Page 1

HOME OWNER / INSTALLER

FOR YOUR SAFETY

THIS MANUAL MUST BE READ IN ITS

ENTIRETY BEFORE OPERATING HEATER

IB35ETRN

IB35ETRLC

Gas Radiant Space Heater

Owners Operation and Installation Manual

WARNING: If the information in these instructions are not

followed exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

xz

Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in

your building.

• Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

This appliance is only for use with the type of gas indicated on

the rating plate.

This appliance is not convertible for use with other gases.

INSTALLER: MUST LEAVE THIS MANUAL WITH THE UNIT AFTER INSTALLATION

OWNER: RETAIN THIS MANUAL SAFELY, FOR FUTURE REFERENCE

Page 2

LIMITED W ARRANTY

RINNAI FIREPLACE HEA TER

WHA T IS COVERED?

This Warranty covers any defects in materials or workmanship, subject to the terms stated below. This

Warranty extends to the original purchaser and subsequent transferees, but only while the product remains at

the site of the original installation. This Warranty only extends through the first installation of the product and

terminates if the product is moved or reinstalled at a new location.

HOW LONG DOES COVERAGE LAST?

Item Period of Coverage

All Parts and Components 2 Y ears from Date of Purchase

WHA T WILL RINNAI DO?

Rinnai will repair or replace the product or any part or component that is defective in materials or workmanship,

except as set forth as follows. Rinnai will pay reasonable shipping costs, provided you obtain prior authorization

from an Authorized Rinnai Distributor . Rinnai will not pay labor charges associated with the repair or replacement

of the product or any part or component. All rep air parts must be genuine Rinnai parts. All repairs or replacements

must be performed by an individual or servicing company that has been authorized by Rinnai or its distributor .

Replacement of the product or replacement of the heat exchanger may be authorized by Rinnai only . Rinnai

does not authorize any person or company to assume for it any obligation or liability in connection with the

replacement of a product or heat exchanger. If Rinnai determines that repair of a product is not possible,

Rinnai will replace the product with a comparable product, at Rinnai’s discretion.

HOW DO I GET SERVICE?

Y ou must contact an Authorized Distributor or Installer for the repair of a defective product under this W arranty .

Failure to contact an Authorized Distributor or Inst aller will void the Warranty . For the name of the Authorized

Distributor or Installer nearest you, please contact your local HV AC dealer or gas service technician, visit the

Rinnai website (www.rinnai.us), call Rinnai at 1-800-621-9419 or write to Rinnai, 103 International Drive, Peachtree

City, Georgia 30269.

Proof of purchase is required. You can show proof of purchase with a dated sales receipt, or by completing

and mailing the enclosed Warranty registration card within 30 days of purchasing the product. Please complete

the enclosed Warranty registration card and mail it to Rinnai at the address shown on the card. Receipt of this

card by Rinnai will constitute proof-of-purchase for this product. However, return of this W arranty registration

card is not necessary in order to validate this Warranty .

WHAT IS NOT COVERED?

This Warranty does not cover any failures or operating difficulties due to accident, abuse, misuse, alteration,

misapplication, force majeure, improper installation, improper maintenance or service, or for any other causes

other than defects in materials or workmanship. This warranty does not apply to any product whose serial

number or manufacture date has been defaced.

Rinnai is not liable for any special, incidental, indirect or consequential damages that may arise, including

damage to person or property, loss of use, or inconvenience. Some states do not allow the exclusion or

limitation of incidental or consequential damages, so the above limitation may not apply to you.

LIMIT ATION ON IMPLIED W ARRANTIES

Any implied warranties of merchantability and fitness arising under state law are limited in duration to the

period of coverage provided by this limited Warranty , unless the period provided by st ate law is less. Some

states do not allow limitations on how long an implied Warranty lasts, so the above limitation may not apply

to you.

This Warranty gives you specific legal rights, and you may also have other rights which vary from state to

state.

2

Page 3

W ARNING

IMPROPER INST ALLATION, ADJUSTMENT , AL TERA TION, SERVICE OR

MAINTENANCE CAN CAUSE PROPERTY DAMAGE, PERSONAL INJURY OR

LOSS OF LIFE.

INST ALLATION AND SERVICE MUST BE PERFORMED BY A QUALIFIED

INST ALLER, SERVICE AGENCY OR THE GAS SUPPLIER.

This manual applies to the following models only:

IB35ETRBN/US IB35ETRSN/US

IB35ETRBL/US IB35ETRSL/US

Inbuilt Fire ETR

Electronic Timer Remote

Table of Contents

Limited warranty ............................................................................................................2

Contacts ........................................................................................................................3

Specifications................................................................................................................4

Dimensions ...................................................................................................................4

Important points / usage and installation musts ...............................................................5

T echnical specifications .................................................................................................7

For your safety read before operating heater..................................................................8

Control panel layout........................................................................................................9

Operation.......................................................................................................................9

Location.........................................................................................................................13

Venting ..........................................................................................................................15

Gas connection..............................................................................................................15

Log installation...............................................................................................................16

T esting and commissioning............................................................................................17

Maintenance instructions................................................................................................ 18

Wiring diagram ..............................................................................................................20

PCB layout.....................................................................................................................20

Wiring diagram-ladder ...................................................................................................21

Trouble shooting ............................................................................................................21

Error codes....................................................................................................................22

Exploded diagrams........................................................................................................23

Parts list.........................................................................................................................25

Installation notes ............................................................................................................27

Installation / commissioning checklist .............................................................................31

Installer details ...............................................................................................................31

