Page 1

These instructions are a guide

to assembling and using the

Impressor 8 (Australia)

Elite (New Zealand)

barbecue.

Please read carefully, and

retain for future reference.

Only to be used outdoors.

Illustration may vary from barbecue

contained in carton.

FOR YOUR SAFETY.

1. Do not store or use

petrol or other flammable

vapours and liquids in the

vicinity of this or any other

appliance.

2. A gas cylinder not connected

for use must not be stored

in the vicinity of this or any

other appliance.

FOR YOUR SAFETY.

IF YOU SMELL GAS:

1. Shut off gas to the appliance.

2. Extinguish any open flame.

3. Open hood.

4. If odour continues,

immediately call your gas

supplier or fire department.

PART NO. P80140004A

Customer’s operating and assembly instructions

Page 2

GENERAL INFORMAT I O N

2

2

A guarantee explanation sheet is supplied separately

with your barbecue. If you are missing the guarantee

explanation sheet, please contact one of the offices listed

on the rear cover to request one to be sent to you.

GUARANTEE

You have just purchased a state of the art Outdoor

Barbecue Cooking System.

We understand your desire to protect an investment

of this nature. As such this booklet has been designed to

assist you in the assembling, testing and operating your

new barbecue, along with important safety information,

helpful maintenance tips and troubleshooting. We thank

you for choosing our product and trust that you enjoy

years of outdoors entertainment.

Happy Gourmet cooking!

CONGRATULATIONS

Purchased from

Date purchased

Serial No.

NOTE:

Sales docket must be kept as proof of purchase date.

FOR CUSTOMER REFERENCE

(Record and file in a safe place)

Inspect barbecue and trolley parts as you proceed.

Contact your place of purchase for assistance regarding

replacement of any damaged or missing parts. Do not

assemble or operate a barbecue that appears damaged.

Check that the barbecue supplied is correct for the gas

type being used. There is a label on the rear panel of the

barbecue.

Barbecues for use with gas cylinders are labelled

‘Universal LPG’. Barbecues for use with natural gas are

labelled

‘Natural Gas’.

Check that the label matches the gas type to be

used.

CHECK BARBECUE FOR ANY DAMAGE

PARTS SUPPLIED SEALED IN THE

CARTON, OR BY YOUR PLACE OF

PURCHASE, MUST NOT BE ALTERED

IN ANY WAY.

!

NATURAL GAS BARBECUES

MUST BE INSTALLED BY AN

AUTHORISED PERSON.

!

While it is possible for one person to assemble the

barbecue, we recommend asking for the assistance of

another person when manoeuvring some of the larger

or heavier pieces.

Remove the barbecue and its components from the

carton. Check against parts list and lay components out

within easy reach. Do not throw the shipping carton

away – unfold flat and use as a protective work surface.

Contact your place of purchase for replacement parts if

necessary.

GENERAL

Standard Phillips-head screwdriver.

Adjustable spanner

(open end shifter).

TOOLS YOU WILL NEED

General Information 2-3

Safety Instructions 4

Pre-Assembly Instructions 5-7

Assembly Instructions 8-15

Operation Instructions 16-18

Fault Finding 19

Cleaning and Maintenance Instructions 20-21

Outdoor Areas 22

Contact Points 23-24

TABLE OF CONTENTS

1. Flatten cardboard packaging and use this as a

protective work surface to assemble upon.

2. Some protective coating may need to be removed

from components prior to assembly.

3. Do not tighten screws and nuts until trolley is fully

assembled.

4. Pre-screwing of connection points for securing the

side shelves will assist in securing shelves smoothly.

ASSEMBLY TIPS

Page 3

GENERAL INFORMAT I O N

3

3

The following minimum clearances from combustible

materials must be maintained: Top – 1000 mm, rear –

450 mm and sides – 250 mm.

Openings at the rear and sides of the appliance

provide air for combustion, and must not be obstructed.

CLEARANCES

Height – Hood closed 1260 mm.

Hood open 1510 mm.

Width – 1900 mm

Depth – Hood closed 655 mm.

– Hood open 725 mm.

OVERALL DIMENSIONS

Australian Gas Association Certificate No. 6468.

Barbecues must be used in accordance with the

installation requirements of your local gas supply

authority, and the appropriate installation standard

AS5601/AG601.

Barbecues for use with cylinder gas are labelled

‘Universal LPG’. Barbecues for use with natural gas

are labelled

‘Natural Gas’ and must be installed by an

authorised person. Check the gas type sticker attached

to the barbecue. Check that the label matches the gas

type to be used.

GAS INSTALLATION CODES HOSE AND REGULATOR SAFETY

NEVER OPERATE THIS BARBECUE

WITHOUT A REGULATOR.

!

FAILURE TO COMPLY WITH THESE

INSTRUCTIONS COULD RESULT IN A

FIRE OR EXPLOSION WHICH COULD

CAUSE SERIOUS BODILY INJURY,

DEATH OR PROPERTY DAMAGE.

!

ACCESSIBLE PARTS MAY BE VERY HOT.

KEEP YOUNG CHILDREN AWAY.

ANY MODIFICATION OF THIS

APPLIANCE MAY BE DANGEROUS.

DO NOT MOVE THIS APPLIANCE

DURING USE.

TURN OFF THE GAS SUPPLY AT THE

GAS CYLINDER AFTER USE.

READ THE INSTRUCTIONS BEFORE

USING THE APPLIANCE.

PARTS SEALED BY THE

MANUFACTURER MUST NOT BE

MANIPULATED.

THIS BARBECUE IS ONLY TO BE USED

AND STORED OUTDOORS.

!

The regulator and hose assembly supplied with the

barbecue is suitable for use with bottled gas.

A gas regulator adjusted to have an outlet pressure

of 2.75 kPa is supplied for connection to the gas cylinder.

The regulator and hose assembly supplied with the

appliance must be used. Replacement regulator and

hose assemblies must be those specified by the appliance manufacturer.

When connecting the hose and regulator assembly

to the gas cylinder, take care to avoid unnecessary

twisting of the flexible hose. After the assembly has

been secured, turn on the gas and check for leaks by

brushing a soap and water solution over all visible and

accessible gas line connections. The presence of bubbles

will indicate a gas escape.

DO NOT TEST FOR GAS

ESCAPES WITH AN OPEN FLAME.

If you are unable to correct the leak by tightening

the connection, turn off the gas and contact your place

of purchase immediately.

Always ensure the appliance is kept away from

flammable materials and the gas cylinder clear of any

heat source.

When changing over from an empty gas cylinder to

a full one, make sure this procedure is carried out in a

flame free atmosphere.

Inspect the gas hose when replacing the gas cylinder

or once a year whichever is more frequent. If the hose

is cracked, cut, abraded or damaged in any way, the

appliance must not be operated. The hose must be

replaced if damaged or when statutory conditions

require it. Contact your place of purchase if uncertain.

The POL fitting of the hose and regulator should be

disconnected from the gas cylinder valve when the

outdoor appliance is not in use.

Appliance specifications can be found on the data label

attached to the rear panel of the barbecue body.

Your barbecue is preset at the factory to operate on

bottled gas only, unless specified otherwise.

SPECIFICATIONS

GAS HOSES ARE FACTORY FITTED AND

LEAK TESTED – DO NOT DISCONNECT.

!

Page 4

SAFETY

4

4

FOR YOUR SAFETY:

DO NOT STORE OR USE PETROL OR

OTHER FLAMMABLE VAPOURS AND

LIQUIDS IN THE VICINITY OF THIS OR

ANY OTHER APPLIANCE.

DO NOT STORE EMPTY OR FULL SPARE

GAS CYLINDERS IN STORAGE

COMPARTMENT OR NEAR THIS OR ANY

OTHER APPLIANCE.

KEEP THE GAS HOSE AWAY FROM HOT

SURFACES. PROTECT GAS HOSE FROM

DRIPPING GREASE.

AVOID UNNECESSARY TWISTING OF

HOSE. VISUALLY INSPECT HOSE PRIOR

TO EACH USE FOR CUTS, CRACKS,

EXCESSIVE WEAR OR OTHER DAMAGE.

REPLACE HOSE, IF NECESSARY.

NEVER TEST FOR GAS LEAKS WITH A LIT

MATCH OR OPEN FLAME.

NEVER LIGHT BARBECUE WITH HOOD

CLOSED.

NEVER LEAN OVER COOKING

SURFACE WHILE LIGHTING BARBECUE.

USE GOOD QUALITY INSULATED OVEN

MITTS WHEN OPERATING BARBECUE.

NEVER ALTER OR MODIFY THE

REGULATOR OR GAS SUPPLY ASSEMBLY.

THIS BARBECUE MUST NOT BE USED

INDOORS.

!

DANGER – IF YOU SMELL OR HEAR THE

HISS OF ESCAPING GAS FROM THE GAS

CYLINDER:

KEEP CLEAR OF THE GAS CYLINDER.

DO NOT ATTEMPT TO CORRECT THE

PROBLEM YOURSELF.

CALL YOUR FIRE DEPARTMENT

(DO NOT MAKE THE CALL FROM

ANYWHERE NEAR THE GAS CYLINDER –

YOUR TELEPHONE IS AN ELECTRICAL

DEVICE, AND COULD PRODUCE A SPARK).

!

READ CAREFULLY BEFORE

ASSEMBLING AND OPERATING

YOUR BARBECUE.

!

NEVER CONNECT AN UNREGULATED

GAS CYLINDER TO YOUR BARBECUE.

!

NEVER STORE YOUR GAS

CYLINDER INDOORS

FOR STORAGE AND CYLINDER

EXCHANGE, DISCONNECT HOSE AT

THE CYLINDER ONLY – DO NOT

DISCONNECT HOSE FROM

THE APPLIANCE.

!

