Rinnai Infinity XR16, REU-V1620WG Infinity HD200, REU-VRM2632WC, Infinity XR20, REU-V2024WG Infinity HD200i Installation Manual

...Page 1

Continuous Flow Water

Heaters

Installation Manual

Models are not suitable as a spa or swimming pool heater.

Internal Rinnai continuous flow internal water heaters (‘i’ models) must be installed with an

approved Rinnai flue system.

Appliance must be installed, commissioned and serviced by a licensed tradesperson in

accordance with these instructions and all applicable local rules and regulations.

Your Rinnai continuous flow water heater complies with NZS 5262. A declaration to this effect

can be found on the Energy Safety web site; www.energysafety.govt.nz..

To suit models:

Rinnai Infinity XR16 REU-V1620WG Rinnai Infinity HD200 REU-VRM2632WC

Rinnai Infinity XR20 REU-V2024WG Rinnai Infinity HD200i/HD200ia REU-VR2632FFUG

Rinnai Infinity XR24 REU-V2426WG Rinnai Infinity HD250/HD250a REU-VR3237WG

Rinnai Infinity XR26 REU-V2630WG Rinnai Efficiency 24 REU-K2430WG

Rinnai Infinity XR26a REU-V2630WGT Rinnai Efficiency HD250 REU-KM3237WD

Rinnai Efficiency HD250i REU-KM3237FFUD

i = internal a = aggressive water units HD = Heavy Duty

Page 2

Rinnai New Zealand Continuous Flow Water Heater Installation Manual:

01-09

2

Contents

WARNING

Improper installation, adjustment, alteration, service or maintenance

can cause property damage, personal injury or loss of life.

For assistance or additional information contact Rinnai on

0800 TO RINNAI (0800 86 746 624).

Before Installation 3

Applicable Models 3

Appliance Location 4

General Installation Information 6

Connections and Fittings 8

Dimensions - XR and HD Range 9

Dimensions - Efficiency Range 10

Condensate Drain - Efficiency Models Only 12

Controllers - General 14

Controllers - Universal Installation 16

Controllers - Kitchen Deluxe Installation 17

Controllers - Bathroom Deluxe Installation 18

Controllers - Communication Cables 19

Commissioning 21

Recommended Solar System Layout 22

Dip Switch Settings 23

Page 3

Rinnai New Zealand Continuous Flow Water Heater Installation Manual:

01-09

3

Before Installation

Unpack appliance and flue components (if applicable) and check for damage.

DO NOT install any damaged items.

Check all components have been supplied and that you have the correct gas type.

Read these instructions to get an overview of the steps required before starting the

installation. Failure to follow these instructions could cause a malfunction of the

appliance. This could result in serious injury and property damage.

For Rinnai continuous flow water heaters used in solar installations, refer

‘Recommended Solar System Layout’.

The Rinnai Efficiency Heavy Duty (HD) models are 32 kg. Please use care when

lifting and seek assistance if required.

This appliance must be installed in accordance with:

Current AS/NZS3000, AS/NZS2500, NZS 5261 and G12/AS1

Rinnai installation instructions

Local regulations and municipal building codes

Installation, service and removal must be by an authorised person only.

•

•

•

32 kg

Heavy

These installation instructions apply to the following Rinnai continuous flow water heaters.

Rinnai Infinity XR16 External REU-V1620WG

Rinnai Infinity XR20 External REU-V2024WG

Rinnai Infinity XR24 External REU-V2426WG

Rinnai Infinity XR26 External REU-V2630WG

Rinnai Infinity XR26a External REU-V2630WGT

Rinnai Infinity HD200 External REU-VRM2632WC

Rinnai Infinity HD200i/HD200ia Internal REU-VR2632FFUG

Rinnai Infinity HD250/HD250a External REU-VR3237WG

Rinnai Efficiency 24 External REU-K2430WG

Rinnai Efficiency HD250 External REU-KM3237WD

Rinnai Efficiency HD250i Internal REU-KM3237FFUD

i = internal

a = aggressive water units

HD = Heavy Duty

Applicable Models

Page 4

Rinnai New Zealand Continuous Flow Water Heater Installation Manual:

01-09

4

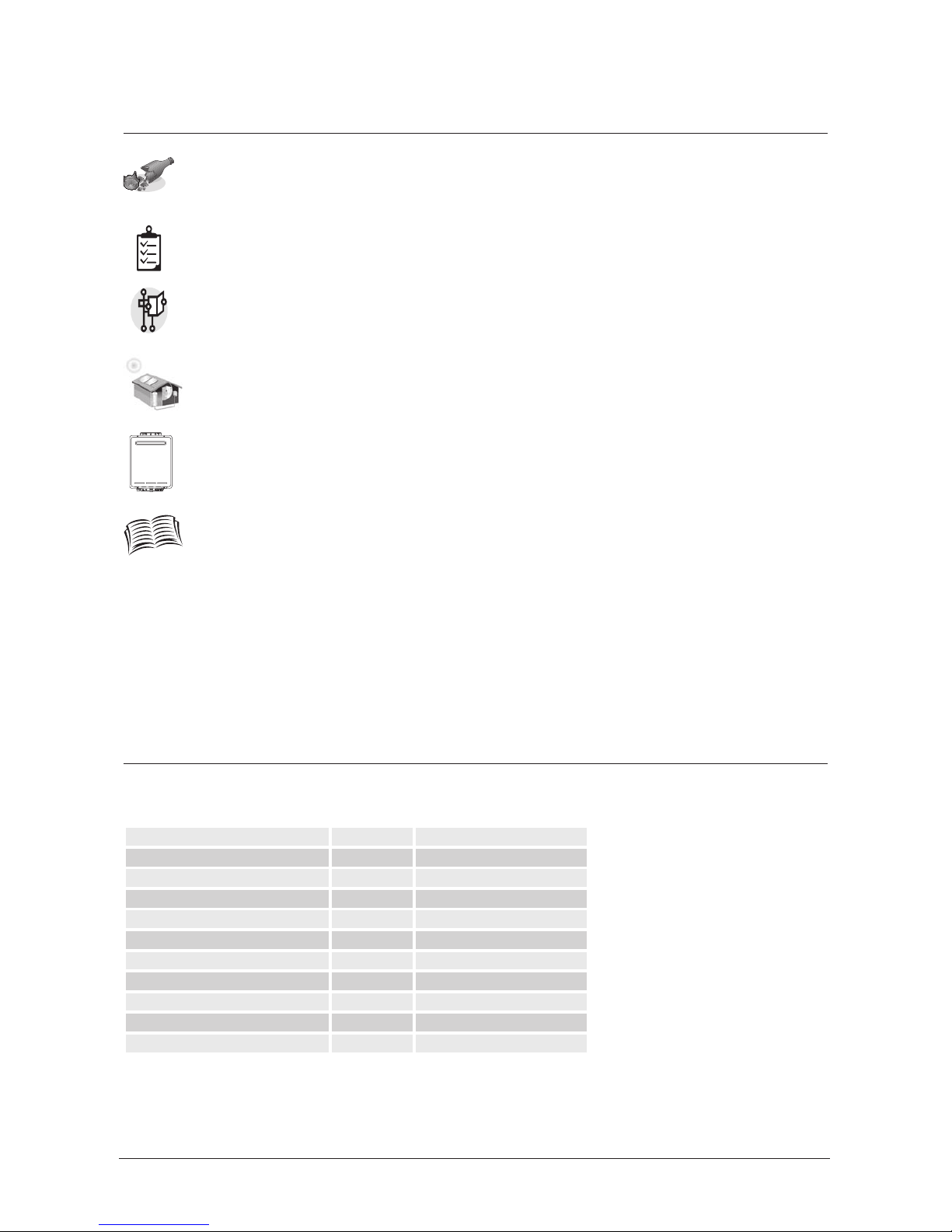

Appliance Location

External models

External models are designed for outdoor installations only. They must be located

in an above ground open-air situation with natural ventilation, without stagnant

areas, and where gas leakage and products of combustion are rapidly dispersed

by wind and natural convection.

