Page 1

FI

( 1 .

~-'

J

I

111

II

:

II

I

SPARE

PARTS

class

and

subclasses

B

CATALO

27·77

GUE

Page 2

-

MACHINE

II

-TECHNICAL

I I I -

TECHNICAL

-

a -

Poaitioning

b - Assembly

c -

lubrication

d-

Assembling

e -

Positioning

f -

Setting

!I

- Needle

I N T R 0 0 U C T I 0 N

IDENTIFICAtiON

DATA

BY

SPECIFICATIONS

I N S T R U C T I 0 N S

INSTALLATION

of

of

of

Thread

Head

TransMission

and Ad'

of

Presaerfoot

front

Cover

Take-up

l N 0 E X

MACHINE

AND

TIMING

juatlng

Plate

Adjustment

CLASS

Sewing

Arm

Parts

Page 5

II

II

Page

II

II

II

II

II

I~

II

I~

II

I~

5

5

9

9

9

9

9

II

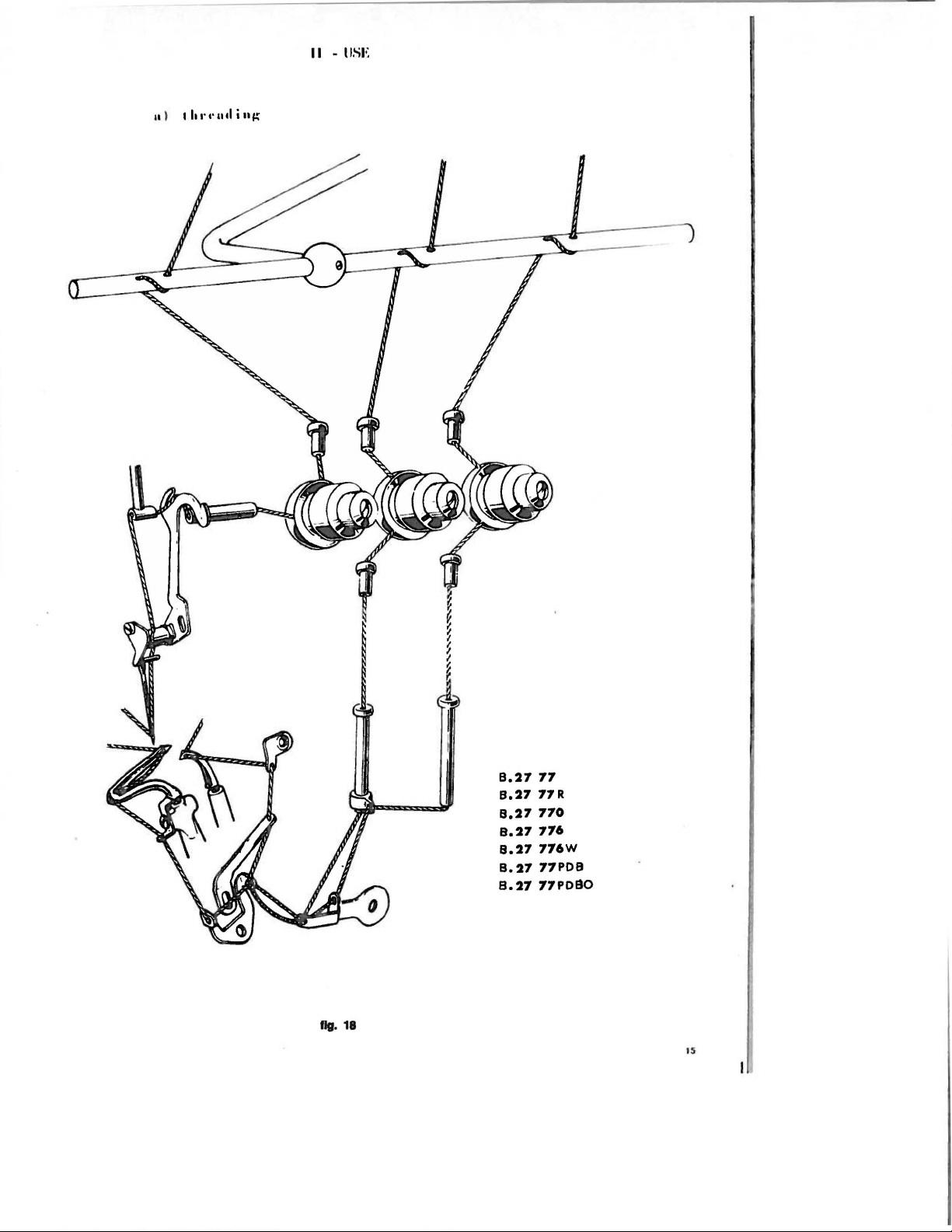

- U S E

a-

Threading

b - Changing

c -

Setting

d -

Setting

e -

Stitch

f -

Adjustment

g-

Problems

II I

-MAINTENANCE

a - Every

b - Every

c - Every

-

Sharpening

d

e

- Changing

-

Introduction

a -

Procedure

b -

-

"

Parts

All

a -

Needles

b -

Ill

- T

t~e

the

of

Length

due

Day

Week

Three

of

SPARE

HOW

TO

TO

HOW

A B L E

Needle

Presserfoot

Tensioning

Adjustment

of

Seam

Width

to

improper

Months

the

Knives

Main

Shaft

PARTS

USE

THIS

ORDER

s

Discs

handling

(if

required)

CATALOG

CATALOG

of

machine

II

15

II

15

II

17

II

17

II

17

II

17

II

17

II

18

II

19

II

19

II

19

II

19

II

19

II

19

II

23

II

23

II

23

II

23

II

23

II

23

II

25

OF

IV -NUMERICAL

INDEX

PARTS

II

72

Page 3

INTRODUCTION

3

Page 4

-

MAC:

III

Nt:

llli':Nl'll'lf.A'I'I

ON

a} lDENTlFlCATlON

l-Each

2-

3 - The

-

Class

-Serial

The

Class

held

Ser

needle

Machine

by

i a I Number

plate.

or

Sub-Class

Number

or

two

NUMBERS

is

identified

Sub-Class

screws

Number

on

is

punched

Number

the

by;

base

Is

on

indicated

of

the

the

machine.

machine

on

base

the

name-plate,

next

to

the

The

machines

the

following

I-

Straight

2 -

Greater

3-

Differential

ij-

Push-Button

5 -

Stitch-Length

6-

Differential

7-

Width

8 -

Speed:

and

9-

iO -Motor:

II

-Outer

12 -Weight:

manufacture.

Lubrication:

and

manufacture.

II -TECHNICAL

depicted

general

Needle,

Needle

of

Bight:

5000

1/3

HP

dimensions

approximately

system

and Upper

can

be

Stitch-Length

Variation

Feed

1/8

to

6000

by

pump.

to

1/2

of

in

this

characteristics:

Ratio

11

RPM,

machine

catalog

RIM.

Looper

regulated

adjustment.

from 7

3.5

to

23/6ij

depending

II'P,

depend

ijij

lbs.

to

head:

DATA

27-

Stroke.

while

to

I and

11

,

lng

BY

MACHINES

are

overedging

Thickness

machine

28

stitches

also

on

the

on

the

11

12

x

9.3/3

90-100-110.

is

running.

per

up

to

ij-J.

type

of

type

of

11

•

machines

inch.

application

application

of

5

Page 5

MACHINE

CLASS

SUB.CL

B.

17.77

B.

17.77 R

OR

ASS

No. ol

threads

B. 27.770 3

J

J I

Ill -TEC:IIN I C:AI.

TECIINIC

Width

ot

bigl•l

64"

8-13

I

8-23

64"

5/ 31-13 1

64"

AL

CIIARACTERISTICS

No.

of

:-.titches

pen

Knives

inch

1-

10

yos

7-10

7-20

yos

Sl •I·:CIFI

yos

C:A

Tl

SPECIFIC

APPLICATIONS

CIN

S

A

TT

For

all

operations

high lah and wi

Same

as

obovo

for

Inserting

seam

Elttro bulky Jcnits

reinlorcomont

ACIIMENTS

requ

iri

d11t

Light

but

with

otlochmant

ng

very

tope into

B. 27.771

B. 27.776

B. 27-776/

B.

27.77/PDB

B.

