Page 1

Rimoldi®

SPARE PARTS CATALOGUE

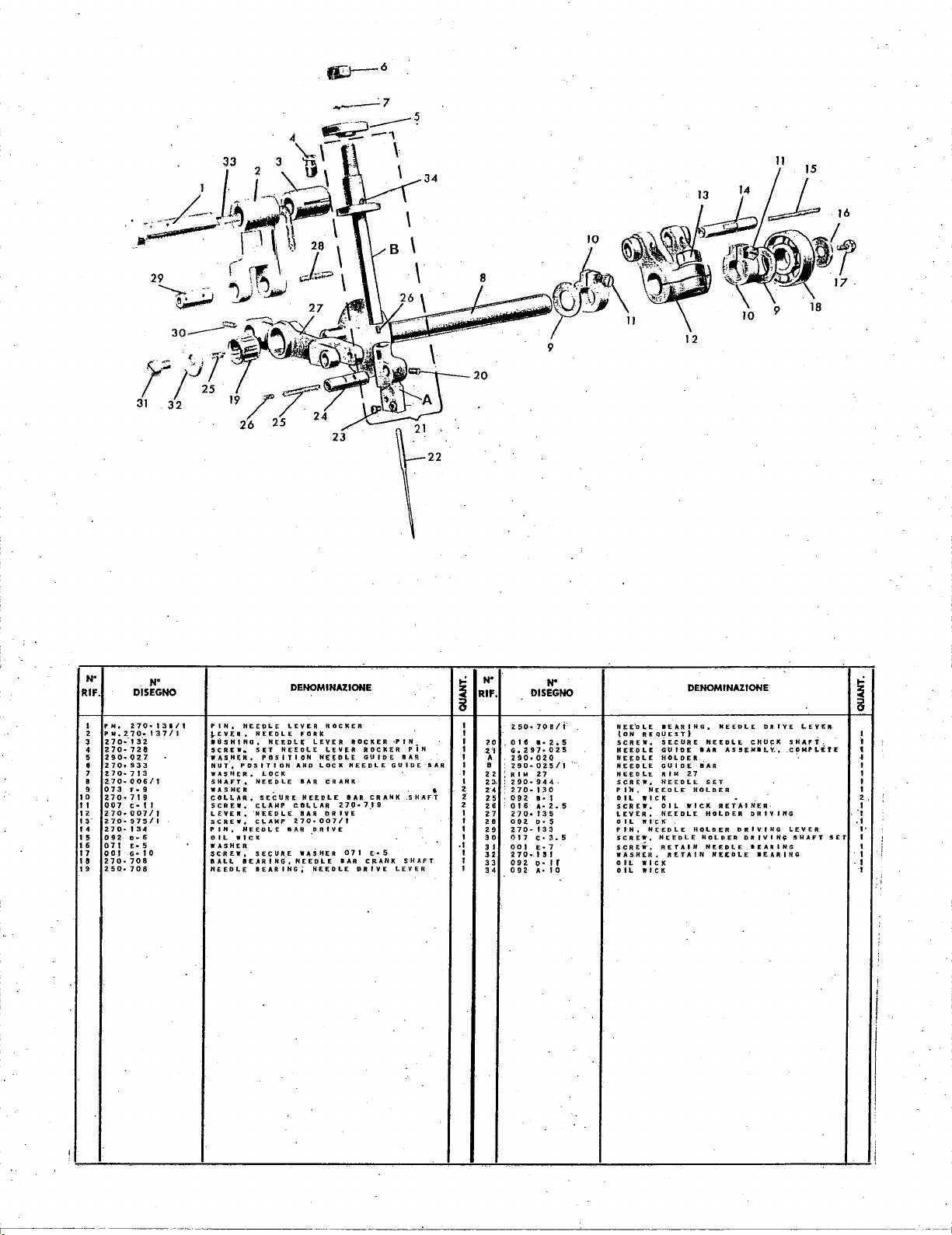

CAT ALOGO PEZZI Dl RICAMBIO

CATALOGUE

ERSA TZTEILELISTE

RECHANGES

8-29

\

_.._,

li.4

Page 2

Page 3

I N

DE

INTRODUCTION

X

-

-1

II

III

MACH

TECHNICAL

TECHNICAL

I INST.ALLAT

a -

Positioning

b - Assembly

c -

Whrication

d-

Msembling

e-

Positioning

f

~Setting

g-

N!edle

~-

Se~ting

.

II

a -

Threading

b - Ol.anging

c-

Setting

d.-

Setting

e-

Stitch

f - Adjustment.

g-

Problems due

of

of

Transmission

and

of

of

Front

Thread

of

Thread

- U

the

the

Presserfoot

of

Tensioning

Length

of

Take-Up

.S

N!e d l e

Adjustment

Seam

to

I NE

IDE

NT·IF.ICATION

DATA

SPECIFICATIONS

INSTRUCTIONS

ION,

He

ad

Adjusting

Presser

Cover

Take-up

Sewing

foot-

Plat:e

Adjustment.

Cam

E

Discs

Width

improper

handling

AND

Arm

BY

MACHINE

T IM·ING

Parts

of

machine

CLASS

Page 5

,

''

' ,

9

, ,

9

, '

9

9

''

9

''

! ,

15

15

''

15

''

, '

16

, ,

16

, '

..

16

, '

17

, ,

17

17

''

17

''

, '

17

',

18

5

6

III

a

,.:_

Every

b - Every

c - Every Three Months

d-

Sharpening

e-

Changing

- MAINTENANCE

Day

Week

the

Knives

of

Main

Shaft

SPARE

I

a -

Introuuction

b -

Procedure

II

a -

All

b-

Needles

III

Parts

HOW

-

IJOW

TABLES

TO

TO

(

if

PAR~S

USE

ORDER

required)

TillS

CATALOG

CATALOG

, '

''

''

''

',

''

''

. '

''

''

'!

''

''

19

19

19

19

19

19

23

23

23

23

23

23

25

IV - NUMERICAL

---·

INDEX

-~--

OF

-~--

PARTS

------

-~--

85

--

Page 4

Page 5

a)

ldentificati"9n Nu•bers

1.

Each machine

-

Class

-

Serial

2.

·the

Class

on.the

is

identified

or

Sttb....Class Nunher

Nunher

or

Sub-Class

base

of

the.machine.

I.

MACHINE

by;

Ntunber

1s

indicated

IDENTIFICATION

on

the

·Name-Plate,

held

by

two

screws

3. The

Serial

Ntunber

II.

is

punched

on

TECHNICAL

the

back

of

DATA

the

machine

BY

MACHINE

bas~.

CLASS

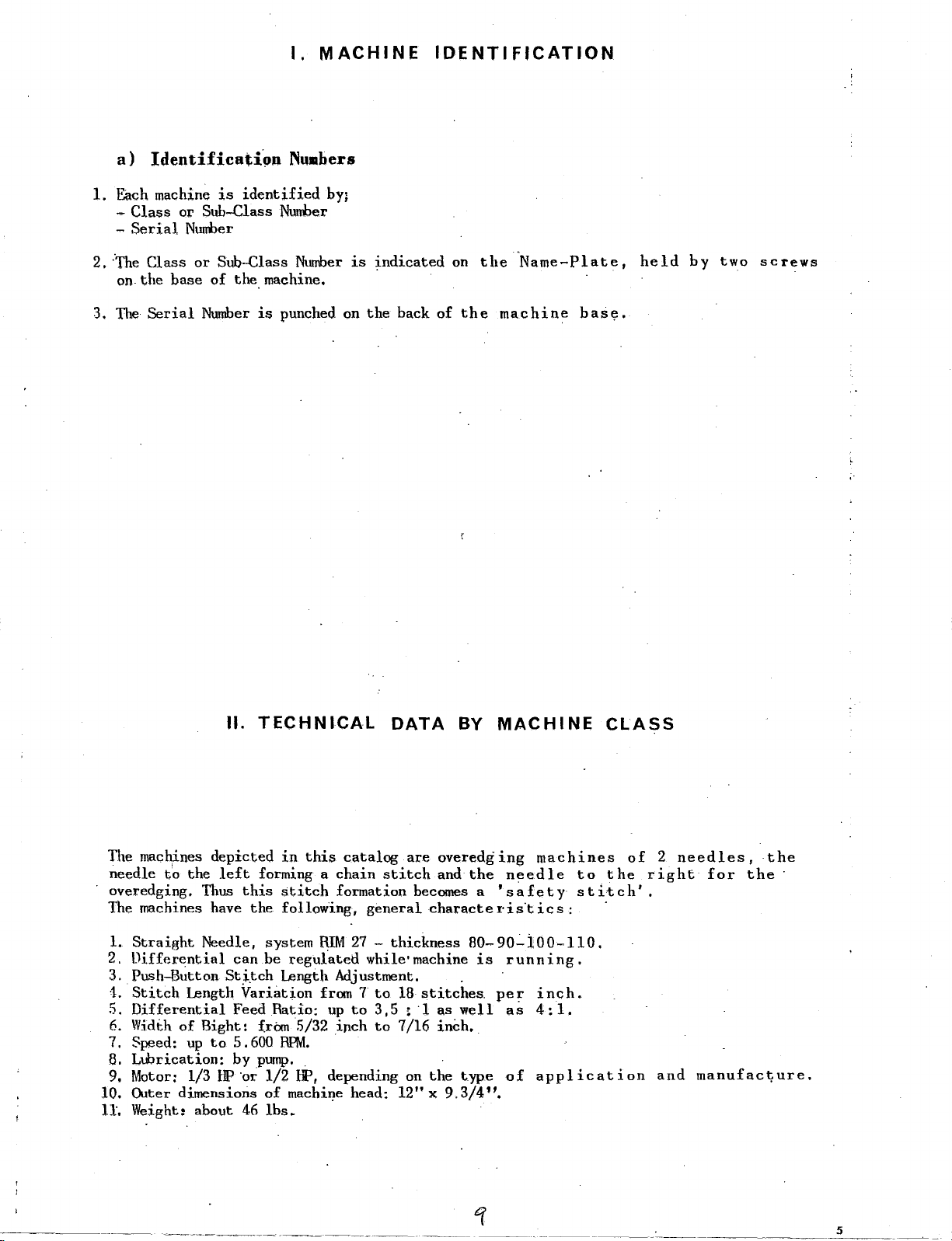

The

mac~ines

needle

overedging.

The machines have

1.

Straight

2.

Differential

3.

Push-Button

•1.

Stitch

5.

Differential

6.

Width

7. Speed;

8.

Lubrication:

9. Motor: 1/3

10.

Outer

11.

Weight:

depicted

to

the

left

Thus

Needle,

Length

of

Bight:

up

to

HP

dimensions

about

in

this

forming a

this

the

system

can

be

catalog

chain

stitch

formation

following,

RIM

regufated

27-

are

overedg

stitch

and

becomes a

general

charactei"is'tics:

thickness

while• machine

St.i.tch Length Adjustment. .

Variation

Feed

Ratio:

frbrn

5 .

600

by

pump

·or 1/2

of

46

lbs~

from 7

up

to

5/32

inch

RHvt.

.

..

HP,

depending on

machi~e

~~·---~-~-··

head:

to

18

stitches.

3, 5 ~ ·1

to

7/16

the

12" X 9.3/4".

-~-

as

inch.

ing

machines

the

needle

'safety

80-9o.:..too~UO.

is

running.

pe ~ inch.

well

as

4:

1.

t.ype

of

application

~-----

--~

to

the

stitch'.

·

-----~-

of 2 needles,

right

and

for

manufact;ure.

the

the

·

5

Page 6

Ill.

TECHNICAL

SPECIFICATIONS

TECHNICAL CHARACTERISTICS

Ill

MACHINE

SUBCLASS

~

Cl)

...

.

,;:;

...,

....

Q

z

0.29.0

,_

B.

·29

.1

B.29.1/B

0.29.1/PUU

B~29.1/PDUO

0.29.17

4

5

4

5

4

5

4

5

4

5

4

5

gauge

3/32''

2,5

3/64

mm.

1

3/64

1

111111.

3/64

mm.

1

3/64

mm.

1

13/64

11!11.

5

mm.

width

or

bight

5,5

4

4

4

4,5

10,5

N.

of

stitches

the

to

inch

7,5-18

7,5-18

7-,5-18

7,5-18

7,5-18

.

7-16

Ill

Cl)

>

ATTACHMENTS

....

J;:

,;,:

yes

yes

yes

Shirrihg

yes

Attachment

Shirring

yes

Attachment

yes

APPLICATIONS

Shil'ts!

Shirts;

Shirts,

general

Curtains,

cloth

Cloth

tion

in

of

general

ornaJtental

Trousers

SPECIFIC

c~oth

cloth

fine

bed-spreads,

in

general

in

general.,,

folded

cord

confection

-

in

in

cloth

tape

general

general

in

inser-

and

1J

..

29.17/PDB

B. 2 9.

1 7

/PD!.JO

8~29.174

B.29.7

U.29.7/R

1----·

8.29.7/W

8.·29. 7 /PDB

5

4

5

4

5

4

5

4

5

4

5

4

5

4

13/64

5

mm.

13/1!4

5

11111.

13/64

5

m111

3/32

2,5

•••

3/32

IIIII,

2, 5

3/32

2,

5

IIIII,

3/32

2, 5 ....

Shirr

10,5

11

10,5

•.

6

7

6

6

7

6

7

7-16

7-16

7-16

7,5-18

7,5-18

7,5-18

7,5-18

yes

yes

yes

yel5

yes

yes

yes

in~

Attachment

SMrr;l.ng

Attachment

Electric

cutter

ch11.in

Shirring

Attach11en t

Bed-spr~ads,curtains,

et.c·.

in

into

in

general,.

cord

confection

-

tape

sea!lls

general,

curtains

Cloth

t1on.of·folded

ornall!ental

TJ:ousers

general

in

shirts-cloth-confection

general

in

Reinforcing

tion

.Shirts-cloth-confection

general

in

Cloth

spread's.

tape

inser-

tnser-

bed-

ahd

m.i

...

•.

6,5

.7,11

6,5

7,5-18

7,5-18

l \

3)32

B.29.7/PDBQ

)}_. 2 9.

