Page 1

(J

Rimoldi®

SPARE PARTS CATALOGUE

CATALOGO PEZZI Dl RICAMBIO

CATALOGUE RECHANGES

ERSA TZTEILELISTE

class 227-00-20

and subclasses

227-00-32

C!

n.24

Page 2

l\

.)~~

].

l

_..-l~

·,

]!!-'

)

l

' '

)

~·

n

\

a

.u

SPARE

class

PARTS

227-00-20

and

subclasses

227-00-32

CATALOGUE

n

n.24

Page 3

r··.,

"'

' '

.-

:·.

INTRODUCTION

I

Page 4

.-

CONTENS

n

,r--,

.

~,

' .

INTRODUCTION

••

0

a .

b .

~.

c·.

'

c .

d .

e

f .

g .

h •

a .

b .

c .

d .

e · Stitch length adjustment

f . Seam width adjustment 19

g .

• MACHINE HEAD IDENTIFICATION

. TECHNICAL DATA

II

TECHNICAL

Ill

· INSTALLATION

Positioning

Assembly

Filling lube oil

Assembly and adjustment

•

Positioning and adjustment

Adjustment

Adjustment

Electric lubrication control device 15

Timing

II

• USE

Threading 17

Needle change

Positioning and adjustment

Tensioning discs adjustment

Trouble due

of

head

of

trasmission 9

sump

of

front cover plate

of

needle thread tak.,.up

table

to

incorrect handling

BY

DATA

BY

AND TIMING

of

of

of

MACHINE HEAD CLASS 5

SUB-CLASS

INTRODUCTIONS

sewing parts 14

presserfoot arm

presserfoot

of

machine

Page

Page

"

Page

"

5

6

9

9

9

14

14

14

16

17

19

19

19

19

20

•'\

0

~~-.

21

Ill · MAINTENANCE

a

• Daily

b · Weekly

c .

Quarterly

d .

Sharpening knives

e .

Instructions for changing Cam

t

~--

a .

a .

b .

INSTRUCTIONS FOR USE

Introduction

· ORDER PLACING PROCEDURE

II

All

spare parts

Needles

Ill · ILLUSTRATIONS Page

Shaft

(if required)

SPARE PARTS CATALOGUE

Page

Page

"

..

..

21

21

21

21

21

25

25

25

25

25

27

Page 5

INSTRUCTIONS FOR USE

a)

Introduction

1. The Spare Parts Catalogue Consists

up

the

basic machine head and its subclasses.

2.

For easy look-up, the illustration index shows

·3.

The conver.sion groups

4. The illustrations show

5.

On each illustration the single parts

parts cannot

equipment with

page and illustrated complete with

6. The catalogue carries a general

machines,

.-

of

of

the basic head and its subclasses are illustrated

the

number identifying subclasses printed in bold

be

supplied separately, are identified

with

the machine

the

number of

but

which can be supplied

all

list of parts in numerical

the

illustration

a set

of

the

of

the assembly

components

where

illustrations

position

shown

by

capital

on

at

the

end

order

the

part

of

the

different mechanisms or assemblies making

of

each assembly

are identified by a number. Assemblies

on

the

machine.

in

individual drawings.

type

at

top

right.

letters. Parts and devices which are

request

of

are listed

the

catalogue.

at

the bottom

by drawing number, covering

can be

found.

of

each illustration

all

the

not

parts

of

which

standard

in

our

II-

ORDER PLACING PROCEDURE

a)

All

spare parts

The following instructions should

thout

delay:

State

1.

2.

3. Write name

4.

machine head serial number

State drawing number

of

spare part required in full.

State quantity required.

of

spare parts ordered.

be carefully followed

to

make sure

that

required spare parts are shipped

I M P 0 R T A N T

RIMOLDI are desirous of throughly studying all cases

countered with parts they have manufactured. For this reason, such parts should be dispatched

the

spare

part order.

b)

Needles

1.

