Page 1

Rinnai

Fan Convector Heaters

Level III Training

1

Page 2

Fan Convector Heaters

FC510 (RCE-391A) FC824 (RCE-691TA)

Page 3

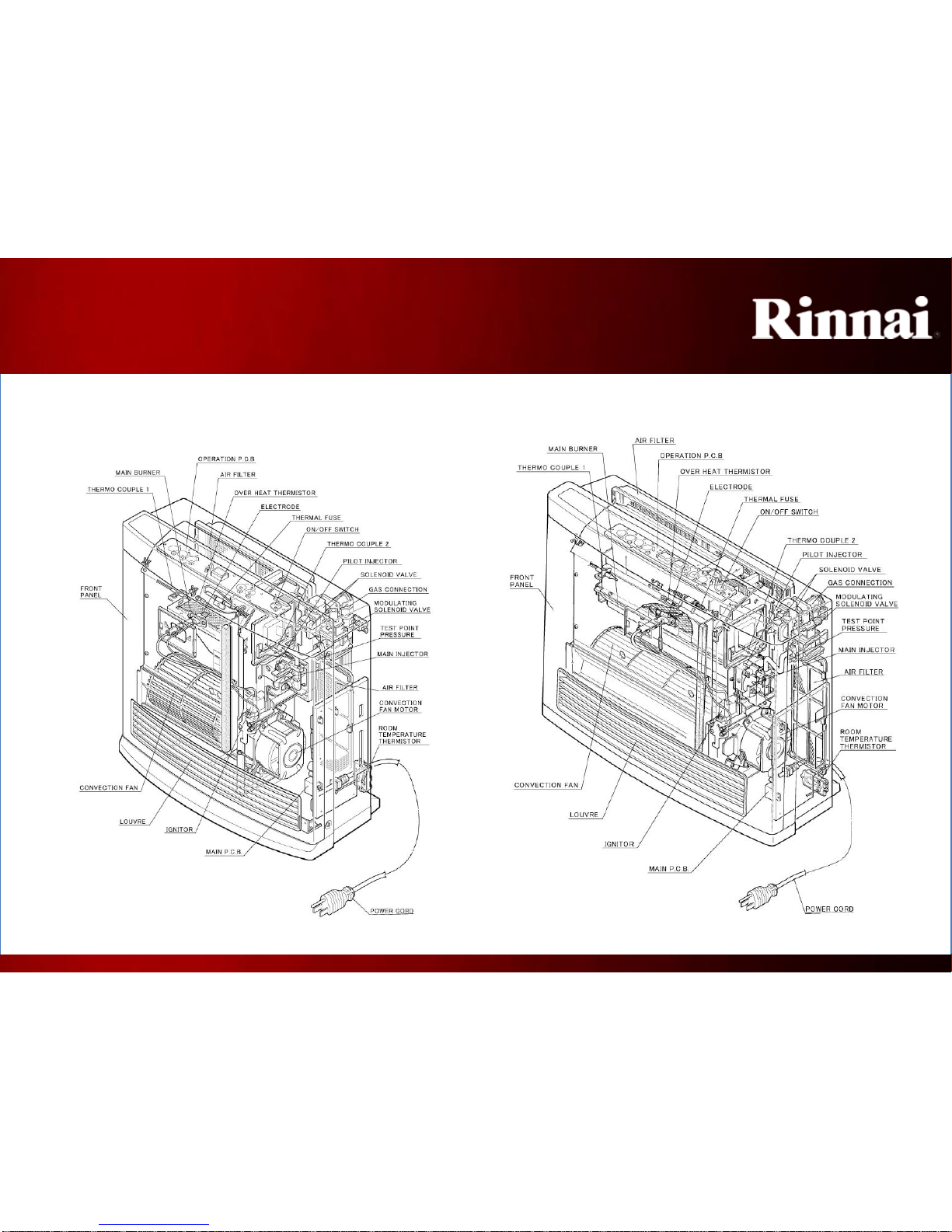

Internal Components

FC510 (RCE-391A) FC824 (RCE-691TA)