They must be mounted on a vertical structure with the water and gas connections

on the underside pointing downwards. For appliances installed on elevated

structures or under floors specific requirements apply. Refer to NZS 5261 for

details.

Location of the appliance flue terminal must be in accordance with NZS 5261 section 2.6.11,

2.6.12 and 2.6.13.

When multiple units of the same model are installed on the same vertical face, with the flue

terminals at the same height, they can be installed next to each other (as shown).

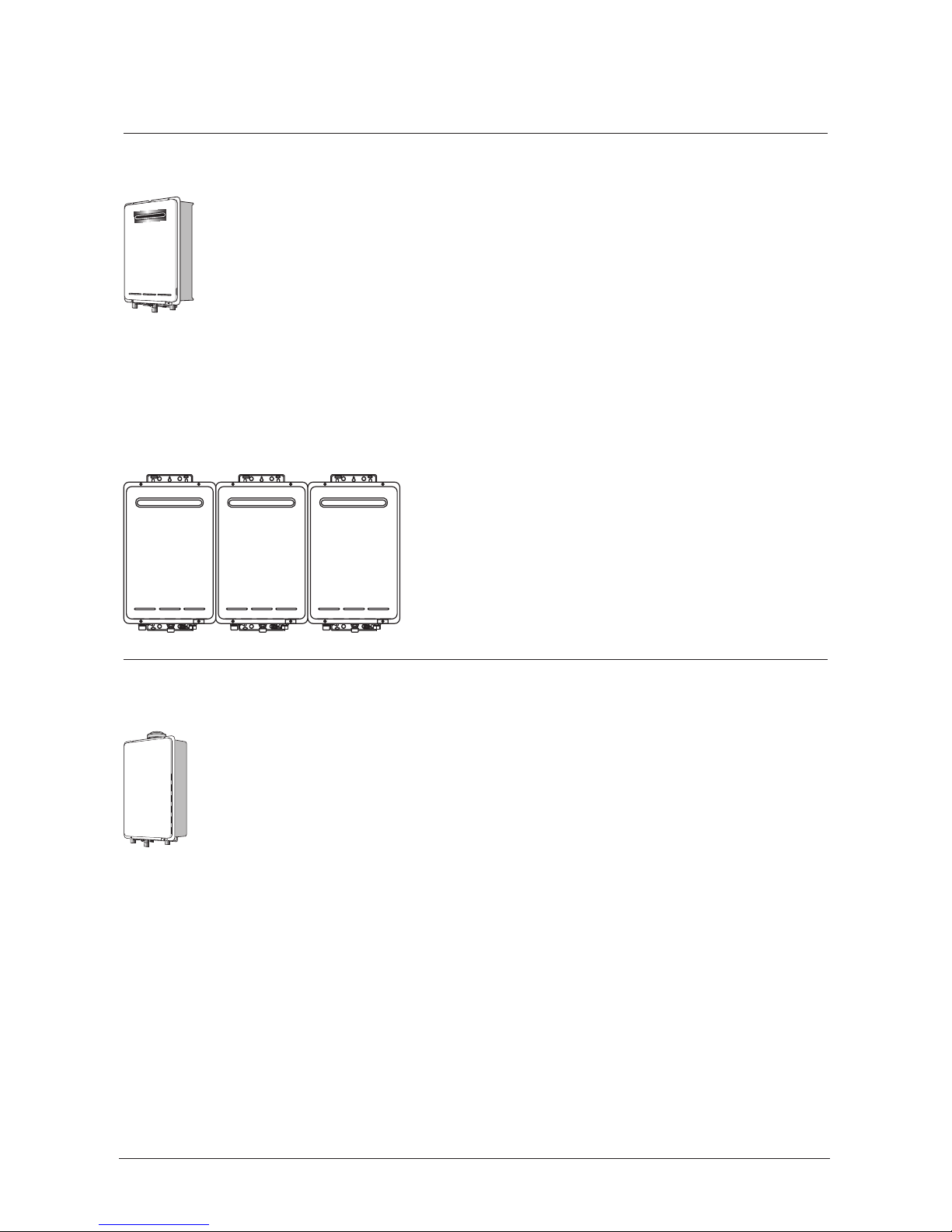

Internal models

Internal models are designed for indoor installations only. They may be installed

in an enclosure if the requirements of NZS 5261 are satisfied. An enclosure is

defined as a compartment, enclosed area or partitioned off space primarily used

for the installation of the appliance. If installed in an enclosure either internally or

externally, the location should be ventilated to allow gas to dissipate.

They must be mounted on a vertical structure with the water and gas connections

on the underside pointing downwards. For appliances installed in roof spaces or elevated

structures, specific requirements apply. Refer to NZS 5261 section 1.6 for details.

This appliance MUST be used with an approved Rinnai flueing system. The use of a non-Rinnai

flueing system may result in a dangerous situation and violates regulations.

This appliance must be located so that the flue terminal exits the building at a suitable point,

refer ‘Minimum Clearances Required for Flue Terminals’, NZS 5261-2003.

Page 5

Rinnai New Zealand Continuous Flow Water Heater Installation Manual:

01-09

5

Appliance Location

All models

This appliance must be placed as close as possible to the most frequently used hot water outlet

or outlets to minimise the delay for hot water delivery.

For installations where the distance between the water heater and the outlets is considerable,

a flow and return system can be used to minimise the waiting time for hot water delivery.

Alternatively, multiple appliances can be strategically placed to serve different outlets. Contact

Rinnai for further information.

An AC230 V, 10 Amp, earthed power point must be provided adjacent to the appliance. For

outdoor installations, this power point must be weatherproof. It must be clear of the gas and

water connections to the appliance and also the flue exhaust and water pressure relief valve.

The power cord of the appliance is 1.5 m long.

All appliances must be installed to ensure access can be gained without hazard or undue

difficulty for inspection, repair, renewal or operational purposes. Sufficient clearances shall

allow access to and removal of all serviceable components.

Appliances should not be mounted higher than 3.5 m above the ground or floor level unless

the customer can arrange permanent and safe access or can provide another means of access

such as scissor or boom lifts.

Page 6

Rinnai New Zealand Continuous Flow Water Heater Installation Manual:

01-09

6

General Installation Information

Catch pan

It is important a suitably drained catch pan is fitted (especially for internal units) where

damage could be caused by discharge from the water heater. Provision must be made for safe

disposal of any leaking water to an external location.

