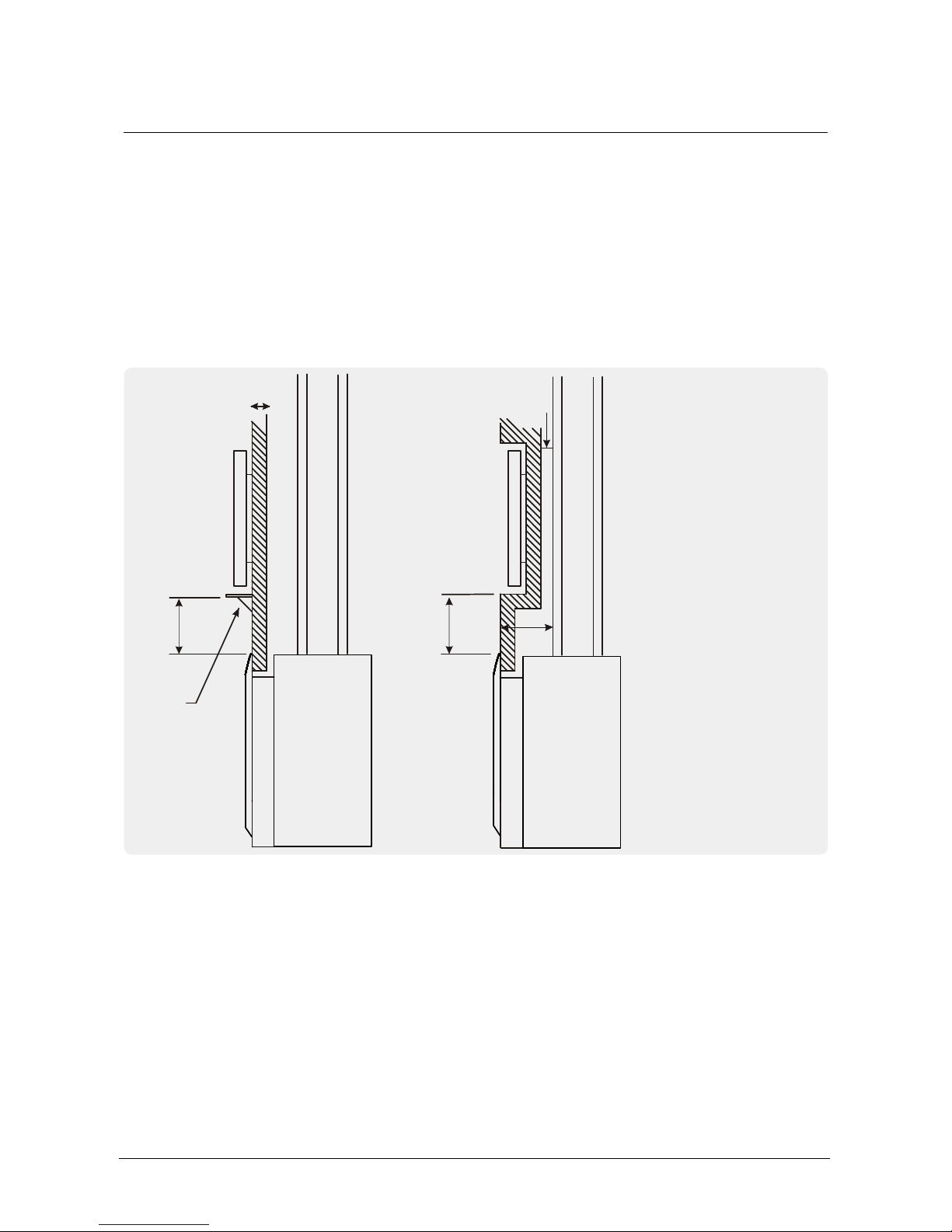

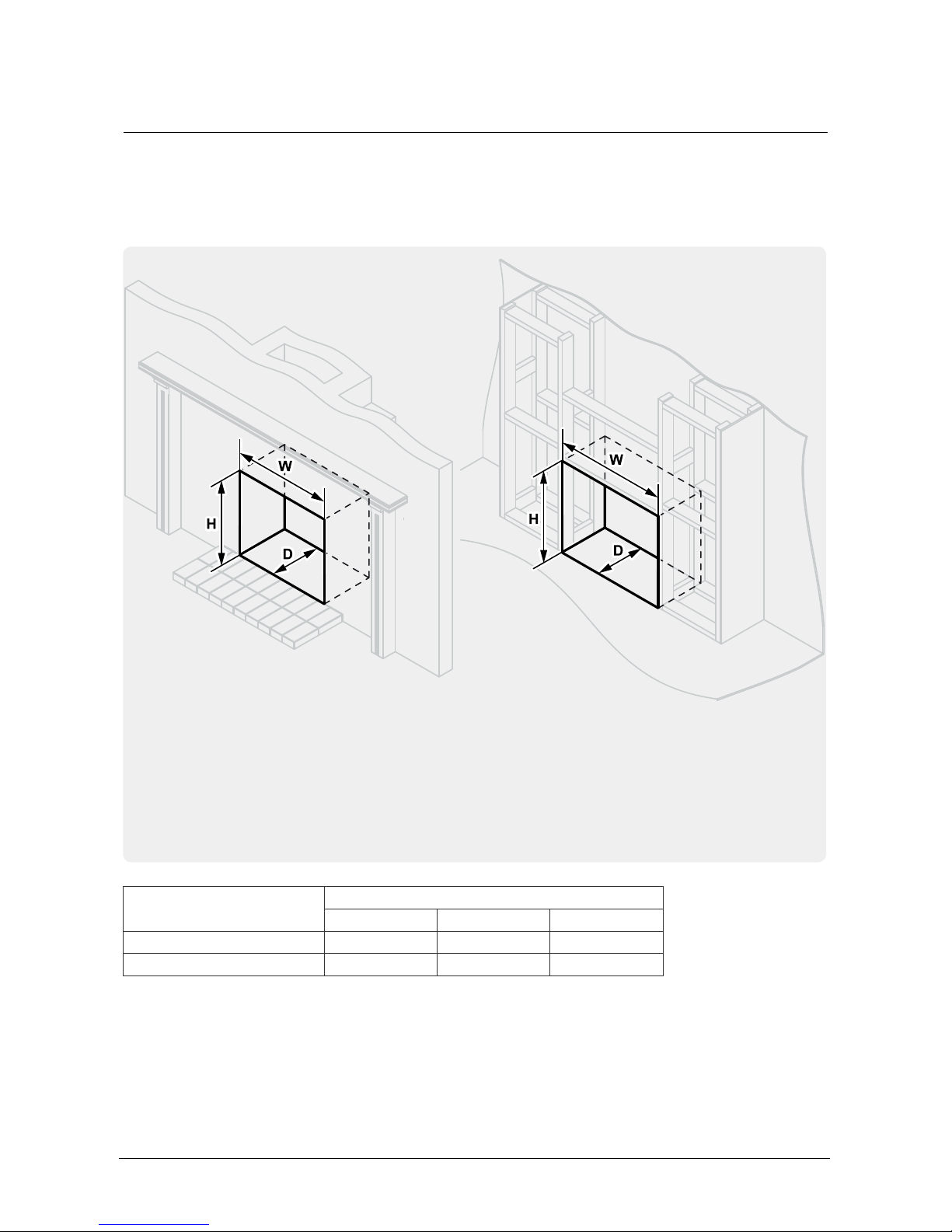

Enclosure dimensions

The enclosure dimensions specied are critical to the successful installation of this appliance.

The appliance must be positioned within the enclosure on a at level surface. If the appliance is

to be elevated from the ground, a base must be constructed with supporting joists capable of

supporting a minimum of 1.5 times the weight of the appliance.

