Page 1

Installation and User Manual

RHFE-556T

RHFE-556T

EnergysaverÑSpace Heater

Operation and Use - Page 2

Installation - Page 12

Important.

Read these instructions carefully before attempting installation or use of

this appliance. All work must be carried out by competent persons.

Page 2

CONTENTS

Warranty ..........................1

Layout of appliance..........2

Features...........................4

Safety Points....................5

Operation .........................7

Adjusting Temperature.....8

Humidifier.........................9

Wiring Diagram ..............23

Gas Conversion .............24

Extension Kits ................28

Service Contact Point ....33

Rinnai Corporation - Japan

Manufactured under a

Quality System Certified

as complying with ISO

9001 by an Accredited

Certification Body.

ISO 9001

APPROVED BY JIA

Page 3

– 1 –

RINNAI WARRANTY OF QUALITY

As the purchaser of this high quality model RHFE-556T product you are provided with the following

warranty:

Free Parts

Heat Exchanger 15 Years

Fan 1 Year

All other parts 1 Year

* Full Heat Exchanger replacement (parts only) for all 15 years.

This warranty does not cover cleaning and normal wear and tear, calls of this nature may be

chargeable. Please check the fault finding charts on page 32, before asking for a service call. You

may be able to overcome the problem without the service call, or the heater may be operating

normally. Service calls to a heater which is operating normally may be chargeable, even when the

heater is under warranty.

The installer is responsible for your heater’s correct installation. There is no requirement to post the

following information back to

Rinnai UK Ltd.

However we advise that you keep it in a safe place.

Date of installation:

Installer’s name:

Address:

Telephone:

Licence number:

CONDITIONS

1. It is a condition of this warranty that the heater shall have been serviced annually during its lifetime

by a suitably qualified service engineer and that it shall have been fitted and used in accordance

with the Company’s Installation and Operating instructions.

2. Failing to use genuine Rinnai spare parts may invalidate the warranty.

3. The serial number of the heater must be supplied prior to any claim being made.

Page 4

– 2 –

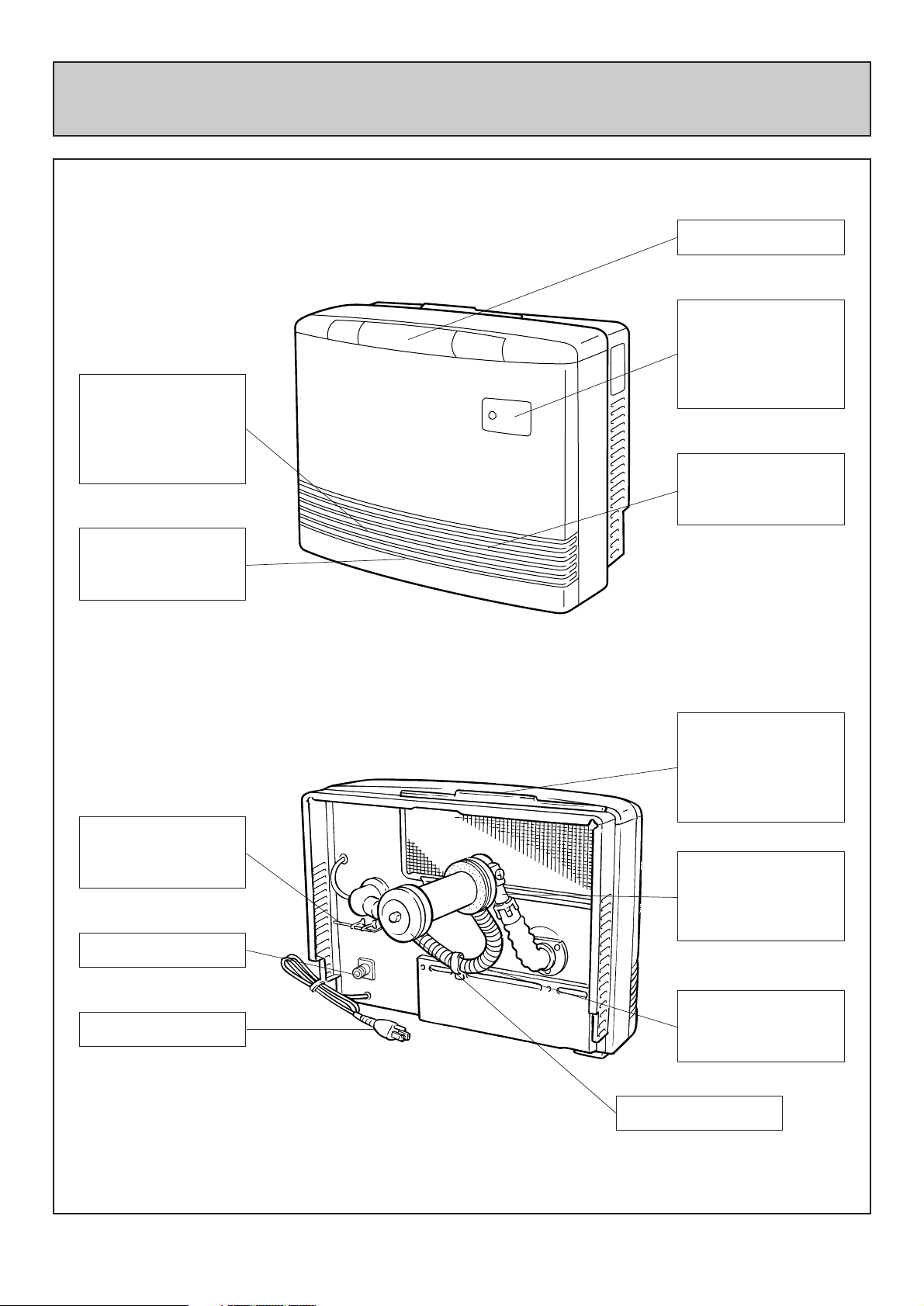

GETTING TO KNOW YOUR NEW RHFE-556T

INDICATOR PANEL

ROOM

TEMPERATURE

SENSOR

GAS CONNECTION

ELECTRICAL CORD

HUMIDIFIER TRAY

Built into the warm air

discharge duct.

Humidifies the warm

air flow.

BOTTOM TRIM

Pulls off to allow filling

of humidifier tray.

LOUVRE

Warm air discharge

duct.

CONTROL PANEL

for

ON-OFF

And

Room Temp. Control

AIR FILTER

Helps to protect the

interior of the

appliance and fan

from dust particles.

EXHAUST OUTLET

Exhausts flue products

to the outside of the

building.

AIR INLET TUBE

Carries air for

combustion.