DO NOT use your barbecue in garages, porches, breezeways,

sheds or other enclosed areas. Your barbecue is to be used

OUTDOORS ONLY. Refer to page 22. The barbecue is not

intended to be installed in or on recreational vehicles

and/or boats and should not be placed under any surface

that will burn. Do not obstruct the flow of combustion and

ventilation air around the barbecue while in use.

LOCATION OF YOUR BARBECUE

Keep children away from barbecue during use and until

barbecue has cooled after you are finished. Do not allow

children to operate barbecue, or to swing on handle.

PROTECT CHILDREN

NEVER TEST FOR LEAKS WITH AN OPEN FLAME.

Prior to first use, and at the beginning of each new season

(or, if using bottled gas, whenever gas cylinder is changed), you

must check for gas leaks.

Follow these steps:

1. Make soap solution by mixing one part liquid detergent

and one part water.

2. Turn burner control(s) to

‘OFF’, then turn on gas at

source.

3. Apply the soap solution to all visible and accessible

gas connections. Bubbles will appear in the soap

solution if connections are not properly sealed.

Tighten or rectify as necessary.

4. If you have a gas leak you cannot rectify, turn off the

gas at the source, disconnect hose from barbecue

and immediately contact the manufacturer for

assistance.

Refer to back cover.

CHECKING FOR GAS LEAKS

The gas cylinder should be filled by a reputable gas dealer,

or exchanged at a reputable cylinder exchange outlet. Gas

cylinders should be visually inspected and requalified

periodically.

Always keep gas cylinder in an upright position.

Always close the cylinder valve when the barbecue is not in use.

Do not subject gas cylinder to excessive heat.

If you store your barbecue indoors, ALWAYS disconnect

and remove gas cylinder FIRST, and store gas cylinder

safely outside. Gas cylinders must be stored outdoors in

a well ventilated area out of reach of children, and must not

be stored in a building, garage or any other enclosed area.

This is a low pressure barbecue and must only be used with

the hose and regulator supplied.

Your barbecue is designed for use with a 9 kg gas

cylinder. Ensure gas cylinder conforms to Australian

standards.

DO NOT CONNECT YOUR BARBECUE TO A GAS

CYLINDER LESS THAN OR EXCEEDING THIS CAPACITY.

GAS CYLINDER USE AND SAFETY

IF YOU SMELL GAS:

1. SHUT OFF GAS TO THE APPLIANCE

AT ITS SOURCE, IF POSSIBLE.

2. EXTINGUISH ANY OPEN FLAME.

3. OPEN HOOD.

4. PERFORM GAS LEAK CHECK

PROCEDURE.

5. IF ODOUR CONTINUES,

IMMEDIATELY CALL YOUR GAS

SUPPLIER OR FIRE DEPARTMENT.

!

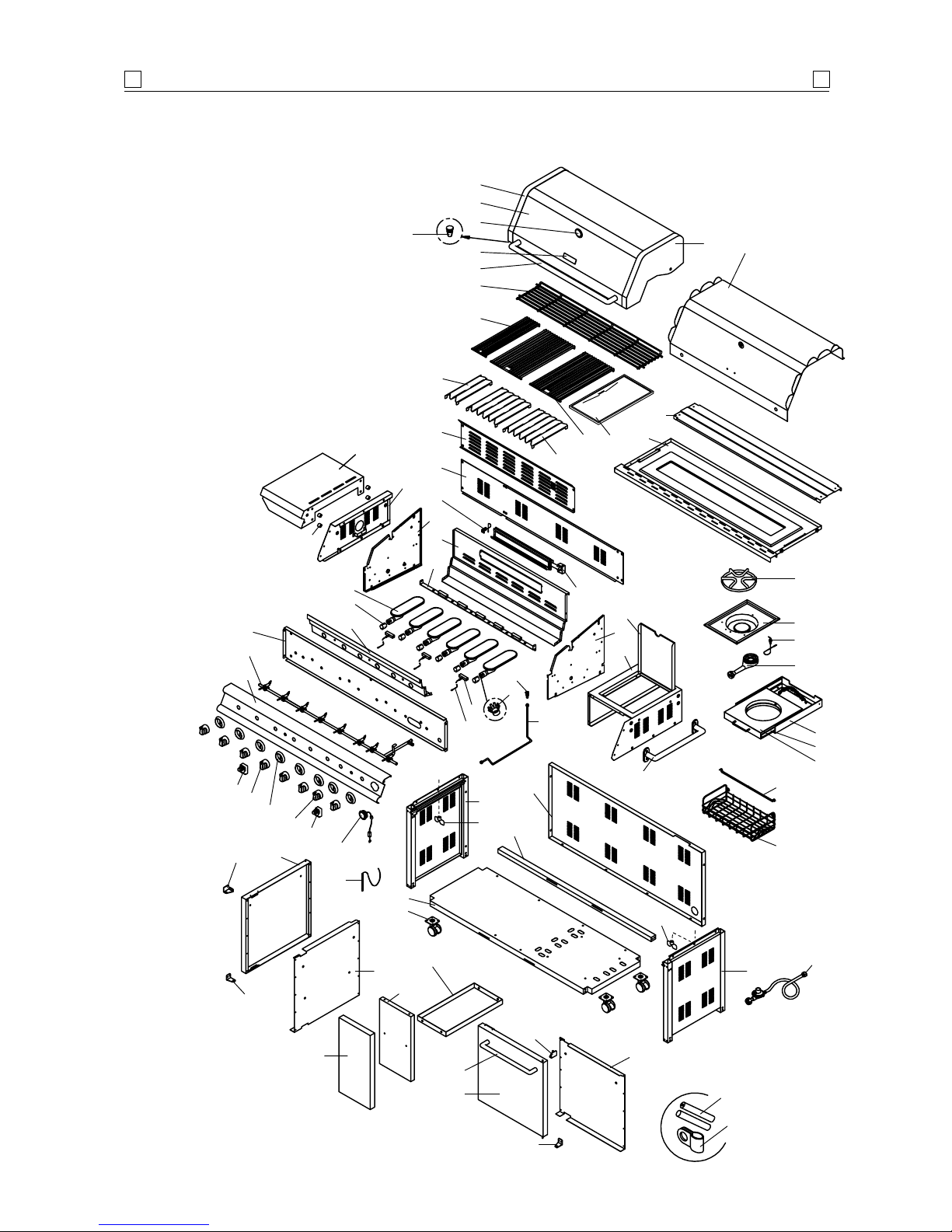

Page 5

6

8

10

12

24

25

35

18

23

14

19

74

39

13

13a

22

29

28

30

17a

32

33

38

17b

59

75

75

54

47

52

43

40

44

64

63

65

66

57

58

56

55b

55a

34

37

62

20

21

42

36

27

9b

9a

26

11

71

16

15

45

49

53

61

50

46

51

69

48

41

60

68

70

31

42

1

3

5

7

67

72 (LPG only)

73 (LPG only)

PARTS DIAGRAM

5

5

This diagram is provided to assist you

identify parts if replacement is necessary.

Contact your place of purchase or the

manufacturer to enquire about parts,

availability and or service.

Page 6

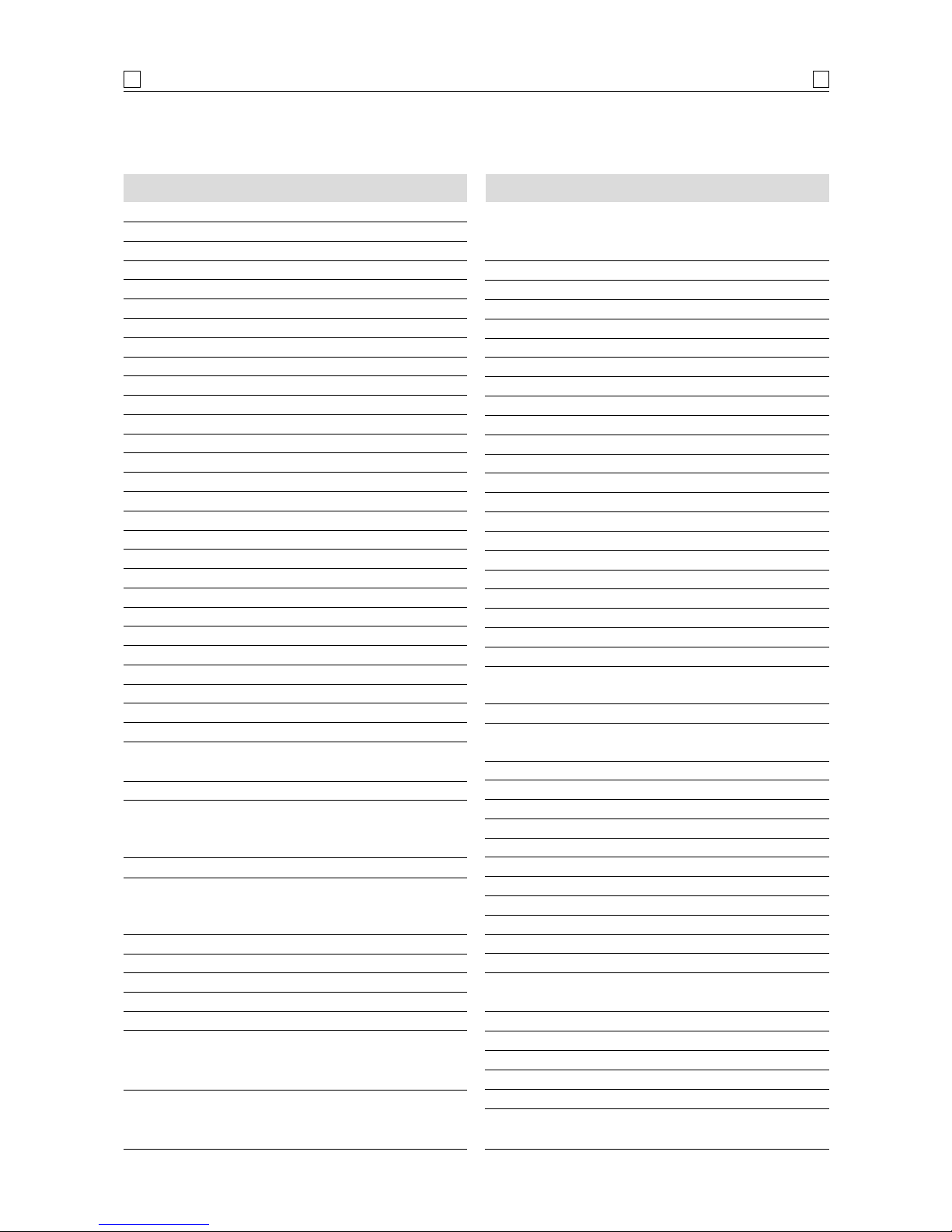

PARTS LIST

6

6

1

2

3

4

5

6

7

8

9a

9b

10

11

12

13

13a

14

15

16

17a

17b

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

36a

Stainless steel hood

Stainless steel hood trim plate

Hood side panel –

left

Hood side panel – right

Temperature gauge

Hood handle

Badge

S/S secondary cooking rack

Stainless steel cooking grid

C/I hotplate ceramic coating

Stainless steel cooking grid –

4"