Model Minimum dimensions (mm)

Height (H) Width (W) Depth (D)

Inbuilt masonry 600 695 370

Inbuilt mock chimney 650 800 370

Inbuilt masonry installaons Inbuilt mock chimney installaons

Important

The total cavity depth MUST also include the

thickness of the external cladding as the zero

clearance box MUST BE installed ush with the

cladding surface to ensure alignment of the

ue.

Page 10

Rinnai New Zealand Limited Neo Installation Manual: 11906-B

02-11

10

Gas supply

Gas pipe sizing must consider the gas input to this appliance as well as all other gas appliances

in the premises. The gas meter and regulator must be specied for the total gas rate. An

approved sizing chart such as the one in NZS 5261 should be used.

The gas supply termination is inside the heater and enters through the rear of the appliance.

Gas supply location

1

2

Gas supply locaon

3

Mark o the location for the vertical centre line of the heater

enclosure . To the right of the vertical centre line, mark o

the vertical and horizontal 3 locations for the gas supply

penetration.

1

2

Inbuilt Freestanding

Masonry Mock Chimney Console Plinth

305 mm to right of

appliance centre line

305 mm to right of

appliance centre line

265 mm to right of

appliance centre line

305 mm to right of

appliance centre line

45 mm from base of

enclosure

45 mm from base of

enclosure

140 mm from oor level 219 mm from oor level

Terminate 230 mm from

front of enclosure

Terminate 230 mm from

front of enclosure

Terminate at wall

clearance plus 125 mm

Terminate at wall

clearance plus 125 mm

2

3

4

F

R

O

N

T

O

F

E

N

C

L

O

S

U

R

E

RE

AR

O

F

E

NCL

O

S

UR

E

4

W

A

L

L

4

M

in

im

u

m

c

le

a

r

a

n

c

e

7

5

m

m

Back of heater

Inbuilt installaons Freestanding installaons

The length of the gas supply

termination is measured from the

front of the enclosure.

The length of the gas supply

termination is measured from the

back of the heater plus 125 mm.

5

5

Installer to terminate to suit, and

t supplied gas connection .

Leak test the joint between

the exible gas connection and

termination.

STEP 1 STEP 2

Gas supply pipe Brass adaptor Flexi

½ ” BSPT

Installer, terminate to suit

Gas connection:

Page 11

Rinnai New Zealand Limited Neo Installation Manual: 11906-B

02-11

11

Flueing opons and components

Installation

Components available

Part no. Description

Inbuilt masonry R1756

R1761

RIB2310 exi ue kit 4 m

Flexiliner extension 2 m (extends to 3.6 m)

Inbuilt mock chimney,

straight vertical ueing

R2340

R2345

R1762Z

R1763Z

R1763SS

RIB2310 zero clearance box

RIB23 spigot assembly

Flue kit galvanised 3.6 m (same as Timberame Radius)

Flue extension 1.2 m galvanised

Flue extension 1.2 m stainless steel

Inbuilt mock chimney,

vertical oset ueing R1764

R1766

All of the above components, plus:

45 ° bend kit (same as Timberame)

Wall penetration kit galvanised (same as Timberame Radius)

Freestanding straight

vertical ueing

R2345

R1762GL

R1763GL

RIB23 spigot assembly

Freestanding ue kit galvanised black 3.6 m

Freestanding ue extension galvanised black 1.2 m

Freestanding vertical

oset ueing R1766GL

R1765GL

All of the above components plus:

Freestanding wall penetration kit galaxy black

Freestanding 45 ° bend kit galaxy black

Inbuilt masonry installaons Inbuilt mock chimney installaons

Freestanding installaons

A =Direct ue (straight vercal)

B = Oset ue

Without exiliner With exiliner

A =Direct ue (straight vercal)

B = Oset ue

Page 12

Rinnai New Zealand Limited Neo Installation Manual: 11906-B

02-11

12

General ueing informaon

Flashings

Flashings to the top of chimney structure do not form part of the ue kit and must be specied.

