Page 1

RLnUTLdL

IL-I

SPARE

PARTS

HEAD

AND

HEAD

CATALOGUE

228•0001

SUBCLASSES

2282BD5

33/A

N.

CAT.

652230400

of

20/68

Page 2

INTRODUCTION

IDENTIFICATION

HEAD

I

-

II

-

TECHNICALDATAOFCLASS

TECHNICALDATAOFSUB-CLASSES

III

INSTRUCTIONS

INDEX

Pag.

5

5

6

INSTALLATION

I

-

-

Positioning

a

b-Transmission

c-Lubrication

d-Assembling

-

Adjusting

e

•

Setting

-

Needle

g

h-Electric

II

front

thread take-up

lubrication

-USE

a-Threading

b-Changing

c-Setting

d-Setting

e

-

Stitch

f

-

Seam

-

Problems due

g

III

-

Every

a

-

Every

b

-

Every

c

the

of

length

width

-

MAINTENANCE

day

week

three

d-Sharpening

head

of

assembly

and

Adjusting

locking

and

cover

the

needle

presserfoot

tensioning

adjustment

adjustment

to

months

the

knives

presserfoot

plate

adjustment

control

discs

improper

AND

Sewing

device

handling

SETTING

Parts

arm

of

UP

machine

Pag.

11

11

11

-

11

11

16

16

16

17

19

19

23

23

23

23

23

24

25

25

25

25

‘

25

PARTS

CATALOGUE

I

-

Introduction

a

II

•

HOW

TO

-

HOWTOORDER

USE

SPARE

THIS

a-Allparts

-

Needles

b

-

TABLES

III

PARTS

IV

NUMERICAL

INDEX

OF

CATALOGUE

29

29

29

29

31

79

Page 3

INTRODUCTION

Page 4

I.

HEAD

IDENTIFICATION

1

2.

3.

Identification

a)

Every

—

class and

—

serial

he

class

ihe

head

head

number

is

sutjclass

and

serial

numbers

identified

sub-class

number

by:

numbers

numbers

is

engravedona

are

engraved

boss

on

on

the

the

nameplate

bottom

on

the

base

of

the

base.

the

of

machine.

ihe

heads

specifications:

Straight

1.

Stitch

2.

3.

4.

5.

6.

7.

8.

9.

length

Differential

Width

of

from

Speed

Lubricatior

Motor:

Overall

Weight:

illustrated

needle

variable

ratio

bight

6,000

by

HP

1/3

dimensions

head

about

system

up

from

double

or

43

to

1/2

lbs.

in

this

RIM

from

to

3,5

3/64”

7,000

stage

HP

catalogue

27

6to40

to

—

15/64”

r,p.m.

pump

according

300x240

II.

-

size

1

TECHNICAL

are of

from

stitches

according

to

sub-class

mm.

55

the

to

per

to

DATA

single

needle

100

inch

performance

CLASS

OF

overedging

type

having

the

following

general

5

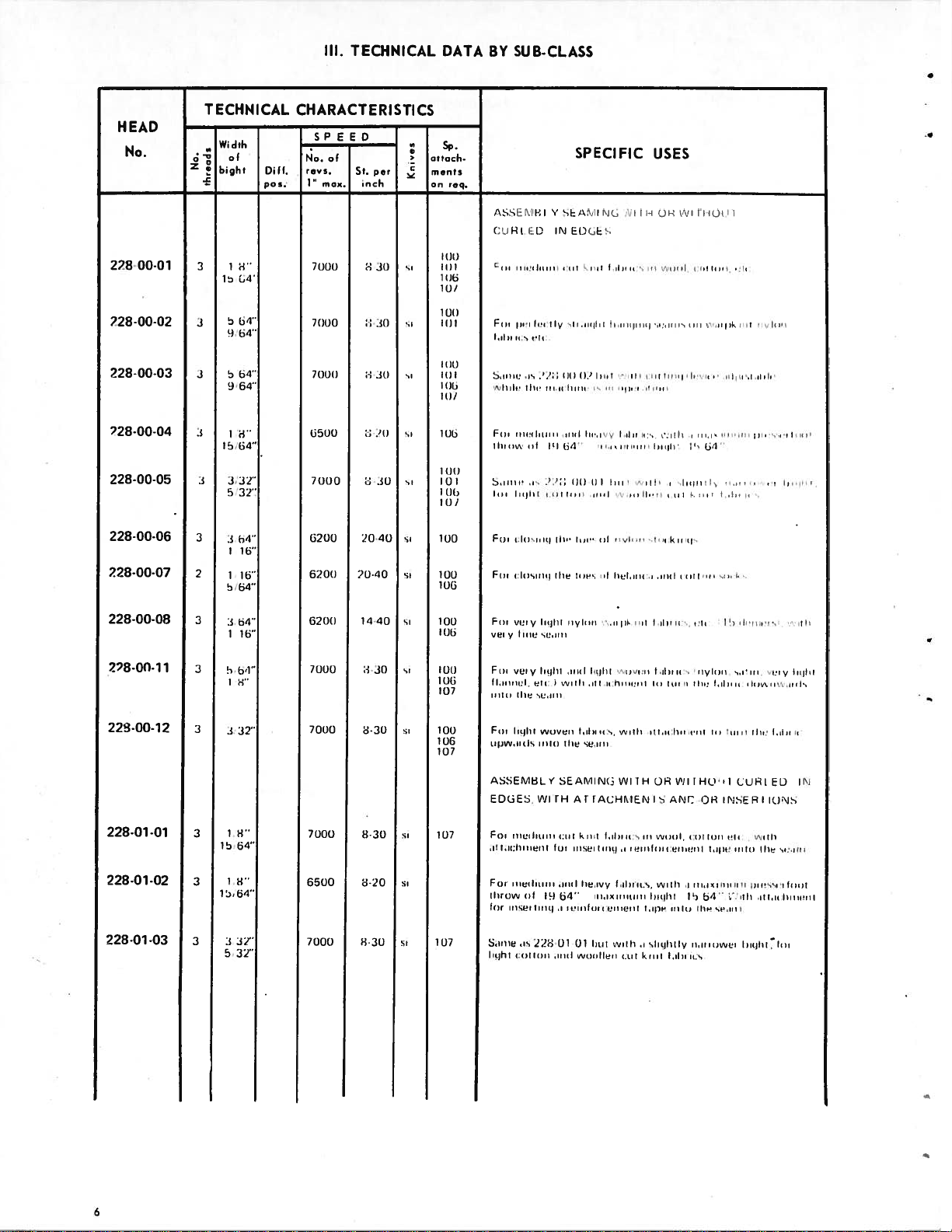

Page 5

III.

TECHNICAL

DATA

BY

SUB-CLASS

HEAD

No.

228

00-01

228-00.02

228-00-03

228-00-04

228-00-05

228-00-06

228-00-07

TECHNICAL

———

Wdth

of

0

Z

bight

&

15

n’)

(14”

5

1)

64”

134”

5

3

04”

1)

3

H”

T5,64”

3,32”

3

5

32”

3

04”

3

1

16”

7

1

16”

64”

5

CHARACTERISTICS

SPEED

N0.

of

revs.

D1If.

pos.

I’

m

ax.

71101)

it

1(1(1

71)1)11

3500

7000

6200

1320))

St.

i

20-40

20-40

—

‘•

per

n

ch

attach.

ments

on

req.

/\s;Eft’IH)

(

HI

EDINEOUC

11)11

II

1(1)3

111/

3(1

1(T))

sc

TI))

Ill))

ITT

TI))

I

11/

si

Ill_i

(It)

su

TI)

Ill,

III

1

si

(JO

sc

100

TOO

Eric

—i_rcrr

‘,‘‘lrrIiltirnru,iuhrurnr-isnr

Fun

ilirui_,’

I

Si_in’

/

Fur

Fri

(i_cr

ui_i

Ii,’,

,i_’,

,iiicrlirr,cn

Iri(Irliniiiurninrnul

Ju’rrnq

r,Iiisi_nnij

Iii

it

is

Tt

‘20

V

ly

nini_,

Fc\iIN11

Ill

i_ri_i_I

lii’

tin’

SPECIFIC

iri_cijIrl

Ir.rcirjirui_

iii

0.)

‘‘nh

iC)(ii’I

hnr•,u’

y

ri,

uinrn’

1))

II

ui_i_i

liii”

ri_I

rrvliinr

(un,’’

nit

trrcl,urni

USES

I))

iVIlIl

‘i_i_iris

i_Ill

r’,irlikrrit

i_i_i_ni,

liii

,ui

Inn

un’s

u’nflr

sins

Iuijti:

,i_

I’’

1,.)’’

,i_

sliuhinI

5

kim1-,

inn

rut

iii

pinlir

,uunlti’n,i_i_uii’,tu,it,iluuu’,

rivlrrrr

nr,unnni_’,’r

228-00-08

228-00-1

228-00-12

228-01-01

228-01-02

228-01-03

3

b4”

3

1

16”

1

3

3

32”

1

H”

3

15

64”

1

H”

3

1564”

32”

3

3

5

32”

6200

71)00

7000

7000

6500

7000

1440

3-30

3-30

H

5-20

i-i

Fur

sPry

InuTti

si

I

01)

I

1)6

si_

(1111

1)13

07

si

IOU

011

07

very

ti_mu

Fur

very

)I,inniriil,

ii

liii

I

Fir,

tight

ui(Ji_’Ji_rilsrnitii

ASSEFIUL

EDOES,

Fit

30

30

107

Sn

Sr

Si

1

07

r

ri_ic

,,tt,i_pttinrpnnt

For

rnrenlrii,nn

utiiui_w

icr

rni_srertrnri,irnci_rilrini-ecnrr’nri

Sin_c

(gIrt

r,rittirnr

semi,

Iii)hi_l

ccli:

liii

icc

‘cc

woven

y

VYITHATI

liii

ni_n

li_c,

ni_I

19

is

221-JUT

isO

rnytirnn

‘.‘

unit

lujiul

u’jrtlr

,i_ii,uu.hriiinmn

ti_Icr

liii

se,irnr

SEAMINC

ACHFILNISAND

k

ri

it

cii

trmrc(

ri_si_in

i_ni_il

tre,uvy

nnr,rxi_irrni_nnr

(14’’

UT

li_i_il

wi_nIle,

,ir1il

‘rivitnr

is,

vvnttr

WITHOH

I

ti_inc

p

ti_hr

with

i_i_ct

nut

liii,

ii

iii,

i_’5

ii,

turin

-itl,ri.tnrr,r’,nt

Eli

,vjui_ii

ri_n

ri_s.

,i

knit

ti_(Dre

slightly

untO

(Itt

t,ihi_r

I

Hill,

,ilrnrhiirr.r,rrru,’cu

,,

i:in

niylniri,

liii,

HOn

I

OR

iii

trill

t,i_)in’

nnr,rurrrrrnr’m

p

Ti

i_i4’’,’:utr

lip

nr,i_i_ruwnr

ri_s

Tb

ilium

ri

‘urn

iT

INSER

p

sr’,nnri

Iii

su’uni,

nIiirmrc,,nrnIs

iii’

CUR)

I

cv

run

r

stun

ttni

,irrm’,sr’rtui_ui_)

,utt,ii.Irrrrflrnt

ri_glut.

‘my

EL)

IONS

(irjtnn

IN

si_li_rn

iii

a

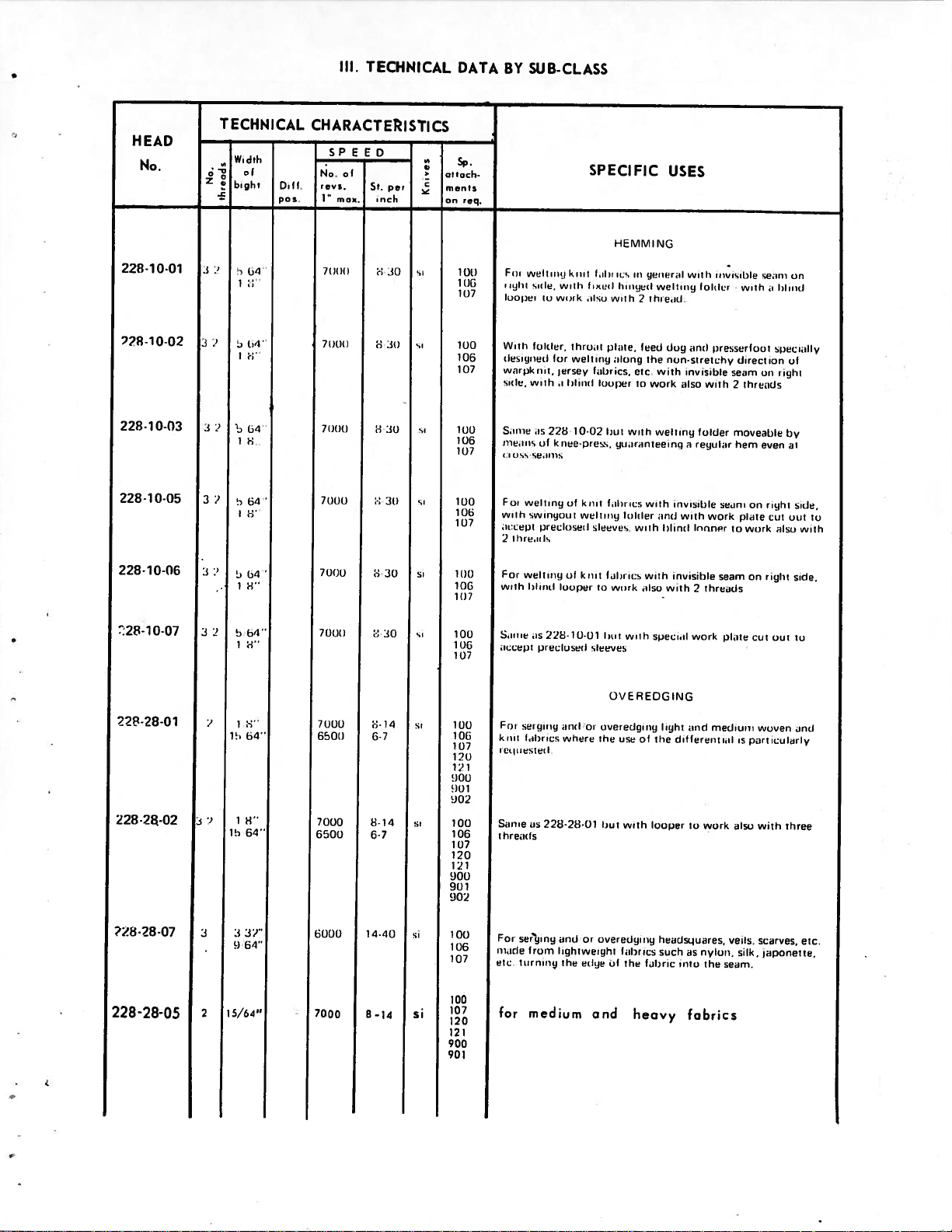

Page 6

III.

