Page 1

Installation and User Manual

Infinity 16e

Infinity 16e

Continuous Flow Water Heater

Important.

Read these instructions carefully before attempting installation or use of

this appliance. All work must be carried out by competent persons.

Page 2

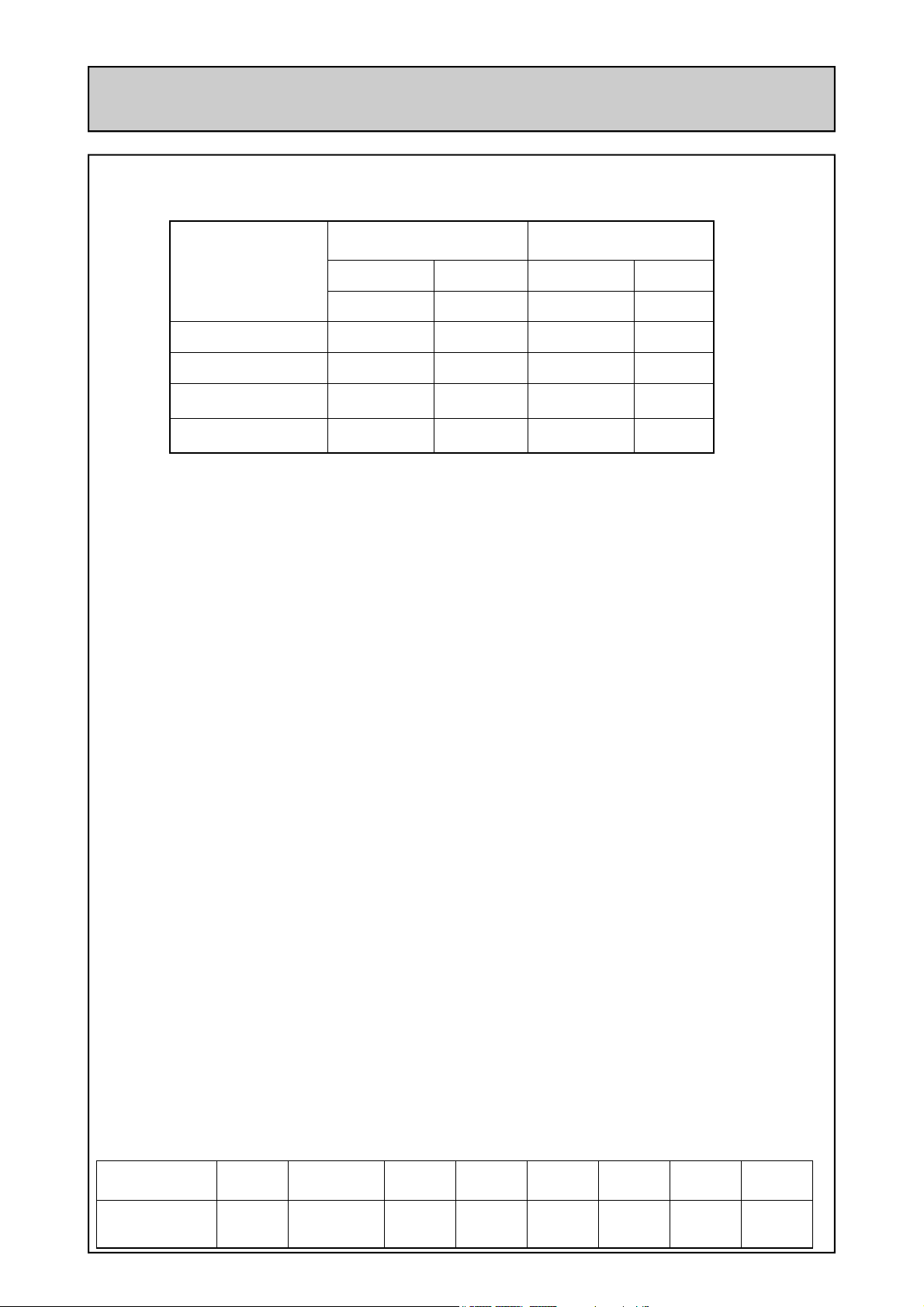

RINNAI UK WARRANTY

As the purchaser of this high quality Rinnai Water Heater you are provided with the

following conditional guarantee.

Standard Use

Commercial Use

Definition of Standard Use.

The warranty period allocated under Standard Use is based on Domestic and Light

Commercial hot water usage. Rinnai Standard Use warranty periods apply only where

Rinnai water heaters are installed in domestic and light commercial situations at

operating temperatures below 65

storage cylinders or building flow and return systems.

The warranty shall apply to any Rinnai water heater from the Infinity range used in this

way.

Definition of Commercial Use.

The warranty period allocated under Commercial Use are for Infinity water heaters

installed at premises such as commercial and industrial buildings, cafes, caravan parks,

and sporting complexes. Commercial Use warranty applies to:

Water heaters supplying a central shower block

Water heaters supplying kitchens used for the bulk preparation of food.

Water heaters set to 65

Water heaters used in commercial or industrial processes.

Any application that uses Rinnai water heaters in conjunction with storage tanks

Any application that uses Rinnai water heaters in conjunction with a flow / return system.

Water heaters installed as components of centralised bulk hot water systems.

Rinnai Infinity units used in Commercial Situations are only subject to a 1 year warranty

across the board. Commercial situations should be supplied by the Rinnai HD range.

No Rinnai warranty will cover faults arising from improper installation or gas supply,

water contaminants beyond defined limits, environmental factors, plumbing fittings, or

other outside influences of which Rinnai is not responsible. Service calls for these

issues will be chargeable.

Heat Exchanger All Other Parts

Parts Labour Parts Labour

3 Years 1 Year 3 Years 1 Year

16e

1 Year 1 Year 1 Year 1 Year

16e

0

C and do not include installations incorporating

0

C or higher.

Description pH

Maximum Recom-

mended Levels

6.5 - 9.0 600 mg/litre 200 mg/litre 300 mg/litre 10 mg/litre 20 mg/litre 150 mg/litre 1 mg/litre

Total Dissolved

Solids (TDS)

Total Hard-

ness

Chlorides Magnesium Calcium Sodium Iron

2

Page 3

CONTENTS

Rinnai UK Warranty..……………………..

Unpacking Rinnai Water Heater…………

Installation Instructions……………………

Flue Requirements………………………...

Dimensions…………………………………

Technical Details..…………………………

Features and Benefits…………………….

Important Information……………………..

Operation without Remotes………………

Temperature Controls……………………..

Testing………………………………………

Gas Pressure Setting……………………..

Dip Switch Setting…………………………

Error Messages……………………………

Restarting the Rinnai Water Heater……..

Wiring Diagram…………………………….

Diagnostic Points…………………………..

Specification………………………………..

Service Contact……………………………

Commissioning Check List………………..