Page 4

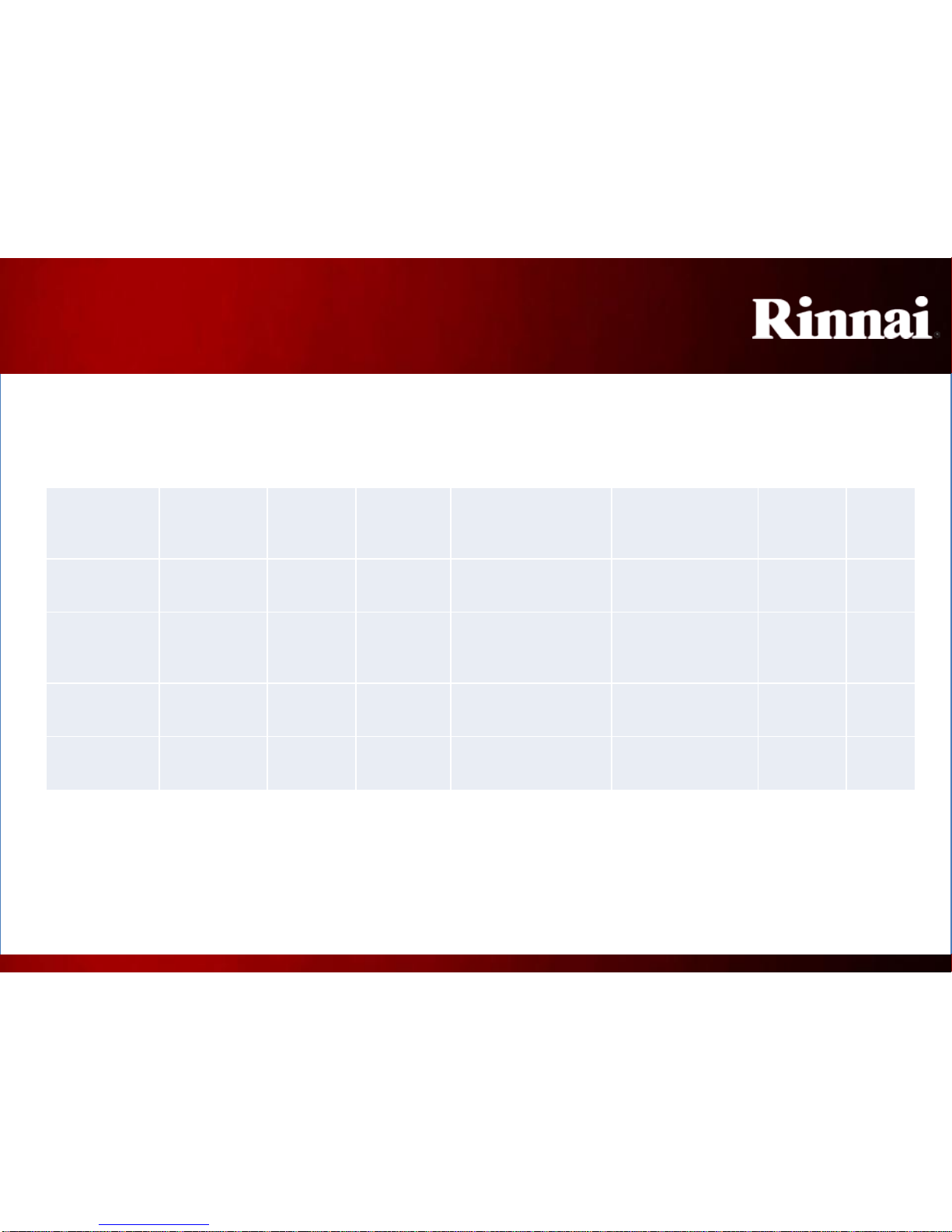

Specifications

Model Gas Type

Input Rating

Btu/hr. HIGH

Input Rating

Btu/hr. LOW

Gas Inlet Pressure

Manifold Pressure

HI/LO Inches W.C.

(mm)

Fan Motor

CFM HI/LO

Fuse

(Amps)

FC510N

(RCE-391AN)

Natural Gas 10,000 5,500

3.5 – 10.5

inches W.C

(89 – 267 mm W.C)

1.8 / 0.64 inches W.C.

(47 / 16.3 mm W.C.)

67.8 Low

97.8 High 5

FC510P

(RCE-391AP)

Propane Gas 10,000 5,600

8.0 -

13.0 inches W.C.

(203 - 330 mm W.C.

3.2 / 1.12 inches W.C.

(82 / 28.6 mm W.C.)

67.8 Low

97.8 High

5

FC824N

(RCE-691TAN)

Natural Gas 24,000 8,400

5.0 – 10.5

W.C

(127 - 267 mm W.C)

3.4 / 0.52 inches W.C.

(87 / 13 mm W.C.)

109.5 Low

215.4 High

5

FC824P

(RCE-691TAP) Propane Gas 22,000 8,000

8.0 -

13.0 inches W.C.

(203 - 330 mm W.C.)

6.3 / 1.00 inches W.C

(161 / 25.5 mm W.C.)

