Rinnai 26i, HD50i SERVICE MANUAL

INFINITY 26i and HD50i

SERVICE MANUAL

Infinity High Capacity Continuous Flow Gas Hot Water System

The Rinnai Infinity 26i and

Heavy Duty 50i water heater,

when correctly installed, comply

with the requirements of the

United Kingdom Water Regulations / Byelaws (Scotland).

These Products can be found

listed in the Water Fittings and

Materials Directory.

The Rinnai Infinity 26i water heater

is CE Marked for UK and Ireland as

allowed by Technigas of Belgium.

Certificate number E0716/5360

ID number 0461BO0739

Date of Issue 28 July 2003

Quality System Standard

ISO 9001 - 1994

The Design, Development, and Manufacture of Gas Water Heating Appliances

done under Rinnai’s Quality Management System is certified under the Quality

Management System Standard ISO 9001.

Registration Number JQ0003D

Registered since: February 1994

Certified by Japan Gas Appliances Inspection Association.

Produced by Rinnai Technical Services Department

August 2004 - Issue 1.

No portion or part of this manual may be copied without prior permission from Rinnai U.K.

Rinnai U.K. reserves the right to make modifications and change specifications without notice.

WARNING

Failure to comply with these instructions may result in serious personal injury or damage to the

appliance.

ALL WIRING INSIDE THIS APPLIANCE MAY BE AT 230 VOLTS POTENTIAL

ALL SERVICE WORK MUST BE CARRIED OUT BY AN AUTHORISED PERSON.

DO NOT TEST FOR GAS ESCAPES WITH AN OPEN FLAME

This manual has been published by Rinnai U.K. Technical Services. While many individuals

have contributed to this publication, it will be successful only if you - the reader and customer find it useful. We would like to extend an invitation to users of this manual to make contact with

us, as your feedback and suggestions are valuable resources for us to include as improvements.

Rinnai are constantly working toward supply improved appliances as well as information, and

specifications may be subject to alteration at any time.

Issue No1

Table of Contents

I

Glossary of Terms and Symbols .................................................................................. iv

1. Introduction ................................................................................................................ 1

2. Specifications ............................................................................................................. 2

3. Water Flow Rates and Pressures ................................................................................ 4

4. Dimensions ................................................................................................................ 8

5. Remote Controls ........................................................................................................ 9

6. Cutaway Diagram .................................................................................................... 13

7. Operational Flow Chart ........................................................................................... 14

8. Operation Principles ................................................................................................ 15

9. Main Components .................................................................................................... 16

10. Time Charts ............................................................................................................ 18

11. Wiring Diagram ..................................................................................................... 19

12. Dip Switch Settings ............................................................................................... 20

13. Fault Finding .......................................................................................................... 21

14. Component Circuit Value Tabl.e / and checks........................................................ 23

15. Maintenance Monitor / Error History ................................................................... 31

16. Gas Pressure Setting Procedure ............................................................................ 33

17. Gas Conversion Procedure .................................................................................... 35

18. Dismantling for Service ........................................................................................ 44

19. Exploded Diagram ................................................................................................ 50

20. Parts List ............................................................................................................... 54

21. SERVICE CONTACT POINTS ..........................................................................58

Infinity REU-V2632FFU / HD200I REU-V2632FFUC - iii - Issue 1 - 8/09/03 ©Rinnai

nfinity 26i and HD50i

Glossary of Terms and Symbols

I

dB(A) - sound pressure level in decibels, “A” range

DC - direct current

AC - alternating current

WFCD - water flow control device

FB - feedback information

FF - feedforward information

Hz - Hertz

IC - integrated circuit

kcal/h - kilocalorie per hour

kW - kilowatts

LED - light emitting diode

L/min - Litres per minute

mA - milliamps

mbar -millibars of pressure

mm - millimetres

bar

- gauge pressure

OHS - overheat switch

PCB - printed circuit board

CPU - central processing unit

POT - potentiometer

rpm - revolutions per minute

SV - solenoid valve

ø - diameter

o

C - temperature rise above ambient

'

POV - modulating valve

TE - thermal efficiency

TH - thermistor

T

IN

T

OUT

Infinity REU-V2632FFU / HD200I REU-V2632FFUC - iv - Issue 1 - 8/09/03 ©Rinnai

nfinity 26i and HD50i

- temperature of incoming water

- temperature of outgoing water

1. Introduction

I

The Rinnai Infinity hot water units represents the latest technology in continuous flow, temperature

controlled hot water.

Features

• The Infinity 26i and HD50i NEVER RUN OUT of hot water. Whilst electricity, water and gas

supplies are connected, hot water is available whenever hot water taps are open.

• Built into the main micro-processor is the facility to LIMIT THE MAXIMUM TEMPERATURE of

the hot water supplied. The water temperature may be limited to various maximum temperatures. This

is particularly useful when the hot water unit is installed where young children or the infirm may be

using the hot water. The Infinity is delivered with a maximum preset temperature of 55 C and the

HD50i at 65° C. If required, the temperature limits can be changed by a service technician. For

further information, please contact Rinnai.

• The Infinity is a power flued appliance. It is COMPACT, saving both floor and wall space.

• The temperature of outgoing hot water is CONSTANTLY MONITORED by a BUILT-IN SENSOR. If

the temperature of the outgoing hot water rises to more than 3 C above the selected temperature

q

shown on the Digital Monitor (or the pre-set limit when Remote Controls are not fitted), the burner will

automatically go out. The burner will ignite again once the outgoing hot water temperature falls below

the temperature shown on the Digital Monitor (or the pre-set limit).

q

• The burner lights automatically when the hot water tap is opened, and goes out when the tap is closed.

IGNITION IS ELECTRONIC, therefore there is not pilot light. When the hot water tap is off, no gas is

used.

• ‘Deluxe’ or ‘Standard’ Remote Controllers are available as an optional extra. Depending on the models

chosen, these offer the following additional features :

- Bath fill function

- Voice Prompting

- Localised Temperature Control for up to four controllers

- Clock

• Temperatures selected at the controllers are retained in the SYSTEM MEMORY.

• Operating NOISE LEVEL IS VERY LOW.

• ERROR MESSAGES ARE DISPLAYED on the Remote Controllers, assisting with service.

