Rinnai Infinity 24i Service Manual

Model - REU-2402 W/FFU

SERVICE MANUAL

Rinnai Australia Pty Ltd

(Head Office)

lo-11 Walker Street

Brrreside Victoria 3195

0 Copyright Rinnoi Aurtrrlir Pty ltd A.C.N. 005 005 138 138 769 769

All rights rotmd

Jwrry 1994 1994

No portion or part thereof of this manual may be copied without prior permission from Rinnai Australia. Rinrai

Australia takes ne responsibility for the accuracy or otherwise of the informatior contained in this nanual. failure

to comply with these instructions may result in serious personal injury or damage to the appliance.

A

11s ini~ilua MS

Tl .

many in iv1 ua s iave cmtn de

and customer - find it useful. Tl

inanua

to include as improvements. Rinnai are constantly working toward supplying improved appliances

as we

11 *

11 1

d. *cl 1 I

to ma e contact with us, as your ee

1 k

as information, therefore specl lcations may

WARNING A

seen coinpi e

‘1

d Ly the Rinnai Australia Technical Services Department. While

d to this puLlication, it will Le successful only if you - the reader

‘1

t

d

le epar nlent would 1 k t

f dlack and

.f*

i e 0 ex en an invitation to users of this

suggestions are valuable resources for us

be subject to alteration at any time.

t d

CONTENTS

x

INTRODU~ION

ABOUTTHE2402MODEL ........................................................... 3

SAFETYDEVICES

GLOSSARY of ABBREVIATIONS

SPECIFICATION ....................................................................

COMBUSTION SPECIFICATION

DIP SWITCH POSITIONS ...........................................................

CUT-AWAYDIAGRAM

SCHEMATICDIAGRAM

DIMENSIONS

INSTALLATIONDIAGRAM

FEEDFORWARD AND FEEDBACK

COLD WATER SANDWICH

....................................................................

...................................................................

.....................................................

......................................................

..............................................................

.............................................................

.....................................................................

..........................................................

..................................................

..........................................................

11

13

15

16

: . 17

18

1

4

5

6

7

8

WATERFLOWS.. ...................................................................

GAS CONSUMPTION

GAS AND WATER CONTROLS

OPERATIONAL FLOW CHART

TIME CHART

OPERATION PRINCIPLE

FAlJLT FINDING PROCEDlJRE

DIAGNOSTIC POINTS

WIRINGDIAGRAM

ELECTRICAL COMPONENT ANALYSIS

FAIJLT DIAGNOSIS

GAS CONVERSION PROCEDl

DISMANTLING FOR SERVICE

..................................................................... 31

.............................................................

.......................................................

.....................................................

...........................................................

...................................................... 34

.............................................................

.................................................................

...............................................

................................................................

RE ...................................................

......................................................

21

23

25

29

33

35

36

37

45

57

59

PARTS LIST - 2402 W . . . . . . .

EXPLODED DIAGRAM - 2402 W ......................................................

PARTSLIST - 2402FFlJ..

EXPLODED DIAGRAM - 2402 FFU

......................................................

..........................................................

....................................................

67

71

75

79

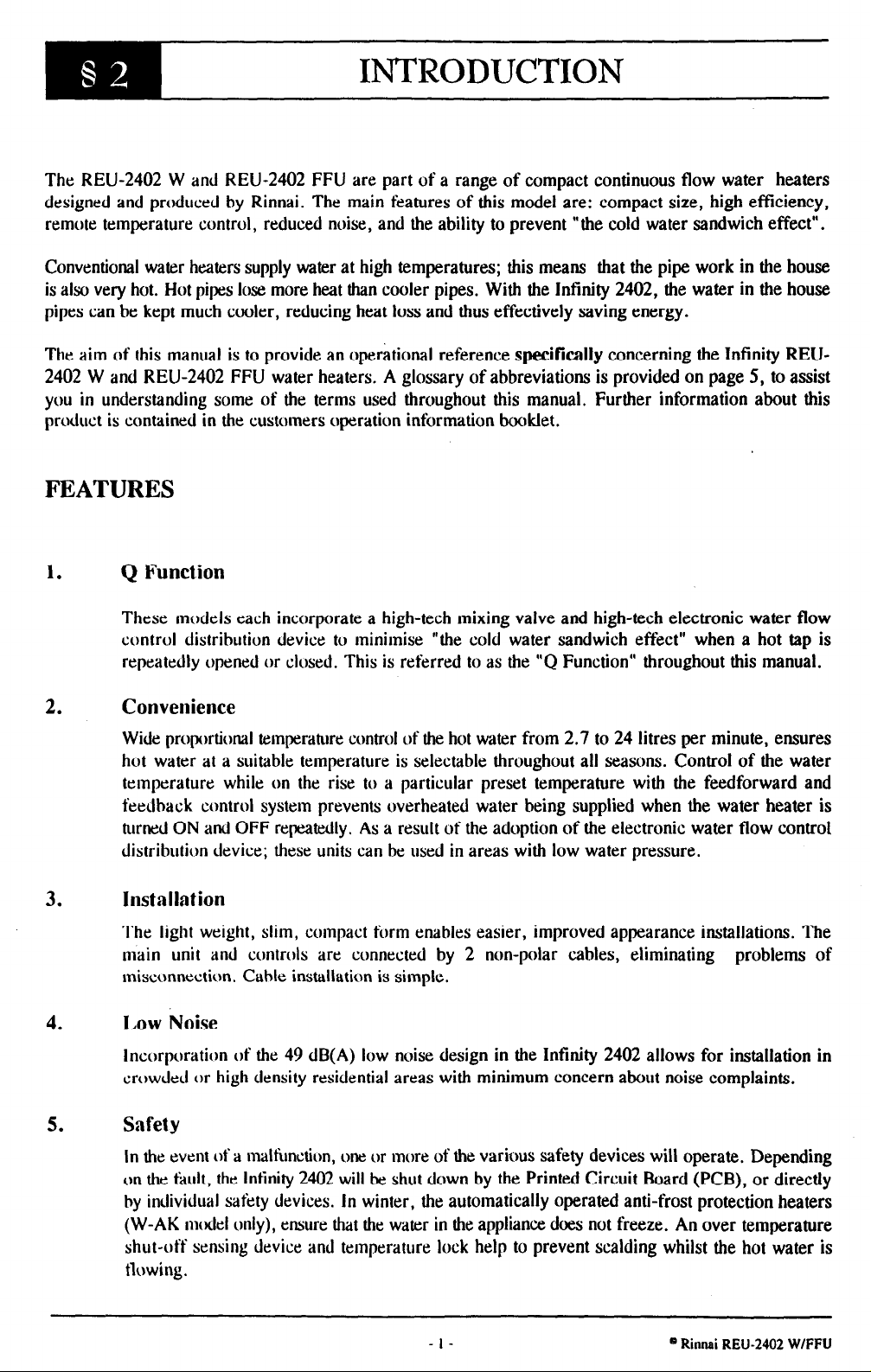

INTRODUCTION

The REU-2402 W and REU-2402 FFU are part of a range of compact continuous flow water heaters

designed and produced by Rinnai. The main features of this model are: compact size, high efftciency,

remote temperature control, reduced noise, and the ability to prevent “the cold water sandwich effect”.

Conventional water heaters supply water at high temperatures; this means that the pipe work in the house

is also very hot. Hot pipes lose more heat than cooler pipes. With the Infinity 2402, the water in the house

pipes can be kept much cooler, reducing heat toss and thus effectively saving energy.

The aim of this manual is to provide an operational reference specifically concerning the Infinity REU2402 W and REU-2402 FFU water heaters. A glossary of abbreviations is provided on page 5, to assist

you in understanding some of the terms used throughout this manual. Further information about this

product is contained in the customers operation information booklet.

FEATURES

1.

2. Convenience

3.

4. Low Noise

Q Function

These models each incorporate a high-tech mixing valve and high-tech electronic water flow

control distribution device to minimise “the cold water sandwich effect” when a hot tap is

repeatedly opened or closed. This is referred to as the “Q Function” throughout this manual.

Wide proportional temperahire control of the hot water from 2.7 to 24 litres per minute, ensures

hot water at a suitable temperature is selectable throughout all seasons. Control of the water

temperature while on the rise to a particular preset temperature with the feedforward and

feedback control system prevents overheated water being supplied when the water heater is

hitned ON and OFF repeatedly. As a result of the adoption of the electronic water flow control

distribution device; these units can be used used in areas with low water pressure.

Instsllstion

The light weight, slim, compact form enables easier, improved appearance installations. The

main unit and controls are connected by 2 non-polar cables, eliminating problems of

misconnection. Cable installation is simple.

incorporation of the 49 dB(A) low noise design in the Infinity 2402 allows for installation in

crowded or high density residential areas with minimum concern about noise complaints.

5. Safety

In the event of a malfunction, one or more of the various safety devices will operate. Depending

on the fault, the lntinity 2402 will be shut down by the Printed Circuit Board (PCB), or directly

by individual safety devices. In winter, the automatically operated anti-frost protection heaters

(W-AK model only), ensure that the water in the appliance does not freeze. An over temperature

shut-off sensing device and temperature lock help to prevent scalding whilst the hot water is

tlowing.

-I-

@ Rinnai REU-2402 WlFFU

6.

Economy

Direct ignition to the main burner eliminates wasteful pilot gas consumption. The air gas ratio

is always controlled to the most suitable level by the PCB, and as the water flow and gas

consumption changes, combustion conditions are controlled, maintaining high efficiency.

7.

Water Temperature Control

The water temperature can be selected in 16 steps from 37°C to 75°C. The temperatures are 3738-39-40-4 l-42-43-44-45-46-47-48-50-55-60-75°C.

ultra-light touch operation buttons. See point 9 for information on fixed upper limit

temperatures. The maximum temperature selectable on the bath-control is 50°C.

8.

Cold Water Sandwich Prevent.ion Device

This device monitors the temperature of water in the heat exchanger, and at the outlet of the

water heater for 8 minutes after the burner extinguishers. If a tap is turned back on during this

time, this device mixes the pre-heated water in the heat exchanger with cold water, before the

main burner ignites. This means that the temperature of water at the tap does not vary by more

than 3°C when the hot water tap is turned off and on repeatedly.

9.

Pre-set Temperature Limits

The Infinity 2402 can be pre-set to supply water at a maximum temperature of 4o”C, 50°C 55°C

and 75”C, with or without remote controls. This means that the Infinity 2402 can be set to

comply with various State laws on temperature control in homes, child care centres, and elderly

care centres. See page IO for additional information.

10. Over Temperature Prot.ection

The remote controls are easy to use with

The Infinity 2402 incorporates a device to prevent the hot water temperature exceeding the preset temperature by more than 3°C.

11. Temperature Locks

The pre-set water temperature cannot be changed whilst the hot water is flowing. This helps to

avoid inadvertently changing the temperature whilst someone is in the shower. The Infinity 2402

can be turned off, but not on again whilst the water is tlowing.

12. Third Remote Control

An optional third remote control is available for use in a second bathroom or ensuite.