Stainless steel flametamer

Stainless steel flametamer –

4"

Main burner

Air shutter for main burner

Main burner bracket

Gas collector box w/ electrode

Ignition wire set

Electric igniter –

4 ports

Electric igniter – 2 ports

Barbecue body panel – left

External body trim panel – left

Barbecue body panel – right

External body trim panel – right

Barbecue body panel – front

Barbecue body panel – rear

Wind shield – A

Wind shield – B

Pull-out grease draining tray and

2 x winged screws

Grease draining tray heat shield

Gas manifold/valve assembly

LPG

NG

Control panel heat shield

Control panel

LPG

NG (no fuel gauge hole)

Hood stopper

Control knob

Control knob seat

Rotisserie burner assembly

Electrode for rotisserie burner

Injector for rotisserie burner

LPG

NG

Injector for main burner

LPG

NG

P00117356A

P0011435EA

P00105347U

P00106347U

P00601171B

P00205033B

P00415006C

P01518028B

P01606030B

P05702004E

P01606031B

P01708031B

P01708032B

P02001050E

P05524137C

P02206271B

P02608050C

P02615053A

P02502024C

P02502012C

P00720291A

P00742296C

P00721291A

P00743296C

P00738304A

P00725304A

P00737309A

P06905006E

P02714291A

P06903009A

Y0060087

Y0060090

P03011132C

P02911291N

P02911291T

P05518100I

P03412331C

P03415264A

P02007049D

P02614006B

P06509010A

P06509012A

P06509011A

P06506002A

1

1

1

1

1

1

1

1

2

1

1

2

1

6

6

1

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

7

8

1

1

1

1

1

1

36b

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55a

55b

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

----

----

Injector for side burner

LPG

NG

Gas tube for rotisserie burner

Control knob for rotiserrie burner

Side shelf – left

Trolley side handle

Bottom shelf

Trolley side panel –

left

Trolley side panel – right

Trolley rear panel

Door bracket

Door panel –

left

Door panel – right

Door trim plate – left

Door trim plate – right

Door axle bracket – left top

Door axle bracket – left bottom

Door axle bracket – right top

Door axle bracket – right bottom

Stainless steel door handle

Wire basket

Division wire for wire basket

Cylinder pull-out tray

– LPG only

Bracket for cylinder pull-out tray

LPG only

Cylinder tray slide

Fuel gauge display with stainless

steel ring assembly –

LPG only

Castor

Manual lighting stick

Stainless steel side burner lid

S/S side burner body –

inner

Pot support

Side burner electrode

Side burner assembly

Regulator and hose assembly

Division panel

Decorative panel

Decorative inside panel

Heat-insulating ring for main

burner valve

AAA battery –

LPG fuel gauge

Wire fastener – LPG only

Side shelf nylon insulating spacers

Winged screws (inc. hardware pack)

Hardware pack

Operating and assembly

instruction booklet

P06522001A

P06522002A

P03717033A

P03412341C

P01106028B

P00205032B

P01005027K

P07617009E

P07618009E

P07702018E

P03301022J

P04302012A

P04303012A

P07506007D

P07507007D

P03314018C

P03314019C

P03314020C

P03314021C

P00205036B

P05204010E

P05204012E

P04009028H

P04010030H

P05516131B

P05310032B

P05115020A

P05313023B

P00115346A

P02301006B

P00805013B

P02607052C

P02002056D

P03603001A

P07512013D

P07501008A

P07509009D

P06801007F

P05301002A

P05310040A

n/a

n/a

P06001028A

P80140004A

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

4

1

1

1

1

1

1

1

1

1

1

6

2

1

4

2

1

1

Ref. Description Part No. Qty Ref. Description Part No. Qty

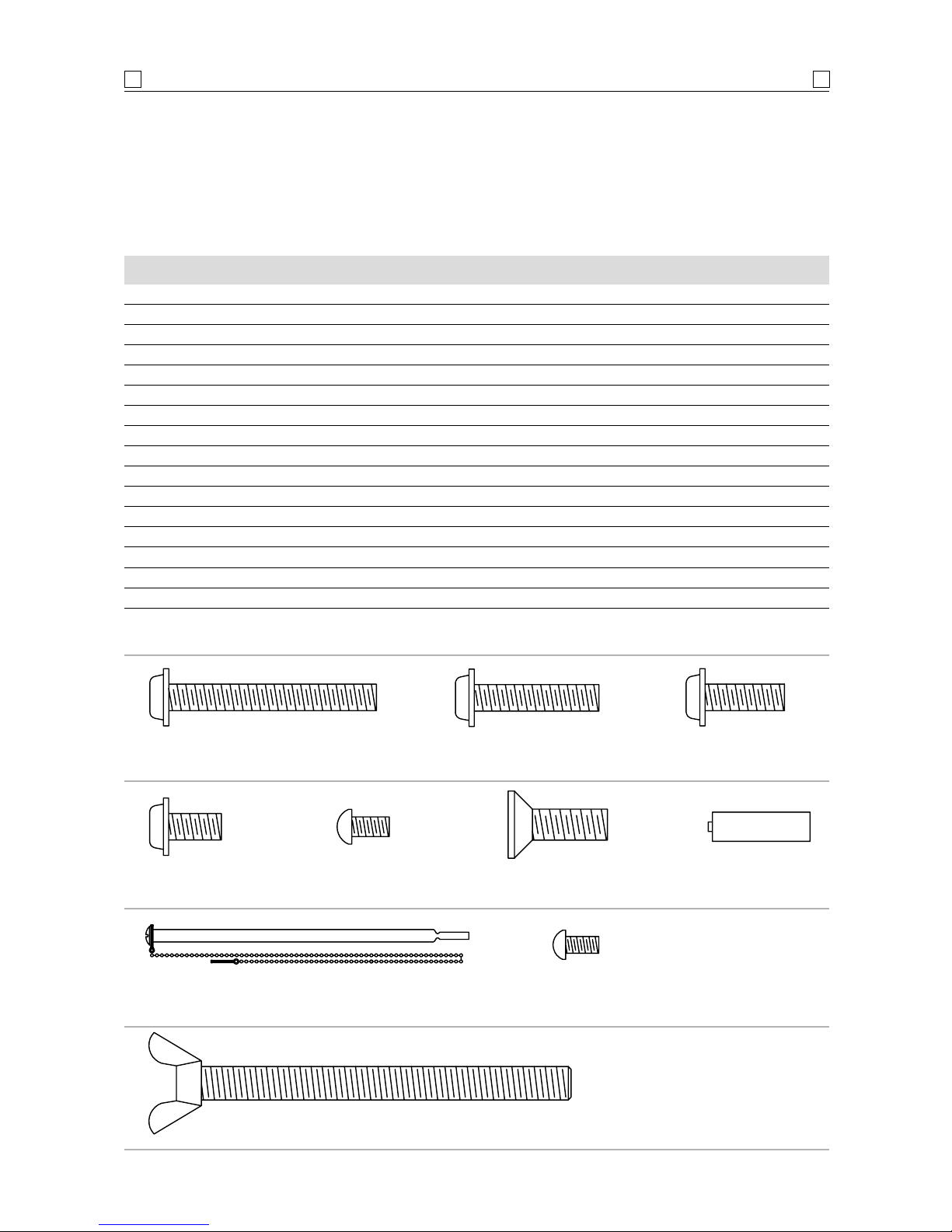

Page 7

1/4"x30 mm Phillips-head screw

Qty. 6 Ref. # H032

1

/4" x 3/4" Phillips-head screw

Qty. 4 Ref. # H031

1

/4" x 3/4" flat-head screw

Qty. 4 Ref. # H034

M4 x 8 mm Phillips-head screw

Qty. 1 Ref. # H035

3

/16"x 9 mm Phillips-head screw

Qty. 8 Ref. # H033

1

/4" x 1/2" Phillips-head screw

Qty. 38 Ref. # H005

1

/4" x 50 mm Phillips-head screw

Qty. 12 Ref. # H030

Manual lighting stick

Qty. 1 Ref. # P05313023B Scale 1:2

5

/16" x 89 mm wing bolt (LPG model only) Qty. 1 Ref. # H029

AA battery Qty. 2

Ref. # P05301001A Scale 1:2

PARTS LIST

7

7

The following information is a breakdown of the hardware pack.

It explains which fittings are used during the various stages of assembly.