TECHNICAL

DATA

BY

SUB-CLASS

HEAD

No,

228-10-01

728—10-02

228-10-03

228-10—05

228-10-06

TECHNICAL

———

Width

Z

bight

‘±

.

J

,i

tn’l’’

.‘

,

1

;-

3

7

64’’

1

3 7

04’

‘‘

1

CHARACTERISTICS

SPEED

D1!l,

reos.

p05.

1

moe.

ill(S)

7000

/(1(1(1

7000

—

St.

SPECIFIC

per

rich

-1

30

8

30

on

req.

HEM

si

10(1

101

si

lug

106

107

si

100

100

1(11

si

100

lOIn

1(17

1(11)

106

10!

Fur

in(lnt

looper

Viiilfr

Iusignur,’d

svirpk

smufc’,

Srurrw

rununis

(isS

Fun

will,

nn’cepi

iOn

2

For

with

vr’Ilrrirr

sine,

u.n

folder,

rr

with

is

of

seuntis

s’e0rrrq

swinqonit

precliuseil

Sun’,

well

blind

with

wnirk

for

II

(ersey

lnlinnnl

i

228

kiree-pruss,

of

eug

of

looper

knit

tlironl

well

10-02

fun

,ulsu

mug

filur

knit

welluurr

1

sleeves,

knit

us

veil

fnrnnn(enl

with

tIltS,

dung

cs,

lool)liitovvoi

but

ilunimnnlteeing

f,i0nicswith

fil

to

work

M

ri

1’

feed

etc

with

funldni’

with

us

N

gruuurr,uI

welunir

1

tlrre,nn(

the

with

welling

rind

with

ilso

USES

(3

dog

non-st

k

invisible

lnlinnl

invisible

with

ssitlr

eurO

invisible

ilso

in

r

with

(runner

2

loluIi

presserfoot

retchy

with

folder

eqolrur

work

thrennis

unrvrsuble

will,

direct

seem

lhrn,rinls

2

moverible

hem

seurli

pinte

to

seam

or

work

on

sennru

i

specinllv

on

or,

even

righi

cut

right

fnlnrrrl

of

right

by

et

out

elso

on

side,

side,

with

to

‘28-10-07

22-28-01

228-2a-02

228-28-05

3

j:’10’

2

7

1,4’’

5

li-I’’

1

15

lb

.1

1)

15/64”

0’’

64’’

64’’

37”

64”

70011

7000

65011

7000

6501)

6000

7000

6-7

8.14

6-7

1440

8-14

1-14

s

100

Smnri

ms

106

107

si

100

106

10/

(1(10

101

002

100

,

000

001

002

Si

100

106

107

100

si

121

900

901

106

107

120

11’

Snow

t

1

For

made

etc.

for

iccept

For

sei

knit

fibi

i5ulmiesleil

hretcis

set’ging

tuurr’uirug

72810-01

pree(oser(

gong

us

‘is

720-28-01

from

medium

sleeves

uuf

oi

wl’iere

rind

or

lightweight

the

edge

hut

with

OVEREDGING

oveiedgii,y

the

use

but

with

overedyniug

fabrics

of

the

and

specuil

of

the

looper

fabric

heovy

work

light

end

clitfereirt

to

herudsqutres,

such

as

unto

fabrics

medium

work

nylon,

the

plmile

nil

jIso

eels.

serum.

is

silk,

cot

woven

pert

with

scarves,

out

icularly

three

ruponette,

to

unrj

etc.

Page 7

0

III

-I

z>n

—c

un

Z>O

ZO..

m

Az-n

Z

-I

—

z

Q

I

Page 8

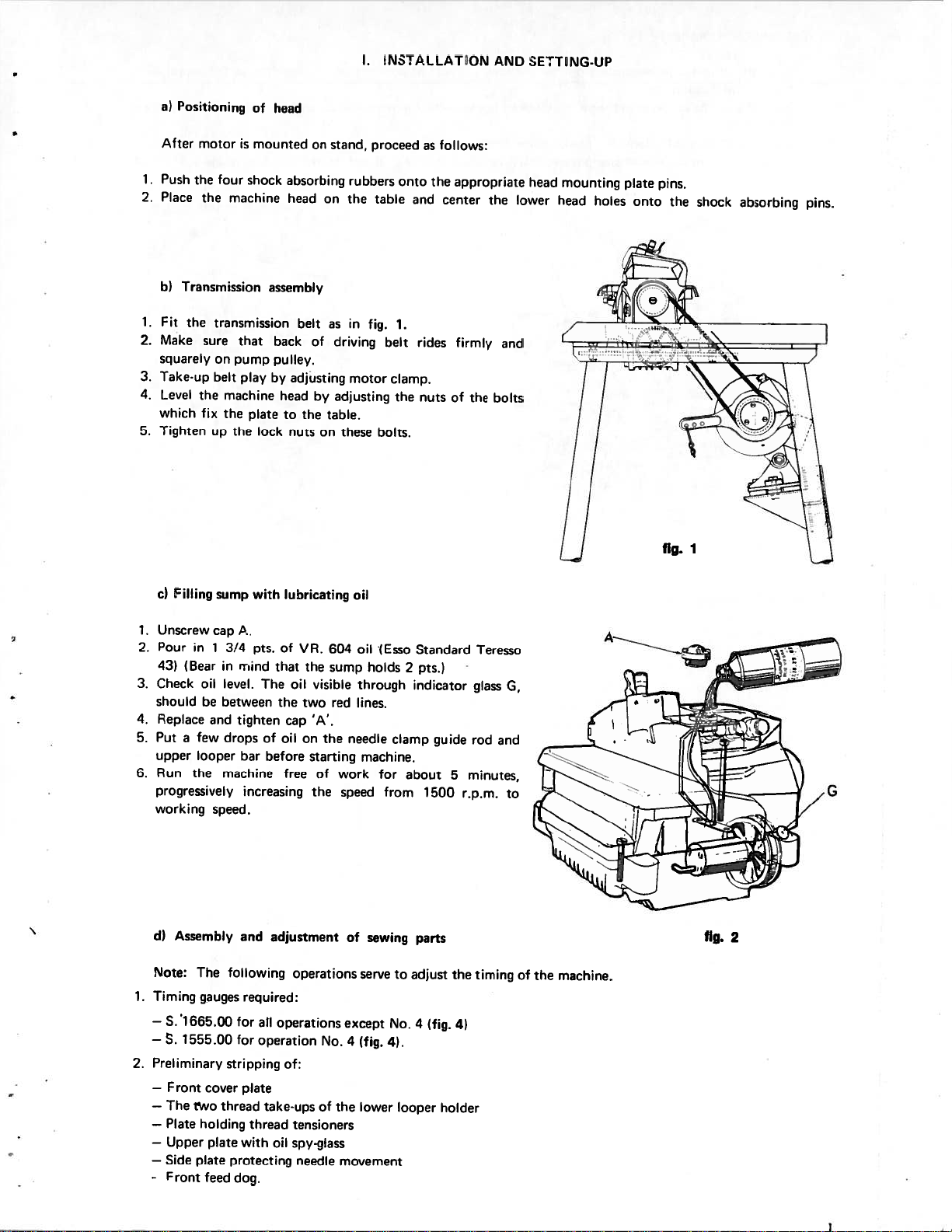

1

2.

1.

2.

3.

4.

5.

Positioning

a)

After

Push

the

Place

Transmission

hI

Fit

the

Make

squarely

Take-up

Level

which

Tighten

motor

four shock

the

machine

transmission

sure

on

pump

belt

the

machine

fix

the

the

up

of

is

mounted

that

play

plate

head

assembly

back

pulley.

by

head

to

lock

on

absorbing

head

on

belt

of

adjusting

by

the

nus

on

stand,

rubbers

the

as

in

driving

motor

adjusting

table.

these

I.

proceed

table

fig.

bolts.

INS

1.

belt

clamp.

the

onto

LLATON

as

the

and

rides

nuts

follows:

appropriate

center

firmly

of

the

£kNDSErTNG-UP

mounting

head

lower

the

head

and

bolts

holes

plate

onto

pins.

the

shock

absorbing

pins.

c)

Unscrew

1.

Pour

2.

431

3.

Check

should

4.

Replace

5.

Put

upper

Run

6.

progressively

working

dl

Note:

Timing

1.

—

S.

—

S.

Preliminary

2.

—

—

The

—

—

—

Side

-

illing

in

(Bear

a

few

looper

the

Assembly

The

‘1665.00

1555.00

Front

rvvo

Plate

Upper

plate

Front

sump

cap

3/4

1

in

level.

oil

between

he

and

drops

machine

speed.

gauges

cover

thread

holding

plate

feed

with

A.

pts.

rriincl

The

tighten

of

before

bar

increasing

and

following

required:

for

all

for

operation

stripping

plate

take-ups

thread

with

protecting

dog.

lunricating

of

VR.

that

the

visible

oil

the

two

IA’.

cap

oil

on

starting

free

the

adjustment

operations

operations

of:

tensioners

oil

spy-glass

needle

of

of

604

sump

red

the

No.

the

oil

oil

(Esso

holds

through

lines.

needle

machine.

work

for

speed

sewing

of

serve

except

4

(fig.

lower

movement

clamp

from

to

No.

4).

Standard

2

pts.)

indicator

about

parts

adjust

4

looper

guide

1500

(fig.

5

the

4)

holder

Teresso

glass

rod

minutes,

r.p.m.

timing

and

G,

to

fig.

I

fig.

2

of

the

machine.

Page 9

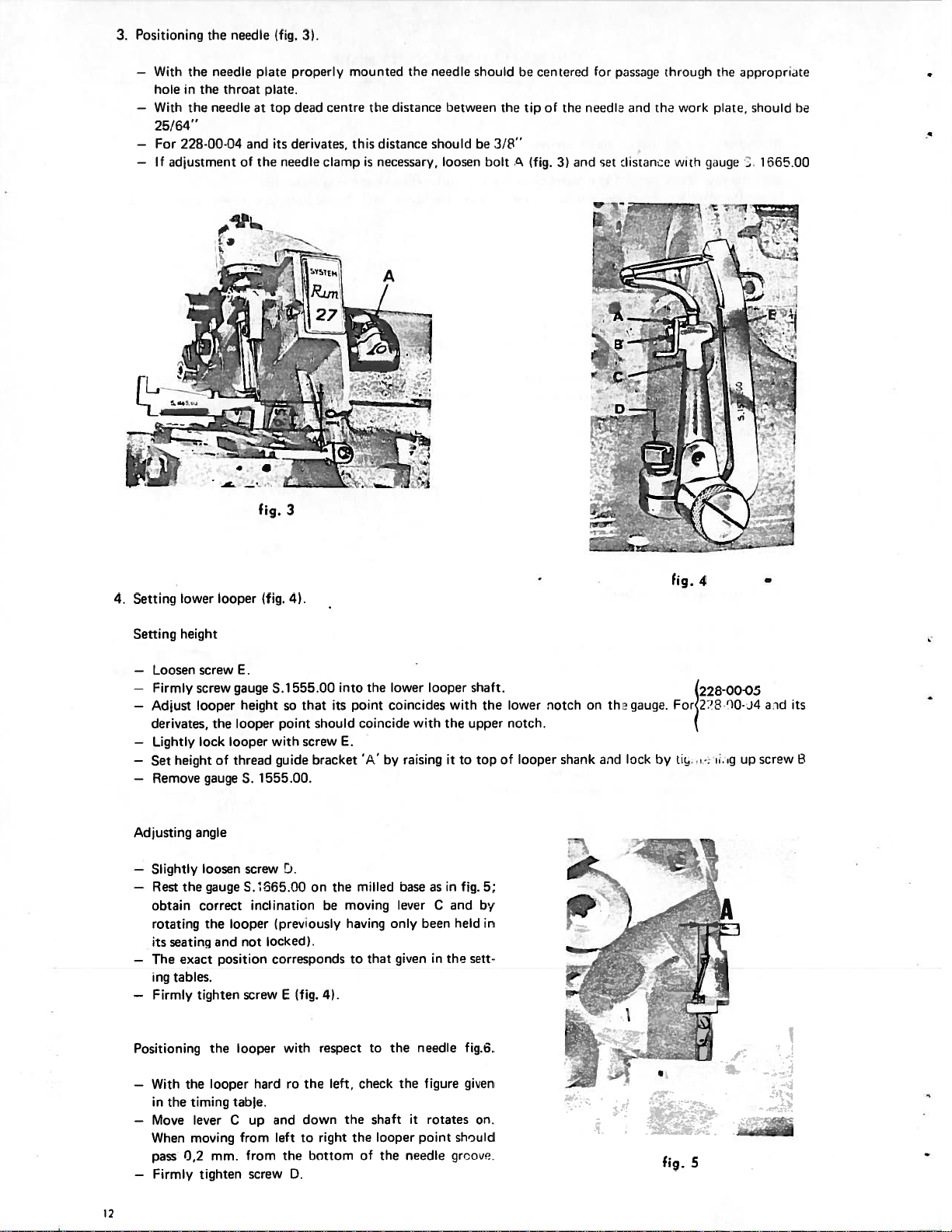

Positioning

3.

