Page 1

ENERGYSAVER

RHFE-308FTR

SERVICE MANUAL

High Efficiency Power Flued Gas Space Heater

Page 2

Proudly a member of The Australian Gas Association.

All of our products are AGA tested and approved.

Distributed and serviced in Australia under a

Quality System certified as complying with ISO

9002 by Quality Assurance Services.

Rinnai New Zealand has been certified to ISO 9001

Quality Assurance by Telarc.

Certified to Australian Standard 3498 by Quality

Assurance Services. Watermark certification is

awarded to products with suitable fittings

complying with safety and water contamination

standards.

Comparative Energy Consumption tested to The

Australian Gas Association requirements of Australian

Gas Code AG 102. An energy rating of 5 stars refers to

an efficiency of approximately 80%, that is, 80% of gas

consumed is converted to useful heat.

ISO 9001 Model for Quality Assurance in design/development, production, installation and servicing,

aimed primarily at achieving customer satisfaction by preventing nonconformity at all stages

from design through to servicing.

ISO 9002 Same as ISO 9001 but excluding design.

AS 3498 Authorisation requirements for plumbing products - water heaters and hot-water storage tanks,

aimed at ensuring safe, quality products.

AG 102 Approval requirements for gas water heaters as set by The Australian Gas Association and

Australian Liquefied Petroleum Gas Association Ltd, to ensure proper safety performance and

quality levels are achieved.

Page 3

© Copyright Rinnai Australia Pty Ltd

A.C.N. 005 138 769 All rights reserved

Produced by Customer Technical Services

July 1998

No portion or part of this manual may be copied without prior permission from Rinnai Australia.

Rinnai Australia takes no responsibility for the accuracy or otherwise of information contained in

this manual, and reserves the right to make modifications and change specifications without notice.

WARNING

Failure to comply with these instructions may result in serious personal injury or damage to the appliance.

ALL WIRING INSIDE THIS APPLIANCE MAY BE AT 240 VOLTS POTENTIAL

ALL SERVICE WORK MUST BE CARRIED OUT BY AN AUTHORISED PERSON.

DO NOT TEST FOR GAS ESCAPES WITH AN OPEN FLAME

This manual has been compiled by Rinnai Australia Customer Technical Services. While

many individuals have contributed to this publication, it will be successful only if you - the

reader and customer - find it useful. We would like to extend an invitation to users of this

manual to make contact with us, as your feedback and suggestions are valuable resources

for us to include as improvements. Rinnai are constantly working toward supplying

improved appliances as well as information, and specifications may be subject to alteration

at any time.

SRV308

Issue No1

Page 4

Table of Contents

Glossary of Terms and Symbols .......................................................................... i

1. Introduction .................................................................................................... 1

2. Dimensions ..................................................................................................... 2

3. Specification .................................................................................................... 3

4. Cut-Away Diagram ........................................................................................ 4

5. Installatio ...................................................................................................... 5

6. Performance Characteristics ......................................................................... 7

7. Schematic Diagram ..................................................................................... 10

8. Control Panel Layout .................................................................................. 11

9. Operating Principles ................................................................................... 12

10. Intelligent Timer [Pre-hea t ...................................................................... 14

11. Safety Devices ........................................................................................... 15

12. Operation Flow Chart .............................................................................. 18

13. Diagnostic Points ....................................................................................... 21

14. Wiring Diagram ........................................................................................ 22

15. Block Diagram ........................................................................................... 23

16. Time Charts ............................................................................................... 24

17. E2 PROM .................................................................................................. 27

18. Error Coded Messag e ............................................................................. 29

19. Fault Finding .............................................................................................. 30

20. Fault Analysis ............................................................................................ 33

21. Electrical Component Analysis ............................................................... 36

22. Testing ........................................................................................................ 40

23. Gas Conversion ......................................................................................... 42

24. Gas Pressure Setting Procedur ............................................................... 43

25. Dismantling for servic ............................................................................. 44

26. Exploded Diagram .................................................................................... 51

27. Parts List ..................................................................................................... 56

Appendix............................................................................................................ 59

-

Page 5

Glossary of Terms and Symbols

This glossary of terms and symbols is provided to assist you in understanding some of the language

used throughout this manual.

dB(A) - sound pressure level in decibels, “A” range

DC - direct current

AC - alternating current

Hz - Hertz

IC - integrated circuit

kcal/h - kilocalorie per hour

kPa - kilopascals

LED - light emitting diode

L/min - Litres per minute

mA - milliamps

MJ/h - megajoule per hour

mm - millimetres

mmH

NO

O - millimetres of water (gauge pressure)

2

X

- oxides of nitrogen (NO & NO2)

OHS - overheat switch

PCB - printed circuit board

CPU - central processing unit

POT - potentiometer

rpm - revolutions per minute

SV - solenoid valve

ø - diameter

∆

POV - modulating valve

TH - thermistor

-

Page 6

1. Introduction

Background

The RHFE -3 08FTR in co rpo ra te s an impr ov e d modulating control syste m t o provide comfo r table heating.

Other features of these appliances are improved safety, operation, installation, and maintenance features.

Characteristics

• Built into the main PCB is the software for connection to a central ON-OFF control.

• Gas flow modulates in 7 steps between High and Low ensuring comfortable and efficient heating.

• Incl u d es a 24 ho u r d ig ital cl ock and dual timer, a n d an economy mode functi on. This reduces gas con-

sumptio n w i thout af fect ing comfort.

• Temperature control is monitored by “fuzzy logic” t ec h n ology - relevanc e to each other.

• All operation and temperature control is with user-friendly push buttons.

• Improvements have been made to the rear convex section for clean-cut design.

• If a prob lem occur s or ser v ic e is requir ed, an error coded mes sa ge appears o n th e digital display to

direct the service technician to the cause of the problem.

• Info rmation about any previous f a u l t s is sto r e d in the PCB and can be re c a lled during servicing.

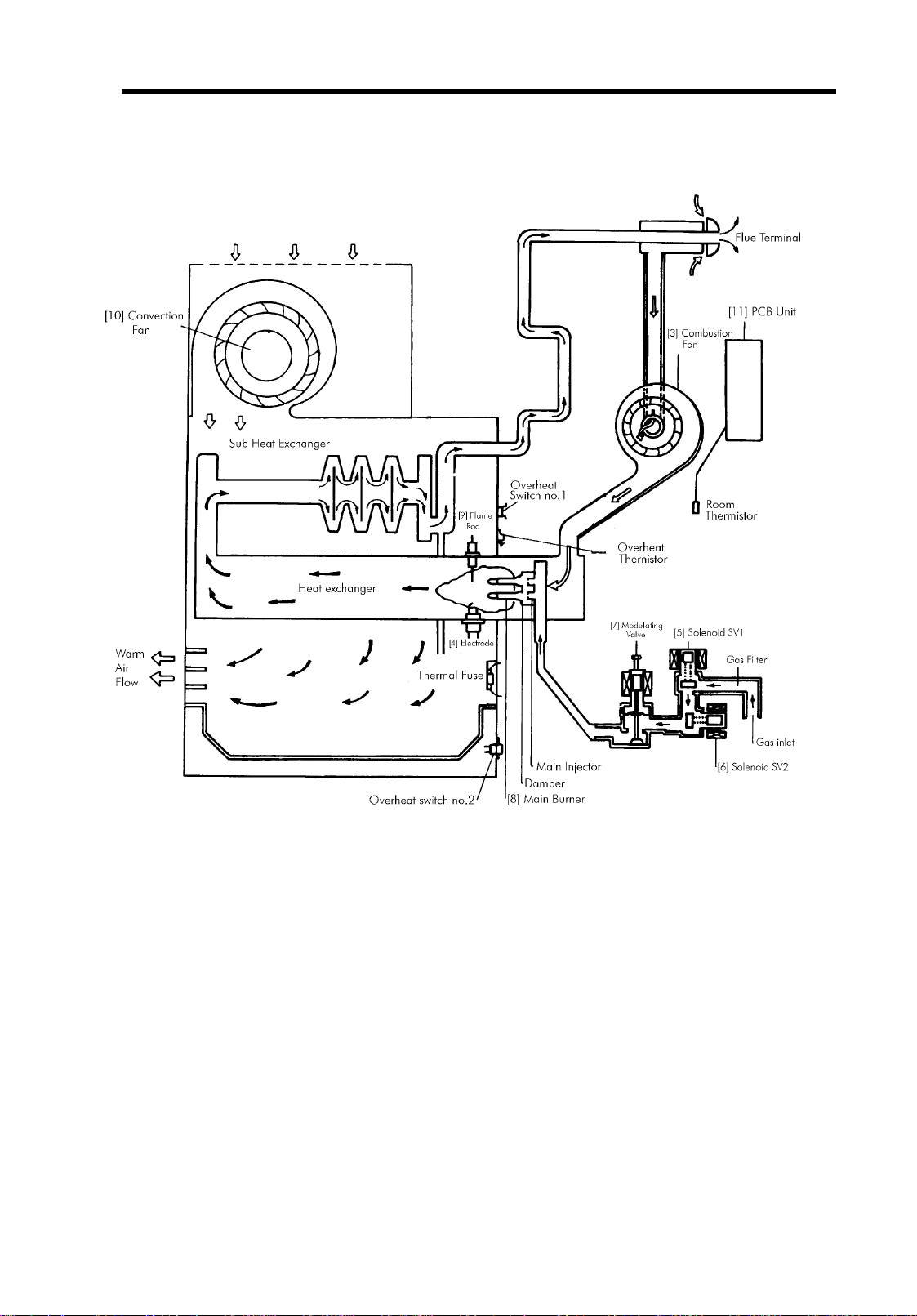

About the 308FTR

The bodywork is formed from 0.6 mm galvanised steel sheet, which forms a box to which the components,

heat exch an gers and bl o wer s a re at ta ch e d . T h is i s th en covered by an outer ca se which is constr ucted from

0.6 mm galvanised steel sheet, and plastic mouldings.

The combustion chamber is constructed from 1.0 mm hot dip aluminium coated steel sheet, located in the

lower centre of the appliance.

The heat e xchanger is com posed of two sub-he at exc hanger se ts . The left hand set, N

1.0 mm alu mi n i s ed s t ee l . T he ri ght ha nd set, N

heat exchange r No1 is c onne cte d to the outlet of t he combus tion c hamb er, the outlet is co nnect ed to subheat exchanger No2. Sub-heat exchanger No2 consists of 3 “sub” sections, constructed from 0.8 mm

stainless steel. The outlet of sub-heat exchanger No2 is constructed from 0.5 mm stainless steel and

connected to the flue by a concertina stainless steel tube.

The combusti on air fan d ra ws combus ti on a ir from the ou t s ide atmosphere through the flue manifold pipe.

Air is then blown into th e c o mb u sti on chambe r via a rubber tube. Com b u stio n pr o ducts in the combus tion

chamber are pushed out into sub-heat exchanger N

flue pipe which is connected through the flue manifold to the outside atmosphere.

The flue system is connected with stainless steel concentric pipe. The inner pipe (34 mm diameter.) is the

combus tion gas outlet, and is connect ed to the outlet of sub-he at exchanger N

diameter ) is the co m b usti o n a i r i nlet and is connected to t h e inlet o f t h e com busti on fan a i r p ipe. Various

flue lengths are avail abl e.

Ignition is continuous spa rk i n conju nct ion with an electrically operate d solenoid a n d cont rol is monitored

by the PCB. Ga s pa ss es th r ou gh the R½ 15 (BSP) inlet fitt ing , then via a flan g e connec ti o n to the solenoid

valves N

o

1, No2, a regulator modulating valve, aluminium injector manifold, before entering the burner.