FLUE SYSTEM

Page 5

– 3 –

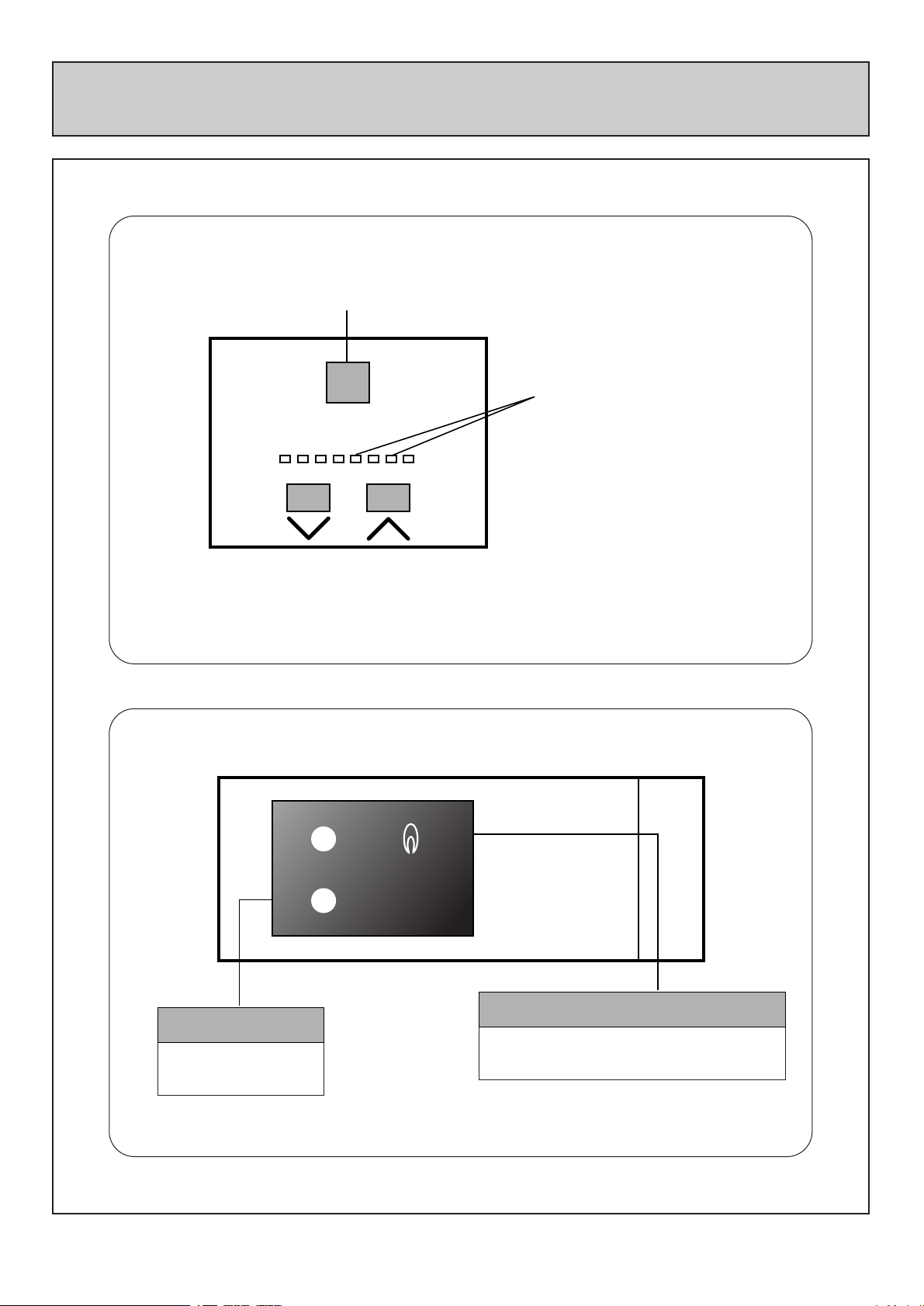

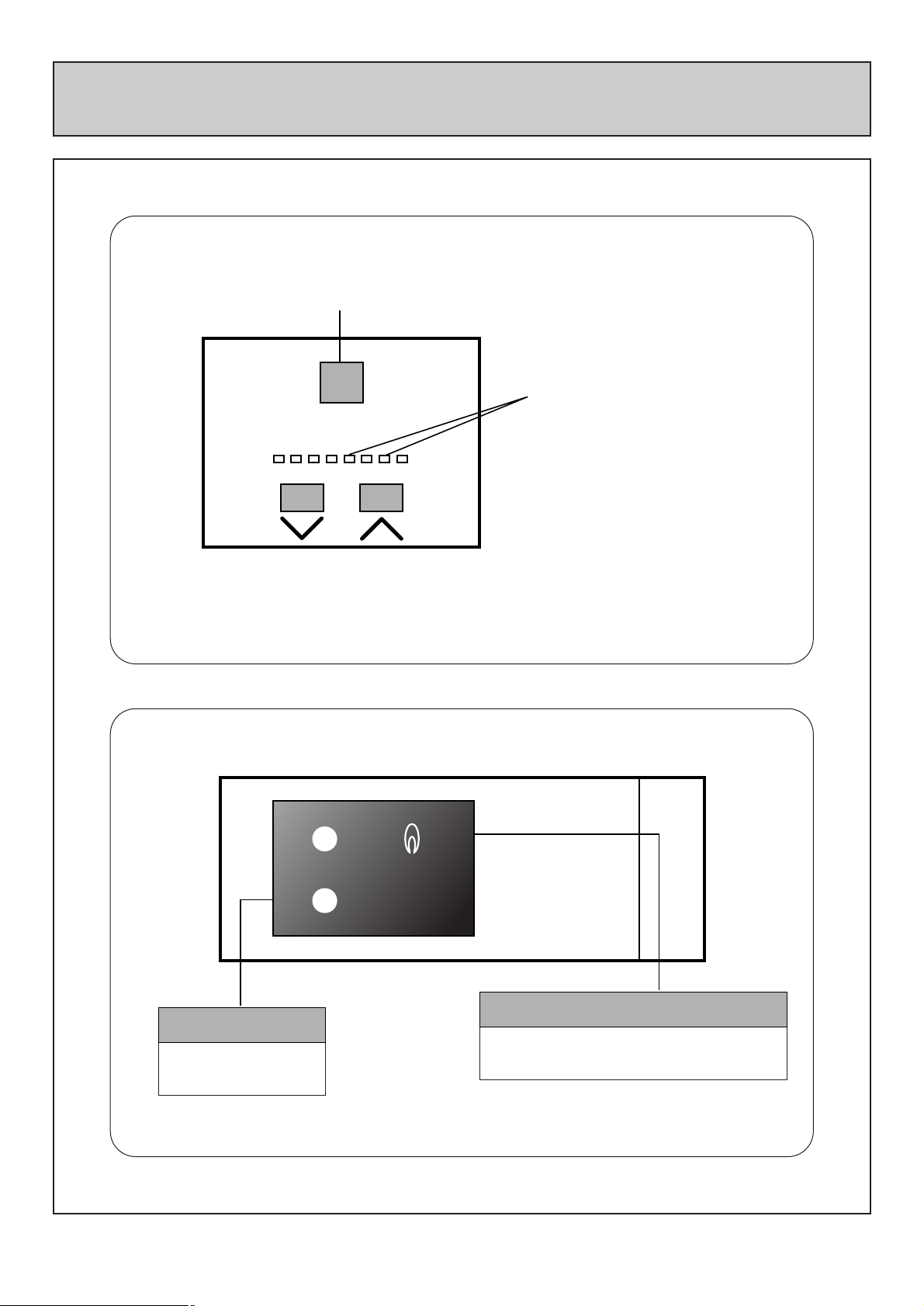

CONTROL PANEL LAYOUT

LO 16 18 20 22 24 26 HI

ON/OFF

Roomadjustment

Roomtemp.indicator

ON

FILTER

-

POWER ON / COMBUSTION INDICATOR

Indicates that the appliance is turned ON and

whether the burner is alight.

FILTER INDICATOR

Indicates that the filter

needs cleaning.

Page 6

– 4 –

FORCED FLUE SYSTEM PUSH BUTTON IGNITION

Air for combustion is taken from outside the

room and the flue products are exhausted

outside, keeping the room air clean.

Only one touch of the ON/OFF switch is

required to operate the heater.

EXHAUST

AIR

INLET

FILTER INDICATOR

When the fan filter becomes covered with

dust and the temperature inside the

appliance rises, the filter indicator will flash.

The filter should be vacuumed at regular

intervals to avoid unnecessary strain on the

appliance.

FILTERINDICATOR

WARM AIR DISCHARGE

Warm air flows from the bottom of the

appliance through the louvres, assisting in

even heat distribution. An integral humidifier

tray is built into the warm air discharge duct.

ON/OFF

CENTRAL CONTROL

This heater may be installed as part of a

centrally controlled Time Clock System. In

this case the heater can only be operated

when the central time clock is “ON”.

AUTO COMFORT

Ensures that the flow of warm air from the

louvres is maintained at a comfortable

volume during the warm-up period by a 8

step modulating convection fan, in

conjunction with the thermostat, reducing

cool draughts.