109.5 Low

215.4 High

5

Product specifications

Page 5

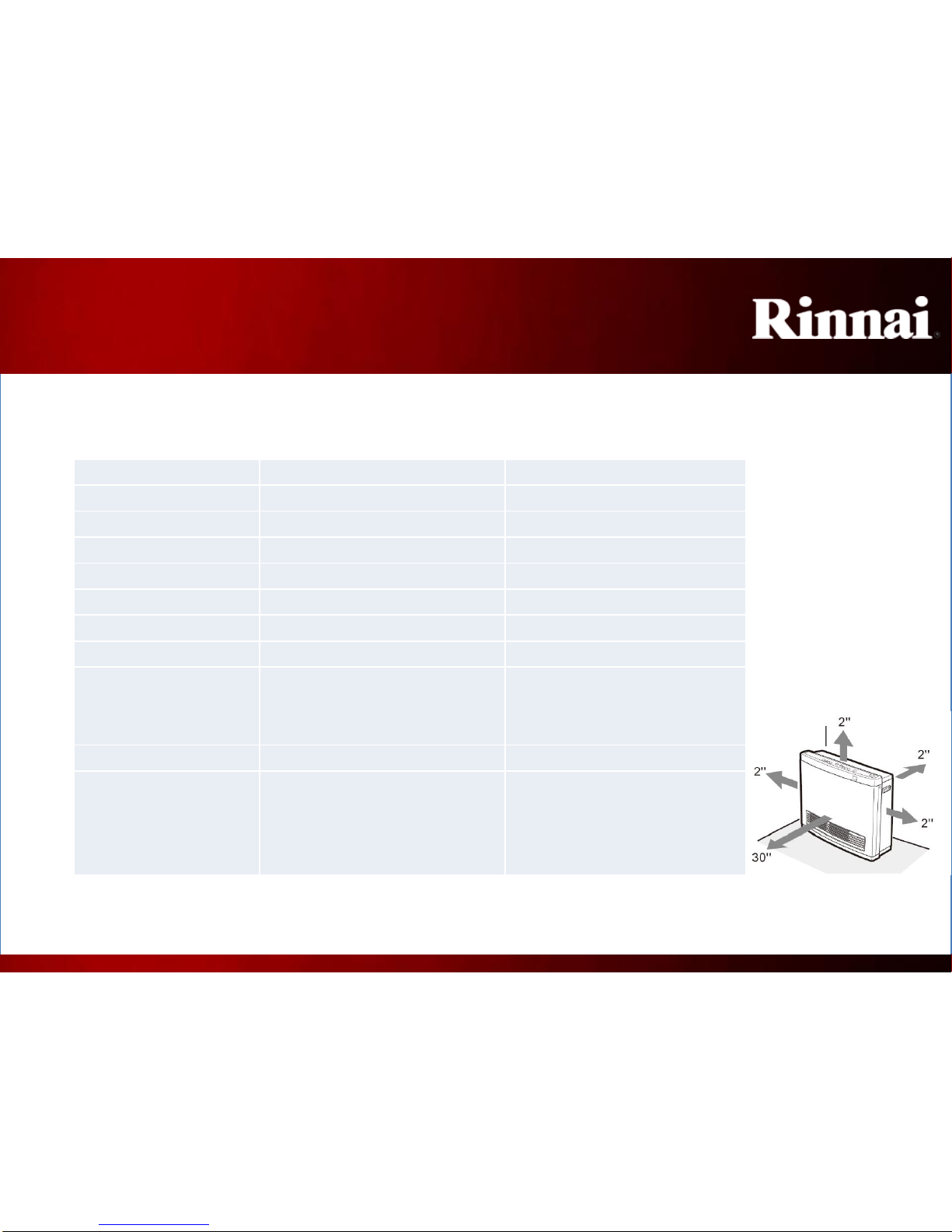

FC510 (RCE-391A) FC824 ( RCE-691TA)

Gas Connection 1/2" Male NPT 1/2" Male NPT

Gas Control Electronic Electronic

Burners Ceramic Burner Ceramic Burner

Temperature Control Electronic Thermostat Electronic Thermostat

Ignition Sdystem Electronic Spark Ignition Electronic Spark Ignition

Electrical Connection AC 120V, 60 Hz., 19 Watts AC 120V, 60 Hz., 29 Watts

Weight 22.1 Lbs. (10kg) 26.5 Lbs. (12kg)

Dimensions

Height: 19.4 Inches (492 mm)

Width: 19.2 inches (487 mm)

Depth: 9.6 inches (244 mm)

Height: 19 Inches (482 mm)

Width: 24 inches (610 mm)

Depth: 9.4 inches (239 mm)

Efficiency 99.90% 99.90%

Clearances

Front 2"

Side 2"

Top 2"

Back 2"

Front 2"

Side 2"

Top 2"

Back 2"

Specifications

Component/Clearance Specifications

Page 6

• The letters “RCE” indicates this is a “Rinnai Convection Export” heater.

• The numbers “510 & 824” indicate the model number of heater.

• The letter “T” indicates duel timers on 824 model, no “T” indicates single timer on 510 model.

• The letter “A” indicates this is an American version.

• The “FC” indicates Fan Convertor Heater.

• These units are not suitable for use in bathrooms or bedrooms. Vent-free heaters installed in

bathrooms and/or bedrooms must be wall mounted. This product can not be wall mount at the

present time.

• Product warranty – 3 year parts, no labor.

Ledger Plate Explanation & Warranty

Page 7

1. Convection fan starts, drawing air in through

the back of the cabinet and across the heat

exchanger / burner chamber and out into the

space. The PCB verifies fan rotation.

2. Once the fan is running at the proper speed,

spark ignition begins.

3. After spark begins, the gas valve solenoids

open allowing gas into the burner.

4. Ignition occurs and flame develops across the

burner.

5. The PCB will verify flame with thermocouples

and turn off the sparker.

6. Warm air then begins to flow into the space.

7. PCB will determine gas input and fan speed

settings based on the room temperature

measurement from the room thermistor.

8. When thermostat set point is reached the gas

valve solenoids close. The combustion fan will

continue to run to cool down the unit.