Flued water heaters (internal units)

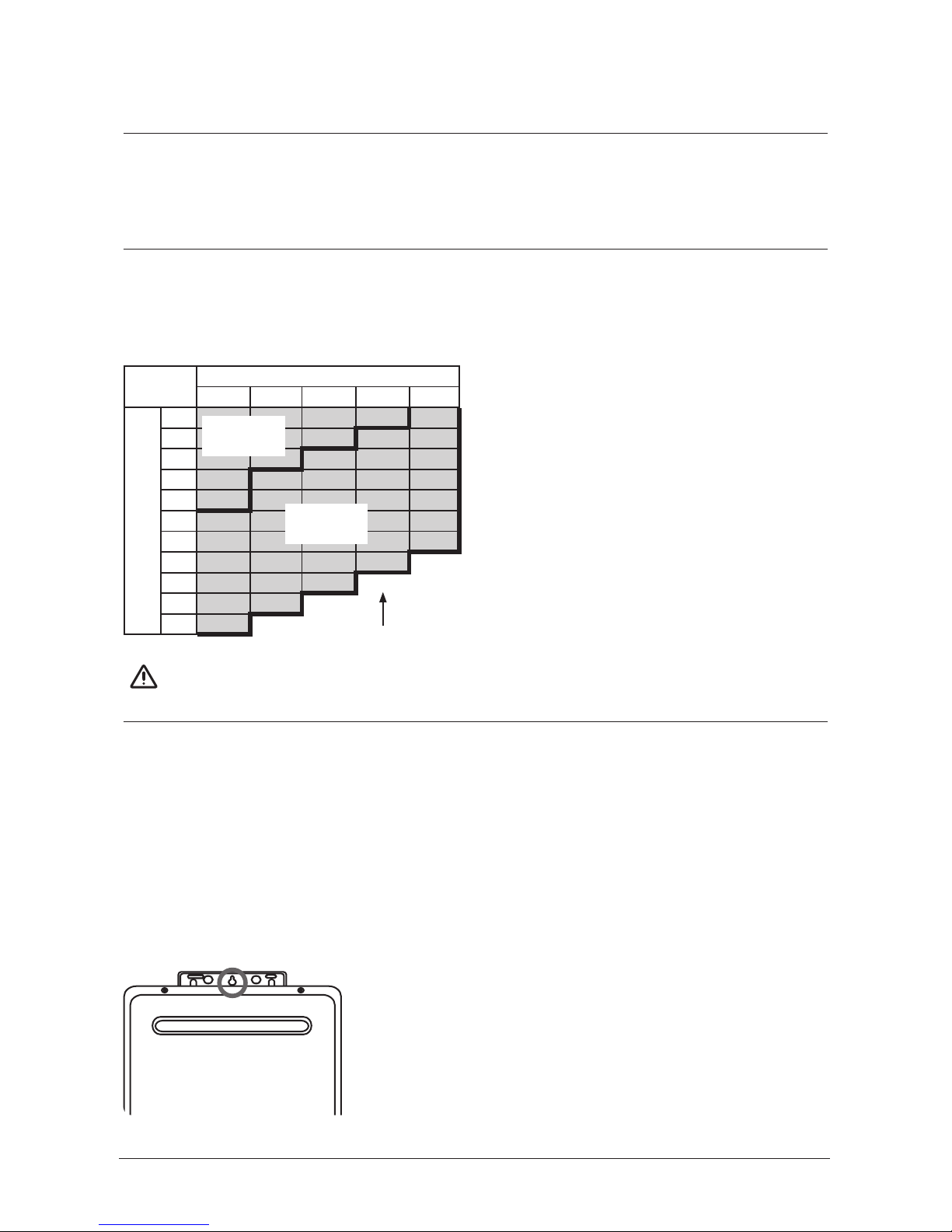

The chart below highlights the maximum flue length and number of bends. It also shows the

difference between a short and long flue—this is important if changing settings (dip switches).

Number of 90 Degree Bends

0 1 2 3 4

Flue Length (m)

1

2

3

4

5

6

7

9

11

13

15

Short flue

setting

Long flue

setting

Maximum flue length

For flues over 2 m there is a dip switch change required. Refer Commissioning Checklist

supplied with this appliance.

IMPORTANT

Mounting the appliance

Refer ‘Connections and Fittings’ for individual appliance weights. The wall or structure on which

these units are to be mounted must be capable of supporting these weights and the associated

pipe work.

Ensure suitable fixing screws or bolts are used to secure the units to the walls, in accordance

with NZS 5261 (section 5.0). Wooden plugs shall not be used.

The top bracket has a keyhole slot (circled below) so the appliance can be positioned by

hanging it on one screw while the other screws are secured.

Page 7

Rinnai New Zealand Continuous Flow Water Heater Installation Manual:

01-09

7

General Installation Information

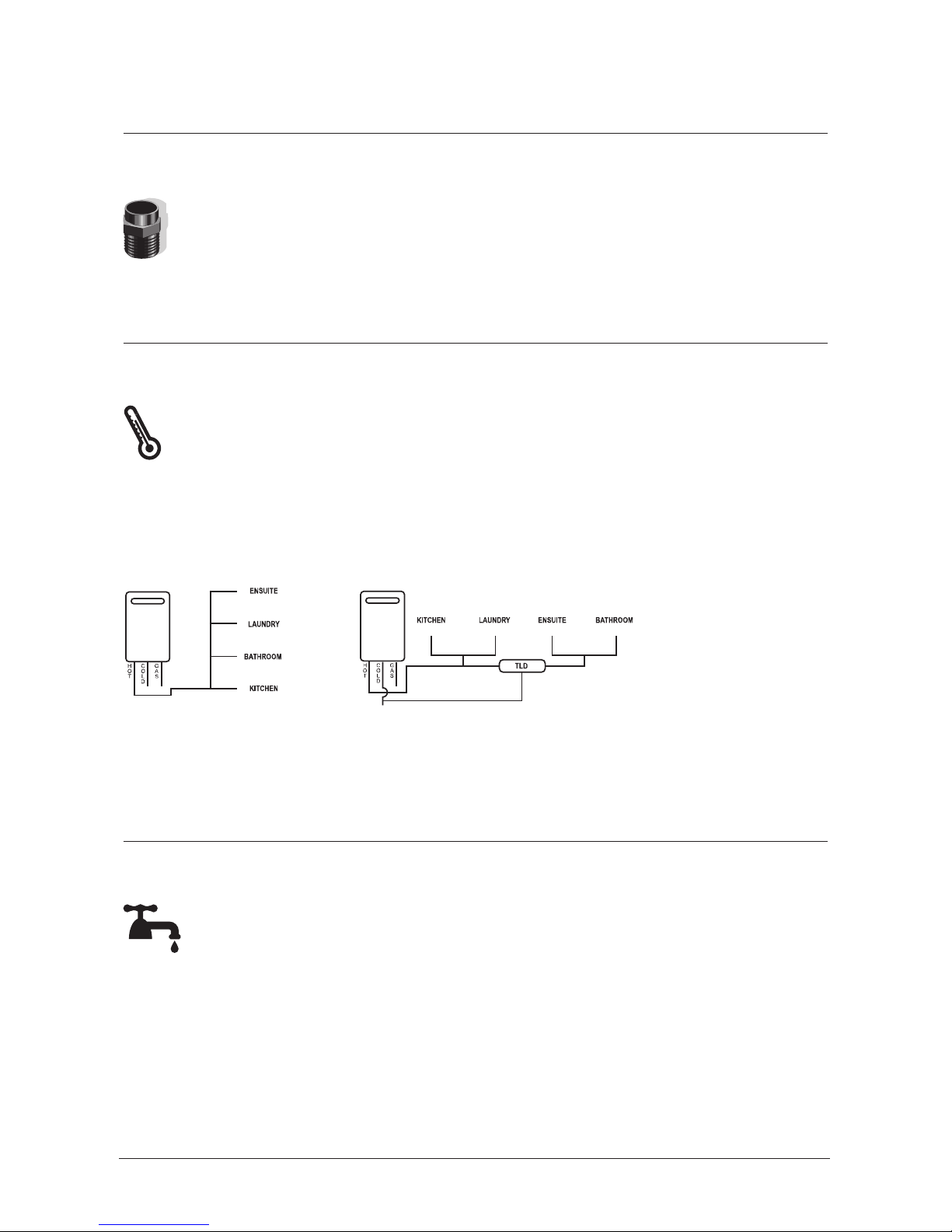

Water delivery temperature

Local regulations and/or requirements of AS/NZS3500.4 must be considered regarding

the temperature limitations of hot water supplied to areas used primarily for personal

hygiene. The temperature of these areas may be limited to 55 °C or less.