H005

1

/4" x 1/2" Phillips-head screw 16 Install castor to castor seats of bottom shelf

H030

1

/4" x 50 mm Phillips-head screw 8 Attach trolley side panels to bottom shelf

H005

1

/4" x 1/2" Phillips-head screw 8 Attach rear panel to trolley

H005

1

/4" x 1/2" Phillips-head screw 4

Attach cylinder pull-out tray kit to bottom shelf (LPG model only)

H030

1

/4 " x 50 mm Phillips-head screw 4 Attach door bracket to trolley

H005

1

/4 " x 1/2" Phillips-head screw 4 Install decorative panel to trolley

H005

1

/4" x 1/2" Phillips-head screw 4 Install division panel to trolley

H033

3

/16" x 1/2" Phillips-head screw 8 Install door axle brackets to trolley

H005

1

/4 " x 9 mm Phillips-head screw 2 Install wire basket to left door trim plate

H032

1

/4" x 30 mm Phillips-head screw 6 Attach barbecue body to trolley

H031

1

/4" x 3/4" Phillips-head screw 4 Attach side shelf to barbecue body

H034

1

/4" x 3/4" flat-head screw 4 Attach trolley side handle to barbecue body

H029

5

/16" x 89 mm wing bolt 1 Secures gas cylinder (LPG model only)

P05301001A AA battery 2 Powers the electric igniter

P05313023B Manual lighting stick 1 Attaches to outside body panel – Left

H035 M4 x 8 mm Phillips-head screw 1 Attaches to outside body panel – Left

Ref. Component Qty. Purpose of Component

Actual size and quantity of each hardware piece

Page 8

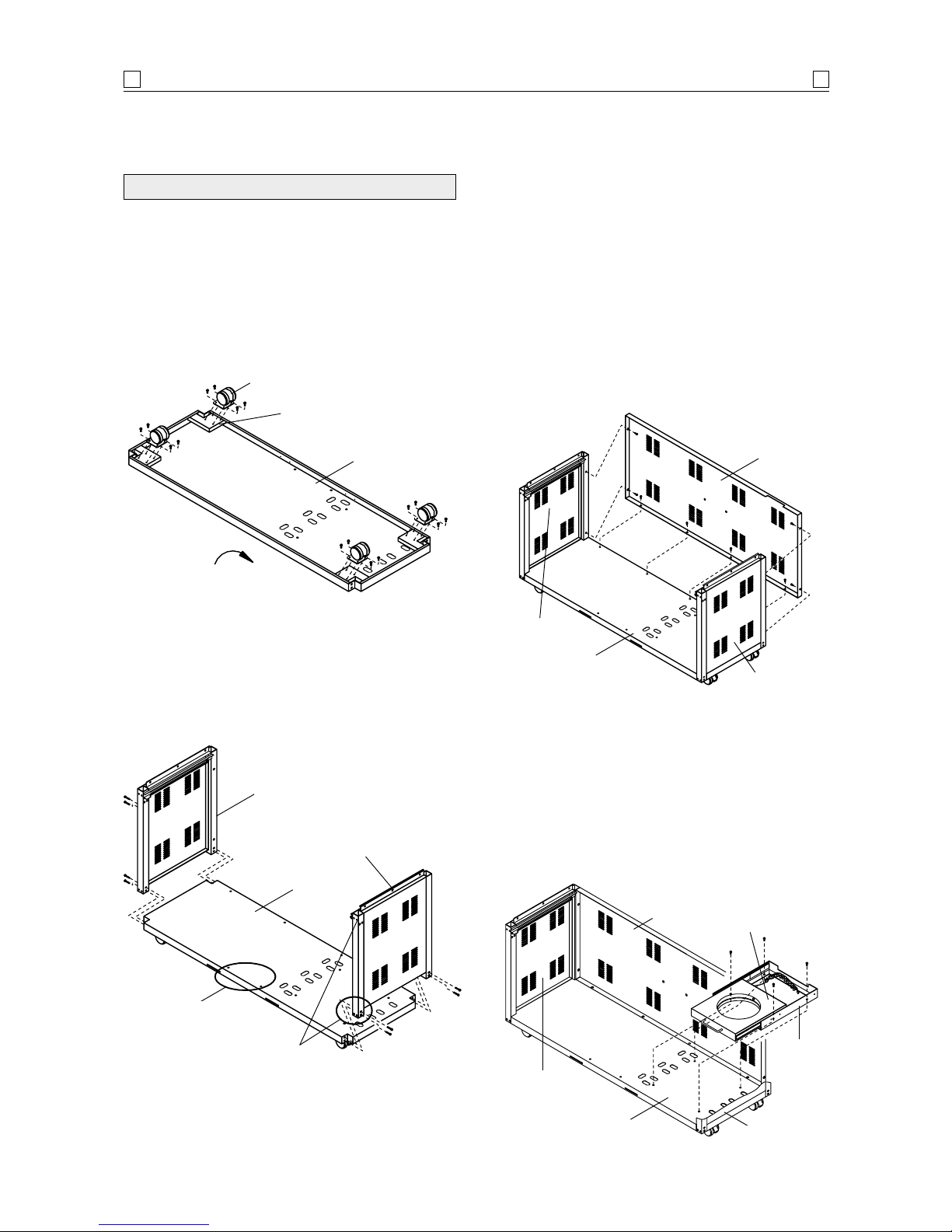

ASSEMBLY

8

8

3. Install trolley side panels to the bottom panel.

Align the holes on trolley side panels with the

threaded holes at the corners of trolley bottom

panel. Tighten securely by using 8 of the

1

/4" x 50 mm

Phillips-head screws provided.

See diagram 2.

4. Install the trolley rear panel to inside of rear trolley

side panels and to rear of trolley bottom panel.

Align the holes on the trolley rear panel with the

threaded holes on trolley side panels and trolley

bottom shelf. Tighten securely by using 8 of the

1

/4" x 1/2" Phillips-head screws provided.

See diagram 3.

5. Place the cylinder pull-out tray kit on the trolley

bottom panel. Extend the cylinder tray outward

from its bracket so you can align the holes on the

bracket with the threaded holes on the top of trolley

bottom panel.

Tighten securely by using 4 of the

1

/4" x 1/2"

Phillips-head screws provided.

See diagram 4.

Slide tray back into bracket after securing to bottom.

2. Before attaching the trolley bottom panel to trolley

side panels be sure door stop for magnets on the

bottom panel and holes for door axle brackets on

trolley side panels are located on the front side.

See diagram 2.

Trolley

bottom panel

Castor

Castor

seat

Diagram 1.

Holes for door

axle bracket

Diagram 2.

Trolley

rear panel

Trolley

bottom panel

Trolley

bottom panel

Trolley side

panel – right

Trolley side

panel – left

Diagram 3.

Door stop

for magnets

Trolley side

panel – left

Diagram 4.

Trolley

rear panel

Trolley

bottom

panel

Cylinder

pull-out tray kit

(LP gas only)

1. Turn over the trolley bottom panel on floor. Install

the 4 castors to castor seats on the trolley bottom

panel.

Align the holes on castor with the threaded holes

on castor seat. Tighten securely by using 16 of the

1

/4" x 1/2" Phillips-head screws provided.

See diagram 1.

ASSEMBLING THE BARBECUE TROLLEY

Cylinder

pull-out

tray

bracket

Trolley side

panel – left

Trolley side

panel – right

Trolley side

panel – right

Page 9

ASSEMBLY

9

9

6. Before installing the door bracket to the inside of

front trolley side panels, check and ensure door

stops for magnets on the door bracket are located

on the front side.

See diagram 5.

7. Install the door bracket to the inside of front trolley

side panels. Align the threaded holes on the door

bracket with the holes on trolley side panels.

Tighten securely by using 4 of the

1

/4" x 50 mm

Phillips-head screws provided.

See diagram 5.

8. Remove the white protective film from the stainless

steel decorative panel.

9. Install the decorative panel to the trolley. Align the

2 threaded holes on the bottom of door bracket and

the 2 threaded holes on the top of bottom shelf

with the 4 holes on the decorative inside plate.

Tighten securely by using 4 of the

1

/4" x 1/2"

Phillips-head screws provided. Then tighten 4

loose screws on the door bracket.

See diagram 6

10. Install the division panel to the trolley. Align the 2

threaded holes on the decorative inside plate and 2

holes on the trolley rear panel with the holes

on the division panel. Tighten securely by using 4

of the

1

/4" x 1/2" Phillips-head screws provided.

See diagram 7.

Trolley

rear panel

Diagram 5.

Decorative

inside plate

Division

panel

Decorative

panel

Diagram 7.

Diagram 6.

Decorative

panel

Door stop

for magnets

Door

bracket

Door

bracket

Trolley side

panel – left

Trolley side

panel – right

Trolley

bottom panel

11. Remove the white protective film from the stainless

steel door panel and stainless steel door axle

bracket.

12. Install the door axle bracket-left bottom to the left

trolley side panel. Align the threaded holes on the

door axle bracket-left bottom with the holes on the

bottom of left trolley side panel. Tighten securely

by using 2 of the

3

/16" x 9 mm Phillips-head screws

provided.

See diagram 8A.

Diagram 8A.

Door axle bracket –

left bottom

Trolley side

panel – left

Trolley

bottom panel

Decorative

inside plate

Page 10

ASSEMBLY

10

10

16. Follow the steps 1 to 5 of the installing the left

cabinet door to install the right cabinet door.

17. Attach the wire basket to the left trim plate

as

shown in diagram 8D.

Tighten securely using 2 of

the

1

/4" x 1/2" Phillips-head screws provided. Place

the division wire on the wire bracket.

14. Before installing the door axle bracket-left top to

the left trolley side panel, with an assistant,

hold the door panel and keep it vertical.

15. Place the axle on top of the left door panel to the

door axle bracket-left top. Install the door axle

bracket-left top to the left trolley side panel. Align

the holes on the door axle bracket-left top with

threaded holes on the top of left trolley side panel.

Tighten securely by using 2 of the

3

/16" x 9 mm

Phillips-head screws provided.

See diagram 8C.

13. Place the axle on bottom of the left door panel to

the door axle bracket-left bottom.

See diagram 8B.

Diagram 8B.

Diagram 8D.

Hole for

door axle

Door axle bracket –

left bottom

Wire basket

hood

Door trim

plate – left

Diagram 8C.