-2-

@ Rinnai REU-2402 WlFFU

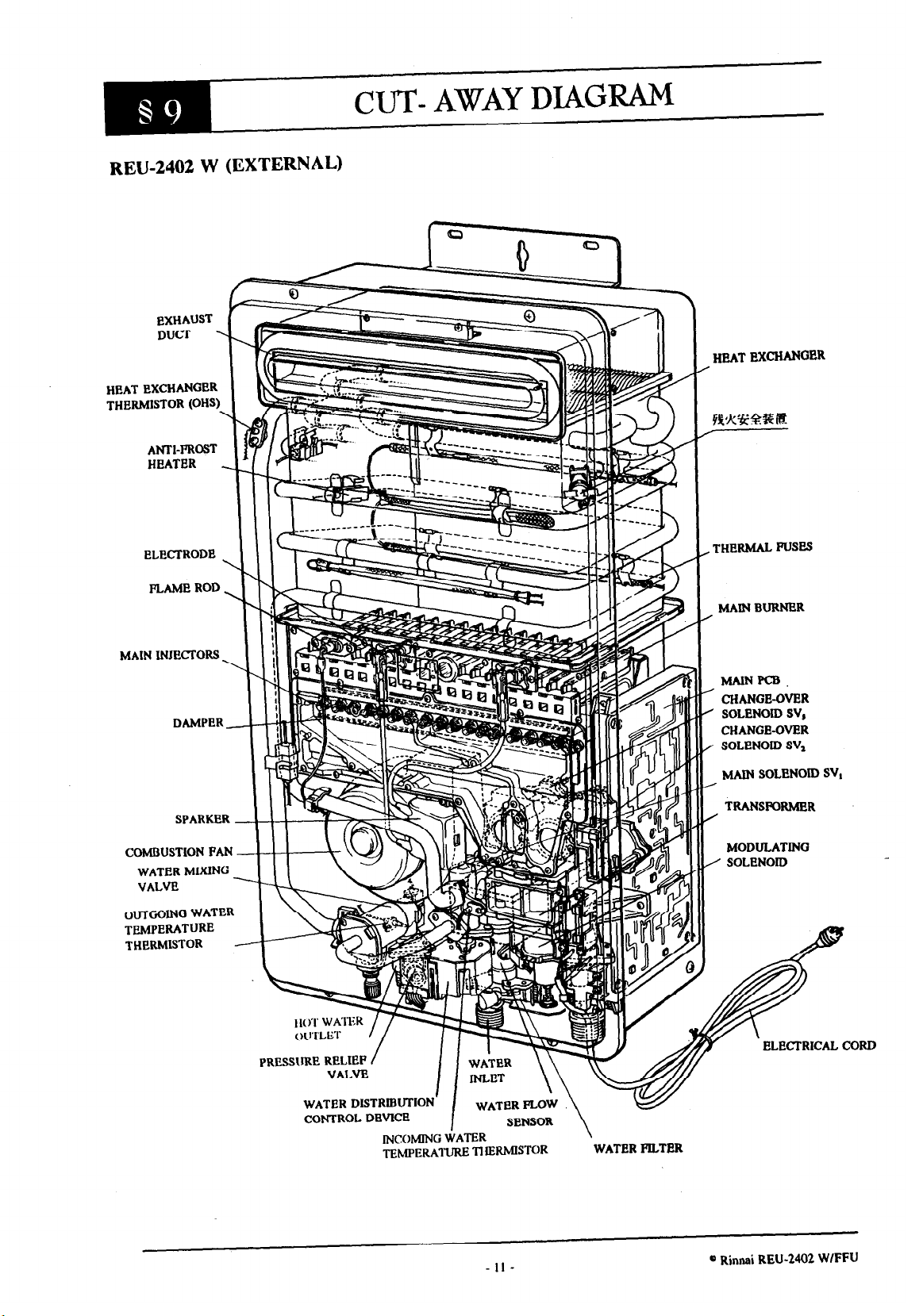

ABOUT THE 2402 MODEL

The front cover of the appliance is formed from 0.6 mm coated steel, secured to the main box

assembly by 4 screws. Seals around the front cover and flue outlet of the externally mounted

Infinity 2402 prevent water from entering the appliance.

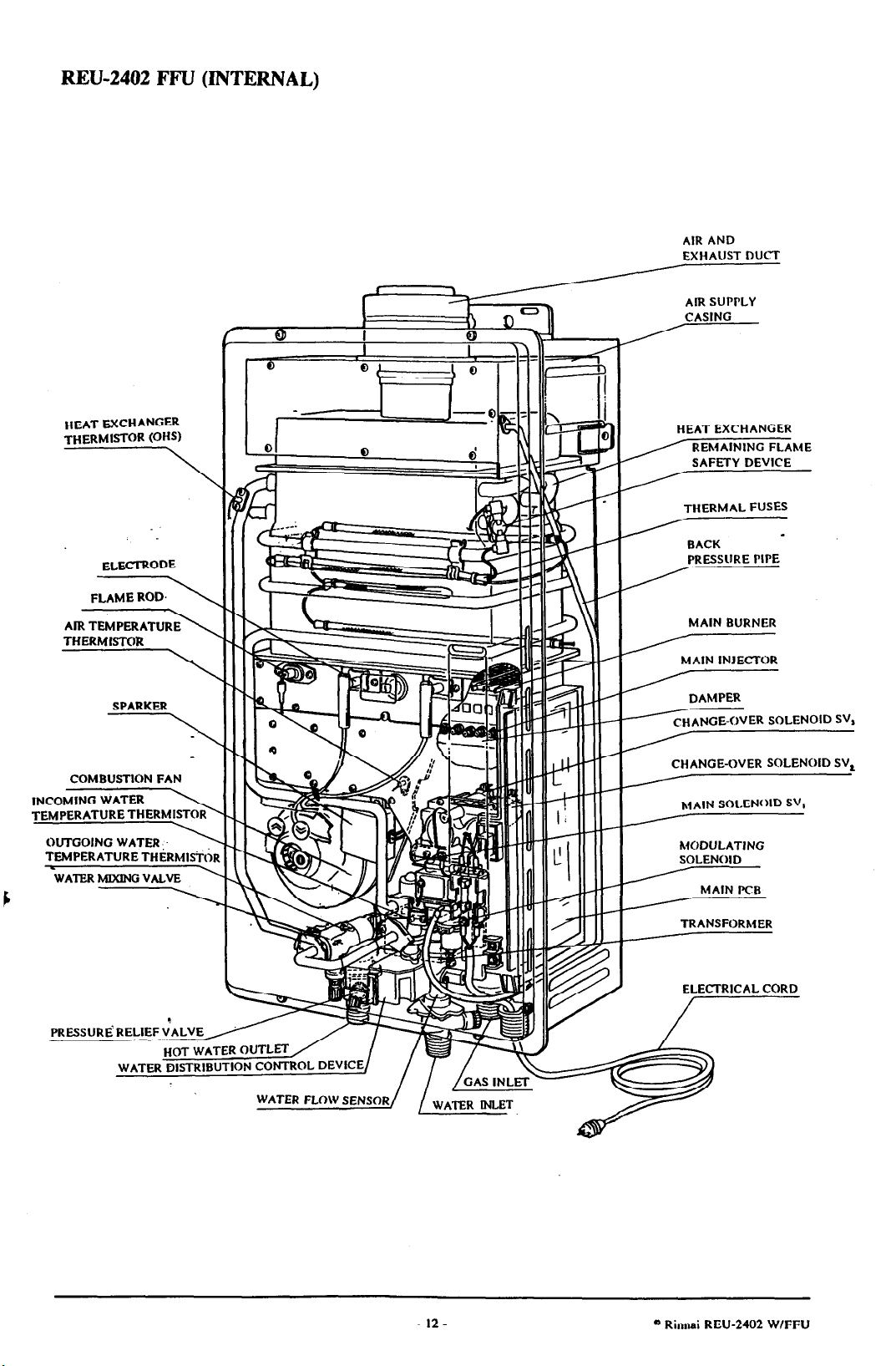

Air inlets are situated in the front panel of the externally mounted Infinity 2402. In the case

of the internally mounted Infinity 2402, air for combustion is drawn from outside the building,

and combustion products discharged outside the building through a co-axial flue system. The

general layout of components is shown on the cut-away diagram on page 11. All components

are supported within a box formed from 0.8 mm coated steel.

The heat exchanger occupies the top section of the box, and the burner is situated in a chamber

formed from 0.6 mm ahuninised steel attached to the bottom of the heat exchanger.

The air for combustion is supplied by a fan which is connected to the burner box by a duct at

the left hand side of the appliance.

Gas and water controls are situated at the bottom right of the appliance, directly under the

manifold. The products of combustion are expelled from the appliance by the combustion fan.

The burner assembly is made up of 18 identical stainless steel bunsen burners, secured by an

aluminised steel framework. A 2 chamber aluminium manifold with 18 injectors supplies gas

to the burners, and is attached to the front lower cover of the burner box.

There are three water temperature thermistors -

one fitted within the electronic water flow

control device, checking the incoming water temperature - part of the feedforward information;

another fitted to the outlet of the heat exchanger, checking the temperature of the water as it

leaves the heat exchanger; and a third situated at the outlet of the unit, checking the outgoing

water temperature. The Infinity 2402 relies on feedforward and feedback information to

operate effectively. See page 17 for further explanation about how this control function

operates. The internally mounted Infinity 2402 has an additional thermistor checking

combustion air temperature.

-3-

@ Rinnai REU-2402 W/FFU

Flame Failure

Situated on the left of the burner at the front, the tlame rods monitor normal combustion, preventing any

discharge of gas to the burner if there is no frame, by sending a signal to the PCB, which in turn isolates

the gas.

Remaining Flame Safety Device

Also referred to as an Over Heat Switch. This device is fitted to a bend section of the heat exchanger. If

the flame remains on the burner after the tap is closed, and the water temperature inside the heat exchanger

reaches 97”C, a DC 90 volt bi-metal cut-off switch isolates the gas to the solenoids.

Boiling Protection

The heat exchanger outlet water temperature thermistor continually monitors the temperature of the water

tlowing from the heat exchanger. Should the temperature of the water at this point reach 105°C then a

signal will be sent to the PCB to shut off the solenoids and isolate the gas.

No Water

Should the incoming water flow become restricted or stop, then the water tlow sensor will cease to send

a magnetic pulse signal to the PCB, in turn isolating the flow of gas to the burner.

Fusible Link

Located in 7 positions covering the entire surface of the heat exchanger. If the heat exchanger burns out,

or the temperature outside it reaches 152°C (129°C FFU), the fusible link melts, breaking the electronic

circuit. Current to the gas solenoid valve circuit is cut, and combustion stops, shutting down the unit.

Pressure Relief Valve

Located on the hot water outlet, this spring and valve seating type valve will, if the pressure inside the heat

exchanger reaches 1400 kPa, release the built up pressure until 1000 k.Pa is maintained.

Combustion Fan Revolution Check

The combustion fan rpm are continually monitored by a magnetic pulse counter connected to the PCB. If

the fan revolutions deviate from the speed required for complete combustion, a signal is sent to the PCB

and the revolutions adjusted accordingly.

Automatic Frost Protection (Used only on units specitied K)

When the outdoor temperature drops below 3S”C, the frost sensing device is activated, and the anti-frost

heaters prevent the water in the appliance from freezing. These anti-frost heaters remain ON until the

outdoor temperature rises to 1 l.YC. There are 5 anti-frost heaters located at various points in the main

water flow area of the appliance. The anti-frost protection device will prevent freezing down to -20°C in

a no wind situation, and -15°C in a windy situation. (Not used on the internally mounted Infinity 2402.)