FEATURES

Page 7

– 5 –

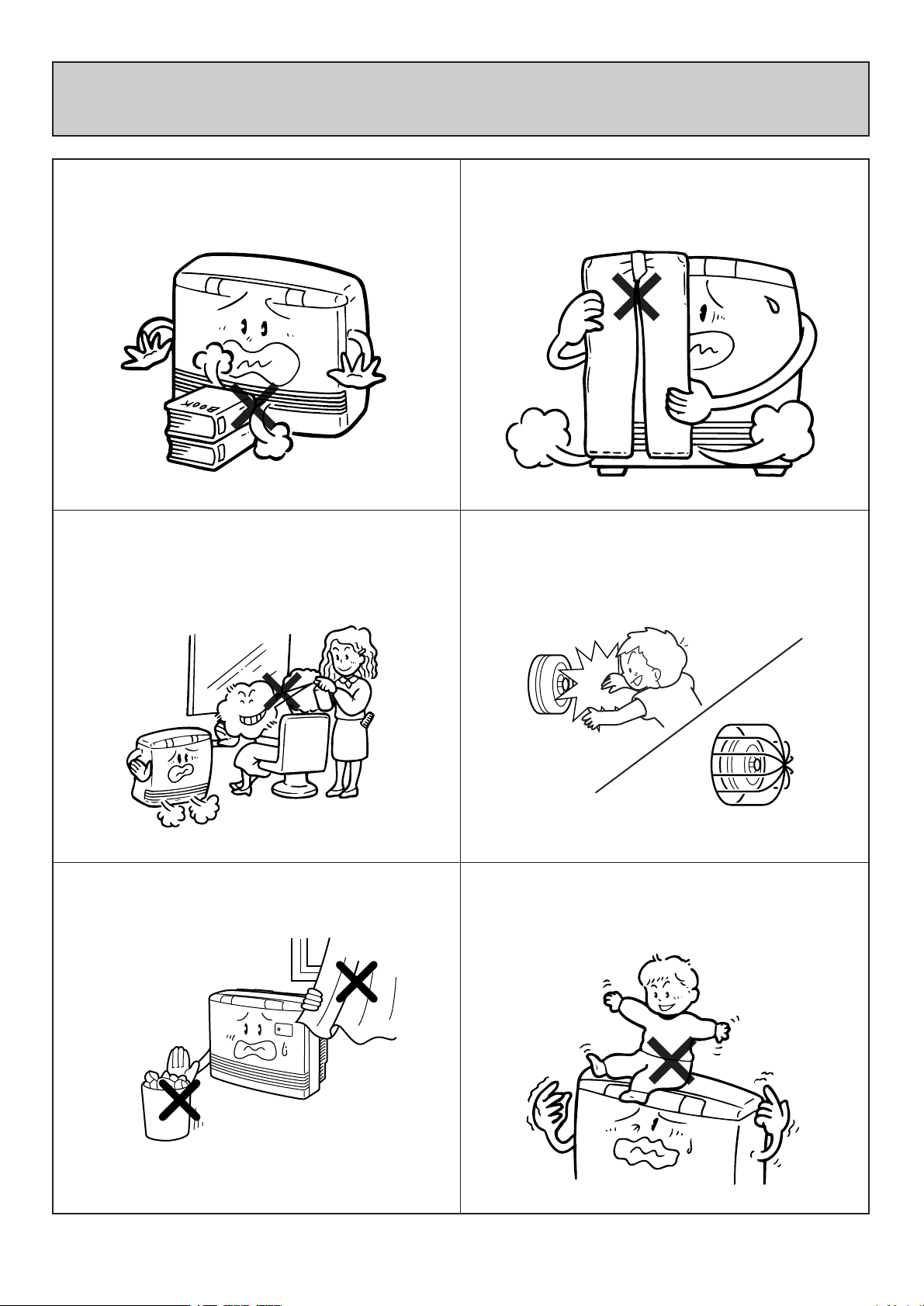

SAFETY POINTS

Do not restrict the warm air discharge by

placing articles in front of the heater.

This appliance must not be used for any

purpose other than heating.

Do not spray aerosols whilst the heater is

operating. Most aerosols contain butane gas,

and can be a fire hazard if used near this

heater when it is in use.

Flue Guard must be fitted if indicated on page

17.

Do not allow curtains or other flammable or

combustible materials to come into contact

with the heater.

Combustible materials must not be placed

where the heater could ignite them.

Do not allow anyone to sit on or lean against

the appliance.

Page 8

– 6 –

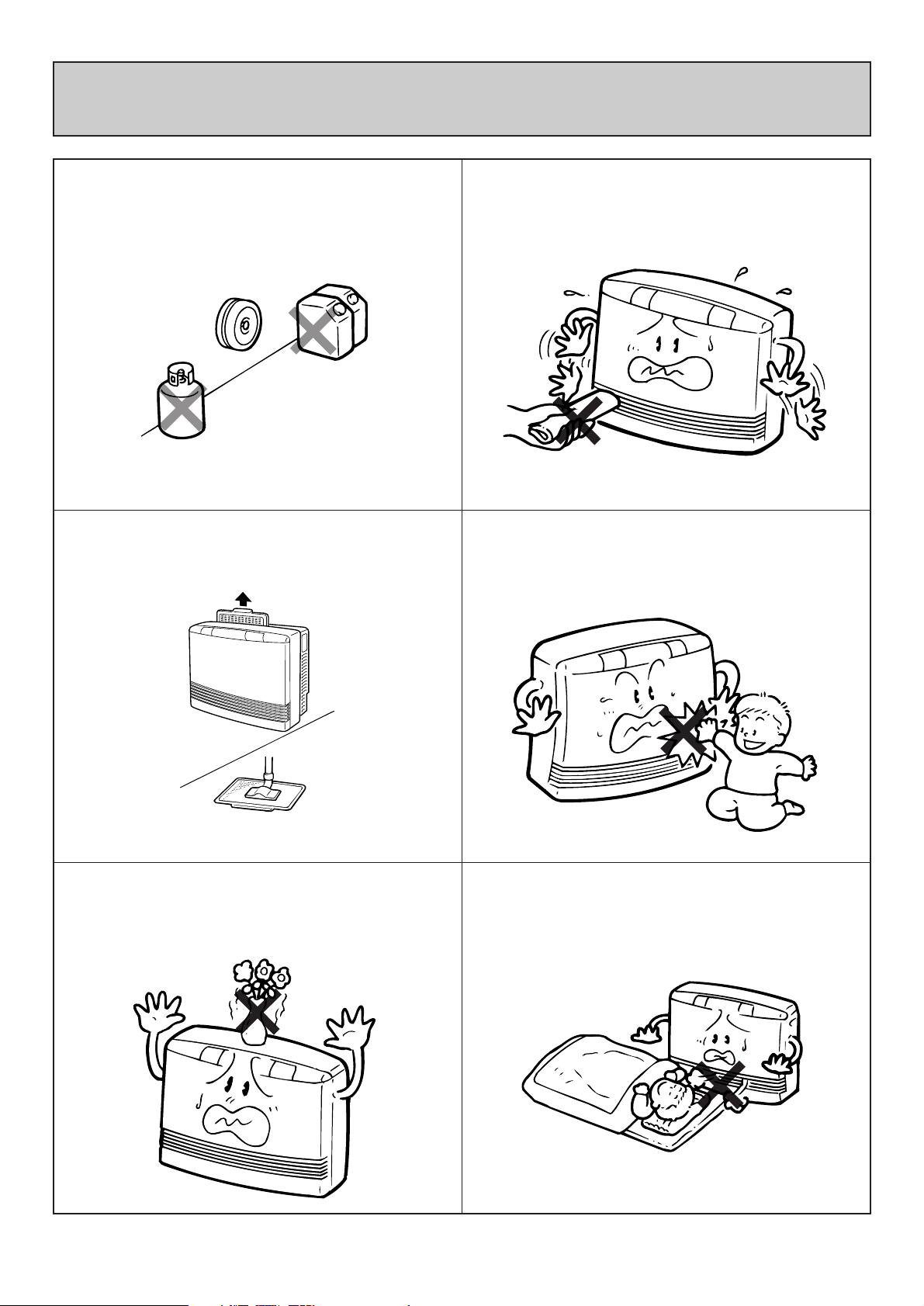

SAFETY POINTS

Keep flammable materials, trees, shrubs, etc,

away from the flue terminal.

Do not allow anyone to post articles through

the louvres.

LPGAS

GAS

Gasoline

Filter should be cleaned at regular intervals. It is strongly recommended that a guard is

fitted around heater where there are young

children, elderly, infirm or handicapped

persons.

Do not place articles containing liquids on top

of the heater. Liquids spilt on the controls may

cause extensive damage.

Do not allow young children or the infirm to

sleep directly in front of the heater.

Clean with vacuum cleaner, weekly.

Page 9

– 7 –

OPERATING YOUR NEW RHFE-556T

■ TO OPEN THE CONTROL PANEL

Open Control Panel Cover with key provided.

■ TURNING ON (For manual operation

please refer to page 21).

Press the ON/OFF button to operate the heater. The

ON indicator will glow green. After approximately 20

seconds the spark generator will be heard before the

burner ignites and the ON indicator glows red,

indicating that the burner is alight. Warm air can be

felt coming from the louvres 15 seconds later.

If the heater does not ignite on initial use, this may be due to air remaining in the gas supply line. The

spark generator will only continue for 15 seconds. After this it will be necessary to press the ON/OFF

button OFF, then ON again.

■ TURNING OFF

Simply press the ON/OFF button to switch off the

heater. The ON indicator will go out. The convection

fan will continue to operate for several minutes after

the burner has gone out in order to cool the appliance.

Do not unplug the appliance while the convection

fan is running.

IMPORTANT NOTE:

DO NOT turn heater off by unplugging at the power point.

The convection fan must continue to run until the appliance cools.

Page 10

– 8 –

ROOM TEMPERATURE ADJUSTMENTS

LO 16 18 20 22 24 26 HI

ON/OFF

Roomadjustment

Roomtemp.indicator

ON

FILTER

-

POWER ON / COMBUSTION INDICATOR

Indicates that the appliance is turned ON and

whether the burner is alight.

FILTER INDICATOR

Indicates that the filter

needs cleaning.

