Rimoldi 227-00-20, 227-00-32 User Manual

(J

Rimoldi®

SPARE PARTS CATALOGUE

CATALOGO PEZZI Dl RICAMBIO

CATALOGUE RECHANGES

ERSA TZTEILELISTE

class 227-00-20

and subclasses

227-00-32

C!

n.24

l\

.)~~

].

l

_..-l~

·,

]!!-'

)

l

' '

)

~·

n

\

a

.u

SPARE

class

PARTS

227-00-20

and

subclasses

227-00-32

CATALOGUE

n

n.24

r··.,

"'

' '

.-

:·.

INTRODUCTION

I

.-

CONTENS

n

,r--,

.

~,

' .

INTRODUCTION

••

0

a .

b .

~.

c·.

'

c .

d .

e

f .

g .

h •

a .

b .

c .

d .

e · Stitch length adjustment

f . Seam width adjustment 19

g .

• MACHINE HEAD IDENTIFICATION

. TECHNICAL DATA

II

TECHNICAL

Ill

· INSTALLATION

Positioning

Assembly

Filling lube oil

Assembly and adjustment

•

Positioning and adjustment

Adjustment

Adjustment

Electric lubrication control device 15

Timing

II

• USE

Threading 17

Needle change

Positioning and adjustment

Tensioning discs adjustment

Trouble due

of

head

of

trasmission 9

sump

of

front cover plate

of

needle thread tak.,.up

table

to

incorrect handling

BY

DATA

BY

AND TIMING

of

of

of

MACHINE HEAD CLASS 5

SUB-CLASS

INTRODUCTIONS

sewing parts 14

presserfoot arm

presserfoot

of

machine

Page

Page

"

Page

"

5

6

9

9

9

14

14

14

16

17

19

19

19

19

20

•'\

0

~~-.

21

Ill · MAINTENANCE

a

• Daily

b · Weekly

c .

Quarterly

d .

Sharpening knives

e .

Instructions for changing Cam

t

~--

a .

a .

b .

INSTRUCTIONS FOR USE

Introduction

· ORDER PLACING PROCEDURE

II

All

spare parts

Needles

Ill · ILLUSTRATIONS Page

Shaft

(if required)

SPARE PARTS CATALOGUE

Page

Page

"

..

..

21

21

21

21

21

25

25

25

25

25

27

INSTRUCTIONS FOR USE

a)

Introduction

1. The Spare Parts Catalogue Consists

up

the

basic machine head and its subclasses.

2.

For easy look-up, the illustration index shows

·3.

The conver.sion groups

4. The illustrations show

5.

On each illustration the single parts

parts cannot

equipment with

page and illustrated complete with

6. The catalogue carries a general

machines,

.-

of

of

the basic head and its subclasses are illustrated

the

number identifying subclasses printed in bold

be

supplied separately, are identified

with

the machine

the

number of

but

which can be supplied

all

list of parts in numerical

the

illustration

a set

of

the

of

the assembly

components

where

illustrations

position

shown

by

capital

on

at

the

end

order

the

part

of

the

different mechanisms or assemblies making

of

each assembly

are identified by a number. Assemblies

on

the

machine.

in

individual drawings.

type

at

top

right.

letters. Parts and devices which are

request

of

are listed

the

catalogue.

at

the bottom

by drawing number, covering

can be

found.

of

each illustration

all

the

not

parts

of

which

standard

in

our

II-

ORDER PLACING PROCEDURE

a)

All

spare parts

The following instructions should

thout

delay:

State

1.

2.

3. Write name

4.

machine head serial number

State drawing number

of

spare part required in full.

State quantity required.

of

spare parts ordered.

be carefully followed

to

make sure

that

required spare parts are shipped

I M P 0 R T A N T

RIMOLDI are desirous of throughly studying all cases

countered with parts they have manufactured. For this reason, such parts should be dispatched

the

spare

part order.

b)

Needles

1.

Only straight

2.

The

needle system and size are

RIM

27 needles should be

mar1<ed

used

on

the

on the needle shank.

of

breakage, wear

or

machine heads illustrated

unsatisfactory performance en-

in

this catalogue.

together

with

,_\

The gauge indicates

3.

The

4.

5.

