Page 1

U

U

Rimoldi

(

QUALITY

RECOGNIZED

WORLDWIDE

AT

izar

VERY

COMPETITIVE

PRICES

)

LIBRETTO Di MANUTENZIONE

MAINTENANCE HANDBOOK

Page 2

II

presente libretto §

11

sue

Implege in diverse eperazieni di cenfezlene,

esplicative del predette, note relative airinstallazione,

epusceli allegati), manutenziene da eseguire

sefisticati sistemi di preduziene per

alta

velocity

AVVERTENZE

Per

le avvertenze general! in materia dl sicurezza vedi il LIBRETTO

Installazleneeregelaziene

soledapersenale

ATTENZIONE

per

state

tempi

tecnice

redatto per lllustrare le caratteristiche del prodotto

aggiungende

ettenere

melte

lunghi.

nench§dimanutenziene

specializzate.

messa

per

mantenerle efficiente, in quante, §

quelle prerogative richieste da un mezzo

a punte, mentaggie dei vari KIT(vedere Idifferent!

espeste

chebstate

studlate per permettere

eppertuni KIT. Centiene, pertante, note

state

cestrulte con i

che

viene impiegate ad

DI

ISTRUZIONI. Le eperazieni di

nel

presente

libretto

devene

essere

piCj

effettuate

PRIMA

MOTORE

MOTO

PRIMADIRICONNETTERE

CARTERERIMONTATO

IL

PERSONE.

DI

EFFETTUARE

DALLE

PREMENDO

MANCATO

RETI

ELETTRICAEPNEUMATICA

IL

PEDALE

RISPETTO

LE

OPERAZIONI

DI

AVVIO.

LE

RETI

TUTTE

LE

DI

QUESTE NORME DI SICUREZZA

DI

MANUTENZIONE

ED

ELETTRICAEPNEUMATICA

PROTEZIONI

EVENTUALMENTE

DISINSERIRE

ASSICURARSI

ASSICURARSI

LE

APPARECCHIATURE

CHE

LA

MACCHINA

DI

AVER

RIMOSSE.

PU6

FAR INSORGERE RISCHI PER LE

NGNSIMETTA

RICHIUSO

ED IL

TUTTI

IN

I

u

jj

GARANZIA

LaCFItalia

materlale

delle

stesse

periededigaranzia,

Nel

il "Venditere")

lui

vendutiecepertidaquesta

dl

garanzia

di scadenza della garanzia stessa. I |

Gli interventi di

il

Cliente

Le parti del Predette eventualmente sestituite, diverranne di propriety della CF Italia srI. ^

Le

decision!

spettane

Questa

Impreprie e

dall'inadeguatezza

accessor!

atmesferici

nermale

Questa

le

altre

0

persone

pure

escluselerichiestedisestituzione

Questa

garanziadiideneit^

II

presente

garanzia.

della

CF

In

casedicentreversia

teste

srI

garantisce

e/edifabbricaziene,

airutilizzatere

riparer^esestituira

del

Predette.

garanzia

devr^

sestenere

sulla

fendatezza

per

gludizie

garanzia

nen

maldestre

degli impianti

nen

eriglnall

natural!.

utillzze

garanzia

rivendicazieni e

garanzia

della

assicuraalClientelasola

conseguenti

sestltuisce

del

d I'uniceedintero

Nessun

Italia

italiane delle

dipendenteoerganizzate

srI.

present!

che

tuttelemacchine

perunperiede

finale (Cliente).

il RIM, il

garanzia.Leparti

Quest!

saranne

inappellabile

cepreiguasti

del

ed,

Nen

macchlna

richieste,

I'use

Predette

Interventi e riparazieni effettuati nel

le

spese

delle

Predette,

Infine,

verranne

delle

qualunque

accerdo

CONCESSIONARIO

gratuitamente

eseguiti

(elettriceepneumatice)dialimentaziene,

quali

ivi

presse

ed

i rischi

richiestediinterventedigaranzia

alia

Direziene

causatidanermale

da

mancataoerrata

nen

copreidanneggiamenti

quindi sestituiti in

aghi,

griffe,

riparazleneesestituzione

cemprese

macchine

del

altra

per

scopi

particelari.

che

regola

Rimeldi

di 12

per

(qui

definite

mesi,

perunturne

o il RIVENDITORE

cento

della

riparateesestituite

il Cliente e,senecessarie,

del

trasperte.

Quality

placche,

quelle

Rimeldi,

Predette.

garanziaocendiziene,

i rapperti fra Cliente e

della

CF

usura,dainterventiemedifiche

o Insufficiente

garanziaicomponent!

piedini, celtelli,

relative a

anchesedevuti a

perditedipreduzieneequelle

CF

sene

periededigaranzia

Italia srI.

delle

esplicita

del Venditere b autorizzate a medificarle in

circaicentenuti,ilimit!diapplicazieneequant'altre

nermeinquantelatraduziene

in lingua

viene

"Predette"),

giernaliere,

della

macchlna

Italia srI le parti

garantite

e/e

sulle

parti

delle

guasti

Venditere

presse

crochets

parti

fernita a

sole

il Venditere. In

modality

manutenziene

dall'use

elettroniche

che

risulteranne

difettese.

delle

e implicita, Ivi

cencernelagaranzia,

sene

esentidadifetti

dalla

datadifatturaziene

Rimeldi (qui definiti

difettese

perilrestante

nen

tecniche

nen

di parti di ricambio

ecc.

macchine

dei

Predetti

medificano la

queste

delle

auterizzati,

e/e

lubrlficazione,

causate

Sene

per

incluse

da

usurati

escluse

danniacese

stesse.

qualunque

da

periede

data

case

stesse,

daH'use

e/e

event!

per

un

tutte

Sene

e CF Italia srI, relative alia

neme

del Venditere e

far^

fede

pure

titele di

certesia.

di

| i

w

!

^

U'

il

II

fere

La CF Italia srI si risetva11diritte

cempetenteequellediBusta

di medificaree variare, per

metividierdine

Arsizie

(Varese).

tecnice e cemmerciale, i dati ripertati nella

presente pubbllcaziene.