CONTACTS

zx

America Corporation

103 International Drive

Peachtree City

Georgia 30269

3

1-800-621-9419

www.rinnai.us

Page 4

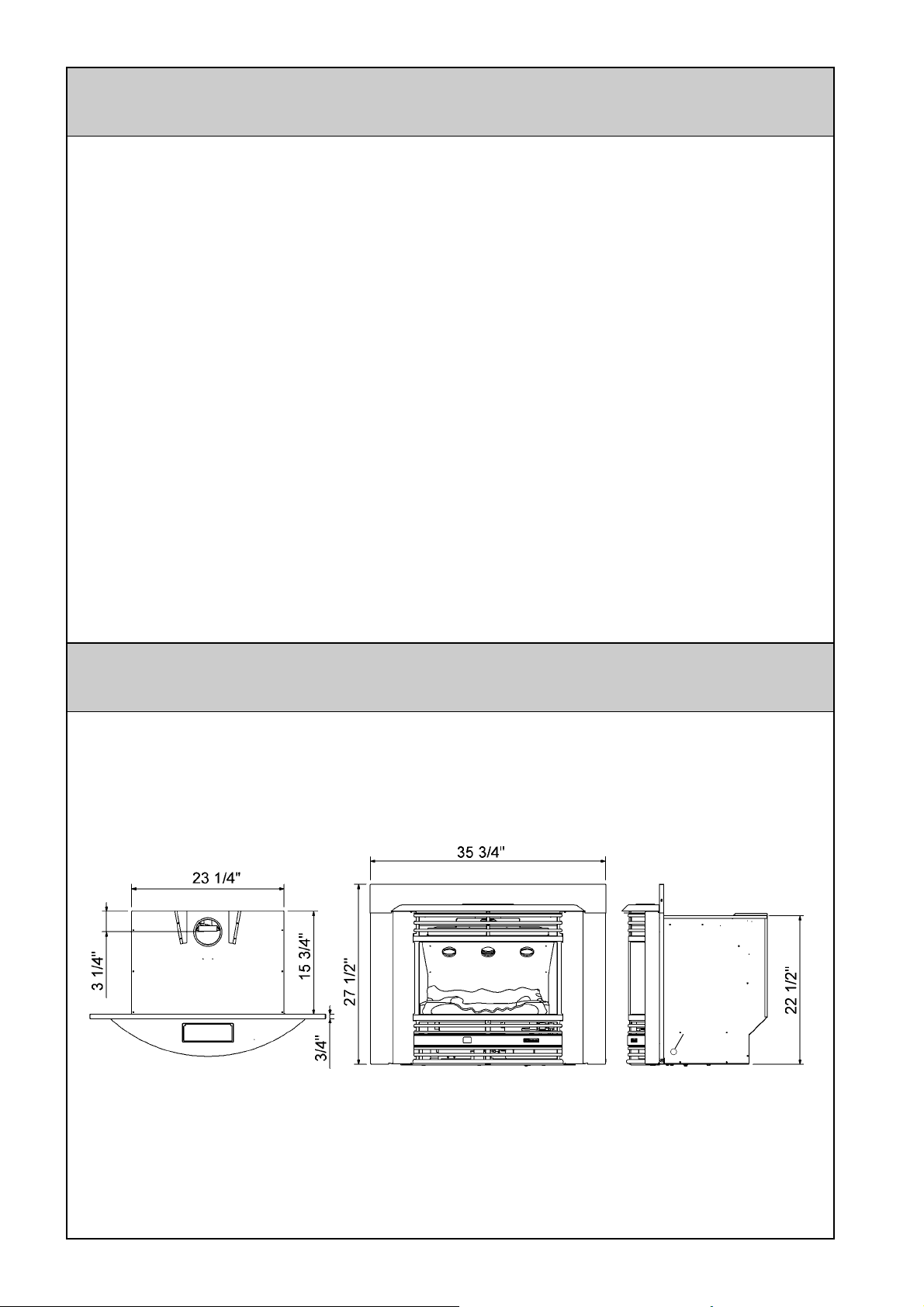

SPECIFICATIONS

Model: IB35ETRBN/US, IB35ETRSN/US (NG) United S tates

IB35ETRBL/US, IB35ETRSL/US (Propane) United S tates

Description: Freestanding radiant/convector, glass-fronted, ceramic log sp ace

heater with forced convection and natural draft flue system

Gas Control: Electronic control valve

Burners: Ember bed flame and heat burner

Warm Air Discharge: T op front louvres

Flue: Natural draft. Approved 4” B vent system

Ignition: Electronic spark

Power Supply: 120V . 60Hz

Rating Plate Location: Bottom right hand side door, inside

Weight: 1 19 lb

DIMENSIONS

Gas inlet

3/8” MNPT

4

Page 5

IMPORT ANT POINTS / USAGE AND INST ALLA TION MUSTS

Unpack the heater and check for damage (DO NOT INST ALL DAMAGED HEA TER). If the

heater is damaged, contact your supplier for advice. Before installing the heater , check the

label for the correct gas type (see rating plate, bottom right hand side of pillar). Refer to local

gas authority for confirmation of the gas type if you are in doubt.

Included in the carton

Customer operation information.

IMPORTANT

Before using this product, please read this manual carefully to ensure proper use of the product:

1 The installation must conform with local

codes, or in the absence of local codes,

the National Fuel Gas Code, ANSI

Z223.1, or the Canadian Installation

Code, CAN/CGA -B149.

2 For information on gas type see the data

plate on the heater.

3 This heater must not be installed where

curtains or other combustible materials

could come into contact with it. In some

cases curtains may need restraining.

4 If you move, check the gas type in the

area where you are moving to. The local

gas authority will be able to advise on

local regulations.

5 This heater discharges a large volume

of warm air to provide even heat

distribution. If the air in the room

contains cooking vapor or cigarette

smoke, and the heater is used on a

carpet, the surface of the carpet may

become discolored. In addition, some

nylon carpets contain dyes which may be

affected by the warm air flow . Some soft

vinyl surfaces are also subject to

distortion, or discoloration by warm air.

T o prevent discoloration of carpets, etc.,

a mat should be placed in front of the

appliance, extending about 30” in front

of it.

6 This heater must be installed on a hearth

at least 2” thick and the width and depth

of the heater.

7 Read these rules and the instructions

carefully . Check all local codes. Failure

to follow these could cause a malfunction

of the heater resulting in death, serious

bodily injury and/or property damage.

8 This appliance is only for use with the

type of gas indicated on the rating plate.

This appliance is not convertible for use

with other gases.

9 WARNING: Any change to this heater

or its controls can be dangerous.

10 If a gas leak is suspected, turn heater

off, turn gas supply valve off at appliance

connector valve. Open windows to

ventilate area immediately and contact

your dealer or gas company .

11 DO NOT PLACE CLOTHING OR

FLAMMABLE MATERIALS,

GASOLINE AND OTHER FLAMMABLE

V APORS AND LIQUIDS, ON OR NEAR

THE HEA TER.

12 Do not spray aerosols when the heater

is in operation.

13 YOUNG CHILDREN SHOULD BE

CAREFULLY SUPERVISED WHEN

THEY ARE IN THE SAME ROOM WITH

THE HEA TER.

14 LPG containers must not be installed

indoors.

15 Do not use this appliance if any part has

been under water. Immediately call a

5

Page 6

qualified service technician to inspect

the room heater and to replace any part

of the control system and any gas control

which has been under water.

16 Adequate clearances for accessibility for

purposes of servicing and proper

operation should be provided.

17 Adequate clearances around air

openings into the combustion chamber

should be provided.

18 Do not install in areas where curtains,

drapes, clothing, or other moving

flammables are within 15 inches of this

unit.

Diagram shows

minimum

clearances from

12”

LEFT

36”

CEILING

combustible

materials

36”

FRONT

12”

RIGHT

19 Periodic examination of the venting

system is required.

20 The flow of combustion and ventilation

air should not be obstructed.

21 A manufactured home (USA only) or

mobile home OEM installation must

conform with the Manufactured Home

Construction and Safety St andard, Title

24CFR, Part 3280, or, when such a

standard is not applicable, the St andard

for Manufactured Home Installations,

ANSI/NCSBCS A225.1 or Standard for

Gas Equipped Recreational Vehicles

and Mobile Housing, CSA Z240.4.