—

—

—

—

With

the

holeinthe

With

the

25/64’

For

228-00-04

If

adjustment

the

needle

throat

needle

needle

and

of

(fig.

plate

properly mounted

plate.

dead

at

top

derivates,

its

needle

the

3)

centre

clamp

this

is

the

distance

distance

necessary,

the needle

between

should

loosen

should

he

bolt

the

3/8”

he

tered

for

and

riinella

sat

pis.,gothioiigh

and the

distiuw

work

with

the

ippi

pl;ite,

should

gauge.1

opriate

be

d6500

con

tip

of the

A

(fig.

3)

4.

Setting

Setting

—

—

—

—

—

—

Adjusting

—

—

—

—

lower

height

Loosen

screw

Firmly screw

Adjust

looper

derivates, the

Lightly lock

heightofthread

Set

Remove

gaugeS.1555.00.

angle

Slightly

Rest

obtain

rotating

its

The

ing

Firmly

loosen

the

gaugeS.1365.00

correct

the

seating and

exact

tables.

tighten

looper

E.

gauge

height

looper

looper with

screw

inclination

looper

not

position

screw

fig.

3

(fig.

4).

S.1555.00

so

point

guide

1).

(previously

locked).

corresponds

E

into

the

that

its

point

should coincide with

screw

E.

be

the

moving

‘/‘

milled

by

bracket

on

having

that

to

(fig.

4).

lower

looper

coincides

raisingitto

baseasin

leverCand

only

been

giveninthe

with

the

upper

fig. 5;

held

sett

shaft.

the

top

by

in

lower

notch.

of

looper

notch

shank

on

th gauge.

a-id

lock

fig.4

228-00-05

2310-j4

For

by

ic

.

aid

its

screw

up

.g

B

and

left

with

the

D.

respect

down

to right

bottom

Positioning

—

With

the looper

in

the

timing

—

Move

When

0,2

pass

—

Firmly

12

looper

the

table.

leverCup

moving

from

mm.

tighten

hardrothe

from

screw

left,

the

check

the

of

to

shaft

looper

the

the

the

it

needle

needle

figure

rotates

point

fig.6.

given

on.

should

groove.

.

5

Page 10

i’

III

I1(J

5

)er

Li

100

1)1

per.

6.

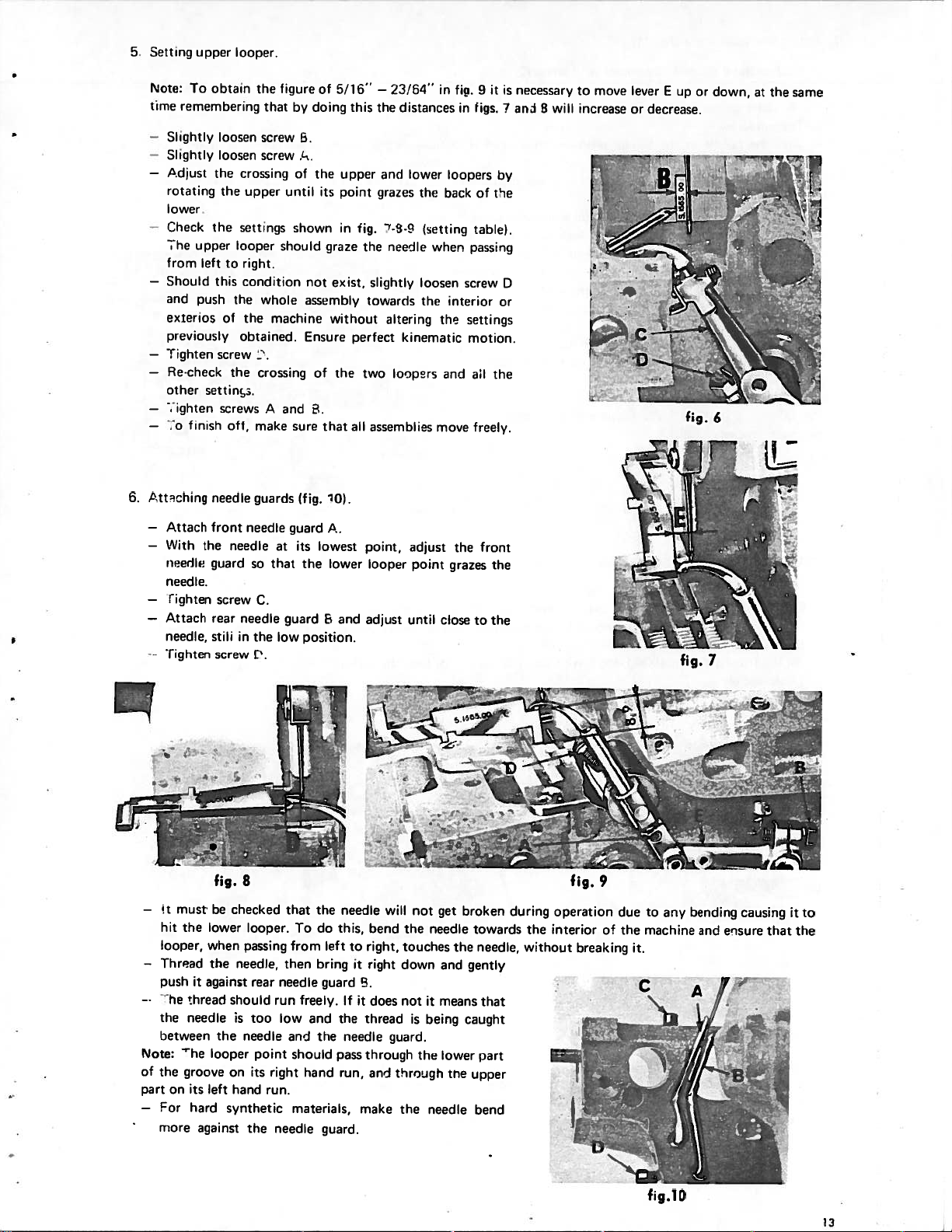

Note:

time

—

Slightly

—

Slightly

—

Adlust

rotating

lower

-

Check

The

from

—

Should

and

exterios

previously

—

fighten

—

Re-check

other

—

lighten

—

.0

Attching

—

Attach

—

With

needle

needle.

—

ighten

—

Attach

needle,

Tighten

obtain

To

remembering

loosen

loosen

the

the

the

upper

left

to

this

push

the

of

screw

the

settin.

screws

off,

finish

needle

front

the

needle

guard

screw

rear

stili

screw

the

that

screw

screw

crossing

upper

settings

looper

right.

condition

whole

the

obtained.

crossing

A

make

guards

needle

so

C.

needle

in

the

t.

figure

by

b.

/-.

of

until

shown

should

machine

and

sure

(fig.

guard

its

at

that

the

guard

low

of

doing

the

its

graze

not

exist,

assembly

without

Ensure

of

.

that

‘O(.

A.

lowest

lower

E

position.

5/16’

this

upper

point

in

the

and

fig.

the

slightly

towarris

perfect

two

all

assemblies

point,

looper

adjust

—23/54”

the

distances

and

grazes

7-S-s

needle

altering

kinematic

ioopsrs

lower

thc

(setting

loosen

the

adjust

point

until

in

back

when

the

and

move

close

fig.

in

loopers

tahle(.

passing

screw

interior

settings

motion.

all

freely.

the

grazes

to

9

figs.

of

front

it

by

t1e

or

the

the

the

is

necessary

ani

D

move

to

8

will

increase

lever

or

‘T

E

decrease.

B

_ii_

ri

up

or

down,

at

the

same

‘k-1j

I

i—

fig.

8

must

—

—

Note:

of

part

—

‘t

hit

looper,

Thread

oush

the

between

the

For

more

he

on

the

it

thread

needle

The

groove

its

hard

against

be

lower

when

the

against

the

looper

on its

left

synthetic

checked

looper.

oass’rig

needle,

rear

should

is

too

needle

point

hand

the

run

right

run.

needle

that

To

from

then

needle

freely.

low

and

should

hand

materials,

the

bring

and

do

left

guard

the

guard.

needle

this,

to

it

If

the

needle

pass

run,

bend

right,

right

.

it

does

thread

through

and

make

will

touches

down

not

guard.

through

the

the

not

is

it

being

the

needle

get

needle

and

means

lower

the

broken

the

caug-it

towards

needle,

gently

that

part

upper

bend

during

without

the

fig.

operation

interior

breaking

9

of

-izJ’

due

to

the

machine

it.

C

\

any

bending

and

causing

ensure

that

it

to

the

t3

Page 11

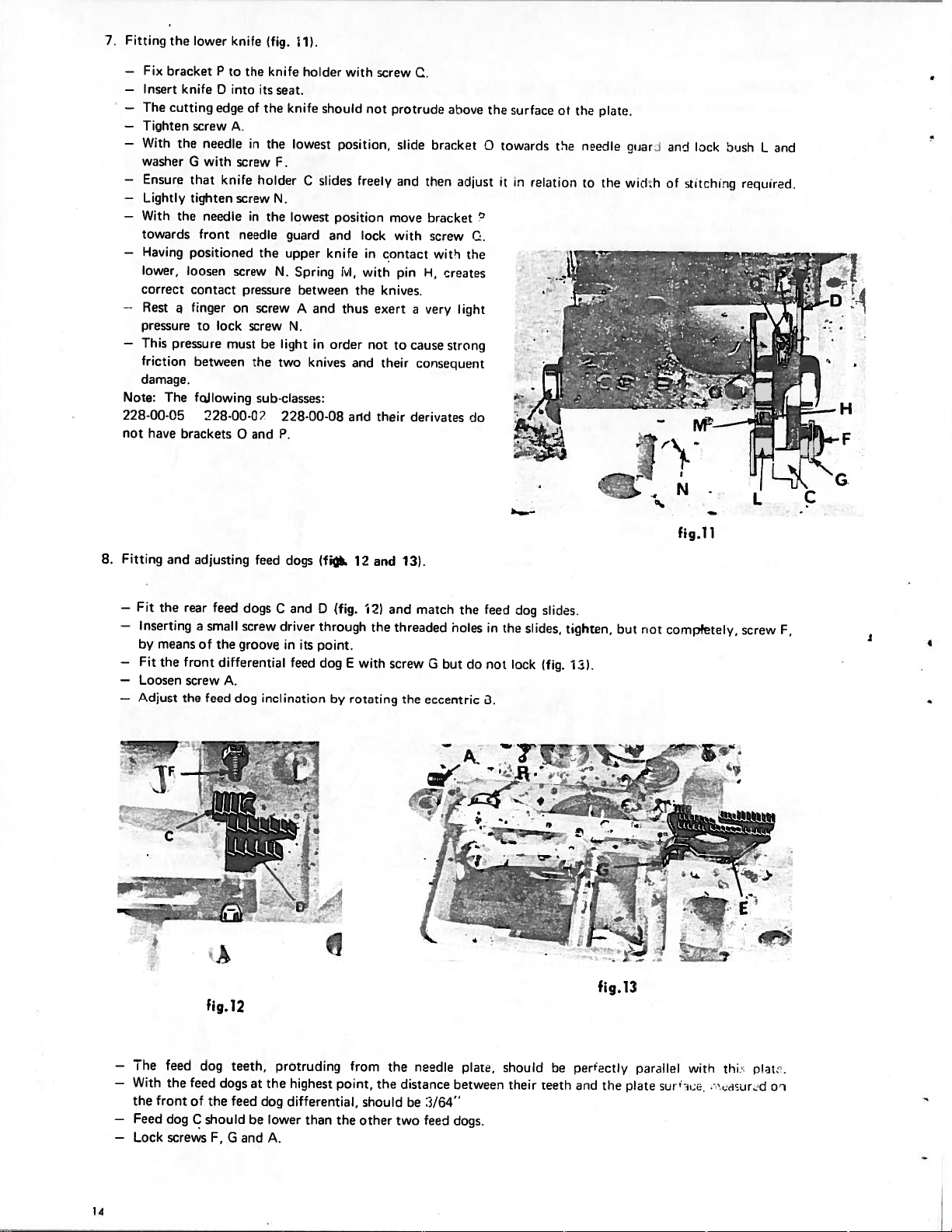

7.

Fitting

--

—

—

—

—

—

—

—

—

--

—

Note:

228-00-05

not

the

Fix

bracket

Insert

The

cutting

Tighten

With

washer

Ensure

Lightly

With

towards

Having

lower,

correct

Rest

pressure

This

friction

damage.

The

have

lower

knifeD

screw

the

G

that

tighten

the

front

positioned

loosen

contact

finger

to

pressure

between

following

brackets

P

edge

needle

with

knife

needle

lock

must

28-00-C2

knife

to

the

into

A.

screw

screw

needle

screw

pressure

on

0

of

in

in

screw

(flu.

knife

its

seat.

the

knife

lowest

the

F.

holder

N.

lowest

the

guard

the

upper

Spring

N.

screw

N.

be

light

the

two

sub-classes:

228-00-08

P.

and

1)

holder

should

C

slides

between

A

and

in

knives

with

position,

position

and

knife

lvi,

thus

order

freely

the

and

arid

not

lock

in

with

not

screw

move

contact

knives.

exert

their

their

C.

protrude

slide

and

with

pin

a

to

cause

consequent

derivates

bracket

then

bracket

screw

witi

H,

creates

very

above

adjust

the

lignt

strong

do

C.

the

J

‘

r

f;ici?

o

i

towar..ls

it

i

relation

:z4-

01

the

the

plit

edle

n

guard

and

lock

oush

L

and

thu

to

wid,h

of

sto:hi;ig

required.

i24

G

L

8.

