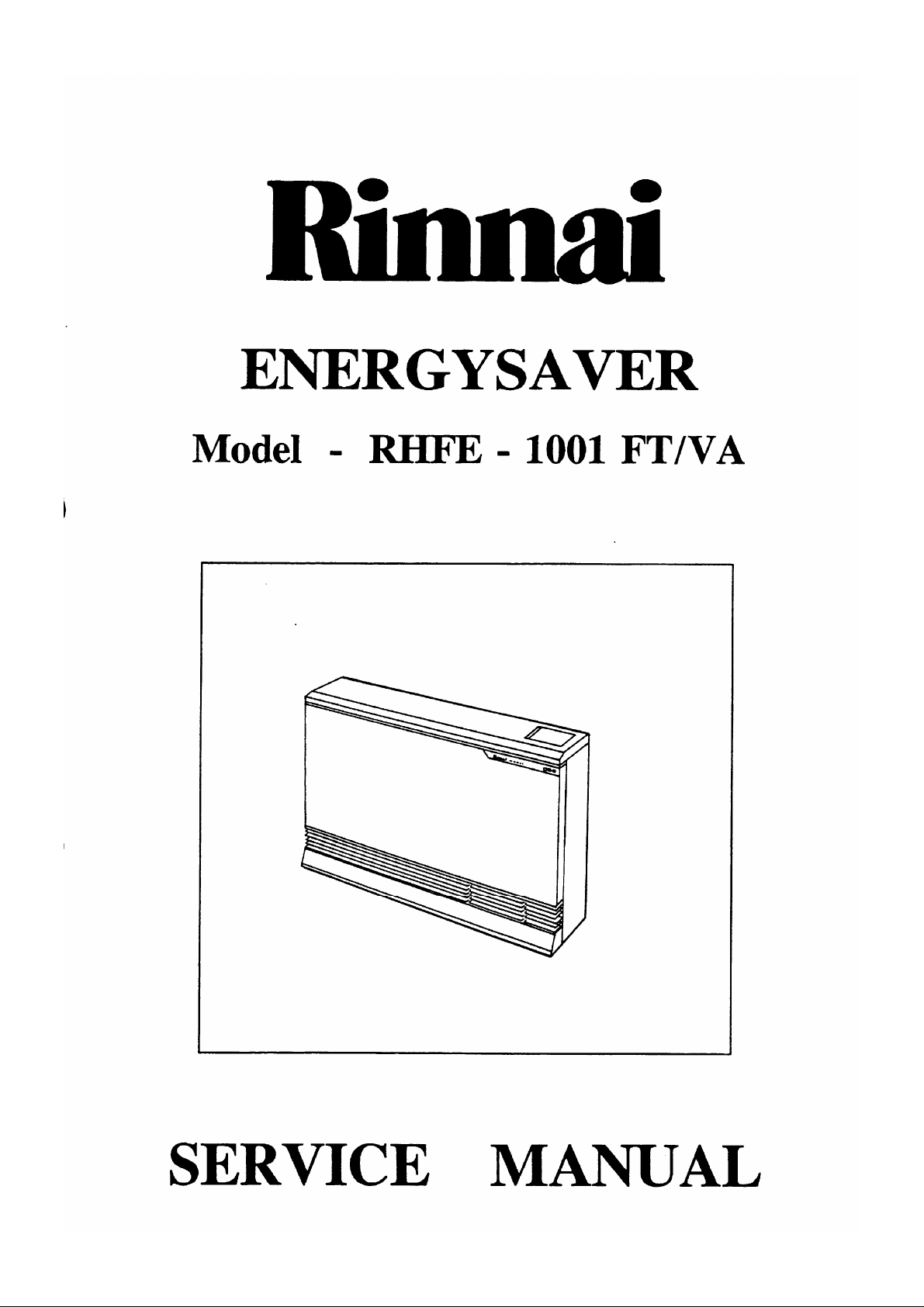

Page 1

Page 2

Page 3

CONTENTS

BACKGROUND

DISTINGUISHING FT & FT/VA

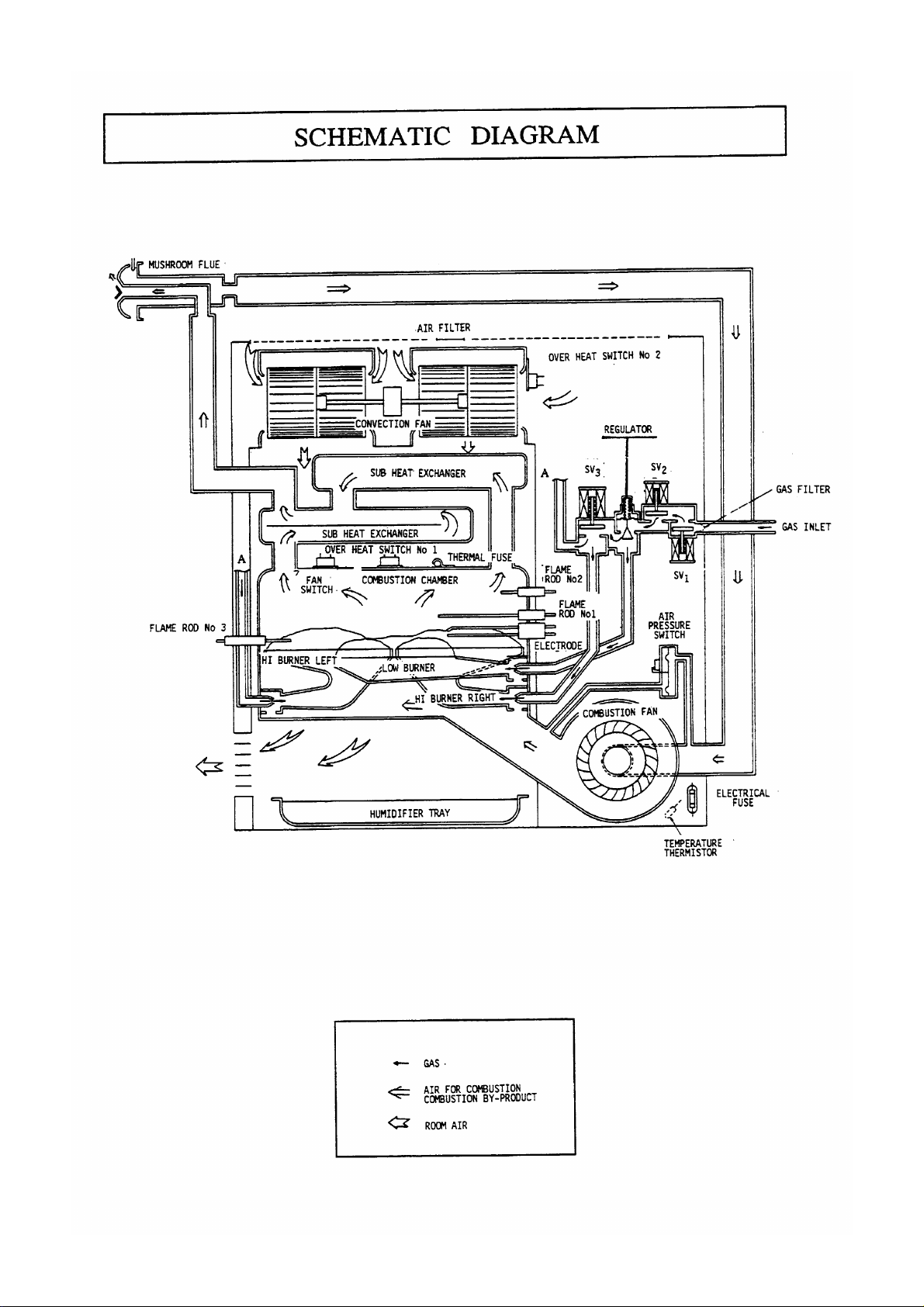

SPECIFICATION

PERFORMANCE CHARACTERISTICS

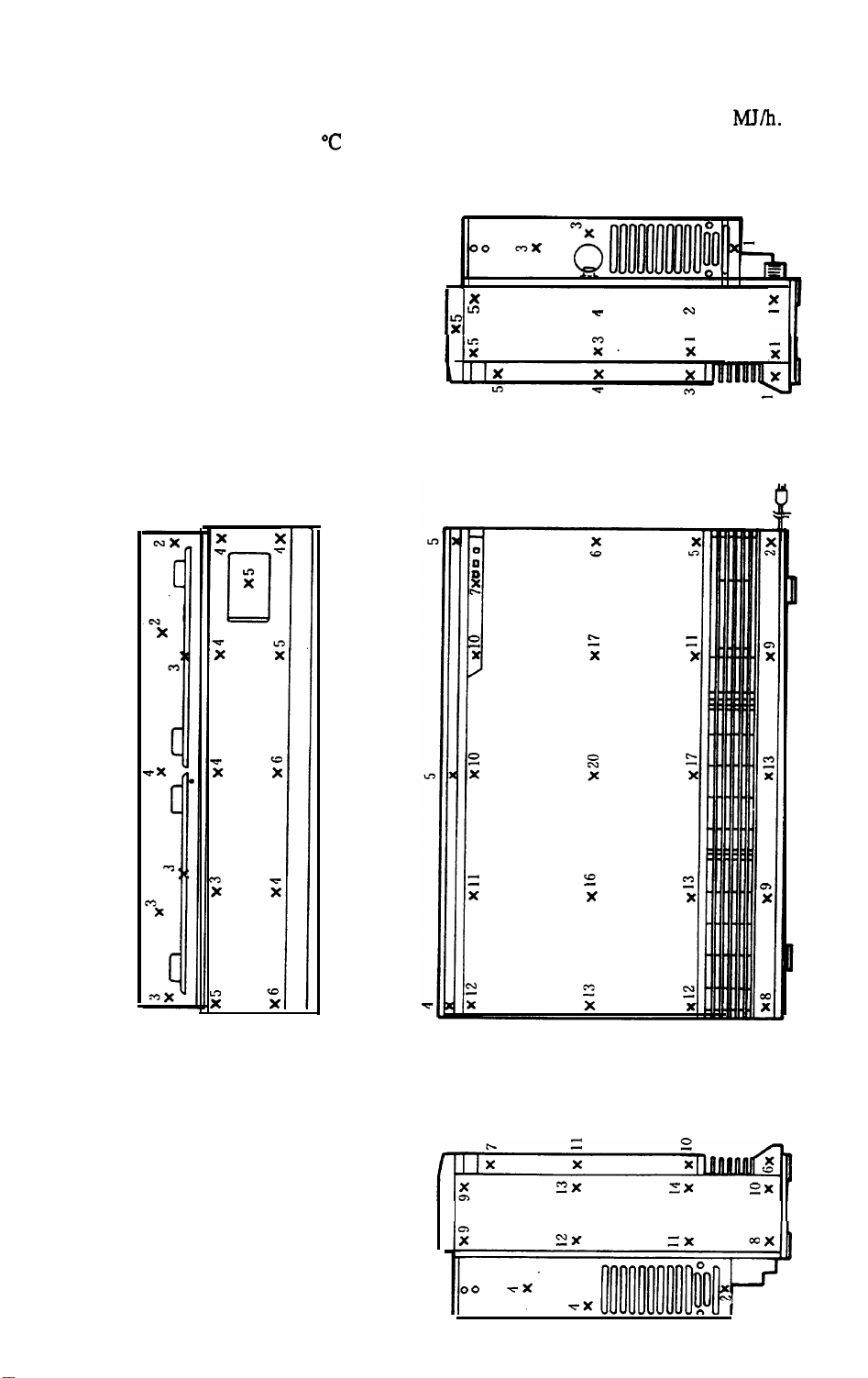

DIMENSIONS

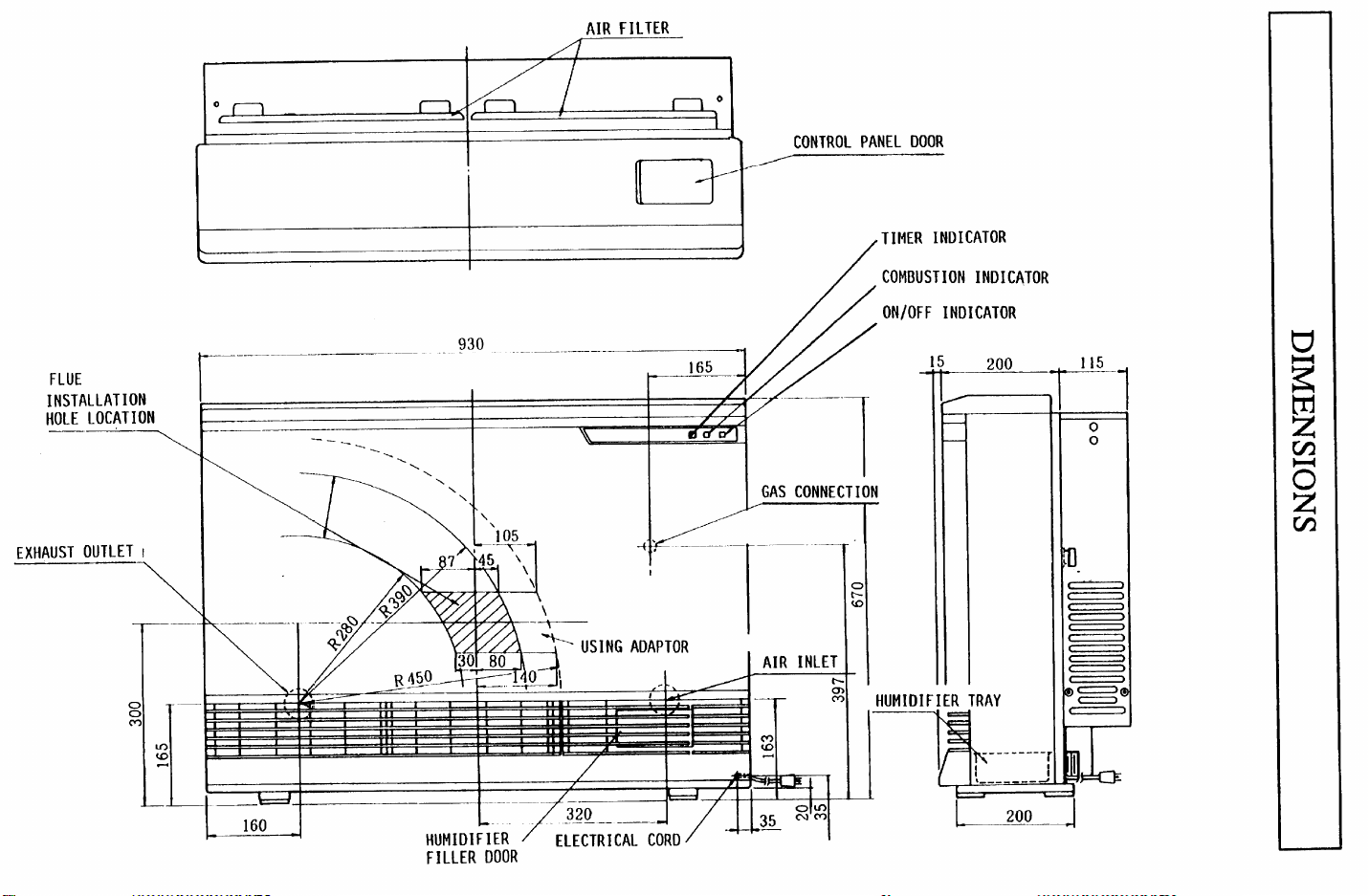

CUT-AWAY DIAGRAM

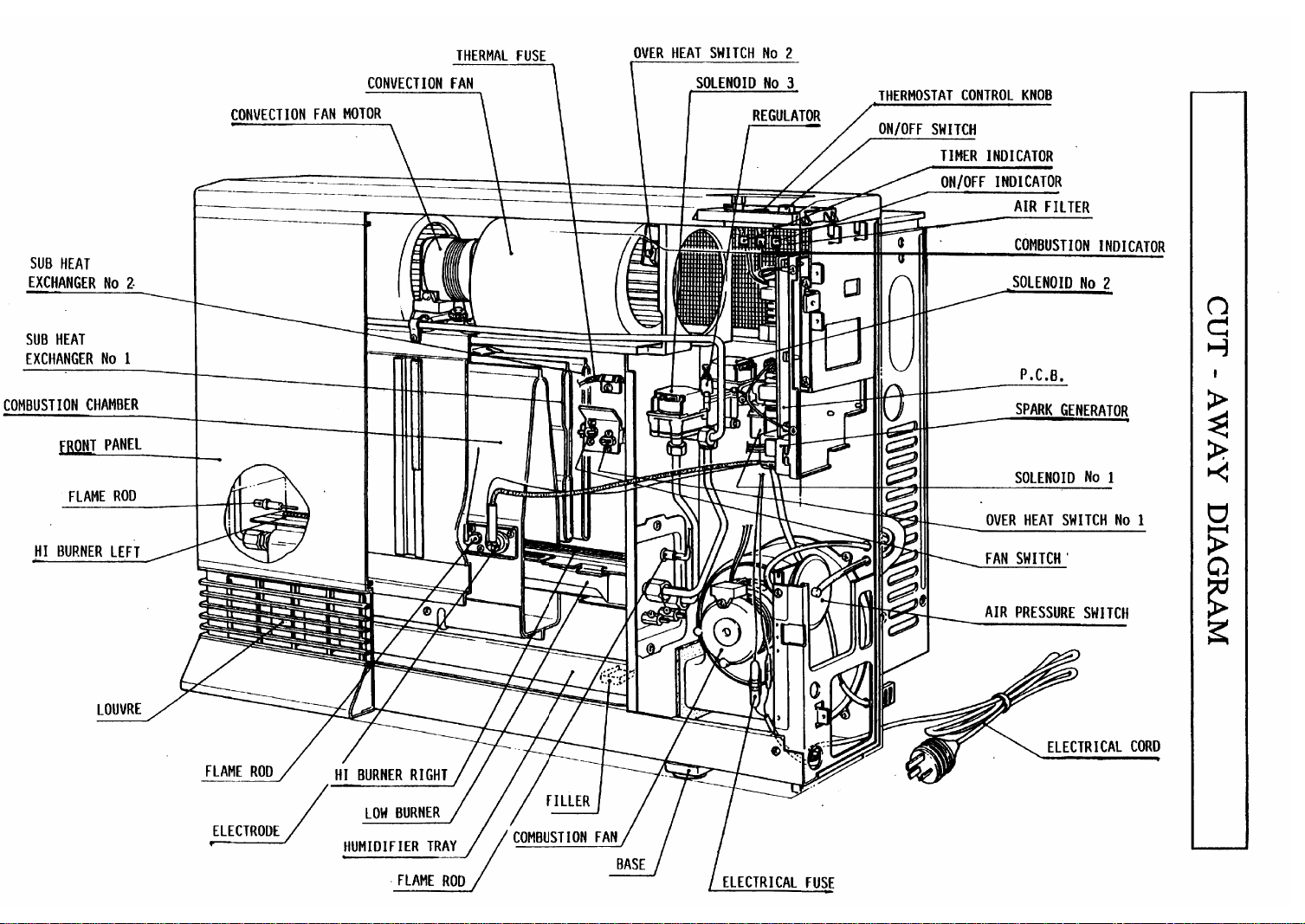

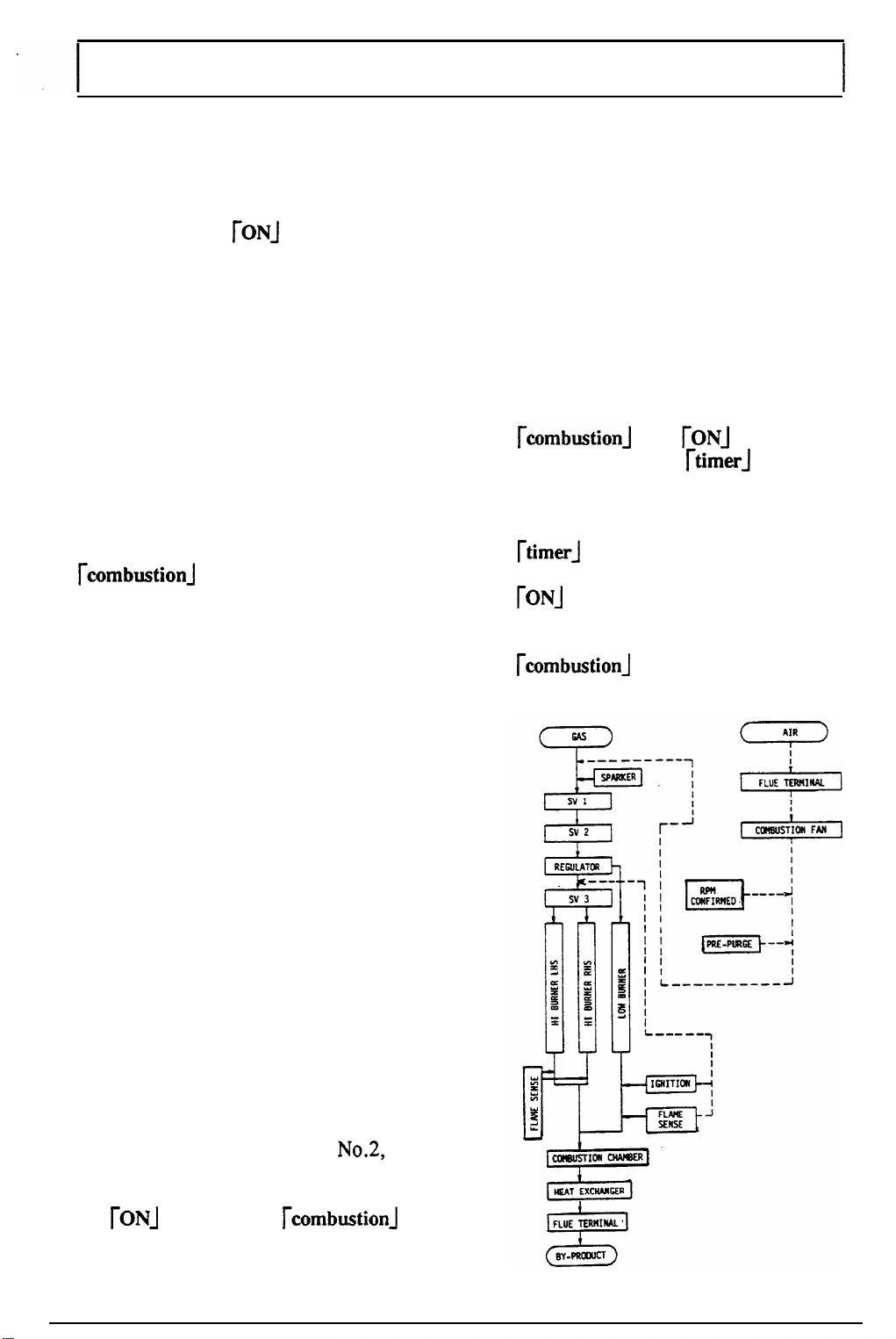

SCHEMATIC DIAGRAM

OPERATION

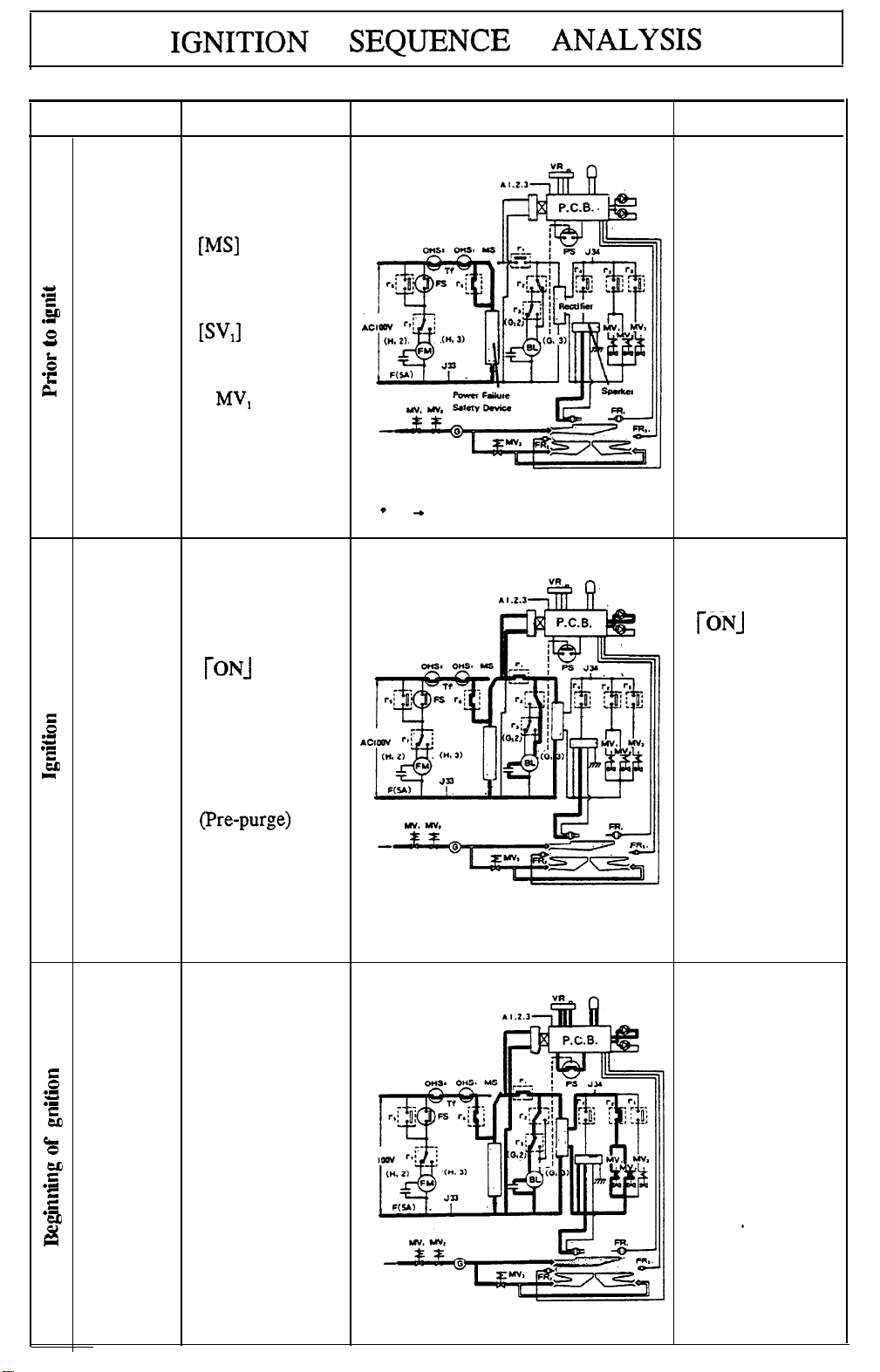

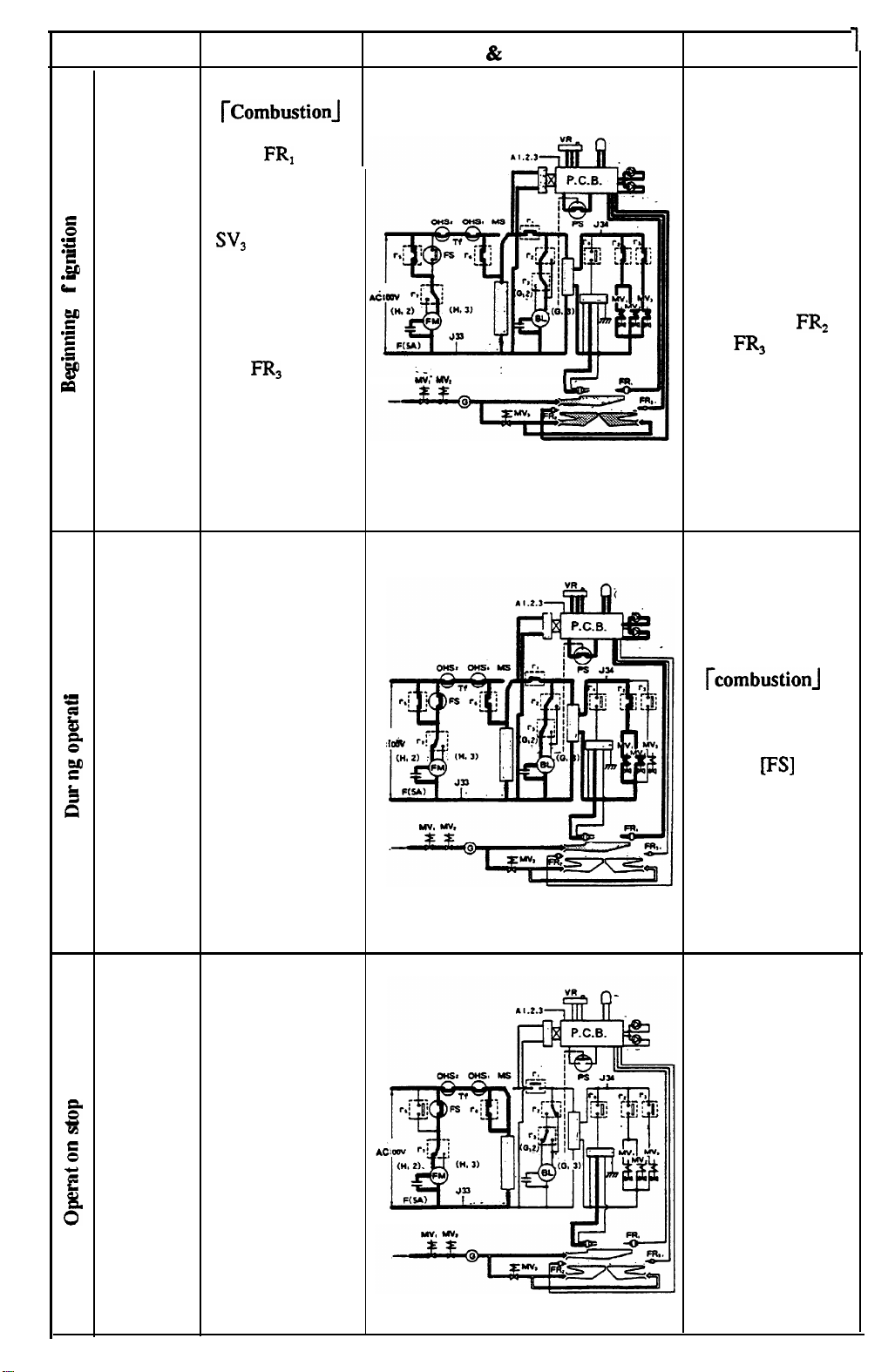

IGNITION SEQUENCE ANALYSIS

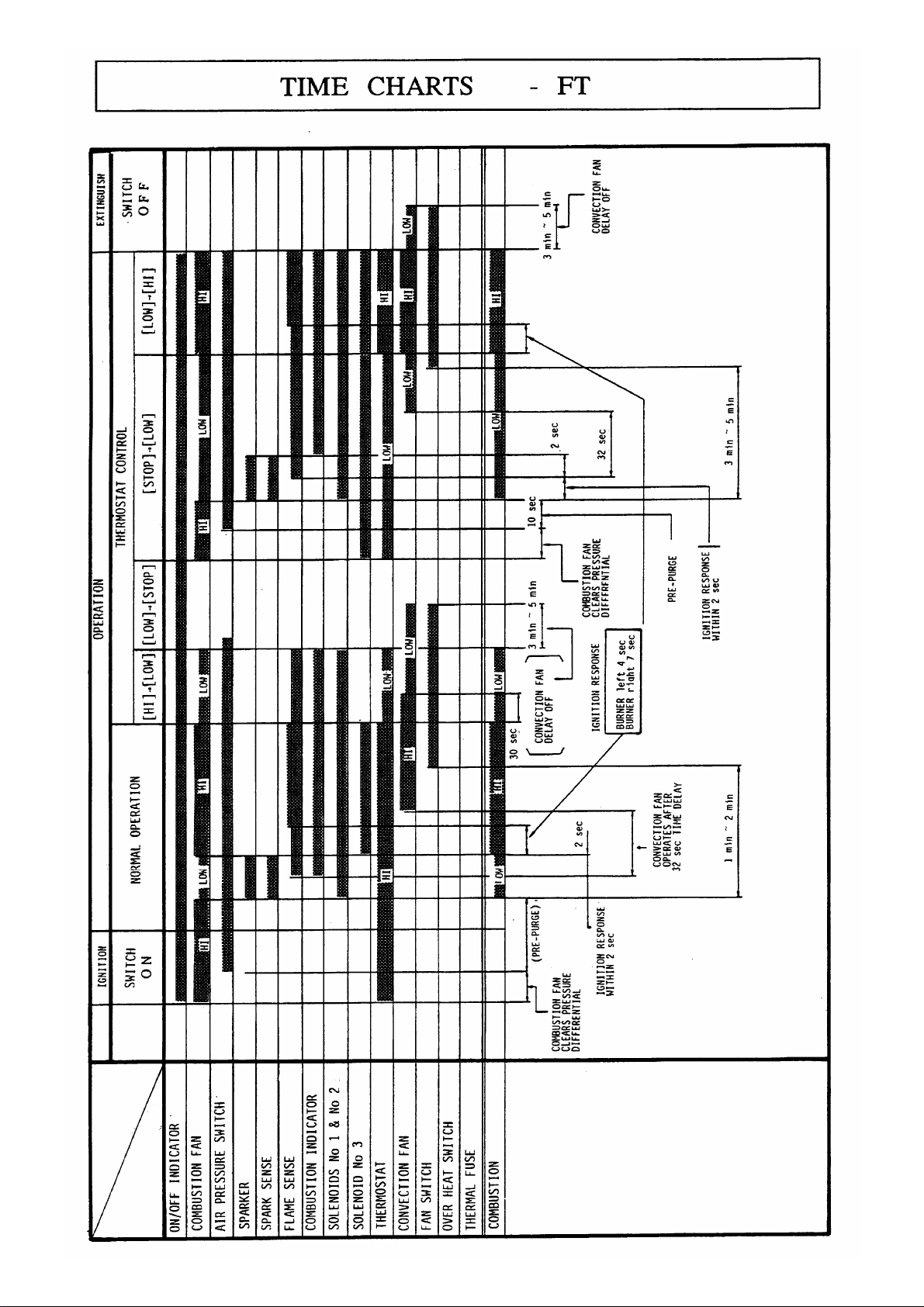

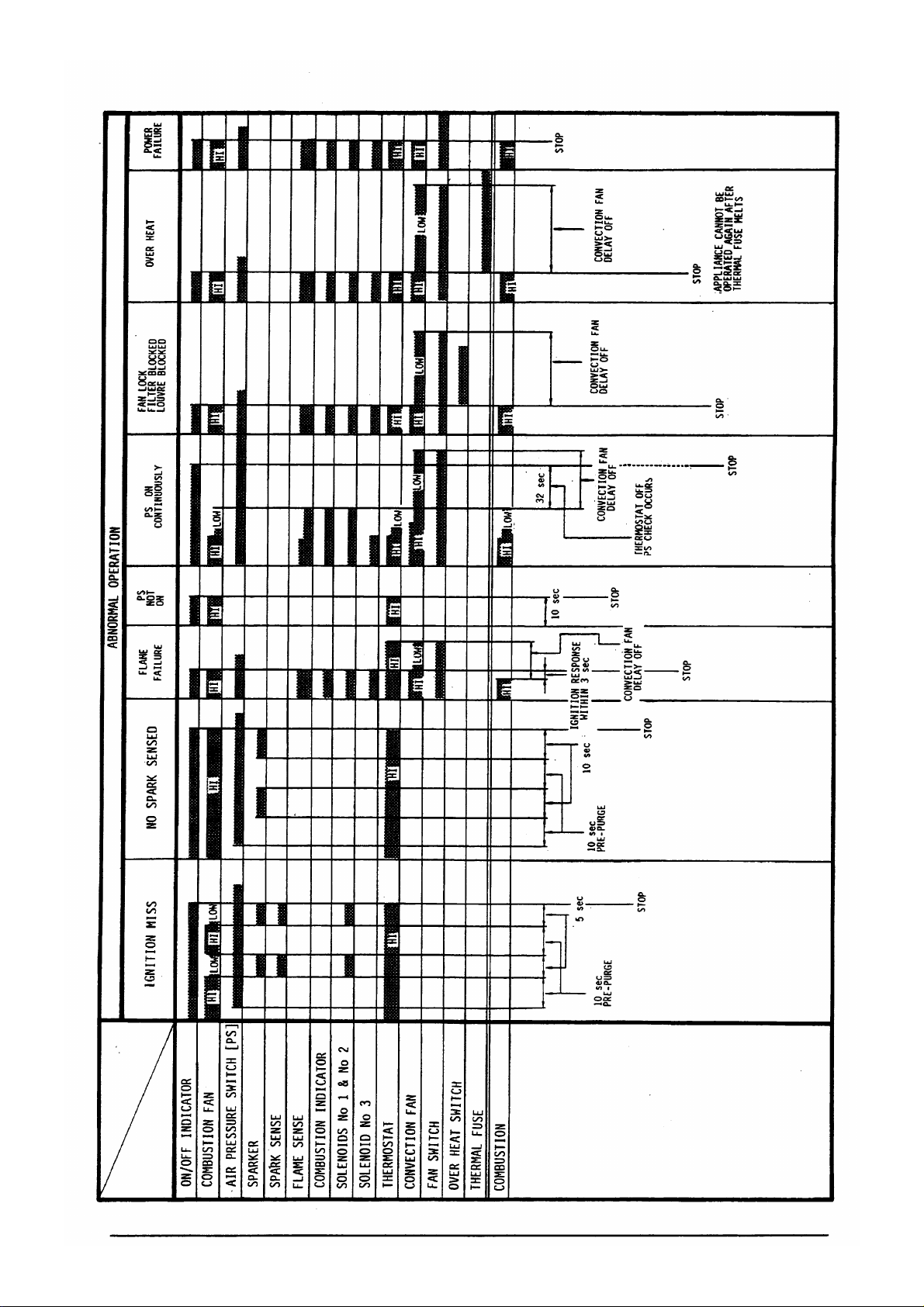

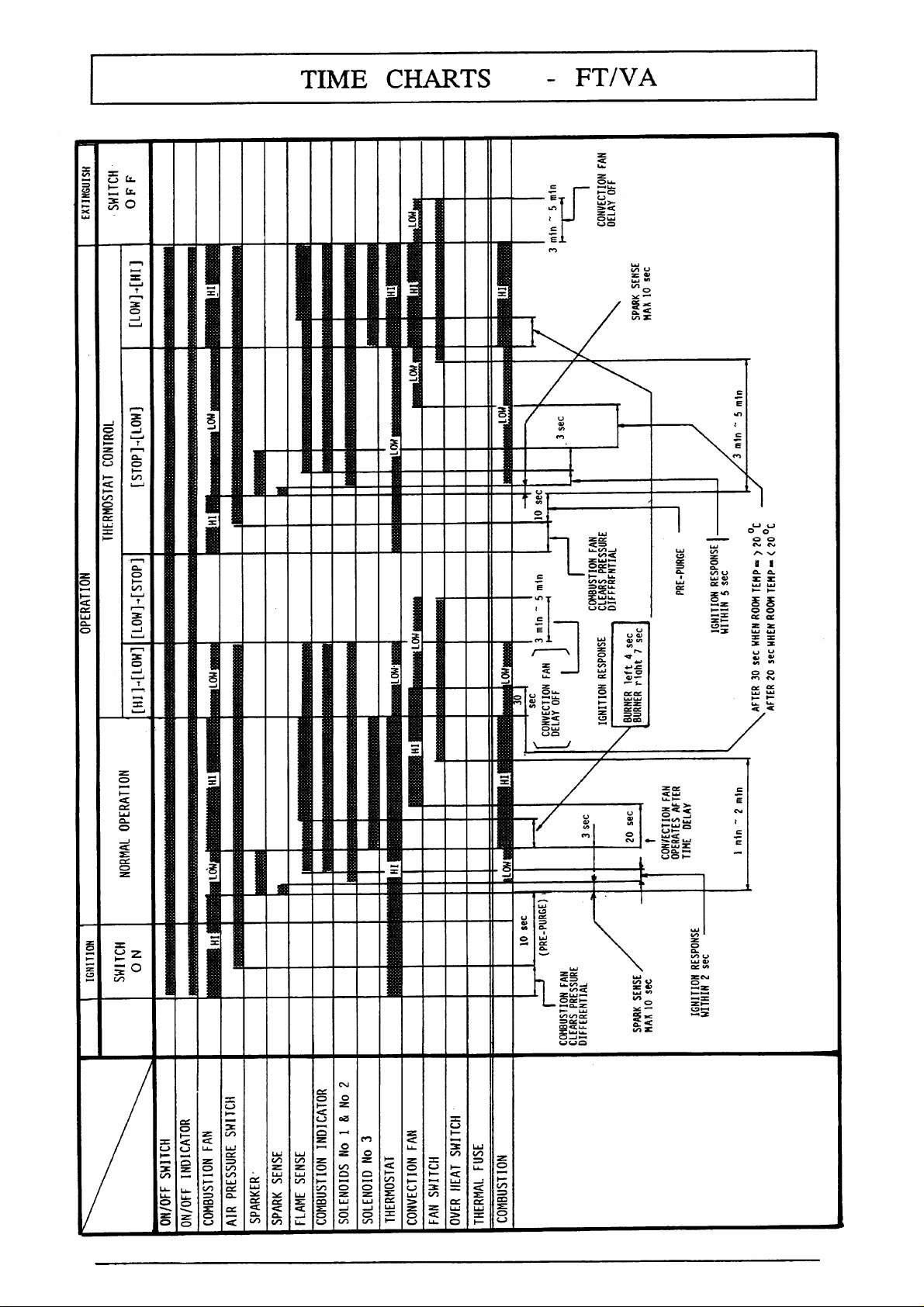

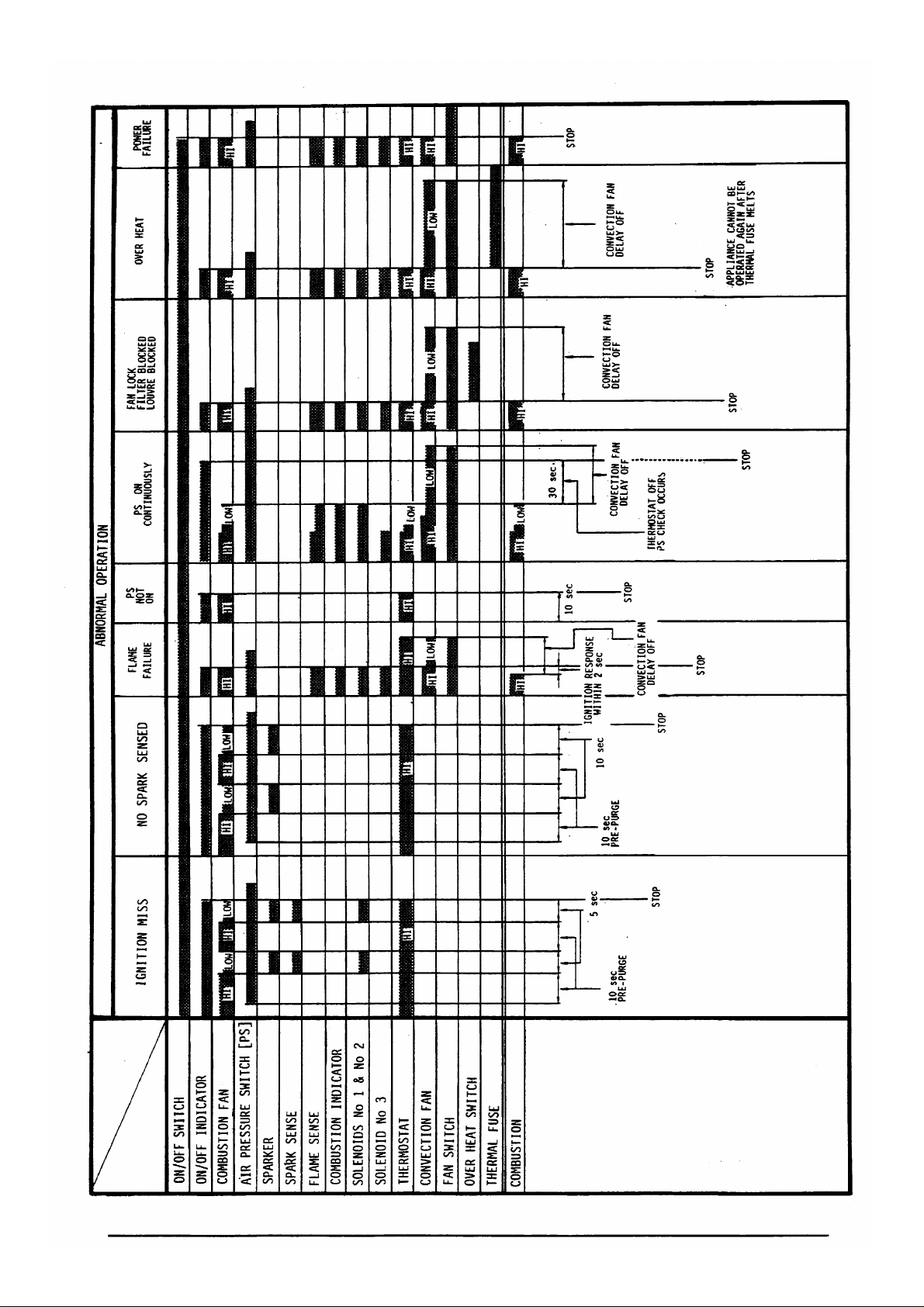

TIME CHARTS

TIME CHARTS

DIAGNOSTIC POINTS

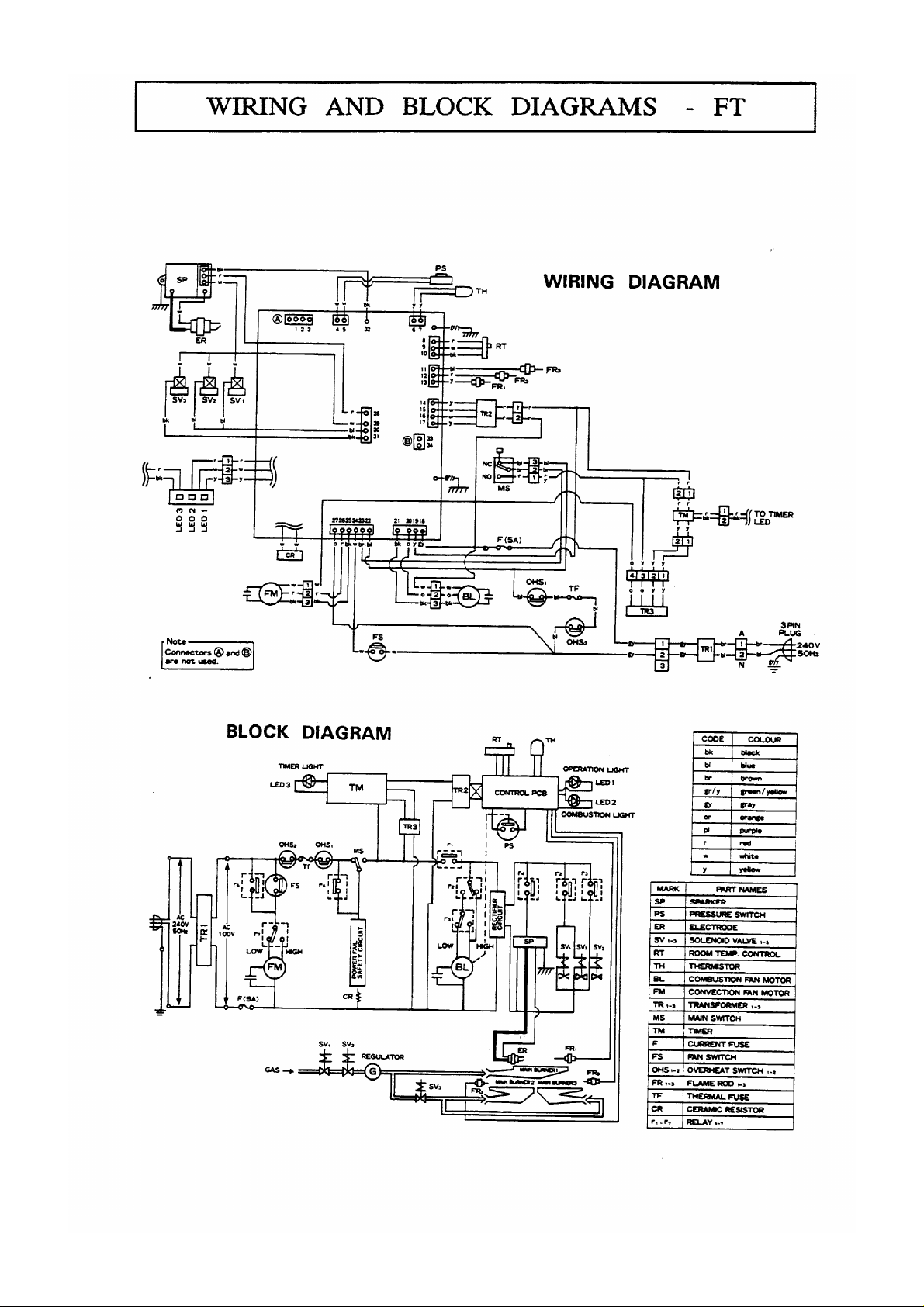

WIRING & BLOCK DIAGRAMS

DIAGNOSTIC POINTS

-T

- FT/VA

-T

-T

- FTfVA

14 - 15

2

3

4

5-7

8

9

10

11

12 - 13

16 17

18

19

20

WIRING & BLOCK DIAGRAMS

OPERATIONAL FLOW CHARTS

SAFETY DEVICES

OPERATION OF SAFETY DEVICES

FAULT FINDING

FAULT ANALYSIS

INSTALLATION

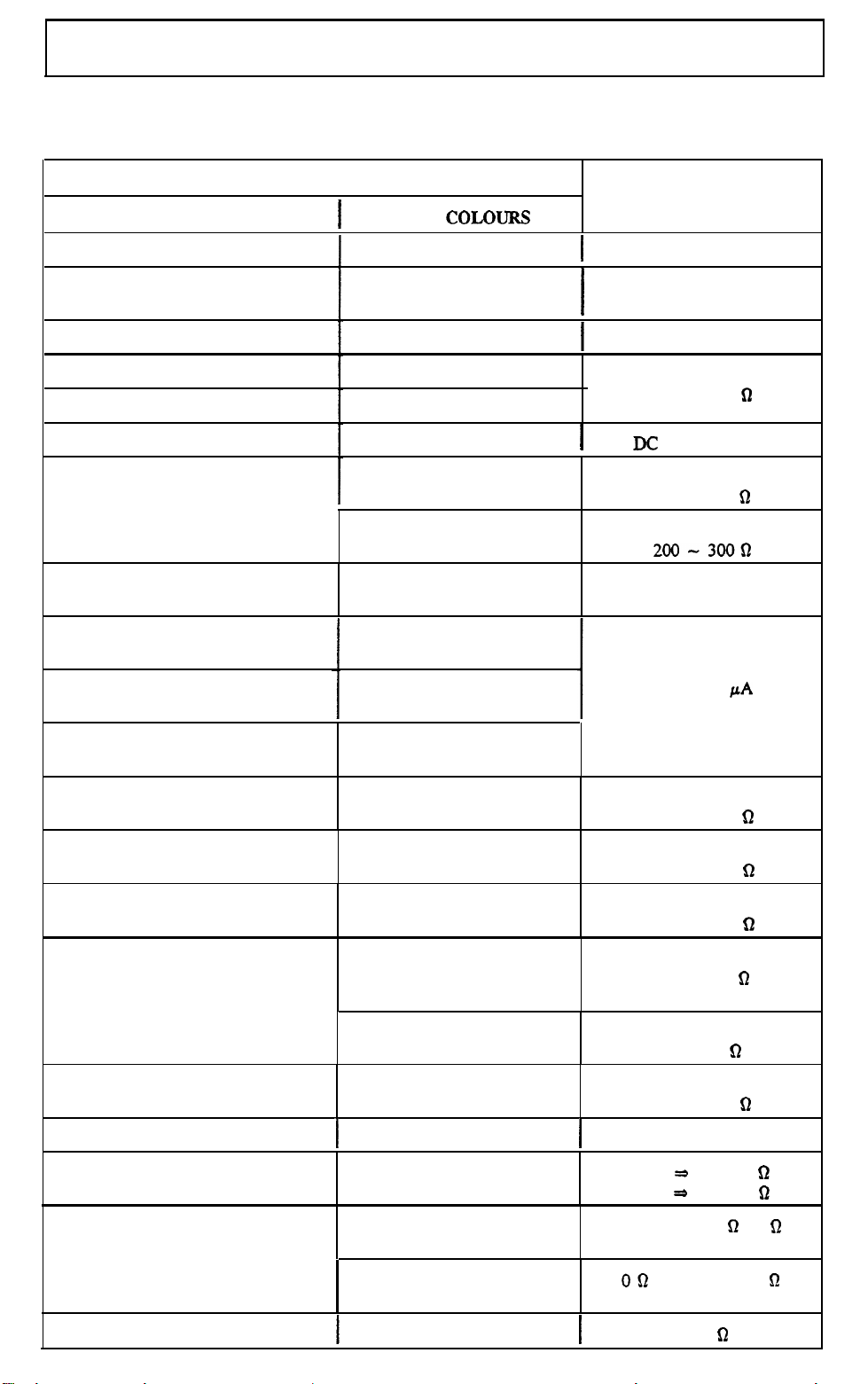

TRANSFORMER VALUES

ELECTRICAL COMPONENTS ANALYSIS

EXPLODED DIAGRAM

PARTS LIST

CONVERSION INSTRUCTIONS

DISMANTLING FOR SERVICE

CUSTOMERS OPERATING INSTRUCTIONS

- FTIVA

21

22 - 23

24 - 25

26 - 27

28 - 29

30-31

32

32

33- 37

38- 44

45- 49

50

51

-63

64- 65

FLUE SYSTEM

SERVICE NOTES

SERVICE CONTACT POINTS

66- 67

68

BACK COVER

Page 4

BACKGROUND

In 1983 the The RHF 1000 was launched onto the market in Australia. This was followed in

1986 by the launch of the RHFE-lOOlF, a completely new appliance with a new control system,

and compact lightweight design. The RHFE-lOOlT, released in 1991 is an updated version of

the

RHFE-1001F with the addition of a 12 hour slide timer. The

suited to commercial applications such as schools and small

domestic applications.

RHFE-1OOlFT

offices,

it is also ideal for large

is particularly

INTRODUCTION

* One

touch ON/OFF control.

*

Warm air distribution is from the bottom of the heater.

*

Three step automatic heat and fan control with the electronic thermostat.

*