o

2 is co nstr ucted of 0.8 m m st ainless steel. The inlet of sub-

o

1, to sub-heat exchanger No2, and then into the 34 mm

o

o

1 is constructed of

2. The outer pipe (70 mm

-

-

-

i

i

Page 7

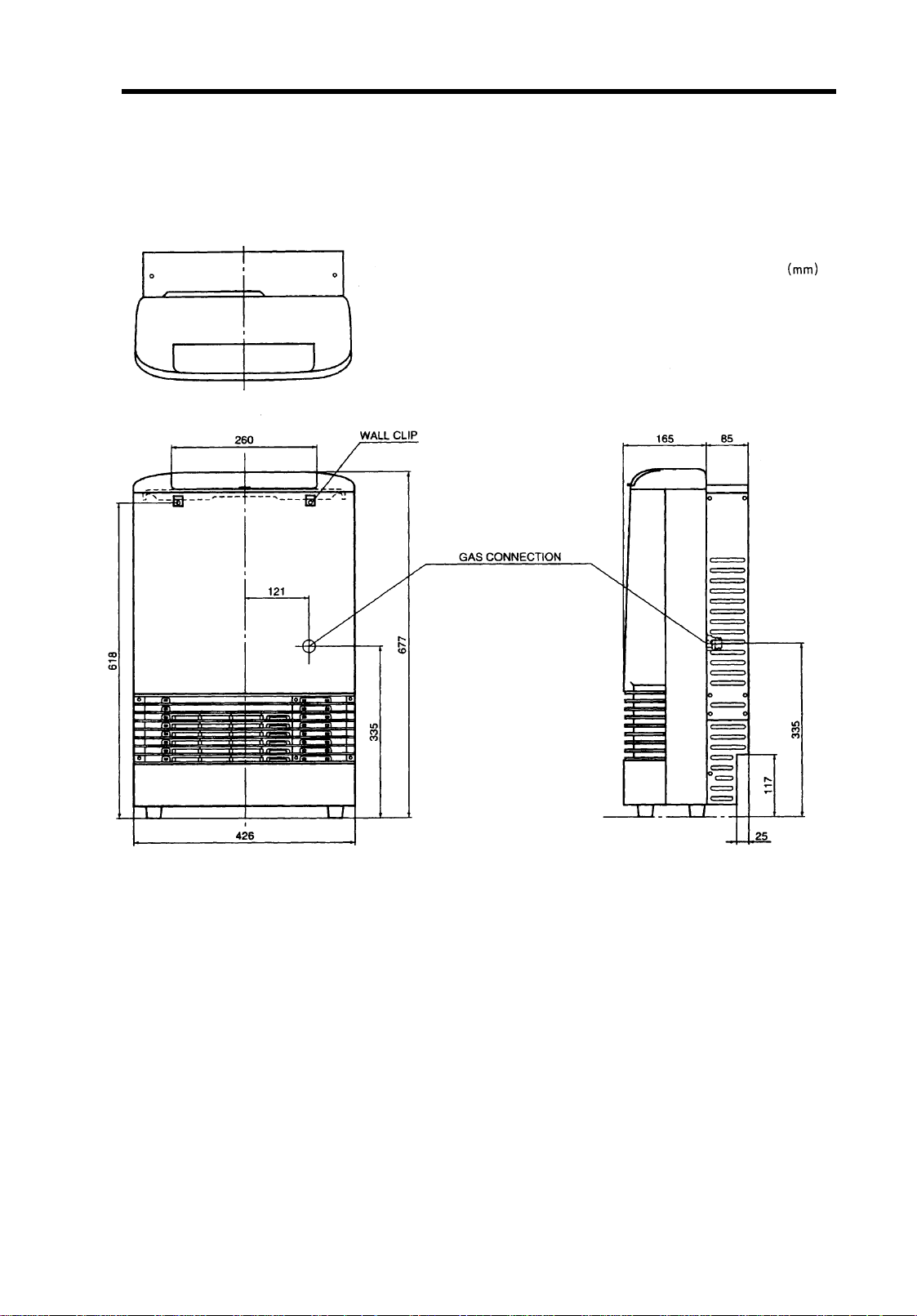

2. Dimensions

Note: All dimensions are in millimetres

-

-

-

Page 8

3. Specification

Type of applia nce Fan forced flued g as s pace heater

Model RHFE-308FTR

Dimensions Width - 425 mm

Depth - 165 mm (with back spacer 250 mm)

Height - 677 mm

Weight Approx 17 kg

Connections Electrical - AC 240 V 50 Hz / 60 Hz

Gas - R½ 15 BSP male threa

Electrical

High: 39 W Low: 30 W

Consumption

Output 10.5 MJ/h

Combustion system Stainless steel bunsen burne

Ignition system Continuous electrical spark, direct to main burner

Operati on Fi ng e r touch cont rol buttons

Temperature control Electronic thermostat, modulating HI-LOW/OFF

Temperature range LOW (10

o

C), 16 ~ 26oC (1oC incre ment s), HIG H (co ntin uous)

Warm air outlet Bottom of appliance

Air volume control HI ~ LOW (automatic)/OFF

Timer operation Dual Timer - 24 hour, ON & OFF Timer

Operation - 24 hour

Clock - 24 hour digital display

Temperature control - 26

o

C limit when using timer program

Indicator Burner ON, child lock, filter, economy, digital display, over-ride, clock

setting, timer setting, timer, temperature display

Operating buttons ON-OFF, up-down, child lock, economy, timer, clock setting, over-ride.

Humidifier tray Capacity - 0.8 Litres

Safety devices Flame failure - flame rod

Over heat - bi-metal switch (130

o

C, 90oC)

- thermal fuse (216oC)

- thermistor (130~90oC)

Power failure - PCB

Power surge - 3 Amp fuse

Fan delay - micro computer timer (Max 210 secs

Pre-purge - combustion fan, pre-purge timer, spark sensor

Room over heat - automatic cut off at 40

-

-

-

o

C after 10 mins

i

i

Page 9

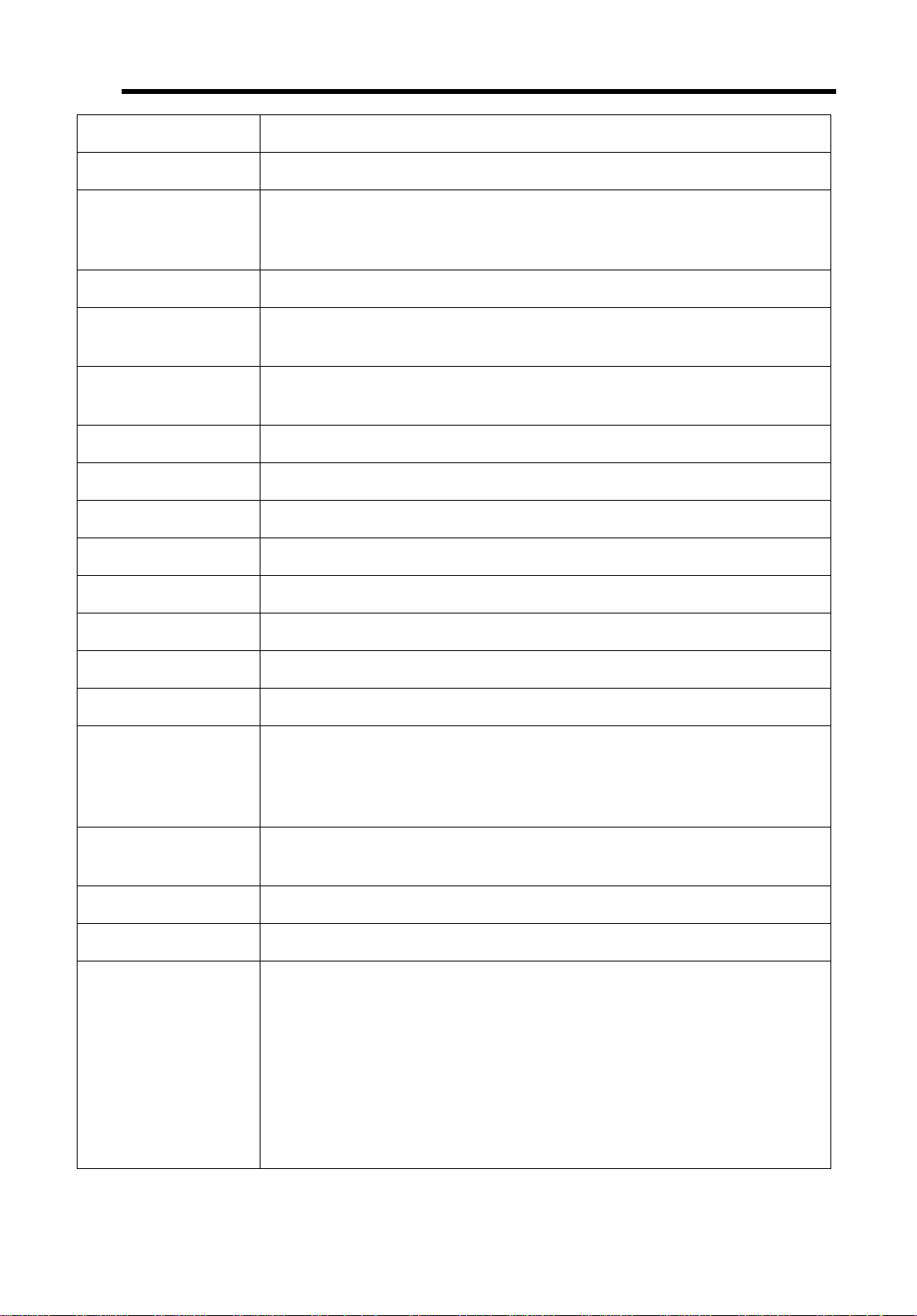

4. Cut-Away Diagram

-

-

-

Page 10

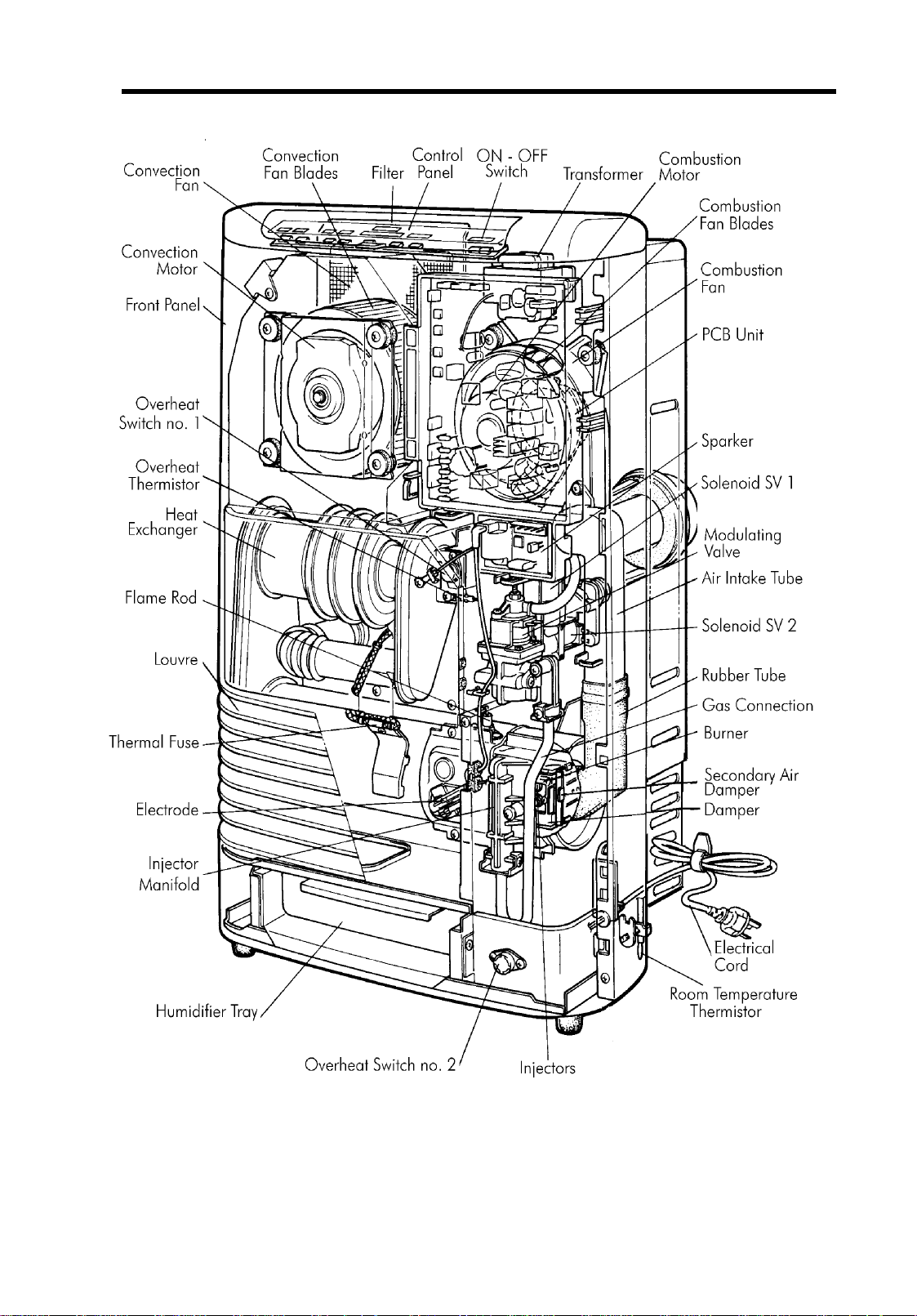

5. Installation

NOTE:

refer to the installation instru ctions in the custome r’s operating instructions.

The informa tion provided he re is on ly a guide. F or full det ails on installa tion proc edures, please

This heater is not designed to be built in. The flue may be positioned directly under opening

windows, with a minimum clearance of 150 mm.

The flue is not designed to be positioned unde

floors or below the level of the heater.

Flue fittings must be kept clear of flammabl

materials.

The flue terminal should be positioned away from

flammable materials.

In areas subject to heavy snowfall, keep snow

clear of flue termin al at all times.

