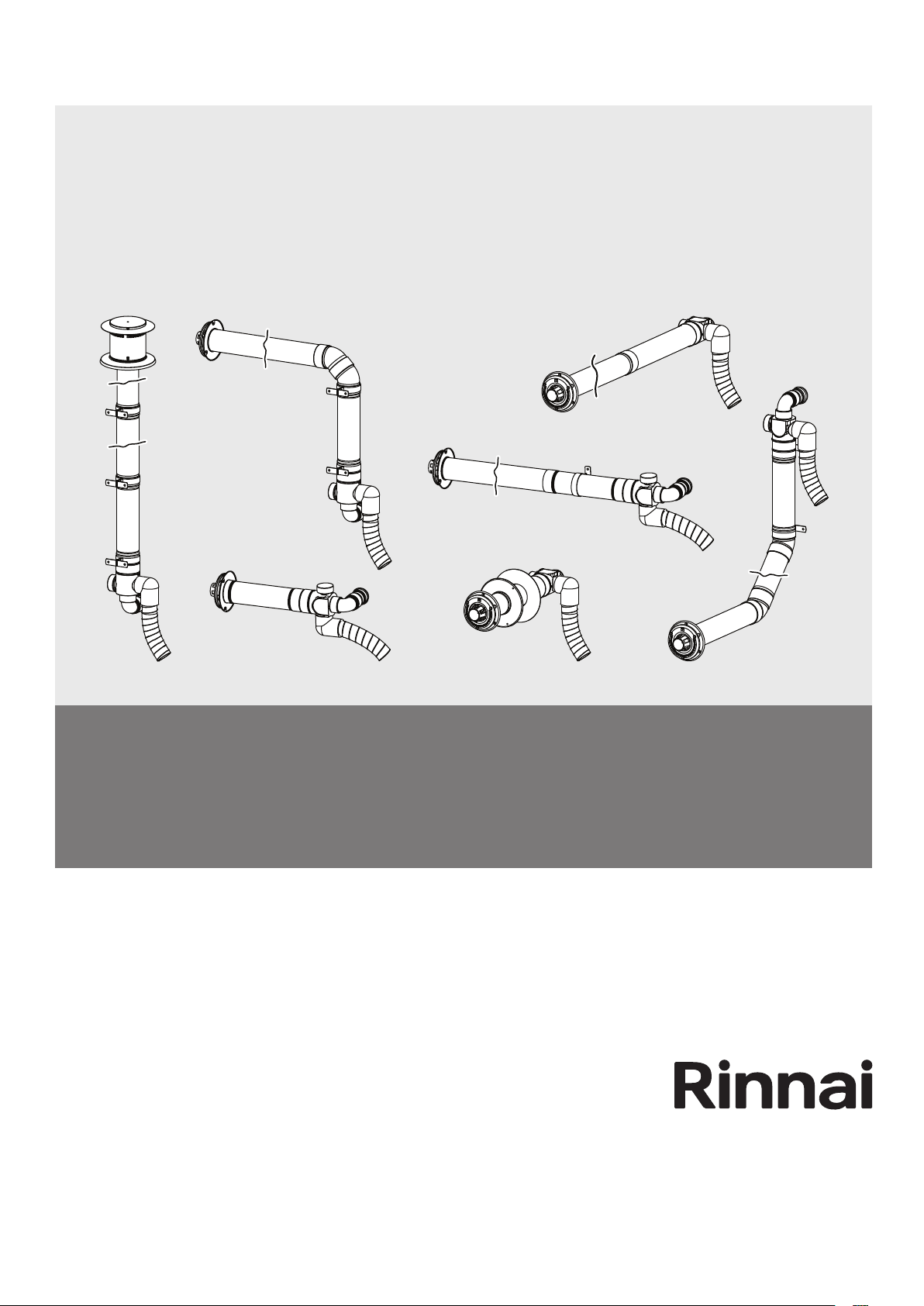

Page 1

Models:

Flametech® (RHFE0800F)

LS1000 (RHFE1000)

LS1500 (RHFE1500)

LS Series - Gas Fireplace

Flue Installation Manual

Page 2

Congratulations on the purchase of your Rinnai LS Series Gas Fireplace. We trust you will have many years of

IMPORTANT

comfort and enjoyment from your appliance.

BEFORE INSTALLING OR USING THIS APPLIANCE

Before proceeding with the operation or installation read this manual thoroughly and gain a full

understanding of the appliance, to ensure safe and correct installation and use.

USE ONLY RINNAI GENUINE PARTS

This Flue Installation Manual provides detailed requirements and instructions for Flue Systems connected to

LS Series Gas Fireplaces.

This appliance must be installed in accordance with:

• Manufacturer’s Installation Instructions

• Current AS/NZS 3000, AS/NZS 3500 & AS/NZS 5601

• Local Regulations and Municipal Building Codes

including local OH&S requirements

This appliance must be installed, maintained and removed

ONLY by an Authorised Person.

For continued safety of this appliance it must be installed

and maintained in accordance with the manufacturer’s

instructions.

This manual to suit LS - Series Heater Models:

®

Flametech

* LS1000 LS1500

RHFE0800SF * RHFE1000S RHFE1500S

RHFE0800DF * RHFE1000D RHFE1500D

®

*Incorporates Flametech

Rinnai 2 RHFE0800F_1000_1500 IM

self burning log technology.

Page 3

WARNING

INSTALLATION TABLE OF CONTENTS

Warnings & Important Information 5

Before Using or Installing This Appliance ........................................................................................................................ 5

Regulatory Information ....................................................................................................................................................... 5

Dress Guard Warnings ........................................................................................................................................................ 5

Mandatory Inspection prior to Installation ........................................................................................................................ 5

Modications. ....................................................................................................................................................................... 6

General Safety Warnings .................................................................................................................................................... 6

Flue Terminal Location ........................................................................................................................................................ 7

Other Conventions Used In This Manual ........................................................................................................................... 8

Terminal Location ................................................................................................................................................................ 8

Flue Installation Congurations 9

Flue Installation Options ..................................................................................................................................................... 9

Installation Conguration Quick Guide ........................................................................................................................... 10

Lubricating Inner Pipe Components ................................................................................................................................ 10

Installation Conguration Detailed Guide ........................................................................................................................11

Installation Conguration Component Guide ................................................................................................................. 12

Flue Exhaust & Air Inlet Connections .............................................................................................................................. 13

Direct Flue Assembly 14

Direct Extended Flue Assembly 15

Vertical Flue, External Wall 17

Vertical Flue, Internal Wall 20

Sideways Flue 21

Under Floor Flue 22

Common component Assemblies 24

Precautions for All Components ...................................................................................................................................... 24

Transition Extension Pipe ................................................................................................................................................. 24

Connecting ESPIPE900 ..................................................................................................................................................... 24

Connecting ESROOFCOWL .............................................................................................................................................. 24

Cutting - ASPDFK, LSFKIT01/02, LSFEXTKIT01, ESPIPE900 & ESROOFCOWL ......................................................... 25

Cutting Components to Achieve a Desired Length ��������������������������������������������������������������������������������������������������������� 25

Cutting Components for a Wall Penetration �������������������������������������������������������������������������������������������������������������������� 25

Wall Terminal Assembly .................................................................................................................................................... 26

On-Wall Terminal Assembly .............................................................................................................................................. 27

Connecting ESBEND ......................................................................................................................................................... 27

Contacts 28

This appliance MUST be installed, maintained and removed ONLY by an Authorised Person.

For continued safety of this appliance it MUST be installed and maintained in accordance with

the manufacturers instructions. Using ONLY Rinnai genuine parts.

Rinnai 3 RHFE0800F_1000_1500 IM

Page 4

This page is intentionally blank

Rinnai 4 RHFE0800F_1000_1500 IM

Page 5

IMPORTANT

WARNING

WARNINGS & IMPORTANT INFORMATION

BEFORE USING OR INSTALLING THIS APPLIANCE

Before proceeding with the operation or installation read this manual thoroughly and gain a full

understanding of the appliance, to ensure safe and correct use.

Failure to carefully read and follow all instructions in this manual can result in equipment

malfunction, property damage, personal injury and/or death.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in

personal injury or death.

WARNINGS: Indicates a potentially hazardous situation which, if not avoided, could result in

personal injury or death.

CAUTIONS: Indicates a potentially hazardous situation which, if not avoided, could result in

minor or moderate injury or damage to the appliance. It may also be used to alert against unsafe

practices.

REGULATORY INFORMATION

This appliance and Flue system shall be installed in accordance with:

Manufacturer’s Installation Instructions.

Current AS/NZS 3000, AS/NZS 3500 & AS/NZS 5601.

Local Regulations and Municipal Building Codes including local OH&S requirements.

This appliance and Flue system has been certied by the Australian Gas Association. The A.G.A.

Certication Number is shown on the data plate.

This appliance and Flue system MUST be installed, maintained and removed ONLY by an

Authorised Person.

For continued safety of this appliance it MUST be installed and maintained in accordance with

the manufacturers instructions.

NOTICE TO VICTORIAN CONSUMERS

This appliance MUST be installed by a person licensed with the Victorian Building Authority.