22 The appliance and its appliance main

gas valve must be disconnected from the

gas supply piping system during any

pressure testing of that system at test

pressures in excess of 1/2 psi (3.5 kPa).

The appliance must be isolated from the

gas supply piping system by closing its

equipment shutoff valve during any

pressure testing of the gas supply piping

system at pressures equal to or less than

½ psi (3.5 kPa).

23 The draft hood on the appliance should

be installed in the same atmospheric

pressure zone as the combustion air inlet

to the appliance and shall be located so

that the relief opening is accessible for

checking vent operation.

24 The appliance, when installed, must be

electrically grounded in accordance with

local codes or, in the absence of local

codes, with the National Electrical

Code, ANSI/NFP A 70, or the Canadian

Electrical Code, CSA C22.1

25 A gas appliance must not be connected

to a chimney flue serving a solid fuel

burning appliance.

26 Do not restrict the warm air discharge

by placing articles in front of heater.

27 This appliance must not be used for any

purpose other than heating.

28 Do not allow anyone to post articles

through the louvres.

29 Do not allow anyone to sit or lean

against the appliance.

30 DUE TO HIGH TEMPERATURES, THE

APPLIANCE SHOULD BE LOCATED

OUT OF TRAFFIC AND AW AY FROM

FURNITURE AND DRAPERIES.

31 CHILDREN AND ADULTS SHOULD BE

ALERTED TO THE HAZARDS OF

HIGH SURFACE TEMPERATURES

AND SHOULD ST A Y A W A Y TO A VOID

BURNS OR CLOTHING IGNITION.

32 CLOTHING OR OTHER FLAMMABLE

MA TERIAL SHOULD NOT BE PLACED

ON OR NEAR THE APPLIANCE.

33 INSTALLA TION AND REP AIR SHOULD

BE DONE BY A QUALIFIED SER VICE

PERSON. THE APPLIANCE SHOULD

BE INSPECTED BEFORE USE AND

AT LEAST ANNUALLY BY A

PROFESSIONAL SERVICE PERSON.

MORE FREQUENT CLEANING MAY

BE REQUIRED DUE TOO

EXCESSIVE LINT FROM CARPETING

6

Page 7

BEDDING MA TERIAL, ET CETERA. IT

L

IS IMPERATIVE THAT CONTROL

COMPARTMENTS, BURNERS AND

35 Do not substitute glass, glowing embers

or logs. Use only glass, glowing embers

and logs supplied by manufacturer.

CIRCULATING AIR PASSAGEWAYS

OF THE APPLIANCE ARE KEPT

CLEAN.

34 The glass window shall be replaced as

one piece as supplied by the

manufacturer. See log and glass

installation on page 17.

36 Caution: Do not operate unit with broken

glass.

37 WARNING: DO NOT OPERATE

APPLIANCE WITH THE FRONT

REMOVED, CRACKED OR BROKEN.

REPLACEMENT OF THE GLASS

SHOULD BE DONE BY A LICENSED

OR QUALIFIED SERVICE PERSON.

TECHNICAL SPECIFICA TIONS

Nat u ral Gas Propane

Gas I n put Rate: Btu /h r Btu /h r

Pilot: 200 200

Low: 11,000 11,000

High: 32,000 32,000

Minimum permissible

gas su pply pressure for

pu rpose of input

adjustment

Gas Connection:

Fl ue Termination:

Fan:

Combustion System:

Ignition System:

Operati on:

Temperature control: Electronic thermostat High ~Low / Off

Tem perature range: Low = 50°F, 60° F~ 80°F, H igh 97°F

Safety Devices:

Fan delay Micro computer timer

Combustion Method:

Flue Type:

Heat transfer:

Ins tallation Type:

Flue Requir em ent:

Min: 7" 10 "

Max: 10.5" 13"

3/8" MN PT

An approved 4" vent cap must be fitted to all installations

90 Watt 2 speed tangen tial

Multi por t burn e r and ce ramic lo gs

Contin uou s spark electronic ignition

Finger touch control buttons or remote cont rol

Flame pictu re selec t option

Up / Down buttons

Flame failure- fl ame rod

Over heat - th ermistors, thermal fus e

Power surge - 3 amp fuse

Room overheat - Automatic cut off at 104°F after 10 minutes

Naturall y aspir ated bu rner

Approved B vent s yst em

Direct radiation and f o rced convection

Inbuilt

Manu facturers minimum, 10 ft vertical.

ocal codes may have a great er

requirement and must be followed

WC WC

7

Page 8

FOR YOUR SAFETY READ BEFORE OPERATING

WARNING: If you do not follow these instructions exactly, a fire or explosion

may result causing property damage, personal injury or loss of life.

A This appliance is equipped with an

ignition device which automatically

ignites the pilot.

Do not try to light the

pilot by hand

B. BEFORE OPERA TING smell all around

the appliance area for gas. Be sure to

smell next to the floor because some

gas is heavier than air and will settle on

the floor.

WHA T T O DO IF YOU SMELL GAS

• Do not try to light any appliance

• Do not touch any electrical switch

• Do not use any phone in your building

• Immediately call your gas supplier from

OPERATING INSTRUCTIONS

a neighbour’s phone. Follow the gas

suppliers instructions.

• If you cannot reach your gas supplier call

the fire dept.

C.Use only your hand to push the gas

control buttons. Never use tools. If the

buttons will not activate by hand, don’t

try and repair it, call a qualified service

technician. Force or attempted repair

may result in a fire or an explosion.

D. Do not use this appliance if any part has

been under water. Immediately call a

qualified service technician to inspect

the appliance and to replace any part

of the control system and any gas control

which has been under water.

STOP Read the safety information

above.

• T o turn the unit on (Refer to diagram

below)

Do not attempt to light the pilot by hand.

Wait for five minutes to clear out any gas.

Then smell for gas, including near the

floor . If you smell gas, STOP! Follow

“B” in the safety information above. If you

don’t smell gas, go to the next step.

Press the On / Off button. This operates

the ignition sequence.

TO TURN OFF GAS TO APPLIANCE

If the appliance does not light it will

automatically turn off.

To re-attempt ignition, press the On / Off

button again.

• T o adjust the heat

Press the “ “ and “ “ buttons to

increase and decrease the room

temperature setting.

• T o turn the unit off

Press the On /Off button. The appliance will

turn off.

If the appliance will not operate; follow the

instructions “to turn off the gas to appliance”

and call your service technician or gas

supplier .

Turn off the appliance by operating the On/

Off button and turn off the power at the wall

switch.

Disconnect the electric plug. This will

isolate the gas supply and prevent the

solenoid valve from opening.

