Ringler GmbH

Robert-Bosch-Straße 4–8 Fon +49 (0)7171-94 888-0 info@ringler.kaercher.com

73550 Waldstetten [Germany] Fax +49 (0)7171-94 888-28 www.ringler-gmbh.de

Translation of the Original Operating Manual

RA 200 D3,0 / D5,5 / D2x3,0 IE2

GERMANY

2015-12-10

GBR

Copyright

Copyright by

Ringler GmbH

Robert-Bosch-Straße 4-8

73550 Waldstetten

GERMANY

2/50

1 Safety Instructions ................................................................................................................................. 6

1.1 Terms ................................................................................................................................................. 6

1.1.1 Operation ....................................................................................................................................... 6

1.1.2 Maintenance .................................................................................................................................. 6

1.1.3 Qualified Staff ................................................................................................................................ 6

1.2 Symbols ............................................................................................................................................. 6

1.3 General safety information ................................................................................................................. 8

2 Delivery, internal transportation, unpacking ....................................................................................... 9

2.1 Delivery .............................................................................................................................................. 9

2.2 Internal transport ................................................................................................................................ 9

2.2.1 Dimensions and weight .................................................................................................................. 9

2.3 Unpacking .......................................................................................................................................... 9

2.4 Packaging material ............................................................................................................................ 9

2.5 Storage conditions ........................................................................................................................... 10

2.5.1 Information for storage ................................................................................................................. 10

3 Appliance description .......................................................................................................................... 11

3.1 Intended Use ................................................................................................................................... 11

3.1.1 Dust class "L" ............................................................................................................................... 11

3.1.2 Dust class "M" .............................................................................................................................. 11

3.2 Non-Intended Use ............................................................................................................................ 12

3.2.1 Dust class "L" ............................................................................................................................... 12

3.2.2 Dust class "M" .............................................................................................................................. 12

4 Layout and function ............................................................................................................................. 13

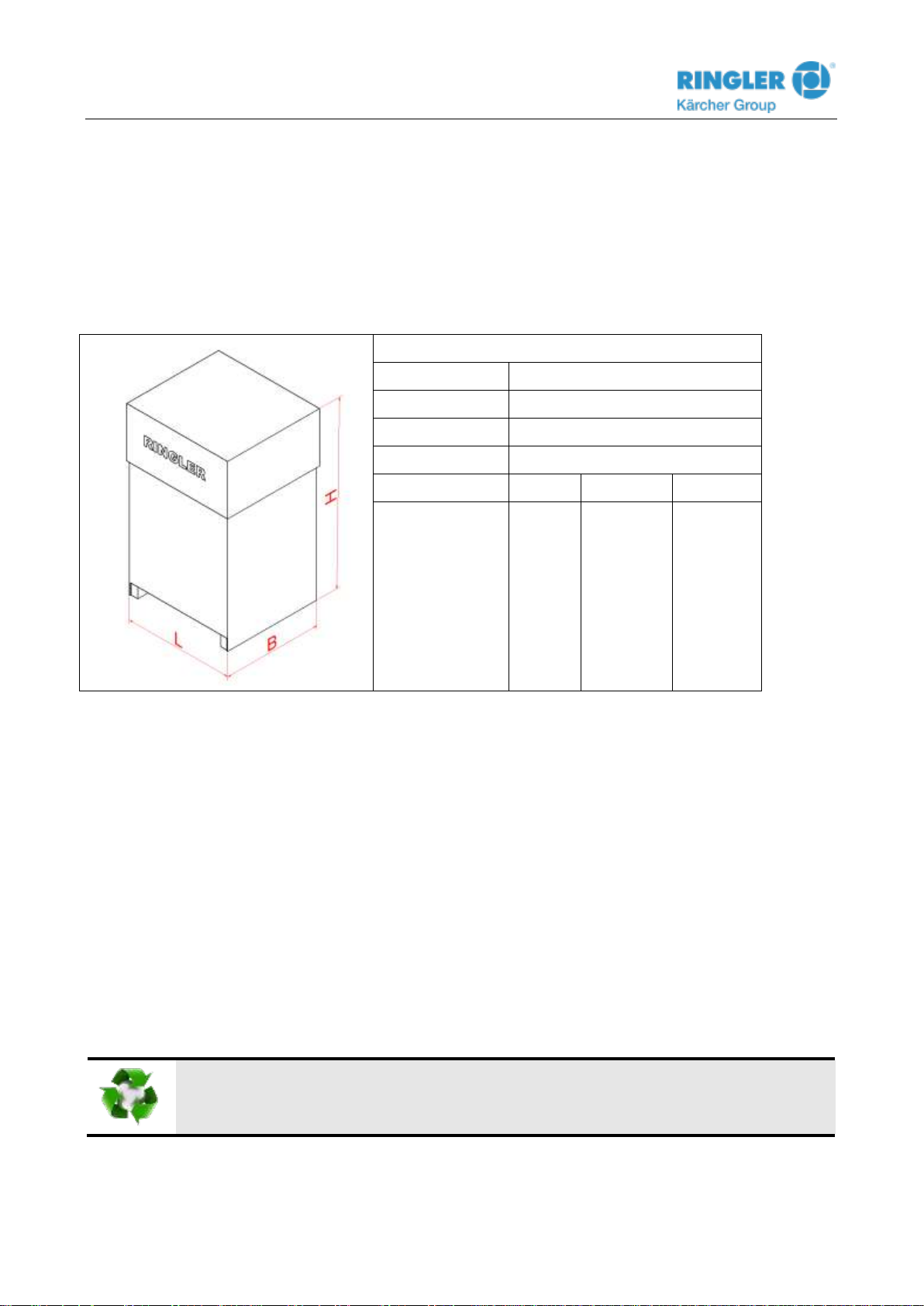

4.1 Main dimensions .............................................................................................................................. 13

4.2 Technical data total device RA 200 ................................................................................................. 13

4.3 Technical Data D3 IE2 ..................................................................................................................... 13

4.4 Technical Data D2x3 IE2 ................................................................................................................. 14

4.5 Technical Data D5.5 IE2 .................................................................................................................. 14

5 Main components ................................................................................................................................. 15

5.1 Components RA 200 ....................................................................................................................... 15

5.2 Function Description ........................................................................................................................ 15

6 Initiation ................................................................................................................................................. 16

6.1 Initial operation ................................................................................................................................ 16

6.2 Connection to the electric mains ..................................................................................................... 16

6.3 Check the following before switching it on: ...................................................................................... 17

6.4 Wrong rotating direction ................................................................................................................... 17

6.5 Potential equalization conductors .................................................................................................... 17

7 Operation ............................................................................................................................................... 18

7.1 Operation ......................................................................................................................................... 18

7.1.1 ON / OFF switch Three-phase current ........................................................................................ 18

7.2 Rotary current switch 5.5 kW (star-delta switch) ............................................................................. 18

7.3 Suction process ............................................................................................................................... 18

7.4 Filter cleaning .................................................................................................................................. 20

7.4.1 Manual filter cleaning ................................................................................................................... 20

7.5 Empty collection container with PE dust bag ................................................................................... 20

3/50

8 Troubleshooting and fault elimination ............................................................................................... 22

8.1 Safety instructions ........................................................................................................................... 22

8.2 Initial fault elimination measures ..................................................................................................... 22

9 Maintenance/Repair.............................................................................................................................. 24

9.1 Maintenance regulations .................................................................................................................. 24

9.2 Maintenance intervals table ............................................................................................................. 25

9.3 Cleaning ........................................................................................................................................... 25

9.4 Changing the filter cloth for the bag-type filter ................................................................................. 26

9.4.1 Work steps for pocket filter change ............................................................................................. 27

9.5 Disassembly of the suction turbine .................................................................................................. 29

9.6 Circuit diagram to motor protection switch D 2x3 kW ...................................................................... 30

9.7 Warnings on the suction device ....................................................................................................... 31

9.7.1 Warning sign for devices in class "L" ........................................................................................... 31

9.7.2 Warning sign for devices in class "M" .......................................................................................... 31

9.7.3 Marking: Vacuum cleaner ............................................................................................................ 31

9.7.4 Type sign ..................................................................................................................................... 31

9.8 Wear parts list .................................................................................................................................. 32

10 Decommissioning, storage ................................................................................................................. 33

11 Disposal ................................................................................................................................................. 34

12 Spare Parts List .................................................................................................................................... 35

12.1 Drawing/spare parts list RA 200 ...................................................................................................... 35

12.1.1 Drawing/spare parts list RA 200 .............................................................................................. 35

12.2 Base frame RA 200 ......................................................................................................................... 36

12.2.1 Base frame RA 200 ................................................................................................................. 36

12.3 Spare parts list/drawing RA drive unit D3 kW IE2 PKZM (3401049) .............................................. 37

12.3.1 Spare parts list/drawing RA drive unit D3 kW IE2 PKZM (3401049)....................................... 37

12.4 RA drive unit D 2x3 kW IE2, with PKZM switch (3401046) ............................................................. 39

12.4.1 RA drive unit D 2x3 kW IE2, with PKZM switch (3401046) ..................................................... 39

12.5 Side channel blowers 3kW IE2 preassembled (2401014) ............................................................... 41

12.6 Side channel blowers 3kW IE2 preassembled (2401014) ............................................................... 41

12.7 RA drive unit D 5.5 kW IE2 with star-delts switch (3401000) .......................................................... 42

12.8 RA drive unit D 5.5 kW IE2 with star-delts switch (3401000) .......................................................... 42

12.9 Collecting Container Type RI 332, RA 200 (2101026) .................................................................... 44

12.9.1 Spare Parts List Container Type RI 332, RA 200 (2101026) .................................................. 44

12.10 Spare parts list/drawing pocket filter 3.2m², Kat. "L" as / "L" as (2350202/2350115) ................. 45

12.10.1 Spare parts list/drawing pocket filter 3.2m², Kat. "L" as / "L" as (2350202/2350115) ............. 45

12.11 Spacer rake for pocket filter 1.75/3.2/5.2m², (2381000), (2381001), (2381002) ......................... 46

12.11.1 Spacer rake for pocket filter 1.75/3.2/5.2m², (2381000), (2381001), (2381002) ..................... 46

12.12 Spare Parts List Suction hose DN 50, all Types (2600398-Z) .................................................... 47

12.12.1 Spare Parts List Suction hose DN 50, all Types (2600398-Z) ................................................ 47

12.13 Spare Parts List Suction hose DN 70, all Types .......................................................................... 48

12.13.1 Spare Parts List Suction hose DN 70, all Types ...................................................................... 48

13 Component documentation ................................................................................................................. 49

13.1 Documentation for side-channel compressor .................................................................................. 49

14 EEC-Declaration of Conformity ........................................................................................................... 50

4/50

Safety Instructions

Pos: 1.1 /1 Grundlegende Sicherheitshi nweise/Kapitelüberschrift 1 Angaben zur Sicherheit @ 0\mod_1261 472663260_131.docx @ 973 @ 1 @ 1

5/50

Safety Instructions

NOTICE

CAUTION

WARNING

DANGER

Significance of the Operating Manual

This Operating Manual is part of the supplied product.

The Operating Manual remains valid throughout the product's lifetime, provided that no

technical changes are made.