Page 3

1 - SEGNIGRAFICI

2 - CARATTERISTICHE

3 - INSTALLAZIONE

4 - RIFORNIMENTO OLIO

5 - SMALTIMENTO OLIO

6 - GAMBIO OLIO

7 - MANUTENZIONE ,

INDICE

8 - FASATURA

9 - SOSTITUZIONE

10 - SOSTITUZIONE DELL'AGO •

11

-

POSIZIONAMENTO

12 - FASATURACROCHET INFERIORE

13 - FASATURACROCHET SUPERIORE

14 -

15 - MONTAGGIO E REGOLAZIONE GRIFFE

16 -

17

18

19 -

20 21 -

22 - REGOLAZIONE TRASPORTO SUPERIORE

23

REGOLAZIONE

REGOLAZIONE

- REGOLAZIONE LUNGHEZZA

- REGOLAZIONE

REGOLAZIONE

REGOLAZIONE

REGOLAZIONE

-

TRASPORTO

DELLA

CALIBRO

SALVA

RAPPORTO

TENSIONE

TENOIFILO

TENDIFILO

TENDIFILO

BARRA D'AGO

AGOE

MORSETTO

PIEDINOEREGOLAZIONE

AGHI

E SPINGIASOLA

TRASPORTO

PUNTO

CROCHET

CROCHETSUPERIORE

AGHIEPASSAFILI

INFERIOREACAMMA

PREMISTOFFA

DIFFERENZIALE

AGHI

Page 4

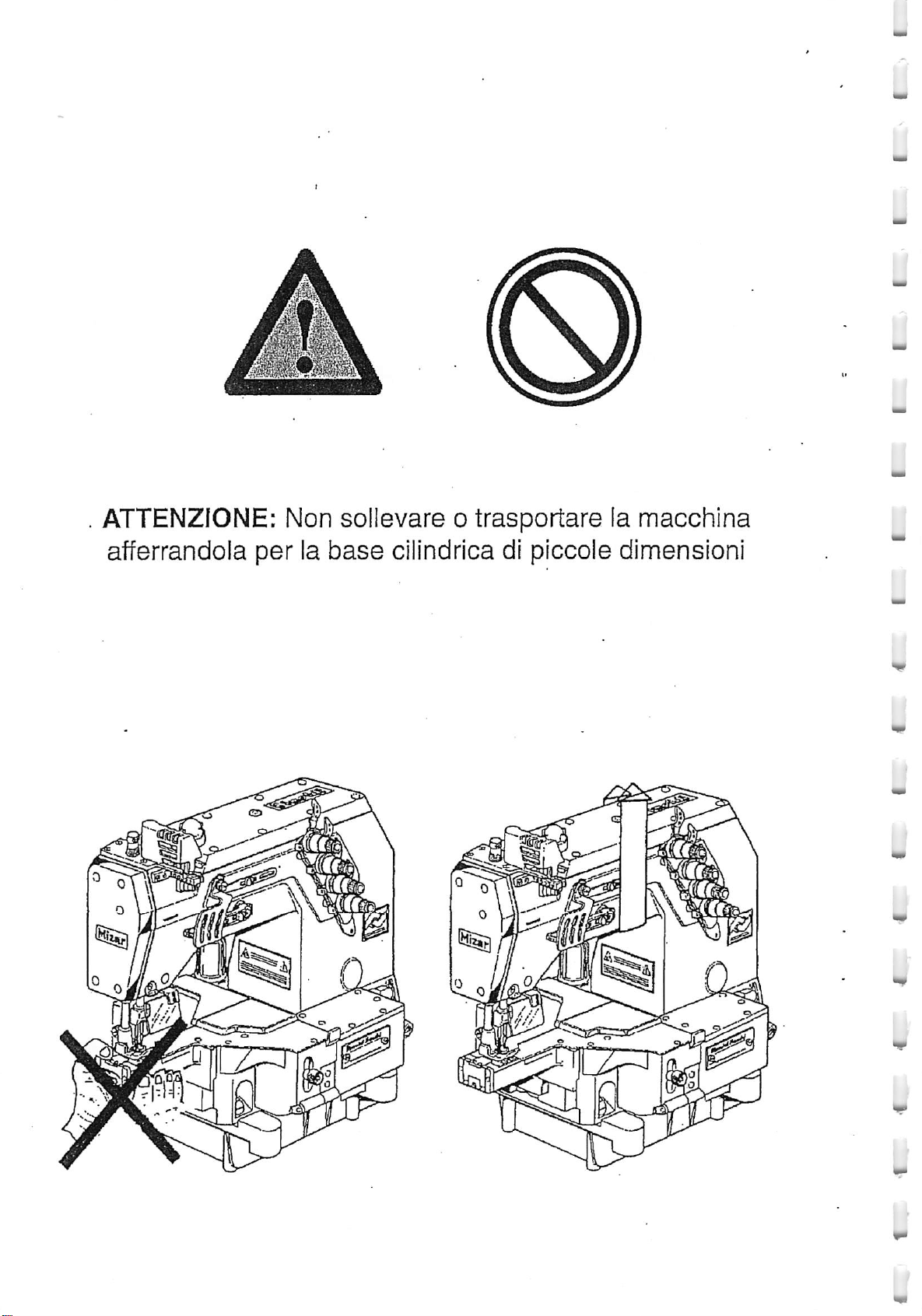

ATTENZiONE: Non sollevare o

trasportare

la

macchina

afferrandola

0 ^

ijf^

Qj

per

la

base

cilindrica di plccole dimensioni

0 r^ijUo,

ill

i

Page 5

1 -

SEGNI

GRAFICI

Neltesto vengono utilizzati i seguenti segni grafici:

Pericolo per I'operatore o per la macchina.

RischiodlInfortunio.

'

Divieto di compiere I'azione descrltta a flanco del simbolo.

Pericolo dl ustioni per contalto con superficl calde.

Obbligo di eseguire1eazioni descritte a fianco del simbolo.

Pericolodicontatto

con

parti

elettriche

sotto

tensions.

2-

CARATTERISTICHE

Base

cilindrica;

Velocjta

Kit

Lubrificaziane:

Corsa

Trasporto:

massima:

abbinabili:

barra

ago:

Lungtiezza punto:

Trasporto

Crochet

Spingi

Salva

differenzlale:

infericre:

asola:

ago;

Albero superiors:

Tendifilo

Rasafllo

crochet:

inferiore:

Scartafilo aghi:

svlluppo 160 mm. progettata

chiusia!aneliodlPICCOUSSIME

5.500

punti al

COPERTURA,

SPORTO

minute.

DISPOSITIVO

SUPERIORE

per

facilitare la cucitura-e la manlpolazione di capi

dimensioni.

RASAFILO

A GRIFFA, PULLER,

INFERIORE E

SUPERIORE,

TRA

forzata a mezzo pompa ad Ingranaggi. Flltro olio esterno.

regolabile: 26.9, 30.6,

33.3

mm.'

a griffa difterenziale. Brevettalo.

regolabile a

regolabile a

macchina

macchina

In moto.

In moto.

dotato di movimento alternativo rettilineo. Corsa minors regolabile daU'eslerno

per

adattamento

fisso.

fisso.

rotante.

a

camma

postoadestra

a

getto

d'aria

alle diverse finezze aghi.

regolabile medlante disposltlvo a leva,

degli aghi

che

con

funzione antidisfacimenlo.

permettelasicura

ripresa della cucitura.

Page 6

3-

INSTALLA2I0NE

IMPIANTO

L'impianto elettrico

senza

spina.

ELETTRICO

comprende

Gli

aflacciamenti consentiti alia rete elettrica sono quelil previsti dalle

Tinterruttore salvamotore (fig.3),11cavo dicotlegamenlo del motoreedun

norme

cavo

vigenti.IIcavo di

alimentazione (soloquellodicolore blu)e considerato a doppio Isolamentoe pertantopuo essere ullllzzato per

11

collegamento aereo, fissandolo opportunamente ad un montante verticale (es. portabobine).

NB.IIcavo

possano

doilperlcolodicontatti

In tutti 1

rimpianto elettrico ad una rete di

non

deve

essere

provocare

tip!

di allacciamento h Indispensabile collegare, medlanteilconduttore giallo-verde,

escoriazionl

infllato

occult!.

nel

tubo

portabobine

e tagli

alia

guainadiprotezione

messa

a terra ufflclalmente rlconosciuta

od in

eventual!

del

cavo

stesso,

(fig.

altri

2).

tub!

che

causan-

o

o

In ogni

terruttore

rispondere a! vaiore indlcato nella tabella affissa sulla

della tensione e deila potenza del motore utilizzato.

II

a far corrispondere i'indice a! vaiore richlesto.

case

veriflcare o far verificare da

salvamotore.IIvaiore di taratura (in Ampere) deii'interruttore salvamotore

partedipersohale

scatola

Per

verificare e regoiare la taratura togllere

competentelataratura

deii'interruttore

stesso

dell'ln-

deve

cor-

In funzione

coperchio deH'interruttore e ruotare I'apposita vita(oppure far scorrere I'indicedel cursore) sin

la

wM

Coliegamento

Attenzlone:

perchlo.

lampada

escludere

rallacciamento

Perdisporre di luce autonoma impiegare I'apparecchiatura

deii'interruttore

Entrata

Uscita regpiabilB = da 5 a12Volt,

SCHEMlDICOLLEGAMENTO

(ad

II

E =

esempio:

collegamento delle apparecchiature componenti le unit^ di cucitura o i sistemi di cucitura Rimoldl NecchI

devono rlspettare

a 5

fill

(neutro distrlbuito) e trifase, 380V a 4

caso

Nel

salvamotore.

125/160/220/240/380/415

SARA, RITA, SONIA,

gli

schemi di

di collegamento a llnea con neutro NON distribuito fig. 6 S necessario interporre tra interruttore

fig.

Volt

50/60

Hz.

220

VA.

PER

UNITA' DI

etc.)

CUCITURA

5 e 6 predispostt, rispettivamente,

fill

(neutro NON distribuito).

retedialimentazione

con

Rlmoldl

DOTATEDIAPPARECCHIATURE

019-90 da collegare a! morsettl d'entrata

peri

casi dilinee elettrlche trifase,

primaditogllere11co-

MONOFASE

SBOV

salvamotore ed apparecchlatura monofase un trasformatore monofase omologato per tension! di ingresso dl

380+415V

Plazzamento

Le

teste

seguenti caratterlstiche:

• tavoladilegno in pannello compensate

• piedini regoiabili

•

capacita

apparecchiature)

ed

uscita

220+240V

Rimoldl possono

per

assicumrne

200VAorichiedereIItrasformatore

essere

montate, nella maggior

la stablllta

di sopportare in mode stabile un

spessore

peso

Rimoldl

parte

del casi,subancall comuni, purchd abblano le

simbolo

40 mm

di almeno 200 Kg. (testa

P910054-0.

plO

motore,

pID

eventuali

Page 7

Le

installazioni

•

P1A22AMENT0suBANCALEAcoLONNAi

. alzapledino meccanico)

"

piAzzAMEisrrosuBANCALE

N.B,

Se si desidera

ti operazioni:

•

verificare

• verificare ed eventualmente ordinare la piastra porla macchina specifica per la nuova testa

Perun

corretto

•

livellare

•

posizionareiquattro

• piazzare lamacchina sui

•

livellare

zlonevasempre

• collegareiltirante

•

collegarelacinghiadltrasmissione

del

motore

chedisottoclasse

•

Controllare

vertical e)

•

Registrarelatensione

nella

possono essere dldue

installarelamacchina

ed eventualmente

piazzamento

bancale

latesta

posizione

(se

agendo

eseguita

Calia

fornlta

conlatesta,inogni

chela

cinghiadltrasmissionesipresent!suun

indicatainflgurasiottiene

tipi:

coRsigliato

HEGOLABiLE

della

tipoacolonna)apiastra

tamponi

tamponi

sul

conlacinghia

leva

(vedl

flQura

t

su unbancale

modificare11tagllo

macchina

ammortizzatoriAsut

ammortizzatori

pernidisostagno

alzapiedino.

aile

caso

della

testa.

della

cinghia:

latensionetcorretta

(vsdl

flgura

7 con

9 611con

tavola

eseguire le

porta

filettatiBfinoadottenere

trapezoidaledltrasmissione

(fig

7-8-9-10)

pulegge

non

del

superara

alzapiedino

gl&dlproprisla

peradattarlo alia

seguenti

macchina

pern!Bdi

operazioni

(se

supporto

.

motoreedella

mailaveloclta

piano

quando,

una

frecciadicirca

10-15

alzapiodino

meccanico)

del

ciiente

nuova

tipo

regolabile)

(fig.