8

Page 9

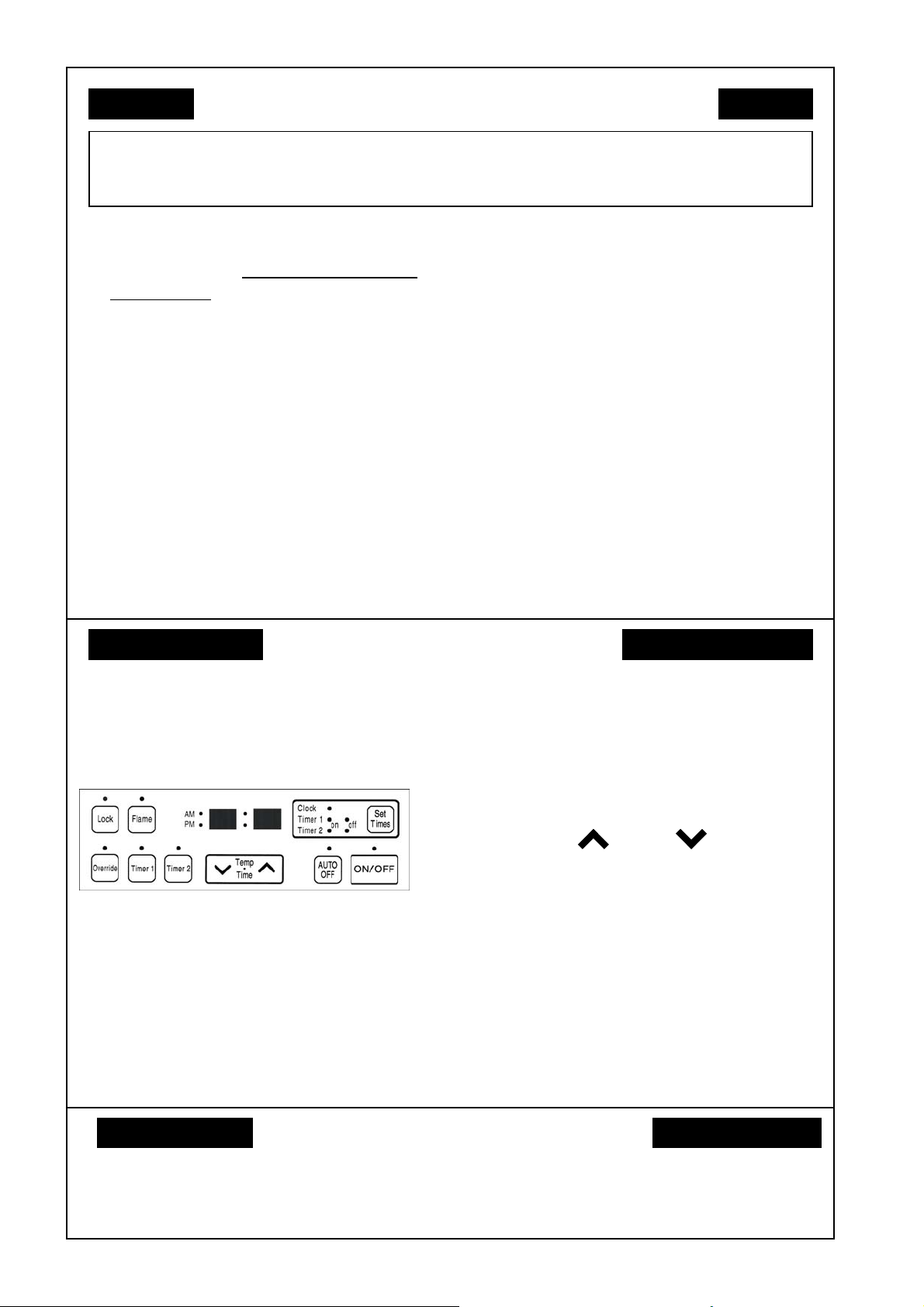

CONTROL P ANEL LA YOUT

For your convenience the controls on your new Flame Fire are situated under the cover on the

top right-hand side of the fire and are accessed by simply lifting the lid. All necessary

adjustments to the operation of your fire can be made with these controls.

OPERATION

• TURNING ON

Press the ON/OFF button to operate the

unit. The ON indicator will glow green. The

spark generator will be heard before the

burner ignites and the ON indicator glows

red, indicating that the burner is alight.

Warm air can be felt coming from the

louvres. The fan will come on automatically

after 4 minutes.

If the unit does not ignite on initial use

this may be due to air remaining in the

gas supply line. The spark generator

will only continue for 15 seconds. Af ter

this it will be necessary to press the

ON/OFF button OFF, then ON again.

• TURNING OFF

fan is running.

• ROOM TEMPERATURE

ADJUSTMENT

The room temperature and preset

temperatures are only displayed and

adjustable while the heater is running.

Press the “ “ button to increase the

temperature setting or “ “ button to

decrease the temperature setting. The

temperatures can be preset to:

a) [L] low (50°F)

b) [61°F] to [79°F] in 1°F steps

c) [H] (97°F)

Once the pre-set temperature has been

reached the burners will cycle between high

and low (or high and pilot only depending

on the auto off setting).

Simply press the ON/OFF button to switch

off the unit. The ON indicator will go out.

The convection fan will continue to operate

for several minutes after the burner has

gone out in order to cool the appliance.

Do not turn off the heater by

unplugging it from the wall. Do not

unplug the heater while the convection

• LOCK

The LOCK function will help prevent

accidental operation of the controls.

LOCK is activated by pressing the button

and the LOCK indicator will glow. To

9

Page 10

deactivate the LOCK press and hold the

button for 3 seconds until the indicator

goes off.

During normal operation the LOCK may be

activated and all controls, other than the

OFF switch, will be locked. Deactivating

the LOCK releases the controls.

you have selected AM or PM as required,

a small indicator on the left hand side of

the Digital Display indicates the AM/PM

setting.

Use the buttons again to set the minutes.

Scroll up or down using the buttons until

the correct time is reached.

If the LOCK is activated while the unit is

turned OFF , then all functions will be locked

including the ON/OFF function. If the unit

is turned OFF while the LOCK is activated,

it cannot be turned ON again until the

LOCK is deactivated.

• FLAME

T o operate the FLAME function, press the

FLAME button. This function will

automatically override the thermostat and

set the unit to a default Medium High heat

setting for full visual flame effect.

• AUTO OFF

AUTO OFF is activated by pressing the

button and the AUTO OFF indicator will

glow when on.

When the AUTO OFF function is on and

the room temperature reaches or exceeds

the pre-set temperature then the burners

will reduce to pilot only .

Press the TIMER SET button five times to

lock in the time. The CLOCK and TIMER

indicators will go out. A small indicator on

the digital display will flash to show that the

clock is operating.

• TIMERS / PREHEAT

This heater has two programmable timers,

these allow you to set a start and finish

time. The temperature is preset each time

the timers are activated.

There is also a preheat function that

measures the temperature of the room and

estimates the time it will take to bring the

room up to the preset temperature by the

programmed start time.

This means that the heater may start

heating an hour or more before the

programmed start time.