9. When the room temperature drops below the

set point, the process will start again.

Sequence of Operation

Spark

Electrode

P

C

B

Room

Temperature

Thermistor

POV SV1

Thermocouple 2

Convection

Fan Assembly

Thermocouple 1

Gas Valve

Solenoids

Combustion

Chamber

Page 8

8

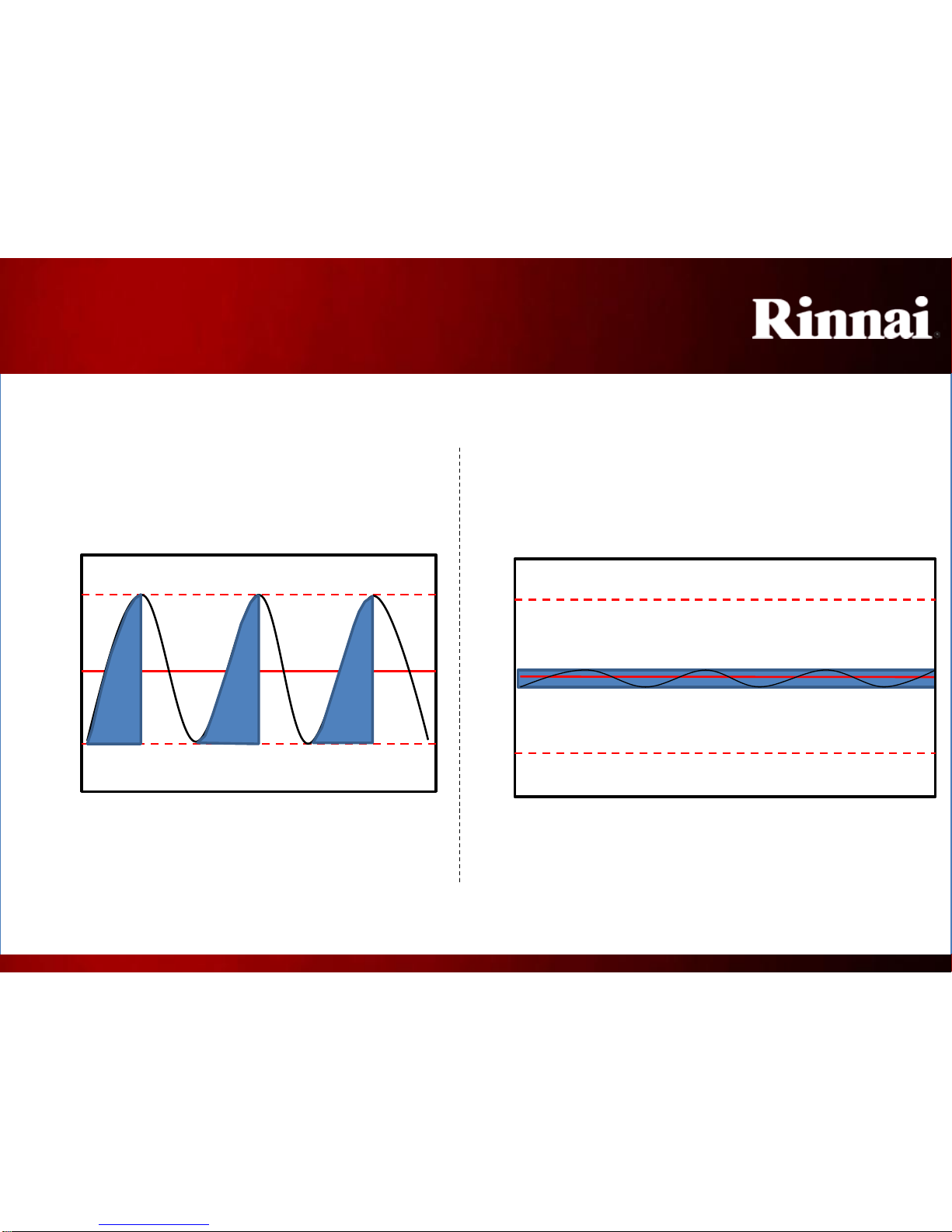

• Variable speed technology – Modulating gas and air based on the heat loss at that moment

74°

72°

70°

68°

66°

74°

72°

70°

68°

66°

On / Off Single Stage Heating Appliance

Continuous-Run Modulating Technology

Gas

Usage

Gas

Usage

Gas

Usage

Continuous gas usage but at much lower levels

• With on/off single stage operation, gas usage

can be high due to alternating periods between

maximum flame and no flame at all

• The Fan Convector modulating technology has the

ability to replace only the heat escaping the

structure by continuously operating at heating levels

based on the demand at that moment

• This results in different layers of temperatures

throughout the structure leading to a less than

comfortable living environment

• This leads to lower gas usage and higher levels of comfort.

Modulating Technology

Note; if the “Auto Off” function is not selected the unit will

run continuously no matter what the room temperature is.

Page 9

• Do not install this appliance above 2,000ft.

• Do not block the warm air discharge.

• Do not allow anyone to sleep directly in front of the appliance.

• Do not insert items into the louvers.