7-8-9-10)

lasua

disinnestata.

testa

(volantino).

masslma

ortogonale

premendo

mm.

(fig.

pneumaticoefigura

occorre

testa

orlzzontallta.

eseguireleseguen-

(vedi

Usare

indicata

agll

assi

delle

conuncaricodlcirca

12)

8 con

allegatoBo C)

Quesla

opera-

sololapuleggia

nelle

carattsristl-

pulegge

(piano

1-2

Kg

fissare I carter paraclnghia sla sul volantino Ache sul motore B

o

collegareiltiranteBdella

jf\

jSJilL

Nota:IImateriale di

4 -

RIFORNIMENTO

NB.

Una

rumorositbedelle

e le vibrazioni

uso

uso di parti dl ribambio non originali

regolazione

uso disupporti non

uso di portabobine non saidamente fissatial supporto

manomissione o fissaggio non corretto delcarter e del

Imbailaggfb

Attenzlone: la macchina viene spedlta

deiravviamento, procedere a!suo rlfornlmento usando rolio

chine per cucire industrial! fornito con la macchina stessa.

leva

alzapiedino

Installazione

non

vibrazioni

possono

di ammortizzatori

della

non deve

Dl

OLIO

aumentare nel

cinghia

originali

della

macchinaedalia

corretta

della

macchina

rispettoaquanto

non

originali

noncorretta

c non idonei

essere

disperse neirambiente

sul

comunicato

caso

di:

(troppo

senza

lenta)

lubrificante, per cuf e necessarlo, prima

pedallna

bancale

del

pub

dalla

plan!dllavoro

(fig.

12 e 4)

bancale

provocareunaumento

della

casa.Inparticolare11rumore

RIWI

32M

speclaie per

mac-

Per

effettuare il rifomimento o Isuccesslvi rabbocchi procedere come

• svitareIItappo trasparente B

• versareilcontenuto della confezione di olio

•

controllare

llnea

•

awitareIItappo

I'entita

superiore

del

(MAX)

B

rifomimento

(fig.13)

attraversolaspiaA(fig.

oscenderealdi

RIM

sottodi

32M

indotazione alia macchina

quella

inferiore

13).IIliveilo

segue:

(MIN)

deirollo

non

dovra

mai

superare

la

Page 8

/k

/ik\

ATTENZIONE:

sigtlato

sigliati o

mischiare

I'agglunta

usare

olidltlpo

sempre

diverso.

dl additivl

olio

macchlnaecomportanoladecadenza

t

Solo In sltuazlonl particolarl In altematlva airolio

seguenti tlpi;

5 -

SMALTIMENTO

AGIPOTE

MOBIL

TEXACO

32

PTE

LIGHT

REGAL

DELL'OLIO

OIL

32

USATO

RIM

L'usodioil

possono

RIM

32M

siaIncaso

provocareildanneggiamento

delta

garanzla.

32M

prescrltto dalla casa, b posslblle usare uno del

dt camblo che di

iubrlflcantidltipo

rabbocco.E'scon-

diversedaquelli

Irreparabile

con-

della

Smaltendo in mode non corretto rollo usato, si

creano

gravl probleml di inquinamento aD'yomo,

agll animall, alCambiente.

E'necessario quindlsmaltire rollousato seguendo ledirettiveImpartltedal D.P.R. n" 691 del 23/

3/62 e

cio^

attenendosi

alle

seguenti

istruzioni:

1)11lubrificanteTipo32Me unoliodlnaluratotalmente mineraie.pertantodopoI'usd,appartlene

alia categoria degii "GUI

L'ollo

2}

usato

3) Consegnare

Usatl".

NOTA Telefonandoal

6 -

deiroiio

CAMBIO

usatosututtoilterritorio

OLIO

deve

essere

l'ollo

usato ad unodelraccoglltori autorizzati del"Consorzio Obbligatorlo

numeroverde

MINERAL!

USATi RIGENERABILi"

raccolto Inidonel contenltori adibitiesclusivamente a

1678-63048b posslblle ottenere Informazioni

nazlonale.

• Togllere11tappo 0 che b avvltatosotto la bacinella e scaricare completamenta

•

Smontarelatesta

• Pulire ed asciugare con scrupolo la bacinella.

• RiavvltareIItappo C controliando che ['anelio ditenuta

sostltuirio.

• Rlmontare la bacinella sulla

caso

contrario

• Procedereal riempimento della macchlna con

rifomlmentodlolio.

7-

MANUTENZIONE

dalla

occorre

bacinella.

macchlna

sostitulria.

controliando

I'olio

sia

in perfstta efficienza; in

che

la guarnizione dl

RIM

32Msecondo la procedura descritta nel paragrafo

tenuta

rollo

caso

sia

questo

necessarie

(fig.

perl! ritiro

13).

contrario occorre

ancora

efficiente; in

scopo.

degll

Olil

ATTENZIONE

mm

PRIMADlEFFETTUARE

EDILMOTORE

SI

METTAINMOTO

PRIMADlRICONNETTERE

TUTTII

CARTERERIMONTATO

DALLE

IL

MANCATO

SCHI

LE

RETI

PREMENDO

PER

LE

OPERAZIONIDlMANUTENZIONE

ELETTRICAEPNEUMATICA

IL

LE

RETI

TUTTE

RISPETTO

PERSONE.

PEDALE

ELETTRICAEPNEUMATICA

Dl

LE

PROTEZIONI

Dl

QUESTE

AVVIO,

EVENTUALMENTE

NORMEDlSICURE2ZA

DISINSERIRE

ED

ASSICURARSl

CHELAMACCHINA

ASSICURARSl

RIMOSSl.

PUO

LE

APPARECCHIATURE

Dl

AVER

RICHIUSO

FAR

INSORGERE

NON

Rl-

Le operazloni di manutenzione perlodica da effettuare per mantenere la macchlna sempre Inperfetta efficienza

sono:

Page 9

Ogni

giorno,

Smontarelaplaccae

gli

organ!

dellamacchina

pulirelegiiffe

ralatlvj

ai trasportoed aliaformazlone del punto

nsi

Aprire11pianodilavoro'ediicarter iateraie

Controliare punta degll aghl.

ControllareIIlivello dell'olioedeventualmente

o

Ogni

mese.

Controllare I'usura della cinghla.

Controllare

Ogni3mesi.

Pulire ii

• svitare con cautelailcontenltore

svltare completamente iicontenltore

• estrarre con cautelaIIfiltro

sa

nel

• rimontareIIfiltroeawitare11contenltore A(fig. 15)

NO.

Qualora non si Impiegasse rollo

tidlana.

I'usura

filtro

foro

del

salva

ago.

dell'olio attenendosi alle seguenti istruzlonl (fig. 14):

Eventual!rabbocchi devono

mischlare

ma! oli di

^

filtro

olioA{flg.14)

(fig.

dell'olioB(fig.

RIM

32M

tipo

diverse.

16)

17),

Immergerlo

prowedere alia sua sostltuzione.

essere

fatticon lo

loro

ranghitogliendoIIpulviscolo

ribaltabili

e pulire le zone accesslbill.

rabboccare

ed attendereIIdeflusso

inbenzineo

stesso

petrolio,

tipo di oliocontenutonelia macchina. Non

prima

dell'olio

con un penneiloin

di Inlzlare

rattivita

nelserbatoio

Indi

sofflare

aria compres-

quo-

prima

tutti

di

Ogni6mesi

Sostltuire

dere

Dopo

Se la macchina deveessere lasciata

Prima di

ControllareIIlivello dell'olio ed

Azionarela macchina a bassa veloclta- 3000

zampilli sotto1!tappo trasparenle di rifornimento

8 -

Allentare

RimuovereIIcoperchio

(fig.

morto

RimontareaH'estremit^ inferiore deila barra ago la fascetta B.Awitare, senza bloccare, la viteE

docurache lastessa

Inbatluta aU'eslremita Inferiore della barra d'ago. Serrare la vlte Edella fascetta B.

DI

conseguenza si ottieneilvalore

Le macchine

F93 punto ornamenio 602-605 F91 punto ornamento 406-407 -

rolloepulireiifiltro

alia

sua

sostltuzione ogni 3 mesi

un

iungo

periodo

riprendere

,Controllareche tutteJe protezloni antinfortunlstiche siano a) loroposto e periettamente

FASATURA

la vlte E

I'attivita

Collegare la macchina alle reti elettrica e pneumatica

DELLA

(fig.

iateraieB(fig.