If the product is sold, the Operating Manual must be handed over to the next owner or user.

This information must be read before first commissioning.

WARNING - Read the instructions before using the machine

CE marking

The CE marking means "Communautés Européennes". It is the external symbol which states

that a product fulfils the requirements imposed on the manufacturer by the European

1 Safety Instructions

Pos: 1.2 /1 Grundlegende Sicherheitshi nweise/Kapitelüberschrift 2 Begriffe @ 0\mod_1261472746655_1 31.docx @ 980 @ 2 @ 1

1.1 Terms

Pos: 1.3 /1 Grundlegende Sicherheitshi nweise/Begriffe-Betrieb @ 0\mod_1261486420512_131.docx @ 10 40 @ 3 @ 1

1.1.1 Operation

includes installation, initiation (placing at disposal for usage), operation (handling, connection,

Pos: 1.4 /1 Grundlegende Sicherheitshi nweise/Begriffe-Instandhaltung @ 0\mod_1261486704783_131.d ocx @ 1046 @ 3 @ 1

1.1.2 Maintenance

Pos: 1.5 /1 Grundlegende Sicherheitshi nweise/Begriffe- qualifiziertes Personal @ 0\mod_126148682925 3_131.docx @ 1052 @ 3 @ 1

1.1.3 Qualified Staff

Pos: 1.6 /1 Grundlegende Sicherheitshi nweise/Kapitelüberschrift 2 Symbole @ 0\mod_1261473167732_13 1.docx @ 987 @ 2 @ 1

1.2 Symbols

Pos: 1.7 /1 Grundlegende Sicherheitshi nweise/Signalwort-Feld "Hinweis" @ 0\mod_1261404960439_131.d ocx @ 905 @ @ 1

Pos: 1.8 /1 Grundlegende Sicherheitshi nweise/Text zu Hinweissymbol @ 0\mod_1261477345812_131.doc x @ 1014 @ @ 1

Pos: 1.9 /1 Grundlegende Sicherheitshi nweise/Signalwort-Feld "Vorsicht" @ 0\mod_1261404898171_131 .docx @ 899 @ @ 1

disconnection, etc.)

includes control and attendance (inspections, revisions), maintenance and repair (detection of errors

and their elimination).

are employees authorised by the person responsible for the security of the installation to carry out

the operations required in each case and who are able to recognise and avoid possible dangers by

reason of their training, experience and instructions as well as their knowledge of relevant norms,

prescriptions, accident-prevention rules and working conditions.

Denotes information that does not relate to personal injuries.

This information contains additional directions or general hints.

Pos: 1.10 /1 Grundlegende Sicherheitshin weise/Text zu Vorsichtssymbol @ 0\mod_1261475623349_131. docx @ 1000 @ @ 1

Dangerous situation, which could result in minor to moderate injury if it is not avoided.

This information must be regarded strictly to avoid damages to the installation or environment!

Pos: 1.11 /1 Grundlegende Sicherheitshin weise/Signalwort-Feld "Warnung" @ 0\mod_1261404807286_13 1.docx @ 893 @ @ 1

Pos: 1.12 /1 Grundlegende Sicherheitshin weise/Text zu Warnsymbol, Allgemein @ 0\mod_12614754346 12_131.docx @ 994 @ @ 1

Dangerous situation, which could result in serious injury or death if it is not avoided.

Pos: 1.13 /1 Grundlegende Sicherheitshin weise/Signalwort-Feld "Gefahr" @ 0\mod_1261404709797_131.d ocx @ 887 @ @ 1

Pos: 1.14 /1 Grundlegende Sicherheitshin weise/Text zu Gefahrensymbol @ 0\mod_1261477187354_131.d ocx @ 1007 @ @ 1

Dangerous situation, which will definitely result in serious injury or death if it is not avoided.

Pos: 1.15 /1 Grundlegende Sicherheitshin weise/Hinweis Bedeutung der Betriebsanleitung @ 0\mod_12 61470697948_131.docx @ 960 @ @ 1

Pos: 1.16 /1 Grundlegende Sicherheitshin weise/Hinweis Lesesymbol @ 0\mod_1261405473678_131.docx @ 911 @ @ 1

Pos: 1.17 /1 Grundlegende Sicherheitshin weise/Hinweis WARNUNG - Vor Benutzung der Maschine @ 4\m od_1358500046626_131.docx @ 37492 @ @ 1

Pos: 1.18 /1 Grundlegende Sicherheitshin weise/Hinweis CE-Zeichen @ 0\mod_1261407630923_131.doc x @ 953 @ @ 1

6/50

Safety Instructions

Community.

Only use with safety shoes (acc. to EN ISO 20345)

Only use with work gloves

Respiratory protection (EN 149:2001)

Use protective clothing (acc. to EN 13982-1)

Use protective glasses (acc. to DIN EN 166 1349-BT)

Before starting work remove the plug from the wall socket!

Disconnect before starting work

While operating electrical machines, certain parts of them are inevitable alive dangerously or

under mechanical stress.

Hand injury warning sign!

Recycling symbol

This information must be observed in order to preserve the environment!

Pos: 1.19 /1 Grundlegende Sicherheitshin weise/Hinweis Sicherheitsschuhe @ 0\mod_1261406516446_1 31.docx @ 925 @ @ 1

Pos: 1.20 /1 Grundlegende Sicherheitshin weise/Hinweis Arbeitshandschuhe @ 0\mod_1261407294655 _131.docx @ 932 @ @ 1

Pos: 1.21 /1 Grundlegende Sicherheitshin weise/Hinweis Atemschutz @ 4\mod_1358754071540_131.docx @ 37562 @ @ 1

Pos: 1.22 /1 Grundlegende Sicherheitshin weise/Hinweis Schutzkleidung benutzen @ 4\mod_135884904 5279_131.docx @ 37727 @ @ 1

Pos: 1.23 /1 Grundlegende Sicherheitshin weise/Hinweis Schutzbrille benutzen @ 4\mod_13588670322 29_131.docx @ 37738 @ @ 1

Pos: 1.24 /1 Grundlegende Sicherheitshin weise/Hinweis Netzstecker ziehen @ 0\mod_1261407392098_ 131.docx @ 939 @ @ 1

Pos: 1.25 /1 Grundlegende Sicherheitshin weise/Hinweis Vor Beginn der Arbeiten freischalten @ 4\mod_13 62652119939_131.docx @ 41545 @ @ 1

Pos: 1.26 /1 Grundlegende Sicherheitshin weise/Hinweis elektrische Spannung @ 0\mod_126140762803 9_131.docx @ 946 @ @ 1

Pos: 1.27 /1 Grundlegende Sicherheitshin weise/Warnung vor Handverletzungen @ 4\mod_136197769919 8_131.docx @ 40751 @ @ 1

Pos: 1.28 /1 Grundlegende Sicherheits hinweise/Hinweis Recyclingsymbol @ 0\mod_1261489835239_13 1.docx @ 1060 @ @ 1

Pos: 2 /0 Allgemeines/Seitenumbruch @ 0\mod_1265272007940_0.docx @ 2191 @ @ 1

7/50

Safety Instructions

WARNING

While operating electrical machines, certain parts of them are inevitable alive dangerously or

under mechanical stress.

CAUTION

Only use with safety shoes (acc. to EN ISO 20345)

Pos: 3.1 /1 Grundlegende Sicherheitshi nweise/Sicherheitsinformationen Wechselstrom-Geräte/Überschrift: Allgemeine Sicherheitsinformationen @ 0\mod_1269504752362 _131.docx @ 3486 @ 2 @ 1

1.3 General safety information

Pos: 3.2 /1 Grundlegende Sicherheitshi nweise/Signalwort-Feld "Warnung" @ 0\mod_1261404807286_131. docx @ 893 @ @ 1

Pos: 3.3 /1 Grundlegende Sicherheitshi nweise/Hinweis elektrische Spannung @ 0\mod_1261407628039 _131.docx @ 946 @ @ 1

Pos: 3.4 /1 Grundlegende Sicherheitshi nweise/Sicherheitsinformationen Wechselstrom-Geräte/Aufgrund ihr er funktionell bedingten elektrischen @ 0\mod_1269504589175_13 1.docx @ 3480 @ @ 1

Due to their electrical and mechanical functional properties, machines can cause severe injuries

and damage to property. This particularly applies in the event of incorrect use, operation or

Pos: 3.5 /1 Grundlegende Sicherheitshi nweise/Sicherheitsinformationen Wechselstrom-Geräte/Alle elektrisc hen und mechanischen Tätigkeiten @ 4\mod_1361281988815_1 31.docx @ 39784 @ @ 1

maintenance, or in the event of unauthorized interventions!

All electrical work must be performed by a qualified electrician. All mechanical work must be carried

out according to instructions (see Maintenance / Repair). The device may be operated only by

Pos: 3.6 /1 Grundlegende Sicherheitshi nweise/Sicherheitsinformationen Wechselstrom-Geräte/Vor dem G ebrauch muss die Bedienperson mit Informationen,... @ 4\mod_1 361284388040_131.docx @ 39794 @ @ 1

qualified personnel who have read and understood the operating instructions.

The operator must be provided with information, instructions and training on the materials to be

Pos: 3.7 /1 Grundlegende Sicherheitshi nweise/Sicherheitsinformationen Wechselstrom-Geräte/Alle Hinweis e und Angaben auf den Maschinen müssen beachtet werden @ 0\ mod_1269504980970_131.docx @ 3498 @ @ 1

Pos: 3.8 /1 Grundlegende Sicherheitshi nweise/Sicherheitsinformationen Wechselstrom-Geräte/Die ein wandfreie und sichere Nutzung dieser Maschine setzt @ 0\mod_126950 5050240_131.docx @ 3504 @ @ 1

absorbed, including a secure procedure for removal of the absorbed material, before use.

All notes and data on the machines must be observed!

Faultless and safe use of this machine includes correct transport and storage, as well as operation

Pos: 3.9 /1 Grundlegende Sicherheitshi nweise/Sicherheitsinformationen Wechselstrom-Geräte/Dieses G erät ist nicht dafür bestimmt....... @ 4\mod_1361284957242_131.doc x @ 39812 @ @ 1

in accordance with regulations and careful maintenance!

This device is not intended for being used by persons (including) with limited physical, sensory or

mental skills or lack of experience and/or lack of knowledge except if they are supervised by a

person responsible for their safety or were instructed in how to use the device by this person.

Pos: 3.10 /1 Grundlegende Sicherheitshin weise/Der Betrieb des Geräts ist nur auf bis zu 10° geneigtem Untergr und mit ausreichender Tragfähigkeit z @ 6\mod_1401894237 321_131.docx @ 60427 @ @ 1

Children should be supervised to ensure that they do not play with the device.

• Operation of the device is only permitted on underground sloping no more than 10° and with

Pos: 3.11 /1 Grundlegende Sicherheitshin weise/Signalwort-Feld "Vorsicht" @ 0\mod_1261404898171_13 1.docx @ 899 @ @ 1

sufficient load-bearing capacity.