Fitting

—

Fit

—

by

—

Fit

—

—

Adjust

and

the

Inserting

means

the

Loosen

adjusting

rear

a

of the

front

screw

the

feed

small

differential

A.

feed

dog

A

feed

dogs

C

driver

and

dogs

screw

grooveinits

feed

inclination

(fi%

D

(fig.

through

point.

dog

by

12

121

with

E

rotating

and

the

131.

and

threaded

screw

the

match

but

G

eccentric

the

noles

do

feed

in

not

B.

the

dog

lock

slides.

slides,

(fig.

tighten,

131.

but

riot

fig.11

compfetely,

screw

F,

fig.12

—

The

feed

—

With

the

the

front

—

Feed

dog

—

Lock

screws

14

feed

of

C

dog

the

should

F,

teeth,

dogs

feed

G

and

at

dog

be

protruding

highest

the

differential,

lower

A.

than

from

point,

the

should

other

the

the

distance

two

needle

be

3/64”

feed

plate,

between

dogs.

should

their

be

teeth

fig.13

perfectly

the

arid

parallel

plate

surt

with

e;e,

thi:

.eeaeur,d

plate.

01

Page 12

1

f—ced

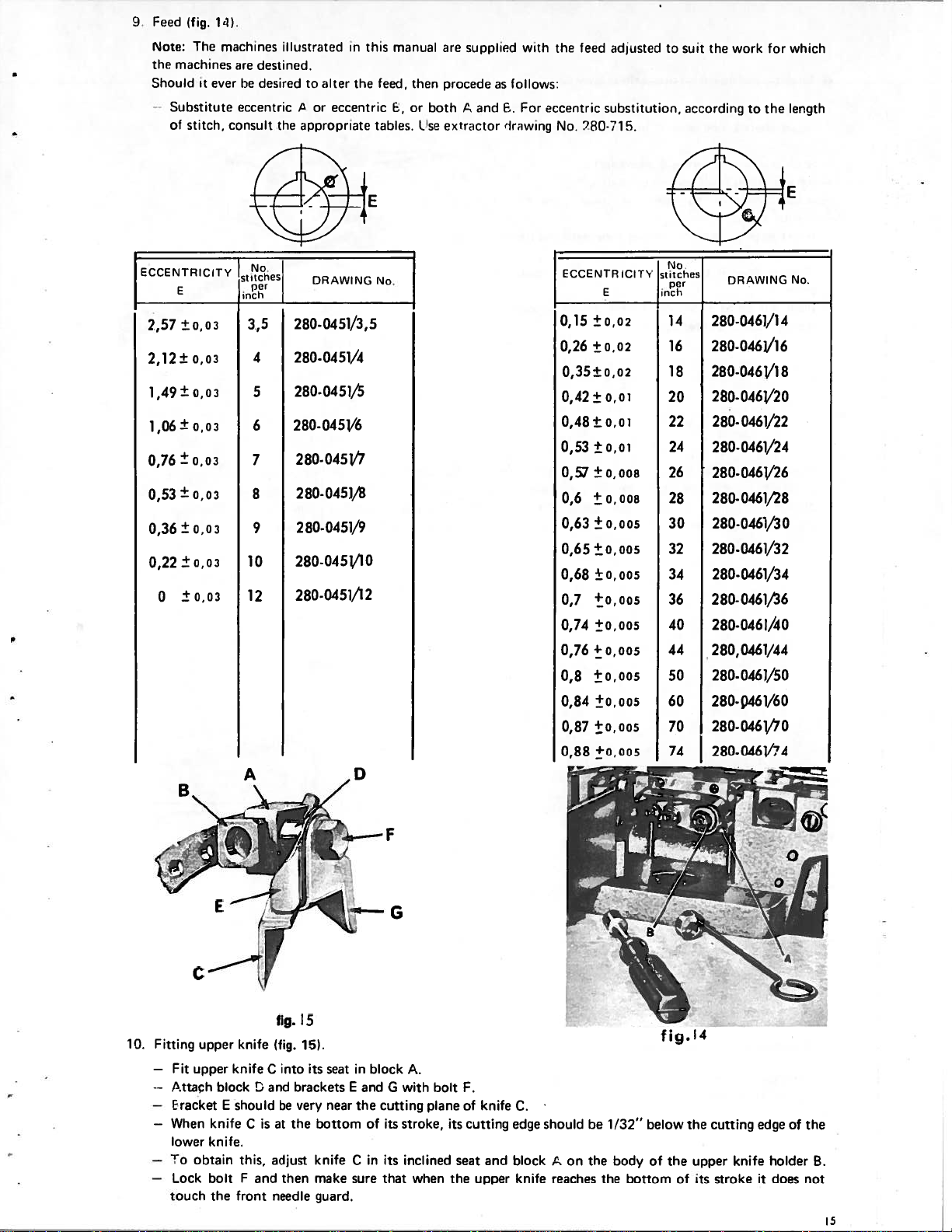

Note:

the

Should

-

Substitute

of

(fig.

The

mechines

It

stitch

1’l).

iteichines

ever

consult

are

destined

he

(lesirirl

eccentric

lIri:,triterl

to

/oreccentric

the

ippropriute

alter

niinurl

in

the

this

feed,

tables.

un:

sLipplietf

then

procede

E

,

or

both

exti:rclor

Lse

and

us

follows:

For

I—

Ii

iwing

with

the

eccentric

No.

f,e(l

280-’1

idjiiste:I

substitution,

5.

tu

suit

iccordirrq

the

work

for

which

length

to

the

ECCENTRICITY

E

±0,03

2,57

0,03

2,12±

±

0,03

1,49

1,06±

0,03

±

0,03

0,76

±

0,03

0,53

±

0,03

0,36

±003

0,22

±0,03

0

B

No.

StiiChCS)

per

3,5

4

5

6

7

8

9

10

12

A

DRAWING

I

280-0451/3,5

280-0451/4

280-0451/5

280-045

280-0451/7

280-0451/s

280-0451/9

280-0451/10

280-0451/12

V6

0

No

ECCENTRICITY

E

0,15

±002

0,26

±002

0,35±0,02

0,01

0,42±

0,01

0,48±

0,53

±0,01

0,57

±0,008

0,6

±o,00s

0,63

0,005

±

0,65

±0,005

0,68

±0,005

+0,005

0,7

0,74

±0,005

0,76

+0,005

+0,005

0,8

0,84

±0,005

0,87

±0,005

0,005

0,88

-.

No

stitches

per

inch

14

16

18

20

22

24

26

28

30

32

34

36

40

44

50

60

70

74

DRAWING

280-0461/14

280-0461/16

280-0461/1

280-046V20

0461/22

280280-0461/24

280-0461/26

280-0461/28

280-0461/30

280-0461/32

280-0461/34

280-0461/6

280-0461/40

280,0461/44

0461/50

280280-

p461/60

280-0461/70

280-0461/74

No

8

F

G

C

fig.

15

10.

Fitting

—

--

—

—

When

lower

—

To

—

touch

Fit

ttach

racket

Lock

upper

knife

upper

block

E

knife

knife.

obtain

boltFand

the front

knife

!.

should

C

this,

(fig.

into

C

and

be

isatthe

adjust

then

needle

15).

its

brackets

very

bottom

knife

make sure

guard.

seat

near

in

block

E

and

the

of

Cinits

with

G

cutting

stroke,

its

inclined

that

A.

when

bolt

plane

F.

of

its

cutting

seat and

the

knife

upper

C.

edge

block

knife

should

,c

reaches

on

be

the

the

1/32”

body

below

of

bottom

fig.

the

of

14

the

upper

its

cutting

knife

stroke

edge

it

of

holder

does

the

B.

not

5

Page 13

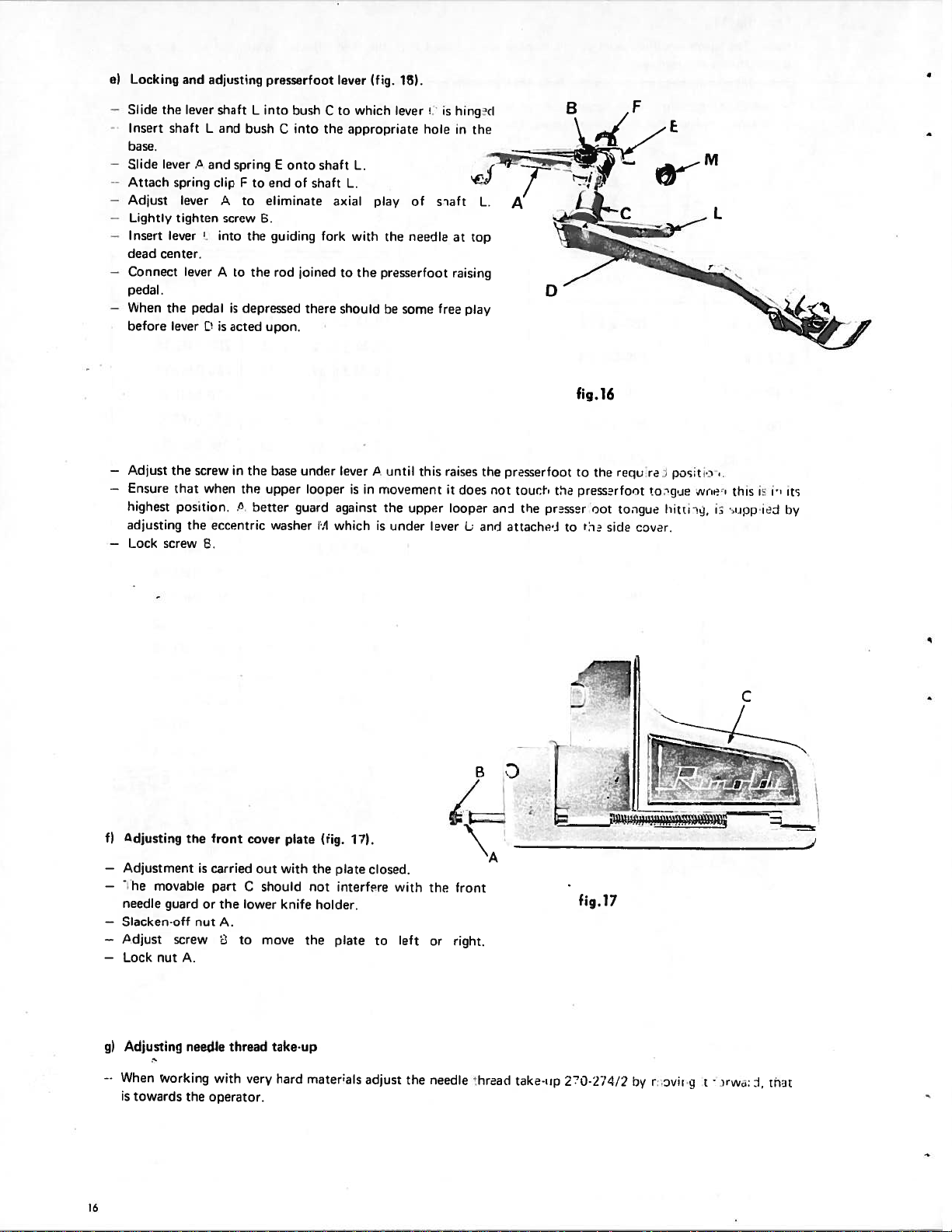

e)

1_ocking

and

adjestnq

presserfoot

lever

(fig.

15).

—

-

--

-

—

—

—

—

—

Slide

Insert

base.

Slide

Attach

Adjust

l_ightly

Insert

dead

center.

Connect

pedal.

When

before

Adjust

Ensure

highest

adjusting

Lock

the

shaft

lever

spring

tighten

lever

the

lever

the

that

position.

screw

lever

lever

lever

pedal

the

L

.

and

.

‘

screw

when

eccentric

E.

shalt

and

clip

,

into

A

is

spring

screw

to

is

acted

in

!

L

into

bush

F

end

to

eliminate

to

B.

the

guiding

the

depressed

upon.

base

the

upper

the

better

washer

E

rod

C

bush

into

onto

of

guard

shaft

joined

there

under

looper

C

the

shaft

axial

fork

‘I

which

to

appropriate

L.

L.

with

the

to

should

lever

in

is

against

which

lever

play

the

pressertoot

be

some

I

until

rriovement

the

upper

is

under

hole

of

needle

this

s

free

lever

hinij

is

in

aft

at

raising

raises

it

looper

play

does

L

the

top

ii

L.

the

not

anh

and

0

presserfoot

touch

the

presser

jttachei

B

the

to

fig.16

the

reqL

to

presserfoot

not

tosgue

t:1e

side

F

cover.

re

to:gJe

ps;t.e

hitti

Niiei

M

L

i

this

is

eipp

.

its

ii

si

by

adjusting

—

--

--

To

f)

Adjustment

—

-

he

needle

—

Slacken-off

isdjust

Lock

g)

Adjusting

When

is

towards

movable

nut

Working

front

the

carried

is

part

guardorthe

nut

A.

screw

A.

needle

with

the

operator.

cover

C

lower

to

thread

very

out

should

move

plate

with

knife

take-up

hard

(rig.

17).

the

plate

not interfere

holder.

the

plate

materals

closed.

to

adjust

with

left

the

the

or

needle

front

right.

