Rinnai VT16-26, HD200, HDi200, EF24, EF250 Installation Manual

...

Continuous ow

water heaters

Installation guide

Models: VT16-26, HD200, HDi200, HD250, EF24, EF250, EFi250

This appliance must be installed in accordance with:

- Manufacturer’s installation instructions

- Current AS/NZS3000, AS/NZS3500, AS/NZS 5601.1 and G12/AS1

- Local regulations and municipal building codes

For use with Natural Gas or Universal LPG as indicated on the appliance.

Not suitable as a spa or swimming pool heater.

Rinnai continuous flow internal water heaters

(‘i’ models) must be installed with an approved Rinnai flue system.

Appliance must be installed, commissioned and serviced by an authorised

person, being in New Zealand a licensed gasfitter, in accordance with

these instructions and all applicable local rules and regulations.

Warning

Improper installation, adjustment, alteration, service or maintenance can

cause property damage, personal injury or loss of life.

For more information about buying, using, and servicing of Rinnai appliances

call: 0800 RINNAI (0800 746 624)

Rinnai New Zealand Limited

105 Pavilion Drive, Mangere, Auckland

PO Box 53177, Auckland Airport, Auckland 2150

Phone: (09) 257 3800, Fax: (09) 257 3899

Email: info@rinnai.co.nz

Web: www.rinnai.co.nz, www.youtube.com/rinnainz

Important:

cnt:

Before installation 4

Appliance location 5

General installation information 7

Flued (internal) water heaters 8

Water delivery temperature 9

Connections and fittings 10

Dimensions: VT and HD models 11

Dimensions: EF models 12

EF250 models: Earthing the unit 13

EF models: Condensate drain 14

Controllers - general information 15

Controllers - Universal (Compact) 16

Controllers - Kitchen Deluxe 17

Controllers - Bathroom Deluxe 18

Controllers - communication cables 19

Commissioning 20

Recommended solar system layout 21

DIP switch settings - important 23

DIP switch settings 24

4 | Continuous Flow Water Heater Installation Guide 04-12

Before installation

Check for damage

Unpack the appliance and flue components (if applicable) and check for damage. DO NOT install any damaged

items.

Check components and gas type

Check all components have been supplied and that you have the correct gas type.

Read these instructions before starting

Read these instructions to get an overview of the steps required before starting the installation. Failure to follow

these instructions could cause a malfunction of the appliance. This could result in serious injury and property

damage.

Solar installations

For Rinnai continuous flow water heaters used in solar installations, refer ‘Recommended Solar System Layout’.

EF models are heavy

The Rinnai Infinity EF models are 32 kg. Please use care when lifting and seek assistance if required.