Infinity REU-V2632FFU / HD200I REU-V2632FFUC - 1 - Issue 1 - 8/09/03 ©Rinnai

nfinity 26i and HD50i

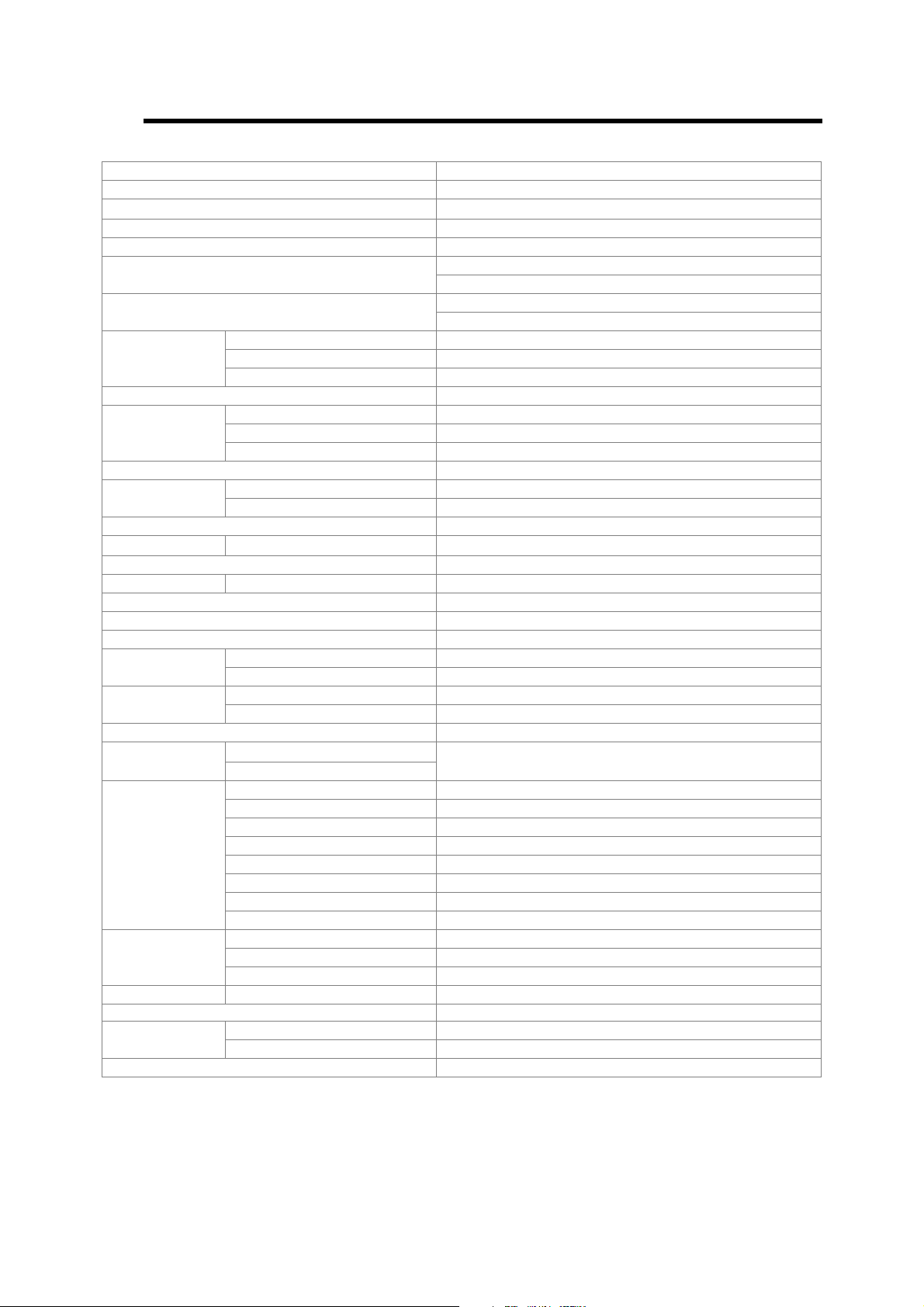

2. Specifications

I

Model No. Infinity 26i and HD50i

Type of Appliance Temp.controlled continuous Flow Gas Hot Water Unit

Operation

Flue System Room Sealed - Forced Draught Flue

Installation Internally mounted (Indoor Only)

Available Default Temperatures (Note 1):

(without Remote Controllers)

Temperature Range (with Remote Controllers) Kitchen controller : 37 ~ 55º C

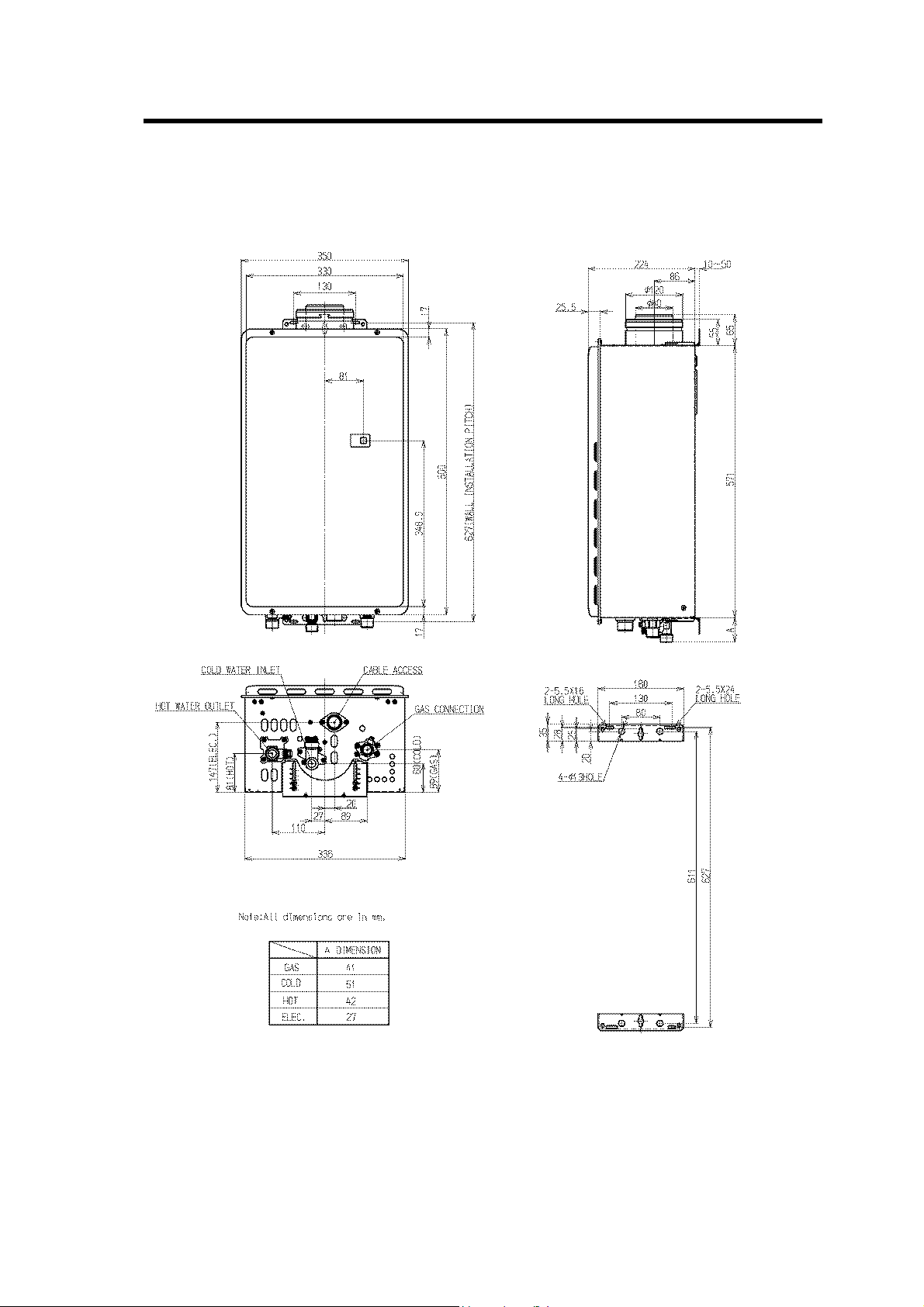

Width 350

Dimensions (mm)

Weight (Kg) 22

Connections

Ignition System Direct Electronic Ignition

Max. / Min. Gas

Consumption

Hot Water Delivery Capacity Max. 26 to 32 L/min.

Noise level 49 dB(A)

Thermal Efficiency 87%

NOXaf 55 ppm Max.

Minimum Operating Water Flow: 2.4 L/min.

Minimum Operating Pressure (Note 2): 1.8 bar

Maximum Operating Water flow 32 L/min.

Nominal Operating Pressure

Power Supply

Water temperature control Simulation feedforward and feedback

Water fl o w

control

Safety Device

Remote

Controllers

(optional)

Remote Controller Cable (Optional)

Electrical

Consumption

Manifold Electronic Control System (Optional) MSA-2M, MSA-2S

Note 1: The default factory setting is 55ºC for the Infinity26i, and 65°C for HD50i. The unit can be ordered

from Rinnai to be pre-set to any of the other temperatures listed. The unit can be pre-set to any of the

temperatures listed by a suitably qualified person.

Controllers are available with default temperatures up to 75º C. When fitted with controllers, only

temperatures not exceeding the default temperatures can be selected. When fitted without controllers, the

unit will deliver water at the default temperature. Controllers are not available with 85° C settings.

Less than 60°C 1.4 bar

Greater than or equal to 60°C 2.0~10.0 bar

Combustion fan rpm check Integrated circuit system

Cold Water Supply 3/4 in. BSP

Hot Water Supply 3/4 in. BSP

Remote Control (optional) DC 12 Volts (Digital)

Remaining Flame (OHS) 97º C bi-metal switch

Over temperature 95º C lockout thermistor

Pressure relief valve Opens 20.6 bar,closes 14.7 bar

Second Bathroom MC91-1A or BC-70-2A

Third Bathroom MC91-1A

Height 600

Depth 224

Natural Gas 54 -- 4.4 kW

Propane Gas 54 -- 4.4 kW

Infinity Unit AC 230 Volts (50 Hz)

Flame Failure Flame rod

Boil dry Water flow sensor

Fusible link 129º C Thermal Fuse

Over current Glass fuse (3 Amp).

Kitchen MC91-1A or MC-70-2A

Bathroom MC91-1A or BC-70-2A

Normal 80W

Standby 7.5 W (with 1 Remote Control)

With/without remote controls, mounted in Kitchen, bathroom, etc.

40º C, 43º C, 50º C, 55º C, 60º C, 65º C, 75º C, 85º C

(set by combination of Dip switches on PCB)

Bathroom controller : 37 ~ 50º C

Gas 3/4 in. BSP

Electronic Water flow sensor, flow control & heat exchanger

by-pass flow control.

Two core sheathed (double insulated) flex with min.cross-sectional area of 0.5 mm²

Note 2: Unit will operate at lower pressures but the maximum rated flow of 32L/min. will not be achieved.