Clearance to combusbles

For installations using the Rinnai zero clearance ue components, the minimum clearance from

inner ue to combustible material must be greater than 50 mm. This equates to 25 mm from

the outer ue when using the Rinnai twin-skin ue.

Flue length and number of bends

Minimum ue length

This is required to ensure adequate draw and prevents spill-back of combustion products which

can cause the safety sensors to shut down the unit.

• minimum ue length before any bends or osets = 1.0 m

• minimum vertical ue length = 3.6 m

Maximum ue length and number of bends

Rinnai recommend a maximum ue length of 8 m with a maximum of two 45° bends.

Self-supporng ue

The weight of the ue system should not be supported by the appliance—it

should be self-supporting. Supporting the ue is usually completed during the

framing stage with ue supports or straps within the cavity.

Every gas replace requires a ue system that will draw eectively and clear ue products

safely under all potential wind and climatic conditions. It is the responsibility of the installer to

ensure that the appliance is provided with an eective ue.

For installations requiring a ue, a Rinnai ue system must be used. The ue system must be

fully assembled and secured in place before the appliance is installed.

Page 13

Rinnai New Zealand Limited Neo Installation Manual: 11906-B

02-11

13

General ueing informaon

Shared ues

Gas appliances must not be connected to a chimney or ue serving a separate fuel burning

appliance.

Flue cowl clearance

To ensure products of combustion are cleared, adequate clearance for the building is required

and the below guideline is recommended.

Flue cowl should have a 500

mm clearance from any part of

the building. This also applies

to steeped and pitched roofs

which should be clear of the

ridge line as shown below.

Lesser clearances may provide

perfectly adequate ue systems

depending on the installation.

Minimum clearances are shown

in NZS 5261.

Page 14

Rinnai New Zealand Limited Neo Installation Manual: 11906-B

02-11

14

Masonry installaons

1. Check dimensions of the opening

Refer 'Enclosure dimensions' and if necessary bring them to the required dimensions.

Check the chimney height as inadequate height can eect product performance. Some

installations may require the chimney height to be extended to reduce down drafts.

2. Check ueway

• Ensure there are no obstructions

• Provide a rm, at and sealed base (sealed means no holes or openings in the replace)

• Ensure adequate support of the appliance (if not properly supported noise and vibration

may result)

3. Install exiliner ue system

To ensure adequate draw for maximum performance of the appliance, Rinnai strongly

recommends the use of a Rinnai exiliner ue system for masonry installations. Failure to meet

this installation criteria may result in an unsafe situation. Performance issues resulting from

inadequate ueing is not covered by the warranty.

Installation without a exiliner is permissible in masonry installations as long as the chimney

has been checked for soundness and ability to achieve a good draw.

Chimney plate

Inbuilt masonry without a flexiliner flue

Inbuilt masonry with a flexiliner flue

Mortar

Approved chimney

cowl

Minimum

200 mm

Minimum

3.6 m

Chimney plate

Mortar

Approved chimney

cowl

Minimum

200 mm

Minimum

3.6 m

Adaptor

Flexible chimney

liner

Appliance

adaptor

Masonry installaon without a flexiliner flue Masonry installaon with a flexiliner flue

Page 15

Rinnai New Zealand Limited Neo Installation Manual: 11906-B

02-11

15

Masonry installaons

4. Installing the heater into the replace

Apply the supplied foam seal strip to the rear of the heater. The strip is intended to form a seal

between the heater and the replace. If an adequate seal cannot be formed with this strip

another means of sealing must be used (non-combustible insulation) between the replace and

the heater body.

If using a exiliner ue, prepare the heater engine by drilling four x Ø 3.2 mm holes in the prepressed dimples on the top panel of the heater. Attach the ue guide rails from the ue kit

using the supplied screws. Align the guide rails with the guide plate and slide the heater engine

into the enclosure until the guide plate is fully against the rear of the front assembly-this will

ensure the heater and ue spigot are correctly aligned.