Page 11

– 9 –

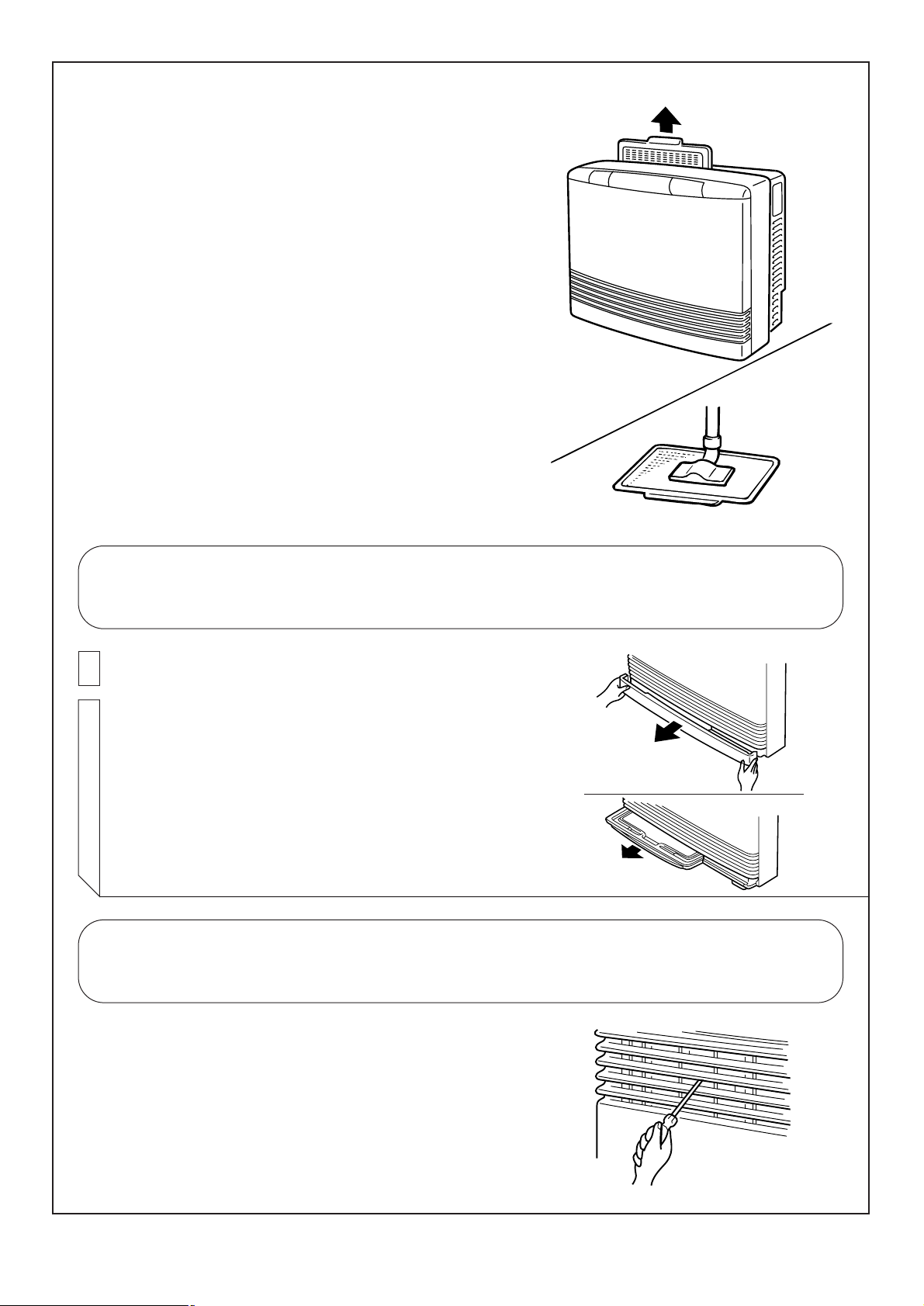

■ FAN FILTER

To protect the room air fan from dust particles or lint, a

filter is situated at the rear of the appliance. When

this filter becomes blocked, the filter indicator will flash

to indicate that it should be cleaned. Clean the filter

weekly during the heating season to avoid

unnecessary strain on the appliance.

Do not remove filter when appliance is operating.

When the filter requires cleaning, clean filter before

using the appliance, or whilst the appliance is not

operating.

If you do not clean the filter at regular intervals and

the filter indicator is allowed to remain flashing, then

the appliance will stop and [14] will flash on the Digital

Display signifying that the inbuilt safety device has

functioned. You must clean the filter before operating

the heater again.

■ HUMIDIFIER TRAY

■ VERTICAL LOUVRE ADJUSTMENT

The warm air flow direction may be altered by

inserting a screwdriver or similar tool and gently

bending the vertical louvre(s) either to the left or the

right.

Note: these louvres are not designed to be

adjusted more than 6 times.

So that you can humidify the air, your Rinnai RHFE-556T is fitted with an enamelled tray at the bottom

of the heater. If you choose to make use of the humidifier tray, it will need filling about once a day

during the heating season. Do not fill the humidifier tray while the heater is running.

The humidifier has the benefit (when filled with water) of raising the humidity in the air. With increased

humidity, the heater can actually be run at a lower temperature while still maintaining the same level of

comfort.

1

To fill the humidifier tray:

Remove the bottom trim panel, below the louvres, by

pulling on both sides. Simply pull the tray forward to

allow it to be filled with water. The warm air will be

humidified as it passes over the water in the tray.

Refit the bottom trim panel after filling the tray. The

RHFE-556T is a very high efficiency appliance,

during operation a small amount of condensation is

produced in the flue system, this drains into the

enamelled humidifier tray.

Page 12

– 10 –

CARING FOR YOUR NEW RHFE-556T

This appliance is safely controlled. If there is something wrong then it will stop, as it is protected by

the following safety devices.

Ignition Safety Device Power Failure Safety Device

Burner Safety Device Power Surge Safety Device

Overheat Safety Device Fan Delay Safety Device

Your RHFE-556T requires very little maintenance,

simply clean the rear fan filter once a week and wipe

the outer case and louvre section with a damp cloth.

DO NOT USE SOLVENTS.

Solvents may melt or distort plastic parts.

Problem

Cause

Not Plugged In

Power Cut

(Initial Installation)

Air in gas pipe

Gas Filter Blocked

Missed Ignition

Flue terminal obstructed

Flue manifold not connected

Louvre obstructed

Air filter blocked

Gas Escape

Gas turned off at meter

Remedy

No ON indicator

Burner doesn't ignite

Unusual

combustion

Combustion stops

during operation

Smell of gas

Noisy Ignition

Takes too long to

warm the room

Remote control

doesn't work

Plug In

Re-ignite manually after

power is restored

Purge air

(Installer)

Service Call

Service Call

Clear obstruction

Service Call

Clear obstruction

Clean filter (weekly)

Service Call

Turn gas on

Page 13

– 11 –

PRE-SERVICE CHECK

Before asking for a service call please check the following points.

These points are part of the normal operation of the unit.

■ At Ignition:

Heater does not operate.

Warm air does not flow when the burner lights.

Smoke or strange smells are produced on the

first trial light up after installation.

Sharp clicking noises at ignition, or when the

unit cuts down on the thermostat, or goes out.

Is the heater plugged in?

Have the fuses or breaker blown at the switch board?

Is there a power failure?

Is the air filter blocked?

Is anything blocking the outlet for the hot air?

Is the flue blocked?

Is a remote timer fitted and set “ON”.

■ During combustion:

Clunking noise when the thermostat operates.

Unit is not heating room.

Air filter is blocked or the louvres are blocked or

obstructed.

Heater will not re-ignite after overheating.

This is the sound of the solenoid gas valves opening and

closing.

■ When the unit is turned off:

Convection fan continues to run after turning

OFF.

This is to remove the residual heat from the heat

exchanger, the fan will stop when the heater cools down.

■ Other Points:

Steam is discharged from the flue terminal.

Unit cuts off without apparent reason.

Power Failure.

High efficiency appliances tend to discharge water

vapour on cold days, this is normal.

Check whether filters are blocked, dirty filters will cause

the heater to overheat.

Switch OFF, then ON again when power is restored to

re-set controls.

Is the air filter blocked?

Is the set temperature high enough?

Is the warm air outlet blocked by anything?

Are the doors and windows of the room closed?

Allow heater to cool, clean air filter, operate again.

Even after unit has cooled down the heater does not

ignite again. Repair is necessary.

Contact your local agent or Rinnai for a Service call.

The fan is started automatically after a short delay.

This is to allow the heat exchanger to warm up, helping

to avoid cold draughts.

This is caused by grease or oil and dust on the heat

exchanger and will stop after a short time.

This is simply expansion noise from the heat exchanger.

R

R

R

R

R

R

R

R

R

R

R

R

Page 14

– 12 –

ERROR MESAGES

The Energysaver 556T has the ability to check its own operation continuously. If a fault occurs, an

Error Message will flash on the Digital Display of the control panel. This assists with diagnosing the

fault, and may enable you to overcome a problem without a service call.

Please quote the code displayed when inquiring about service.

In all cases, you may be able to clear the Error Message simply by turning the heater OFF, then ON

again.

If the Error Message still remains or returns on the next operation contact Rinnai UK Ltd or your

Supplier and arrange for a service call.