Door axle –

left top

Hole for

door axle

Door axle bracket –

left top

Trolley side

panel – left

Trolley side

panel – left

Division

wire

Diagram 9.

Trolley side

panel

bracket

Barbecue

hood

Barbecue

body side

panel

1. Now that you have assembled the barbecue trolley

you can install the pre-assembled barbecue body.

See diagram 9. If you haven't already done so, open

the barbecue hood and remove the packed

components. Lock the castors. Even with the

components removed, the next step requires 2

people.

2. With an assistant, carefully lift and position the

barbecue body onto the barbecue trolley. Align the

6 holes of the body side panel to the threaded holes

on the trolley side panel mounting bracket. Secure

firmly by using 6 of the

1

/4" x 30 mm Phillips-head

screws provided.

INSTALLING THE BARBECUE BODY

BE CAREFUL NOT TO PINCH FINGERS

WHEN LOWERING HEAD ONTO TROLLEY

!

Page 11

1. Unscrew the igniter cap located on the control

panel and remove the contact and spring from the

igniter slot.

2. Place the supplied AA battery into the igniter slot

with the positive pole facing toward you.

3. Place the spring with contact over the battery.

screw the igniter cap back onto the control panel.

IGNITION BATTERY INSTALLATION

AA battery

Spring

Contact

Diagram 13.

1. Remove the white protective film from the stainless

steel side shelf.

2. With the aid of an assistant, attach side shelf to left

side of barbecue. Install nylon spacers onto the

1

/4" x 11/2" Phillips-head screws and then align the

holes on side shelf with the threaded holes on left

outside body panel. Tighten securely using 4 of the

1

/4" x 11/2" Phillips-head screws with spacers in

place.

See diagram 12.

3. Attach trolley side handle to right side of barbecue.

Align the holes on trolley side handle with the

threaded holes on right outside body panel.

Tighten securely using 4 of the

1

/4" x 3/4" flat-head

screws provided.

See diagram 12.

INSTALLING SIDE SHELF

AND TROLLEY SIDE HANDLE

Side shelf – left

Nylon

spacer

Diagram 12.

External body

trim panel –

right

Barbecue hood

BARBECUES ON TROLLEYS ARE HEAVY:

TO AVOID POSSIBLE INJURY CAUSED

WHEN MOVING THE BARBECUE AND

TROLLEY, THE BARBECUE SHOULD

BE PUSHED FORWARD, AND NOT

PULLED FROM BEHIND.

!

1. Attach the manual lighting stick to the external

body trim panel –left

as shown in diagram 11. Align

the hole at the end of manual lighting stick wire

with the threaded hole on the external body trim

panel. Tighten securely using the M4 x 8 mm

Phillips-head screw.

INSTALLING MANUAL LIGHTING STICK

Outside

barbecue body

panel – left

Diagram 11.

M4 x 8 mm

Phillipshead screw

Manual

lighting stick

ASSEMBLY

11

11

Diagram 10 (LP gas model only).

Control panel

Slot for wire

plug ‘A’

Fuel gauge

display

(LP gas

model only)

3. Open the front doors of cabinet. Remove fastening

band from fuel gauge display wire plug

‘A’ that is

behind the heat shield of the control panel.

4. Place the wire plug

‘A’ through the slot in side of

right trolley side panel

as shown in diagram 10.

Igniter cap

Page 12

KECHCE

CE

DF LU E IN

IN

F

AIC TOR

OR

ASSEMBLY

12

12

IMPORTANT: Before installing batteries be sure the gas

cylinder is not mounted in the cylinder pull-out tray.

1. Open the front doors of cabinet. Pull out the gas

cylinder storage tray. Connect the wire plug

‘A’

from fuel gauge display with the wire plug ‘B’

from rear of cylinder storage tray. Unscrew 1/4" x

1

/2" Phillips-head screw (lower) from rear panel

and fix wire plug

’A’ into wire fastener. Install wire

fastener to rear panel. Tighten securely using the

same screw.

See diagram 16A.

2. From the underside of the control panel, unscrew

the fuel gauge display cover on the fuel gauge

display box.

See diagram 16B.

3. Carefully remove the battery box from the back of

the fuel gauge display box and insert two ‘AAA’

batteries

(provided). Be sure to follow correct

polarity when inserting batteries.

4. Return the battery box with electric wire into the

fuel gauge display box. Screw the fuel gauge

display cover onto the fuel gauge display box.

FUEL GAUGE DISPLAY INSTALLATION

NOTE: Cylinder must be positioned in tray for fuel

gauge display check

Press the ‘CHECK’ button to operate fuel gauge display.

1.

Fuel display: Indicates gas cylinder fill level

2.

Fuel Warning display: When the gas cylinder fill

level is on the last row a warning signal will

sound for approximately 3 seconds to warn you

that the cylinder volume is near empty.

3.

Battery Warning display: A low battery warning

light will illuminate when the battery voltage

drops to a low level. Replace the batteries.

IMPORTANT: When the gas cylinder is removed from

the cylinder storage tray, the fuel gauge display will

not operate.

FUEL GAUGE DISPLAY OPERATING

Diagram 16A.

Diagram 16B.

Trolley side panel – right

Wire plug ‘A’

Wire plug ‘A’

Wire plug ‘B’

AAA battery

Wire plug ‘A’

Fuel gauge

display

Fuel gauge

display cover

Check button

Fuel warning

display

Battery

warning

display

Fuel level

display

Fuel gauge

display box

Cylinder

pull-out tray

Wire fastener

Rear panel

Install the 5/16" x 89 mm wing bolt as shown below

to secure the gas cylinder in place during use.

GAS CYLINDER LOCK

Wire

Battery box

Cylinder

pull-out tray

5/16"x 89 mm wing bolt

Page 13

GAS INSTALLATION

13

13

1. Attach hose and regulator assembly to the main

barbecue gas piping. Tighten securely with a

shifter.

2. Locate the gas cylinder onto the gas cylinder storage

tray on the RHS of the trolley bottom panel.

Refer diagram below.

3. Attach the cylinder connection device of regulator

and hose assembly to cylinder valve outlet.

4. Open the gas cylinder valve fully to allow gas to

flow.

5. Leak test all accessible connections thoroughly

with a soapy water solution prior to lighting the

barbecue.

Refer to Safety information at beginning of booklet.

6. If a leak is found, turn gas cylinder valve off and do

not use barbecue until repairs or replacement can

be made by a local gas supplier.

DISCONNECTING FROM GAS SOURCE

1. Turn the burner control ‘OFF’.

2. Turn the gas cylinder valve off fully.

3. Detach the regulator assembly from gas cylinder

valve.

CONNECTING AND DISCONNECTING

TO GAS SOURCE

TEST FOR LEAKS WITH A

SOAP SOLUTION, NEVER WITH AN

OPEN FLAME. (Refer page 4)

!

Gas

cylinder

CONNECTING TO GAS SOURCE

IF THIS INFORMATION IS NOT

FOLLOWED EXACTLY, A FIRE

CAUSING DEATH OR SERIOUS INJURY

MAY OCCUR!

DO NOT STORE A SPARE GAS CYLINDER

IN THE STORAGE COMPARTMENT OR

NEAR THIS APPLIANCE.

NEVER FILL THE CYLINDER BEYOND

80% FULL.

THIS BARBECUE IS ONLY TO BE USED

OUTDOORS.

!

DISCONNECT OR REMOVE GAS

CYLINDER WHEN MANOEUVRING THE

BARBECUE OVER UNEVEN SURFACES

OR CARRYING UP AND DOWN STAIRS

!

IMPORTANT: Before connecting and disconnecting

barbecue to gas source, make sure all burner controls

are in ‘OFF’ position.

NOTE:

The ‘OFF’ position on the control panel is

identified by a black vertical line. When the line or the

word ’OFF’ printed on the control knob aligns with the

black vertical line on the control panel, the burner is in

the fully ‘OFF’ position.

CAUTION:

When the appliance is not in use, the gas

must be turned off at the gas cylinder.

Familiarise yourself with the general information

and safety guidelines located at the front of this

manual. Check to see that gas cylinder is filled and that

the end of each burner tube is properly located over

each valve orifice. Set burner controls to

‘OFF’ position.

ENSURING BURNER CONTROLS ARE OFF

This barbecue is also certified for use on natural gas.

Contact the distributor for advice in relation to using

your barbecue on natural gas.

Refer back cover.

If your barbecue is supplied direct from the factory

in a natural gas specification, then it must be installed

by an authorised person.

SETTING OF THE ‘APPLIANCE TEST POINT

PRESSURE’ ON NATURAL GAS

Operate 4 right burners on ‘HI’. Attach manometer to an

injector of one of the unlit burners. Adjust regulator

until 1 kPa pressure is achieved with 4 burners operating.

NATURAL GAS INSTALLATION

Page 14

INSPECTION

14

14

Product shipping can reposition the back burner spark

electrode. If your barbecue and side burner are

completely assembled and this rotisserie burner electrode

does not continuously

spark, then conduct

this adjustment.

1. Turn the gas supply off at the gas cylinder.

2. Be sure the AA battery is installed and follow all

ignition wires to ensure the connections are secure.

3. Push the ignition button and watch for a small blue

spark at the rotisserie burner electrode tip. If there is

no spark you must adjust the gap between the

electrode tip and the stainless steel rotisserie burner

screen. The gap should be adjusted to 5 mm or closer.

ROTISSERIE BURNER

SPARK ELECTRODE TEST AND ADJUSTMENT

Do not touch the

white ceramic

electrode insulator

CHECK PERFORMANCE OF

BURNERS PRIOR TO INSTALLING

BARBECUE PLATE COMPONENTRY.

DO NOT SMOKE WHEN ATTEMPTING TO

IGNITE BARBECUE.

NEVER USE VOLCANIC ROCK,

HEAT BEADS OR OTHER MATERIAL

ON FLAMETAMER.