…………………………………………………2

…………………………………….…………..4

…………………………………………………5

…………………………………………………8

…………………………………………………9

……………………………………………….10

……………………………………………….11

……………………………………………….12

……………………………………………….14

……………………………………………….15

……………………………………………….25

……………………………………………….26

……………………………………………….28

……………………………………………….30

……………………………………………….32

……………………………………………….33

……………………………………………….34

……………………………………………….35

………………………………………………36

………………………………………………36

3

Page 4

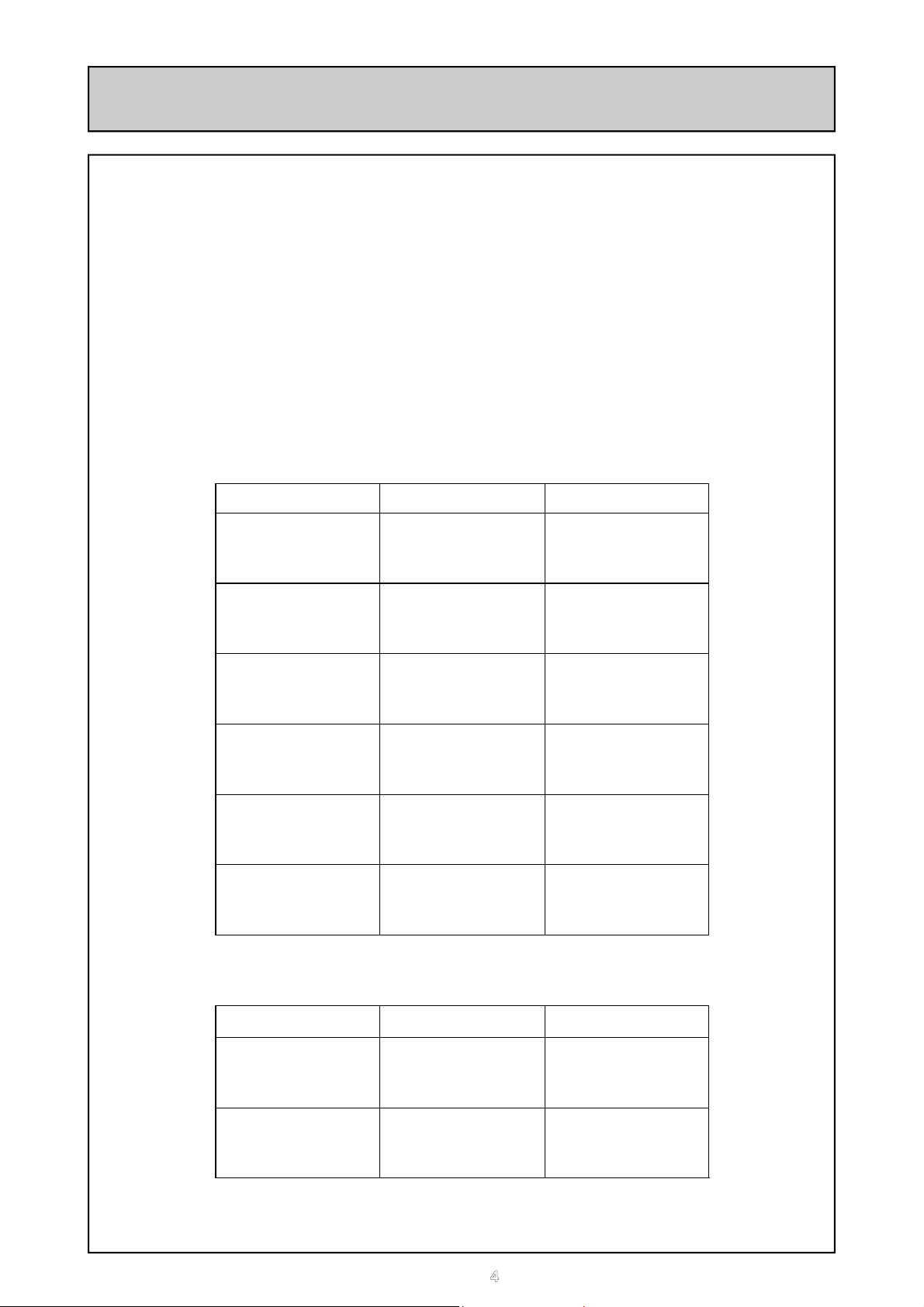

UNPACKING RINNAI WATER HEATER

• After unpacking the appliance check for damage, if the heater is damaged contact

your supplier immediately. Do not install a damaged appliance before checking

with your supplier.

• One remote control and heater accessories pack are inside the carton.

• Check that the appliance supplied is the correct gas type for the installation. Refer

to the data plate located on the left-hand side of the appliance.

• Remove the heater and the accessories from the carton, and check that all the

parts are included . The remote control cable is provided with spade connectors.

Remote Control Parts

Quantity Diagram Description

1

1

1

5

1

1

Cable clamp

Cable Clamp

Spade connectors

Clamp screw

Temperature con-

troller MC-91-1A

Control cable 20

metres

Unit Mounting Fasteners

Quantity Diagram Description

5

5

Screw

Screw

4

Page 5

INSTALLATION INSTRUCTIONS

IMPORTANT INFORMATION

1. Gas safety (Installation & Use) regulations 1998 are the ‘Rules in force’. In your

own interest and that of safety, it is law that all gas appliances are installed by

competent persons in accordance with the above regulations. Failure to install

appliances correctly could lead to prosecution. Other persons should NOT attempt to

install this equipment.

2. Unpack the appliance and check it carefully. If it appears to have any defects or

damage DO NOT INSTALL, contact your supplier.

3. This appliance is for normal hot water supply only and should not be used as pool or

spa water heater.

4. The heater must be installed in the vertical position with the gas and water

connections on the underside pointing vertically downward.

5. Installation must be carried out in accordance with the current issue of the following:

Building regulations issued by the Department of the Environment and

Building Standards (Scotland) Regulations.

I.E.E. Wiring regulations for electrical installations.

Gas safety (Installation and Use) Regulations current issue.

BS 5546

BS 5440

BS 6891

BS 5482

BS 6700

Local byelaws

Water regulations

Health and safety at work etc. Act 1974

Such other specifications and regulations that may supersede or complement the

above documents.

Please be sure that you are fully aware of your obligations and responsibilities

under these regulations.

5

Page 6

INSTALLATION INSTRUCTIONS - POSITIONING

General Installation Information.

External Installations.

The Rinnai Infinity 16e is for external mounting only.

The unit is classed as a Category A3 flueless appliance as described by CEN CR1749.

Although BS 5440 does not relate directly to heaters in this category the rules must be

followed when positioning the appliance, especially with regard to other appliances,

openings, and boundaries. Figure C.1 from BS5440-1:2000 is provided for your

guidance.

The appliance must be mounted on a vertical wall or structure with the water and the gas

connections on the underside pointing towards the ground.

THIS APPLIANCE MUST NOT BE USED AS A DOMESTIC SPA OR SWIMMING

POOL HEATER.

Appliance Location.