Carefully move the appliance into the enclosure ensuring the gas supply feeds into the rear

access hole and fasten heater to the replace.

Drill

4 x Ø 3.2mm

holes

Flue guide rails

Guide rails

Guide plate

Rear of front

assembly

Page 16

Rinnai New Zealand Limited Neo Installation Manual: 11906-B

02-11

16

Mock chimney installaons

1. Construct frame and install zero clearance box

Refer 'Enclosure dimensions' and construct frame. Assemble and install the RIB2310 zero

clearance box. Installation needs to be on a level base. If this is not done the appliance may

twist and become damaged—this will void any product warranty.

The zero clearance box is installed ush with the cladding surface.

For installations into a mock chimney a Rinnai zero clearance box and zero clearance ue kit is

required to isolate the appliance from combustible materials. Failure to meet this installation

criteria will void any product warranty.

800 mm

650 mm min.

370 mm min.

7

2. Install the ue and complete electrical connecon

The weight of the ue system should not be supported by the appliance—it should be selfsupporting. Supporting the ue is usually completed during the framing stage with ue

supports or straps within the cavity. Flue supports have been included with the ue kit to assist

with this. These are to be riveted to the ue.

Please note, a twin-skin ue requires a 25 mm clearance (from the outer ue) from

combustibles.

Combusble Material

(must be greater than 50 mm from inner flue)

Flue

Inner flue 100 mm

Outer flue 150 mm

Page 17

Rinnai New Zealand Limited Neo Installation Manual: 11906-B

02-11

17

Mock chimney installaons

Clamping spacer

Flue cowl

Sealing collar

(not supplied)

Twin-skin flue

Outer flue 150 mm

Inner flue 100 mm

Any residual heat in the zero clearance box is ducted

away via the outer ue

3. Installing the heater into the replace

Carefully move the appliance into the enclosure ensuring the gas supply feeds into the rear

access hole and fasten heater to the replace with the four xings either side of the unit as

shown below.

50 mm

Bring the ue down within 50 mm of the unit and then

use the slip collar provided in the ue kit.

Page 18

Rinnai New Zealand Limited Neo Installation Manual: 11906-B

02-11

18

Freestanding installaons

1. Aach the ue spigot to the Neo engine

Using a 3.3 mm drill bit, drill through the four dimples at the rear of the back panel of the Neo

engine. Attach the ue spigot (ordered separately) with the screws provided.

Aach flue spigot

2. Assemble, posion and secure base assembly to the oor

Assemble the base assembly provided in the Neo freestander kit and place on the oor where

the Neo is to be located. Using three appropriate bolts or screws secure the base assembly to

the oor. This also acts as a seismic constraint.

The diagram below shows the base assembly for the Neo Console model. The Neo Plinth base

assembly has a pillar section attached.

Fixing posions

While the following diagrams depict the Neo Freestanding Console model, the steps to

constructing the Neo Freestanding Plinth are the same.

Page 19

Rinnai New Zealand Limited Neo Installation Manual: 11906-B

02-11

19

Freestanding installaons

3. Aach heater to base assembly and t back panel

Lift the Neo freestanding engine into position over the base assembly and x into position

using the four M5 x 10 screws supplied.

Remove the three screws from the base of the unit (do not discard) and screw the back

freestanding panel into position—nine screws in total.

Four screw posions for

securing the unit to the

base assembly

4. Add top and side panels

Install the freestanding top panel using three M5 x 10 and three self tapping screws. Install the

freestanding side panels (ensure you push up to minimise the gap) using six screws per side.

1

2

3

4

5

6

Three screws from unit base (screws 7,8 & 9)

Self tapping screws

M5 x 10 screws

Screw posions for

side panels

Minimise

gap

Page 20

Rinnai New Zealand Limited Neo Installation Manual: 11906-B

02-11

20

Log set installaon

The granule pack and log set, consisting of ve log

pieces, comes packaged inside the appliance, you will

need to remove the glass retainer (four screws) before

installing the granules and log set. Use extreme care

when handling the log pieces, they are made from a

fragile material and will damage easily.