• Do not place clothing or other flammable material on or near the appliance

• Do not spray aerosols near the appliance while it is operating. Most aerosols contain butane gas

which is flammable.

• Do not install this appliance in areas where spray painting or plating is taking place, or in places such

as hair salons where there may be large amounts of dust, chemical residue, or debris. Using the

appliance in such areas may result in strong odors or irritated eyes and sinuses.

• Do not sit on the appliance.

Installation Instructions

Page 10

• Do not unplug the appliance while it is operating or while the fan is on.

• Do not use a plug in type timer with this appliance.

• Do not install in a windy area such as facing a window or a door leading to the outside.

• Do not recess this appliance or mount it directly in a wall

• If the flooring is carpet, tile, or other combustible material other than wood, then the appliance

must be installed on a metal or wood panel extending the full width and depth of the appliance.

• This appliance discharges a large volume of warm air next to the floor. Any particles in the air

such as cigarette smoke, lint, dust, or debris could cause discoloration in nylon carpets

containing dyes or vinyl surfaces.

• Rinnai suggests that a dedicated electrical circuit with a 120VAC, 60 hz, 10 amp power source be

used.

• The flow of combustion and ventilation air shall not be obstructed.

• Note that in some regions, an unvented gas heater will increase the amount of humidity in the

room.

Installation Instructions

Page 11

11

• Check Federal, State and/or local codes in your state before using vent-free products. Some

areas of the country do not allow vent-free products.

• International Fuel Gas Code Standard 620-6 under “Prohibited Use” states that; “One or more

unvented room heaters shall not be used as a sole source of comfort heating in any dwelling

unit”. Refer to the International Fuel Gas Code and International Fuel Gas Standard, Charter 6,

section 6-11, standard 620-2 for conformation of the above statement.

• Code pertaining to bathroom installations. Refer to the 2000 International Fuel Gas Code,

section 303.3 “Prohibited locations”. under Exception 3. for prohibited use when installing

unvented heaters in a bathroom. It states, “A single wall mounted unvented room heater

equipped with an oxygen depletion safety shutoff system and installed in a bathroom

provided that the input rating does not exceed 6000 Btu per hour (1.76kW) and the bathroom

is not a confined space”.

• Code pertaining to bedroom installations. Refer to the 2000 International Fuel Gas Code,

section 303.3 “Prohibited locations”. under Exception 4. for prohibited use when installing

unvented heaters in a bedroom. It states, “A single wall mounted unvented room heater

equipped with an oxygen depletion safety shutoff system and installed in a bedroom provided

that the input rating does not exceed 10,000 Btu per hour (2.93kW) and the bedroom is not a

confined space”.

• The contractor installing this equipment has the responsibility to ensure the product being

installed meets all local and State building codes. Please check with your local code officials if

you have any questions related to vent-free products.

Code Limitations

Page 12

Servicing Fan Convector

There’s very little service required on the Fan Convector heaters. Below you will find three items that

can be checked and/or cleaned in the event you are experiencing problems with you appliance.

NOTE; ALL Service must be performed by a qualified installer, service agency or gas technician.

1. Gas control valve – The gas valve can be checked by verifying the manifold gas pressures are properly set. The

manifold gas pressure setting procedures can be found in the technical data sheet under the unit’s front cover.

2. Burner Assembly – The burners are ceramic type burners and should never fail if the unit is not over fired

for any reason, dropped or abused. I would recommend that the burner compartment be blown out with

compressed air (120 psi) at least annually. This will clear out any foreign matter that has been drawn into the

combustion chamber. Low pressure blowers do not generate enough air pressure to properly clean the burner. See

the parts breakdown in the Owner’s manual for directions on how to remove the burner’s top plate in order to

access the burner.

3. Annual Cleaning – Rinnai recommends that you blow out all compartments inside the unit. In addition, blow out

the squirrel cage fan. Care should be taken when blowing out the fan. Keep the air nozzle at least twelve inches

away from the fan when blowing it out. Otherwise, high pressure air will cause damage to the fan blades.

Page 13

Maintenance

Cleaning Air Filters:

Both air filters should be cleaned frequently

during the heating season.

1. Unscrew the black cap (Phillips screw in the

center of large filter) securing the air filter.

Pull the filter up and away from the unit.

2. Remove the small filter simply by pulling the

two tabs away from the unit.

3. Place both filters in warm water and wash

all dust and dirt out the filter.

4. Dry filter with a soft cloth. Make sure they

are dried completely before reinstalling in

the reverse order as above.

1

2

Page 14

Error Codes

&

Troubleshooting

14

Page 15

15

ERROR FAULT REMEDY

00 Power Failure

- Press ON/Off button and allow unit to cycle on.

03

Tilt Switch Activated

- Return unit to the upright position. Restart heater using the “ON” power button.

11

ODS #1

Missed Ignition

Burner Sensor

Pilot Sensor

- Verify the gas supply is turned on to the appliance, gas meter, or tank

- Ensure gas type and inlet gas pressures are correct

- Bleed all air from gas lines

- Ensure gas line, meter, and / or regulator is sized properly

- Ensure appliance is properly grounded

- Verify ODS #1 and ODS #2 are producing the proper milli-voltage when unit fires.