27.77/PDBD

WI

2

3

3

3

3

9-'32"

21

/ 64-23/

21/64-23/64"

3/16-1/4"

3/16-1/4"

64"

up

7-20

7-20

to

7-16

7-16

Busts

28

yos

yos

yos

yos

Edge

no

guide

Electric

cutter

Shirring

attachment

Shirring

attachment

chain

and wo i st

stitch

Attaching

Attaching

Cloth

In

curtains,

Cloth

in goneroJ

roinlorcemont

ornamental

zippers

zipper

genoral

etc.

cord

)

tape

bands

ornamental

on

pants

on

pants

(bed-spreads

with

insertion

folded

and

~

of

6

Page 6

INSTRUCTIONS:

_

INSTALLATION

_ USE

-

MAINTENANCE

FOR

AND

TIMING

7

Page 7

a )

l'u

s i I i 1111 i 111-:

Aftur motor iu mounted

I.

Soc

that

machine

2.

Soc

that

machine

11

cradle

rests

I.

INSTAI.I.ATIUN

I'

l~t•tJtl

on

Gldnd, proceed as

IS

square lo

evenly

on

dll

follows:

tdblc

lop (fig. 1).

four rubber i

ANII

TIMINC;

nsulators.

b ) ,\ s

1.

2.

Make

and

3. Check lho

11.

Level the head

machine

5.

Lock

NOTE:

clockwise,

clockwise

1.

Unscrew

2. Pour I ,775

funnel 8.

Please

Pts.

3. Check oi I-level

be

glass

II.

Replace

5. Put a

rod

6.

Start

culating

crease

NOTE:

reservoir

commercial

Insure thorough removal of

cing

.,

,.

Ill

h I

~

"

Line

up

pulleys.

important

that

dr i ving

(fig.

sure

squarely

i l wi

the clamp

cradle

the

counter

The driving

c ) I.

II

..

bear

of

oil.

between both red I ines

G.)

and

few

and

upper looper bar

machine slowly

(check spyhole A).

speed

Change

fresh

boll

I)

that

back

on

lop

that

the

ll

nol sli p from

tension

of

the

motor.

of

bolts.

nuts

and

the

rotat

ion.

I' i I '

II I II

cap

A.

Pts.

TERESSO

in mind

(red

tighten

drops of

gradually

oil

and

filters

cleanser,

oi 1.

every

..

I I '

It

II

,..

Ill

i

,..

square

to

machine

of

drivrng

of

pump

driving

of

the

the

machine

of

wheel

of

pump-pulley runs

II

113

that

tip

cap

A.

oil

on

before

makin,9

to

three

with

and

belt

pulley.

belt

the

bell

by

the

machine

the

machine runs in a

(

I'

i ~ . 2

oi l

into

the

tin C holds

of

oi 1

of

oil

the

needle clamp guide ,

starting

sure

After

normal working speed.

months. Rinse

kerosene

replace

cleanser

s i

II

II

and

motor

rides

firmly

It

is

is

I ined

pump

very

up

pulley.

loosening

by

means

of

cradle

bolt~

in a counter

machine using

2,012

indicator

level i ndica t or

must

machine.

that

oi 1 is

or

fresh

other

repla-

cir-

out

oil

5 minutes,

with

before

so

the

the

in-

fig. 2

d )

Ass

t•

m h I i n

NOTE:

The

1.

Timing gauge

-

S.

1552.00

-

S.

1555.00

2. Preliminary Disassembly

-

front

side

main

cover

thread

cover

Feed

- both

-

-

A'

following

required:

for

all

for

operation

plate

take-ups

plate

Dog

and

.ttl

j u s 1 i n

operations

operations

n. q

of:

of

lower looper holder

(casing)

of

serve

except

(fig.ll).

needle

I! s t•

w i n

to

adjust

operation

movement

1-:

r a r t s

the timing

n.ll

(fig.ll).

of

the

machine:

9

Page 8

3)

SElliNG

-if

-lhu

-if

H[IGHT

the noodle

noodlca

the

respective

dislunce

lhc lop

when

(fig.3)

usiny

fig. 3 to

screw

udj

A.

surfucc

tho

ustmenl

needle

OF

NEEDLE

BAR

plate

is

in

must be

and

obtain

centred

noodle holes of lhe needle

between lhe

of the needle

needle

is

is

necessary, I oosen

move

needle

gauge

H.

th11correcl

proper

for

point

ul

ils

bar

S 1552.00 as

(fly.

of

plate

clamp

setting.

3)

position,

passage

the

is

highest

indicated

~)

lho

through

plate.

needle

and

27/6~

inch

point.

screw

up

or

down

Retighten

SETTING

Setting

-loosen

-mount

-raise

-Slightly

-Set

-Retighten

-Remove

in

PRIMARY

of Height:

screw E

looper

primary looper

with

gauge as

or

the

lower 1 ine

thread

guide

bracket

shank.

looper height gauge n.

A

LOOPER

height

shaft

shown

lower looper so

tighten

guide

to

screw B

on

screw E

the

and

fig.

3

(fig.

~)

gauge n.

with

in

fig.

timing

bracket A by rai

top

E.

special

~.

that

gauge

(fig.

of

S.l555.000

ita

~)

the

primary

S.

1555.00.

on

screw auppl ied

point

n.

S.

sing

the

contacts

1555,00

thread

looper

fig. 4

SETTING

-Loosen

-Rest timing gauge

the

OF

ANGLr

slightly

of

the

base

and

on

backward

primary looper lever C Antil the

looper is obtained

screw

adjust

-Reteghten screws 0

SETTING

-When

-If

and

to

-With primary looper

primary

needle

possible

and

of

needle.

-Retighten

10

the

to

the

position,

looper

adjustment

move

the

proper

looper

on

the

THE

PRIMARY

primary looper has completed

left

and

the

distance

to

the

needle

is

looper

holder C (fig.

setting.

holder C (fig.&)

looper

on

its

needle

its

above

stroke

screw

shaft

stroke

the

scarf

0.

D.

n.

S.

on

and

E.

LOOPER

with

the

between

required,

aet

as

so

to

center

to

the

with

1552.00

looper

(fig.5)

lever C (fig.

timing gauge n.

IN

RELATION

needle

is

loosen screw D

shown

forward

that

the

of

left,

no

in

the

1/6~

inch

6)

left

in

or

looper

right

the

needl~

below

deflection

fig. 6 adjuat

on

the

milled

~)

correct

s.

1552.00

TO

THE

NEEDLE

its

stroke

its

lowest

point

of

the

(fig.

61

(fig.6

or

righ

backw~rd

paaaea

as

tha

clo1e

5Carf,

center

te

on

the

••

the

surface

forward or

angle of

(fig.

5).

fig. 5

fig. 6

Page 9

5) SETTING

Selling

-When

to

looper

f ig.

I

- f

unli I

-Place

shown

-Loo~on

unt1 I

timing gauge

-Retighten screw 4.

Timing:

-The

completed

-To

looper

-Tighten

-~hen

looper

lou(:hif'lg.

-When

loft

-If

passes

-Loosen screw

-Raise

proper

-Retighten

-With

to

deflection.

dary

may

-Special

a

looper

OF

of

the

aecondary looper has completed i

the

left,

point

9).

adjuatment

looper

liming gauge

in

fig.

screw 4 and raise

point

distance

adjust,

adjustment

the

perfect

its

is

sot

slightly

the

secondary looper

must

entering

of

the

behind primary

or

lower

setting

screw

the

needle

right,

looper

be

required

care

alignment

pivot

SECONDARY

Height

tho

distance

to

lhe

needle

is needed,

has completed

H.

S.

9.

of

looper

H.

S.

from the

stroke

loosen screw B

properly.

screw B.

enter

the

balI

on

is

needed,

Band A (fig.

lever

.

B.

on its

the

This

is

driving

to

must

sleeve

1552.00

sets

1552.00.

point

to

the

the

scarf

scarf,

the pri

looper.