ONLY a licensed person will have insurance protecting their workmanship.

So make sure you use a licensed person to install this appliance and ask for your Compliance

Certicate. For further information contact the Victorian Building Authority on 1300 815 127.

DRESS GUARD WARNINGS

The guard is tted to this appliance to reduce the risk of re or injury from burns and

no part of it should be permanently removed. For protection of young children or the

inrm, a secondary guard is required.

The wire dress guard supplied with this appliance MUST NOT be permanently removed as it

fulls an operational safety function. Additional dress guards including free standing types may

be used in conjunction with, but NOT replace, the dress guard supplied with this appliance.

MANDATORY INSPECTION PRIOR TO INSTALLATION

Immediately report any damage or discrepancies to the Supplier of any components. This

appliance was inspected and tested at the time of manufacture and packaging, and released for

transportation without known damage. Upon receipt, inspect the exterior for evidence of rough

handling in shipment. Ensure that the appliance is labelled correctly for the gas and electrical

supply, and/or other services it is intended to be connected to.

For safety and warranty purposes, appliances or ue components that may be damaged or

incorrect MUST NOT be installed or operated under ANY circumstances. Installation of

damaged or incorrect appliances may contravene local government regulations. Rinnai disclaims

any liability or responsibility whatsoever in relation to the installation or operation of damaged

or incorrect appliances.

Take care when opening or unpacking this appliance. Failure to do so may result in serious

injury or product failure. Check the label for the correct gas type (refer rating plate, inside the

appliance). Refer to local gas authority for conrmation of the gas type if you are in doubt.

Rinnai 5 RHFE0800F_1000_1500 IM

Page 6

400mm

400mm

WARNINGS & IMPORTANT INFORMATION

MODIFICATIONS.

DO NOT MODIFY THIS APPLIANCE, modifying from original specications may create a

dangerous situation and will void your warranty. Failure to comply with these instructions could

result in a re or explosion, which could cause serious injury, death or property damage.

DO NOT modify the electrical wiring of this appliance.

If the power cord is damaged or deteriorated then it MUST be replaced by an authorised person.

Failure to do so may result in electric shock, re, serious injury or product failure.

Improper installation, adjustments, service or maintenance can cause serious injury, death or

property damage. Such work MUST ONLY be performed by an authorised person.

GENERAL SAFETY WARNINGS

This appliance is HEAVY, during installation the use of a mechanical lifting aid is recommended,

noting that improper lifting may result in serious personal injury or damage to the appliance.

WARNING: This heater MUST NOT be used if any of the glass panels are damaged.

Flue terminal MUST always vent directly to outdoors. DO NOT extend the ue vertically or

horizontally in ways other than prescribed in this appliance manufacturer’s installation

instructions. ONLY the ue components specied by Rinnai must be used.

When considering installation ensure

minimum clearances as follows are

adhered to, refer Fig. 1.

Heat radiating from the front of

this heater may over time aect the

appearance of some materials used

for ooring such as carpet, vinyl, cork

or timber. This eect may be amplied

if the air in the room contains cooking

vapours, candle vapours and cigarette

smoke, etc. To avoid this possibility, it

is recommended that a mat or similar

protective sheet be placed in front of

the appliance, extending at least 750

mm in front of the dress guard. Refer

to the installation manual for mantle

clearances, additional installation

information and warnings.

This appliance MUST NOT be installed where curtains or other combustible materials could

come into contact with it. In some cases curtains may need restraining.

This appliance is NOT intended for use by persons (including children) with reduced physical,

sensory or mental capabilities or lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the appliance by a person responsible for their

safety.

The appliance is NOT intended for use by young children or inrm persons without supervision.

Young children and the inrm SHOULD be supervised at all times when in the vicinity of this

heater while it is in operation.

The heater MUST NOT be located immediately below a power socket outlet.

A dedicated 230 V earthed 10 Amp power point must be used with this appliance.

Suitable ONLY for indoor installation.

NOT to be connected to an LP gas cylinder located indoors.

Please keep this instruction booklet in a safe place for future reference. All dimensions referred

to in these instructions are in millimetres, unless otherwise specied.

DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE.

DO NOT USE OR STORE FLAMMABLE MATERIALS IN OR NEAR THIS APPLIANCE.

DO NOT PLACE ARTICLES ON OR NEAR THIS APPLIANCE.

400mm

400mm

1000mm

1000mm

750mm

750mm

Note that side and vertical

clearances are measured

from the edge of the glass.

400mm

400mm

Fig .1

Rinnai 6 RHFE0800F_1000_1500 IM

Page 7

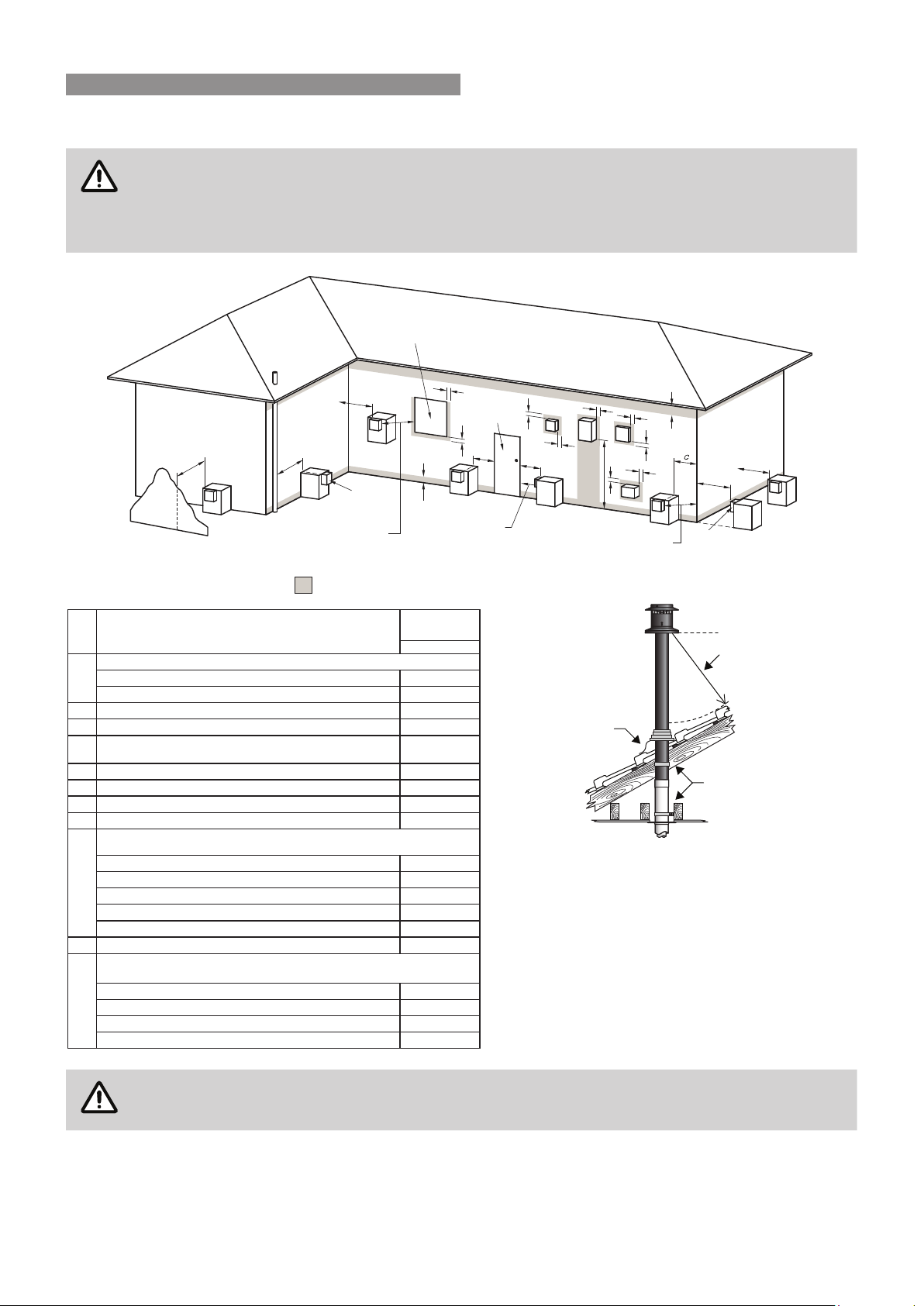

FLUE TERMINAL LOCATION

Ensure that the location of the ue terminal can comply with the requirements of AS/NZS 5601 -

Fig. 6.2 which is reproduced in part below.

AS/NZ 5601 was current at the time of printing but may have been superseded. It is the installer’s

responsibility to ensure that requirements of the current version of AS/NZS 5601 are met.