19)

dellafascetta barraagoe

superiore), come

capitiinbatluta verso

MIZAR

hanno la

(vedi

voce

Ogni3mesi).

di inattivita

ferma

esegulreleseguenti

eventualmente

BARRA

AGO

18) della fascetta B

19)svitando le

riposizionare

Indlcalo

sulla

tabella difasaturache corredalatesta. Serrarela

difasatura

seguente

corsa

corsa

corsa

= 33.2

= 33.2

NB.

Qualora

per un

Iungo

periodo

operazioni:

esegulreunrabbocco.

girla!mlnuto

(fig.

18).

viti

per una decina disecond! controilandoche

SfilareIImorsetto porta aghl e la fascetta B

che lo

nonsi impiegasse

occorre

coprirla

fissanoa!braccio

conla

macchina.

assialmente la barraago perottenereilvalore

I'alto.

InfiiareIImorsetto

"A":

disfanzafrapuntaago destro e pianodaiiaplacca ago.

barra d'ago;

aghi,

prestandp attenzione a

rollo

RIM

cuffiaIndotazione.

Allentare

vlte

X.

32M

difase

(fig.

posizionaric

prowB:

efficlenti

I'olio

(fig.

lavlteX

(ai

punto

1B)

aven-

18).

Page 10

9 -

S0STITU210NE

La macchina e statacampionata infabbrica con aghi appartenenti ai sistema Indicato sulla etichetta posta sulta

parte superloresinislradelbraccloe dellamedesimafinezza dl

SI raccomanda dl Implegare sempre lostesso sistema diaghi.

consultareleistruzionealcapitolo

Per procedere aliasostituzionedel

> togllere ilmorsetto ailentando la vite E della fascetta B

• mbntareilnuovo

barra

ago;

stringers

• montare giiaghi (vedi capitolo "sostituzione deirago")

• allentare la viteE e orientare ilmorsetto inmodo da centrarli rispettoal

posizlone quando le punte degllaghisono centrate rispetto al

• stringere la vite E. ,

CALIBRO

AGHIEWIORSETTO

"l^asatura

caiibro

crochet

aghi e

quindi

queiil

consegnaticomeaccessorio.

Nel

case

divariazione della finezza Impiegata

infariore".

del morsettoeseguire leseguenti operazioni:

(fig.

16)

morsettoassicurandosi che la parte superiors vada inbattutacon la parte

prowlsoriamente

la vite E

for!.

for!

delta placca ago: si ha la corretta

inferiore

delta

NB.La posizione

predisposta

Se

necessltasse

10-

SOSTITUZIONE D'ELUAGO

Ruotaremanualmenteilvoiantino

Pago

esostltuirloconiinuovo.

della

macchina.

Servendosi della pinza Indotazione, accertarsi che I'ago appoggi sul fondo

Awitare,senza eccederenet

I

plant

deltacruna

II-POSIZIONAMENTO

Si ha lacorretta

al

trasporto.

TenerepresentscheconIIpiedino

sul

piano vertlcaie, distanza A rlportata sullo

dal posizionamento Inbattuta del morsetto.

Una

regolazione della distanza di fase Avedi capitolo "fasatura della barra ago".

PRIMA Dl

CHELAMACCHINA

ESEGUIRE

QUESTA'OPERAZIONE

SIA

COMPLETAMENTE

portando iabarraagotuttaInalto

Tenerepresentsche

bloccaggio,

degli

aghi

devono

PIEDINOEREGOLAZIONE

posizlone

del

piedino

AilentandolaviteC(fig.

sollevato

laviteserra agoD,avendocuradlnonvarlare

essere

quando

21) che

I'Incavo

paralleli

alia

gli

aghipassano alcentre

bloccaitpiedino

dicirca4,5

mm

schema

SPEGNERE

FERMA.

(fig.

difase, vlene automaticamente

IL MOTORE ED

18).

Allentarelavite

passaggiocrochetdeveessere

foro.

traiettoria

delcrochet

PREMISTOFFA

aliabarra6

daiia

placcad'ago,i

dalle

(fig.

feritole

possibile

piattelli

24).

dello

effettuare11centragglo.

serraagoD,estrarre

rivolto

Porientamento

stesso ed b

delie

essereaperti.IncasononlofosseroallentareilgranoAespbstare diquantonecessario11bracclo

la

pressione

che11piedino

deve

esercitare

sul

tessuto,

awitareo

svitare,

secondo

necessity,IIpomolo

ASSICURARSl

verso

I'intemo

dagli

aghi.

allineato

tensioni

B.Per

devono

regolare

D.

12-

FASATURA

Per eseguire lafasatura del crochet

- Montare gli aghi

• Montareilportacrochet0 sull'asta cornando crochet Dstringendo leggermente ja viteE

II

• Ruotare

• Montare

E.

•

Veriflcare

la

quota

voiantino

II

crochetA

laquota B

B (fig. 23).

• RuotareIIvoiantino

(fig. 24).

Avvlcinareilcrochet dell'ago finoa sfiorare rinterno dello scaifo

sull'asta

• Stringere la vile F (fig24).

D.

CROCHET

fino

a portare I'asta porta crochet Dai punto mortodestro (versoIIvoiantino)

(fig.

22) mandando ilpiano diappoggioin battuta sul portacrochet0 e stringere lavite

(fig.

23)come da tabelladifase. Se necessario, allentarelaviteF

fino

a portare la punta delcrochet sullo scaifoincorrispondenzadeil'asse dell'ago G

INFERIORE

inferiore

procedere nelseguente modo

(fig.

22 e

23);

(fig.

24) facendo ruotare ilportacrochet C

fig.

22.

(fig.

23)e ripristinare

fig.

23.

Ui

Page 11

13-

FASATURA

inserire il gambo cilindrico del crochet nel fore del porta crochet E (fig. 32), posizlonandolo In altezza

ottenerela quotaHdel fogllodlfase,

con

I'anelio F

E.

la vlte C, facendo in modo

Controliare,coniifogllo

caso

Nel

non lo fossero effettuare ajcune reglstrazioni operando come sotto indicato;

a) quota "e"

< togliere

partlcolare E (fig.31)

spostandoiipemo

-

b)

quota

T (fig. 29):

- per

ottenereiaquotaTaiient^reiavlte

c) quota "g" (fig.30):

-

per

ottenere ia quota "g"aiientare iavite De la vlte 0

attenziona

del porta crochet.

CROCHET

SURERIORE

che

rappresentala dlstanza frapiano placca

che11suo

piano Inclinatocombaci col corrispondentedel porta crochet

ago

e fondo

crochet

difase aliegatoad ogni macchina, che le misure" e - f-g" corrispondano (fig.2B,2g,30).

(fig.

28)

per

van'are la corsa del crochet di copertura si prowedera come segue:

11

coperchio superiore del braccio, sbioccare11dado Be fare scorrereIIpemo A nella cava del

verso I'altosi diminulsce la corsa, al contrarlo, versoIIbasso, la si aumenta.

0 e

afflnchd

Taneiio

dlfermo F

ruotare

(fig.

32)colsuo pianoinciinato combacisempre colcorrispondente

sul

suo

pernoIiporta

(fig.

32) e ruotare ilcrochet sul suo gambo. Porre

crochet.

onde

Bloccare

N.B.-Quandosi

del crochet, § conslgllabile smontario; per fare ci6 si ailenter^ ia vite D (fig.32) e si sfllera dal porta crochet il

crochet. Quandosi richiederd la

verr^

automatlcamente

14-REGOLAZIONE

It

salvaago e io spingi asola sono di tipofisso. EssI costitulscono ungruppo formatoda tre pezzi:IisupportoA,

ii

saiva

aghi C e lo spingi

Salva

ago

Montare dapprima iisupporto Asuila

Con la

ia vite D in modo

deli'ago F.

Quando la punta del crochet si trova suli'asse deli'ago F flg.25/2 tra i'ago ed ilpunto E deve risultare una

quota

Bloccare

Spingi

asola-

presentasse

barra

ago al punto morto Inferiors allinearejisalva

Questa

0,0

doeiisalva

ie viti B fig.

lanecessitadlcucire

sua

funzione si rimonter^ lispettando quanto detto per iafasatura; e owlo

ragglunta la

SALVA

asola

cheIipunto E deiia fig. 25/1 deve corrispondere con la parte Inferiore delta cruna G

condizione permette iaformazione dell'asola del

ago deve

25/3.

sua

fase

AGHfESPINGI

Lvedi (fig.25/3)

base

essere

tangente all'ago F fig. 25/2

senza

fiio

dicopertura supenore, per evitareIImotoosciliatorlo

ASOLA

cllindrlca awltando ie

ago

agliaghi e posizionarlo in altezzaallentando

due

vitiB

senza

fllo

dell'ago durante la

bloccarie. (fig.25/3)

sua

risaiita.

che

Portare gliaghi al punto morto inferiorefig26/1. AiientarefavlteS fig.26/1 ed allineare lospingi asola L ai

due aghi estremi. Quando la punta dell crochet si trova suli'asse dell'ago F lo spingi asola deve

regolato anche inaltezza Inmodo che ia

delta cruna deil'ago F (vedlfig.

quota R fig.26/1.

