Rimoldi 507, 508, 509, 510, 511 User Manual

...

JRunuidi

i

SETTING

the:

)

j

THREAD

ADYUSTMENTS

507

511

-

508

-

512

CUTTING

-

-

TESTING

509

513

ATTACHMENTS

-

-

510

514

CAT.

N.

OF

652030510

del

2/70

\ttact^ent

uescnption

.507

508

509

fPneumatically

the

looper

at

the

operation,

gripped

latter

ones

picked-up

'allowing

the

beginning

skipping.

At

beginning

the

presserfoot

control.

synchronized

needle.

Same

pneumatic

cycle,ofpresserfoot

This

attachment

pneumatic

presserfoot

article,atbeginning

seaming, if necessary

Same

pneumatic

of

presserfoot

with

an

lifting

the

made-up

when

seaming, if necessary (handling of article).

controlled

and needle

end

of seam.

the

threadsoflooper

under

needle

are gripped

from

the

removalofpartly

ofanew

andatendofseam

by

The

attachment

withamotor

as

507

attachment

control,

knee

when

as

507

attachment

control,

lifteratendofseam.Itis

additional

presserfoot

article,atbeginningofseam,aswell

attachment

threads,

lower

meansofmechanical

depending

lifteratthe

is

fitted

press

introducing

of

(handlingofarticle).

depending

pneumatic

when

below needle

Immediately

plate

and

above

gripping

made-up

seam

must

for

but

with

control

the

seam,aswellaswhen

but

from

introducing

after

and

afterwards

needle

position

without

the

operator

positioning

with

from

endofthe

an

for

partly

with

cutting

pedal

for

cutting'

cutting

needles

plate

article

always

automatic

the

cutting

additional

lifting

made-up

automatic

also

control

the

plate

are

the

being

for

and

stitch

lifts

pedal

be

of

seam.

the*

cycle,

fitted

for

partly

as

510

511

512

513

Pneumatic

of:

502

,

507

Pneumatic

of:

502

508

attachment

device

(for

pushbutton

device

(for

attachment

device

(for

pushbutton

device

(for

presserfoot

knee-press

obtained

closing-up

control)

thread

cutting)

obtained

closing-up

control)

thread

lifter

control

stitches

stitches

cutting

fitted

for

with

with

lifting

with

with

with

with

presserfoot

beginningofseam). ^

Pneumatic

combination

502

device

pushbutton

509

device

pneumatic

pedal

,

beginningofseam).

Pneumatic

combination

503

device

knee-press

509

device (for thread cutting with automatic

pneumatic

^

additional

presserfoot

attachment

of:

(for

closing-up

control)

(for

thread

control,

control

for

lifting

attachment

of:

(for

closing-up

control)

presserfoot

pedal

control

at beginningofseam).

obtained

stitches

with

cutting

with

fitted

with-

the

obtained with

stitches

with

lifter,

for

combination

pneumatic

combination

pneumatic

automatic

additional

with

pneumatic

automatic

additional

presserfoot

pneumatic

fitted

lifting

the

^

the^

with

the

at

at

514

Pneumatic

combination

503

device (for closing-up stitches with pneumatic

knee-press

^07

device

attachment

of:

control)

(for

thread

obtained

cutting).