Only straight

2.

The

needle system and size are

RIM

27 needles should be

mar1<ed

used

on

the

on the needle shank.

of

breakage, wear

or

machine heads illustrated

unsatisfactory performance en-

in

this catalogue.

together

with

,_\

The gauge indicates

3.

The

4.

5.

6.

7.

system and size are also stamped

When ordering, always

system

In

For sewing elastic or elasticised materials special ball-point needles classed as SKU

RIM

case of

27).

doubt,

the

average diameter

state clearly

in

hundredths of a millimetre taken on the blade

on

the

RIMOLDI needle envelope.

the

required needle system and size. (Example: 100 needles, size

attach a sample needle or art empty envelope

of

the needle required.

are

available.

of

the

needle.

90,

Page 6

-----

.-

SPARE PARTS

CATALOGUE

Page 7

-·

r]j

1

HI

'I

••

:t

Ull

N0tldl!l:tS1CJ

~~

....

-(Ji

:._

?,

.

•\

-:.!.::·:

("0·.: t '-'.ilf·l.'

Hjllllli

'tl''il•l.ll

un:m~

il~il\l:h'LII

A.•l'l

-~li:Cl!

'aciAI

;)1111'11

achlr.:

A.ol:ji!!C"I:lil"·

ilji'IC!

~

g

:H

N

".UiVd

N01ldi!IJS"3C

···;-·.

i

I

Page 8

,

...

.....................

I

I

I

I

I

I

'',,

...

--

--

,---------------------

--

1

~-

~.