Pos: 3.12 /1 Grundlegende Sicherheitshin weise/Hinweis Sicherheitsschuhe @ 0\mod_1261406516446_1 31.docx @ 925 @ @ 1

Pos: 3.13 /6 Inbetriebnahme/Gliedmaßen h erausziehen @ 6\mod_1401955740123_131.docx @ 60484 @ @ 1

• Do not place any limbs between parts to be joined during assembly of the machine parts. When

Pos: 3.14 /6 Inbetriebnahme/Spänesaug er/Netzanschlussleitungen überprüfen @ 0\mod_126934998070 5_131.docx @ 3197 @ @ 1

moving the parts, pull limbs from tightening spaces in time.

• Make sure that the power supply cord is not damaged by being run over, crushed, tugged etc..

Stop the industrial vacuum cleaner immediately if necessary!

• The power supply cord must be regularly inspected for signs of damage or ageing!

• Connectors of power supply cords must at least be splash-proof!

Pos: 3.15 /6 Inbetriebnahme/Spänesaug er/Die Inbetriebnahme ohne Filter oder einem beschädigten Filter ist nicht zulässig @ 0\mod_1269350986591_131.docx @ 3227 @ @ 1

• Starting without a filter or with a damaged filter is not allowed

Pos: 3.16 /1 Grundlegende Sicherheitshin weise/Sicherheitsinformationen Wechselstrom-Geräte/Das Saugg erät darf nicht betrieben werden, wenn an Verschlüssen @ 0\ mod_1269505708187_131.docx @ 3510 @ @ 1

The suction device must not be operated if wear is detected on fasteners or mounting brackets.

Pos: 3.17 /1 Grundlegende Sicherheitshin weise/Sicherheitsinformationen Wechselstrom-Geräte/Service A dressse Ringler @ 0\mod_1269505846364_131.docx @ 3516 @ @ 1

Please arrange for a service immediately, or send the industrial vacuum cleaner for repair to:

Ringler GmbH

Abt. Service

Robert-Bosch-Straße 4-8

73550 Waldstetten

Pos: 4.1 /2 Verpackung, Transport, Lager ung/Anlieferung, innerbetrieblicher Transport, Auspacken @ 0\ mod_1261397580765_131.docx @ 840 @ 1 @ 1

Tel: ++49-7171-94888-23

8/50

Delivery, internal transportation, unpacking

Packaging

Colli 1 Colli 2

L (mm)

800 800

B (mm)

900 900

H (mm)

1700 1700

3kW

5,5kW

2x3kW

Weight with

packaging (kg)

220

259

251

Recycling symbol

This information must be observed in order to preserve the environment!

2 Delivery, internal transportation, unpacking

Pos: 4.2 /2 Verpackung, Transport, Lager ung/Anlieferung @ 0\mod_1261401230055_131.docx @ 853 @ 2 @ 1

2.1 Delivery

Unload the scope of delivery on level ground with sufficiently sized industrial trucks.

Pos: 4.3 /2 Verpackung, Transport, Lager ung/Innerbetrieblicher Transport @ 0\mod_1261401337747_1 31.docx @ 860 @ 2 @ 1

2.2 Internal transport

Transport scope of supply to the site of setup secured against movement or tipping with a sufficiently sized

industrial truck.

Pos: 4.4 /2 Verpackung, Transport, Lager ung/Überschrift: Abmessungen und Gewicht @ 0\mod_1269507 946238_131.docx @ 3536 @ 3 @ 1

2.2.1 Dimensions and weight

Pos: 4.5 /2 Verpackung, Transport, Lager ung/Tabelle: Abmessungen und Gewicht RA 200 @ 7\mod_140 9147578500_131.docx @ 64988 @ @ 1

Pos: 4.6 /2 Verpackung, Transport, Lager ung/Auspacken @ 0\mod_1261401340912_131.docx @ 867 @ 2 @ 1

2.3 Unpacking

Make sure that no components are left in the packaging.

Scope of delivery: -Suction device

-Technical Manual

Pos: 4.7 /2 Verpackung, Transport, Lager ung/Verpackungsmaterial @ 0\mod_1261401408372_131.doc x @ 874 @ 2 @ 1

2.4 Packaging material

Pos: 4.8 /1 Grundlegende Sicherheitshi nweise/Hinweis Recyclingsymbol @ 0\mod_1261489835239_131.d ocx @ 1060 @ @ 1

Pos: 5.1 /2 Verpackung, Transport, Lager ung/Lagerbedingungen, Hinweis zur Lagerung @ 0\mod_12634 72277994_131.docx @ 1350 @ 23 @ 1

The packaging materials must be disposed of in accordance with the valid legal requirements.

Correct disposal of this product (electrical waste) (applicable in the countries of the European Union

and other European countries with a separate collection system)

The identification on the product and on the associated literature states that it must not be disposed of

along with normal domestic waste at the end of its service life. Please dispose of this device

separately from other waste, in order to prevent damage to the environment or to human health

through uncontrolled waste disposal. Please recycle this device, in order to promote sustainable reuse of material resources. Private users should contact the dealer from whom they purchased the

product or the competent authorities, in order to find out how they can recycle the device in an

environmentallyfriendly manner. Commercial users should contact their supplier. This product must not be disposed of

along with other commercial waste.

9/50

Delivery, internal transportation, unpacking

2.5 Storage conditions

2.5.1 Information for storage

Should the industrial exhauster not be operated for a longer period of time, so it has to be stored in

dry, dust and vibrationless rooms.

Temperature T: -10…+40°C

Humidity: max. 85%

Pos: 6.1 /3 Beschreibung der Maschine, Verwendung/Gerätebeschreibung-Überschrift @ 0\mod_1261493 001970_131.docx @ 1076 @ 1 @ 1

10/50

Appliance description

NOTICE

WARNING

3 Appliance description

Pos: 6.2 /3 Beschreibung der Maschine, Verwendung/Überschrift: Bestimmungsgemäße Verwendung @ 1\ mod_1335181714405_131.docx @ 11500 @ 2 @ 1

3.1 Intended Use

Pos: 6.3 /1 Grundlegende Sicherheitshi nweise/Signalwort-Feld "Hinweis" @ 0\mod_1261404960439_131.d ocx @ 905 @ @ 1

Pos: 6.4 /3 Beschreibung der Maschine, Verwendung/Anlage, die in Baugruppen ausgeliefert für Einsatz in G ewerbe (Nass für stationäre Geräte) @ 4\mod_1362726130523 _131.docx @ 41582 @ @ 1

• This plant, which is delivered in assemblies, is designed as a wet and dry vacuum cleaner for

commercial and industrial applications e.g. in hotels, schools, hospitals, factories, shops, offices

and rent transactions. It is particularly suitable for vacuuming up chips, granulate, silt and non-

Pos: 6.5 /3 Beschreibung der Maschine, Verwendung/Die Maschine darf nur betrieben werden, wenn alle Filter ric htig eingesetzt und unbeschädigt sind @ 4\mod_1361286 688952_131.docx @ 39834 @ @ 1

Pos: 6.6 /3 Beschreibung der Maschine, Verwendung/Bei Schaum- oder Flüssigkeitsaustritt sofort abschalt en! @ 0\mod_1269510877136_131.docx @ 3568 @ @ 1

Pos: 6.7 /1 Grundlegende Sicherheitshi nweise/Signalwort-Feld "Warnung" @ 0\mod_1261404807286_131. docx @ 893 @ @ 1

Pos: 6.8.1 /3 Beschreibung der Maschine , VerwendungÜberschrift: Staubklasse "L" @ 2\mod_13452071 06541_131.docx @ 20618 @ 3 @ 1

3.1.1 Dust class "L"

flammable liquids.

The machine may only be operated when all filters installed correctly and undamaged.

• Switch off immediately if foam or liquid escapes!

Pos: 6.8.2 /3 Beschreibung der Maschine , VerwendungGeeignet für trockene, gesundheitsgefährliche, nicht brennbare Stäube nach Staubklasse L @ 2\mod_1344406097 881_131.docx @ 20190 @ @ 1

Observe warning sign on the device!

• The device is suitable for dusts hazardous to health and not flammable with workplace

limit >1mg/m³ according to dust class L (max. permeability <1%) according to DIN EN

Pos: 6.9.1 /3 Beschreibung der Maschine , Verwendung/Überschrift: Staubklasse "M" @ 2\mod_1345207 107097_131.docx @ 20627 @ 3 @ 1

60335-2-69 Annex AA:2010.

3.1.2 Dust class "M"

Pos: 6.9.2 /3 Beschreibung der Maschine , Verwendung/ Staubklasse „M“ beinhalt et die Staubklasse „ L“. @ 3\mod _1350479497308_131.docx @ 31982 @ @ 1

Dust class "M" contains dust class "L".

Pos: 6.9.3 /3 Beschreibung der Maschine , Verwendung/Geeignet für trockene, gesundheitsgefährliche, nicht brennbare Stäube nach Staubklasse M @ 2\mod_1344406331161_131. docx @ 20198 @ @ 1

Observe warning sign on the device!

• The device is suitable for dusts hazardous to health and not flammable with workplace limit

≥0.1mg/m³ according to dust class M (max. permeability <0.1%) according to DIN EN

Pos: 6.10 /0 Allgemeines/Seitenumbruc h @ 0\mod_1265272007940_0.docx @ 2191 @ @ 1

60335-2-69 Annex AA:2010.

11/50

Appliance description

NOTICE

WARNING

DANGER

Pos: 6.11 /3 Beschreibung der Maschine, Verwendung/Überschrift: Nicht bestimmungsgemäße Verwendung @ 1\mod_1335941486446_131.docx @ 12040 @ 2 @ 1

3.2 Non-Intended Use

Pos: 6.12 /1 Grundlegende Sicherheitshin weise/Signalwort-Feld "Hinweis" @ 0\mod_1261404960439_131. docx @ 905 @ @ 1

Pos: 6.13 /3 Beschreibung der Maschine, Verwendung/Personen- und Sachschäden, nicht bestimmungsge mäße Verwendung @ 4\mod_1361974611424_131.docx @ 407 32 @ @ 1

For all personal injuries and material damages, which are caused by a not -asdirected-

use, the operator and not the manufacturer of the machine is

Pos: 6.14 /3 Beschreibung der Maschine, Verwendung/Einsatz im Freien nicht gestattet! @ 6\mod_140292 7556366_131.docx @ 61608 @ @ 1

Pos: 6.15 /1 Grundlegende Sicherheitshin weise/Signalwort-Feld "Warnung" @ 0\mod_1261404807286_13 1.docx @ 893 @ @ 1

Pos: 6.16 /3 Beschreibung der Maschine, Verwendung/Nicht geeignet für brennbare Stäube @ 4\mod_136 1865721690_131.docx @ 40592 @ @ 1

Pos: 6.17 /3 Beschreibung der Maschine, Verwendung/Nicht geeignet für brennbare Flüssigkeiten @ 4\mo d_1360573519166_131.docx @ 39443 @ @ 1

responsible for !

• May not be used outdoors!

• This device is not suitable for taking up and extracting combustible dusts.