6.

7.

system and size are also stamped

When ordering, always

system

In

For sewing elastic or elasticised materials special ball-point needles classed as SKU

RIM

case of

27).

doubt,

the

average diameter

state clearly

in

hundredths of a millimetre taken on the blade

on

the

RIMOLDI needle envelope.

the

required needle system and size. (Example: 100 needles, size

attach a sample needle or art empty envelope

of

the needle required.

are

available.

of

the

needle.

90,

-----

.-

SPARE PARTS

CATALOGUE

-·

r]j

1

HI

'I

••

:t

Ull

N0tldl!l:tS1CJ

~~

....

-(Ji

:._

?,

.

•\

-:.!.::·:

("0·.: t '-'.ilf·l.'

Hjllllli

'tl''il•l.ll

un:m~

il~il\l:h'LII

A.•l'l

-~li:Cl!

'aciAI

;)1111'11

achlr.:

A.ol:ji!!C"I:lil"·

ilji'IC!

~

g

:H

N

".UiVd

N01ldi!IJS"3C

···;-·.

i

I

,

...

.....................

I

I

I

I

I

I

'',,

...

--

--

,---------------------

--

1

~-

~.

,\

ltEF,

••

1

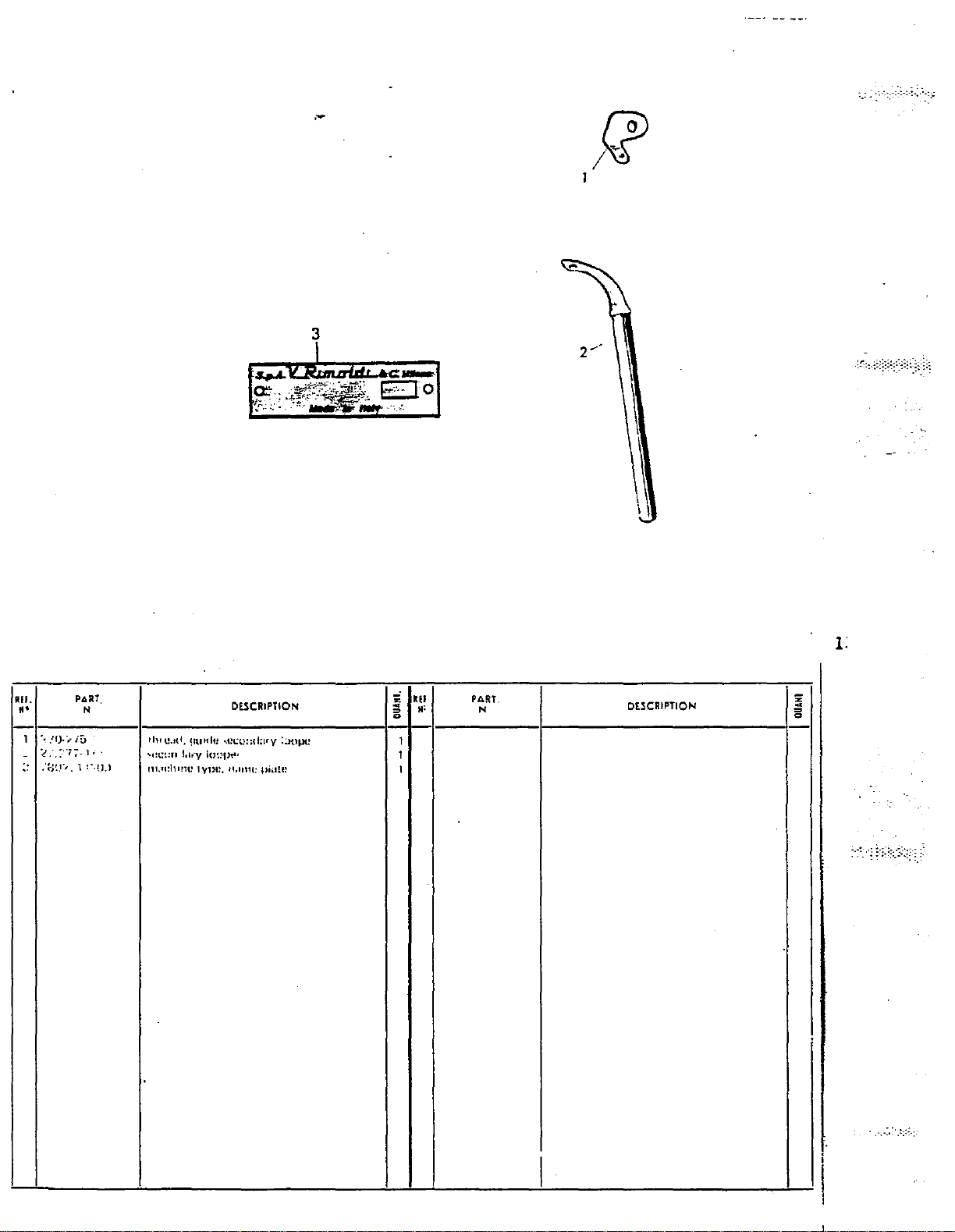

270-016

2 270-09711

3

270-05812

4 270-05711

5

270-268

6

202004·0·11

7

202005-3·11

PART.

N•

IEF.

OESCRIPT10N

bushing, needle hilr shaft 1 B

bushing,

rear bushing,looper

front

guide

base, rnachine

base

upper

bushing.

tube.

with

bushings and

knife

looper

looper

holder 1

shaft

shaft

thread

thread

guides

s

a

2

2

2

1

1

..

10

11

12

13

9

PART.

N'

270-912

202045·0·11

270-042/3

270-642

270-082/1 hushing, presserfuut lifter lever

270-264

latch pin,

bushing, differential

bushing

pin,

coverplate

thread

OESCRIPTION

work

plate

{left), differential

guide, needle

shaft

centeriny

shaft

s

~

=

1

1

1

2

1

1

.-

20

IS

2

-~

/ '

' '

33

'

'

'

'

36----1

'

,/

'

'

'

'

'

15

'

'

22

IEF.

..

1 PM.27·n·009/3

2