E and

downward

ball

of

accomplished

assembly complete with bushing

obtain

be

taken

between

in bushing

LOOPER

from

the

point

turn

handwheel

its

stroke

on

or

lower secondary looper

firmly

of

the

left,

9) and

behind

of

point

looper

handwheel

rotate

stroke

secondary

by

proper

when

adjusting

secondary

C.

is

the

(fig.

passes

the

mary

rotate

9).

the

the

ls

bottom

is

25/6~

clockwise

to

the

needle

in c

ut

secondary looper

5/32 inch (fig.

move

the

primary

of

the secondary looper must pass immediatly

without

secondary

and

loosening screws D

setting.

looper

stroke

of

the

inch

left.

plate

as

out

of

looper

primary

looper

touching.

clockwise

looper

the

secondary

looper

the

touches

secondary

driving

to

the

needle,

7).

lever E (fig

looper,

until

C(fig.

the

as

close

the

in

looper

looper

the

and B (fig.9)

9) forward

looper

arm E

fig

when

. 9)

point

as

possible

secondary

holder

starting

needle

assembly

(fig.

9)

. 7

the

up

or

of

the

looper's

to

slightly

and

moving

or

backward

to

and

looper

down

until

secondary

without

to

obtain

to

move

without

secon-

maintain

secondary

has

the

point

the

to

as

5)

SETTING

-To

set

-With

needle

-Retighten

-To

set

-With

needle

without

-Retighten

Setting

-With

screw f

bracket

needle guard.

-Retighten

-Loosen screw

fig. 8

THE

front

screw

rea~:

deflection.

screw

needle

the

needle

(fig.

P so

screw

NEEDLE

in

needle guard

in

GUARDS

needle guard A

its

lowest

C.

its

lowest

D.

guard

in

its

II

land

K.

it

adjust

touches

tha{

H.

(fig,

position,

B,

loosen screw

position,

support

lowest

needle guard

the

10), loosen screw

set

front

needle guard so

D.

set

rear

needle

bracket

position

back

of

·,

loosen

support

the

rear

,fig. 9

c.

guard so

that

that

it

it

touches

fig.

touches

10

needle.

needle

"

Page 10

-Adjual lower

wldlh of

-Rotlyhlon

-Wllh

lhe

acrew Q

ao

lhol

7)

SEfTING

-Loosen acrow A

-Slide

bollom

of lhe needle

-Retighten

soam

ucrow

noedlc

and

odjusl

il

roGla

LOWER

knlfe

acrew

knlfu

holdur C r i

doa irud.

H.

In

ogolnsl

TRIMMER

(fig.

0

plalo

.

A.

yhl

ils

lowu

lhu

s l

fronl

noodlo guard

KNIFE

II).

upward

unl1 I

or

lefl

position,

support

needle

culling-edge

lo

the

loosen

bracket

gu~rd.

of kni le

is

flush

wilh tho top

surface

Setting

-~lace

-Mount upper

-Turn handwheel clockwise

Slide

edge

&tlllent

conditions

-Retighten

-Turn handwheel clockwise

most

-Loesen screw

-Activate

-Release lower

pressure

applied

-Retighten

8)

SET

Rear

-Turn

needle

needle

-At

(fig.

dogs C

of

above

plate.

-Ret

Differential

-Set

in

with screw

-Loosen screw G

-Raise

-Ret

C

In

centric B (fig.

-Retighten

12

upper

upper

upper

of

top

is

required,

described above,

Jcrew

pos

it

I on.

lower

to

against

screw H

T I H G 0 F

and

chaining

handwheel

point

hole

this

point

12) and

and

teeth

the

i g h

ten

the

front

on

or lower

12)

event

D so

top

differential

G.

the

slot

ighten screw

(fig.

the

screw

trimmer

knife C (fig.

knife

knife C against

knife

F.

H.

(fig.

knife

knife

the

screw A

FEED

is

in

raise

that

of

surface

s c r

or

feed

slightly.

front

G.

for

chaining

it

is

13)

A.

fig.

11

knife

nrove

15) in upper

block D

until

upper

are

holder

overlaps

until

I I)

holder C

holder so

cutting

(fig.

edges

when

II).

D 0 G S

feed

clockwise

just

entering

the

needle

loosen

the

ew

screw

or

lower

half

the

feed

dog

of

the

F ( f i g • I 2 ) •

front

dog E (fig.

feed

feed

d~g

(fig,

13).

off

found necessary

in

the direction

kn

upper

lower

1/16

knife

obtained.

upper

(fig.

that

of

setting

and

inch

the

ife holder

trimming guards E

knife

knifeD

I I)

knife

holder block A is

(fig.

the

cutting

holder

.

knife

holder

by

hand

holder

trimmer

the

trimmer knives.

edge

block A

block A

to

the

pressure

knives.

A.

II)

and

(fig.

left.

At

dog:

until

the

plate.

F

feed

depth

are

needle

hed

dog:

13) fig.

lever

unt i l

its

height

is

~ven

It

may

purposes.

to

be

necessary

tilt

feed dogs, loosen screw A

required

to

1n

get

with

some

the

and G {fig.

1n

check

of

the

bottom knive.

IS)

left

(fig.

spring

wil I apply

no

time should

the

rear

cases

to

proper

setting.

fig. 12

15) with screw

1ts

lowest

to

see

that

or

right

15)

is

in

pressure

13

feed dog.

lower

chaining

(fig.

position.

cutting

If

until

its

upper-

the

correct

13)

and

F.

adju-

the

be

feed

turn

dog

e~

Page 11

9)

ADJUSTMENT

MOTE:

The

work

For

Annuli

ino

-Loosen nut B

- Raise lever

-Retighten

-Lower

Differential

-Loosen nut B

-Raise

-Retighten

-Set

lever H

Differential

-Loosen nut B

-Set

screw Q

-Retighten

-set

lever H

Differential

-Raise C to

-Loosen nut B

-Set

screw Q

-Retig~en

Set lever H

OF

machines

to which they

eventual,

of

differential

by

Z

to

nut B

lever H to

feed

screw Q to

nut B

against

feed

to

nut B

against

feed

its

to

nut B

against

DIFFERENTIAL

depleted

are

other

adjustments of food, proceed as

means

ita

stop F and

ratio

its

ratio

its

ratio

highest

its

feed:

of

wroxh

highest

2 : I

highest

stop

G

3. 5 : I

loweat poi

stop G

4 : I

position

lowest

position

stop G

Q

OR

FRONT

In

thia

destined

calaloo, are

.

A supplied with machine

position

tighten

nt

position

on

slide-bar

A

nut R

5

FEED (fiy.

del ivurod with lhe food

S

14)

follows:

already

set

for

the

10.

Mounting

-Mount the upper

-Mount the small block D

-The

small cover

-The

blade of the

the blade of the lower

-For

this

upper knife holder

-Lock

screw F

the

front

the

upper knife

knife C in

plate E must

knife C when

adjustement

and

ensure

needle guard.

move

B.

its

and

the

knife.

knife C in

that

H

R

(fig.l5)

seat

cover

be

very near

same

is

the upper

F G

fig. 14

in

knife

holder block

plates E and G positioning

to

the

at

its

knife,

its

. i

lowest

nclined

when

cutting

position

point

it is

A.

surface

and

at

F

G

-·-

them

of

knife

for a minimum

and

the

plate A on

its

lowest

by

means

of screw

c.

of

0.8

the

point,doesnot

F.

mm with

body

of

touch

fig. 15

13

Page 12

e)

l~t,.,il

iunin~

-Pres&

-Loouon sli

-Wtth I i

il

rests on

-Hold i

arm A by

-Remove

pres

serfool

-Rol iyhlen screw

-Swing back in

-Lift

-Connect

-Rotate

-Loosen screw in slop M

-With

strike

-~etighten

ul'

down

on

lover B (fig. 20)

ghtly

flcr

lever

pin in

ng

prussorfool

selling

end-play

arm

up

presserfool raised in

position

lever B (fig.

prosserfoot I ifliny

handwheel clockw ise

looper.

screw in

)II'I'S

M'I'fuul

screw B (fig.

arm

cast

arm

it i n approx imately a

in pre&so

shaft against

B.

slop

111'111

and

A in u

presserfool

20) to enyaye

(fig

16)

vertical

ing. '

shaft

L in

rfool

arm

bush i

fool

pedal with I

unt

i l secondary

.

16).

its

highest

11.

(

l'i~.

lh)

swing out

to

release

pos i

its

lowest

~5

shaft L by

ng

c.

holder

presserfool

p

~esserfoot

spring

tion,

angle.