-

-

-

i

i

Page 11

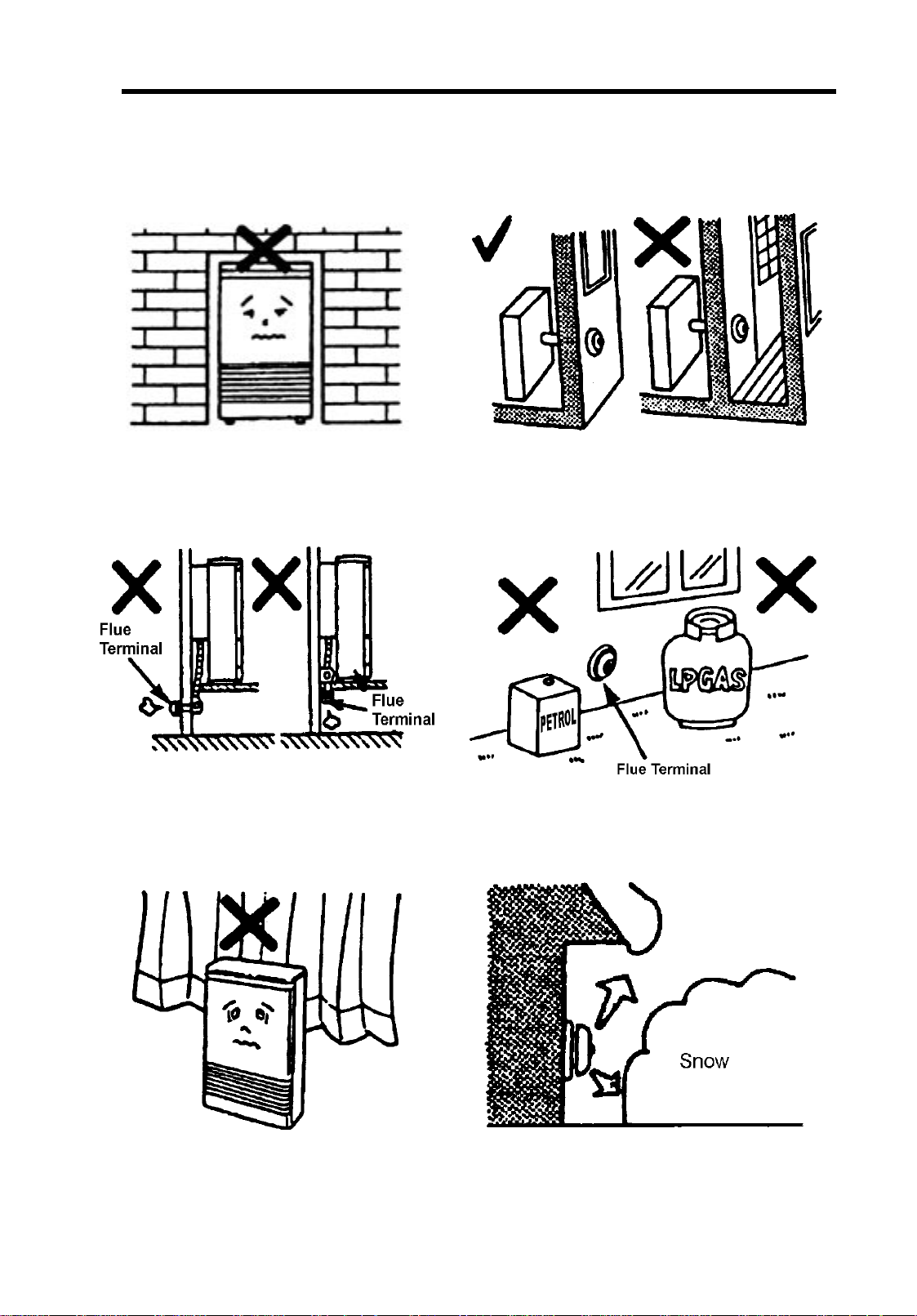

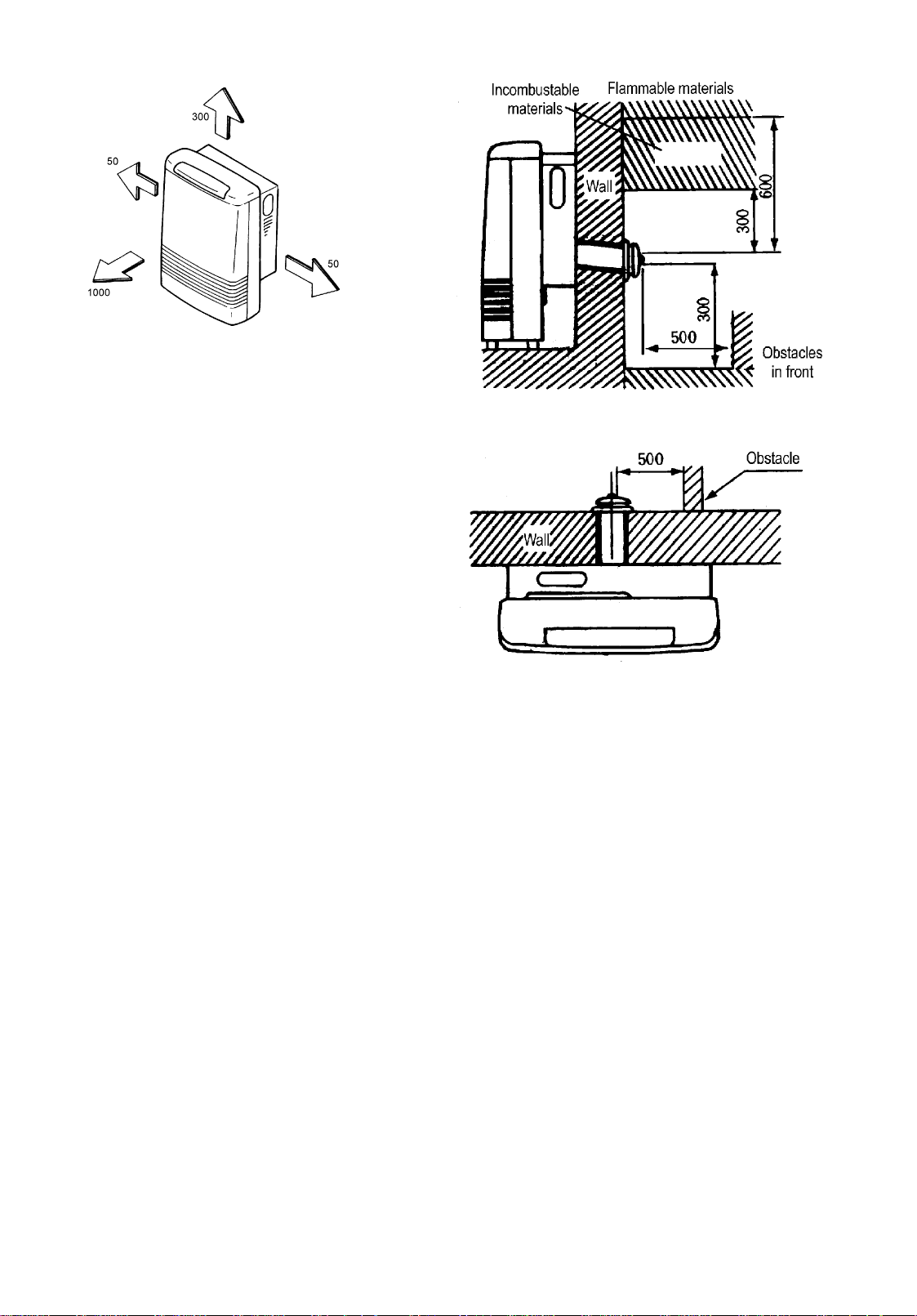

Recomme nded mi nimu m cle ara nce s an d dist anc es from obs truc tions.

-

-

-

i

i

Page 12

6. Performance Characteristics

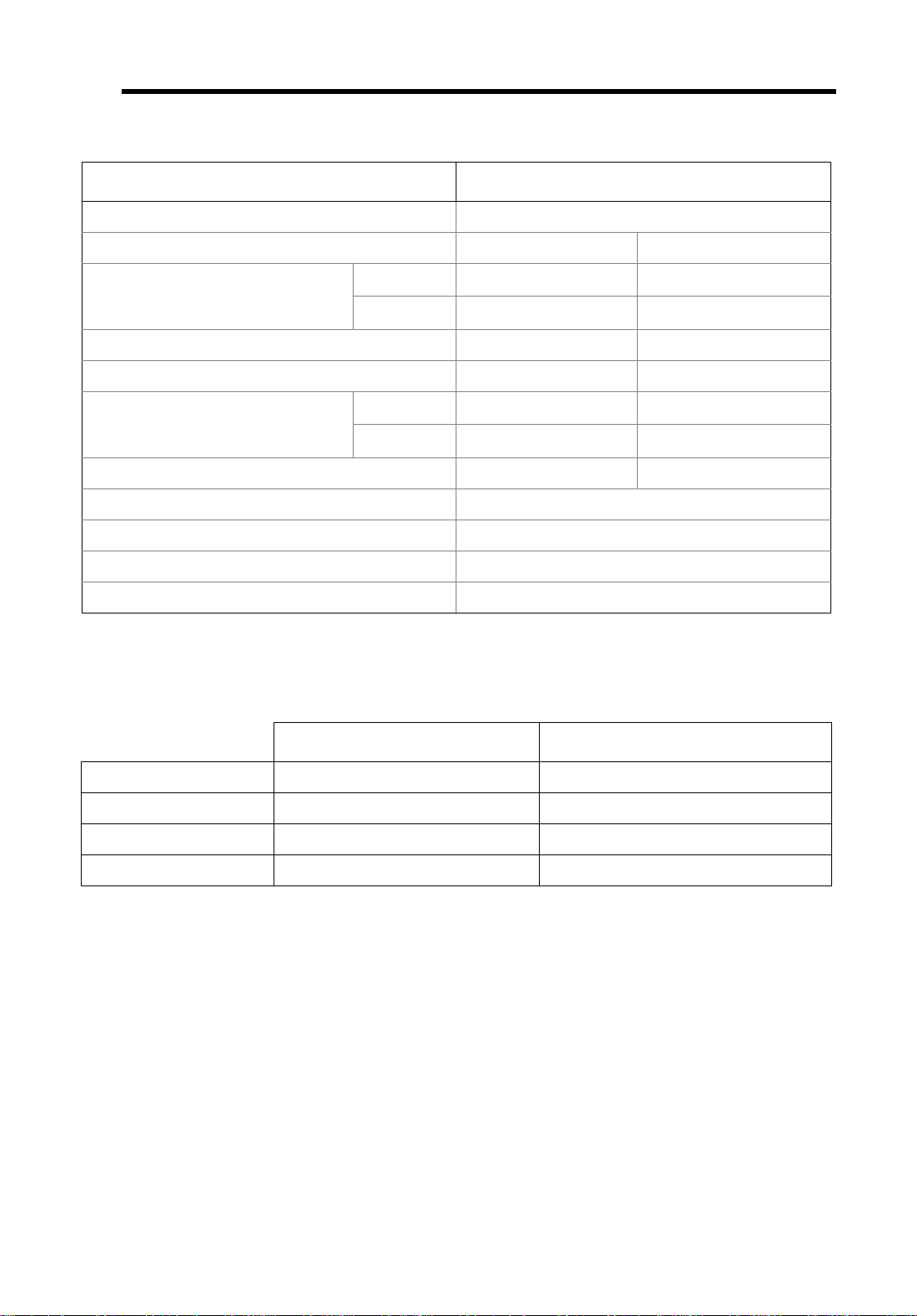

1. Basic Combustion Specification

Item Specification

Rinnai model number RHFE-308 FTR

Gas typ NG Propane/LPG

Gas consumption MJ/h

Injector size (∅ mm) 1.30 0.90

Injector quantity 2 2

Regulator pressure (kPa)