• This device is not suitable for taking up and extracting flammable liquids (flammable, highly

flammable, highly flammable hazardous substances according to Directive 67/548/EEC)

Pos: 6.18 /3 Beschreibung der Maschine, Verwendung/Nicht in explosionsgefährdeten Räumen zugelassen! @ 0\mod_1269511242762_131.docx @ 3587 @ @ 1

Pos: 6.19 /1 Grundlegende Sicherheitshin weise/Signalwort-Feld "Gefahr" @ 0\mod_1261404709797_131 .docx @ 887 @ @ 1

Pos: 6.20 /3 Beschreibung der Maschine, Verwendung/Bei nicht bestimmungsgemäßer Verwendung besteht Explosions- und Brandgefahr @ 1\mod_1335941594717_131.doc x @ 12048 @ @ 1

Pos: 6.21.1 /3 Beschreibung der Maschin e, VerwendungÜberschrift: Staubklasse "L" @ 2\mod_1345207 106541_131.docx @ 20618 @ 3 @ 1

(Flash Point under 55°C) as well as mixtures of combustible dusts with flammable liquids.

• The vacuum cleaner is not approved for operation in potentially explosive areas!

• With improper use may cause explosion and fire!

3.2.1 Dust class "L"

Pos: 6.21.2 /3 Beschreibung der Maschin e, VerwendungNicht geeignet für Staubklasse M und H @ 2\mo d_1345205305674_131.docx @ 20609 @ @ 1

• The device is not suitable for dust class M and H.

Pos: 6.21.3 /3 Beschreibung der Maschin e, Verwendung/Nicht geeignet für krebserregende Gefahrstoffe ge mäß GefStoffV, TRGS @ 8\mod_1424100115484_131.docx @ 784 70 @ @ 1

Observe warning sign on the device!

• The device is not suitable for carcinogenic hazardous substances purs. to GefStoffV §10,

Pos: 6.21.4 /3 Beschreibung der Maschin e, VerwendungNicht geeignet für Asbest @ 2\mod_134484222280 5_131.docx @ 20352 @ @ 1

Pos: 6.22.1 /3 Beschreibung der Maschin e, VerwendungÜberschrift: Staubklasse "M" @ 2\mod_13452071 07097_131.docx @ 20627 @ 3 @ 1

TRGS 905 or TRGS 906.

• The device is not suitable for asbestos pursuant to TRGS 519.

3.2.2 Dust class "M"

Pos: 6.22.2 /3 Beschreibung der Maschin e, VerwendungNicht geeignet für Staubklasse H @ 2\mod_1344 840346272_131.docx @ 20343 @ @ 1

• The device is not suitable for dust class H.

Pos: 6.22.3 /3 Beschreibung der Maschin e, Verwendung/Nicht geeignet für krebserregende Gefahrstoffe ge mäß GefStoffV, TRGS @ 8\mod_1424100115484_131.docx @ 784 70 @ @ 1

Observe warning sign on the device!

• The device is not suitable for carcinogenic hazardous substances purs. to GefStoffV §10,

Pos: 6.22.4 /3 Beschreibung der Maschin e, VerwendungNicht geeignet für Asbest @ 2\mod_134484222280 5_131.docx @ 20352 @ @ 1

Pos: 7.1 /4 Aufbau und Funktion, Technisc he Daten/Aufbau und Funktion @ 0\mod_1263203845612_131. docx @ 1120 @ 1 @ 1

TRGS 905 or TRGS 906.

• The device is not suitable for asbestos pursuant to TRGS 519.

12/50

Layout and function

Weight without base frame

D3

D5,5

D2x3

ca. 176Kg

ca. 219Kg

ca. 211Kg

Sound pressure level LpA

Determined to EN 60335-2-69

70dB(A)

69dB(A)

70dB(A)

Uncertainty KpA

2dB(A)

Protective class

I

ambient temperature

-15°C to +40°C

intake temperature medium

max. +40°C

Installation altitude

max. 1000m over NN

Power

3,0kW

3,45kW

Frequency

50Hz

60Hz

Hedging

16A

16A

Voltage/

power consumption

200-260V / 11,4A Δ

230-290V / 10,8A Δ

350-450V / 6,5A Y

400-500V / 6,2A Y

Pressure

-260 / +270mbar

-240 / +230mbar

Blower Output

315m³/h

375m³/h

Degree of protection

IP 55

of efficiency

IE2-85,5

cosφ 0,82

4 Layout and function

Pos: 7.2 /4 Aufbau und Funktion, Tech nische Daten/Ringler Industriesauger und Absauganlagen in stationär er Ausführung werden in Baugruppen @ 1\mod_128895962260 5_131.docx @ 6993 @ @ 1

Ringler industrial vacuum cleaners and suction systems designed as stationary models are supplied in

components and assembled on site.

Pos: 7.3 /4 Aufbau und Funktion, Technisc he Daten/Überschrift: Hauptmaße @ 1\mod_1288959443995_1 31.docx @ 6980 @ 2 @ 1

4.1 Main dimensions

Pos: 7.4 /4 Aufbau und Funktion, Technisc he Daten/RA/Zeichnung RA 200 @ 7\mod_1408955367221_ 0.docx @ 64642 @ @ 1

Pos: 7.5 /4 Aufbau und Funktion, Technisc he Daten/IE2/RA/Technische Daten RA 200 IE2 @ 8\mod_1423 122613270_131.docx @ 77258 @ 2 @ 1

4.2 Technical data total device RA 200

Pos: 7.6 /4 Aufbau und Funktion, Technisc he Daten/IE2/AntriebeTechnische Daten D3 IE2 @ 7\mod_1417 004880972_131.docx @ 73285 @ 2 @ 1

4.3 Technical Data D3 IE2

Pos: 7.7 /0 Allgemeines/Seitenumbruch @ 0\mod_1265272007940_0.docx @ 2191 @ @ 1

13/50

Layout and function

Power

6,0kW

6,9kW

Frequency

50Hz

60Hz

Hedging

16A

16A

Voltage/

power consumption

200-260V / 22,8A Δ

230-290V / 21,6A Δ

350-450V / 13,0A Y

400-500V / 12,4A Y

Pressure

-260 / +250mbar

-230 / +220mbar

Blower Output

630m³/h

750m³/h

Degree of protection

IP 55

of efficiency

IE2-85,5

cosφ 0,82

Sound pressure level

63dB(A)

Output

5.5 kW

6.3kW

Frequency

50Hz

60Hz

Hedging

25A

25A

Voltage/

Power intake

350-450V / 11.1A Δ

400-500V / 11.0A Δ

610-725V / 6.4A Y

690-725V / 6,4A Y

Pressure

-240 / +220mbar

-180 / +170mbar

Air displacement

volume

495m³/h

595m³/h

Protection type

IP 55

Efficiency

IE2-87.0%

cosφ 0.92

Pos: 7.8 /4 Aufbau und Funktion, Technisc he Daten/IE2/AntriebeTechnische Daten D2x3,0 IE2 @ 6\mod _1402990032699_131.docx @ 61719 @ 2 @ 1

4.4 Technical Data D2x3 IE2

Pos: 7.9 /4 Aufbau und Funktion, Technisc he Daten/IE2/AntriebeTechnische Daten D5,5 IE2 @ 6\mod_14 02985884820_131.docx @ 61638 @ 2 @ 1

4.5 Technical Data D5.5 IE2

Pos: 8.1 /5 Anlagenbeschreibung, Bedi enungs- und Anzeigeelemente, Betriebsarten/Hauptkomponenten, Kapitelüberschrift @ 0\mod_1263387349738_131.docx @ 1276 @ 1 @ 1

14/50

Main components

A

Base Frame

B

Collecting Container

C

Filter-Shaker

D

Lifiting device

E

Manometer

F

Main switch

G

Drive unit

5 Main components

Pos: 8.2 /5 Anlagenbeschreibung, Bedi enungs- und Anzeigeelemente, Betriebsarten/RA/Überschrift: Bestan dteile RA 200 @ 7\mod_1408973465208_131.docx @ 64883 @ 2 @ 1

5.1 Components RA 200

Pos: 8.3 /5 Anlagenbeschreibung, Bedi enungs- und Anzeigeelemente, Betriebsarten/RA/Zeichnung Haupt bestandteile RA 200 @ 7\mod_1408973916545_0.docx @ 64896 @ @ 1

Pos: 8.4 /5 Anlagenbeschreibung, Bedi enungs- und Anzeigeelemente, Betriebsarten/RA/Tabelle zu Zeichnu ng Hauptkomponenten RA 200 @ 7\mod_1408973951787_131.d ocx @ 64908 @ @ 1

Pos: 8.5 /5 Anlagenbeschreibung, Bedi enungs- und Anzeigeelemente, Betriebsarten/RA/Funktionsbeschrei bung RA 200 @ 7\mod_1409053727999_131.docx @ 64938 @ 2 @ 1

5.2 Function Description

The stationary device comprises a drive unit and a frame connected by hose to the filter and collection

container. A turbine in the drive part generates a vacuum. This vacuum sucks in contaminated "raw

air" at the suction socket. Heavy particles drop directly down at the input into the hose connection

because of gravity. Dusts and finer particles are separated at the pocket filter. The dedusted "pure air"

flows through the hood and a hose to the turbine from where it is extracted. At the turbine output, the

air exists into the environment through a muffled outlet channel. The collection container is emptied

via the lifting device.

Pos: 9.1 /6 Inbetriebnahme/Inbetriebnah me, Kapitelüberschrift @ 0\mod_1263481987997_131.docx @ 13 62 @ 1 @ 1

15/50

Initiation

Only use with safety shoes (acc. to EN ISO 20345)

CAUTION

6 Initiation

Pos: 9.2 /1 Grundlegende Sicherheitshi nweise/Hinweis Sicherheitsschuhe @ 0\mod_1261406516446_13 1.docx @ 925 @ @ 1

Pos: 9.3 /6 Inbetriebnahme/Haube zentrisc h aufsetzten und Spannring anziehen. Stutzen über Schlauch mit Antriebseinheit verbin @ 1\mod_1336456552701_131.docx @ 1 2488 @ @ 1

• Apply hood centrically and tighten clamp ring. Connect socket to drive unit via hose and tighten

Pos: 9.4 /6 Inbetriebnahme/Alle Schlauch- und Rohrl eitungsverbindungen herstellen @ 1\mod_1336456942153_131. docx @ 12512 @ @ 1

Pos: 9.5 /6 Inbetriebnahme/Spänesauger/ Sammelbehälter einsetzen und mit Hebeeinrichtung verriegeln. @ 2\mod_1348752534022_131.docx @ 30787 @ @ 1

Pos: 9.6 /6 Inbetriebnahme/Gerät nach VD E-Vorschrift elektrisch anschließen und montieren. @ 1\mod_1 336456820375_131.docx @ 12504 @ @ 1

Pos: 9.7 /6 Inbetriebnahme/Verantwortung B etreiber Installation Schutzeinrichtung Trennung Anschlussphasen @ 6\mod_1401953418877_131.docx @ 60458 @ @ 1

Pos: 9.8 /6 Inbetriebnahme/Überschrift: Ersti nbetriebnahme @ 1\mod_1336455358905_131.docx @ 12457 @ 2 @ 1

6.1 Initial operation

Pos: 9.9 /1 Grundlegende Sicherheitshi nweise/Signalwort-Feld "Vorsicht" @ 0\mod_1261404898171_131 .docx @ 899 @ @ 1

Pos: 9.10 /6 Inbetriebnahme/Spänesaug er/Netzanschlussleitungen überprüfen @ 0\mod_126934998070 5_131.docx @ 3197 @ @ 1

Pos: 9.11 /6 Inbetriebnahme/Spänesaug er/Die Betriebsbedingungen stimmen mit den Schildangaben @ 0\ mod_1269350197077_131.docx @ 3203 @ @ 1

Pos: 9.12 /6 Inbetriebnahme/Spänesaug er/Die Inbetriebnahme ohne Filter oder einem beschädigten Filter ist nicht zulässig @ 0\mod_1269350986591_131.docx @ 3227 @ @ 1

Pos: 9.13 /6 Inbetriebnahme/Spänesa uger/Der Industriesauger ist ordnungsgemäß montiert, @ 0\mod_1 269351204934_131.docx @ 3239 @ @ 1

Pos: 9.14 /6 Inbetriebnahme/Spänesa uger/Die Kühlluftführung ist nicht beeinträchtigt @ 0\mod_1269351 426579_131.docx @ 3245 @ @ 1

Pos: 9.15 /6 Inbetriebnahme/Spänesa uger/Industriesauger mit dem an der Antriebseinheit befindlichen Ein/Au sschalter in Betrieb setzen @ 0\mod_1269351880561_131.doc x @ 3281 @ @ 1

Pos: 9.16 /6 Inbetriebnahme/Anschluss a n das Stromnetz (Drehstrom) (mobile Geräte) @ 1\mod_1289830 710106_131.docx @ 7127 @ 2 @ 1

6.2 Connection to the electric mains

hose clamps.

