Page 1

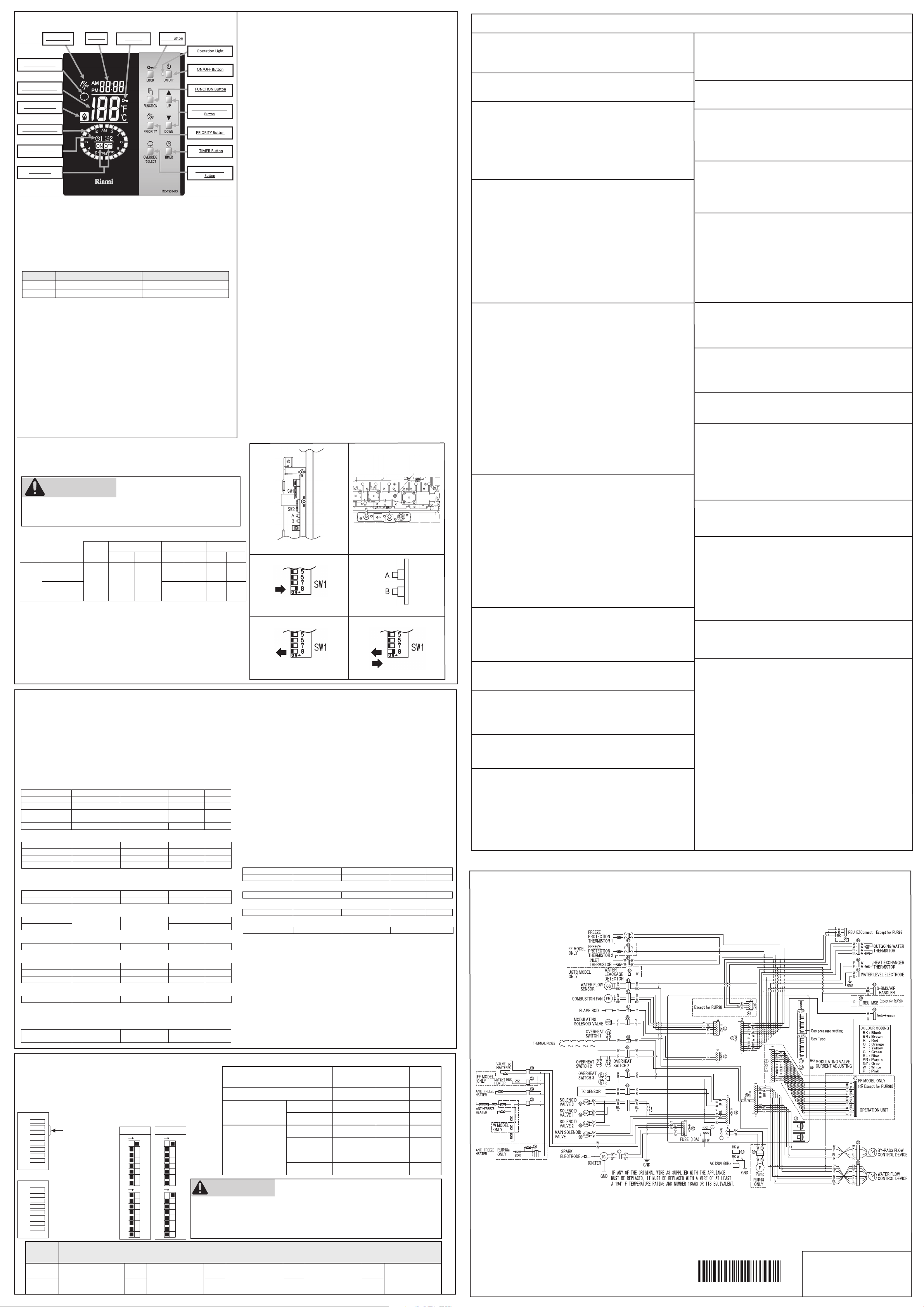

Controller

PRIORITY Icon

CIRCULATION Icon

TEMPERATURE Icon

COMBUSTION Icon

TIMER SETTING Icon

TIMER 1 & 2 Icon

ON/OFF Icon

TIME Icon

Diagnostic Use of the Controller

1. To display the most recent diagnostic codes press and hold the

“On/Off” button for 2 seconds on the MC-195T controller.