Installation of the flue system requires only an 80 mm hole through a wall to the exterior of

the building.

*

The thermistor controls the room temperature within the range of 12.5 * 3°C to 35 + 7°C

with a differential of 1.5 +

*

In the event of a malfunction, one or more of the various safety devices will be activated,

ensuring complete safety.

OST.

The outer casing of the appliance is formed from 0.8 mm galvanised and painted steel, secured

to the main body assembly. The bodywork is formed from 1.2 mm galvanised steel sheet,

forming a casing to which the heat exchanger, blower assembly, solenoid valves, printed circuit

board and other componentry is attached.

The general layout of components is shown in the cut-away diagram on page 9. The heat

exchanger is composed of two (2) sub-heat exchangers which are constructed from 0.5 mm

stainless steel sheet. A combustion chamber is connected to the sub-heat exchangers, which in

turn are connected to the flue system.

The combustion chamber, constructed

occupies the middle of the appliance. Its dimensions are 622 mm wide x 94 mm deep x 319 mm

high. The burner is composed of two (2) large burners and one (1) small burner. The large

burners are slit port

0.5 x 7 mm, and the number of slits is 103 for each burner. The small burner is also a slit port

bunsen

The air for combustion, both primary and secondary is supplied by a 134 mm diameter Sirocco

fan. The air is drawn

right hand side of the combustion chamber. The primary air ports are adjustable within the range

of 0 to 135

by a screw.

type made of 1 mm stainless steel sheet, with 95, 0.5 x 7 mm slits.

mm2

bunsen

by means of the aeration shutters. The aeration shutter adjusting rod is fixed

type, made of 1 mm stainless steel sheet. The burner slit sizes are

from

the outside enviroment through the flue system and into the lower

f?om

1.0 mm hot dip aluminium coated steel sheet,

Three injectors are mounted inside the gas connection tubes, where they connect to each burner.

The gas inlet connection is an R

%“/

15 male thread, located at the rear on the

left

hand side

Page 5

[viewed from the rear] and situated approximately 400 mm

through the inlet to the double block solenoid valve No.1 and No.2 , then on to the regulator