3°C Over Temperature Cut-Off

The temperature of the outgoing hot water is constantly monitored by the outgoing water temperature

thermistor. If the outgoing water temperature rises to more than 3°C above the preset temperature, the

burner will automatically go out. The burner will ignite again once the outgoing hot water temperature falls

below the preset temperature.

-4- @ Rind REU-2402 WlFFU

GLOSSARY of ABBREVIATIONS

This glossary of abbreviations is provided to assist you in understanding some of the terms used throughout

this manual.

dB(A) AC DC EWFCD -

FB

FF

Hz

IC

kcal/h

kPa

Llmin

LED

mA

MJ/h

mm

sound pressure level in decibels, “A” range.

alternating current.

direct current.

electronic water flow control device.

feedback information.

feedforward information.

Hertz.

integrated circuit.

kilocalorie per hour.

kilopascals.

Litres per minute.

light emitting diode.

milliamps.

megajoule per hour.

millimetres.

mmH,O

NO,

OHS

PCB

CPU

PO1

rpm

SV

TE

TIN

TOUT

WDC

millimetres of water (Gauge pressure).

oxides of nitrogen (NO & NO,).

over heat switch.

printed circuit board.

central processing unit.

potentiometer.

revolutions per minute.

solenoid valve.

thermal efficiency.

temperature of incoming water.

temperature of outgoing water.

water distribution control device

-5-

e Rinnai REU-2402 WlFFU

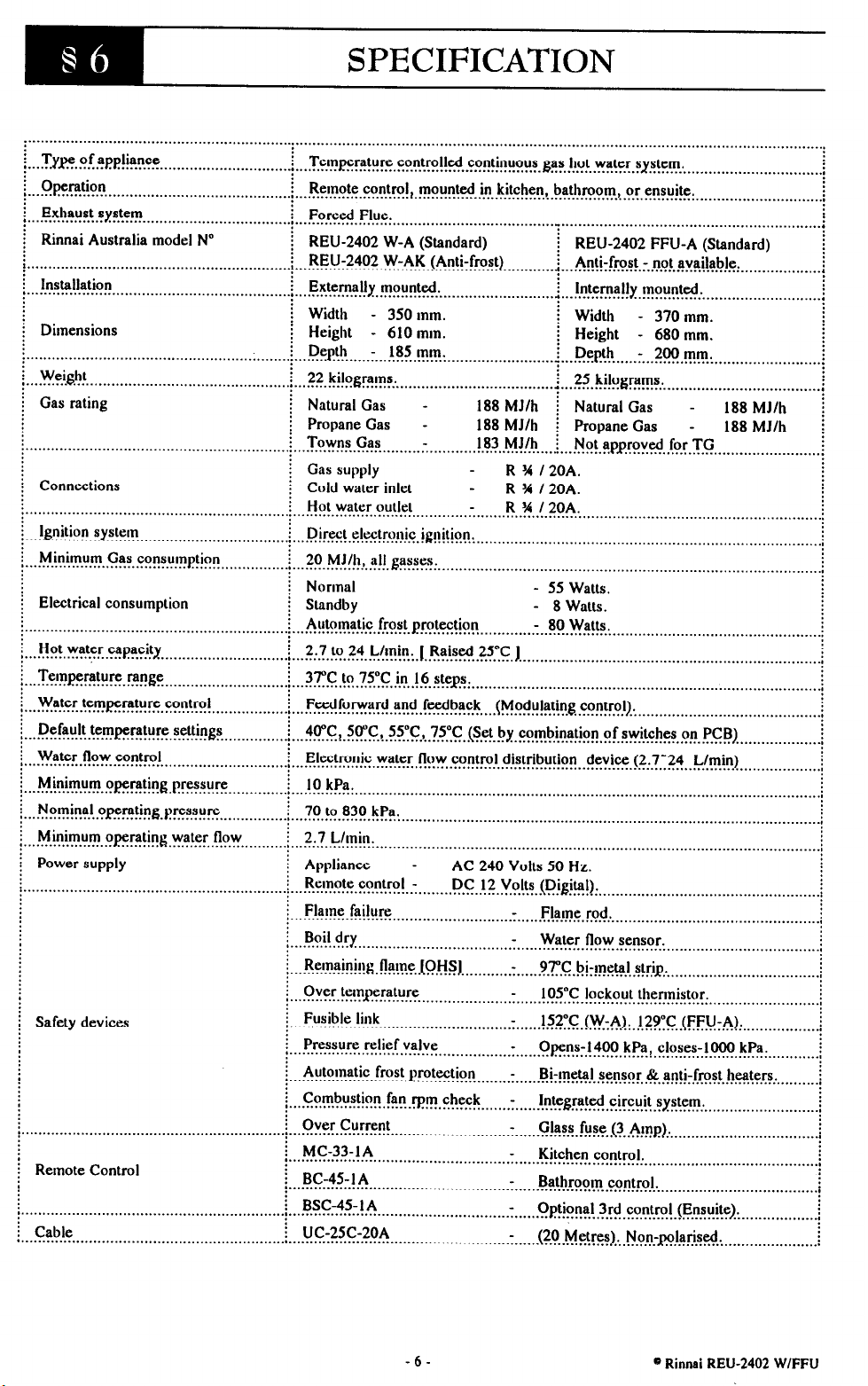

SPECIFICATION

........................................................................................................................................................................................

:’

Type of appliance

i.

.........

..........................................

Operation

;.

..... ............ ...........................................

Exhaust system

.................

i.

.........................................

Rinnai Australia model N”

;.

.............................................................

Installation

:.

...

...........................................................

Dimensions

;.

..............................................................

Weight

i.

......... ...

..............................................

Gas rating

:.

.............................................................

Connections

........................................................................................................................................................................................

i.

Ignition system

:..

...

.....................................................

Minimum Gas consumption

:..

... ................

.......

...........

.....................

Electrical consumption

:..

.............................................................

Hot water capacity

;..

.....................

Temperature range

;..

.........

......................................................

Water temperature control

;..

.. .......... .....

Default temperature settings

i..

.. ............ ..... ....................

Water flow control

;..

..........................................................

Minimum operating pressure

................... ..........

i-

Nominal operating pressure

:..

................. .........

Minimum operating water flow

i..

...................

.........................................

..........................................

~.~.~...~.~.~...~~~.~...........................~

...........................

...........................

...................................

Power supply

1..

.............................................................

Safety devices

i..

.............................................................

Remote Control

;..

..........................................................

Cable i UC-25C-20A

:...

..

..........................................................

:

Temperature controlled continuous gas hot water system.

..........

.

.............

: Remote control mounted in kitchen bathroom or ensuite

i..

.. ............

i Forced Flue.

..!.............................................................-

.................

.......... .1.

i REU-2402 W-A (Standard)

i REU-2402 W-AK (Anti-frost)

.

............................................................

i Externally mounted.

.............

....

i Width

i Height

i Depth

....

....

i 22 kilograms.

..! .... .....

............................................

- 350 mm.

- 610 mm.

- 185 mm.

.............................................................

.....

.............................................. .... ....

i Natural Gas i Propane Gas i Towns Gas -

.

...........................................

/ Gas supply

i Cold water inlet -

i Hot water outlet i Direct electronic ignition.

..~

.... ..........

i 20 MJ/h, all gasses.

..f

.... ..... ..........

................ ..........................................................................................

....

.................................................................................................

/ Normal

i Standby

i Automatic frost protection

.....

.................

i

2.7 to 24 L/min. 1 Raised 25°C J

...... ....

i

37°C to 75°C in 16 steps.

........

i Feedforward and feedback

................................................

.

.......

.............................................................................................

...........

.....

.... ......... .... .....

40°C 50°C 55°C 75°C (Set by combination of switches on PCB)

i

Electronic water flow control distribution device (2 7’24 L/min)

..~...................................................................................~

i 10 kPa

. .............. .

i 70 to 830 kPa

..!.........................~

i 2.7 Llmin.

...........................................................................................................................

...!

...........................................................................................................

.................................................................................................

! Al’pliance i Remote control -

....

............ .............

i Flame failure

~..........................................................................~

i Boil dry

I ..............

j Remaining flame [OHS]

, ....

i Over temperature

~~.~.~.~.~.~.~.~.~

i Fusible link

! .... ............

i Pressure relief valve

! .... ..............

i Automatic frost protection -

: ............................

i Combustion fan rpm check -

I ..............................

i Over Current

.... ........

............................................................................................................

............... .......... ...................

....................................

........................................

i.. MC:.??.!.!?. ..

i BC-45-lA

!......................................................................................~

i BSC-45-IA

..~ ....

................................................

.....

................................................

.........

........................................................................................................

.........

.........................

..............................................................................................

......

................................................................................................

. ..............

.................

....

.....................

.......................................

............. ............. ..~................:

...........................................................

i REU-2402 FFU-A (Standard)

i

Anti-frost - not available

.

.........................................

: Internally mounted.

............

188 MJlh ;

188 MJ/h ;

183 MJlh

............

.......

....

i Width

i Height

i Depth

i 25 kilograms

Natural Gas Propane Gas -

i

Not approved for TG

............

..........................................

- 370 mm.

- 680 mm.

- 200mm.

..................................................

.............. . .................................. .

.............................................

- R ?4 I20A.

R 1c I 20A.

R W I20A.

- 55 Watts.

- 8 Watts.

- 80 Watts

.. ...........

........

.....................................................................

......................................................................................

(Modulating control)

.................

................ i ............

....................................................

.: .........................................

..........

.

AC 240 Volts 50 Hz.

DC 12 Volts (Digital).

..........

....... ....

... ..........................................................

- Flame rod

-

Water flow sensor

- 97°C bi-metal strip

.......

........ ..............

-

105°C lockout thermistor.

-

152°C (W-A). 129°C (FFU-A).

.......

.......... .............

-

Opens-1400 kPa closes-1000 kPa.

.......

.................. .... ..! .

................................................

....

: ...................................

..........

....................

Bi-metal sensor & anti-frost heaters

Integrated circuit system

............................

.....

.............................

-

Glass fuse (3 Amp).

..........

.......

.......

... .....

. ...................................

- Kitchen control

- Bathroom control

-

Optional 3rd control (Ensuite)

....... ............. ......

- (20 Metres). Non-polarised

.......

.............

....................................

............

.......................

............................

.................

.

188 MJlh

188 MJlh

..................

...........................

...........

..................

.................

. ..........................

............

.: .................

. .....................

.