2. To enter or exit the maintenance monitor information mode press

and hold the down button for 2 seconds and without releasing it

press the ON/OFF button.

01

02

Outgoing water temperature Degrees Fahrenheit

To Change the Temperature Scale (ºF / ºC)

With the water heater turned on, press FUNCTION button to reach

Function 4. Once at Function for use

2 for C.

To Turn Off the Controller Sound (Mute)

With the water heater turned on, press FUNCTION button to reach

Function 2. Once at Function for use

Locking the Controller

The MC-195T controller can be locked or unlocked by pressing and

holding the LOCK button for approximately 3 seconds.

LOCK Icon

LOCK B

WATER TEMPERATURE

OVERRIDE/SELECT

tinUataD.oN

nim/lag 1.0etar wolf retaW

▲ and ▼to select 1 for F and

▲ and ▼to select ON or OFF.

Gas Pressure Setting

NOTE: For additional installation and commissioning information refer

to the Operation and Installation Manual.

WARNING

This appliance must be installed,

serviced and removed by a trained

and qualified person. During pressure testing of the consumer piping,

ensure gas valve is turned off before unit is shut off. Failure to do so

may result in serious injury to yourself or damage to the unit.

APPLIANCE OPERATING PRESSURES

Gas Inlet Min./Max Forced Low Forced High

Nat. G LPG Nat. G LPG Nat. G LPG

4” W.C.

/10.5”W.C.

RUR98i

Water

Inlet Max

Short flue length

150 PSI

Long flue length

Table 1

8” W.C.

/13.5”W.C.

0.51”W.C. 0.52”W.C. 3.1”W.C. 3.7”W.C.

0.53”W.C. 0.55”W.C. 3.3”W.C. 3.9”W.C.

Commissioning

With all gas appliances in operation at maximum gas rate, the

flowing inlet pressure at the incoming test point on the Rinnai

water heater should read 4” W.C. - 10.5” W.C. on natural gas

and 8” W.C. - 13.5 W.C. on propane gas. If the pressure is

lower, the gas supply is inadequate and the unit will not operate

to specification. Check the gas meter regulator and pipework for

correct operation/sizing and correct as required.

Troubleshooting

Important Safety Notes

There are a number of (live) tests that are required when fault

finding this product. Extreme care should be used at all times to

avoid contact with energized components inside the water heater.

Only trained and qualified service technicians should attempt to

repair this product. Before checking for resistance readings,

disconnect the power source to the unit and isolate the item from

the circuit (unplug it).

(SV1, SV2, SV3 and POV) Gas valve and Modulating solenoids: (Set meter above 2K)

Wire color Voltage Resistance Connector # Pin #'s

(Main) Black - Pink

(SV1) Black - Blue

(SV2) Black - Yellow 11 ~ 13 VDC 35 ~ 41 ohms B2 4 - 7

(SV3) Black - Red

(POV)

Yellow

(M) Water Flow Control Device Servo or Geared Motor:

Red - Pink N / A 44 ~ 52 ohms G2 3 - 4

White - Blue N / A 44 ~ 52 ohms G2 1 - 2

Grey - Brown N / A N / A G2 5 - 7

Grey - Orange N / A N / A G2 6 - 7

NOTE: The grey wire listed above turns to black at G connector on the PCB.

(QS) Water Flow Sensor:

Black - Red 11 ~ 13 VDC N / A L3 E10 - G7

Yellow - Black 4 ~ 7 VDC N / A L3 E1 - G7

By-pass Flow Control:

White - Blue

(IG) Ignition System:

Grey - Grey 110 ~ 130 VAC N / A C1 1 - 3

(FM) Combustion Fan Motor:

Red - Black 6 ~ 45 VDC N / A L2 5 - 6

White - Black 5 ~ 10 VDC 9.60 ~ 9.75 K ohms L2 3 - 5

Yellow - Black 11 ~ 13 VDC 3.90 ~ 4.05 K ohms L2 4 - 5

Recirculation Pump:

White - Black 108 ~ 132 VAC 17 ~ 21 ohms H1 1 - 2

Set your meter to the hertz scale. Reading across the white and black wires at terminals 3 and 5

you should read between 60 and 420 hertz.