Opening into

a building

WARNINGS & IMPORTANT INFORMATION

C

T

g

T

S

LE G EN D:

I = M e c ha ni cal air in let

M = G as m ete r

P = E lec tr ic it y me ter or fuse box

S = S t r uc ture

f

T

Se e N ote 1

T = Fl ue ter minal

Z = F a n-a ss is ted a ppli ance only

Sh adin g in di c at es pro hibite d a rea for flue terminal s

Min. Clearances

metI.feR

Below eaves, balconies and other projections:

a

• Appliances up to 50 MJ/h input

• Appliances over 50 MJ/h input

From a gas meter (M) (see 5.11.5.9 for vent terminal location of regulator )

(see Table 6.6 for New Zealand requirements)

d

From an electricity meter or fuse box (P) †

e

epip lios ro epip niard a morFf

Horizontally from any building structure* = or obstruction facing a terminal

g

From any other flue terminal , cowl, or combustion air intake †

h

Horizontally from an openable window, door, non-mechanical air inlet, or any other opening into a

building with the exception of sub-floor ventilation:

• Appliances up to 150 MJ/h input *

• Appliances over 150 MJ/h input up to 200 MJ/h input *

j

• Appliances over 200 MJ/h input up to 250 MJ/h input *

• Appliances over 250 MJ/h input *

• All fan-assisted flue appliances , in the direction of discharge

Vertically below an openable window, non-mechanical air inlet, or any other opening into a

building with the exception of sub-floor ventilation:

n

• Other appliances up to 50 MJ/hr input

• Appliances over 50 MJ/h input and up to 150 MJ/h input

• Appliances over 150 MJ/h input

Natural Draught

b

Di re ction of

disch arge

(mm)

300

500

003* ecafrus rehto ro ynoclab a evoba ,dnuorg eht morFb

005* renroc lanretxe ro llaw nruter a tnorFc

1000

500

150

500

500

500

1500

1500

1500

-

0051rewolb aps a gnidulcni ,telni ria lacinahcem a morFk

051tupni rh/JM 05 ot pu sretaeh ecapS •

500

1000

1500

j

h

Door

n

j

T

e

T

P

I

h

j

Z

d

e

Se e N ote 1

a

k

k

d

M

T

T

g

g

i

iii

ii

i Minimum clearance 500mm to nearest part of roof

ii Minimum clearance 25mm to any combustible materials

iii Decktite or lead collar flashing

* - unless appliance is certified for closer installation

† - Prohibited area below electricity meter or fuse box extends to ground level.

NOTES:

1

Where dimensions c, j or k cannot be achieved an equivalent horizontal distance

measured diagonally from the nearest discharge point of the terminal to the opening

may be deemed by the Technical Regulator to comply.

2

See Clause 6.9.4 for restrictions on a flue terminal under a covered area.

3

See Figure J3 for clearances required from a flue terminal to an LP Gas cylinder.

A flue terminal is considered to be a source of ignition.

4

For appliances not addressed above acceptance should be obtained from the

Technical Regulator.

FIGURE 6.2 (in-part) MINIMUM CLEARANCES REQUIRED FOR FAN-ASSISTED FLUE TERMINALS,

ROOM-SEALED APPLIANCE TERMINALS AND OPENINGS OF OUTDOOR APPLIANCES

T

The ue terminal must be positioned away from ammable materials.

Rinnai 7 RHFE0800F_1000_1500 IM

Page 8

!

DO NOTDO NOT DO NOT DO NOT

WARNINGS & IMPORTANT INFORMATION

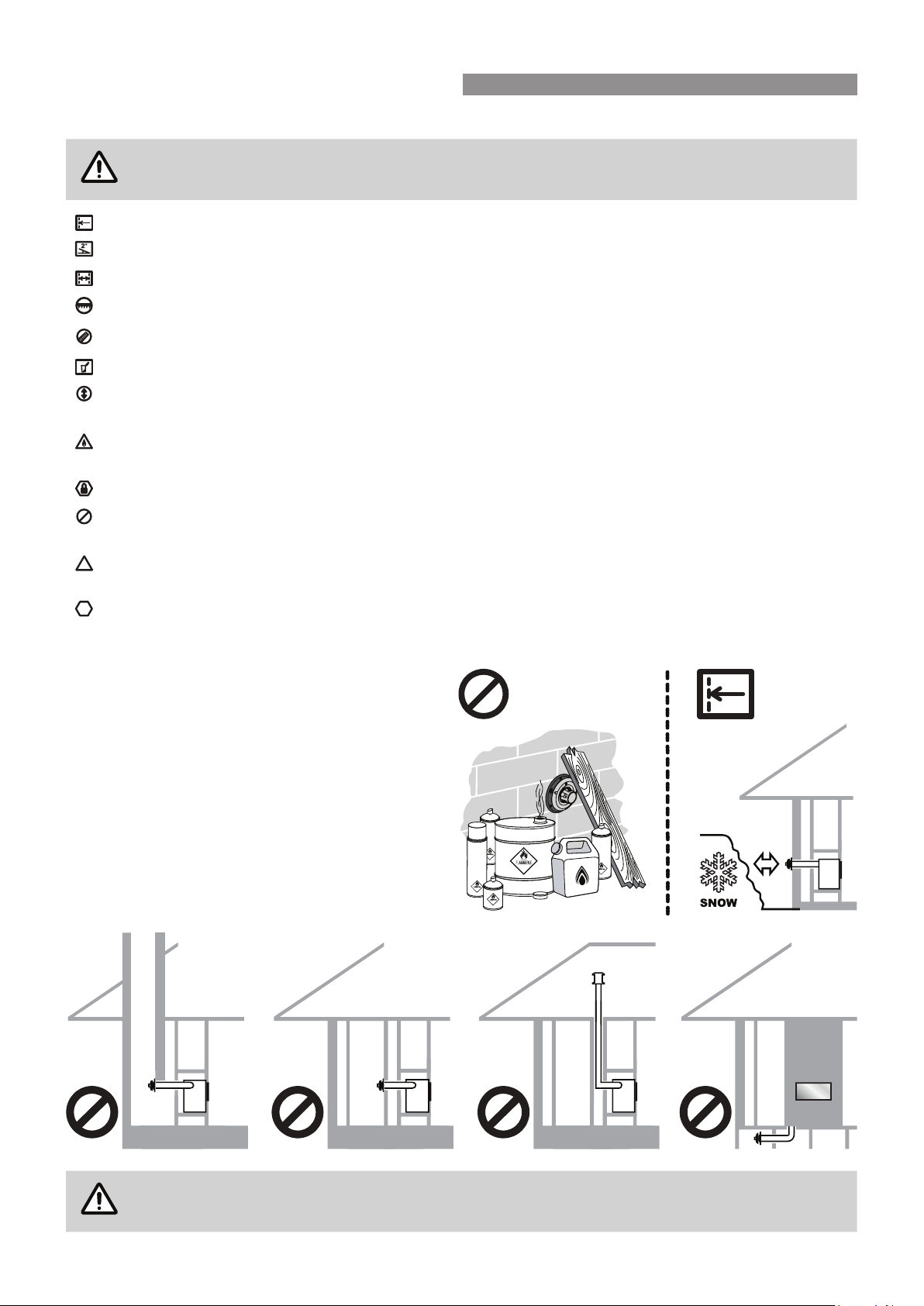

OTHER CONVENTIONS USED IN THIS MANUAL

The following are additional terms that may be used to highlight specic requirements during

installation steps and MUST be observed.

CLEARANCES: Where required clearances will be provided and must be observed.

FALL: Ensure that the specied 2° fall is maintained to either the terminal or the appliance as stipulated.

MEASURE: Required measurements will be provided and MUST BE observed for correct installation.

CUT: Cut as required to the specied measurements.

FINISH: Ensure that burrs and swarf are removed from all cut ends.

DISCARD: Denotes items that are not required for the specic installation.

OBSERVE CORRECT ORIENTATION: Where specied ensure that components are installed with the

correct vertical or horizontal orientation.

LUBRICATE: Use the supplied container of silicone grease to lubricate components. DO NOT use other

lubricants as these may damage the ue components.

SECURE: Where specied secure components with either installer provided or component supplied xings.

DO NOT: Failure to observe DO NOT instructions will void the warranty of an appliance and may cause injury

or death.

NOTE / IMPORTANT: Where specied secure components with either installer provided or component

supplied xings.

!

INSTALLATION STOP CAUTION: Installation stop caution notes and or warnings that MUST BE observed

for safe and correct installations.

TERMINAL LOCATION

The ue terminal MUST BE positioned away from

ammable materials.

In areas subject to heavy snowfall, keep snow clear of

DO NOT

ue terminal at all times.

DO NOT ue into natural draught ues or replaces.

DO NOT ue into other rooms.

DO NOT ue into roof spaces.

DO NOT ue into under oor spaces.

DO NOT Install the heater in an unusually dusty area.

For other important information regarding the location of the heater refer to the installation and

operation manuals supplied with the appliance.

Rinnai 8 RHFE0800F_1000_1500 IM

Page 9

NOTE

NOTE

NOTE

~380 mm

445 mm

(to clear flue)

300 mm min.