If the appliance is to deliver water primarily for the purposes of personal hygiene in an

early childhood centre, school, nursing home or similar facility as defined in AS/NZ3500.4 a

Temperature Limiting Device (TLD), such as a Tempering Valve may be required (even if the

appliance is set to 55 °C or less). For these types of applications contact Rinnai.

Diagram 1 - 55 °C Appliance

55 °C

Diagram 2 - Not a 55 °C Appliance

(TLD = Temperature Limiting Device)

> 55 °C > 55 °C < 55 °C < 55 °C

Requirements for Rinnai Continuous Flow Units Installed Without Controllers

Pipe sizing

Refer ‘Connections and Fittings’ for appliance gas consumption. If the gas pipe sizing is

insufficient the customer will not get the full performance benefit. Gas pipe sizing must

consider the gas input to this appliance as well as all the other gas appliances in the

premises. The gas meter and regulator must be specified for this gas rate. An approved

sizing chart such as the one in NZS 5261 should be used.

Water pipe sizing and layout should be performed in accordance with AS/NZS3500. All hot

water pipe work should be insulated to optimise performance and energy efficiency.

When the continuous flow unit is set to deliver water at a temperature higher than 55 °C, it will

be necessary to fit a Temperature Limiting Device for delivery to areas used for the purposes of

personal hygiene. Refer Department of Building and Housing G12.

Water supply

Refer ‘Connections and Fittings’ for applicable water pressures. Approved pressure

limiting valves may be required if the stated maximum rated water supply pressures

are exceeded. To achieve the rated flow, the stated minimum water supply

pressures must be supplied. The water heaters will operate at lower pressures but

will not achieve the rated flow.

Water chemistry and impurity limits are stated in our detailed warranty statement. Most

metropolitan water supplies fall within these requirements. If you are unsure about the quality

of the water, please contact Rinnai and we will provide you with the details of an authorised

agency who are able to test your water for compliance to Rinnai standards. If sludge or foreign

matter is present in the water supply, a suitable filter or strainer should be incorporated in the

water supply to the water heater.

Page 8

Rinnai New Zealand Continuous Flow Water Heater Installation Manual:

01-09

8

Connections and Fittings

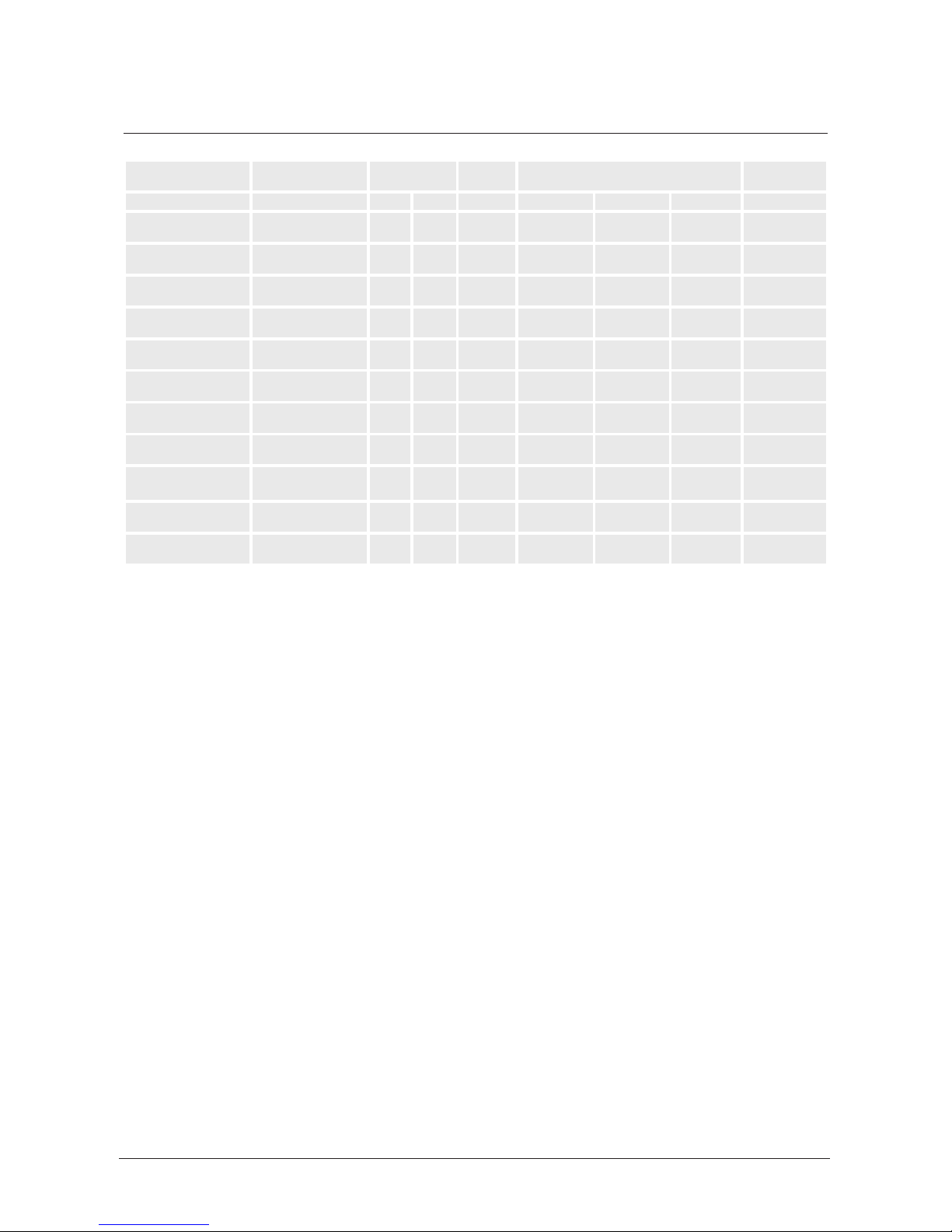

Models Gas Consumption

MJ/h

Water

Supply kPa

Weight

kg

Fittings Condensate

Min. Max. Hot Cold Gas

XR16 Ext

REU-V1620WG

125 120 1000 15

R½

(15 mm)R½(15 mm)R¾(20 mm)

XR20 Ext

REU-V2024WG

160 160 1000 15

R¾

(20 mm)R¾(20 mm)R¾(20 mm)

XR24 Ext

REU-V2426WG

188 180 1000 15

R¾

(20 mm)R¾(20 mm)R¾(20 mm)

XR26 Ext

REU-V2630WG

199 130 1000 17

R¾

(20 mm)R¾(20 mm)R¾(20 mm)

XR26a Ext

REU-V2630WGT

199 130 1000 17

R¾

(20 mm)R¾(20 mm)R¾(20 mm)

HD200 Ext

REU-VRM2632WC

199 140 1000 21

R¾

(20 mm)R¾(20 mm)R¾(20 mm)

HD200i/HD200ia Int

REU-VR2632FFUG

195 140 1000 21

R¾

(20 mm)R¾(20 mm)R¾(20 mm)

HD250/HD250a Ext

REU-VR3237WG

250 200 1000 29

R¾

(20 mm)R¾(20 mm)R¾(20 mm)

Efficiency 24 Ext

REU-K2430WG

162 240 1000 27

R¾

(20 mm)R¾(20 mm)R¾(20 mm)

R½

(15 mm)

Efficiency HD250 Ext

REU-KM3237WD

211 240 1000 32

R¾

(20 mm)R¾(20 mm)R¾(20 mm)

R½

(15 mm)

Efficiency HD250i Int

REU-KM3237FFUD

211 240 1000 32

R¾

(20 mm)R¾(20 mm)R¾(20 mm)

R½

(15 mm)

Service connection points

These dimensions are NOT an indication of the pipe sizes required.