A

thread

take-up

fig.17

2O-274’2

by

r,

oviru

t

:1,

tnst

Page 14

ELECTRICAL

EOU1PMENT

FOR

LUBRICATION

CONTROL

(PRESSURE

SWITCH)

Dismantling

h)

—

Remove

—

Remove

—

Remove

—

Remove

—

Remove

—

Attach the

appropriate

—

Replace

Chauging

—

Carry

—

Remove

—

Re-attach

--

Replace

Electrical

the

sump

the

screw

the

two

the

ptastiO

the

support

cable

screw.

the

sump

the

pressure

operations

out

tube,

the

sump

connection

and

extract

tUbe,

and

repIaing

from

fixing

screws

tube

bracket

with the

end

and

switch

1

the

position

fill

with

of

pressure

the

the

base

the

holding

from

fill

with

bulb.

and

2asexplained

bulb,

the

oil

pressure

and

empty

pressure

and

the

the

pressure

fix

switch

cable

it

to

screws, slide

oilasdescribed

which

hasabayonet

pressure

as

explained

on

switch

switch

the

brackettothe

end.

switch

the

new

the

for

switch

on

Zefir

oil.

which

pressure

plastic

page

on

the

substitution

in

pag.

motors.

fitting,

the

11

connects

tube

11

sump

para.

sump.

switch.

into

pare.

of

and

and

c.

to

the

c.

the

replace

attach

the

rubber

pressure

pressure

with

with

union.

switch

switch.

a

new

the

one.

screws.

and

replace

in

sump

with

—

Plug

motor.

if

Note:

take-off

—

Cut

pinsofthe

—

Plug

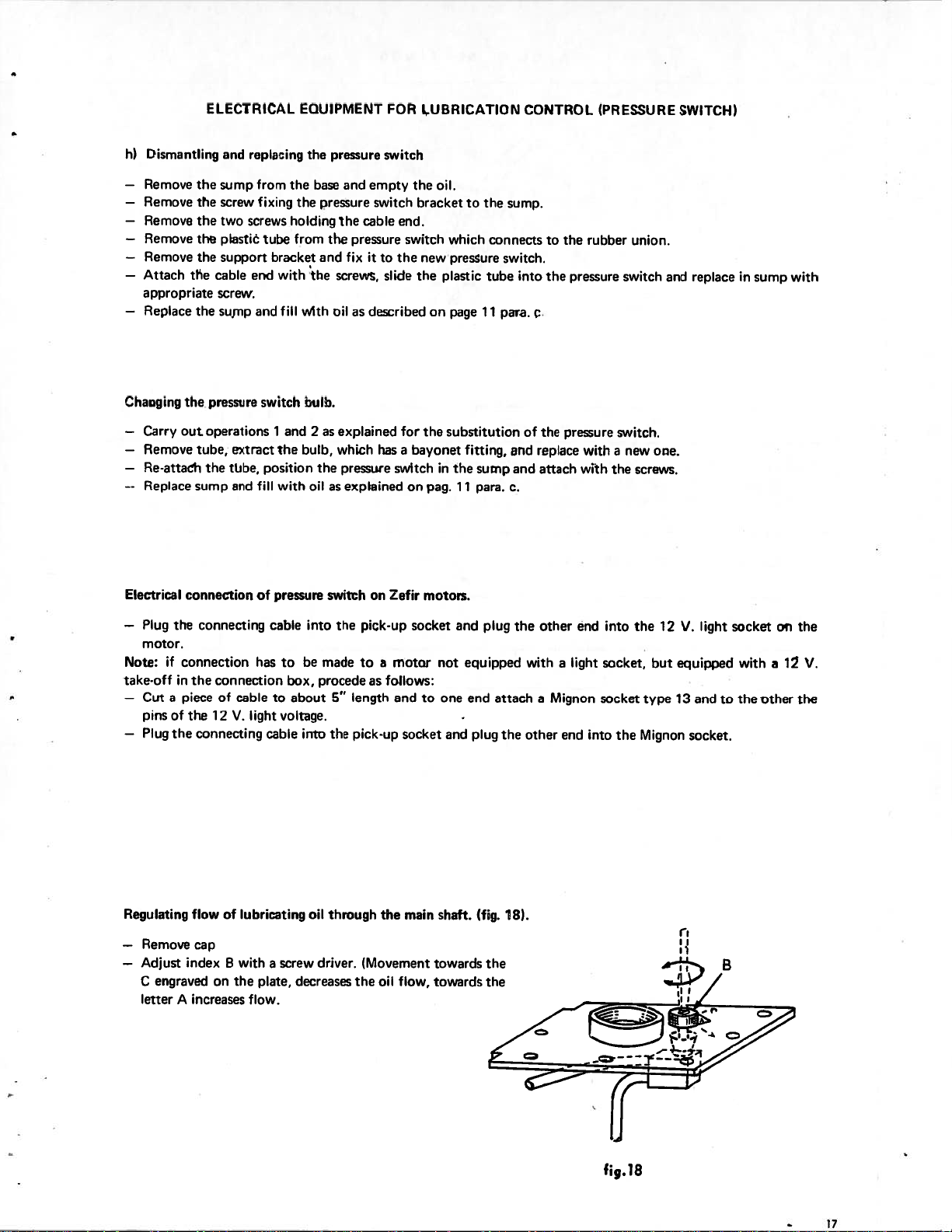

Regulating

—

Remove

—

Adjust

engraved

C

letter

the

connecting

connection

in

the

connection

a

pieceofcable

12V.light

the

connecting

flow

of

cap

index

B

on

A

increases

cable

has

cable

lubricating

with

a

plate,

the

flow.

to

box,

to

about

voltage.

screw

into

be

made

procede

5”

the

into

oil

through

driver.

decreases

the

pick-up

to motor

length

pick-up

(Movement

the

as

the

oil

socket

follows:

and

socket

main

flow,

not

to

shaft.

towards

towards

and

equipped

one end

-

and

plug

plug

(fig.

the

the

the

attach

the other

8).

with

other

Mignon

a

a

end

end

light

into

into

socket,

socket

the

12

the

but

V.

equipped

type13and

Mignon

Ii

light

socket.

socket

with

to

the other

on

the

a1V.

th

fig.18

—

17

Page 15

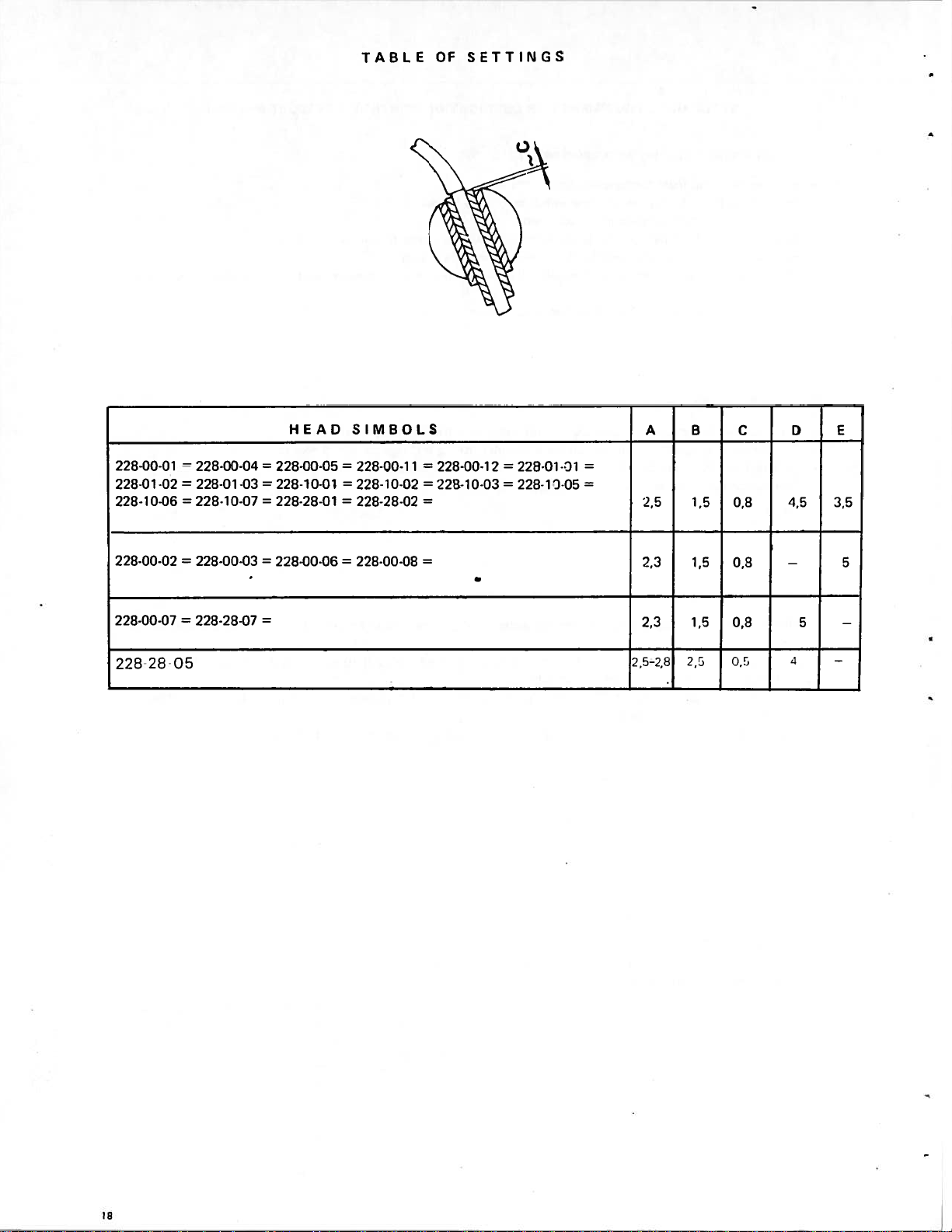

TABLE

OF

SETTINGS

228-00-01

=

228-00-04=228-00-05

228-01-02=228-01-03

228-10-06 228-10-07

228-00-02=228-00-03

=

228-00-07

228-28-07

228-28-05

HEAD

228-10-01

=

228-28-01

=

228-00-06

=

SIMBOLS

228-00-11

=

228-10-02

=

228-28-02

=

228-00-08

228-00-12

=

228-10-03

=

=

228-01-D1

228-13-05

A

=

2,5

2,3

2,3

2,5-2,8

B

C

1,5

0,8

1,5

0,8

1,5

0,8

(j,5

25

4,5

—

4

E

D

3,5

5

5

—

—

18

Page 16

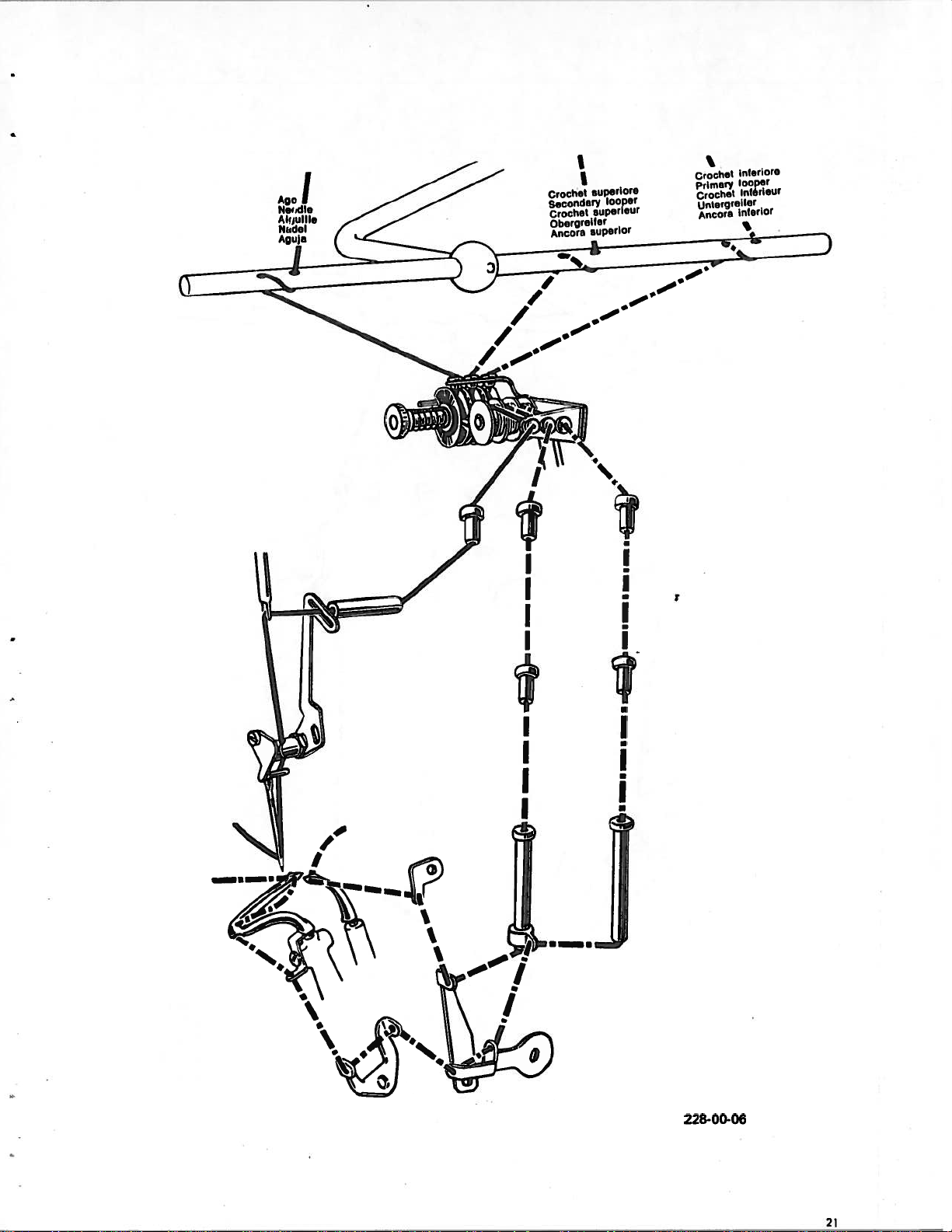

USfS

.

a)

Thread

Ago

Needle

Alguille

Nadel

Agula

inq

1’

Crochet

Secondary

Crochet

Obergreiter

Ancora

I

I

superior.

looper

superieur

supertor

Crochet

Primary

Crochet

Unlorgreiler

Ancora

I

Interior.