• PROGRAMMING THE ON / OFF

TIMERS

When the AUT O OFF is off then the burners

will reduce to the front (ember) burner and

pilots.

• SETTING THE CLOCK

When the appliance is first plugged in or

after a power failure, the Digital Display will

show

Press the SET TIMES button once, the

Clock indicator will flash. Press and hold

the “ “or “ “ button, the minutes will

begin to count up or down until they reach

00, the time will now change by one hour

increments.

Release the button when the correct hour

shows on the Digital Display . Confirm that

--:--.

Before programming the Timers you must

ensure that the clock has been set to the

correct time.

Press the SET TIMES button twice. The

digital display will show AM 6:00 and the

TIMER 1 - ON indicator will flash.

Set the desired start time the same way

as for setting the clock. Be aware that the

heater may start up much earlier than the

programmed start time due to the preheat

function, as explained earlier.

Press the SET TIMES button again, the

TIMER 1 - OFF indicator will flash.

Set the desired stop time the same way

as for setting the clock.

Press the SET TIMES button once to

10

Page 11

proceed to TIMER 2 - which is

programmed in the same way - or three

times to return to the clock display. This

must be done within 1 minute of setting the

time to lock it into the memory .

The digital display will show the current

time. A small indicator on the digital display

will flash to show that the display has

returned to the clock.

After setting timer 2 the SET TIMES button

must be pressed once within one minute

of programming to lock in the times and

return to the clock display .

The timers operate over a 24 hour period,

and will activate 7 days a week when set.

• OPERATING THE TIMERS

again when the power comes back on, but

the time will be slow by the duration of the

power failure. To set the clock to the

correct time after the power has come

back on, simply follow the instructions on

page 9.

• OVERRIDE

This function is intended to be used to

manually override the current operation of

the heater. For example; If the heater is in

stand-by mode (ie. between finishing time

and starting time of a timer), and the

OVERRIDE button is selected, then the

heater will begin to operate and heat the

room.

Press the OVERRIDE button to activate.

The indicator light will flash when active.

Before operating the timer(s), the clock

time must be correct and a starting time

and finishing time for the timer(s) must be

programmed, see page 9. Both timers

operate in the same way .

Ignite the heater and select the preset

temperature as for normal operation.

Press the timer 1 and / or timer 2 button(s).

The timer indicator(s) will glow and the unit

will change to stand-by mode. The burners

will extinguish and the ON indicator will

change from red to green. The display will

show the start time for the selected timer

briefly before returning to the clock display .

When the heater is in stand-bys mode, you

can display and change the clock and the

on and off times for both timers in the same

way as described earlier .

The timers can be deactivated by either

pressing the timer button(s) that you want

to deactivate or by turning the heater off

using the ON/OFF button.

NOTE: If there is a power failure, the

system memory will retain the Timer

programs, and the clock will stop at the

time the power goes off. The clock will start

To manually deactivate the OVERRIDE

press the OVERRIDE button again. The

OVERRIDE indicator will go out, and the

heater will return to stand-by mode.

The heater will continue to operate on

OVERRIDE until the OVERRIDE button is

pressed again, or one of the timers takes

over the operation of the heater. This

means that the OVERRIDE mode will

automatically turn off if a programmed

starting time is reached. The heater will

then return to operating at times

programmed into the timer(s). T urning the

heater off will also deactivate the

OVERRIDE.

• REMOTE CONTROL

The remote control can only be used for

manual operation of the heater. If the

heater is in stand-by (timer) mode then only

the OFF button will work. Pressing the OFF

button when the heater is in stand-by mode

will deactivate the timers and the heater

can now be operated manually .

The ON and OFF buttons on the remote

work in the same way as the ON / OFF

button on the control panel as do the “

“ and “ “ buttons.

11

Page 12

ON BUTTON

Operates the unit

manually .

OFF BUTTON

Stops unit

manually .

TEMPERA TURE

ADJUSTMENT

Increases or

decreases

the temperature

setting.

NOTE: Some fluorescent lights may

interfere with the transmission of remote

control signals, in this case changing the

position from which you are operating the

remote control may help.

Avoid getting the remote control wet, or

dropping it.

The remote control works within 15 feet and

an angle of 40° to the receiver on the unit.

• TO REPLACE REMOTE CONTROL

BATTERY

The battery is held in a clip that slides out

the bottom of the remote control. The clip

is removed by inserting a coin or similar

into the recess in the back of the remote

control and sliding downwards.

The battery must be of type CR 2032 and

will only operate if installed the right way

up, as shown below .

Remove the battery if the remote control is

not going to be used for a long period. This

will help avoid damage from leaking

batteries.

REMOTE CONTROL

BACK

BA TTERY

Note the + side of the battery is

facing the rear of the remote

control

12

Page 13

LOCA TION

When positioning the heater, the main points governing the location are:

1. Flue connection and proper venting

2. Warm air distribution.

3. Adequate air supply .

4. The heater must not be installed where

curtains or other combustible materials

could come into contact with it. In some

cases, curtains may need restraining.

See below for minimum clearances

required.

36”

12”

CEILING

LEFT

12”

RIGHT

36”

FRONT

• Mantles

A mantle is allowable providing that it is

outside the minimum clearances and the

distance it protrudes is no more than half

the distance it is above the heater .

See diagram below

5. The heater is not designed to be built

into bookcases or shelves or any

combustible opening.

6. Check that room ventilation complies

with local regulations.

7. This heater must be mounted on a

hearth not less than 2” thick and at least

the width and depth of the heater .

8. Installation location shall provide

adequate combustion and ventilation air.

9. A gas appliance must not be connected

to a chimney flue serving a separate

solid-fuel burning appliance.

10. Before installing the heater , inspect the

chimney, flue piping and/or solid fuel

burning fire place and remove any

combustible materials.

11. A zero clearance kit is available from

your gas appliance retailer .

• Fireplace

Cutting any sheet metal parts of the

fireplace, in which the gas fireplace insert

is to be installed is prohibited.

Refractory, glass doors, screen rails,

screen mesh and log grates can be

removed from the fireplace before

installing the gas fireplace insert.

13

Page 14

• Fireplace dimensions

There are two types of installation that may be used with this heater .

• Non-combustible (masonry , brick etc) fire place.

• Zero clearance kit installation, for installation in combustible materials.

In each case there are minimum and maximum dimension that the fire place or opening must

fall within, as shown in these diagrams.

Solid Fuel Burning Fireplace

6” minimum

chimney flue

This may require a sheet of noncombustible material to be laid under the

heater or a layer of cement to be poured

on the hearth.

The fireplace flue damper can be fully

blocked open or removed for installation

of the gas fireplace insert.

The fireplace and fireplace chimney must

be clean and in good working order and

constructed of non-combustible materials.

For a non-combustible fire place, the hearth

must be not less than 2” thick and at least

the width and depth of the heater . The base

where the heater is to sit must be flat with

no protrusions that could damage the base

of the heater.