(top of adaptor

to first bend)

ESROOFCOWL

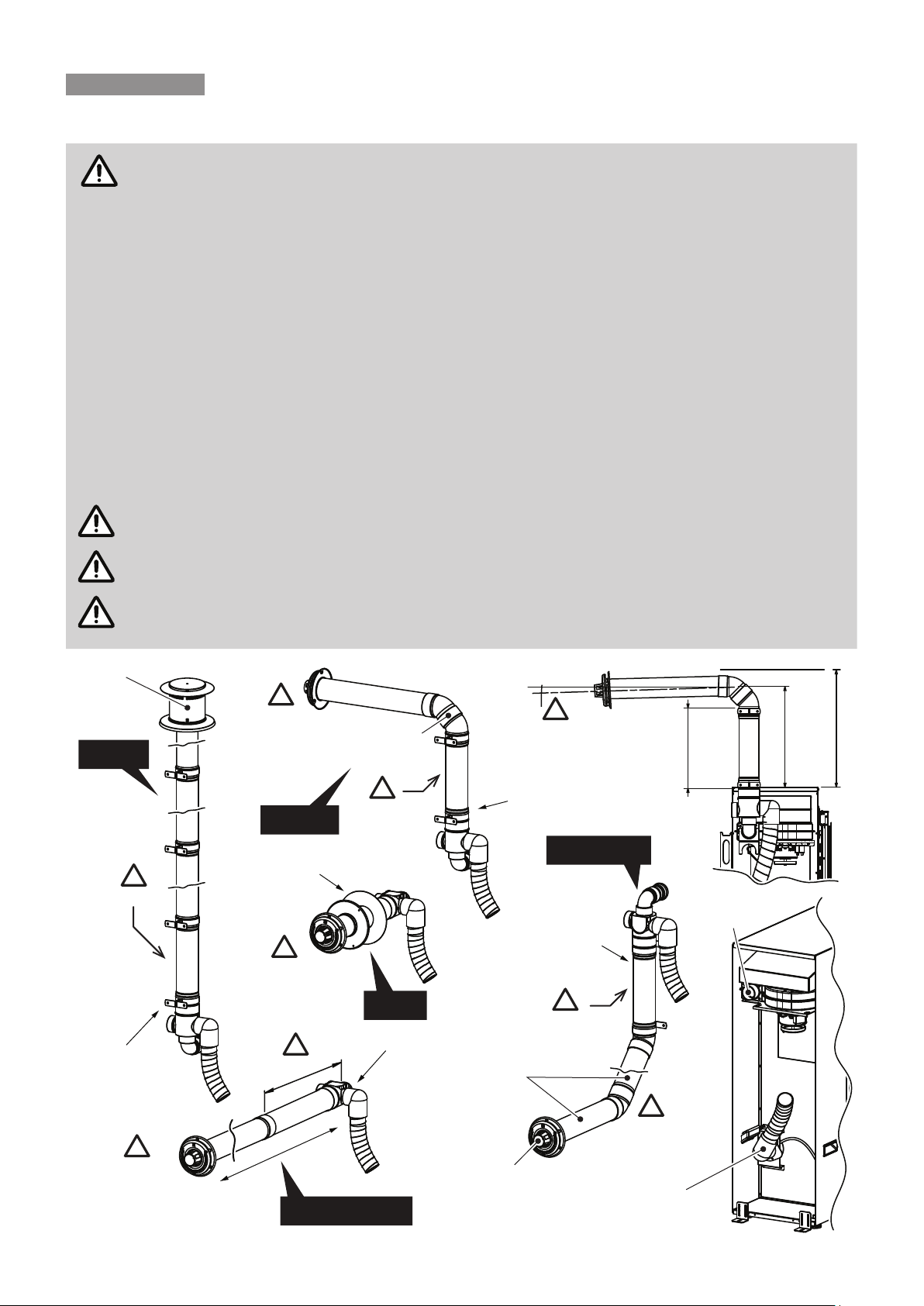

FLUE INSTALLATION CONFIGURATIONS

FLUE INSTALLATION OPTIONS

The following diagram provides an overview of the ue installation options available for LS-series

heaters.

ONLY the Rinnai ue system components specied in this reference manual MUST be used.

Components NOT specied in these manuals, whether manufactured by Rinnai or otherwise, are

NOT compatible and MUST NOT be used!

Use ONLY the supplied silicone grease when lubricating the O-rings.

Rinnai appliance warranty conditions may be voided if non Rinnai ue components are tted.

ONLY an authorised person MUST install, service and remove the Rinnai LS-series heater &

ue system.

The maximum ue length is 8.5m* and the maximum number of 90° bends is 3**.

* For every 90 ° bend, the overall ue length MUST be reduced by 1m.

** The 90° bend of the ue transition piece is NOT counted as a 90 ° bend.

LS-series heaters are factory set for "long ue installations", which is for ue runs that are 3

metres or less. Flue runs that are greater than 3 metres in length, are specied as "long ue

installations" and will require a dip switch change, refer commissioning instructions for details.

Note 1. When cutting the ue transition for joining to other components the minimum total length

is NOT to be less than 300mm!

Vertical

LSFKIT01/02

Note 2. The ue extension all aluminium component MUST be tted at this point.

Note 3. Where stipulated a Minimum 2° fall is required to ensure correct drainage of condensation

formed in the discharge ue.

!

See Note 3.

Min 2° fall towards

the appliance

Sideways

ASPDFK

45 ° bends

!

See note 2.

!

See Note 3.

Min 2° fall towards

the flue terminal

LSFKIT01/02

Under Floor

!

See note 2.

LSFKIT01/02

Flue Exhaust

Outlet

!

See Note 3.

Min 2° fall towards

the flue Terminal

!

See note 1.

Direct

ASPDFK

ESPIPE900

!

See note 2.

!

m

to 3

up

S

o

h

e

flu

t

r

Direct Extended

ESWTERM

!

See Note 3.

Min 2° fall towards

the flue Terminal

Rinnai 9 RHFE0800F_1000_1500 IM

See Note 3.

Min 2° fall towards

the flue Terminal

Air Inlet Pipe

(supplied pre fitted)

Page 10

CAUTION

FLUE INSTALLATION CONFIGURATIONS

INSTALLATION CONFIGURATION QUICK GUIDE

The information presented on this page is intended as quick reference guide to the basic

recommended installation congurations currently available for the LS-series appliances. For

alternatives to these congurations contact Rinnai.

For component congurations in greater detail and installation restrictions for these congurations

refer to the "Installation Conguration Detailed Guide" on page 11.

For full descriptions of all the available LS-series compatible ue components kits and there

contents refer to "Installation Conguration Component Guide" on page 12.

Detailed installation instructions for each of these congurations begin from page 9.

Direct / Extended External wall Internal wall Sideways Under floor

Installation

Type

Direct

Extended

Vertical

External

Wall

Vertical

Internal

Wall

Sideways LSFKIT01

Under Floor LSFKIT01 or LSFKIT02 ESPIPE900*# ESBEND**# LSFEXTKIT01 ESWTERM ESWFG

The maximum ue length is 8.5m* and the maximum number of 90° bends is 3**.

* For every 90 ° bend, the overall ue length MUST be reduced by 1m.

** The 90° bend of the ue transition piece is NOT counted as a 90 ° bend.

Transition Kit

Recommended Option

ASPDFK

or

LSFKIT01

A

B

A

ASPDFK

B

LSFKIT01

or

LSFKIT02

A

B

A

B

Common Additional Components

ESWFG

ESPIPE900*# LSFEXTKIT01 ESWFG

ESPIPE900*# ESBEND**# ESROOFCOWL

ESPIPE900*# ESBEND**# LSFEXTKIT01 ESWTKIT

ESPIPE900*#

ESPIPE900*# ESBEND**#

ESPIPE900*# ESWTERM ESWFG

ESPIPE900*# ESBEND**# ESWTERM ESWFG

# Order extra components as required

LUBRICATING INNER PIPE COMPONENTS

The inner ue pipe joints are sealed with an "O" ring seal.

To ease assembly, a small container of silicone grease is provided with the Direct Flue Kit (ASPDFK) and the Flue

Adaptation Kit (ASPKIT03). Use this silicone grease to lubricate the "O" ring on the inner pipes prior to assembly.

To obtain the desired amount of protrusion for termination, the ESPIPE900 may need to cut. Do

this in accordance with "Connecting ESPIPE900" on page 24

Rinnai 10 RHFE0800F_1000_1500 IM

Page 11

IN-WALL

Note 1. When cutting the flue transition for joining to other components the minimum total length is NOT to be less than 300mm!

FLUE INSTALLATION CONFIGURATIONS

INSTALLATION CONFIGURATION DETAILED GUIDE

Note 2. The flue extension all aluminium component MUST be fitted at this point.

IMPORTANT

Note 3. Where stipulated a Minimum 2° fall is required to ensure correct drainage of condensation formed in the discharge flue.

The maximum flu length is 8.5m and the maximum number of 90° bends is 3, however for every 90 ° bend, overall flue length MUST be

reduced by 1m (For LS-series heaters the bend of the transition piece is NOT counted as one of these 3 90 ° bends).

Cut to correct

length & discard

See note 1.

Cut to correct

length & discard

!

!

See Note 3.

Min 2° fall towards

the flue Terminal

• DIRECT

DIRECT

• DIRECT EXTENDED

Cut to correct

length & discard

!