looper

inlérteur

interior

I

I

I

/

I

228.00-0.,

228.00-02

228.00-03

228.00-05

228.00-08

228.00-11

228.00.12

228.01.01

228.0102

228.01.03

228.70.01

228.10-02

228.10.03

228-10.05

228.10-o6

0-07

228-i

228.28.02

228.207

Page 17

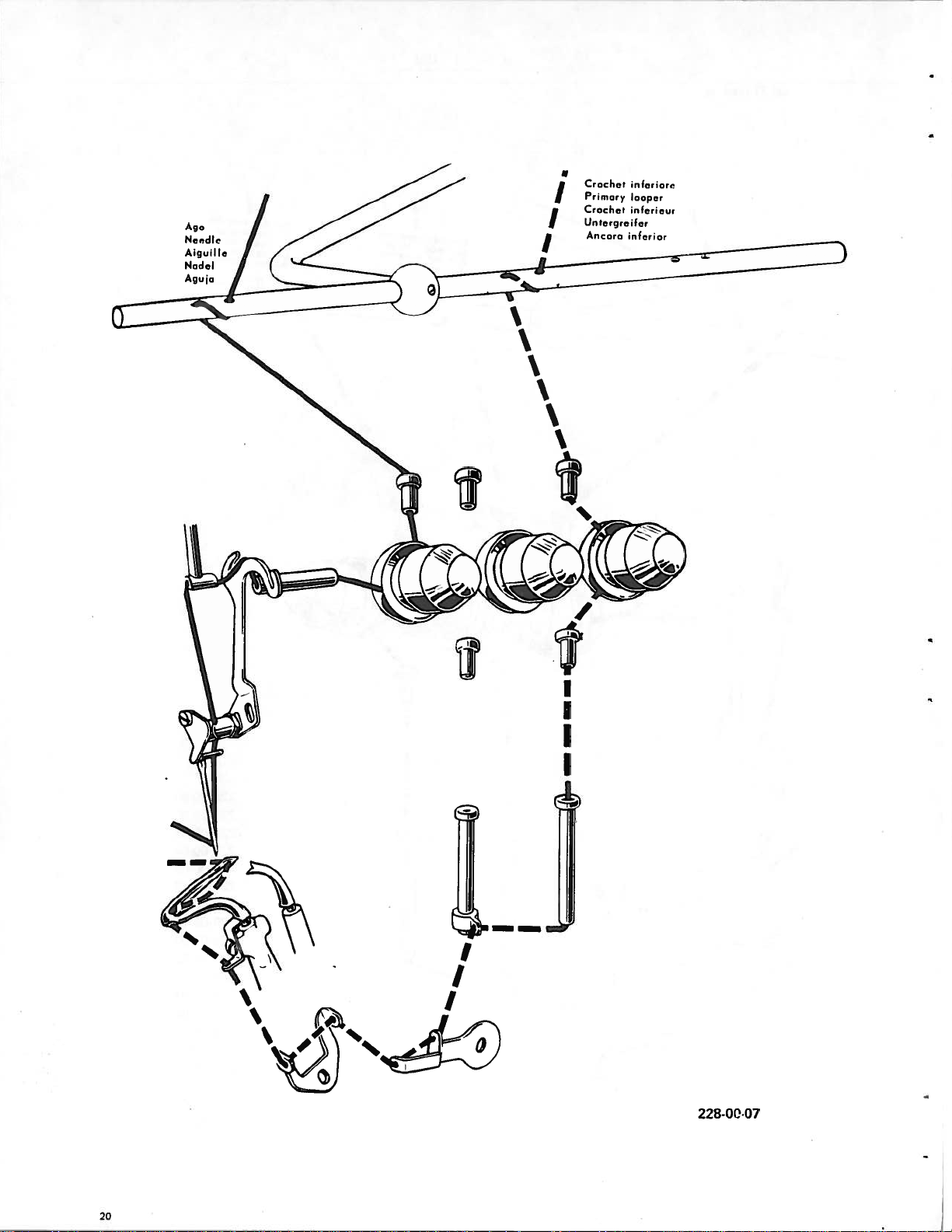

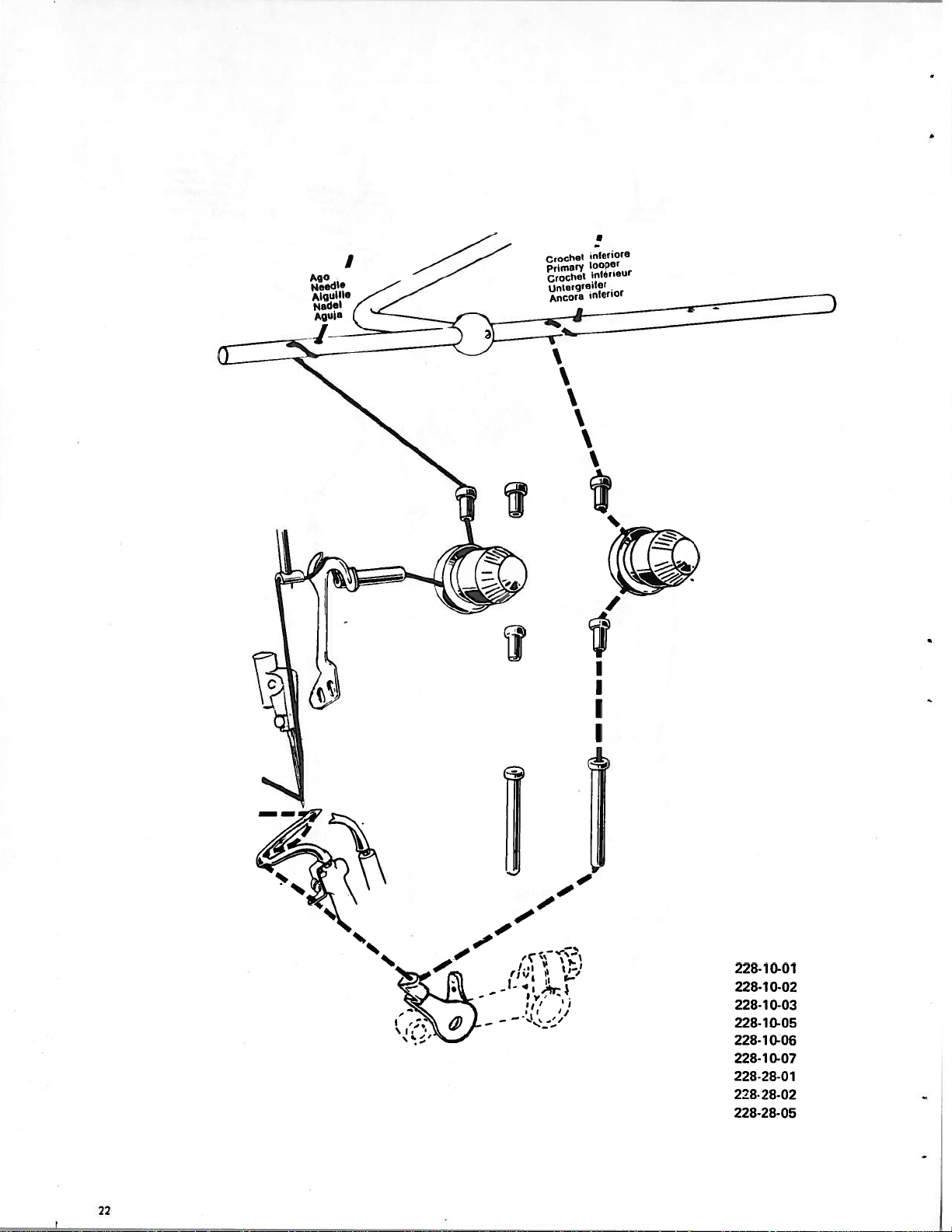

Ago

Nedl

A

Nodal

Ag,

10

guilje

I

‘

‘

a

Crochet

Primary

I

Crochet

linteryrorfer

Ancora

k

‘flhc•rior,.

looper

flfCrIeur

I

I

I

228-OQ-07

20

Page 18

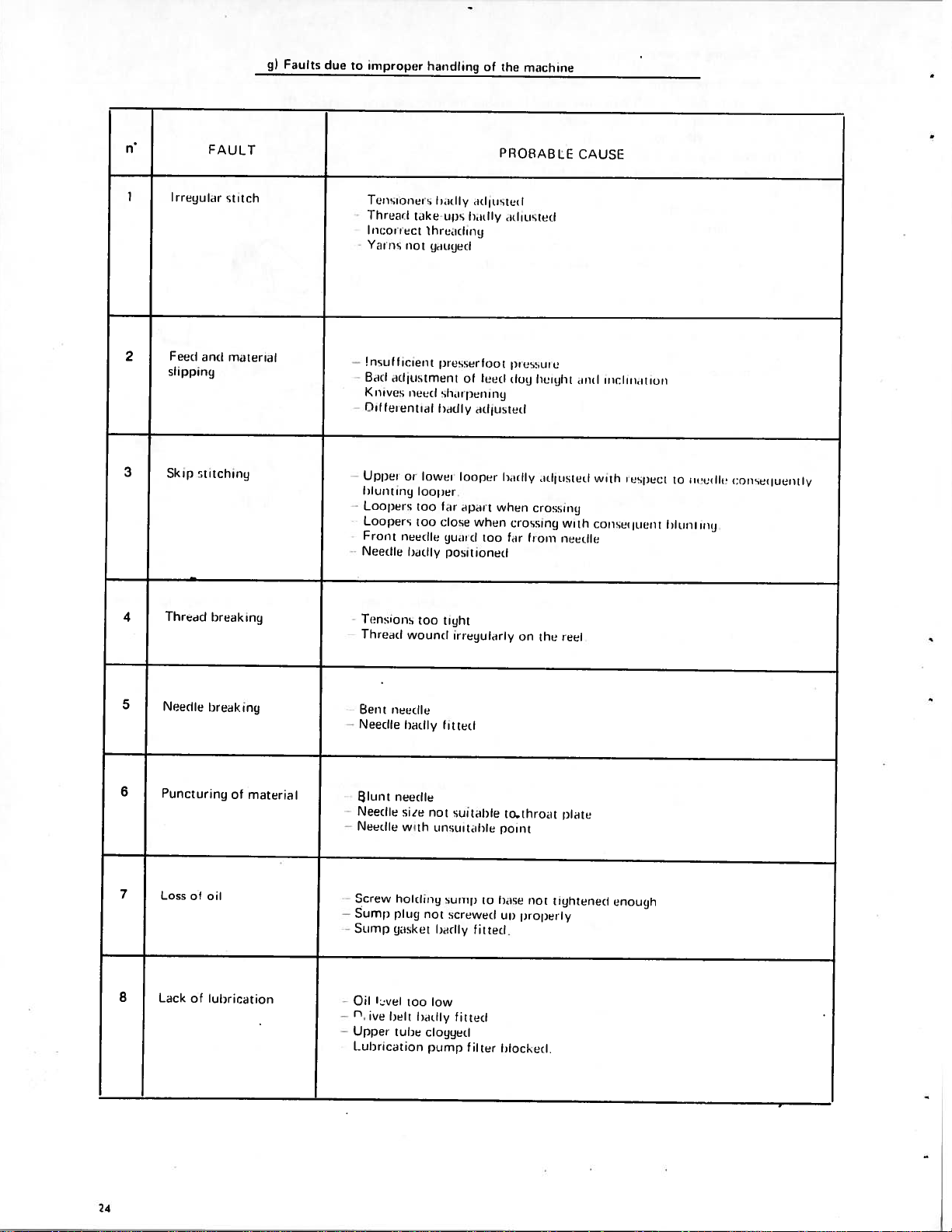

I

Crochet

Secofldery

Crochet

Obergrelter

.ncora

I

euperlore

euperleUr

euperlor

looper

Crochet

prlmftPl

Crochet

lJnLerqreIter

ncora

InferiOre

looper

nterIeUr

lnt00r

I

t

I•

•

I

I

I

=

228-00-06

21

Page 19

nicriora

CrOCh

I

primary

Crochet

nmerqt0

AncOra

oopor

irrierleUr

or

inlerlOr

7,

I

228-10-01

228-10-02

228-1

0-03

228-10-05

228-10-06

228-10-07

228-28-01

228-

28-02

228-28-05

22

Page 20

10.

11.

12.

1.

2.

3.

4.

5.

6.

7

8.

9.

Lnanging

b)

Switch

L’epress

Muve

Press

emovu

Slacken

driver

lemove

Fit

new

The

notch

towards

of

the

Using

iouches

Tighten

position

o

not

the

off

the

the

pedal

needle

the

leverPright

presserfoot

the

needle

the

11

91/2.

ns’rlle.

the

needle.

through

the

reai

machine.

tweezers

the

end

the

the

locking

of

the

over-tighten.

neetfie

motoi

to

needle

of

needle.

which

top

clown

locking

which

the

screw

starts

dead

(fig.

from

the

guard,

supplied

needle

being

the

center.

9).

its

screw

looper

that

holder.

motor

working

half

is

ensure

careful

to

position.

turn

a

passes

towards

that

nottoalter

ensure

with

should

th

the

the

screw

face

interior

needle

machine

the

is

completely

B

G

off.

1.

2.

3.

4.

5.

6.

1.

2.

Posicioning

c)

Check

The

adjust

o

Center

To

knob

Lock

Tension

d)

Tighten

Never

Stitch

e)

For

stitch

correct

needle

should

presserfoot

the

presserfoot

increase

A.

knobAwith

adjustment

tensioners

the

tighten

length

length

and

positioning

or

decrease

much

too

adjustment

adjustment

adjusting.

pass

slacken

in

screw

pressertoot

presserfoot

of

between

off

correct

the

presserfoot

the

6.

sufficiently

(fig.

see

the

screw

14).

para.

presserfoot

F.

position

permit

to

9

Feed,

a)

pressure

shoe

and

pressure,

a

pag.

Ifia.

lock

slacken

regular

and

15.

F.

l9).

tongue.

stitch

off

formation.

screw

fig.

19

with

sparner

633-742

and

adjust

6

Adjustment

1.

2.

3.

4.

5.

f)

The

To

vary

Slacken

Slacken

Move

Lock

Lower

seam

upper

screw

width

the

off

off

knife

width

screw

screw

knife

F

(fig.

holder

seam

of

can

onlybevaried

within

N

in

F

(fig.

support

15).

widtn.

these

the

lower

15).

A

re-setting

(fig.

fine

knife

15)

should

to

a

limits

holder

to

rightorleft

be

very

proceed

carried

limited

(fia.

as

11).

out

extent

follows:

till

desired

in

accordance

after

seam

which

width

with

the

is

needle

obtained.

the

instructions

plate

has

to

be

changed.

in

para.