An approved full flow isolation valve and disconnection union MUST be fitted to the cold water

inlet. A non-return valve is not required unless required by local regulations.

Isolation valves must be fitted so the appliance can be removed.

Purge gas and cold water supply lines to remove air and swarf before final connection of the

appliance. Swarf in the gas or water supplies may cause damage.

Page 9

Rinnai New Zealand Continuous Flow Water Heater Installation Manual:

01-09

9

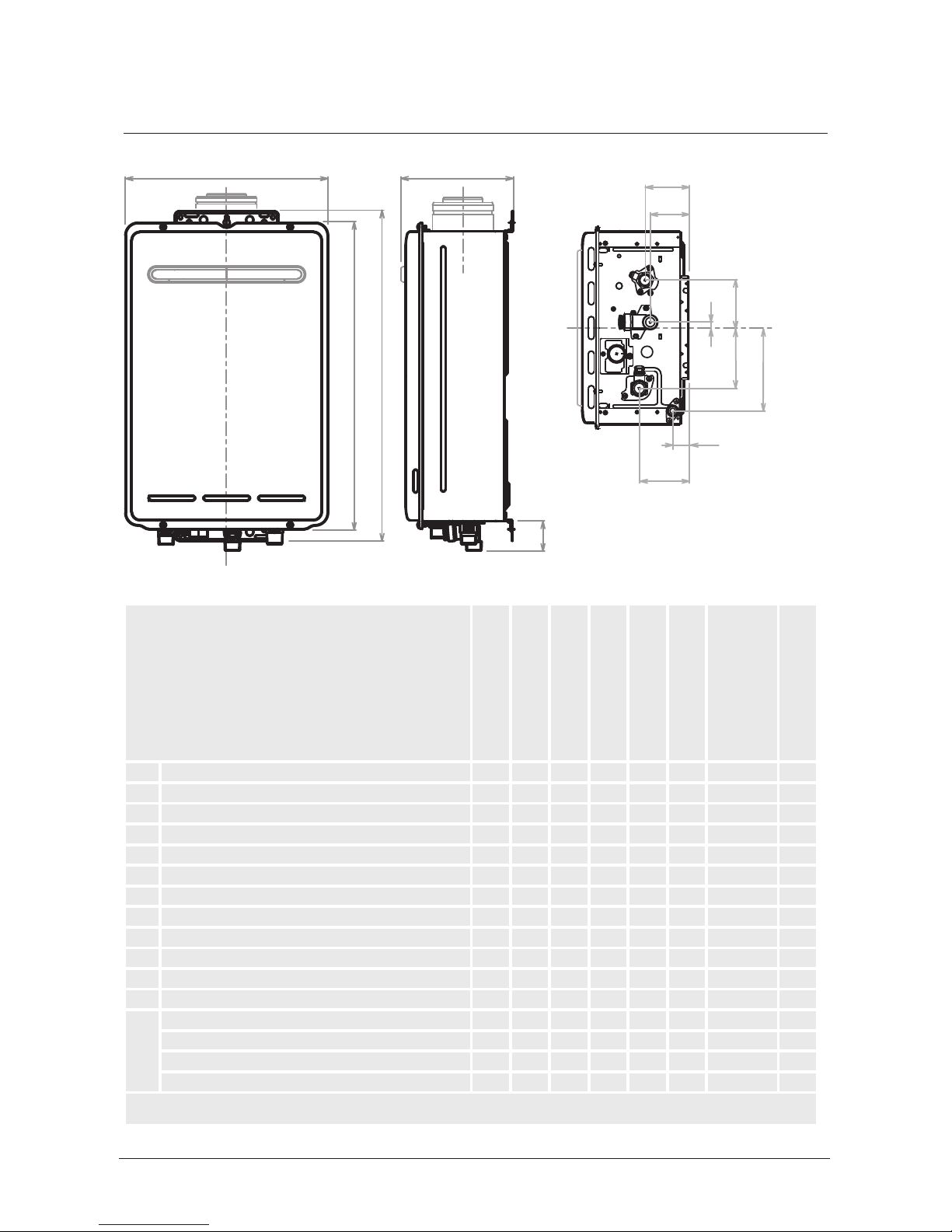

Dimensions - XR and HD Range

B

DC

M

A

E

F

J

L

H

G

I

K

Dimension (mm)

XR16 Ext

(REU-V1620WG)

XR20 Ext

(REU-V2020WG)

XR24 Ext

(REU-V2426WG)

XR26 Ext

(REU-V2630WG)

XR26a Ext

(REU-V2630WGT)

HD200 Ext

(REU-VRM2632WC)

HD200i/HD200ia Int

(REU-VR2632FFUG)

HD250/HD250a Ext

(REU-VR3237WG)

A Width 350 350 350 350 350 350 350 470

B Depth 194 194 194 194 194 250 235~275 244

C Height - Unit 530 530 530 530 530 600 600 600

D Height - Including Brackets 571 571 571 571 571 636 641 644

E Hot Water Outlet (from wall) 87 87 87 87 87 95 91~131 115

F Hot Water Outlet (from centre) 105 105 105 105 105 10 110 61

G Cold Water Inlet (from wall) 68 68 68 68 68 74 70~110 99

H Cold Water Inlet (from centre) 10 10 10 10 10 27* 27* 52

I Gas Connection (from wall) 77 77 77 77 77 103 99~139 61

J Gas Connection (from centre) 83 83 83 83 83 89 89 110

K Condensate Outlet (from wall) • • • • • • • •

L Condensate Outlet (from centre) • • • • • • • •

M Gas: Length Gas Connection (from base) 40 40 40 40 40 41 41 41

Cold: Length of Cold Water Inlet (from base) 50 50 50 50 50 51 51 51

Hot: Length of Hot Water Outlet (from base) 42 42 42 42 42 42 42 42

Condensate Connection Length (from base) • • • • • • • •

* this measurement is to the left of the centre line

Page 10

Rinnai New Zealand Continuous Flow Water Heater Installation Manual:

01-09

10

Dimensions - Efficiency Range

Dimension (mm)

Eff 24 Ext

(REU-K2430WG)

Eff HD250 Ext

(REU-KM3237WD

Eff HD250i Int

(REU-KM3237FFUD)

A Width 350 470 470

B Depth 277 283.1 257~307

C Height - Unit 600 654 654

D Height - Including Brackets 644 721.6 721.6

E Hot Water Outlet (from wall) 164.5 100 100~150

F Hot Water Outlet (from centre) 100 100 100

G Cold Water Inlet (from wall) 83 64.6 64.6~114.6

H Cold Water Inlet (from centre) 53* 27.2 27.7

I Gas Connection (from wall) 70.5 89 89~139

J Gas Connection (from centre) 25 103.2 103.2

K Condensate Outlet (from wall) 33 122.6 122.6

L Condensate Outlet (from centre) 132 195 195

M Gas: Length Gas Connection (from base) 51 40.2 40.2

Cold: Length of Cold Water Inlet (from base) 62 50.2 50.2

Hot: Length of Hot Water Outlet (from base) 41 41.2 41.2

Condensate Connection Length (from base) 24 22.4 22.4

* this measurement is to the left of the centre line

B

DC

M

A

E

F

J

L

H

G

I

K

Page 11

Rinnai New Zealand Continuous Flow Water Heater Installation Manual:

01-09

11

This page has been intentionally left blank

Page 12

Rinnai New Zealand Continuous Flow Water Heater Installation Manual:

01-09

12

Condensate Drain - Efficiency Models Only

The Efficiency water heater generates condensate continuously at a rate of up to five litres per

hour as a by-product of a highly efficient gas burner. Condensate must be drained via a pipe to

a suitable discharge point.