• Create all hose and pipe line connections.

Collection container insert and lock with lifting equipment.

• Connect and install device electrically according to VDE-provision.

• The operator shall be responsible for installation of protective equipment that will recognise a short-

circuit in case of fault and isolate all connection phases.

• Make sure that the power supply cord is not damaged by being run over, crushed, tugged etc..

Stop the industrial vacuum cleaner immediately if necessary!

• The power supply cord must be regularly inspected for signs of damage or ageing!

• Connectors of power supply cords must at least be splash-proof!

• The operating conditions must match the data on the plate and the supplied documentation, if

applicable.

• Starting without a filter or with a damaged filter is not allowed

• The industrial vacuum cleaner must be correctly installed, with all necessary lines and tubes

connected.

• The cooling air duct must be fully functional, the cooling effect must also not be impaired by soiling

of the cooling surfaces.

Start up the industrial vacuum cleaner with the on/off switch located on the drive unit.

• Check that the industrial vacuum cleaner is in correct condition before commissioning.

• Before connecting the industrial vacuum cleaner to the mains, make sure that the voltage specified

on the typeplate matches the supply voltage.

• The industrial vacuum cleaner is set to clockwise rotating field at delivery.

• Connect the device cable plug to a socket installed with correct earthing. The industrial vacuum

cleaner must be switched off!

• Check correct connection between plug and socket.

• Only use industrial vacuum cleaners with mains cables in perfect condition (damaged cables can

cause electric shocks!).

• Regularly check the mains lead for damage, cracks or cable wear.

• Always use the plug to remove the mains lead from the socket (do not use the cable itself).

• When replacing the mains lead, always replace it with a type that matches the original lead.

• The mains lead may only be replaced by the manufacturer or its customer service department, or a

Pos: 9.17 /0 Allgemeines/Seitenumbruc h @ 0\mod_1265272007940_0.docx @ 2191 @ @ 1

similarly qualified person.

16/50

Initiation

Before commissioning, always check that the potential equalization

conductors (earthing conductors) are connected!

Pos: 9.18 /6 Inbetriebnahme/Vor de m Einschalten prüfen @ 1\ mod_1336455105494_131.docx @ 12450 @ 2 @ 1

6.3 Check the following before switching it on:

Pos: 9.19 /6 Inbetriebnahme/Spänesaug er/Alle Filter müssen richtig eingesetzt sein. @ 1\mod_13364590 33816_131.docx @ 12528 @ @ 1

• All filters must be inserted correctly.

Pos: 9.20 /6 Inbetriebnahme/Spänesaug er/Der Absaugschlauch und das Zubehör bzw. die Rohrleitung müss en korrekt verbunden sein. @ 1\mod_1336459141674_131. docx @ 12536 @ @ 1

• The extraction hose and the accessories or pipe lines must be connected correctly.

Pos: 9.21 /6 Inbetriebnahme/Falsche Dre hrichtung Radialgebläse @ 0\mod_1277977261012_131.docx @ 5735 @ 2 @ 1

6.4 Wrong rotating direction

Drives with radial blowers do not convey the suction air with the full suction power if the rotating

direction is not correct.

If this is the case, the suction system must be switched off immediately. The mains plug must be

removed from the socket and technical specialists must be informed to have the phase conductor

connections in the mains connection line relocated.

The suction system is set to clockwise rotation in the factory.

Pos: 9.22 /6 Inbetriebnahme/Bauart 22/Üb erschrift: Potentialausgleichsleitungen @ 2\mod_13455311461 99_131.docx @ 20892 @ 2 @ 1

6.5 Potential equalization conductors

Pos: 9.23 /6 Inbetriebnahme/Bauart 22/Te xt zu Warnsymbol, Potentialausgleichsleitungen prüfen @ 0\ mod_1262875164082_131.docx @ 1100 @ @ 1

Pos: 10.1.1 /7 Betrieb, Bedienung/Betrieb , Bedienung, Kapitelüberschrift @ 0\mod_1263539997200_13 1.docx @ 1414 @ 1 @ 1

17/50

Operation

CAUTION

NOTICE

7 Operation

Pos: 10.1.2 /7 Betrieb, Bedienung/Betrieb , Überschrift 1.1 @ 0\mod_1263544263702_131.docx @ 1432 @ 2 @ 1

7.1 Operation

Pos: 10.1.3 /1 Grundlegende Sicherheits hinweise/Signalwort-Feld "Vorsicht" @ 0\mod_1261404898171_ 131.docx @ 899 @ @ 1

Pos: 10.1.4 /7 Betrieb, Bedienung/Gerät nur mit aktivierten Feststellbremsen aktivieren @ 6\mod_1401971 694391_131.docx @ 60511 @ @ 1

• Only operate the device with the parking brakes activated.

• Only move the device at walking speed. Act with care. In case of sloping paths, bring in a second

person to help.

Pos: 10.1.5 /7 Betrieb, BedienungÜbersc hrift: EIN / AUS Schalter Drehstrom @ 1\mod_1289982526820_1 31.docx @ 7170 @ 3 @ 1

7.1.1 ON / OFF switch Three-phase current

Pos: 10.1.6 /7 Betrieb, Bedienung0=Mot or aus, 1=Motor ein @ 1\mod_1289983926964_131.docx @ 7182 @ @ 1

0 = Motor "OFF"

1 = Motor "ON"

Pos: 10.1.7 /7 Betrieb, Bedienung/alte Mo duleSkizze: EIN / AUS Schalter Drehstrom @ 1\mod_12899827 59050_0.docx @ 7176 @ @ 1

Pos: 10.2 /7 Betrieb, Bedienung/RA/Skizze : Schalter RA 200/220 5,5 kW (Stern- Dreieckschalter) @ 5\ mod_1363702965097_131.docx @ 42570 @ 2 @ 1

7.2 Rotary current switch 5.5 kW (star-delta switch)

Pos: 10.3.1 /7 Betrieb, Bedienung/Spänes auger/Überschrift Absaugvorgang @ 0\mod_1269355638357_1 31.docx @ 3324 @ 2 @ 1

7.3 Suction process

Pos: 10.3.2 /1 Grundlegende Sicherheits hinweise/Signalwort-Feld "Hinweis" @ 0\mod_1261404960439_ 131.docx @ 905 @ @ 1

Pos: 10.3.3 /7 Betrieb, Bedienung/Spänes auger/Beim Saugen von Flüssigkeiten nur halb eintauchen, um ge nügend Luft mitzufördern @ 0\mod_1269355003866_131.docx @ 3312 @ @ 1

• When vacuuming up liquids only immerse halfway, so that sufficient air is absorbed

Pos: 10.3.4 /7 Betrieb, Bedienung/Spänes auger/Beim Saugen von Stäuben nur halb eintauchen, um genügend Luft mitzufördern @ 4\mod_1358320668235_131.docx @ 37 423 @ @ 1

• When vacuuming up dust only immerse halfway, so that sufficient air is absorbed

Pos: 10.3.5 /6 Inbetriebnahme/Spänesa uger/Gewünschte Absaugdüse in Steckkonus am Handgriff des Absa ugschlauches einsetzen. @ 0\mod_1269351562967_131.docx @ 3251 @ @ 1

• Insert desired suction nozzle into the plug-in cone on the handle of the suction tube.

Pos: 10.3.6 /7 Betrieb, Bedienung/Spänes auger/Skizze Saugdüse falsch-richtig @ 0\mod_1269356113020_ 0.docx @ 3336 @ @ 1

18/50

Operation

Do not immerse the entire area of the nozzle!

Hold the nozzle diagonally to the suction surface,

so that both air and liquid are absorbed

Pos: 10.3.7 /7 Betrieb, Bedienung/Spänes auger/Düse nicht mit der ganzen Fläche aufsetzen @ 0\mod_1 269355889461_131.docx @ 3330 @ @ 1

Pos: 10.4 /0 Allgemeines/Seitenumbruc h @ 0\mod_1265272007940_0.docx @ 2191 @ @ 1

19/50

Operation

CAUTION

WARNING

Disconnect before starting work

Suitable work gloves must always be worn when carrying out maintenance and service tasks,

in order to prevent injuries and soiling with contaminated substances

Respiratory protection (EN 149:2001)

Use protective glasses (acc. to DIN EN 166 1349-BT)

Use protective clothing (acc. to EN 13982-1)

Pos: 10.5.1 /7 Betrieb, Bedienung/Übersc hrift Filterabreinigung @ 2\mod_1337326637205_131.docx @ 1 3380 @ 2 @ 1

7.4 Filter cleaning

Pos: 10.5.2 /7 Betrieb, Bedienung/Übersc hrift Manuelle Filterabreinigung @ 2\mod_1337326667859_131.d ocx @ 13387 @ 3 @ 1

7.4.1 Manual filter cleaning

Pos: 10.5.3 /1 Grundlegende Sicherheits hinweise/Signalwort-Feld "Vorsicht" @ 0\mod_1261404898171_ 131.docx @ 899 @ @ 1

Pos: 10.5.4 /7 Betrieb, Bedienung/Nach A bschalten der Saugturbine Feinstaubtaschenfilter durch vor- und z urückbewegen des Hebels @ 2\mod_1337326762584_131.doc x @ 13401 @ @ 1

• After deactivation of the extraction turbine, clean the fine dust pocket filter

by manual filter cleaning by shaking movement of the hand shaker grip.

Pos: 10.5.5 /7 Betrieb, Bedienung/Anlage i m Dauerbetrieb eingesetzt muss ein Abreinigungszeitpunkt festegel egt werden @ 2\mod_1337327368592_131.docx @ 13408 @ @ 1

• If the plant is operating permanently a certain point of time for cleaning

has to be fixed by the operating staff and the fine dust pocket filter has to

be cleaned.

