Rinnai EHPA315VMA, EHPA250VMAH, EHPA315VMAH, EHPA250VMA, EHPA250VMAW Installation and Operation Guide

...Page 1

Models:

EHPA250VMA

EHPA250VMAW

EHPA250VMAH

EHPA250VMAWH

EHPA315VMA

EHPA315VMAW

EHPA315VMAH

EHPA315VMAWH

This manual does NOT

suit any other models

Enviroflo Heat Pump Hot Water Systems

Operation & Installation Manual

Page 2

This appliance must be installed in accordance with:

• Manufacturer’s Installation Instructions

• Current AS/NZS 3500

• Plumbing Code of Australia (PCA)

• Local Regulations and Municipal Building Codes

including local OH&S requirements

This system must be installed, commissioned, serviced,

maintained and removed ONLY by an Authorised Person.

NOT SUITABLE AS A POOL OR SPA HEATER

For continued safety of this appliance it must be installed and

maintained in accordance with the manufacturer’s instructions.

AS3498 Lic W00169

SAI Global

Rinnai 2 EHPA_A Heat Pump OIM

AS/NZS 2712

Lic No. 1849

SAI Global

Page 3

TABLE OF CONTENTS

Warnings and Important Information 4

Safety and Regulatory Information ����������������������������������������������������������������������������������������������������������������� 4

Transport and Storage of Appliance ��������������������������������������������������������������������������������������������������������������� 5

Scald Hazards ��������������������������������������������������������������������������������������������������������������������������������������������������� 6

Operation Principle ������������������������������������������������������������������������������������������������������������������������������������������ 7

Safety Devices �������������������������������������������������������������������������������������������������������������������������������������������������� 8

Pressure & Temperature Relief (PTR) Valve �������������������������������������������������������������������������������������������������� 8

Excessive Discharge from Safety Devices ���������������������������������������������������������������������������������������������������� 8

Pressure & Temperature Relief (PTR) Valve �������������������������������������������������������������������������������������������������� 8

Expansion Control Valve (ECV) - if required �������������������������������������������������������������������������������������������������� 8

Hydrogen Gas ��������������������������������������������������������������������������������������������������������������������������������������������������� 9

Turning O the Water Heating System ����������������������������������������������������������������������������������������������������������� 9

Turning On the Water Heating System ����������������������������������������������������������������������������������������������������������� 9

Draining and Filling ������������������������������������������������������������������������������������������������������������������������������������������ 9

Maintenance and Regular Care ����������������������������������������������������������������������������������������������������������������������� 9

Save a Service Call 10

Specications 12

System Specications ����������������������������������������������������������������������������������������������������������������������������������� 12

Dimensions ����������������������������������������������������������������������������������������������������������������������������������������������������� 13

Clearances ������������������������������������������������������������������������������������������������������������������������������������������������������ 14

Installation 15

Regulations and Occupation Health and Safety (OH&S) ���������������������������������������������������������������������������� 15

Location ���������������������������������������������������������������������������������������������������������������������������������������������������������� 15

Internal Installation ��������������������������������������������������������������������������������������������������������������������������������������� 15

Condensation ����������������������������������������������������������������������������������������������������������������������������������������������� 16

Drainage ������������������������������������������������������������������������������������������������������������������������������������������������������� 16

Water Supply ���������������������������������������������������������������������������������������������������������������������������������������������������16

Storage Temperature ������������������������������������������������������������������������������������������������������������������������������������� 16

Hot Water Delivery Temperature ������������������������������������������������������������������������������������������������������������������� 16

Valves and Fittings ����������������������������������������������������������������������������������������������������������������������������������������� 16

Transport and Handling ��������������������������������������������������������������������������������������������������������������������������������� 17

Positioning the Heat Pump ���������������������������������������������������������������������������������������������������������������������������� 17

Connect the PTR Valve ����������������������������������������������������������������������������������������������������������������������������������18

Plumbing Connections ���������������������������������������������������������������������������������������������������������������������������������� 18

Connect Cold / Hot Water Supply ����������������������������������������������������������������������������������������������������������������� 18

Connect Condensate Drain line �������������������������������������������������������������������������������������������������������������������� 19

Electrical Tests ����������������������������������������������������������������������������������������������������������������������������������������������� 19

Conducting Insulation (Megger) Tests ���������������������������������������������������������������������������������������������������������� 19

Electrical Connections ����������������������������������������������������������������������������������������������������������������������������������� 19

Filling the System ������������������������������������������������������������������������������������������������������������������������������������������� 20

Finishing the Installation ������������������������������������������������������������������������������������������������������������������������������� 21

Operation Sequence of Controller ��������������������������������������������������������������������������������������������������������������� 21

Controller LED Flashing Codes �������������������������������������������������������������������������������������������������������������������� 22

Contact 24

Rinnai 3 EHPA_A Heat Pump OIM

Page 4

WARNING

WARNING

WARNINGS AND IMPORTANT INFORMATION

SAFETY AND REGULATORY INFORMATION

DO NOT operate this system before reading the manufacturers instructions.

This appliance must be installed, commissioned and serviced by an authorised person in

accordance with all applicable local rules and regulations.

Access covers of water heating system components will expose 240V wiring and MUST only be

removed by an authorised person.

This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance by a person responsible for

their safety.

For continued safety of this appliance it must be installed, operated and maintained in accordance

with the manufacturer’s instructions.

Children should be supervised to ensure they DO NOT play with the appliance.

The unit is rated at 15 amps (2 core and earth) so the power mains supplying the unit must have a

15 amp minimum double pole circuit breaker tted. If the power supply cord is damaged, it MUST

BE replaced by an authorised person in order to avoid a hazard. Take care not to touch the power

connections or plugs with wet hands.

Care should be taken not to touch the pipe work as it may be HOT!

RISK OF FIRE

DO NOT place articles on or against this appliance.

DO NOT store chemicals or ammable materials near this appliance.

DO NOT operate with collectors or covers removed from this appliance.

DO NOT activate heat pump unless cylinder is full of water.

NEVER use a ammable spray such as hair spray, paint, etc near this unit as this may cause a

re.

This appliance uses R290 (propane) refrigerant, which is a ammable gas class 3 according to AS

5149 and MUST be handled by a refrigeration mechanic with appropriate Australian refrigerant

handling licence.

WARNING Risk of re / ammable material. If the refrigerant is leaked, together with an external

ignition source, there is a possibility of ignition.

MANDATORY INSPECTION PRIOR TO INSTALLATION

Immediately report any damage or discrepancies to the Supplier of the appliance. This

appliance was inspected and tested at the time of manufacture and packaging, and released for

transportation without known damage. Upon receipt, inspect the exterior for evidence of rough

handling in shipment. Ensure that the appliance is labelled correctly for the gas and electrical

supply, and/or other services it is intended to be connected to.