0.

ifter

looper

position,

pressure

press

posil

1on, apply

apply i

holder arm.

arm

has completed i

set

down

ng

A.

slop

holder D (f

on

on

presserfool

spring

sl ighl

M so

ig.

l i

fter I ver

pressure

pressure

ts

that

16).

arm A (f

arm

to li

on

l i

fter

movement

presserfool

ig. 16}

shaft L until

fter

lever

arm

A and

to

the

left

does

not

.

f)

Sc

Ll

i

-Setting

is

done

-The movable

to

the

with

knife

-If

adjustment

and

left

screw

-Lock nut

g)l'll>f"dlf'

When

ward

14

ng

of

f

I'll

n 1

of

the

front

with

the

part

left

as

front

cover

may

A.

possible

needle

is

plate C to

be

necessary

the

holder.

move

as

B.

Llu·patJiakf'

sewing very hard

the

operator.

I'

o vI' r Jllal.l• ( f i

cover

plate C (fig.

cover

C,

required,

should

without

guard

up

plate

be

or

loosen

the

by

atjustmf'nl

cloth, set

closed.

set

as

interfering

the

lower

nut

right

adjusting

the

needle

g.

I 7 )

17)

far

A

or

(n. 5 tabl

thread

.

.. 9)

take

up

270-27~/2

fig. 17

sliding

it

forward,

to-

Page 13

II - liSE

8.27

77

8.27

77

R

8.27

770

8.27

776

8.27

776W

8.27

77PDB

8.27

77P080

llg.

18

IS

Page 14

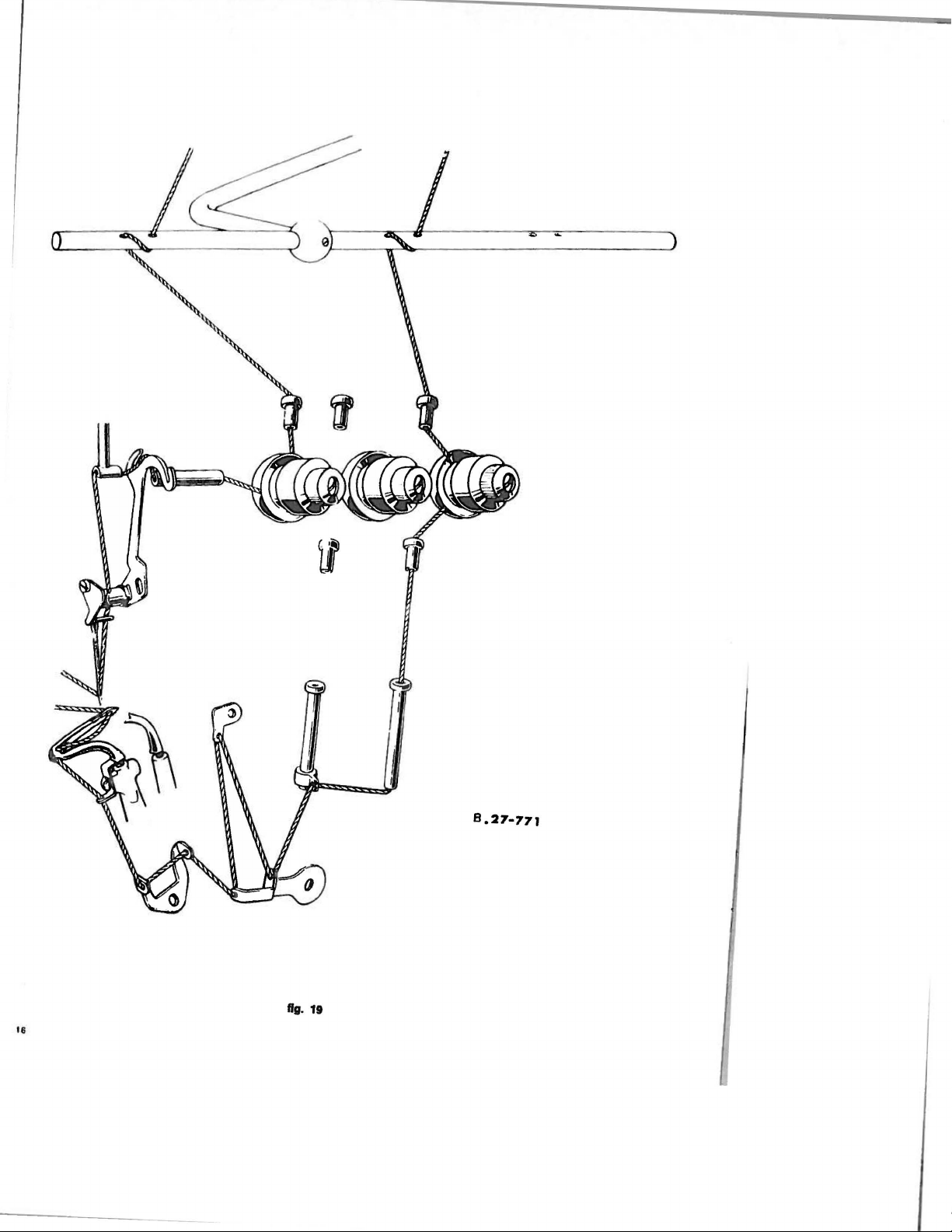

~

'

8.27·771

fig. 19

18

Page 15

b)

t:luu~i•lf(

-

Rotate

is

Prees

out

-

~oosen

and

lnaert

facing

mu&t

ned in

needle-holder.

Retighten

c)

d)

S.·ll

-

-

llu•

"'"""''

handwheel

at

Its

highest

down

on

the

needle-set

needle.

new

noodle

towards

taken

its

upmost pos i t i

lever B (f

that

presserfoot

remove

be

needle-set

So·

II

in~

I

ho•

lll't•

-With

presserfoot

point

enters

-Loosen screw F

-Retiyhten screw

To

increase or

N.

633-7112,

-Retighten screw

inA'

Tighten

Do

not

and

of lt•

the

tighten

tension

clockwise

position

holder D (fig.

rear

with

of

the

.

ig. 22)

scrow

scarf

the

needle is

screw.

s;wl'l'unl

arm D (fig.

presserfoot.

(fig.

22)

F.

decrease

turn

knob

G.

u.•<iuninA

too

tlist·s

discs

mucn.

until

needle

and swi

18)

.

by

half

of

positio-

within

needle

machine. Care

on

18)

and

center

the

pressure

A (fig . 22).

(fig.

21)

ng

turn

the

locked in

presserfoot

of

the

sufficiently

B

position,

in

relation

presserfoot,

as

turn

handwheel

to

the needle.

loosen screw G

to

permit a regular

clockwise

(fig.

22) with wrench

stitch

till

needle

formation.

e)

S1

ilc·h

lt•n,:tlh

-Unscrew

-Loosen screw L of

-

Set

shortened.

-Tighten screw

-Replace cap

f)

Ad

jusLml'nl

Tne

to

-loosen screw N

-loosen screw F

-push upper

width of

-tighten

-turn

N

-Activate

sure

aga i

-Retighten screw N

screw 0 of

width

change

handwheel

(fig.

to

nst

capT

of

the

seam

screw F

13)

lower

the

screw A

mljuslmcnl

of plexiglas&

eccenter.

stitch

L.

T.

of

st•am

widt

the

seam

needle

plate.

of

lower kni

(fig.

knife-holder

cutting

17)

(fig.

clockwise

knife

holder so

edges

(fig.

(fig.

(fiA·

16)

plate.

length adjustment. Rotating

h

may

be

block A

17)

till

13/

3)

adjusted

To

vary

fe

holder

knife-holder

that

of

the

when

setting

the

(fig.