3 270-116/2 control rod, knife

4 270-061/2 control

5 270-060/1

6 270-059/1 steeve,

7

a

··:.

9

10

11

12

13

14

15

16

17 270-612/1 washer

1a

19 270-608/5 cover

37

PART,

N'

280-012/3

270-009/4

270·707

270·613

270-709 ball bearing, left

270-062 guide,

270-704 snao-ring, right ball bearing

270-705

260-620 flange, right

270-614

270-00a/1 handwheel

270-9a1

1

PM

276

6 270:060/1

7

270-009/3

PM

B-009/6

270-060/1

main

control rod, needle bar

sleeve, secondary looper control rod

main

ball bearing, right

spacer, bearing

sr.•ring,

spacer, main shaft right

set~rew,

for

main shaft. with connecting. rods

slnve,

main

sleeve assembly

DESCRIPTION

shaft,

with

connecting rods

rod,

secondary

primary

shaft

connecting

cup

with

guide

hanwheel

with

handwheel

227-00-32

primary looper control rod

shaft

looper

looper control rod

rod

z

llf.

"'

~

..

~

1

20

21

1

1

22

73

2

1

24

1

1 25

2 26

1

27

1

28

29

2

30

1

1

31

37

1

1

33

34

1

1

35

1

36

1 37 PM.271J.059/1

38

1

1

1

1

PART.

N•

270·510 pivot, handwheel

270·617/2

270-999

010-H-13,7

270-975

290·944

092-D-14

092·C·2

270-01012 bush, intermediate

074-A·12 washer, differential

270-722 ring, adjustment

270-750 cap, main shaft

016-D-5 screw, adjustment ring

270-938 lock-screw, intermediate bush

023-N-5.5 grub-screw, pin

001-E-10

01

0-0·11,5

PM.270-060/o sleeve assembly 1

·

rockers

screws.

for control

screw

and 270-116/2 4

screw, sleeve 4

lock-screw, connecting rod guide

oil

wick,

wick

screw, right flange

screw, looper control rod

sleeve assembly ·

N. B. Beatings reference number B can

supplied as separate spares, however

it is

order sheet the A oman numeral

pearing

moved bearing.