See note 1.

UNDER FLOOR

!

See Note 3.

Min 2° fall towards

the flue Terminal

DIRECT EXTENDED

!

See note 2.

!

A

See note 2.

• EXTERNAL WALL

• IN-WALL

!

See note 2.

!

See Note 3.

Min 2° fall towards

the flue Terminal

SIDEWAYS

• UNDER FLOOR

A

• SIDEWAYS

!

Cut to correct

length & discard

!

See Note 3.

Min 2° fall towards

the flue Terminal

Rinnai 11 RHFE0800F_1000_1500 IM

!

See Note 3.

Min 2° fall towards

the flue Terminal

A

See Note 3.

Min 2° fall towards

the appliance

EXTERNAL WALL

!

See note 1.

Page 12

FLUE INSTALLATION CONFIGURATIONS

INSTALLATION CONFIGURATION COMPONENT GUIDE

ASPDFK

(Direct Flue Kit for Rinnai Flamefires)

Internal Wall Plate

External Wall Plate

Flue Terminal

Silicone Grease

Flue Transition

22mm

x6

Mounting/Securing Screws

ESBEND

Co-ax Bends & Pipe Locating

Spacer x2

7mm

x2

BOTH spacers are

required for all offset

and extended offset

installations!

ESPLATE

Mounting/Securing Screws

(This manual also included)

External Wall Plate

22mmx37mm

x2

LSFKIT01

(Flue Adaption Kit

for Rinnai LS-series heaters)

Transition Extension Pipe

Spacer

Flue Transition

Wall Clip

Silicone Grease

(This manual also included)

LSFEXTKIT01

Transition Extension Pipe

LSFKIT02

(Extended Flue Adaption Kit

for Rinnai LS-series heaters)

Co-ax Vertical Terminal

3x Co-ax Pipe

Co-ax Bends & Pipe

Locating Spacers x 2

Transition Extension Pipe

Spacer

ESPIPE900

Co-ax

Pipe

ESROOFCOWL

Co-ax

Vertical

Terminal

Spacer

Silicone Grease

ESWTERM

External Wall Plate

Flue Terminal

22mm

x6

Mounting/Securing Screws

ESWTKIT

(Wall Terminal Kit)

Wall Clip

7mm

x2

External Wall Plate

Extension Pipe

Silicone Grease x2

(This manual also included)

ESWFG

Wall Clips x5

Flue Guard

Wall

Clip

Wall

Clip

22mm

x3

Mounting/Securing Screws

7mm

x2

Pipe Spacer

Flue Outlet Grill

Rinnai 12 RHFE0800F_1000_1500 IM

Page 13

Flue exhaust

Air inlet hose

(shown installed)

FLUE INSTALLATION CONFIGURATIONS

FLUE EXHAUST & AIR INLET CONNECTIONS

The following steps in the installation are critical. If the connections are not secured correctly,

then products of combustion could disperse into living areas.

1. Connect the ue terminal exhaust connection to the ue exhaust outlet, and secure in place (two screws) with

the ue locking bracket (supplied in the accessories plastic bag with the remote control).

2. Secure the ue transition to the framing using a wall clip (supplied with LSFKIT01/02 or ASPDFK).

3. Attach the air intake hose to the large air inlet connection on the ue transition (LSFKIT01/02 or ASPDFK)

and secure in place with the supplied cable tie (also supplied), noting that the other end of the air inlet hose

is already pre-installed to the appliance.

4. Ensure that the rubber cap remains secured in place on the unused (small) air inlet connection.

locking bracket

Flue exhaust outlet

Flue exhaust

locking bracket

(shown installed)

Air inlet hose

(This end is to be

fitted to LSFKIT01/02

or ASPDFX)

Air inlet hose

(This end is supplied

pre-fitted to the appliance)

(Extension piece not shown)

ASPDFK

Air inlet hose

Flue exhaust

locking bracket

LSFKIT01/02

Flue exhaust

connection

Large air inlet

connection

Flue exhaust

connection

Flue exhaust

locking bracket

(shown installed)

Air inlet hose

(This end is supplied pre fitted to the appliance)

Flue exhaust

connection

Small air inlet connection

(Rubber cap MUST remain in place)

Rinnai 13 RHFE0800F_1000_1500 IM

Page 14

ASPDFK

CAUTION

NOTE

ASPDFK

See note 1.

!

Direct Extended

Min 2° fall towards

the flue Terminal

Air Inlet Pipe

(supplied pre fitted)

Flue Exhaust

Outlet

ESPIPE900

LSFKIT01

DIRECT FLUE ASSEMBLY

Follow the engine and ue installation instructions detailed

in the Installation manual provided with appliance.

The Direct ue kit (ASPDFK) is suitable for walls up to

385mm thick. ASPDFK can be cut to length to suit wall

thickness’s less than 385mm thick.

For wall thickness’s greater than 385mm Co-axial Pipe(s)

(ESPIPE900) can be fastened onto ASPDFK to extend

the ue length. Refer to the section "Direct Extended Flue

Assembly" on page 15 for details.

With heater engine installed into the support framing:

1. Create the wall penetration(s).

The minimum diameter required for wall

the penetration for a DIRECT ue installation is

80mm to non-combustible surfaces such as brick

and 100mm to combustible surfaces such as plaster.

Allow for a continuous 2° fall from the heater

connection point to the wall terminal.

2. Slide the internal wall plate over the terminal end of

the ASPDFK pipe until it is nested on the raised ring

of the ue transition.

3. Pass the ASPDFK through the internal wall

penetration.

Min 2° fall towards

the flue Terminal

LSFKIT01

Flue Exhaust

Outlet

Direct

Air Inlet Pipe

(supplied pre fitted)

4. Make the heater exhaust and combustion air hose

5. Slide the internal wall plate so that it is ush with the

6. Create the wall terminal in accordance with "Wall

7. Refer to Installation Manual provided with appliance

connections.

Air hose and heater exhaust connections

MUST be made and checked in accordance

with "Flue Exhaust & Air Inlet Connections"

on page 13. Improper connections may

result in dangerous situations, for example,

the dispersion of combustion products in

the space being heated and living areas.

wall.

Terminal Assembly" on page 26

to nalise installation and commissioning of the

heater.

Use ONLY the supplied silicone based

“O Ring” seal lubricant. DO NOT use

petroleum based lubricants such as

petroleum jelly. The use of petroleum jelly,

Vaseline® or similar petroleum based

lubricants will cause rapid deterioration of

the ‘O Ring’ seals.

For non-condensing heaters a 2° fall of the

ue away from the heater helps prevent

rainwater or sprinkler water etc from entering

the ue system.

Interior wall

1

Max’ wall thickness 385mm

Min’ required protrusion 15mm

2

Internal wall plate, outer face

Exterior wall

3

Rinnai 14 RHFE0800F_1000_1500 IM

Page 15

CAUTION

CAUTION

NOTE

Flue Exhaust

DIRECT EXTENDED FLUE ASSEMBLY

Follow the engine and ue installation instructions detailed

in the Installation manual provided with appliance.

To create a DIRECT EXTENDED FLUE, Co-axial Pipe(s)

(ESPIPE900) can be fastened onto ASPDFK.

Use ONLY the supplied silicone based

“O Ring” seal lubricant. DO NOT use

petroleum based lubricants such as

petroleum jelly. The use of petroleum jelly,

Vaseline® or similar petroleum based

lubricants will cause rapid deterioration of

the ‘O Ring’ seals.

ONLY use PVC cement between

externally located joints of PVC pipes to

secure and seal these joints against ingress

of dust and water.

ONLY use non-acidic silicone sealant

between externally located joints of PVC ue

pipe and any mating aluminium components

(such as the condensate trap) to secure and

seal these joints against ingress of dust and

water. Silicone containing acetic acid,

(characteristically having a vinegar odour),

as the curing agent or other acids may cause

corrosion of aluminium components and

MUST NOT be used.

Secure the vertical ue sections to the

wall using the clips provided to prevent

accidental dislodgement.

NOTE 1. When cutting the ue transition for

joining to other components the minimum

total length is NOT to be less than 300mm!

ESPIPE900

Min 2° fall towards

the flue Terminal

LSFKIT01

Interior wall

1

Min’ required protrusion 50mm

!

See note 1.

ASPDFK

Direct Extended

Air Inlet Pipe

(supplied pre fitted)

Outlet

With heater engine installed into the support framing.

1. Create the wall penetration(s).

The minimum diameter required for wall

the penetration for a DIRECT ue installation is

80mm to non-combustible surfaces such as brick

and 100mm to combustible surfaces such as plaster.

Allow for a continuous 2° fall from the heater

connection point to the wall terminal.

2. Join ESPIPE900 to ASPDFK. Fit additional lengths

of ESPIPE900 as required. Slide the internal wall

plate over the terminal end of the ASPDFK pipe until

it is nested on the raised ring of the ue transition.

Internally located joints between ASPDFK

and ESPIPE900 and any additional

ESPIPE900 lengths MUST be secured by a

pop rivet or screw through the outer Co-axial

pipes to prevent accidental or erroneous

dislodgement.