(fig.

knife

trimmer

to

a very

width of

13)

17)

to

block A

holder

knives.

the

trimmer knives.

to

the

right

limited

seam

right

is

within

or

left

in

extend

its

pressure-spring

At

no

time should

(clockwise)

beyond which

these

very

in

order

uppermost

wil l apply

stitch

fine

to

obtain

position.

pressure

it

limits

the

be

length

is

necessary

:

the

required

Loosen

correct

applied

is

screw

pres-

17

Page 16

f)

Irregularities

duo

to

improper

horulling

of

machine

n

1

2

IRREGULARITY

Irregular

Feed

slipping

stitch

fabric - lnsuH

and

sidewayo

PROBABLE

- Tensions badly adjusted

-

Thread

- Incorrect threading

-

-

-

-Differential

take-ups badly adjusted

Yarns

not

gauged

ic

Feed

Knives

ient presserfoot pressure

dogs badly adjusted

need

sharpening

badly adjusted

in

CAUSES

height

and

slant·

-

Skip-stitchiny

3

Thread

4

·--

breakage

-

Primary

consequently blunting the looper

Loopers

-

-

Loopers

- Front needle guard too

-

Needle

-Tensions

-

Yarn

irregularly

-·---

--

or secondary looper badly

too

far

apart

at

too near

at

badly positioned

too

taut

wound

crossing

crossing with consequent blunting

far

from

on

reel

adjusted

needle

in

respect

to

the

need

1 e

Needle

5

Puncturing of fabric

6

Loss

7

8

Lack

18

breakage

of oi I -

of lubrication

Keadle

-

-

- Blunt needle

-

-

-

-

-

- V-belt incorrectly

-

-

bent

Needle

badly

mounted

Needle

gauge

not

low

pump

suitable

filter

Needle

with unsuitable point

Screw

joining base

Pump

plug not tightened underneath

Pump

gasket badly arranged

level too

Oi

I

Upper

tube clogged

Luor

ication

and

pump

mounted

clogged

for

plate

not tightened

underneath

- ---

Page 17

II.

M A I N 'I'

I

1•:

N A N C I•:

a ) E v 4'

Clean

1.

Clean

2.

Open

3.

Clean

c ) E \ 4'

I.

Wash

2.

Wash

3.

Blow

~.

Fill with fresh

d ) S

Sharpen

J'

) d

11

y

the

feed

and

stitch

formation elements

thoroughly dismounting feed dogs, rear

front cover plate

the

inside

,.

) I h

the

oil basin

the

pump

filters

pump

and

filter

and

carefully clean the front opening.

of

the cover plate containing the needle

•.

4' 4'

Ill u II

I h s

with

kerosene or other

with kerosene.

with

compressed

air.

oil.

l111

1'114'

II j II

A"

I lu•

1,.

II

j V 4' S

the knives using the

RIMOLDI

knife sharpener

exact angle of sharpening. This block is supplied

e )

Ins

I

1'114'

I i u

II

r u

I' , •••

m u v i II

A"

-Tools

necessary

- Pincers type

- Pincers

- Extractor S

type

S

S

sup~lied

0560/00

0~59[00

0~16/00

on

request only.

briefly.

and

front needle guards,

commercial

cleanser.

and

on

request.

I

h..

•.

u m

and

primary looper.

movement

assembly.

using the appropriate block

shu

r I

that

guarantees the

It

is absolutely necessary

tial

position. Therefore

Reassemble

-

-Leave

-Connecting

head

-

The

rod.

The

handwheel.

-Carefully

flanges G

all

locking

rods J and

of

connecting

positioning

The

two

assembly

cuts are

positi

observe the order of

that

proceed

and T in

screws

of the connecting

L are distinguished

rod

Land three lines

of

the connecting

on

the

on

of connecting

I M P 0 R T A N T

the

main

as follows:

the lubrication hole, towards the

same

assembly

elements of the shaft-connecting rod, are re-assembled keeping

rod

cao

in

from

on

rod

side of the part.

the surface of connecting

cap is determined

rod

N is given

of

the

their

oneillotherbythe

by

a cut

by

the

drawing

cup

springs.

bottom.

own

holes.

number 2 engrayed

made

number

rod

both

J.

on

that

the

must

on

the surface of the

body

of the connecting

be

on

the

part

ini-

of the

19

Page 18

I.

Pushing plunger

Remove

2.

3. Pushing plunger

~.

5. loosen the

6.

7.

8. loosen screws of ring F.

9.

10.

11. loosen hexagonal screw

12.

13.

1~.

15.

16.

17.

18. Diaaaaeable

11.

screw

Remove

flange

Remove

ball

Take

out

Remove

caps pf connecting rods

Remove

cover Y

.

Take

out washer

Extract

Remove

Pull out

Remove

Extract

Re~ve

handwheel

flange

cup

snap-on ring P

ahaft.

bar,

z.

bor. turn

G.

two

eccentric

bearing

spring D of

from

W.

Y.

T.

spacer

U.

springs

aection K and

A.

handwheel •

S.

SEQUENCE

turn

handwhool

hondwhoel

screws

washer 8

regulator

X.

by

means

Q.

C.

and

E,

N,

of

OF

OPERATIONS

reference

reference

eccentric

using

pincers

0,

J,

and

pincers

No. 5 opposite

No.

P oppos i

C,

using

S 0560/00.

L.

S

0~59/00

extractor

moving

te

of I i

of

the

nc

marker

line

marker

S

0~16/00

shaft

.

sligtly

on

on

to

machine

machine

the

body.

body.

right.

20

Page 19

SPARE

PARTS

CATALOGUE

21

Page 20

u } I

11

I. fhc spdrc

ous

part~

r i

2.

In

order

rosilion

3.

The

conversion groups of the

i n G i

ny

q,

On

each

by a

number.

ferenced

number

&upplieo

5.

Thu

catalog

order,

pnge

number

b)

Jus

I.

If

the drawing

the

general index.

2.

If

the drawing

position

tables

I.

llfiW TU

I ,.

••

eln • I i u

parts

and

to

make

of edch group

I e tab I

table

the vdr i

The

oy

capital

with

an

if

required

is

thd drawing numbers of

of tha

I

I'

II

I'

inside

the

relative

11

catalog

groups

it

e~.

groups

dsterisk

is

which

is

easy

inside

ous

whose

letters

are

for

special

groups

completed with a

table

in

I i

1111

''

number

number

the

page

is

known

of

a component

machine

is

liSE

TillS

made

up

of a series

make

up

the

to

use

this

the machine.

basic

machine

of

components

parts

cannot

of

the

seaming

general

all

these

its

known,

found.

alphabet.

the

position

not normally

which

is

easily

f:ATAI.tl4;

basic machine

of

catalog

and

its

illustrated

be

subblied

The

supplied

operations.

index in which

component

parts

are

is

immediately found

is

not

known,

by

consulting

taoles

and

the

index of

subclasses

separately,

parts

cross-referenced

with

the

parts

is

of

illustrated.

but

only

the

illustrating

its

subclasses.

tables

are

illustrated

are

cross-referenced

are

machine ana can

given,

the

illustrated

in

machine and

by

consulting

its

approximate

the

va-

shows

the

cross-re-

by

be

numerical

the

index of

a

a}

A I I

I.

To

~uarantee

necessary

2. give

3. Jive

4.

write

5.

The

The

irregularity

that

u)l\e'l'!il~

1.

On

the

be

used.

2.

The

3.

The

gauge

calculated

11.

The

5.

It

is

the

of

In

case

6.

qu

ired should

7,

Sp

ec ial

otic

to

the

serial

the

drawing

in

full

quantity.

Rimoldi

these

machines

needle system

indicates

on

system

and

advisable

needle required (ex:

of

douot a sample needle

ball-pointed

ised fabric&.

II.

HOW

ru

I'

I

...

an

carry

the

Company

found

parts

immediate

out

number

number

name

are

the

of

of

of

wishes

on

parts

sent

des1

foliowing

the

machine

the

the

part

M P 0 R T A N T

to

be

produced

with

only

illustrated

and

gauge

the

the blade of the needle.

the gauge

when

placing

be

attached

needles,

in

are

average diameter expressed

are

also

orders

100

to

the

SUK,

TU UHDER SPARE PARTS

dtch of

part

the

this

marked

needles gauge

the

spare

rules

exactly:

reauested

itself

able

to

analyse

by

order

stamped

or

order.

are

t~em.

for

spare

manual

to

on

the

on

always

straight

shank

the

state

90

empty envelope of

available

parts

any

case

For

this

parts.

RIM

of

the

In

hundredths

envelopes

clearly

system

for

seaming

required

27

RIM

the

it

of

breakage, wear

reason

please

needles

needle.

of a millimetre

of

R imold I .need

the system

27).

type

of

needles

on

elastic

is

directly

ensure

only must

lea.

and

gauge

or

ela-

or

re-

Page 21

INDI

BUSSOLE - PASSAFILI

SPINE

NELLA BASE

- FORZATI

CE

TAV.