-6-

0 Rinnai REU-2402 WIFFU

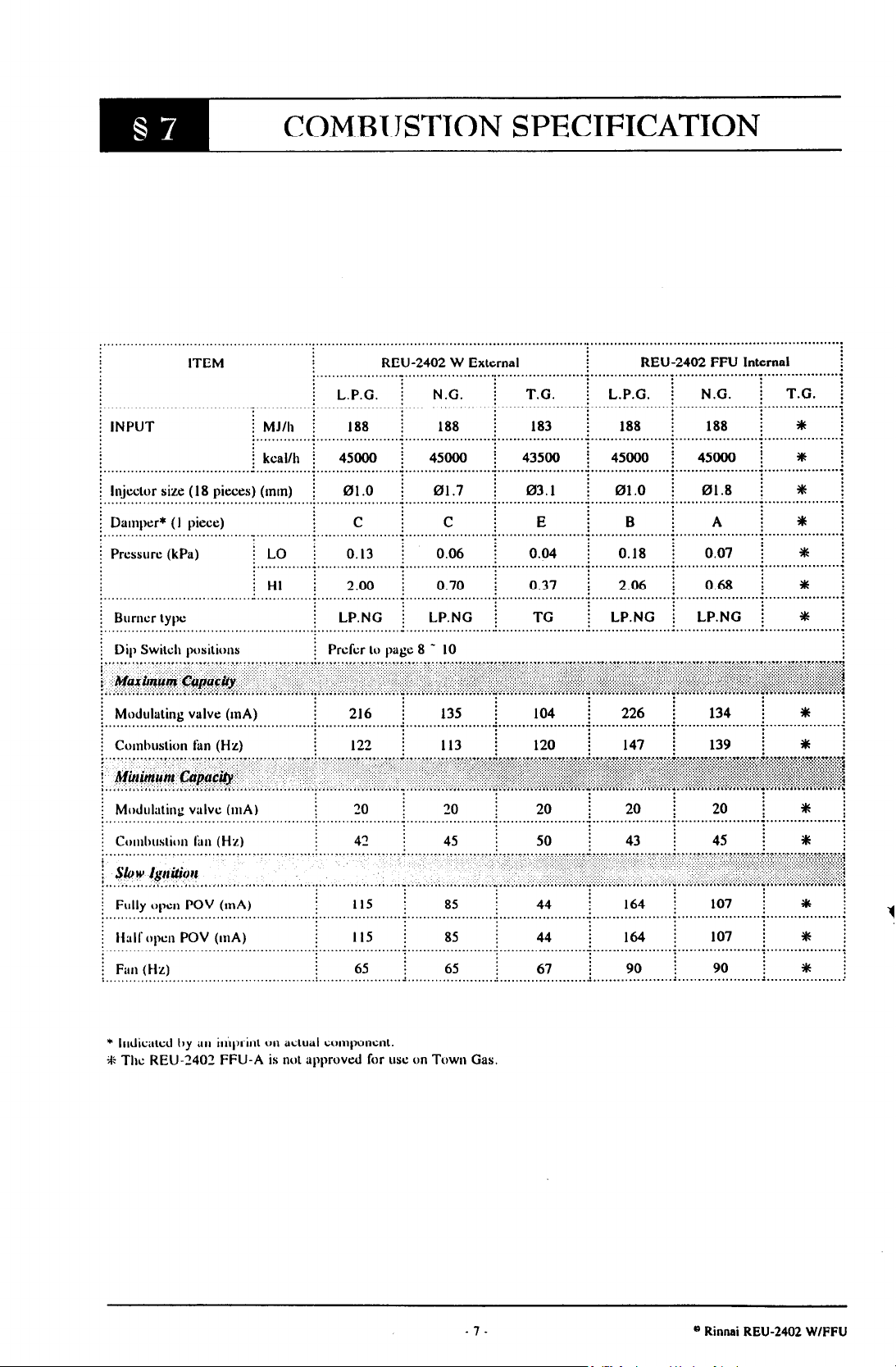

COMBUSTIONSPECIFICATION

I’-j:i~.:~,~,~2K82:~,~:~,~:?~~~:~,~~~:~~,:,~~~:,~

.-:~::.i--:l:.:.~l:~:~:~:~:~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~:~~:~:~~~:~:~:~:~:~~.~:~~~~~~~~~~~~~:~:~:~:~~.~.~.~.~.~.~.~~:~~:~:~:~:~:~:~~~~:~:~:~:~:~~~~~~~~~~~~~~~:~~~~~~

..,._,_).............,,,.,..,.,..,,,,,,.,.,,,,,,,,,,,,.,,,~

.,:.:,,,,,,,,,,,,,,,,.,,,,,,,.,.,.,,,

1

ITEM

i.....................................~..............~.....................~......................~......................~....................~.....................~..........

; INPUT ; MJh :

i.....................................~..............~.....................~......................~......................~....................~.....................~...................~

i Injcclor sh (18 pieces) (mm) i 01.0 ;

~,.........,,.........................................~........,............~.......................~......................~....................~.....................~.........~.........~

! Damper* (1 piece)

:.,...................................~..............~.....................~.......................:......................~....................~.....................~...................~

! Pressure (kPa)

i.....................................-..............~.....................~.......................:.......................~....................~..........,..........~...................~

i Burucr type i LP.NG : LP.NG ; TG ; LP.NG :

~.....................................................:.....................~......................~......................~....................~.....................~...................~

j Dip Switch positions i Prch tu page 8 - 10

. .

~..“..“.~“..“..“...,..~ < ..:,........: “....‘.!“.. !‘!I: ,...,,..,...,...,,... ;y !!,’ I1 !‘..., (.,,, (,y.‘,,: ,.,*,(: ,.,. 5: ,!!’ :yI’.,.~“’ “,, :y...

; &fax&& Q&&y ,,,,, : : .,,;

i ..:.. ‘2.. . . . . . .:.!.....:::..:.:~~.~r; . . . . . .;;.:;.:..;;...:;..:.~~..~.~~....’.i. :‘;.y. . . . . . . . . . . . . . . . . . . . . . 1 . . . . . . . . . . . . . . . . . . . . . . 1 . ..I... / . . . . . . . ‘ . . . . . . . . . . . ..*....... l . . . . . .-...... d........ /.*

: Modulating valve (mA)

I.....................................................~.....................~......................~.,....................~....................~.....................~...................~

/ Combustion fan (Hz) 122 ;

;...............,..,.,. k” ,... j ‘“,.:“.:““.‘““‘....~.~..~.~.~!..,~..~.!....,....,..~.~~.~,,.~.~.,,...~*....~~“,..~*...~*,...~*,...,*....~~ ,... e.,*,..*f....,f ,... *y..:.: ,,,,,.,.,.,.,.,._,,

i &q@& Q&$.; ., : ,,:. ., ,: .,

j / / ; , / ; ,;. /. .“. . j; 1. ,;. , . . . / . .: . . . .:: . . . , . . , . . . . / : ‘ /, :. . . ..d.‘.: .“ :;: .‘i!‘.. i A, ~.‘r’i’..:P~~‘,‘~~“.‘~~~,“‘~.~“,’~~,. , ..;‘,‘i::~,p;:~:;::~:;Q~i’i~;S’ii.~,’~~~“~~~, L.VI.V,IL\yI L\Vl.

Modulating valve (mA) 20

.,....,.,,...,,,.....................................~.....................~.......................~......................~....................~.....................~...................~

~..............~.....................~......................~......................~....................~.....................~...................~

i kcnlh i

;J-J i

:..............I.....................:.......................~......................~....................~.....................~...................~

/HI i 2.00 i 0.70 ; 0.37 i

~.....................~.......................~......................~....................~.....................~......... . . . . . . . . . . .

i L.P.G. i N.G. i T.G.

,~ ::, :j I, .::I: .:%J, .:,y::, :I.; .:‘l:~.l,i~:‘:~~~~~~~:,:ii.j:iji:j:i::i;:’:’.lii’liijiil:j:~

Couhus~ion llrn llrn (Hz)

slow IgGtioll

REU-2402 W External REU-2402 FFU Internal

; L.P.G. i N.G. i T.G. i

188 ;

188 i

183 ! 188 !

45OOO ; 45OOO i 43500 i 45OOO i

01.7 i

c ; c

0.13 i 0.06 :

03.1 : 01.0 i

E ; B i A ; #l ;

0.04 ;

0.18 i

188 ; *

45OOO ; m

01.8 ; #

0.07 : ilc i

. . . . . . . . . .

2.06 : 0.68 i m i

LP.NG : I

216 ;

...:.:‘$,.

:

. -

. . . . . . . . . .A.. . ..\..//.. .:.: ,,,, .,

.,.. ,., . . . . . . . . . . . . . . . . .:. . . . .., ..,.. ..,.,...,...,., ..,.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .,., ,. ., ,.....,............. . . . . . . . . . . . . . . . .

,. ,. ,., ., .;

135 ; 104 i

113 ;

.: .:., j:::.:;

.‘:::.::::...:.:...:.:,: .,.,.,., “““.““.“““““:‘:‘:‘.‘.‘:.~:.:.:.:.’.’.’.’.’.’.’.‘.‘.‘.‘.‘.’.’.’.’.‘...‘.‘.‘.‘.‘.‘.:.:::::

.:; :;::I:.; ;:

20

120 ; 147 i

.::::::::.:.:.:.:.:.:.:.:.:.:.:.:.:.:.:.:.:.:.:.:.:.:.:.:.:.:.:.:.;.:.:.:.:.::~:,~:.,:~.:.~.:.:.:.:.: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

“““““““““““““‘::‘:‘.‘:‘:~:.~.:.... .A... . ..\.......,,,,.,,.,,,.,.,.,,,,,,,,,,,~,,,,,,,,,,,,,~,,~,,,,,,,,,,,,,,,,

:: ,.~~::...:.:.:.:.:.:...:.:.:.:.:.:.:.:.:.:.:.:.:.:.:.:.:.:.:.:.:.:.:.: .,.(.,..,.,, ., .,

20 ; 20 / 20 ; * ;

I

..I’.‘.<! . . . . ,

. . . . :,,:::.,::::: .:::.,:::::::::::.:.:,.:.:::::.: .:::::::, ::):.:.: ..::,.::i:j:J:j:::ji:j:j:j:::::::::::::::::::::,:::::...: x:::.:.:.:.~:...:.. ,.,.,.....,.......)

:~.~~:‘“.‘..~““-“rr~...~~~..r~,~I~~,.~~.~::.:.~~:~~~.~~;:~~~~

226 f

f ,... i . . . . . v .,.. 139 i

>:.: ..,. :.>:...: .,.. :.:.:,:.:.:.,.:.:.:.:.:.:

134 ; * i

. . . . . . . ..i............... :.:.:.:.:.:.:.:.:.:.:.;.:.:.:.;.:...:.:.:

. . . . . . . . . . . . . . . . . . . . . .,., i

,:,:,:,::::,:,;;;:,.,

42 ; 45 i 50 ; 43 i 45 ; * !

. . . ,.

.: I :,.: :‘::,.:.:yy:::: :::f: :r::: :i:+..+~.-:?.q

:. . . . . . ...\..

,., ,::.:.:.:.:.:.:.:.:.:.:.:.:.:.:.:.:.:.: .,.,.,. .,.j,.,.,.,.j,.,.,.,.,.,.,.,., L

;,, ;,, ,,I,: .’ .:I :,, :: :,.: :,; r,: .:.:., :.fi::::;:;:;:;::.;:;:j

. . . . . . . . . . . . . . . . . . . . . . . . . ...”

:,:,: ~

:,:,.!

!

;

i

:

Fully qxn qxn POV (mA)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..~.....................~.......................~.......................~....................~.....................~...................~

HitIC open open POV (mA)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fit11 (HZ)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..~......................~......................~....................~.....................~...................~

. . . . . . . . . . . . . . . ..~.....................~......................~......................~....................~.....................~...................~

115 ; 85 ; 44 164 i

115 ;

85 j 44 ; 164 ;

65 ; 65 ; 67 i 90 ; 90 i $# i

107 i m i

107 ; * ;

* Iiidic;~lcd by mi mi iniprinl 011 011 actual componenl.

S The REU-2402 FFU-A is not approved for use use on Town Gas.