ASPDFK and ESPIPE900 DO NOT require

cutting to be joined.

Internal wall plate, outer face

2

Exterior wall

3

Rinnai 15 RHFE0800F_1000_1500 IM

Page 16

CAUTION

DIRECT EXTENDED FLUE ASSEMBLY

4. Pass the ASPDFK through the internal wall perforation.

5. Make the heater exhaust and combustion air hose connections.

Air hose and heater exhaust connections MUST be made and checked in accordance with "Flue

Exhaust & Air Inlet Connections" on page 13. Improper connections may result in dangerous

situations, for example, the dispersion of combustion products in the space being heated.

6. Slide the internal wall plate so that it is ush with the wall.

7. Create the wall terminal in accordance with "Wall Terminal Assembly" on page 26

To obtain the desired amount of protrusion for termination, the ESPIPE900 may need to cut. Do

this in accordance with "Connecting ESPIPE900" on page 24

8. Refer to Installation Manual provided with appliance to nalise installation and commissioning of the heater.

Rinnai 16 RHFE0800F_1000_1500 IM

Page 17

CAUTION

NOTE

NOTE

VERTICAL FLUE, EXTERNAL WALL

Follow the engine and ue installation instructions detailed

in the Installation manual provided with appliance.

The creation of the horizontal section of ue installation is

the same as creating a DIRECT or DIRECT EXTENDED

ue installations with the following exceptions:

The direction of horizontal fall of the ue pipe is

reversed. For Wall External ue installations, a 2° fall is

required from the wall penetration towards the heater.

An ESBEND rather than the ESWTERM ue terminal is

tted at the end of the horizontal ue run.

The maximum ue length is 8.5m* and the

maximum number of 90° bends is 3**.

* For every 90 ° bend, the overall ue length

MUST be reduced by 1m.

** The 90° bend of the ue transition piece is

NOT counted as a 90 ° bend.

Note 1. When cutting the ue transition for

joining to other components the minimum

total length is NOT to be less than 300mm!

Possible kits and components required for creating

VERTICAL EXTERNAL WALL installations:

ESPIPE900

Min 2° fall towards

the appliance

ASPDFK

!

See note 1.

Direct Extended

Air Inlet Pipe

(supplied pre fitted)

Flue Exhaust

Outlet

ASPDFK (LSFKIT01/02 may also be used)

A

ESPLATE#

B

ESBEND#

C

LSFEXTKIT01# (require for change of connection

D

direction when terminating with an ESROOFCOWL)

ESPIPE900#

E

ESPLATE#

F

ESROOFCOWL or ESWTKIT

G

# Available separately or as part of kit see "Installation

Conguration Component Guide" on page 12 for kit

component contents.

1. Follow the installation method for a "Direct Flue

Assembly" on page 14 or for a "Direct Extended

Flue Assembly" on page 15 to the completion of

step 4.

If required, components of LSFKIT01 and

LSFKIT02 may be utilised as an alternative

to using the ASPDFK kit to create a DIRECT

or DIRECT EXTENDED installation to reach

the point of the external wall penetration.

G

F

E

D

When using LSFKIT01 and LSFKIT02 a

sideways conguration will be required

to reach the point of the external wall

penetration.

For details on how to create a sideways

ue conguration refer to “CREATING A

“SIDEWAYS” FLUE INSTALLATION” on page

14.

Rinnai 17 RHFE0800F_1000_1500 IM

C

B

A

Page 18

CAUTION

CAUTION

VERTICAL FLUE, EXTERNAL WALL

2. Slide the external wall plate over the outer pipe

protruding through the exterior wall. Ensure a 2°

fall of the horizontal section of ue pipe towards the

appliance as required.

!

Once the external wall plate is in the correct

position secure it to the wall using the three 22mm

screws into the holes provided. The wall plate is then

secured to the outer pipe of the ue protrusion using

the two horizontal holes and the two 7mm screws

provided.

22mm x 3

7mm x 2

2

3.

Cut the ue pipe end protruding through the

exterior wall in accordance with "Connecting

ESPIPE900" on page 24.

Use ONLY the supplied silicone based

“O Ring” seal lubricant. DO NOT use

petroleum based lubricants such as

petroleum jelly. The use of petroleum jelly,

Vaseline® or similar petroleum based

lubricants will cause rapid deterioration of

the ‘O Ring’ seals.

ONLY use PVC cement between

externally located joints of PVC pipes to

secure and seal these joints against ingress

of dust and water.

ONLY use non-acidic silicone sealant

between externally located joints of PVC ue

pipe and any mating aluminium components

(such as the condensate trap) to secure and

seal these joints against ingress of dust and

water. Silicone containing acetic acid,

(characteristically having a vinegar odour),

as the curing agent or other acids may cause

corrosion of aluminium components and

MUST NOT be used.

3

4

Min’ require

For installations being terminated

!

with ESROOFCOWL !

d protrusion 50mm

!

Secure the vertical ue sections to the

wall using the clips provided to prevent

accidental dislodgement.

4. Now prepare the vertical section of the ue system by assembling, connecting and securing ESBEND,

ESCONDK and subsequent ESPIPE900 lengths as required in accordance with the relevant sections

under "Connecting ESBEND" on page 27, “COMPONENT ASSEMBLY & CONNECTION ~ TRANSITION

EXTENSION PIPE (LSFEXTKIT01)” refer to page 24 and “COMPONENT ASSEMBLY & CONNECTION ~

ESPIPE900” refer to page 24.

!

For installations being terminated with ESROOFCOWL a Transition Extension Pipe

(LSFEXTKIT01)* will need to be installed at this point. This is required to enable the change of

connection direction necessary when tting the ESROOFCOWL.

* All ue installations that use LSFKIT01/02 MUST be tted with Transition Extension Pipe.

5. If a vertical roof terminal is used cut in accordance with “CUTTING ~ ASPDFK, LSFKIT01/02, ESPIPE900 &

ESROOFCOWL FLUE PIPES” on page 23 and assemble and connect in accordance with “All “External Wall”,

Rinnai 18 RHFE0800F_1000_1500 IM

Page 19

VERTICAL FLUE, EXTERNAL WALL

“Internal Wall”, “Sideways” and “Under Floor” ue installations MUST be tted with Transition Extension Pipe

when using LSFKIT01/02.” on page 23.

If a horizontal terminal is used cut in accordance with “CUTTING ~ ASPDFK, LSFKIT01/02, ESPIPE900 &

ESROOFCOWL FLUE PIPES” on page 23 and assemble and connect in accordance with “ASSEMBLING

AN ON-WALL TERMINAL ~ ESWTKIT, ESBEND & ESPIPE900” on page 23.

6. Refer to Installation Manual provided with appliance to nalise installation and commissioning of the heater.

Rinnai 19 RHFE0800F_1000_1500 IM

Page 20

CAUTION

NOTE

CAUTION

VERTICAL FLUE, INTERNAL WALL

Follow the engine installation instructions detailed in the

Installation manual provided with appliance.

The vertical ue installation is installed against an internal

wall within a false re place or other suitable cavity and is

run vertically upwards to the termination point.

When considering the location of the heater due care

MUST be taken to ensure that the ue path in the roof

space are free of obstructions such as studs, noggins,

joists, braces, and electricals etc.

The maximum ue length is 8.5m* and the

maximum number of 90° bends is 3**.

* For every 90 ° bend, the overall ue length

MUST be reduced by 1m.

** The 90° bend of the ue transition piece is

NOT counted as a 90 ° bend.

Note 2. The all aluminium ue extension

component MUST be tted at this point.

With heater engine installed into the support framing

complete the following:

1. Assemble the components of the Flue Adaptation Kit

(LSFKIT01/02), by joining the ue transition and the

transition extension pipe components together.

Flue Exhaust

Outlet

ESROOFCOWL

Vertical

!

See note 2.

LSFKIT01/02

Air Inlet Pipe

(supplied pre fitted)

1

The transition extension pipe connections are the

same at each end, so either end may be connected.

All ue installations that use LSFKIT01/02 MUST be tted with Transition Extension Pipe.

Use ONLY the supplied silicone based “O Ring” seal lubricant. DO NOT use petroleum

based lubricants such as petroleum jelly. The use of petroleum jelly, Vaseline® or similar petroleum

based lubricants will cause rapid deterioration of the ‘O Ring’ seals.

The join between the ue transition and ue transition extension MUST be secured by a pop

rivet or screw through the outer Co-axial pipes to prevent accidental or erroneous dislodgement.

The assembled LSFKIT01/02 is to be clipped to the structure using the stand o clips supplied or

other suitable method.

LSFKIT01/02 components and ESPIPE900 DO NOT require cutting to be joined.

2. Make the heater exhaust and combustion air hose connections in accordance with"Flue Exhaust & Air Inlet

Connections" on page 13.

Air hose and heater exhaust connections MUST be made and checked in accordance with "Flue

Exhaust & Air Inlet Connections" on page 13. Improper connections may result in dangerous

situations, for example, the dispersion of combustion products in the space being heated.

