Page 1

Rinnai New Zealand Compact Op/Install Manual: 10170-C 02-09

1

TIMBERFLAME COMPACT

Operation and Installation Manual

(for serial numbers 0901 7042 and above)

Suitability

Domestic heating appliance, suitable for living rooms and open plan

areas.

This heater is not designed:

To be built directly into a combustible opening, for combustible

opening installations a Rinnai Zero Clearance Box and Flue Kit is

mandatory

To be installed or operated in places where painting is taking place, or

in places such as hair salons where there is a lot of dust and uff, and

where aerosols are used

•

•

Appliance must only be installed with an approved Rinnai ue system.

Appliance must be installed, commissioned and serviced by a licensed

tradesperson in accordance will all applicable local rules and regulations.

Please retain this manual for future reference.

Page 2

Rinnai New Zealand Compact Op/Install Manual: 10170-C 02-09

2

LIMITED WARRANTY

Please keep these instructions in a safe place for future reference.

RECORD AND ATTACH YOUR PROOF OF PURCHASE BELOW:

Your Retailer:__________________________________________________

Name:________________________________________________________

Address:______________________________________________________

_____________________________________________________________

Telephone:( _______ ) __________________________________________

Date of Purchase: ______ / ______ / _________

TERMS AND CONDITIONS

1. During the 24 month period from date of

purchase and subject to clauses 2 and

3 below, Rinnai New Zealand Limited

(“Rinnai”) will, at its own discretion, either

replace or repair any defective product at

no charge to the customer.

2. This warranty covers manufacturing defects

only. This warranty will not apply if (for

example) the product has been improperly

installed or is otherwise installed contrary

to manufacturer’s recommendations, has

been damaged during or after installation,

has not been operated in accordance

with operating instructions, or has been

subjected to damage or abuse beyond that

expected from conditions of normal use.

3. Warranty claims may be invalid if not

accompanied by details of the installing or

supervising gas tter’s registration number

and the gas tting certication number.

4. This warranty commences from the date of

purchase. Proof of purchase is required at

the time of any warranty claim.

5. Servicing of the product is to be carried out

by a Rinnai authorised service centre.

All Rinnai appliances meet or exceed the

safety standards required by New Zealand

gas and electrical regulations. The company

is constantly improving its products and as

such specications are subject to change or

variation without notice.

Rinnai brings you peace of mind

with a 2 year minimum warranty.

Page 3

Rinnai New Zealand Compact Op/Install Manual: 10170-C 02-09

3

Contents

WARNING

Improper installation, adjustment, alteration, service or maintenance

can cause property damage, personal injury or loss of life.

For assistance or additional information contact Rinnai on 0800

RINNAI (0800 746 624).

Customer Information

Limited Warranty 2

Introduction 4

Safety 5

General Information 6

Operation 8

Troubleshooting 9

Installation Information

Before Installation 10

Specication 10

Appliance Location 11

Flueing - General Flueing Guidelines 12

Flueing - Masonry Installations and Flexiliner Flue Systems 13

Flueing - Decorative Fireplace Installations and Flueing 14

Installation - Preparation 15

Installation - Gas Connection 16

Installation - Installing the Logset 17

Testing Procedure 18

Commissioning 19

Installer Details 19

Wiring Diagram 20

Customer Contacts 20

Page 4

Rinnai New Zealand Compact Op/Install Manual: 10170-C 02-09

4

Customer Information - Introduction

Made for New Zealand, made in New Zealand

All Rinnai ame res are designed and made here in New Zealand to suit our unique climatic

conditions and the needs to New Zealand homeowners.

A great all-round re in a smartly designed package

Adaptable and safe

The Timberame Compact has the exibility to t into even the tightest of masonry replaces.

As with all Rinnai res, it’s got built-in safety features including an overheat switch and ame

failure detectors.