As condensate is a by-product of gas combustion it is mildly acidic. For this reason copper tube

and fittings MUST NOT be used as it will corrode. Instead Rinnai recommend plastic pipes and

fittings.

Important considerations for condensate drain pipe

Content of AS3500.4.2003 section 5.12 ‘Temperature/Pressure Relief and Expansion Control

Valve Drain Lines’ has been used as a guide in preparing these considerations.

Water heater drain outlet connection, ½ ˝ (15 mm) BSP male.

PE ½ ˝ BSP (15 mm) female to barbed ignition system connector (13-19 mm) or

equivalent plastic fitting.

Drain pipe and fittings to match (B).

Continuous fall of at least 2° from water heater to discharge point, length and bends in

accordance with those stated below.

Suitable points of discharge are deemed to be sewers or pits. DO NOT discharge onto

electrical connections, earth stakes, copper pipes, concrete paths or into a pond.

A)

B)

C)

D)

E)

Maximum length and changes of direction greater than 45°

Length and Changes of Direction

Maximum length (m) 9 8 7 6

Maximum changes of direction (> 45°) 3 4 5 6

Page 13

Rinnai New Zealand Continuous Flow Water Heater Installation Manual:

01-09

13

Condensate Drain - Efficiency Models Only

Installation of a condensate drain

Point of discharge from each drain line shall be located so the release of condensate does not

cause a nuisance, is readily discernible and incurs no risk of building damage. There shall be

no tap, valve or other restrictions in any line. Each line shall fall continuously from the valve to

the approved point of discharge.

Drain lines shall not discharge into a storage water heater safe tray. The end of the condensate

drain line shall be:

Not lower than 200 mm or higher than 300 mm above an unpaved surface; or

Not lower than 75 mm or higher than 300 mm above a gravel pit and not less than 100

mm in diameter in a paved surface.

Where discharging over a tundish or gully trap, drain lines shall have an air gap of a size at

least twice the diameter of a drain line.

Joining of condensate drain lines

Condensate drain lines from multiple water heaters may be joined together provided they

conform with the installation requirements above.

Common stack discharge

Where individual heaters are installed in a multistorey building, the condensate drain lines may

discharge into a common stack subject to the following:

Drained to a tundish having a discharge line that is not less than the common stack,

directly connected to a fixture trap, and installed in a connection with any adjacent soil or

waste stack

Discharge point of the common stack is readily visible and does not cause any nuisance

Common stack is vented by extending the pipe upwards, above the roof level

Tundish drain lines

The drain line from any tundish shall be not less than DN 20 or less than one size larger than

that of the largest drain line discharging into the tundish. Tundish drain lines shall comply with

the installation requirements above.

Areas subject to freezing

In areas where water pipes are prone to freezing, the drain pipe from any valve

shall be insulated and not exceed 300 mm in length. It shall discharge into a

tundish through an air gap of not less than 75 mm and not exceed more than 150

mm measured from the outlet of the drain pipe to the rim of the tundish.

•

•

•

•

•

Page 14

Rinnai New Zealand Continuous Flow Water Heater Installation Manual:

01-09

14

Controllers - General

Water controllers are available as an optional extra. Universal (Compact), Deluxe and Wireless

Controllers can be used together. A maximum of four water controllers can be fitted with the

following limitations:

Maximum of one Kitchen Deluxe Controller (MC-100V)

Maximum of two Bathroom Deluxe Controllers (BC-100V)

Only one controller can be set to deliver 55 °C, this cannot be a Bathroom Deluxe

Controller

This section refers to wired controllers. For details on Wireless Controllers, refer to separate

instructions.

•

•

•

IMPORTANT

Other manufacturers’ controllers are not compatible with this appliance.

Do not install controllers:

near a heat source such as, a cook top, stove or oven (heat, steam, smoke or hot

oil may cause damage)

in direct sunlight

outdoors unless protection from dust ingress and sunlight are provided

against a metal wall unless in accordance with AS3000.

•

•

•

•

A

B

C

D

Dim’ Description Universal

(MC-91)

Kitchen Deluxe

(MC-100V)

Bathroom Deluxe

(BC-100V)

A Distance between mounting holes 83 83 181

B Width 90 128 195

C Height 120 120 97

D Depth 20 20 22

Dimensions (mm)

Page 15

Rinnai New Zealand Continuous Flow Water Heater Installation Manual:

01-09

15

Controllers - General

Positioning

Controllers must be installed in shaded and clean locations. They should be fitted out of reach

of children (suggested height 1.5 m). The Compact and Bathroom Deluxe Controllers are

water resistant, however, durability is improved when positioned outside the shower recess or

at least 400 mm above the highest part of a sink, basin or bath.

Water controller cables

Water controllers operate at extra low voltage (12 Volts DC) which is supplied from the water

heater. Controllers come with 15 m of electrical cable. The appliance end of the controller

cables are fitted with spade terminals.

Extension cabling is available as an accessory from Rinnai. Alternatively, a two core sheathed

(double insulated) flex with a minimum cross sectional area of 0.5 mm2 may be used.

Maximum individual cable runs:

One controller = 100 m

Two controllers = 50 m (per controller)

Three or more controllers = 20 m (per controller)

Water controller cables are not polarity sensitive.

Page 16

Rinnai New Zealand Continuous Flow Water Heater Installation Manual:

01-09

16

Controllers - Universal Installation

Fitting the Universal (Compact) Controller

Determine the most suitable position for the controller.

Drill three holes as shown (Fig.1 and Fig.2) for the securing screws and one to provide

cable access.

When running cable through the access hole ensure the connector end of the cable is

located nearest to the controller (Fig.2).

Carefully remove the face plate from the controller using a screwdriver (Fig.3).

Fix the controller to the wall using appropriate fittings as shown (Fig.4).

Remove protective plastic from the controller face as shown (Fig.4) and replace the face

plate.

1.

2.

3.

4.

5.

6.

83

41.5

120

Outline of Water Control

90

Securing

Screw

Ø20 Cable Access

Connector

Controller Cable

Face Plate

Face Plate

Screw

Film

Fig.1 Fig.4Fig.2 Fig.3

Optional programming of the Universal controller

Step 1

Are four controllers connected? No, refer step 2. Yes, you will need to

activate the fourth controller as follows:

For the controller in the kitchen only, press and hold the ‘Transfer’ and

‘On/Off’ buttons simultaneously until a beep is heard (approximately five

seconds).

Check display on all four controllers is displaying a temperature when

switched on. If any controller displays two dashes, repeat above step.

1.

2.

Step 2

For the controller in the kitchen only, press and hold the ‘Transfer’ and

‘On/Off’ buttons simultaneously until a beep is heard (approximately five

seconds).

When the controller fitted in the kitchen is switched on it will be possible

to select temperatures higher than 50 °C (at this controller). If not repeat

above step.

1.

2.

If the kitchen controller is replaced or swapped repeat the programming procedure.

Page 17

Rinnai New Zealand Continuous Flow Water Heater Installation Manual:

01-09

17

Controllers - Kitchen Deluxe Installation

Determine the most suitable position for the controller.

Use the wall mounting bracket as a template to mark and drill three holes, locating the

cable access hole as shown below.

Fix the mounting bracket to the wall using the appropriate fixings.