CODE DISPLAYED FAULT

Missed Ignition16

LO

20

HI

22・24

24・26

18・20・22

20・22・24

LO・16・18

16・18・20

18・20

LO・16

26

22・24・26・HI

Flame failure

Overheat

Room overheat

Room Temperature

Sensor faulty

Overheat Temperature

Sensor faulty

Sparker failure

Combustion fan failure

Faulty ON/OFF switch

Faulty solenoids

Faulty Flame Rod

Communication Error

REMEDY

Check gas is turned ON.

Service call if repeated.

Check gas is turned ON.

Service call if repeated.

Clean filter

Service call if repeated.

Lower room temperature

to less than 40˚C.

Service call.

Service call.

Service call.

Service call.

Service call.

Service call.

Service call.

Turn heater OFF,

then ON again.

16・18・20・22・24

Flue Block Check around flue terminal

Page 15

– 13 –

INSTALLATION INSTRUCTIONS

Important Safety Instructions

1. Gas Safety (Installation & Use) Regulations 1998 are the ‘Rules in Force’.

In your own interest and that of safety, it is law that all gas appliances shall be installed by

competent persons in accordance with the above regulations.

Failure to install appliances correctly could lead to prosecution. Other persons should NOT

attempt to install this equipment.

2. Unpack the appliance and check it carefully. If it appears to have any operating defects DO NOT

INSTALL, but contact the supplier.

3. This appliance is intended to be used to raise the temperature in a room or office etc. You should

NOT use it for any other purpose without seeking advice from the supplier.

4. This appliance is safe if correctly installed and sited. Please comply CAREFULLY with the

instructions.

5. This appliance is to be used for NATURAL GAS (G20) and PROPANE (G31) only. It must NOT

be used with any other type of gas.

6. Installation MUST be carried out in accordance with the current issue of:

a) Building Regulations issued by the Dept. of the Environment and Building Standards (Scotland

Consolidation) Regulations.

b) I.E.E. Wiring Regulations for electrical installations.

c) Gas Safety (Installation and Use) Regulations 1998.

d) BS5871 Part 1:2001

e) BS5440 Part 1:2000 and Part 2:2000

f) BS6891 Part 1:1998 (Natural Gas) and BS5482 Part 1:1994 (Propane).

g) Local Byelaws

h) Children & Young Persons Act 1933 revised 1952

i) Health and Safety at Work etc. Act, 1974

j) Such other specifications or legislation that may have superseded the above documents.

7. Should the heater be fitted in a room where there are young children; elderly; infirm or

handicapped persons, it is strongly recommended that a guard is fixed around the heater.

Guards conforming to British Standard Specification 6778:1986 (Fireguards for Use with Portable

Free Standing or Wall Mounted Heating Appliances) in respect of fixing, strength and painted

finish are acceptable and overall dimensions should be such that there is a gap of at least 100mm

(4 inches) between the guard and the heater. Standard guards that meet these requirements are

available from the supplier.

Please be sure you are aware of the implications of these notes.

Page 16

– 14 –

INSTALLATION INSTRUCTIONS

SPECIFICATION

Input: 6.4kW (21840 Btu/h) Burner: Stainless Bunsen Type

Ignition: Continuous Spark Gas Inlet: 1/2 inch BSP Male Connection

Flue: Forced Flue (Components are supplied with appliance).

Gas Control: Rinnai Electronic Modulating Controls.

Electrical Supply: 230V, 50Hz This appliance is fitted with a supply lead and 3 pin plug.

■ Remove parts from carton and check that all parts shown below are included in the installation kit.

Back Spacer

Set

Wall Bracket

Customers operating

information and

Installation Instructions

Air Filter

Flue Securing Screws

Wall Bracket Screws

For Flue Lock Stopper

For Air Intake Clip

For Back Spacer Set

(M4)

(M4)

Angle Bracket

Flue Locking

Clamp

Flue Lock

Stopper

Insulation

Clip

Hose Clip

Plastic tie for

air inlet

(M4×20)

(M4)

(M4.8×32)

Wood

Screws

1

2

1

1

4

5

1

1

1

2

3

1

3

2

Check the unit supplied is correct for the gas type in your area.

Refer to local gas authority for confirmation of gas type if in doubt.

Refer to data plate located on the right hand side.

Check for damage, if the unit is damaged contact Rinnai.

Do not install a damaged unit before checking with your supplier.

Refer to an approved pipe sizing chart if in doubt about size of gas line.

Page 17

– 15 –

LOCATION

When positioning the heater the main points

governing the location are:

1. Flueing

2. Warm air distribution

This heater must not be installed where curtains or

other combustible materials could come into

contact with it.

In some cases curtains may need restraining.

See diagram for other recommended clearances.

Flue fittings must be kept clear of flammable

materials.

This heater is not designed to be built in.

The flue is not designed to be positioned under

floors, or below the level of the heater.

The flue terminal should be positioned away from

flammable materials.

300mm

50mm

50mm

1000mm

Flue

Terminal

Flue

Terminal

LP GAS

Flue Terminal

Page 18

– 16 –

LOCATION

Do not flue into natural draught flues or fireplaces,

this unit can only be used with one of the six types

of Rinnai flue kits.

Do not flue unit into other rooms.

Flue terminal must be outside.

When fitting the terminal beneath any ventilation

opening i.e. openable window, inlet to a ventilation

system etc., check that no part of the terminal will

finish within 300mm when measured vertically from

the bottom of such openings. When the terminal

will finish less than 2m above the level of any

ground to which any person has access, a terminal

guard of durable material must be fitted, and these

are available from your supplier.

FLUE SIZES

6 Flue lengths are available.

S flue suits wall 75 - 115 mm

A flue suits wall 115 - 240 mm

B flue suits wall 240 - 400 mm

C flue suits wall 400 - 600 mm

D flue suits wall 600 - 800 mm

E flue suits wall 800 - 1000 mm

25mm spacers are available for wall thickness less

than 75mm.

SNOW AREAS

In areas subject to heavy snowfall, keep snow clear

of flue terminal at all times.

STANDARD INSTALLATION OF FLUE

MANIFOLD.

Diagram below shows minimum clearances and

distances from obstructions. Also check local

regulations.

Flammable

Wall

Non

Flammable

600mm

300mm

Opposite

Wall

Floor

600mm

300mm

Side Clearances

FIT BACK COVERS (SIDES ONLY)

Fit back covers (sides only) as shown below.

Engage Lugs

Secure with

Screws

300mm

Obstruction

Snow

Page 19

– 17 –

POSITIONING THE FLUE TERMINAL

Dimension

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

Terminal Position

Directly below an opening, air brick, opening windows, etc.

Above an opening, air brick, opening window, etc.

Horizontally to an opening, air brick, opening window, etc.

Below gutters, soil pipes or drain pipes.

Below eaves.

Below balconies or car port roof.

From a vertical drain pipe or soil pipe.

From an internal or external corner.

Above ground, roof or balcony level.

From a surface facing the terminal.

From a terminal facing a terminal.

From an opening in a car port. (e.g. door, window) into a dwelling.

Vertically from a terminal on the same wall.

Horizontally from a terminal on the same wall.

From the wall on which the terminal is mounted

From a vertical structure on the roof.

Above an intersection with roof.

Distance

300mm

300mm

300mm

75mm

200mm

200mm

150mm

200mm

300mm

600mm

1200mm

1200mm

1500mm

300mm

N/A

N/A

N/A

P

Q

I

F

J

L

B

G

Q

D,E

C

A

I

O

H

H

Q

N

M

N

M

K

Page 20

– 18 –

LOCATION

Do not install the heater in an unusually dusty area.

Use a flue guard if the terminal is easily accessible

to children.

Check local regulations.

Guards are available as an optional extra.

Floor must be level, but see page 23 regarding

adjustable legs. Do not use electrical extension

cords to connect unit to power supply. Keep the

power cord away from the flue.

FLUE MANIFOLD POSITION.

Centre of hole for flue manifold can be drilled

anywhere within the shaded area. (To avoid studs

etc.)

Before drilling the flue hole, check for water and

gas pipes as well as electric cables.

Use an 80mm (8cm) drill for hole through wall.

MOUNTING TO WALL

Assemble Angle Brackets to Back Spacer Top with

screws provided. Locate heater in position, hold

Wall Bracket in position around Angle Bracket and

mark hole positions, remove heater. Secure Wall

Bracket to wall. Relocate heater in position

ensuring Angle Bracket engages with Wall Bracket.

FLUE EXTENSION KITS

Flue extension Kits are available to allow longer

flueing lengths. Contact Rinnai for information.

Guard

300

Cavity Opening

280

R279

R206

22

214

Flue Hole

φ80

217

Page 21

– 19 –

SLEEVE AND MANIFOLD INSTALLATION

METHOD FOR STANDARD WALLS

1. Dis-assemble Manifold from Sleeve.

The flue consists of 3 parts, sleeve, inside

connectors and tube, outside terminal; (disassemble by pulling hard on outside terminal

and inner connections, then pull sleeve off outer

terminal).