,\

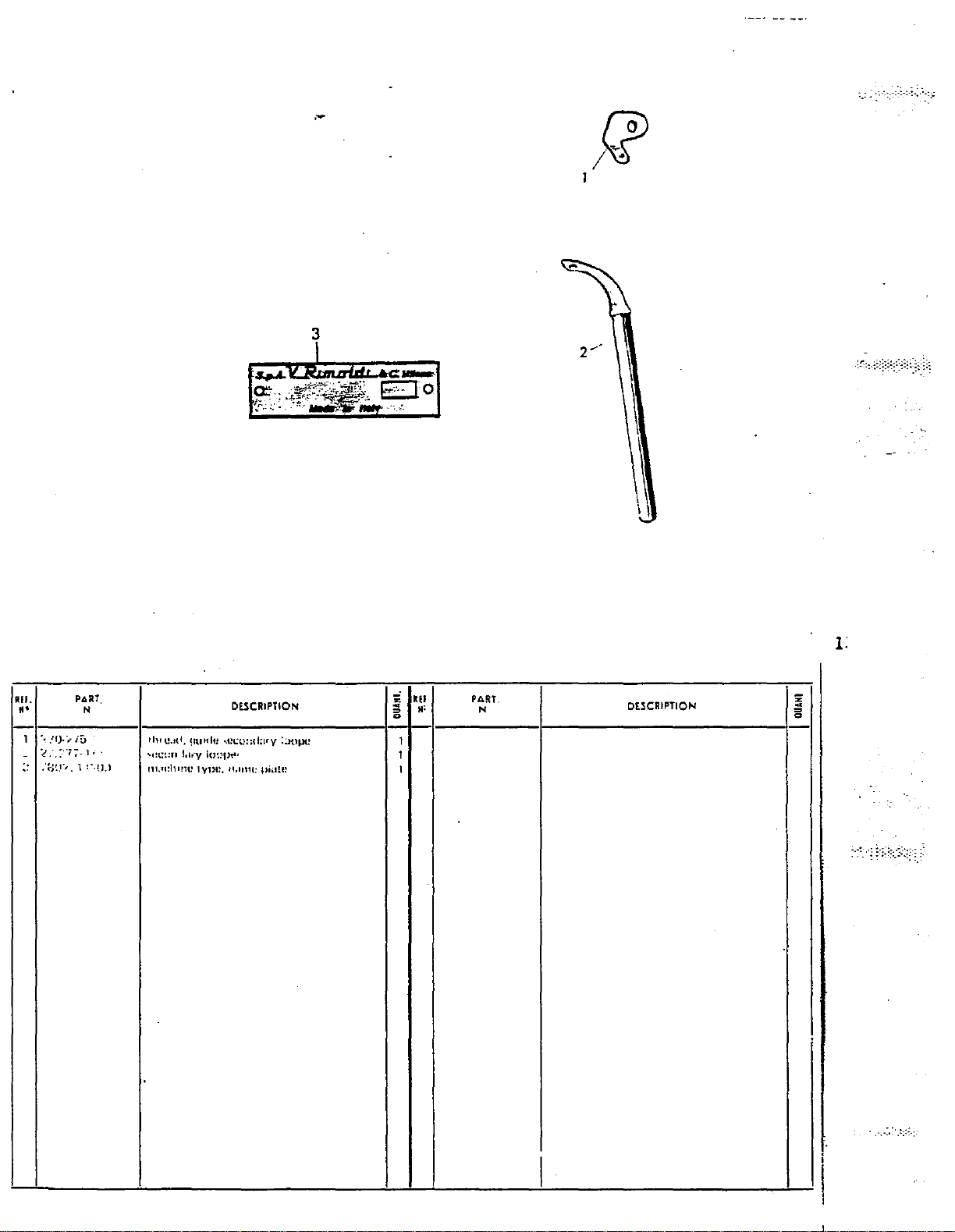

ltEF,

••

1

270-016

2 270-09711

3

270-05812

4 270-05711

5

270-268

6

202004·0·11

7

202005-3·11

PART.

N•

IEF.

OESCRIPT10N

bushing, needle hilr shaft 1 B

bushing,

rear bushing,looper

front

guide

base, rnachine

base

upper

bushing.

tube.

with

bushings and

knife

looper

looper

holder 1

shaft

shaft

thread

thread

guides

s

a

2

2

2

1

1

..

10

11

12

13

9

PART.

N'

270-912

202045·0·11

270-042/3

270-642

270-082/1 hushing, presserfuut lifter lever

270-264

latch pin,

bushing, differential

bushing

pin,

coverplate

thread

OESCRIPTION

work

plate

{left), differential

guide, needle

shaft

centeriny

shaft

s

~

=

1

1

1

2

1

1

Page 9

.-

20

IS

2

-~

/ '

' '

33

'

'

'

'

36----1

'

,/

'

'

'

'

'

15

'

'