Combustible installation

For combustible installations a zero

clearance kit must be used.

Make sure that chimney cleanouts fit

properly.

Refractory, glass doors, screen rails,

screen mesh and log grates can be

removed from the fireplace before

installing the gas fireplace insert.

Smoke shelves, shields and baffles may

be removed if attached by mechanical

fasteners.

Cutting any sheet metal parts of the

fireplace, in which the gas fireplace insert

is to be installed is prohibited.

14

Page 15

VENTING

Use only an approved B vent system.

An approved chimney liner must be

used.

It is recommended that the flue be

installed vertically only. If installation

prevents this then there must be

at

least 4 feet of vertical flue before any

bends. The flue must not fall below

horizontal at any stage. There must

not be more than 2 bends in any

system. Any horizont al section of flue

must be less than 1/3 the length of

vertical flue which follows it.

See diagram

An approved B vent system must be

attached by mechanical means to the flue

spigot and sealed using an approved high

temperature sealant.

**

X

X/3 maximum

10 ft

4 ft

minimum

maximum

2 bends

Minimum **

** Refer to local codes for other minimum

requirements.

GAS CONNECTION

• RUN GAS SUPPLY

For pipe sizing, refer to your local gas

installation codes.

• PURGE SUPPLY OF AIR AND

DEBRIS

All foreign materials such as filings must

be purged from the gas supply , as they may

cause the gas valve to malfunction.

A means to measure the gas pressure

immediately upstream of the supply

connection to the appliance shall be

provided by the installer.

Use a soapy solution on all gas

connections. Leaks will be visible when the

soapy solution forms bubbles. When

finished wipe soapy solution with rag to

remove residue.

3/8 MNPT

Connect and tighten union.

On completion of work, check for gas leaks.

15

Page 16

ELECTRICAL CONNECTION

There is a junction box provided at the front

of the heater for the electrical connection.

WARNING: This appliance must be

properly grounded for your protection

against shock hazard.

Connecting the power supply:

Refer to the diagram opposite,

1 Open the side doors.

2 Loosen the screws holding the front

panel in place.

3 Remove the front panel by sliding to one

side to release it and then sliding back

again to release the other end. T ake care

not to place strain on the wires from the

remote control receiver on the front panel.

4 Remove the three lowest louvres from

the heater by sliding to one side to release

the end and then sliding back again to

release the louvre completely .

7 Once all three connections have been

made, make sure that all connections are

safe and that the power connections cannot

come into contact with the appliance

casing.

5 Remove the two screws holding the front

cover of the junction box in place and

remove the cover. A hole is provided on

the right hand side of the junction box for a

suitable electrical gland to be attached and

the electrical supply to pass through.

6 There are two wires (one black, one

white) that have been partially bared inside

the box and a grounding (earth) pole with

a green wire attached. It is important that

the power supply is connected to the

correct wires and that the appliance is

properly grounded by attaching a ground

connection to the grounding pole.

Black wire = Hot (1 15V AC 60Hz)

White wire = Neutral

Replace the cover on the junction box and

reassemble the heater in the opposite

order .

T ake care not to trap or damage any wires

when reassembling the appliance.

WARNING: Failure to properly ground this

appliance with affect its operation and may

cause damage to the appliance or

personal injury .

16

Page 17

LOG INST ALLA TION

The logset is packed inside the unit and

the packaging must be removed prior to

installing the logset in its correct position.

• Open both side panels.

• Remove fasteners on both sides of the

top glass retainer .

• Lift retainer away from unit.

• Loosen screws on bottom glass retainer.

• Carefully lift glass out of bottom channel.

• Carefully remove log packaging.

The logset has two holes underneath for

location onto the pins inside the unit.

Place the logset into the unit ensuring that

the locating pins enter the two locating

holes on the bottom face of the logset.

Gently place loose ember bed material

in front of the front log only. Do not

pour as dust particles from the plastic

bag may block the burner ports.

Level it with a pencil or screwdriver and

remove excess material. Note: The ember

bed material must be placed after the logs

are fitted. If the logs are to be removed for

any reason, the ember bed material must

be removed first and replaced after the

logs are refitted. Any material that prevent s

the logs sitting flat on the burner top can

upset the burning pattern and performance

of the heater.

• Replace glass and top glass retainer,

tighten bottom glass retainer screws.

Note: Fit glass so that the joint in the glass

seal is at the bottom.

• T ake care not to damage seals.

WARNING: Failure to position the parts

in accordance with these diagrams or

failure to use only parts specifically

approved with this appliance may result in

property damage or personal injury .

• Reinstall side panels.

Note: When first lighting the heater, the

logs need to be burnt in, which may take

approximately 2 hours. The flame color

may change after the initial burning in

period.

17

Page 18

TESTING AND COMMISSIONING

• TESTING PROCEDURE

Turn gas supply on and plug the unit into

the power supply . (Caution 1 15V)

• TO CHECK BURNER PRESSURE

• Refer to rating plate.

• Remove the wiring cover panel.

• Remove test point plug and attach

manometer to test point.

The test point is on the front injector

block.

• Light heater, turn to High heat setting and

check pressure.

• If adjustments are necessary, the

regulator is situated on the front of the

gas control.

• After checking pressure, turn the unit off,

remove manometer and replace test

point plug.

• Turn the heater on and of f a few times to

check ignition.

It is the responsibility of the installer

to check that under normal operating

conditions of the appliance, all flue

gases are exhausted to the outside

atmosphere and that there is no

spillage of combustion gases into the

room.

COMMISSIONING

• INSTALLATION / COMMISSIONING

CHECKLIST

Complete the installation checklist and the

installer details on page 31 and make sure

that this instruction book is left with the

customer .

• INSTRUCT CUSTOMER ON USE OF

UNIT

Explain to the customer about use and care

of unit. Make sure the customer

understands the instructions.

• EXPLAIN

Ignition (on / off), adjusting heat level,

programming timers, flame setting, auto

off, lock, override and the remote control.

• When you are satisfied that the heater is

working correctly , reassemble panels.

• All burner aeration is factory preset and

cannot be adjusted.

• If you are unable to get the unit to operate

correctly, refer to Troubleshooting on

Page 22 before contacting your local

service contact as listed on Page 3.

• It may take approximately 2 hours for the

logs to achieve their full flame pattern

and glow.

• During the initial burning in period,

some smoke and smell may be

experienced. The heater should be run

on the high position in a well ventilated

room until these dissipate.

NOTE:

THE MANUFACTURE RESER VES THE

RIGHT TO CHANGE OR MODIFY

SPECIFICA TIONS WITHOUT NOTICE

18

Page 19

MAINTENANCE INSTRUCTIONS

IMPORTANT MAINTENANCE INSTRUCTIONS

ANNUAL INSPECTION

The unit should be inspected at least once

a year by a qualified service technician

including inspection of the flue system.

The appliance area must be kept clear and

free from combustible materials, gasoline

and other flammable vapors and liquids.