ALWAYS USE PROTECTIVE

GLOVES WHEN HANDLING HOT

COMPONENTS.

!

1. With burner controls in ‘OFF’ position, open the gas

cylinder valve or connect to gas supply.

2. Upon first assembly the gas lines and burners will be

full of air. In order for the burners to light properly

the lines must fill with gas. It may require several

attempts at lighting the burners before you are

successful.

3. Push the igniter button and check for sparking at the

stainless steel gas collector, located adjacent to each

burner.

4. If a spark is not evident at the gas collector, check that

the ignition lead is firmly attached to the spark plug.

5. With sparking established at collector box, turn the

burner control to

‘HI’ to establish a flame on the burner.

6. Push and turn the required burner control as required

in an anti-clockwise direction to the

‘HI’ position.

Cross lighting channels inside the barbecue body

enables the flame to transfer across to the centre and

opposite side burners to ignite them.

7. If any burners fail to light after several attempts, turn

off gas supply at source.

Wait until burners cool and inspect for obstructions to gas

flow.

See also Safety instructions (page 4), Lighting and

Operating instructions (page 16)

.

BURNER OPERATION

AND IGNITION SYSTEM CHECK

Burner tubeOrifice

Gas

valve

Gas collector box Screw

Continuous igniter

Spark electrode Burner port

Foot

Cotter pin

Burner control

Burner

5 mm

Before placing the cooking components into your

barbecue body, ensure that the spark electrode tip is

properly positioned within each gas collector box

(a wide

stainless steel mechanism found at the front between each set

of burners)

. The easiest way to ensure this is to perform the

following electrode check:

1. Be sure all control knobs are set to

‘OFF’. Open the

barbecue hood. NEVER put your face inside the

barbecue body.

2. Press igniter cap and look down at the gas collector

box. If a spark is present the electrode tips are properly

positioned.

3. If no spark is seen, then the spark gap shown below

needs to be adjusted as follows:

• Using an adjustable wrench, loosen the inside nut just

until the gas collector box can be manoeuvred and

turned upward.

The gap between the spark electrode tip and spark

receiver should be approximately 5 mm.

• If the gap is wider the 5 mm use a pair of long nose

pliers and gently squeeze the gas collector box until

the gap is correct.

• Return the gas collector box to its original horizontal

position, secure the inside nut and try the electrode

check again.

MAIN BURNER ELECTRODE CHECK

Gas collector box

Inside nut

5 mm spark gap Spark electrode tip

4. Adjust the gap using needle nose pliers. DO NOT

adjust the gap by hand or touch the white ceramic

electrode insulator. Using one set of needle nose pliers,

securely hold the electrode as shown above. With

another set of pliers, gently bend the tip end of

electrode to within 5 mm of the stainless steel screen.

Be careful not to puncture the screen or break electrode

tip.

5. Try spark electrode test again. Re-adjust if necessary.

Page 15

Check and ensure that each burner is properly located

over each orifice prior to installing the flametamer.

1. The flametamer is designed to reduce flaring.

Place the flametamers on the lower edge above

burners. Flametamers must always be located under

the grillplate.

2. Position the cooking plates as shown below.

3. Place the secondary cooking rack into the slots

on the barbecue body rails.

INSTALLING COOKING COMPONENTS

Place heat shield into pull-out grease draining tray. The

heat shield must be present and centred for your safety.

Slide the pull-out grease draining tray into the tracks on

the trolley side panels and push until it stops.

See diagram 18.

With the grease tray fully pushed in, install the 2 x M5

winged screws into the weld nuts located on the

underside of the grease tray rails. These can be accessed

from the inside of the cabinet and are approximately

85 mm from the front.

NOTE: The grease tray must be properly installed and

fully pushed in when the barbecue is operating.

INSTALLING PULL-OUT GREASE TRAY

Cooking

grid

Secondary

cooking rack

Slots for rack

Flametamer

Pot support

Hotplate

Side burner

Diagram 14.

INSPECTION

15

15

CONTENTS OF FAT/GREASE

DRAINING TRAY AND FAT/GREASE

RECEPTACLE MAY BE VERY HOT

DURING COOKING.

ALLOW TO COOL COMPLETELY

BEFORE DISPOSING OF THE

CONTENTS.

LINING THE FAT/GREASE

RECEPTACLE WITH ALUMINIUM FOIL

ENABLES EASIER CLEANING.

REMEMBER:

REPLACE FAT/GREASE

DRAINING TRAY FOIL REGULARLY.

AFTER CONTINUOUS USE, FAT AND/

OR COOKING JUICES MAY BUILD UP.

TO AVOID ANY FLARE-UPS, IT IS

RECOMMENDED THAT THE

FAT/GREASE TRAY AND RECEPTACLE

BE EMPTIED REGULARLY.

!

DO NOT GRIP THE LEFT SIDE SHELF

TO ALTER ITS POSITION; ALWAYS

GRIP THE STAINLESS STEEL HANDLE

ON THE RIGHT SIDE OF BARBECUE

TO CHANGE ITS POSITION.

!

Page 16

The fats and juices that drip from the meat may cause

flare-ups. Since flare-ups impart the distinctive taste

and colour for food cooked over an open flame, they

should be expected and encouraged within reason.

Nevertheless, uncontrolled flaring can result in a ruined

meal.

FLARE-UPS

OPERATION

16

16

Before first use and at the beginning of each barbecue

season:

1. Please read

Safety, Lighting and Operating

Instructions

carefully.

2. Check gas valve orifices, burner tubes and burner

ports for any obstructions

eg. spiders, webs, insects.

3. Check and ensure the gas cylinder is full.

4. Ensure all connections are securely tightened.

Check for gas leaks.

See page 3.

NOW YOUR BARBECUE IS READY TO USE

1. Open barbecue hood before attempting to light

burners.

2. Set control knobs to

‘OFF’

and open the gas cylinder

valve.

3. Push and turn the required

control knob to

‘HI’.

4. Immediately press the

continuous spark igniter

for 3 - 4 seconds to light the

burner.

5. If the burner does not light,

turn the control knob to

‘OFF’, wait 5 minutes for

gas to clear, then retry.

6. Once the burner is ignited,

the adjacent burner can be

lit by simply turning its control knob to ‘

HI’.

7. Adjust control knobs to your desired cooking

temperature.

8. If ignition cannot be achieved, perform ignition

check procedure.

Refer page 14.

MAIN BURNER IGNITION

THE HOOD MUST BE IN THE OPEN

POSITION, FOR LIGHTING

DO NOT SMOKE AT ALL TIMES WHEN

ATTEMPTING TO IGNITE BARBECUE.

CAUTION:

DO NOT MOVE TROLLEY

WHILE BARBECUE IS IN OPERATION

!

CAUTION: DO NOT LEAVE THE

BARBECUE UNATTENDED WHEN

BURNER/S IS ALIGHT.

!

ANY OF THE FOLLOWING SIGNS MAY

INDICATE THAT THE APPLIANCE IS

NOT OPERATING PROPERLY AND MAY

NEED SERVICING:

• EXCESSIVE YELLOW FLAME

• IRREGULAR SIZE OF FLAME

ACROSS BURNER

•‘POPPING’ OF FLAME

• SOOTING

• ABNORMAL NOISE(S)

• HISSING SOUND

NOTE:

Before requesting service,

please refer to page 19 ‘If Barbecue Fails to

Operate Properly’

!

If for some reason, igniters fail to produce a spark at the

electrode, barbecue can be lit carefully with a match.

To light barbecue with a match, refer previous

steps. Insert match into lighting stick provided and

insert lit match through lighting hole located on left side

of barbecue body, after turning the left burner control

to the

‘HI’ position.

Sequentially light the remaining burners from left

to right.

MANUAL IGNITION

NEVER LEAN OVER THE BARBECUE

COOKING AREA WHILE LIGHTING THE

APPLIANCE.

KEEP YOUR FACE AND BODY AT A SAFE

DISTANCE (AT LEAST 450 mm) FROM THE

MANUAL LIGHTING HOLE OR BURNERS.

!

Page 17

NOTE: The location of the rotisserie burner makes it

more susceptible to wind conditions that will decrease

the performance of your rotisserie cooking. For this

reason you should not operate the rotisserie burner

during windy weather conditions.

1. Open barbecue hood before attempting to light

rotisserie burner.

2. Set control knobs to

‘OFF’ and open the gas cylinder

valve.

3. Push and turn rotisserie burner control knob to ‘

HI’.

4. Then immediately press the continuous spark

igniter for 3 - 4 seconds to light the burner.

5. If the burner does not light, turn the control knob

to ‘

OFF’, wait 5 minutes, then retry.

6. Once the burner is ignited, the rotisserie burner

will reach cooking temperature quickly. The

orange/red glow will even out in about 5 minutes.

7. For best results, always rotisserie cook with the

hood down.

NOTE: If extra heat is required, then any of the main

burners may be used on the ‘LOW’ setting only.

ROTISSERIE BURNER IGNITION

OPERATION

17

17

CAUTION: IF BURNERS GO OUT

DURING OPERATION, CLOSE GAS

SUPPLY AT SOURCE, AND TURN ALL

BURNER CONTROLS OFF.

OPEN HOOD AND WAIT 5 MINUTES

BEFORE RE-ATTEMPTING TO LIGHT

(ENSURE ACCUMULATED GAS FUMES

HAVE CLEARED).

CAUTION:

SHOULD A GREASE FIRE

OCCUR, ATTEMPT TO CLOSE GAS

SUPPLY AT SOURCE, TURN OFF ALL

BURNERS AND REMOVE FOOD

IF POSSIBLE.

KEEP THE VENTILATION OPENINGS OF

THE CYLINDER ENCLOSURE FREE AND

CLEAR FROM DEBRIS.

!

THE SIDE BURNER IS DESIGNED FOR USE

WITH A WOK UP TO 360 mm DIAMETER,

AND COOKING PAN OF UP TO 200 mm

DIAMETER.