Thermal Fuse / Overheat Switch:

Red - White 11 ~ 13 VDC Below 1 ohms

11 ~ 13 VDC 24 ~ 28 ohms B1 3 - 4

11 ~ 13 VDC 35 ~ 41 ohms B3 4 - 6

11 ~ 13 VDC 39 ~ 42 ohms B4 4 - 5

-

Yellow 2 ~ 15 VDC 67 ~ 81 ohms D1 1 - 2

N / A

44 ~ 52 ohms

G1 10 - 11

B8

B7

12 - 131GRed - Pink

B1 - G8

Gas Pressure Setting

Ensure gas pressure check under Commissioning has been

completed first! The regulator is electronically controlled and

factory pre-set. Under normal circumstances it does not require

adjustment during installation. Make adjustments only if the unit is

not operating correctly and all other possible causes for incorrect

operation have been eliminated.

1. Turn OFF the gas supply.

2. Turn OFF the water supply.

3. Remove the front panel (four screws).

4. Check the gas type using the data plate on the side of the unit.

Confirm that the gas type switch is in the correct position

(SW1 in DIPSW2 is ON for natural gas, NG, and OFF for

propane gas, LPG.) Figure 1.

5. Remove the screw and attach the manometer to the burner test

point located on the gas control. Figure 2.

6. Turn on the gas supply and the power supply.

7. Flow water through the water heater at the maximum flow rate

obtainable. (At least 3 gallons per minute is recommended. If

there is not enough water flowing, the water heater could shut

off or sustain damage due to overheating.)

8. Move SW8 in DIPSW1 to ON. Figure 3.

9. Push the PC board switch A for one second. Figure 4.

10. Calibrate “Forced Low” combustion using switch A (up) and

switch B (down).

11. Move SW8 in DIPSW1 to OFF and then back to ON. Figure 6.

12. Push the PC board switch B for one second. Figure 4.

13. Calibrate “Forced High” combustion using switch A (up) and

switch B (down).

14. Move SW8 in DIPSW1 to OFF. Figure 5.

15. Close hot water taps.

16. Turn off gas supply and 120 V power supply.

17. Remove manometer and re-install screw.

18. Turn on the gas supply and 120 V power supply.

19. Operate the unit and check for gas leaks.

20. Install the front panel using four screws.

Burner

test point

Fig. 1

Fig. 3

Fig. 2

Fig. 4

6 .giF5 .giF

Flame Rod:

Place one lead of your meter to the flame rod and the other to ground.

With the unit running you should read between 5-150 VAC. Set your

meter to the μ amp scale and series your meter in line with the flame

rod. You should read 1 μ amp or greater for proper flame circuit. In

the event of low flame circuit remove the flame rod and check for

carbon or damage.

Heat Exchanger, Outgoing Water Temperature and

Inlet Thermistors:

Check all thermistors by inserting meter leads into each end of the

thermistor plug. Set your meter to the 20 K scale and read

resistance. Applying heat to the thermistor bulb should decrease

the resistance. Applying ice to the thermistor bulb should increase

the resistance. See below for examples of typical temperatures and

resistance readings.

Example:

Outgoing Water Thermistor:

White - White N / A See example above E6 2 - 3

Blue - Blue N / A See example above E6 4 - 5

Heat Exchanger Temperature Thermistor:

Pink - Pink

Inlet Thermistor:

White - White N / A See example above E9 4 - 9

Remote Controls:

Terminals J 10 ~ 13 VDC 1.5 ~ 3.0 K ohms J 1 - 2

59°F = 11.4 ~ 14KΩ

86°F = 6.4 ~ 7.8KΩ

113°F = 3.6 ~ 4.5KΩ

N / A See example above E5 4 - 7

140°F = 2.2 ~ 2.7KΩ

221°F = 0.6 ~ 0.8KΩ

Frost Protection:

This unit has frost protection heaters mounted at different points to

protect the water heater from freezing. All of them should show a

positive resistance reading.

