Page 1

JRunuidi

i

SETTING

the:

)

j

THREAD

ADYUSTMENTS

507

511

-

508

-

512

CUTTING

-

-

TESTING

509

513

ATTACHMENTS

-

-

510

514

CAT.

N.

OF

652030510

del

2/70

Page 2

\ttact^ent

uescnption

.507

508

509

fPneumatically

the

looper

at

the

operation,

gripped

latter

ones

picked-up

'allowing

the

beginning

skipping.

At

beginning

the

presserfoot

control.

synchronized

needle.

Same

pneumatic

cycle,ofpresserfoot

This

attachment

pneumatic

presserfoot

article,atbeginning

seaming, if necessary

Same

pneumatic

of

presserfoot

with

an

lifting

the

made-up

when

seaming, if necessary (handling of article).

controlled

and needle

end

of seam.

the

threadsoflooper

under

needle

are gripped

from

the

removalofpartly

ofanew

andatendofseam

by

The

attachment

withamotor

as

507

attachment

control,

knee

when

as

507

attachment

control,

lifteratendofseam.Itis

additional

presserfoot

article,atbeginningofseam,aswell

attachment

threads,

lower

meansofmechanical

depending

lifteratthe

is

fitted

press

introducing

of

(handlingofarticle).

depending

pneumatic

when

below needle

Immediately

plate

and

above

gripping

made-up

seam

must

for

but

with

control

the

seam,aswellaswhen

but

from

introducing

after

and

afterwards

needle

position

without

the

operator

positioning

with

from

endofthe

an

for

partly

with

cutting

pedal

for

cutting'

cutting

needles

plate

article

always

automatic

the

cutting

additional

lifting

made-up

automatic

also

control

the

plate

are

the

being

for

and

stitch

lifts

pedal

be

of

seam.

the*

cycle,

fitted

for

partly

as

510

511

512

513

Pneumatic

of:

502

,

507

Pneumatic

of:

502

508

attachment

device

(for

pushbutton

device

(for

attachment

device

(for

pushbutton

device

(for

presserfoot

knee-press

obtained

closing-up

control)

thread

cutting)

obtained

closing-up

control)

thread

lifter

control

stitches

stitches

cutting

fitted

for

with

with

lifting

with

with

with

with

presserfoot

beginningofseam). ^

Pneumatic

combination

502

device

pushbutton

509

device

pneumatic

pedal

,

beginningofseam).

Pneumatic

combination

503

device

knee-press

509

device (for thread cutting with automatic

pneumatic

^

additional

presserfoot

attachment

of:

(for

closing-up

control)

(for

thread

control,

control

for

lifting

attachment

of:

(for

closing-up

control)

presserfoot

pedal

control

at beginningofseam).

obtained

stitches

with

cutting

with

fitted

with-

the

obtained with

stitches

with

lifter,

for

combination

pneumatic

combination

pneumatic

automatic

additional

with

pneumatic

automatic

additional

presserfoot

pneumatic

fitted

lifting

the

^

the^

with

the

at

at

514

Pneumatic

combination

503

device (for closing-up stitches with pneumatic

knee-press

^07

device

attachment

of:

control)

(for

thread

obtained

cutting).