USE OF VERY LARGE POTS MAY RESULT

IN DISCOLOURATION OF THE SURFACE

FINISH, OR CAUSE POOR COMBUSTION.

!

1. Open side burner lid before attempting to light

side burner.

2. Set control knobs to

‘OFF’ and open the gas cylinder

valve.

3. Push and turn the control knob for side burner to

‘HI’.

4. Immediately press the continuous spark igniter for

3 - 4 seconds to light the burner.

5. If the burner does not light, turn the control knob

to

‘OFF’, wait 5 minutes, then retry.

6. Adjust control knob to your desired flame level.

SIDE BURNER IGNITION

BURN-OFF

Before cooking on your barbecue for the first time,

burn-off any residual oils or foreign matter from the

cooking plates.

ENSURE THE HOOD IS OPEN, and

operate at

‘HI’ setting for approximately 15 minutes.

Allow to cool then wash grillplates/hotplate thoroughly

with soap suds and scrubbing brush. Rinse thoroughly

and wipe clean with a cloth.

PREHEATING

It is necessary to preheat the barbecue before

cooking. Operate the burners under the cooking surface

to be used at

‘HI’ for approximately 10 minutes before

cooking. Hooded barbecues should be pre-heated with

the hood down.

OPERATING PROCEDURE

‘HI’ setting – Use this setting only for warm up, for

searing steaks and chops, and for burning food residue

from the plates after the cooking is over. Rarely, if ever,

do you use the ‘

HI’ setting for extended cooking.

‘MED’ setting (mid-way between ‘HI’ and ‘LOW’).

Use this setting for most grilling, and for cooking

hamburgers and vegetables.

‘LOW’ setting – Use this setting when cooking very

lean cuts such as fish.

Actual cooking surface temperatures vary with

outside temperature and the wind conditions.

COOKING TEMPERATURES

Page 18

OPERATION

18

18

Cooking with the hood in the closed position helps to

cook food more quickly than in conventional open-style

barbecues with a lid. The hood

(when closed) helps to

retain the heat more evenly and conserves energy. For

the best cooking results, always use the burners on

‘MED’ or ‘LOW’ and use the indirect cooking method

(explained below) when the hood is down. High direct

heat on the cooking plates when the hood is down may

result in burnt food, or damage to your barbecue.

The following methods are referred to as

‘INDIRECT

COOKING’

. Poultry and large cuts of meat cook slowly

to perfection on the barbecue by indirect heat.

The heat from the selected burners circulates gently

throughout the barbecue, cooking the meat or poultry

without any direct flame touching it. This method

greatly reduces flare-ups when cooking extra fatty cuts,

because there is no direct flame to ignite the fats and

juices that drip during cooking.

REMEMBER: Only use burners on ‘LOW’ for indirect

cooking. Only use outside burners for indirect cooking.

Remove solid hotplate from barbecue body and

position grillplate and flametamers over centre burners.

With the hood open, ignite the outer left and right

burners. Once ignition is established, close the hood.

Leave the burners on ‘

HI’ for 10 minutes or until the

temperature reaches a suitable level for cooking.

Modulate the required temperature by turning the

outermost burners progressively to

‘MED’ or ‘LOW’.

Do not ignite the burners directly under the meat.

Food should be positioned in the centre position either

in a shallow ovenproof dish or a disposable aluminium

foil to retain juices for basting.

Extremely large cuts of food, such as turkey may be

placed in the baking dish directly over the flametamer .

BARBECUING WITH THE HOOD DOWN

NEVER USE ANY BURNER, OR

COMBINATION OF BURNERS ON ‘HI’

WHEN COOKING WITH THE HOOD

DOWN.

!

ROTISSERIE COOKING

Rotisserie cooking produces foods that are moist,

flavourful and attractive. The rotisserie system is most

commonly used for cooking meat or poultry and is

designed to cook food from the rotisserie burner using

infrared heat. The rotisserie burner is an infrared type,

which provides intense searing radiant heat. The

intense heat sears in the natural juices and nutrients

found in quality cuts of meat.

The cooking times on a rotisserie will vary

accordingly depending on the size and the cut of the meat.

BALANCING THE FOOD

In rotisserie cooking, balancing the food is of utmost

importance. The rotisserie must turn evenly or the

stopping and starting action will cause the food to cook

unevenly and possibly burn the heavier side.

The easiest foods to balance are those of uniform

shape and texture. To test if the food is balanced

correctly when secured, place the ends of the rotisserie

spit loosely in the palms of your hands. If there is no

tendency to roll, give the spit a quarter turn. If it is still

stable, give it a final quarter turn. It should rest without

turning in each of these positions.

To load the spit rods, begin with handle in place on

slot located in barbecue side panel. Slide one of the

holding forks

(with prongs facing away from the handle)

onto the spit rod. Push the spit rod through the centre

of the food to be basted, and then slide the second

holding fork,

(prongs toward the food) onto the spit rod.

It is very important to centre and balance the food to be

cooked on the spit rod, then push the meat holding

forks firmly together. Tighten the wing nuts with pliers.

It may also be necessary to wrap the food with butcher

string

(never use plastic or nylon string) to secure any

loose portions.

A rolled piece of meat requires the rotisserie skewer

to be inserted through the centre of the length of meat,

then secured and balanced.

For meats that contain bones, it is best to secure the

rotisserie skewer diagonally through the meaty sections.

If protruding bones or wings brown too quickly, cover

with pieces of foil.

GUIDE TO ROTISSERIE COOKING

WITH THE ROTISSERIE BURNER

Page 19

FAULT FINDING

19

19

1. Turn off gas at source, turn burner control to ‘OFF’.

2. Wait five minutes before trying again.

3. Check gas supply/connections.

4. Repeat lighting procedure and, if barbecue still

fails to operate properly,

TURN OFF GAS AT

SOURCE, TURN BURNER CONTROLS TO ‘OFF’,

wait for barbecue to cool and check the following:

a) Misalignment of burner tube(s) and over orifice(s).

CORRECTION: Reposition burner tube to properly

sit over orifice.

b) Obstruction in gas line

CORRECTION: Remove hose from barbecue.

DO NOT SMOKE! Open gas supply for one second

to blow any obstruction from fuel hose. Close off

gas supply at source and reconnect hose to barbecue.

c) Blocked orifice

CORRECTION: Remove grillplates, flametamers,

fat/grease draining tray. Remove burners from

bottom of barbecue body by pulling cotter pin from

beneath burner ‘foot’ using a screwdriver or needle

nose pliers.

See burner diagram on page 14. Carefully

lift each burner up and way from gas valve orifice.

Remove the orifice section of gas valve from each

gas valve and gently clear any obstruction with a

fine wire. Re-install each orifice section, re-install

burners over orifices and place each burner ‘foot’

into mounting bracket at bottom of barbecue body.

Replace cotter pins. Replace cooking components,

fat/grease draining tray.

d) Misalignment of igniter on burner

CORRECTION: Check for proper position of

electrode tip. The tip of the electrode should be

pointing toward the tip of the collector box. The

gap between the spark electrode and the tip of the

gas collector box should be 5 mm. Adjust if

necessary by carefully pressing the gas collector

closer to the spark electrode.

If re-ignition is necessary while the barbecue is still

hot, you must wait for a minimum of five minutes

before commencing to re-ignite.

(This allows accumulated

gas to clear).

If all check/corrections have been made and

barbecue still fails to operate properly, consult your

place of purchase, or contact the manufacturer.

IF BARBECUE FAILS TO OPERATE PROPERLY

BEWARE OF SPIDERS.

BURNER TUBES SHOULD BE

INSPECTED AND CLEANED

PERIODICALLY.

SPIDERS AND SMALL INSECTS CAN

OCCASIONALLY SPIN WEBS OR MAKE

NESTS IN THE BURNER TUBES.

THESE WEBS CAN LEAD TO A GAS

FLOW OBSTRUCTION WHICH COULD

RESULT IN A FIRE IN AND AROUND

THE BURNER TUBES.

THIS TYPE OF FIRE IS KNOWN AS

‘FLASH-BACK’ AND CAN CAUSE

SERIOUS DAMAGE TO YOUR

BARBECUE AND CREATE AN UNSAFE

OPERATING CONDITION FOR THE USER.

ALTHOUGH AN OBSTRUCTED BURNER

TUBE IS NOT THE ONLY CAUSE OF

‘FLASH-BACK’ IT IS THE MOST

COMMON CAUSE AND FREQUENT

INSPECTION AND CLEANING OF THE

BURNER TUBES IS NECESSARY TO

PREVENT ITS OCCURRENCE.

!

SAFETY POINTS

• Do not operate damaged rotisserie.

• Do not use rotisserie in poor weather conditions.

• Avoid contact with hot surfaces.

• Always load rotisserie to barbecue before switching

motor on.

• Always turn rotisserie

‘OFF’ before removing from

barbecue.

• Do not leave rotisserie on barbecue when not in use.

LOADING THE SPIT RODS

• Assemble rotisserie rod as shown.

• Centre food on the spit rod.

• Use butcher string to secure loose portions.

Rotisserie is available as an optional extra from your place of

purchase.

ROTISSERIE

Occasionally check burner

flame for correct operation

as shown

. Either view

flame through manual

lighting opening on left

side of barbecue body

panel or remove cooking

plates

.

VISUALLY CHECKING BURNER FLAMES

Page 20

MAINTENANCE

20

20

To reduce the chance of flash-back, the procedure below

should be followed at least once a month in late summer

or early autumn when spiders are most active, or when

your barbecue has not been used for an extended period

of time.

1.

Remove grillplates, flametamers, fat/grease draining

tray from barbecue body.

2. Remove burners from bottom of barbecue body by

unscrewing the burner securing screw at the burner

‘foot’ using a screwdriver.

3. Carefully lift each burner up and away from gas

valve orifice.