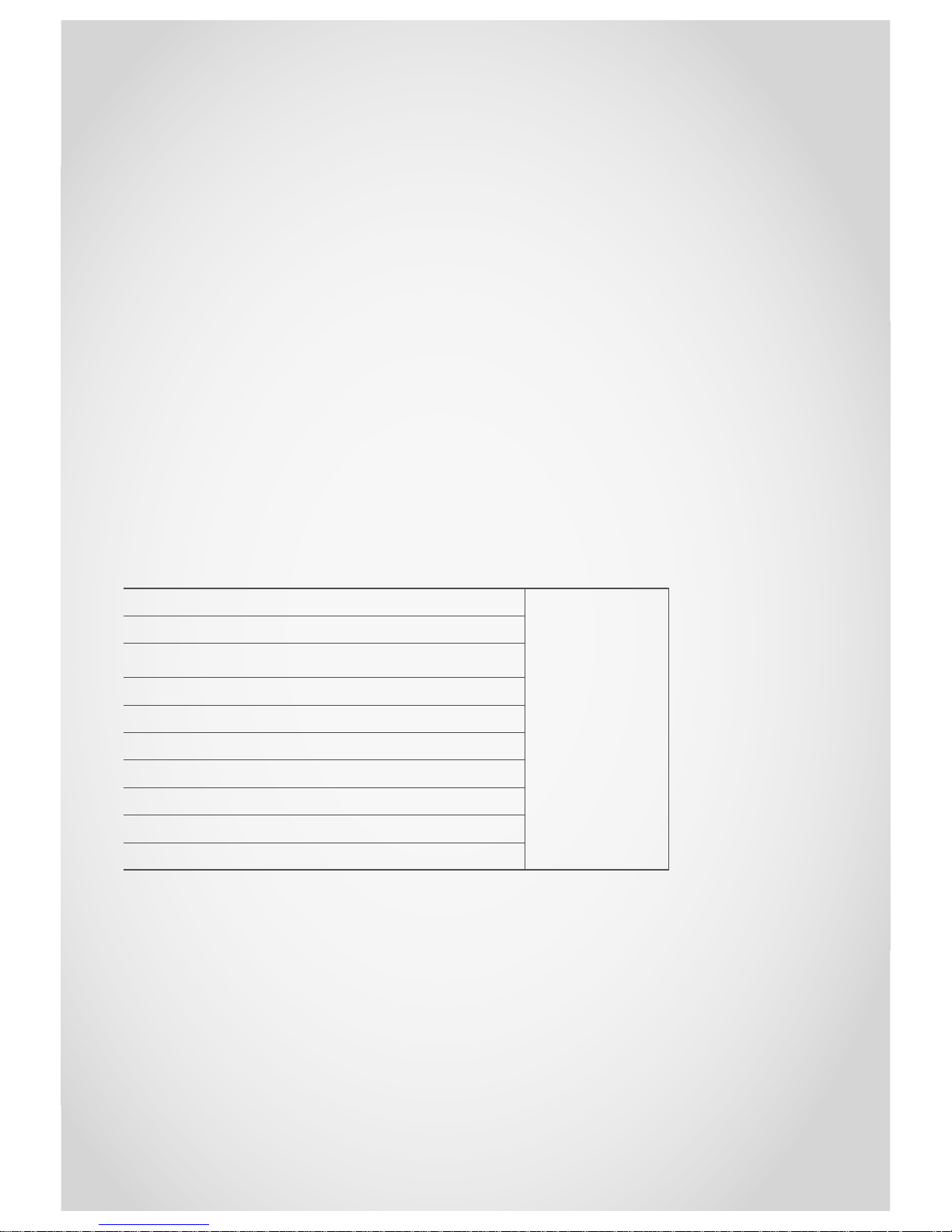

Applicable models

These installation instructions apply to the following Rinnai continuous flow water heaters.

Rinnai Infinity VT16 External REU-VR1620WG

Model number

Note: The model

number is written on

the data plate on the

left hand side of the

appliance.

Rinnai Infinity VT20 External REU-VR2024WG

Rinnai Infinity VT24 External REU-VR2426WG

Rinnai Infinity VT26 External REU-VR2626WG

Rinnai Infinity HD200 External REU-VRM2632WC

Rinnai Infinity HDi200 Internal REU-VR2632FFUC

Rinnai Infinity HD250 External REU-VR3237WG

Rinnai Infinity EF24 External REU-K2430WG

Rinnai Infinity EF250 External REU-KM3237WD

Rinnai Infinity EFi250 Internal REU-KM3237FFUD

i = internal—these must be installed with an approved Rinnai flue system

For nominated gas consumption, gas pressures, and gas types please refer to the data plate on the left hand side

of the appliance.

Continuous Flow Water Heater Installation Guide 04-12 | 5

Appliance location

Installation in environments

free from corrosive compounds

Air surrounding the water heater,

venting and vent termination(s) is

used for combustion and must be

free from compounds that cause

corrosion of internal components.

These include corrosive

compounds that are found in

aerosol sprays, detergents,

bleaches, cleaning solvents,

oil based paints/varnishes, and

refrigerants. Therefore Rinnai

recommends outdoor models be

used for these locations where

possible. The water heater, venting

and vent termination(s) should not

be installed in any areas where the

air may contain these corrosive

compounds. Chemicals that are

corrosive in nature should not

be stored or used near the water

heater or vent termination.

Damage and repair due to

corrosive compounds in the air is

not covered by warranty.