Burner marking P P

Combustion method Bunsen burner

Burner type Stainless slit style

Solenoid valve Direct s i n g le seated valve type

Modulating solenoid valve Direct single seated valve type

HI

LO

HI

LO

13 13

55

0.60 1.04

0.12 0.19

2. Combustion Fan Speeds (rpm)

Natural Propane/LPG

Ignition 1710 1560

Re-ignition 1800 1680

Normal - High 3000 3090

Normal - Low 1440 1440

-

-

-

i

i

Page 13

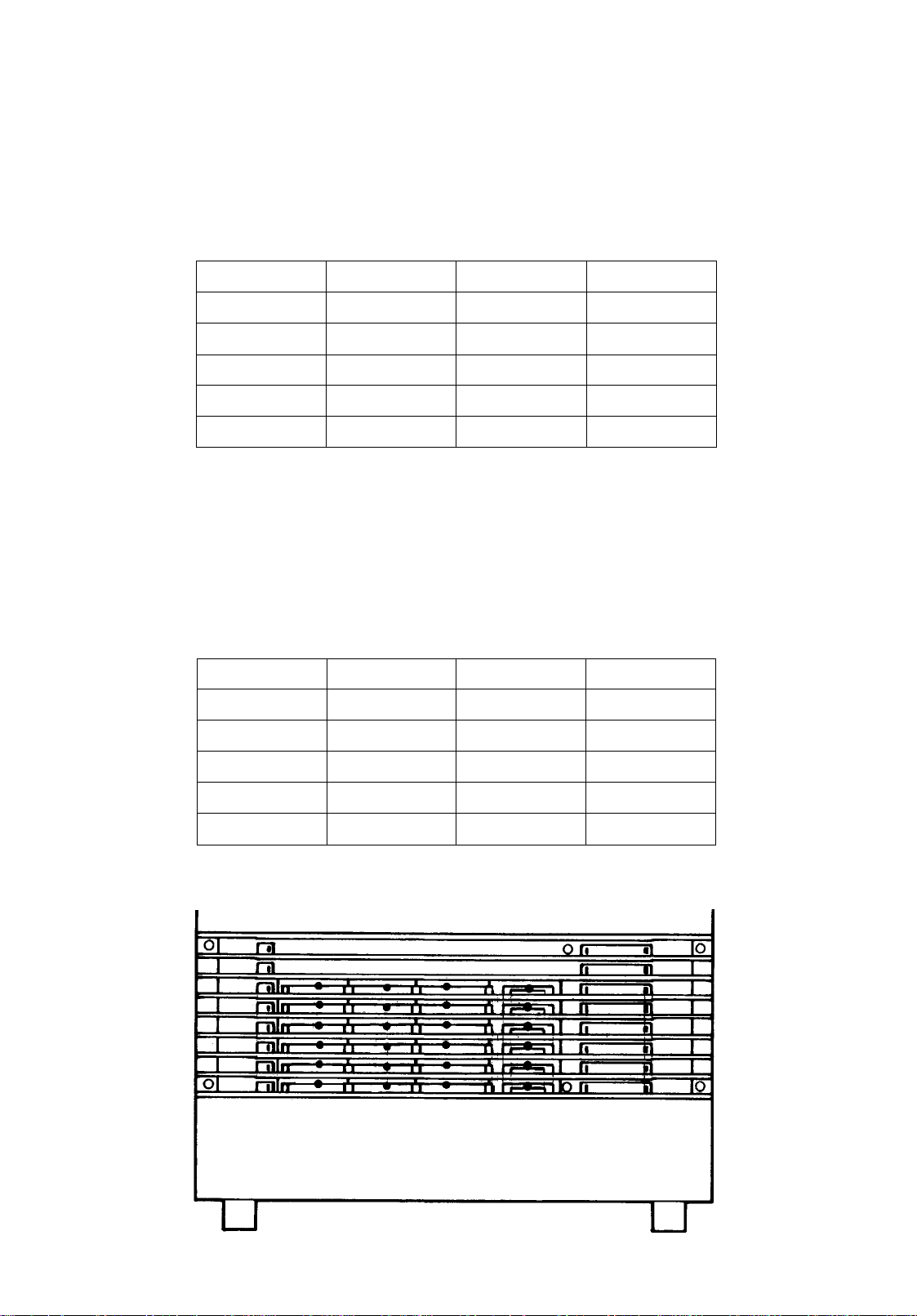

3. Warm Ai r Discha rge Temperature Di stribution

Condition: < High Combustion >

Test gas: Natural

Measured input: 12.55 MJ/h

Nominal input: 13 MJ/h

Room temperature: 25oC

(Unit

24 24 55 9

45 72 64 18

56 81 83 36

62 66 77 42

68 43 70 45

42 39 57 45

Condition: < Low Combustion >

o

∆

C)

Test gas: Natural

Measured input: 5.27 MJ/h

Nominal input: 5 MJ/h

Room temperature: 25oC

10 17 30 9

23 39 38 13

29 48 42 28

35 44 46 37

37 28 43 34

22 26 31 28

4. Measurement Points

(Unit

o

∆

C)

-

-

-

i

i

Page 14

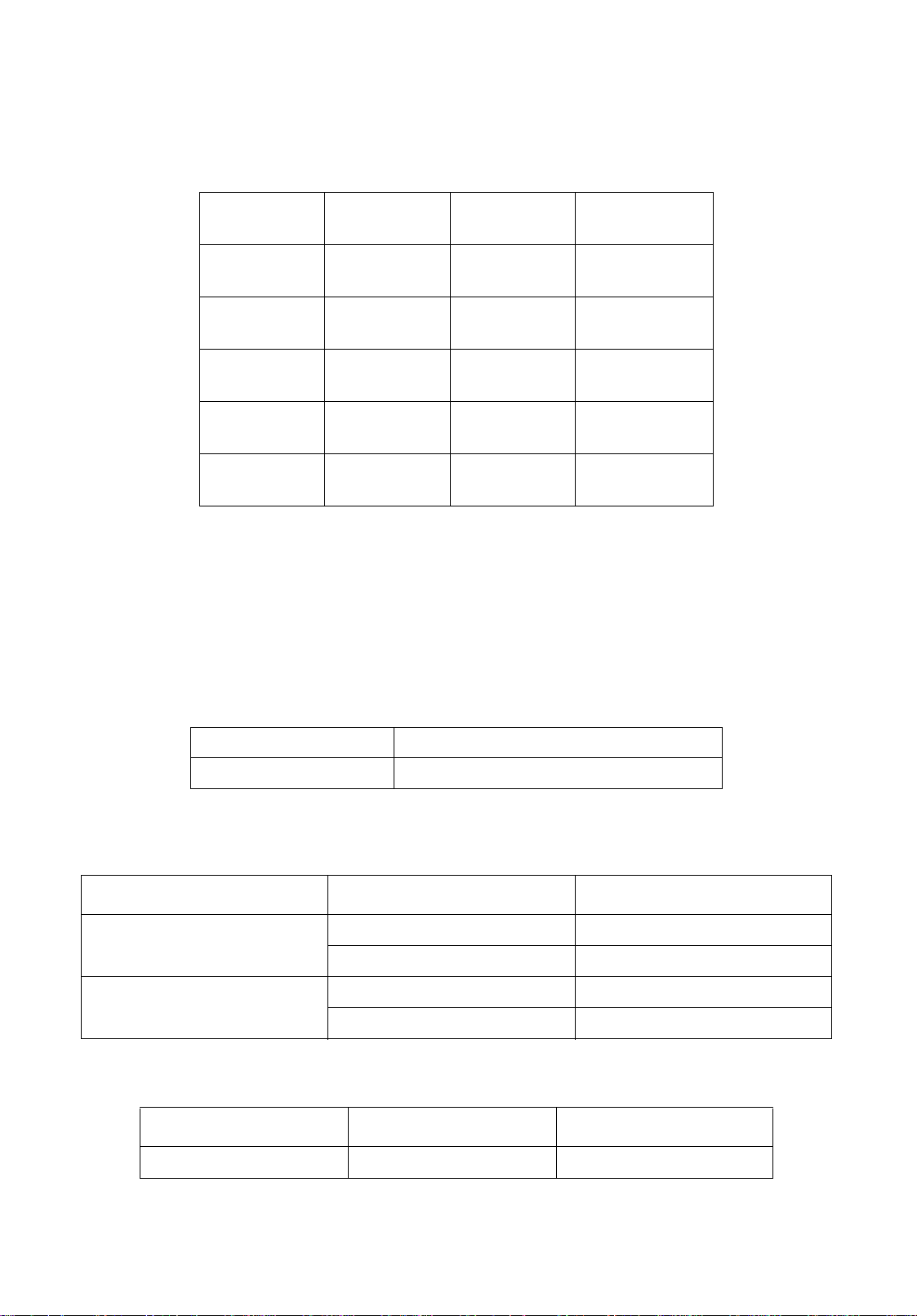

5. Warm Air Discharge Velocity

Convection Fan rpm HIGH: 740

LOW: 550

Room Temperature: 22oC

(Unit: m/sec)

1.62

1.46

1.99

1.78

3.20

2.61

3.35

2.66

3.27

2.47

3.13

2.37

2.57

1.32

2.57

1.92

3.54

2.53

3.44

2.60

3.37

2.52

2.11

1.23

1.70

1.34

2.89

2.15

3.12

2.44

3.14

2.28

3.33

2.62

3.33

2.54

Air Flow: Average air velocity on High: 2.784 m/sec

Average air velocity on Low: 2.10 m/sec

Air flow rate on High: 3.82 m3/min

Air flow rate on Low: 2.89 m3/min

Air flow outlet area: 0.0229 m

2

6. Noise Level

1.08

0.84

2.12

1.58

2.51

1.91

2.75

2.08

3.32

2.46

3.42

2.58

Unit: dB(A).

High 36.5

Low 31.5

7. Th ermal Eff iciency

Conditions: Horizontal mushroom flue with unit installed with back spacers.

Gas Type Combustion Thermal Efficiency (%)

Natural

High 81.3

Low 84.8

High 83.5

Propane

Low 88.1

8. Humidifier Capacity

Method Tray Capacity Evaporation

Evaporation 0.8 Litres 0.1 Litres/hour

Note: Evaporation rate varies depending on conditions of use.

Conditions: Standard setting: High combustion

Measurement Method: According to JIS (Japanese Industrial Standard)

-

-

-

i

i

Page 15

7. Schematic Diagram

-

-

-

i

i

Page 16

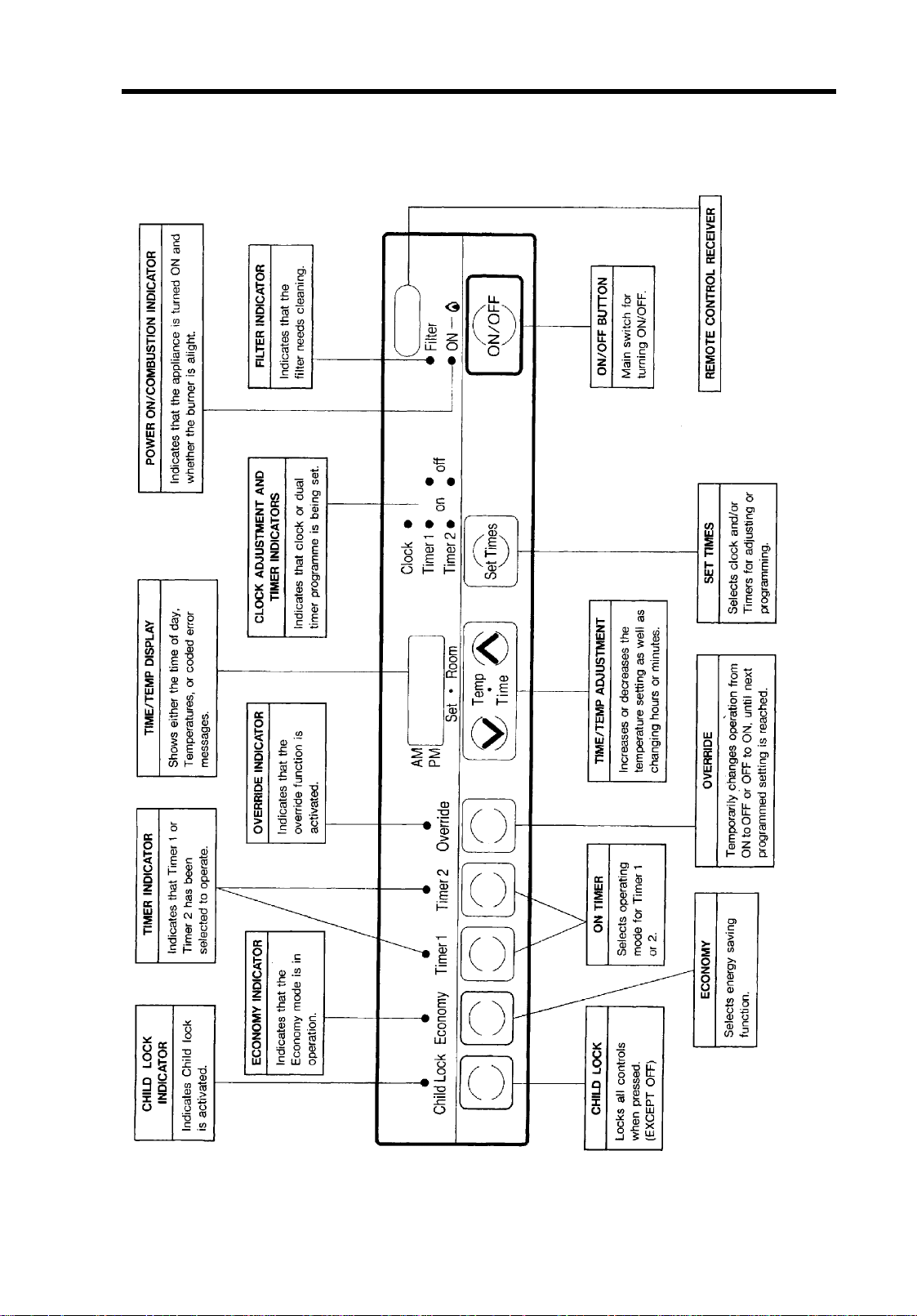

8. Control Panel Layout

* Refer to “Appendix” on page 59 for explanation on setting clock and programming timers.

-

-

-

i

i

Page 17

9. Operating Principles

1. Normal Operation

Push the ON/O FF Button to operate the a ppliance. T h e Po wer ON/Combustio n Ind i c a t or will glow green.

The comb ust ion fan will run o n high until p re-purge is completed.

Pre-purge is completed after approximately 15 seconds, following which, the c ombustion fan will decrease

revolutions to enable ignition to occur. After the combustion fan reaches a pre-determined speed,

(depend ing on gas type) the electrode pr od u c e s the sp a r k to begin t he i gnition cycle.

After the spark i s sen sed as having crosse d the spark gap by t he PCB, the solenoids (SV

as the modulati ng valve will open and allow ga s to flow to the burner.

The flame rod senses the flame on the main burner. After the flame is sensed, the Power ON/Combustion

Indica tor chang es to red and the spark stops. After an additional 15 secon ds the convect ion fan begins to

operate.

The room temperature is se nsed by the temperature thermistor located at the rear of the appliance. The

printed c ircuit b oard cont rols th e air/gas ratio to the optimu m level according t o the select ed temperature.

The combustion fan is adjusted in conjunction with the opening degree of the modulating valve. The

convection fan is adjusted in the same manner.

& SV2) as well

1

2. Thermostat Control

The selected and room tem peratures are display ed on th e Time/Temp Display. T ime and temperature are

displayed alternately depending whether the heater is running or not. The selected temperature is altered by

pressing the Time/Temperature Adjustment buttons.

3. Turnin g Off

Simply press the ON/OFF Button. The solenoids, together with the modulating valve will close. The

combus tion f an will also sto p, and all indi cat ors will go out. After the burner ex t i n gu is h es, the convection

fan will c ontinue to run for up to 210 seconds, ensur in g the appliance is cool.