Infinity REU-V2632FFU / HD200I REU-V2632FFUC - 2 - Issue 1 - 8/09/03 ©Rinnai

nfinity 26i and HD50i

Sensors and Safety Devices

I

• Heat Exchanger Thermistor: Measures hot water temperature at heat exchanger outlet. If water

temperature reaches a predetermined limit, gas supply is stopped.

• Hot Water Delivery Thermistor: Measures hot water temperature at the outlet valve (i.e. the ‘mixed’

temperature).

• Flame Rod: Monitors combustion characteristics inside the combustion chamber. If the flame fails, gas

supply is stopped.

• Overheat Switch: Situated on the heat exchanger, gas supply is stopped when water temperature

reaches 97ºC for a number of seconds.

• Fusible Link: Situated on the heat exchanger, electrical power supply is stopped if the temperature

exceeds 129ºC.

• Water Pressure Relief Valve: Safeguards the water circuit against excessive inlet pressure. Opens at

20.6 bar, closes at 14.7 bar.

• Electrical Fuse: (3A glass fuse) prevents against over-current.

Surge Protector: prevents against over-current.

• Boil Dry Prevention: If water flow sensor detects no flow, gas supply is stopped.

• Combustion Fan Speed Sensor: In case of combustion fan defect (no rotation of fan) gas supply is

stopped.

• Temperature Cutout: If the delivered hot water temperature rises above the required delivery

temperature for a number of seconds, the gas supply is stopped.

Combustion Specifications

Gas Type Injector

Size (mm)

Upper /

Lower

1.00

Natural

1.7

Propane 0.75

1.15

Nominal TPP (mbar) * * Gas Input (kW)

Low High Low High

1.98.5 4.4 54

2.3

10.8

4.4 54

* * The TPP is measured with the cover ‘off’ the appliance at the regulator test point with supply pressures

of 20 mbar (NG) and 37 mbar (Propane).

Infinity REU-V2632FFU / HD200I REU-V2632FFUC - 3 - Issue 1 - 8/09/03 ©Rinnai

nfinity 26i and HD50i

3. Water Flow Rates and Pressures

I

Water Flows

Table 1 shows unmixed and mixed water flow rates and approximate gas consumptions for various

temperature rises. The unmixed flow rates are the flow rates available at the given temperature rise directly

at the outlet of the water heater. The mixed water flow rates are available at the given temperature rise by

mixing hot water from the outlet of the water heater with cold water from the mains supply.

Water Flows can also be calculated by the following formula:

M = 60 x ( Q / C x T )

Where M = Water flow rate in litres/minute. If M is dto 26, the water is unmixed. If M is !, the water

is mixed.

Q = Heat energy output in kW = 47kW for the Infinity 26i and HD50i

C = Specific heat of water = 4.2KJ/Kg C. C does not change for the purpose of this calculation.

T = Temperature rise required ( C)

'q

Example:

What is the flow rate available with an incoming water temperature of 10 C and a required temperature of

20 C?

q

T = 20 - 10 = 10 C

'q

Q = 47

C = 4.2

M = 60 x ( 47 / (4.2 x 10) ) = 67 l/min. Since 67 is greater than 26 this flow rate is mixed. This result

corresponds with the value in Table 1.

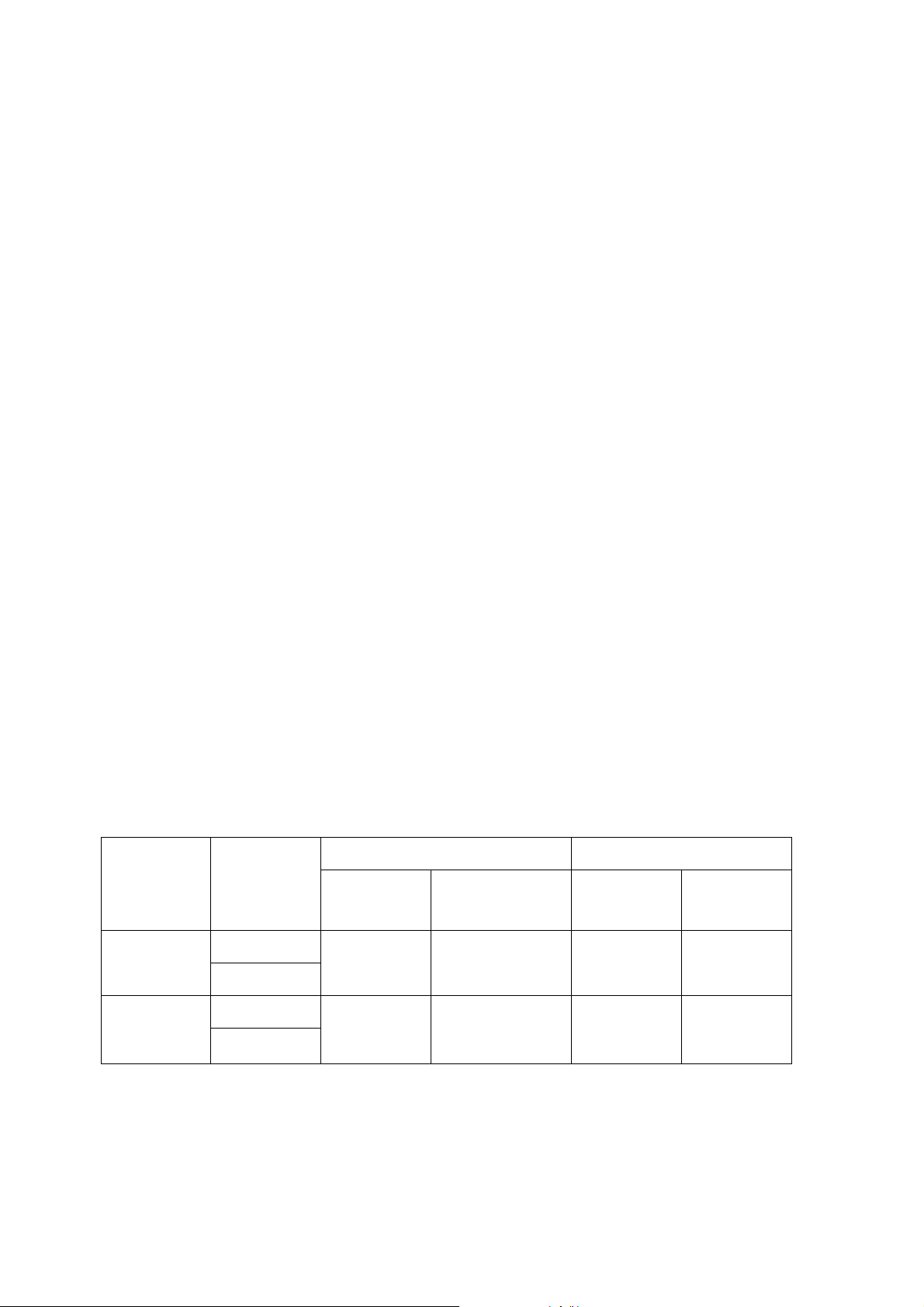

Table 1: Approximate Water Flows & Gas Usage - Rinnai Infinity 26i and HD50i - Preset Table

'

q

q

Infinity REU-V2632FFU / HD200I REU-V2632FFUC - 4 - Issue 1 - 8/09/03 ©Rinnai

nfinity 26i and HD50i

Table 1. Approx. Water Flows & Gas Usage - Rinnai 26i and HD50i Preset Temp. Less than 60°C.

I

20

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

kW

Cons.

bar

kW

Cons.

bar

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

kW

Cons.

bar

kW

Cons.

bar

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

kW

Cons.

bar

kW

Cons.

bar

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

kW

Cons.

bar

kW

Cons.

bar

10 15

5

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

kW

Cons.

bar

kW

Cons.

bar

30 35 40

25

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

kW

Cons.

bar

kW

Cons.

bar

50 55 60

45

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

kW

Cons.

bar

kW

Cons.

bar

65 70 75 80

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

kW

Cons.

bar

kW

Cons.

bar

Approx.

Min / Max

less than 60 C)

Models (Preset temps

Gas Input

kW

4.4-54 0.53 32 1920 1.4 13 0.53 32 1920 1.4 26 0.53 32 1920 1.4 39 0.53 32 1920 1.4 52

Infinity 26 i and HD 50i

(º C)

Temp Rise

(º C)

Temp Rise

Infinity REU-V2632FFU / HD200I REU-V2632FFUC - 5 - Issue 1 - 8/09/03 ©Rinnai

nfinity 26i and HD50i

Approx.

Min / Max

less than 60 C)

Models (Preset temps

Gas Input

kW

4.4-54 0.44 26.4 1584 1.0 54 0.37 22.2 1332 0.65 54 0.32 19.2 1152 0.5 54 0.28 16.8 1008 0.4 54

(º C)

Temp Rise

Infinity 26 i and HD 50i

Approx.