22

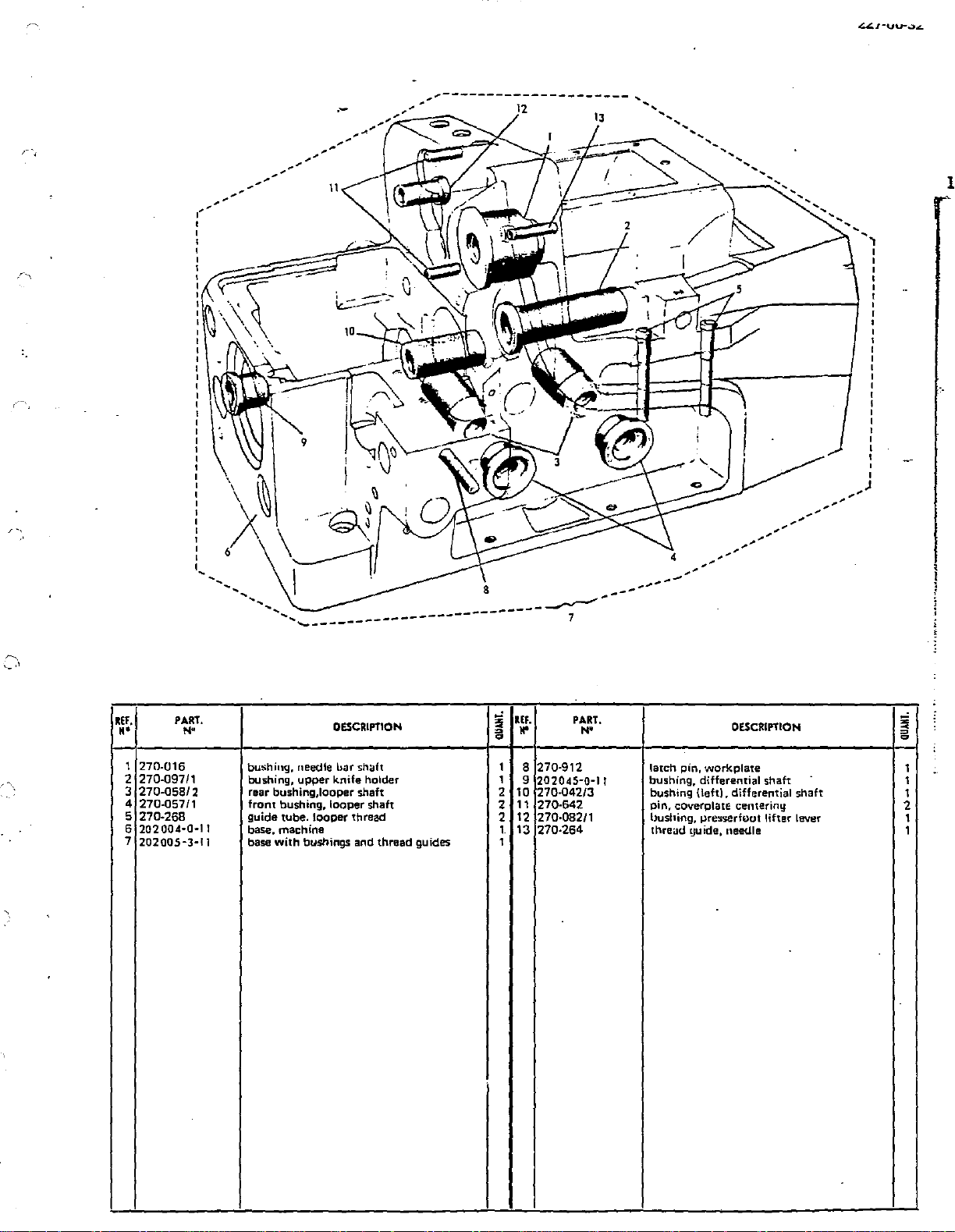

IEF.

..

1 PM.27·n·009/3

2

3 270-116/2 control rod, knife

4 270-061/2 control

5 270-060/1

6 270-059/1 steeve,

7

a

··:.

9

10

11

12

13

14

15

16

17 270-612/1 washer

1a

19 270-608/5 cover

37

PART,

N'

280-012/3

270-009/4

270·707

270·613

270-709 ball bearing, left

270-062 guide,

270-704 snao-ring, right ball bearing

270-705

260-620 flange, right

270-614

270-00a/1 handwheel

270-9a1

1

PM

276

6 270:060/1

7

270-009/3

PM

B-009/6

270-060/1

main

control rod, needle bar

sleeve, secondary looper control rod

main

ball bearing, right

spacer, bearing

sr.•ring,

spacer, main shaft right

set~rew,

for

main shaft. with connecting. rods

slnve,

main

sleeve assembly

DESCRIPTION

shaft,

with

connecting rods

rod,

secondary

primary

shaft

connecting

cup

with

guide

hanwheel

with

handwheel

227-00-32

primary looper control rod

shaft

looper

looper control rod

rod

z

llf.

"'

~

..

~

1

20

21

1

1

22

73

2

1

24

1

1 25

2 26

1

27

1

28

29

2

30

1

1

31

37

1

1

33

34

1

1

35

1

36

1 37 PM.271J.059/1

38

1

1

1

1

PART.