Run the water controller cable through the hole in the wall.

Carefully remove face plate from the controller, using a screwdriver as shown below.

Connect the controller cable to the kitchen water controller. At this point cables from other

controllers (if fitted) may also be connected to the kitchen water terminals, eliminating the

need for multiple cable runs directly to the water heater. Feed excess cable lengths into the

wall cavity to avoid pinching of cables between the wall and the water controllers.

Fasten water controllers to wall mounting bracket. Avoid the use of impact drills and overtightening of fixings as this may damage the controllers.

Remove the protective plastic from the controller face and replace the face plate.

1.

2.

3.

4.

5.

6.

7.

8.

Outline of Water Controller

Screw Securing Points

128

120

Ø

20 Cable Access

Page 18

Rinnai New Zealand Continuous Flow Water Heater Installation Manual:

01-09

18

Controllers - Bathroom Deluxe Installation

Determine the most suitable position for the controller.

Mark and drill three holes, locating the cable access hole as shown (Fig.1).

When running a cable through the access hole ensure the connector end of the cable is

located nearest to the controller (Fig.2).

Affix the double sided self-adhesive seal to the back of the controller (Fig.3).

Carefully remove the face plate from the controller. Do this by placing your thumbs on the

front digital display while hooking your fingers behind the top plate and gently push down

as shown (Fig.4). Do not use a screwdriver as this may damage the controller.

Connect the cable to the bathroom controller. Feed excess cable lengths into the wall cavity

to avoid pinching of cables between the wall and the controller.

Fix bathroom controller to the wall using appropriate fixings. Avoid the use of impact drills

and over-tightening of fixings as this may damage the controller.

Remove the protective plastic from the controller face and replace the face plate.

1.

2.

3.

4.

5.

6.

7.

8.

181

195

Outline of Water Controller

97

Securing

Screw

Ø20 Cable Access

Connector

Controller Cable

Backing Seal

Remove

to expose

self-adhesive

Fig.1

Fig.4

Fig.2

Fig.3

Page 19

Rinnai New Zealand Continuous Flow Water Heater Installation Manual:

01-09

19

Controllers - Communication Cables

Communication cables connect the water heater to the water controllers and operate at an

extra low voltage (12 Volts DC) which is supplied from the water heater. Communication

cables are supplied with the water controllers (15 m) and are fitted with spade terminals for

connection to the water heater. Up to two cables can be connected to the cable connector at

the water heater.

Extension cables are available from Rinnai. Alternatively two core sheathed (double insulated)

flex with a minimum cross sectional area of 0.5 mm2 may be used (refer maximum individual

cable lengths on p. 15).

Do not attempt to connect cables to the cable connector at the water heater unless the

electric power supply to the water heater is switched off otherwise damage to electrical

components may occur.

CAUTION

To connect up to two cables to the cable connector

Turn off power supply and unplug water heater from the power point.

Remove retaining screw of the cable connector at the base of the appliance.

Swing the cable connector door open. Thread the cable through the weather seal of the

cable access hole (B) in the direction shown allowing sufficient cable length so the cable

sheath can be secured with the cable clamp (C) supplied with the transceiver.

Loosen screw terminals (D) and (E) and connect cable spade connectors to these terminals

and re-tighten. Polarity is not important, either wire colour can be connected to either

terminal.

Return the cable connector to the original position taking care not to damage cable wires in

the process and replace the retaining screw.

1.

2.

3.

4.

5.

B

C

E

D

Cable connector for XR26/26a, XR24, XR20, and XR16

B

C

D

E

Cable connector for HD250/250a, HD200/200i/200ia and Efficiency

Page 20

Rinnai New Zealand Continuous Flow Water Heater Installation Manual:

01-09

20

Controllers - Communication Cables

Connecting three to four controllers

Repeat steps 1-3 on previous page.

To connect three to four controllers, separate all the cables to be fitted into pairs. Cut off

the existing spade connectors from each pair and re-terminate each pair into a new spade

connector (F) (available from your local electrical supplier) so there are only two sets of

spade connectors. Four spade connectors in total to be terminated.

Repeat steps 4 and 5 on previous page.

1.

2.

3.

Three

Cables

Four

Cables

F F F

Spade connectors are available from your local electrical supplier.

Page 21

Rinnai New Zealand Continuous Flow Water Heater Installation Manual:

01-09

21

Commissioning

Testing

Ensure building occupants do not have access to the hot water outlets during this

procedure.

Before final connection of the water heater, purge the gas and hot and cold water supply

lines. Swarf in the gas or water supplies may cause damage.

Turn on the gas and water supplies and test for leaks (gas and water) near the unit.

Isolate gas supply. Remove test point screw located on the gas inlet and attach pressure

gauge.

Turn the power on at the power point socket and turn on the gas.

If water controllers are fitted ensure they are on. Select the maximum delivery

temperature and open all available hot water taps including the shower. If water controllers

are not fitted, open all available hot water taps.

Operate all other gas appliances at their maximum gas rate.

With all gas appliances operating on maximum, the pressure should read between 1.0-

3.5 kPa (NG) or 2.75-3.5 kPa (LPG). If the pressure is lower, the gas supply is inadequate

and the appliance will not operate to specification. It is the responsibility of the installer to

check the gas meter, service regulator and pipe work for correct operation and sizing. The

gas regulator on the appliance is electronically controlled and factory preset. Under normal

circumstances it does not need adjustment during installation.

Close all hot water outlets.

Inspect and clean the strainer located on the cold water inlet connection. This may need to

be repeated to ensure the strainer remains clear, especially on new installations.

If water controllers are fitted, it is necessary to test their operation through the complete

range of functions (refer operation manual).

Confirm hot water delivery temperatures using a thermometer. If controllers are fitted,

ensure temperatures exceeding 55 °C cannot be selected on bathroom controllers.

After testing is completed, explain to the customer how to operate the water heater and

water controllers (if fitted). Ensure your details are completed (p. 26 of the operation

manual).

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

Gas pressure setting

The gas regulator on the appliance is electronically controlled and factory preset. Under

normal circumstances it does not need adjustment during installation. Make adjustments only

if the unit is not operating correctly and all other causes for incorrect operation have been

eliminated. Instructions for gas pressure setting are in the instruction pocket located inside the

appliance front cover.

Commissioning checklist

Commission the unit in accordance with the Commissioning Checklist supplied with the

appliance (front cover of appliance). Ensure you leave the completed checklist with the

customer.

WARNING

Page 22

Rinnai New Zealand Continuous Flow Water Heater Installation Manual:

01-09

22

Recommended Solar System Layout

Warning about hot water

Rinnai continuous flow water heaters configured for solar systems produce hot water

at 75 °C and are not suitable for use with water controllers. The household water

supply MUST be protected by a suitable tempering valve.

Installation

Rinnai continuous flow water heaters in solar installations are only suitable as gas boosters in

solar hot water systems. These models produce water at higher than normal temperatures and

must be connected to the hot water supply by use of a suitable tempering valve.

Install a Rinnai continuous flow water heater using a flow diversion valve as shown below.

Remember ‘B to Boiler’ when setting up the flow diversion valve.

The water heater must be set to 75 °C (refer dip switch settings on following pages).

Rinnai water controllers cannot be used with Rinnai Infinity solar units as the:

Hot water does not always pass through the Rinnai Infinity

Rinnai Infinity dip switch setting of 75 °C is unable to be adjusted

•

•

Recommended system layout using a Rinnai Continuous Flow water Heater and Flow Diversion Valve

System configuration to protect for Legionella

If the system is configured according to the details above it will meet the requirements of the

Acceptable Solution G12/AS2 for protection against Legionella. Section 3.5.2 states:

b) the instantaneous water heater must heat all water passing through it to not less

than 70 °C.