If it is necessary for a water heater

to be located in areas which may

contain corrosive compounds,

Rinnai strongly recommends the

following:

Indoor (internal) water heaters

- DO NOT install in areas where

contaminated air is present.

- Consider, before installation,

where air has the ability to

travel within the building.

- Where possible, install the

heater in a sealed closet so

that it is free of contaminated

indoor air.

Outdoor (external) water heaters

and vent terminations of indoor

(internal) water heaters

- Install as far away as possible

from exhaust vent hoods

- Install as far away as possible

from air inlet vents—corrosive

fumes may be released

through these vents when air

is not being run through them

Internal models

Internal models are

designed for indoor

installations only.

They may be installed

in an enclosure if the

requirements of

AS/NZS 5601.1 are satisfied.

An enclosure is defined as a

compartment, enclosed area or

partitioned off space primarily

used for the installation of the

appliance. If installed in an

enclosure either internally or

externally, the location should be

ventilated to allow gas to dissipate.

They must be mounted on a

vertical structure with the water

and gas connections on the

underside pointing downwards.

For appliances installed in roof

spaces or elevated structures,

specific requirements apply. Refer

to AS/NZS 5601.1 for details.

Catch pan

It is important that a suitably

drained catch pan is fitted

where damage could be

caused by discharge from the

water heater. Provision must

be made for safe disposal

of any leaking water to an

external location.

This appliance MUST be used with

the appropriate Rinnai flue system.

This appliance must be located

so that the flue terminal exits the

building at a suitable point, refer

‘Minimum Clearances Required for

Flue Terminals’, in AS/NZS 5601.1

Fig 6.2.

Manufacturer’s instructions for

model REU-KM3237FFUD (EFi250);

for reference j, gas appliances over

200 MJ/h input, use ≥ 300 mm.

External models

External models are

designed for outdoor

installations only. They

must be located in an

above ground open-air

situation with natural

ventilation, without stagnant

areas, and where gas leakage and

products of combustion are rapidly

dispersed by wind and natural

convection.

They must be mounted on a

vertical structure with the water

and gas connections on the

underside pointing downwards.

For appliances installed on

elevated structures or under floors

specific requirements apply. Refer

to AS/NZS 5601.1 Fig 6.2 for details.

This appliance must be located

so that the flue terminal exits the

building at a suitable point, refer

‘Minimum Clearances Required for

Flue Terminals’, AS/NZS 5601.1

Fig 6.2.

Manufacturer’s instructions for

model REU-KM3237WD (EF250);

for reference j, gas appliances over

200 MJ/h input, use ≥ 300 mm.

Horizontal obstructions

AS/NZS 5601 stipulates a minimum

horizontal clearance of 500 mm

between a building structure and

obstruction facing the terminal.

At 500 mm the obstruction needs

to be the full height of the unit

(as shown), and not a partial

obstruction. A partial obstruction

of less than 1 m could result in wind

pushing flue gases back into the

flue terminal.

CAUTION

500 mm

At 500 mm the obstruction

needs to be the full height of

the unit.