N•

270·510 pivot, handwheel

270·617/2

270-999

010-H-13,7

270-975

290·944

092-D-14

092·C·2

270-01012 bush, intermediate

074-A·12 washer, differential

270-722 ring, adjustment

270-750 cap, main shaft

016-D-5 screw, adjustment ring

270-938 lock-screw, intermediate bush

023-N-5.5 grub-screw, pin

001-E-10

01

0-0·11,5

PM.270-060/o sleeve assembly 1

·

rockers

screws.

for control

screw

and 270-116/2 4

screw, sleeve 4

lock-screw, connecting rod guide

oil

wick,

wick

screw, right flange

screw, looper control rod

sleeve assembly ·

N. B. Beatings reference number B can

supplied as separate spares, however

it is

order sheet the A oman numeral

pearing

moved bearing.

DESCRIPTION

rocker

rods

2~0.01213

main. shaft 1

indisQensable to specify

on

the outer race

of

on

the

ap·

there·

be

•I

1

2

4

2

2

1

1

1

1

2

1

2

3

a

1

---

--·

Page 10

.-

'\

<:J

;"

'""

'1r

3

11

82

0

,

9 1 3 /

57

85

6

21

23

L

L/

2•

s

2

~,[I

16

,b.

IS

·:.

Rlf.

••

PART,

N•

DESCRIPTION

-~~

.~·~"~-'t'