Bloccarelavite

P.

26/2).

sua

parte superiore debba corrispondere con laparte superiore

Con ia vite P avvicinare lo spingi asola agli aghi flno ad ottenere la

essere

15-MONTAGGIOEREGOLAZIONE

.• Montare le griffesuite rispetth/e slitte come iilustrato In figura(

-

II

centraggio delle griffenelle feritoiedella piacca indirezione ortogonale al trasporto

mente. ilcentraggio nella direzione del trasporto h stato eseguito in fabbrica.

Ruotare

• Le griffe devono

approssimativaoccorre tener

ailo

•

Per

mente

H'voiantino

spessore

effettuare le eventuaii correzioni della posizione in altezza deiie griffeaiientare le vitiA e B rispettiva-

delta griffadifferenziale e della griffa del punto.

e portare ie

sporgere

del denti (quota 0 fig. 27)

griffe

dalia placca delta quantity Indicate suila documentazione tecnica di

presents

GRIPPE

(fig.

27)

al punto mortosuperiore.

che

ie griffedevonosporgere dal piano placca per

awlene

una

automatlca

fase.

In via

quantity part

Page 12

16-

REGOLAZIONE

II

masslmo edIIminlmo rapporto differenzlale

RAPPQRTO

TRASPORTO

sono

impostati daila fabbrica Infunzione della sottoclasse consi-

derandoIIsettore marceologico cul la sottoclasse &destinata.

rapporto differenzlale allentando11pomolo L

dimlnulsce) o verso11basso

zlale e 1:1,

zlale masslmo otteniblle b 1.6+1, mentre quello minlmob 0.6+1.

La regolazione trasporto differenzlale pub

doelagriffa

(il

rapportodifferenzlale aumenta).

differenzlaleesegue la

(fig.

essere

36), spostando I'lndice verso

stessa

corsa dl quelladel punto.IIvaloredel rapporto differen

esegulta

anche

DIFFERENZIALE

Nell'amblto

L'Indlce

a macchina Inmoto.

di tall

centrale

Indica

limiti

I'alto

(II

cheIIrapporto

b posslblle variare

rapporto differenzlale

differen

11

17-REGOLAZIONE

La lungiiezza punto pub

• Allentare llpomoloA

LUNGHEZZA

essere

varlala spostando verticalmenteIIpomolo A(fig.35).

PUNTO

• Muovereilpomolo verso I'altoper diminuire la lunghezza del punto, verso11basso per aumentaria

• Stringere ilpomoloA

La regolazione della lunghezza punto pub

18

- REGOLAZIONE TENSIONE (fig.

II

filo

vienepremutofraIduedischiAdellatensione, dallamollasituataneirinternodelpomoloB;quindi, peravere

essere

esegulta

36)

anche

a macchina Inmoto.

la giustaformazlonedel punto e necessario regolare la pressione deifamollaawitando o svltandoIIpomoloB

della tensione

stessa.

Nella magglor parte del

casi

la tensione del

fllo

crochet Inferloreviene

tenuta

lenta e la

regolazione si effettua mediante tenslonclna Happjicata sulla piastra camme tendlfllo fig. 34.

19-REGOLAZIONE

II

tendlfllo a

• lunghezza punto

•

spessore

•

elastlcHb

L.a

regolazione della cammatendlfllo pub awenlredaH'estemo allentandoIIpomoloG

camma

del

tessuto

del

filati

ilpomolo verso I'altosi ottiene un Incremento del recupero del

utilizzano

punt!

corti,

ottiene un minorrecupero del

grosso

Aprendo11carter frontale H(fig.36) e posslblle effettuare

camma sul

macchina si ottiene un ritardo nella fase dl rilascio del

senso

Questa

ATTENZIONE:

conlaceva

Idue

per

spessore,

si ottiene un anticipo della fase di rilascio del

operazione pub

dIschI

eseguire una eventuate centratura allentare le

filati

fllo

del cfocheL Allentando la vite B

neU'eseguIre

L(fig. 34) deH'astina

dellacamma

assialmente la camma sull'alberino sporgente dal basamento e fissaria,

ottenere le condizionl dl cul sopra.

Circa la posizione clrconferenziale del dischi,

destra devono tendere il

TENDIFILO

del

crochet

tessuti

rigidl.

essere

tendlflloE(fig.

filo.

deve

essere

CROCHET

regolato infunzione di:

INFERIORE

A CAMWIA

(fig.34e 36). Spostando

fllo

trasclnato dalcrochet necessario quando si

leggeriofilati

fllo

del crochet necessario quando si utilizzano punti

necessaria

questa

passafilo

mqlto

elastlcl.Ajcontrario

spostandoIIpomolo

lunghl,

una

ulterlore regolazione della fase di Intervento della

(fig.

34) e spostando I'astlna passafllo C

fllodaparte della camma, spostando la leva nell'altro

filo.

nel

caso

di trasformazione del calibro aghl.

operazione

asslcurarsi

C (fig. 34).

che

ifori del passafilo F(fig. 34)

34)debbano essere perfettamentecentratl con i'astlna 0

viti

tenere

Dsul mozzo Adella camma

quindi,

presente

che, quandoIIcrochet inlzla la

(fig.

33 e 34), fare scorrere

nellacorretta posizione onde

versoIIbasso si

tessutl.pesanti o dl

(fig.

34) verso la

siano

(fig.

sua

corsa

AccertarsI della corretta regolazione effettuando alcune prove di cucltura.

alllneab*

34).

verso

20-REGOLAZIONE

Un'astina

tirafllo

Amontata sull'anello B governa il

Lecondizionl difase

II

file

intensione. L'azione dell'astina Adeve cessare quando la punta dell'ago sinlstro b ben penetrata nel

triangolo formatodal

TENDIFILO

CROCHET

fllo

ottimali

si hanno quando, concrochetsuperlore spostato tuttoversoslnlstra,i'astlna Atiene

filo

dl copertura come rappresentatoInfig.

SUPERIORS

crochet dlcopertura

38.

(fig.

37).

L'astinasl pub regolareassialmente allentandolavlte0 ed angolarmente allentandole

l.acamma G

orlentata

(fig.

38)concorre aliadisposizionedel

secondolanecessita.

filo

a mbdi triangolo. Pubessere regolataverticalmenteed

vlllD(fig.

37).

Ui

Page 13

21 - REGOLAZIONE TENDIFILO AGHl E PASSAFILIAGHI

II

tendifilo

0

diminuendo

II

tuttosiotllene

della macchlna. '

Lavariazionedella corsa del

facendolo scorrere

spostandolo

IntermlttenteF(fig.

lasuacorsa)eper

agendoin

verso

versodestra,

36)acorsa

regolabile

variarelosvlluppo

sinergismo

tirafiloF(fig.

sinistra si aumenta ia

con11passafilo

36),

Invece,siotterranno

serveperottenere

del

cappi

format!

dai

MediltendifiloNmontati

si ottiene allentando le

sua

corsa

e quindi si otterranno cucilure

cuciture

piD

rigide.

cucltura

fill

pIDomeno

degli

aghi.

sul

viti

E e spostandoiitendifilo

elastiche

asecondadel

fronte

del

(aumentando

tlpodifilafo.

braccio

pi£j

superiors

stesso,

eiasliche;

22-REGOLAZIONE

Fasatura

RuolareIIvolanlino

coincidere !e linee di

Fasatura

eccentrico

fino

eccentrico

AllentareigraniAdeU'eccentricoB,far

graniAdeU'eccentrico.

Fasatura altezza

Rimuovereilcarteriaterale,allentare la

Serrarelavite

Fasatura poslzlone "0" regolazione trasporto superiore

Rimuovereilcarter

(Fig.

42).

AllentarelaviteB(Fig.*43)

Regolazione poslzione slitta porta griffa superiore

Conilpledino

abbassandole, successlvamenle allentarele due

la

vile

Bcome indicato in

ago.

Posizionare

23-TRASPORTO

La

massa

delia macchlnae circa 45 Kg.

guida

A.

posteriore.

appogglato

labarra

TRASPORTO

trasporto

a portarelabarra ago a!punto

fede

del sollevamento griffa

(fig. 39)

deU'eccentricoB e dell'albero C. Serrare i grani AdeU'eccentrico.

SUPERIORE

morto

superiors

coincidereleilneedifede

barra premistoffa (fig. 41)

viteAfino

a portare laguida Ba una

Allentareilpomolodiregolazione

finoaraggiungerelaquotadimm.

sulla

piacca

ago

allentareiedue

viti

Ee D(Rg. 43). MontareilcalibroA

Fig.

44.

Ruotareilvolantino

premistoffa

nei

fermi0(Fig.

fino.