It is important you position the pieces in the order

shown below. Incorrect placement can create carbon build up and eect performance.

Malfunctioning due to improper log placement is not covered under warranty. The unit must

never be used with broken logs and should not be mixed with other burn media (except the

Rinnai Neo granules).

1. Check to ensure that the ports of the main

burner are clean and clear of any particles and all

packaging.

1

2. Select the thicker ‘Y’ log and t into position by

lining up the two pin holes onto the two pins of

the locating bracket that is xed to the centre of

the main burner.

2

1

3. Select the thick straight log and t onto the

metal locators on the left rear of the panel. When

correctly located this log will be touching the

burner box walls.

4. Select the thinner ‘Y’ log and t into position by

linking up the two pin holes onto the two pins of

the rst two logs. Ensure this log is seated all the

way down until it touches logs 1 and 2.

3

1

2

5. Select the longest log and t onto the metal

locators at the right rear of the panel. When

correctly located this log will be touching the

burner box walls and resting on log 1.

4

1

3

4

6. Locate the nal bowed log onto the metal locater

at the base of the right side panel and the bracket

xed to the main burner. Lean the log back until

it rests on log 4.

Page 21

Rinnai New Zealand Limited Neo Installation Manual: 11906-B

02-11

21

Granule pack installaon

The granules as well as being added to create a more realistic log ame eect (by

diusing the gas ames through the burner ports) also assist in soot prevention and

are CRITICAL to the performance of the heater.

Never pour the granules directly from the pack as dust particles from the plastic bag

may block the ports.

NG installaons

Place the granules evenly across the burner—use the whole pack.

ULPG installaons

Carefully place 30 of the granules as close as possible to the front burner ports as shown on

the diagram below. DO NOT cover any of the front right side ports. It’s important this is done

correctly as incorrect placement can cause high yellow ames (dirty combustion) that may

cause sooting.

It is desirable that the ames touch the granules as this diuses any ‘candling’ eect and

enhances the realistic log burning look of the heater.

Page 22

Rinnai New Zealand Limited Neo Installation Manual: 11906-B

02-11

22

Test pressures

To check and set the burner pressures

1. Refer to the data plate located inside the appliance on the front left hand side for the

correct gas pressure settings.

2. Using a screw driver loosen the captive Appliance Test Point Pressure Screw (ATPP) and t

the manometer.

3. Remove the dust cap from the regulator adjusting nut and screw.

Gas control valve

High pressure

adjusng nut

Low pressure

adjusng screw

Gas

inlet

Inlet test

point

Cap

Gas outlet

Appliance test point

pressure

Gas control power connecon

Page 23

Rinnai New Zealand Limited Neo Installation Manual: 11906-B

02-11

23

Test pressures

High pressure setting

4. Turn the appliance on and set the heater to its highest setting (refer operation manual).

Using a screw driver hold the low pressure adjusting screw stationary while adjusting the

high pressure setting nut with a 10 mm spanner. Turning the nut clockwise will increase the

outlet pressure while turning the nut anti-clockwise will decrease the outlet pressure.

Low pressure setting

5. Disconnect the power to the Gas Control Valve (GCV) by separating the connector for the

power supply (yellow wires). The GCV will automatically default to low pressure operation.

Using a 10 mm spanner hold the high pressure adjusting nut stationary while adjusting

the low pressure screw with a screw driver. Turning the screw clockwise will increase the

outlet pressure while turning the screw anti-clockwise will decrease the outlet pressure.

6. Replace the dust cap to its original position. It’s important this is done correctly to ensure

the correct operation of the GCV.

7. Reconnect the power to the GCV by rejoining the connector (yellow wires).

8. After conrming the correct pressures, turn the appliance o, remove the manometer,

tighten the ATPP sealing screw and leak test.