We suggest several different ways of cleaning the

burner tubes. Use the procedure most convenient for

you:

Bend a stiff wire

(a light weight coat hanger works

well)

into a small hook. Run the hook through each

burner tube and into the burner several times.

CLEANING THE BURNER TUBES AND

BURNER PORTS (TO PREVENT FLASH-BACK)

OR Using a narrow bottle brush with a flexible handle

(do not use a brass wire brush), run the brush through

each burner tube and into the burner several times.

OR Use an air hose to force air through the burner tube

and out through the burner ports. Observe each

port and make sure air comes out every hole. Wear

eye protection.

NOTE: Do not use compressed air with injectors.

Regardless of which burner cleaning procedure

you use, we recommend that you complete the following

steps to help prolong burner life.

1. Wire brush entire outer surface of burner to

remove food residue and dirt.

2. Clean any blocked ports with a stiff wire such as an

open paper clip.

3. Inspect the burner for damage

(cracks or holes) and

if such damage is found, order and install a new

burner. After installation, check to ensure that gas

valve orifices are correctly placed inside ends of

burner tubes. Also check position of spark electrode.

If fire occurs in and around the burner tubes, immediately

turn off gas at its source and turn the burner control(s)

to

‘OFF’. Wait until the barbecue has cooled, then clean

the burner tubes and burner ports as described,

opposite.

FLASH-BACK

As with all appliances, proper care and maintenance will

keep them in top operating condition and prolong their

life. Your new gas barbecue is no exception. By

following these cleaning procedures on a timely basis,

your barbecue will be kept clean and working properly

with minimum effort.

CARE AND MAINTENANCE

After cooking, turn burner controls to ‘OFF’ and let

barbecue cool before attempting to clean your cooking

plates.

Before first use and periodically it is suggested that

you wash the cooking plates in a mild soap and warm

water solution. You can use a wash cloth, a vegetable

brush, or steel wool to clean your barbecue plates if you

desire.

CLEANING THE COOKING PLATES

Washing the flametamer after every use is not necessary

but periodically it is suggested you clean off any

build-up of food residue. Use a wire brush to remove

stubborn burnt on cooking residue.

Dry the flametamer thoroughly before re-installing it

into the barbecue body.

NOTE: Flametamers are coated with a ceramic material

which can be easily damaged if not handled with care.

CLEANING THE FLAMETAMER

The fat/grease draining tray should be emptied and

wiped down periodically and washed in a mild detergent

and warm water solution. Lining the tray with aluminium

foil will enable easier cleaning.

CLEANING THE FAT/GREASE DRAINING TRAY

Follow the instructions provided on page 11.

IGNITION BATTERY REPLACEMENT

Page 21

MAINTENANCE

21

21

INTERIOR:

1. Turn the burner controls to ‘OFF’ position.

2. Turn the cylinder valve off fully.

3. Detach the regulator assembly from cylinder valve.

4. Remove and clean the cooking plates, flametamers

and burners.

5.

Cover the gas valve orifices with a piece of aluminium

foil.

6. Brush the inside and bottom of the barbecue with a

stiff wire brush, and wash down with a mild soap

and warm water solution. Rinse thoroughly and

let dry.

7. Remove aluminium foil from orifices and check

orifices for any obstruction.

8. Check spark electrode, adjusting as instructed.

Electrode tip pointing toward the bottom of gas

collector and approximately 5 mm from the bottom

of collector box.

9. Replace burners and adjust spark electrode collector

box.

10. Replace flametamer, plates and warming rack.

11. Reconnect to gas and observe burner flame for

correct operation.

As with all appliances, proper care and maintenance

will keep them in a top operating condition and prolong

their life. Your barbecue is no exception. By following

these cleaning procedures on a timely basis, your

barbecue will be kept clean and working properly with

minimum effort.

EXTERIOR:

Your gas barbecue is made of durable grade stainless

steel, it should provide you with years of trouble-free

service.

Refer to care of stainless steel, opposite.

DO NOT USE OVEN CLEANER

TO CLEAN THE BARBECUE.

!

Burning-off the barbecue after cooking will keep it

ready for instant use, however, once a year you should

give the entire barbecue a thorough cleaning to keep it

in top operating condition.

ANNUAL CLEANING OF BARBECUE BODY

The stainless steel over time will be affected by ‘tea

staining’

(the brown discolouration of some stainless steel).

Tea staining can be reduced by washing the surface

with mild detergent and warm water. This should then

be followed by rinsing with clean cold water. We

recommend the surface then be wiped dry with a clean

cloth.

CARE FOR STAINLESS STEEL SURFACE

We recommend that you minimise the unit’s exposure

to the elements. High moisture content in the air

(rain,

mist, salt spray etc.)

can affect metal components of this

appliance and lead to material breakdown. If left in an

area subjected to high moisture content, we strongly

recommend that you observe the cleaning procedure on

a regular basis and cover the appliance whilst not in use

(covers are available as an optional extra if not supplied with

the appliance)

. Material breakdown from high moisture

conditions can be avoided if the appliance is well

protected from the weather and regular cleaning is

carried out.

STORAGE

IN COASTAL AREAS, FREQUENT

CLEANING AND THE USE OF A COVER

IS RECOMMENDED TO PROLONG THE

LIFE OF THE APPLIANCE.

SALTY AIR WILL ADVERSELY AFFECT

EXPOSED PARTS.

!

Page 22

OUTDOOR AREAS

22

22

The following diagrams are examples of outdoor areas. The same principles apply to shaded areas.

Page 23

RINNAI NEW ZEALAND. LTD

Head Office: 691 Mt. Albert Rd, Royal Oak, Auckland.

PO Box 24-068.

Tel (09) 625 4285. Fax (09) 624 3018.

Internet: www.rinnai.co.nz

Email: sales@rinnai.co.nz

For your local

Service Centre

contact: 0800 RINNAI (0800 746624).

Customers in Australia, refer to back cover.

23

23

✁

YOUR DETAILS

Mr Mrs Ms Other:

Surname: Given name:

Address:

Suburb/Town: P/code:

Telephone ( ) A/H, Bus:

YOUR BARBECUE DETAILS

Date of purchase:

Place of purchase:

Serial No. located on front/side panel:

ADDITIONAL DETAILS

(Optional questions to assist our continuous improvement program)

Before this purchase, were you aware of Rinnai? Yes No

If yes, were you aware that Rinnai produced

an extensive barbecue range? Yes No

What was your final choice based on?

Colour Price Features Style Other:

Were you recommended to this product by

Retailer Friend Advertising Past Experience Other:

Did you previously own a barbecue? Yes No

If yes, what kind? Portable Kettle Inbuilt

Volcanic Rock/Charcoal Same Other:

If you changed, why?

Your age 20-25 26-30 31-35 36-40 41-45 46-50 50+

✁

YOUR DETAILS

Mr Mrs Ms Other:

Surname:

Given name:

Address:

Suburb/Town:

State: P/code:

Telephone ( )

A/H, Bus. ( )

YOUR BARBECUE DETAILS

Date of purchase:

Place of purchase:

Serial No. located on front/side panel:

ADDITIONAL DETAILS

(Optional questions to assist our continuous improvement program)

Before this purchase, were you aware of

Rinnai Aust? Yes No

If yes, were you aware that Rinnai

produced an extensive barbecue range? Yes No

What was your final choice based on?

Colour Price Features Style Other:

Were you recommended to this product by

Retailer Friend Advertising Past Experience

Other:

Did you previously own a barbecue? Yes No

If yes, what kind? Portable Kettle Inbuilt

Volcanic Rock/Charcoal Same Other:

If you changed, why?

20-25 26-30 31-35 36-40 41-45 46-50 50+

All personal information collected through this request is primarily for

purposes of enquiry warranty information. From time to time Rinnai

may be running special product promotional or product servicing offers.

If you would like to receive any informational on these offers please tick

this box .

For more information regarding our privacy statement, please contact our

privacy officer on (03) 9721 6625 during business hours or write to

PO Box 460, Mordialloc VIC 3195.

Your

age

Page 24

PART NO. P80140004A Printed 6/2003 All specifications are subject to change without notice.

Freepost Rinnai NZ Ltd

Marketing Department

P O Box 24068

Royal Oak

Auckland

Rinnai Australia has a service network in most states.

Our service network personnel are fully trained and

equipped to give the best service on your Rinnai appliance.

If your barbecue needs service please ring one of the

contact numbers on this page.

RINNAI AUSTRALIA PTY. LTD. ABN 74 005 138 769

Rinnai

Help Line: 1 300 366 388, 8.30am - 6.00pm EST Mon - Fri

(Cost of a local call. Higher from mobile or public phones).

Internet: www.rinnai.com.au

e-mail: enquiry@rinnai.com.au

Head Office:

Sales,

Spare Parts 10-11 Walker Street, Braeside, Vic 3195.

& Service: Tel 1 300 366 388. Fax (03) 9271 6611.

N.S.W. Branch:

Sales & 62 Elizabeth St, Wetherill Park, NSW 2164.

Service: Tel (02) 9609 2888. Fax (02) 9609 5260.

S.A. Branch:

140 Days Rd, Ferryden Park, SA 5010.

Tel 1300 366 388. Fax (03) 9271 6611.

W.A. Branch:

Sales & 18 Belgravia St, Belmont, WA 6014.

Service: Tel (08) 9479 9479. Fax (08) 9277 2531.

QLD Branch:

Sales & 1/6 Booran Dve, Logan City, QLD 4114.

Service: Tel (07) 3209 4622. Fax (07) 3209 4722.

Tasmania: Contact Rinnai Melbourne on

Sales &

Service: Tel 1300 366 388. Fax (03) 9271 6611.

OUR BRANCHES

Delivery Address:

PO Box 460

MORDIALLOC VIC 3195

Rinnai Australia Pty Ltd

Reply Paid 460

MORDIALLOC VIC 3195

No stamp required

if posted in Australia

Loading...

Loading...