Amp Fuses:

This unit has one inline (10) amp glass fuse. Remove the fuse and

check continuity through it. If you have continuity through the fuse

then it is good. Otherwise the fuse is blown and must be replaced.

Diagnostic Codes

Power interruption during Bath fill (Water will not flow when

03

power returns)

Turn off all hot water taps. Press ON/OFF twice.

•

Bypass Servo

05

Replace bypass servo

•

Air Supply or Exhaust Blockage

10

Ensure approved venting materials are being used.

•

Check that nothing is blocking the flue inlet or exhaust.

•

Check all vent components for proper connections.

•

Ensure vent length is within limits.

•

Verify dip switches are set properly.

•

Check fan for blockage.

•

Burner Sensor (see code 31)

•

No Ignition

11

Check that the gas is turned on at the water heater, meter, or cylinder.

•

If the system is propane, make sure that gas is in the tank.

•

Ensure appliance is properly grounded.

•

Ensure gas type and pressure is correct.

•

Ensure gas line, meter, and/or regulator is sized properly.

•

Bleed all air from gas lines.

•

Verify dip switches are set properly.

•

Ensure igniter is operational.

•

Check igniter wiring harness for damage.

•

Check gas solenoid valves for open or short circuits.

•

Remove burner cover and ensure burners are properly seated.

•

Remove burner plate; inspect burner surface for condensation/debris.

•

Check the ground wire for the PC board.

•

No Flame

12

Check that the gas is turned on at the water heater, meter, or cylinder.

•

Check for obstructions in the flue outlet.

•

If the system is propane, make sure that gas is in the tank.

•

Ensure gas line, meter, and/or regulator is sized properly.

•

Ensure gas type and pressure is correct.

•

Bleed all air from gas lines.

•

Ensure proper venting material was installed.

•

Ensure condensation collar was installed properly.

•

Ensure vent length is within limits.

•

Verify dip switches are set properly.

•

Check power supply for loose connections.

•

Check power supply for proper voltage and voltage drops.

•

Ensure flame rod wire is connected.

•

Check flame rod for carbon build-up.

•

Disconnect and reconnect all wiring harnesses on unit and

•

PC board.

Check for DC shorts at components.

•

Check gas solenoid valves for open or short circuits.

•

Remove burner plate; inspect burner surface for condensation/debris.

•

Thermal Fuse

14

Ensure SW5 in DIPSW2(white) is in the off position.

•

Check for restrictions in air flow around unit and vent terminal.

•

Check gas type of unit and ensure it matches gas type being used.

•

Check for low water flow in a circulating system causing short-cycling.

•

Ensure dip switches are set to the proper position.

•

Check for foreign materials in combustion chamber and exhaust piping.

•

Check heat exchanger for cracks or separations.

•

Check heat exchanger surface for hot spots which indicate

•

blockage due to scale build-up. Refer to instructions in manual

for flushing heat exchanger. Hard water must be treated to

prevent scale build up or damage to the heat exchanger.

Measure resistance of safety circuit.

•

Ensure high fire and low fire manifold pressure is correct.

•

Check for improper conversion of product.

•

Over Temperature Warning

16

Check for restrictions in air flow around unit and vent terminal.

•

Check for low water flow in a circulating system causing short-cycling.

•

Check for foreign materials in combustion chamber and exhaust piping.

•

Check for blockage in the heat exchanger.

•

Electrical Grounding

19

Check all components for electrical short.

•

Condensate Trap

25

Condensate trap is full. Check condensate trap and drain pipe for

•

blockage.

Replace condensate trap.

•

Burner Sensor

31

Measure resistance of sensor.

•

Replace sensor.

•

Outgoing Water Temperature Sensor

32

Heat Exchanger Outgoing Temperature Sensor

33

Outside Temperature Sensor

41

Inlet Water Temperature Sensor

51

Check sensor wiring for damage.

•

Measure resistance of sensor.

•

Clean sensor of scale build-up.

•

Replace sensor.

•

Wire Diagram

Modulating Solenoid Valve Signal

52

Check modulating gas solenoid valve wiring harness for

•

loose or damaged terminals.

Measure resistance of valve coil.

•

Burner

57

Contact a service provider.