500 mm

DO NOT

6 | Continuous Flow Water Heater Installation Guide 04-12

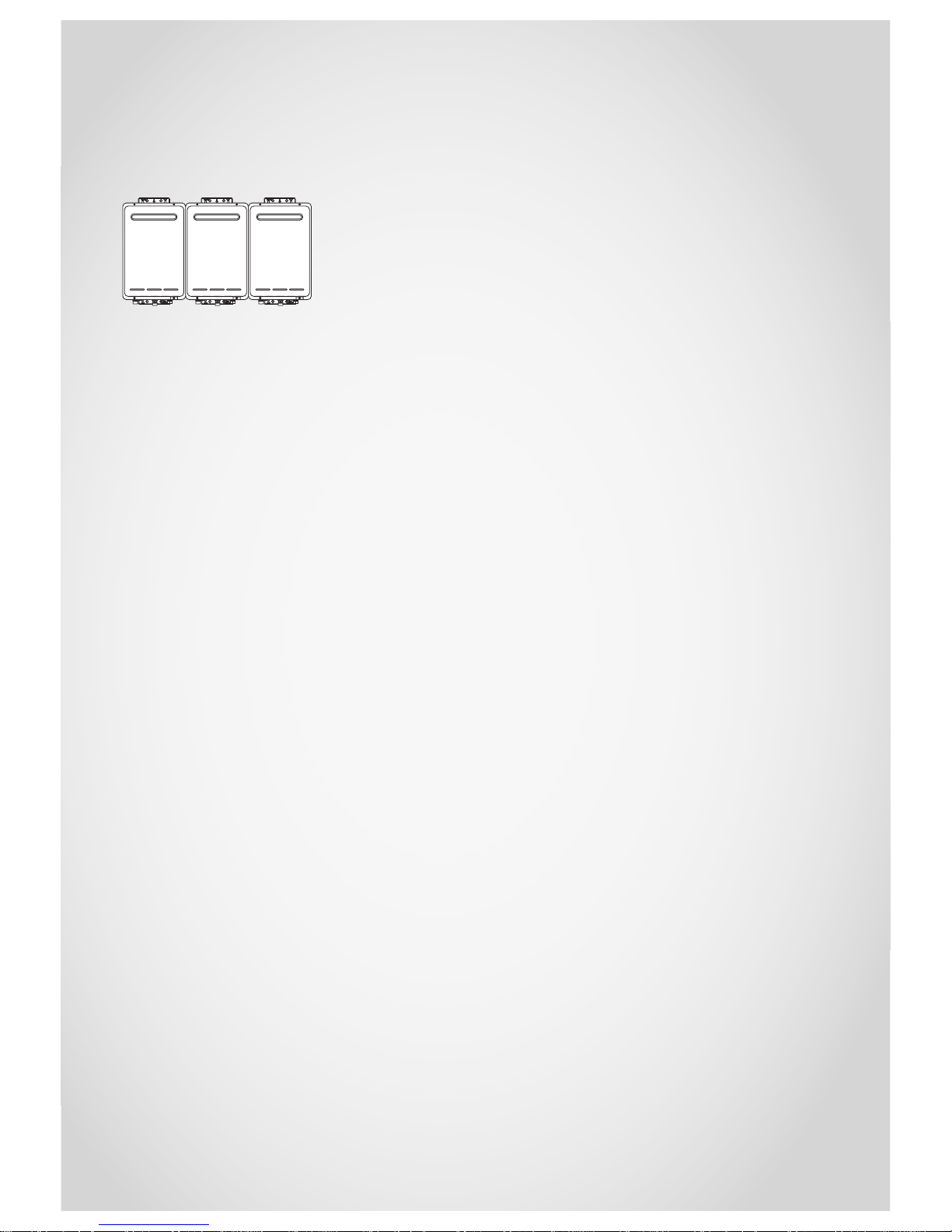

When multiple units of the

same model are installed on the

same vertical face, with the flue

terminals at the same height, they

can be installed next to each other

(as shown).

All models

This appliance must be placed

as close as possible to the most

frequently used hot water outlet

or outlets to minimise the delay for

hot water delivery.

For installations where the distance

between the water heater and

the outlets is considerable, a

flow and return system can be

used to minimise the waiting

time for hot water delivery.

Alternatively, multiple appliances

can be strategically placed to serve

different outlets. Contact Rinnai

for further information.

An AC 230 V, 10 Amp, earthed

power point must be provided

adjacent to the appliance. For

outdoor installations, this power

point must be weatherproof. It

must be clear of the gas and water

connections to the appliance and

also the flue exhaust and water

pressure relief valve. The power

cord of the appliance is 1.5 m long.

All appliances must be installed

to ensure access can be gained

without hazard or undue difficulty

for inspection, repair, renewal or

operational purposes. Sufficient

clearances shall allow access to

and removal of all serviceable

components.

Appliances should not be mounted

higher than 3.5 m above the

ground or floor level unless the

customer can arrange permanent

and safe access or can provide

another means of access such as

scissor or boom lifts.