with

the

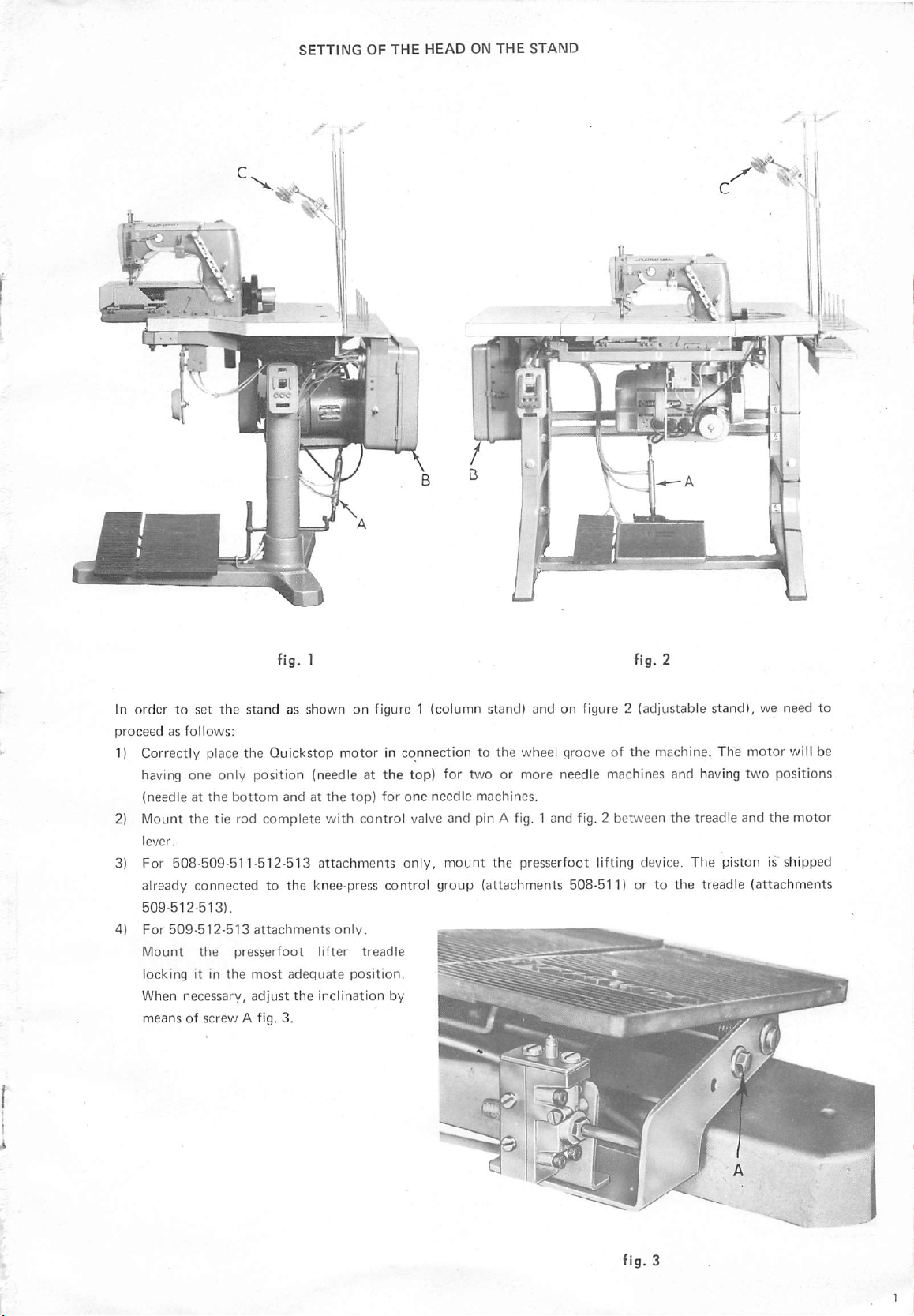

In order to set the stand as shown on figure 1 (column stand) and on figure 2 (adjustable stand), we need to

proceedasfollows;

1) Correctly place

having one only position (needle at

(needleatthe

2) Mount

the

bottom

tie rod

the

Quickstop

complete

motorinconnectiontothe

the

top)

for two or

andatthe

top)

for

one

needle

with control valve and pin A fig. 1 and fig. 2 between

wheel groove of

more

machines.

needle machines and having two positions

the

machine. The

the

motor

treadle and

the

will be

motor

3) For 508-509-511-512-513

already

509-512-513).

connected

to the knee-press control

attachments

only,

mount

group

the presserfoot lifting device.

(attachments

508-511) or to

the

The

piston is'shipped

treadle

(attachments

ifi

5) For 508-511 attachments only For submerged adjustable stand mount the presserfoot lifting knee-press on

the

front

cross

brace

fig. 4.