Perfect features

stylish brushed stainless steel or matt black steel

electronic push-button ignition

2-speed convection fan ensures even heat dispersal over a wide area

•

•

•

Gas Consumption: 25 - 9 MJ/h (high to low)

Output: 5.0 - 1.6 kW

Efciency: 73%

Heats Area Up To: 56 - 78 m2 (depending on the region you live in)

Page 5

Rinnai New Zealand Compact Op/Install Manual: 10170-C 02-09

5

Customer Information - Safety

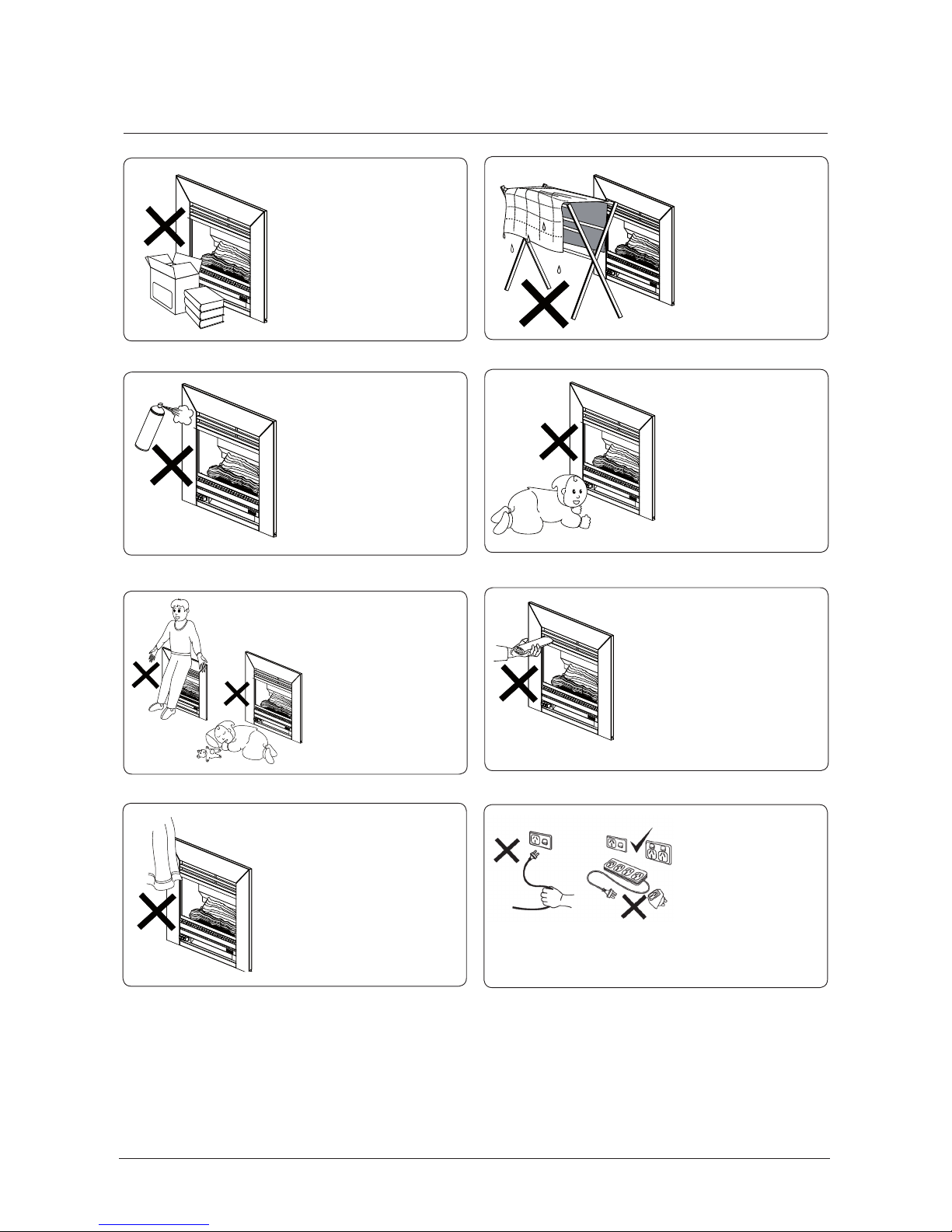

Do not restrict warm

air discharge by placing

articles in front of the

appliance.

This appliance

must not be used

for any other

purpose than

heating.

Do not spray aerosols

while the appliance

is operating. Most

aerosols contain

butane gas, this

can be a re hazard

if used near the

appliance.