For safety and warranty purposes, appliances that may be damaged or incorrect must not be

installed or operated under any circumstances. Installation of damaged or incorrect appliances

may contravene local government regulations. Rinnai disclaims any liability or responsibility

whatsoever in relation to the installation or operation of damaged or incorrect appliances.

NOTICE TO VICTORIAN CONSUMERS

This appliance must be installed by a person licensed with the Victorian Building Authority.

Only a licensed person will have insurance protecting their workmanship.

So make sure you use a licensed person to install this appliance and ask for your Compliance Certicate.

For further information contact the Victorian Building Authority on 1300 815 127

Rinnai 4 EHPA_A Heat Pump OIM

Page 5

TRANSPORT AND STORAGE OF APPLIANCE

IMPORTANT

WARNING

The refrigerant used in the heat pump is a ammable gas.

WARNINGS AND IMPORTANT INFORMATION

RISK OF FIRE

The appliance(s) shall be stored and transported in an area without ignition sources (for example:

open ames, an operating gas appliance or an operating electric heater)

DO NOT pierce or burn the appliance.

Be aware that refrigerants may not contain an odour.

Compliance with AS/NZS 5149 MUST be observed while storing the appliance.

National and state regulations exist for storage, handling and transport of hazardous goods

including ammable gasses. The maximum number of pieces of equipment or the conguration

of the equipment, permitted to be transported or stored together will be determined by the

applicable regulations.

IMPORTANT

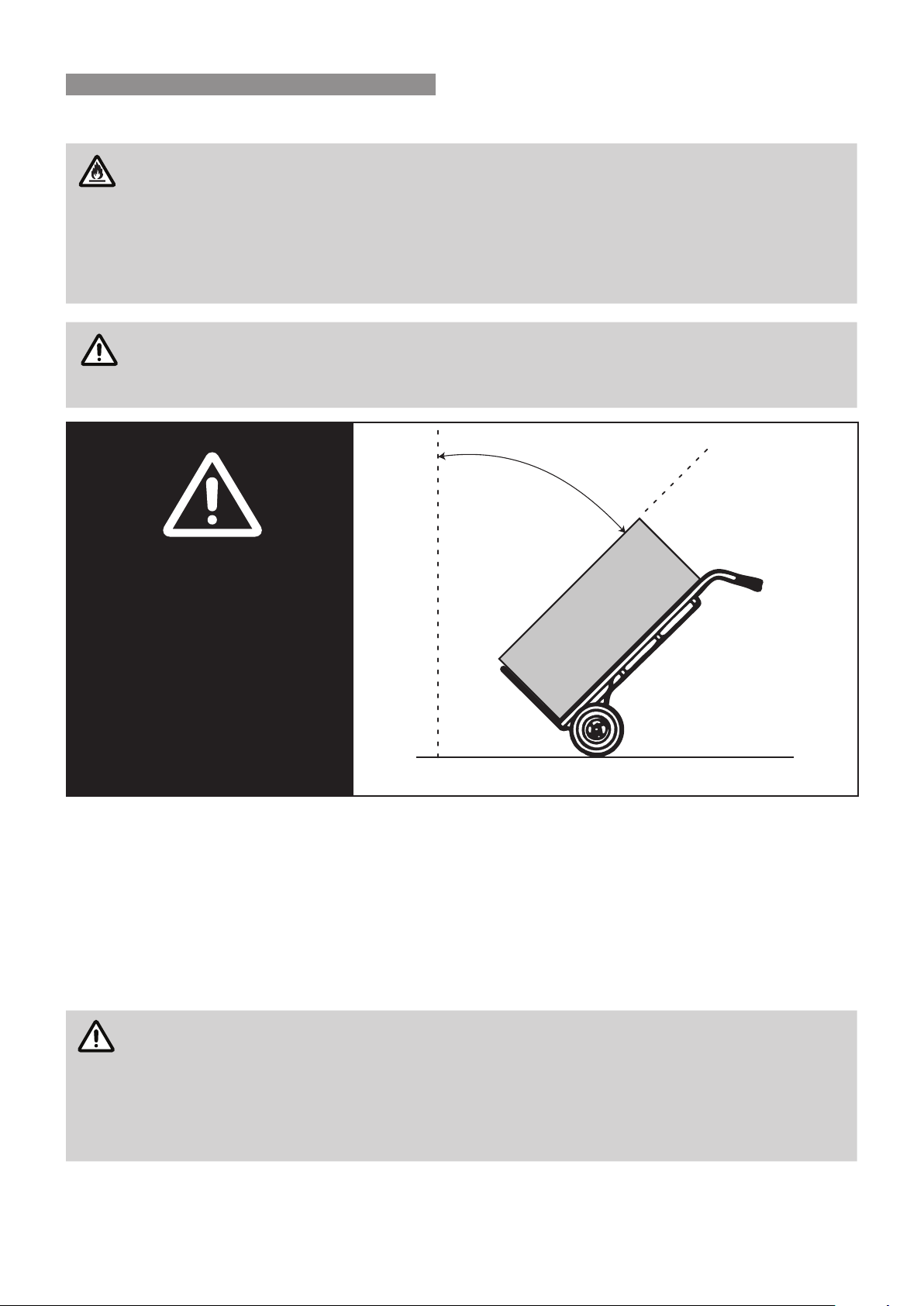

DO NOT TILT

45°

MORE THAN 45

FROM VERTICAL°

The Rinnai Enviroo Electric Heat Pump must be transported at an angle no greater that 45º from vertical. As the

compressor unit is located at the top of the electric heat pump, should the heat pump be tilted at a greater angle

than 45º from vertical, the lubrication oil within the compressor can run down into the mufers. This will leave the

compressor motor without sufcient lubrication and lead to premature failure of the compressor unit.

As a general good practice it is better to keep the compressor upright as much as possible to avoid any risks.

Returning the Rinnai Electric Heat Pump to a vertical position will not allow the oil to properly ow back into the

compressor motor.

Tilting Rinnai Hoto Electric Hot Water beyond 45º from vertical will also place undue strain on compressor motor

mounts and associated piping

Do not use means to accelerate the defrosting process or to clean, other than those recommended

by the manufacturer.

The appliance shall be stored in a room without continuously operating ignition sources. For

example, open ames, an operating gas appliance or an operating electric heater.

Do not pierce or burn.

Be aware that refrigerants may not contain an odour.

Rinnai 5 EHPA_A Heat Pump OIM

Page 6

WARNINGS AND IMPORTANT INFORMATION

SCALD HAZARDS

HOT WATER CAN CAUSE SCALDS.

CHILDREN, DISABLED, ELDERLY AND THE INFIRM ARE AT THE HIGHEST RISK OF

BEING SCALDED.

FEEL WATER TEMPERATURE BEFORE BATHING OR SHOWERING.