The appliance should be placed as close as practicable to the most frequently used hot

water outlet point or points to minimise the delay time for hot water delivery. For

installations where the distance between the unit and hot water outlet points is

considerable, the appliance can also be fitted in a 'flow and return system' which

minimises the waiting time for hot water delivery. Alternatively, multiple appliances can

be strategically placed to service outlet points with minimal delay time. Contact Rinnai

for further information.

Location of the appliance flue terminal must be in accordance with the clearances shown

on page 8. Ensure that the flue terminal and hot water outlet connection cannot be

touched by children. The appliance must be clear of obstructions and shrubbery.

The wall or structure on which it is mounted must be capable of supporting the weight of

the appliance (15 kg) and associated pipework. Ensure that suitable screws or bolts are

used to secure the water heater to the wall. Bracket and fixing hole locations are shown

on page 9. The top bracket has a keyhole slot so that the appliance can be hung on one

screw, and then the other fixings can be added to secure the unit.

The appliance must be in an accessible location. Sufficient clearances shall allow

access to, and removal of, all serviceable components. The appliance should not be

mounted higher than 3.5 metres from the ground or floor level unless the customer can

arrange permanent and safe access or can arrange another means of access, for

example, by means of scissor or boom lifts.

Multiple heater installations can be installed with the heaters manifolded together.

The heater draws combustion air through the casing for the external model.

Heater guards and pipe cover boxes for security and safety are available from Rinnai.

6

Page 7

INSTALLATION INSTRUCTIONS - CONNECTIONS

Water Supply.

Where the water supply pressure exceeds 10 bar, an approved pressure reducing

device is required at the inlet of the appliance. To achieve the rated flow a minimum

water supply pressure of 0.8 bar is required at the appliance inlet. The unit will operate

at lower supply pressures but the rated flow will not be achieved. Contact Rinnai for

'gravity fed' or 'low pressure' hot water installations.

Water pipe sizing and layout should be designed correctly to ensure the given water

flows from the Rinnai Infinity are available. All hot water pipework should be insulated to

optimise maximum performance and energy efficiency.

Water Connection.

Connect the hot and cold water supply pipes. An approved isolation valve and strainer

MUST be installed in the cold water inlet pipe. An approved isolation valve should be

installed in the hot water outlet pipe. There must be a union or release fitting on the

heater side of the isolation valves. A non return valve is not required unless dictated by

local regulations. A pressure relief valve should be installed in the pipework to

discharge safely into a suitable drain if used in a flow and return configuration.

Position of the cold water inlet, hot water outlet and gas connection is shown on page 9.

Water connections are 1/2 inch BSP, gas is 3/4 inch BSP. This is NOT an indication of

the pipe sizes required.

If the heater is in a hard water area a suitable water conditioning device should be installed to prevent the build up of limescale within the heat exchanger. Heat exchangers

damaged by scaling are not covered by the manufacturers guarantee. Guidelines are

given below. If the local water exceeds these values the heater must be protected.

Description pH

Maximum Recommended

Levels

6.5 - 9.0 600 mg/litre 200 mg/litre 300 mg/litre 10 mg/litre 20 mg/litre 150 mg/litre 1 mg/litre

Total Dissolved

Solids (TDS)

Total Hardness Chlorides Magnesium Calcium Sodium Iron

Gas Connection

Check pipe sizing required for the heater input. The heat input for the Infinity 16e is 34.7

kW. Refer to BS6891 (Natural Gas) and BS5482 (Propane) for guidance on correct pipe

sizing calculation.

Check that the size of the gas meter and pipework will be sufficient for all appliances on

the main. Sufficient gas must be available at the appliance if correct operation is to be

expected. An approved gas isolation valve must be fitted at the gas inlet. A union or

release fitting should be installed after the isolation valve.

Electrical Connection.

The appliance must be earthed. The appliance is suitable for 230VAC – 50hz mains

only and all wiring must be carried out to the I.E.E regulations latest edition. The heater

electrical supply must be provided with a fused (3A) local isolator with a contact

separation of 3mm minimum on all poles for servicing. Observe polarity and ensure that

wiring is correctly restrained.