•

Secondary Heat Exchanger

58

There is scale build up in the secondary heat exchanger and it needs

•

to be flushed to prevent damage. Refer to the flushing instructions in

the manual. Hard water must be treated to prevent scale build up or

damage to the heat exchanger.

Combustion Fan

61

Ensure fan will turn freely.

•

Check wiring harness to motor for damaged and/or loose

•

connections.

Measure resistance of motor winding.

•

Circulation Pump

63

Ensure cold inlet and hot outlet valves are open to plumbing.

•

Inspect/clean inlet filter for debris.

•

If application is using thermal bypass valve inspect/clean pump filter. If

•

installed with dedicated return, inspect return line.

•

If draining pump, purge air from recirculation pipe before running fixture.

•

If installed in a cold climate, open hot water fixture and run for 5 min.

•

Repalce Pump.

•

Water Flow Servo

65

The water flow control valve has failed to close during the bath fill

•

function. Immediately turn off the water and discontinue the bath fill

function. Contact a licensed professional.

PC Board

70

Check PC board DIP switches for correct positons.

•

Check the connection harness at the connection on the PC board.

•

Replace PC board.

•

Solenoid Valve Circuit

71

Replace the PC Board.

•

Flame Sensing Device

72

Verify flame rod is touching flame when unit fires.

•

Check all wiring to flame rod.

•

Remove flame rod;check for carbon build-up; clean with sand paper.

•

Check inside burner chamber for any foreign material blocking flame

•

at flame rod.

Measure micro amp output of sensor circuit with flame present.

•

Replace the PC Board.

•

Burner Sensor Circuit

73

Check sensor wiring and PC board for damage.

•

Replace sensor.

•

LC#

(when checking Scale Build-up in Heat Exchanger

maintenance code history “00” is substituted for “LC”)

LC0~LC9 indicates that there is scale build up in the heat exchanger

•

and that the heat exchanger needs to be flushed to prevent damage.

Refer to the flushing instructions in the manual. Hard water must be

treated to prevent scale build up or damage to the heat exchanger.

To operate the water heater temporarily until the heat exchanger can

•

be flushed, push the On/Off button on the temperature controller 5

times. Repeated LC# codes will eventually lock out the water heater.

Maintenance Performed

FF

Indicates a service provider performed maintenance or repair. Enter

•

this code by pressing up, down, and ON/OFF simultaneously.

No Code (Nothing happens when water flow is activated.)

Clean inlet water supply filter.

•

On new installations ensure hot and cold water lines are not reversed.

•

Verify you have at least the minimum flow rate required to fire unit.

•

Check for cold to hot cross over. Isolate circulating system if present.

•

Turn off cold water to the unit, open pressure relief valve; if water

•

continues to flow, there is bleed over in your plumbing.

Verify turbine spins freely.

•

Measure the resistance of the water flow control sensor.

•

If the display is blank and clicking is coming from the unit, disconnect

•

the water flow servo motor (GY, BR, O, W, P, BL, R). If the display

comes on then replace the water flow servo motor.

Dip Switches Settings

Adjust SW2 and 3 in DIPSW1(tan) depending on your

altitude according to the table below.

RUR98i

SW

No.

2

3

High Altitude

DIPSW 1

DIPSW 2

High Altitude

ON

O

F

F

ON

O

F

F

Off

Off

NAT.GLPG

1

2

3

4

5

6

7

8

1 1

2

3

4

5

6 6

8

ON

O

F

F

ON

O

F

F

Level 0

0-2000 ft

(0-610 m)

1

2

3

4

5

6

7

8

WARNING

2

DO NOT adjust the other dip switches unless specifically instructed

3

4

to do so. Incorrect Dip Switch Settings can cause the Rinnai water

5

heater to operate in an unsafe condition and may damage the water

77

heater and void the warranty.