Young children

should be

supervised at all

times. Hand or

body contact with

the appliance must

be avoided.

Do not allow

anyone to sit, lean

against or sleep

directly in front of

the appliance

Do not allow anyone to

post articles through

into the heater.

Do not unplug

the appliance

while it is

operating. Do

not use power

boards or double

adaptors to

operate this

appliance.

Do not allow curtains

or other combustible

materials to come

into contact with the

appliance

Page 6

Rinnai New Zealand Compact Op/Install Manual: 10170-C 02-09

6

Customer Information - General

Before operation

Read these instructions to get an overview of how to operate, maintain and service your

Timberame Compact.

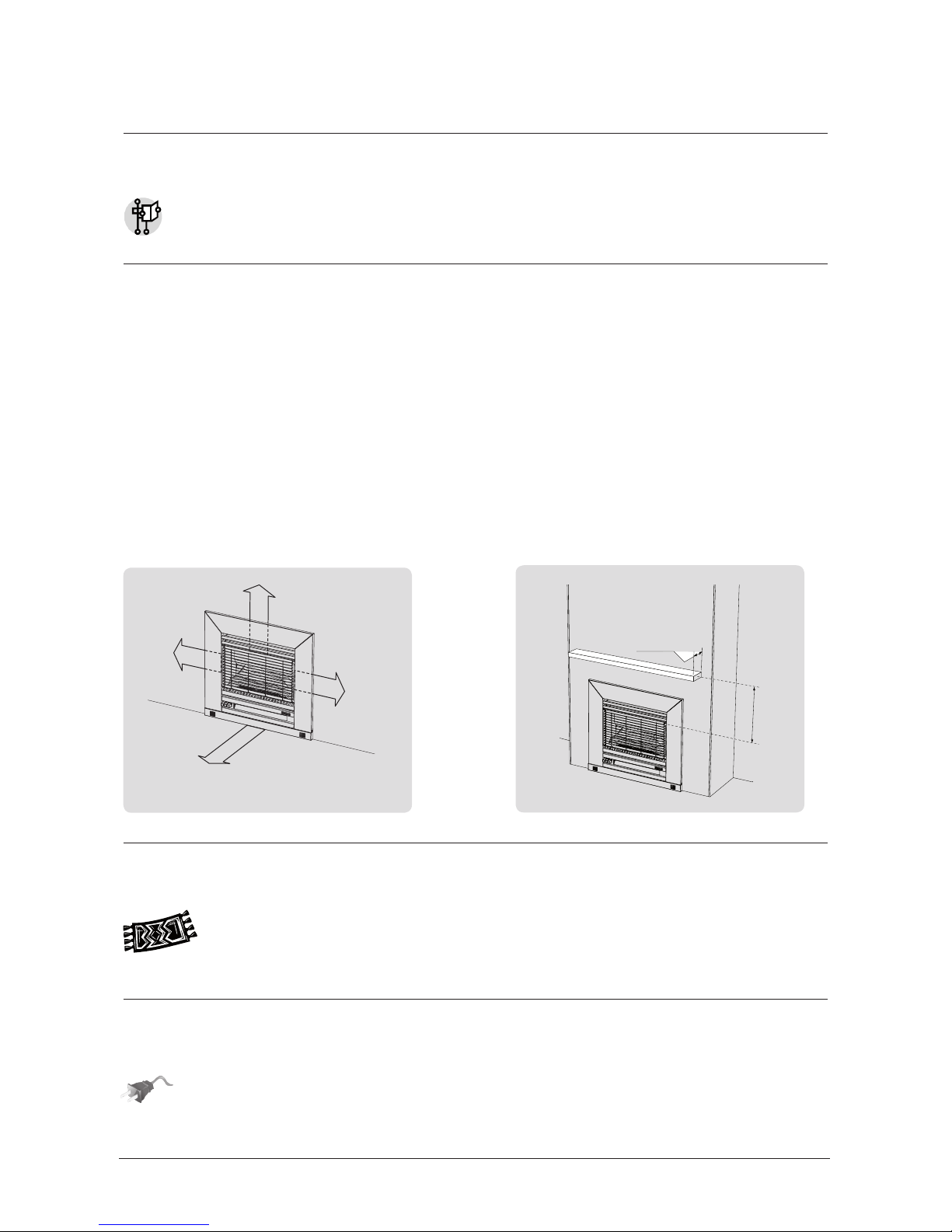

Clearance to combustibles, mantles and surrounds

Combustible clearances

The appliance must not be installed where curtains or other combustible materials could come

into contact with the heater. In some case curtains may need restraining.