6

7 8

4

~

4

5

~.~~

3/32

:r,5

yes

yes

Shlrrlng

Attach11en t

of

sea•

in

in

Cloth

tion

or·na•ental

Cloth

ged

general,

fold-ed

general-overed.o

curled

cord

tape

downw·ard

inser-

and

Page 7

INSTALLATION

and

TIMING

-THREADING

- .MAINTENANCE

/

13

7

Page 8

Page 9

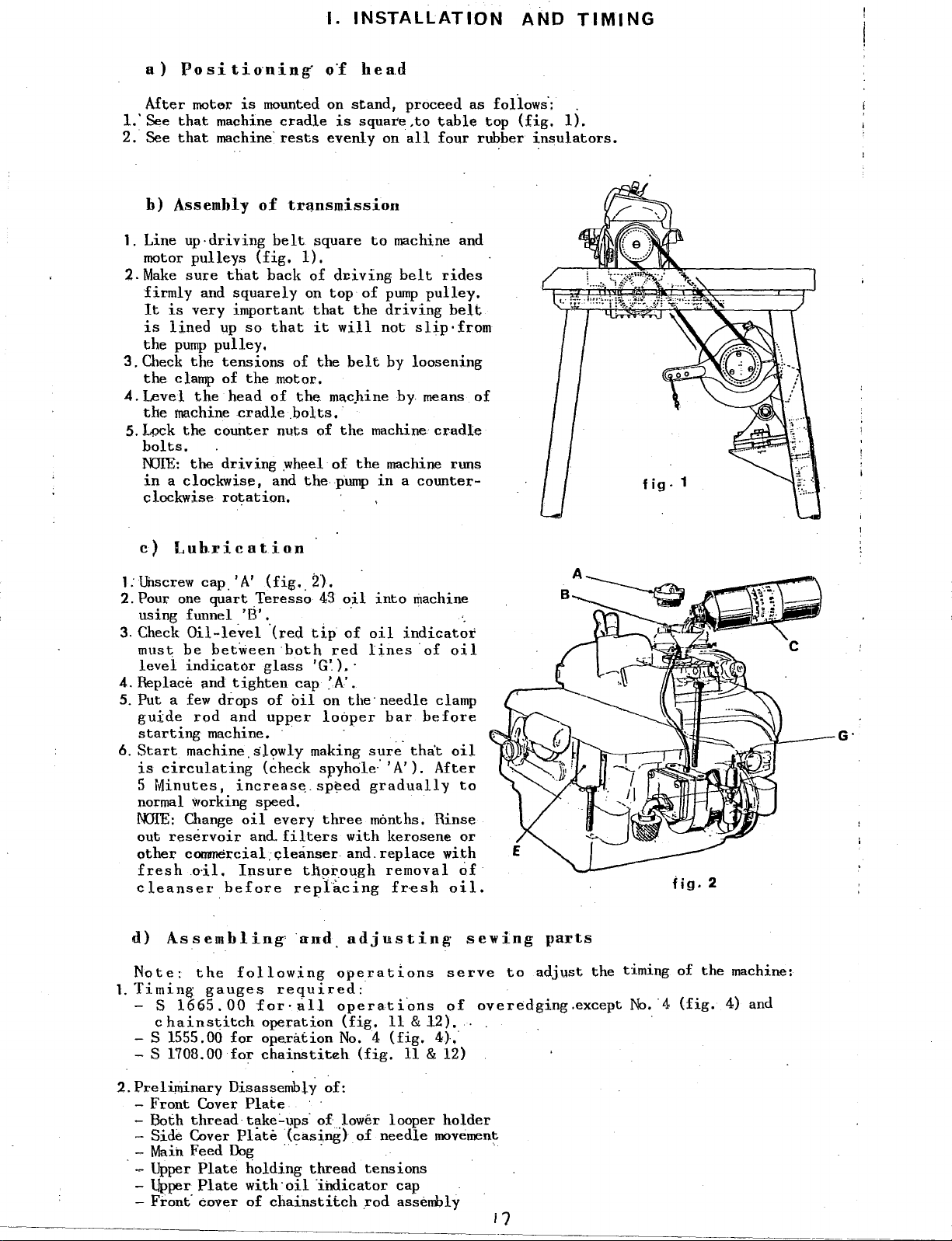

a)

After

1.'

See

2. See

b)

PositioninK

mot~r

that

that

is

machine

machine·

Assembly

I.

INSTALLATION

o~

head

mounted on

cradle

rests

of

tr~nsmission

stand,

is

sqnare,to

evenly

on

AND

proceed as follows·:

table

all

four rubber

top

{fig,

insulators.

TIMING

1).

1. Line

2.

3.

4.

5.Lock

motor

Make

firmly

It

is

is

lined

the

pump

Check

the

clamp

Level

the

machine

up-driving

pulleys

sure

that

and

squarely

very

important

up

so

pulley.

the

tensions

of

the

the

head

cradle.bolts.·

the

counter

bolts,

NJIE:

the

driving

in a clockwise,

clockwise

c)

L u b.r i

l:l.Ji:lscrew

2.Pour

using funnel

3. Check

must

levei

4.

Replace and

5.

Put a few

guide

starting

6.

Start

is

circulating

5

Minutes,

rotation.

cation

cap_

'A' (fig._

one

quart

_Teressa

'B',

Oil-level

be

bet~een

indicator

tighten

drops

rod

and

machine. · ·

machine.slowly

increas~.sp~ed

normal working speed.

l'DIE:

out

other

cleanser

fresh

Change

reservoir

oil

and.

commercial_c;leanser and.

~il.

Insure

before

belt

square

{fig.

1).

back

of

d1:iving

on

top

that

that

it

will

of

the

.motor.

of

the

mac.hine

nuts

of

the

.wheel

and

of

thepump

:n.

43

·(red

tip

both

glass

of

upper

(~heck

every

filters

red

'G~).

cap

'A'.

oil

on

looper

making

spyhole:

three

th~~ough

replicing

to

machine and

belt

of

pump

the

driving

not

belt

by loosening

by

machinecradle

the

machine runs

in a counter-

oil

into

machine

of

oil

indicator

lines

·

the.

needle

bar

sur~·

that

'A').

gradually

months. Rinse

with

kerosene

replace

removal

f~esh

rides

pulley,

slip·

means

of

clamp

before

After

with

belt

from

oil

oil

to

or

~~

oil.

of

fig.

1

fig.

2

d)

Assembling

Note:

1.

Timing

- S

- S 1555.00

- S

2.Preliminary

-

- Both

- Side Cover

-

. - Upper

-Upper

- Front· cover

the

1665.00

hainstitch

c

1708.00

Front

Cover

thread

Main

Feed

Plate

Plate

following

gauges

for

for

DisassembLy

Plate

tlllke:..ups·

Plate

Dog

holding

with·oil

of

and

adjusting

operations

required:

for·all

operation

ope.ration

chainstiteh

operati"ons

(fig,

11 & 12)

No. 4 (fig.

(fig.

11 & 12)

of:

of)ower

(casing)

of

looper

needle

· · · · ·

thread

·indicator

chainstitch

tensions

cap

rod

assembly

-------

sewing

serve

of

..

4}..

holder

movement

to

overedging.except

---------------~-~~-----~-

parts

adjust

the

timing

No.-4

of

(fig.

the

machine:

4) and

Page 10

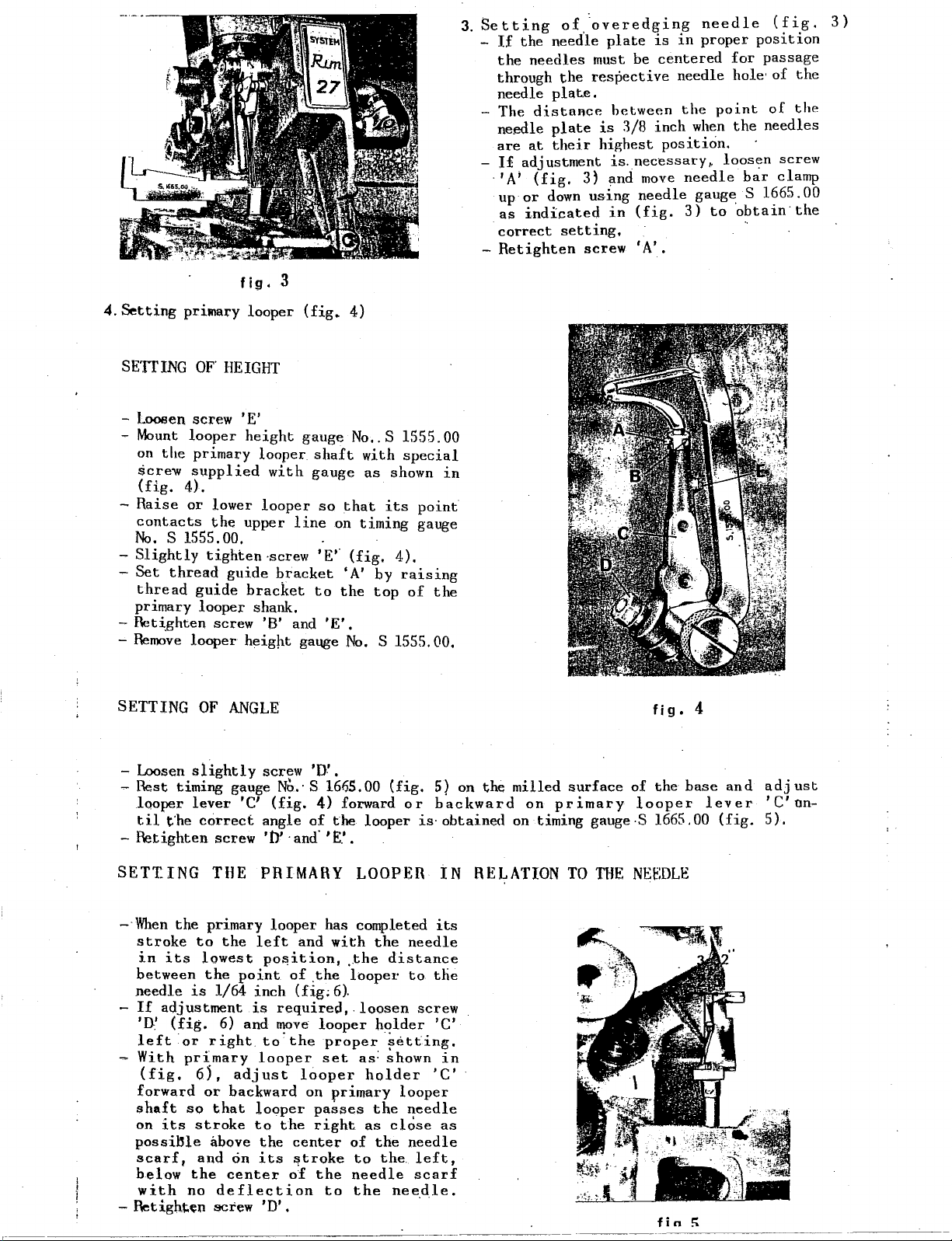

fig.

3

3.

Setting

-

If

the

through

needle plat.e.

- The

needle

are

- I£

·'A;

up

as

correct

-Retighten

of

.overedging

the

need"!e

needles

the

distance

plate

at

their

adjustment

(fig.

or

indicated

down

setting,

3) and

using

screw

plate

must be

respective

is

highest

is

centered

between

3/8

inch

is.

necessary,.

move

needle

in

(fig.

'A'.

needle

in

proper

needle

the

point

when

position.

needle

gauge S

3)

to

(fig,

position

for

passage

hole·

of

the

of

the

the

needles

·

loos':!n screw

bar

clamp

1?65.00

obtaw·the

3}

4.Setting

SETTING

- Looaen screw 'E'

-Mount

on

-

Raise

contacts

No.

-Slightly

-Set

thread

primary

-

Ret~ghten

-Remove

SETTING

pri~ary

OF'

looper

the

primary

screw

(fig.

supplied

4).

or

lower

the

s 1555.00. . .

tighten·screw

thread

guide

looper

screw

looper

OF

looper

HEIGHT

height

looper

with

looper

upper

guide

bracket

bracket

shank.

'B'

height

ANGLE

(fig.

gauge

shaft

gauge

line

to

and

gaqge

so

'E'.

'E'.

4)

No

•. S 1555.00

with

as

that

on

timing

(fig.

'A'

by

the

top

No.

S 1555.00,

special

shown

its

4).

raising

of

in

point

gauge

the

fig.

4

- Loosen

- Rest timing gauge

looper

til

-

Retighten

SETTING

-·When

stroke

in

between

needle

-If

'D:'

left

-

With

(fig,

forward

shaft

on

possi~le

scarf,

below

with

-

Retigh~en

r·--·-----·

slightly

lever

t"he

correct

screw

THE PRIMARY LOOPEI\

the

primary

to

the

its

lowest

the

is

1/64

adjustment

(fig.

6) and

or

right

primary

6,,

or

backward on

so

that

its

stroke

above

and

on

the

center

no

deflection

screw

screw

No.· S 16155.00

'C'

(fig.

angle

of

'0'

· and·

looper

left

and

po~ition,

point

adjust

of

inch

(fig;

is

required,.loosen

move

to.the

looper

looper

looper

to

the

the

center

its

~troke

of

'D'.

'D'.

(fig.

4)

forward

the

looper

'E:.'

.

has completed

with

the

.the

distance

.the

looper

6).

looper

proper

set

passes

right

the

to

holder

as: shown

holder

primary

the

as

of

the

to

needle

the

~~tting.

close

the.

needle.

5) on

or

backward

is·

its

needle

to

the

screw

'C'

'C'

looper

needle

needle

left,

scarf

· ·

the

obtained

IN

RE~ATION

in

·

as

milled

on

primary

on timing gauge·S 1665.00

surface

TO

THE

of

the

looper

NEf:DLE

fin

base

lever

;

and

(fig.

adjust

'C'

on-

5).

Page 11

5.Settin~

of

secondary

looper

fig_. 7

-

Special

the

c&re must

secondary

maintain a perfect

secondary

secondary

looper

looper

'C'.

-

Retighten

- Check

as

all

-.Retighten.

- Machine must

~he

screw

crossing

ot~er

settings.

screws 'A' and 'B'.

secondary looper. assembly.

turn

-Note: To

as

indicated

or

down

the

decreases.

·-

Slightly

-

Adjust.

looper,

that

ble

touchin

.,...

OJ.eck

- The •Secondary

left

close

If

screw

driving

or

proper

be

taken

looper

alignment

driving

pivot

sleeve

'D'.

of

both

loopers.

freely

setting

crossing

its

behind

obtain

considering

loosen

turning

poirit

the

distance

in

f:lg.

9,

move

lever

that

in

fig. 7 and B increases

in."

screw 'B' and 1 A'

of

secondary

the

l?econdary

-,passes·.as

th~-primary

and

Close

looper

• .

the

distance

to

rightt

as

possible

adjustment

'D'

and

assembly

backward

indicated

looper,,

must

without

l.s needed,

push

the

with

as

required

in

in

its

pass

the

touching.

loosen

comp,l~te

bushing

to

setting.

when

adjusting

assembly,

to

between

arm

'E'

and

in

bushing

as

well

. .

after

adjusting

of

11/32.,'

'E'

~oing

so;

primary

looper

as

possi-

witho~t

·fig.

7-8--9. ·

stroke

from

needle

slightly

looper

'C'

forward

obtain

the

up

or

·"""';"

'i'

so

I

':·;;,<:~·

·

as

fig·

6

fig

fig.

.10

9

- To

set

guard

it

slightly

. -

Set

the

- With

set

primary

to

right,

-'Tighten

-Set

while

-

Tighten

·-

Insert

position

needle

6.Setting

the

'D' on

needle

machine

the

needle

front

needle

looper,

barely

screw

needle

guard

needle

the

needle;

pushing

guard

the

needle

needle

with

guard

base.

'C'.

is

needle

bring

'Aj.

fig.

8

needle

guards

guards,

guard 'A; and

screw

'D'

'B',

with

·

in

its

lowest

guard

so

in

its

stroke

touches

'A'

in

close

its

guard

needle.

lowest

with

iri

it

slightly

mount

screw

that

to

to

(fig.

needle

tighten

'C'

position,

point

from

·the

needle

position,

screw

its

lowest

against

10)

on

of

left

'B'

.