SCALDS FROM HOT WATER TAPS CAN RESULT IN SEVERE INJURIES TO YOUNG

CHILDREN.

SCALDS OCCUR WHEN CHILDREN ARE EXPOSED DIRECTLY TO HOT WATER WHEN

THEY ARE PLACED INTO A BATH WHICH IS TOO HOT.

ALWAYS......

Test the temperature of the water with your elbow before placing your child in the bath, also carefully

feel water before bathing or showering yourself.

Supervise children whenever they are in the bathroom.

Make sure that the hot water tap is turned o tightly.

CONSIDER.....

Installing child proof tap covers or child resistant taps (both approaches will prevent a small hand being

able to turn on the tap).

Installing tempering valves or thermostatic mixing valves which reduce the hot water temperature

delivered to the taps. Your local plumbing authority may already require that these be tted. Contact

your installer or local plumbing authority if in doubt.

NEVER….

Leave a toddler in the care of another child. They may not understand the need to have the water

temperature set at a safe level.

Rinnai 6 EHPA_A Heat Pump OIM

Page 7

WARNINGS AND IMPORTANT INFORMATION

OPERATION PRINCIPLE

The operation of an electric heat pump is very similar to a refrigerator, but in reverse. A heat pump operates by

transferring heat from the ambient outside air into the water. Electricity is just used to operate the system, but not

to directly heat the water. Because of this energy consumption is signicantly reduced as compared to an electric

element hot water system. The warmer the climate in which the heat pump is installed, the more efcient the heat

pump system will be at heating water.

The heat pump unit includes a circulation pump which draws water from the bottom of the storage tank and returns

it to the tank at a higher temperature. A temperature sensor in the tank is used to control the heat pump operation

to achieve suitable tank temperatures.

During the occasional times when the ambient weather conditions aren’t suitable for the heat pump to operate, the

electric element will provide heating to ensure a supply of hot water.

7

3

2

8

1. Cold water inlet pipe

2. Circulation Pump

6 5

12

11

13

12

1

13

4

10

9

8. Compressor

9. Heating Element

3. Plate Heat Exchanger

4. Hot Water from Heat Exchanger to the Tank

5. Intake Air

6. Discharge Air

10. Water Temperature Sensor

11. PTR Valve

12. Display & Control Panel

13. Mode Button

7. Fan Coil Unit

There are four indicators on the Display & Control Panel (12) which display the current operational mode /status of

the heat pump. To select one of the three available operation modes described below, press the Mode Button (13)

until the desired mode is illuminated.

MAX

For fast recovery the water will be heated to 60°C using a combination of the compression system and the

heating element.

MID

ECO

ERR

The water will be heated to 57°C using the compression system only.

The water will be heated to 55°C by economical use of the compression system (this is the factory default).

This will ash red only if an error is detected with the heat pump operation, please call Rinnai for assistance

if this should occur, and refer to “Save a Service Call” on page 10 for additional information.

Rinnai 7 EHPA_A Heat Pump OIM

Page 8

WARNING

WARNING

WARNING

WARNINGS AND IMPORTANT INFORMATION

SAFETY DEVICES

The water heating system is supplied with various safety devices including temperature sensors, overheat sensors

and switches and a Pressure & Temperature Relief (PTR) valve. These devices must not be tampered with or

removed. The water heating system must not be operated unless each of these devices is tted and is in working

order.

DO NOT tamper with or remove safety devices.

DO NOT operate the water heater unless all safety devices are tted and in working order.

DO NOT block or seal the PTR Valve and drain pipe.

Pressure & Temperature Relief (PTR) Valve

This valve is located near the top of the water heater and is

essential for safe operation. It is normal for the valve to release

a small quantity of water through the drain line during heating.

Lift lev er until w ate r

flows fr om d rain line

(L o w er lever g enlty !)

However, continuous leakage of water from the valve and its

drain line may indicate a problem with the water heater.

NEVER block the outlet of the PTR valve or it’s drain line for any reason. The easing gear MUST

be operated at least every 6 months to remove lime deposits and verify that it is not blocked.

Failure to do this may result in the water heater failing.

If the valve does not discharge water when the easing gear lever is opened, or does not seal again

when the easing gear is closed, attendance by an authorised person MUST be arranged without

delay. The PTR valve is not serviceable.

EXCESSIVE DISCHARGE FROM SAFETY DEVICES

Pressure & Temperature Relief (PTR) Valve

It is normal and desirable that this valve allows a small quantity of water to be discharged during the heating cycle.

If it discharges more than a bucket of water during a 24 hour period or discharges continuously there may be

another problem.

If the valve dribbles continuously, try easing the valve gear for a few seconds as described above. This may

dislodge any foreign matter and alleviate the problem.

If the valve discharges at high ows, especially at night, it may be as a result of the water pressure exceeding the

design pressure of the water heater. Ask your installer to t a Pressure Limiting Valve (PLV).

NEVER replace the PTR valve with one which has a higher pressure rating than is specied for your

water heater.

Expansion Control Valve (ECV) - if required

It is normal that this valve allows a small quantity of water to be discharged during the heating cycle. If it discharges

more than a bucket of water during a 24 hour period or discharges continuously there may be another problem.

If the valve leaks continuously, try easing the valve gear for a few seconds. This may dislodge any foreign matter

and alleviate the problem. If this does not alleviate the problem contact Rinnai.

Operate the easing gear regularly to remove any lime deposits and to verify that it is not blocked.

Rinnai 8 EHPA_A Heat Pump OIM

Page 9

WARNING

WARNINGS AND IMPORTANT INFORMATION

HYDROGEN GAS

If the hot water unit is not used for two weeks or more, a quantity of hydrogen gas, which is highly ammable,

may accumulate in the water heater. To dissipate this safely, it is recommended that a non electrically operated

hot tap be turned on for two minutes at a sink, basin, or bath, but not a dishwasher or other appliance. During

this procedure there must be no smoking, open ame or any electrical appliance operating nearby. If hydrogen is

discharged through the tap, it will probably make a sound like air escaping.

TURNING OFF THE WATER HEATING SYSTEM

If you plan to be away for only a few nights, we suggest you leave the water heating system switched on. If it is

necessary to switch off the water heater, do so as outlined below:

DO NOT turn power off to the heat pump unit if snow or frost conditions are expected as components

in the system may be damaged by freezing. If power needs to be turned off or power failure occurs and

freezing conditions are expected, the water needs to be drained from the heat pump unit. Follow the

procedure described below in the section the section ‘Draining and Filling’ on page 9.

TURNING ON THE WATER HEATING SYSTEM

Switch on the electric supply to the heat pump unit. Water heating will now occur as required. It may take a number

of hours before hot water is available.

DRAINING AND FILLING

Draining or lling of the complete system normally only occurs during installation or servicing and must be carried

out by an authorised person.