Clearances from combustible

materials

The appliance can be mounted

directly against the wall or

structure. There is no need to

use non-combustible sheeting

or leave an air gap between the

appliance back panel and the wall

or structure for the purposes of

meeting the temperature hazard

requirements of AS/NZS 5601.

Continuous Flow Water Heater Installation Guide 04-12 | 7

General installation information

Catch pan

It is important a suitably drained

catch pan is fitted (especially for

internal units) where damage

could be caused by discharge

from the water heater. Provision

must be made for safe disposal of

any leaking water to an external

location.

Mounting the appliance

Refer ‘Connections and Fittings’ for

individual appliance weights. The

wall or structure on which these

units are to be mounted must

be capable of supporting these

weights and the associated pipe

work.

Ensure suitable fixing screws or

bolts are used to secure the units

to the walls, in accordance with

AS/NZS 5601.1. Wooden plugs shall

not be used.

The top bracket has a keyhole slot

(circled below) so the appliance

can be positioned by hanging it on

one screw while the other screws

are secured.

Circuit diagrams

Refer to commissioning sheet

supplied with the appliance (inside

front cover of appliance).

Pipe sizing

Refer ‘Connections and

Fittings’ for appliance

gas consumption. If

the gas pipe sizing is

insufficient the customer will not

get the full performance benefit.

Gas pipe sizing must consider the

gas input to this appliance as well

as all the other gas appliances in

the premises. The gas meter and

regulator must be specified for this

gas rate.

An approved sizing chart such

as the one in AS/NZS 5601.1, or

proprietary system manufacturer

guide should be used.

Water pipe sizing and layout should

be performed in accordance

with AS/NZS 3500. All hot water

pipe work should be insulated to

optimise performance and energy

efficiency.

Water supply

Refer ‘Connections

and Fittings’ for

applicable water

pressures. Approved

pressure limiting valves may be

required if the stated maximum

rated water supply pressures are

exceeded. To achieve the rated

flow, the stated minimum water

supply pressures must be supplied.

The water heaters will operate

at lower pressures but will not

achieve the rated flow.

Water chemistry and impurity

limits are stated in our detailed

warranty statement. Most

metropolitan water supplies fall

within these requirements. If you

are unsure about the quality of

the water, please contact Rinnai

and we will provide you with the

details of an authorised agency

who are able to test your water for

compliance to Rinnai standards. If

sludge or foreign matter is present

in the water supply, a suitable filter

or strainer should be incorporated

in the water supply to the water

heater.

8 | Continuous Flow Water Heater Installation Guide 04-12

Flued (internal) water heaters

This water heater must be fitted with the appropriate Rinnai flue system.

The chart below highlights the maximum flue length and number of bends. It also shows the difference between a

short and long flue—this is important if changing settings (DIP switches).

Number of 90 Degree Bends

0 1 2 3 4

Flue Length (m)

1

2

3

4

5

6

7

9

11

13

15

Refer to separate Rinnai flue guide for further details.

Short flue

setting

Long flue

setting

Maximum flue length

Continuous Flow Water Heater Installation Guide 04-12 | 9

Water delivery temperature

Local regulations and/or requirements of AS/NZS3500.4 must be considered regarding the temperature

limitations of hot water supplied to areas used primarily for personal hygiene. The temperature of these areas may

be limited to 55 °C or less.

If the appliance is to deliver water primarily for the purposes of personal hygiene in an early childhood centre,

school, nursing home or similar facility as defined in AS/NZ3500.4 a Temperature Limiting Device (TLD), such as

a Tempering Valve may be required (even if the appliance is set to 55 °C or less). For these types of applications

contact Rinnai.

Requirements for Rinnai continuous flow units installed without controllers

When the continuous flow unit is set to deliver water at a temperature higher than 55 °C, it will be necessary to fit a

Temperature Limiting Device for delivery to areas used for the purposes of personal hygiene.

Diagram 1 - 55 °C Appliance

55 °C

Diagram 2 - Not a 55 °C Appliance

(TLD = Temperature Limiting Device)

> 55 °C > 55 °C < 55 °C < 55 °C

Loading...

Loading...