with

the

Page 3

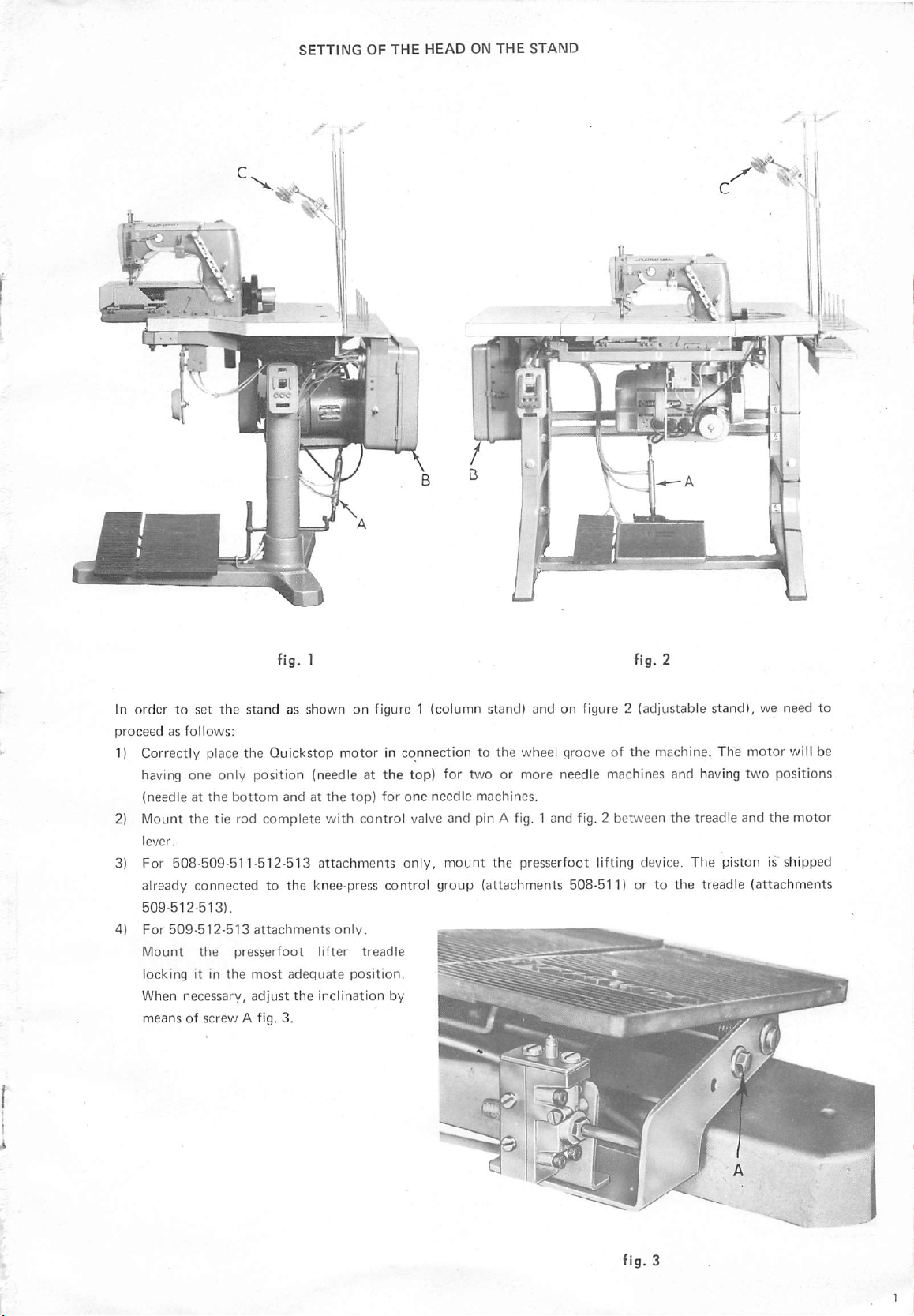

In order to set the stand as shown on figure 1 (column stand) and on figure 2 (adjustable stand), we need to

proceedasfollows;

1) Correctly place

having one only position (needle at

(needleatthe

2) Mount

the

bottom

tie rod

the

Quickstop

complete

motorinconnectiontothe

the

top)

for two or

andatthe

top)

for

one

needle

with control valve and pin A fig. 1 and fig. 2 between

wheel groove of

more

machines.

needle machines and having two positions

the

machine. The

the

motor

treadle and

the

will be

motor

3) For 508-509-511-512-513

already

509-512-513).

connected

to the knee-press control

attachments

only,

mount

group

the presserfoot lifting device.

(attachments

508-511) or to

the

The

piston is'shipped

treadle

(attachments

ifi

Page 4

5) For 508-511 attachments only For submerged adjustable stand mount the presserfoot lifting knee-press on

the

front

cross

brace

fig. 4.

For normal adjustable stand

mount

the knee-press on

the

table fig. 5

For column stand mount the knee-press on the head support fig. 6

6) For

513-514

attachments

only

Mount the stitch closing-up control knee-press following the procedure as per point 5.