Draining water from the heat pump unit is necessary if the power will be shut off to the unit and snow or frost

conditions are expected. Arrange for an authorised person to carry out this task.

To drain the heat pump:

1. Turn off power to the heat pump

2. Close the cold water mains supply stop cock

3. Open a hot tap to relieve pressure

4. Disconnect the hot outlet near the top of the storage cylinder

5. Disconnect the cold inlet near the bottom of the storage cylinder.

6. The system will now drain completely.

MAINTENANCE AND REGULAR CARE

Operate the easing gear of the PTR and the ECV if tted as described in the section ‘Safety Devices’ on page 8.

The overow tray (supplied by installer) and drain underneath the storage cylinder (if tted) should be periodically

checked to ensure there are no blockages.

Rinnai 9 EHPA_A Heat Pump OIM

Page 10

SAVE A SERVICE CALL

Rinnai’s servicing network personnel are fully trained and equipped to give the best service on your Rinnai

appliance. If your appliance needs service, ring one of the service contact numbers on the back of this booklet.

The pressure and temperature relief valve and expansion control valve (if tted) must be replaced by an authorised

person at intervals not exceeding 5 years or more frequently in areas where the water is classied as scaling water.

If the power supply cord to the heat pump unit is damaged, they must be replaced by an authorised person in order

to avoid a hazard.

Use the following guide to avoid the need for an unnecessary service call.

INSUFFICIENT OR NO HOT WATER

Heat Pump Unit Not Powered Check to ensure the electric isolating switch at the switchboard (usually

marked “Hot water” or “Water heater” is turned on. (note that the

compressor will not start up for 2 minutes after power is turned on).

Excessive hot water

consumption

Pressure & Temperature

Relief (PTR) Valve continually

discharging water

Expansion Control Valve (ECV)

continually discharging water

Often end users are surprised at the amount of hot water used, especially

when showering. If the amount of hot water used during the day exceeds

the storage capacity of the cylinder, it is likely there will be insufcient hot

water.

It is normal and desirable that this valve allows a small quantity of water

to be discharged during the heating cycle. If it discharges more than a

bucket of water during a 24 hour period or discharges continuously there

may be another problem.

If the valve dribbles continuously, try easing the valve gear for a few

seconds as described in the section ‘Excessive Discharge from Safety

Devices’ on page 8. This may dislodge any foreign matter and alleviate

the problem.

If the valve discharges at high ows, especially at night, it may be as a

result of the water pressure exceeding the design pressure of the water

heater. Ask your installer to t a Pressure Limiting Valve (PLV).

It is normal and desirable that this valve allows a small quantity of water

to be discharged during the heating cycle. If it discharges more than a

bucket of water during a 24 hour period or discharges continuously there

may be another problem.

If the valve leaks continuously, try easing the valve gear for a few seconds

as described in the section ‘Excessive Discharge from Safety Devices’

on page 8. This may dislodge any foreign matter and alleviate the

problem. If this does not alleviate the problem contact Rinnai.

Ambient conditions too hot To protect the components of the heat pump unit it may not operate when

the ambient temperature is higher than 45°C. The heating element will

operate if water heating is required, but may take longer to heat the water.

Ambient conditions too cold To protect the components of the heat pump unit it may not operate when

the ambient temperature is less than -1°C. The heating element will

operate if water heating is required, but may take longer to heat the water.

NO WATER FROM THE TAP

Restriction in the hot tap or

failure of the cold water supply

to the water heater

Rinnai 10 EHPA_A Heat Pump OIM

Check for water ow at the other taps and that the cold water isolation

valve is fully open.

Page 11

HIGH ELECTRICITY BILLS

SAVE A SERVICE CALL

Excessive hot water

See entry under the heading ‘Insufcient or no hot water’

consumption

High Electricity Taris The electricity tariff will determine the running costs of the system. It is

important the end user is aware of the applicable tariffs. Contact your

electricity supplier to conrm what these tariffs are.

Higher Element Usage In extremely cold conditions the element may be operating more than

normal.

WATER FLOW FLUCTUATIONS

One or more hot taps opened

at the same time

More than one or two hot taps in use at the same time may cause a

decrease in the hot water ow from the taps.

Is there more than one or two hot taps open, or are appliances such as a

dishwasher or washing machine, in use at the same time?

Ensure only one or two hot taps are on at one time.

WATER HAMMER

Hot and cold water plumbing in

the premises

Have a plumber check clipping of hot and cold water pipe work and install

a pressure limiting valve and water hammer arrestor as required.

HEAT PUMP ICES UP

Defrosting function The heat pump has a built in hot bypass defrosting function which may

operate and remove any ice.

HEAT PUMP ERROR INDICATOR

Red ERR indicator is ashing

on the Display & Control Panel

This will ash if an error is detected with the heat pump operation, please

call Rinnai for assistance if this should occur.

Rinnai 11 EHPA_A Heat Pump OIM

Page 12

SPECIFICATIONS

SPECIFICATIONS

SYSTEM SPECIFICATIONS

EHPA250VMA

EHPA250VMAW

EHPA250VMAH

EHPA250VMAWH

Net Weight / Filled Weight 123 kg / 400 kg 138 kg / 451 kg

Sound Level 48 dB(A)

Ambient Temperature Limits

(for heat pump operation - element will operate

beyond these limits)

Ingress Protection IP24

Storage Cylinder - Hot Outlet and Cold inlet

Connections

Storage Cylinder - PTR Valve Connection ISO 7.1 ½” RP

Pressure & Temperature Relief (PTR) Valve

(Supplied) Setting / Rating

Fit PLV if mains

ECV Fitted

pressure exceeds

Recommended PLV

pressure rating

Fit PLV if mains

ECV Not Fitted

pressure exceeds

Recommended PLV

pressure rating

Rated Input Electric Element

(Factory Wired)

Rated Input Refrigeration Module

(Factory Wired)

-1°C to 45°C

ISO 7.1 ¾” RP

1000 kPa / 10kW

680 kPa

500 kPa

800 kPa

500 kPa

2.4 kW

1.0 KW

EHPA315VMA

EHPA315VMAW

EHPA315VMAH

EHPA315VMAWH

Total Rated Input (To be wired by installer) 3.4 KW

Maximum Energy Output

(Use to size PTR)

Power Supply 240 V AC, 50 Hz.

Rated Current 15 A

Refrigerant Type / Mass R290 / 270 g

Refrigerant Compressor Oil Type / Charge Type: ISO VG 32 ESTER / 500 cm³

Refrigerant Circuit Maximum Pressure 3800 kPa

Start-up Protection

Defrosting Function

Protection Systems

Coefcient Of

Performance (COP)

Heat Output

32.6°C Ambient

21.1°C cold water inlet

32.6°C Ambient

21.1°C cold water inlet

When the power is rst turned on to the heat pump or power is cut then restored, the

unit will not start for 2 minutes to protect the compressor

When the fan coil unit temperature reaches 0°C, the hot discharge bypass defrosting

mode will operate for 15 minutes or until the evaporator temperature reaches 5°C.