DESCRIPTION

rocker

rods

2~0.01213

main. shaft 1

indisQensable to specify

on

the outer race

of

on

the

ap·

there·

be

•I

1

2

4

2

2

1

1

1

1

2

1

2

3

a

1

---

--·

.-

'\

<:J

;"

'""

'1r

3

11

82

0

,

9 1 3 /

57

85

6

21

23

L

L/

2•

s

2

~,[I

16

,b.

IS

·:.

Rlf.

••

PART,

N•

DESCRIPTION

-~~

.~·~"~-'t'

........

~~~·-~~

55

,_,

IEF.

;::

z

H'

~

PART.

N'

61

'J!.

I 69

ti'

2

r;

DESCRIPTION

~

;;:

1

PM.270-049/1

27-27-051 feed dog, rear 1 48

2

3 270-977

4 270-640/3

5

092-B-1

6

270-937/1 .

7

27·27·052 feed dog, chaining

8

27U-b11/1 eccentric, feed dog lifter

9 270-979

10 070-M-4,5

11

270-035

12 !1030-06

13

270-048

14

073-C-8

15 270-054

16 071-M-5,5

17

279-047/2

18

070-F-4

19

057-F-4

20 270-975

21

270-039

22 270-7391

23

071·H·5

24

270-036/1

25 270-935

26

026·C·7

-27

PM.270-038/3

28

270-040

29 270-031/1

30 092-D-6 oil

31

092-D-12 oil

270-041/1

32

33

250-471

017-E-11

34

039-H-9

3S.

j6

064-F·5

37 270-992

J8

270-287/1

39 073-A-8

40 PM.270-562/2 lever,

41

270-28811

42

270-567

065·0-6

43

44

270-568

45

270-702

46

270-703

,5

assembly,

screw,

guide

oil

securing screw, differential eccentric

securing screw,link

washer,

bush.

collar

link,

washer,

pin,

washer,

guide

washer,

nut

screw,

shaft,

securing

washer.

sliding

counter-washer

screw,

complete

yoke,

pin.

rear

screw,

securing

screw,

washer,

screw,

upper

washer,

stop

sector

washer,

knurled

snap

needle

differential

attach

block,

wick

for

wick,

wick,

right

differential

differential

differential

pin

differential

diff.

ratio

segment,

diff.

ratio

pin

270-054

segment

differential

pin

differential

block,

counter-washer

adjustable

connecting

fork

yoke

dowel

rear