TAV.

DELLE

1

2

TAVOLE

ALBERO

CON BIELLE

GRUPPO

DIFFERENZIALE

ALBERI

COMANDO CROCHET

PRINCIPALE

E BIELLE

TAV. 3

TAV.

4

GRUPPO

BARRA D'AGO

GRUPPO COL

SUPERIORE

ED

MOVIMENTO

INFERIORE

TELLI

TAV.

TAV. 6

5

25

Page 22

MOVIMENTO

ALZA PIEDINO -

PLACCA D'AGO

COPERCHI

Plllt..IO

01

LAVORO

PASSAFILI

E TENDIFILI

BACINELLA

E POMPA OLIO

TAV. 7

TAV. 8

TAV. 9

TAV.

10

.

01

'.

'

PIASTRA SUPPORTO

MACCHINA

E GINOCCHIELLO

PORTA-BOBINE

E PEDALINA

ACCESSORI

TAV.

TAV.

TAV.

12

13

11

:

=~----='

-~-$

~

-~·8-

---.

.

...

":

Page 23

CLASSE 8.27.77 R

CLASSE 8.27.770

TAV.

TAV.

14

15

CLASSE 8.27.771

CLASSE 8.27.776

CLASSE 8.27.776 W

CLASSE 8.27.77 PD8

TAV. 16

TAV.

TAV.

TAV.

17

18

19

TAV.

TAV.

20

21

CLASSE 8.27.77

DISPOSITIVO

PD80

TAGLIA CATENELLA

ELETTROMAGNETICO

w

21

1

Page 24

1

...

RIP.

1 270 016 bun ola pl'r perno co nlondo

2 270·097

J

•

5 270·768

6 270·643

DISEGNO

770·0SSII

270·057/1

...

11

bu

nol

a

p~r

bu

buuole onten

luhclli puuof

$1JIU

porto colt

uole po:.lenon p

prr

•I I

DENOMINAIIONE

er perni de1

ori

ptor

pern

th

per fil, dc i

vf'

llo

ol

ello

o

barru

!oUJJt!fiOf~

,

dei

creche

crochch

d'ogo 1

crochets

IS

l

1

2

2

2

I

N'

RIF.

1

270·644

8 270·912

9

270.04~/2

10

270

11

270 642

...

DISEGNO

042/l

bun

ola

Spinello

bu

n ola per

bun ola

spine

DENOMINAIIONE

ov•da

golleggiante

di

fermo

perno

de,

.tro per cliRerenz•

per

ct'ntraluro cortor

per

piano

d1

del

Iovato

differem:•ole I

alc

30

i

8

1

1

1

2

Page 25

26

--1--

..

"

I 2

:(; /

\

~

/

" ( )

7

2

14

N"

DISEGNO

RIF.

1 PM.27.77-009

(A)

270

012/1

(B)

270-116/1

(C)

270-061/2.

(0)

27.77-060

(E) 270.060/1

(F)

271).009/1

(G)

270-707

2 270.704

3 270.705

4 270-620

5 270.614

6 270-008/1

7 270-612

8

270.981

• 270.608

10 270.610

11

270

-617/1

--

N"

olboro prlnclpolo comploto di blollo 1

blella

biallo

biello comondo

moni

rnonlcotto por

otllfl:tO

cusc

anello

malic

flangio

dls.tonziale

volontlno 1 25

rondello

Yi

le

coperchio con volontino 1 L

perno

nllorl

DENOMINAZIONE

comondo pOrto ogo 1

comondo

cohollo

supttrioro 1

crochet•

colto

per

blolla comando

bella

pr

ncipolo l 18

netto

a slore

destro

Seeger por cusc lnetto

o lozza

per

Iota

destro

deslro

per allxoro

con

guido

fis.so

Yolontrno

per

volontl

no

eli

biloncl

omtnto

comondo

pa

r o l

bero

porto

crochet

porto

destro

principale

prlncipole 1

sup 1 16

crochet lnf. 1

2

2

l

.4

1

1

1 H

1 M

2

73

26

14

15

17

19

20

21

:1:1

24

:ti1

12

13

15

DISEGNO

270.999

01

G-H

·I3 7

27(1.97

5

004 E-7

092 0-15

270.615

27(1.010/1

07~

A-12

270-

722

073

M-10

0160·5

270.938

011

c-•.5

001

E-10

010 0 -11,5

270.613

709

270-

270.062

PM

:'1 n Oh0

PM

. 710·060 I

N"

viti pot s.elton d•

viti pe r biollo 270.010/1 o

vit i p

viei Iissa covollolto

s.topplno

custodia

bunola

rondollo per dlfterenziale

onollo

rondollo

viti

vito

viii fiuo spinelte

vii i par flonglo

viti

Dbtanz

ru

scinallo a sfere

cov

bielle com a

b•ello coma

N.B. I cuscineltl con

uro

l'ordinoztone

il

meri Romani sullo

nelli stessi.

OENOMINAZIO~IE

bilanciomcnl"

or

monlcot

H

per

olboro principahr

pelt

olio

lntermedia

di

te-iJ•slro

per

olbaro

per

onello dl registro

Ossa

buuolo

lata

par

b•ollo comando crocho1

lolo

per

cuscinotli

o11

otlo

per

b.ello

ndo

porto1

ndo

poria

fornili come riccmbi s.toc.coti, rna nel-

blwgno

numoro di s.elezione contrassegnato in

per

b:ello

per

o1bero

eccentrlco

principal•

inlermodio

destro

slnislro

crochet

crochet 1nf.

riferlmcnto

anolutamenlo

corona

27(1.116/1

print

regolobile

per

albero

1.up

.

G possono cs-

cslorna

del cusci-

pole

indicate

princ.

nu·

4

4

4

2

1

I

1

1

I

I

2

1

2

3

8

1

1

1

)

1

32

Page 26

N"

RIF.

45

N"

DISEGNO

DENOMINAZIONE

.

N'

I RIF.

80

N"

DISEGNO

70

DENOMINAZIONE

71

3

72

1 PM. 270.049

2

277·DSI

3 270.977

4 270-640/1

5 092·8 I

6 270-937

7

277

·DS

7o

"277-0521 S

8 270-611/1

9 270·979

10

070·M·4 5

II

270-035

12

4030·06

13

007·C·II

14

270-048

IS

07J.C.8

16

270·

0!4

17

071

·M·5.5

18

270.

~47/1

IO

070F

20

Q57

.f ·4

21

270.975

22

270·039

7.1

092·0-14

24

071

·H·S

25 270-036/1

26 270.935

27 026·C 7

28

PM.

270-038/1

(A)

770.046(1

(B)

270.038

20 270-040

3~

770-

031

31

002·

0·6

32 092 -0·

33 270-o.tl

34 250.471

~S

D17E·11,5

36 039 H·9

37

064FS

38 270-992

39 270·281/1

40 073 A·8

accopplamento

gr.Ra t.uu ld.Dfio

v te

squodretlo

,

loppino

vile

gr

2

.4

12

lffino

Qrtflino

blocchello a.corravole

vile

rondello

bunolino

Iosee

v1

1J

giunto

rondello per

per

no

rondfllo se11ore I

sellorc

rondello

dodo

vile

pe:rno ec:cenltlco del d fferenzi

stoppino

rondollo

blocchello

rondello

vito

$.CHore

cursoro

$.ellore

ollocco

$.pina

stoppino

stopplno

perno

vile

viii

vile

rondelle

v11i

sellore

rondello

slitle

dt l dtftercnz alo

fino griRo

fino

r.~W)