-7-

e Rinnai REU-2402 W/FFU

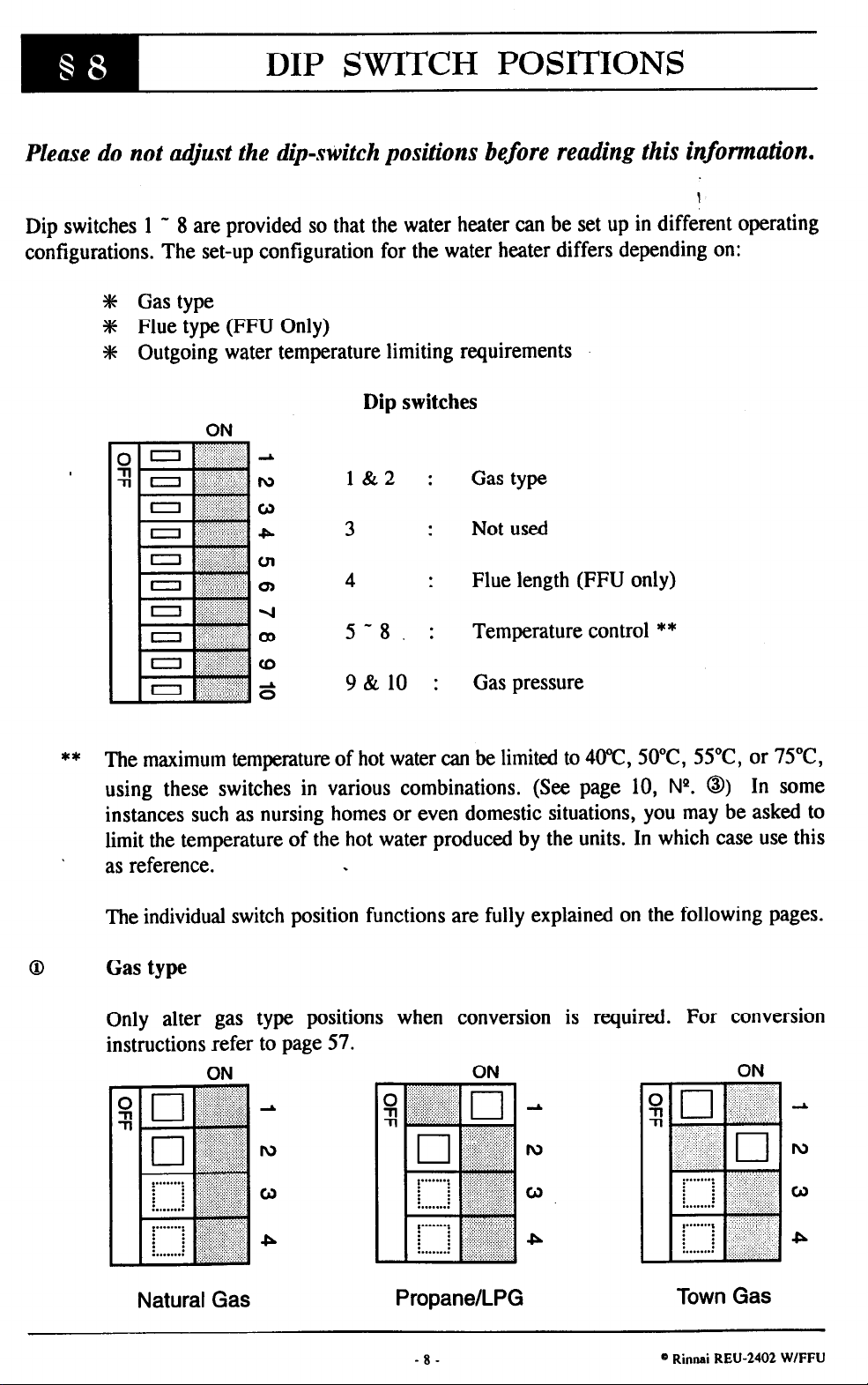

DIP SWITCH POSITIONS

Please do not adjust the dip-switch positions before reading this information.

1

Dip switches 1

configurations. The set-up configuration for the water heater differs depending on:

3~ Gas type

+K Flue type (FFU Only)

;Ic Outgoing water temperature limiting requirements

- 8 are provided so that the water heater can be set up in different operating

Dip switches

ON

l&2 :

3 :

Gas type

Not used

4 : Flue length (FFU only)

5’8, :

Temperature control **

9&10 : Gas pressure

** The maximum temperature of hot water can be limited to 4o”c, 5O”C, 55”C, or 75”C,

using these switches in various combinations. (See page 10, N*. 0) In some

instances such as nursing homes or even domestic situations, you may be asked to

limit the temperature of the hot water produced by the units. In which case use this

as reference.

.

The individual switch position functions are fully explained on the following pages.

0 Gas type

Only alter gas type positions when conversion is required. For conversion

instructions refer to page 57.

ON

Natural Gas

ON

Propane/LPG

-8-

Town Gas

e Rinnai REU-2402 WlFFU

ON

@

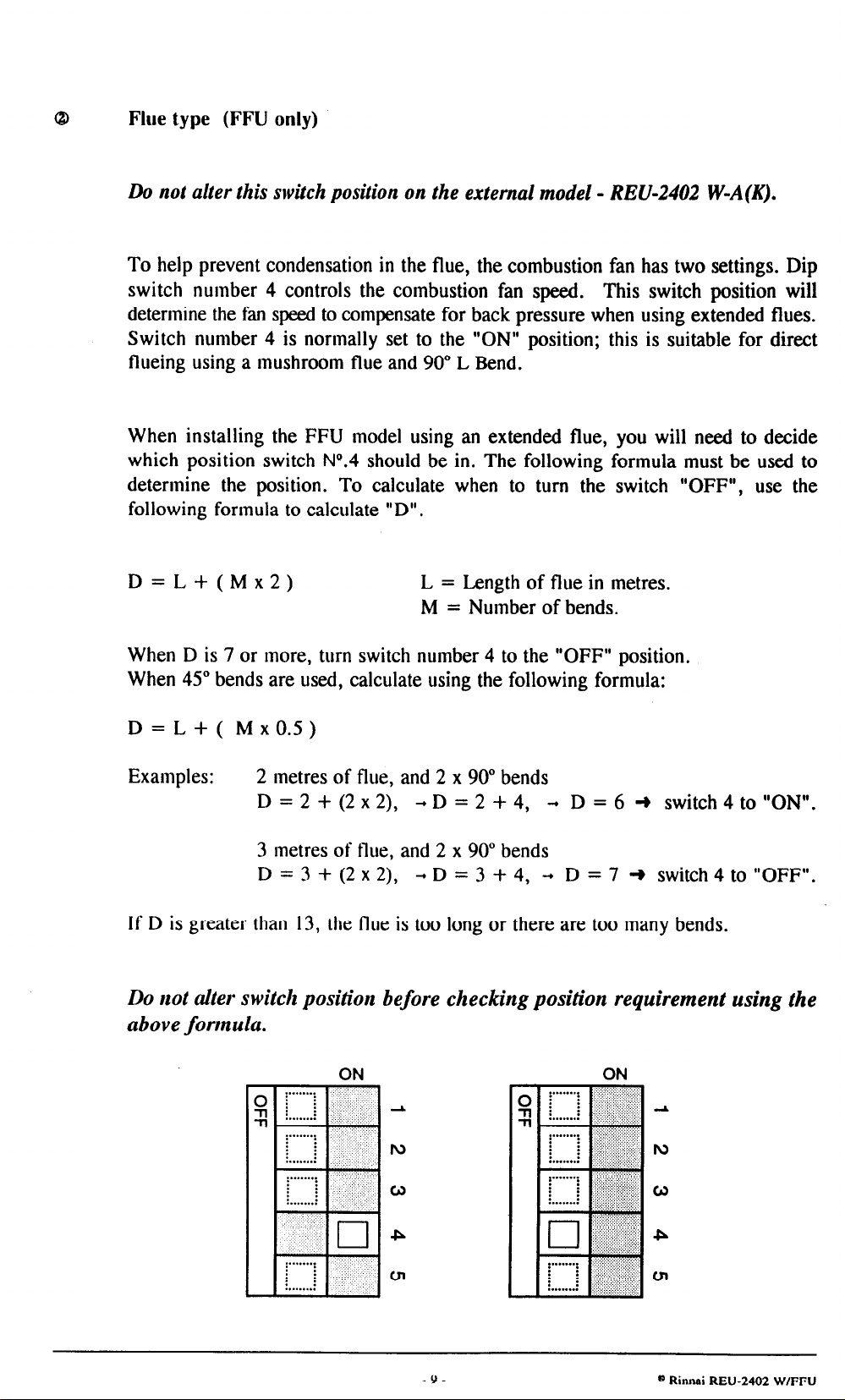

Flue type (FFU only)

Do not alter this switch position on the external model - REU-2402 W-A(K).

To help prevent condensation in the flue, the combustion fan has two settings. Dip

switch number 4 controls the combustion fan speed. This switch position will

determine the fan speed to compensate for back pressure when using extended flues.

Switch number 4 is normally set to the “ON” position; this is suitable for direct

flueing using a mushroom flue and 90” L Bend.

When installing the FFU mode1 using an extended flue, you will need to decide

which position switch N*.4 should be in. The following formula must be used to

determine the position. To calculate when to turn the switch “OFF”, use the

following formula to calculate “D”.

D=L+(Mx2)

L = Length of flue in metres.

M = Number of bends.

When D is 7 or more, turn switch number 4 to the “OFF” position.

When 45” bends are used, calculate using the following formula:

D=L+( Mx0.5)

Examples: 2 metres of flue, and 2 x 90” bends

D = 2 + (2 x 2), + D = 2 + 4, - D = 6 -) switch 4 to “ON”.

3 metres of flue, and 2 x 90” bends

D = 3 + (2 x 2) -, D = 3 + 4, + D = 7 -) switch 4 to “OFF”.

If D is greater than 13, the flue is too long or there are too many bends.

Do not alter switch position before checking position requirement using the

above formula.

ON

: . . . . . . . :

i i

: . . . . . . . i

:-““Y

; i

: . . . . . . . f

:----:

i i ‘,

: . . . . . . . .

-. -

”

-L

N

cd

ON

q

: . . . . . . . .

i i

: . . . . . . . .