7) Carry

out

the mounting of the presserfoot lifter piston fixing same with the relative screws

To the crossbrace supporting the machine for setting on adjustable stands or similar ones (fig. 7 submerged

edition)

To

the

(fig. 8

bracket

normal

fig. 9

edition).

for

settingoncolumn

stands.

8) Mount the control box B fig. 1 and 2 fixing it to the bobbin holder (column stand) or to the table (adjustable

Page 5

9)

Fixinthe

figure 10.

10)

Connect

the

air

rear

partofthe

Tighten

air.

Before

passage of air are

to

the

corresponding

the

various pins to

tubes.

For

connection

box

aretobe

well

the

locking

connecting

carefully

tubeisequipped

holeonthe

the

followed.

screwofthe

every

single pin

cleaned

with

the

table

box

taking

of

the

pins,

instructions

pinsinordertoavoid

make

and

that

seal ring, fig. 10.

pin A by

care

sure

every

meansofflange

nottobendorentangle

indicated

useless loss

that

the

orifices

single

connector

on

for

joined

B

the

of

the

Ik

fig.10

11) Place

the

belt

adjusting tension

Connect

12) Connect

13) Mount on

proportioned

entangled,aminor

•

The

adjustmentiscarried

head on

the

the

the

stand taking care

presserfoot

of same and

lifting

checking

pistontothe

pins joined to the control unit with

the

bobbin-holder shaft the

according to the

locking

type

of yarn used. A greater locking is required for yarns with

for

stable

yarns.

outbyactioniny

not

to damage

the

presserfoot

'C

thread lockings, fig. 1 and fig, 2, The thread locking will be

the

alignment.

the

talMe

above clamping element B fig. 16. Mounj

lifting lever by means of

the

fitted

adjustable

socket as per point 10.

tendency

lever A, fig.

11,

the

tie

to get

drive

rod.

Page 6

ADJUSTPyiEIMTS

TO BE CARRIED OUT BEFORE COIMNECTING ATTACHMENTS 507-508-509-510.511.512-513-514

TO

THE

COMPRESSED

AIR

LINE.