7

Page 8

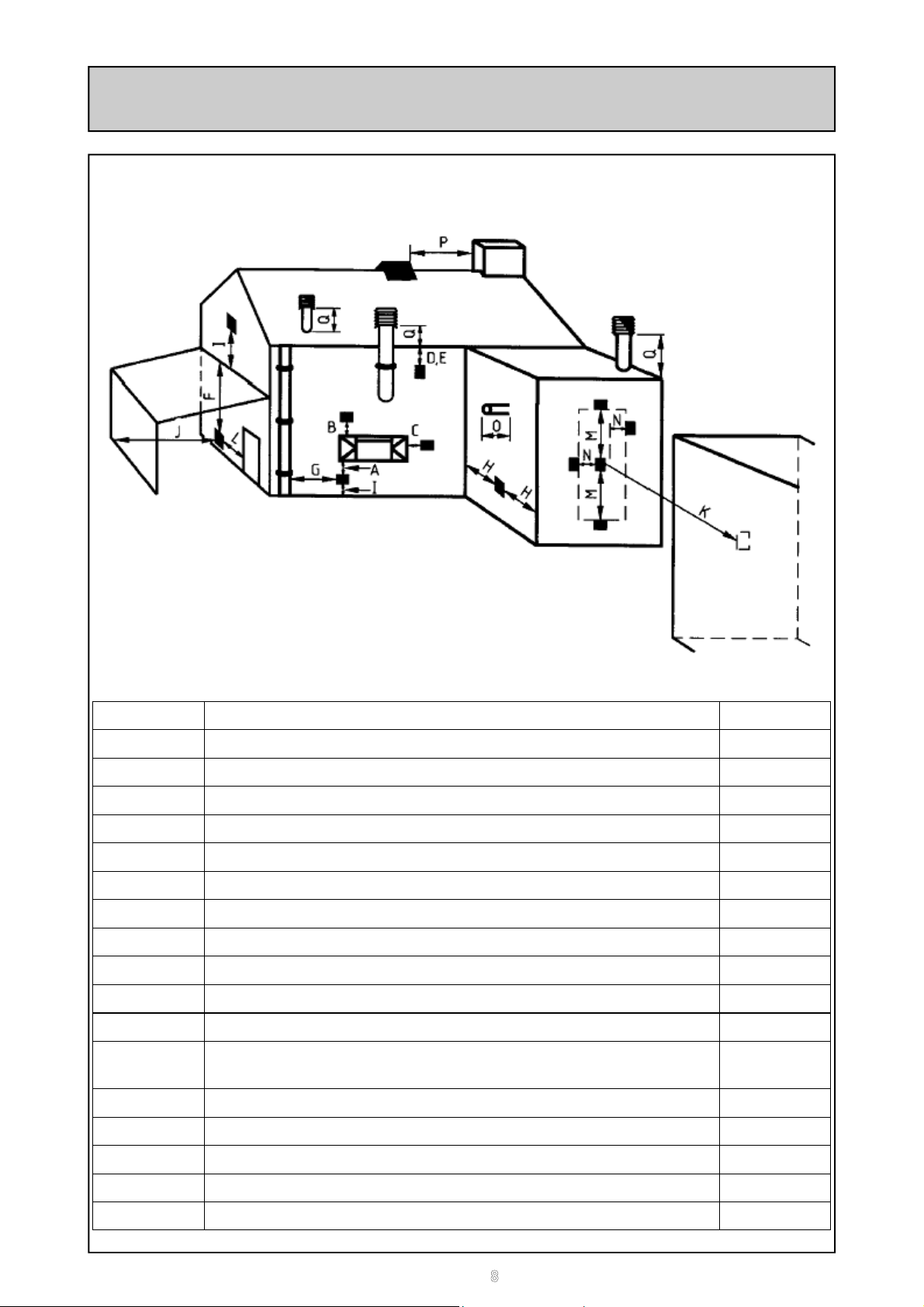

FLUE REQUIREMENTS - POSITIONING

Dimension Terminal Position Distance

A Directly below an opening, air brick, opening windows, etc. 300mm

B Above an opening, air brick , opening window, etc. 300mm

C Horizontally to an opening, air brick , opening window, etc. 300mm

D Below gutters, soil pipes or drain pipes. 75mm

E Below eaves. 200mm

F Below balconies or car port roof. 200mm

G From a vertical drain pipe or soil pipe. 150mm

H From an internal or external corner. 200mm

I Above ground, roof or balcony level. 300mm

J From a surface facing the terminal. 600mm

K From a terminal facing a terminal 1200mm

L

M Vertically from a terminal on the same wall. 1500mm

N Horizontally from a terminal on the same wall. 300mm

O From the wall on which the terminal is mounted N/A

From an opening in a car port. ( e.g. door, window) into a dwelling

1200mm

P From a vertical structure on the roof. N/A

Q Above an intersection with roof. N/A

8

Page 9

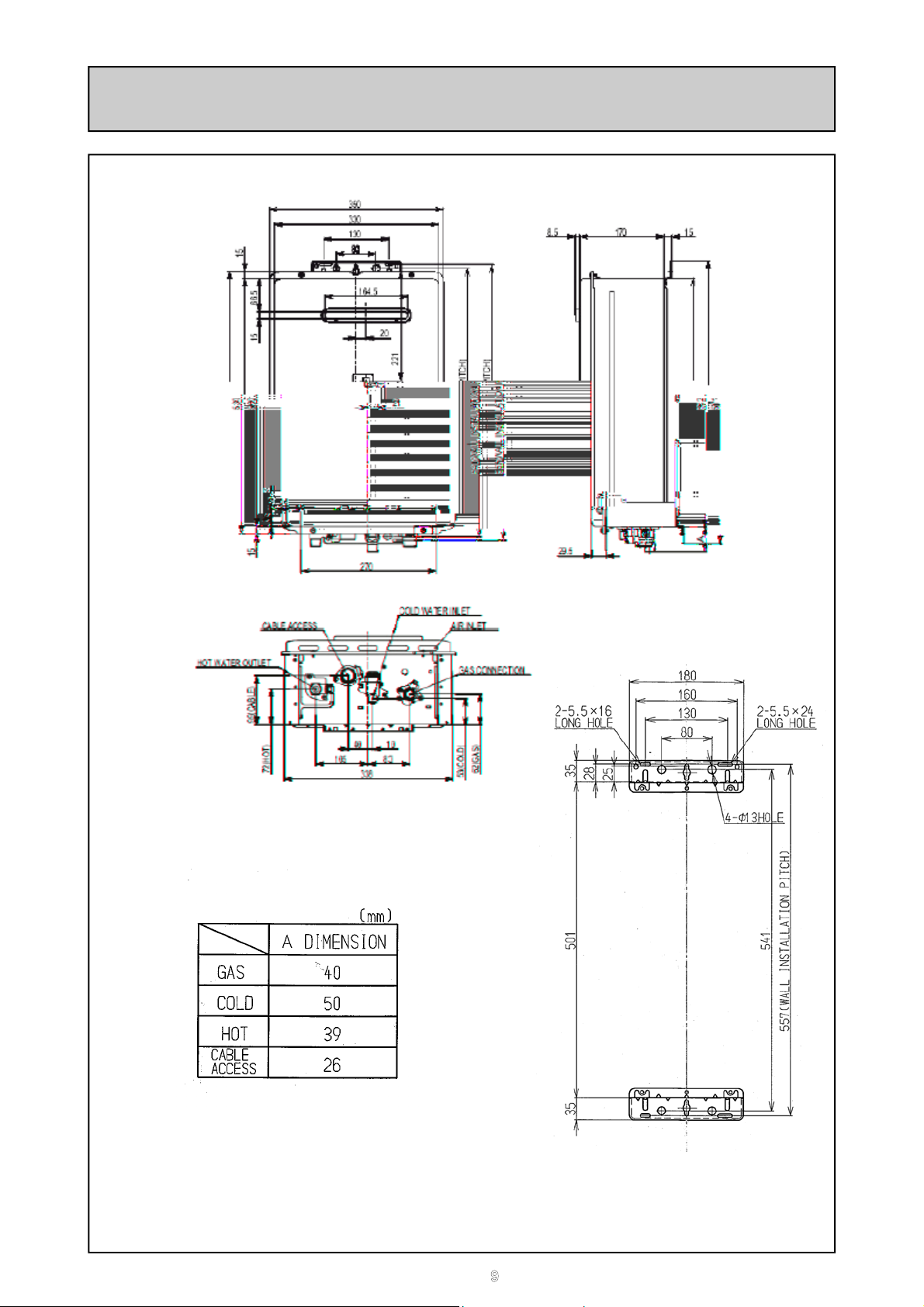

DIMENSIONS

9

Page 10

TECHNICAL DETAILS

* Factory Setting

**Minimum operation flow based on temperature setpoint and inlet conditions.

Infinity Model

Installation External

Nat Gas Press Low 1.8 mbar

Nat Gas Press High 8.8 mbar

LPG Press Low 1.8 mbar

LPG Press High 8.1 mbar

Height 530 mm

Width 350 mm

Depth 170 mm

Weight 15 kg

Flue System Forced Exhaust

Temp. Range Controllers 37 - 75 deg C

Temp. Range without

Controllers

Ignition Direct Electronic

Gas Consumption Low

Nat Gas 5.2 kW

LPG 5.0 kW

Gas consumption High

Nat Gas 34.7 kW

LPG 34.7 kW

Max Flow raised 33C 12 L/min

Min Operation Flow 2.4** L/min

Water Pressure Nom. 0.8 - 10 bar

Power Supply

Electric Consumption 74 Watts

Infinity 16e

37,40,43,50,

55*,65,75

230 V / 50 Hz

Units

deg C

10

Page 11

FEATURES AND BENEFITS

Congratulations on purchasing the Technologically Advanced, Temperature Controlled,

Rinnai Hot Water System.