which supplies the gas to the (central )

connection tube, injector and finally into the lower part of the combustion chamber where it is

ignited on the burner. When the appliance is operating on HI, the gas also passes through

solenoid valve No.3 whic h in turn allows the gas suppl y to the HI burners to be ignited.

Prior to ignition any combustion product or raw gas remaining in the combustion chamber is

purged by the combustion fan, preventing explosive ignition or flame vitiation by any remaining

by-products.

Ignition is by the continuous spark method in conjunction with the solenoid valves and micro

switch. The spark is monitored and controlled by the printed circuit board. The spark gap is 3.0

f

0.8 mm. [Generated voltage is llkv]

The products of combustion pass through the combustion chamber and sub-heat exchangers,

heating the room air before being expelled outside via the concentric dual pipe flue system.

Ai r is drawn in through the steel mesh filters located at the top of the rear panel by the

centrifugal convection fans and blown onto the outer surface of the combustion chamber and

sub-heat exchangers, before passing over the open vessel type humidifier out into the room

through the louvres, located at the bottom front of the outer cover. The average humidification

is 300 cc/h WI setting].

LOW

operating burner via a 10 mm diameter alurninium

fro m

floor level. The gas passes

The humidifier tray is fabricated from 0.6 mm cold rolled carbon steel sheet, black enamellecl

with a maximum capacity of 3 litres of water. Any condensation in the flue manifold is drained

into the humidifier tray.

The warm air outlet consists of six (6) fixed horizontal louvres and eight (8) vertical adjustable

air guides.

DISTINGUISHING T & FT/VA

The

RHFE-1OOlF T

main difference is in the printed circuit board

The RHFE-lOOlFT/V A can be identified by the

appears printed on the printed circuit board. The

1OOlF A

This manual provides information on servicing and fault finding for both FT and

versions. Where data differs between the appliances, seperate sets of information are provided.