pivot,

differential

yoke

screw,

differential

segment

differential

sector

differential

complete

with

setting

knurled

knob,

ring 1

roller

bearing cage

slide

rear feed dog 1

differential

links

feed

slide

feed slide

segment

increase

ratio

pin

eccentric

differential

segment

segment

drive

shaft

marks

segment

increase

shaft

eccentric

control

assembly

diff.

eccentric

for

differential

rod

pivot

adjustable

differential

knob

lever lock

shaft

1 47 270-037/3

270-984

49

070-B-3

023-N-5,5 securing screw, pin 1

1 50

4

51

270-735 eccentric regulation

1

PM.270-045/2

52

270-033/1

1 53

54

1

270-980

1 55 270-943

56

270-034

2

1 57 005-L-11 securing screw for guide

1 58 270-997

1 59 270-566/1

1

092-D-4 oil

60

1

61

270-978

1 62 27-27·050

1

290-700

63

1 64 270-736/3

1

270-738

65

001A·2,5

1 66

1 67 270-729

279-249/1

1

68

1

69

270-250/2

1

70

270-253

71

1

004-L-7

1 72 PM.270-732/3

1

73

270-734

74

1

270·032/3

1 75 004-P-6

1

76

270-928

1

77

270-929

1 78 270-747

1 79

007-C-11

1

80

023-E-12

1

270-595

81

2 82 270-717

2 83 270·927

1

84

270-915 plu·g,

2 85 Olj2-D·11

1

86

092-D-23

87

270-594

1

1 A 270-046/3

1 B

270-038/3

1 c 279-733/1

D

270-732.'3

'

rod, differential

screw,

feed

washer, feed lever

attachment,

link,

securing screw, differential link

grub-screw,

bush

screw,

control

securing

front

snap-ring

shank,

soring,

screw

set-screw

shield

rubber

gasket,

securing

housing

flat

plate,

securing

grub-screw,

lock-screw,

gib,

screw,

set-screw.

gasket,

collar,

screw,

oil

oil

gasket

slide

segment

slide,

stitch

for

227-00-32

lever 1

differential

differential

securing

for

differential

difierential

lever.

wick,

spring

eccentric

wick

wick

for