Min / Max

less than 60 C)

Models (Preset temps

Gas Input

kW

4.4-54 0.25 15 900 0.3 54 0.22 13.2 792 0.25 54 0.2 12 720 0.23 54 0.19 11.4 684 0.2 54

(º C)

Temp Rise

Infinity 26 i and HD 50i

Approx.

Min / Max

less than 60 C)

Models (Preset temps

Gas Input

kW

4.4-54 0.17 10.2 612 0.19 54 0.16 9.6 576 0.18 54 0.15 9 540 0.17 54 0.14 8.4 504 0.16 54

Infinity 26 i and HD 50i

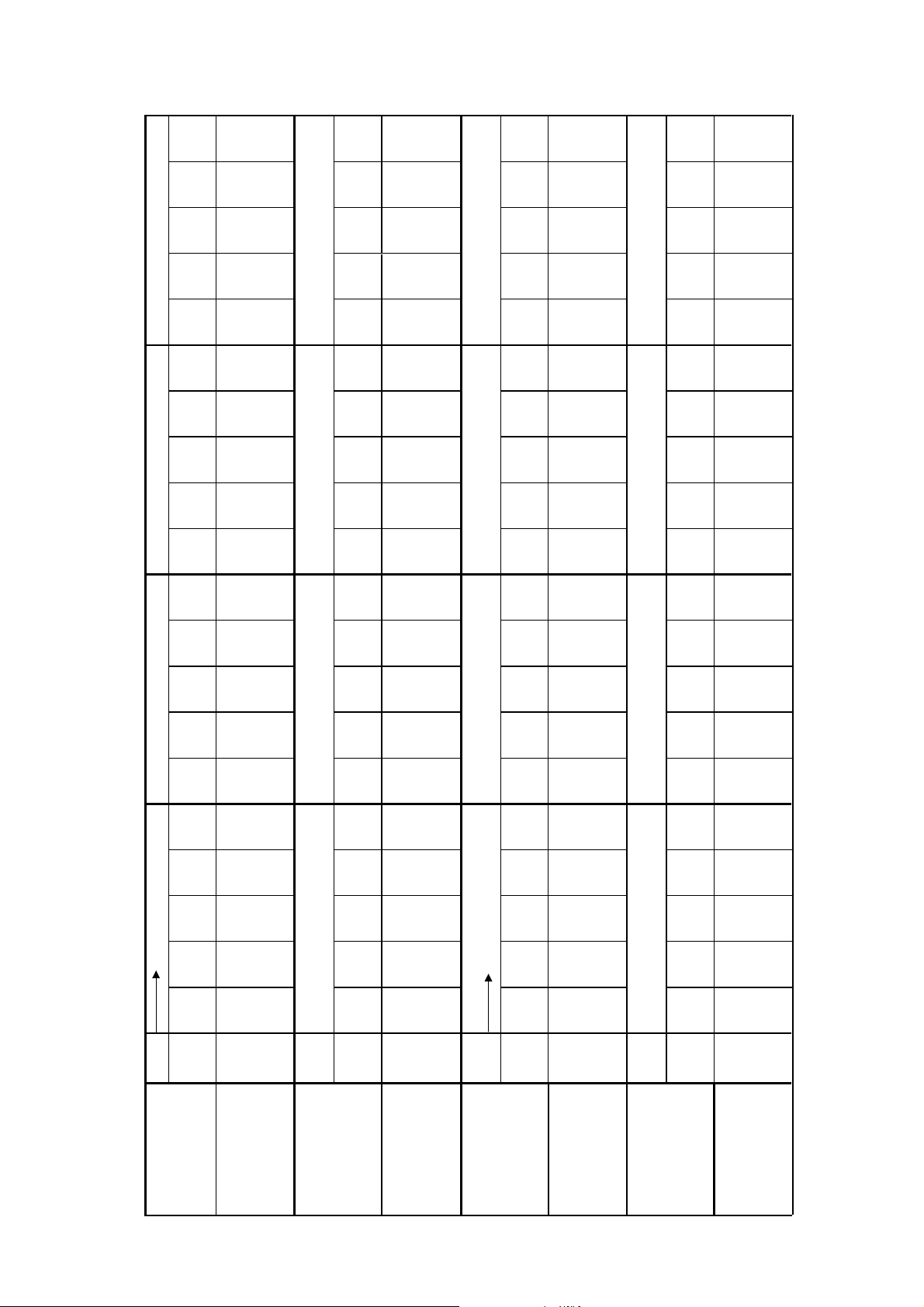

Approx.Water Flows & Gas Usage -Rinnai Infinity26i and 50i Preset Temp.Greater than or equal to 60°C

(

)

(

)

(

)

I

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

Cons.

kW

bar

Cons.

kW

bar

40

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

Cons.

kW

bar

Cons.

kW

bar

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

Cons.

kW

bar

Cons.

kW

bar

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

Cons.

kW

bar

Cons.

kW

bar

10 15 20

5

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

Cons.

kW

bar

Cons.

kW

bar

30 35

25

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

Cons.

kW

bar

Cons.

kW

bar

50 55 60

45

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

Cons.

kW

bar

Cons.

kW

bar

65 70 75 80

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

Gas

Approx

Pressure

Min Water

L/sec L/min L/hr

Cons.

kW

bar

Cons.

kW

bar

ºC

Approx.

Min / Max

kW

Gas Input

Temp Rise

60 C)

than or equal to

Models (Preset temps greater

Infinity REU-V2632FFU / HD200I REU-V2632FFUC - 6 - Issue 1 - 8/09/03 ©Rinnai

nfinity 26i and HD50i

4.4-54 0.4 24 1440 2.0 10 0.4 24 1440 2.0 20 0.4 24 1440 2.0 30 0.4 24 1440 2.0 40

Infinity 26 i and HD 50i

(º C)

Temp Rise

than or equal to

Models (Preset temps greater

60 C)

Approx.

Min/Max

4.4-54 0.4 24 1440 2.0 50 0.37 22.2 1332 1.1 54 0.32 19.2 1152 0.8 54 0.28 16.8 1008 0.6 54

kW

Gas Input

Infinity 26 i and HD 50i

ºC

Temp Rise

than or equal to

Models (Preset temps greater

Approx.

Min / Max

60 C)

4.4-54 0.25 15 900 0.5 54 0.22 13.2 792 0.4 54 0.2 12 720 0.4 54 0.19 11.4 684 0.3 54

kW

Gas Input

Infinity 26 i and HD 50i

ºC

Temp Rise

than or equal to

Models (Preset temps greater

Approx.

Min / Max

60 C)

Gas Input

kW

4.4-54 0.17 10.2 612 0.3 54 0.16 9.6 576 0.3 54 0.15 9 540 0.27 54 0.14 8.4 504 0.25 54