8

Off

On

Operation

Pump OFF

Dedicated Return

Cross Over Short Loop

Cross Over Long Loop

NOTES

Level 1

2001-5200 ft

(610-1585 m)

Recirculation DIP Switch Settings

Level 2

SW 4 in

DIPSW2

OFF

OFF

OFF

Economy Mode

Comfort Mode

Economy Mode

Comfort Mode

Economy Mode

Comfort Mode

On

5201-7700 ft

Off

(1585-2347 m)

ON

ON

ON

ON

SW 7 in

DIPSW2

OFF

ON

ON

ON

ON

OFF

OFF

On

Level 3

SW 8 in

DIPSW2

OFF

OFF

ON

OFF

ON

OFF

ON

RUR98i (KBP3237FFUD-US)

7701-10200 ft

On

(2347-3109 m)

070 00012 37150 4

U306-1460(00)X01

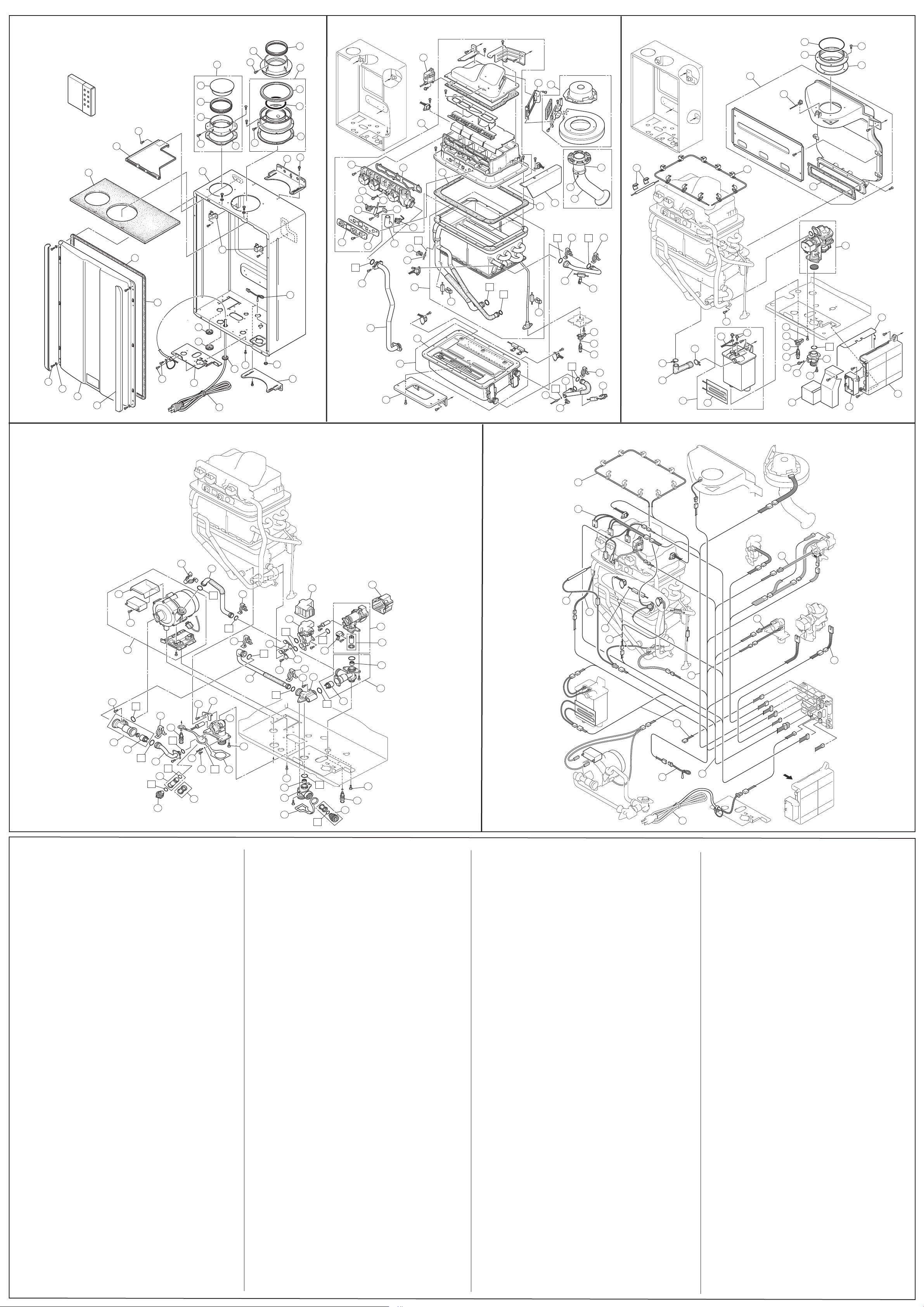

Page 2

MC-195T-US

030

017

819

TENIBAC-WEIVDEDOLPXE

002

171

144

145

163

149

800

174

173

172

823

001

176

175

170

830

812

EXPLODED VIEW - INTERNALS

A

111

706

103

113

A

B

C

D

110

B

126

125

131

EXPLODED VIEW - INTERNALS

716

E

F

G

139

713

711

163

162

808

161

E

801

802

006

011

007

008

806

004

015

014

720

022

003

806

016

712

002

119

825

117

154

101

805

118

120

826

164

708

153

160

709

423

116

143

824

114

717

703

829

820

138

102

817

100

701

702

G

700

option

133

132

121

112

433 434

815 815

709

824

423

432

431

815

718

D

407

828

422

434

718

444

443

440

445

744

447

803

446

F

821

405

828

422

101

813

815

719

C

EXPLODED VIEW - INTERNALS

435

410

805

414

810

466

424

813

813

436

422

816

467

811

471

818

470

EXPLODED VIEW - ELECTRICAL

725

731

715

462

422

822

413

401

402

464

461

714

709

743

750

712

715

733

724

722

722

720

404

805

435

413

465

814

813

813

727

813

424

412

815

468

406

436

435

403

815

805

813

805

463

815

809

H

801

402

400

405

815

409

805

H

730

804

824

469

Description

Item

001 Main Body

002 Wall Bracket

Part Number

109000443

109000143

Qty

003 Rubber Bushing-A CF79-41020-A 1

004 Connection Reinforcement Panel

006 Front Panel

007 Gasket - Top and Bottom

008 Gasket - Side

011 Screw Cover

109000445

109000227

109000120

109000121

109000230

ACF10-120X01

109000276

108000074

022 Attachment Bracket

030 Top Plate Insulation

100 Gas Valve Assembly

109000274

109000421

106000101

101 Test Port Set Screw C10D-5 2

102 Gas Connection 3/4" NPT

106000065

103 Burner Unit Assembly 106000070 1

110 Manifold Assembly-LPG

110 Manifold Assembly-NG