• The Rinnai Infinity 16e NEVER RUNS OUT of hot water. As long as electricity,

water, and gas supplies are connected, hot water is available when hot water taps are

open.

• Built into the main micro-processor is the facility to LIMIT THE MAXIMUM

TEMPERATURE of the hot water supplied. The water temperature may be limited to

various maximum temperatures. This is particularly useful when the hot water unit is

installed where young children or the infirm may be using the hot water. The Infinity

16e is delivered with a preset temperature of 55

can be changed by an authorised person. For further information, please contact

Rinnai.

• The Rinnai Infinity external unit is a powered flue appliance. This makes it

COMPACT, saving both floor and wall space.

• The temperature of outgoing hot water is CONSTANTLY MONITORED by a BUILT-

IN SENSOR. If the temperature of the outgoing hot water rises to more than 3°C

above the selected temperature the burner is shut OFF and only turned ON again

when the temperature falls to below the selected temperature.

• The burner lights automatically when the hot water tap is opened, and distinguishes

when the tap is closed. IGNITION IS ELECTRONIC, so there is no pilot light. When

the hot water tap is off, no gas is used.

• Up to three temperature controllers can be mounted remotely from the heater. This

offers the following additional features:

Localised temperature setting.

Diagnostic message.

• ‘Deluxe’ Temperature Controllers are an optional extra. These provide functions

including Bath Fill, Voice Prompt, and Clock Setting.

• Temperatures selected at the controllers are retained in the SYSTEM MEMORY.

• Operating NOISE LEVEL IS VERY LOW.

• ERROR MESSAGES ARE DISPLAYED on the Temperature Controllers, assisting

with service.

• FROST PROTECTION device built in as standard.

0

C. If required, the temperature limits

11

Page 12

IMPORTANT INFORMATION

Excessively hot water is dangerous, especially for young children and the infirm. The

water heater allows you to control the temperature of your hot water to safe levels.

DO

DO

NOT

Water temperature over 50ºC can cause severe

burns instantly or even death from scalding.

Children, disabled and the elderly are at the

highest risk of being scalded by excessively hot

water.

Always test the temperature of the water before

bathing or showering.

Burns from hot water taps can result in very

severe injuries to young children.

Hot water at 65°C can severely burn a child in less

than half a second. At 50°C it takes five minutes.

Burns can occur when children are exposed

directly to hot water or when they are placed into a

bath which is too hot.

Do stay with children

whenever they are in the bathroom.

• Consider child—resistant taps

Do take them out of the bathroom if

you need to answer the phone or

door.

Do test the temperature of the water

• Consider reducing the

with your elbow before placing your

child in the bath.

Do make sure that the tap is turned

off tightly.

Do consider setting your Rinnai

Infinity 16e at a maximum

temperature of 50

0

C.

Do install a child proof tap cover

OR,

Do install a child resistant tap.

Do not leave a toddler in the care of

another small child. The older child

may not have safely set the temperature.

or inexpensive tap covers,

both of which prevent a child’s

hand from turning on the tap.

temperature of the water

supplied to the hot tap to

0

50

C.

This approach can be extremely

valuable because it requires a

one time action for a long term

reduction in risks of scalds.

This type of automatic protection

is important during times when a

parent or carer has been

distracted.

12

Page 13

IMPORTANT INFORMATION

Always check water temperature before

use.

Refer to warning about hot water on

page 12 for important safety information.

The Infinity 16e controls the water

temperature automatically. For high

temperatures it may reduce the flow. The

water from the hot tap may be reduced

after the temperature shown on the

remote control is raised. The water flow

may also vary with the temperature of the

incoming water supply.

Hot water may go out without warning at

low water flows.

OFF

If freezing temperatures

are expected, turn off the

water and gas, and

drain the water

heater.

1. Water Off

2. Gas Off

3. Drain Water

If the power is left on the

Automatic Frost Protection

will prevent the unit from

Freezing. Frost protection

is standard on the external

units.

Keep flammable materials, trees, shrubs,

chemicals etc. away from the heater.

Do not touch the unit cover or the flue

outlet. Do not insert objects into the flue

outlet.

On cold days steam may be discharged

from the flue outlet. This is normal, do

not be alarmed. It does not indicate a

fault.

13

Page 14

OPERATION WITHOUT REMOTES

Rinnai Infinity products have no pilot light and when installed without Temperature

Controllers, the appliance will operate automatically as soon as a hot water tap is

opened.

The burner ignites with electronic ignition and the flame extinguishes as soon as water

flowing through the appliance stops.

Turn On by opening the hot water tap

Rinnai Infinity water heaters without controllers are factory pre-set to a temperature limit

of 55°C. Other limits, lower or higher, are available on request for the Infinity range.

Temperature controllers are available that allow precise digital temperature control.

Higher temperatures may be necessary for circulation loop systems.

Controllers can be easily added at any time after installation.OTE

14

Page 15

TEMPERATURE CONTROLS - GENERAL

When deciding on the best position for the temperature controls, the following points

should be taken into account.

• Fit the controls out of reach of children (suggested height from the floor 1.5m.)

• Avoid positions where the controllers will become hot. Do not fit them near stoves or

ovens, or above radiators or heaters.

• If possible, avoid exposure to direct sunlight or positions where bright lights will make

the digital display difficult to read.

• Position away from areas where the controller will be prone to splashing by cooking

products such as oils and fats.

• The temperature controllers are water resistant, however they should be positioned

away from areas where direct or persistent splashing could occur.

• Refer to the I.E.E electrical wiring regulations current edition for location requirements

in shower and bath areas.

• The cables to the temperature controller carry only 12VDC (extra low voltage.)

• When using more than one temperature controller the signal cable should be run in

parallel. That is, from controller to controller to heater, or from each controller to the

heater. Do not wire the controllers in series.

The installation in every application will vary, therefore the temperature controller cable

has been provided so that you may cut the length accordingly and fit the spade

connectors, ensuring a good connection.

Cables are simply ‘piggy-backed’ at the water heater or at the primary temperature

controller. Polarity is not important when connecting the cables, either colour wire can

be connected to either terminal at both the heater or primary temperature controller. If

more cable is needed any cable with similar specification to the cable supplied with the

controller can be used. Maximum length is 50 metres.

15

Page 16

TEMPERATURE CONTROLS - INSTALLATION

Universal Temperature Controller

MC-91-1A

1. Determine the most suitable position for the

temperature controller.

2. Drill 3 holes in the wall as shown in fig. 1, one

for the cable and two for the securing screws.

Ensure holes are drilled deep enough. Fit wall

plugs if needed. (ensure controller is level.)

3. Run the cable provided through the hole in the

wall ensuring that the end fitted with the

connector is nearest the controller. (fig. 2.)

4. Remove the face plate from the controller using

a flat screwdriver. Take care not to damage the

cover (fig. 3.)