9. Turn the appliance on and o a few times to check ignition.

10. When you are satised that the heater is working correctly, reassemble and start the

appliance to check the ame pattern (refer next page).

Decrease

Increase

Low pressure

adjusng screw

Increase

Decrease

High pressure

adjusng nut

Cap

POV power connector

Appliance test

point pressure

Page 24

Rinnai New Zealand Limited Neo Installation Manual: 11906-B

02-11

24

Checking the ame paern

It may take approximately two hours of operation for the logs to achieve their full ame

pattern and glow. During the initial burning in period, some smoke and smell may be

experienced. The appliance should be run on the high setting in a well ventilated room until

these dissipate. It is important to check the ame pattern during this time.

Abnormal ame paern

Abnormal ame performance and/or pattern can indicate a problem with the re, such as

blocked gas injectors, log movement during installation or incorrect ue installation. There are

some warning signs that could indicate a problem.

• Unusual smell from the appliance

• Continued diculty or delay in establishing a ame

• Flame appears either very short or very long

• Flame only burns part way across the burner

• Severe soot building up on the inside of the glass door

Normal flame paern

Abnormal flame paern

Soot build up

It is the responsibility of the installer to check that under normal conditions of the

appliance, all ue gases are exhausted to the outside atmosphere and that there are no

spillage of combustion gases into the room.

If the appliance cannot be made to perform correctly, please contact Rinnai.

Page 25

Rinnai New Zealand Limited Neo Installation Manual: 11906-B

02-11

25

Fing the frame assembly

Before tting the frame assembly, ensure that it is not scratched or damaged in any way. The

frame assembly comes packaged in one box and contains the outer frame, glass dress guard

and inner frame.

When placing the assembly down ensure it is placed on its lower edge or at. If it is

placed on its left or right edge the glass may slide out o the stand-o posts. If this

should occur ensure that the silicon rubber mounts are not dislodged when sliding the

glass back into position.

1. Before installing the frame assembly remove the two black screws that are already

positioned in the appliance. These are located on the bottom of the unit, one each side.

2. Take the inner frame and hook the slanted edge (bottom is at) over the top of the glass

retainer brackets and swing down into position onto the magnets.

3. Carefully lift the outer frame assembly complete with glass dress guard, taking care not

to tilt it on its edge as the glass may slide out o the stand-o posts. Come in close to the

heater and plug in the CAT cable into the control panel.

NOTE

Control panel

plug

CAT cable

Posion of the CAT cable and control panel plug (step 3)

Page 26

Rinnai New Zealand Limited Neo Installation Manual: 11906-B

02-11

26

Fascia assembly

Rear view of fascia

for reference

Posion of black screws

CAT cable

Fing the frame (steps 4 and 5), ensure you do not place excessive tension or pinch the CAT cable

4. Lift and slot the assembly over the top and swing down, the lower screws need to be

positioned over and inside the bottom ange.

5. Push the outer frame assembly into position and screw in place with the two screws

removed in step 1.

Commissioning

Complete the installation and commissioning checklist in the customer operation manual and

make sure you leave the manual with the customer.

Explain to the customer about the use and care of the unit and that they understand the

instructions.

Fing the frame assembly

Page 27

Rinnai New Zealand Limited Neo Installation Manual: 11906-B

02-11

27

Wiring diagram

Page 28

Address: 105 Pavilion Drive, Mangere, Auckland

PO Box 53177, Auckland Airport, Auckland 2150

0800: 0800 RINNAI (746 624)

Phone: (09) 257 3800

Fax: (09) 257 3899

Email: info@rinnai.co.nz

Website: www.rinnai.co.nz

All Rinnai appliances meet or exceed the safety standards required by New Zealand

gas and electrical regulations.

Rinnai is constantly improving its products and as such information and

specications are subject to change or variation without notice.

Loading...

Loading...