........

~~~·-~~

55

,_,

IEF.

;::

z

H'

~

PART.

N'

61

'J!.

I 69

ti'

2

r;

DESCRIPTION

~

;;:

1

PM.270-049/1

27-27-051 feed dog, rear 1 48

2

3 270-977

4 270-640/3

5

092-B-1

6

270-937/1 .

7

27·27·052 feed dog, chaining

8

27U-b11/1 eccentric, feed dog lifter

9 270-979

10 070-M-4,5

11

270-035

12 !1030-06

13

270-048

14

073-C-8

15 270-054

16 071-M-5,5

17

279-047/2

18

070-F-4

19

057-F-4

20 270-975

21

270-039

22 270-7391

23

071·H·5

24

270-036/1

25 270-935

26

026·C·7

-27

PM.270-038/3

28

270-040

29 270-031/1

30 092-D-6 oil

31

092-D-12 oil

270-041/1

32

33

250-471

017-E-11

34

039-H-9

3S.

j6

064-F·5

37 270-992

J8

270-287/1

39 073-A-8

40 PM.270-562/2 lever,

41

270-28811

42

270-567

065·0-6

43

44

270-568

45

270-702

46

270-703

,5

assembly,

screw,

guide

oil

securing screw, differential eccentric

securing screw,link

washer,

bush.

collar

link,

washer,

pin,

washer,

guide

washer,

nut

screw,

shaft,

securing

washer.

sliding

counter-washer

screw,

complete

yoke,

pin.

rear

screw,

securing

screw,

washer,

screw,

upper

washer,

stop

sector

washer,

knurled

snap

needle

differential

attach

block,

wick

for

wick,

wick,

right

differential

differential

differential

pin

differential

diff.

ratio

segment,

diff.

ratio

pin

270-054

segment

differential

pin

differential

block,

counter-washer

adjustable

connecting

fork

yoke

dowel

rear

pivot,

differential

yoke

screw,

differential

segment

differential

sector

differential

complete

with

setting

knurled

knob,

ring 1

roller

bearing cage

slide

rear feed dog 1

differential

links

feed

slide

feed slide

segment

increase

ratio

pin

eccentric

differential

segment

segment

drive

shaft

marks

segment

increase

shaft

eccentric

control

assembly

diff.

eccentric

for

differential

rod

pivot

adjustable

differential

knob

lever lock

shaft

1 47 270-037/3

270-984

49

070-B-3

023-N-5,5 securing screw, pin 1

1 50

4

51

270-735 eccentric regulation

1

PM.270-045/2

52

270-033/1

1 53

54

1

270-980

1 55 270-943

56

270-034

2

1 57 005-L-11 securing screw for guide

1 58 270-997

1 59 270-566/1

1

092-D-4 oil

60

1

61

270-978

1 62 27-27·050

1

290-700

63

1 64 270-736/3

1

270-738

65

001A·2,5

1 66

1 67 270-729

279-249/1

1

68

1

69

270-250/2

1

70

270-253

71

1

004-L-7

1 72 PM.270-732/3

1

73

270-734

74

1

270·032/3

1 75 004-P-6

1

76

270-928

1

77

270-929

1 78 270-747

1 79

007-C-11

1

80

023-E-12

1

270-595

81

2 82 270-717

2 83 270·927

1

84

270-915 plu·g,

2 85 Olj2-D·11

1

86

092-D-23