5. Connect the cable to the temperature controller.

6. Fix the controller to the wall and fasten with the

phillips head screws supplied as shown in (fig.

4.)

7. Remove the protective plastic film from the

controller face as shown in fig. 4.

8. Replace the face plate.

NOTE

16

Page 17

TEMPERATURE CONTROLS - INSTALLATION

Connecting One or Two Controllers

1. Isolate the power supply.

2. Remove the front cover from the Appliance (4

screws) fig. 1.

3. Thread the cable through the cable access hole

at the base of the appliance.

4. Connect the spade connectors to the terminals

marked "Remote Control" on the printed circuit

board (fig.2). Polarity is not important. Either

wire colour can be connected to either terminal.

5. Replace cover of the Appliance. Ensure that the

special earth screw is placed at the bottom right

hand corner for earthing purposes.

Connecting Three Controllers

1. Isolate the power supply.

2. Remove the front cover from the Appliance (4

screws) fig.1.

3. Thread the cables through the cable access

hole at the base of the appliance.

4. Cut the spade connectors from two controller

cables (4 connectors should be cut off) and

discard. Connect the wires and terminate into

two new spade connectors as shown in fig. 3.

5. Thread the 3 cables through the cable access

hole at the base of the appliance. Connect the

4 spade connectors to the terminals marked

“Remote Control" on the printed circuit board

(fig.2). Polarity is not important. Either wire

colour can be connected to either terminal.

6. Replace cover of the Appliance. Ensure that the

special earth screw is placed at the bottom right

hand corner for earthing purposes.

17

Page 18

TEMPERATURE CONTROLS

The purpose of a Temperature Controller is to enable the user to have complete control

over the hot water supply. Used correctly, the hot water unit will supply hot water at the

temperature selected, even when the water flow is varied, or when more than one tap is

used. Adjustments to the operation of your hot water unit can be made with any of the

Temperature Controllers. Each Temperature Controller can be individually programmed.

Up to three Universal and Deluxe Temperature Controllers can be fitted with the Infinity

16e. Universal Controllers allow temperature selection only and come as standard with

the water heaters. Deluxe Temperature Controllers are an optional extra. These

controllers have temperature selection, bath fill, voice recognition, and time clock

functions. When more than one Universal Controller is used one may be set as the

Master Controller to allow higher temperatures.

Various water temperatures (°C) can be selected as follows:

Universal Controller:

37, 38, 39, 40, 41, 42, 43, 44, 45, 46, 48, 50

Master Universal Controller:

37, 38, 39, 40, 41, 42, 43, 44, 45, 46, 48, 50, 55, 60, 65°C

Deluxe Bathroom Controller:

Hot Water Delivery: 37, 38, 39, 40, 41, 42, 43, 44, 45, 46, 48, 50°C

Bath fill Delivery: 37, 38, 39, 40, 41, 42, 43, 44, 45, 46, 47, 48°C

Deluxe Kitchen Controller:

37, 38, 39, 40, 41, 42, 43, 44, 45, 46, 48, 50, 55, 60, 65°C

If a temperature 43°C or higher is selected on any controller and this temperature is then

decreased to below 43°C and increased again whilst the water is running, the maximum

selectable temperature will become 43°C. This provides additional safety for the

consumer.

Suggested temperatures are:

Kitchen 50°C - 65°C*; Shower 39°C - 43°C; Bath fill 39°C - 45°C

* This temperature may not be available on all installations.

These temperatures are suggested starting points for selection. You may find higher or

lower temperatures are more comfortable. Maintaining lower temperatures helps to save

energy. To obtain water temperatures lower than 37°C simply add cold water.

Up to three controllers can be used for one Infinity 16e. When multiple temperature

controllers are used they allow the temperature to be set from various locations by

pushing the transfer button which gives that controller priority over the system. The

temperature selected by the controller with priority will be available to all outlets.

0

C

18

Page 19

TEMPERATURE CONTROLS - OPERATING

Remote temperature controllers are a feature that provides control over the water

temperature. Rinnai Infinity water heaters can be operated with 1, 2, 3 or no temperature

controllers. The Universal controller MC-91-1A comes as standard with all Infinity water

heaters.

NOTE:

Each time a button is pressed, a BEEP will sound.

The BEEP sound can be muted by depressing the Temperature Controller Up and Down

buttons simultaneously for more than 3 seconds.

This can be done for each Temperature Controller.

To return to original settings, repeat this step.

19

Page 20

TEMPERATURE CONTROLS - OPERATING

Using 1 Universal Temperature Controller.

Press the On/Off button on the temperature controller.

The ON indicator will glow on the Temperature Controller.

This indicates that the heater is ready to supply hot water

when a tap is opened.

Adjusting Temperature

Simply press the Hot Water Temperature Up or Down arrow

button until the desired temperature is displayed on the

digital display.

To operate the heater, simply turn any hot water tap on. This

will automatically light the burner providing hot water. The

red In Use indicator will glow on the temperature controller.

Caution: Always check water temperature before use.

Note:

With the hot water tap open and a temperature of 430C or higher selected,

if the temperature is decreased below 43

maximum available temperature will be 43

temperature ‘priority’ cannot be transferred between controllers when a

hot water tap is open.

0

C, and then raised again the

0

C. For safety reasons

20

Page 21

TEMPERATURE CONTROLS - OPERATING

Using 2 or more Universal Temperature Controllers.

Switching the system ON.

The hot water system and all controllers can be

switched ON and OFF from any controller by pressing

the On/Off button as shown. When the system is

turned ON the water temperature display will be lit.

During normal operation the system is left ON. Do

not push the On/Off button when water is running.

Using hot water.

Ensure the system is switched On by verifying the

temperature display is lit. Ensure the controller has

priority by verifying the Transfer LED indicator is lit. If

it is not then press the Transfer button once. This

gives the local controller priority of temperature over

the system.

Select the desired temperature using the Hot water

temp. buttons. The selected temperature will be

displayed on all controller displays. This is the water

temperature which will be supplied from the heater.

Bathroom temperatures should be no more than 500C.

Open the hot water tap. The appliance

will be activated and the In Use

indicator will be lit.

21

Page 22

TEMPERATURE CONTROLS - OPERATING

Using High Temperature Display Controllers.

You will need to program the Master controller if you want to display and use

temperatures over 50

controllers; other universal controllers will not allow this, and Deluxe Kitchen Controllers

are supplied already programmed to allow high temperatures. Temperatures in

bathrooms should never exceed 50

STEP 1: On the Master controller only press and hold the Transfer and On/Off

buttons simultaneously (see fig 2.) until a “beep” is heard (approx. 5 seconds)

STEP 2: When the Primary controller is switched on it should be possible to select

temperatures higher than 50ºC. If not repeat STEP 1.

Note:

If the master controller is replaced, repeat STEP 1 above for the new controller.

0

C. Programming only needs to be done on Master universal

0

C.

22

Page 23

TEMPERATURE CONTROLS - OPERATING

To turn off your hot water system.