4. Economy Mode

To enga ge t he economy funct io n press the Economy b u tt on while the heater is operational. The Economy

Indicator will glow. Once the selected temperature has been reached, the economy function is designed to

drop this temperature by a total of 2oC over a period of one hour. Aft er 3 0 min u te s t he tem p eratu re will be

reduced by 1oC. After a further 30 minutes the temperature will be reduced by another 1oC. This does not

result in a loss to th e heatin g effect ivene ss , and is an e nergy s avi ng feat ure. Y ou may press the Economy

button again at any time, to cancel the economy function.

5. Child Lock

To act iv ate th e chi ld lock press the Child Lock b ut t on. The Lock Indic a tor will glow.

If the child lock is activated during normal operation, then no functions other than the ON/OFF Button will

be operable until the lock is released.

If the child loc k is activated whi lst the appliance is OFF, then the complete range of functions will be

locked.

-

-

-

i

i

Page 18

6. Fi lter Indicator

When the air filter becomes covered in dust and the temperature inside the appliance rises, the Filter

Indicator will glow.

7. Fu zzy Logic

a. The Purpose of Auto Comfort [Fuzzy Logic]

The main aim of the Auto Comfort function is to heat a room by controlling the flow of the warm air coming

from the heater. This increases heating efficiency as well as improving control over the flow of warm air

being disch ar ged by th e app liance.

In order to achie ve comfortable heating, it is preferable to avoid cold d ra fts o r draughts from the appliance.

Also, for incre as ed efficien c y i t is import ant to redu ce ove r h e ati ng i n the room an d concen trate heating in

the area where people are most oft en situated.

Fuzzy Logic is us ed i n order to ac h ie ve the followi ng impro ve d h eati ng pattern.

Standard Control

'Room temper ature' and 'the time elapsed since the start of combustion’ are the basis for fuzzy logic. Th

means of contro l is t he s pe ed of the convection fan and modulation of gas combustion.

Fuzzy Co ntrol

b. Fuzzy Logic Summarised

In the case of a conventional fan heater, the convection fan operates normally from the time of ignition, and

a cold draught may accompa ny the flow of air from the appliance. To solve thi s problem, fuzzy logic

controls the speed of the convection fan after taking into consideration the room t emperature at the time of

ignition. For example, in the case of t he room temperature being low, the fan is made to rotate at a low

speed, raising the dis charge air temper ature. As the room temperature rises, the speed of the convection

fan is g radua lly incre as ed. In this way i t is possible to e nsure a comforta ble volume of warmed a ir whilst

decreas ing the possibility o f cold draughts immedi ate ly after ignition.

The fan s p eed incre as es proportiona l ly as time passes and the room gradu a lly he a t s u p. This improves the

warm air distribution, assisting in a reduction of stratification throughout the room and resulting in more

effective heating conditions. The PCB then continually monitors the room temperature, and adjusts the fan

speed according t o t he conditions at the time.

8. Clock and Timer Setting and Operation

Refer to “Appendix” on pa ge59 of this manual.

9. Intelli gent Timer [Pre Heat]

This func tion en a bl e s th e room to be heate d t o the pr e- se t temper a tur e pr ior t o the time pro grammed in the

On Timer. See Intelligent Timer [Pre-heat]” on pa ge14 for more information.

-

-

-

i

i

Page 19

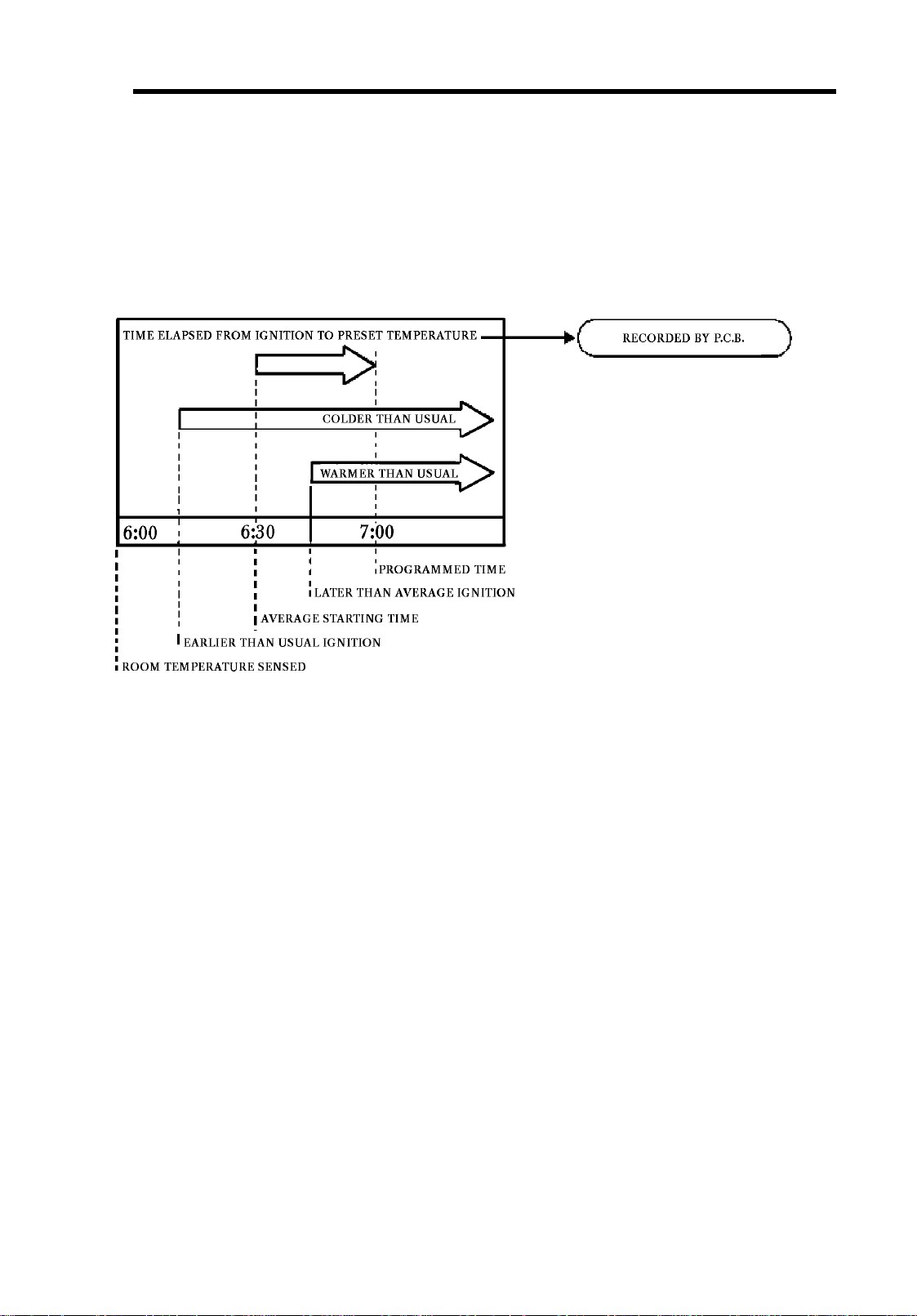

10. Intelligent Timer [Pre-heat]

The Intelligent 2-way 24-hour programmed dual digital Timer [Pre-Heat] function operates in

conjunction with either “On-Timer”. It enables the pre-set temperature to be reached by the time

programmed by starting ignition up to an hour before the time programmed to start heating.

The actual ignition time is calculated using the difference between the room temperature and set

temperature and the warming-up time which elapsed the last time the appliance was used. The

maximum time ignition will precede the pre-set time is 1 hour. The following chart illustrates how

the intelligent timer operates.

The two timers can be programmed and used individually, or sequentially. Timer operation, once

set, will remain on stand-by for the next day after the final OFF sequence, unless ON/OFF switch is

pressed.

-

-

-

Page 20

11. Safety Devices

Flame rod sensor

Senses main burner ignition an d s huts off the solenoid v al ves when the flame cu r r ent drops below 0.1 µA.

Spark sensing circuit

Senses the location of spark a nd opens the solenoid v alve s only whe n the spark locat ion is confirmed as

correct.

Pre-purge circuit

Purges heat exchanger and flue prior to spark commencing.

Combustion fan rpm s ensing circuit

Senses the operation of the combustion fan and maintains a pre-determined rotation speed.

Overheat protecti on switches

Shuts of f th e so len o i d valves and cut off gas supply in the case of over heating.

i) Bimetal OHS1

Operates at 130 ± 5°C

Recovery at 115 ± 7°C

ii) Bimetal OHS2

Operates at 90 ± 5°C

Recovery at 75 ± 7°C

iii) Thermal Fuse

Cuts o u t at 21 6 ± 2°C (one shot)

iv) Thermistor

Operates at 130 ~ 90

o

C (High ~ Low).

Fan delay

The convection fan starts after a short delay to avoid cold draughts, and keeps running after burner

extinction to allow the uni t to cool down.

ON AT 15 sec, after ignition commences

OFF AT max. 210 sec, after combustion

Power failure circuit

Shuts off the solenoid valves if a power p ower failure occurs. The unit will relight afte r the power is

restored , and t he c lo c k t i m e will be slow by the amount of tim e the p o we r was off.

Thermistor Type Temperature Control

Controls r oom temperatur e wit h i n the ran ge of 16~26oC in 1oC steps.

-

-

-

i

i

Page 21

10.Overheat Control Method

The overheat thermistor activates the overheat sensor and the filter indicator, as well as increasing the fan

rpm.

(A) Overheat Sensor

The overh ea t thermistor act iv ates at different temperatures for dif f eren t g as r ates ( c omb ustion).

(B) Filter Indicator

Note 1: Once the over h eat li mit t emp eratur e has been se nsed and the f ilter in dic ato r be gins f lash ing, it

will not go o ut , even if th e temperature falls b elow t he limit.

Note 2: Once the filter indicator begins flashing, gas input is limited to roughly 88% of high combustion.

-

-

-

i

i

Page 22

(C) Convection Fan RPM Increas

The fan rpm increas es t o compen sa te for a redu ction in a ir flow due to a clogged air filt er or other causes.

The convection fan rpm is normally determined by combustion level. The speed increases by

approxim at e ly 100 rpm at High.

-

-

-

i

i

Page 23

12. Operation Flow Char t

p

ON/Comb

O.H

R

C

)

)

)

)

(

)

(

(

ON/Comb

1

Turn ON/OFF switch ON

A

i

Room temp. displayed

2

3

4

6

Combustion Fan HI ON

Connect power cord

ower ON

and turn

EProm trans-

mission Normal

Yes

ustion

i

SV circuit

Normal

Yes

OHS & TF

Normal

Yes

Thermistor

Yes

oom

Temp.Thermistor

Yes

Flame rod

current below

A

0.1

Yes

No

a

No

No

After 2 Sec from a

No

(After 2 Sec from a)

No

(After 20 Sec from a)

No

Problem eliminated

73

ON/Combustion

71

ON/Combustion

indicator flashes red

14

Filter indicator flashes

ON/Combustion

indicator flashes red

33 (open circuit

34 (short circuit

ON/Combustion

indicator flashes red

33 (open circuit

34 (short circuit

ON/Combustion

indicator flashes red

72

ON/Combustion

indicator flashes red

Problem eliminated

All indicators OFF

Turn ON/OFF

switch OFF

Combustion

15

Fan >1710

Combustion Fan LOW

Flame rod

current below

6

Combustion

9

fan > ignition +

Sparker activates

10

Spark sensing

Solenoid SV1 Opens

11

Solenoid SV2 Opens

12

Mod. Valve half opens

Flame sensed

6

above >1

ON/Combustion

indicator flashes red

Sparker OFF

Combust'n fan (med) ON

0.1A

60 rpm

Normal

(After 15 Sec)

No

rpm

Yes

Yes

Yes

No

No

No

(After 10 Sec)

After 20 Sec)

(After 30 Sec)

After 2 Sec)

Combustion Fan OFF

Combustion Fan OFF

Combustion Fan OFF

Combustion Fan OFF

Sparker OFF

Yes

61

ON/Combustion

indicator flashes red

72

ON/Combustion

indicator flashes red

61

ON/Combustion

indicator flashes red

53

ustion

indicator flashes red

b

Solenoids SV1, 2 close

No

No

c

A

Yes

15 sec after b

Yes

Spark sensor

Normal

Yes

Solenoids SV1, 2 close

No

(After 1 sec)

11

ON/Combustion

indicator flashes red

53

ON/Combustion

-

-

-

Page 24

C

(POV) C

O

O

(

)

p.

(

)

(

)

(

)

N

Modulating Valve HI

g

(

)

g

No.

30

C

No.