- The

NOIE: The

Scarf

- For

and

thread

that

in

its

very

must

the

point

upper

hard

run

thread

of

the

portion,-

sythetic

freely.·

is

pressed

looper,·

fabrics,

and

If

this

between

in

in

its

its

the

is

not

needle

stroke

stroke

needle

the

to

must

case,

and

froot

the

touch

needle

left

left,

it

the

means

guard.

to

right,

in

needle

its

that

lower

the

must

guard

needle

enter

is

the

portion.

considerably.

too

low

needle

11

Page 12

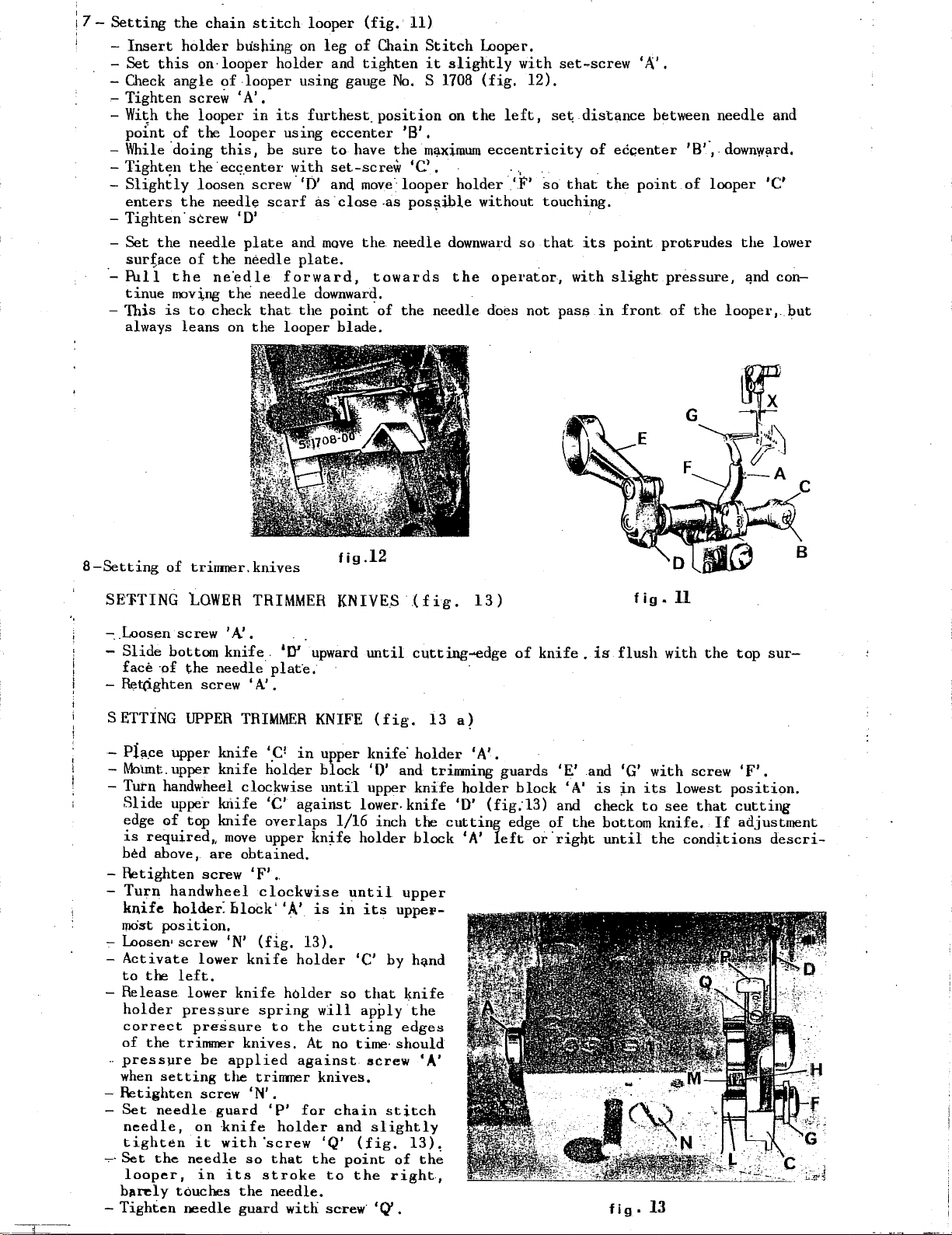

7-

Setting

-

Insert

-Set

-Check

the

this

angle

holder

on·

- Tighten screw I A'.

-

Wi~h

the

looper

point

-While

- Tightt;n

-Slightly

enters

-Tighten.

-

Set

sur;ace

·_Pull

tinue

-'This

always

of

·doing

the

the

the

moving

is

leans

the

the·

loosen

screw 'D'

needle

of

to

chain

stitch

bushing

looper

of

-looper using gauge

in

looper

this,

ec~_enter

screw

need!~

plate

the

needle

ne"edle

the

needle

check

on

that

the

on

holder

its

using

be

sure

~ith

'D'

scarf

and

plate,

forward,

the

looper

looper

furthest_

(fig,

leg

of

and

tighten

eccenter

to

have

set-screw

and

move.

as-close

move

the

downward.

point

blade.

11)

Chain

Stitch

it

No.

S

position

'B',

the

m~imum

•c,

looper

.as

pos~ible

needle

towards

·of

the

Looper.

slightly

1708

on

(fig.

the

with

12).

left,

eccentricity

..

holder

downward

the

needle does not

'F'

without touching.

so

.

operator,

set~screw

se~

dist~nce

of

eccenter

so

that

the

that

its

point

with

slight

pass

in

front

1

A',

between

point

protrudes

pressure,

of

'8'·,.

of

the

needle

downw!lrd,

looper

the

~nd

looper,.

and

'C'

lower

con-

but

fig

KNIVES

upper

block

until

lower.

l/16

holder

until

in

'C' by

so

will

cutting

no

time·

knives,

chain

and

'Q'

(fig.

point

to

the

screw·

.12

{fig.

until

cutting--edge

(fig,

knife'

'0'

upper

inch

its

that

apply

screw

slightly

1

(l

13

a)

holder

and trinming guards

knife

knife

block

the

holde.r

'D'

cutting

'A'

upper

uppeF-

h~nd

~nife

the

edges

should

'A'

stitch

13).

of

th~

right,

.

13)

'A'.

(fig;l3)

left

of

block

edge

or·

knife.

'E'

and check

of

right

8-Setting

SE'FTING

•,

-

..

-

-

SETTING

-

-

of

trinmer.knives

tOWER

Loosen screw 'A! , .

Slide

face ·of

~t(ighten

bottom knife_ 10'

the

screw 'A' ,

UPPER

Pi!i.Ce

Mo'unt.

upper

upper

needle plat·e,

knife

knife

- Tutn handwheel clockwise

Slide

edge

is

bed above,

-

Retighten

-

Turn

knife

mast

upper

of

top

required,,

screw

handwheel

holder:

position.

knife

knife

move

are

- Loosen• screw 'N'

-

Activate

to

the

lower

left,

- Release lower

holder

correct

of

-

pressure

when

-

Retighten

Set

needle,

tighten

~-Set

looper,

b~rely

-

Tighten

the

setting

needle

the

pressure

pressure

trimmer

be

screw

guard

on

·knife

it

with

needle

in

touches

needle

applied

the

its

TRIMMER

TRIMMER

'P

holder

'C'

overlaps

upper

obtained.

'F'

,

clockwise

bloek'

knife

(fig.

knife

spring

to

knives.

trinmer

'N'.

'P'

holder

'screw

so

that

stroke

the

needle.

guard

'A'.

holder

with

upward

KNIFE

in

against

kn~fe

is

13),

holder

the

At

against

far

the

'A'

the

is

flush

and 'G'

is

~n

bottom

until

fig

fig.ll

with

its

to

knife.

the

• 13

with

the

screw

lowest

see

that

If

conditions

top

sur-

'F',

position.

cutting

adjustment

descri-

Page 13

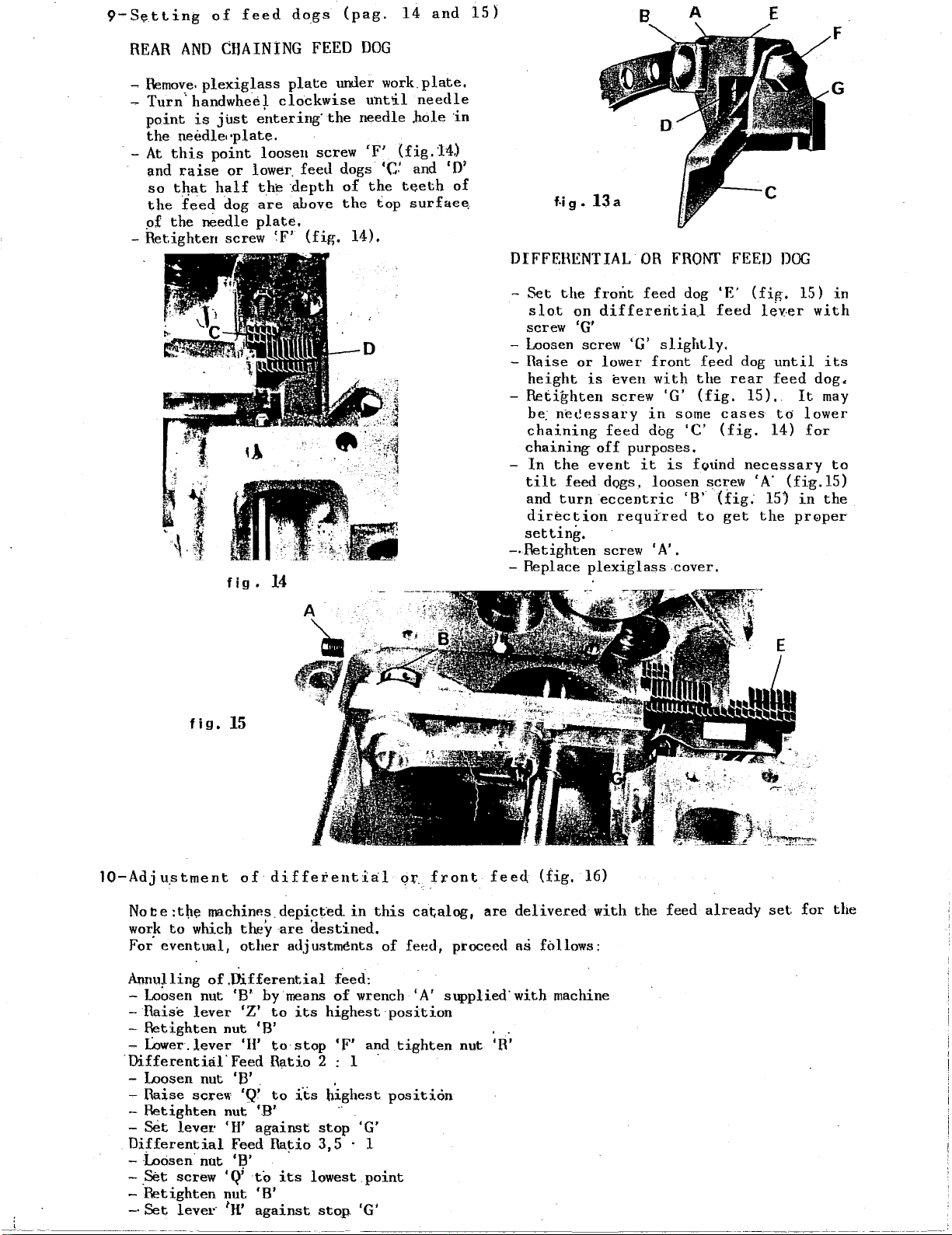

9-S~tting

REAR

of

AND

CHAINING

feed

dogs

FEED

(pag.

DOG

14

and

15)

B

A

E

F

-Remove.

-

Turn'

point

the

needle··plate.

· -

At

this

and

raise

so

t4at

the

f~ed

p£

the

-Retighten

plexiglass

handwhe.el

is

just

e"ntering·

point

needle

loosen

or

lower.

half

the

dog

are

plate.

screw 'F'

fig

•

plate

clockwise

the

screw

feeu

.depth

above

(fig.

14

under

needle

'F'

dogs

of

the

14).

work.

until

the

needle

hole

.

(fig

•c:

and 'D'

teeth

top

surfae~

plate.

in

.14.)

of

f.j

g.

13 a

DIFFERENTIAL

-Set

- Loosen screw

-

-Retighten

-

-·Retighten

- Replace

the

front

slot

on

differeritia.l

screw 'G'

'G'

Raise

height

h~

chaining

chaining

In

tilt

and

dir~ction

setting.

or

lower

is

even

screw

ne~essary

feed

off

purposes,

the

event

feed dogs, loosen screw 'A'

turn

eccentric

required

screw 'A' .

plexiglass

OR

FRONT

feed

slightly.

front

with

'G'

in

dog

it

is

dog

feed

the

(fig.

some

'C'

fotind

'B'

to

cover,

FEED

'E'

(fig.

feed

dog

rear

15).

cases

(fig.

necessary

(fig:

get

DOG

leyer

until

feed

td

14)

(fig.l5)

15)

the

G

15)

in

with

its

dog.

It

may

lower

for

to

in

the

pr0per

fig.

15

10-Adj

i

,-.-~------·-----·---------

u_stment

Not:

e

:th~

wor~

to

which

For

eventual I other

Annu~ling

- Loosen nut

-

Raise

-

Retighten

- Lower.lever 'H'

·rafferential'Feed

- Loosen nut 'B' . .

- Raise

-

Retighten

-

set

Differential

-

-i..oosen·

-_Set

-

Retighten

-·

Set

lever

screw

lever

screw

lever·

of

differential

machinP.s.

of.DQfferential

nut

nut '.B'

'H'

nut

'Q;

nut

1

H'

they

'B'

'Z'

'Q'

against

Feed

'B'

to

'B'

against

depicted.

are

adjustments

by

·means

to

its

'B'

tostop

R~tio

to

i'ts

Ratio

·

its

destined,

2 : 1

stop

3,5

lowest

st()p. 'G'

Qf.

front

in

this

cat;alog,

of

feed, proceed as follows:

feed:

of

wrench 'A' supplied·

highest

'F'

highest

··

position

and

position

tighten

'G'

· 1

point

nut

feed

are

'R'

(fig.

delivered

with

machine

16)

with

the

feed

already

set

for

the

Page 14

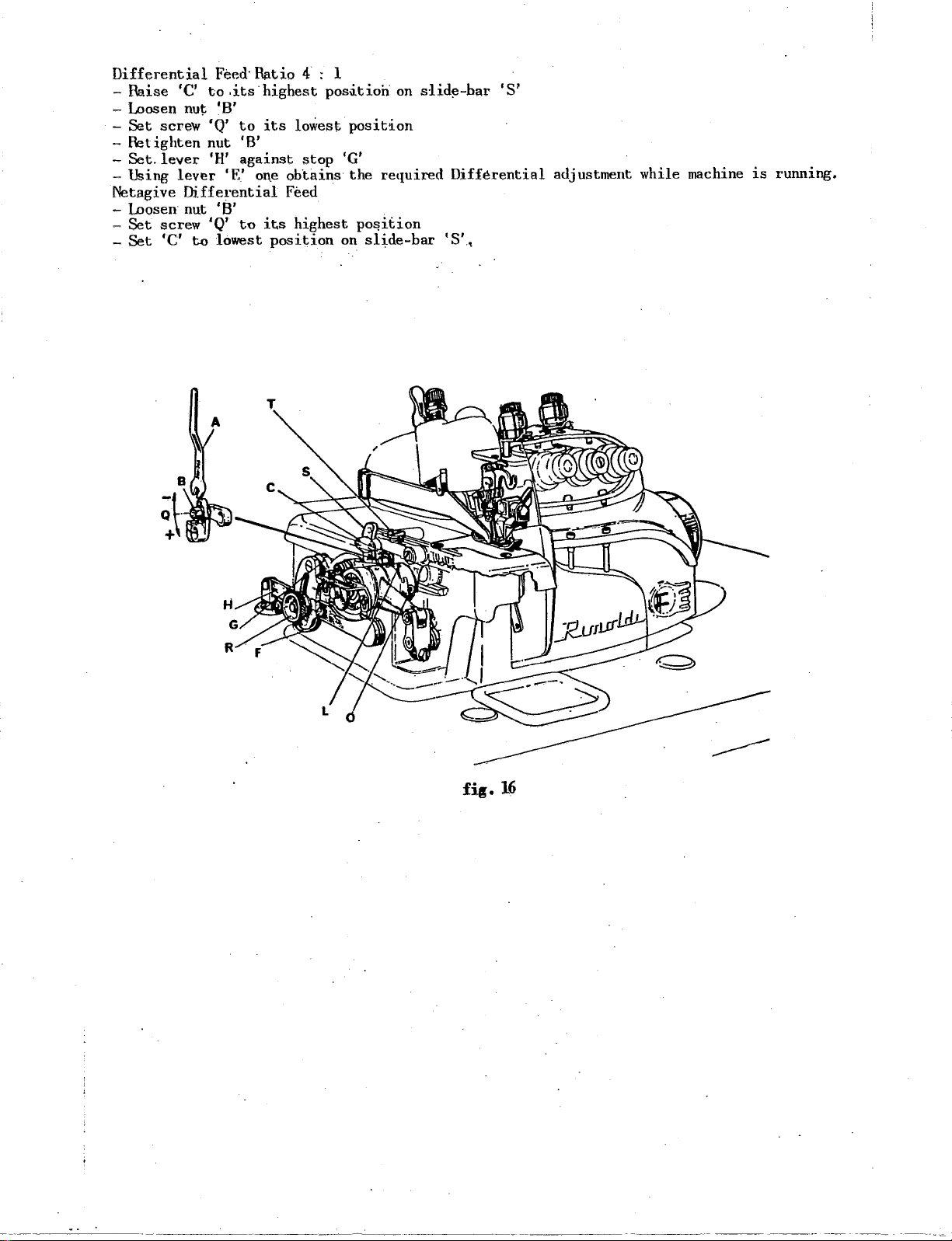

Differential

-Raise

-Loosen

-

Set

-&tighten

-Set.