For normal adjustable stand

mount

the knee-press on

the

table fig. 5

For column stand mount the knee-press on the head support fig. 6

6) For

513-514

attachments

only

Mount the stitch closing-up control knee-press following the procedure as per point 5.

7) Carry

out

the mounting of the presserfoot lifter piston fixing same with the relative screws

To the crossbrace supporting the machine for setting on adjustable stands or similar ones (fig. 7 submerged

edition)

To

the

(fig. 8

bracket

normal

fig. 9

edition).

for

settingoncolumn

stands.

8) Mount the control box B fig. 1 and 2 fixing it to the bobbin holder (column stand) or to the table (adjustable

9)

Fixinthe

figure 10.

10)

Connect

the

air

rear

partofthe

Tighten

air.

Before

passage of air are

to

the

corresponding

the

various pins to

tubes.

For

connection

box

aretobe

well

the

locking

connecting

carefully

tubeisequipped

holeonthe

the

followed.

screwofthe

every

single pin

cleaned

with

the

table

box

taking

of

the

pins,

instructions

pinsinordertoavoid

make

and

that

seal ring, fig. 10.

pin A by

care

sure

every

meansofflange

nottobendorentangle

indicated

useless loss

that

the

orifices

single

connector

on

for

joined

B

the

of

the

Ik

fig.10

11) Place

the

belt

adjusting tension

Connect

12) Connect

13) Mount on

proportioned

entangled,aminor

•

The

adjustmentiscarried

head on

the

the

the

stand taking care

presserfoot

of same and

lifting

checking

pistontothe

pins joined to the control unit with

the

bobbin-holder shaft the

according to the

locking

type

of yarn used. A greater locking is required for yarns with

for

stable

yarns.

outbyactioniny

not

to damage

the

presserfoot

'C

thread lockings, fig. 1 and fig, 2, The thread locking will be

the

alignment.

the

talMe

above clamping element B fig. 16. Mounj

lifting lever by means of

the

fitted

adjustable

socket as per point 10.

tendency

lever A, fig.

11,

the

tie

to get

drive

rod.

ADJUSTPyiEIMTS

TO BE CARRIED OUT BEFORE COIMNECTING ATTACHMENTS 507-508-509-510.511.512-513-514

TO

THE

COMPRESSED

AIR

LINE.