Mantles and surrounds

A mantle is allowable providing it is outside the minimum clearances shown.

For an additional overhang, 100 mm of vertical clearance is required for every 50 mm of added

depth. For example, a 100 mm mantle depth requires 400 mm of vertical clearance.

Floor protection

Heat emanating from this re may over time affect the appearance of some

materials used for ooring, such as, carpet, vinyl, cork or timber. This may be

amplied if the air contains cooking vapours or cigarette smoke. To avoid this

occurring, it is recommended that a mat be placed in front of the appliance.

Combustible Clearances Mantles

300mm

300mm

300mm

1000mm

300 mm minimum

from top of glass

50 mm maximum

at 300 mm above

Electrical connection

Appliance must not be located below a power socket outlet. If the supply cord is

damaged and requires replacing, it must be replaced by a licensed tradesperson. This

must be a genuine replacement part available from Rinnai.

Page 7

Rinnai New Zealand Compact Op/Install Manual: 10170-C 02-09

7

Customer Information - General

Hearths

A hearth is not necessary but can be used for decorative

purposes or protection of sensitive ooring if required.

Some general guidelines when installing a hearth such as

in an existing masonry replace.

It must not obscure the front of the re

The bottom of the appliance must be level with the

top of the hearth so there is a continuous level

Size should be at least the width and depth of the re

Remember to adjust the dimensions of the cavity to

allow for the hearth

In some instances an increase in hearth is desired. For the Timberame range this may affect

aesthetics. The increase in hearth height may cause you to look directly into the vents where

the wiring is visible instead of the ame prole.

•

•

•

•

Ensure continuous level

Adjust dimensions of cavity to

allow for the hearth

Maintenance and servicing

Maintenance

Your heater needs very little maintenance to keep it looking good. All parts of the heater

can be cleaned using a soft, damp cloth and mild detergent. Do not use solvents and do not

attempt to clean the heater while it is hot or operating.

Servicing

Rinnai has a service and spare parts network with personnel who are fully trained and

equipped to give the best advice on your Rinnai appliance. If your appliance needs

servicing, please call Rinnai (0800 746 624) and select option 1 for a service centre in

your area.

For reliable operation Rinnai Flame Fires should be serviced every 2 years (including inspection

of the ue system). If they are in a particularly dusty environment or subject to excess lint,

for example dog hair or where there are newly laid carpets then annual servicing would be

benecial.

Regular servicing is not covered by the Rinnai warranty.

Do not attempt to carry out any service work other than that mentioned in the troubleshooting

section. If you have any other faults or problems, please refer to your installer or call Rinnai.

Page 8

Rinnai New Zealand Compact Op/Install Manual: 10170-C 02-09

8

Customer Information - Operation

Ignition

Firmly press the IGN button for 10 seconds and release. This operates the built-in safety

device and starts the electronic spark (lights to pilot).

If the pilot does not remain alight, wait 2 minutes before retrying ignition. If the heater does

not ignite on initial use it may be due to air remaining in the gas supply line.

HIGH LOW

IGN

Adjusting the heat

Press the buttons from ‘LOW’ to ‘HIGH’. This will ignite additional burners as shown above.

Turning off

Press and release the buttons from ‘HIGH’ to ‘IGN’ until they are in the off position. The fan

will stop when the heater cools.

Fan operation

The fan will operate automatically when the heater warms up and will stop when it cools.

When the heater is on the ‘LOW’ setting the fan may turn off as the heater cools and restart

when warm.

In the event of a power failure

If there is a power failure, turning the heater to the ‘LOW’ setting may allow the heater

to continue operating without overheating. Remaining on the ‘HIGH’ setting will cause the

overheat protection switch to activate. This will shut down the appliance.

The words HIGH, LOW and IGN are not part of

the control panel. They have been displayed to

highlight what each of the different settings mean.