~

P

UI

-Y-

e Rinnai REU-2402 WlFFU

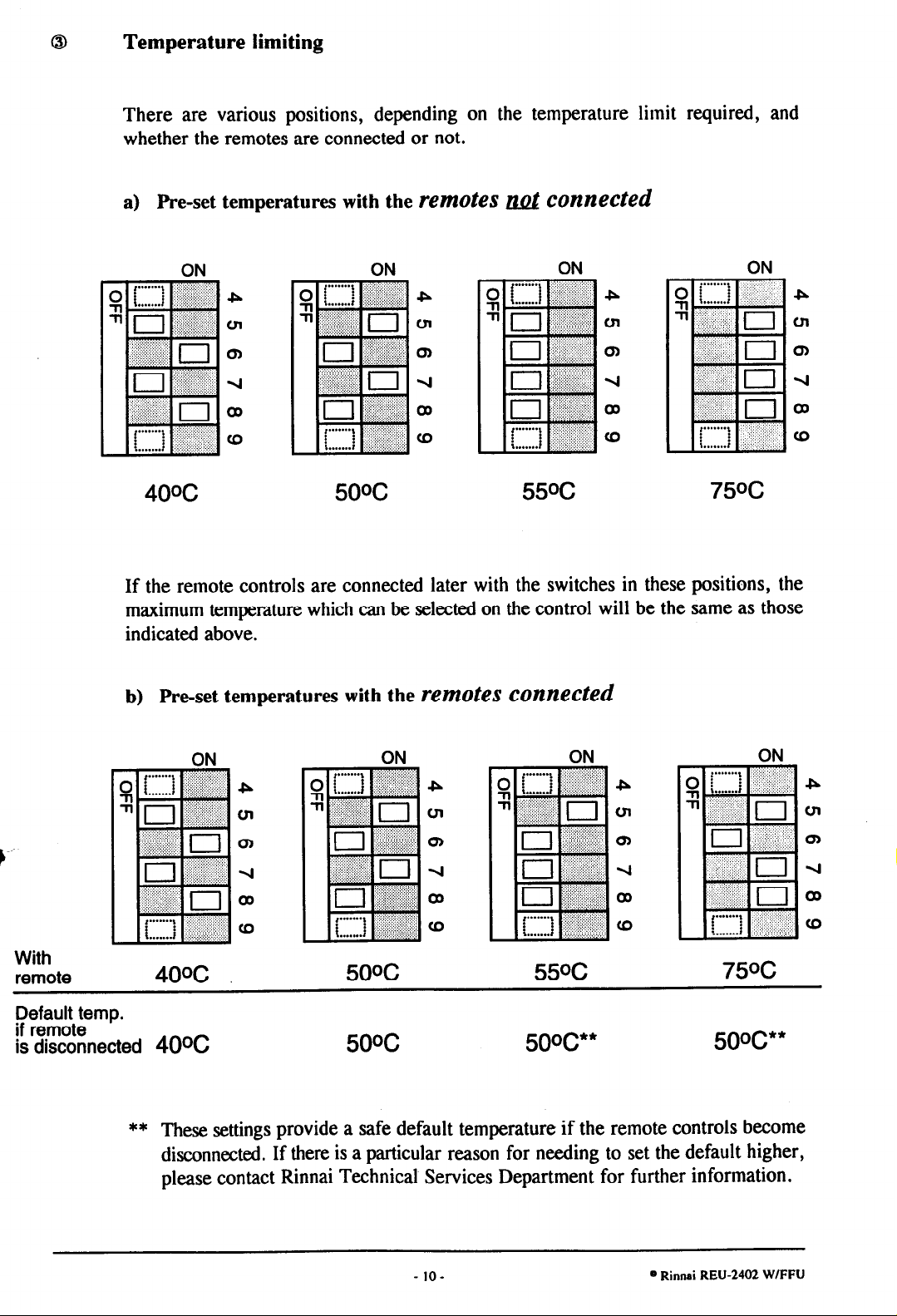

0 Temperature limiting

There are various positions, depending on the temperature limit required, and

whether the remotes are connected or not.

a) Pre-set temperatures with the remotes U connected

ON

40%

If the remote controls are connected later with the switches in these positions, the

maximum temperature which can be selected on the control will be the same as those

indicated above.

b) Pre-set t.emperatures wit.h t.he remotes connected

ON

50%

ON ON

55%

75%

With

remote

Default temp.

if remote

is disconnected 40%

** These settings provide a safe default temperature if the remote controls become

disconnected. If there is a particular reason for needing to set the default higher,

please contact Rinnai Technical Services Department for further information.

ON

ON

!

I

5ooc 5ooc**

ON

!

:

5ooc**

-IO-

@ Rind REU-2402 WlFFU

REU-2402 W (EXTERNAL)

EXHAUST

DUa

HE

TH

ELECTRODE

CUT- AWAY DIAGRAM

FLAME ROD

MAIN JNJBCXORS

OUKXXNG WATER

TEMPERATURE

THERMISTOR

-

, MAIN BURNER

MAINPCB.

’ CHANGE-OVER

SOLENOLD sv,

0”. ullo tmmn

II II

brl~)L.“Lr”. a..R

SOLENOID SV,

D

MAIN SOLENOI

TRANSFORMEI

MODULATJNQ

SOLENOID

SVI

t

CONTROL DEVICJ.!

INCOMMG WATER

lW.,Q'BRAl~ TJJERMJSTOR

I

SENSOR

- II -

\

\

WATER FILTER

0 Rinmi REU-2402 WlFFU

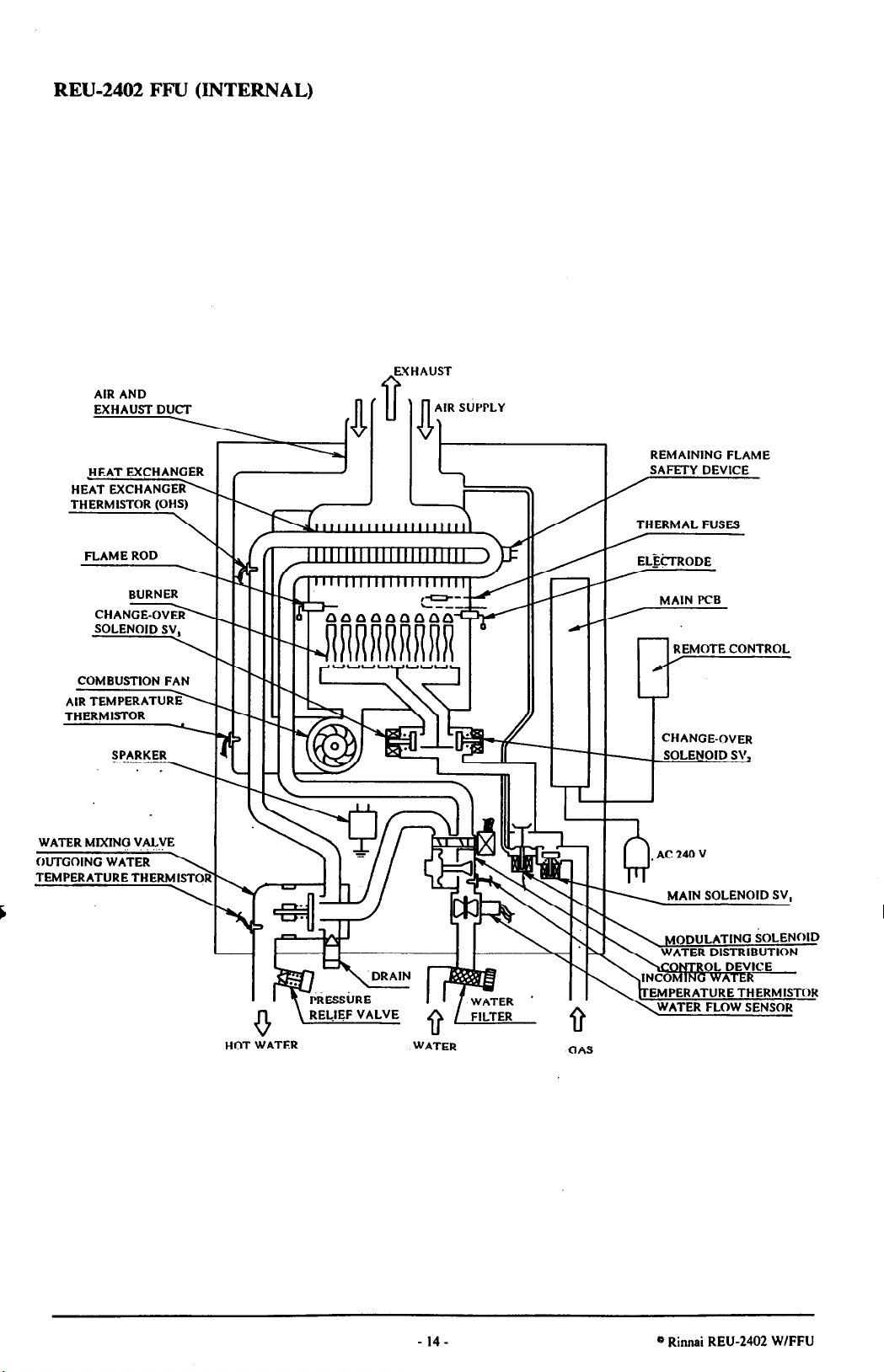

REU-2402 FFU(IPJTERNAL)

AIR AND

EXHAUST DUCT

AIR SUPPLY

CASING

HEAT EXCHANGER

THERMISTOR (OHS)

ELECTRODE

FLAMB\

SPARKER

\\

COMBUSTION FAN

INCOMING WATER \

TEMPERATURETHERMISTOR\

OUTGOING WATER \

TEMPERATURE THkRMISTbR

WATER MIXING VALVE

\

HEAT EXCHANGER

REMAINING FLAME

SAFEI-Y DEVICE

THERMAL FUSES

BACK

PRESSURE PIPE

MAIN BURNER

MAIN INJECIIIIR

DAMPER

CHANGE-OVER SOLENOID SV,

CHANGE-OVER SOLENOID SV,

MAIN SOLENOID SV,

MODULATING

SOLENOID

’

e

PRESSURE

- 12-

TRANSFORMER

ELECTRICAL CORD

o Rind REU-2402 WIFFU

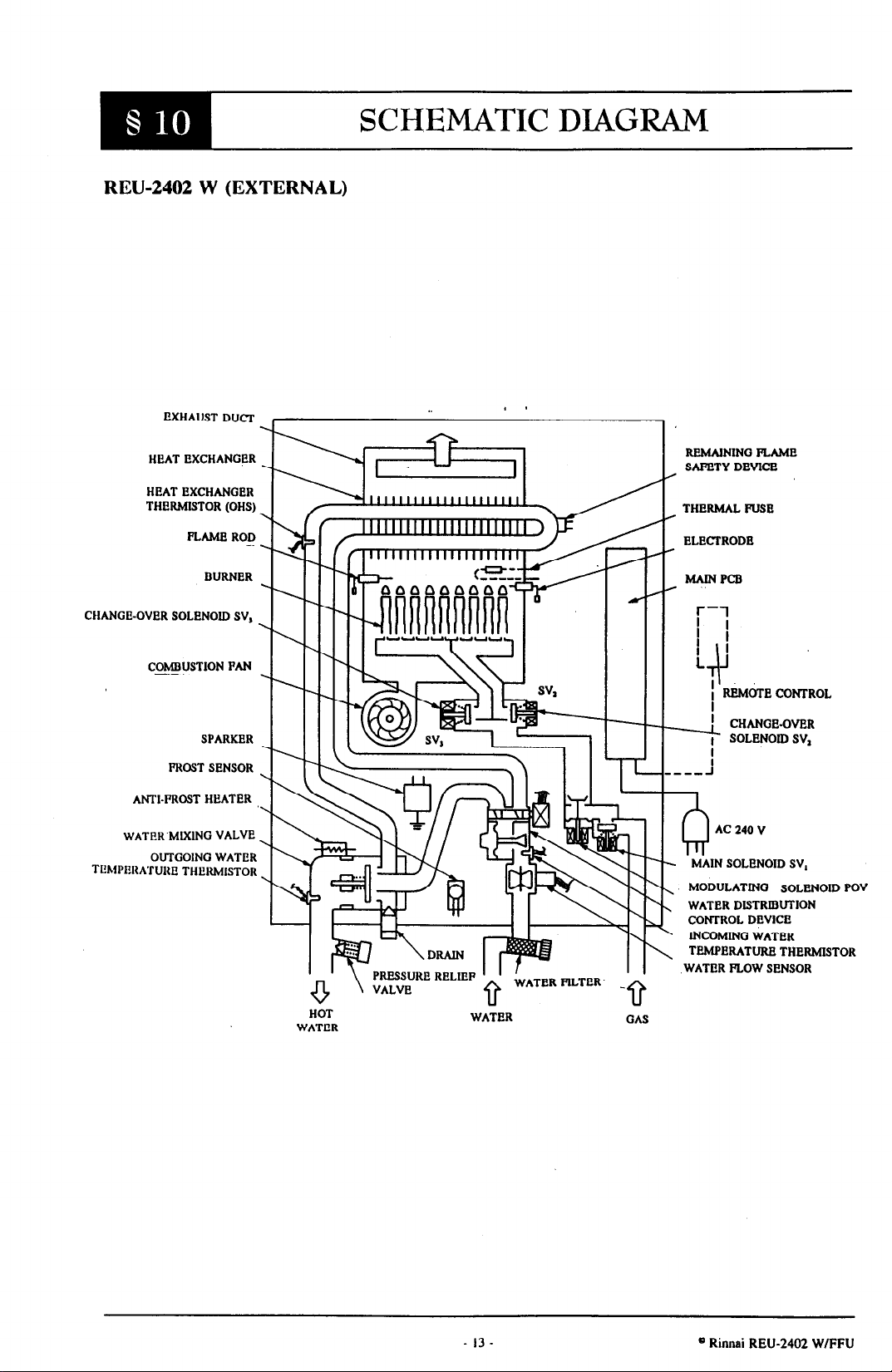

REU-2402 W (EXTERNAL)

SCHEMATICDIAGRAM

EXHAUST DUcr

HEAT EXCHANGER

HEAT EXCHANGER

THBRMSTOR (OHS).