90C

Combustion Fan HI

Convection Fan HI

Temp. control begins

Convection Fan ON

14

4

OH Thermistor

Temp. normal

Filter indicator

flashes red

Room temp.

within 2C of

set tem

Modulating Control

POV

Modulating Control

Combustion Fan

Modulating Control

Convection Fan

Safety Devices

Operate

Less than 255 sec

o

Yes

12

ON/Combustion

Power reinstated

Operation stops

Power failure

Less than

5 times

Combustion

rate < medium

90 secs>ignition

Flame Senser

Device Operates

Convection Fan

FF

Convection Fan

MED OFF

Combustion Fan

FF

Solenoid Valve

Modulating Valve

losed

> 90 Sec

from c

Room temp >

Set temp by over

4

4

1C

Temperature Control OFF

Solenoids SV1, 2 OFF

Modulating Valve Closed

Combustion Fan OFF

ON/Combustion

indictor

Convection Fan

MED ON

Convection Fan OFF

Room temp

> Set temp

reen

Room temp.>40C

4

for over 10 mins

ON/Combustion

indicator flashes red

d

Less than 60 sec

4

16

Room >Set temp

within 2C

16

2

Yes

O.H. Thermistor

Overheat Switch

Overheat Switch

Thermal Fuse melts

ON/Combustion

indicator flashes red

within ran

1 > 1

2 >

14

Filter indicator

flashes red

e

ON/OFF SW failure

1

ON/Combustion

indicator flashes red

Combustion Motor

rpm abnormal

70

61

ON/Combustion

10 mins after d

-

-

-

Page 25

OFF

(

)

ECONOMY

TIMER OPERATION

ON/OFF Switch OFF

Temperature

Control ON

Yes

Solenoids SV1,2 OFF

Modulating Valve OFF

Combustion Fan OFF

Convection Fan MED

Operation/Combustion

Indicator OFF

Change from Room

& Set Temp to clock

All Indicators OFF

Convection Fan

No

Less than 255 sec

Economy Switch ON

Economy Indicator ON

Room Temperature

drops max. 2C

Economy Switch OFF

Economy Indicator OFF

Temperature Control

Operates

ON/OFF Switch ON

Timer Switch ON

Timer Indicator ON

Pre-Heat set

up Time

Yes

Timer indicator flashes

Normal operation start

Set-up Time

Yes

Normal Operation Stops

No

No

-

-

-

Page 26

13. Diagnostic Points

* “Flow” denotes references on the “Operation Flow Chart” on page 18.

* “CN” denotes connector number on the “Wiring Diagram” on page 22.

Flow CN Component Wire Colour Value (Normal)

1 I ON-OFF Switch red - blue

blue - blue

H Overheat Circuit white - black

H1 Overheat SW 1 white - red

H2 Overheat S W 2 red - black

2

H3 Thermal Fuse white - white

3 A Overheat

Thermistor

4 A Room Temp.

Thermistor

6 E1 Flame Rod yellow-yellow < DC 0.1 µA

7 G Combustion Fan red -black

9 G Combustion Fan

white - white

temperature

yellow-yell ow

temperature

white - black DC 1 ~ 4 V; > 3420 pulse/min (> 57 Hz

black - whi te below ignitio n revolution + 120 rpm

initial ignition LP: 3480, NG: 3600 pulse/min

0.6 ~ 523 k

20°C: 78 k

1.8 ~ 844 k

DC 3 ~ 10 V, resistance 1

(current flows when switched on)

Less than DC 1 V; < 4

< DC 1 V

(current flows)

< 1

Ω

( < 0.6 kΩ: short, >523 kΩ: open

Ω

, 100°C: 3.6 kΩ, 150°C: 1.1 k

Ω

( < 1.8 kΩ: short, >844 kΩ: open

Ω

0°C: 123 k

, 20°C: 39 kΩ, 40°C: 14 k

Ω

DC 7 ~ 40 V; > 10 M

Ω

Ω

(current flows)

Ω

Ω

Ω

re-ignition LP: 3720, NG: 3780 pulse/min

10 F Sparker blue-red AC 85 ~ 110 V

11 F Solenoids 1 & 2 black - yellow

12 H Modulating Valv grey - grey

Over-heat

14 A

15 G

16 A

17 D Convection Fan grey - pink

Thermistor

Combustion

Fan

Over-heat

Thermistor

white - white

(filter

indicator

white - black

(normal rpm)

white - white

(OHS on)

high

low

high LP: 5760, NG: 5700 pulse/min

low LP: 3000, NG: 3240 pulse/min

high

low

DC 78 ~ 100 V, 1.3 ~ 2.2 k

DC 1 ~ 15 V (low ~ high) 8 0 ~ 100

flashes below 50 Hz; 2.2 k

flashes below 8.6 k

operates belo 1.7 k

operates below 5.3 k

AC 50 ~ 108 V (low ~ high ) , 9 0 ~ 180

Transformer Values

Wiring Diagram Australia [240 V] New Zealand [230 V]

Yellow - Blue

AC 130 ~ 180 V; 200 ~ 400

Ω

AC 130 ~ 180 V; 200 ~ 400

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

E

B Grey - Grey AC 216 ~ 264 AC 207 ~ 253 V

Blue - Black

Red - Red

-

AC 10 ~ 16 V; 1 ~ 3

AC 25 ~ 50 V; 1 ~ 3

-

Ω

Ω

-

AC 10 ~ 16 V; 1 ~ 3

AC 25 ~ 50 V; 1 ~ 3

Ω

Ω

i

i

Page 27

14. Wiring Diagram

-

-

-

Page 28

15. Block Diagram

-

-

-

Page 29

16. Time Charts

-

-

-

Page 30

-

-

-

Page 31

-

-

-

Page 32

17. E2 PROM

Memory Function for Error History, Estimated Combustion Time, and Estimated Number of Operations

E2 PROM (Electrically Eraseable and Programmable Read Only Memory) is a ROM in which data

is electronically programmed or erased. Programmed data will be stored semi-permanently even if

the power fails or is disconnected.

The most recent data on the past nine errors, estimated combustion time and estimated number of

operations are included in the information stored in E

2

PROM.

• How to Read the Data

Confirm the unit is off, press “/\”, “\/” and “Economy” buttons at the same time for at

least 2.5 seconds (a beep will be heard once). The data will be displayed on the LED display in the following order: Error Messages, Estimated Combustion Time, Estimated

Number of Operations.

• Data Display

The most recent error message (No. 1) will be displayed first, then it will be followed by

up to eight previous errors (No. 2~9) displayed for 2 seconds each, as shown below. Following this, Estimated Combustion Time and Estimated Number of Operations data will

be displayed for 4 seconds each as in the example below (No error messages “-- . --” will

be displayed if no errors were recorded).

Estimated Combustion Time will be displayed as below if between 0 ~ 9,999 hours. However, if it

is more than 10,000 hours, then “H” is added to the beginning of the display. Hours will be rounded

up to the nearest 100 as shown below.

9999 hours 10000~10099 hours 10100~10199 hours

Estimated Number of Operations will be displayed as below (1=10 times) if between 10 ~ 99,999

times. However, if it is more than 100,000 times, then “H” is added to the beginning of the display.

Operations will be rounded up to the nearest 1000.

99990~99999 times 100000~100999 times 101000~101999 times

*

Note:

Estimated Number of Operations is the number of ON-OFF movements on the solenoid

valve.

-

-

-

Page 33

• Deleting Data from E2 PROM

Confirm the unit is turned off, and press “/\”, “\/”, “Economy” and “Lock” buttons at

the same time for at least 1 second. (Lock beep will be heard once and another beep wil

be heard a second later).

Digital display turns off and displays “- - : - -” when the data is deleted completely. However, the data on Estimated Combustion Time and Estimated Number of Operations

cannot be deleted.

Once recorded in E2 PROM, the data is protected from power failures.

Permanent Data Deletable Data** (initial settings)

• Modulating Valve Supplement

Current Value (HIGH)

• Modulating Valve Supplement

Current Value (LOW)

• Convection Fan Supplement

Current Value (HIGH)

• Convection Fan Supplement

Current Value (LOW)

• Estimated Combustion Time

• Estimated Number of Operations

This data can be deleted as described above.

**

• Error History (none)

• Clock (12:00 am)

• Economy Operation (OFF)

•Lock (OFF)

• Preset Room Temperature (22oC)

• ON Timer (06:00 am)

-

-

-

Page 34

18. Error Coded Messages

Error is displayed as a number on clock flashing. (Filter indicator will also flash in the case of overheat.)

Error Code Probable Cause Comments Ref †

--:--

11

12

14

16

31

32

33

34

Power failure When power failure is sensed operation

stops.

Miss ignition Flame current does not reach 0.1µA within

the given time, after solenoid valve opens.

Flame failure Flame rod current remains below 0.1 µA for

3 seconds during initial combustion.

Over heat safety

device

Over temperature

cut off

Room temperature

thermistor

disconnection

Room temperature

thermistor short circuit

High-limit thermistor

disconnection

High-limit thermistor

short circuit

High-limit temperature thermistor or

thermal fuse has activated.

Room temperature is sensed as being above

o

C for longer than 10 minutes.

40

Room temperature thermistor open circuit 4

Room temperature thermistor wire trapped,

touching bare metal

High limit thermistor open circuit for over 2

seconds

High limit thermistor short for over 2

seconds

-

6

6

2

4

4

3

3

Sparker not OFF within 20 seconds at time

of ignition

53

61

70

71

72

73

† Refers to the number on the operational flow chart, page 18, and diagnostic points, page 21.

Abnormal spark

sensed

Abnormal combustion

fan motor rpm

ON/OFF switch

failure

Solenoid valve check Solenoid valve(s) (SV1, SV2) signal and

Flame rod failure Flame rod current should not go below

Communication

failure

1st spark sensed not within 2 seconds

2nd spark sensed spark not continuous for 1

second after solenoid valve opens

Speed is not achieved within time or goes

over speed level

ON/OFF switch on continuously for more

than 15 seconds

response signal are different.

0.1µA within 20 seconds of starting.

2

Data transfer between CPU and E

fails.

PROM

-

15

1

11

6

-

* To reset error codes, press the ON switch while the error code is showing. This will not reset error codes “71"

and “73"; power needs to be reset to erase these codes.

-

-

-

Page 35

19. Fault Finding

Main Faults and their Remedies

* Numbers on the right hand side of this table refer to “Causes of Faults and Suggested Remedies” on pa ge31.

Fault Sym ptom Error Codes Check Points / Remedy

The Economy

indicator will not

come ON.

After having

pressed the ON OFF switch the

appliance will not

operate.

Insufficient he a ting. * Check s el ected roo m temperatur e setting

Burner goes out

during operation.

11

12

14

16

* Confirm t ha t Economy M o de has been selected

* Confirm e l ectr ical co rd is s ecur el y in to the power point

* Check ga s s upply

* Confirm no gas escapes

* Check for air in the gas supply

* Reconfir m ga s t yp e specified

* Check for blocked air filter

* Check fo r an obstructi o n i n the warm air flow

* Reconfir m ga s pressure at appliance

* Ensure flue terminal is not blocked

* Ensur e air filter is not b lo cked

* Power Failure

* Check fo r an obstructi o n i n the warm air flow

* Reconfirm gas type specified

* Confirm no gas escapes

* Check for flash back

* Check for high room temperature

* Reconfirm electrical supply at power point

. . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . 1

. . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . 7

. . . . . . . . 2

. . . . 4

. . . . 4

. . . . . . 8

Gas odour. * Confirm no gas escapes (at connection)

* Product of combustion leak

Power failure.

† Error is displayed as roo m tempe ratu r e LEDs flashing

-

--:--

* Power failure ( > 0.2 seconds

. . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . 8

-

-

i

i

Page 36

Causes of Faults and Suggested Remedies

1. Gas supply

In cases of miss ignition, insufficient heating and gas

smell, ch eck that:

• The gas supply pressure is correct.

• The specified gas type is correct for the area.

• There are no breaks/escapes in gas supply.

• There is no air in the gas supply .

⇒

Check the gas pressure at both the meter and the

appliance.

⇒

Air in the gas line will prevent the appliance from

igniting.

2. Thermostat sett ing

When the room does not reach the selected temperature, or

the appliance will not remain alight, check that:

• The selected temperature is not set lower than the

room temperature.

⇒

Select the required temperature setting with the UP/

DOWN se l ec tion buttons.

3. Blocked air filter

If insufficient hea ting or l ockout occurs, ch eck that:

• The air filter is not blocked with dust.

⇒

If the air filter is blocked, the safety device will operate.

..... 14 flashing

⇒

The filter must be cleaned at least once pe r month.

4. Air flow obstruction

If insufficient hea ting or l ockout occur red, check that:

• There are no obstacles in front of the appliance or

louvres.

..... 14 flashing

⇒

There should be no articles within one (1) metre of the

front of the appliance.

5. Flue termi nal

If flame failure occurs during normal operation, check

that:

• The flue terminal on the exterior wall is not

obstructed in any way.

..... 12 flashing

⇒

Check in particu lar for shrubs growing over the flue

terminal or a thick build up of spider webs.

6. Flash back protection

If flame failure occurs during normal operation, check:

• The flue terminal air intake is not blocked.

• For dust or foreign material on the burner.

• Combustion specification and gas type.

..... 12 flashing

7. Room temperature

• Is the room temperature unusually high?

⇒

10 minutes after having sensed 40°C the appliance will

automatically go out.

..... 16 flashing

8. Power failure

• If there has been a power failure for 0.2 seconds

or longer. Current time will be displayed on display when “set times” button is pressed once.

(Time will be slow by duration of power failure).

..... -- :-- flashing

9. Smell of products of combustion

If there is a smell of gas or products of combustion, check

that:

• The flue manifold behind appliance has not come

undone.

⇒

The pro duc ts of co mb ustio n a re leav ing t h e a ppliance

through the flue terminal.

-

-

-

i

i

Page 37

Before conta cting Rinna i, please c h eck the following p oi nt s . T hese p oints are part of the nor ma l ope ration of the unit.

At Ignition

Is the heater plugged in? Is there a power failure?