3. Create the ceiling and or wall penetration(s).

The minimum diameter required for wall the penetration for a Vertical ue installation is 80mm to non-

combustible surfaces such as brick and 100mm to combustible surfaces such as plaster.

4. Fit lengths of ESPIPE900 to LSFKIT01/02 in accordance with “COMPONENT ASSEMBLY & CONNECTION

~ ESPIPE900” on page 24. Determine the location of roof and or ceiling penetration points. To avoid

obstructions in the ue path a horizontal oset can be created using ESBEND.

5. Create a vertical roof terminal in accordance with “CUTTING ~ ASPDFK, LSFKIT01/02, ESPIPE900 &

ESROOFCOWL FLUE PIPES” on page 23.

6. Refer to Installation Manual provided with appliance to nalise installation and commissioning of the heater.

Rinnai 20 RHFE0800F_1000_1500 IM

Page 21

CAUTION

NOTE

CAUTION

SIDEWAYS FLUE

Follow the engine installation instructions detailed in the

Installation manual provided with appliance.

The SIDEWAYS ue installation will instead of terminating

through the ceiling run sideways to the left or right of the

cavity and terminate through an external wall.

A 2° fall

is required from the wall penetration towards the heater.

When considering the location of the heater due care

MUST be taken to ensure that the ue path is free of

obstructions such as studs, noggins, joists, braces, and

electricals etc.

The maximum ue length is 8.5m* and the

maximum number of 90° bends is 3**.

* For every 90 ° bend, the overall ue

maximum allowable length MUST be

reduced by 1m.

** The 90° bend of the ue transition piece is

NOT counted as a 90 ° bend.

Note 2. The ue all aluminium extension

component MUST be tted at this point.

With heater engine installed into the support framing.

1. Assemble the components of the Flue Adaptation Kit

(LSFKIT01/02), by joining the ue transition and the

transition extension pipe components together.

!

Min 2° fall towards

the terminal

See note 2.

LSFKIT01/02

Sideways

45 ° bends

!

Air Inlet Pipe

(supplied pre fitted)

1

Flue Exhaust

Outlet

The transition extension pipe connections are the

same at each end, so either end may be connected.

All ue installations that use LSFKIT01/02 MUST be tted with Transition Extension Pipe.

Use ONLY the supplied silicone based “O Ring” seal lubricant. DO NOT use petroleum

based lubricants such as petroleum jelly. The use of petroleum jelly, Vaseline® or similar petroleum

based lubricants will cause rapid deterioration of the ‘O Ring’ seals.

The join between the ue transition and ue transition extension MUST be secured by a pop

rivet or screw through the outer Co-axial pipes to prevent accidental or erroneous dislodgement.

The assembled LSFKIT01/02 is to be clipped to the structure using the stand o clips supplied or

other suitable method.

LSFKIT01/02 components and ESPIPE900 DO NOT require cutting to be joined.

2. Make the heater exhaust and combustion air hose connections in accordance with "Flue Exhaust & Air Inlet

Connections" on page 13.

Air hose and heater exhaust connections MUST be made and checked in accordance with "Flue

Exhaust & Air Inlet Connections" on page 13. Improper connections may result in dangerous

situations, for example, the dispersion of combustion products in the space being heated.

3. Create the wall penetration(s).

The minimum diameter required for wall the penetration for a DIRECT ue installation is 80mm to non-

combustible surfaces such as brick and 100mm to combustible surfaces such as plaster.

Allow for a continuous 2° fall from the heater connection point towards the heater.

4. Fit combinations of ESPIPE900 and ESBEND to LSFKIT01/02 as required to reach the termination point in

accordance with “COMPONENT ASSEMBLY & CONNECTION ~ ESPIPE900” on page 24 and “COMPONENT

ASSEMBLY & CONNECTION ~ ESBEND” on page 24.

5. Create the wall terminal in accordance with “ASSEMBLING WALL TERMINAL ~ ASPDFK & ESPIPE900” on

page 24.

6. Refer to Installation Manual provided with appliance to nalise installation and commissioning of the heater.

Rinnai 21 RHFE0800F_1000_1500 IM

Page 22

CAUTION

NOTE

CAUTION

4

Interior wall

Internal

wall plate

Stand off clip

5

Interior wall

Interior wall

Floor Penetration

location

3

UNDER FLOOR FLUE

Follow the engine installation instructions detailed in the

Installation manual provided with appliance.

The UNDER FLOOR FLUE ue installation allows for a

Flue Adaptation Kit (LSFKIT01/02) to face downwards

and the ue to be run vertically though a hole in the oor,

and then horizontally to a suitable location outside.

When considering the location of the heater due care

MUST be taken to ensure that the ue path under the

oor is free of obstructions such as studs, noggins, joists,

braces, and electricals etc.

The maximum ue length is 8.5m* and the

maximum number of 90° bends is 3**.

* For every 90 ° bend, the overall ue length

MUST be reduced by 1m.

** The 90° bend of the ue transition piece is

NOT counted as a 90 ° bend.

Note 2. The ue all aluminium extension

component MUST be tted at this point.

With heater engine installed into the support framing.

1. Assemble the components of the Flue Adaptation Kit

(LSFKIT01/02), by joining the ue transition and the

transition extension pipe components together.

The transition extension pipe connections are the

same at each end, so either end may be connected

Under Floor

LSFKIT01/02

See note 2.

ESPIPE900

ESWTERM

1

!

!

See Note 3.

Min 2° fall towards

the flue Terminal

Air Inlet Pipe

(supplied pre fitted)

Flue Exhaust

Outlet

Interior wall

2

All ue installations that use LSFKIT01/02 MUST be tted with Transition Extension Pipe.

Use ONLY the supplied silicone based “O Ring” seal lubricant. DO NOT use petroleum

based lubricants such as petroleum jelly. The use of petroleum jelly, Vaseline® or similar petroleum

based lubricants will cause rapid deterioration of the ‘O Ring’ seals.

Use ONLY the supplied silicone based “O Ring” seal lubricant. DO NOT use petroleum

based lubricants such as petroleum jelly. The use of petroleum jelly, Vaseline® or similar petroleum

based lubricants will cause rapid deterioration of the ‘O Ring’ seals.

The joint between the ue transition and ue transition extension MUST be secured by a pop

rivet or screw through the outer Co-axial pipes to prevent accidental or erroneous dislodgement.

The assembled LSFKIT01/02 is to be clipped to the structure using the stand o clips supplied or

other suitable method.

LSFKIT01/02 components and ESPIPE900 DO NOT require cutting to be joined.

2. Make the heater exhaust and combustion air hose connections in accordance with"Flue Exhaust & Air Inlet

Connections" on page 13.

Then secure LSFKIT01/02 in place with the provided wall bracket.

Air hose and heater exhaust connections MUST be made and checked in accordance with "Flue

Exhaust & Air Inlet Connections" on page 13. Improper connections may result in dangerous

situations, for example, the dispersion of combustion products in the space being heated.

Rinnai 22 RHFE0800F_1000_1500 IM

Page 23

Interior wall

Internal

wall plate

Interior wall

UNDER FLOOR FLUE

Interior wall

Floor Penetration

location

3

3. Create the oor penetration(s).

Mark o the penetration point through the oor and cut the hole through the oor at this point.

Ensure the hole edges are smooth. The minimum diameter required for a oor penetration is 80mm to noncombustible surfaces such as brick and 100mm to combustible surfaces such as plaster, oor boards, etc.

4. Pass ESPIPE900 through the internal wall plate and through the oor penetration. Then lift ESPIPE900 up and

secure it to LSFKIT01/02 in accordance with “COMPONENT ASSEMBLY & CONNECTION ~ ESPIPE900”

on page 24.

5.

6. Fit combinations of ESPIPE900 and ESBEND to LSFKIT01/02 as required to reach the termination point in

7. Create the wall terminal in accordance with “ASSEMBLING WALL TERMINAL ~ ASPDFK & ESPIPE900” on

Secure internal wall plate in place to seal the oor.

accordance with “COMPONENT ASSEMBLY & CONNECTION ~ ESPIPE900” on page 24 and “COMPONENT

ASSEMBLY & CONNECTION ~ ESBEND” on page 24.

Allow for a continuous 2° fall from the heater connection point to the wall terminal.

page 24.

4

Stand off clip

5

8. Refer to Installation Manual provided with appliance to nalise installation and commissioning of the heater.

Rinnai 23 RHFE0800F_1000_1500 IM

Page 24

CAUTION

Socket (O-ring) end

of previous componenet

COMMON COMPONENT ASSEMBLIES

PRECAUTIONS FOR ALL COMPONENTS

The following precautions are to be observed for all ue pipe assemblies.

Use ONLY the supplied silicone based “O Ring” seal lubricant. DO NOT use petroleum

based lubricants such as petroleum jelly. The use of petroleum jelly, Vaseline® or similar petroleum

based lubricants will cause rapid deterioration of the ‘O Ring’ seals.

ONLY use PVC cement between externally located joints of PVC pipes to secure and seal

these joints against ingress of dust and water.