Page 9

Rinnai New Zealand Compact Op/Install Manual: 10170-C 02-09

9

Customer Information - Troubleshooting

Symptom Cause Solution

Burner will not light No power present

No gas present

Power cut

Air in gas pipe

Ignition failure

Ensure power cord is plugged in and turned on

Ensure gas supply is turned on

Re-ignite after power is restored

Installer to do - purge air

Repeat ignition steps

Smell of gas Leaking gas Turn off gas at meter or LPG cylinder and call installer

Fan not working Heat switch is not activated

No power present

Allow heater to run on HIGH for approximately 5 mins

Ensure power cord is plugged in and turned on

Small soot deposit Normal operation No action required

Severe soot

deposits forming

on logs or glass

Inadequate ue system, incorrect

gas pressure or log misalignment

Call a Rinnai Service Centre

Condensation on

glass

Normal operation Allow heater to warm-up and condensation will

disappear

Streaky lines on

glass

Normal operation Clean glass

During installation there will be an initial burning in period where some smoke and smell may

be experienced. This is a normal part of the operation.

The appliance is tted with an overheat safety switch. Under overheating conditions this switch

will shut off the appliance. If the appliance shuts off repeatedly servicing may be required.

Abnormal ame pattern

Each Rinnai Flame Fire has a distinct ame pattern. This should look the same every time you

start your re, after an initial warm up period of approximately 20 minutes.

Abnormal ame performance and/or pattern can indicate a problem with your re, such as

blocked gas injectors or articial logs/burn media have shifted from when the re was rst

installed. There are some warning signs that could indicate a problem.

Unusual smell from the appliance

Continued difculty or delay in establishing a ame

Flame appears either very short or very long

Flame only burns part way across the burner

Severe soot building up on the inside of the glass door

If any of the above signs occur, please call Rinnai to discuss.

•

•

•

•

•

Normal

Abnormal

Page 10

Rinnai New Zealand Compact Op/Install Manual: 10170-C 02-09

10

Installation Information - General

Before installation

Unpack the appliance and components and check for damage. DO NOT install any

damaged items.

Check all components have been supplied and that you have the correct gas type.

Read these instructions to get an overview of the steps required before starting the

installation. Failure to follow these instructions could cause a malfunction of the

appliance. This could result in serious injury and property damage.

Specication information

Data Plate Inside appliance - bottom panel front right hand side

Dimensions H-645 mm, W-750 mm, D-277 mm

Fan Type Tangential 2-speed, rating 28 W

Flue - Masonry Rinnai strongly recommends the use of a Rinnai Flexiliner Flue system. Failure to meet this

criteria may result in an unsafe situation. Installation without a exiliner ue is permissible

as long as the chimney is checked for soundness and ability to achieve a good draw.

Terminal 43 mm x 245 mm rear discharge (spigot)

Flue - Decorative Natural draft twin skin ue. Termination, an approved 100 mm cowl must be tted to

all installations. Decorative chimney installations require a Zero Clearance Box and Zero

Clearance Flue Kit. Flue dimensions, outer - 150 mm, inner - 100 mm.

Gas Connection ½ “ BSP male are to barrel union

Gas Type NG or LPG

Noise Level 49 dB(A)

Power Consumption High 80 W, Standby 4 W

Weight 39 kg

Page 11

Rinnai New Zealand Compact Op/Install Manual: 10170-C 02-09

11

Installation Information - Location

Positioning the appliance

Main points governing location are ueing and warm air distribution. The heater must not

be installed where curtains or other combustible materials could come into contact with the

appliance. In some cases curtains may need restraining.

Standard ued appliances draw the air for combustion from the room itself so there is a need

for permanent ventilation (for example, xed open louvres). This xed ventilation must be

provided as per NZS:5261.

Enclosure requirements

The heater must be positioned on a at level surface that allows free movement of the

appliance.

Masonry installations, use a slurry of sand and cement to level base as required

Decorative installations, the zero clearance box needs to be supported, either construct a

base using board with supporting joists or support with the frame itself

Enclosure Dimensions

Masonry Installation Decorative Fireplace

W-Width 590 - 740 mm 680 mm

H-Height 640 mm 675 mm

D-Depth 360 mm 370 mm

All dimensions provided are critical to the installation of this

appliance and must be adhered to.