Ito

per

per

per

per

per

per

liuo

per

per

:iUUid1orio

di

guido

ptJr

perno

dol d•fterenziole

(montara

con plocco 277·

gl

per

per

fonf!lle

per

per setlora

Incr

per

~rno

MUOf'tl

per

per

scorrevole

d $.pollomento

rondolla di

per

per

per difi

per

otloc:c:

per

par per

poSieriore

ollocco

eccentrico

seuore

ptr

sellore

superiore

per

per

unlo del difterenziole

giunll

del

difterenz~ole

ilillo

del

11itlo

porto gri

perno

poster

inc'fml!nlo

ncremento

emento

ropporlo

JMtno

rapporto

270·054

perno

eccentr

perno

d.l

diRr

per

\pollomento

cunore

d.Rerenr l

ale

erenz&al•

biollo dell'rc:cenrric:o regolobile

a o for

cello

Sp&nOIIO

no

posU:rioro dol difterenziolc

del diReremiole

regolobile

comondo dlffcrenriole

seuori

limite

del

dift'orenziole

limUe

perno

comondo diflerenziale

d fhm:nz1ole

d•florenzlole

ioro

diflt-re~nrtole

c:ono

coua

Jl1

110

ffo

suuldiorio

del

dtfteranziole

dlfferen.zlole

differenziole

difletenz•ole

ale

co

renziole

del

diRerenziole

(deitro)

1l4/S)

difltrenz

ioli

differenziole

diflerenziole

I

I 42

I 43

I 44

~

1 46

I 47

I

I 49

I

2 51

1 52

2 53

2

I

I 56

1

I 58

1 59

1 60

I

I 62

1 63

I 64

I 65

I 66

I 67

I 68

1 69

I 70

I

I

I 73

I

1

I 74

I 75

2 76

I

2 78

2 79

I

2

(C)

(0)

-n

61

71

72

BD

41

45

~8

SO

54

55

57

PM

.270.562/ I

270.288/1

270-567

065 0 ·6

270·568

270-702

270-703

270-037

270·984

070-

B-3

OI

7·C·4,5

270·735

270-045

270-033

270.980

070·M·4,5

270-034

DDS.L-11

270.997

270.566/1

270.641 / 1

270-978

277·050

290·700

270-736/1

270-738

270.737

092

D-16

270.249

270·250/1

270·251/1

Oo.t

L·7

PM

. 270-732/2

270.733/1

270-732/2

271).734

270.032/1

004 P·6

270.928

27().929

270.747

270.943

leva comondo

setlore

•et

tore

ronde-Ito per pomolo

~molo

onello

gobbielto o

blella

vile

rondello

vic

regolotorc

ollacco

giunlo

vile

rondelle

buu

viii

vile

leva comondo

squod

vi

le

gri

fl'o

ont~llo

gombo

mollo

pomolo

stoppmi

corteri

prot

squodre

viii fiu oggio

cofpo

slitta dell'ec:centrico regolobile

corpo dell'eccentrlco

mollo

piasrrina

vile

vile

vile

latdonc

JMrno per blocc.aggio pulsonte

dtRerentiole

infer lore

per

c

on

per

elottico

comondo difforenziolc

per leva

JMr

Iissa spr

per

per

fino g l

per

olino

~r

squadrallo

per

leva comondo

retca d• guido

list.a grlfl'a

pri

ndpole

ela

per

per

pe

per

no

d1

~•o

no

Uo frs

e s

ll

o lu-.guctta

per cursorc

li$.SO

piostrino del

per

slitta

per

si1IIO

per slillo

HmHe con o

indiCa di

regolonu~nto

bloccoggio leva comondo differenz.

rulll

per

blello

del

differenzlole

leva del differenziale

netta

dell'eccenlrico

setlore

del

dol difteronziole

del differenziole

slillo

del d&fferenziale

differemlole

seuare

del diflerenziole

per

princlpolc

por

pulsonte

giunto

del

porto

gamma

per

protezione

protezione

dell'eccentrico

ngalablle

diffcrcnd ole

cursarc

ec:c:entr

ico

ccccnlrico

ecce

ntrico

difl'erenziale

diflerenziolc

differenziale

shllo

unto

g•unli del differenz.iale

par

sti

ca

pulsonte

pulsonte

r pulsonte

prolezione

in

sogglo

llo

c:omplelo

griffe

diR~tentlole

ollungo

cohcllo

in

gommo

regolobile

punta

(sinhtra)

sup~tlore

1

I

I

1

I

1

I

1

I

I

I

1

I

I

I

2

1

2

I

I

I

I

I

I

1

I

I

2

I

I

I

3

I

I

1

I

2

2

2

I

I

34

Page 27

. 1

a-

--

51

8

4

15

·

14

13

..

10

\

9

~

/

N"

RIF.

I

2

3

4 270.064

5

Sa

6

7

8

9

10

N"

DISEGNO

092 0 ·

16

073 N· 10

270.070

27.77·074 crochet 1.uperlore con foro largo

"27DC·D74f1 crochet s.uperf

vo.rnsr2

"270·075 crochet inf. can foro

270.069

250·471

270·068{2

G27.77·065

s.toppmi

rondelle per perni comontlo

lp

no p~r leva cornoN!o

ptrno

crochet lnfe d

perno comando crochet inler l

vi1i

porto

guida osc•llantc con

DENOMINAZIONE

~r

ptorni doi

comondo

crochet

ora

orc

per

leva del

crochet inferlore

con foro larva per

cieco

crocheu

huuolo

crochols

trocheu

I.Upltf

croch.:t

do

re

' upe

per

strnllo

per filoti cotone

ore

o vile 1

iO t e 1

filoti lana 1

filch

lana

N"

RIF.

~

(A)

2

(B)

2

(C)

(D)

1

11

1 12 016·B·4 v

1

13

1

14

1

15

2

16

1

17

N•

DISEGNO

071 B·5

27 77 ·056

77 n .o

os

270·063{1 1

270.974/1

016·R·2 .5

27.77·067

097 B· l

27.77·314

092

0·5

DENOMINAZIONE

rontiello 1

buuolo

reqolol:ule

QU1dO

0"1llon1•

.....

porto

crochet

Ylli

fruo croc hel s

11:1:

f.

u o movimento crochet infer

grana

per

leva comon

stoppani

vile forolo I

slopp

no

s.uper ore

lp

ino 1

do

crochet

1.pina

supenorc

..

,

ore

36

~

)

)

1

2

1

1

2

1

Page 28

r

31

_ _ 7

17

10

\

N'

RIF.

2

3

•

5

6

7

8

9

10

11

12

1J

14

15

16

17

IS

I

N'

DISEGNO

PM

270·13~1

PM

270·132 1

270-132

220-728

2Q0.027

270·933

270-713

270·006/1

073 F-9

270-719

007

C-11

27.7J.C'IJ7

270-975/1

270-13<4

092 [).6

071

E·S

001

G-10

270-708

DENOMINAZIONE

lf"vn a forcella

perno

per

leva o forcella

bunola

per leva a forccllo

Illite

nssa

bu

u oln del c

,

no

del

nlhero

bero

ollncco

no

nlbe

olbe

ourllorr

gu

1

cia

porto

perno

porto sllllo

supr.riorr

llo

ro

~uperlore

ro

~uperiora

ago

porto

ogo I

nnello

per per

cfocto

per perno ou do porto ago I

rmello

elosticu

olbero

comondo leva

per

ronrlelle

fo~ene

por olbero supcriore

per foscette 2

VI

II

ollacco

per o l

v i

iCt

per ottocco

ip

jnot

to

..

itopp

lno per l P i

ron

r4e

llo

"'"

Yf

iC

per

rondello

cu

sc<

neotlo

per

N'

RIF.

~

I

I?

2~0.708/1

016 B-2,5 Yl

1

2a

1

21 c 27

{A)

I

27

I

290·025/1

tBl

RIM

n

003 A

23

270·130

I

~·

0'12B

25

2

016 A·

26

2

~7

270-135

I

28 092

I

29 270-133

I

3D

011 r.

I

Jl

001 £ 7

I

32 270

I

33

092 D

I

J•

092A·IO

N'

DISEGNO

77-025

77 020

27

4,5

·I

2,5

OS

J.s

Ill

II

DENOMINAZIONE

gabblrllo a rull

llt f11o

gruppo

Monello

Borro ago

oqo

VIle

sp111111o per morsetlo

"

oppi

vite

levn

s.tontlino per

splnn P

grnno

vi

tc

ro

ndelto ch

llcpp

)toppino

l

per

leva

S0

spina

boT

ro ago c

porto ogo

per m':lr!.

elln

no per

spuM!IIO

'"no

c::omo

nrio

shllo

""'

spmollo

I!'

' leva a forcf'llo 1

r.

ua

lo

v<'

pe

t

tt

lbc

ro

rosomento pt!r

<nn

..