During normal operation the system is left on.

To turn the system off simply press the On/Off

button on any temperature controller (where

fitted). This will shut the water heater down

completely including the temperature controller

digital display.

The on indicator will go out.

If hot water taps are opened when the Rinnai

Infinity is off, cold water will flow from the taps.

If the system is to be left off over the winter be

sure to drain it down if there is a possibility of

freezing temperatures.

Additional safety features.

Whilst the hot water tap is open, the following

safety features apply:

• Temperature selection cannot be transferred.

• If a temperature of 43

and the temperature is decreased to below

0

43

C, and then raised again the maximum

available temperature will be 43

• Other controllers are unable to change the

delivery temperature of the water.

Note

The temperature of the outgoing water is constantly monitored by a built in

sensor. If the temperature of the outgoing hot water rises to more than 3ºC

above the selected temperature shown on the digital display, or the preset

limit if controllers are not fitted, the burner will automatically go out. The red

operation indicator will also go out. The burner will ignite again once the

outgoing hot water temperature falls to that shown on the digital display (or

the pre-set limit of the Rinnai Infinity heater).

0

C or higher selected,

0

C.

23

Page 24

TEMPERATURE CONTROLS - INFORMATION

Do not push the On/Off button on the

Master controller after transferring priority

of temperature selection to a Secondary

controller as the system will shut down.

Do Not Turn OFF

the Master

Controller

If a temperature higher than 50ºC has

been selected on the Master controller

and priority of temperature selection is

transferred to another controller (or it is

turned off), then back again (or turned on

again), the temperature on the Master

controller will automatically drop to 50ºC.

If the set point is less than 50

0

C it will not

alter. This is a safety feature.

Master Another Master

Controller Controller Controller

Temperature priority can not be switched

to another controller when the water is

flowing through the water heater.

500C

Controller 1

in use

Controller 2

cannot take

priority

Do not clean the remote control with

solvents or detergents. Use only a soft

damp cloth.

Depending on the weather conditions

and the length of the pipe between the

heater and the tap in use, there may be a

variation between the temperature displayed at the controller and the temperature at the tap.

480C

If a temperature higher than 420C has

been selected on the Universal control-

ler and priority of temperature selection is

transferred to another controller (or controller is turned OFF), then back again (or

turned ON again), the temperature will

automatically drop to 42

point is less than 42

0

C. If the set

0

C it will not alter.

This is a safety feature.

Universal Another Universal

Controller Controller Controller

24

Page 25

TESTING

1. Purge gas, hot water and cold water supply lines before making the final connection

of the water heater. Swarf in either the gas or water supplies may cause damage.

2. Turn on gas and cold water supplies.

3. Test for water leaks and gas escapes near the unit.

4. Isolate gas and electric supply. Remove test point screw located on the inlet gas

valve connection inside the heater and attach pressure gauge.

5. Turn the power on at the switch and turn on gas. Warning: There are 230V AC live

supplies inside the heater.

6. If remote controllers are fitted, turn the controller on, select the maximum delivery

temperature and open ALL available hot water outlets. If remote controllers are not

fitted, simply open all available hot water outlets. (CAUTION: Ensure building

occupants do not have access to hot water outlets during this procedure).

7. The gas pressure check must be carried out with all other appliances on the same

main operating at maximum capacity to ensure that there is sufficient gas pressure.

8. With all other appliances operating the pressure at the test point on the inlet to the

gas valve should read 20 mbar for Natural Gas. For LPG (Propane) the pressure

should be 37 mbar. If the pressure is lower, the gas supply is inadequate and the

water heater will not operate to specification. Check gas meter, regulator and

pipework for correct operation/sizing and rectify as required. Note that the gas

regulator on the appliance is electronically controlled and factory pre-set. Under

normal circumstances it does not need adjustment during installation.

9. Close hot water outlets.

10.Inspect and clean the strainer and the filter located on the cold water inlet pipe. This

procedure may need to be repeated to ensure the strainer remains clear.

11.If temperature controllers are fitted, it is necessary to test their operation through the

complete range of functions.

12.Confirm the hot water delivery temperature using a thermometer. If controllers are

fitted, compare the measured value to the set point.

13.After testing is completed, explain to the user the functions and operation of the

water heater and temperature controllers.

25

Page 26

GAS PRESSURE SETTING

The working gas pressure on the water heater is electronically controlled and factory set.

Under normal circumstances it does not require adjustment during installation. Perform

this procedure only if the unit is not operating correctly and all other possible causes for

incorrect operation have been eliminated.

attempting to alter the gas pressure. Failure to do so could void

the warranty.

1. Turn 'OFF' the gas supply.

2. Turn 'OFF' 230V power supply.

3. Remove the front cover from the appliance.

4. Check gas type switch no.1 of SW2 (fig. 1) is

in the correct position for the type of gas

(Nat. or LPG) you are using. (SW2 is top set

of switches.)

5. Attach pressure gauge to burner test point.

(fig. 2)

6. Turn 'ON' the gas supply.

7. Turn 'ON' 230V power supply.

8. If remote controllers are fitted, turn the unit

'ON' at the master controller, select a

maximum delivery temperature and open a

hot water tap fully. (CAUTION: Ensure

building occupants do not have access to

hot water outlets during this procedure.)

9. Set the appliance to 'Forced Low'

combustion by setting No. 3 dipswitch of the

bottom set of dip switches (SW1) to 'ON'.

(fig 3)

10.Check the burner test point operating

pressure.

Contact Rinnai UK before

Nat. Gas

Propane

26

Page 27

GAS PRESSURE SETTING

11.Remove rubber access plug and adjust the

regulator screw on the modulating valve (fig.

4) as required to the pressure below.

12.Lock the regulating screw on the modulating

valve.

13.Set the appliance to 'Forced High' combustion

by setting both no. 3 and no. 4 dipswitches of

the bottom set of switches (SW1) to 'ON'.

(fig.5) Ensure maximum water flow.

14.Check the burner test point pressure.

15.Adjust the high pressure potentiometer on the

Printed Circuit Board between SW1 and SW2

to the pressure shown below. The potentiometer is very sensitive, turn no more than a few

degrees at a time; then let the pressure settle

down before turning it more.

16.IMPORTANT: Set dip switch no. 3 and no. 4

on the bottom set of switches (SW1) to 'OFF'

to return the appliance to 'Normal' combustion.

(fig. 6)

17.Close hot water tap.

18.Turn OFF the gas supply and 230V power

supply.

19.Remove pressure gauge, and replace sealing

screw.

20.Turn 'ON' the gas supply and 230V power

supply.

21.Operate unit and check for gas leaks at test

point.

22. Replace the front cover of the appliance.

N.G 1.8 mbar

Propane 1.8 mbar

N.G 8.8 mbar

Propane 8.1 mbar

LEGEND:

Black Section indicates

position of dip switch.