2. Adjustment of Sleeve Length.

Measure wall thickness through previously

drilled 80mm hole.

End of sleeve should protrude 5-10mm from

outside wall. Adjust sleeve length to wall

thickness plus 5-10mm. (Sleeve is threaded for

adjustment).

3. For A and S flues only

Depending on flue set and wall thickness

extension piece ‘C’ may need to be removed.

Cut plastic, remove extension, then follow

instruction 2.

This applies to ‘A’ and ‘S’ flues only.

There is no extention on other flues, they can

be fully adjusted by turning the threaded

section.

4. Fixing Sleeve.

Fix to the wall, using the 3 screws provided.

NOTE:

The flange is marked “TOP”, sleeve must be

fitted with this mark UP.

Check sleeve protrudes 5-10mm on the

outside.

Connections

Sleeve

Terminal

Extension joint

under plastic

Extension

(‘A’ and ‘S’ flues only)

Adjust length by turning sleeve.

A

B

C

Remove extension at this

point if necessary.

Fixing Screw

2°

"TOP"

5-10mm

Don't remove green plastic covering from sleeve.

Page 22

– 20 –

SLEEVE AND MANIFOLD INSTALLATION

METHOD FOR STANDARD WALLS

5. Check rubber seal is in place on terminal.

6. Installation of Terminal

From outside, insert terminal into sleeve with

the “A” mark at the top. Left hand side fixing tie

is marked “LEFT” (from inside).

7. Attaching Ties

Pull hard on left and right hand side ties, clip

ties over lugs inside sleeve. You should be

able to pull ties 2 or 3 slots past the starting

point. Cut the ties, leaving about 20 mm past

the lugs. Bend ties so they are parallel with the

wall.

8. Insert Inner Connection Assembly. Push

assembly into the terminal tube, make sure

“TOP” mark is uppermost. Fix with 3 screws

provided.

9. Manifold can still be turned after attaching.

Terminal seal

Label

Fixing Tie

Terminal

"TOP" mark "A"

Cut (leave 20mm free)

Pull hard

Fixing tie

Lug

Sleeve

Terminal

lnner

Connections

Screw

Top Mark

Inlet

20˚

Outlet

Rubber cap

Page 23

– 21 –

FITTING UNIT

AIR INLET HOSE

LOCKING CLAMP, SCREW CLAMP AND

INSULATION.

The following components can be fitted by reaching

down the rear of the appliance as it is positioned

against the wall.

1. Connect the flue outlet to the manifold by

extending the stainless steel sliding tube until it

is fully inserted into the manifold.

Detail of Hose clip

Hose clip

Inlet hose

Manifold

2. Fit the locking clamp over connection between

sliding tube and manifold. Engage the hook

and rotate it until it snaps against the body of

the clamp.

Locking

clamp

Flue outlet

Sliding tube

Manifold

Hook

Locking

Clamp

3. Fit the screw clamp between the sliding tube

and the flue elbow. Secure with the 4 mm

screw supplied. The flue outlet is now locked

into position.

Flue elbow

Flue Outlet

sliding tube

Manifold

Locking clamp

screw

Flue Outlet tube

screw clamp

4. Slide the insulation sleeve up to the flue

manifold, slip the securing clip over the sleeve

as shown.

Flue elbow

Sock

Flue outlet

Sliding tube

Slide to here

Fit clip

Slide insulation sock

Plastic tie

Inlet elbow

Inlet hose

Sliding Tube

Do not extend flue tube

beyond red line.

Manifold

Slide

Page 24

– 22 –

CONNECTING GAS AND ELECTRICAL SERVICES

1. GAS CONNECTION.

Purge any air or swarf from the gas line. Connect up the appliance to the gas supply using a

union service cock to facilitate servicing. Do not use hot works near the unit or the gas valve may

be damaged.

Inlet connection size Gas (1/2 inch BSP Male Connection)

Check gas soundness using leak detection fluid, not naked flame. Connection can be easily

reached from right hand side rear of appliance. Remove bottom trim (pulls off). Remove louvres

(6 screws) and front panel.

2. ELECTRICAL CONNECTION.

WARNING: This appliance must be earthed.

This appliance is suitable for 230V - 50Hz mains only and external wiring must be carried to out

I.E.E. regulations.

Connect appliance to electrical supply using moulded plug supplied. A means of completely

isolating the heater from the supply with contact separation of at least 3mm. on all poles must be

provided for servicing. The fuse should be 3amp.

Observe polarity and ensure that wiring is correctly restrained

E Earth Green / Yellow

L Live Brown / Red

N Neutral Blue or Black

IMPORTANT

Do NOT use a clock or any type of switch on the electrical supply apart from the means of isolating

the supply for servicing. (A clock or switch would also turn OFF the convection fan causing

overheating).

3. On the rear right hand side of the heater (seen from the front) there is a terminal block with 3

numbered terminals. As delivered there is a link between terminals 2 and 3 and should be left like

that where the dimension between the heater and the flue does not exceed 1.8 metres. For

dimensions of more than 1.8 metres, change the link to connect between terminals 1 and 2.

4. This heater may be controlled (1) individually and manually OR (2) from a central clock. If the unit

is to be controlled form a central timeclock the wiring for the clock must be done before the heater

is fixed into position.

1. For simple manual control, disconnect the plug on the top of the printed circuit board

and use ON / OFF switch and adjust thermostat as required.

2. For central timer control, a transformer kit is required. See price list or contact Rinnai

for advice.

3. For use in Offices or Schools etc. where all heaters are connected to a central control

system which shuts down all services at the end of the working day but where

individual heaters can still be set up to separate users needs, refer to

Rinnai for

appropriate Conversion Kit.