• CLEANING INSTRUCTIONS.

Before cleaning, make sure the electrical

power and gas are turned off and that the

unit has cooled down.

WARNING:Do not clean the glass or unit

when hot.

Do not remove any internal wiring covers.

Do not use abrasive cleaners.

Do not use solvent based cleaners.

A heater should not be used if you suspect

there may be a problem, and a service

agent must be called to investigate the

cause of the problem.

The main burners are designed to produce

some yellow flame but should not produce

smoke or excessive soot.

Normal

Abnormal

• OUTER CASE

The outer case of the fire place should be

cleaned with a soft, damp cloth.

Do not use aerosol polishes to clean the

casing while the fire is in operation. Do

not damage or distort any part of the heater .

Do not use wet cloth or spray cleaners on

burners.

• VENT MAINTENANCE

The flue should be inspected annually for

blockages and signs of damage.

• VISUAL INSPECTION OF FLAME

Check that the pilot and burner flames are

operating normally .

If the flames appear either very short or very

long and streaky or are producing smoke

or soot deposits then there may be a

problem with the heater or the gas supply .

Normal

Abnormal

NOTE:

The flames may take up to 15 minutes to

settle from ignition when heater is cold

19

Page 20

• ELECTRIC MOTOR MAINTENANCE

Motors are permanently lubricated and

need no lubrication.

Keep fan and motor free of dust and dirt,

clean annually .

The heater should be serviced

annually only by an authorised person.

• GLASS REPLACEMENT AND

CLEANING. (May be performed by the

owner)

It is best to handle the glass with clean

gloves to avoid smearing the glass with

finger prints which might show after

replacement.

Refer diagram opposite

Open the side panels.(1) Access can now

be obtained to the two top glass retaining

screws.(2)

Gently lift the retaining trim away from the

glass.(3)

Carefully lift the glass out of the bottom

retaining channel, taking care not to

damage the fiber seal on the perimeter of

the glass.(4)

The glass may be cleaned with a damp

sponge and soapy water. If the seal is

damaged it should be replaced. Remove

any soot deposit from the log set with a

soft brush and a vacuum cleaner. Soot

deposit may indicate that the flue is not

drawing properly . Check the flue for correct

operation.

It is best to handle the glass with clean

gloves to avoid smearing the glass with

finger prints which might show after

replacement.

• BURNERS

Due to the design of the burners in this

heater , they do not require cleaning by the

owner. The burners should be cleaned

once a year by a qualified service agent.

FAN REMOVAL Refer diagram below

NOTE: The fan has a permanently

lubricated bearing. DO NOT OIL.

NOTE:

When replacing the glass make sure that

the joint of the fiber seal is at the bottom of

the glass.

20

Page 21

WIRING DIAGRAM

PCB LA YOUT

Caution: Label all wires prior to

disconnection when servicing

controls. Wiring errors can cause

improper and dangerous

operation.

Verify proper operation after

servicing.

21

Page 22

WIRING DIAGRAM-LADDER

TROUBLE SHOOTING

SYMPTOM CA US E SOLUTION

No power present Ensure power cord is plugged in and turned on

No gas present Ensure gas supply is turned on

Bu rn e r will n o t lig h t

Smell of gas Leaking gas Turn gas off at meter and call installer

Fan not working

Fan does not stop Heater cooling down

Small soot deposit Normal operation No action required

Soot deposit forming on

glass or logs

Condensation on glass Normal operation Allow fire to warm up

Streaky lines on glass N ormal operation Remove and clean glass

power cut Re-ignite after power is restored

Air in gas pipe Purge air (installer)

Ignition failure Repeat lighting procedure.

H e a te r still wa rmin g u p

Inadequate flue system

Log misalignment Call service department/agent

I n correct g a s pressu r e

The fan is programmed to start after the heater has

been operating for 4 minutes.

The fan is programmed to continue running for 4

minutes after the burners have been extinguished

Digital error message on

control panel

NOTE:

If you have any other faults or problems, please refer to your Installer or local qualified service agency

Electronic fault detected Refer Error Messages page 23

22

Page 23

ERROR CODES

• ERROR CODE MESSAGE

The Flame Fire ETR has the ability to check its own operation continuously . If a fault occurs,

an Error Message will flash on the Digital Display of the control panel. This assists with

diagnosing the fault, and may enable you to overcome a problem without a service call. Please

quote the code displayed when enquiring about service.

Error code Probable cause Comments

11

12

14

16

31

32

33

70

71

72

I gnition failu re

Flame f ail ure

Overheat Serv ice cal l

Room overheat

Room t emper atu r e sensor fau lty

Overheat t em per at ure sensor f aulty Serv ice cal l

faulty ON / OFF sw itch Serv ice call

Faul t y solen iods Serv ice cal l

Fau lty flame rod Serv ice call

Check gas is turned on.

Serv ice cal l if r epeat ed

Check gas is turned on.

Serv ice cal l if r epeat ed

Lower r om t em per aure t o

less t h an 104° F

Service call

Service call

73

99

--:--

In all cases, you may be able to clear the Error Message simply by turning the unit OFF , then

ON again. If the Error Message still remains or returns on the next operation, please contact

your nearest service contact and arrange for a service call.

Communication error Serv ice call

Flue bloc k Service cal l

Power f ailure Serv ice call

23

Page 24

EXPLODED DIAGRAMS

24

Page 25

25

Page 26

PARTS LIST

ITEM NO. QTY. PART NO.

1 1 7993-1 FLUE SPIGOT ASSY NAT IB USA

2 1 7074 HEAT EX CHANGER FRONT ASSY 3+3H

3 1 7075 HEAT EXC H A N GER REAR ASSY 3H

4 6 6624 BURNER EXCHANGER TRANSFER T UBE

5 2 6625 BURNER HEAT EXCHANGER BRACKET

6 1 7927 COM B C H AMB ASSY IB ETR USA PAI

7 1 7616V FRONT PANEL IB35ETR VIPER BLACK

1 7616SP FRONT PANEL IB35ETR SP SILVER

8 1 7141 FAN QLN65/0030-3038LH MVL 110V

9 9 7130 FAN M TG SLEEVE

10 9 7129 FAN MTG GROMMET

11 9 9028 SCREW 8X5/8 MUSH HEAD 33611923

12 3 6651 CUSHION RUBBER REH 210

13 1 7950 INJECTOR BLOCK BRKT FRONT MKII

14 1 7951 INJECTOR BLOCK BRKT REAR MKII

15 1 7338 INJECTOR BRAY 260 CAT33 MULTI NG

1 7175 INJECTOR BRAY 120 CAT23 SINGLE LP

17 1 7337 INJECTOR BRAY 560 CAT33 MULTI NG

1 7183 INJECTOR BRAY 200 CAT33 MULTI LP

19 1 7906 INJECTOR BRAY 180 CAT23 SINGLE NG

1 7173 INJECTOR BRAY 95 CAT23 SINGLE LP

20 6 9064 SCREW M4 X 8 PHPMZ SPRINGWASH

21 2 7870 PILOT BODY TOP CONVERTIBLE

22 2 7871 PILOT CONVERTIBLE HOOD 2 FLAME

23 2 7875 ELECTRODE

23 2 7520 THERMOCOUPLE

24 2 7876 ELECTRODE NUT (S.I.T)