Infinity 26 i and HD 50i

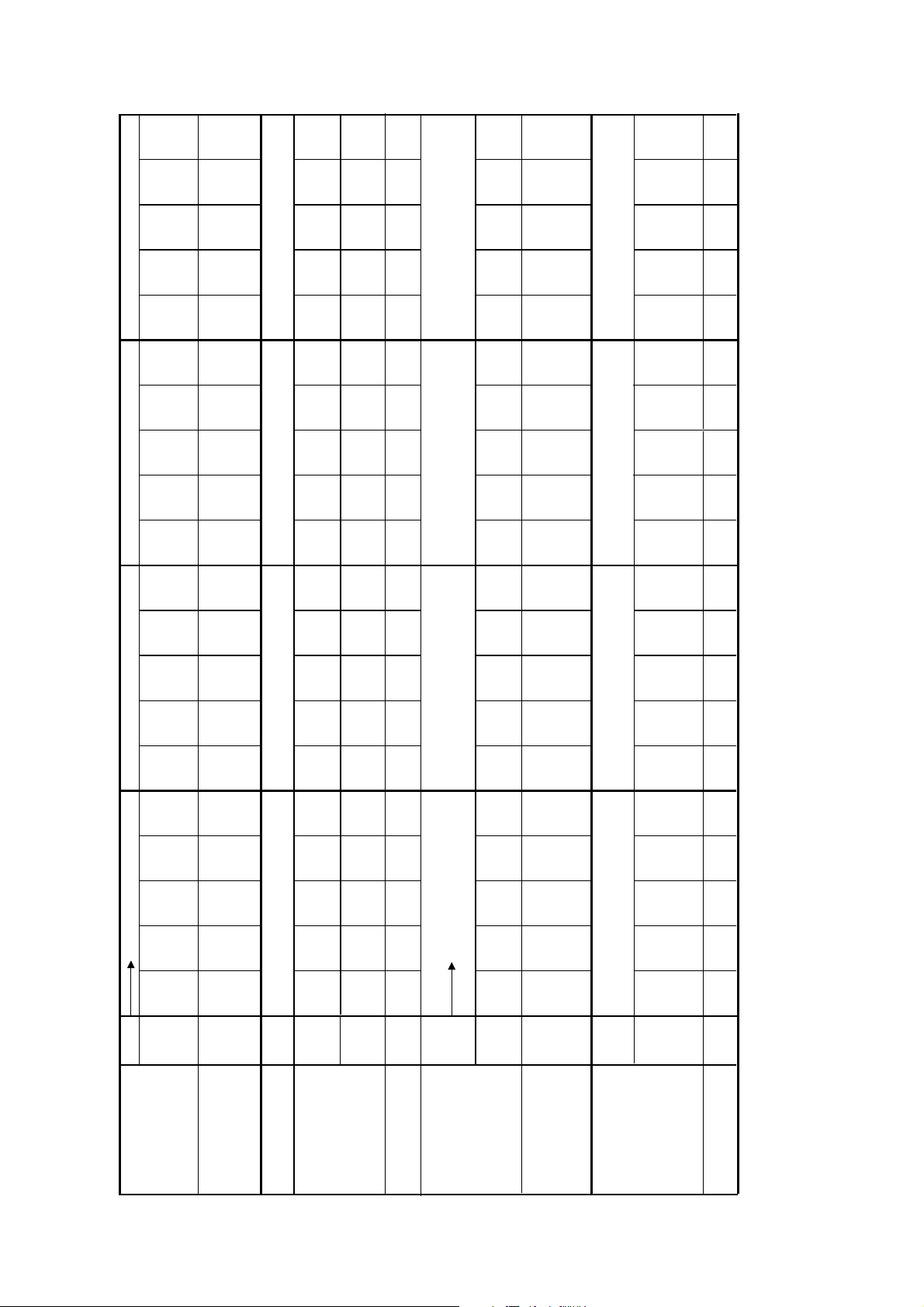

Water Pressure

I

The water pressure vs flow characteristics are as follows:

WATER PRESSURE/FLOW RATE

35

INFINITY 26i AND HD50i웛37ദ-55ദ

30

25

INFINITY 26i AND HD50i:60ദ+LJKHU

20

WATER FLOW RATE (L/min)

15

10

5

0

1.0 2.0 3.0 4.0

WATER PRESSURE(bar)

Infinity REU-V2632FFU / HD200I REU-V2632FFUC - 7 - Issue 1 - 8/09/03 ©Rinnai

nfinity 26i and HD50i

4. Dimensions

I

Infinity REU-V2632FFU / HD200I REU-V2632FFUC - 8 - Issue 1 - 8/09/03 ©Rinnai

nfinity 26i and HD50i

5. Remote Controls

I

Remote Controls

Remote Controllers are an optional extra. 'Standard' and 'Deluxe' controllers can be

fitted.

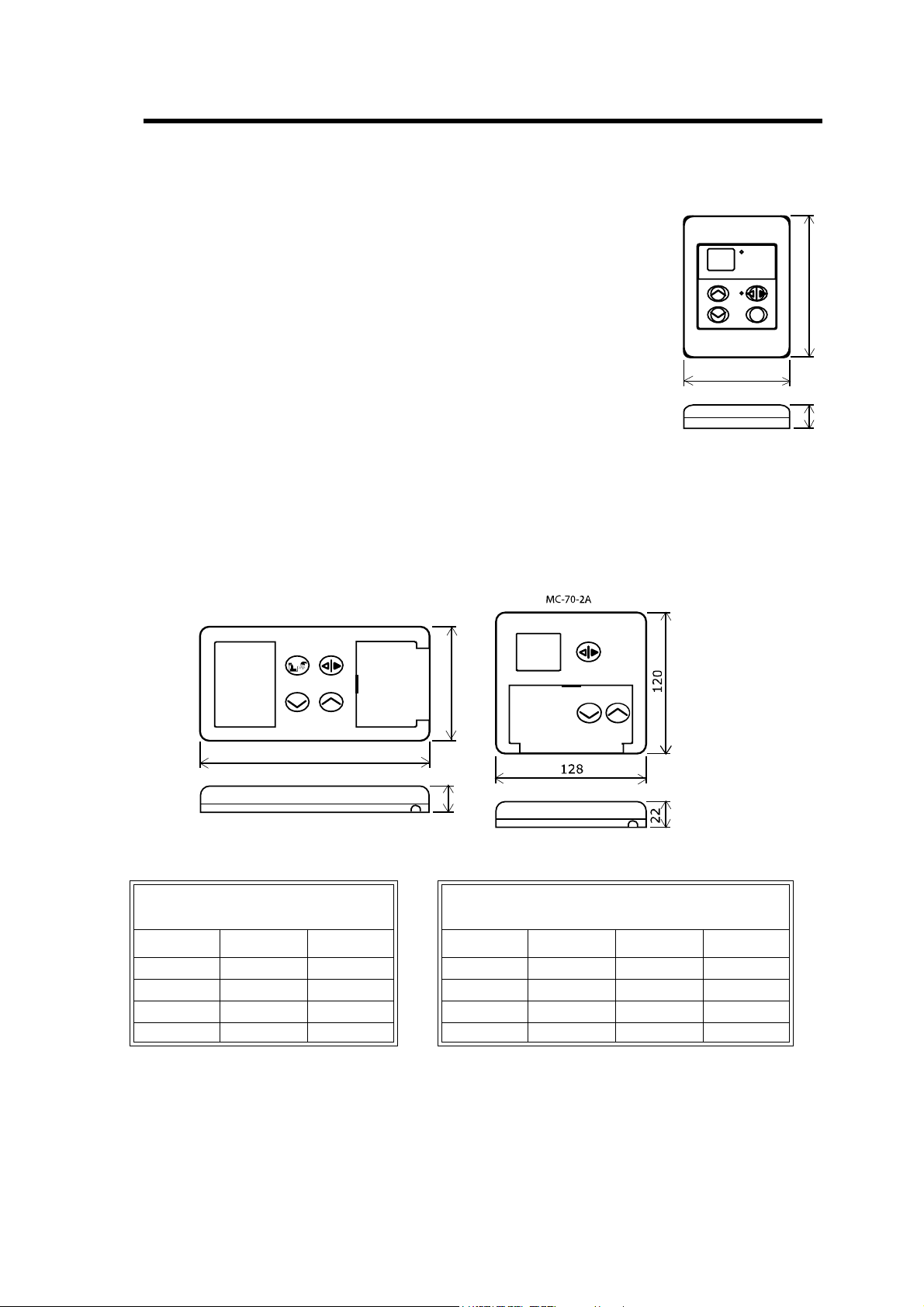

MC-91-1A

Standard controllers allow temperature selection only. Deluxe controllers have

temperature selection, bath-fill and voice prompting functions. For detailed

information regarding controller operation refer to the 'How to use your water

heater' booklet supplied with the appliance. Other manufacturers' controllers are

120

NOT compatible with this appliance.

Standard Controller (Model MC-91)

90

Up to 4 Standard Controllers can be fitted to the appliance. They are normally

installed in the areas where the majority of hot water is used, for example, the

kitchen, bathroom, ensuite and laundry.

20

Deluxe Kitchen Remote Control (MC-70) and (BC-70A)

Deluxe controllers have 'Kitchen' (MC-70-2A) and 'Bathroom' (BC-70-2A) versions. 'Kitchen' controls are

intended for the Kitchen or other convenient area where the majority of hot water is used. Bathroom

Controllers are intended to be fitted in the bathroom or ensuite and allow the user to have a bath filled to

the required level and temperature automatically.