Have the fuse or breaker blown at the switchboard?

Heater does not o pera t e.

Warm air does not flow when the burner lights. The fan is started automatically after a short delay.

Are the air filter, flue, or warm air outlet blocked?

Are Timers set? Clear Timers and operate again.

Is the central timer on? (where fitted)

This is to allow the heat exchanger to warm up.

Smoke or strange smells are produced on the first trial

light u p after in stallation.

Sharp clickin g noises at ign it ion , o r wh en the unit cuts

down on the thermostat, or goes out.

This is caused by grease or oil and dust on the heat

exchanger a nd will s top af te r a short time.

This is simply expansion noise from the heat exchanger.

During Combustion

Clunking noise when the therm ostat operates. This is the sound of th e solenoid gas valves.

Is the air filter or warm air outlet blocked?

Unit is not heating room?

Air filter or louvres are blocked or obstructed. Allow heater to cool, clean air filter, ope rate again.

Heater will not reignite after overheating. Heater does not reignite. Repair is necessary.

Is the set temperature high enough?

Are the doors and windows of the room closed?

When the Unit is Turned Off

Convection fan cont inues to r un after tu rning off. This is to remove the residual heat f ro m the heat exchanger,

the fan will stop when the heater cools down.

Other Points

Steam is discha rged from the flue terminal. High efficiency appliances tend to discha rge water vapo ur

on cold days, this is normal.

Check is central timer is switched off (where fitted), or

Unit cuts off without apparent reason.

Power failure.

Remote control does not operate. Check battery. Try moving closer to the heater.

-

-

whether filters are blocked, (dirty filters will cause the

heater to overheat).

When power is restored, the appliance will begin to heat if it

was on at the time of power failure. Clock will be delayed by

the length of the power failure.

-

i

i

Page 38

20. Fault Analysis

After having operated the appliance and:

A.

i) The combustion fan doesn’t begin to rotate, or suddenly stops after running for a short time.

ii) There is no spark (after 30 seconds).

iii) The solenoids do not open, preventing gas flow to the burners.

iv) The convection fan does not begin to rotate, approximately 15 seconds after ignition.

Is there electrical supply NO 1. Confirm the connection at the wall socket

2. Is the 3 amp fuse blown?

YES

a. The appliance does not operate.

i) Open circuit or loose pin connector on PCB or wiring loom.

ii) ON/OFF button faulty. ...

iii) Faulty Printed Circuit Board.

iv) Control panel PCB faulty.

v) OHS is ‘OPEN’. (‘CLOSED’ Normal) ...

vi) Thermal fuse has melted.

vii) Solenoid circuit is faulty. ....

70 flashing

14 and filter indicator flashing

71 flashing

b. The combustion fan doesn’t rotate, or the appliance fails after a short time.

i) Combustion fan shaft allen screw loose.

ii) An obstruction in the combustion fan is preventing it from rotating.

iii) Combustion fan does not go over 1710 rpm. ...

iv) The flame rod current is greater than 0.1 µA during pre-purge....

v) The combustion fan rpm not below ignition rpm + 60. ...

vi) Faulty spark generator. ...

vii) Faulty PCB.

c. There is no spark.

i) High tension cord disconnected or broken.

ii) Insulation leak from the high tension cord, (Spark sound is not regular).

iii) The spark gap is not correct (normal spark gap is 3.5 ± 0.5 mm).

iv) Weak or shorting spark.

v) Faulty PCB.

61 flashing

72 flashing

61 flashing

53 flashing

d. The solenoids do not open, preventing gas flow to the burners.

i) Open circuit or loose pin connectors on PCB or wiring loom.

ii) Faulty solenoid, or coil.

iii) Faulty sparker, (no spark is sensed).

iv) Faulty PCB (no current to SV).

-

-

-

Page 39

e. The convection fan doesn’t rotate.

i) Convection fan shaft allen screw loose.

ii) An obstruction in the convection fan is preventing it from rotating.

iii) Flame rod faulty.

iv) Faulty PCB.

B. After repeated efforts to operate the appliance, it will not ignite. ...

11 flashing

i) Air in the gas supply line.

ii) Incorrect gas pressure.

iii) Incorrect gas type, or a kink or break in the gas supply.

iv) Faulty or weak spark.

v) Blocked injector. Is the combustion specification correct?

C. There is the sound of ignition, however the ‘combustion’ injector does not glow red.

After 15 seconds the spark stops and mis-ignition occurs.

Miss-ignition Ignition OK

Confirm the flame rod current.

Has the current risen above 1.0 µA.

Ye s

Faulty PCB

-

No

1. Faulty indicator/incorrect wiring.

2. Faulty PCB.

1. Check combustion specification, gas

type, and gas pressure.

2. Check the combustion condition.

3. Check flame rod is firmly positioned.

4. Check the flame rod lead.

-

-

Page 40

D. The flame fails during normal operation.

: ” flashing when power reinstated

1. Power failure for 0.2 seconds or longer. ...

“

2. Safety devices are activated.

* Room temperature is sensed at above 40°C for 10 minutes. ...

* Air filter is blocked and the OHS is activated. ...

* Obstruction in the flue terminal. ...

* Blockage or insufficient gas supply. ...

14 and filter indicator flashing

12 flashing

12 flashing

* Gas pressure is abnormally low.

* The area surrounding the flue terminal may be restricted.

* Obstruction in front of the heater. ...

14 and filter indicator flashing

3.

Safety Devices activated

no fault evident.

Have you ensured that the connectors are in the correct positions, and also the wiring is not disconnected anywhere?

Flame failure 30~60 mins after ignition. “12” flashing.

16 flashing

Is flame rod current > 1.0 µA?

Ye s

Faulty PCB.

1. Confirm specification of regulator, restrictor, injector, etc..

1. Confirm specification of regulator, restrictor, injector, etc..

2. Check condition of flame rod and burner.

2. Check condition of flame rod and burner.

No

4.

Flame failure (makes a loud noise).

1. Blocked flue terminal).

2. Dust in the burner terminal

3. Incorrect gas type or pressure setting

5.

Flame faillure occurs between 2 and 3 minutes after ignition. “12” flshing.

No

Is flame rod current greater than 1.0 µA?

*Is the gas pressure normal?

*Is the flame rod faulty?

Yes

Combustion fan motor control may be faulty

PCB faulty

-

-

-

Page 41

21. Electrical Component Analysis

* Before starting inspection, check wiring harness and double check that all connectors are tight.

* Before carrying out checks marked

∗

, remove power cord from wall socket.

Nature of

Fault

A. "12:00" fa ils to

flash when power

cord is pugged in,

and temperature

is not displayed

when unit is

turned on (normal

sequen ce can not

proceed).

Examination

Point

1) Is the voltage

correct?

((2) Blow n or

defective fuse?

Diagnostic

Point

Check electric socket

and voltage.

1. Measure fuse

resistance.

2. Measure convection

*

motor coil resistance

after removing 2P connector.

3. Measure combus-

*

tion motor coil resist ance after removing 4

connector.

4. Me asure res is tanc e

*

of transformer after

removing 8P connector.

Values Y/N Action

AC 230 - 240 V Yes Go to (2).

No Repair electric source.

< 1

Ω

(D) Grey - Pink

90 - 180

(G) Red - Black

> 1 M Ω

(E) White - White

(E) Red - Red

(E) Black - Blue

0.5 - 3

(E) Blue - Yellow

250-450 Ω.

Ω

5-20 Ω.

1 - 8 Ω.

Ω

Yes Go t o (3) .

No Replace fuse.

Go to (2) - 2.

Yes Go to (2) - 3.

No Replace convection

motor .

Yes Go to (2) - 4.

No Replace combustion

motor.

Yes Go to (2) - 5.

No Replace transformer.

(3) Is the transformer

OK?

5. Remove solenoid

*

valve lead w ires (SV

SV

) and measure coil

2

resistance between

terminal s.

6. Remove modulat-

*

ing va lve l ead wi re( s)

(POV) and measure coil

resistance bet wee n

terminals.

Check t r ansformer

sec onda ry volt ag e.

(F) Black - Yel-

,

1

low

SV

1.3-2.2KΩ.

1

SV

1.3-2.2KΩ.

2

(H) Grey - Grey

80 - 100

(E) Red - Red

AC 24 - 41V

(E) Black-Yellow

AC 10 -17V

(E) Blue-Yellow

AC 130 - 180 V

Yes Go to (2) - 6.

No Replace solenoid

valve.

Yes Replace PCB.

Ω

No Replace modulating

valve.

Yes Replace PCB.

No Replace transformer.

-

-

-

i

i

Page 42

B. Error code

appears soon

after turning

heater on (normal

sequence cannot

proceed).

(4) Is overheat switch

1 or 2 OFF?

(... 14 flashing)

If unit over heated, it

will turn back ON once

the unit cools down.

With ON/OFF switch

∗

OFF, check continuity

between both terminals.

(H1) White-Red

< 1 Ω

(H2) Black - Red

< 1

Ω

Yes Go t o (6) .

No Replace overheat

switch 1 and/or 2.

(5) Overheat thermistor broken/short

circuit?

(broken. ..33 fl ashes

(short...34 f l ashes)

(6) Has the thermal

fuse melted?

(... 14 flashing)

(7) Is the combustion

motor wiring OK?

(... 61 flashing)

C. No spa rk (8) Is there any spark

leakage due to lo ose or

disconnected hig h

tension lead

(9) Is the spark unit

voltage low?

D. Spark fails to

produce igni ti on

(stops after

approx. 15 sec.)

(... 11 flashing)

(10) Are the solenoid

valves (SV

ON?

, SV2)

1

Measure resistance

∗

between unit and

thermistor (Differs

according to temperature)

With ON/OFF switch

∗

OFF, check continuity

between both terminals.

Check combustion

∗

motor coil resistance

using same procedure

as (2)-3 above.

Check connection visually and by hand.

Measure sparker input

voltage.

1. Check solenoid

∗

valve coil resistance

using same procedure

as (2)-5 above.

2. Check solenoid

valves terminal voltage.

(A) White-White

o

20

C 78 k

Ω

o

100

C 3.6 k

Ω

) White-White

(H

3

0

Ω

Red - Yellow

>1 M Ω

Good connection

and no l eakage.

(F) Blue - Red

AC 85 - 110 V

(F) Black - Yel-

low

SV

1.3 - 2.2 k Ω.

1

SV

1.3 - 2.2 k Ω.

2

(F) Black - Yel-

low DC 78 - 100

V

Yes Replace PCB

No Replace thermistor

Yes Replace PCB.

No Replace temperature

fuse.

Yes Go t o (9) .

No Replace combustion

motor.

Yes Go t o (10 ).

No Conn ect p roperly.

Yes Re pl a ce s p ark er.

No Replace PCB.

Yes Go to (11) - 2.

No Replace solenoid

valve.

Yes Go t o (12 ).

No Replace PCB.

E.Ignition

occurs, but combustion indicator

does not operate.

(Sparker stops

after approx. 15

sec)

(... 11 flashing)

(11) Is the modulating

valve (POV) OK?

(12) Is the modulating

valve OK?

(13) Is the current of

the flame rod (FR)

circuit >1.0 µA .

1. Check test point

pressure.

(Modulat ing valve P

2. Check position of

SW6 switches on PCB.

3. Check modulating

∗

valve coil resistanc e.

Measure test point

pres sure as in (12)-1

above.

Check flame rod cir-

∗

cuit cur rent. (Dis connect, measure between

connect or and l ead.)

2

Is it at th e specified

pressure?

)

Refer to

(Gas changeover

switch)

(H) Grey - Grey

80 - 100

Is it at the preset

pressure?

2

(E1) Yellow -

Yellow flame rod

>1.0 µA.

Yes Check injector /

damper.

No Go to (12) - 2.

Yes Go to (12) - 3.

No S et to proper position

Yes Adjust regulator

Ω

pressu re. If it does no

match, replace PCB.

No Replace modulat ing

valve.

Yes Go to (14) after

checking injector and

damper.

No Adjust regulator

pressure.

Yes Replace PCB.

No Replace flame rod.

-

-

-

i

i

Page 43

F. Heat er does not

reach preset room

tempera ture.

(14) Is the thermistor

OK?

Disconnect thermis-

∗

tor from unit and measure resistance between

terminal s. As ther e may

be some variance due to

temperature s etting, use

the chart at the right as a

guide.

(A) Yellow -

Yellow

o

0

C : 123 k

o

20

C : 39 k

Yes Replace PCB.

No Replace thermistor.

Ω

Ω

G. Heater stops

during use (t urns

off prematurely:

broken indicator

motor).

(15) Shut off m echanism activated.

(... 12 flashing)

(16) OFF function

activat ed.

(... 16 flashing)

(17) Overh eat switch

activated.

(... 14 flashing)

Check flame rod circuit

current .

Was the heat er used f o r

a long period at a high

temp erature?

1. Check for dust on air

filter, convection fan

and air outlet.

2. Check combustion

specifications

3. Is the convection fa

revolution speed

correct?

Measure motor coil

resistance. See (2)-2.

4. Check voltage at 2P

terminal D on PCB

(convection fan) .

(E1) Yellow -

flame rod > 1.0

A.

µ

(Disconnect,

measure between

connecto r and

lead.)

Over ten minutes

at above 40

Is the dust build

up extrem e?

Correct? Yes Go to (18) - 3.

(D) Grey - Pink

90 - 180

HIGH - LOW

AC 50 - 108 V

Ω

Yes Check for dust, FR

wire and connector.