111 Gasket

112 Gasket

113 Gasket

114 Gasket

116 Electrode

117 Flame Rod

118 Electrode Packing

119 Electrode Holder

120 Gas Pipe Assy

121 Plate

125 Fan Motor All Assembly

126 Fan Bracket

131 Noise Filter A

132 Noise Filter B

106000066

106000067

109000232

109000233

109000234

109000235

105000145

105000146

109000236

109000237

106000084

109000447

108000052

108000053

108000054

108000055

109000427

139 Exhaust Duct Assembly

108000056

143 Heat Exchanger Assembly 107000132 1

144 Flue Connection Assembly

145 O-ring

149 Gasket

153 Burner Sensor Gasket

108000058

109000239

109000240

109000241

Description

Item

1

2

154 Burner Thermistor

160 Secondary Heat Exchanger

161 Outlet Pipe Packing

1

1

2

162 Outlet Pipe

163 O-ring

164 Secondary Heat Exchanger Bracket

2

2

1521-542UgnihsuBrebbuR410

1Rubber Bushing015

1Gasket016

1Air Intake Diverter017

IriA571

teksaGepiPekatn

2

1

1

1

40

0 Water Inlet 3/4" NPT H73-501-2 1

401 Water Flow Servo & Sensor Assy

403 Bypass Flow Assembly

Part Number

105000147

107000089

109000161

107000064

108000018

109000242

102000012

102000013

102000014

102000015

102000016

102000017

102000018

107000090

107000091

1

1

1

1

1

408 Plug Band

409 Stop Bracket

2

1

1

1

1

1

1

1

1

1

1

1teviRretliF331

1832000901teksaG831

1

412 Water Filter Assembly H98-510-S 1

413 Servo Cover

414 Recirculation Pump Assembly

422 Drain Plug

423 Clip

424 Check Valve

431 Connecting Pipe - Inlet

432 Connecting Pipe - HEX

433 Clip

434 Clip

435 Clip

436 Clip

440 Condensate Trap

443 Condensate Drain Tube

1

1

1

1

444 Band

445 Band

446 Screw

447 Connection Harness

109000428

109000429

109000465

U211-322X01

109000448

107000093

107000133

107000058

105000090

107000134

107000135

107000095

109000132

109000244

109000133

109000450

109000245

109000246

109000137

109000138

109000155

105000105

Qty

1

1

1

1

2

1

1gniRretpadAtsuahxE071

1gniR-OtsuahxE171

1epiPekatnIriA271

1gniR-OekatnIriA371

1paCekatnI471

1

1ylbmessAekatnIriA671

1

2501000701reifitceR204

1

2013-96HAtekcarBpotS404

2810000901dnaBgulP504

1Drain Valve Band A406

1Plug Band407

1

1

1014

1Condenser Cover

2

1

4

2

2

1

1

1

2

3

2

1

1

1

1

2

1

Description

Item

461 Water Flow Turbine

462 Pump Outlet Tube

463 ByPass Tube

464 Cold Water Connection