The differing information is: time charts; diagnostic points; block and wiring diagrams;

operational flow chart; electrical component analysis; and parts list.

and has a ceramic resistor attached to it by 2 white wires.

and the RHFE-1OOlFTN A are basically the same appliance. However, the

P.C.B. ]

markin,,

and its related wiring harnesses.

a

Rinnai-RBC

RHFE-1OOl T

RHF-lOOlF(VA) ,

P.C.B. is marked

which

RHFE-

FTNA

All other information is common to both appliances.

Please ensure that yo u have identified the heater correctly before attempting servicing as

well as when ordering spare parts.

Chang e to FT/VA model

occure d

in September 1992

Page 6

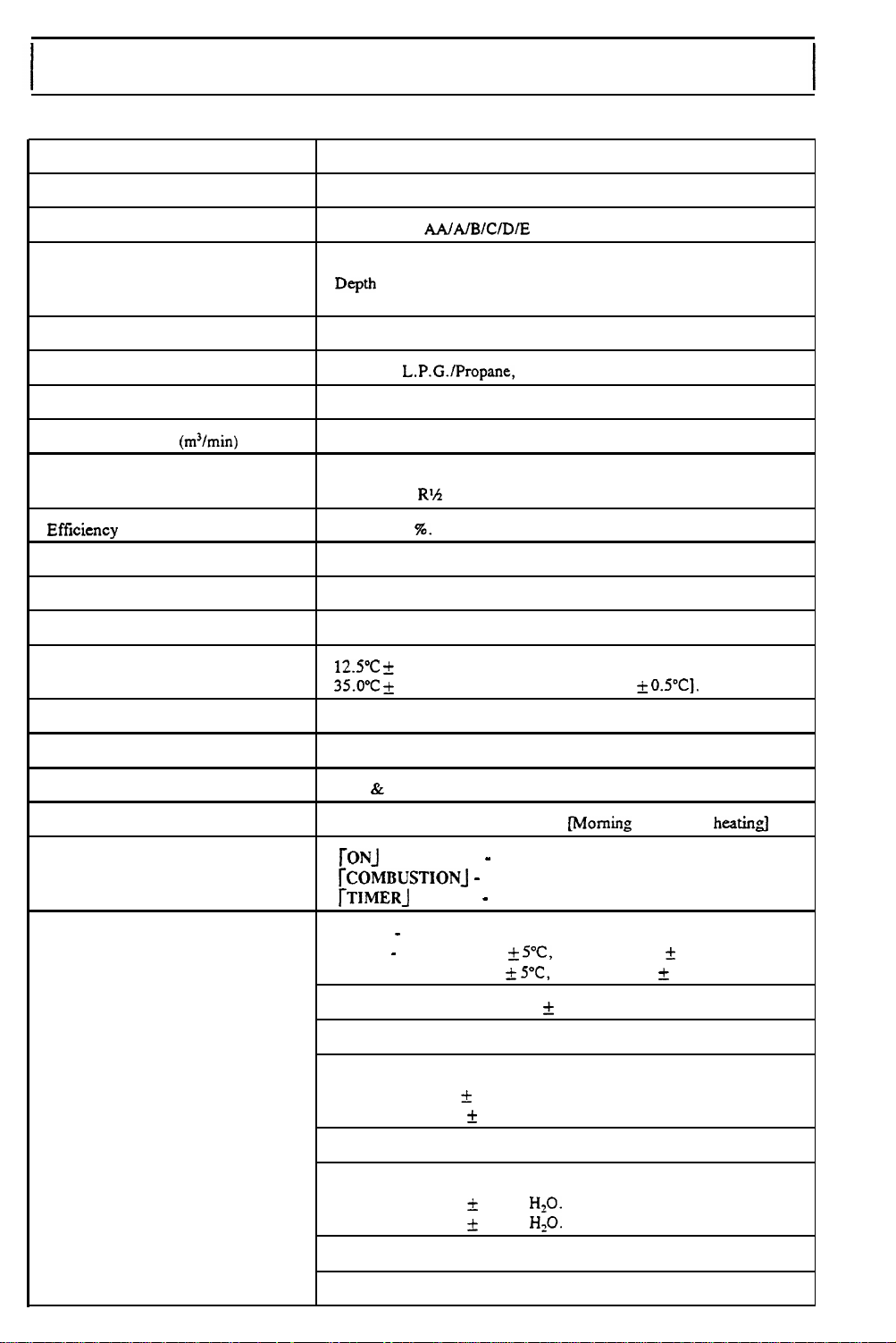

SPECIFICATION

Type of appliance

Model

Exhaust system

Dimensions

Weight

Gas type

Gas controls

Heated air volume

Connections

Efficiency

Combustion system

Ignition system

Temperature control

Temperature range

(m3/min)

Forced flue gas space heater.

-

1001 FT. RHFE - 1001 FTNA.

RHFE

Mushroom -

Width = 930 mm.

Depth

Height

41 Kg [Standard].

Natural,

Solenoid and combined regulator.

HI - 8.1 LOW

Electrical - 240 V

Gas

Approx 85

Forced combustion with stainless bunsen burner.

Automatic flame sensing continuous spark.

OFF

-

12.s0c + 3°C [LOW).

35.O”C k

AA/A/B/C/DIE

= 330 mm with spacers.

= 670 mm.

L.P.G./Propane,

-

5.0

50

Hz.

-

RX

(l5mm).

%.

MED - HI [Slide mechanism]. Electronic thermostat control.

7°C [HI-j.

Differential of 1.5

Co-axial approved.

T.L.P.

[NZ:

230 V 50 Hz].

& OYC].

Warm air outlet

Humidifier tray capacity

Fan control

Timer operation

Indicators

Safety devices

Bottom of appliance at front. [Adjustable]

Approx 3 Iitres. Evaporation rate 300 cc/h.

& Fan switch.

PCB

12 hr delay slide operated timer.

-

rONJ

rCOMBUSTION] -

rTlMERJ

O.H.S.- Bi-metal.

No.1- OFF app 130 +

No.2 - OFF app 65 +

Thermal fuse Flame failure - flame rod. Flame rectification]

Fan switch - Bi-metal.

ON- 60 + 5°C.

OFF Power failure -Power failure circuit.

Air pressure -

- 6.0 & 2mm

ON

OFF - 4.8 + 2mm H,O.

green.

red.

-

green.

Melt s at 152

+ 5°C.

43

Air pressure differential.

Morning

ON app 110 + 10°C.

YC,

ON app 50 + 10°C.