Pos: 10.5.6 /7 Betrieb, Bedienung/Nachla ufzeit der Turbine, darf der Rüttelvorgang erst ca. 1-2 min nach d em Abschalten @ 2\mod_1337327717412_131.docx @ 13415 @ @ 1

• Because of the slowing-down time of the turbine, the vibration process

must only be started 1-2min after turn off.

Pos: 10.5.7 /7 Betrieb, Bedienung/Warte n Sie ca. 30sec., bevor Sie das Gerät wieder in Gang setzen @ 2 \mod_1337328413779_131.docx @ 13436 @ @ 1

• Wait approx. 30sec. for the dust to settle, before restarting the device.

Pos: 10.6.1 /7 Betrieb, Bedienung/Sonder- Zubehör/Überschrift: Sammelbehälter mit PE-Staubsack entleer en @ 5\mod_1363942997804_131.docx @ 43060 @ 2 @ 1

7.5 Empty collection container with PE dust bag

Pos: 10.6.2 /1 Grundlegende Sicherheits hinweise/Signalwort-Feld "Warnung" @ 0\mod_1261404807286 _131.docx @ 893 @ @ 1

Pos: 10.6.3 /1 Grundlegende Sicherheits hinweise/Hinweis Vor Beginn der Arbeiten freischalten @ 4\mod_ 1362652119939_131.docx @ 41545 @ @ 1

Pos: 10.6.4 /1 Grundlegende Sicherheits hinweise/Hinweis Arbeitshandschuhe, Wartungs-und Servicearbei ten @ 0\mod_1269595688871_131.docx @ 3760 @ @ 1

Pos: 10.6.5 /1 Grundlegende Sicherheits hinweise/Hinweis Atemschutz @ 4\mod_1358754071540_131. docx @ 37562 @ @ 1

Pos: 10.6.6 /1 Grundlegende Sicherheits hinweise/Hinweis Schutzbrille benutzen @ 4\mod_13588670322 29_131.docx @ 37738 @ @ 1

Pos: 10.6.7 /1 Grundlegende Sicherheits hinweise/Hinweis Schutzkleidung benutzen @ 4\mod_135884904 5279_131.docx @ 37727 @ @ 1

Pos: 10.6.8 /1 Grundlegende Sicherheits hinweise/Text zu Warnsymbol, PSA Schutzausrüstung, PE-Staubsac k @ 2\mod_1346072747858_131.docx @ 21295 @ @ 1

These work processes may only be carried out in compliance with the valid legal requirements and by

trained specialized personnel with appropriate protective gear. Make sure that no dust is raised during these

work processes. Wear protective mask P3. The disposal of the PE dust bag may only be carried out by

trained personnel, in accordance with the valid regulations.

Pos: 10.6.9 /0 Allgemeines/Seitenu mbruch @ 0\mod_1265272007940_0.docx @ 2191 @ @ 1

20/50

Operation

Pos: 10.6.10 /7 Betrieb, Bedienung/Sond er-Zubehör/Sammelbehälter Typ RI 332 mit PE-Staubsack entleere n (SB 100 Liter) @ 4\mod_1358323420930_131.docx @ 37434 @ @ 1

Before emptying the dust container, switch off the device and wait for the motor to stop. Additionally,

the pocket filter "1" should be shaken off. Then wait for about 60 s until the dust has deposited in the

collection container.

• Lower the dust container “3” with the lifting device "2" and pull it out.

• Activate suction system again to prevent dust from escaping from the filter container by vibration.

• Downholder remove "4"

• Carefully pull the PE dust bag over the bead at the collection tank and close it tightly with cable ties

"7" (not included).

• Remove PE dust bag "8" from the collection container.

• If required, clean the collection container and insert a new PE dust bag (see wear parts list);

carefully push the edge over the bead at the collection container to avoid damage to the PE dust

bag.

• Downholder insert "4"

• Check the condition of the seal "5" at the filter container.

• Switch off the suction system, then place the collection container "3" under the filter container,

while ensuring that you do not clamp in the pressure balancing hose "6", and lift with the lifting

device "2".

Pos: 11.1 /8 Störungssuche und Störungs beseitigung/Störungssuche und Störungsbeseitigung @ 0\mo d_1263801277821_131.docx @ 1480 @ 1 @ 1

21/50

Troubleshooting and fault elimination

WARNING

Before starting work remove the plug from the wall socket!

Interference

Possible cause

Remedy

Reduced

suction power

Extraction hose or nozzle clogged

Extraction hose leaking

Extraction hose not fitted correctly in

extraction socket

Collection container full

Area filter/pocket filter contaminated

Seal between drive unit and collection

container defective

Extraction turbine defective

Remove clogging

Replace hose

Insert hose correctly

Empty collective

container

Clean or replace filter

Clean or replace seal

Replace suction

turbine by electrician

Extraction motor

is not running

correctly

2 phase run

Motor protection switch has triggered

Fuse triggered

Inspection by

electrician

Fuses trigger

Fuse too low

Defective switch

Defective motor

Inspection by

electrician

Motor runs too

hot

Cooling air volume too low, cooling air

paths clogged

Mains voltage deviates from the motor

nominal voltage by more than 5%

Ensure uninhibited

supply and exit of

cooling air

Inspection by

8 Troubleshooting and fault elimination

Pos: 11.2 /1 Grundlegende Sicherheitshin weise/Sicherheitsinformationen Wechselstrom-Geräte/Überschrif t: Sicherheitshinweise @ 0\mod_1269594836071_131.docx @ 3742 @ 2 @ 1

8.1 Safety instructions

Pos: 11.3 /1 Grundlegende Sicherheitshin weise/Signalwort-Feld "Warnung" @ 0\mod_126140480 7286_131.docx @ 893 @ @ 1

Pos: 11.4 /1 Grundlegende Sicherheitshin weise/Hinweis Netzstecker ziehen @ 0\mod_1261407392098_ 131.docx @ 939 @ @ 1

Pos: 11.5 /8 Störungssuche und Störungs beseitigung/Bevor Arbeiten zur Störungsbeseitigung begonnen werd en müssen die Feststellbremsen am Fahrgestell ak @ 8\mod _1424241177667_131.docx @ 78746 @ @ 1

Before work for troubleshooting is started, the parking brakes at the undercarriage must be activated.

Pos: 11.6 /8 Störungssuche und Störungs beseitigung/Sollten schädliche Substanzen entweichen, Maschin e ausschalten, Raum lüften bzw. verlassen. @ 2\mod_134855133 0162_131.docx @ 30232 @ @ 1

If harmful substances escape due to a defect (eg filter defect), the machinery must be switched off

Pos: 11.7 /1 Grundlegende Sicherheitshin weise/Sicherheitsinformationen Wechselstrom-Geräte/vor Begi nn jeder Arbeit.... frei zuschalten @ 0\mod_1269594559993_131.docx @ 3730 @ @ 1

Pos: 11.8 /1 Grundlegende Sicherheitshin weise/Sicherheitsinformationen Wechselstrom-Geräte/Die nachs tehend genannten Maßnahmen dürfen erst dann zurückgenommen werden @ 0\mod_1269594747884_131.docx @ 3736 @ @ 1

Pos: 11.9 /1 Grundlegende Sicherheitshin weise/Sicherheitsinformationen Wechselstrom-Geräte/Die üblich en Sicherheitsregeln lauten hierbei z.B. nach VDE 0105 @ 0\mod_1 269594914059_131.docx @ 3748 @ @ 1

Pos: 11.10 /8 Störungssuche und Störungs beseitigung/Erste Maßnahmen zur Störungsbeseitigung @ 0\ mod_1263802336933_131.docx @ 1492 @ 2 @ 1

8.2 Initial fault elimination measures

Pos: 11.11 /8 Störungssuche und Störungs beseitigung/Text vorTabelle der aufgeführten Störungen @ 0\ mod_1263802646340_131.docx @ 1504 @ @ 1

könne

Pos: 11.12 /8 Störungssuche und Störungs beseitigung/RI/Tabelle Störungen Spänesauger Drehstrom @ 1 \mod_1290413366922_131.docx @ 7310 @ @ 1

immediately and the room has to be aired or leave!

• Before starting any work on the industrial vacuum cleaner, but particularly before opening covers of

live or moving parts, the industrial vacuum cleaner or system must be correctly disconnected from

the mains and the drive unit must have stopped

• The measures specified below may only be withdrawn when the industrial vacuum cleaner is

completely reassembled and the maintenance is concluded.

• The usual safety regulations are, for example, in accordance with VDE 0105:

– Disconnect from mains

– Provide a safeguard to prevent unintentional restarting

– Check that the equipment is not live

– Cover or shield adjacent live parts.

All the errors mentioned in the table below may be eliminated by yourself. In case of major problems

or other failures please contact the customer service of Ringler immediately.

Tel. ++49-(0)7171-94888-0

Perform maintenance tasks in accordance with the description in the Maintenance/Servicing chapter

22/50

Troubleshooting and fault elimination

Motor switched to triangle instead of star

electrician

Pos: 12.1 /9 Wartung/Instandsetzung/Wart ung/Instandsetzung, Kapitelüberschrift @ 0\mod_1263808011 795_131.docx @ 1516 @ 1 @ 1

23/50

Maintenance/Repair

NOTICE

Suitable work gloves must always be worn when carrying out maintenance and service tasks,

in order to prevent injuries and soiling with contaminated substances

Before starting work remove the plug from the wall socket!

Respiratory protection (EN 149:2001)

Use protective glasses (acc. to DIN EN 166 1349-BT)

Use protective clothing (acc. to EN 13982-1)

Only use with safety shoes (acc. to EN ISO 20345)

9 Maintenance/Repair

Pos: 12.2 /9 Wartung/Instandsetzung/Üb erschrift: Wartungsvorschriften @ 0\mod_1269596336046_131.do cx @ 3767 @ 2 @ 1

9.1 Maintenance regulations

Pos: 12.3 /1 Grundlegende Sicherheitshin weise/Signalwort-Feld "Hinweis" @ 0\mod_1261404960439_131. docx @ 905 @ @ 1

Pos: 12.4 /1 Grundlegende Sicherheitshin weise/Hinweis Arbeitshandschuhe, Wartungs-und Servicearb eiten @ 0\mod_1269595688871_131.docx @ 3760 @ @ 1

Pos: 12.5 /1 Grundlegende Sicherheitshin weise/Hinweis Netzstecker ziehen @ 0\mod_1261407392098_ 131.docx @ 939 @ @ 1

Pos: 12.6 /1 Grundlegende Sicherheitshin weise/Hinweis Atemschutz @ 4\mod_1358754071540_131.docx @ 37562 @ @ 1

Pos: 12.7 /1 Grundlegende Sicherheitshin weise/Hinweis Schutzbrille benutzen @ 4\mod_13588670322 29_131.docx @ 37738 @ @ 1

Pos: 12.8 /1 Grundlegende Sicherheitshin weise/Hinweis Schutzkleidung benutzen @ 4\mod_135884904 5279_131.docx @ 37727 @ @ 1

Pos: 12.9 /1 Grundlegende Sicherheitshin weise/Hinweis Sicherheitsschuhe @ 0\mod_1261406516446_1 31.docx @ 925 @ @ 1

Pos: 12.10 /9 Wartung/Instandsetzung/Hi nweistext Wartungs-und Instandsetzungsarbeiten @ 0\mod_126 3808344190_131.docx @ 1528 @ @ 1

• Careful and periodical inspections and maintenance works are necessary to enable an early detection

and elimination of possible errors before they cause bigger problems and damages.