25 2 7872 INJECTOR NG 51 NG

2 7873 INJECTOR LPG 31 LP

27 2 7900 ELECTRODE NUT ETR

28 2 7902 SPACER ELECTRODE PILOT

29 2 7986 ELBOW 6mmx1/8"BSPT BFM690602

30 1 7904 PILOT BRACKE T FRONT USA

31 1 7985 PILOT BRAC KET REAR ETR USA

32 1 7931 GAS SUPPLY TUBE A IBETR

33 1 7932 GAS SUPPLY TUBE B IBETR

34 1 7933 GAS SUPPLY TUBE C IBETR

35 1 7945-1 TUBE IBETR FRONT CUT

36 1 7946-1 TUBE CUT IBETR REAR

37 3 7952 INJECTOR BLOCK A+B

38 1 7924 FRONT BURNER US ASSY PAINTED

39 1 4990 MAIN BURNER NG USA FLAME NG

4990L MAIN BURNER LP USA FLAME LP

40 1 7044 CERAM IC LOG SET c/w G RANULES

41 1 6384 BURNER COSYPANEL

42 1 7276 BURNER BRACKET

43 1 7258 AERATION SLEEVE SHORT

44 2 7564 ELECTRODE SLEEVE

45 2 7240 LOG LOCATING SLEEVE

46 2 9115 SCREW M5 X 25 PHSMZ PHIL

47 7 7029 LOUVRE TU BE FS 9.5 GOLD BLACK

7 7029BN LOUV RE TUBE FS 9.5 BLK NICKE L SILVER

48 1 7099 LOUVRE TU BE RD 15.8 GOLD BLAC K

1 7099BN LOUVRE TUBE RD 15.8 BKL NICKLE SILVER

49 1 4996 GLASS PANEL ASSY IB/FS35

50 1 7004 BURNER DIVERT PANEL PTD ETR

51 1 7033 GLASS RET TOP ASSY PAINTED

52 1 7037 GLASS RET BOTTOM ASSY PAINTED

DESCRIPTION

26

Page 27

53 1 7920 FRONT PILOT SHIELD USA PAINTED

54 1 5327G BRAND BADGE GOLD

55 1 4993 GAS CONTROL ASSY NG US IB35ETR NG

1 4994 GAS CONTROL A SSY LP US IB35ETR LP

57 2 6308 O RING MAIN GAS

58 2 6313 GAS TUBE RETAINER

59 1 7536 RECEIV ER UNIT ETR-015X01

60 1 7537 RECEIV ER UNIT HOLDER 35ETR-016

61 1 7539 RECEIV ER COVER 35ETR-017

62 1 7542 SPA RK IGNITOR ETR EI-145

63 1 7544 PCB ASSY ETR 35ETR-020

64 1 7596 PCB MOUNTING BRKT PNT IB35ETR

65 1 7549 THERMISTOR OH SWIT.35ETR-023

66 1 7545 CONTROL UNIT A SSY 35ETR-010BX0 BLACK

1 7545S CONTROL UNIT 35ETR-010B SILV ER SILV ER

67 1 7541 REMOTE CONTROL 556F-2005

68 1 7899 TRA NSF. USA ETR ET-277 100V

69 2 7288 FAN MOUNTING BRACKET IBR

70 1 7072 FAN MTG PANEL IBR

71 1 7614 REGULATOR SUPPORT IB35ETR

72 1 7202 FAN PARTITION PANEL LOWER IBR

73 1 7610 GAS MANIFOLD MTG BRKT IB35ETR

74 1 7220 FAN DIVIDING PANEL BRKT IB

75 1 7858 FAN PARTITION PANEL IBR ETR US

76 1 7601-1 FAN GUIDE TOP NAT IB35ETR

77 1 7613 FAN DIVIDING BRKT RH IB35ETR

78 2 7554 CLIP THERMISTER CP-90125-2-B

79 1 7989 REAR PANEL IBR USA

80 1 7197 REAR TOP PANEL IBR

81 1 7198 REAR SIDE PANEL LH IBR

82 1 7563 BRACKET THERMA L FUSE IB35ETR

83 1 7621 THERMISTER BRKT REAR IB35ETR

84 1 7190V SURR TOP PANEL IBR VIPER BLACK

1 7190SP SURR TOP PANEL PAINTED IBR SP SILVER

85 1 7191V SURROUND LEFT HAND IBR VIPER BLACK

1 7191SP SURR LH PAINTED IBR SP SILVER

86 1 7192V SURROUND RIGHT HAND IBR V IPER BLACK

1 7192SP SURR RH PAINTED IBR SP SILVER

87 4 7177 DOOR SPRING IBR

88 1 7193V DOOR LH IBR VIPER BLACK

1 7193SP DOOR LH PAINTED IBR SP SILVER

89 1 7194V DOOR RH IBR VIPER BLACK

1 7194SP DOOR RH PAINTED IBR SP SILVER

90 1 7227 AIR GUIDE TOP IBR

91 1 7228 FRONT TRIM PAINTED IBR

92 2 7598 CABLE COVER PA INTED IB35ETR

93 1 7615V TOP PANEL A SSY IB35ETR VIPER BLACK

1 7615SP TOP PANEL A SSY IB35ETR SP SILVER

94 1 7230 FAN DIVIDING PANEL IBR

95 1 7617 PROTECTIVE SHIELD IB35ETR PNT

96 1 7857 FAN PARTITION PANL DGREASE USA

97 1 7221 FAN DISCHARGE GUIDE IBR

27

Page 28

INST ALLA TION NOTES

28

Page 29

INST ALLA TION NOTES

29

Page 30

INST ALLA TION NOTES

30

Page 31

INST ALLA TION / COMMISSIONING CHECKLIST

1. Was a fireplace inspection carried out?

(i.e. clearances, combustibles etc.)

2. Was a manufactured flue system installed?

3. Has specified gas pressure been set?

4. Are decorative logs located correctly on pins?

5. Have ember granules been placed and free of dust and

powder?

NO YES

6. Has appliance been sealed around the fireplace?

7. Has the appliance been test fired for correct operation

(All burners light without delay)

8. Is the end-user fully aware of operating procedure?

INST ALLER DET AILS

Company name: _______________________________________________________

Installers name: ______________________________________________________

Address: ______________________________________________________

______________________________________________________

Phone: __________________ Mobile: ___________________

Permit number for installation:_________________

Signed: __________________________ Date: ___________________

31

Page 32

zx

Part Number 7919B

Loading...

Loading...