The heat pump has protection systems that will stop the operation of the unit if:

Suction pressure drops due to refrigerant charge loss or air ow blockage

Over pressure (551 Psi) or over temperature (110°C) in the refrigerant system

4.29 kW

7.22

5.20 kW

Rinnai 12 EHPA_A Heat Pump OIM

Page 13

DIMENSIONS

SPECIFICATIONS

EHPA250VMA / EHPA250VMAW /

EHPA250VMAH / EHPA250VMAWH)

Cylinder height 1847 2134

Hot Outlet / PTR 1215 1430

Cold water inlet 90 90

Cylinder diameter 627 627

Unit Width 675 675

EHPA315VMA / EHPA315VMAW /

EHPA315VMAH / EHPA315VMAWH)

Rinnai 13 EHPA_A Heat Pump OIM

Page 14

SPECIFICATIONS

CLEARANCES

Allow 500mm on the fan discharge side and 150 mm clearance on the fan suction side to allow for sufcient air

ow through the fan.

100 mm

150 mm

150 mm

500 mm

300 mm

500 mm

Rinnai 14 EHPA_A Heat Pump OIM

Page 15

WARNING

WARNING

INSTALLATION

REGULATIONS AND OCCUPATION HEALTH AND SAFETY (OH&S

Installation and commissioning MUST be performed by authorised persons.

The heat pump MUST be installed in accordance with these instructions and all regulatory

requirements which exist in your area including those in relation to manual lifting.

Applicable publications and regulations may include:

AS/NZS 3500 National Plumbing and Drainage

•

AS/NZS 3000 Wiring Rules

•

Building Codes of Australia (BCA)

•

Local Occupational Health and Safety (OH&S) regulations

•

This appliance is not suitable for use as a domestic spa pool or swimming pool heater.

Electric Heat pumps are heavy and bulky items. Australian States and Territories have a Principal

Occupational Health and Safety (OH&S) Act which contains requirements relating to the handling

of large, bulky or awkward items. Persons installing heat pump systems MUST be aware of

their responsibilities and be adequately trained and qualied, in accordance with local OH&S

requirements.

LOCATION

The electric heat pump can be installed externally or internally.

The electric heat pump should be placed as close as practicable to the most frequently used hot water outlet point

or points to minimize the delay time for hot water delivery. This will usually be the kitchen tap. For installations

where the distance between the heat pump and the outlets is considerable, a ow and return system can be used

which minimize the waiting time for hot water delivery.

)

It is recommended that all components are installed at ground or oor level. The heat pump MUST be installed in

a vertically upright position. All components MUST be accessible without the use of a ladder or scaffold. The unit

MUST NOT be installed in roof spaces.

As the heat pump contains a ammable refrigerant, ensure the installation location complies with

the requirements of AS/NZS 60335.2.40 & AS / NZS 5149.

The air inlet and outlet of the heat pump module MUST be away from areas with strong wind and MUST be

provided with sufcient clearances as per those shown in the section ‘’ on page 13.

The heat pump MUST be connected to an independent AC 240 V, 50 Hz power supply.

Ensure the pressure and temperature pressure relief (PTR) valve and any access covers have sufcient clearances

and are accessible for service and removal. The information on the rating plates MUST also be readable.

The heat pump MUST be installed free-standing on a level and stable base. The cylinder should be mounted on a

concrete base at least 50mm thick or on well-seasoned, evenly spread hardwood slats with a thickness of at least

25mm. Where property damage can occur as a result of water leakage, the storage cylinder MUST be installed

with a safe tray (overow tray) and drain in accordance with AS 3500.4. Ensure the storage cylinder DOES NOT

stand on wet surfaces.

The air inlet and outlet of the heat pump module MUST be away from areas with strong wind and MUST be

provided with sufcient clearances as per those shown in section “Clearances” on page 14.

The heat pump MUST be connected to an independent AC 240 V, 50 Hz power supply.

Internal Installation

For internal installations the area MUST meet the following requirements:

Minimum room volume of 39m3 per unit.

•

Good Ventilation (i.e minimum 200 L/s per unit)

•

Away from any ignition sources or corrosive environments.

•

If the heat pump is installed internally careful consideration should be taken in regards to positioning and limiting

the effect of unit noise and reverberation during operation.

Rinnai 15 EHPA_A Heat Pump OIM

Page 16

INSTALLATION

Condensation

As this heat pump is highly efcient the surrounding air temperature could be cooled by up to 4°C and condensate

formed, the condensate will need to plumbed to a suitable drain.

Drainage

Where property damage can occur as a result of water leakage, the water heater MUST be installed with a safe

tray (overow tray) and drain. Construction, installation and draining of the safe tray MUST comply with local

regulatory requirements and. AS/NZS 3500.4 also requires the use of a safe tray for particular situations.

WATER SUPPLY

This appliance is intended to be permanently connected to the water mains and not to be connected by a hose set.

The maximum water pressure is listed on page 12. An approved pressure limiting valve may be required if the

maximum rated water supply pressure is exceeded.

Water chemistry and impurity limits are detailed in the separate warranty document. Most metropolitan water

supplies fall within these requirements. If you are unsure about water quality, contact your water authority.

A water lter MUST be tted on the inlet to the tank to prevent sludge or foreign matter entering the system.

In a scaling water supply, calcium carbonate and possibly other compounds are deposited out of the water onto

any hot metallic surface and form a scale. Scaling water may cause scale deposits to form onto the metallic

surfaces of the PTR valve and may prevent it from operating properly. To prevent this, an expansion control valve

(ECV) MUST be tted on the cold water line after the non-return valve in areas of scaling water. ECVs’ MUST

be tted in South Australia and Western Australia to comply with local regulations.

STORAGE TEMPERATURE

To meet regulatory requirements the thermostat control on the heat pump water heater is factory pre-set to heat all

the water in the tank to 60°C once a week. This cannot be altered.

HOT WATER DELIVERY TEMPERATURE

This appliance may deliver water at high temperature. Refer to the Plumbing Code of Australia (PCA), local

requirements and installation instructions to determine if additional delivery temperature control is required.

The PCA, local regulations and the requirements of AS/NZS 3500.4 MUST be considered regarding the

temperature limitations of hot water supplied to areas used primarily for personal hygiene.

The temperature of water to certain areas is limited to different temperatures according to purpose, for e.g. early

childhood centres, primary and secondary schools and nursing homes or similar facilities for young, aged, sick

or people with disabilities and for all other buildings. To comply with these requirements, a temperature limiting

device, such as a thermostatic mixing or tempering valve, will be required on hot water systems.