•

•

Electrical connection

This appliance has a power cord with a 3-pin plug supplied. The power

cord passes through the slot in the lower left or right hand side of the

heater front assembly.

Rinnai recommends that the heater be plugged into a 230 V 10 Amp

earthed power point. The power point must be a minimum of 300 mm

to the side and must not be above the unit. Alternatively the unit can be

direct wired if the power supply is to be concealed.

The electric isolation switch must be accessible after the appliance has been installed. The

electrical cord is not re rated and should not come into contact with the re.

POWER CORD

RUBBER GROMMET

Page 12

Rinnai New Zealand Compact Op/Install Manual: 10170-C 02-09

12

Installation Information - Flueing

General ueing guidelines

Every appliance requires a ue system that will draw effectively and safely clear ue products

under all wind and climatic conditions.

It is the responsibility of the installer to ensure that the appliance is provided with an effective

ue. Some guidelines to assist with ue design is listed below. These must be read and

modied as necessary with reference to the particular installation.

Flue Terminal Locations

Must be compliant with ‘Clearances Required for Flue Terminals’ from NZS:5261.2003.

Flue Length

This is required for adequate draw and prevents spill-back of combustion products that can

cause safety sensors to shut down the re.

Minimum 3.6 m vertical (1.2 m of vertical ue required before any bend or offset)

Maximum Rinnai recommend a maximum ue height of 8 m

Flue Systems

For new replace installations (installations into a combustible opening) a Rinnai Zero

Clearance Box and Flue Kit is a mandatory requirement to meet warranty conditions.

For masonry installations, to ensure adequate draw, Rinnai strongly recommends the

use of a Rinnai Flexiliner Flue System. Failure to meet this installation criteria may

result in an unsafe situation. Installation without a exiliner ue is permissible as long

as the chimney has been checked for soundness and ability to achieve a good draw.

Shared Flues

Gas appliances must not be connected to a chimney or ue serving a separate solid fuel

burning appliance.

Flue Cowl Clearance

To ensure the products of combustion are cleared, adequate clearance from the building is

required. The following guideline is recommended.

Flue cowl should have a 500 mm clearance from any part of the building. This also applies to

steeped and pitched roofs which should be 500 mm clear of the ridge line as shown below.

Lesser clearances may provide perfectly adequate ue systems depending on the installation.

•

•

500 mm

500 mm

500 mm

500 mm

Page 13

Rinnai New Zealand Compact Op/Install Manual: 10170-C 02-09

13

Installation Information - Flueing

Masonry installations and exiliner ue systems

Check dimensions of opening

Ensure opening is within range provided and if necessary bring them

to the required dimensions. Also check chimney height as inadequate

height can affect product performance. Some installations may require

the chimney height to be extended to reduce down drafts.

Check ueway

Ensure there are no obstructions. Provide a rm, at and sealed base

otherwise noise and vibration may result. Sealed means no holes or

openings in the replace.

Install a Rinnai exiliner ue system

Ensure a minimum vertical rise of 1.2 m before any change of

direction. Avoid sharp bends as this will restrict the chimney’s ability to

draw.

Installation without a exiliner is permissible as long as the chimney

has been checked for soundness and ability to achieve a good draw.

Some criteria for checking soundness:

All loose/broken bricks must be replaced or repaired ensuring the

chimney is of sound construction and does not leak

Chimney must be swept clean and be free from soot and creosote

that may have built up if previously used for a solid fuel re

Any damper plate must be xed in the open position or removed

Any underoor air supply to the replace must be completely

sealed off to prevent secondary air draw

An approved chimney cap and cowl must be installed

•

•

•

•

•

640 mm

590 - 740 mm

360 mm minimum depth

100mm Chimney Cowl

Compact

Heater

100mm Galvanised

Chimney Flashing

300 x 400 mm

100mm Top

Flexi Flue Adaptor

Flexiliner

Flue Adaptor

Aluminium

Flexible

Flue

Page 14

Rinnai New Zealand Compact Op/Install Manual: 10170-C 02-09

14

Installation Information - Flueing

New replace installations and ueing

For installations into new replaces (installation into a combustible opening) a Rinnai Zero

Clearance Box and Zero Clearance Flue Kit is required. Failure to meet this installation criteria

will void any product warranty.