Joints between the ue transition and ue transition extension MUST be secured by a pop

rivet or screw through the outer Co-axial pipes to prevent accidental or erroneous dislodgement.

ONLY use non-acidic silicone sealant between externally located joints of PVC ue pipe and

any mating aluminium components (such as the transition extension piece) to secure and seal

these joints against ingress of dust and water. Silicone containing acetic acid, (characteristically

having a vinegar odour), as the curing agent or other acids may cause corrosion of aluminium

components and MUST NOT be used.

TRANSITION EXTENSION PIPE

All “External Wall”, “Internal Wall”, “Sideways” and “Under Floor” ue installations MUST be

tted with Transition Extension Pipe when using LSFKIT01/02.

1.

Observe the above precautions. Lubricate all ‘O-Rings’ with

the silicone grease provided.

Assemble the components of the Flue Adaptation Kit

(LSFKIT01/02), by joining the ue transition and the transition

extension pipe components together and secure components

together. Noting that the transition extension pipe connections are

the same at each end, so either end may be mated.

CONNECTING ESPIPE900

1.

Observe the above precautions. Lubricate all ‘O-Rings’

with the silicone grease provided.

The socket end of the pipe (female outer and the male inner)

contain the ‘O-Rings’ and remain orientated to the same end.

They DO NOT alternate.

Connect the non- socketed end to the socketed end of the

previous component and secure.

CONNECTING ESROOFCOWL

1.

Observe the above precautions. Lubricate all ‘O-Rings’

with the silicone grease provided

Connect the non- socketed end to the socketed end of the

previous component and secure.

Non-socket end

Non-socket end

Rinnai 24 RHFE0800F_1000_1500 IM

Socket (O-ring) end

Page 25

CAUTION

CAUTION

CAUTION

COMMON COMPONENT ASSEMBLIES

CUTTING - ASPDFK, LSFKIT01/02, LSFEXTKIT01, ESPIPE900 & ESROOFCOWL

Cutting is not required for the purposes of joining ASPDFK, LSFKIT01/02, ESPIPE900 and

ESROOFCOWL ue pipes together.

Cutting of the last component in the ue assembly (the component furthest away from the heater)

may be required to achieve the required ue system length. Cutting is also required at a wall

penetration. Cutting for both purposes is described below:

Cutting Components to Achieve a Desired Length

1

1.

Minimum ASPDFK

length 300mm

Desired length

2 3

!

Measure and mark o the outer pipe at the desired length (AA).

12mm

4

The minimum length (ZZ) of ASPDFK when measured from the back plate of the casting MUST

NOT be less than 300mm when joining to other components.

2.

3.

Cut the outer pipe to the required length. Take care NOT to cut the inner pipe.

From the ‘new’ end of the outer pipe (cut in Step 2), measure and mark o an additional 12mm on the

inner pipe (BB). Cut the inner pipe at this mark. Take care to keep the cut parallel with that of the outer pipe.

4.

Ensure all burrs and swarf are removed from all cut ends.

Cutting Components for a Wall Penetration

1

Minimum ASPDFK

length 300mm

2 3 4

!

12mm

Allow 50mm

beyond any

wall penetration *

1.

Measure and mark o the outer pipe at a point ush with the surface of the wall penetrated (CC) plus an

* Required wall

penetration

additional 50mm (DD).

The minimum length (ZZ) of ASPDFK when measured from the back plate of the casting MUST

NOT be less than 300mm when joining to other components.

2.

3.

Cut the outer pipe to the required length. Take care NOT to cut the inner pipe.

From the ‘new’ end of the outer pipe (cut in Step 2), measure and mark o an additional 12mm on the

inner pipe (EE). Cut the inner pipe at this mark. Take care to keep the cut parallel with that of the outer pipe.

4.

Ensure all burrs and swarf are removed from all cut ends.

Rinnai 25 RHFE0800F_1000_1500 IM

Page 26

CAUTION

COMMON COMPONENT ASSEMBLIES

WALL TERMINAL ASSEMBLY

Flue MUST terminate in accordance with AS/NZS 5601 Figure 6.2. Especially relevant is the

requirement to have a minimum of 300mm clearance between the ue terminal and the nished

ground level. It is NOT permissible to excavate a hole to obtain the required 300mm clearance,

unless there is sucient drainage provision.

ONLY the direct ue kit (ASPDFK), Flue Extension Pipe LSFEXTKIT01 and the Co-axial ue pipe

(ESPIPE900) can be modied to create a wall terminal.

!

Exterior wall

22mm x 3

!

7mm x 2

Exterior wall

!

Exterior wall

1 32

1. Fit the supplied external wall plate over the outer pipe of the ue protrusion.

As an installation aid the wall plate has a 2°oset. As such the orientation of the wall plate will set the

ue system with either a 2° fall or rise as required. Set the ue system with a 2° fall away from the heater by

aligning the arrow symbol so that it is upper most.

!

Once the external wall plate is in the correct position secure it to the wall using the three 22mm

screws into the holes provided. The wall plate is then secured to the outer pipe of the ue protrusion using the

two horizontal holes and the two 7mm screws provided.

2.

3.

! Carefully cut through the outer and inner pipes of the ue protrusion as close to the external wall

plate as possible. Take care to avoid cutting the external wall plate and keep the cuts of both internal and

external pipes as parallel as possible. All burrs and swarf are to removed from all cut ends.

Align the arrows of the metal mushroom ue terminal and the wall plate to point in the same direction

and screw the terminal to the external wall plate using the 22mm screws into the holes provided.

22mm x 3

Rinnai 26 RHFE0800F_1000_1500 IM

Page 27

ON-WALL TERMINAL ASSEMBLY

CAUTION

CAUTION

IMPORTANT

Flue MUST terminate in accordance with AS/NZS 5601 Figure 6.2.

ONLY the direct ue kit (ASPDFK) and the Co-axial ue pipe (ESPIPE900) can be modied to

create a wall terminal.

1 2

!

COMMON COMPONENT ASSEMBLIES

35mm

3

!

1.

! Measure o the required terminal length then mark o for cutting allow an additional 50mm for

joining to other components. Cut the outer pipe at this mark. Take care to NOT cut the inner pipe while cutting

the outer pipe.

2.

From the end of the cut outer pipe measure o an additional 35mm on the inner pipe and mark o for

cutting.

3.

! Ensure that burrs and swarf are removed from all cut ends. Attach the pipe spacer to the outer

pipe and the ue outlet grill to the inner pipe. When preparing an on wall terminal ensure a continuous 2° fall

from the ue termination point back towards the heater.

The creation of an on wall terminal can only be achieved by using a combination of ESWTKIT,

ESBEND and ESPIPE900 ue components.

CONNECTING ESBEND

2 3 4 5 61

Centering Spacer

Centering Spacer Centering Spacer

1.

Lubricate an ESBEND inner pipe ‘O-Ring’ and t to the inner pipe of the nominated component. Use

ONLY the supplied silicone based “O Ring” seal lubricant. DO NOT use petroleum based lubricants such as

petroleum jelly.

Centering Spacer

2. Fit an ESBEND outer pipe to the outer pipe of the same nominated component.

3.

Insert one of plastic centring spacer provided with ESBEND, then Lubricate the a second ESBEND inner

pipe ‘O-Ring’ and t to previously tted inner component.

The centring spacer is a MANDATORY component, that is required for the correct alignment

of Co-axial components when ESBEND kits are used. When tted correctly the inner and outer

pipes of ESBEND will be self centring.

4. Fit a second ESBEND outer pipe to the previously tted outer component.

5. Insert the remaining plastic centring spacer provided with ESBEND, before connecting further components.

6. For extended oset installations use the same procedure ensuring the centring spacers are inserted as

shown.

Rinnai 27 RHFE0800F_1000_1500 IM

Page 28

Rinnai Australia Pty Ltd

ABN 74 005 138 769 | AU24752

100 Atlantic Drive, Keysborough, Victoria 3173

P.O. Box 460, Braeside, Victoria 3195

Tel: (03) 9271 6625

Fax: (03) 9271 6622

National Help Line

Tel: 1300 555 545* Fax: 1300 555 655

Monday to Friday, 8.00 am to 5.00 pm EST.

*Cost of a local call higher from mobile or public phones.

For further information visit www.rinnai.com.au

or email enquiry@rinnai.com.au

Rinnai New Zealand Ltd

105 Pavilion Drive, Mangere, Auckland

PO Box 53177, Auckland Airport, Auckland 2150

Tel: (09) 257-3800

Toll Free: 0800 764-624

For further information visit:

www.rinnai.co.nz

youtube.com/rinnainz

facebook.com/rinnainz

or email info@rinnai.co.nz

Rinnai has a Service and Spare Parts network with

personnel who are fully trained and equipped to give

the best s ervice on your Rinnai appliance. If your

appliance requires service, please call our National

Help Line. Rinnai recommends that this appliance be

serviced every 2 years.

With our policy of continuous improvement, we

reserve the right to change, or discontinue at any time,

specifications or designs without notice.

RNZ 13579_B / RA 15401101 28 RHFE0800F_1000_1500 IM Issue 2 - Sep 2019

Loading...

Loading...