VALVES AND FITTINGS

The following valves and ttings are supplied with your solar hot water system:

A combined pressure and temperature (PTR) relief valve, capacity 10 kW is supplied with the heat pump.

•

This valve is tted at the top of the storage cylinder. The PTR valve is a safety device and it is mandatory

that it is tted by the installer in all installations.

The following valves & ttings are to be supplied by the installer:

A cold water expansion control valve (ECV). An ECV MUST be tted in Western Australia and South Australia

•

to the cold water supply to the storage cylinder to comply with local regulations. An ECV is recommended in

all other geographical areas where the water supply has a tendency to cause scaling. This will reduce hot

water discharge from the pressure and temperature relief (PTR) valve which minimises wear on this valve.

A stop cock, non return valve and line strainer. Combination valves incorporating two or more of these

•

functions (such as ‘Trio’ valves) are suitable. These are tted to the cold water supply to the storage cylinder

by the installer.

Cold water supply and hot water discharge pipework to and from the storage cylinder. This pipework MUST

•

be insulated as specied in AS/NZS3500.4

An approved pressure limiting valve (supplied with some systems) is required if the maximum rated water

•

supply pressure on page 12 is exceeded.

Tempering valve(s) or thermostatic mixing valve

•

Rinnai 16 EHPA_A Heat Pump OIM

Page 17

TRANSPORT AND HANDLING

IMPORTANT

NOTE

e

d

s

t

a

l

l

a

t

i

o

n

p

o

s

i

t

i

o

n

When moving the unit, it MUST be close to vertical at all times.

When using a trolley to move the unit, ensure it is not tilted more than 45° from the vertical.

Non compliance will void warranty and severely a ect product performance and operation

The Rinnai Enviro o Electric Heat Pump MUST be

transported at an angle no greater that 45º from vertical.

As the compressor unit is located at the top of the

electric heat pump, should the heat pump be tilted at a

greater angle than 45º from vertical, the lubrication oil

within the compressor can run down into the muf ers.

This will leave the compressor motor without suf cient

lubrication and lead to premature failure of the

compressor unit.

As a general good practice it is better to keep the

compressor upright as much as possible to avoid any

risks. Returning the Rinnai Electric Heat Pump to a

vertical position will not allow the oil to properly ow

back into the compressor motor.

INSTALLATION

45°

Tilting the heat pump beyond 45º from vertical will also

place undue strain on compressor motor mounts and

Never tilt unit more than 45˚ from vertical

associated piping.

POSITIONING THE HEAT PUMP

Arrive at site and conduct a safety audit (Safety audits can also be

known as Work Method Statements (WMS) or Job Site Analysis (JSA).

Park your vehicle as close as allowable to your installation. Unload all

materials in a safe manner.

Position all materials in a convenient position near the work area.

Where the requirements for internal installation can’t be met, the heat

pump MUST be installed outdoors.

The location MUST consider noise impact on living areas. Avoid

positioning near bedrooms or neighbours’ bedrooms. Although the

running noise level is very low it can be expected that the heat pump will

run during the night.

Adequate access MUST be available to the relief valve and anode.

Safely position the new unit on a level surface in accordance with all

plumbing and building regulations.

A properly drained over ow tray MUST be used where property

damage could occur from water spillage. (See AS/NZS3500.4.2 for

further details.)

Install a plinth under the heat pump

where it is subjected to wet conditions

DO NOT drain on to grass or garden beds.

DO NOT commence a job where the risks cannot be

controlled.

3

Allow 200m

of free space surrounding the unit. This provides clear

ambient air ow assisting the product’s performance. Ensure the

clearance requirements speci ed in the section ‘Dimensions’ on page

13. are complied with. The area MUST also be clear of debris such

Optimum installation location is on the

warmest side of house.

as leaves and tree branches.

Rinnai 17 EHPA_A Heat Pump OIM

Page 18

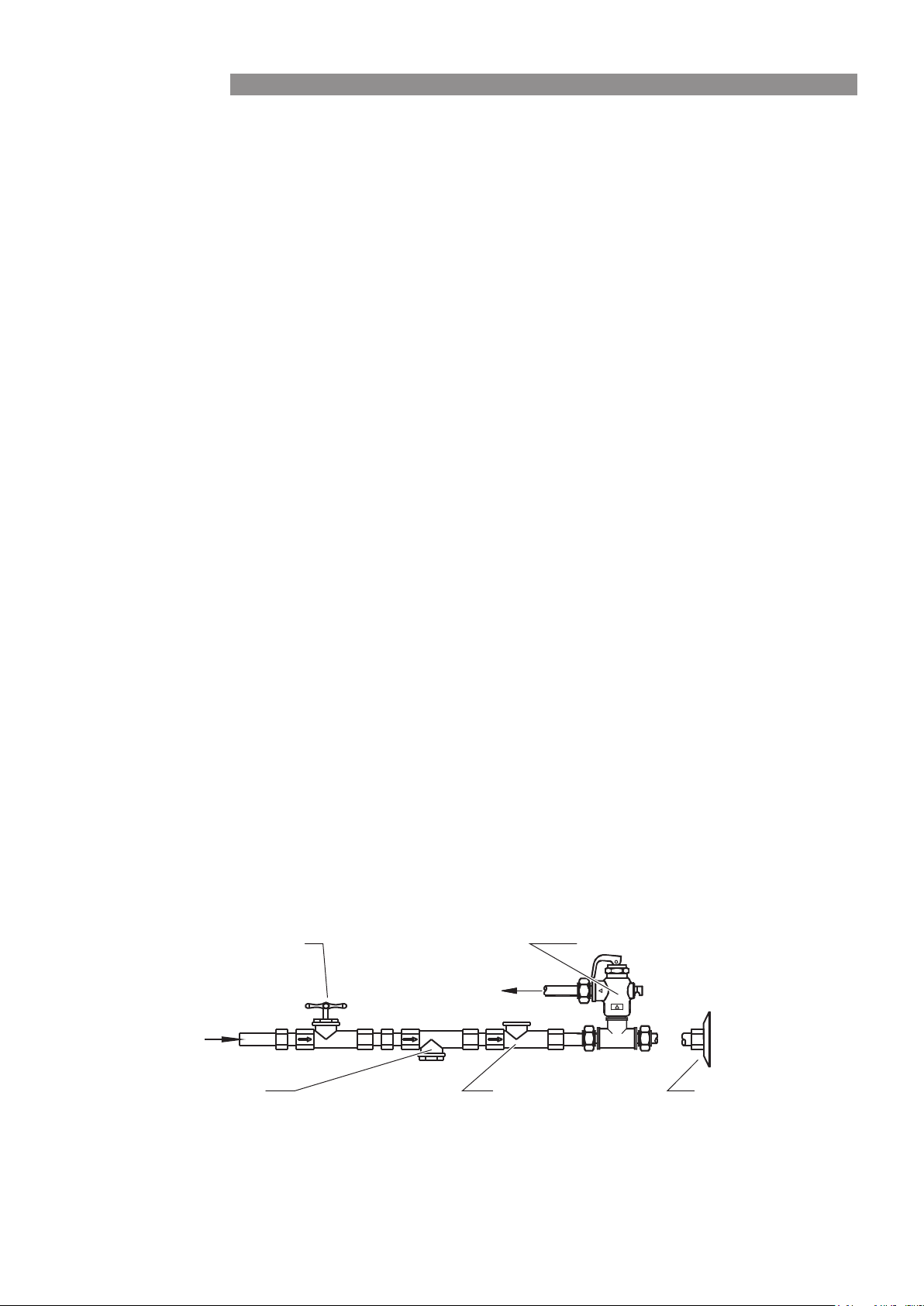

Union Connection

Isolating Valve (Spindle Vertical)