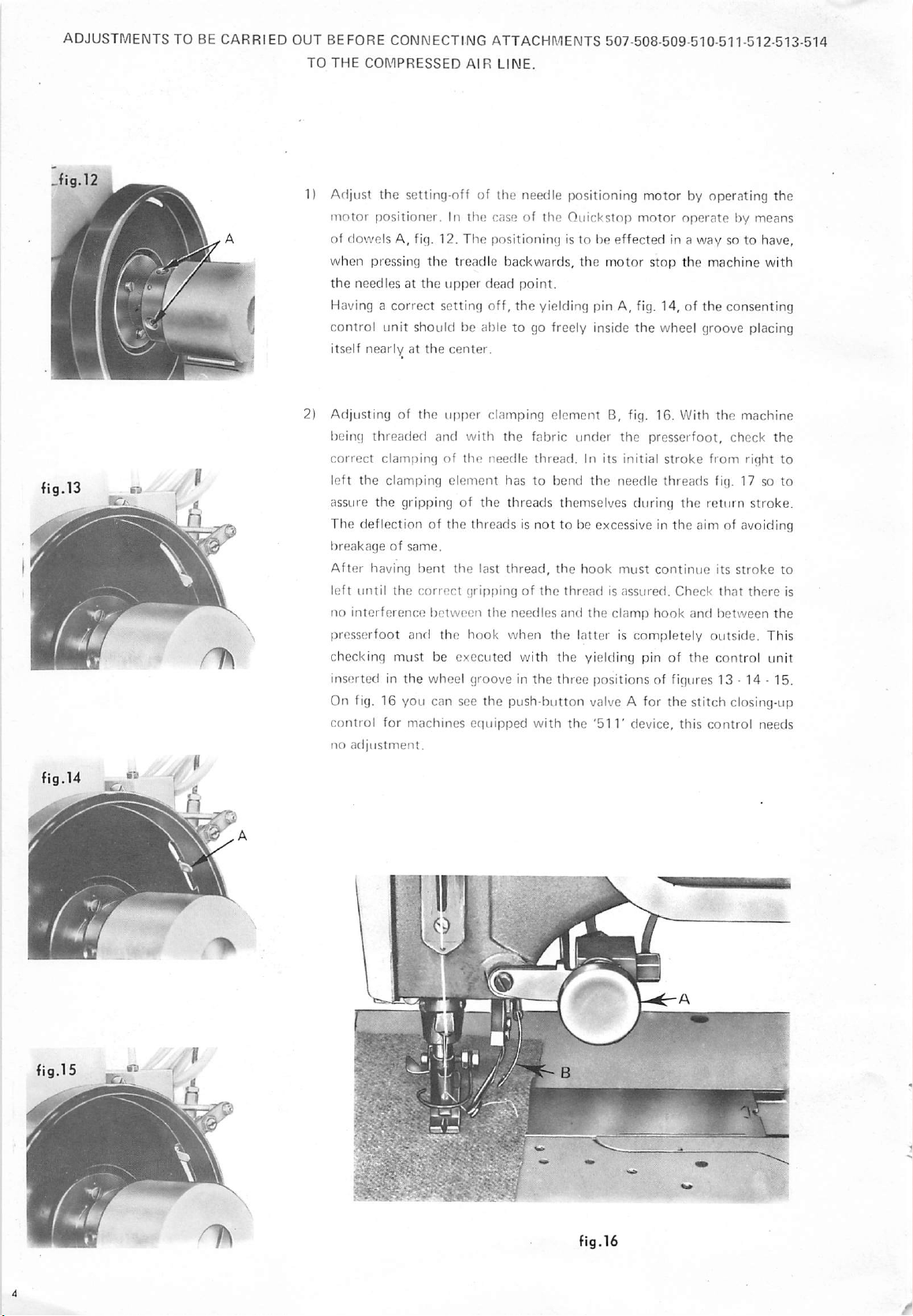

1) Adjust

motor

of

when

the

Having a

control

itself

2) Adjusting of

being

correct

left

assure

The deflection of the threads is

breakageofsame.

After

left

no

presserfoot

checking must be executed with

inserted in

the

setting-nff of the needle positioning

positioner.Inthe

dowels

A, fig. 12.

pressing

needles at

correct

unit

should be able to go freely inside

nearlyatthe

threaded

clamping of

the

clamping

the

gripping of

having

until

the

interference

and

the

case of

The

positioning

the

treadle

the

upper

dead

setting

off,

center.

the

upper

clamping

and

with

the

needle

element

the

bent

the

last

correct

grippingofthe

between

the

hook

the

wheel groove in

the

Quickstop

is to be

backwards,

the

motor

point.

the

yielding pin A, fig. 14, of

element

the

fabric

thread.

hastobend

threads

thread,

needles

when

themselves

not

to be excessive in the aim of avoiding

the

and

the

the

the

three

B, fig. 16. With

under

In its initial

the

hook

thread

is asstired.

the

latteriscompletely

yielding pin of

[jositions of figures 13 • 14 • 15.

motor

motor

effected

the

the

needle

during

must

clamp

by operating the

operatebymeans

in a

way

stop

the

machine

the

wheel groove placing

the

presserfoot,

stroke

from

threads

continue

hook

the

Check

and

fig. 17 so to

return

its

that

between

outside.

the

control unit

On fig. 16 you can see the push-button valve A for the stitch closing-up

control

no

for

adjustment.

machines

cciuipped

with

the

'511'

device, this

control

so to have,

with

consenting

machine

check

the

right

stroke.

stroke

there

the

This

needs

to

to

is

a «

iB-

-y

i X

fig.16

Page 7

In

order

to obtain

In

ordertoobtain

ordertoobtain

In

u

the

vertical displacement of

the

horizontal

the

correct

displacementofthe

positioningofthe

M

fig.17

the

clamping element

clamping

hook

in respect to

operate

element

the

on screws A fig. 18.

operate

threads

on screws B fig. 18.

operate

on dowel A fig. 19.

fig.18

fi9.19

Page 8

CONNECTION

OF

THE

ATTACHMENT

TO

THE

COMPRESSED

AIR

LINE

FIG.