- Using

Net.agive

lnosen·

-

-

Set

-

Set

'C'

nut

screw

lever

lever

Differential

nut

screw 'Q'

'C'

to

Feed·

to

.its

'B'

'Q'

to

nut

'H'

'E'

'B'

lowest

Ratio

highest

its

'B'

against

on.e

to

its

position

4 : l

posiitioh

lowest

stop

obtains

Feed ·

highest

on

slid!'l-har

position

'G'

the

required

po~1t1on

on

slide-bar

'S'

Differential

'S'.,

adjustment

while

machine

1s

running.

fi«.

16

Page 15

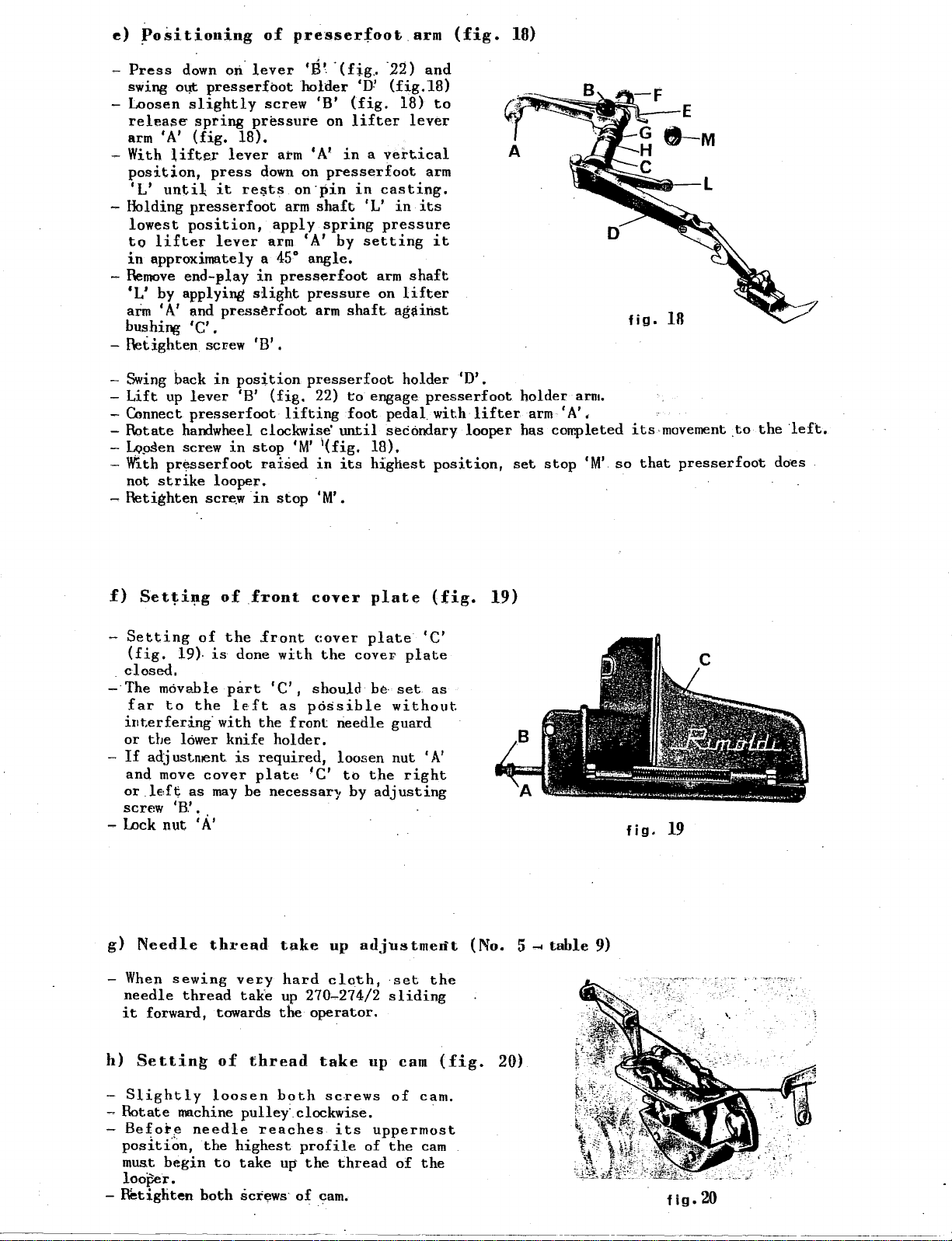

e)

~o~itioning

of

presserfoot

arm

(fig.

18)

-Press

swing

- Loosen

release

arm

- With

position,

'L'

- Holding

lowest

to

in

-

Remove

down

o~

slightly

spring

'A'

(fig.

lifte.r

untiL

presserfoot

position,

lifter

approximately a

end-~lay

'L' by applying

aim

'A'

and

bushing 'C' .

-

Retighten

-Swing

-

Lift

- Connect

-Rotate

-

Lo~en

- With

not

-

Retighten

back

up

lever

presserfoot

handwheel clockwise

screw

pr~sserfoot

strike

on.

lever

presserfoot

pressure

18).

lever

press

it

re~ts

lever

in

slight

press~rfoot

screw 'B' .

in

position

'B'

in

stop

looper.

scre.w

in

'B'.

holder

screw

down

arm 'A' by

(fig.

raised

'B'

on

arm

'A'

on

presserfoot

on·pin

arm

shaft

apply

spring

45°

angle.

presserf~ot

pressure

arm

presserfoot

22)

lifting

1

'M'

(fig.

in

stop

'M'.

'(fig

..

·22)

'D!

(fig.l8)

(fig.

lifter

in a vertical

shaft

to

foot

until

its

18)

lever

in

casting.

'L'

in

pressure

setting

arm

shaft

on

lifter

ag~inst

holder 'D'.

engage

pedal

secondary looper has completed its-movement

18),

highest

and

to

arm

its

it

presserfoot

with

lifter

position,

A

holder

arm

set

'A',

stop

arm.

'M'

so

fig.

that

18

.to

presserfoot

the

"left.

do~s

f)

Setti~g

-

Setting

(fig.

.

closed.

- The movable

far

interfering·

or

the

-

If

adjustment

and

or

.le:f~

screw 'B.'.

- Lock

g)

Needle

-

When

needle

it

forward, towards

19).

to

lower

move

as

nut

sewing

thread

of

the

cover

'A'

of

the

is

done

part

left

with

knife

is

may

be

thread

ve£y

take

front

front

with

'C',

as

the

front

holder.

required,

plate

necessaq.

take

hard

up

the

cover

cover

the

should

p6~sible

'C'

270-274/2

operator.

plate

plate

covet'

be·

set

without

needle guard

loor>en

to

up

cloth,

nut

the

by

adjusting

adjustmerit

set

sliding

(fig.

'C'

plate

as

'A'

right

the

19)

(No. 5

.....

table

9)

fig.

19

h)

Settin~

-

Slightly

-

Rotate

-

Be~ot~

position,

must

begin

looper.

-

Retighten

of

thread

loosen

machine pulley: clockwise. ·

needle

the

both

highest

to

reaches

take

screws

both

profile

up

of

take

screws

the

cam.

up

its

of

thread

cam

of

cam.

uppermost

the

cam

of

the

(fig.

20)

fig.

20

Page 16

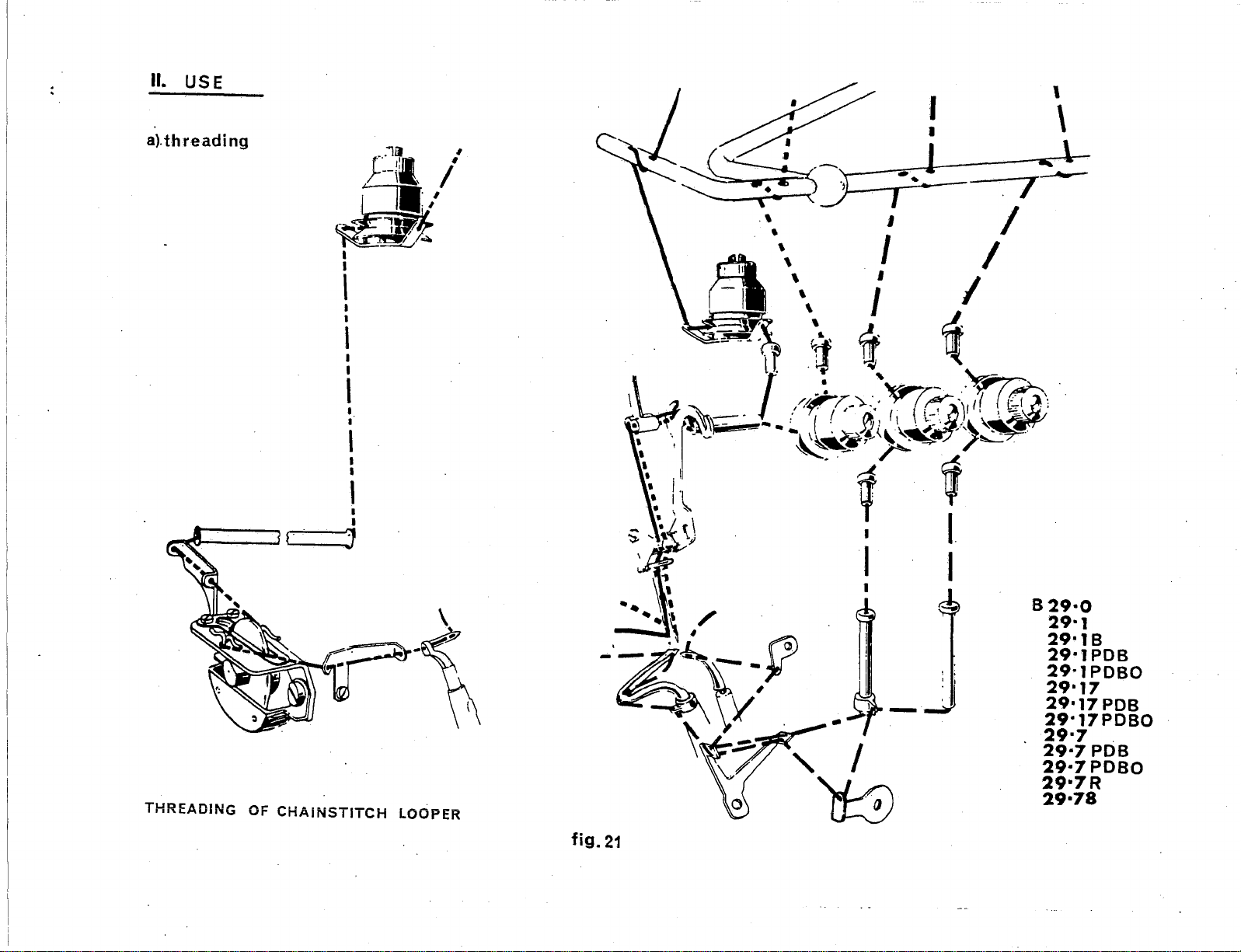

II. USE

a).

threading

...

1~

f--\1,

--

la:,

a

I

I

=-.,I

~

I

. I '

J~

/

~

~

~):

: I \

,.

.\

\ . I .

--~

.-1

7--

' I

f I

~~---.1

THREADING

! .

..,.... . .__.

OF

CHAINSTITCH

-:'

I

I

'

I

I

I

I

..

•

I

I

I

I

I

'

LOOPER

. I I

I '

l[

..

.'1

.

~~

~

·-.~~

-·~rv:?

~-

...

r~J~--~

II

I.

.

~

~

/~,-_,.~-

I

(

,~,~https://manualmachine.com/'''~«:.

~

•.

,(~\)

.

.,

/

-·

,~..,....?7',

~

tt

:J

'

~-

~·~

~~

\

c;.:~·),,(

-·

~~

, ·

~

..

y

I I .

_

_J

I

~

~

I

Yr'P.

~

-')·

'

~)

\.~r;Ji,

~'7"'·

,·

"~

! I;

829·0

29·1

29•18

29·1PDB

29·1

PDBO

29•17

29•17

29•17PDBO

29·7

29·7

29•7PDBO

29•7R

29·78

PDB

PDB

~

fig.

21

Page 17

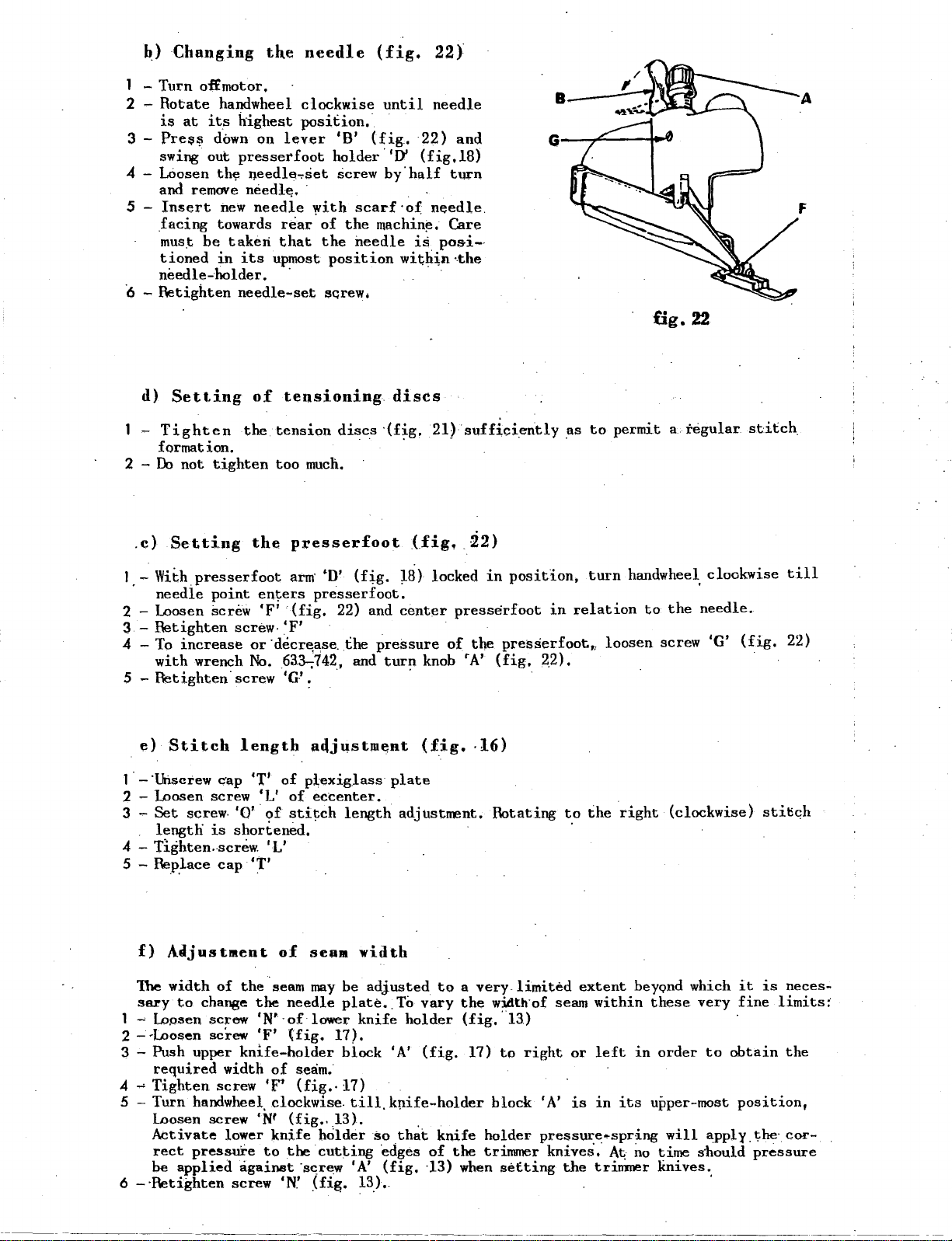

~)

Changing

1 -

Turn

of£

2 -

Rotate

is

at

its

3 -

Pres~

swing

down

out

4 - LOosen

and

remove

5

Insert

,facing

mus.t

be

tioned

needle-holder.