5”C,

+

2°C.

H1O.

or evening

heati@

Power surge- 5 Amp fuse.

Pre-ignition

- Spark sensor.

Page 7

I

1,

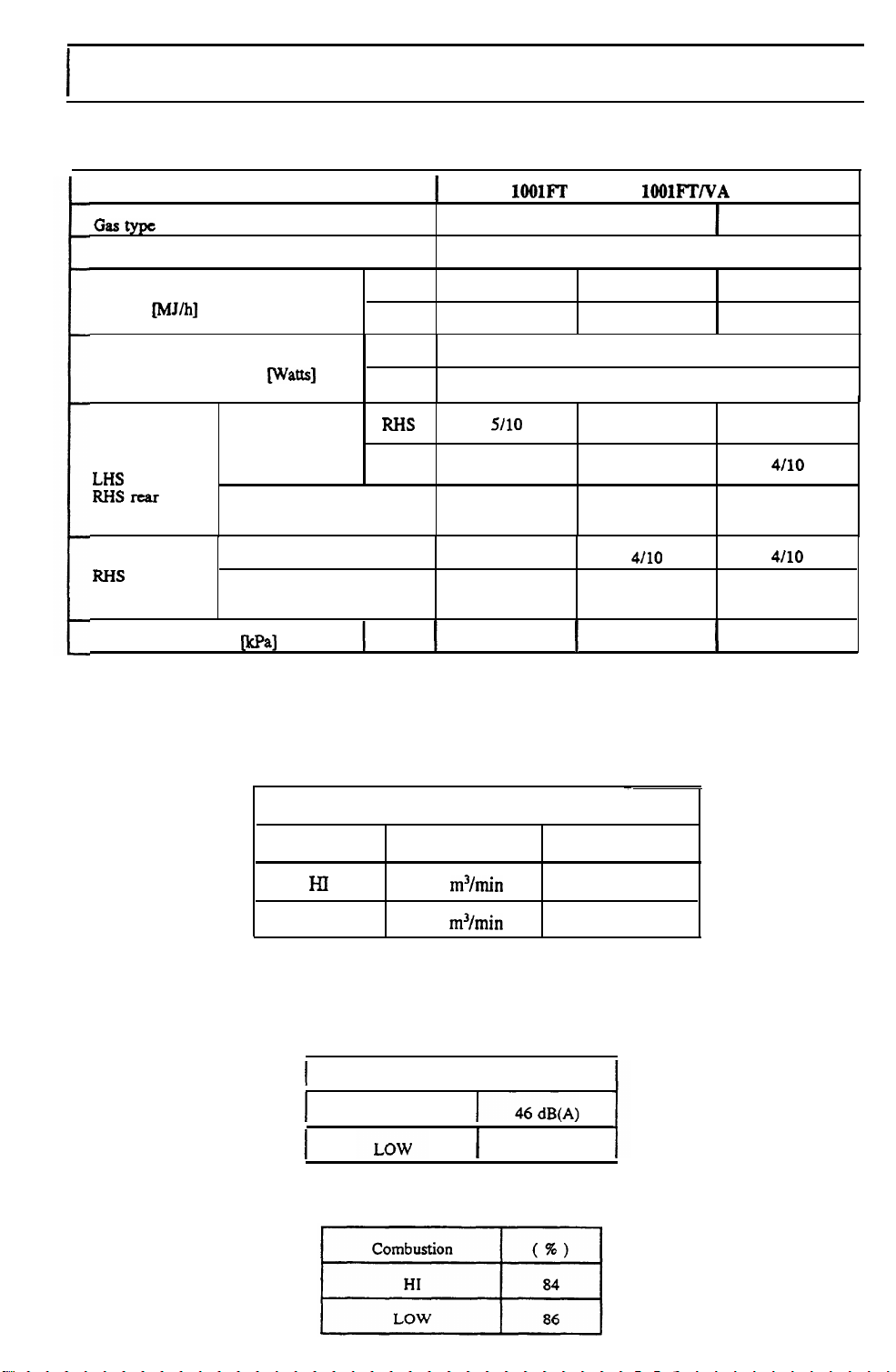

COMBUSTION SPECIFICATION

PERFORMANCE CHARACTERISTICS

I

Model

G=typc

Combustion method

Input

Electrical Consumption

HI burners

LIiS

RI-iSX-ar

burner

LOWburner

R&IS front

Regulator pressure

mJ/h]

Damper

Opening

burner

Injector

Damperopening

injector

Fprt]

HI

LOW

HI

watts]

LOW

RI-IS

LHS

size

size

HI

RHFE - 1OOlFT

Natural

Stainless steel

37

14.5 18.6

s/10

5/10

1.65 mm

x2

7110

1.75 mm

Xl

0.98

RHFE-

I

bunsen

I

1OOlFTNA

T.L.P.

type burner.

37 38

110

65

5/10

5/10

3.25 mm

x2

4110

3.25 mm 1.05 mm

xl xl

0.45

Propane/L.P.G.

16.5

4110

4110

0.95 mm

X2

4/10

I

2.75

2.

OPERATING NOISE LEVELS

3. EFFICIENCY

Convection Fan

Air Flow

HI

LOW

I

I

8.1

m3/min

5.0

m3/min

Standard noise levels

HI

I

35 dB(A)

Fan Speed

840

510 rpm

_

rpm

Page 8

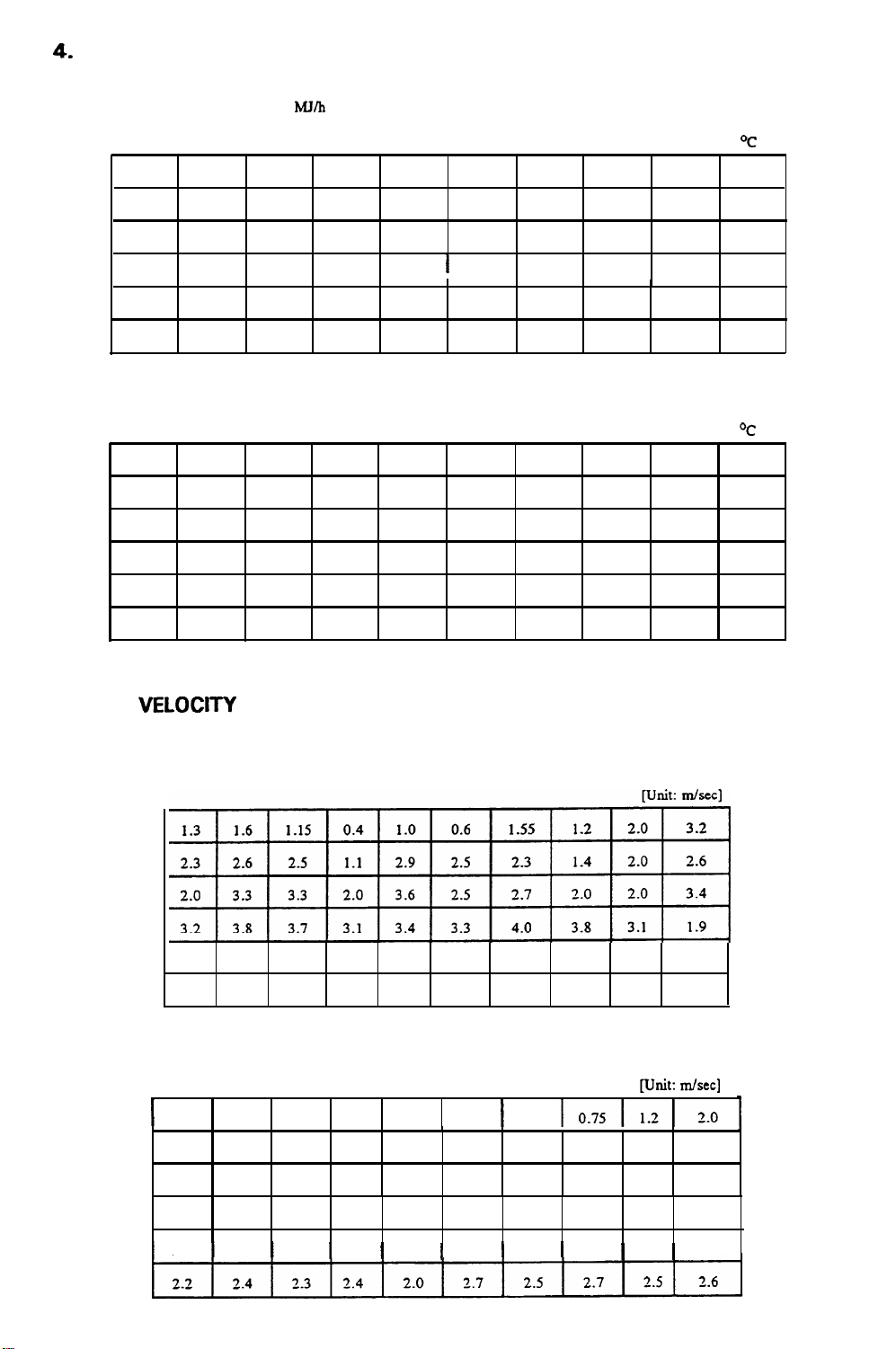

LOUVRE TEMPERATURES

4.

HI Combustion

54

80

78

58

61

60

LOW Combustion

30

38

38 35

31

30

30

59 66

82

62

54

53

54

36

45

30

28

29

:

38

Input

Input

MJRI

36 32

86 80

63 94

55

52 70

52

:

14.5 MJ/h

46 36 34

60

40

33

29

28

77 75 ’ 63

74

61

68 46

47 44

40

40

52

69 85

72

76

73

60

42 34

42

77 64 68

61

57

43

71

51

34

33

Temperatures are above ambient.

72

85 63

61

59

55

49 26

59

39

33

32

31

45

59

59

58 58

36

37 30

31

31

30

37

67

53 56

55

55

34

35

30 29

30

31

unit: oc

Unit:

OC

44

51

52

56

26

30

30

30

5.

AIR

VELCKXI-Y

HI Combustion

LOW Combustion

I

3.8 4.0 3.8

3.4

4.1

0.7 0.7 0.65

1.55 1.7 1.7

1.05 1.95 1.9

1.8

2.2 2.2 1.7 2.1 1.95 2.5 2.0 1.7 1.3

3.7

3.8 3.6 3.9 4.2 4.3 3.5

3.9 3.9 3.9

3

._

0

0.7

1.0 2.0

0.7 0.6

1.45

4.1 4.1

1.35

1.5

0.95

1.45

1.8

0.8

I.15

4.2

[Unit:

1.2

1.0

3.8

m/set]

I

1.7

1.9

2.2 2.4 2.3

1

2.3

1

2.0

2.5 2.6 2.5

1

1

2.0

1

Page 9

SURFACE TEMPERATURES

6.

Temperatures were taken with the appliance operating on Natural Gas at 38

AI1

temperatures shown are “C above ambient.

In

x

II

x

In

X

c

W/h.

X

N

%

-11

Page 10

Page 11

Page 12

Page 13

OPERATION

Normal Operation Operating the Timer

After the ON/OFF button is set to the

ON position, the

glow. The combustion fan will begin to

rotate, and pre-purge begins.

As pressure rises in the heat exchanger

the pressure switch will operate, and

after approximately 10 seconds the spark

will occur.

The spark sensor checks that the spark

has

occured

Solenoids No.1 and No.2 will open to

allow the gas to flow and ignite on the

LOW burner [LOW combustion]. When

the flame rod senses the flame, the

rcombustionj

As the spark ceases, solenoid No.3 will

open allowing the gas to

on the HI burner

depending on the thermostat position.

Approximately 30 seconds after the flame

rod senses the flame, the convection fan

will begin to operate, and warm air will

flow through the louvres at the front of

the appliance.

across the spark gap.

rONJ indicator will

indicator will glow.

flow

and ignite

[HI

combustion],

Press the ON/OFF button to the ON

position. Position the thermostat control

knob in the desired position. Decide upon

the number of hours delay after which

you would like the heater to begin

heating, and move the vertical slide timer

select knob accordingly. If the delay is

less than 2 hours, the slide timer

should be moved to 12 hours then back

to the desired delay. The

rcombustion]

will go out and the

will glow.

When the time of ignition arrives, the

[timer1

ignition sequence will occur and the

[ON] indicator will glow.

When

rcombustionj

and

rONj

indicators

[timer-J

indicator will go out, the

the burner ignites, the

indicator will glow.

indicator

Room Temperature Control

Temperature is selected by positioning

the horizontal thermostat control knob to

the desired locationalong the slide.

Turning OFF

After the ON/OFFbutton is set to the

OFF position, solenoids No. 1,

No.3 will shut off the gas supply to the

burners and the combustion fan will stop.

The

rONA

indicator and

indicators will go out. Several minutes

later the fan switch will turn off, and the

convection fan will stop.

rcombustion]

No.2, &

Page 14

Action

Operation

Gas passage & electrical circuitry

Remarks

Insert

plug into

wall

socket.

c

0

.I

Y

rrl

5

.-

0

b

.I

k

ON/OFF

button to

ON

Current

through to

micro switch.

[MS]

Gas through

to solenoid.

ISVJ

= sv,

MV,

MV, = SV,

MV, = SV,

Micro switch

[MS] is

activated.

*

240 + 100 inside appliance

position.

TONJ

indicator

5

.-

d

.C

&

glows green.

AC

Combustion

fan operates

on HI.

(Pre-purge)

No obstacles

in gas supply

connection tube.

If there is air

in the supply

line, then it

will take time

to ignite the

appliance upon

initial ignition.

Confirm power

supply if

r0NJ

indicator

doesn’t glow.

If ON/OFF

button is in

ON position at

time of placing

electrical

plug into wall

socket, unit

won’t operate

due to power

failure safety

circuit.

Air pressure

switch is

activated. Spark

g

.II

Y

.I

5

.I

CL

0

z

-4

z

.L

2

#

occurs

approximately

10 seconds after

current passes

through the

P.C.B. unit.

Solenoids SV,

&

gas ignites on

the LOW

burner.

SV, open and

AC

Spark sense

checks that the

spark has

occured

across the

spark gap.

Combustion

fan operates

from HI to

*

LOW

Page 15

Action

Operation

Gas passage & electrical circuitry

Remarks

[Combustionj

indicator glows

after

senses a flame.

5

.-

U

.”

EE

.cr

0

z

.C

g

‘Eb

&

2 seconds later

SV,

combustion fan

operates on HI.

Combustion

continues as FR,

and

flame.

Convection fan

operates with in

32 seconds of

flame sense.

Position

the temp

control

knob to

the

desired

8

.-

position.

3

As the

thermistor

senses the room

temp, the

P.C.B. adjusts

the burner

setting

automatically.

$

?

.I

L

a’

The convection

fan operates for

30 seconds on

HI after burner

setting changes

to

FRI

opens and

FR,

sense a

LOW.

AC

Mu; uvr

Two attempts at

ignition occur.

Appliance will

lock out if

ignition does not

occur the second

time.

Appliance

locks out if

FR2

and FR, cease to

sense a flame.

When the

appliance

modulates from

LOW to OFF,

the

rcombustionj

indicator goes

out, within a few

minutes the fan

switch

IFS]

goes

OFF and fan

stops.

ON/OFF

Solenoids close.

button to

OFF

position.

3

m

E

.I

z

%

0”

Combustion fan

stops operating.

After a delay,

fan switch goes

OFF and the

convection fan

stops.

The electrical

plug must not be

removed from the

wall socket whilst

the convection

fan is operating.

Page 16

Page 17

Page 18

Page 19

Page 20

DIAGNOSTIC POINTS -FT

Note:

Main switch Blue - Red

Over heat switch No. I

Over heat switch No.2

Thermal fuse Blue

LED 1 Yellow

LED 2

LED 3 Red

Combustion fan

Air pressure switch white - White

Numbers under wire colours indicate pin markers on wiring diagram. See page 19

MEA- POINTS

COMPONENT

I

WIRE

coLouRs

Blue - Blue

Red

White

White - Orange

4

VOLTAGE OR

RESISTANCE

VALUES

I

I

-

Blue

-

White DC 14 - 23 Volts

-

White

-

Black

-

Black

- 5

I

I

Below AC 1 Volt

Below AC 1 Volt

Below AC 1 Volt

Above 1 M

DC

30 - 40 Volts

AC 90 -

AC 90 -110 Volts LOW

Below DC 1 Volt

110 Volts HI

120 - 180

200-3OOs2

Q

Q

Flame rod No.