20

1) Connect the attachment to

pressureofthe

attachmentis4,5

the

compressed air line or to the compressor. Check

• 5

Atm.

This

pressure is indicated by

the

that

manometer

the work

A.

Should the pressure be different from the one abovesaid, operate on screw B in order to get the pressure to

the

required

N.B. When necessary to diminuish

metal

2) Fill

lubricator

This

filling is carried

N.B. In order to fill

After

done

screw

At

least

The condensate level must never be exceeding metal ring I.

The

condensate

filter.

Once

washing and

the

filter by unscrewing

be

cleaned

Fig.20control

N.B.

the

'PRESSERFOOT

level.

ring'Cand

adjustment

'D'

up to

having completed

F, is of 1

G.

one

drop

a week

proceed

discharge is

every 6

months,

subsequent

with

gasolineorderivatives).

box

for

For

the

507-510-514

the

pressure, you should release first

screw

B.

the

indicated

out

removing screw E.

the

lubricator, it is necessary to disconnect the

the

testing of

every 30 •50complete

with

carried

proceed

with

blastofcompressed

the

knurled

508-509-511-512

attachments

LIFTER'

PRESSERFOOT

grip

maximum

the

machine, check

level

with

trimming cycles. Such an

the

condensate

discharge

outbyoperatingonpush-button

the

metal

with

LIFTER

cleaning of

and

the

the

the

sintered

air.

For

this

ring 0 fig.20(the

513

attachments.

control

relative

box

connections.

CONSENTING

the

air of the circuit and

oil VR

604

(ESSO

attachment

that

the

oil inflow, visible from

adjustment

which

gets

accumulated

A fig. 21 placedatthe

bronze

operation,

filter and

filter L fig. 20 by

it is necessary to disassemble

lubricator

fig. 20 will be lacking of

ATTACHMENT

then

STANDARD

TERESSO

from the compressed air line.

the

lubricator small

is obtained by operating on

inside filter H.

bottomofthe

meansofpetroleum

the

cups

'H'

and

'D'

the

components

TO

THE

R.T. and of

TREADLE

are

loosen

body

not

OR

43).

of

to

KNEE-PRESS

Page 9

1)

Adjustmentofthe

The

consenting

a) It permits

the

point);

in

the

wheel groove (fig. 23)

b)

with

allows

trimming

It is,

screw C (fig.

down;

The

machine

have to

quickly

Check

wheel is

adjustment.

ADJUSTMENTS

(It is advisable to remove the needles, before proceeding with the above adjustments).

machine

consenting

control

the

trimming cycle only when

with

unit

the

control

has a

needles in

only under these conditions,

wheel groove (fig. 14). If

the

trimming of threads

the

slow

exitofthe

the

machine

operation.

therefore,

22).

whilstbyturning

optimum

stopping

start

stop

it by pressing

that

the

not

running.

to

completely

necessarytoadjust

By

turning

the

speed is

the

yielding

when

time.Inordertocarry

machine

backwards

pin

The

return

TOBECARRIED

unit (fig.

double

function;

the

the

the

yielding pin does

piston

A (fig.

stop

the

piston

this

screw in,

screw

out,

the

exit

gettingitto

the

gets

into

speed is very high

OUT

WITH

22).

the

motor

has stopped

upper

part

(upper

dead

yielding pin A fig. 22 fits

not

fit in the

cannot

take

place.

23),

the

control

before

the

time

out

the

treadle.

the

effecting

exitbyoperating

the

piston

pistonisaccelerated.

coincidestothe

this

adjustment,

rating

loop

only

and

is slowed

speed

when

needs no

unit

the

you

and

the

ATTACHMENT

on

UNDER

PRESSURE

fig.22

2)

Adjustmentofthe

The

valve

function:

a) by pressing forth the treadle to

created

b) by pressing backwards

unit,

the

trimming

c) it does not permit the repeating of the cutting

of

at

necessary

unthreading.

adjusted

minor

of

getting

essential

machine

By

loosening

unscrewing or screwing

necessary to

valve

adjustment

I) press

II)

forth

executing

the

treadle,acomplete

If

this

excessive stress and it is,

(fig.