BC-70-2A

97

195

22

:

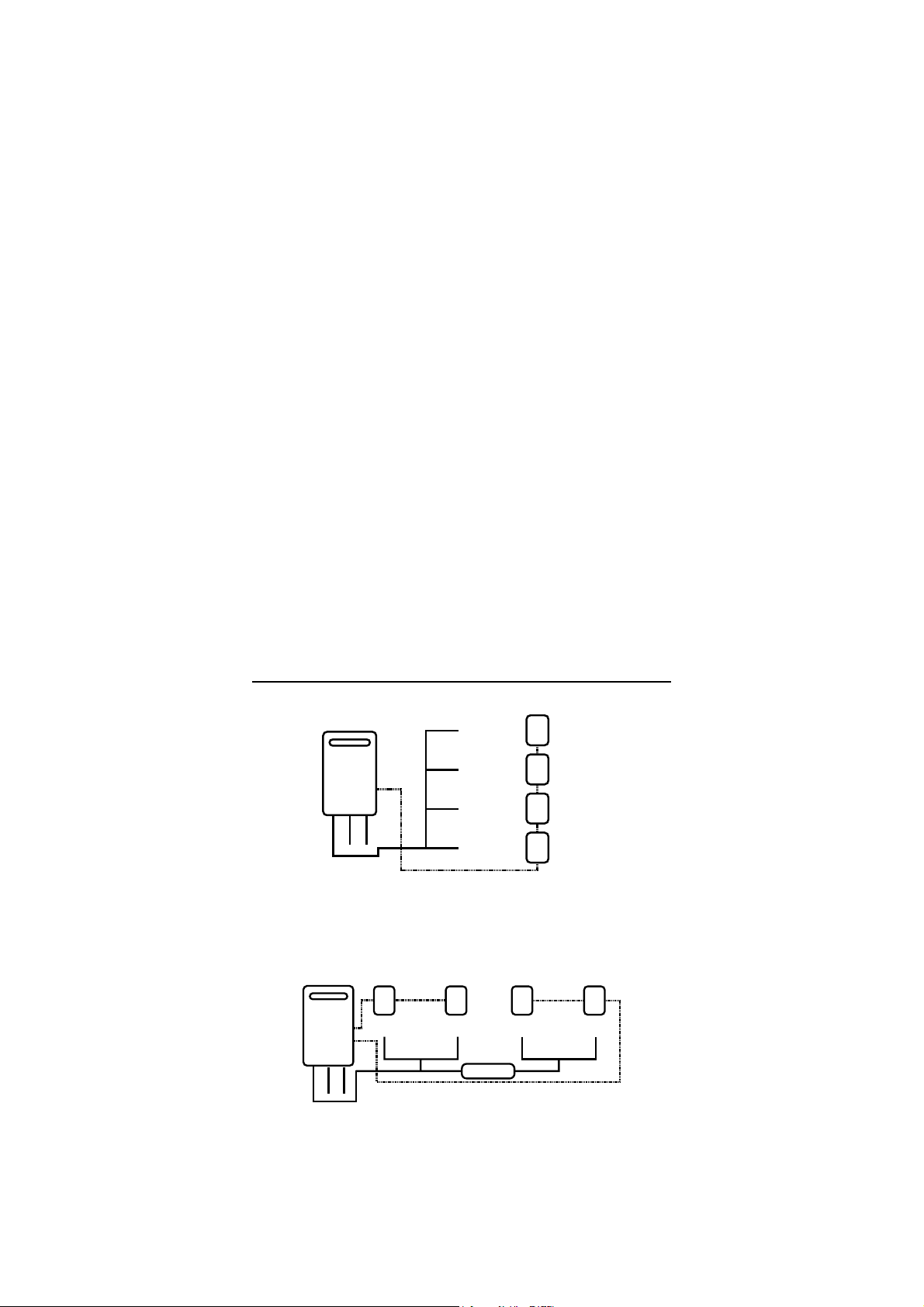

Up to three ‘Deluxe’ Controllers

can be connected

Kitchen Bathroom Ensuite Kitchen Bathroom Ensuite Laundry

MC70-2A MC70-2A

MC70-2A MC70-2A

MC70-2A BC70-2A MC70-2A BC70-2A

MC70-2A BC70-2A BC70-2A MC70-2A BC70-2A BC70-2A MC91-1A

If a fourth Controller is required a ‘Standard’

Controller can be included

Positioning of Controllers

Controllers must be installed in shaded and clean locations. They should be fitted out of reach of children

(suggested height from floor at least 1500mm). Controllers are water resistant, however, durability is

improved when positioned outside the shower recess or at least 400mm above the highest part of a sink,

basin or bath.

Infinity REU-V2632FFU / HD200I REU-V2632FFUC - 9 - Issue 1 - 8/09/03 ©Rinnai

nfinity 26i and HD50i

DO NOT INSTALL THE CONTROLLERS

e

e

e

e

I

• NEAR A HEAT SOURCE, SUCH AS A COOK TOP, STOVE OR OVEN. HEAT, STEAM,

SMOKE AND HOT OIL MAY CAUSE DAMAGE

• IN DIRECT SUNLIGHT

• OUTDOORS UNLESS AN ENCLOSURE IS PROVIDED WHICH PROTECTS THE

CONTROLLER AGAINST SUNLIGHT AND DUST INGRESS.

• AGAINST A METAL WALL UNLESS THE WALL IS EARTHED IN ACCORDANCE

WITH CURRENT REGULATIONS.

Remote Controller Connection

Remote controls operate at extra low voltage (12 Volts DC) which is supplied from the appliance.

Controllers are supplied with 15 m of electrical cable. The cable wires for connection to the appliance are

fitted with spade terminals.

Extension cables are available from Rinnai. Alternatively, a two core sheathed (double insulated) flex with

minimum cross-sectional area of 0.5 mm² can be used. Maximum cable length is 50 m.

For connection refer to the “CONNECTING REMOTE CONTROL CABLES” section.

If the front cover of the appliance contains the following text install it in accordance with Diagram 1 below:

Water Heater and Controller installation configurations

Temperatur

KITCHEN

LAUNDRY

BATHROOM

ENSUITE

H

O

T

50º C

C

O

L

D

G

A

S

Diagram 1. Max. 50º C Appliance

If the front cover of the appliance does NOT contain the above text install it in accordance with Diagram 2:

Temperature

controller

(optional)

KITCHEN

Temperature

controller

(optional)

LAUNDRY BATHROOM

Temperature

controller

(optional)

controller

(optional)

Temperatur

controller

(optional)

Temperatur

controller

(optional)

Temperatur

controller

(optional)

Temperature

controller

(optional)

ENSUITE

G

H

C

A

O

O

S

T

L

D

IMPORTANT: If the appliance is to deliver water primarily for the purposes of personal hygiene in an

early childhood centre, primary or secondary school, nursing home or similar facility for young, aged, sick

or disabled persons a Temperature Limiting Device (TLD), such as a Thermostatic Mixing Valve,

may be required even if the appliance is set to 50ºC or less. For these types of applications contact

Rinnai UK.

Infinity REU-V2632FFU / HD200I REU-V2632FFUC - 10 - Issue 1 - 8/09/03 ©Rinnai

nfinity 26i and HD50i

Diagram 2. Not a 50º C Appliance

Note: TLD = Temperature Limiting Device Recommended.