7.

a)

23

Page 21

ij)

Foults

due

iinpropt,r

to

hutidling

of

tiw

nincliinn

fl

I

2

3

i

I

sju

Fold

slipPiflg

Skip

FAUI.T

lii

(nil

stitching

stitch

motel

PROBABLE

si

Tet

into

idly

ii

el

of

lOu

looper

liii

l)iill’

rig

I

irl1usrud

when

rI

Icil

too

0

flij

i

st

loudly

when

fir

iditistitil

)IitstLiiU

log

crossing

from

—

F1i

ii

tikit

iti:t

riot

irtitO

or

lOoj

too

too

needle

badly

hi

t

jilutfiji

I

lower

iiiis

piussuirlont

sItu

barfly

icr

lii

lose

gUii

positioned

liii

——

I

Vii

us

iii

!nsulficiuoi

Boil

lvi

Kit

Oil

luluential

odlristnuent

Uppot

f

ii

Ohtlug

—

Loopers

Loopers

Front

Needle

height

ilIftistliti

ci

ossung

c;AUSE

nuel

with

nucrlliu

iiiu:lurritiuuu

with

inspect

(;oirsru(j000i

to

h1uotiiu

tuttle

i:oosurjuuiitl

/

Thrwid

4

5

Needle

6

Puncturing

7

Loss

8

Lack

break

&

oil

of

lubrication

breaking

of

ny

materia

Tensions

Thi

end

Bent

needle

Needle

I

lunt

needle

Needle

Needle

Screw

Sump

Sump

Oil

.

ive

Uppei

holding

plug

gasket

Led

belt

tLihe

—

—

--

f_uhricutioii

wound

badly

size

with

too

too

not

unsumtilrle

not

badly

low

badly

clogged

1Jun11)

tight

irregularly

lit

ted

sui

sump

screwed

fitted

Ill

table

fitted

ten

to

tothroat

Point

hose

LII)

I

docked

on

the

reel

plate

not

tightened

open

Pb

y

enoLigh

24

Page 22

briefly

1.

2.

3.

1.

2.

3.

4.

Air

5.

Soak

Every

a)

clean

Every

b)

Remove

.‘pen

‘arefully

Every

c)

Using

Remove

Extract

blast

front

the

felt

day

all

week

needle

cover

clean

three

spanner

screw

filter

filter

with

machine

plate

plate

inside

months

supplied,

007-

and

and

clean

parts

and

the

L

clean

sump

and

oil.

clean

plate

20

relating

carefully

remove

which

by

immersing

plug.

to

the

feed

clean

covering

the

attaches

feed

dogs,

the

sump

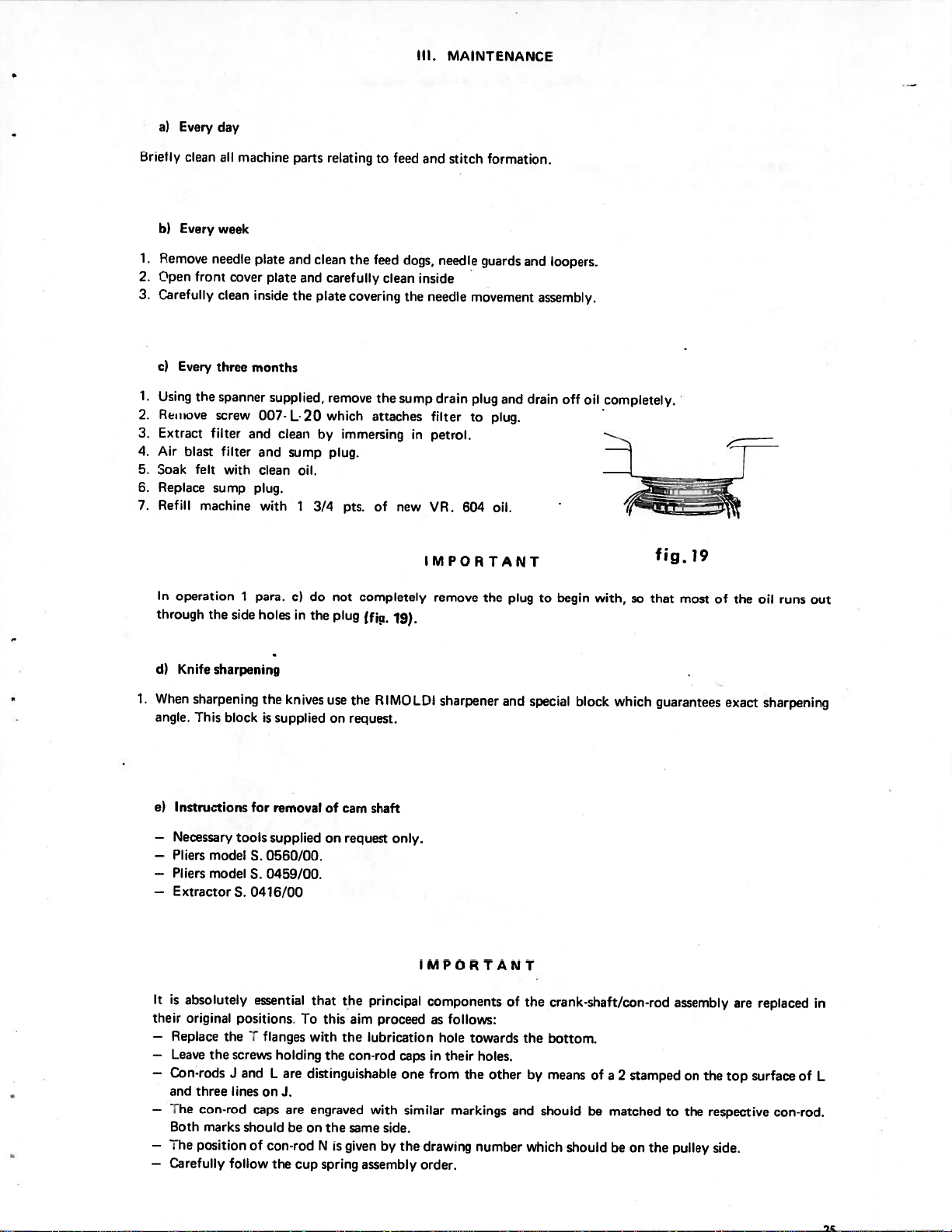

Ill.

MAINTENANCE

and

stitch

needle

inside

needle

drain

filter

in

petrol.

formation.

guards

movement

plug

and

to

plug.

and

assembly.

drain

loopers.

off

oil

completely.

.

1.

In

operation

through

Knife

d)

When

angle.

Instructions

e)

—

Necessary

—

Pliers

—

Pliers

—

Extractor

the

side

sharpening

sharpening

This

block

tools

model

model

S.

1

para.

holes

the

is

for

S.

S.

0416/00

1

c)

in

knives

supplied

removal

supplied

0560/00.

0459/00.

3/4

do

the

not

plug

use

on

of

on

pts.

completely

ffja.

the

request.

cam

shaft

request

new

of

19).

RIMOLDI

only.

yR.

604

IMPORTANT

remove

the

sharpener

oil.

and

plug

to

special

begin

block

with,

so

which

fig.19

that

most

guarantees

of

the

exact

runs

oil

sharpening

out

IMPORTANT

is

It

their

—

—

—

Con-rods

and

—

The

Both

—

The

—

Carefully

absolutely

original

Replace

Leave

three

con-rod

marks

position

the

positions

the

screws

J

and

lines

should

follow

essential

flanges

T

holding

L

on

caps

of

con-rod

the

that

To

this

with

are

distinguishable

J.

are

engraved

be

on

N

cup

spring

the

the

is

the

the

given

principal

aim

proceed

lubrication

con-rod

with

same

assembly

side.

by

caps

one

similar

the

drawing

order,

components

as

follows:

hole

towards

in

their

holes,

from

the

markings

number

other

of

the

the

and

crank-shaft/con-rod

bottom.

by

means

of

should

which

be

should

assembly

a

2

stamped

on

matchedtothe

be

on

pulley

the

are

the

top

respective

side.

replaced

surface

con-rod,

in

of

L

Page 23

10,

11.

12.

13.

14.

1.

2.

3.

4.

5.

6.

7.

8.

9.

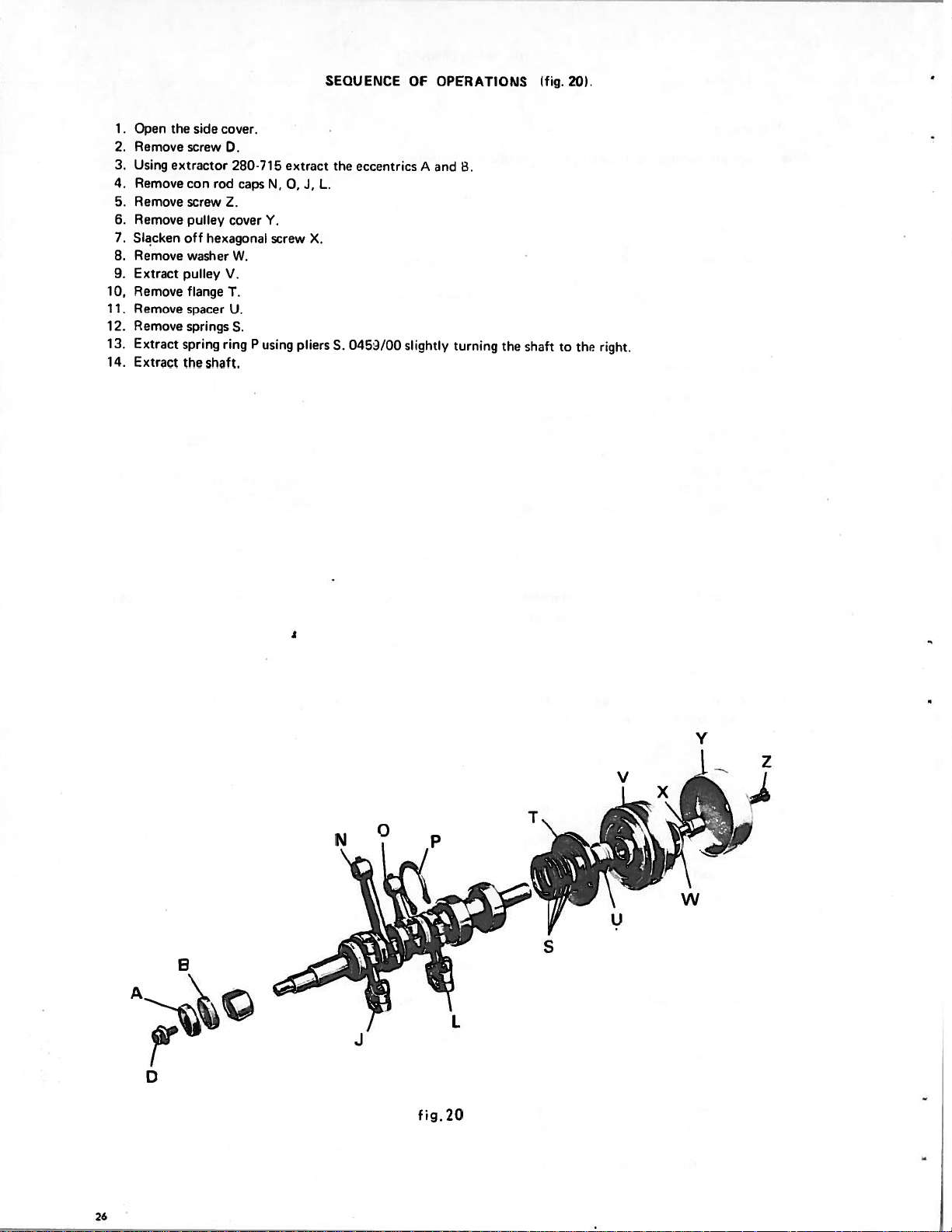

Open

Remove

Using

Remove

Remove

Remove

Slacken

Remove

Extract

°emove

Remove

emove

Extract

Extract

the

side

screw

extractor

rod

con

screw

pulley

off hexagonal

washer

pulley

flange

spacer

springs

spring

the shaft.

cover.

D.

280-715

caps

Z.

cover

W.

V.

T.

U.

S.

ring

P

N,

Y.

screw

using

extract

J,

0,

pliers

SEQUENCE

the

L.

X.

0453/00

S.

eccentrics

OF

OPERATIONS

an’J

A

slicihtly

b.

turning

the

shaft

fig.

20).

to the

right.

V

V

T

N

P

w

y

S

L

J

fig.

20

26

Page 24

U)

m

-I

U)

-I

0

I

0

C

m

Page 25

Page 26

Page 27

Introduction

a)

HOW

I.

TO

USE

fHIS

CATALOGUE

1

This

up

In

2.

the

The

3.

4.

In

On

5.

assemblies,

and

of

The

6.

machine

spare

parts

the

basic

head

ordertomake

head.

conversion

tables,

the

each

equipment

each

catalogue

the

table

whose

table

and

and listing

catalogismarIeupofaseriesoftables

sub-classes.

and

its

the

useofthis

assembliesofthe

numbers

various

the

components

not

normally

illustrated

are

general

has

a

the

table

catalogue

basic head

which

identify

components

cannot

with

the

complete

numerical index

which

on

II.

HOW

easier,

and

the

of

the

be

supplied

machines

with

the

parts

TO

its

sub-classes

a.semhly

but

all

giving

are

ORDER

illustratnq

the table

sub

classes

are

illustrated,

separately,

which

canhesupplied

their

particularsatthe

the

cross-reference numbersofall

illustrated.

SPARE

the

index

shows

are

iliustracadinsinqle

printed

are

at

are

crossrefere

PARTS

various

parts

the

positionofsuch

rioht

top

cross-referencea

on

reauat,

end

-of

assemblies which

or

tables.

of

the

in

book.

black.

by

are

giveatthe

compo

page

iced byacapital

assembly

number. The

a

letter.

cent

partsofthe

make

inside

Parts

botto:

a)

To

1.

Quote

Quote

2.

G)ve

3.

4.

The

The

manufactured

spare

b)

1.

Only

The

2.

he

3.

needle.

4.

The

5.

When

RIM

6.

In

7.

For

All

parts

ensure

immediate

serial

the

drawing

the

full

the

quantity.