·6 -Retighten

d)

Setting

-

Tighten

formation.

2 -

Do

not

tighten

the

motor,

handwheel

highest

presserfoot

th~

needle~set

needl~.

new

needle

towards

taken

in

its

needle-set

of

the

clockwise

position.·

on

lever

rear.of

that

upmost

.

tensioning

tension

too

needle

'B'

holder

screw

with

the

the

position

SGrew;

discs

much,

(fig.

until

(fig.

.,D'

by'half

scarf

machi~~.

needle

22)

needle

22)

and

(fig,l8)

turn

·of

needle.

Care

is

pos-i-·

wit;h:i,n ·.the

dises

·(fig.

· · ·

21)

sufficiently

B

G-~"----t-

fig.

as

to

permit a regular

22

stitch.

.c)

Setting

1.-

With

needle

2 -

Loosen

3-

Retighten

4 - To

5 -

1 ·

2

3 -

4 -

5 - Rep.J.ace

2

3-

4 4

5

6

increase

with

Retighten·

e)

Stitch

-'Unscrew

-Loosen

Set

screw.

lengtli

Tighten

f)

A~justment

1he

width

sftl'y

to

~

l.opsen

--Loosen

Push

upper

required

Tighten

-Turn

-·Retighten

handwheel

Loosen

Activate

rect

pressure

be

applied

the

presserfoot

point

screw

wrench

screw

is

chanse

screw

screw

screw

en~ers

'F'

screw-'F'

or

No.

screw

length

c·ap

'T1 of

'L'

'0'

·of

shortened

..

screw.

cap

'T'

of

the.seam

the

'N'·of

'F'

knife-bolder

width

screw

'Nf

lower

agaiMt

screw

p~esserfoot

arm·

•n•

(fig.

presserfoot.

·(fig.

"decr~ase.

63.3-;742, and

'G'.

22)

the

. ·

a!ljustiUent

plexig.lass

of

eccenter.

stitch

'L'

of

needle

(fig.

of

seam.

'F'

(fig.·

clockwise.

(fig,.l3).

knife

to

the

'N.'

..

seam

may

lower

17).

holder

cutting

·screw

_(fig.

length

width

be

plate

knife

block

17)

till

'A'

13).

(Jig,

W)

and

center

pressure

turn

(fig.

plate

adjustnent.

adjusted

..

To

vary

holder

'A'

knife-holder

. . .

so

that

'ed.ges

(fig.

knob

(fig.

~2)

locked

in

presserfoot

of

the

presserfoot,,

'N

(fig,

position,

·16)

Rotating

to a very.limited

the

w:idth·of seam

(fig

•.

l3)

17)

to

right

block

knife

of

·13) when

the

holder

trimner

setting

turn

handwheel.

in

relation

loosen

to

the

screw

needle.

2_2).

to

the

right

extent

within

or

left

'A'

is

1n

its

pressure~spring

knives."

A~

the

triDIJ~er

(clockwise)

beyond

these

in

order

upper-most

will

no

time

knives.

which

very

to

apply.the·

s·hould

clockwise

'G'

(fig.

stitic:h

it

is

fine

obtain

position,

pressure

·

till

22)

neces~

limits:

the

cor-

~~-·-~-

~------~·---~-~~--···--.

Page 18

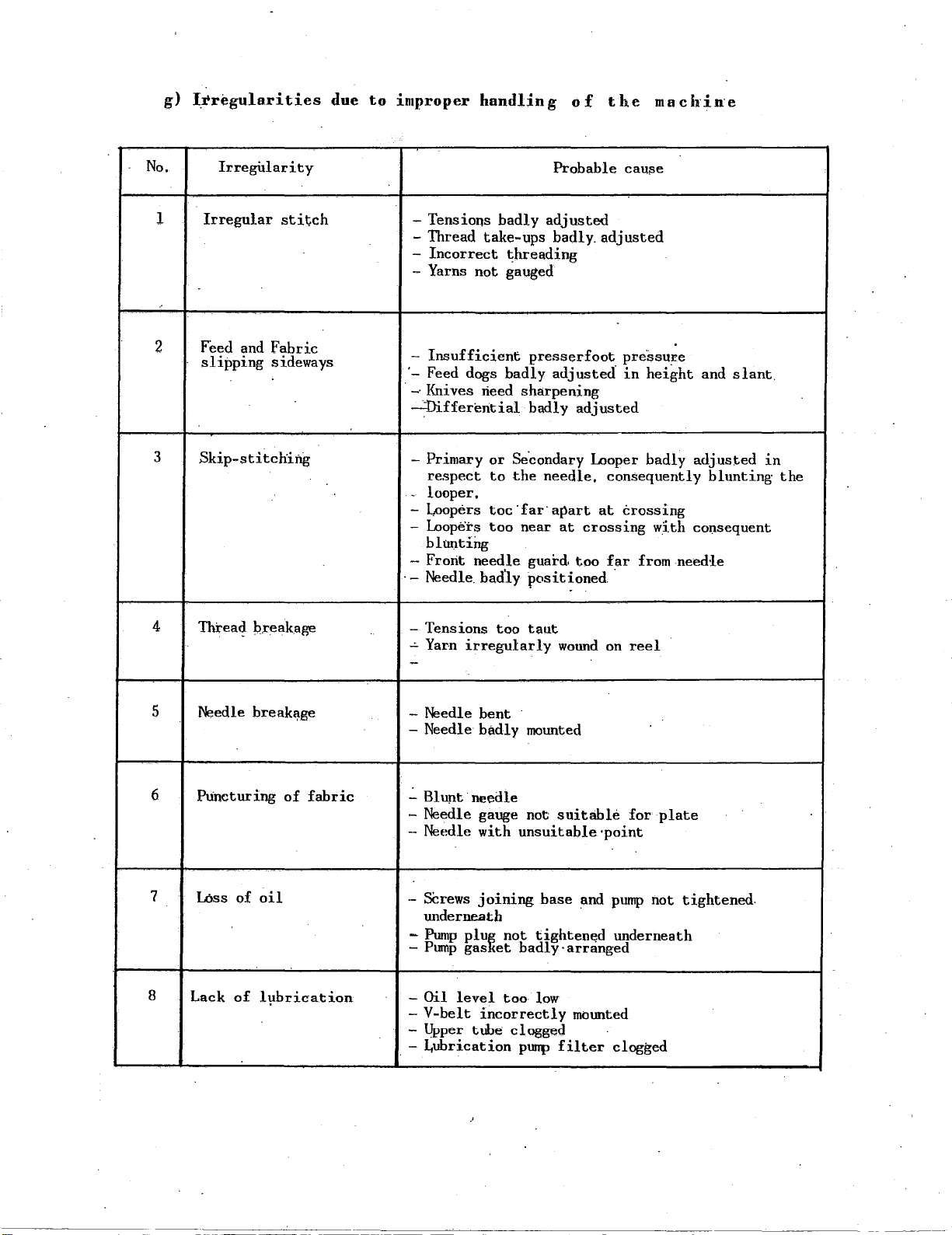

g)

I.rregularities

due

to

improper

handling

of

the

macb·in·e

No.

1

..

2

3

Irregitlarity

Irregular

stitch

Feed and Fabric

slipping

sideways

Skip-stitching

- Tensions

-Thread

-

Incorrect

badly

take-ups badly.

~breading

- Yarns not gauged

Insufficient

-

·-

Feed dogs badly

-Knives

~fferential

need sharpening

- Primary

respect

looper,

-

Loopers

-

-

Loope·rs

presserfoot

badly

or

Se.condary Looper badly adjusl:.ed

to

the

toc·far·apart

too

near

blUI:ttiilg

- Front

·-

Needle. bad'ly

needle guard

posit~oned

Probable

cau~e

adjusted

adjusted

pre.ssure

adjusted

in

height

adjusted

needle, consequently

at

crossing

at

crossing

too

far

with

from

co1;1sequent

needle

.

and

slant.

blunting

in

the

4

5

6

7

Threa?

Needle

Ptincturing

L6ss

Q.reakage

break~ge

of

fabric

of

oil

- Tensions too

-'-

Yarn

irregularly

-

- Needle

-Needle

.:_

.

bent

badly

Blunt needle

taut

mounted

- Needle gauge not

-Needle

-

SCrews

with

unsuitable·point

joining

wound

suitable

base

and

on

reel

for

pump

not tightened.

plate

underneath

Pump

plu~

not

-

-Pump

8

Lack

of

l1;1brication

-Oil

-

-

. -

gas

level

V-belt

Upper

incorrectly

tube clogged

Lubrication

tighten~d

et

badly-arranged

too

low

purrp

filter

underneath

mounted

clogged

----------~----~------------------------------~----------

--------~

Page 19

a)

Every

Ooy

Ill.

MAINTENANCE

.

1.

2,

3,

1.

2

•.

Clean

b )

Clean

looper

(\len

Clean

c)

Wash

Wash

the

Every

thoroughly

•

front

the

Every

tne

oil

tfle

pump

Week

Dtrec

3. Blow· purrp and

4.

Fill

with

fresh

d) Sharpening-the

Sharpen

block

request.

the

that

e) IJ.lst;.ruct·ions

feed

and

dismounting

c6ver

plate

inside

M-:mths

basin

with

filters

filter

oil.

knives

guarantees

using

for

stitch

and

of

the

kerosene

with

with

Knives

the

the

.removing_

formation

feed

carefully

cover

kerosent::

compres~ed

'Rimold1'

exact

plate

or

angle

i_he

elements

dogs,

clean

other

au.

cam

rear

containing

Knife

of

shaft

briefly.

and

front

the

fr-ont

commercial

Sharpener

sharpening.

needle

opening,

t-he

needle

cleanser.

and

This

guards,

movement

using

block

and

the

appropriate

is

supplied

primary

assembly.

on

-

Too~s

-

Pincers

-

Pincers

-

ExtractQr

It

re-assenhled

-

-

-

- The

-

-Carefully

necessary

is

absolutely

Reassamble

beave

·all

Cor.necting

e~graved

2

the

surface

position:ir'g

cap

and

th~

_par.t;

The

assembly·

must

he

supplied

type

S

0590/00

type

S

0459/00

S

0416/00,

necessary

kecpjng

flanges

locking

rods

on

the·

of

ccrmecting

on

the

hocly

pusit·ion

on

the

part-of

obser~e

on

request

·

IMPORTANT

that·,the

theh·initial·posjtion.

'G'

and

screws

'J'

surface

of

the

and

the

cC-nnecting

of

the

._of

the·

o.t'der

of.the

'L'

of

the

rod

comt(':c;ting'

connecting

handwheel,

of

only.

-rpain

-elements

'T'

in

the

connecting-rod

are

distinguished

head

of

'.J'.

rod

cep

rod.

rod

assembly·

of

of

Therefore

lubrication

cap

from

connecting'·

is

detern:ined

The two

'N'

is

give~

the

Cl.lf!

the

shaft-connecting

proceed

hole,

1n

their

oneanother

rod

'L'

by a cut

cuts

are

by

the

springs.

as

follows:

towards

own

hol~s.

and,

made-

on

t-he same

drawing

by

three

red,

the

.

tlie

lines

both

number

ar.e

bottom.

number

on

on

the

side

of

that

--------------

-------

----------

Page 20

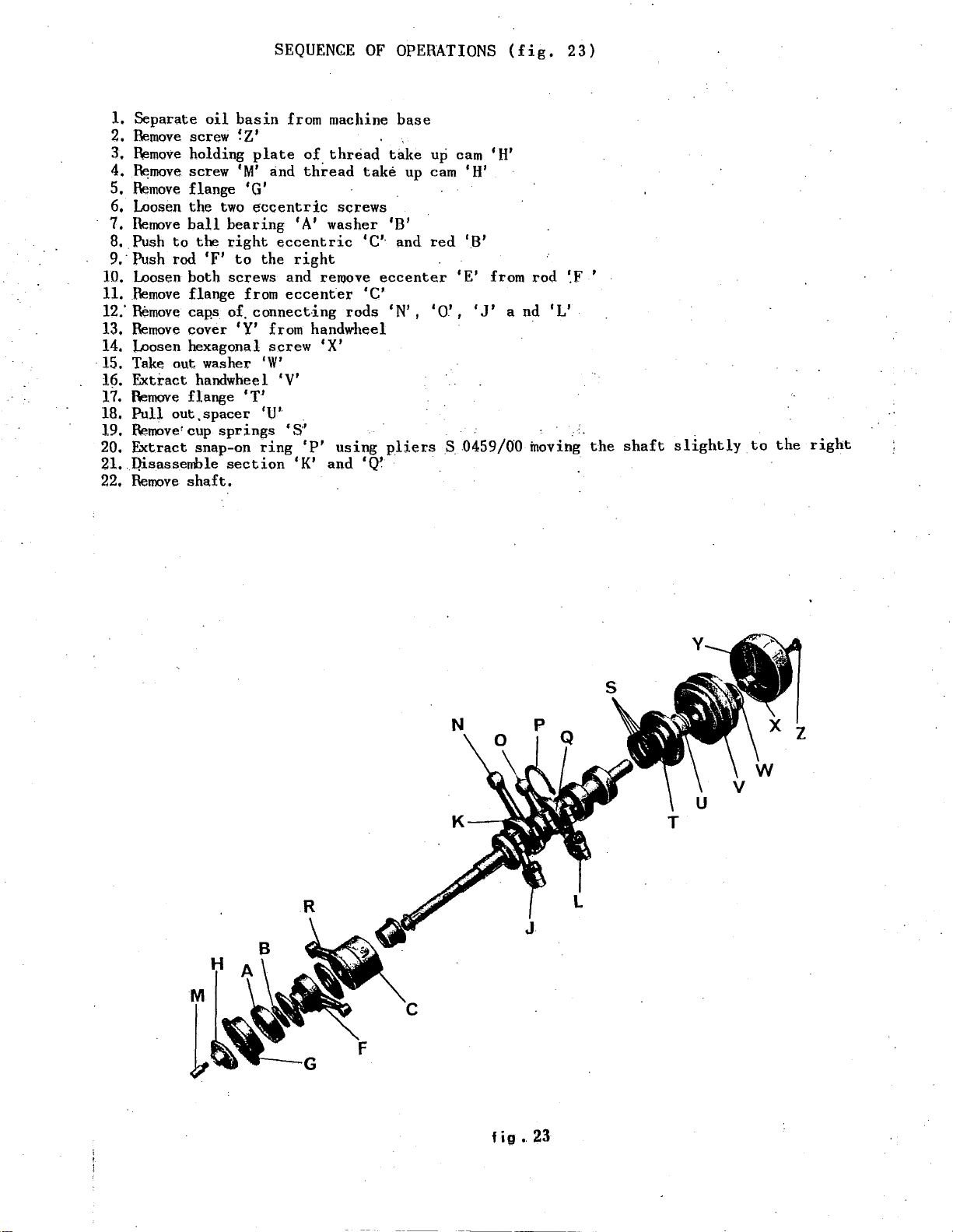

1.