Cold water expansion

control valve

INSTALLATION

CONNECT THE PTR VALVE

Connect the PTR valve to the uppermost tting of the storage cylinder. See the diagram on page the section

‘Dimensions’ on page 13.

The PTR pressure rating MUST be suited for the cylinder and adequate for the thermal loading applied to the

storage cylinder, as specied in the table on 12. The supplied PTR valve input rating is 10.0 kW. The PTR

valve rating MUST EXCEED the total input from the heat pump. For example, the maximum output from the

EHPA_A250VM is 4.29 kW (see the table on page 12). This is less than 10.0 kW, hence the supplied PTR valve

is of sufcient capacity.

Use Teon thread tape on the valve, never use hemp or other sealing materials. Ensure the tape does not protrude

past the end of the thread, which could result in it hanging over the end of the thread and blocking the water

passage through the valve.

The PTR valve MUST be installed on the connection marked ‘hot water outlet’ near the top of the cylinder. Leave

the valve outlet pointing down. Tighten the valve using the spanner ats - never use the valve body.

Connect the supplied PTR valve into the top socket marked “Relief Valve” and discharge according to plumbing

regulations. PTR Valves for the unit are rated at 1000kpa.

The drain line from this valve MUST run in a continuously downward direction with the discharge end left

permanently open to atmosphere.

PLUMBING CONNECTIONS

Refer to the diagram on page 13 for detailed information on position of plumbing.

An approved isolating valve, non return valve, line strainer, and union MUST be tted between the supply main

and the RP ¾ socket in the water heater. All ttings MUST be approved by the relevant installation Authority.

An ECV MUST be tted in Western Australia and South Australia to the cold water supply to the storage cylinder

to comply with local regulations.

An ECV is recommended in all other geographical areas where the water supply has a tendency to cause scaling.

This will reduce hot water discharge from the pressure and temperature relief (PTR) valve which minimises wear

on this valve.

This water heater is designed for direct connection to water supply pressures of no greater than those specied on

page 12. Where the mains pressure can exceed or uctuate beyond this, a pressure limiting device (complying

with AS1357) MUST be tted.

CONNECT COLD / HOT WATER SUPPLY

Connect cold water supply, Pressure Limiting Valve (PLV) and or Expansion Control Valve (ECV).

Connect cold water supply to the storage tank (refer to Diagram BELOW).

A stop cock, non return valve and line strainer MUST be tted.

D rain

Cold Water Inlet

Connect the pipe work supplying hot water to the premises to the hot water outlet on the tank.

A temperature limiting device may be required as detailed in the section the section ‘Hot Water Delivery Temperature’

on page 16

It is recommended that all hot water lines are insulated with high temperature, UV resistant 13mm closed cell

insulation.

Rinnai 18 EHPA_A Heat Pump OIM

Non-return ValveLine Strainer

Page 19

WARNING

WARNING

IMPORTANT

INSTALLATION

CONNECT CONDENSATE DRAIN LINE

A condensation drain line is required to be tted to carry

discharge clear of the water heater.

Condensate

Drain

The condensate drain line should not be connected to

the PTR drain line but can exit to the same point.

The diagram below shows the location of the condensate

drain on the heat pump.

Independent 15mm copper pipes MUST be tted to

the drain outlets of the PTR and ECV.

Each pipe MUST be open to atmosphere and run with

a continual downward grade in a frost free environment

to a visible discharge point.

Drain lines MUST not exceed 9 meters in length.

Valves or other restrictions MUST NOT be placed in

the relief valve drain outlet line.

ELECTRICAL TESTS

DO NOT turn on the power supply to the appliance until it has been lled with water and a satisfactory insulation

(Megger) test has been performed.

Conducting Insulation (Megger) Tests

When conducting an insulation test using a Megger on this appliance, observe the then the following:

This appliance contains electronic components, when performing insulation tests (500 Volts)

this MUST ONLY be conducted the across active terminal to earth and then across the neutral

terminal to earth.

Tests between the active to neutral terminals MUST NOT be performed as this WILL damage

the electronic components.

Insulation test results of between 100 KΩ and 660 KΩ are normal for this appliance.

In accordance with AS/NZS 3000 an insulation test with a result less than 1 MΩ is permitted where the appliance

is approved to a Standard applicable to that class of appliance.

This appliance is categorised as a ‘stationary Class 1 motor operated appliance’ and therefore satises the

requirements of AS/NZS 60335.2.40 for leakage current and electric strength. As such, this appliance complies

with the insulation resistance requirements of AS/NZS 3000.

ELECTRICAL CONNECTIONS

The power supply to the heat pump module MUST NOT be activated until the system is lled

with water.

The premises wiring to the heater MUST be capable of withstanding the appliance load. Refer to

specication table for load details.

All electrical connections and wiring MUST be installed, maintained and removed by authorized

persons in accordance with AS/NZS 3000, and all other relevant local regulations and municipal

building codes including OH&S requirements.

The Heat Pump is NOT tted with a power cord & plug , It MUST have the supply terminals

connected to an independent, fused, AC 240V 50 Hz power supply with an isolating switch

installed at the switch board, which shall eectively isolate all active supply conductors from the

circuit and means for disconnection MUST be incorporated in the xed wiring in accordance

with the wiring rules.

A Residual Current Circuit Breaker is recommended for the power supply to this appliance (this

may be a mandatory requirements in some states or jurisdictions).

Rinnai 19 EHPA_A Heat Pump OIM

Page 20

IMPORTANT

Automatic Air

INSTALLATION

Electrical access is via a 20 mm hole beneath the element

cover for mounting with an approved weatherproof electrical

conduit nipple.

For entry to the element cover remove the two xing screws.

Connect all ACTIVE and NEUTRAL wires in accordance with

the wiring diagram which is also included at the rear of the

element access cover.

Ensure the incoming EARTH wire is securely xed to the earth

post provided on the heater case.

Inspect and ensure that all wiring links are secure prior to

xing the access cover and turning the POWER ON.