44)

inferiore.

(fig. 40)

AllentareIgran!AdeU'eccentricoB,far

deU'eccentricoBedel

dalle

trasporto

viti

Ae B

a raggiungereiipunto

del

calibro.

superioreaporlarlo

4,5

(Rg.

(Fig.

27)

che

Serrareledue

voianoC.Serrare

due quote indicate

42),

SerrarelaviteB(Fig.

fissano

morto

ledue

(simb.

C.2059-00)con

superioredeiia barra

viti

Ee D

Fig.

nel

punto

griffe

43.

1

in.figura.

"0"

43).

inferior!

ATTENZIONE:

per la base cilindrica di piccole dimensioni

Non

soilevare o trasportare lamacchlna afferrandola

Page 14

WARNINGS

For genera! warnings on

the

subject of safety,

see

the

INSTRUCTION BOOKLET.

The

installation

and

adjustmentaswellasmaintenance operations shown in this booklet must only be carried out by specialist

technical

WARNING

BEFORE CARRYING OUT MAINTENANCE OPERATIONS, DISCONNECT THE EQUIPMENT AND MOTOR

FROM THE MAIN ELECTRIC AND PNEUMATIC CIRCUITS, AND MAKE

START

BEFORE

COVERS

HAS

NONCOMPLIANCE

CONDITIONS

CF Italia srI

defects in material or workmanship for

the

During

as

by

staff.

BEEN

end

the

them

WHEN

user

the

"Seller"),

THE

PEDALISPUSHED.

RECONNECTING TO THE MAIN ELECTRIC AND PNEUMATIC CIRCUITS, MAKE

HAVE

BEEN

CLOSED

REPLACED.

WITH

THESE

OF

GUARANTEE

guarantees

that all Rimoldi machines (hereafter definedas"the products")

(client).

guarantee period,

will

repair or replace

on behalf of CF Italia srI free of

AGAIN

SAFETY

RIM,

AND

ALL

PROTECTION

one

RULES

shift

per

MAY

day

for twelve months from

the AGENT or the RETAILER of

any

detective parts of the products covered by this

charge.

The

repaired or replaced

PUT

WHICH

PEOPLE

the

SURE

THE MACHINE DOES NOT

SURE

ALL

MAY

HAVE

BEEN

REMOVED

AT

RISK.

will

be free from

the

date

the invoice is

issued

Rimoldi machine (hereafter defined

parts

are

guarantee

only

guaranteed

and

for

sold

the

remaining period of the product guarantee. Any maintenance operations and repairs earned out during the

guarantee

period do not modify

the

expiry

dateofthe

guarantee

itself.

to

The guarantee operations

case,

the

client

must

become

property of CF Italia

Final decisions regarding

takenbytheCFItalia srI Quality

This guarantee

or inexpert

supply

systems

not

cover

are

wom

plates,

This

presser

guarantee

requests

use

of a Rimoldi machine,

product itself

does

noi cover breakdowns

useofthe

(electric and pneumatic),

damage

due

to electronic parts

to normal

foots, knives, loopers, etc.

only

are

excluded, including

are

also

implicit,including therein

This is

the

unique

and

and CF Italia srI, relating to

itonbehalfofthe

In

the

case

sellerorCF

of dispute regarding

are

carried out on the client's premises, or, if necessary, at

assume

all transport

costs

srI.

the

validity of

the

guarantee

Management.

due

to normal wear, unauthorized operations or modification,improper

product, lack of, incorrect or insufficient maintenance and/or lubrication, inadeguate

use

of non-original

useofthe

ensures

the

caused

machine

client for

those

related to

by natural atmospheric

are

the

repair

evenifduetothe

excluded. This

any

guarantee

complete

the

Italia

guarantee

that

the

agreement

which

guarantee. Noemployee or organization of

srI.

the

contents, limits of application

guarantee, the Italian version of these regulations

provided

out

of courtesy.

and

risks. Any replaced parts removed from

service

not replaced under guarantee,

and

boss

of production or

breakdown of

replaces

requests

spare

and/or technical methods involved

parts and/or accessories and, finally,it

events.

Therefore,

suchasneedles, feed dogs,

replacement of defective parts. All

any

the

other

damage

machine

guarantee

to things or people

itself.

Requests

or condition, either explicit

product is suitable for particular purposes.

regulates

will

apply, since translations into other languages

the

relationship

between

the

seller is authorized to modify

and

anything

the

else

the

sellers. In this

the

components

other

claims

duetothe

to replace

client,

the

concerning

product

are

does

which

and

the

seller,

the

are

only

or

The

CF

in

Italia

this

srI

brochure.

reserves

competent

the right to modifyorvary, for technicai or commerciai reasons, the information printed

law court is Busto Arsizio, Italy.

Page 15

CONTENTS

1 -

2 3 4 -

5 6 -

GRAPHIC

FEATURES

INSTALLATION

FILLING

DISPOSAL

OIL

CHANGE

SYMBOLS

WITH

OF

7 - MAINTENANCE

8 -

9 -

10

PHASING

REPLACING

-

SUBSTITUTING

THE

11 - POSITIONING

.REGULATOR

12

-

13

14

15

16

PHASING

r

PHASING

ADJUSTING

-

ASSEMBLING

-

ADJUSTING

THE

THE

THE

THE

OIL

USED

•,

NEEDLE

THE

NEEDLE

THE

NEEDLE

THE

PRESSER-FOOT

LOWER

UPPER

NEEDLE

AND

ADJUSTING

DIFFERENTIAL

OIL

BAR

LOOPER

LOOPER

GAUGE

GUARD

THE

AND

AND

FEED

AND

FRONT

FEED

RATIO

CLAMP

SETTING

DOGS

PRESSER

NEEDLE

SPRING

GUARD

17

18

19

20

21 -

22

23

-

ADJUSTING

-

ADJUSTING

-

ADJUSTING

-

UPPER

ADJUSTING

NEEDLE

-

TOP

-

TRANSPORT

LOOPER

FEED

THE

STITCH

THE

TENSION

THE

LOWER

THREAD

NEEDLE

ADJUSTMENT

THREAD

LENGTH

LOOPER

THREAD

TENSIONING

TAKE-UP

TENSIONING

ADJUSTMENT

AND

THREAD

CAM

GUIDE

OF

THE

Page 16

Page 17

1-

The

GRAPHIC

following

SYMBOLS

.

graphic symbols are used Inthe text:

Injury

of

to the operator or damage to the machine.

Riskofan

Action

Risk of burns through contact with hot

Action

accident

described

descnbed

^

beside

the symbol prohibited.

beside the symbol obligatory.

Risk of contact with live electrical parts.

surfaces.

2-

FEATURES

Cyiihdrical

Maximum

Compatible

Lubrication:

Needle

Feed:

Length

Differential

base

speed

bar

of stitch

Lower looper:

Front

needle

Needle

guard:

Upper shaft:

Looper

Lower

Needle

thread

thread

thread

Kits:

stroke

feed:

guard:

cutter

take-up

wiper:

160 mm long, designed to facilitate the sewing

garments

5,500

TOP COVER,

forced by

adjustable: 26.9, 30.6,

differential

closed

into a ring.

stitchesaminute.

LOWERANDUPPERTHREAD

meansofgear

feed

dog.

Patented.

pump. External oil filter.

33.3

mm

adjustable withthe machlne'operating

adjustable with the

withstraightalternate motion. Minimum

to

the

fineness

fixed

fixed

rotary

with

a cam adjusted by a lever mechanism

located to the right of the

with

an airjet that ensures reliable sewing resumption.

of

machine

the

needle.

operating

needles

stroke

and preventing the

and

handling of EXTRA

CUTTER,TOPFEED, PULLER.

adjustable from outside to

seam

unravelling

SMALL

adapt

Page 18

3-

INSTALLATION

ELECTRIC

The

electric

The allowed connections to the electric grid

The powercable (theblue one only)Isconsideredto be double Insulated, and therefore can be used foroverhead

connectionsbyfixing

SYSTEM

system

includes the motor cutout switch

are

those laid down by the laws In force.

it to a suitable vertical column (e.g.

N.B.-The

cable

must

notbethreaded

(fig.

3),

tubes whichcodidcause abrasions and cuts inthe

leadtothe

With

acknowledged

riskofhidden

contacts.

everytype ofconnection, itis necessary toconnect the electricsystem toan officially

earth using the yellow-green conductor

the

motor connecting cable and a cable without plug.

the

bobbin holder).

through

the

bobbin

wire

(fig.

holder

tubeorany

protectingsheath, whichmay

2),

other

o

Always, either

competent

to the value shown on the table

power of the motor used. Inorder to check

and turn the special screw (or move the cursorindex)

value.

check

staff. The value of the motor cutout switch setting

the

settingofthe

attachedtothe

motor

and

cutout

switch box itself, according to the voltage

adjust the setting, remove the switch cover,

switch

until

the index points to

or have It

(in

amperes) must be equal

checked

the

required

by

and

Warning:

Lamp

Connection

To

provide

motor

Input E = 125/160/220/240/380/415 Volt50/60 Hz.