465 Cold Water Separation

466 Pump Connection Assy

467 Recirculation Tube

468 Hot Water Outlet

469 Bypass Filter

470 Filter Plug

471 Bypass plug

700 PC Board

702 PC Board Cover Side

703 PC Board Cover Front

706 Ignitor

Part Number

107000088

107000136

107000137

107000138

107000139

107000140

107000141

107000142

109000451

109000452

109000453

105000203

109000247

109000426

106000068

105000197

708 Electrode Sleeve

109000249

1HrotsimrehT907

711 Thermal Fuse Clip

712 Frost Sensing Thermistor Assembly

713 Frost Sensing Thermistor-5

714 Anti Frost Heater 120V

715 Valve Heater 120V

109000250

105000150

105000151

105000152

105000154

716 Anti Frost Heater Clip CF29-742 2

717 Anti Frost Heater Clip A AU124-618 1

718 Anti Frost Heater Clip U250-625 2

719 Anti Frost Heater Clip

722 IG Anti Frost Harness

724 Sensor Harness US-5

725 Thermal Fuse Harness Assembly

727 Water Flow Sensor

730 Twin Thermistor

73

1 Solenoid Connection Harness

733 Connection Harness

743 Secondary Heat Exchanger Heater

109000251

105000205

105000198

105000175

105000176

105000108

105000177

105000178

107000106

105000106

ssenraHhctiwStaeHrevO057

801 Screw

105000199

0150DHIZwercS008

KU

109000178

10X481-33UArehsaW208

Qty

1

1

1

1

1

1

1

1

1

1

1

1

12-3781-591UBtinUtsorFitnA107

1

1

1

1ylbmessAdroCnoisneThgiH707

1

2056-11

10

1

1

1

1

1

108509-PCdroCrewoP027

1

1

1

1

1

1

1

1

1ssenraHparTetasnednoC447

1

8

4

4

Description

Item

O-ring

814

O-ring

O-ring

6

1

8

O-ring

O-ring

Screw

Screw

823 Intake Cap Fastener

O-ring

825

O-ring

Manual-US988

900 Front Panel Label-RUR98

Part Number

108000021

109000255

109000466

ZHAA0412UK

109000454

2.5

1

-

2

-

B

0

1

M

ZQAA0514UK

ZQAA0512UK

ZQAA0508UK

109000432

109000252

100000352

109000461

Qty

2Screw803

1944-712UwercS408

9KU014-38802-PCwercS508

4KU8040ABZwercS608

4Screw For Air Duct Fixation808

4Screw809

2Self Tapping Screw810

1O-ring811

1109000433Exhaust Adapter Ring Fastener812

781-2-B01MO-ring318

161-2-B01M

1041-2-B01M518

1

142-1-B01M718

1109000456818

1109000430Truss S Screw819

4Screw028

1128

4228

1

34-2-B01M428

2

1109000459O-ring628

4109000182O-ring828

1M10B-13-4O-ring928

1109000433Exhaust Adapter Ring Fastener830

1100000376Technical Data Sheet-FF888

1

1

Loading...

Loading...