Installing the heater last minimises building debris/dust entering the re which is common

when building or renovating.

Construct frame and install a zero clearance box BEFORE the dry wall

Refer to instructions supplied with the zero clearance box.

Installation of the zero clearance box needs to be on a level base. If

this is not done the appliance may twist and become damaged and

will void any product warranty.

Install the ue

The ue should be self supporting. This is usually done at the framing stage with ue supports

(x2) provided in the ue kit. These are riveted to the ue. The ue kit components are twin-

skin and require a 25 mm clearance from combustibles.

Complete electrical connection

Electrical cord is not re rated and should not come into contact with the re. An electrical

isolation switch is also required so positioning of this switch needs to be considered when

assessing where to install the unit.

Flat wall Construct frame Install zero

clearance box

Install ue Plaster and

paint

Install heater

680 mm

675 mm

370 mm

Flue

Combustible Material

Inner ue

Outer ue

must be ≥ 25 mm from inner ue

Page 15

Rinnai New Zealand Compact Op/Install Manual: 10170-C 02-09

15

Installation Information - Installation

Preparation

Position plinth into cavity or zero clearance box. The plinth correctly positions the heater

at the required level and the air slots at either end allow air to pass through and cool the

heater and/or zero clearance box

Place the heater on a at surface and remove the 3 screws holding the fascia (1) in place.

Pull the bottom of the fascia forward until clear of the gas control buttons and lift up to

remove from frame.

Remove the 2 screws holding the top glass retainer in place and lift off (2).

Loosen the 2 screws holding the lower glass retainer in place and remove glass panel (3).

Remove the barrel elbow from the gas connection bracket on the base of the heater at the

front right hand side (4). Make sure that the gas are tting and gas supply pipe are clean

and free from damage. Fit together ready for tting to the heater.

For installation into a masonry replace, the foam strips (5) must be attached to the

heater to provide a seal around the replace. If this does not provide an adequate seal an

alternative must be used.

Insert the heater into the cavity on top of the plinth, taking care when inserting the gas

supply tube.

There are 4 levelling screws at the base of the heater held in place with locknuts. If the

heater does not sit at when in place it may be necessary to adjust these. The front screws

are accessible with the front of the heater removed. If adjustment of the rear feet is

required, the burner assembly and gas control will need to be removed (6).

Once the heater is sitting at attach it to the wall using the 4 holes (2 per side) on the front

anges.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

1

2

3

4

5

6

7

8

9

10

11

Plinth Supplied with Heater

Air Slots

Air Slots

Page 16

Rinnai New Zealand Compact Op/Install Manual: 10170-C 02-09

16

Installation Information - Installation

Gas connection

Gas pipe sizing must consider the gas input to this appliance as well as other appliances in the

premises. The gas meter and regulator must be specied for the total gas rate. An approved

sizing chart such as the one in NZS:5261 should be used.

Copper supply should be run leaving a ared connection at the position shown. The gas

supply terminates inside the heater and enters the appliance from the rear. As this is a are

connection, sealant is not recommended.

260

79

43

½" BSP MALE FLARE

Purge supply of air and debris

All foreign materials such as lings must be purged from the gas supply, as they may cause

the gas control valve to malfunction.

Fit heater into place

When the heater is in place and properly secured, attach the gas supply to the supplied barrel

union and tighten.

On completion of work a gas leak test must be carried out. Use a soapy solution on all gas

connections. Leaks will be visible when the soapy solution forms bubbles. When nished, wipe

soapy solution with a rag to remove residue.

Page 17

Rinnai New Zealand Compact Op/Install Manual: 10170-C 02-09

17

Installation Information - Installation

Installing the logset

Logset preparation

Remove logset and granule packet from packaging. To achieve the correct location of the

logset hold as shown below.

Logset positioning into combustion chamber

Tilt the back of the logset upwards locating the front feet (1) behind the unpainted inner

horizontal lip (2). Ensure sides do not touch the combustion chamber walls.

Rotate the back of the logset down using the location of the front feet as pivot points.