Separate

2.

Bemove

3,

R¢move

4.

~move

5.

Remove

6, Loosen

7.

Remove

8,

Push

9.-Push

10, Loosen

11.

Remove

12.'

Remove

13.

Remove

14.

Loosen hexagonal

·

15.

Take

16.

Extract

17.

Remove

18.

Pull

19.

Remove'

20.

Extract

21..l}:i.sassemble

22.

Remove

screw

holding

screw

flange

the

ball

to

the

rod

both

flange

cap,s of.

cover

out

handwheel 'V'

flange

out

,spacer

cup

snap-on

shaft.

oil

SEQUENGE

basin

~Z'

'M'

from machine

plate

and

of

thread

OF

thread

take

OPERATIONS

base

take

up cam 'H'

up cam 'H'

'G'

two

bearing

right

'F'

screws

eccentric

eccentric

to

the

and

from

eccenter

connecting

1

A'

right

reroove

screws

washer

'C'·

'C'

rods

'B'

and

red

eccenter

1

N'

, 1 0'

'E'

,

'Y' from handwheel ·

washer

springs

section

'T

screw

'W'

1

'U'

ring

'S''

'K'

'P'

'X'

and

using

'Q'

pliers S 0459/00

'B'

1

from

J'

(fig.

a

nd

23)

rod

~F

1

L'

inoving

'

the

shaft

slightly

to

the

right

M

l

fig

•

23

Page 21

' -

. .

SPARE

PARTS

-CATALOG

- l -

. \

. i

'

'

!

i.

I

i

!

i

'

i

'

(

. !

..,,

;

!

I

I

.

Page 22

Page 23

a)

1 ·

The

parts

all

2 ·

In

order

of

each

3-Ttie

single

4

·The

. a number,

·by

capital

not

seaming

5

-The

numbers

these

1 -

If

the

numerical

·

If

2

the

is

known,

renee,

Introduction

spare

derived

conversion

var-ious

normally

catalogue·

parts

and

groups

from

to

make

group

tables,

TI1e

letters.

operations.

of

all

pacts

are

number

in'dex,

·ntllllher

the

inside

groups

group

groups,.

supp.lied

is

component

of

of a part

illustrated

HOW

catalog

which

Basic

the

comp:leted

illust~ated,

the

make up

Class

use

of

the

machine. ·

of

of

components

whose

TI1.e·

parts

with

part

is·

TO

is

made up

the

29,

this

catalog

the·

basic

illustrated

parts

the

with a general

parts

1s

.not. known .

index

canriot

cross-referenced

machine,

of

the

known,

of

USE

tables

THIS

of a series

basic

easier.

machine

be

but

machine

its·

drawiiJg

."

but

machine

numeric.a~

·

its

w~ll

CATALOG

of

and

the·

and

its.

on

each

supplied

by a nunher

can

be

and

listing

may

approximate

give

tables

index

sub~lasses,

separately,

supplied

index

be

the

its

table,

found

position

relative

illustrating

subclasses,

of

tables

are

are

cross-referenced

are

w·ith

an

upon

request

.

g1V1ng

the

at

the

page

once

page

asterisk

or

within

the

various

the·

latter

shows

the

position

illustrated

cross--referenqed

(*)

for·

special

cross-reference

pages

by

for

in

consulting

the

machine

easr.

which

refe-.

are

1n

by

are

the

a)

All

1-To

insure

have

2-Give

3·Give

4-

5-Indicate

'the

List

The

Rimoldi

gularity

along

b) Needles

1·

Only

catalog.

2-

The

needle

3-

The

gauge

calculated

4 -The

5-It

the

system

is

needle

parts

immediate

to

be

stricly

serial

th~

referenc~

the

full

,and corr(>lete

qu~ntity

Company

found

with

the

only

straight

system

inP,icates'

on

the

and

advisable,

required

HOW

shipment

ooserved·~

number

on

order

RIM

the

when

of

number

desir~d.

wish~s

parts

27

and

blade

gauge

for

needles

gauge

the

placing

(ex.:

produced

spare

average

of

are

TO ORDER SPARE

of

the

required

the

machine,

of

the·

name

re~1ired

of.

the

part,

part"

I M P 0 R T A N T

tobe

the'rteedle.

100

parts,

may

are

marked

alscr

ordersr

needles,

able

to

by

them

be

·used

on

diameter

stamped

to

gauge

analyse

•.

the

on

always

PARTS

spare

parts,

itse~f.

any

case

For

th_is

reason

on

the

·machines

shank

expressed·

the

-90,

of

envel!:!pes

state

clearly

system

in

the

of

the

needle.

hundredths

of

RIM

27).

.following·

breakage,

please

illus"trated

Rimoldi

the

remit

of a millimetre

system

instructions

wear

these

within

needle,

and

or

irre-

gauge

parts

this

of

Page 24

-------

----

Page 25

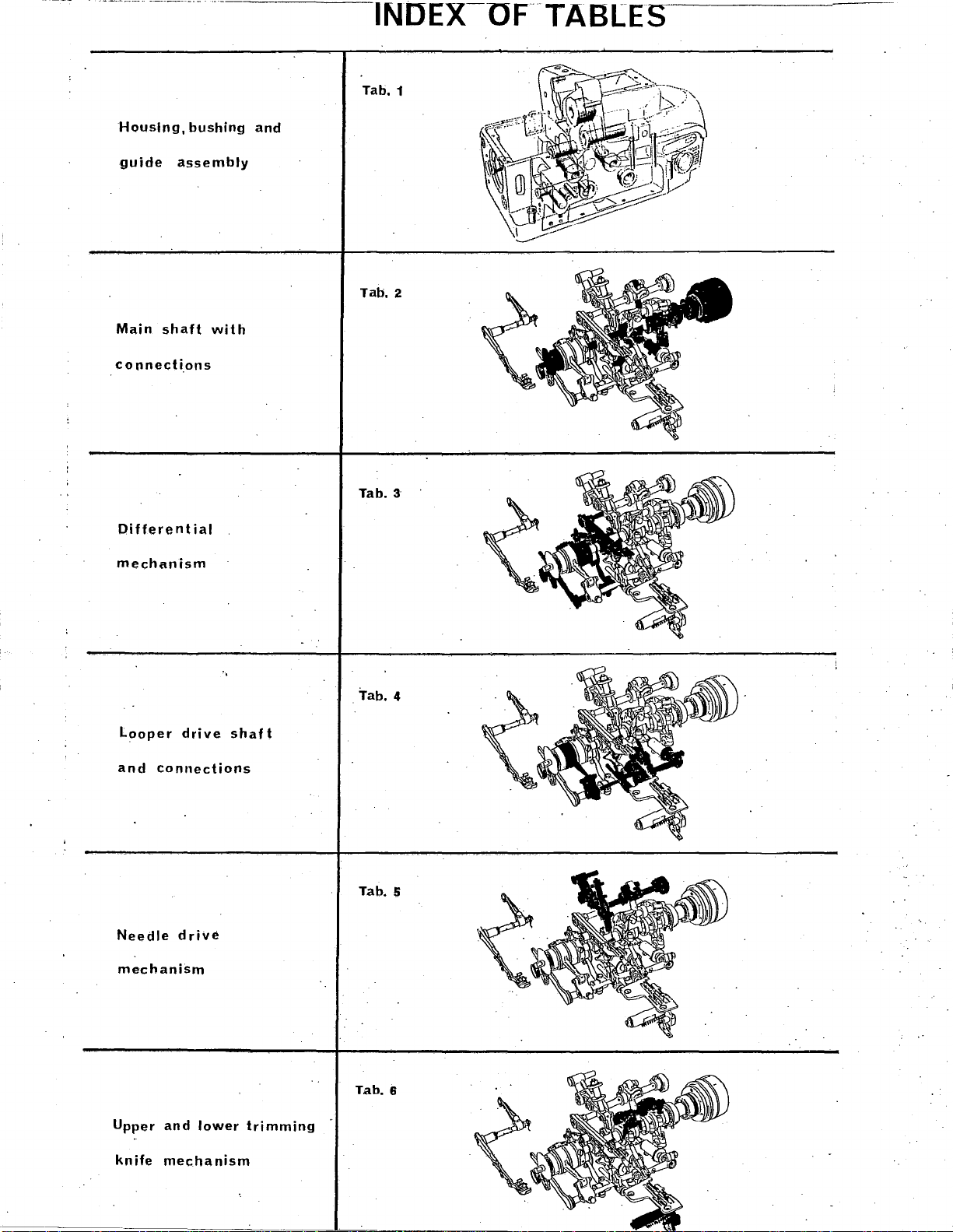

INDEX-OF

Tab. 1

nTABLES

Housing,

guide

Main

connections

Differential

mechanism

assembly

shaft

bushing

with

and

Tab.

Tab. 3

2

Looper

and

connections

Needle

mechanism

Upper

drive

and

drive

lower

shaft

trimming

Tab. 4

Tab. 5

Tab.

6

knife

mechanism

--------'----

Page 26

Tab. 7

Presserfoot

and

needle

Machine

work

Thread

and

plate

tensions

plate

cover

take-up

linkage

and

Tab.

Tab. 9

8

Oil-pump

oil

basin

Machine

and

knee

Thread

foot

pedal

and

mounting

contro·l

stands

and

brackef

Tab. 10

Tab.

11

Tab. 12

-rr-

··~-

~4

..

~JL_

.

.