FLAME ROD

BURN@R

CHANGE-OVER SOLENOtD SV,

COMBUSTION FAN

-.-

SPARKER

FROST SENSOR .

ANTI-PROST HEATER ,.

WATEKMtXtNU VALVE.

TEMPERATURB THEKMISTOR

OUTGOING WATER

-- .

r

.

.

\

.

.

.

.

.

.

\

\

\

\

REhWNINQ FLAME

SAFETY DEVICE

c

THERMAL FUSR

c

ELECl%ODB

MAtNPCB

r

r-i

I

I

I

LJ

4

; ’ RtiM6TE CONTROL

I

- CHANGE-OVER

, SOLENOID SV,

!

J

B-m

AC 240 V

0

- MAIN SOLBNOID SV,

. MODULATINQ SOLENOID POV

WATER DtSTRlBUTlON

CONTROL DEVICE

’ tNCOMINCI WATER

TEMPERATURE THERMSTOR

WATBR FLOW S@NSOR

HOT

WATER

WATER

- 13-

e Rinnai REU-2402 W/FFU

REU-2402 FFU(lNTERNAL)

AIR AND

EXHAUST DUCT

HEAT EXCHANGER

HEAT EXCHANGEh

THERMISTOR (OHS)

FLAME ROD

BURNER

CHANGE-OVA

COMBUSTION FAN

AIR TEMPERATUR-

THERMISTOR

SPARKER

. .

WATER MDnNG VALVE

OUTGOING WATER

TEMPERATURE THERMISTOR

n

“oi suppLy

d!J

/

0

-

r r

I

I

t :_

REMAINING FLAME

SAFEI-Y DEVICE

THERMAL FUSES

ELEtiRODE

/

MAIN PCB

/

REMOTE CONTROL

r

-I-

,AC24OV

4

\ MAIN SOLENOID SV,

HOT WATER

CiIRF -Hz,, *

WATER

- 14- e Rink REU-2402 WIFFU

MODULATING SOLENOID

WATER DISTRIBUTION

EMPERATURETHERMISTOR

WATER FLOW SENSOR

GAS

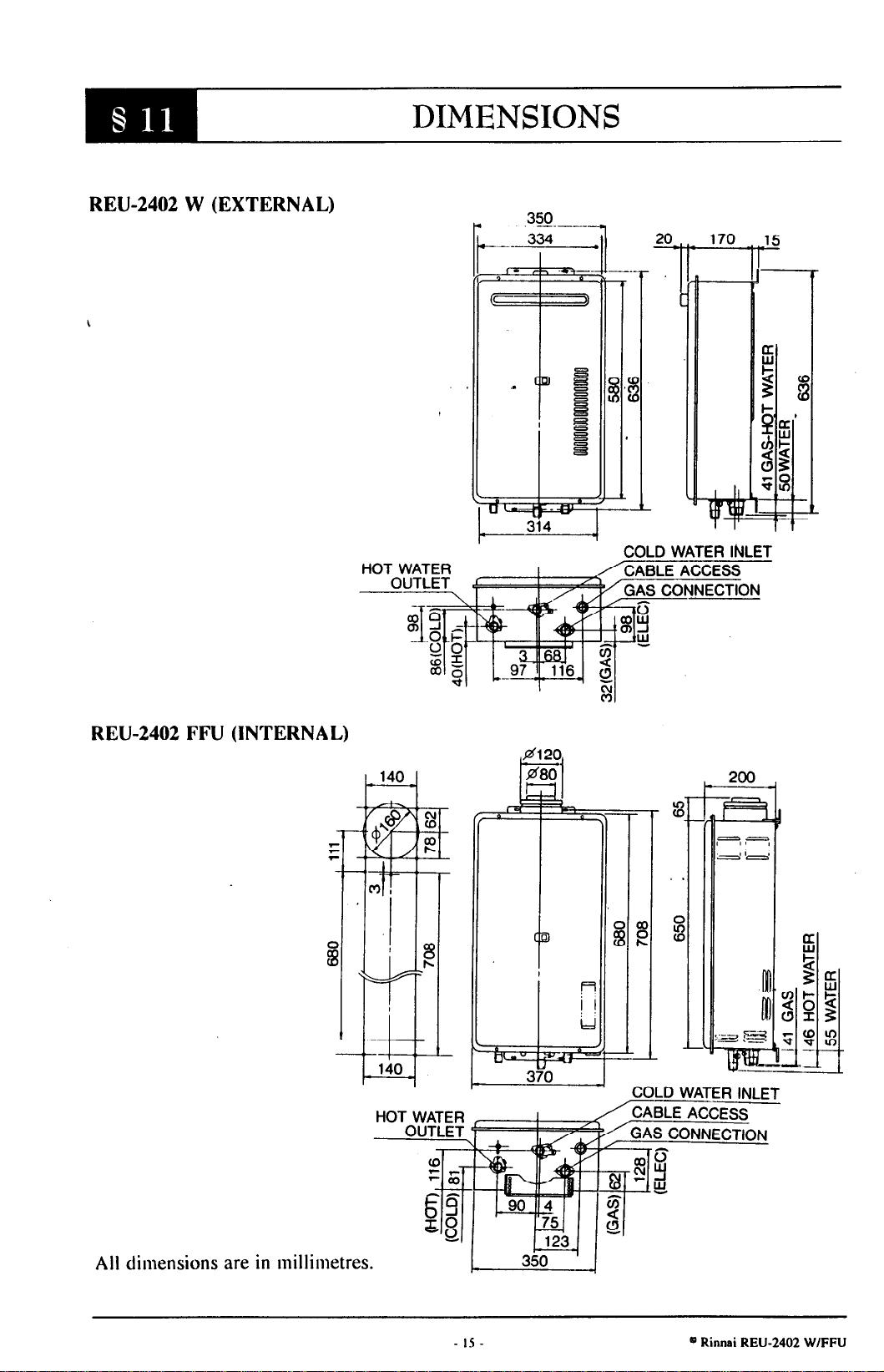

REU-2402 W (EXTERNAL)

DIMENSIONS

REU-2402 FFU (INTERNAL)

It

t

-.

-I-

,%

d

-.

COLD WATER INLET

All dimensions are in millimetres.

Ll

L

370

I

-

i

7

I I

ti

COLD WATER INLET

/CABLE ACCESS

-IS- @ Rinnai REU-2402 W/FFU

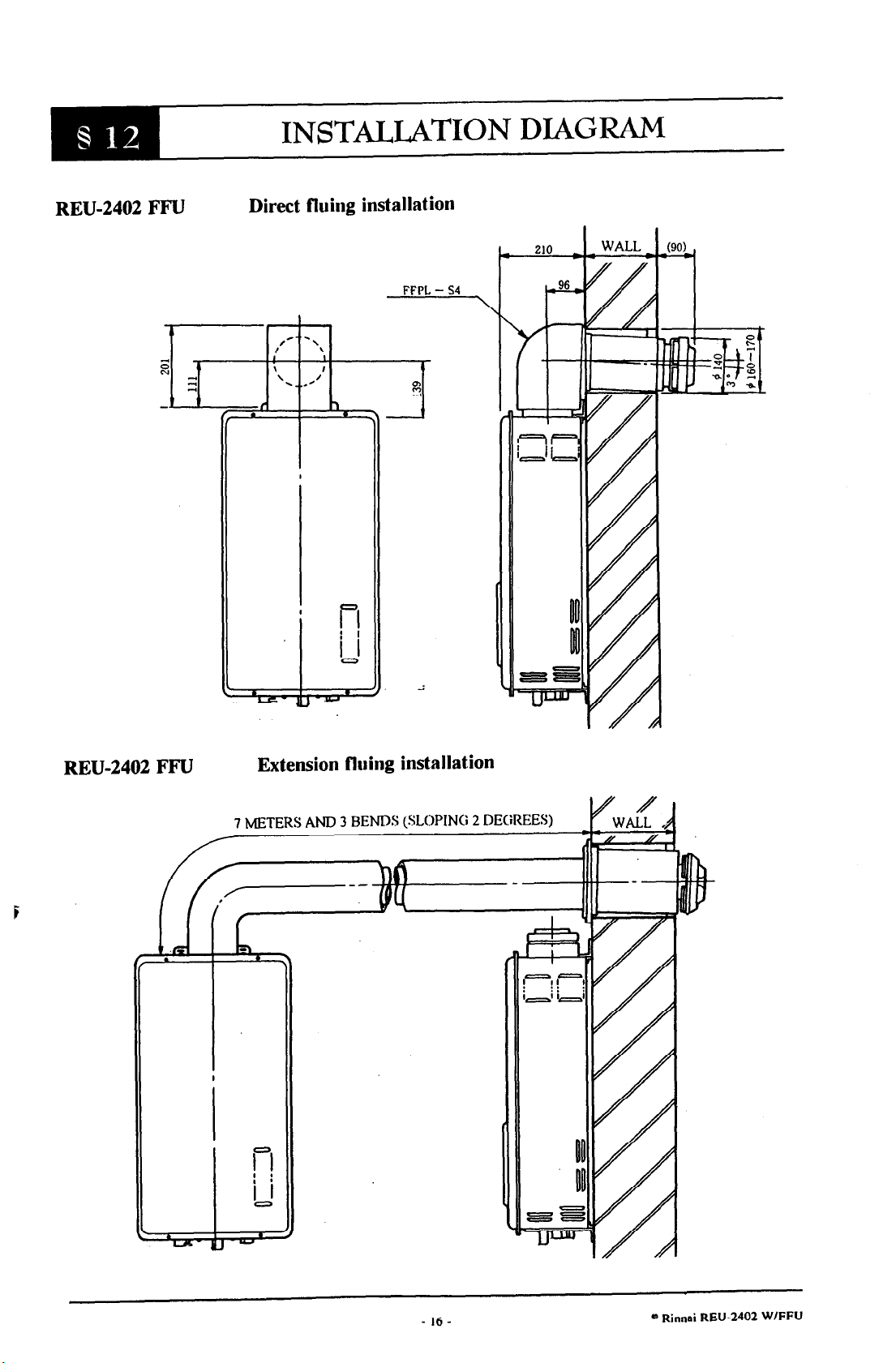

INSTALLATION DIAGRAM

REU-2402 FFU

Direct fluing installation

FFPL - S4

REU-2402 FFU

Extension fluing installation

7mTERSAm3 BENDS (SLOPING2DEGREES)