Disconnect

Page 25

– 23 –

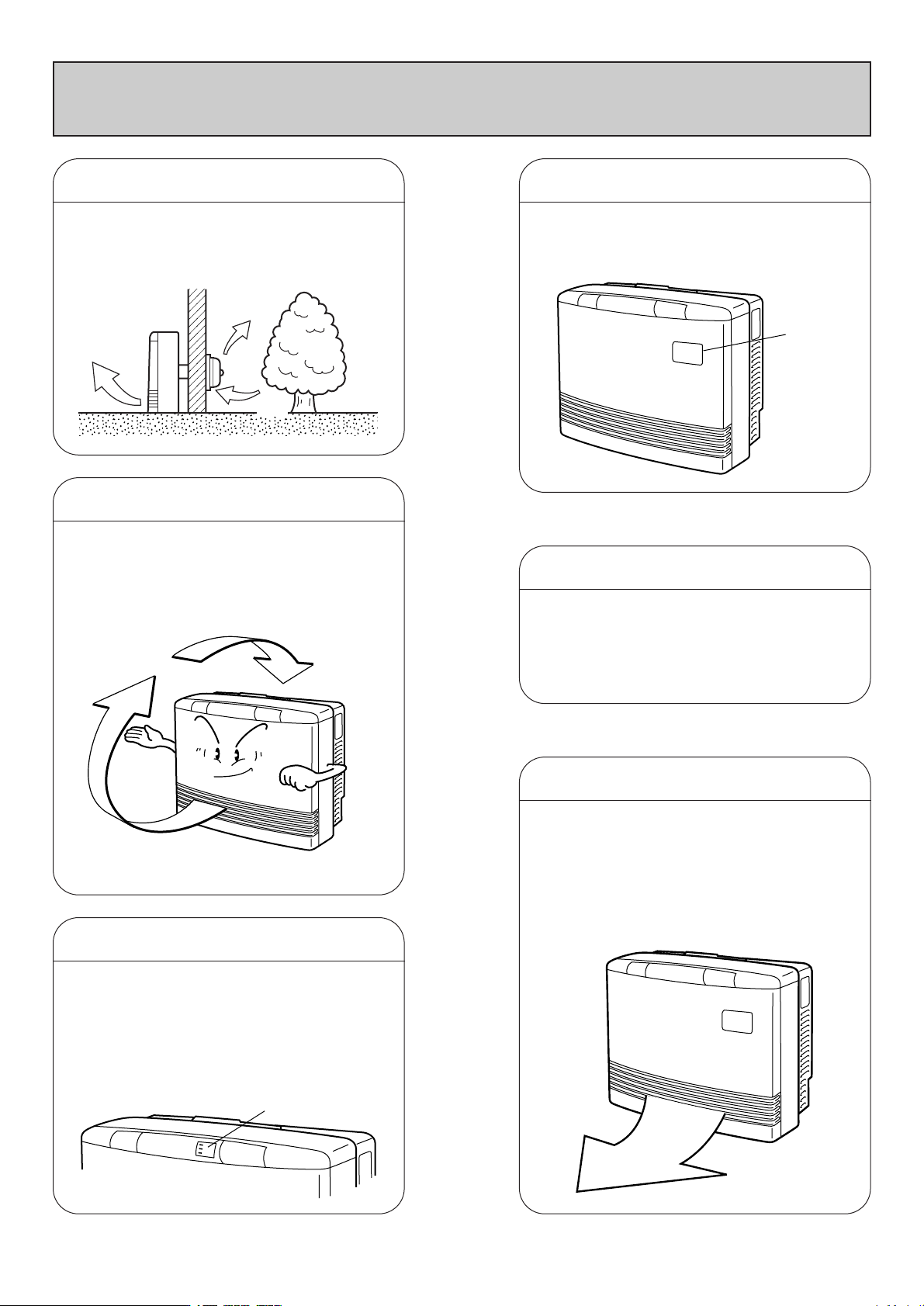

RINNAI 1004T/556T WIRING DIAGRAM USING RANDALL 851 PROGRAMMER

RINNAI1004T RINNAI1004T

L

N

10:1transformer

RinnaiUK

Partnumber

957-000-001

RINNAI556T

L

N

L

N

N

RANDALL851TIMER

L

Page 26

– 24 –

GAS CONVERSION

CAUTION

RISK OF ELECTRIC SHOCK

❈ Disconnect electrical supply

1. Remove bottom trim (pull)

2. Remove 8 screws inside bottom louvre,

pull complete front panel forward at bottom,

unclip from escucheon panel and remove

from heater

3. Replace small gas label on gas inlet.

4. Replace large gas label on back of

appliance

5. Change very small gas label on Data Plate

6. Complete details on conversion sticker,

place sticker inside left hand side panel

7. Undo main gas tube connection at

manifold, 1 screw, push tube down

8. Remove “O” ring from manifold connection

and refit to main gas tube (to avoid

trapping “O” ring when re-assembling)

9. Remove manifold, (2 screws) take care

with gasket

10. Carefully remove front damper, (1 screw)

see drawing 4.

11. Using pointed nose pliers, carefully pull the

right hand damper forward, and out of the

burner assembly

12. Gently fit new damper-tag faces to the right

13. Refit front damper

14. Remove injectors

15. Fit new main injectors

16. Refit manifold, (slide into pin locators) then

secure with screws, take care with gasket

17. Connect main gas tube, take care with “O”

ring

18. Connect appliance to electricity (and gas if

disconnected).

19. Follow gas pressure setting procedure, see

next page.

20. Test for gas escapes

21. Replace front cover

BottomLouvre

Louvre

ScrewPositions Drawing1.

FrontPanel

Louvre

Drawing2.

Screw

Manifold

HI-LimitSwitch

No.2Bracket

Drawing3.

BurnerBracket

Marking

BurnerBox

BurnerBoxCover

Mainlnjector

MainBurner

Manifold

FrontDamper

RHSDamper

Drawing4.

Page 27

– 25 –

TESTING

PRESSURE CHECKING PROCEDURE:

Caution- 230 V inside appliance.

1. Check that SW6 (Dip switches) are correct for the gas

type for which the appliance is to be used. (Refer to

diagram opposite).

2. There are two test points, one on the heat exchanger, one

on the gas manifold. Connect a differential pressure

gauge between both test points. (Connect one side of the

gauge to one point, the other side of the gauge to the

other). If you are using an electronic manometer, connect

the - side to the heat exchanger test point.

3. Press the ON/OFF button to operate the appliance.

4. With the appliance operating, press SW5 once.

5. Press SW4 to operate the appliance on forced low.

6. Compare the pressure to the low pressure shown on the

bottom of this page.

7. Press SW4 again.

8. Press SW3 to operate the appliance on forced high.

9. Check the pressure against the high pressure shown on

the bottom of this page.

10. Press SW3 again.

11. Press SW5 again to return the heater to normal operation.

12. Turn the heater OFF, remove the pressure gauge, and

replace the test point screws.

13. Reassemble appliance, set the remote clock if fitted, (see

page 21) and check appliance operaton. When appliance

is on check test points for gas tightness.

THE REGULATOR HAS BEEN FACTORY PRE-SET. IF

THE PRESSURE IS INCORRECT, CHECK THE SUPPLY

PRESSURE FIRST, BEFORE MAKING ANY ADJUSTMENT

TO THE APPLIANCE.

ADJUSTMENT OF BURNER DIFFERENTIAL PRESSURE IS

BY MEANS OF THE ROOM ADJUSTMENT BUTTONS ON

THE CONTROL PANEL AND FOLLOWING THE

INSTRUCTIONS GIVEN BELOW:

1. Follow checking procedure 1-6, reset the low pressure by

using the “

▲” or “▼” buttons on the control panel.

2. Press SW4 again to lock in the selected setting.

3. Follow checking procedure 8 and 9, reset the high

pressure by using the “▲” or “▼” buttons on the control

panel.

4. Press SW3 again to lock in the selected setting.

5. Press SW5 to return the heater to normal operation.

6. Turn the heater OFF, remove the pressure gauge, and

replace the test point screws.

7. Reassemble appliance, set the internal and / or remote

clock if fitted, and check appliance operation. When

appliance is on check test points for gas tightness.

556T

NG

LPG

SW6 DIP SWITCH

OFF

1234

ON OFF OFF

ON

1234

OFF OFF OFF

SW6

SW1

SW2

SW3

SW4

SW5

Manifold

TestpointB

GasValve

Test

pointA

Adjustingscrew

BURNER

PRESSURE

SETTINGS

INJECTOR

SIZE

HIGH

LOW

9.2mbar

1.8mbar

1.13

NG

10.6mbar

2.0mbar

0.85

LPG

Page 28

– 26 –

FITTING TOP SPACER + WALL CLIP

■ SECURE HEATER TO WALL

Fix angle bracket to back spacer with screws

provided.

Fix wall bracket to wall, so that the tongue of

the anglebracket will fit into it, when the back

spacer is fitted to the top of the heater.

Tighten all screws, fit fan filter.

Fanfilter

Adjustable Leg

Up to 10 mm

Levelling screws(Adjustable legs)

If necessary, the unit can be levelled using the

adjustable legs under the front right and left hand

side legs.

■ INSTRUCT CUSTOMER ON

USE OF HEATER

When you are satisfied that the appliance is

operating correctly, explain operation of heater to

the customer.

FAULT-FAILURE PROCEDURE

If unable to get the heater to operate correctly

contact Rinnai.

Page 29

– 27 –

BLOCK AND WIRING DIAGRAM

WIRING DIAGRAM

BLOCK DIAGRAM

SW6. DIP SWITCH

TB1

SUB-P.C.B

SW1 FM. ADJUST SWITCH

〔Hi〕

SW2 FM. ADJUST SWITCH〔Lo

〕

SW3 POV. PRESSURE ADJUST SWITCH〔Hi

〕

〈SHORT CIRCUIT PATTERN〉

2, 3 SHORT: FOR DIRECT EXHAUST

1, 2 SHORT: FOR EXTENSION KIT

(FROM 1.8 m TO MAX LENGTH)

SW5. TEST SWITCH

SW4 POV. PRESSURE ADJUST SWITCH

〔Lo〕

TH

TB2

AC

ER

SP

230V

AC

24V

OH.TH

INDICATOR

OPERATION P.C.B

ON/OFF BUTTON

H2

H1

H3

OHS

FR

TR

130℃

TF

TF

OHS

OHS

No 3〔130℃

〕

No 1〔130℃

〕

No 2〔90℃

〕

〔

152℃

〕

44

45

43

46

39

40

31 32

33

24 25

2728

23

29

30

21

22

19

15

〔F〕

3A

16

17

1820

12

13

9

1 2 3 4

12

3

12

3

8

OFF

26

38

37

34 3536

41

42

I J

J1

A

D

B

C

H

F

G

E

E1

SV

1

SV

2

POV

BL

FM

r

r

r

r

r

r

rr

bl bl

bl

bl

bl

bl

y

y

Y

y

y

y

Y

y

w

w

bl

w

r

w

bk

bk

bk

bk

br

bk

bk

or

or

gr/y

w

ww

w

wr

r

47 48 49 50 51 52 53 54 55 56

57 58 59 60 61 62 63 64 65 66 67 68 69 70 71

bl bl bl blbl bl bl blbl

W

w

w

w

w

w

w

w

w

w

W

w

gr/y

gygy

gy

gr/y

gy

gy

gy

gy

gy

5

4

7

6

K

w

bk

w

bk bk

rr

INDICATOR

CONTROLDISPLAYUNIT

CONTROLDISPLAYCIRCUIT

TEMP

CONTROL

CIRCUIT

CENTRALTIMER

CONTROL

CIRCUIT

CENTRALTIMER

CONTROL

SUB-P.C.B

TH

AC24V

TB1

556T

OH.TH

OH.TH

Hi

Lo

135°C

110°C

OHS2

90°C

OHS1

130°C

OHS3

130°C

TF

152°C

AC230V

F(3A)