Tab,

13

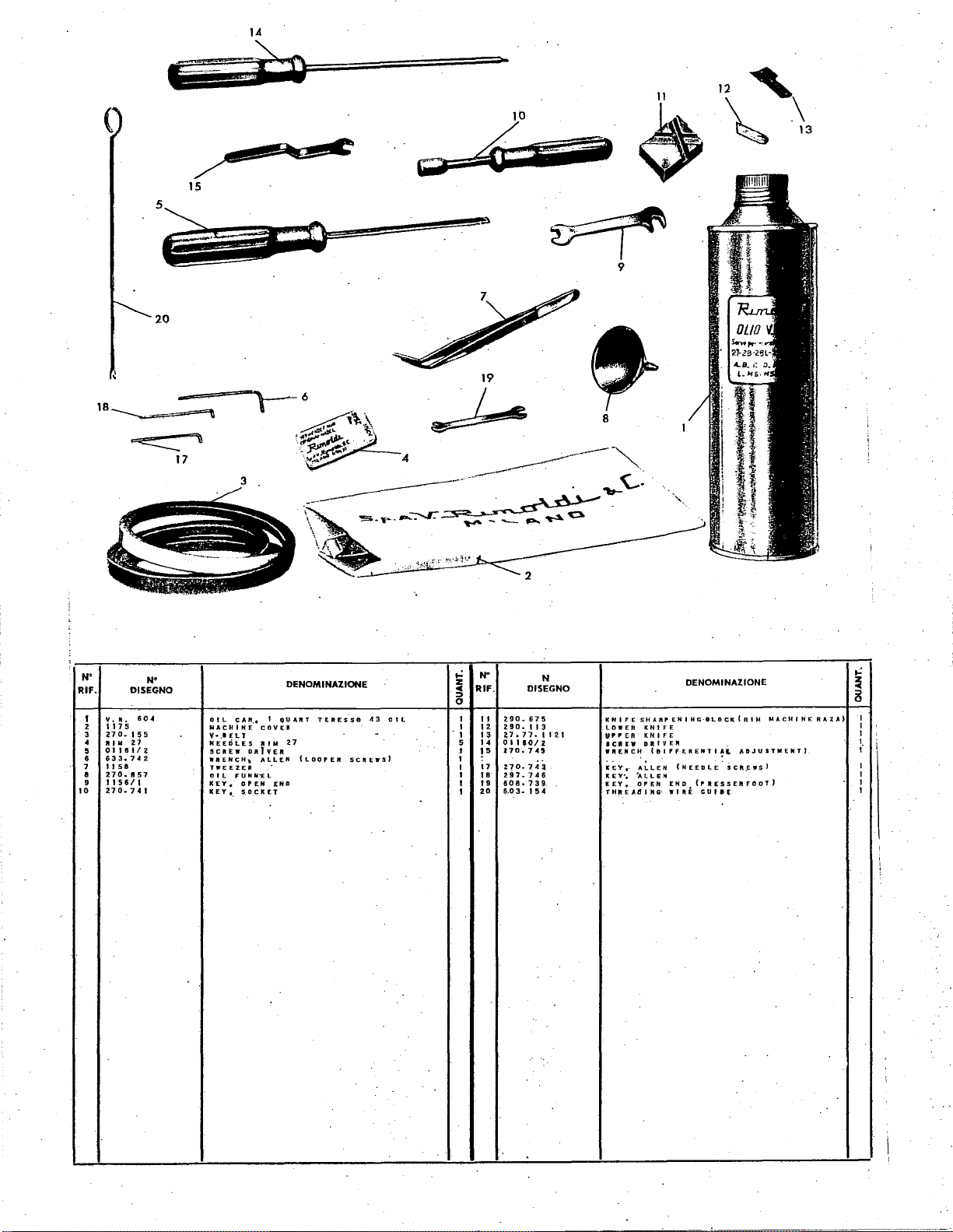

Accessories

Page 27

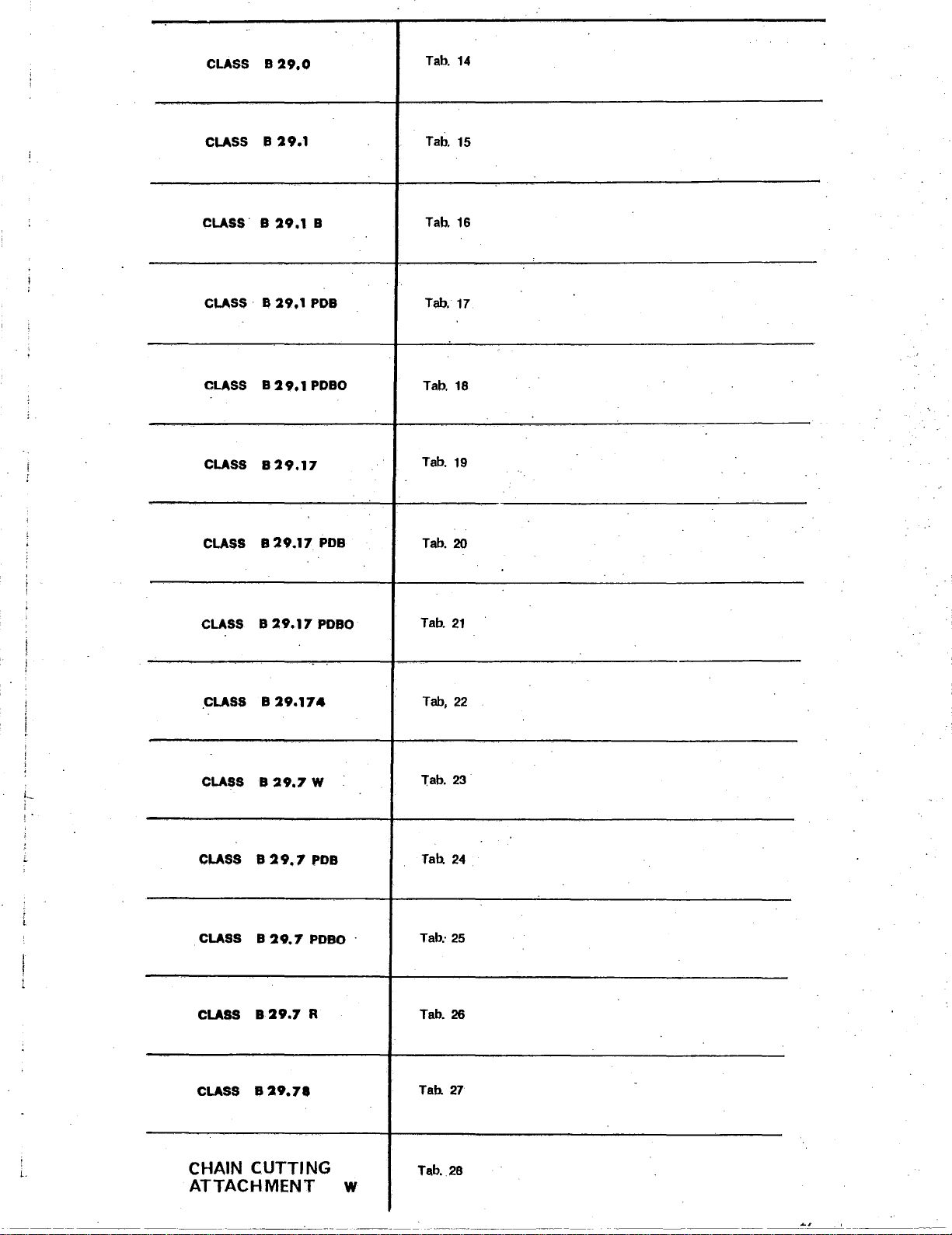

CLASS

CLASS

B

B

29.0

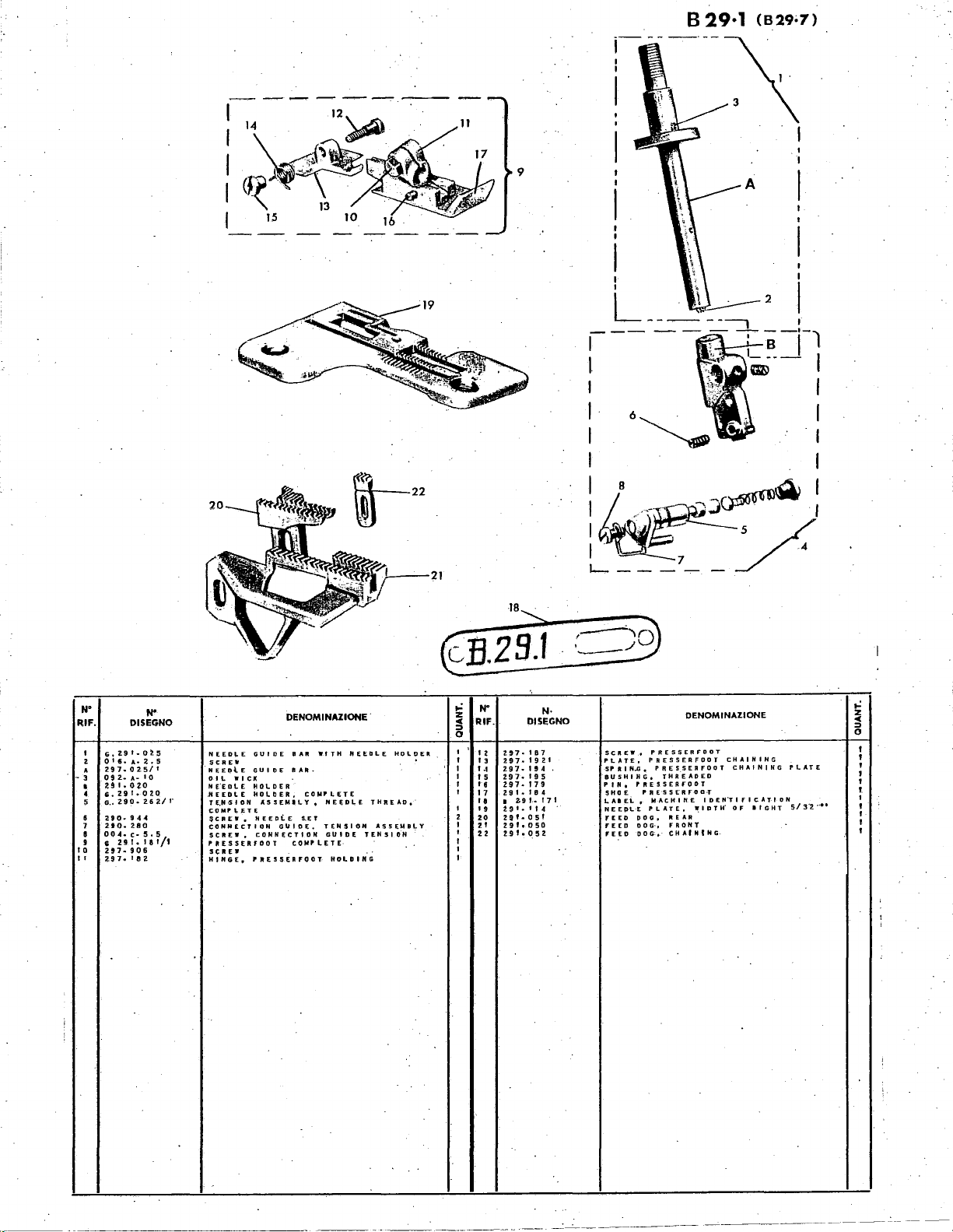

29.1

Tab.

Tab.

14

15

CLASS B

CLASS · B

CLASS B

CLASS

CLASS

CLASS B

29,1

29.1

29.1

829.17

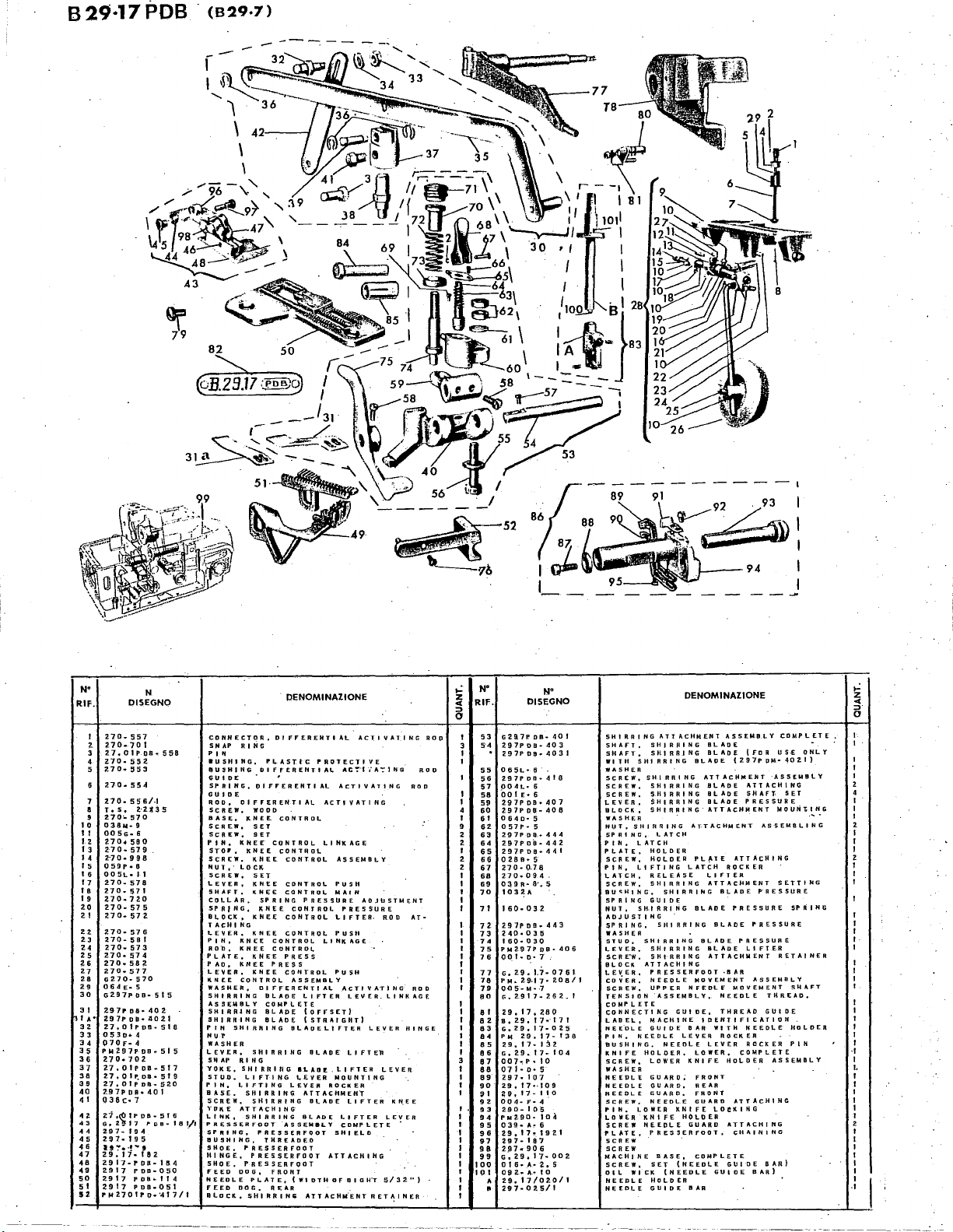

B

29.17

29.17

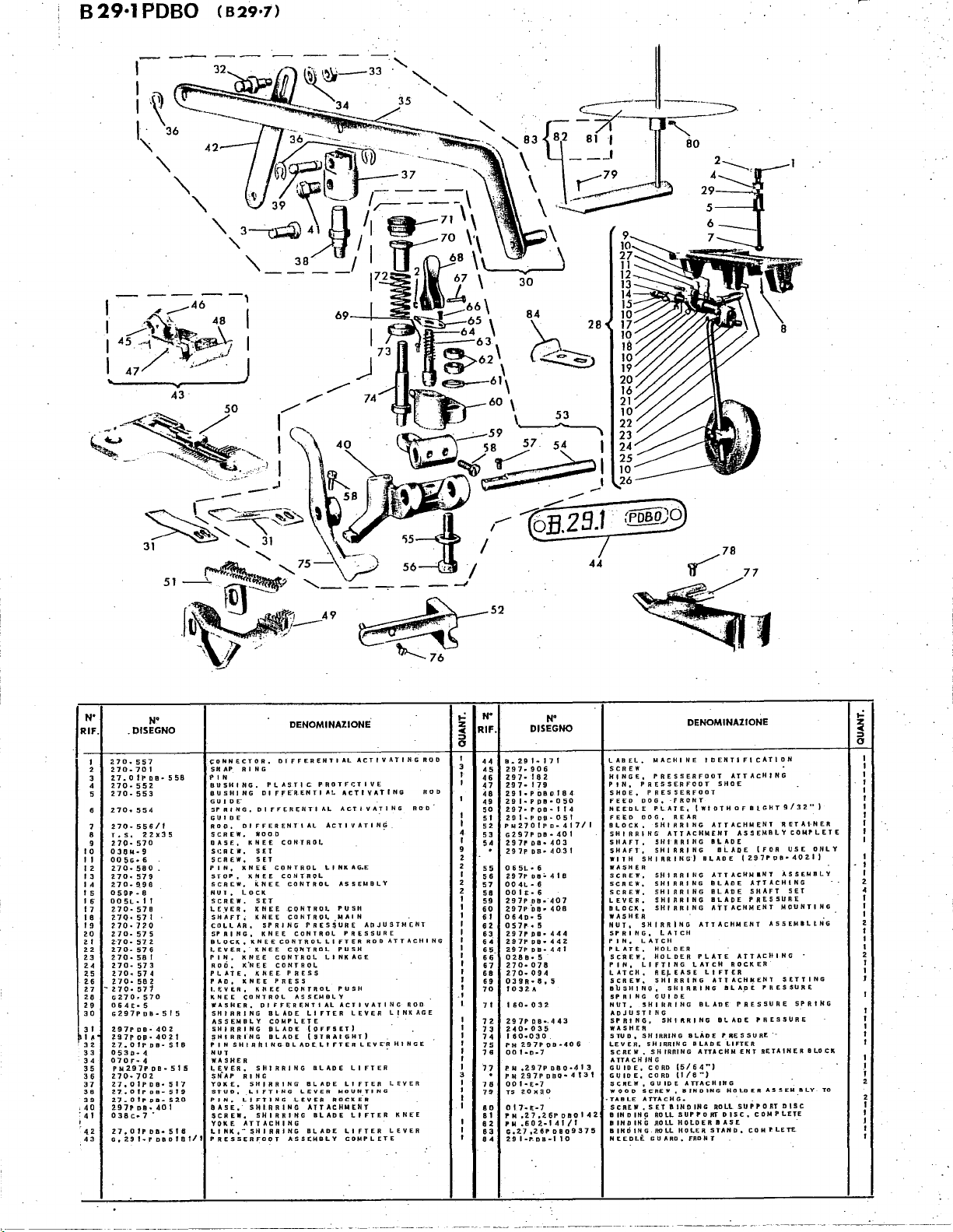

B

PDB

PDBO

PDB

PDBO

Tab. 16

Tab. 17

Tab. 18

Tab. 19

Tab. 20

Tab.

21

CLASS

CLASS

i

I •

CLASS

CLASS

CLASS

CLASS B

B

29.174

B

29.7

B

29,7

B

29.7

829.7

29.71

W

PDB

PDBO

·

R Tab.

Tab,

Tab.

Tab.

Tab:

Tab.

23

24

25

26

27

22

..

CHAIN CUTTING

ATTACHMENT

w

Tab. 28

Page 28

Page 29

11

N"

RIF.

t

2.

3

4

5

6

7

e

10

'

DISEGNO

Z7o.ote,

270.

097'/

27().051!1/1

2.70

..

057/1

270.2Ei8

• 7

o.

6.

Z7o.e

Ho.

''

Z70·0HIZ

270

..

042/3

3

H

z

...

I

lUSH

IUSHIHG

IU$HIHG

.USHI

.THREAD

0

ll

JOSHING

...

•

U5HIHG

•usHING

lNG

"EEOLE

UPPEA

..

lt.{-•'~'

HG

r·'JJINT'

GU1o~

G

AUG£

W

OJ~

woaK

Pl.ATl

(LEfT)1,DifFEIIENTI

(.RIGHT)

DENOMINAZIONE

SHAfT

•••

SHAfT

KNIFE

·

~UJ£5

fl&,D

"'tEVEL

.l.OOP.£11

LOOPER

0 J

LATCH

DIFFERENTIAL

SHAFT

STtCK

SHAFT

r

11

...:

N'

z

-c

RIF.

5

It

'

'z

'

13

z

z

'.

z

'5

.,

16

17

I

'

AL

SHAF'J

5

HAFT'

••

'9

'

'

'

DISEGNO

270-6H

290.351

290·9'.6

z·go.

3

~7

Z90·J54

PN.Z90-315

00

1.;

E•

090--396

270~

26

N .

PI

lUSH

PLUG

lUSH

BUSHING

t 8 5 C R

4

BRACKET

TUIE.