Page 23

Rinnai New Zealand Continuous Flow Water Heater Installation Manual:

01-09

23

Dip Switch Settings - Important

Dip switch settings must only be changed by a licensed gasfitter. They have been provided as

there may be a requirement to change the temperature of the water delivered from the water

heater.

Care must be taken when changing the temperature settings as the dip switches are

small and can be easily switched or bumped into the wrong position. Please use this

information carefully and fully check the operation of the water heater before leaving

site including the temperature of the water delivered.

The cover of the water heater will need to be removed to carry out this operation.

As this will expose live mains voltage wiring please disconnect the power supply

before removing the front cover.

We wish to draw your attention to the requirements of the New Zealand Building Code and

compliance document G12. This requires that water delivered to sanitary fixtures be no more

than 55 oC. Increasing the water heater set temperature will therefore require that you protect

all sanitary fixtures to which the appliance is plumbed with suitable tempering valves or

similar.

Rinnai will accept no liability for issues arising out of the use of this dip switch information.

If you have any doubts about the performance of the water heater please contact Rinnai by

phoning 0800 TO RINNAI (0800 86 746 624).

The setting of water temperatures in domestic model Infinity units (white cases) to greater

than 55 °C (with the exception of units set to 75 °C in domestic solar installations) will

reduce the warranty period. Refer to warranty information in the Operation Manual for further

information.

The following pages detail dip switch settings for the specific Rinnai continuous flow water

heaters listed. They ARE NOT applicable for older models.

WARNING

Legend for Dip Switch Settings (black section indicates position of switch)

On

Off

Short and long flues

Reference to what is a short and long flue can be found on page 6.

Page 24

Rinnai New Zealand Continuous Flow Water Heater Installation Manual:

01-09

24

Dip Switch Settings

Dip Switch 1: Upper SW(8P)

SW No. Note

1 Off

2

Fixed temperature

(with controllers)

Off Fixed temperature On With controllers

3

4

5

Temperature settings See Chart A

6 Off

7

Gas pressure

Off

Normal

On

Forced min.

On

Forced max.

8 Off Off On

Chart A: Temperature Settings

Dip Switch 2: Lower SW(4P)

SW No. Note

1 Gas type Off LPG On NG

2,3,4 Model settings See Chart B

Chart B: Model Settings

Dip.SW.2-SW No.(4P) Model (REU-number)

2 3 4

Off Off Off XR26 (V2630WG), XR26a (V2630WGT) and Efficiency 24 (K2430WG)

Off On Off XR24 (V2426WG)

Off Off On XR20 (V2024WG)

Off On On XR16 (V1620WG)

Applicable models and REU-numbers

Rinnai Infinity XR16 External REU-V1620WG

Rinnai Infinity XR20 External REU-V2024WG

Rinnai Infinity XR24 External REU-V2426WG

Rinnai Infinity XR26 External REU-V2630WG

Rinnai Infinity XR26a External REU-V2630WGT

Rinnai Efficiency 24 External REU-K2430WG

On

Off

Dip.SW.1-SW No.(8P) SW No.2 = Off

(fixed temperature)

SW No.2 = On

(with controllers)

3 4 5 No controllers

(fixed temp.)

No controllers

(fixed temp.)

With controllers

(max. set temp.)

Off Off Off 55 55 55

On Off Off 75 55 75

Off On Off 65 55 65

On On Off 60 55 60

Off Off On 50 50 50

On Off On 42 42 42

Off On On not to be used 40 40

On On On not to be used 55 75

Page 25

Rinnai New Zealand Continuous Flow Water Heater Installation Manual:

01-09

25

Dip Switch Settings

Applicable models and REU-numbers

Rinnai HD200 External REU-VRM2632WC

Rinnai HD200i/HD200ia Internal REU-VR2632FFUG

Rinnai HD250/HD250a External REU-VR3237WG

Dip Switch 1: Upper SW(8P)

SW No. Note

1

FF model Flue setting Off Long flue (p. 6) On Short flue (p. 6)

W model Model setting Off

2

Fixed temperature (with

controllers)

Off Fixed temperature On With controllers

3

4

5

Temperature settings See Chart A

6 Off

7

Gas pressure

Off

Normal

On

Forced min.

On

Forced max.

8 Off Off On

Chart A: Temperature Settings

1

95 °C setting only available for HD250 model

Dip Switch 2: Lower SW(4P)

SW No. Note

1 Gas type Off LPG On NG

2,3,4 Model settings See Chart B

5,6 Not in use Off

Chart B: Model Settings

Dip.SW.2-SW No.(4P) Model (REU-number)

2 3 4

Off Off Off HD250/HD250a (VR3237WG)

Off Off On HD200 (VRM2632WC)

Off On On HD200i/HD200ia (VR2632FFUG)

On

Off

Dip.SW.1-SW No.(8P) SW No.2 = Off

(fixed temperature)

SW No.2 = On

(with controllers)

3 4 5 No controllers

(fixed temp.)

No controllers

(fixed temp.)

With controllers

(max. set temp.)

Off Off Off 55 55 55

On Off Off 75 55 75

Off On Off 65 55 65

On On Off 60 55 60

Off Off On 50 50 50

On Off On 42 42 42

Off On On 85, 95

1

40 40

On On On 85 55 75

Page 26

Rinnai New Zealand Continuous Flow Water Heater Installation Manual:

01-09

26

Dip Switch Settings

Applicable models and REU-numbers

Rinnai Efficiency HD250 External REU-KM3237WD

Rinnai Efficiency HD250i Internal REU-KM3237FFUD

Dip Switch 1: Upper SW(8P)

SW No. Note

1 Flue settings Off

Efficiency HD250 Ext & Eff

HD250 Int long flue (p. 6)

On

Efficiency HD250 Internal

short flue (p. 6)

2

Fixed temperature

(with controllers)

Off Fixed temperature On With controllers

3

4

5

Temperature settings See Chart A

6 Not in use Factory setting is ‘Off’

7

Gas pressure

Off

Normal

On

Forced min.

On

Forced max.

8 Off Off On

Chart A: Temperature Settings

Dip Switch 2: Lower SW(6P)

On

Off

Dip.SW.1-SW No.(8P) SW No.2 = Off

(fixed temperature)

SW No.2 = On

(with controllers)

3 4 5 No controllers

(fixed temp.)

No controllers

(fixed temp.)

With controllers

(max. set temp.)

Off Off Off 55 55 55

On Off Off 75 55 75

Off On Off 65 55 65

On On Off 60 55 60

Off Off On 50 50 50

On Off On 42 42 42

Off On Off 95 40 40

On On On 85 55 75

SW No. Note

1

Gas type settings

Off

LPG

On

NG

2 Off Off

3

Type settings

Off

External

Off

Internal

4 Off On

5 Automatic return Off Inactive On Active

6 External device Off S-BMS On AH

Page 27

Page 28

Consumers: 0800 RINNAI (746 624)

Installers: 0800 TO RINNAI (86 746 624)

Address: 105 Pavilion Drive, Airport Oaks, Mangere, Manukau

PO Box 53177, Auckland Airport, Manukau 2150

Phone: (09) 257 3800

Fax: (09) 257 3899

Email: info@rinnai.co.nz

Websites: www.rinnai.co.nz and www.rinnai-tradesmart.co.nz

All Rinnai appliances meet or exceed the

safety standards required by New Zealand

gas and electrical regulations.

Rinnai is constantly improving its products

and as such information and specifications

are subject to change or variation without

notice.

U287-2779(00)

070 0001 2 31314 6

Loading...

Loading...