24).

push

forth

having

backwards no cutting cycle should

occur,itmeans

therefore,

The

balance

several

valve

mountedonthe

mounted

and same charges bag P fig.20containedinthe

cycleisreleased.

air

on

the

contained

motor

the

treadle,

in bag P fig. 20

tie rod (fig. 24)

actioning

start

the machine, an air passage is

after

the

consent of

tie

which

rod

cycle"

least a few

to

accordingtothe

resistance

the

that

has

startedtosew.

nut

operate

the

about

cycle

the

the

machine

necessary to

trials.

stitches

avoid

the

This

valve, in

opposed

perfect

the

valve charges bag P (fig. 20)

A (fig.

shaft

valve fig.24is increased or

and

control,

treadle

ten

stitches:bypressing

does

not

treadle

run.

that

the

between

point

has

taken

dangerofthe

ordertoperform

typeofsetting

by

the

motor

performance

24)

on

side

guiding bushing B (fig.

you

should

having

cutting

occur,itmeans

without,

screw

the

cycle

therefore,

By,

subsequently,

valve

requiresatoo

bushing B (fig.

I) and

however, reaching

point

place.

This

needles

clucth.Infact,inthe

of

with

proceed

machine

subsequently

oughttotake

that

necessary to loosen bushing B

take

place. Should this cycle

II) is to be

and

function

andtothe

the

attachment,

only

numbers

24),

diminuished.

as follows:

started

place.

the

valve

pressing

little

24).

has a

triple

box.

the

control

controls

unless a seam

condition

the

looper

C, istobe

greater

when

6-1

and

the

stress

For

slowly

backwards

requires

the

stage of

the

treadle

stress

and

found

through

the

is

or

aim

it is

the

by

the

^nd

an

it is,

1"^

fig.23

/

Xa

fig.24

Page 10

CUTTING

STAGES

I)

Correct

cutting

Needle

positioningofthe

cycle:

above—Looper

fe)

A^ 1I

needle

totallyonthe

flg.25

andofthe

left

looper

so as to

permit

the

II)

Exitofthe

the

the

accomplishareduced

Rotationofthe

central knife (A) which passes through

needle

thread

counter-knifeBandofthe

wound

upper

stroke.

clamp

around

hook

fig.26

the

lower

D

looper.

clamping

the

Contemporaneous

loop formed by

elementCwhich

exit

of

III)

Returnofthe

thread.

Delayed

thread

returnofthe

above

the

central

needle

knife

superior

plate.

that

clamp

hooks

the

hookDwhich

looper

and

grips

the

the

needle

needle

IV)

Clamping

the

Taking over of the needle thread and clamping of same above the

needle

of the looper thread below the needle plate and return of

three

knives A B C to

plateonthe

side of

the

rest position.

clamp

D.

/

Page 11

ADJUSTMENTS

PRESSURE

TO

AND

BE

WITH

CARRIED

THE

OUT

WITH

MACHINE

ATTACHMENT

BEING

THREADED.

UNDER

1) Setting-off and threading of

enclosed to

2)

Adjust

3)

For

the

machine. A precise setting-off is

the

stitch

length

510-511-512-513-514

closing-up in such a way so to avoidthe undoingof the

According to

closing-up.

4)

Adjustment

25-26-27-28).

In

the

necessarytoverify

small

threadofthe

a)

cut

the

seam exigencies, never exceed in the stitch " "

and setting-off of

aimofobtainingaperfect

that,

knife

A (fig. 26) goes

needleorof

out

the

compressed

the

machine. Carefully follow the setting-off and threading instruction sheets

whichisrequired

attachments

the

thread

during

the

cutting

into

the

the

needles

air

line

from

the

guarantee of a good performance and of a perfect seam.

during

the

seam.

adjust

the

stitch

seam.

trimming knives (fig.

trimming,itis

stage,

the

central

loop

formed

woundonthe

the

circuit.Inorder

by

the

looper.

to cut out the compressed air from the circuit it is p

(508-511

b)

executeaseamof4-5

c) check, by hand operating on the piston shaft,

needle

position

with

N.B. This setting-off can be carried

stress

5) Adjustment of the needle thread enriching cylinder (fig. 30).