- Inspect all wiring harnesses /connectors for loose, damage or broken connections .

- Replace defective ODS sensor

12

ODS #1

ODS #2

Flame Failure

Burner ODS #1 & Pilot ODS #2

13

ODS #1

Overheat - Burner ODS #1

- ODS #1 left hand side of burner has sensed an over heat condition. Check filter

for blockage first. Then check fan for bad bearing, improper operation or hertz.

- Replace ODS #1 Sensor

14

No Ignition

(No flame inside burner assembly)

Overheat Sensor

Thermo fuse

- Verify air filter is in place and not clogged.

- Verify proper clearances around the appliance for air flow. Remove any obstructions.

- Check gas type of unit and ensure it matches gas type being used

- Verify low and high fire manifold gas pressures are properly set.

- Ensure DIP switches are set to the proper position on the PC board

- Check burner chamber for signs of heat stress, cracks and/or separations

- Check burner assembly for damage.

- Measure resistance of safety circuit

16 Room Overheat

– Verify unit was sized properly for space being heated.

– Check for restrictions in air flow around unit.

18 Thermocouple #1

–Check thermocouple wiring for damage, loose or broken wires.

– Measure resistance of thermocouple

– Replace thermocouple

An error code will flash on the unit’s display when a fault occurs. Refer to the list of error codes below for details on your unit’s

fault code. All troubleshooting and repairs should be made by a licensed contractor.

Fault Codes

Page 16

31

Room Temperature Thermistor

– Check thermistor wiring for damage, loose or broken connections or wires.

– Measure resistance of thermistor

– Replace Sensor

32

Room Temperature Thermistor

– Short circuit, replace thermistor

33

Overheat Thermistor

–Check thermistor wiring for damage, loose or broken connections or wires

– Measure resistance of thermistor

– Replace Sensor

34

Overheat Thermistor

– Short Circuit, replace thermistor

62

Combustion Fan Failure

– Ensure fan will turn freely

– Check wiring harness to motor for damaged and/or loose connections

– Measure resistance of motor windings

– Replace fan motor

70

ON/OFF Switch Faulty

– Check wiring harness from control panel to P.C board for loose or damaged wires or

connections.

– Replace control panel

71

Solenoids or Modulating Valve Circuit

– Check to ensure all gas solenoids or plugged into the solenoid valves.

– Check to ensure they are plugged into the correct solenoid valve.

– Check resistance value of all gas solenoid valves

– Replace defective solenoid.

– Replace P.C. board.

72

ODS #1

ODS #2

Burner ODS #1 & Pilot ODS #2 initial

value abnormal

– Verify low and high fire gas pressures were properly set.

– Replace defective ODS Sensor

73

P.C Board abnormal –Press the ON/Off button twice to reset heater

Fault Codes

Page 17

Wiring Diagram

Page 18

Electrical Components Values

Diagnostic Points

Components Mark Wire Colors Value

Pin #

Convection Fan Motor CFM

Blue - Brown 10 - 12 VDC

3 & 4

Blue - Yellow

2,000 -

5,000 Pulses/Min.

(33 -

84 Hz)

2K - 10 KΩ

1 & 3

Blue - Red

11 -

14 VDC

0.1K - 1 K

2 & 3

Modulation Gas Valve POV White - Red

1 -

14 VDC

65 - 90Ω

9 & 10

Oxygen Depletion Sensor #1 (TC1) ODS1 Yellow - Blue See next slide for details

5 & 7

Oxygen Depletion Sensor #2 (TC2) ODS2 Yellow - Blue See next slide for details

1 & 2

Sparker (IG) IG White - White 96 - 144 VAC

1 & 2

Gas Solenoid Valves

SV1

SV2

Blue - Brown

11 -

14 VDC

35 - 53Ω

1 & 2

4 & 5

Room Temperature Thermistor TH Black - Black

50°F (10°C) = 58K - 73K

Ω

68°F (20°C) = 33K - 44K

Ω

104°F (40°C) = 9K - 19K

Ω

1 & 2

Over Heat Thermistor OH.TH. Black - Black

68°F (20°C) = 70K - 85K

Ω

104°F (40°C) = 25K - 40K

Ω

158° (70°C) = 8K - 15KΩ

3 & 4

Thermo-fuse TF

White - White

Below 1Ω

6 & 8

Page 19

Warnings

There are a number of (live) tests that are required when fault finding this product. Extreme care should be used

At all times to avoid contact with energized components inside the heater. Only trained and qualified service

Technicians should attempt to repair this product. Before checking for resistance readings, disconnect the power

Source to the unit and isolate the item from the circuit (unplug it).

Follow the steps below prior to servicing or replacing any components within the heater in order to protect yourself from harm:

• Turn off the electrical power supply by unplugging the power cord or by turning off the electricity at the circuit breaker. (The

product’s on/off switch does not control the electrical power).

• Turn off the gas at the manual gas valve, usually located behind the unit or within six foot of the appliance.