Flame rod No.2

Flame rod No.3 Blue - F R

Solenoid

SolenoidvalveNo.2

SolenoidvalveNo.3

Convection fan

Sparker

Fan switch

1

valveNo.

1

I

Yellow

White -Blue

White

White-Black

White - Red

White

Red

White - White

-

F R

13

Red

-

F R

12

11

29 -30

-

Blue

29 -30

29-31

-

Black

-

White

-

29

28

AC 90 -

AC 90 -

I

Above 0.8

DC 80

DC 80-

DC 80

DC 80 -

-

110 Volts

1.3

-1.8 k

110 Volts

1.3

-1.8 k

100 Volts

-

1.3

-1.8 k

110 Volts LOW

100 - 140

110 Volts HI

50 - 70

100 Volts

Above 1 M

Below AC 1 Volt

PA

Q

Q

Q

f2

Q

Q

Thermistor Yellow - Yellow

-

Red

Slide control

Ceramic resistor

White

9

-

8

White - Black

9

-

10

White

-

White 1.8 k

Approx 30 k

10°C

=$

app 65 k

20°C 9 app 39 k

Q

- 0

OQ- approx 30 k

C?

Q

Q

Q

!I

Page 21

Page 22

DIAGNOSTIC POINTS

-

FT/VA

N0t.C

FC - refers to the numbers in circles on the flow chart at the Iefi of the sequence. [see page

WD - refers to the position of the connections on the wiring

Numbers under wire colours indicate pin markers on

MEAsuREMEhT

FC COMPONENT

113

PI ’

PI

[41

Main switch

O.H.S. No.1

Thcxmal

fuse

O.H.S. No.2

Timer

transformer

LED 2 assembly

Combustion fan

Air pressure switch

POINTS

F,

G,

G,

G,

C*

C,

G,

Sparker

diagram.[see

wiring

diagram.

WIRE

COLOIJR

Brown - Red Below AC 1 Volt

Grange - Orange Below AC 1 Volt

Orange - Orange

Orange - Blue

Yellow - Yellow AC 20

white -

Yellow

-

Black

White

white -

orange

Brown

-

Brown

6 7

Blue

- Grey

37

38

page

211

VOLTAGE

VALUES

Below AC

Below AC I Volt

DC 14

AbovelMO

AC90

120 - 180

-

AC 90

200 -

Below DC 1 Volt

DC 80

AbovelMQ

OR

RESISTANCE

I

Volt

-

28 Volts

-

23 Volts

110 Volts HI

-

110 Volts LOW

3000

-

100 Volts

231

n

Solenoid No. 1

Solenoid No.2

Flame rod No.1

1111

LED 1 assembly

Slide thermostat

w1

Thermistor

1131

Solenoid No.3

1141

’

Convection fan

WI

Fan switch

Air pressure switch

Black - Grey

33 SV, 36

Blue

34

Yellow - FR,

C,

A

B

H

F,

White - Red DC 14 - 23

White -

white -

Yellow - Yellow

white

35

White - Black AC 90

White - Red AC 90 -110 Volts LOW

Yellow

Brown

-

Grey

SV, 36

16

Red

Black

4 5

- Grcy

SV, 36

-

Yellow

-

Brown

6

-

7

DC 80 -

DC80 -

App 30 k 0 - 0

OR

10°C =

2K *

DC 80 - 100 Volts

Below AC 1 Volt

Below DC 1 Volt

lOOVolts

1.8 k

1.3

-

lOOVolts

1.5 k

1.0

-

Above 0.8

Above 1 M

- app30kO

app 65 k

app 39 k

1.8 k

-

1.3

110 Volts HI

-

50 - 70

100 -

1409

Above 1

R

R

/LA

Volrs

Q

Q

Q

M R

fl

Q

Q

Flame rod No.2

Flame rod No.3

LED 3 Assembly

Red

- FR,

15

Blue - FR,

14

-

Black DC 30 - 40 Volts

Red

Above 0.8

Above 0.8

fi

PA

Page 23

Page 24

Page 25

Page 26

SAFETY DEVICES

PRE-PURGE

This circuit ensures that fresh air is provided for mixing with the gas supply before ignition

occurs, as well as clearing the combustion chamber of any previous products of combustion

which may have remained since the last combustion cycle.

AIR PRESSURE SWITCH

The air pressure switch confirms the operation of the combustion fan, and confirms that

sufficient air for combustion isflowing through the appliance.

-

ON pressure differential

OFF pressure differential

SPARK SENSOR

6.0 * 2mm

-

4.8 + 2mm

H,O }

H,O ]

Water

Guage

Confirms that the spark has crossed

the solenoid valves are opened only

FLAME FAILURE SYSTEM

Confirms that the main burner is alight (or extinguished). If the ignition cycle is incomplete or

the flame fails, and the flame rod current drops below 0.1

Ignition sensing occurs above 0.8

OVER HEAT SWITCH

Shuts

blockage or convection fan breakdown.

CONVECTION FAN DELAY CIRCUIT

The PCB turns the fan ON, however after the flame is extinguished, the fan switch will remain

ON, depending upon the residual heat inside the appliance, this is to prevent overheating

occuring

off the

Over Heat Switch No.1

Over Heat Switch No.2- OFF app 65 &Thermal Fuse

as well as increasing efficiency. The fan will remain ON until 43 + 5°C is reached.

gas

supply by closin,

the spark gap correctly. In order to prevent miss ignition,

after the spark location has been sensed as being correct.

PA,

then the solenoid valves close.

PA.

0

the solenoids in the event of any overheating, louvre

-

OFF app 130 + 5°C ON app 110 +

5”C,

ON app 50 k 10°C

-

Melts at 152 + 2°C

10°C

from

POWER FAILURE SAFETY DEVICE

In the event of a power failure or power cut the solenoids will close immediately. After the

power is re-instated the appliance must be operated manually. ie: Turn OFF then ON again.

OVER CURRENT PROTECTION

5 Amp fuse will blow and the appliance will lock out.

Page 27

THERMISTOR

The thermistor is a semiconductor which reacts

to changes in temperature by altering its

RELATIONSHIP BETWEEN

RESISTANCE

&

TEMPERATURE

resistance. The relationship between temperature

and resistance is outlined in the graph. The

resistance value is detected electronically, and

activates the amplification circuit, which in turn

operates the gas input control circuit [temperature

control].

I

TEMPERATURE

b

Compared to the previous types of thermostats [Vapour pressure and Liquid expansion],

thermistors offer increased sensitivity, as well as a lower

differentiaI

enabling precise

temperature control.

FLAME RECTIFICATION

Flame rectification is

utilised

to check flame presence. A flame sensing electrode consisting of

a stainless steel rod supported in a ceramic insulator [flame rod] is positioned above the main

burner. An

body of the burner and the flame guard amplifier

a.Itemating

current is applied to the flame rod by the flame guard amplifier. The

FGA]

are both earthed.

The principle of flame rectification relies on the ability of the flame to conduct positively

charged ions more easily than negatively charged ions. This characteristic is called flame

rectification, as the current leaving the burner, having passed through the flame, is no longer

an alternating current. The signal returning to the FGA has been rectified by the flame, this

signal is used to determine flame presence.

The signal can only be produced by the flame. Short circuits, dirty contacts and other fault

situations cannot simulate the rectified signal. The FGA section of the P.C.B. sends an amplified

signal to the main P.C.B. to indicate flame presence,

n

FLAME ROD

e

t) ’

IOY -

DIRECTION OF

ALTERNATING CURRENT

AC 200 VOLTS

allowing the gas valves to remain open.

MAIN

\

BURNER

FLAME GUARD

AMP

-I

P.C.B.

c---

GAS VALVE CIRCUIT

1-4

SOLENOID

1

Page 28

OPERATION OF SAFETY DEVICES

NATURE OF FAULT

FLAW FAILURE

* No gas.

* Miss ignition.

OVER

HEAT

*

Fan not

operating.

*

Over gassed.

*

Blocked filter

or louvre.

* Obstruction at

front of

appliance.

POUER

FAILURE

* Power cut

during normal

operation.

* Power cord

disconnected.

SAFETY DEVICE SEQUENCE

ACTION REQUIRED

*

Check for any kinks,

blockages or breaks in the

gas supply.

*

Check that the flue

terminal is not obstructed

in any way.

* Reset ON/OFF button and

try to operate appliance

again.

*

Check for blocked injector

and aeration shutter.

over heating.

*

Check fan.

*

Check injectors.

*

Reset ON/OFF button and

try to operate appliance

again.

FUSE

BLOWN

*

Power surge

*

Short circuit

inside

appliance

.

, * locate and remove the

cause of the excessive

electrical current.

*

Replace the 5 Amp fuse.

Page 29

NATURE OF FAULT SAFETY DEVICE SEQUENCE

SPARK

SENSOR

*

Confirmation

of the spark

between the

spark

electrode and

the spark

sensor fails.

Solenoids don't open.

PRESSURE SWITCH

*

Confirms that

the combustion

fan is

providing

sufficient air

for

combustion.

I

ACTION REQUIRED

* Check the spark gap.

* Investigate the cause of

the spark sequence not

being completed.

NORMAL OPERATION

r

FANDElAY

*

Convection fan

continues to

run after the

flame has gone

Out*

PRE-PURGE

* Expels any

previous

products of

combustion or

raw gas from

the combustion

chamber before

ignition.

SEQUENCE

IGNITION

Page 30

FAULT FINDING

NATURE REMEDY

Ignition does not occur

after having switched the * Check gas type

appliance ON.

* Check gas supply

*

Air in gas supply

*

Flue manifold obstruction

[see

...................

...................

...................

...................

following]

1

1

:

Room does not warm up.

Flame Failure.

There is a smell of gas.

* Position of thermostat

*

Blocked air-filter

*

Insufficient gas supply

*

Warm air short circuit

*

Blocked flue terminal

* Blocked air filter

*

Power failure

*

Obstruction in front

*

Gas type

* Blockage in gas supply

* Check gas supply and appliance

...................

................... f

...................

...................

...................

................... z

...................

...................

...................

...................

...................

1

4

8

4

7

7

1

DISTINCTIVE CONDITIONS CAUSES AND REMEDY

Gas

supply [non-ignition, not warming up,

*

Is there sufficient gas pressure, and is the gas supply clear of air, kinks or obstructions of any

smeI1

of gas].

nature? Check for gas escapes.

Thermostat control

[room doesn’t warm up].

Is

the thermostat control knob in the LOW position?

=

Move the knob to a higher setting.

Blocked air filter [no gas, room doesn’t warm up].

Check that the air filter is clear of dust. If the filter is blocked then the O.H.S. safety device

may have been activated. In extreme cases the thermal fuse may have melted thus preventing

ignition from

=S

Clean filters thoroughly and re-operate the appliance.

3

Ensure thermal fuse is O.K.

4

Louvre obstruction [no gas, room doesn’t warm up].

occuring.

Is there a one (1) metre clearance in front of the appliance? Also check to see if there is

anything blocking the louvre or convection fan. An obstruction may be causing air to divert back

Page 31

to the thermistor.

*

Remove any objects in front of the

FIUe

system.

appIiance.

Blocked flue system.

-

Ensure that the flue system is clear of any obstructions.

Flame failure.

Blockage in the flue system. Dust or foreign material inside the combustion chamber.

*

Check these areas as well as the gas pressure and type.

Power

*

failure

When the power fails for more than 0.2 seconds, the appliance will lockout. To reset, push

the ON/OFF button to the OFF position and then ON again.

CONDITIONS THAT ARE ARE NOT FAULTS

COHDITIOW

The convection fan continues to

run after the appliance is

switched OFF.

A clicking sound when the burner

lights.

A resonant sound shortly after

ignition.

The interior of the appliance must cool

sufficiently before the convection fan

will stop. This is to ensure that there is

no overheating and also increases

efficiency.

This is the normal ignition sound, and the

extent of the sound will vary depending

upon the pressures and

the burner.

This is the movement of the flame as it

travels across the burner.

EXPIANATION

temerature of

The heater will not ignite when

being first test fired.

There is smoke or an unusual smell

upon initial use.

After ignition there is a ticking

or clicking noise.

The flame goes out while

operational, however the

indicator remains on.

rmJ

There may be air in the gas supply

preventing the appliance igniting

Mediately. After two (2) cycles of 15

seconds the spark will

will lock out. The ON/OFF button must be

re-set to re-attempt ignition.

Caused by grease, oil or dust in or on the

heat exchanger. This will stop after a

short period.

This is the expansion of the combustion

chamber metal.

The room temperature has reached the

temperature selected on the thermostat

control. When the room temperature drops,

ignition will automatically re-occur and

combustion will continue.

stop and the heater

Page 32

FAULT

AFTER

HAVING OPERATED THE APPLIANCE AND:

l-

The

cahstion

time,

2. There is

3, The solenoids do

4.

The convection fan does not begin to rotate.

IKI

spark.

fan

dwsn’t kgin

not

open, preventing gas flow to the burners.

to rotate, or it suddenly stops after having run for a short

ANALYSIS

Is there electrical supply?

v:s

1

a

1. Broken wiring or loose pin connector on P.C.B. or on wiring loom.

2. ON/OFF button faulty.

3. Faulty P.C.B.

4. Over heat switch is in the OPEN position. [Closed

5. Thermal fuse blown.

6. Solenoid circuit faulty.

7. Air pressure switch faulty.

b

i

1. Combustion fan shaft

2. An obstruction in the combustion fan is preventing it from rotating.

3. Open circuit or bad connection in motor circuit.

4.

The flame current was greater than 0.8 PA during

5.

Weak or shorting spark.

I

6. Faulty P.C.B.

C

1. High tension cord disconnected or broken.

2. Insulation leak from the high tension cord. [The spark sound is not regular]

3. The spark gap is not correct. [Normal spark gap is 3.0

4. Weak or shorting spark.

5. Faulty P.C.B.

The appliance does not operate.

I

1

The combustion fan doesn't rotate or the appliance fails after a short time.

allen

1

There is no spark. [Spark not audible or sounds irregular]

-NO

e

screw loose.

Confirm the connection at the wall socket.

1

2

Is the 5 amp fuse blown?

=

Normal]

pre-purge.[False

*

0.8

flame check]

IITII]

3

1

d

/

The solenoids will not open.

1. Wiring or pin connectors have come out of place. [P.C.B. or wiring loom]

2. Solenoid coil is broken.

3. Faulty spark. [No spark sensing]

4. Faulty P.C.B. [No DC 90 volt circuit to solenoid]

1

e

1.

Convection fan grub screw loose.

2. An obstruction in the convection fan is preventing the fan from rotating.

3. Open circuit or bad connection in motor circuit.

4. The ceramic resistor is faulty.

5. Faulty flame rod.

I

6. Faulty P.C.B.

The convection fan will not rotate.

Page 33

After repeated efforts to operate the appliance, it wilt not ignite.

1.

Air in the gas supply.

2. Incorrect gas pressure.

3. Incorrect gas type, or a kink or break in the gas supply.

4. Faulty spark.

5. Blocked injector.

There

is

the soundof ignition,

After two (2) cycles of 15 seconds the spark stops and miss ignition occurs.

Is it the correct specification?

hamerthe

rc&ustionJ

indicator

does

notameON.

Ignition OK

1

Confirm the flame rod current

Miss Ignition Indicated

1. Faulty lamp

2. Faulty

1

1

/

incorrect wiring.

P.C.8.

1

Has the electrical current

risen above 0.8

1

Yes 3. Check flame rod is firmly positioned.

Faulty P.C.B.

The

flare fails during

1.

Power failure. [Indicator out]

2. Safety devices are activated.

* Air filter is blocked and the

*

Obstruction in the flue system.

*

Blockage in the gas supply.

*

Gas pressure is abnormally low.

*

The area surrounding the flue terminal may be too constricted, hindering air flows in and out

of the flue terminal.

* Obstruction in front of the heater.

fi?

nomal

operation,

A

0.H.S

is activated.

Check combustion specification, gas type,

tlaveyx~ensured

positions, and also the wiring is not

Items in No.2 have been checked, but after ignition flame failure occurs.

that*

connectors areinthecorrect

broken any&n?

1

Flame failure safety

Confirm flame

c

Faulty P.C.B.

rod current is correct and stable at above 0.5

u:s

1

device will shut-down the unit.

1. Does the test point pressure, and injectors

conform to the specification?