TRANSFORMER

POWER

SUPPLY

CIRCUIT

CONVECTION

FAN

CIRCUIT

CF

FM

TB2

BL

FCC

COMBUSTION

FAN

CIRCUIT

IGNITION

CIRCUIT

FLAME

ROD

CIRCUIT

MODULATING

VALVE

CIRCUIT

GAS

SV1SV2

POV

FR

ER

SP

MAIN

BURNER

CPU

MS

SAFETY

TIMER

CIRCUIT

SOLENOID

VALVE

CIRCUIT

MARK

MS

RC

TH

TF

F

CF

FCC

ER

POV

TR

PART NAME

MAIN SWITCH

REMOTE CONTROL

THERMISTOR

THERMAL FUSE

FUSE

CONVECTION FAN

FAN CONTROL CIRCUIT

ELECTRODE

MODULATING SOLENOID VALVE

TRANSFORMER

MARK

RCR

TB1〜2

OH, TH

OHS1〜3

FM

BL

SP

FR

SV1〜2

CPU

PART NAME

REMOTE CONTROL RECEIVER

TERMINAL BLOCK

OVER HEAT THERMISTOR

OVER HEAT SWITCH 1〜3

FAN MOTOR

COMBUSTION FAN MOTOR

SPARKER

FLAME ROD

MAIN SOLENOID VALVE 1〜2

CENTRAL PROCESSING UNIT

CODE

pl

y

w

gr/y

gy

bl

r

bk

or

br

gr

COLOUR

purple

yellow

white

green/yellow

grey

blue

red

black

orange

brown

green

Page 30

– 28 –

FORCED FLUE HEATER EXTENSION KITS

• This extension set is to be used for installations requiring extra distance.

MAXIMUM FLUE LENGTH 7 METRES. Reduce length 1 metre for each bend used. (e.g. 4 metres, 3 bends).

■ NAMES AND NUMBERS OF PARTS

EXTENSION KIT PARTS AND INSTALLATION GUIDE

FOT - 155 0.5m EXTENSION KIT

FOT - 156 1.0m EXTENSION KIT

FOT - 157 2.0m EXTENSION KIT

FOT - 158 BENT ELBOW KIT

FOT - 160 LONG FLEX TUBE 600 KIT

A FOT-155(290-515mm)

B FOT-156(533-1005mm)

A FOT-155(750mm)

B FOT-156(1250mm)

C FOT-157(2000mm)

AEXHAUST PIPE

BEXHAUST PIPE (STRAIGHT) 1 Metre

CAIR INTAKE HOSE

DBENT ELBOW

EHOSE JOINT

FPIPE STOPPER A

GPIPE STOPPER B

HPIPE CLAMP

IWALL-FIXTURE

JNUT

KSCREW A

LSCREW B

L=600

⑬LONG FLEX TUBE

A

C

B

A

B

A

B

C

D

E

F

G

H

I

J

K

L

⑬

EXHAUST PIPE

EXHAUST PIPE

EXHAUST PIPE (STRAIGHT)

AIR INTAKE HOSE

AIR INTAKE HOSE

AIR INTAKE HOSE

BENT ELBOW

HOSE JOINT

PIPE STOPPER A

PIPE STOPPER B

PIPE CLAMP

WALL FIXTURE

NUT

SCREW A

SCREW B

CONG FLEX TUBE

PARTS No.

FOT 081-2

FOT 082-2

FOT 157-3

RHF 300-51-6

RHF 300-51-7

RHF 300-51-3

FOT 087-002

FOT 062-12

305F-0017

FOT 081-4

FOT 062-8

FOT 062-9

FOT 062-10

ZAA0422SC

ZEAA0412SZ

FOT160-2

FOT-155

1

1

1

1

1

1

1

2

1

4 SET

4

4

4

8

1

1

1

1

3 SET

3

3

3

6

1

1

1

2 SET

2

2

2

4

11

1

FOT-156 FOT-157 FOT-158

1

FOT-160

Page 31

– 29 –

■ TYPES COMPATIBLE WITH EXTENSION KIT

RHFE - 556FTR / 556T

INSTALLING AN EXTENSION KIT

Installing an extension kit requires construction of an air line and the exhaust line. The air line is

connected between the Air Supply Elbow at the rear of the heater and the air inlet port on the Flue pipe.

Similarly, the exhaust line is connected between the joint pipe at the rear of the heater, and the exhaust

port on the Flue pipe.

Caution: Check to see there is no debris in pipe or hose.

■ HOW TO INSTALL

MODEL: RHFE - 556FTR / 556T

Example: Using 2 sets of extension kit and 1 bend kit. Example: Using 2 Metre side pipe kit.

Mushroom Flue

(comes with main unit)

Air intake elbow

(comes with main unit)

Pipe stopper A

Pipe stopper B

Pipe stopper A

Bent elbow

Pipe stopper A

Hose joint

Pipe stopper B

Exhaust pipe

Hose joint

Pipe stopper A

Pipe stopper B

Air intake hose

Mushroom Flue

(comes with main unit)

Air intake elbow

(comes with main unit)

Pipe stopper A

Pipe clamp

Pipe stopper B

Pipe clamp

Pipe clamp

Exhaust pipe

Pipe stopper A

1 metre straight pipe

Pipe clamp

Pipe stopper A

Pipe stopper B

Hose joint

Air intake hose

Pipe clamp

IMPORTANT NOTE:

When the appliance is installed using a flue extension that exceeds 1.8 metres you must

change the link on the flue extension

terminal block as shown.

Terminal is located at the rear of unit

next to gas inlet.

1

2

3

FOR DIRECT

EXHAUST

USED FOR EXTENSION KITS

Page 32

– 30 –

1. How to connect exhaust pipes

To connect the exhaust pipes, fit the male end into the female end and clamp with pipe stopper A to

prevent slipping. The exhaust pipe can be telescoped to the required length; do not cut it.

Female end

Exhaust pipe

Pipe stopper B

Male end

Pipe stopper B

Pipe stopper A

Female end

Male end

Exhaust pipe

Fit inside

2. How to connect air intake hose

Screw hose joint half of its length onto the air intake hose, then screw another air intake hose into the joint.

The hose can be cut to the required length.

IMPORTANT: The PVC air line is longer than the exhaust line and may need to be cut to size. Be

sure, however, to thoroughly deburr all rough edges.

Main unit air intake hose

Air intake hose

Hose joint

Screw in counterclockwise

Air intake hose

Air intake elbow

Pipe stopper A

Fit inside

Connect bent pipe

Female end

Male end

3. Affixing the air intake hose and exhaust pipe 4. How to use the bent pipe

Screw B

Wall

Air intake

hose

Screw A

Pipe clamp

Exhaust pipe

Wall fixture

Wall

Air intake

hose

Screw A

Nut

Pipe clamp

Exhaust pipe

Adjust the angle

• Set the air intake hose and exhaust pipe into

the pipe clamps, screw the clamp onto the

wall fixture, and affix to the wall with screw B.

• The air intake hose and exhaust pipe can

also be screwed onto the wall using the pipe

clamp and the nut.

With the exhaust pipes inserted into the ends,

bend the bent pipe to the angle required for

installation.

This part is mainly used for curves and for

connection to vent terminal.

Page 33

– 31 –

■ CAUTIONS

1. Maximum extendable length

FOR BEST ROOM AIR HUMIDITY, KEEP

WATER IN THE HUMIDIFIER TRAY.

2. To prevent water condensation

Condensed water

may accumulate

here, and cause a blockage

preventing combustion.

MAXIMUM FLUE LENGTH 7 METRES.

Reduce length 1 metre for each bend used.

(e.g. 4 metres, 3 bends).

• The bend where the hose and pipes leave

the body is not counted.

• The air intake hose should run along the

exhaust pipe.

3. Condensed water formed by

combustion, will run back to the

unit, and may overflow from the

condensation pan if pipes are

longer than 2.5m. Therefore,

pipes exeeding these lengths

should be made to drain to the

outside by giving their horizontal

portions 75mm or more downward

and outward slope.

CAUTION

Never allow the exhaust pipe to sag, as

condensed water may accumulate and

cause incomplete combustion.

75mm slope(approximate)

Less than 2.5m

Page 34

– 32 –

4. Wherever the air intake hose and exhaust pipe

run sideways, try to have the exhaust pipe on

top (to prevent the air intake hose from sagging

onto the exhaust pipe).

Exhaust pipe

Exhaust pipe

Air intake hose

Air intake hose

Page 35

– 33 –

DIMENSIONS

SERVICE CONTACT POINT

300

50

214

R279

R206

217 245

632

750

WALLOPENINGRANGE

AIRSUPPLYCONNECTION

554

280

280

77

85165

GASCONNECTION

134

36

Contact: Rinnai UK Ltd.

9 Christleton Court

Manor Park

Runcorn

WA7 1ST

Tel: 01928 531870

Fax: 01928 531880

www.rinnaiuk.com

Page 36

Jan 2006 556F-2190

Loading...

Loading...