Page 20

Failure to correctly assemble the components according to the instructions contained within this presentation

May result in a gas leak or explosion

Inspect all gaskets/packings for signs of damage or corrosion. Gaskets/packings found to contain damage or that

Appear questionable MUST BE REPLACED. Failure to replace damage or questionable gaskets may result in gas

leak or explosion.

Warnings

Page 21

TC1 & TC2 Milli-volt Readings

1. Set voltage meter to read at least 35 milli-volts. Insert meter leads into the output test port holes on the

rear of the unit, see below for proper test ports for each thermocouple.

2. Fire the unit up and check the milli-volt output on each thermocouple per readings listed above. Readings

below those listed above will cause the unit to code out. Verify inlet/manifold high/low fire gas pressures

if your readings are not within the specifications as listed above.

Procedure for measuring TC1 & TC2 Thermocouple Outputs

FC510 (RCE-391A) Thermocouple Output

FC824 (RCE-691TA) Thermocouple Output

TC1 (mV) Brown & White

Wires

TC2 (mV) Black & White

Wires

TC1 (mV) Brown & White

Wires

TC2 (mV) Black & White

Wires

Gas Type High Fire Low Fire High Fire Low Fire

High Fire Low Fire High Fire Low Fire

Propane Gas

23 - 26 16 - 20 23 - 31 16 - 24

23 - 26 16 - 20 23 - 31 16 - 24

Natural Gas

26 - 29 17 - 21 18 - 26 15 - 23

26 - 29 17 - 21 18 - 26 15 - 23

TC1 test ports - Top is the brown

& bottom right is white wire.

TC2 test ports - Bottom left is the

black & bottom right is white wire.

TC1

TC2

Page 22

Gas Valve Removal

Gas Control Valve

Inlet Gas Connection (Rear of Unit)

Caution: Shut off gas and power supply to the unit before proceeding.

1. Disconnect gas piping to unit at the inlet gas connection shown below.

2. Disconnect the POV gas solenoid valve wiring harness, (red & white wires).

3. Disconnect SV1 & SV2 gas solenoids valves, (blue & brown wires).

4. Remove (1) screw from retainer on the burner gas feed line. Slip retainer off the feed line, pull gas line out of

the gas valve assembly. Replace O-ring on this line.

5. Remove (3) screws from the inlet gas connection on the rear of the unit, pull gas vale assembly free from unit.

3

2

4

5

1

Page 23

P.C. Board Removal

Caution: Disconnect the power and gas from the unit before proceeding.

1. Remove (1) screw from plastic P.C. board casing, front of unit 1/3 the way up the unit.

2. Lift up on the P.C. board casing and pull board out of unit.

3. Disconnect all wire connectors from P.C. board. Take care not to stress the connections when unplugging them.

Press in on the latch to release the connector before unplugging connection. You can use a small screw driver to

push in on these latches.

10 Pin Connector

Safety Circuit/POV.

15 Pin Connector

Control Panel

4 Pin Connector

Fan Motor

2 Pin Connector

Igniter

2 Pin

120 Volt Power Supply

6 Pin Connector

Thermocouple

output terminal

on rear of unit

5 amp

fuse

Ground wire

Push button

used to

program gas

pressures

SV1 & SV2

Connector

2 Pin Connector

Room Thermistor

Page 24

Safety Circuit

Caution: Shut off gas and power supply to the unit before proceeding.

1. Burner sensor mounted on the left hand side of the burner assembly is designed to detect the burner temperature. If combustion

conditions cause the burner temperature to drop below a predetermined temperature, the sensor will shut the unit off and flash an

error code related to the fault.

2. The thermal-fuse located on the top of the burner chamber is designed to shut the unit down in the event the unit senses an abnormal

temperature due to improper gas pressure settings, cracked or damaged burner chamber or restricted air flow through the appliance.

This safety device activates at 4200F or 216 0C.

3. The overheat thermistor on top of the burner chamber is designed to shut the unit down in the event the unit senses an abnormal

temperature due to improper gas pressure settings, cracked or damaged burner or restricted air flow through the appliance. This

safety device activates at 131 0F or 55 0C.

4. The pilot burner sensor is located on the right hand side of the burner assembly. This sensor serves as an Oxygen Depletion Sensor

or (ODS). If the oxygen level in the room drops below a preset limit, this sensor disables the gas supply to the heater shutting the unit off.

1

3

2

4

Page 25

Igniter & Igniter Module Removal

Caution: Shut off gas and power supply to the unit before proceeding.

Igniter/electrode:

1. To remove the igniter unplug the black/green wires from the igniter. The green wire has a latch that has to be

pushed in, in order to release the connector. Remove cover plate with (1) screw.

2. Remove (2) screws from igniter bracket assembly, pull igniter/bracket assembly out of unit.

3. Replace igniter gasket before reassembling in reverse order.

Igniter Module:

4. To remove the igniter module unplug the wiring harness with two white wires from the PC board.

5. Pull large black wire out of module connection. Remove (1) screw and pull module from unit.

Igniter/electrode

1

2

4

5

Igniter module

Page 26

Burner Assembly Removal

Next Seven Slides

Page 27

Burner Assembly Removal

FC824

FC510

1

1

2 2

Caution: Shut off gas and power supply to the unit before proceeding.