2. Flame rod or burner may be in worn condition.

‘

fi.

i0

1

9

Page 34

I

NOTE

The information provided here is done

so only as a guide. For full details on

installation procedures you are advised

to contact Rinnai directly

250 mm

INSTALLATION

I

50mm

c

50mm

>

TlXANSFORh!IER

T2

Transformer terminal voltage

and resistance values

VALUES

-

240

voltage and resistance values

100 Supply transformer

ON

Red

-

Red

Yellow

E

Yellow

White

White

-

-

AC90 -

45 - 70

AC 180 - 220V

390

AC 12

1.8

-

550 a

- 15V

-

2.5

1lOV

Q

Q

Page 35

ELECTRICAL COMPONENTS ANALYSIS

Before proceeding with any dismantling, be sure to follow the instructions exactly

where disconnection of electrical or gas supplies is indicated.

Before proceeding with any of the following fault finding,

electrical supply, as well as confirming that all the connectors are firmly in the correct

positions.

Where ” # ” appears, it is to indicate that you should remove the electrical cord from

the wall socket before attempting to measure.

TABLE

TABLE A

SYMPTOM

The

rONJ indicator does not glow after

check that there is gas and

D

P-34

FTtVA

P.36

having switched the appliance ON.

TABLE

B

The electrical fuse blows when the

P.34

P-36

appliance is turned ON.

TABLE C

10 seconds after switching ON the appliance,

P.34

P-36

the [ONJ indicator goes out, and the burner

does not ignite.

TABLE

D

During the first 10 seconds after switching ON

P.35

P.37

the appliance, the combustion fan operates twice

from

HI to LOW before the indicator goes out.

TABLE E

TABLE F

TABLE

TABLE H

TABLE I

G

There is no spark generated and the

rcombustionj

indicator does not glow.

The appliance lights on the LOW burner

but goes to lockout after several seconds.

The

thermostat control does not modulate.

The flame goes out during normal operation.

Operation of the appliance continues as normal

but the

rcombustionj

indicator does not

glow.

P.35

P.35

P.35

P.35

P-35

P.37

P.37

P-37

P-37

P.37

Page 36

Relevant

Where

n

f "

values.

appears,

to

RHFE -1001

FK

it is to indicate that you should remove the electrical cord from the wall socket before attempting to measure

HIRE OF FAULT

.,: . . ._

:w!F&::: :_.:,:,’ :,,: j

: & +j$,:&$,& : Ii; ;, ‘, ,’

:

$$?@w&&T;g

.‘~appWadq 4y;,> .; j, I. .:

:.,:

*:.~::-‘f&&+

safety

$$%zc&z~~~js.,

I@s&@ff, w ":i,.

.

,_,_ ,,

._:

_...

“’

. .

_..’

..’

.’

” ,,: :_.:..:

._

:

_. :

:

”

._

_.

._

:

.:

.

_::

EfrqfE.:.tbe :‘I

: ,_ ., :

.::.

. . ,_ _,

:

.._. .

.,,

,,

.: .:

: ,i. :.

j: _..

.:,

_,_:

.

...,,

,,:__. . .

. .

:_.

I...

_:._

:.

. .

.:_

,.

,, .:. . .

.:..

!

‘.

.;

. .

T&B

:~~Iec&ig

;#w

fuse

is+

DWIIIIATIOW WIHr

IS

the electrical plug in the wall* Check the electrical connection

socket firmly?

normal?

the

G.H.S.

in the OFF position?

Has the thermal fuse blown?

Is the movement of the ON/OFF

button normal?

j

_.:

.:.

.>..

_:

1

,I

#2 Is

:

13

:.

.

14

‘:

.

: #5

Is the transformer O.K.?

:

.,

:.

: #6 Is

the electrical fuse blown?

..__.

f

7 Is the LED P.C.B. O.K.?

‘.

#I Is

the transformer O.K.?

Is the voltage

(TR

(TR

2)

2)

Dmc

POINT

and voltage.

*

Check the O.H.S. continuity.

* $$k

the continuity through the

*

With the appliance OFF, remove Blue - Brown

the connector and check the

;;;inulty of.the

-

red wires.

l

Check the resistance of the

transformer

* Check continuity of fuse.

l

Check the voltage of the white

ellow indicator connectin wire.

Lmfimation

the

first 30

aritching ON.

Check the resistance of the

transformer.

blue - brown,

_

mst

be

suomds

ade &ring

after

210 - 260 Volts?

App 0 Q - normal

AppOQ-

;r;Mi 0 fteds

- App - Q is O.K.

Red - Red

ii 72

App 1.8

App 3.0

-

APP I4

White- White

Red - Red

R

-

1.8 ^ 2.5

-

45 -70 Q

VALES

normal

-

70

-

White

-

2.5 Q?

-

6.0 Q?

-

23 Volts

O.K.

sl?

0

AcrIcm

YES -

Go to 2

NO

-

Rectify

YES -

Go to 3

NO- Replace O.H.S.

-

Got04

YES

NO

- ;:[Jace

thermal

-

Go to 5

$'

-

R$;c,e ON/OFF

-

Goto6

iis

-

Replace

transformer

-

Got07

Z'

-

See table

-

Replace LED P.C.B.

$'

-

Replace main P.C.6.

-

Got02

Z'

-

Replace

transformer

B

.._..

. . :

.:

_.

”

‘..

.

‘,

”

I

‘.’

.TuKE C,': 1. '. :

p

_& && “:., :

.aritxhfng OU;tlk: .‘,.’

ow

tadfcator~gwz

oyt_

‘. . . .

72

~o~&~~~‘~“

mt m+,

'F*pqs

:

,.

”

._.

..,’

:

:. .:.

. .

,_

.,

. .

: .,

. .

fl

IS the combustion fan motor

..:

. .

,, ,” : “’

"

:

.

,:,.

,....

.”

: 12 Is

the spark generator O.K.?

53

Is combustion

correctly?

.

W

Are the solenoids operating

:

correctly?

._

. . .: .,

,

..

#S Is

the convection fan motor

operating correctly?

:

operating

correctly?

..-

2 Is the combustion fan motor

capacitor

O.K.?

i

i

3 Is the P.C.B. O.K.?

fan

motor

operating

*

Check the resistance between the

points shown

here.

Is the value - Q?

w

White -

Oran

*

Check the resistance of the

combustion fan motor.

*

Release the pin connectors from

each solenoid valve

resistance between both solenoid

terminals.

pull on the wires.

*

Release the convection fan motor

pin connector. Check the

resistance.

l

Check the AC voltage at the

combustion fan motor W - 0 pin

connectors within the IO seconds,

before the ON indicator goes out.

*

Alternate the tester between the

e 8 c

terminals of the capacitor

and

check the resistance.

*

Check the AC voltage at the AC 90 -110 Volts

combustion fan motor W - 0 pin

connectors within the 10

before the ON indicator goes out.

Mrning:

and

check the

Do

not

seconds, contact.

White - Black

1.3 k Q - 1.8 k Q YES -

White - Red

White -

AC 90

Does the tester

oscillate for a NC

moment,

return to -

e

-

200 -

308

-

120 - 180 Q?

-

100

-

!40

Black

- 50 -

70

R?

- 110

Volts

:hen

R?

Q?

Q?

- Go to 3

ES

- g:;::;

-

Go to 4

2'

- ~~~l~acocombustion

Go to 5

N3- Replace solenoids

-

Replace the P.C.B.

ii'

-

Replace convection

-

Go to

YES

NO- Replace combustion

-

Go to 3

YES

-

Replace the

-

Confirm combustion

YES

-

Replace the P.C.B.

NO

7.

fan motor

2

fan motor

capac:tor

fan

motor connector

-

34-

"

Rinnai 1001

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

PARTS LIST

This parts list incorporates both FT and

FWA

models for the RHFE -

1001.

Interchangeability or otherwise is identified as follows:

Interchangeable

FT

modelonlv

c

FT

22

23

‘24

25

26

27

28

29

Frame Comer

Top Panel Reinforcement

Control Panel Bracket IOOIF- 185 x 06

Thermostat Slide Stopper

Slide Thermostat Assembly

ON/OFF Switch

Slide Timer Assembly

Control Box

IOOIF-064x02

lOOIF-

110

262F-

1103 c

lOOlF-

122x01

lOOlF-

121 x02

lOOlF-

1517 x 01

lOOlF-

1522

90 142894

90

143025

90164385

90164500

4274

4290

4014

429 1

C

C

C

Fr

C

C

C

@

Rinna; llM1

!

Page 48

EPL PART

NAME

RI

PART No

FtA

PART No

RN2

PART No

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

Control Panel

Thermostat Control Knob 302F - 0814

ON/OFF Button Knob

Heat Shield

Viewing Window Glass

Electrode Viewing Panel

Electrode Cover

Insulation Sheeting 302F - 0523

O.H.S. Protector 302F - 0506 x 01 c

Speed Clip

Humidifier Tray

Water Level Indicator

Fixing Bracket Support

Base Support Rubber

Rubber Bracket Assembly

Base Assembly

Back Spacer Left

lOOlF-

1246x01

2116A-0906bxO2

1OOlF -

159 x 04

lOOlF-

137

lOOlF-062x04

1OOlF -

070 x 01 c

CP-90077-

lOOIF lOOlF-

1OOlF 55OF 550F-0220x01

lOOlF- 157x02

1OOlF -

1

037

172 c

155 x 01

0225 x 01

1215 - 2 x 02

90164492

90141615 3720

90163247 4016

90145566 4038

90168329 4024

90168337

90122797

90164427

4015

1610

4341 C

c

C

c

C

C

C

C

C

C

C

C

C

C

47

48

49

50

51

52

53

54

55

56

57

58

59

60

Back Spacer Right

Back Spacer

Back Spacer Top

Air Filter Assembly RC-320 - 49 - 8 x 04

LOW Burner Assembly

HI Burner Right Assembly

HI Burner Left Assembly

Damper Panel RHF250 - 075 x 01

Burner Bracket Packing

Burner Bracket Left

Burner Bracket Right

HI Injector NG 1.65 x 2

HI Injector

HI Injector

LOW Injector NG 1.75

LOW Injector LPG 1.05

LOW Injector TLP 3.25

Flame Rod

Support

LPG 0.95 x 2

TLP 3.25 x 2

lOOlF- 1211-2x02

lOOlF-092x01

lOOIF

-165 - 5

1OOlF -

147 - 2

lOOIF- 144-2x04

1OOlF -

150 - 2 x 04

1OOlF -

049

1OOlF -

149

IOOIF -

148

RHF400 RHF400 RHF400 -

1OOlF lOOlF1OOlF 1OOlF -

75 - 2 - a-l.65

75 - a-O.95

75 - 2 - a-3.25

192 - 1 - 1.75

192

-

1

-

1.75

192 - 1 - 1.75

104 - 2 x

03

90164435 4342

901644 19 4343 C

90164450 4294

90168345 4308

90168352 4309

90168360 4344

90168378

90142720

90143983 4296

90158130

90142712

90143975

90157934

I

90 142803

4295 C

4297

4298

4299

C

C

C

C

C

C

C

C

C

C

C

C

C

c

C

C

61

62

63

64

Damper RHF250 - 076

Electrode Clip RHF250 - 038

Burner Shield Right

Burner Shield Left

lOOlF-

041

lOOlF-

042 c

-

46

-

90 123449

”

Rinnai 1001

c

C

C

Page 49

EPL

65

PART NAME

P.C.B. Bracket

RJ

PART No

1OOlF

- 005 x 02

RA PART No

RN2

PART No

C

66

68

I

69

70

71

72

73 Fan Securing Nut CP

74

7s L/h Convection Fan A Drum RHFlooO-

76

77

78

79

80 Combustion Chamber Assy

sparker

P.C.B. Support ES - 10018

Convaction Fan Motor

Capacitor

Conv’n FM Motor Bracket

Mounting Rubber

R/h Convection Fan B Drum

Fan Case Assembly

Bell Mouth

O.H.S. Bracket

Over Heat Switch No.2 ES - 01152

EM-lx01

ES - 02035

550F -

RCK - 8273

- 30310

RHFlOOO- 164N-b

1OOlF

RHFlOOO-89x01

1OOlF -

1OOlF

90142928

90142944

0903

164N-a

- 152 x 03

217

(65°C

OFF)

- 138 x 04

90122847

90122862

90 132242

90132234 4030

90168188

90158501

1607

4302 c

4303

4028

4042

4301

Fr

C

C

C

C

C

C

C

C

C

C

C

C

81

82 Viewing Glass

83

84

85

86 Electrode Seal Packing

87 Blanking panel

88

89

90

91

92

93

94 Air Intake

95 Heat Exchanger - No. 1

96

97 Sound Buffer Material

Glass Widow Packing

Glass Clip

Electrode

Electrode Clip Bracket

0-H-S.

Bracket

Gver Heat Switch No. 1 Es -

Fan

Switch

Sub Heat-Exch Clip B

Sub Heat-Exch Clip B

Heat-Exch Bracket Slip

Seal

Sub

Heat&t&

Clip A

3OOI=r-

14x03

3OOI=r-

15x01

3OoFr-

12

1OOlF -

216 90142993

1OOlF -

168 x 01

lOOlF- 175 90168386

lOOlF- 115 x 01 90168394

1OOlF -

116 x 03

Oll51(13cPC OFF) 90168196

ES - 01050

1OOlF -

1OOlF -

RI-IF1000 - 174

RI-IF1000 - 167

1OOlF -

lOOlF-021-

lOOlF- 188

o

(60

C

ON)

183 x 02

021 - 2

142 x 04

1 x01

90 168204

90143058 4304

90158502 4306

90158478

43 10 C

4305

4064

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

98

99

100

101

Sound Buffer Clip

Sub Heat Exchanger

Locking Spacer

Transformer Bracket

No.2

lOOlF- 187

1OOlF

- 143 x 03

1OOlF

- 169 x 01

1OOlF -

1201 x 05

-

47

-

90 158395

4060

@

Rinnai 1001

C

C

C

C’

Page 50

EPL PART NAME

102

103

104

105

106

107

240 Volt Supply Transformer

Combustion

Combustion Fan Casing

Combustion

Air Intake Duct

Air Frcssure Switch

Fan

Motor

Fan Seal

RJ PART No RA PART No

lOOlF-

1225

lOOIF -

203

1OOlF -

153 x 01

1OOlF -

053

1OOlF

- 054

ES - 13002

901445 1

90 168402

90158379

90158478

9014295 1

RN2

PART No

4105

4325

4043

4323

c

C

C

C

C

C

108

109

110

111

112

114

115

116

Pressure Tube Blue IN

Pressure Tube Clear OUT

Timer Transformer

Main

Transformer

Gas Control Assy (Threaded)

a. Solenoid Bracket B

b. Regulator

d. Pressure Point Screw

e. Packing

f. Solenoid Assembly

g. Solenoid Assembly

h. Filter

Gas Supply Tube - Rear

Gas Supply Tube - Front

Gas Supply Tube - Top

lOOlF-

184

1OOlF

- 108 x01

ES

-

14019

ES - 14017

RHFlOOOC25B-3-3

ClOD -

RC

C23B C23J

RCK

loOlF-088x01

lOOlF1OOlF -

110

3

- 3010

23

- 1

-

6262

087

089

90158411

90158395 4048

90164476

90143041

90142795

90123233

90164518

90145665

90158460

90158452 4312

90158437

4056

4018

4322

4314

9994

9995

43 15

4316

4311

4317

C

C

C

J=r

FT

Fr

118

119

120

121

122

123

124

125

126

127

128

129

Exhaust Elbow

Cover

Exhaust Stopper

Exhaust Slide Tube

Flue Extension

Exhaust Adaptor

‘0’ Ring B

Gas Supply Tube - Clip A

Gas Supply Tube - Clip B

Revolving Stopper D

Flange Bracket

‘0’ Ring A

lOOlF-

101 - 1

lOOlF- 101-2x01

1OOlF -

228

100lF -

224 x 03

lOQlF-

131 90158395

RHFlOOO -

lOOlF-

111 x 03

RHFlOOCI -

lOOlF-

132

1OOlF -

133

RHFIOOO RHFlOOO -

x01

142 - a

145

141

142 - b

-

48

-

90131723

90158361

90145616 4276

90132820

90158353 4047

4007

4026

4318

4033

4275

C

C

C

C

C

C

C

C

C

C

@

Rinnai 1001

Page 51

EPL

PART

NAME

RJ PART No

RA PART No RN2 PART No

1

130 Slide

131

132

133

134

135

136

137

138

141

142

Air Met Seal

Air Inlet Assembly

Air Intake Elbow B

Air Intake Flexible Hose

AirInletElbowA

Flexible

Mushroom Flue AA

Timer Harness

Flame Rod Lead

Sparker Lead

Guard

Hose Clip

lOOfF- 134 4318

RHFlOOO - 136

RHFlOOO - 132 x 01 9013 1798

RHFlOOO- 132

RHFIOOO- 130-d

RHFIOOO- 131

RHFlOOo- 119x01

lOOIF

A

B

C

D

E

lOOIF- 1247 x 01 90168246

1OOlF

1OOlF

1224 x 01

IOOIF

1221 x 01

lOOiF

1222 x 01

lOOiF

1223 x 01

lOOIF

1228 x 01 FM0551D

lOOIF

1229 x 01

- 124 x 04 90168287

- 120 x 04

90132002

90145806

90145632 4327

90145640

90141250

FM055

1AA

FM055

1A

FMO55lB

FMo551c

FM055 1 E

4321

4320

4328 c

4319

4267

4116

4117

1586

4121

4268

4300

4331

4074

‘*

C

C

C

C

C

C

C

Fr

C

Fr

143

144

145

146

.

Sparker Sensing Lead

Thermistor Assembly

High Tension Cord

Electrical Cord CP -

Timer Harness

Wire Harness No.2

Fuse

Glass Fuse 5 Amp ES-03001 90145699

Mushroom flue guard

Co-axial

Regular co-ax flue kit

45” bends

1200 mm extension

Through the wall kit

Cord Holder

Conversion kits RHFIOOONG -

:.:.>;.>>fX.X.BX.n:

~~~~~~~~~~~~~~~

.,. .,. .,... . . .,. . .,...,.