In

the

the

right

lower

the cylinder by operating on

In the

the

seam

attachments).

thread

wound

the

knives block (fig. 29) loosening

closed-up

will be

neededtoget

caseinwhich

side

of the

caseinwhich

after

the

stitch

there

seam

there

cutting

crn.

on

the

looper.

for

510-511-512-51

the

shouldbean

executed

should

cycle

with

Should

3-514

out

also with

trimming

knife

excessofthread

afterthe

screwsA(fig.

be an

irregular

slip

stitching,

that

the

the

attachments.

out

cutting

30).

starting

the central knife goes perfectly in the loop of the

mentioned

2 screws A (fig.

the

being

on v J ^

cycle,

lift

the

_

^

^

'

r-'

Tig.29

fig.29

condition

attachment

the

small

of I

failtooccur,

29).

Repeat

under

pressure. In this case, a greater

piston

under

shifttothe

the

abovesaid setting-up

pressure.

M

,««—

'

J

tn

correct

y*

'

N.B.

By

lifting

needle

sameisdiminuished.

6)

Adjustmentofthe

enriching

adjustmentiscarried

stroke-limiter

greater

in

the

The

by

threadisincreased

initial

order

to

beginningofthe

shiftingofthe

operatingonscrews

the

cylinder

strokeofthe

small

avoid

piston

out

A,

whenever

enrichmentofthe

the

lossofsome

seam.

stroke-limiterisobtained

B.

(fig.

30),

the

enrichmentofthe

whilstbylowering

looper

thread

(fig.

31).

This

through

necessarytohave

shifting

looper

stitches

thread,

fig.31

^

the

cylinder,

of

a

at

fig.

J

30

Page 12

7)

Adjustment

Should

sufficient or

perfectly

screws

of the

the

tension

automatic opening of

viceversa,

closed,

A.

lift or

opening

small

the

piston

(fig.

tensions be

should the tensions fail to get

lower

the cylinder by operating on

32).

not

rr!rii

8) Stitch closing-up group

attachments

This group is to be adjusted only when varying the degree of

closing-up of the stitch and the stitch length.

In

case

C.With a clockwise rotation the stitch closing-up ratio is diminuished whilst with a counterclockwise rotation

sameisincreased.

only.

of modification in the

(fig.

33) for 510-511-512-51 3-514 ^ig. 32

degree

of the stitch

closing-up

loosen

screw

S

Bandrotate of

some

degrees

lever

fig.

33

iO

Page 13

PNEUMATIC

SKETCH

®

OF

(3)

THREAD

(D

CUTTING

ATTACHMENT

507

®

d)

© (D (I)

I —

group

made

up of

5—2

6 —

8 — 4

9 —

10 —

II

— 4

13

—

A —

B —

C —

D —

E —

ways valve

Impulse

ways

valve

adjustable

thread

trimming

ways

piston

Attachment

tension

needle

threads

knife

controlling

looper

enrichment

needle

threads

controlled

bag P fig.

controlledbya

delaying

valve

small

opening

enriching

clamping

filter-reducer-manometer-lubricator

by a

treadle

(with

20

valve

operation

controlling

pistons

piston

piston

piston

treadle

C fig.

2^

consenting

spring impulse S fig.

fig.

32

piston

fig.

fig.

29

fig. 31

piston

fig. 16

(with

device

30

traction)

compression)

fig.

fig.

20

fig, 24 side 6-1

fig. 24

22-23

20

side

3-4

11

Page 14

PNEUMATIC

SKETCH

OR

OF

THREAD

AUTOMATIC

CUTTING

ATTACHMENT

PRESSERFOOT

®

LIFTER

®(9)

WITH

508-509

PNEUMATIC

HAND

® (i) ©

(2)

©

3 —

group

made

up of

4 — 4

5 —

6 —

7—2

8 —

9—4

10 —

11 —

ways

piston

presserfoot

commutator

ways

valve

impulse

bag P fig.

ways

valve

adjustable

thread

trimming

filter-reducer-manometer-lubricator

valve

controlling

lifting

cylinder

valve T fig.

controlled

20

controlled

delaying valve C fig.

operation

12 — 3 ways valve controlled by air for the

13 — 4

15 —

A —

B —

C — knives

D —

E — needle

ways

piston

attachment

tension

needle

threads

controlling

looper

thread

threads

valve

controlling

small

opening

pistons

piston

enrichment

piston

enrichment

clamping piston fig. 16

fig. 7-8-9

20

by a

treadle

by a

treadle

22

consenting

spring'S'impulse

fig.