No Replace PCB

Yes Explain usage .

o

C.

No Replace PCB.

Yes Cl ean.

No Go to (18) - 2.

No Adjust accordingly

Yes Go to (18) - 4.

No Replace motor.

Yes Check fan lock /

obstruction, spin, etc.

No Replace PCB.

H. All other

problems.

Note:

If a problem is not remedied by replacing the appropriate part, the wiring harness is defective (short

circuit, open circuit and/or de fective connector s). Check for any short or o pen circuit. Lightly

wiggle wires and harness to check for loo s e or f au l ty connectors.

Are there any loose or

defective

connections?

Yes Repair

-

-

-

i

i

Page 44

22. Testing

Test Mode Summary

Test Mode 1 - This mode cancels temperature control, and starts combustion mode.

Test Mode 2 - This mode controls the modulating valve and convection fan (Normally, this test

mode is used when converting gas type and changing the PCB).

* Operating Procedures and Indicator

(A) Test Mode 1

Operating Procedures Illuminated Indicators

1. Turn the appliance on (combustion indicator illuminates).

Press test mode switch (SW 5) at top of the PCB (combustion

mode changes to “Low” test mode).

2. Change combustion and convection fan mode using the

Temperature/Time setting switch located on the control

panel.

The mode changes from LOW

time the “/\” switch is pressed.

The mode changes HIGH

“\/” switch is pressed.

3. Return operation to normal by pressing the test mode switch

(SW 5) again.

Note:

Indicators (digital display “00" and “22", “24", “26" and “HIGH” indicators) show that

→

MED → HIGH each

→

MED → LOW each time the

LOW

MEDIUM

HIGH

Displays temperature.

modulating valve and/or convection fan adjustment is complete.

Digital Display

Sections of the digital display show that the

following adjustments have been completed:

1) Modulating Valve (LOW)

2) Modulating Valve (HIGH)

3) Convection Fan (LOW)

4) Convection Fan (HIGH)

The indicators will be off when the PCB unit is replaced.

Indicators will illuminate after test mode 2 adjustment is completed.

2. Indicators (digital display “LO”, “Cu”, “Hi” and “LO”, “16", “18", “20" indicators) may be flashing

at times. This means the combustion mode is in transition (eg. Changing from LOW

→

MED). The

indicators will glow steadily once combustion mode stabilises.

(B) Test Mode 2

(Adjusting Modulating Valve)

See “Gas Pressure Setting Procedure” on pag e43.

-

-

-

Page 45

(C) Test Mode 2

(Adjusting Convection Fan rpm)

Convection fan rpm is prerecorded in the PCB unit software. Therefore, adjustment is not required

when the PCB unit is replaced.

Operating Procedure Indicators

1. Turn the appliance on (combustion indicator

illuminates). Press test mode switch (SW 5) at the

top of the PCB (combustion mode changes to

“LO” Test mode).

2. Press convection fan adjusting switch LO (SW).

Sections of the indicators will flash to show that

adjustment is in progress.

3. Adjust by using the Temperature/Time setting SW

located above the control panel. “/\” SW increases

and “\/” decreases the rpm.

4. Once the adjustment is complete, press SW2 again.

Low current supplement value is recorded in

2

E

PROM and will be confirmed. Indicators will

stop flashing and will glow steadily.

5. Press convection fan adjustment SW HI (SW1)

located at top of PCB unit. (Combustion mode

changes to “HI” test mode)

6. Adjust by using the Temp/Time setting SW located

above the control panel. “/\” SW increases and “\/

” decreases the rpm.

7. Press SW1 again, once the adjusting is completed.

2

High current supp valve is recorded on E

and will be confirmed. Indicators will stop flashing

and will glow steadily.

8. Return operation to normal by pressing the test

mode SW (SW 5) again.

Note:

The convection fan rpm changes by approximately 10~15 rpm each time “\/” or “/\” SW is

PROM

Displays tempera ture.

pressed.

-

-

-

Page 46

23. Gas Conversion

* Disconnect electrical supply and isolate gas supply.

1. Remove bottom trim. (see diagram 1)

2. Remove screws inside bottom louvre, pull complete

front panel forward at bottom, unclip from escutcheon

panel and remove from heater.

3. Replace small gas label on gas inlet.

4. Replace large gas label on back of appliance.

5. Place “new” very small gas label (indicating new gas

type) over existing one on data plate.

6. Complete details on conversion sticker, place sticker on

the inside front cover.

7. Undo main gas tube connection at manifold, push tube

down.

8. Remove “O’ ring from manifold connection and refit to

main gas tube (to avoid trapping “O” ring when reassembling).

9. Remove manifold. Take care with gasket (see diagram 3).

10. Remove damper (3 screws). (see diagram 4)

11. Replace the damper.

Diagram 1.

Diagram 2.

Diagram 3.

12. Remove 2 injectors.

13. Fit new injectors (see diagram 4)

14. Refit manifold, secure with screws. Take care with gasket.

15. Connect main gas tube; take care with “O” ring.

16. Reconnect appliance to electricity and gas.

17. Follow gas pressure setting procedure, (see next page).

18. Check for gas escapes.

19. Replace front cover

Diagram 4.

Diagram 5

Diagram 6

-

-

-

Page 47

24. Gas Pressure Setting Procedure

1. Set dip switch (SW6) to correct position (see diagram

opposite).

2. Remove test pressure point screws from heat exchanger

manifold (B) and gas valve (A). Connect pressure gauge

to both test points (connect one side of gauge to one point,

and the other side of the gauge to the opposite point). If

using an electronic manometer, connect th

heat exchange r t est point and

point.

3. Turn appliance ON.

LOW

4. When the comb u sti o n in di cator comes on, pu s h SW5

once (see PCB dip switch posit i on opposite).

5. Adju st the LOW pressure to the correct pressure (see

table below) wi th the “/\” and “\/” butto ns on t he control

panel. (The RHFE-308FTR has E

there should be no need to adjust the modulating valve

screw).

6. Press SW4 ag ain to l ock in t he l o w pressure set ting.

side to the gas valve test

2

PROM operation;

side to the

HIGH

7. Press SW3 t o se t th e ap p li ance o n forc e d HIGH.

8. Adju st the HIGH pressure to the correct pressure (see

table below) us i n g the “\/” and “/\” buttons on th e control

panel.

9. Press SW3 ag ain to l ock in t he h i gh pressu re setting.

10. Press S W 5 ag ain to re t ur n the a ppl iance to normal

operation.

11. Turn the ap pl i an ce OFF.

12. Disconne ct the p res su re gauge and r e pl a c e the test point

screw.

Natural Gas Propane Gas

HIGH 0.60 kPa 1.04 kPa

LOW 0.12 kPa 0.19 kPa

-

-

-

i

i

Page 48

25. Dismantling for service

NOTE: Before proceeding with dismantling, be sure to follow

the

CAUTION instructions before each explanation.

Item

1. Removal of the Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2. Removal of the Top Panel, Control Panel / PCB Unit . . . . . . . . . . . . . . . . . . . . . 45

3. Removal of the Convection Fan Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Page

4. Removal of the Heat Exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5. Removal of the Burner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6. Removal of the Flame Rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7. Removal of the Main PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8. Removal of the Combustion Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9. Removal of the Sparker PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

10. Removal of the Main Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

11. Removal of the Gas Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

12. Removal of the Room Temperature Thermistor . . . . . . . . . . . . . . . . . . . . . . . . . . 50

13. Removal of the Thermal Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Unless otherwise stated, re-assembly is the reverse of dismantling

-

-

-

Page 49

1) Removal of Front Panel

CAUTIO

240 volt potential inside applaince.

Disconnect electrical supply.

a. Grip sides of skirt and pull forward to

remove.

2) Removal of Top Panel, Control Panel,

and Control Panel PCB.

CAUTION

240 volt potential inside applaince.

Disconnect electrical supply.

a. Remove front panel assembly, see section

1.

b. Remove (2) two screws, one on each side of

control panel.

c. Release (3) three multi-pin connectors

from main PCB, releasing the control panel

PCB harness from wire clip on main PCB

casing.

d. Lift both sides of ocntrol panel and pull

forward to remove.

b. Remove seven (7) screws to release louvre

& front panel.

c. Grip bottom left and right hand corners of

front panel, pull forward to release.

e. Grip control panel cover and lift up,

applying light strength on one side to

disconnect the hinge pin from control

assembly.

f. Unscrew seven (7) screws to remove

control PCB from control panel.

-

-

-

Page 50

3) Removal of Convection Fan Motor

4) Removal of Heat Exchanger

CAUTIO

240 volt potential inside appliance

Disconnect electical supply.

a. Remove front panel assembly, see section1.

b. Remove top panel and control panel

assembly, see section 2 b)~d).

c. Loosen allen screw securing the fan blade

to the fan motor shaft using a 3 mm allen

key (from back of unit).

CAUTION

240 volt potential inside appliance

Disconnect electical supply.

a. Remove front panel assembly, see section 1.

b. Remove one (1) earth connection on front

heat shield.

c. Release fusible link (pull down) on front of

heat shield.

d. Release five (5) screws securing heat shield.

e. Disconnect overheat switch and

thermistor, two (2) screws.

d. Remove four (4) screws securing the motor

to the casing and remove fan motor cover.

f. Disconnect flame sensing lead (pull hard).

g. Remove spark sensing lead, and high

tension lead (pull off gently).

-

-

-

Page 51

h. Remove blanking panel, one (1) screw.

n. Remove flue spigot, three (3) screws.

i. Remove side panel, one (1) screw.

j. Remove one (1) gas supply tube securing

screw and one (1) air intake tube securing

tube.

o. Remove five (5) heat exchanger securing

screws.

p. Grip heat exchanger and pull forward to

remove.

k. Rotate clip at end of gas supply tube and

push down on tube to release from

manifold.

l. Disengage gas supply tube.

m. Remove two (2) burner securing screws

and cable tie, to remove gas supply tube.

-

Refer section 5 f)~g) to disconnect burne

Note:

from heat exchanger complete assembly.

5) Removal of Burner

CAUTION

240 volt potential exposure. Isolate the

applaince and reconfirm with a neon

screwdriver or multimeter.

a. Remove front panel assembly, see section

1.

b. Remove front heat shield, see section 4 b)

~ d).

c. Remove blanking panel, one (1) screw.

d. Remove spark sensing lead, and high

tension lead (pull off gently).

e. Remove one (1) gas supply tube securing

screw.

-

-

Page 52

f. Remove six (6) burner cover screws.

g. Gently manoeuvre burner and cover

forward and out of burner chamber by

pulling on manifold. Take care not to

damage gasket.

7) Removal of Main PCB

CAUTION

240 volt potential exposure. Isolate the

applaince and reconfirm with a neon

screwdriver or multimeter.

a. Remove front panel assembly, see section

1.

b. Release PCB by removing two (2) screws

on left hand side.

6) Removal of Flame Rod

CAUTIO

240 volt potential exposure. Isolate the

applaince and reconfirm with a neon

screwdriver or multimeter.

a. Remove front panel assembly, see section

1.

b. Remove front heat shield, see section 4

b)~d).

c. Remove two (2) screws (using a stubby

phillips screwdriver).

c. Lift PCB on right hand side and gently

manoeuvre it out.

d. Disconnect all multi-pin connectors, and

wire harness from clips of PCB casing.

e. Remove one (1) earth connection on front

heat shield and one (1) earth connection on

convection fan housing.

-

-

-

Page 53

8) Removal of Combustion Fan

10) Removal of Main Transformer

CAUTIO

240 volt potential exposure. Isolate the

applaince and reconfirm with a neon

screwdriver or multimeter.

a. Remove front panel assembly, see section

1.

b. Remove main PCB, see section 7 b)~e).

c. Remove four (4) combustion fan securing

screws.

CAUTION

240 volt potential exposure. Isolate the

applaince and reconfirm with a neon

screwdriver or multimeter.

a. Remove front panel assy, see section 1.

b. Remove main PCB, see section 7 b)~e).

c. Remove one (1) securing screw from

transformer mounting bracket.

d. Grip fan motor plate and pull forward to

remove fan from casing.

e. Remove connector from fan motor.

Arrow should be aligned when fan

Note:

assembly is replaced.

9) Removal of Sparker PCB

CAUTIO

240 volt potential exposure. Isolate the

applaince and reconfirm with a neon

screwdriver or multimeter.

a. Remove front panel assembly, see section

1.

b. Remove one (1) earth lead from heat

shield.

c. Disconnect 5-pin power supply connector.

d. Unclip sparker PCB from main PCB

housing from securing lugs on side.

d. Pull forward.

11) Removal of Gas Control

CAUTION

240 volt potential exposure. Isolate the

applaince and reconfirm with a neon

screwdriver or multimeter.

a. Turn off gas supply at the meter and

disconnect appliance from installation.

b. Remove front panel assy, see section 1.

c. Release solenoid connectors and gas

supply tube securing screw (1), release gas

supply tube. Take care with O-ring.

-

-

-

Page 54

d. Remove four (4) screws surrounding the

gas inlet flange at back of heater.

e. Pull gas control assembly forward to

remove from appliance.

Ensure test point screw is fitted to gas

Note:

controls, if fitting new control.

12) Removal of Room Thermistor

Room temperature thermiator and heat

Note:

exchanger overheat thermistor are connected

together as one harness.

13) Removal of Thermal Fuse

CAUTION

240 volt potential exposure. Isolate the