THREAD

DENOMINAZIONE

~

8

ZING

lUTTON

WI

CJt

.

JOSHING

IU'SHING

NEEDL~

COVER

lEY

ER

HOLE

LOOPER

IJtACKtT

(It

E

ATTACH

~R)

STAll

E'W

lNG

lNG

PUSH

0

ILl

THREADED

CHAIHSTITCH

fRONT

FRONT

ll

GUIDE

H

rLATE

z

I

I

I

I

I

IN

'

I

I

-

Page 30

·--

~1-·-.

_,

, I

N"

RIF. !liSEGNO

I

t

AI

lei

•

(c)

I o I

(E)

(G)

2

3

4

5

6

7

B·

9

10

11

I 2

N"

~10-

PW

i7D~012./2.

2.70rft6/2:

270-0$1/2

ZJ0.060/1

H0-05~/1

2.10·

7Q7

270·

70

4

HO•

70

5

~70

..

620

270.

61

.4

27.0

..

001/1

270.612

270-981

270~

608

270,

61

0

270-617/1

270

..

999

009/~

MAIN

SHAFT

,

CONNECTING

CONNECTING

CONNECT J NG

UPPER

CR

AN~

CR

AN

1\:,

I. 0 WE R

II

ALL

IEARfNG,,

SNAP

RING

JP R IN

0

WASH

FI,.ANGE,

SPACER,

p

IJ

ll

y •

DRIVING

WASH

£It,

$HAFT

SCREW,

ATTACHING

COY

Ell,

PULLY

STUO

_8ALAJ.ICERS,

SCREW

"ATTACHING

DENOMINAZIONE

CQMP

R

DO,

.ROD,

R D

D,

LOOPER

LOOPER

RIGHT

E;

It

RIGHT

HANDWHEEL

POSITIONING

MAIN

I.,.ETE.

flEE~(,.[

UP P Eft

UPPER

,

UlLY

PULLY

5 HAFT

IALANCERS

&

kN

•••

If

LOWE

OVER

TO

t

SHAFT

A

I. 0 CH E R

MAIN

,_:

z

RIF.

:::>

""

0

I

I

I

2 1 6

I

1

2

1

4

1

1

I

I

1

1

1

2

4

N"

OIOH

1 3

2.70

14

004

15

092p

270-615

1 7

1 B

270.010/1

074A.I2

19

290.308

zo

073N

21

ao.

22

270.938

23

24 0 17

25

00

01Do-11.5

26

2704613

H

270-709

L

270.062

29

30

017.c-3

DISEGNO

..

..

975

..

£7

..

•.

307

c;4

I E• 1 0

4.

I3,7

l5

IO

N

SCREW,

SCR

E

ir,

SCREW,

WICX

01~

RING.

BUSHING,

I

5

W~SHEJ

THREAD

CAN,

WA$Hfift

SCREW,

SCR

E

!',.

5 CREW

..

SCREW,

'sc11 EW,

WASH~R

IIAI..L

BEARING,

CONNECTION

SCREW,

CONNECTING

CRANK

ATTACHING'

0

I~

SHIELD

MAIN

TAICEUP'

ATTACHING

SHAFT

MAIN

COrlNECTING

MAIN

sHAFT

CONNECTING

BALL

•

G'u

THRtAD

DENOMINAZIONE.

aoo

CAP

CDNNECT.ION

(lEFT)

SHAFT

zgo

..

JOB

BUSHING

ROO

P IN

FLANGE

ROQ

c

UP

·~

S~A.C

CAN

BEARING

LEFT.

IDE

lAKE

1

I

NG

HOLDING

GUIDE

,_:

z

:::>

"'

0

3

B

1

4

4

2

I

1

1

I

I

1

2

I

2

1

1

2.

'

NOTE:

ORDERING

WH[N

fT

•

0 R D

ER

•(ll'T

THE

REMOVED.

Is

NECESSARY

THE

ER

ROM

RAC~

AN

BALL

OF

lEAR

TO

NU~ERAl.

THE

lNG

REF.

INDICATE

STAMPED

~~.\RINGS

ON

!

NO.

ON

THE

·.

'

..

·--

--------·

_,

_____

~

..

----

·-

------

Page 31

28

1

~~E[

\

61

60

59

13

N"

RIF.

~

(j

7

0

9

10

II

12.

13

14

15

16

17

18

t9

20

21

22

23

24

25

2.6

l1

28 , ...

A

B

2.9

30

31

32

33

34

35

DISEGNO

""'·

2.70-0.11!!

297

..

051

297

..

0511

2.70~

977

270

.. 6 40/1

Q9;!.a-1

2.70

..

937

272·8·052

270.611/1

270.979

070.J,1.4.5

270.035

4030

..

06

007.c

..

270.048

07J.c

..

~70-0541

0 7 t

..

M·

270

..

047/1

070

..

F•

057_-

G•

270

..

975

270

..

039

092-o071-H·S

270.036/

270

..

935

026·

C•

270

270.046/1

270-.038

?..70·

040

270

..

031

092-o-6

osz

..

o-12.

270-041

250-

471

017-1::.8

ll

B

5.

4

4

7

..

N"

14

5

t

038/1

FEED

LEVERS

FEED

DOG,

fEED

SCREW,

GUIDE

1.£Y[R

OIL

SCREW,·

FEED

ECCENTRIC,

SCREW,

WAS}!ER,

BUSNING,

COl-lAR

SCREW,

LINK,

WASIIER.

STUD,

WASHtA

GUIOF1 INCRCASE

WASHER

NUT,

SCREW,

SHAFT

OIL

WASHER.

Bt.DCK,

~~=~~~

ADJUSTABLE

COMPLETE

S L I D E

SEGMENT,

RQCKER,

SHAFT,

OIL

(HL

SHAFT,

SCREW

SCREW,

SETTING

SCREW,

REAR,

DOG,

REAR

ATTACH

flLOCK,

WICK

SETFEEO

DOG~

CHAINING

ATTACHINI.i

REAR

REAR

FOR

REAR

DIFFERENTIAL

ATTACHING r IN

CLAMP

FEE~

WICK

FEE()

ATTACH

D I F F•E R

1

DIFFERENTIAL

FEED

FEED

WICK

WICK

DIFFERENTIAL

LOCk

sfJTCH

DifFERENTIAL

DENOMINAZIONE

REAR

fEED

RIGHT

DIFFERENTIAl

LEVE~

ECCE~TR!C

FEEP

DOG

LIFTER

REAR

FEED

L£V.ER

FEED

LEVER

COLl-AR

rt£0

LF.VER

SE6MENT

DIFFERENTIAL

27.0.0541

270.047/1

~EVER

ECCENTRIC

l.E-VER

SLIDING

WASHE-R

ntrrERENTIAL

£NT

I A L

AD

LEVERS

LEVER

ROCKER

041

REGULATOR

AND

SEGMENT

2.70.

DOG

~IN

F.::ED

LEVER

Ll

NK

SEGMENT

270.935

ASSEMBLY,,

J U 5 T I N G S E G M

ADJUSTMENT

FEED

R~CKER

ECCENTRIC

FEED

LINK

..: N"

~

RIF.

N"

DISEGNO

DENOMINAZIONE

5

37

064

..

r-5

36

270~99~

39

270-

~87/1

40

o7J

.. A ..

PM

;no-56?11

2.70-288/1

270

..

;567

065-D·6

270-568

270

..

Z-90

..

290

..

270

..

070

..

017-c-4.5

270·

270-0;13

270.

270.034

00

5.

270-997

270

..

270-

2.70-978

2.97-050/1

092.-D-16

270

..

~70

..

no.2s111

004

.. L ..

PM

290

2.90-733

290-732

290.734

270

..

004

......

003·A•4,5

290·715

028-

702

"703

037

984

B•

045

960

L•

566/

641/l-

2.49

2.50/1

032/1

A• 5

a.

.

3

II

I

7

..

732

6

41

I

4

42

I

43

I

44

I

45

I

46

2

47

I

2

48

2

49

I

50

I

51

I

I

53

I

54

I

55

I

56

I

57

I

58

I

I

•59

1

60

1

61

1

62

63

1

64

1

EN

T

65

1

66

1

67

1

1

68

1.

c;

1

p

1.

71

7 2

73

•

1.

74

75

76

WASHER

SCREW,

DIFFEREfiTIAL

STOP.

UPPER

DIFFERENTIAL

l.E_

17

'\

i-

1.·~

16

~,·.~

45

•

0:!'~c

-;.

~·

I

I I

49

.....

/

.

,.,

.

..-:.-·

1~\

..

50

i!

t'

1

3.-.

26

48

19

36

47

:

fL

14"'-o

I

__

;.-

:

I

I

8

121\

I

h-·.~

3

43

if!

r-.

3

15

..

....

--13

N'

RIF.

7

9

10

c

n ~70-0D3/t

II

I 2 0 I

13

14

15

16

11

IS

19

2.0.

2-l

22

~3

2

3

4

5

SA

6

8

I

092•P•16

073.

N•

270·

070

no.oG4

27

..

2.77-0745

270•0•

270-0751

270-069

Z50·471

290-068

o-.270·065

071·e·S·

270·056/1

270·065

270•

!]7.4/l

6·

1!!1•

016·•·2.5

270·067

092·8·1

250.314

osz

.. o-s·

90·298

290·312

PM

..

290•JI3

2.90-363

290

..

412

290

..

923

DISEGNO

10

(174

4

LE;VER

SET

LEVER

• I

,.:

z

c(

::::>

0

·1

~I

I

I

I

I

I

I

J

I

I

I

I

2

I

I

I

I

2

I

I

f

1

2·

I

1

I

,.:

N"

OIL

WICKS

WASHERS

PIN.

UPPER

SHAFT.

~OOP£R§

·"

LOOPER • UPPER

~DOPER,

SHAFT,

SCREWS,

HOLDER.

GUIDE.

COMPLk.TE

WASHER

BUSHING,

I.ATABLE)

GUID~.

HO~PtR,

SCREWS,

SCREWo

SCR£.,

LEVER,

01'-

WICK

SCREW,

OIL

WICK

lEVER,

CONNECTING

DRIVE

CONNECTING

PIN,

5AFETYSTYSTITCH

CUP

SfAING

SCREW,

DENOMINAZIONE

LOOPER

LOOPER

LOOP~R

LOOPER

~OOPER

UPPER

WICK

LOOPER

R~U.

ROO

~EVER

{SMALL

{tJl

..

IHp)

LOOPER

LOOPER

lOOPER

LOOPCA

SETTING

LPOPER

RETAINER

UPPER

SAFETYSTITCH

SETTING

EY~)

HOLDERS

OSC.ILLATING,

DRIVE

OSCILLATING

LOOPER

LOOPER

LODPE·R

UPPER

UPPER

LOWER

LOWER

CLAMP

LdWER

UPPER

UPPER

UPPER

UPPER

LOOPER

SET

OIL

UPPER

ATTACH

J:AT~":''!"ST!":':;:H

ECCENTRIC

ROCKER

(R[GU•

GUIDE

DRIVE

LOO~ER

PIN

z

~

0

2

2

I 2 6

1 n

I

1 2 9

1

2

I 3 I

1

I

I 3 8

1 3 9

2

I 4 I

I 4 2

I

2

I

I · 4 6

I

I 4 8

1

1 <

..t-

· 5 I

I

w

RIF.

24

25

28

30

32

33

34

35

36

J1

40

43

44

45

47

4.

50

52

N

DISEGNO

Z9D·954

PM

290•071

297·

055

297·281

HO·

071

2~0·

075/1

290·

075/2

290·

352.

290·356

290·

360

0.~90·361

290·716

297·

362.

290•022

0 7

2•

II• 6

OH•C:C·

e

059•G•6

2~0·700

290·

944

290·

124

G,

297•

068

092·c~2

092·8·2

0 1 7 • F • I 1

Ol7·c

..

4.5

290

..

703

028•

A•

5

092•0•

16

270·

..

975/1

09

2.

o

..

I I

OENOMINAZIONE.

WASHER

S"AFETYST

ECCENTRIC

!!USHING,SP.ACER,FOR

SAFETYSTITCH

l.QOPER,

I,..ODPER,

8

US

COLLAR,

P

SHAfT,

WASHER

PIN,

PIN•

WAStiER

WAS

NUl,

SNAP

SCREW,

SCREW.

LOWER

OIL

OIL

SCREW,

SCREW,

l.EVER

NEEDLE

SCREW,

OIL

SCREW,

D

ITCH

LOOPER

HOLDER o COMPL.E·TE

SAFETYSTITCHLOOPER

!,..DOPER

SAFETYSTI:rc.H

SAFETYSTITCH

H I N G o

s·L

f T 1

ECCENTRIC

IN

SAFETYSTITC:H

ECCENTRIC

5AFET'I'S11TCH

II

t:

R I

Cl.-AMP

LOWER

R

lNG

ECCENTRIC

CLAMP

LOOPER

WICK

WICK

UPPER

LOOPEP

SAFETYSTITCH

PIN

SET

!tEARING

SETTING

wt.cK

SAFETYSTITCH

It.

WIcK

HOLDER

E.

D I

PJr.

SETTING

LOOPE.R

LOOPER

DRIVE

LOOPER

HOLDER

PIN

290·716

COLLAR

LOOPoEI1

ASSEMBLY

DRIVE

LOOPER

LOOPER

HOLDER

IIU.SHING

DRIVE

DRIV-E

LOWER

HOLDER

SETTING

Page 33

N•

RtF.

I

2

~

4

5

•

7

•

9

10

II

I 2

q·

14

I 5

6

I

I 7

I 0

I 9

270•13111

r

M'

Plto2.70•

no-·13·2

?70-

728

H0·027

270

..

933

270·713

2..70·006/1

073

f•

270

..

719

007

c

270o(J07/I

270·975/t

270·

'34

D•

092

071

E•

001

G•

210·

708

250

..

708

DtSEGNO

..

N"

13:7/1

9

t '

0 D I L

5

10

PIN

J.EVtR 0 NEEI)LE

IUSHING o NEEDlt

S II;

.,ASHtR,

N l,l

WASHER

SHAFT

WASH~

COLLAR,

SCREW.

LEVER,

SCREW.

P I

WASHER

SCREW,

llALL

NEEDLE

A£

,·,

H,

o

NEEOLE

W.,

POSITION

o

R

Ht:EDLE

WICK

IE.AR

SET

P~SITION

o

LOCK

NEEDLE

SECURE

CL-AMP

"NEEDLE

Ct.

AMP

SECURE

lNG·,

BEARING~

DENOMtNAZtONE

ROCKER

I.

EYER

fORk

LEVER

NE;EDLt-

a,.~VER

Nf;,Dl.E

AND

LOCK

OAR

CRANK

NEEDLE

2.

•••

DRIVE

WA;HER

NEEDLE

DRIVE

70·

07

•••

COLLAR

270·007/1

•••

NEEDLE

·PIN

"OCKER

NEEDLE

•••

I

DRIVE

P j N

A

OCKER

GU

I 0 E

OAR

GUIDE

CRANK

.SHAFT

7,1 g 2

E • 5 I

SHAFT

C

fl.

AN

K

LEVER

...

•

,.:

~

8

I

I

I

I

I

I

I

I

2

t

I

I

I

I

.I

I

I

N"

RtF.

20

.n

A

•

22

23- :

24

25

26

27

20

29

30

3 I

32

33

34

N"

DtSEGNO

250·

708/f

.

ore

••

2.

G.297•0Z5

290•

OH

290·

02SII

27

:

RIM

2.90·

944

:no-130

. 0 9 2

o • I

: 0 I 6

•·

2.

270•

IU

••

5

ou

UO·

133

017

c.

3.

001

<·1

270ol!

I

092

u.

1 r 0 I L

092

A• I 0 0 I L

DENOMtNAZtONE

i

8