- 16-

@ Rinnai REU-2402 WlFFU

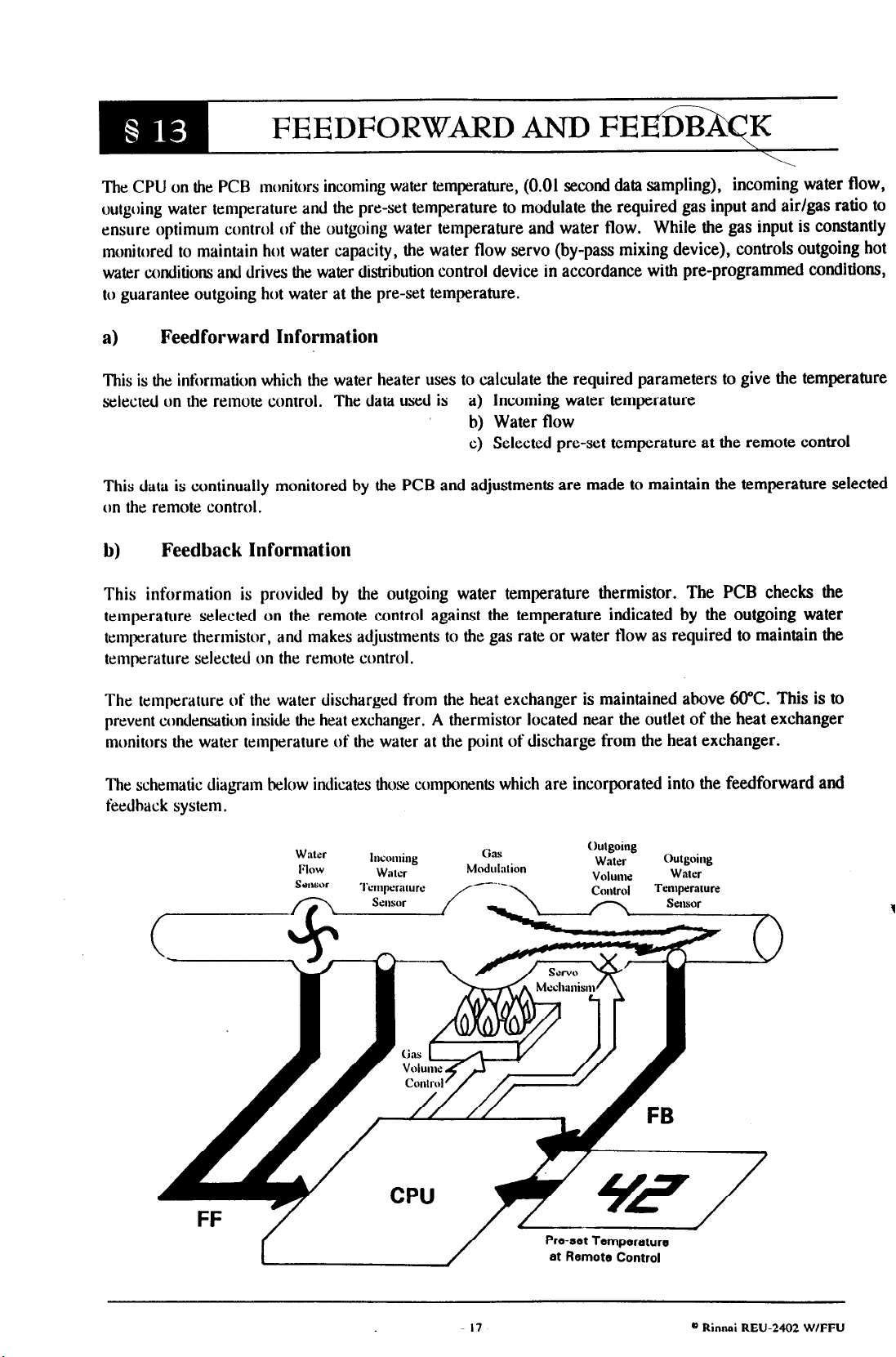

FEEDFORWIRD AND

FEEfiDBq

The CPU on the PCB monitors incoming water temperature, (0.01 second data sampling),

incoming water flow,

outgoing water temperature and the pre-set temperature to modulate the required gas input and air/gas ratio to

ensure optimum control of the outgoing water temperature and water tlow.

While the gas input is constantly

monitored to maintain hot water capacity, the water flow servo (by-pass mixing device), controls outgoing hot

water conditions and drives the water distribution control device in accordance with pre-programmed conditions,

to guarantee outgoing hot water at the pre-set temperature.

a)

Feedforward Informat.ion

This is the information which the water heater uses to calculate the required parameters to give the temperature

selected on the remote control. The data used is

a) Incoming water temperature

b) Water flow

c) Selected pre-set temperature at the remote control

This data is continually monitored by the PCB and adjustments are made to maintain the temperature selected

on the remote control.

b)

Feedback Information

This information is provided by the outgoing water temperature thermistor. The PCB checks the

temperahlre selected on the remote control against the temperature indicated by the outgoing water

temperature thermistor, and makes adjustments to the gas rate or water tlow as required to maintain the

temperature selected on the remote control.

The temperature of the water discharged from the heat exchanger is maintained above 60°C. This is to

prevent condensation inside the heat exchanger. A thermistor located near the outlet of the heat exchanger

monitors the water temperature of the water at the point of discharge from the heat exchanger.

The schematic diagram below indicates those components which are incorporated into the feedforward and

feedhack system.

oils

. lodulnlion

Chlgoiug

Water

volunlc

Outgoing

Water

Temperature

Seceor

I

Preset Temperature

at Remote Control

- 17- e Rinnai RN-2402 WlFFU

COLD WATER SANDWICH

What is the Cold Water Sandwich effect ?

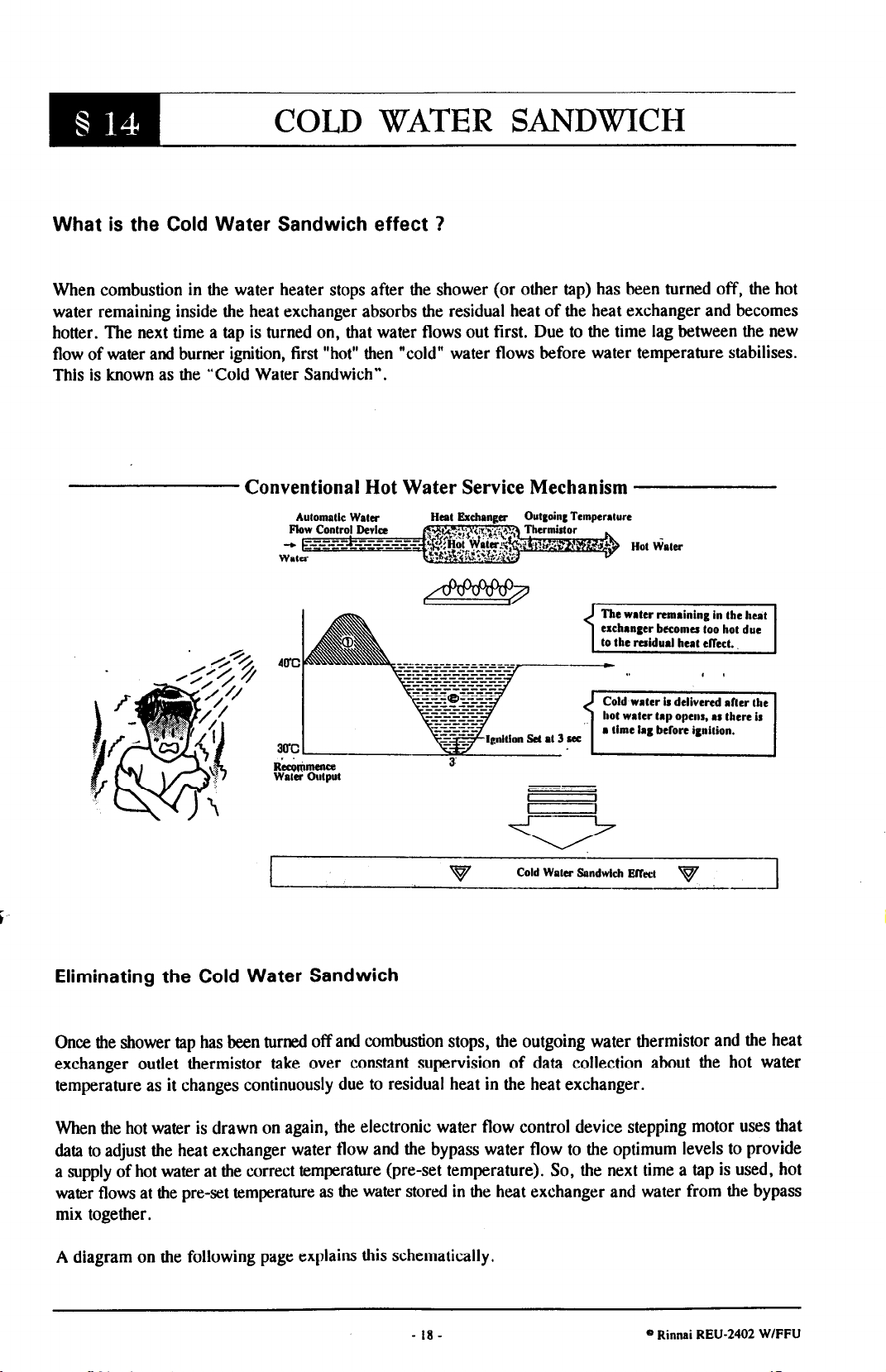

When combustion in the water heater stops after the shower (or other tap) has been turned off, the hot

water remaining inside the heat exchanger absorbs the residual heat of the heat exchanger and becomes

hotter. The next time a tap is turned on, that water flows out first. Due to the time lag between the new

flow of water and burner ignition, first “hot” then “cold” water flows before water temperature stabilises.

This is known as the “Cold Water Sandwich”.

Conventional Hot Water Service Mechanism

Automatic Wow

Outgoing Temperature

Eliminating the Cold Water Sandwich

Once the shower tap has been turned off and combustion stops, the outgoing water thermistor and the heat

exchanger outlet thermistor take over constant supervision of data collection about the hot water

temperature as it changes continuously due to residual heat in the heat exchanger.

When the hot water is drawn on again, the electronic water flow control device stepping motor uses that

data to adjust the heat exchanger water tlow and the bypass water flow to the optimum levels to provide

a supply of hot water at the correct temperature (pre-set temperature). So, the next time a tap is used, hot

water flows at the preset temperature as the water stored in the heat exchanger and water from the bypass

mix together.

A diagram on the following page explains this schematically,

-IS-

* Rinnai REU-2402 WlFFU

Loading...

Loading...