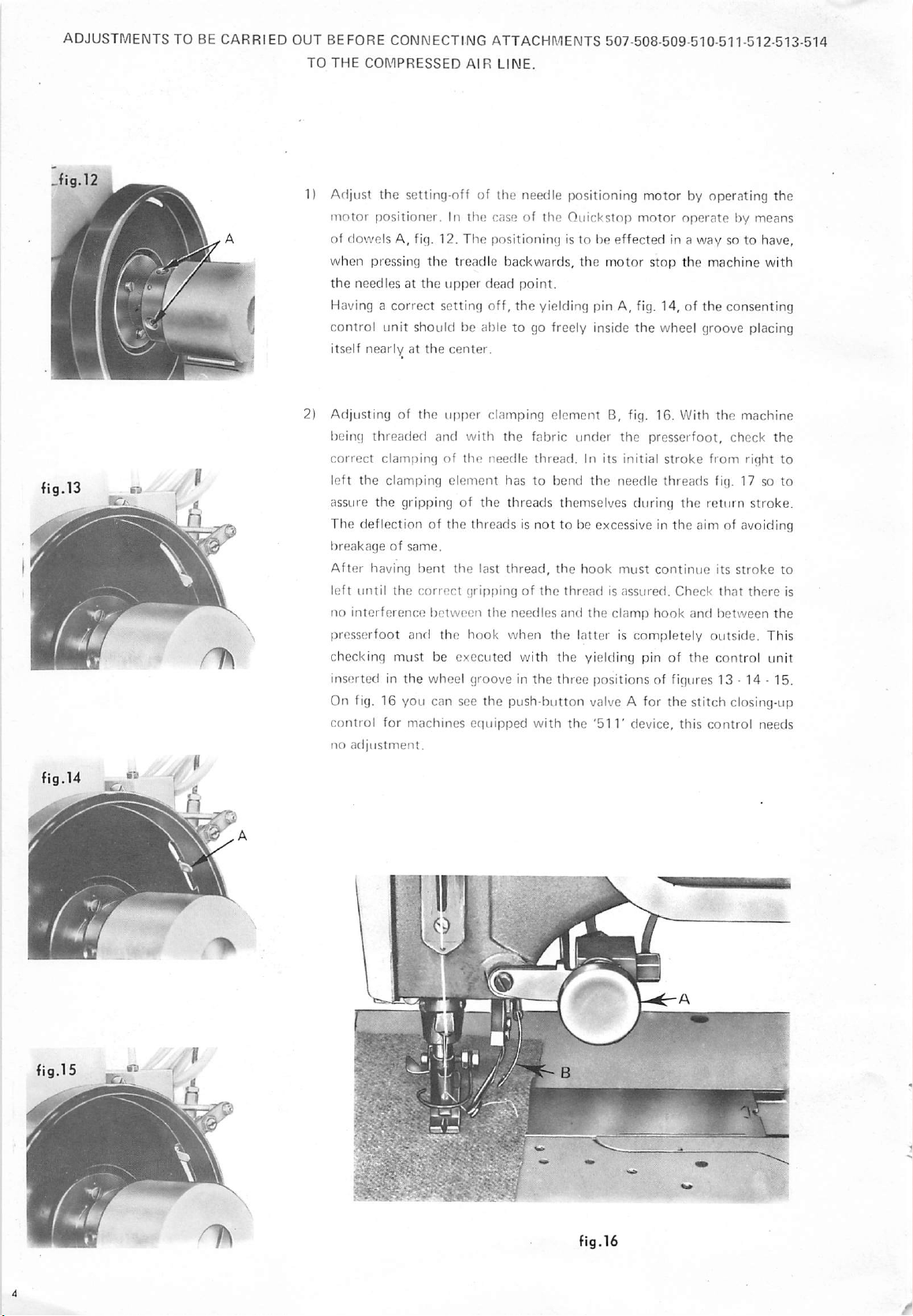

1) Adjust

motor

of

when

the

Having a

control

itself

2) Adjusting of

being

correct

left

assure

The deflection of the threads is

breakageofsame.

After

left

no

presserfoot

checking must be executed with

inserted in

the

setting-nff of the needle positioning

positioner.Inthe

dowels

A, fig. 12.

pressing

needles at

correct

unit

should be able to go freely inside

nearlyatthe

threaded

clamping of

the

clamping

the

gripping of

having

until

the

interference

and

the

case of

The

positioning

the

treadle

the

upper

dead

setting

off,

center.

the

upper

clamping

and

with

the

needle

element

the

bent

the

last

correct

grippingofthe

between

the

hook

the

wheel groove in

the

Quickstop

is to be

backwards,

the

motor

point.

the

yielding pin A, fig. 14, of

element

the

fabric

thread.

hastobend

threads

thread,

needles

when

themselves

not

to be excessive in the aim of avoiding

the

and

the

the

the

three

B, fig. 16. With

under

In its initial

the

hook

thread

is asstired.

the

latteriscompletely

yielding pin of

[jositions of figures 13 • 14 • 15.

motor

motor

effected

the

the

needle

during

must

clamp

by operating the

operatebymeans

in a

way

stop

the

machine

the

wheel groove placing

the

presserfoot,

stroke

from

threads

continue

hook

the

Check

and

fig. 17 so to

return

its

that

between

outside.

the

control unit

On fig. 16 you can see the push-button valve A for the stitch closing-up

control

no

for

adjustment.

machines

cciuipped

with

the

'511'

device, this

control

so to have,

with

consenting

machine

check

the

right

stroke.

stroke

there

the

This

needs

to

to

is

a «

iB-

-y

i X

fig.16

Loading...

Loading...