To ensure the over-temperature and energy cut-out is set,

press the (red) ‘reset’ button on the Thermostat

This appliance MUST NOT be connected via a

switchable or a solar (photovoltaic - PV) power

supply without manufacturer consultation.

The switching of the supplies will place the water

heater into a re-start cycle which reduces the

available heating time and may result in a lack

of hot water.

NEUTRAL

CONTROLLER

Electrical

Connections

Access

ROLLER

CONT-

NEUTRAL

CONTROLLER

Disconnect all power prior to installation and commissioning.

This appliance is designed for single phase 240 Volts, AC

mains electrical operation.

FILLING THE SYSTEM

Open hot water tap at sink.

Open the stop cock in the cold water main supply line. Allow

the system to ll and the air to bleed through the tap.

Turn off the hot tap at the sink when water ows freely without

any air bubbles or air bursts.

Bleed any remaining air from the PTR valve.

It is recommended this appliance is connected to

either a 24 hour continuous tari or an extended

o-peak power supply (minimum 16 hours per

day, noting that the minimum required running

time is governed by hot water demand and the

climate zone.

If this appliance is replacing an electric water

heater with a capacity of 250 litres (or greater),

then a connection to a 24 hour continuous tari

supply is recommended.

EARTH

Bleed Valve

An automatic air bleed valve is tted on top of the circulation

pump of the heat pump module:

Turn on power to the heat pump unit and wait 30 seconds for

the circulation pump to turn on. Any remaining air will be bled

from the automatic air vent.

If leaks are detected turn off power to the heat pump, repair

any leaks and repeat the lling process to remove any air.

If no leaks are detected water heating can commence. The

heat pump will start up after the 2 minute protection time.

Rinnai 20 EHPA_A Heat Pump OIM

Page 21

2 3 4 5 6 7

10 11 12

INSTALLATION

FINISHING THE INSTALLATION

After testing is completed explain to the householder the functions and operation of heat pump water heater

components. Explain to the householder the need to drain the heat pump if freezing conditions are likely and power

is likely to be shut off.

Also explain to the householder the importance of carrying out maintenance in accordance with this manual.

Leave this manual with the householder.

OPERATION SEQUENCE OF CONTROLLER

When the power supply turns on, the heat pump control system initiates and will check the unit’s operating

parameters. The controller will check on all sensors, pressure switches and also main voltage. If conditions are

suitable (i.e All reading within the reasonable range) and there is enough energy available in the surrounding air,

the fan, circulating pump and compressor will turn on. If not enough energy is detected in ambient air then the

controller calls for the booster heating element to run.

There will be a delay of approximately 2 minutes from the time the main power is switched on before the pump, fan

and compressor begin operating.

The unit is self regulating so there are no internal adjustments to be made during commissioning. When the unit is

operated for the rst time, it runs through an initial heat up cycle, allow time for the initial heat up cycle. Depending

on the ambient conditions this can take several hours.

Once its rst heat up cycle is complete, empty approximately 60 litres of hot water from the tank through the PTR

valve outlet then allow the water in the tank to re-heat. Once the re-heat cycle is completed measure the water

temperature at the PTR outlet again. The temperature will be approximately 60º C.

If for any reason the unit does not start, the water is cold and the controller unit is not displaying any LED lights, an

electrician should test that power is available to the heat pump.

9

8

1

1 DIP Switch Test & Conguration 7 LED Display / Control Panel Output

2 Tank Temperature Sensor 8 Programming Serial Port (Wi-Fi)

3 Compressor Discharge Temperature Sensor 9 HMI (Accessory for service) Port

4 Fan Coil (Evaporator) Temperature Sensor 10 Compressor, Element , Main Power

5 High Pressure Switch 11 2 Amp Fuse

6 EEV Output (Electric Expansion Valve) 12 Fan, Pump, Defrost Power

Rinnai 21 EHPA_A Heat Pump OIM

Page 22

INSTALLATION

CONTROLLER LED FLASHING CODES

12

12

13

14

13

12

13

Ensure the controller unit is not displaying the ERR indicator once unit has been switched on.

Indicator Explanation

Display /

Control Panel

Indicators

MAX 60°C using a combination of the compression system and the heating element.

MID 57°C using compression system.

ECO 55°C using compression system.

If the Display & Control Panel (12) is displaying the red ashing ERR indicator (14) then refer to the table below

to nd the fault:

Flash Code Explanation

1 ash Tank Sensor- FAILURE

2 ashes Ambient Sensor - FAILURE

3 ashes Evaporator Sensor - FAILURE

Red ERR

Indicator

4 ashes Compressor Discharge Sensor- FAILURE

5 ashes Compressor Discharge Sensor ≥ 110° C

7 ashes High Pressure Switch Open

8 ashes Under Voltage <207 V AC

9 ashes Over Voltage > 265 V AC

The dip switches can be used to go to the test mode for the functionality of various components. In test mode the

output relays L1. L2, L3, L4 will be controlled manually by dip switches irrespective of input reading.

DIP Switch(s) Switch Position(s) Explanation

No. 8 OFF Normal Operation Mode (Factory set)

No. 7 OFF Normal Operation Mode (Default)

DIP Switch

Congurations

No. 7 & No. 1 ON Compressor (L1) ON

No. 7 ON Test Mode -

No. 7 & No. 2 ON Fan/Pump (L2) ON

No. 7 & No. 3 ON Element (L3) ON

No. 7 & No. 4 ON Defrost Solenoids (L4) ON

Any changes to the normal operating settings may adversely affect the performance of the heat pump.

Rinnai 22 EHPA_A Heat Pump OIM

Page 23

NOTES

Rinnai 23 EHPA_A Heat Pump OIM

Page 24

CONTACT

Rinnai Australia Pty Ltd

ABN 74 005 138 769 | AU45204

100 Atlantic Drive, Keysborough, Victoria 3173

P.O. Box 460, Braeside, Victoria 3195

Tel: (03) 9271 6625

Fax: (03) 9271 6622

National Help Line

Tel: 1300 555 545* Fax: 1300 555 655

Monday to Friday, 8.00 am to 5.00 pm EST.

After Hours Hot Water Service Line

Tel: 1800 000 340*

*Cost of a local call may be higher from a mobile phone.

(National calls from public phones in Australia are free.)

For further information visit www.rinnai.com.au

or email enquiry@rinnai.com.au

Rinnai has a Service and Spare Parts network with

personnel who are fully trained and equipped to give

the best service on your Rinnai appliance. If your

appliance requires service, please call our National

Help Line. Rinnai recommends that this appliance be

serviced every 3 years.

With our policy of continuous improvement, we

reserve the right to change, or discontinue at any time,

specifications or designs without notice.

S112069 24 EHPA_A Heat Pump OIM - Issue A - May 2022

Loading...

Loading...