TLD

Connecting remote control cables

I

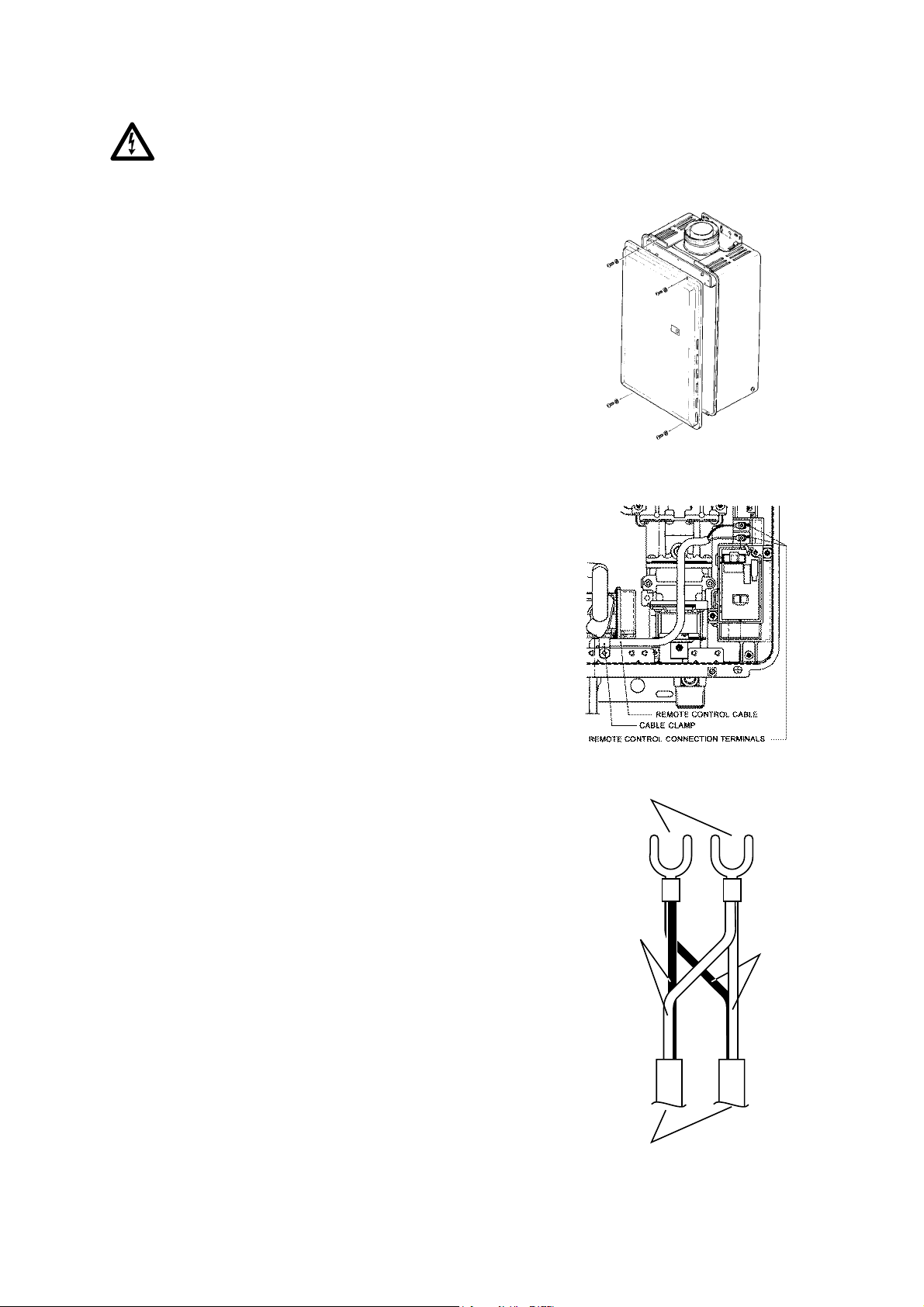

Do not attempt to connect the remote control cable terminals to the appliance with the power on.

RISK OF ELECTRICAL SHOCK.

Connecting One or Two Controllers

1. Isolate the power supply

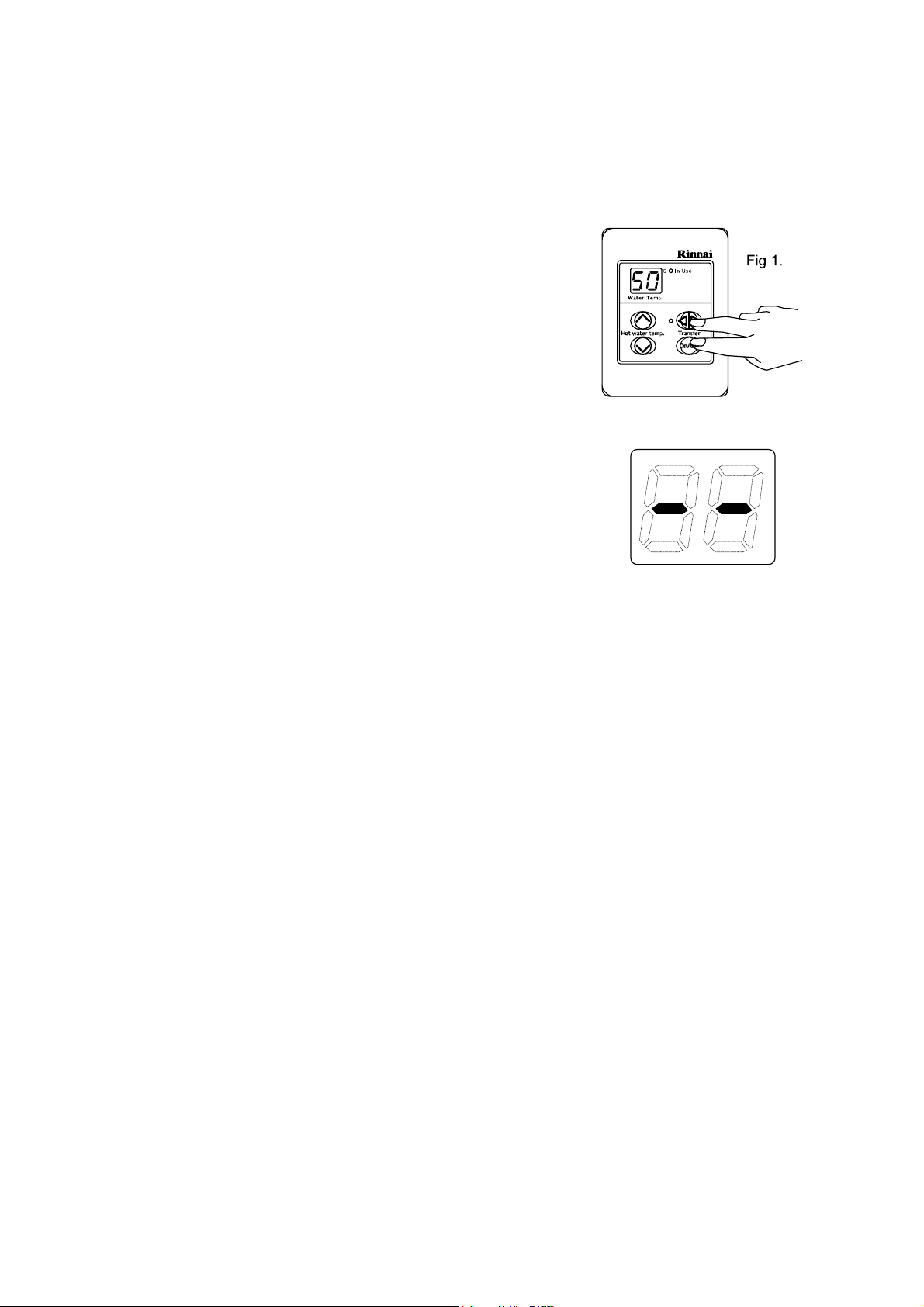

2. Remove the front cover from the Appliance (4 screws) fig. 1.

3. Thread the cable(s) through the cable access hole at the base

of the appliance.

4. Connect the spade connectors to the terminals marked

"Remote Control" on the printed circuit board (fig. 2).

Polarity is not important. Either wire colour can be

connected to either terminal.

5. Replace cover of the Appliance. Ensure that the screw with

the star washer is placed at the bottom right hand corner for

earthing purposes.

Connecting Three Controllers

6. Isolate the power supply

7. Remove the front cover from the Appliance (4 screws) fig.1.

8. Thread the cables through the cable access hole at the base of

the appliance.

9. Connect the 4 spade connectors to the terminals marked

"Remote Control" on the printed circuit board (fig. 2).

Polarity is not important. Either wire colour can be connected

to either terminal.

10.Replace cover of the Appliance. Ensure that the screw with

the star washer is placed at the bottom right hand corner for

earthing purposes.

Connecting Four Controllers

11.Isolate the power supply

12.Remove the front cover from the Appliance (4 screws) fig 1.

13.Cut the spade connectors from all four controller cables to be

connected to the appliance (8 spade connectors should be cut

off) and discard. Connect the wires from two cables and

terminate into two new spade connectors as shown in (fig. 3).

Repeat for the remaining two cables. Spade connectors are

available from your local electrical component retailer.

fig.1

fig.2

New spade connectors

Cable

wires

Cable

wires

14.Thread the 4 cables through the cable access hole at the base

of the appliance. Connect the 4 spade connectors to the

terminals marked "Remote Control" on the printed circuit

board (fig 2). Polarity is not important. Either wire colour

can be connected to either terminal.

15.Replace cover of the Appliance. Ensure that the screw with

the star washer is placed at the bottom right hand corner for

earthing purposes.

Infinity REU-V2632FFU / HD200I REU-V2632FFUC - 11 - Issue 1 - 8/09/03 ©Rinnai

nfinity 26i and HD50i

Remote control cables

fig. 3

MC-91A Controller Programming

I

Question 1: Are four Controllers connected ?

IF YES: You will need to activate the fourth controller.

STEP 1:

For the Controller in the ‘KITCHEN’ only, press and hold the

‘Transfer’ and ‘On/Off’ buttons simultaneously (see fig. 1) until a

‘beep’ is heard (approximately 5 seconds).

STEP 2:

Check that the display on ALL FOUR controllers is lit and

displaying a temperature when ‘switched on’. If any ONE of the

controller displays two dashes (see fig. 2) in the display repeat

STEP 1.

This completes the activation procedure. Ignore Question 2.

IF NO: (You have three controllers or fewer), go to Question 2.

Fig 2.

Question 2: Does your kitchen controller temperature go higher than 50 deg C?

IF YES: No further action required.

IF NO: You will need to program the Kitchen controller to enable selection of temperatures higher than

50º C.

STEP 1:

For the controller in the KITCHEN only, press and hold the 'Transfer' and 'On/Off' buttons

simultaneously (see fig 1.) until a 'beep' is heard (approximately 5 seconds).

STEP 2:

When the controller fitted in the KITCHEN is switched on, it should be possible to select temperatures

higher than 50º C. If not, repeat Step 1.