1. Remove louver assembly by removing (3) screws as shown below.

2. Remove (2) screws from each side of the front cover, then pull cover away from unit.

Page 28

1. Remove (4) screws on the FC510, (3) on the FC824 ,as shown below.

2. Unplug 15 pin connector from P.C. board.

3. Pull top panel away from unit.

1

1

2

Burner Assembly Removal

Page 29

Caution: Shut off gas and power supply to the unit before proceeding.

1. Disconnect the burner gas line from the gas control valve, (1) screw. Pull retainer clip off burner gas line. Pull gas

line loose from the gas control valve. Verify O-ring is intact and in good condition.

2. Unplug the fan motor wiring harness from the P.C. board.

3. Unplug (10) pin safety circuit wiring harness from the P.C. board.

4. Unplug the POV gas solenoid valve.

5. Unplug (2) pin connector at P.C. board for the igniter.

6. Disconnect both ground wires shown below.

10 pin connector for safety circuit

POV solenoid valve

4 pin connector for fan motor

Ground wires for PCB and power supply

Burner gas line

2 pin connector for igniter

4

3

2

5

6

1

Burner Assembly Removal

Page 30

Burner Assembly Removal

1. Remove the (4) screws on the rear of the unit.

2. Remove (1) screw from left side of burner housing down next to floor base.

3. Slide the complete burner and fan assembly out of the unit.

1

1

3

Page 31

Burner Assembly Removal

1. Remove the burner sensor on the left hand side of the burner housing, (3) screws. Pull the

burner sensor retainer clip off the tab.

2. Remove the pilot assembly sensor and burner plate located on the right hand side of the burner

housing, (4) screws.

3. Remove the cover plate off the igniter (1) screw and the (2) screws in combustion box. Pull

igniter out of unit.

3 2

1

Page 32

Burner Assembly Removal

1. Remove (2) screws from bracket and pull loose from unit.

2. Remove (4) screws for the combustion box cover and remove cover.

3. Remove (2) screws from burner assembly cover and remove cover.

2

1

3

Page 33

1. Remove (3) screws holding burner assembly to heater housing.

2. Slide burner assembly out of the burner chamber from right side of unit.

3. Complete burner assembly after removed from unit.

4. Install new burner assembly in reverse order.

1

2

3

Burner Assembly Removal

Page 34

Cleaning Burner Assembly

Page 35

Caution: Shut off gas/power supply to the unit before proceeding. Wear safety glasses to preform task below.

1. Follow procedure for removing burner assembly, with exception to pulling the burner. The burner does not

have to be removed to clean it.

2. Inspect burner for damage and/or cracks before proceeding.

3. Blow the ceramic burner out using 120 psi of compressed air. Hold the air nozzle back about six inches from

surface during this process. It is recommended the unit be disconnected and moved outside while blowing

out the burner due to the amount of dust created by this process.

4. Reinstall ALL covers and the top panel in the reverse order.

5. Restart unit and check to verify it is operating as designed.

Cleaning Burner

1

Page 36

Cleaning ODS Pilot Orifice

Page 37

Cleaning ODS Pilot Orifice

Caution: Shut off gas/power supply to the unit before proceeding. Wear safety glasses to preform

task below.

1. Remove front cover on unit (4) screws.

2. Locate pilot and burner orifice on the right hand side of unit, center of burner housing.

3. Blow out the orifices shown in picture 1 with 120 psi of compressed air. Hold the air nozzle back

at least six inches from all components to prevent damage from the high pressure air.

4. Install front cover and verify unit operates as designed.

2

Burner orifice

Pilot orifice

Page 38

Fan Motor/Squirrel Cage Blower Removal

Next Six Slides

Page 39

Fan Motor Removal

Caution: Shut off gas and power supply to the unit before proceeding.

1. Remove louver assembly by removing (3) screws as shown below.

2. Remove (2) screws from each side of the front cover, then pull cover away from unit.

FC824

FC510

1

1

2 2

Page 40

Fan Motor Removal

1. Remove (1) holding the igniter module in place and (1) screw holding ground wire in place.

2. Remove (2) screws holding partition board in place.

3. Unplug fan motor from P.C. board.

1

2

3

Page 41

1. Remove (2) screws on the rear of unit.

2. Remove (2) screws on left side of burner housing.

3. Remove (2) screws on right side of burner housing.

4. Slide fan motor and housing assembly out of the unit.

Fan Motor Removal

1

2

3

Page 42

Fan Motor Removal

1. Remove (4) screws holding fan motor to unit’s housing.

2. Loosen screw on fan motor shaft and pull fan motor loose from unit.

1

2

Page 43

Squirrel Cage Blower Wheel Removal

2

1. Remove (2) screws on squirrel cage bearing housing assembly, left hand side of unit. Remove

bearing housing.

2. Loosen screw on fan motor shaft, right side of unit. Slide blower wheel out of unit from left side

of unit.

3. Reassemble in the reverse order.

1

Page 44

The End

Fan Convection Heater

Service Training

44

Loading...

Loading...