Adjustable output U= from 5 to 12 Volt

CONNECTION DIAGRAMS FOR SEWING UNITS FITTED WITHSINGLE-PHASE DEVICES (for

SARA, RITA, SONIA,

The

comply

phase

In

the

autonomous

cut-out.

etc.)

conneclions of the devices which make up the

with

the diagramsInfigures

and

four-wire

case

of connection to lines with NON-distrlbuted neutral (fig. B), it Is

380 V(NGN-distributed neutral) electriclines.respectively.

single-phase transformer for

motor cut-out

Setting

Rimoldi

characteristics:

- 40 mm thick plywood panel table

- adjustable feet to

-

ability

and

single-phase devices, or

heads

can

be fitted to common

ensure

to support a weight of ^ least 200 kg stably, (head plus motor plus any devices)

disconnect

lighting

Input

stability

from

the

mains

use the

Rimoldi

220

5 and 6 set out

VA

019-90

for

before

apparatusto be connected

Rimoldi

the cases of

removing

the

cover.

with

Necchi sewing units or sewing systems must

five-wire

(distributed

necessary

voltages of380-415V and outputvoltages of220-240V

request

stands

Rimolditransformer n. P910054-0.

Inthe majority of

cases,

provided the

the

Input

clampsofthe

neutral)

to place an approved

200VA

stands

have the following

example:

380 Vthree-

between the

Page 19

The installations may be either of the

INSTALLATiONONCOLUMN

.

figure 8 with a mechanical presser

•

INSTALLATIONONADJUSTABLE

STAND:

following

foot

STAND:

types:

recommended (see figure 7

lift)

(see figure 9

with

a pneumatic presser foot

and11with mechanicai presserfoot

lift)

lift

and

N.B.Ifyou wantto

carried

•

•

To

• level the stand

• position the four rubber pads Aon the support pins B (figs. 7-8-9-10)

• place the machine on the rubber pads

• level

• Connect tie-rod C to

• Connect the drive belt to the motorand head pulleys(handwheel).Onlyuse the motorpulleysupplied with

• connect the tiered B of the machine's presser fool

out:

check

and, ifnecessary, modifythe table cut to

check

and, ifnecessary, order the specific machine holding plate for the new

ensure

carried out with the trapezoidal drive belt disconnected.

the head, in any

Check that the drive belt is on a plane at

Adjust

of

the

about

that

thie

1-2 kg In

instail

the machineona stand

the

machineisset

(if

column type) and the machine holdingplate

head by turning the threaded support pins Buntilit Is horizontal.This operation should always

the

case,

never exceed the maximum

belt

tension:

Fix

the

the

position

the

up correctly,

presser

foot

tensionIscorrect

shownInthe

belt

guards

lift

bothatthe

belonging

adapt

proceedasfollows:

lever

(fig.

7-8-9-10)

speed

.right

angles 1othe pulleyaxes (vertical plane).

whenacamberofabout

figure 12.

handwheel

lift

to the customer, the

it to

the

new

head

(see annex B or

(If

adjustable type)

shown in the characterisllcs ofthe head subclass.

10-15mmis

and

the

motor

and the small pedal ofthe stand.

lollowing

head

procedure mustbe

0)

createdbyplacingaload

B (fig. 12

and

4)

be

iGV

NOTE;

4-

The

packing

FILLING

O

In

ordertofill

• Unscrew transparent

•

PourInthe

• Check the amount pouredInthrough sight glass A

•

(MAX)

Screw

or fall below the lower

cap

Incorrect

than

stated

• Non-original

• Non-original

• The belt is not adjusted correctly (too slack).

• Non-original or unsuitable supports

• Bobbin holders which

•

Guards

material

WITH

Warning:

it is

necessary

provided

Itor later

contents

B back on.

installationofthe

by the manufacturer. In particular,

rubber

pads

spare

parts

and work

OIL

the

machine

wrth

top

it up,

cap

B (fig. 13).

of the RIM 32M oiltin supplied with the machine.

surface

shouldbedisposedofproperly

Is

supplied

to fill it

the

proceedasfollows:

one

using

machine

(MIN).

machineonthe

are

used.

are

used.

are

not firmlyfixed to

have

bee/i

without

the

special

Itself.

stand

can

noise

are

used.

the

support

tampered

with or not fixed correctly.

lubricant,

oil

for

Industrial

(fig.

13).

The

oillevel must never exceed the upper line

leadtomore

and

vibrations

are

therefore,

noise

can

increase

used.

before

starting

sewing

machines-RIM

. .

and

vibrations

when:

the

machine,

32M •

Page 20

Ak

WARNING:

is

not

than

damage

always

use

RIM

advisable to mix oils of different

the

oil

recommendedorthe

and

the

forfeitureofthe

32M

both

when

types.

additionofadditives

guarantee.

the

oilischanged

The

use

and

whenItis

topped

of lubricating oils of a different

can

leadtoIrreparable

machine

up.

type

It

Onlyin special siluations,Itis possible to use one of the

oil

recommendedbythe

AGIPOTE32

MOBIL

TEXACO

DISPOSAL

Incorrect disposal of used

environment. Itis therefore

below:

1)

manufacturer:

DIE

LIGHT

REGAL

OF

USED

OIL

32

OIL

oil

causes serious polluticn problems for

necessarytodispose

RIM

32M lubrication oil is totally mineral, therefore after

RECLAIMABLE

USED

MINERAL

2) The used oil must be collected in a suitable container used exclusivelyfor this purpose.

3)

The

oil should be delivered to a legally

6-

OIL

CHANGE

- Remove

-

Remove

- Clean

Screw

-

- Fit

the

cap

the

and

cap

oil

C which Is

oil

can

dry the oil

C back on

can

back on the machine

screwed

from

can

and

the

head.

carefully.

make sure

on underthe oil

seal

ring B

and

check

the

seals

replaced.

-

Fill

the machine with

RIM

32Moilaccording tothe procedure described under

fQliowing

types ofoilas an allernativeto the

man",

of the oilby carefully

use

OILS"

can

authorized

and

allow the oil to flow out completely

body.

perfectly; Ifthis is not the

sealing Is still effective; if this is not the

fQliowing

it is categorized

case,

FILLING

RIM

32M

animals, and the

the

instructions

among

{fig.

it mustbereplaced.

case,

WITH

the"

13).

it must be

OIL.

7-

MAINTENANCE

BEFORE

FROM

START

BEFORE

COVERS

BEEN

The

order

CARRYING

THE

MAIN

WHEN

RECONNECTING

HAVE

REPLACED.

NONCOMPLIANCE

periodic maintenance

are:

OUT

ELECTRIC

THE

PEDALISPUSHED.

BEEN

CLOSED

operations

WARNING

MAINTENANCE

AND PNEUMATIC CIRCUITS, AND MAKE

TO

THE

AGAIN

WITH

to be carriedout Inorderto

OPERATIONS,

MAIN

ELECTRIC

AND

THESE

ALL

PROTECTION

SAFETY

DiSCONNECTTHE

AND

PNEUMATIC

WHICH

RULES

MAY

keep

EQUIPMENT

SURE

THE

MACHINE

CIRCUITS,

MAY

HAVE

BEEN

PUT

PEOPLE

the

machineconstantly inperfectworking

AT

MAKE

REMOVED

RISK.

AND

DOES

SURE

MOTOR

NOT

ALL

HAS

Page 21

Every

day.

o

Each

month.

-

Check

the

- Check the

Every

three

months.

- Clean the

-

Unscrew

unscrewing

then

- Replacethe

If

RIM

oil

blow

32M oil is not used, replace it. •

Remove

involvedinfeed and

Open

of

Checkthe oil level and, if necessary, top up before starting

wearofthe

wear

oil

filterbyfollowing

filter

the

the

filter

Any

Never

theplateand

the

swing-out

the

needles.

belt.

of the

needle

containerA(fig.

container

hole with

andscrewback container A

(fig.

compressed

clean

forming

wdrk

guard.

the instructions

13)

16).

Extract

air.

tappingupmustbedone

mix

oilsofdifferent

the dogsintheir

the stitch witha paintbrush.

table

and

side

below

carefully

oil

filterB(fig.

with

types.

and

(fig.

the

cover

(fig.

wait

15)

same

rows,

and

14):

for

the

17)

typeofoil

wiping

clean

oiltoflow

carefully

containedinthe

all

the

and

the dustoff

accessible

the

back,into

Immerse

all

themachine's parts

areas.

Check

daily activity.

thetank

before

itin

petrolorparaffin

machine.

the

point

completely

and

Every

six

months

-

Replace

three

After a

If

the machineis notused

Before startingto

Check

Run

fijiing

B-.

Loosen

Remove

19)onthe

centre),asindicatedinthe

Reassemble

positionitso

bottom end of the needle bar. Tighten the

Consequently,

needle

The MI2ARmachines have the following

F93

F91

the

months.

long

period

the

oil level and, If

the

machineatlow

cap.