32

piston

fig. 29

piston fig. 31

the

presserfoot

fig.

(with

traction)

(with

compression)

device fig.

automatic

30

fig.

lifter

22-23

20

fig. 3-4-5-6

fig. 24

side

fig. 24 side 3-4

6-1

actioning of the presserfoot lifter cylinder

fig.

20

12

Page 15

PNEUMATIC

SKETCH

FOR

THREAD

CUTTING

ATTACHMENTS

CLOSING-UP

510-514

WITH

PNEUMATICALLY

CONTROLLED

STITCH

® ®

(D

® (i) © ® ©

s,

I —

5—2

6 —

8—4

9 —

10 — thread cuttingoperationconsenting

II

13 —

A — tension

B — needle

C — knives

D —

E —

14

15 — 3

j

✓

— 4

—

group

made

ways

valve

impulse

ways

valve

adjustable

ways

piston

attachment

opening

threads

controlling

looper

thread

needle

threads

stitch

closing-up

ways

valve

up of

filter-reducer-manometer-lubricator

controlled

bag fig.20part

controlled

delaying

valve

small

pistons

piston fig.

enrichment

piston

enrichment

clamping

controlling

controlling

valve fig.

controlling

by a

P

by a

fig.

piston

piston

the

treadle

treadle

22,

32

piston

29

piston

stitch

part

spring

fig.

fig. 31

fig.

16

fig.

closing-up

(with

(with

C

device

impulse

30

33

traction)

compression)

fig.

22-23

fig.

piston

fig.

20,

fig.16or

fig.

24

part

fig.

20

S

24

figures

4-5-6

13

Page 16

PNEUMATIC

SKETCH

PRESSERFOOT LIFTER

FOR

THREAD

WITH

CUTTING

ATTACHMENTS

PNEUMATICALLY

CONTROLLED

0

®@

WITH

HANDORAUTOMATIC

STITCH

CLOSING-UP 511-512-513

PNEUMATIC

©00

1 — stitch closing up control piston

2 — 3 ways valve controlling

the

stitch closing up piston

3 — group made up of filter-reducer-manometer-lubricator (see fig. 20)

4—4

5 —

6 7 — 2

8 —

9—4

10

11 —

12—3

13 — 4

15 —

A —

B —

C —

D —

E —

ways piston valve controlling

presserfoot

commutator

impulse

—

adjustable

thread

attachment

tension

needle

knives

looper

needle

ways

ways

ways

ways

lifter

valve T fig.

valve

controlledbya

bag

P, fig.

valve

controlled

delaying

trimming

valve

controlled

piston

valve

small

opening

threads

enrichment

thread

enrichment

threads

enrichment

clamping

cylinder

20

valve C fig.

operation

controlling

pistons

piston

piston

fig.

20

by a

by air

fig.

piston

fig.

piston

piston

the

presserfoot lifter (see fig. 3-4-5-6)

7-8-9

treadle

(with

traction)

treadle

(with

the

fig.

compression)

device

automatic

impulse

30

fig.

22-23

actioningofthe

S fig.

22

consenting

for

spring

32

29

fig. 31

fig. 16

see

26

fig.

24

see fig. 24

presserfoot

lifter

cylinder

\4

Page 17

STAMPATO

A

CURA

NELLE

DELL'UFF,

OFF.

RIMOLOl

CATAL06HI

Page 18

SEDE

! 1* ^

D!

MILANO

S.p.A.

STABILIMENTO

VIRGINIO

RIMOLDI

D1

OLCELLA

&

C.

VIA

VESPRI

TEIEF

470.152/153/154/155

TElLGRAMMI

SICILIAN!,

VIRIMOLOI

9 -

-

-

MILANO

479.558

MILANO

PrintedInItal;

Loading...

Loading...