differential

differential

screw,

feed

dog

for

pushbutton

pushbutton

pushbutton

guard

for

slide

guide

screw,

and

cam

differential

screw,

for

for

slide

collar

eccentric

differential

differential

collar

differential

differential

for

differential

stLtch

length

len~;~th

eccentnc

control

segment

slide

pushbutton

slide

control

link

front

feed

feed

dogs

guard

stitch

length

mechanism

cursor

plate

eccentric

grub-screw

control

collar

pinion

adjustment

adjustment

eccentric

cam

lever

segment

dog

slide

lever

bore

cam

eccentric

cursor

1

1

1

1

1

1

1

1

2 I

2 I

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

2

2

2

1

2

1

1

1

1

1

1

1

1

1

1

1

,

i

'

4

.-

r

?-

·.···

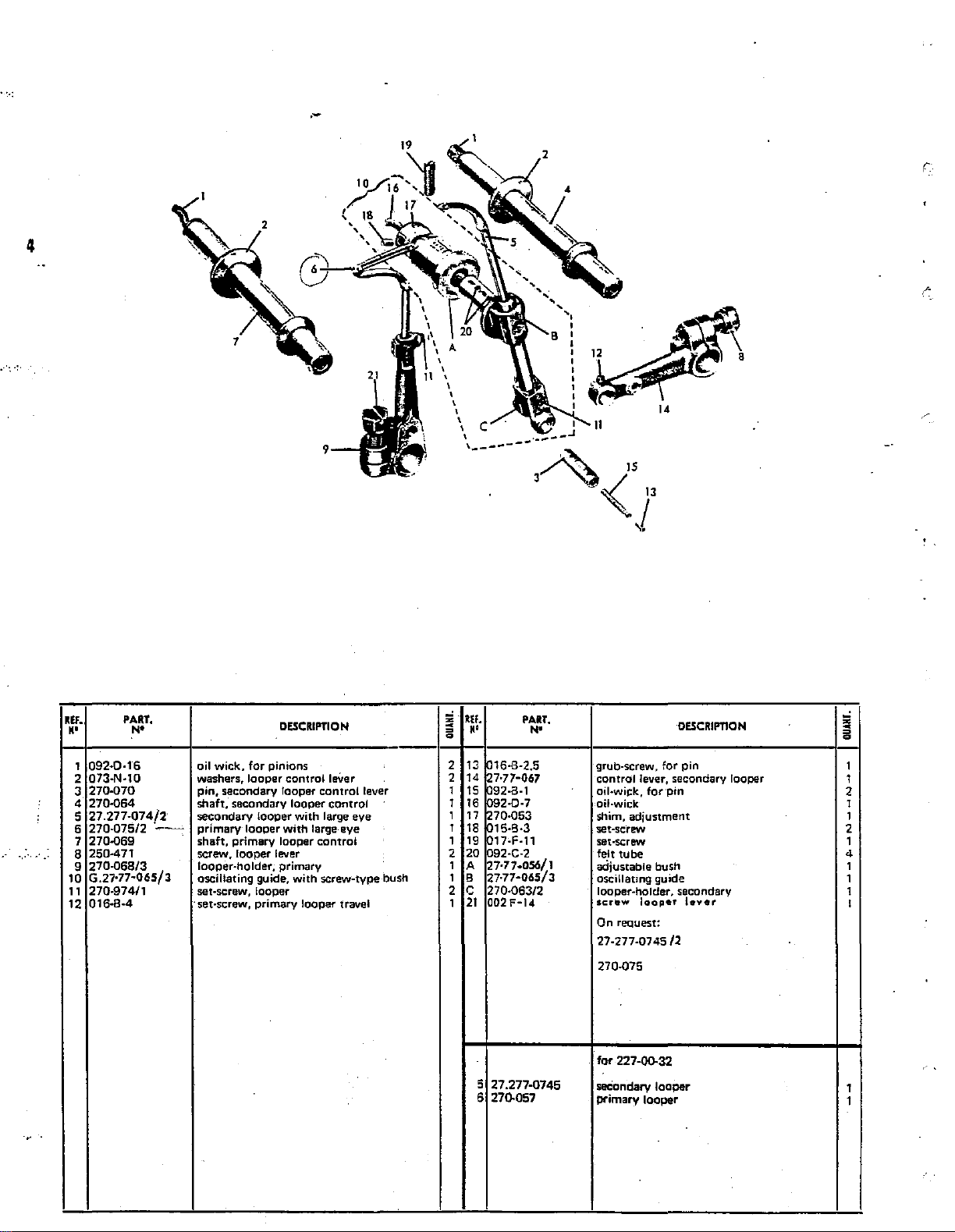

Rlf.

••

1

092·0·16

2 073-N-10

3

270·070

4 270-064

5

27.277-074/2

6 270-Q75/2

7 270-Q69

8 250·471

9

270-068/3

10

G.27-77·065/l

11

270-97411

12

016·8·4

PART.

N'

DESCRIPTION

oil

wick,

for

looper

looper

primary

pinions

looper

lever

primary

washers, looper

pin, secondary looper

shaft,' secondary looper

secondary

·~-

primary

shaft,

screw, looper

looper-holder;

oscillating guide,

set-screw, looper

·set-screw, primary looper travel

control

control

with

large

with

large eye

control

with

screw-type bush

leVer

control

eye

lever

s

,.Ef.

a

K'

2 13 16·8·2.5

2 14 7-77·067

1

15

I

16

1 17 70-053

1

18

1

19

2 20 092-C-2

I A 27-77-0SIJ/1

1 8

2 c 270-063/2

21

I

PART.

N•

92·8·1

2·0·7

15·8·3

17-F-11

27·77·065/3

002F·14

~

A"".

3'

"-.}<

grub-screw,

control lever, secondary looper

oil-wick,

oil-wick

shim,

set-screw

set-screw

felt

adjustable

oscillating

looper-holder, secondary

screw

On reQuest:

27-277-0745/2

270-075

IS

l

'·

for·pin