Pos: 12.11 /9 Wartung/Instandsetzung/Hi nweistext Haftung und Garantie @ 0\mod_1263809657689_131.d ocx @ 1540 @ @ 1

• Ringler assumes liability and guarantee only in case of proper use and compliance with the following

maintenance instructions.

Pos: 12.12 /9 Wartung/Instandsetzung/Hi nweistext Wartung-Zwangsentlüftung @ 0\mod_12638100456 46_131.docx @ 1546 @ @ 1

• For maintenance by the user the device must be disassembled, cleaned and maintained, as far as

practicable, without causing danger for the maintenance personnel or other people. Appropriate

precautions include cleaning before disassembly, providing for filtered forced venting in the location

where the device is disassembled, cleaning the maintenance area and wearing suitable personal

protective equipment.

Pos: 12.13 /9 Wartung/Instandsetzung/Hi nweistext Wartung-jährliche technische Überprüfung @ 0\mod_ 1263810635254_131.docx @ 1558 @ @ 1

• The manufacturer or a trained person must carry out a technical inspection at least once a year, which

comprises, for example, inspection of the filters for damage, checking the machine for leaks and

checking correct functioning of the control device.

Pos: 12.14 /9 Wartung/Instandsetzung/Hi nweistext Wartung/Verunreinigte Gegenstände @ 2\mod_134121 5087130_131.docx @ 18910 @ @ 1

• When performing maintenance or repair work, all contaminated objects which cannot be satisfactorily

cleaned must be disposed of. Such objects must be disposed of in impervious bags, in compliance

with the valid regulations for the elimination of such waste. All machine parts must be considered

contaminated when removed from the hazardous area, and appropriate measures must be taken to

avoid dust distribution.

Pos: 12.15 /1 Grundlegende Sicherheitshi nweise/Die Betriebssicherheit des Industriesaugers...zugelassene Ersa tzteile @ 0\mod_1269595489051_131.docx @ 3754 @ @ 1

• The operational reliability of the industrial vacuum cleaner can only be maintained if original or

approved spare parts are used exclusively for all maintenance and repairs.

Pos: 12.16 /0 Allgemeines/Seitenumbruch @ 0\mod_1265272007940_0.docx @ 2191 @ @ 1

24/50

Maintenance/Repair

WARNING

NOTICE

Interval

Check

Measure

daily

Suction hose leaking? (see

wear parts list)

Collection container full?

Pocket filter contaminated?

Seal between hood and filter

container, between filter

container and pre-separator

interim ring, between preseparator interim ring and

collection container (see wear

parts list)

Replace hose

Empty collection container

Start cleaning

Clean or replace seal

weekly

Collection container

clean

monthly

Drive unit, bearing noise

Device/plant

Filter (see wear parts list)

Replace bearings on

demand

Check for air-tightness

Check for

damage/replace

NOTICE

Pos: 12.17 /1 Grundlegende Sicherheitshi nweise/Signalwort-Feld "Warnung" @ 0\mod_1261404807286_1 31.docx @ 893 @ @ 1

Pos: 12.18 /9 Wartung/Instandsetzung/W arntext Elektrofachkraft @ 0\mod_1264055838943_131.docx @ 1 680 @ @ 1

• These works may only be carried out by an electrician.

Pos: 12.19 /1 Grundlegende Sicherheitshi nweise/Sicherheitsinformationen Wechselstrom-Geräte/vor Begin n jeder Arbeit.... frei zuschalten @ 0\mod_1269594559993_131. docx @ 3730 @ @ 1

• Before starting any work on the industrial vacuum cleaner, but particularly before opening covers of

live or moving parts, the industrial vacuum cleaner or system must be correctly disconnected from

Pos: 12.20 /1 Grundlegende Sicherheitshi nweise/Sicherheitsinformationen Wechselstrom-Geräte/Die üblic hen Sicherheitsregeln lauten hierbei z.B. nach VDE 0105 @ 0\mod_ 1269594914059_131.docx @ 3748 @ @ 1

Pos: 12.21 /1 Grundlegende Sicherheitshi nweise/Signalwort-Feld "Hinweis" @ 0\mod_1261404960439_1 31.docx @ 905 @ @ 1

Pos: 12.22 /9 Wartung/Instandsetzung/Hi nweistext Einsaugen von Graugussspänen / -Staub mit Kühlemulsi on @ 2\mod_1337329466643_131.docx @ 13450 @ @ 1

Pos: 12.23 /9 Wartung/Instandsetzung/T abelle Wartungsintervalle, Überschrift @ 0\mod_1263810791405_1 31.docx @ 1564 @ 2 @ 1

9.2 Maintenance intervals table

Pos: 12.24 /9 Wartung/Instandsetzung/R A/Tabelle Wartungsintervall Spänesauger RA 200 @ 7\mod_1408 973207345_131.docx @ 64857 @ @ 1

the mains and the drive unit must have stopped

• The usual safety regulations are, for example, in accordance with VDE 0105:

– Disconnect from mains

– Provide a safeguard to prevent unintentional restarting

– Check that the equipment is not live

– Cover or shield adjacent live parts.

• Concurrent extraction of grey iron chips/dust with cooling emulsion may lead to deposits in the

extraction system. This mainly affects: Pipe line, pre-separator and emptying flap. Depending on

extracted volume, the customer therefore must have cleaning cycles performed by service staff based

on experience.

Pos: 12.25 /1 Grundlegende Sicherheitshi nweise/Signalwort-Feld "Hinweis" @ 0\mod_1261404960439_13 1.docx @ 905 @ @ 1

Pos: 12.26 /9 Wartung/Instandsetzung/R einigung Gerät @ 2\mod_1340195497910_131.docx @ 17554 @ 2 @ 1

9.3 Cleaning

Dust on the appliance must be avoided and must be removed by regularly cleaning.

Before cleaning the device, be sure to switch off the motor protection switch and unplug the device from the

power supply. Cleaning can take place with a damp cloth or a suitable industrial vacuum cleaner. Do not use

solvents such as thinner, alcohol or benzene. Never immerse the device in water.

Pos: 12.27 /0 Allgemeines/Seitenumbruch @ 0\mod_1265272007940_0.docx @ 2191 @ @ 1

25/50

Maintenance/Repair

WARNING

Before starting work remove the plug from the wall socket!

Suitable work gloves must always be worn when carrying out maintenance and service tasks,

in order to prevent injuries and soiling with contaminated substances

Respiratory protection (EN 149:2001)

Use protective glasses (acc. to DIN EN 166 1349-BT)

Use protective clothing (acc. to EN 13982-1)

Pos: 12.28.1 /9 Wartung/Instandsetzung/Ü berschrift, Filtertuchwechsel für Taschenfilter @ 0\mod_126381 6608939_131.docx @ 1582 @ 2 @ 1

9.4 Changing the filter cloth for the bag-type filter

Pos: 12.28.2 /1 Grundlegende Sicherhei tshinweise/Signalwort-Feld "Warnung" @ 0\mod_126140480728 6_131.docx @ 893 @ @ 1

Pos: 12.28.3 /1 Grundlegende Sicherheitshi nweise/Hinweis Netzstecker ziehen @ 0\mod_1261407392098 _131.docx @ 939 @ @ 1

Pos: 12.28.4 /1 Grundlegende Sicherheitshi nweise/Hinweis Arbeitshandschuhe, Wartungs-und Servicearbeit en @ 0\mod_1269595688871_131.docx @ 3760 @ @ 1

Pos: 12.28.5 /1 Grundlegende Sicherheitshi nweise/Hinweis Atemschutz @ 4\mod_1358754071540_131.d ocx @ 37562 @ @ 1

Pos: 12.28.6 /1 Grundlegende Sicherhei tshinweise/Hinweis Schutzbrille benutzen @ 4\mod_1358867032 229_131.docx @ 37738 @ @ 1

Pos: 12.28.7 /1 Grundlegende Sicherheitshi nweise/Hinweis Schutzkleidung benutzen @ 4\mod_13588490 45279_131.docx @ 37727 @ @ 1

Pos: 12.28.8 /1 Grundlegende Sicherheitshi nweise/Persönliche Schutzausrüstung (Einweganzüge, Maske, Sc hutzbrille) tragen @ 1\mod_1337148996760_131.docx @ 132 92 @ @ 1

• At the work it is absolutely necessary to wear personal protection equipment (single-way suits,

protecting mask and protective goggles)!

Pos: 12.28.9 /9 Wartung/Instandsetzung/Filt erwechsel/Ausgetauscht Filter müssen in verschlossenen Kunst stoffsäcken entsorgt werden. @ 1\mod_1337147366357_131.docx @ 13278 @ @ 1

• The contaminated filter must be disposed of in closed plastic bags in compliance with the valid

regulations for the elimination of such waste.

Pos: 12.28.10 /9 Wartung/Instandsetzu ng/Filterwechsel/Während dieser Arbeitsvorgänge keinen Staub aufwir beln! @ 1\mod_1337149925746_131.docx @ 13313 @ @ 1

• Do not raise any dust during these work processes!

Pos: 12.28.11 /1 Grundlegende Sicherheits hinweise/Gefährdung anderer Personen auschschließen @ 1\m od_1337149203940_131.docx @ 13299 @ @ 1

• While carrying out this work, an endangering of other persons must be ruled out!

Pos: 12.28.12 /9 Wartung/Instandsetzung /Filterwechsel/Filter erstetzten durch anderen der gleiche Merk male, Feinheit, Kategorie @ 2\mod_1337151567167_131.docx @ 1 3320 @ @ 1

• Replacing the filter is an important procedure. It must be replaced with another filter which has the

same attributes, the same fineness, the same filter area, and which belongs to the same category.

Pos: 12.28.13 /0 Allgemeines/Seitenum bruch @ 0\mod_1265272007940_0.docx @ 2191 @ @ 1

26/50

Maintenance/Repair

Pos: 12.28.14 /9 Wartung/Instandsetzung /Filterwechsel/Überschrift Arbeitsschritte beim Taschenfilterwechsel @ 1\mod_1337149436978_131.docx @ 13306 @ 3 @ 1

9.4.1 Work steps for pocket filter change

Pos: 12.28.15 /9 Wartung/Instandsetzung /FilterwechselAufzählung für Filtertuchwechsel mit Skizze @ 0\ mod_1263816925305_131.docx @ 1588 @ @ 1

(1) Remove bag-type filter insert complete from (2) filter case.

Removing the filter cloth:

(3) Place on a suitable flat surface with perforated plate side down,

(4) Loosen hexagon nuts, (5) Remove spacer grille with leaf springs,

(6) Put impervious plastic bag over soiled filter cloth,

(7) Loosen retaining band,

(8) Raise filter cloth together with plastic bag 200mm, rotate by 180° and place on a flat surface,

(9) Remove spacer frame from individual pockets of filter cloth,

(10) Seal plastic bag with filter cloth inside tightly and ensure correct disposal.

Clean remaining parts for re-use.