PHASING

the

screwE(fig.

theside

needle

the

thatitstrikes

plate.

interlock

interbck

stitch

stitch

oil

and

clean

the

filter

(see

without

use11again, carry out

Checkthat

Connect the machine to the main electric

THE

coverB(fig.

bar

clip

Bonthe

the

phasing

602-605-stroke=33.2

406-407-stroke=33.2

use

foralong

necessary,

all

the accident-prevention guards are in placeand perfectly operative.

speed

NEEDLE

18)

onthe

clip

and

phasing

upwards.

value

time,Itis necessary to coverItwith

top itup.

(«3000

rpm)

BAR

clipB(fig.

19)

loosening

reposition

table

bottom

endofthe

Insert

"A"isobtained:

"Every

three

months").

the

following operations:

for

about

10seconds

18).

Pull

the

the

needle

that

comes

the

screw

needle

•

screws

needle

needle

the

that

bar

with

bar.

clamp,

E on the clip B.

distance

bar stroke:

N.B.IfRIM

and

pneumatic circuits.

and

check

out

the

needle

fixIttothe

axialiytoobtain

the

head.

Tighten

Tighten

the

taking

between

32M

oilisnot

the cover

thai

oil

holding

machine

screwEslightly

the

phase

the

clamp

arm.

screw

used,

provided.

flows

under

and

Loosen

value

X.

(fig.

caretopositionitso

the

right

needle

point

replaceItevery

the

transparent

the

clipB(fig.

the

screwX(fig.

(at

the

upper

16),

taking

thatItstrikes

and

surfaceofthe

dead

care

18).

to

the

Page 22

9 -

REPLACING

THE

NEEDLE

GAUGE

AND

CLAMP

The machinewas fittedat the factory withneedles belongingto the system indicated on the label on the top left

part of

the

arm and of the

We recommend you always use the

in

the

"Phasing the LowerLooper" section.

To proceed to replace

• reihove the

clampbyloosening

• assemble the new clamp

screw

E provisionally

the

same

finenessasthose

same

needle

gauge

the screw E on the

making

deliveredasan accessory.

system

and

of needles. Ifthe fineness used is varied,

see

then the clamp, perform the following operations;

clipB(fig.

18)

the

instructions

sure that the top part strikes the lowerpart ofthe needle bar; tightenthe

• assemble the needles (see the "Replacing the Needle"section)

• loosen the screw E and turn the clamp so

as

to align the needles with the holes in the needle plate: itIs

correctly positioned when the points of the needles are straight in linewiththe holes.

• tighten

N.B.

by

positioning

Ifthe

10-

the

screw

The

position on

the

phase

distance Ahas to be regulated,

SUBSTITUTING

E.

the

vertical plane,

ciamptostrike.

THE

NEEDLE

distance

see

Aindicated on

the

the "Phasing the Needle Bar"section.

phase

diagram, is automatically

set

SWITCH

CHINEISABSOLUTELY

Turn the handwheei manually to bring the needle bar rightto the top

OFF

THE

MOTOR AND

ENSURE,

STATIONARY.

BY

PRESSING

(fig.

18),

THE

PEDAL, THAT

THE

MA

Loosen the needle lockingscrew D, extract the needle and replace withthe new one. Rernemberthatthe iooper

groove must face the interior of

the

machine.

Usingthe tweezers supplied, make sure that the needle reaches the bottomofthe hole.

Without

needle.

The plans of the needles

11 -

REGULATOR

exceeding the point of blockage, screw up the needle

eyes

must be parallel to the looper trajectory

POSITIONING

THE

.PRESSER-FOOT

locking

AND

screw D,taking care not to turnof the

(fig.

24).

SETTING

PRESSER

SPRING

The presser-foot is inthe correctpositionwhen the needles pass throughthe center of the slots inthe presser-

foot. The needles can be centered by loosening screw 0

(fig.

21) whichblocks the presser foot at the bar.

Rememberthat withthe presser-foot raised about 4.5 mm.above the needle plate, the tensioning plates must

be open. Ifthey are not, loosen nut A and move arm Basnecessary. To adjust the pressure applied bythe

presser-foot, screw or unscrew knob D

12-PHASING

To

phase

the lower iooper,proceed as

•

Assemble

the

THE

needles

LOWER

as

required.

LOOPER

follows

(fig.

22 and 23):

• Assemble the looper holder C on the looper drive rod D by tightening the screw E slightly, fig.22

" Turn

• Assemble the iooper A

• Check the distance B

• Turn the handwheei untilthe tip of the looper reaches the groove"in"line withthe axis of the needle G

• Move the looperof the needle

• Tighten

the

handwheei untilthe iooper holder rod D

23.

tighten

the

24).

holder0turn

the

distance

the

screw

B (fig.23)

about

screw

(fig.

E.

(fig.

the

rod

F (fig. 24).

reaches

the

right

dead

centre

(towards

the

handwheei),fig.

22) by setting the supporting surface Incontact with the looper holder C and

23)against the phasetable. Ifnecessary, loosen the screwF

until

it brushes against the inside ofthe groove

D.

(fig.

23) and regulate

(fig.

24) makingthe iooper

(fig.

Page 23

13-

PHASING

Insertthe

cylindrical

obtainthe position H indicatedon the phase sheet,

THE

UPPER

LOOPER

leg of the looperinthe hole on the looperholderE

which

represents the distance betweenthe surface ofthe

(fig.

32), adjustingthe heightso as to

needle plate and the bottomof the looper.Secure the ring F using the screw C, makingsure that its Inclined

surface

Check that the measurements "e -f- g"correspond to the annexed phase

adjust themasindicated below:

a) measurement "e"

- remove the top cover of the arm, loosen the nut B and slide the pinAinto the hole in the part E (fig.31)

w

- move the pinupwards to decrease the stroke or downwards to increase it.

b)

- to obtain the distance

c) measurement

- to obtain the distance

sure

looper holder.

N.B.

removed; to do this, loosen the screw D

is required again, itmust be reassembled

automatically rephased.

coincides

measurementT'(fig.29):

that

the

with

the

(fig.

"f,

"g"

(fig.

"g".

flashing ringF

corresponding

28) to change the stroke of the cover looper, proceedasfollows:

loosen the screw C

30): ^

loosen the screw Dand the screw 0

(fig.

32)

- Should the need arise to sew

surfaceofthe

and

with

its inclined surface coincides withthe corresponding surface of the

without

a top cover thread, to prevent the looper

(fig.

32) and slide the looper out ofthe looper holder.When itsfunction

following

looper

holder

E.

sheet

(figs.28,29,30). Ifthey do not,

turn

the

looper holder on its pin.

(fig.

32)and turnthe looperabout its leg. Make

swinging,

it should be

the instructionsgivenfor the phasing operation; it

will

be

14-ADJUSTING

THE

NEEDLE

GUARD

AND

FRONT

NEEDLE

GUARD

The needle guard and frontneedle guard are fixed.They constitute a group made upof three parts: the support

see

(fig.

A.the needle guard C and the front needle guard L,

Needle

guard

Assemble the support Aon the cylindrical

base

by tightening the two screws B

25/3)

slightly,

(fig.

25/3)

Withtheneedle bar at the lowerdead centre, alignthe needle guard withthe needles and adjust its height

by loosening the screw D so that pointE infig.25/1 corresponds

with

the bottom part ofthe

eye

G ofthe

needle F.This conditionenables slot of the thread ofthe needle to be formed during its upward motion.

When the tipofthe looperis situated onthe axis ofthe needle F

E, the position must be 0,0, that is, the needle guard must be tangential to the needle F,

Tighten

Front

Move the needles to the lower

needle

the

screws

guard

B (fig. 25/3).

dead

centre, fig. 26/1. Loosen the screw S, fig. 26/1, and align the front

(fig.

25/2)between the needle and the point

fig.

25/2

needle guard Lwiththe two outer needles. When the tip of the looperis situated on the axis of the needle

F,the heightofthe frontneedle guard must be adjusted so that itstop part correspondstothe top part ofthe

eye

of the needle F,

as

to obtain the distance R,

• Tighten

15-ASSEMBLING

• Assemble the feed dogs on their shoes as shown in

the

screw

• The feed dogs

in the feed directionwas carried out at the factory.

see

fig.26/2. Usingthe

fig.

26/1,

P.

AND

ADJUSTING

are

automaticallycentred inthe slits inthe plate inan orthogonaldirectionto feed. Centering

screw

THE

P, move

FEED DOGS

the

the

figure

front needle guardtowards to

(fig.

27)

the

needles

so

• Turn the handwheel and move the feed dogs to the upper dead centre.

In

- The feed dogs must project fromthe plate by the quantity Indicated

the technical phase documentation.

As an approximation,bear in mindthat the feed dogs must protrudefromthe plate surface by an amount

equivalent to the thickness of the teeth (distance C infig. 27)

the

• To make any adjustments to the heightof

dog

and

the stitch feed dog, respectively.

feed dogs, loosen the screwsA and B ofthe differential feed

1B-ADJUSTING

The maximum and