,

per no

comondo

on

morsrtlo

~erro

ngo I

porto

ago

porto

·

ago

"•I

porto-ago

comondo

barro

!.Upetiore 1

gabbiella o rulli

ago 1

. non

scompon

d'ogo I

38

. I

i

I

I

1

I

I

2

I

I

I

I

1

I

Page 29

10

8

7

9

;

12

I

13

\

,

..

'I

14 15

/\

/ \

' I

~

---=·

16

N"

RIF.

770

210 096

27 11· 112

"21 77 ·

277·110

•

270.111

5

210.987

6

7 710 099

270

8

9

07J.F.9

770.71Q

10

m1c.11

11

270.109

12

300008

11

1A

092 C·2

09?09

15

N"

DISEGNO

10='

1121

101

5

31

pofln roh

(lf'

f U O

pf'l

pnrtn

cnft~llo

cn

ltello

~uPf!r•nrr

co lt

ello

Jou

pt>ro

cortcr

in o pr.r port

cnne

rmt.

per (OIIto

Vtlf:

fi

u n

rnlt~ll

:-

rhelln 1.0r1o cnltello

rJin

nn~elln

f1\

.loO

cnlt

,.,

rr:nrle lt n

fnueolln

..

,

vltl prr fc

i1Cf'II

.. ,

1P

Ot'll

n

n

tlncro o fo

rcf'llo

P"'

'

per poria

1pinettn

s!Ofll""

~o

topp1n

DENOMINAIIONE

ello

~u

'unPrior,.

cnn

rlentnt

nr e 'en:rn tient

roltello

o

llo .lollpNinre

o

~urMrinre

suncriore

r.ll

o

.~o

upe"ore

p

.or

tn

cn lttollo

po

rln co•tello

O

CliiO

CCO

forct>llo

cohello

per.ore

urn

nturo

.1ouper

SU!')I"tiOtl!

~uper,nre

ore

,.:

~

g

N"

RIF.

. 16

:18

30 71

31

29

DISEGNO

250·•

1/

001?

07 1

D-5

18

19

270·1

210.10S

20

~1

211·113

n 270 ·100

;1]0.106

~J

24

003

l

2S 770.

101

070 F

26

?Jn

QB

27

o2•

n \

00.4

A·~

29

11-n&

'}

7 77

""'

N"

11

10

0•/1

l2

.4

B

117

~

0"

\ \

26

DENOMINAIIONE

vi

te

per

le

va

cl.-1

croci~

vi

le

r.

..

m

colu~lln

ronrlelf n n

er

,

,orin

·coiJell

ln guu:fn

ncfelln

rlf'r ,.,orin

por

pN

o

tn

cohrllo

mferiore

coltello inferiore

I'C'

rtn cohe-llo

nr.r buuolo

pprno

cnltell('l

molln

puntnlinn

vita fissn rm

huuo

rr:

v•le per coltello •nferiore

v•l~

v•te fin n squndratlo

1quocfret1n te••uto s.pingi 01olo

1quoclre-1to tet'tuto

perno

inferiore

porto

1upporto

CC"'Itrllo

,:,~Iva

I

inferiore

dpl

coltello

infe-riore

collr.llo

inlenore

coltr.llo inferiore

del co

~ouperiore

OQO

21

1

27

infedore

hello

6

~

supcrtore

infenore

~0

Page 30

--

14

24

w

DISEGNO

RIF.

I 270 077

2 270-081/ 1

270-083

3

..

072 L-7

072P

5

6

270-087/1

7 270-9

270 0

8

9

270-714

10

270-

701

II

28.778-076 l

12

27.01P-403/1

27

26

13

..

210

""~II

15

270-091

16

004 L·9

17 27.77-1

18

27 77· 196

~

1

I

I

I

I

1

1

1

1

1

1

1

2

1

I

1

7

22

t/28

w

lpina

per

no

buuoln

7

85

9'1

/1

186

1J

rom!wllo

rcncft.ll

lr

vn nl1o

VIII!

ma li n

" ' " " • IDE

onello el m lic:o

c:

vo

VIII! f

iquodrello

perno

ght

ern

vile

p

tos

lrm

slo

Ro fiuo piedino

DENOMINAIIONE

per

leva

porln pitocfino

per

leva

per

levn

onlrr.nre

n po,IP.rtorv

p1~1inn

lrvo ah a p•rrfi

per

l

eva

AL

• p

oprib

ile

porto

.u

o

u

~uarirello

di

ferm~

ptrr

rcgolo

ziont-levn

per

bunola

guetto

del pi

lin

o

nha pirdino

oprib

i le olzo pt

pemo

llfll

per

per

no

pi e

dina

nl:o

t>r

porno

pied

ino

del

piedino

di regolmi

('cf

ino

edino

no

abo pirdino

abo

pfedmo I

one

N'

RIF.

i

1 19 27 77

20

I

21 27 70.184

I

22 G 77 77·

I

23

I

I

1

I

I

I

I lmontorrt

I

23<

24 27.77. 107/1

I

25

26 270-934/2 vile f n o salvo

I

I 27

I

28

I

'/9

30

31

32

23 a

w

DISEGNO

191

27 17.

10'1

/ 1

181

27.77·11~

'27

.77-

1141

.

'27

.77-1145 ploccn ri'

'27.77-114/S

'277-114/S

'27.77·1142

270-

936/2

092 D-

11

032 L· 10,5

DOIA-l ,2

271-185

270-

073

PM

270-091/1

DENOMINAIIONE

lln

'l)

ucllo

dol p

~alv

a

~tllla

p

ed

lfl

plocca

placco

(mcnrore

plocco ri'ogo · larghon:o

placco d ' ogo · lorghezzo

plocca

1oplng•

vile rtu O sp1ngi osoJo

1otopp

VIII! ft1SO

vHe fino pl

pfcnlri~ta

tubetto

per

no

edino

ago

del p

edmo

o CCYnplelo

ci

'ogo •

larghena

·

forgheuo

-

lorgheuo

caner

grlfrmo

lorgh~uo

ogo

perno

ci'ogo

cuciluro

cucitura

cuci1uro

PM.2B-774-20B

cuciluro

cucituro mm. 6,3

217.0S2/S)

cuciluro

piedino

C"fooo

ago

c.on

con

d'cmo •

asolo

ino

del

pfOCCO

allrina

guido colenello I

levo olza

...

mm

6.3 I

mm.

4,7

mm

. 9

mm.

8

mm.

3.3

42

Page 31

411

110

~-.

\

If

1

\

2

32

~

-3i'

..

.

I

I

8

I

\I

47

I

N•

RIF.

1

2

3

4 270-241/2

5

6

7

B

9

10

ll

12

13 605-412

14

15

16 270.086

17 270-078 sp

18

19 270-993

20 270.995/1 viti

21

22

Zl

24

25 270·247

26

27 270.090

28

29

30

N"

DISEGNO

PM

270·208/2

'PM

20 774 200

007 H

25

PM. 270-205/2

270.965/2

270-9

113

PM.270·?18/I

007 R·7 ,5

PM. 270.245/2

270-206

270-093

032 F-9.5 vila

270

-094

270.701 onello

27

01

p.Q92

270

-066/1

026 C-12

026 E-10

026 G-7

PM

' 70-095

270-248

270-940

PM

270.2iO/I

44

DENOMINAZIONE

CCN"htr

lnlnralf!

con

cnrtltr lnlnroht con huuolo

(mont

vile

PC'

coppello

cupollnn

guornizion

vile per fiuOijlfl o cnp

utrniero con

vile

per finoog o f» as

ptoSiro

uvorniziont! per p os

JlOmolo

per rnndt

r

onde

Ito

leva blocco

rlmtico

motto

per lironte

ina

per

mol lo

prem

vitrt di fermo per o

fis~n

ID

tlPi poUoriori

vi

le

fLSs.o

vile

f•u

n losselto per bose

vile

fiua

carter

poco

borro

do oll i

tironte

blocca piod

tauello per

Ieppo

pc~r

pi

CV10

di

hunolo

ore con nlocco

cntlc:

r supt!r i

uu

ola puuof'ili

h

con

rlo

spt a pe<

fl

rxt

r cupolino 1

pe

tubelti

con bu

no

la

per

lro

per

rpgolnz•ont mollo

llo

eccrnlnca

ecconlr

•c