adjustment

tube

bush

guide

looper

14

DESCRIPTION

for

pin

l•ver

~

I

1

2

1

I

2

1

4

I

1

I

I

for 227-QQ.32

5127.277-0745

6 270.057

seCondary

t:H"imary

looper

looper

.-

a::.·-6

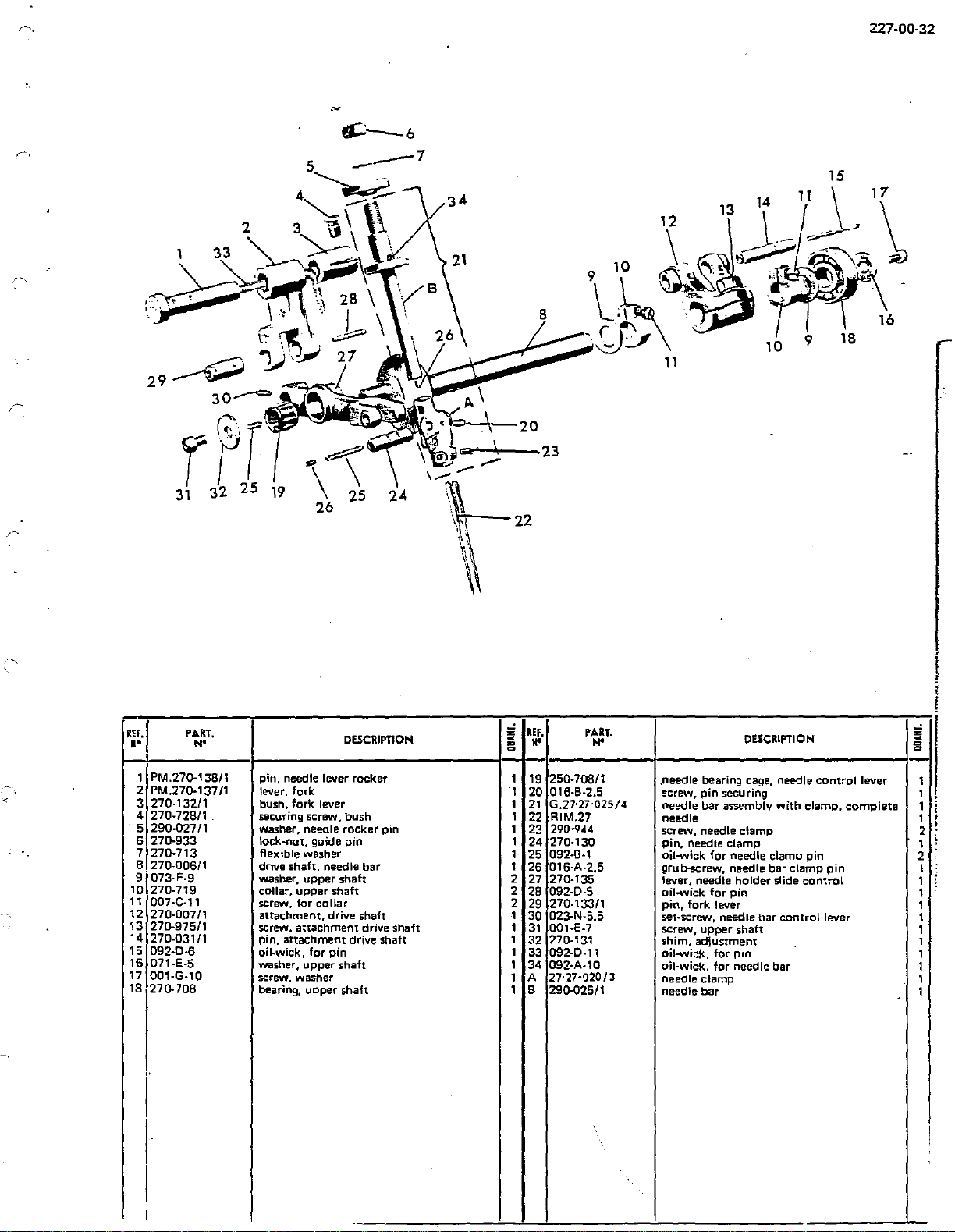

227-00-32

REf.

H'

1 PM.27Q-138/1

2 PM.270-137/1

3 270-132/1

4 270-728/1

5

6 270-933

7 270-713

8

9 073-F-9

10

11

12

13

14

15 092-D-6

16

17

18

PA.kT.

N"

290-027/1

270-006/1

270-719

007-C-11

270-007/1

270-975/1

270-031/1

071-E-5

001-G-10

270-708

DESCRIPTION

pin, needle lever rocker

lever, fork

bush. fork lever 1

securing screw. bush 1

washer, needle rocker pin

lock·nut, guide pin

flexible washer

drive shaft, needle bar 1

washer, upper

collar, upper shaft

screw. for

attachment, drive shaft 1

screw. attachment drive shaft 1

pin, attachment drive shaft

oil-wick,

washer,

screw, washer

bearing,

collar

for

upper

upper

pin

shah

shaft

shaft

~

a

=

'1

lEF.

II'

1

19 250-708/1

20 016-B-2.5

21

G.27·27-025/4

22 RIM.27

290-944

1

23

1

24 270-130

1

25 092-B-1

26

016-A-2,5

2

27

270-135

2

28 092-D-5

2

29 270-133/1

30

023-N-5,5

31

001-E-7

,

270-131

32

1

33 092-D-11

1

34

092·A-10

27·27-020/3

1

A

1

B 290-025/1

PART.

N'

DESCRIPTION

.needle bearing cage, needle

screw,

pin

needle bar assembly with clamp,

needle

screw, needle clamp

pin, needle clamp

oil-wick for needle clamp pin

grub-screw,

lever, needle

oil-wick for pin

pin, fork lever

set-screw, needle bar control lever

screw. upper shaft

shim,

oil-wick,

oil-wick,

needle clamp

needle

securing

needle

holder

adjustment

for

pm

for

needle bar

bar

bar

clamp pin

slide

control

control

lever

complete

I

!

!

-'

;!;

= 0

1

1

1

1

2

1

2

I

1

1

1

1

1

,

1

1

1

1

Loading...

Loading...