Logset correctly positioned

Logset will look like picture shown when installed correctly.

1.

2.

3.

1 2 3

Adding granules

Gently place granules in front of the main log. Level it with a pencil or screwdriver and remove

excess material. Do not pour granules as dust particles from plastic bag may block the burner

ports. If the logset is to be removed for any reason the granules must be removed rst.

Any material that prevents the logs from sitting at on the burner top can upset the burning

pattern and performance of the heater.

Replace glass

Replace the glass ensuring the joint in the glass sealing tape is at the bottom.

4.

5.

Page 18

Rinnai New Zealand Compact Op/Install Manual: 10170-C 02-09

18

Installation Information - Testing

Testing procedure

Turn gas supply on and plug the unit into the power supply.

Refer to data plate for burner pressure and remove front cover panel.

Remove test point screw and attach manometer to test point. The test point is on the front

injector block.

Light heater, turn to high setting and check pressures.

If adjustments are necessary, the regulator is situated on the front of the gas control and

should be set to the pressures on the data plate.

After checking pressures, turn the unit off, remove manometer and replace test point

screw.

Turn the heater on and off a few times to check ignition.

When you are satised that the heater is working correctly, reassemble the panels.

All burner aerations are factory preset and cannot be adjusted. If you are unable to get the

unit to operate correctly refer to troubleshooting section of this manual before contacting

Rinnai.

It may take approximately 2 hours of operation for the logs to achieve their full ame pattern

and glow. During the initial burning in period, some smoke and smell may be experienced. The

heater should be run on the high setting in a well ventilated room until these dissipate.

It is the responsibility of the installer to check that under normal conditions of the

appliance, all ue gases are exhausted to the outside atmosphere and that there are no

spillage of combustion gases into the room

1.

2.

3.

4.

5.

6.

7.

8.

Page 19

Rinnai New Zealand Compact Op/Install Manual: 10170-C 02-09

19

Installation Information - Commissioning

Complete the installation and commissioning checklist below and make sure this manual is left

with the customer. Explain to the customer about the use and care of the unit and understands

the instructions and operation of the appliance.

If operating without a dress guard please following safety instructions to prevent the risk of

injury.

NO YES

Appliance positioned in a suitable location? (i.e. clearances, combustibles

etc.)

Was a Rinnai approved ue system installed and is the ue drawing

effectively?

Has specied gas pressures been checked and set?

Is the logset located correctly?

Have the granules been placed evenly and on top of the burner and free of

dust?

Has the appliance been tested for correct operation?

Is the customer fully aware of the operating procedure?

Installer Details

Company name:______________________________________________________________

Installer name:_______________________________________________________________

Address:____________________________________________________________________

___________________________________________________________________________

Phone:_______________________________ Mobile:______________________________

Permit number for installation:___________________________________________________

Signed:______________________________ Date:_______________________________

Page 20

Rinnai New Zealand Compact Op/Install Manual: 10170-C 02-09

20

Consumers: 0800 RINNAI (746 624)

Installers: 0800 TO RINNAI (86 746 624)

Address: 105 Pavilion Drive, Airport Oaks, Mangere, Manukau

PO Box 53177, Auckland Airport, Manukau 2150

Phone: (09) 257 3800

Fax: (09) 257 3899

Email: info@rinnai.co.nz

Websites: www.rinnai.co.nz and www.rinnai-tradesmart.co.nz

Wiring Diagram

1

1

2

B L

2

1

220~240 v

50 Hz

BR

G /Y

B L

W

W

B L

B L

W

IGN S WITC H

(MICR O)

B L

S PAR K E R

ELECTR ODE

FAN

2

BR

FAN S W ITCH

ON/OF F

(T HE R MAL)

-+

1

2

3

R

B L

B L

R

W

FAN S W ITCH

HI/LOW

(MICR O)

W

S V

OHS

( - )

(+)

TC

W

R Red

BL Blue

BR Brown

W White

G/Y Green/Yellow

OHS Overheat Switch

SV Solenoid Valve

TC Thermocouple

If the supply cord is damaged or requires replacing, it must be replaced by a licensed

tradesperson. This must be a genuine replacement part available from Rinnai.

Loading...

Loading...