Holder

flue kits

r~~~:.:.~:.:_.:~:~~::~::::::

.:5.:.:.:+X.:.>>:.:.m:.:.>>*>:.::.:

::... .:. > ..+:: .>. . . . .

. . . . . . . . .

lOOIF- 125 4332

lOOlF- 123

RC-323-45-6 90158346 4103

9014568 1

4133

. . . . . . .

:.:.:.,. . ..y

90303

>::::: A:.

.,

:...: . . . . . . . ‘,<S$$$::::$+$+.. . . . . . . . :.:. . . :Sf~~~5..: . . . . . . . . . . ..: . . :

~~~~~~~~~~~~~~~~

. . . . . . . . .:... . :.. .:.. ,. . : . . : . : . . :. . . . ::... .:. ,.... :: . .4. : . . . . ..-

IOOlF- 1247 90165788 4063

lOOiF -

120 x 03 901657% 4330

ES-04002

RHFlOOO - 120

RHFlOOONG RHFlOOOLP -

RHFlOOOLP

RHFlOOO TLP

RHFlOOO TLP - LP

LP 90145707

TLP 90168477

NG 90145715

-

TLP 90168485

-

NG

90138793

FGM

FCAKIT

FCABEND

FCA12OOM

FM055 1ATW

90 168493

90168501

1593 C

4110

4087

4088

408 1

Fr

C

FT

C

C

C

C

C

,

C

C

- 49

-

@

Rinnri lfM-Il

Page 52

CONVERSION INSTRUCTIONS

Before proceeding with any conversions, please check the contents of the conversion

kit supplied and ensure that the correct parts have been provided. If you are unsure,

contact Rinnai immediately.

1.

Disconnect power supply [Unplug from wall

socket] Remove the front panel. [Two (2)

screws]. Disconnect LED connectors.

2.

Remove the two (2)

screws and loosen the three (3) at the rear of

the same panel. Remove panels.

3.

Undo the gas connection supply tube nuts of

both the LOW and HI burners. Slightly

loosen them at the solenoid ends.

The injector is located inside the gas

4.

connection tube. Check the table on page 5

for the correct specification.

left

hand side panel

LEFT SIDE PANEL

REGULATOR SCREW

Remove the injectors and replace them with

5.

the new injectors

as shown in the

specification. [Refer to the chart on page

Replace tubes and secure at both ends.

6.

Adjust the damper to the correct position,

according to the specification table on page

5.

Insert the plug into the wall socket, turn on

7.

the gas and turn ON the appliance. Check

for gas escapes. Take care to avoid dripping

soapy water into any electrical components.

8.

Readjust the pressure. [Refer to the table on

page

51

9.

Mark clearly on the front heat shield the new

gas type, also date of conversion, and your

registration number.

10.

Label with appropriate gas type stickers, and

A.G.A. approval badge.

Be sure that the Data plate clearly shows the

11.

gas type for which you have converted.

51.

GAS

LOW

BURNER'

DAMPER

LEFT

HI- BURNER

RIGHT DAMPER

.

GAS CONNECTION

HI BURNER

LEFT DAMPER

SCREW

DAMPER

PRES$URE

"

POjNT

SCREW

12.

Re-connect LED connectors. Replace the

outer casing, check the operation of the

appliance once again.

O/10

CLOSED

rcrrc

-

50-

3*

lO/lO

OPEN

(’

Rinnai 1001

Page 53

I

DISMANTLING FOR SERVICE

Before proceeding with any dismantling, be sure to follow the

instructions exactly where disconnection or isolation of electrical or gas

supplies is indicated.

Index

1. Removal of the FRONT

2. Removal

3.

Removal

4.

RemovaI

5.

Removal

6.

Removal

7.

Removal

8.

Removal of the

9.

Removal

10,

Removal of the

11. Removal of the

12. Removal

13. Removal of the

14.

Removal of the

of the TEMPERATURE THERMISTOR.

of the ELECTRICAL FUSE

of the LED INDICATOR ASSEMBLY

of the MAIN, P.C.B. UNIT.

of the SPARK GENERATOR.

of the SUPPLY TRANSFORMER.

TOP PANEL

of the OPERATION PANEL

ON/OFF SWITCH, THERMOSTAT, TIMER P.C.B.

O.H.S. No.2

of the

O.H.S.

FLAME ROD [LOW BURNER] & ELECTRODE.

FRONT

PANEL LOUVRE

No.1,

FAN SWITCH, THERMAL

HEAT SHIELD

&

CASING.

FUSE

15. Removal of the

16. Removal of the

17. Removal of the

18. Removal of the

19. Removal of the

20. Removal of the

21. Removal of the

22. Removal of the

23. Removal of the

CONVECTION FAN ASSEMBLY.

AIR PRESSURE SWITCH.

INJECTORS

SOLENOID ASSEMBLY

INJECTORS

COMBUSTION FAN.

FLAME ROD

FLAME ROD

HEAT EXCHANGER.

[RHSJ

&HS-J

IHI

BURNER]

IHI

BURNER]

-51

H2HS-J

[LHSJ

-

~9 Rink

1001

Page 54

ANALITICAL

FLOW CHART

e

AND

ELECTRICAL FUSE

OVER HEAT SWITCH No 2

RELATIONSHIP OF COMPONENTRY

SPARKER

l

CONTROL PANEL .

ON/OFF SWITCH

THERMOSTAT CONTROL

TIMER CONTROL

OVER HEAT SWITCH No 1

-

ELECTRODE

FLAME ROD [LOW]

--+

COMBUSTION FAN

+

BURNER LH

FLAME ROD LH

HUMIDIFIER

HEAT SHIELD

GAS CONTROLS

I

BLADES

+

COMBUSTION

FAN MOTOR

,

CONVECTION FAN

GAS FILTER

14

SOLENOID

LOW BURNER

l&2 1

INLET

Page 55

1. Removal of the FRONT PANEL, LOUVRE,

CASING.

Disconnect the electrical supply

(1) Remove one (1) screw from each side of the front

panel to release it from the main casing.

(2) The panel can be pulled forward, however it will

remain connected by the indicator wiring harness.

2.

Changing the TEMPERATURE THERMISTOR

Disconnect the electrical supply.

To enable

(1)

remove

panels.

Screws

Remove the screw which is holding the thermistor

(2)

clamp in position. One (1) screw.

ease of maintenance it may be

e top and right hand side back

tl

1

easier to

spacing

(3) Release the indicator connectors to completely

release the front panel.

(4) Release the six (6) securing

louvre guard, pull forward.

(5) An additional six (6) screws must be removed to

release the louvre assembly.

screws to remove the

Remove the

(3)

Remove the

(4)

connector from the P.C.B. and replace with a new

thermistor assembly.

The1

conr

(6) Reverse

front panel section. Refer to

thermistor [yellow - yellow] pin

(3),

(2) & (1) procedure to re-assemble.

1

-

(1).

Page 56

3. Changing the ELECTRICAL

F’USE.

5. Removal of the MAIN P.C.B. ASSEMBLY

Disconnect the electrical supply.

(1) Follow sectio n

(2) Open the fuse holder to release the fuse.

1

-

(l),

(2), (3) first.

Disconnect the electrical supply.

(1) Follow section 1

- (l),

(2), (3) first.

The PCB is very fragile, please use extreme

care when removing it. Avoid touching its

components with your fingers as the static

electricity in your body could damage it.

Take note of where the pin connectors are

removed from.

Release all the pi n connectors from the P. C.B.,

(2)

including the sparker connections.

Connr

‘Screws

4.

Removal of the LED INDICATOR ASSEMBLY

Disconnect the electrical supply.

(1) Follow sectio n

1

-

(l),

(2), (3) first.

The PCB is very fragile, please use extreme

care when removing it. Avoid touching

components as the static electricity in

your body could damage it.

(2) Bend the two (2) securing tabs forward until the

indicator P.C.B. can be removed without damaging

11.

Undo two (2) screws at the front and gently lift the

(3)

P.C.B. forward to release it from the appliance.

Release the earth connections.

(4)

FJJ

Only Remove the ceramic resistor. One (1)

(5)

screw.

There are nine (9) P. C.B. plastic supports which are

(6)

holding the P.C.B. to the base plate.

[FT - x 2 , IT/VA

P.C.B. Support

Page 57

6. Removal of the SPARK GENERATOR.

8. Removal of the TOP PANEL.

Disconnect the electrical supply.

(1)

FoIlow section 1 -

The spark generator is mounted on the P.C.B. bracket.

There are two (2) possible ways of removing it. One is to

release it directly from the P.C.B. bracket, the other is to

remove the main P.C.B. assembly completely.

(2) Release the pin connections from the spark

generator.

(l), (2),

(3) first.

Disconnect the electrical supply.

Follow section

Remove the three (3) screws from the front and five

(5) screws from the rear, where the back spacer

joins to the main body of the appliance.

Top panel lifts off.

9.

Removal of the OPERATION PANEL.

1

-

(l), (2),

Screws x 5

(3) first.

Disconnect the electrical supply.

(1) Follow section

1 + 8

-

(l),

(2), (3) first.

7.

Removal of the SUPPLY TRANSFORMER.

Disconnect the electrical supply

1

-

(1) Follow section

(2) Disconnect the two (2) pin connections as indicated

above.

(l), (2),

(3) first.

r

(3) One (1) screw secures the transformer to the rear

casmg .

(2) Undo and release the ON-OFF switch, thermostat

and timer pin connections.

(3) Remove the two (2) control box securing screws and

the complete assembly can be removed from the top

CaSiIl,o.

Page 58

10. Removal of the ON/OFF SWITCH,

THERMOSTAT

&

TIMER PCB.

Disconnect the electrical supply.

(1) Follow section

9 first.

(2) Remove the timer and thermostat control knobs.

[See section

(3) Turn the assembly over to release the thermostat

control. One (1) screw.

Thermostat

control

91

\

11. Removal of O.H.S. No 2.

Disconnect

(1) Follow section

(2) The O.H.S. is connected to the RHS of the convection

fan housing assembly.

the electrical supply.

1

-

(l),

(2), (3) first.

I’o

release the ON/OFF switch or timer mechanism,

(4)

bend the four (4) tabs forward to allow the control

panel

escucheon to drop out of the control box.

(3) Release the two (2) connectors.

Do not pull on the

wires.

(4) Two (2) screws hold the O.H.S. to the bracket.

12. Removal of the O.H.S. No 1,

FAN SWITCH & THERMAL FUSE.

Disconnect the electrical supply.

(1) Follow section

(2) Remove the one (1) screw to release the thermal

fiW3.

1

-

(l), (2),

(3) first.

(5) Two (2)

releases the timer

screws release the ON/OFF switch, and one

machanism.

(3) Undo one (1) screw to remove the O.H.S. and Fan

switch cover.

Page 59

Remove the harness connections from both switches.

13. Removal of the FLAME ROD

Disconnect the electrical supply and isolate the gas

supply *

&

ELECTRODE

Remove the two (2) O.H.S. securing screws to release

it.

Remove the two (2) screws to release the fan switch

from the bracket.

(1) Follow section 1 -

(2) Remove the plastic electrode cover, (2) screws.

Release the high tension cord and electrode

(3)

connections.

(l),

(2), (3) first.

Remove the electrode viewing panel by removing an

(4)

additional two (2) screws from the top and bottom.

Remove the seal packing to locate the three (3)

(5)

electrode clip securing screws.

(6) Undo the screws securing the electrode clip bracket

and remove. Three (3) screws.

Page 60

14. Removal of the FRONT HEAT SHIELD.

Disconnect the electrical supply.

(4) There are five (5) screws that secure the convection

fan assembly to the main assembly. Two (2) at both

ends and one (1) in the centre.

(1) Follow section 1

(2) Follow section 12.

(3) Follow sectio n

(4) There are 7 screws to remove in order to release

the front heat shield from the main assembly.

- (l) ,

(2) , (3) first.

13 (2) , (3) & (4).

(5) Convection fan assembly lifts out.

16, Removal of the AIR PRESSURE SWITCH.

Disconnect the electrical supply.

15. Removal of the CONVECTION FAN ASSEMBLY.

Disconnect the electrical supply.

(1) Follow section 14 first. (No need to remove louvre.)

(2) Remove three (3) screws to release the top panel

support.

(3) Release the pin connector.

(1) Follow section 1

(2) Release the two (2) plastic tubes and two harness

connections from the air pressure switch.

- (l) , (2) ,

(3) first.

ure

Page 61

17. Changing the INJECTORS. [RHS

Photos show FT model.

Disconnect the electrical and gas supplies.

NOTE: This explanation is only applicable to the right

hand side burners of the appliance.

only]

(3) Remove the solenoid harness connections. Six (6) in

total. Do

not pull on the wires.

(1) Follow section

(2) FT

(3) The injectors are located in the injector port at the

model Release the gas supply connection tube by

undoing nuts at both ends.

VA model Nut only at burner end.

burner end of the gas supply connection tube.

1 first.

(4) Remove the two (2) solenoid assembly screws to

release from the bracket (rear), and unscrew securing

bracket to inner side panel.

18. Removal of the SOLENOID ASSEMBLY.

Photos show FT model.

‘isconnect the electrical and gas supplies.

3

(1) Follow section 1 -

(2) Release the gas supply connection tubes from the

solenoid assembly.

(l),

(2), (3) first.

(5) Gas filter is located inside the gas inlet flange where

it joins to the solenoid assembly. Take care that the

sealing washer is in place at rear of solenoid when

replacing.

Page 62

19.

Changing the INJECTOR.

&HS

only]

Disconnect the electrical and gas supplies.

(1) Follow sectio n

(2) Remove the left hand side back spacer and left hand

side panel. Two (2) screws at front and three (3)

screws at rear.

1 first.

(2) Release the six (6) securing screws to remove the

louvre guard, pull forward.

(3) An additional six (6) screws must be removed to

release the Louvre assembly.

Screws x

(3) Release the gas supply connection tube to allow

.3

access to the injector.

Gas

SUPPlY

cork

-

[21

mm spanner]

sx2

(4) Release the convection fan motor harness

(5) Undo the four (4) securing screws to release, the

combustion fan then comes out by lifting forward

out of the casing.

connectc

3r.

I

20. Removal of the COMBUSTION FAN.

Disconnect the electrical supply and isolate the gas

suPPl Y *

(1) Follow sectio n 1 first.

Page 63

21. Removal of the FLAME ROD, [RHS only]

and HI/LOW BURNER ASSY.

Disconnect the electrical and gas supplies.

(1) Follow section

1

-

(l),

(2), (3) first.

(2) Follow section 16

(3) Follow section 20 (2) & (3).

(4) Release the gas supply connection tubes.

(5) Release the flame rod lead.