RIMOLDI

parts.

Needles

caseofdoubt

straight

needie

size

ind;cates

system

ordering

27).

stitching

only

system

and

dispatch

numberofthe

numberofthe

nameofthe

Company

by

them.

system

elastic

and

the

size

always

send

RiM

average

are also

or

part required.

likes

For

needles

27

are

size

shown

give

the

a

sample

elasticised

of

required

head.

part

to

this

reason

marked

diameter

system

needle

materials

should

on

required.

analyse

they

on

expressed

the

and

or

spare

IMPORTANT

any

kindly

be

usedonthe

the

needle

packets

size

ar

empty

there

parts,

casos

in

hundredths

containing

of

the

packet

are

ball

following

the

of

breakage,

ask

youtoreturn

machines

shank.

needle

of

point

of

a

RIMOLDI

reouired

the

type

needles

instructions

wear

such

iiljstrated

limeter

needles.

e.g.

reoured.

classified

shouldacarefully followed:

or

irregularhie’;

pieces

along

in

this

calculated

n.

1QJ

SKU.

ma’ual.

needles

with

on

arising

the

the

size

dade

dO

in

order

systerr,

of

parts

for

the

29

Page 28

INDEX

OF

TABLES

BUSHES

STUDS

BASE

MAIN

CON—RODS

DIFFERENTIAL

ASSEMBLY

—

THREAD

PRESSED

SHAFT

INTO

WITH

GUIDES

THE

Toy.

Toy.

2

3

4

SHAFTS

OPERATING

NEEDLE

MECHANISM

UPPER

KNIFE

AND

AND

MECHANISM

CON—RODS

LOOPER

DRIVE

LOWER

Toy.

Toy.

Toy.

5

6

7

31

Page 29

PRESSERFOOT

MECHANISM

NEEDLE

CASING

WORK

THREAD

TENS

—

PLATE

ION

PLATE

GUIDES

E

RS

LIFTING

—

AND

Tav.

Toy.

Tov.

8

9

10

11

12

13

:r(..’9

‘,

[1

AND

SUMP

MACHINE

BRACKET

KNEE

REEL

AND

ACCESSORIES

OIL

MOUNTING

AND

CONTROL

HOLDERS

PEDAL

PUMP

Toy.

15

32

Page 30

HEAD

“

“

“

“

“

22B00-02

228-00-03

228-00-04

228-00-05

228-00-06

2280-07

Tab.

lah.

Tab.

lab.

lab.

ab.

19

20

21

22

23

18

HED

228-10-01

228-10-02

228-10-03

228-10-05

228-10-06

228-10-07

Tab.

Iab

Tatj.

ab.

Tab.

lab.

30

31

32

33

34

35

‘

“

“

‘

“

“

228-00-08

228-00-11

228-00-12

228-01-01

228-01-02

228-01-03

Tab.

lab.

Tab.

Tab.

lab.

Tab.

25

26

27

28

29

24

TABLE

TABLE

PARTS

228-28-01

228-28-02

228-28-07

Wi

(100)

Xl

(101

ON

REQUEST

36

lab.

lab.

37

Tab.

38

lab.

39

Tab.

40

Tab.

41

.

Tab.

42

I______________________

Page 31

Page 32

22800-01

228-28-05

1

I.

S

REF.

3

4

5

6

7

8

1

2

PART.

270-016

202125-0-1

270-058

270-057/1

270-268

270-938

280-010/3

2041093-l1

a

DESCRIPTION

bush,

1

2

shaft

bush knife

bush

rear

bush

front

tubes

thread

bolt

bush

bush

main

base

with

holder

shaft

bush

guide

and

thread

guides

1

9

1

10

11

2

12

2

13

1

14

1

1

PART.

270-264

204107-0-Il

270-642

280-830

270-082/1

270-912

thread

base

studs

lube

bush

Icinkliuj

guide

machine

cover

centering

oil

presserfoot

presserfoot

oin

DESCRIPTION

needle

lift

work

plate

1

1

2

1

1

1

Page 33

22H-UU-U1

2

22

24ft

24

254i\

II

21

\—___

J26

3g

l8

6

I,,

4\

I

“I

,‘

4

4

‘5

i____j”%%j

S

7I”l

27

5

--:;S

“\“2

Rh.

PM280.009/4

1

270-704

2

270-705

3

4

270-620

5

270-614

270-008/1

6

7

270-612/1

8

2

128-608/5

9

10

270-610

11

780-009/4

270-707

171

010-H-i

13

14

20-975

790-944

15

PM.270-060/1

16

10-981

PART.

3,7

main

seeger

spring

ffange

spacer

pulley

washer

bolt

cover

stud

main

ball

-bolt

bolt

screw

con-rod

shaft

ring

right

right

with

pulley

pulley

pulley

shaft

bearing

for

con-rod

coupling

guide

with

DESCRIPTION

complete

for

right

side

guide

fixing

right

280-012

fixing

coupling

bearing

REF.

1

17

1

18

4

19

1

20

1

21

1

22

1

23

24

1

1

25

1

25

1

27

28

2

and

270-116

3

-

2

-i

29

4

33

1

1

1

1

1

17

29

PART

PM.270-05’3

270-052

280-925

21-10-019

032-D-25

023-N-5,5

001-E-10

01

0-U-i

280-0123

270-1162

30-06i

270-050,1

370-95-3,1

70-6i

3

POP

HEAD

PM236

33i3-OO3

PM270-060,

270-060

1

1,5

2

5-0033

3

1

DESCRIPTION

1

con-rOd

with

228

guide

bolt

woodruff

wick

screw

bolt

bolt

con-rod

con-rod

i.un-ioif

coupling

couiding

spacer

28-05

main

main

coin-rod

cuuplinq

con-rod

eccentric

for

shaft

gudqeon

flange

for

looper

needle

knife

upper

con-rod

con-rod

bearing

shaft

shit

with

con-rod

coupling

locking

key

shalt

looper

complete

couialinq

pin

locating

con-roil

bar

1

2

2

3

8

1

2

1

1

Page 34

228-00-01

3

8

9

\.

22

‘‘

24

13

/

4

I

A)’

1

12

28

29

27

31

21

20

REF.

PM.280-049/1

1

2

280-31

026-C

3

4

280-023

5

270-935

092-31

6

7

270-039

8

270-937/1

092-D-1

9

10

270-035,1

11

280-035

12

280-034

13

280-926

14

280-0451/10

280-0151

15

004-L-7

16

17

230-048

PART.

1/1

-7

1

1

1

DESCRIPTION

slide

chfferentiiil

block

sliding

screw

countersunk

bolt

for

feed

dog

shaft

for

for

slide

fixing

fixing

holder

for

differential

subsidiary

differential

feed

feed

dog

dog

washer

wick

eccentric

screw

shaft

wick

block

sliding

bushing

bushing

nut

‘9

eccentric

eccentric

screw

connector

slide

Joint

shield

oint

REF.

1

13

1

19

1

23

2

21

3

22

1

23

1

24

1

25

2

25

27

1

1

28

1

29

2

30

1

31

1

A

2

3

1

2$0-033i1

280-253

270-540/3

005-L-1

071-1-1-5

230-207/2

026-C-7

270-978

270-050

280-051

270-052

270-977

270-250/2

270-249/1

280-09/1

280-043/1

PART.

1

connector

gasket

guide

screw

washer

guard

screw

screw

feed

feed

feed

screw

shield

shield

slide

slide

On

280-C51

30

19

-—---i

slide

block

guide

oi

oil

guard

differential

dog

differential

dog

subsidiary

dog

chaining

subsiiiary

rubber

main

feed

subsidiary

request:

j::;

5

i:

DESCRIPTION

block

fixing

fixing

feed

feed

dog

feed

dog

dog

dog

fixing

fixing

Tab

1

1

1

2

1

1

2

1

1

1

1

1

1

1

1

-

38

Page 35

226-28-05

4

8

g

\j

6

10

.‘rl

20

\-

REF.

PART.

5

22

/

2I

26

N)

DESCRIPTION

REF.

PART.

DESCRIPTION

10

11

12

1Cr

1

2

3

4

5

6

7

8

9

PM

2868-049

286

B-61

C-?

026

280-023

-270-935

8-1

292

270-039

270-937i1

092

0-11

276

8-036

286

8-034

280-926

286

S-0

1,1

1

1

slide

differential

block sliding

screw

contersunk

bolt

for

washer

wick

eccentric

screw

shaft

wick

block sliding

bushing

loint

slide

nut

spacer

feed

shaft

dog

fixing

holder

for

differential

14

230-04561

1

15

004

1

16

230-033.

1

17

236

2

18

26

19

005

1

20

276

1

21

236

22

326

23

270-978

1

24

286

1

25

276

1

26

270-249,1

1

L-7

B-253

8-640

1

L-1

B-5

8-207

C-7

0-050-1

8-250

5

eccentric

1

1

screw

connector

gasket

3

guide

screw

1

washer

guard

screw

screw

feed

1

shield

shield

dog

shiek

block

guide

oil

oil

feed

ui

for

slide

guard

dog

her

teed

fixing

block

fixin

fixing

dog

fIxing

1

2

2

1

1

Page 36

—I

228-00-01

6

2

7

8

4

H

10

5

N

1

092-0-16

2

073-N-b

3

270-070

4

270-064

5

27277-074

270-075/2

6

7

270-069

8

250-471

270-068/3

9

10

G.270-065/3

PAIT.

wick

looper

washer

for

gudgeon

shaft

upper looper

lower

shaft

bolt

holder

guide

pin

upper

looper

lower

looper

lower

oscillatinq

DESCRIPTION

shaft

looper

shaft

upper looper

looper

with

small

with

small

looper

lever

Inoper

with

eye

screw

eye

lever

for

bush

cotton

13

REF.

2

11

2

12

1

13

1

14

1

15

1

i

2

17

1

18

1

A

1

B

C

D

270-974/1

016-B-4

016-0-2,5

270-067

092-B-i

017-F-il

092-D-7

016-B-3

270-053

270-056/2

270-065/3

270-063/2

P1.

screw

fixing

grub

lever

gudgeon

screw

wick

grub

ring

bush

guide

holder

On

request:

looper

screw

screw

upper

pin

bush

screw

play

adjustment

adjustable

oscillating

upper

DESCRIPTION

fixing

for

upper

gudgeon

looper

wick

fixing

looper

loopers

27.277-0745

270-D-074/1

270-075

looper

pin

shownintab.

gudgeon

2

pin

1

1

2

1

2

1

1

38

FOR

5

270

D-074,1

6

270-075

HEAD

228-28-05

upper

lower

looper,

looper

blind

1

Page 37

228:08-Ui

6

5

—7

3_

2

-

29

3

H

‘_r

j

.

j\

\/\

l

\,/

,3\

34

13

21

1

10

8

\

\

(j,

I

•Fi

;I

/,-

11

15

j’•

7

30

/

25

19

31

32

.-

26

25

‘I

24

23

20

A

1

REF.

10

11

12

13

14

15

16

17

18

1

2

3

4

5

6

7

8

9

PART.

PM.270-1

PM.270-137/i

270-132/1

270-728/1

290-027/1

270-933

270-713

270-006/1

073-F-9

270-719

007-C-i

270-007/1

270-975/1

270-031/1

092-D-6

071-8-5

001

-G-i

0

270-708

DESCRIPTION

38/1

1

shaft

for

fork

lever

bush

for

screw

ring

for

nut

for

spring

shaft

operating

washer

collar

collar

screw

attachment

attachment

gudgeon

wick

gudgeon

washer

washer

bolt

bearing

fork

fork

bush

fixing

needle guide

guide

washer

for

upper shaft

for

upper

shaft

screw

pin

for

upper

for

holding

for

upper

lever

lever

bsr

slide

shaft

attachment

pn

shaft

for

shaft

bar

lever

270-007.1

REF.

19

1

1

20

1

21

22

1

1

A

B

1

1

23

24

1

2

25

13

2

27

2

1

28

1

29

1

30

1

31

1

32

1

3.3

1

3-

21

A

PART.

250-708,1

016-8-2,5

G.270-025,2

RIM. 27

770-020/1

2-20-025/1

‘cL,5

003-’-

270-130

092-B-i

016-A-2,5

270-1.35

092-0-5

270-133/1

023-N-5,5

00i-E-7

170-131

092-0-1

0)2-A-i

0

FOR

G27.77-025,2

27,77-020

DESCRIPTION

for

roller

gudgeon

needle

retaining

gudgeon

needle

slide

gudgeon

screw

upper

for

needle

bar

shim

needle

pin

drive

pin

fixing

shaft

shaft

needle

bearing

holder

clamp

pci

bar

pin

fork

holder

pin

bar

needle

wick

end

bar

fixing

lever

needle

needle

-

retaIning

bar

drive

drive

lever

lever

1

1

1

2

2

1

1

1

1

1

1

cage,

screw

assembly

needle

clamp

needle

screw

gudgeon

wick

screw

bar

wick

qudgeon

grub

bolt

HEAD

washer

wick

wick

228-28-05

assembly

clamp

1

Page 38

228-00-Ui

2

28

-3

14

7

çcbsJ

l6jJ

8

29

R

1

1

2

3

4

5

6

7

8

9

10

1

1

1.2

13

14

15

270-102

270-096/1

270-1

2777-228

128-111

270-987

270-099

270-T03

073-F-9

270-19

Oçl7-C-1

270-108/1

270-098

U92-C-2

092-D-9

12

PT.

DESCRIPTION

pin

for

upper

knife

holder

upper

knife

upper

guard

guard

upper

bolt

upper

upper

upper

for

ring

lock

pin

gudgeon

knife

for

fork

knife

upper

ring

holder

block

snug

washer

1

lock

screw

gudgeon

coupling

wicks

wick

knife

serrated

knife

knife

knife

upper

for

pin

holder

fixing

holding

locking

knife

knife

attaching

holder

holder

fork

RE.

1

16

1

17

1

18

1

19

1

20

1

21

1

22

1

23

1

24

1

25

1

26

1

27

1

28

29

2