OFF ON

OFF ON

OFF ON

CAUTION

27

Page 28

DIP SWITCH SETTING

Dip Switch Positions Explained

OFF ON

OFF ON

Dip Swiches Explained

GAS TYPE

LPG

OFF ON

SW2 (top)

1 - Gas Type

2 - Temperature

3 - Temperature

4 - Temperature

SW1 (bottom)

1 - Computer Programming

2 - Computer Programming OFF ON

3 - Combustion

4 Combustion

SW2

1 off

2

3

4

NAT GAS

OFF ON

COMPUTER PROGRAMMING

OFF ON

COMBUSTION

NORMAL

OFF ON

SW1

1 - Switches are always in these

2 - positions for the Infinity 16e.

3

4

SW1

1

2

3 off

4 off

FORCED LOW FORCED HIGH

OFF ON

SW2

1 on

2

3

4

SW1

1

2

3 on

4 off

LEGEND:

Black Section indicates

position of dip switch.

OFF ON

OFF ON

OFF ON

SW1

1

2

3 on

4 on

28

Page 29

DIP SWITCH SETTING

Infinity 16e

Temperatures - With or Without Remotes

off on

SW2

1

2

3

4

off on

SW2

1

2

3

4

off on

SW2

1

2

3

4

40 deg C 43 deg C 50 deg C

off on

SW2

1

2

3

4

55 deg C

off on

65 deg C

SW2

1

2

3

4

off on

75 deg C

SW2

1

2

3

4

29

Page 30

ERROR MESSAGES

Rinnai water heaters have the ability to check their own operation continuously. If a fault

occurs, an error code will flash on the Digital Display if you have temperature controllers

installed. This assists with diagnosing the fault, and may enable you to overcome a

problem without a service call. Please quote the code displayed when enquiring about

service. Error codes flash.

Code

Fault Remedy

Displayed

- Noticeable reduction in water

flow

10

11

12

14

16

32

Not enough combustion air Check for physical blockages around

No Ignition / Gas supply Check gas valves, gas supply and

Flame failure / Low Gas flow Check gas valves and gas supply.

Remaining flame safety device Service Call

Over temperature warning Service Call

Outgoing water temperature

sensor faulty

Inlet water filter needs to be cleaned.

air intake or exhaust. Check

combustion fan.

sparker unit.

Check flame rod.

Check exhaust is clear.

Check remote control.

Service Call

33

Heat Exchanger Thermistor

Service Call

Error

52

61

65

71

72

Gas modulating valve faulty Service Call

Combustion fan failure Service Call

Water Flow Control Device Service Call

Micro-processor failure Service Call

Flame rod circuit error Service Call

* In all cases, you may be able to clear the Error code by turning the hot water tap OFF,

then ON again. If this does not clear the error, try pushing the On/Off button OFF then

ON again. If the Error Code still remains contact Rinnai or your nearest service agent for

advice.

** Faults caused by insufficient gas/water supply or gas/water quality and installation

errors are not covered by the manufacturer’s guarantee.

30

Page 31

ERROR MESSAGES

Troubleshooting without controllers

If you have not installed temperature controllers and experience the following

symptoms, please carry out the suggestions below. If symptoms continue, please

contact Rinnai for advice.

Fault Remedy

Heater does not attempt

to start at all.

Heater starts then shuts

down immediately.

Heater starts then the

water goes cold.

NOTE: Faults caused by insufficient gas/water supply or gas/water quality and

installation errors are not covered by the manufacturer’s guarantee.

Check the power is on at the heater.

Check the cold water valve supplying the heater is open.

Check the power is on.

Check the gas valve at the heater and at the gas meter is fully open.

Open the hot water tap fully.

Check the power is on.

Open your hot water tap further or try another hot outlet.

Installations with circulation pumps

With temperature controller fitted.

If you have an installation using a secondary circulation pump this must be

switched off so that there is no flow through the heater when starting or after a

power failure. If the pump is running the unit will not operate (no display on the

controller). Isolate pump then start heater before restarting pump. This is a safety

feature.

The pump should also be fitted with a thermostat to prevent the return temperature

reaching the heater set point temperature.

Without temperature controller fitted.

The heater should automatically reset and provide water at the temperature set by

the internal limit switches.

31

Page 32

RESTARTING THE RINNAI WATER HEATER

Following a power cut the heaters should be restarted in this manner.

Standard system.

Single or multiple water heaters without remote controllers.

The heaters will automatically reset without any user involvement.

Single or multiple water heaters with remote controllers.

The heaters will be required to be switched on using the ON/OFF button on a remote

controller. Ensure that all taps/water outlets are closed and no water is flowing through

heaters.

Hot water system incorporating secondary recirculation pump.

Single or multiple water heaters without remote controllers.

The heater(s) will automatically reset without any user involvement.

Single or multiple water heater(s) with remote controller(s).

To reset the heaters follow the steps.

1. Turn off all hot water taps.

2. Turn off supply to secondary circulating pump or alternatively, if heater and pump

are fed from the same electrical supply, isolate pump flow.

3. Turn on heater at remote control.

4. Select required temperature.

5. Switch on supply to secondary circulating pump or open valve on pump flow.

The heater will now be ready to supply water at the set temperature.

If following the above procedure does not reset the heater switch it on and off at its main

supply, and then go through these steps again. If heater is still not working call your local

service agent or Rinnai for assistance.

32

Page 33

WIRING DIAGRAM

33

Page 34

DIAGNOSTIC POINTS

Diagnostic Points- To be read in conjunction with the wiring diagram.

34

Page 35

SPECIFICATION

Model………………………………………………..….......………………………..Infinity 16e

Installation…………………………………………...…….…...……. External location only

Fuel…………………………………………………..….…..…………...Natural Gas or LPG *

Control………………………………………………….…….………...……….…..Modulating

Input……………………………………………………..……….……………....5.1 to 34.7 kW

Exhaust type………………………………………..……..Forced Draught Direct Exhaust

Ignition……………………………………………………………….…………...…..Electronic

Burner……………………………………………………...……….…………...Stainless steel

Weight…………………………………………………...……….….…………..…..………15kg

Water flow rate ………………………………………..………….…….…...2.4** to 16L/min

Minimum operating water pressure…………………..……….…..………..……….0.8 Bar

Connections

Gas…………………………………………………………...….………………….…….3/4BSP

Water Inlet………………………………………….………...…………………….……1/2BSP

Water outlet…………………………………….………...………………………….…..1/2BSP

Electrical Supply…………………………….…………..……………….230V AC 50Hz 1ph

* Separate models available for Natural gas or LPG fuel.

** Minimum flow rate based on temperature setpoint and inlet conditions.

Rinnai are continually updating and improving products and reserve the right to

alter model specifications without prior notice.

35

Page 36

SERVICE CONTACT

Rinnai

Rinnai

9 Christleton Court

Manor Park

Runcorn

Cheshire

WA7 1ST

Tel. 01928 531870

Fax. 01928 531880

E-mail. info@rinnaiuk.com

Web. www.rinnaiuk.com

UK LTD.

36

Loading...

Loading...