Note:

• If the kitchen controller is replaced, repeat STEP 1 above for the replacement controller.

• If the kitchen controller is swapped with another controller (for example, the controller fitted

in a bathroom), repeat STEP 1 for the controller moved from the kitchen to the bathroom.

Then perform STEP 1 for the controller moved from the bathroom to the kitchen.

Infinity REU-V2632FFU / HD200I REU-V2632FFUC - 12 - Issue 1 - 8/09/03 ©Rinnai

nfinity 26i and HD50i

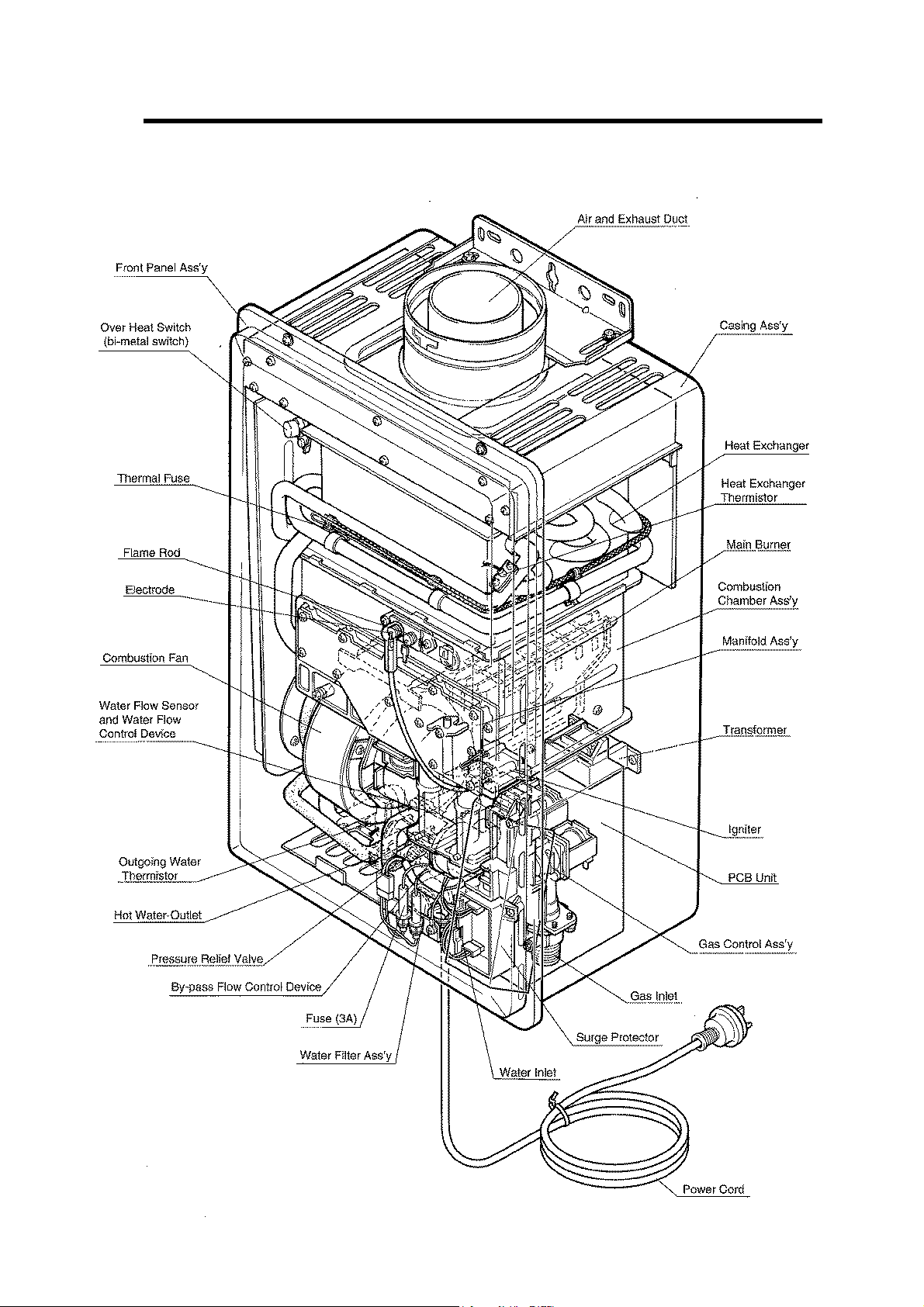

6. Cutaway Diagram

I

i

I

nfinity 26i and 50

Infinity REU-V2632FFU / HD200I REU-V2632FFUC - 13 - Issue 1 - 8/09/03 ©Rinnai

nfinity 26i and HD50i

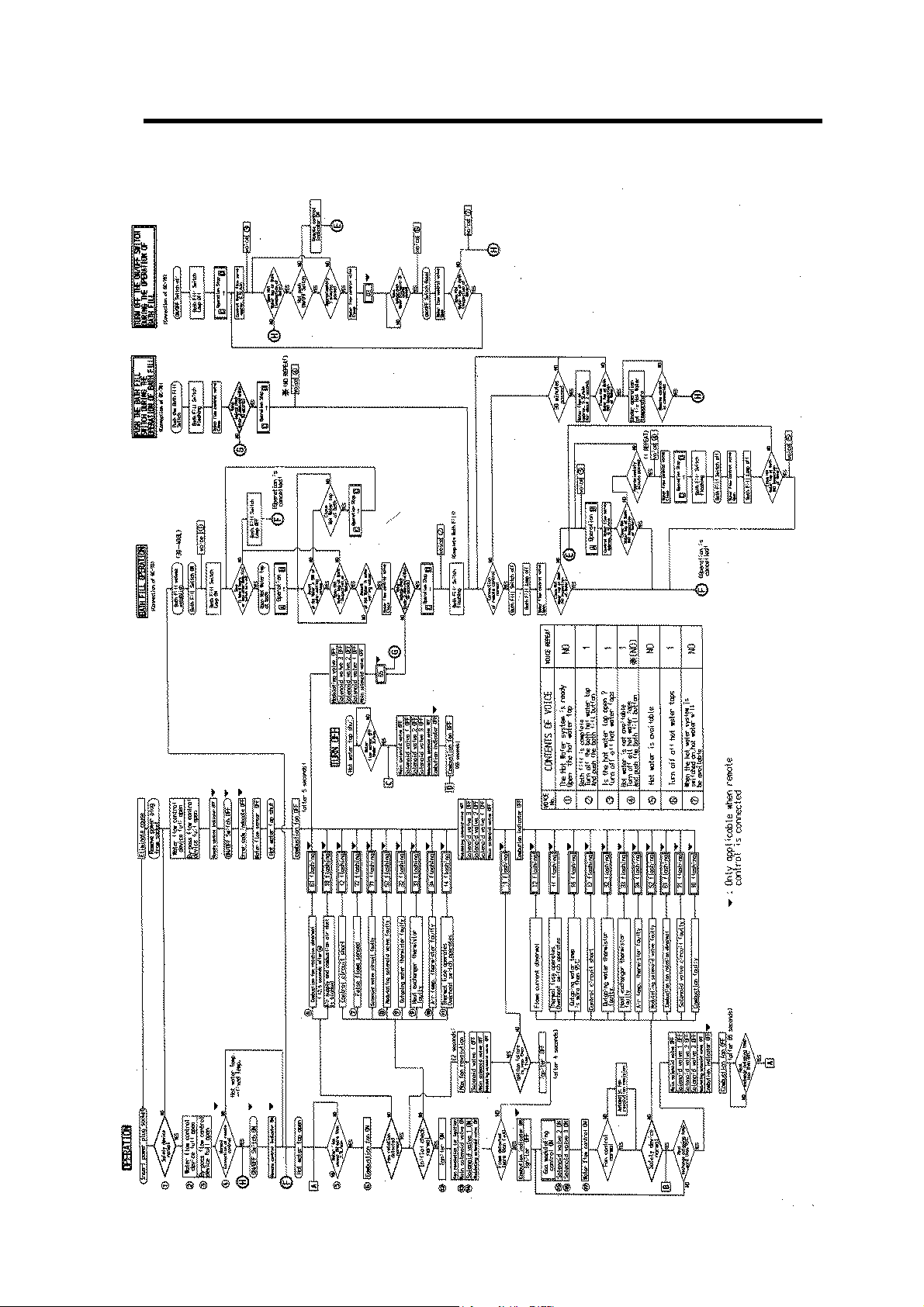

7. Operational Flow Chart

I

Infinity REU-V2632FFU / HD200I REU-V2632FFUC - 14 - Issue 1 - 8/09/03 ©Rinnai

nfinity 26i and HD50i

Loading...

Loading...