Fitting the filter cloth:

Insert spacer frame into new filter cloth (see wear parts list)

Rotate filter cloth with spacer frame by 180° and position on filter insert,

Fix retaining band over the filter cloth in the area of the bead,

Mount spacer grille with leaf spring, align pockets of filter cloth with holes on spacer grille.

Pos: 12.28.16 /0 Allgemeines/Seitenum bruch @ 0\mod_1265272007940_0.docx @ 2191 @ @ 1

27/50

Maintenance/Repair

1

2

Pos: 12.28.17 /9 Wartung/Instandsetzung /Filterwechsel/Lage des Taschenfilter @ 3\mod_1353327555446 _131.docx @ 34532 @ @ 1

• At installation, in particular correct position of the fine dust pocket filter in the

pre-separator container must be observed!

At manual filter shaker:(1)

The tab at the filter insert must be inserted into the shaft.

At electric filter shaker:(2)

The tab at the filter insert must be inserted into the recess

Pos: 12.29 /0 Allgemeines/Seitenumbruch @ 0\mod_1265272007940_0.docx @ 2191 @ @ 1

28/50

Maintenance/Repair

WARNING

Before starting work remove the plug from the wall socket!

Pos: 12.30.1 /9 Wartung/Instandsetzung/RI /Überschrift: Ausbau der Absaugturbine @ 0\mod_126959767 1546_131.docx @ 3779 @ 2 @ 1

9.5 Disassembly of the suction turbine

Pos: 12.30.2 /1 Grundlegende Sicherhei tshinweise/Signalwort-Feld "Warnung" @ 0\mod_126140480728 6_131.docx @ 893 @ @ 1

Pos: 12.30.3 /9 Wartung/Instandsetzung/ Warntext Elektrofachkraft @ 0\mod_1264055838943_131.docx @ 1680 @ @ 1

• These works may only be carried out by an electrician.

Pos: 12.30.4 /9 Wartung/Instandsetzung/ Arbeiten an der Turbine Oberflächentemperatur @ 6\mod_1401 954130950_131.docx @ 60471 @ @ 1

• Before any work near or at the extraction turbine, let its surface cool down to below 50°C or wear

Pos: 12.30.5 /1 Grundlegende Sicherheitshi nweise/Hinweis Netzstecker ziehen @ 0\mod_1261407392098 _131.docx @ 939 @ @ 1

Pos: 12.30.6 /9 Wartung/Instandsetzung/R A/Skizze Ausbau Saugturbine (5,5kW) @ 9\mod_1428485186 205_0.docx @ 90044 @ @ 1

safety gloves and work protection clothing that isolate against the arising temperatures.

Pos: 12.30.7 /9 Wartung/Instandsetzung/R A/Skizze Ausbau Saugturbine (3kW) @ 4\mod_1359375264465 _0.docx @ 38165 @ @ 1

Pos: 12.30.8 /9 Wartung/Instandsetzung/R A/Ausbau der Turbine RA-Geräte @ 1\mod_1336487925596_ 131.docx @ 12739 @ @ 1

• Loosen screw connection of the front cover (1), remove front cover (2).

• Disconnect motor connection cable (3), loosen screw connection at the back (4) and remove back.

(5)

• Loosen hose clamps of the hose attachment at the turbine (6), remove hoses (7).

• ATTENTION: Do not reach into the turbine openings with your hands or other body parts.

There is a danger of injury!

• Loosen screw connection of the turbine to the basic plate (only at 3 kW and 2x3kW) (8), turbine

may be removed (9).

• Attachment is performed in the opposite order.

Pos: 12.31 /0 Allgemeines/Seitenumbruch @ 0\mod_1265272007940_0.docx @ 2191 @ @ 1

29/50

Pos: 12.32.1 /9 Wartung/Instandsetzung/ Stromlaufpläne/Überschrift Stromlaufplan zu Motorschutzschalter D0,5 5 /Überschrift Stromlaufplan zu Motorschutzschalter D0,55 /D1,5 @ 6\mod_1402911862795_131.docx @ 61469 @ 2 @ 1

Pos: 12.32.2 /9 Wartung/Instandsetzung/ Stromlaufpläne/Stromlaufplan Motorschutzschalter D0,55; D1,5; D 3; D4; D5,5 @ 8\mod_1421939052462_0.docx @ 75536 @ @ 1

Maintenance/Repair

Pos: 12.33.1 /9 Wartung/Instandsetzung/ Stromlaufpläne/Überschrift Stromlaufplan zu D2x3 Motorschutzsch alter @ 4\mod_1360136233453_131.docx @ 39093 @ 2 @ 1

9.6 Circuit diagram to motor protection switch D 2x3 kW

Pos: 12.33.2 /9 Wartung/Instandsetzung/ Stromlaufpläne/Stromlaufplan Motorschutzschalter D2x3,0 @ 8\ mod_1423130978418_0.docx @ 77300 @ @ 1

Pos: 12.34 /0 Allgemeines/Seitenumbruch @ 0\mod_1265272007940_0.docx @ 2191 @ @ 1

30/50

Maintenance/Repair

Pos: 12.35.1 /9 Wartung/Instandsetzung/ Warnhinweise,Etiketten, Aufkleber/Warnhinweise auf dem Sauggerät, Ü berschrift 1.1 @ 0\mod_1264142788742_131.docx @ 1879 @ 2 @ 1

9.7 Warnings on the suction device

Pos: 12.35.2 /9 Wartung/Instandsetzung/ Warnhinweise,Etiketten, Aufkleber/Warnschild für Geräte der Klasse " L" @ 0\mod_1264144949869_131.docx @ 1903 @ 3 @ 1

9.7.1 Warning sign for devices in class "L"

Attention: This device contains harmful dust. Emptying and maintenance procedures, including the

disposal of dust collectors, may only be performed by expert personnel wearing the appropriate

protective equipment. Do not operate without the complete filtration system

Pos: 12.35.3 /9 Wartung/Instandsetzung/ Warnhinweise,Etiketten, Aufkleber/Warnschild für Geräte der Klasse "M" @ 0\mod_1264143266485_131.docx @ 1891 @ 3 @ 1

9.7.2 Warning sign for devices in class "M"

Attention: This device contains harmful dust. Emptying and maintenance procedures, including the

disposal of dust collectors, may only be performed by expert personnel wearing the appropriate

protective equipment. Do not operate without the complete filtration system.

Pos: 12.35.4 /9 Wartung/Instandsetzung/ Warnhinweise,Etiketten, Aufkleber/Kennzeichnung: Staubsauger @ 6 \mod_1392113609587_131.docx @ 53181 @ 3 @ 1

9.7.3 Marking: Vacuum cleaner

0431009

0431002

Pos: 12.35.5 /9 Wartung/Instandsetzung/ Warnhinweise,Etiketten, Aufkleber/Kennzeichnung Typenschild @ 0 \mod_1264149046489_131.docx @ 1922 @ 3 @ 1

No suck in glowing dust or other ignition sources

9.7.4 Type sign

Pos: 12.35.6 /9 Wartung/Instandsetzung/ Warnhinweise,Etiketten, Aufkleber/Seriennummer und Baujahr @ 5\mod_1387531439010_131.docx @ 48475 @ @ 1

Serial number e.g.: 99851650000004 means:

Pos: 13 /0 Allgemeines/Seitenumbruch @ 0\mod_1265272007940_0.docx @ 2191 @ @ 1

Material number : 99851650 Consecutive number: 000004

0431024

0431006

31/50

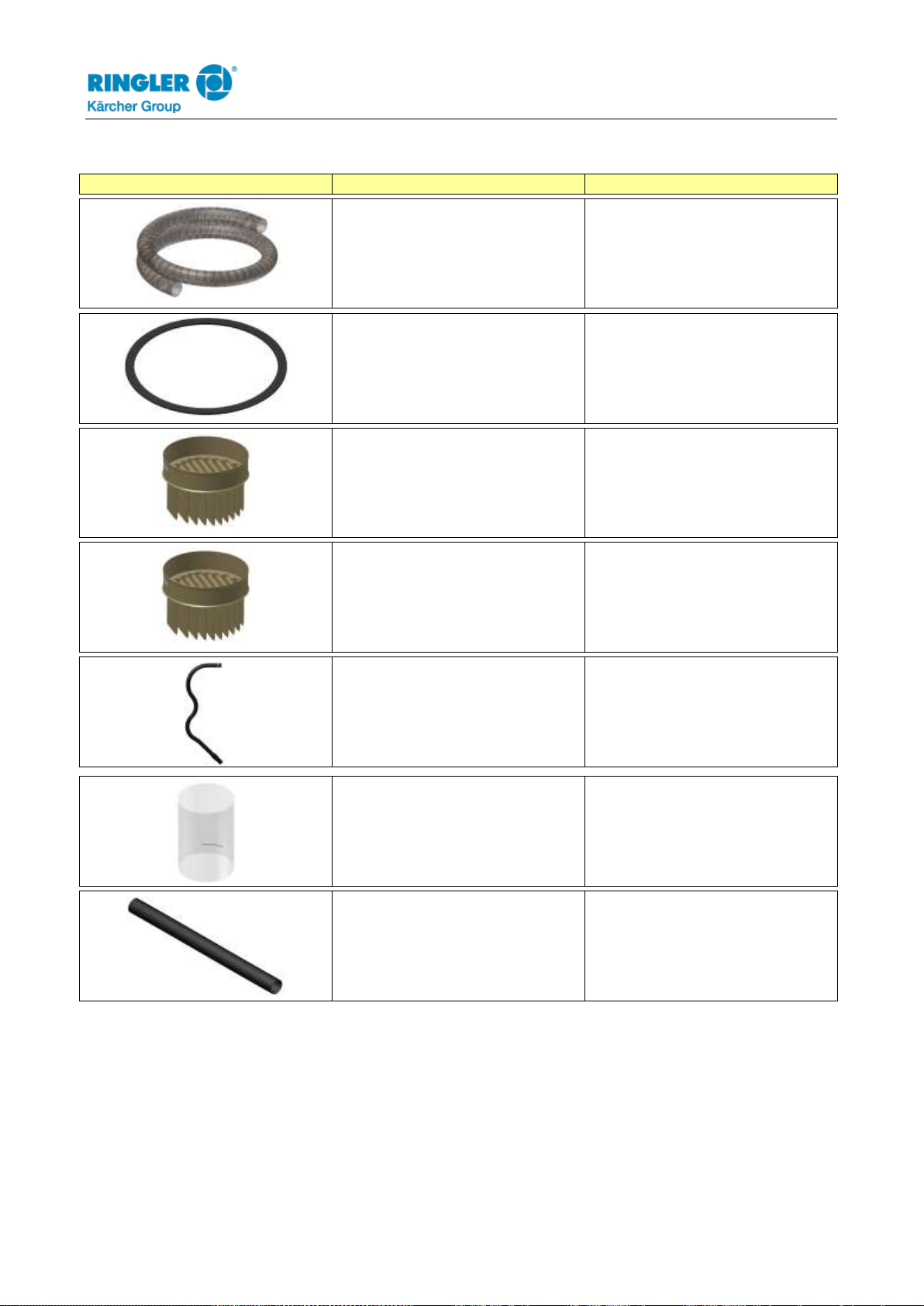

Figure

Designation

Order number