87

270-594

1

1 A 270-046/3

1 B

270-038/3

1 c 279-733/1

D

270-732.'3

'

rod, differential

screw,

feed

washer, feed lever

attachment,

link,

securing screw, differential link

grub-screw,

bush

screw,

control

securing

front

snap-ring

shank,

soring,

screw

set-screw

shield

rubber

gasket,

securing

housing

flat

plate,

securing

grub-screw,

lock-screw,

gib,

screw,

set-screw.

gasket,

collar,

screw,

oil

oil

gasket

slide

segment

slide,

stitch

for

227-00-32

lever 1

differential

differential

securing

for

differential

difierential

lever.

wick,

spring

eccentric

wick

wick

for

differential

differential

screw,

feed

dog

for

pushbutton

pushbutton

pushbutton

guard

for

slide

guide

screw,

and

cam

differential

screw,

for

for

slide

collar

eccentric

differential

differential

collar

differential

differential

for

differential

stLtch

length

len~;~th

eccentnc

control

segment

slide

pushbutton

slide

control

link

front

feed

feed

dogs

guard

stitch

length

mechanism

cursor

plate

eccentric

grub-screw

control

collar

pinion

adjustment

adjustment

eccentric

cam

lever

segment

dog

slide

lever

bore

cam

eccentric

cursor

1

1

1

1

1

1

1

1

2 I

2 I

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

2

2

2

1

2

1

1

1

1

1

1

1

1

1

1

1

,

i

'

Page 11

4

.-

r

?-

·.···

Rlf.

••

1

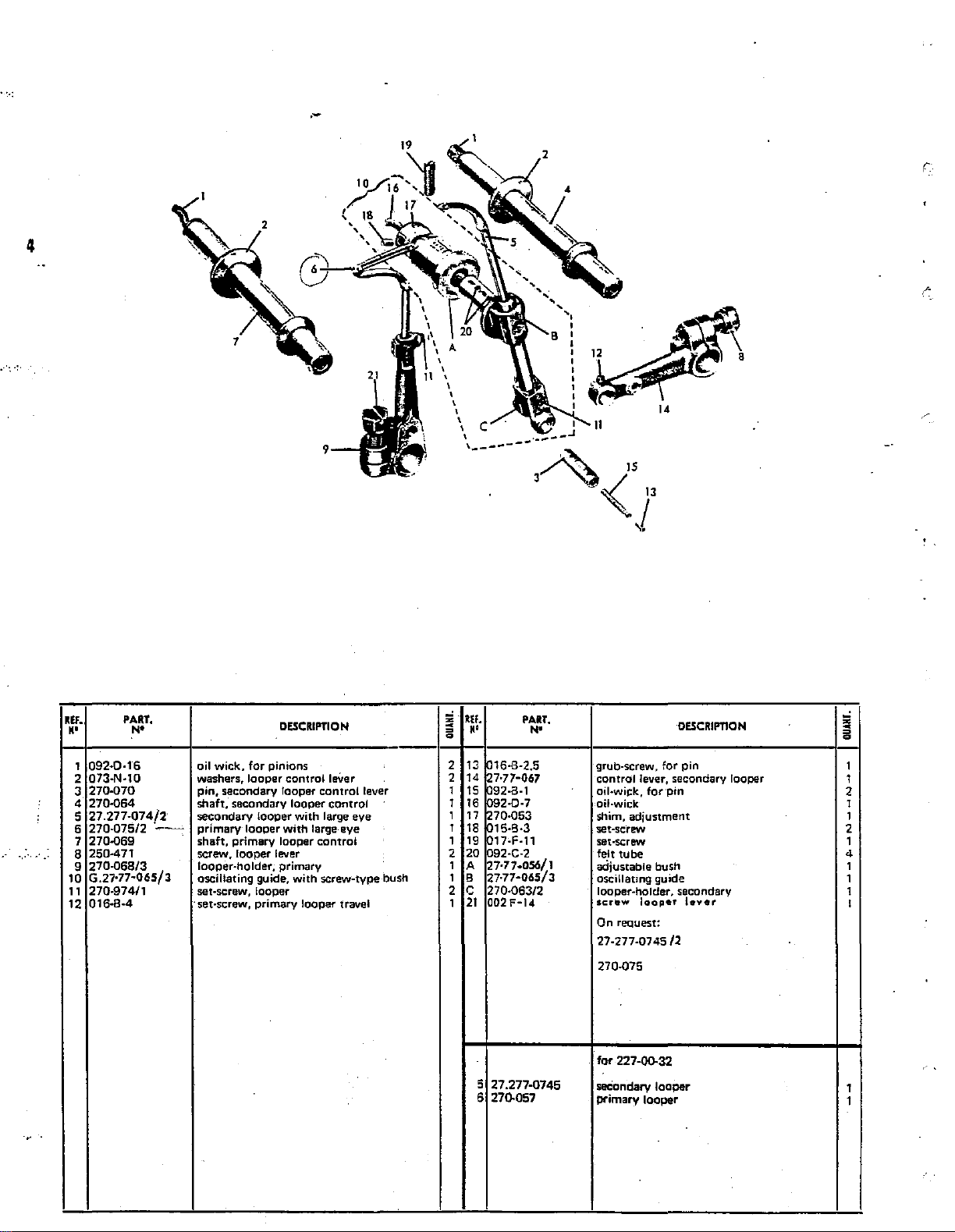

092·0·16

2 073-N-10

3

270·070

4 270-064

5

27.277-074/2

6 270-Q75/2

7 270-Q69

8 250·471

9

270-068/3

10

G.27-77·065/l

11

270-97411

12

016·8·4

PART.

N'

DESCRIPTION

oil

wick,

for

looper

looper

primary

pinions

looper

lever

primary

washers, looper

pin, secondary looper

shaft,' secondary looper

secondary

·~-

primary

shaft,

screw, looper

looper-holder;

oscillating guide,

set-screw, looper

·set-screw, primary looper travel

control

control

with

large

with

large eye

control

with

screw-type bush

leVer

control

eye

lever

s

,.Ef.

a

K'

2 13 16·8·2.5

2 14 7-77·067

1

15

I

16

1 17 70-053

1

18

1

19

2 20 092-C-2

I A 27-77-0SIJ/1

1 8

2 c 270-063/2

21

I

PART.

N•

92·8·1

2·0·7

15·8·3

17-F-11

27·77·065/3

002F·14

~

A"".

3'

"-.}<

grub-screw,

control lever, secondary looper

oil-wick,

oil-wick

shim,

set-screw

set-screw

felt

adjustable

oscillating

looper-holder, secondary

screw

On reQuest:

27-277-0745/2

270-075

IS

l

'·

for·pin

adjustment

tube

bush

guide

looper

14

DESCRIPTION

for

pin

l•ver

~

I

1

2

1

I

2

1

4

I

1

I

I

for 227-QQ.32

5127.277-0745

6 270.057

seCondary

t:H"imary

looper

looper

Page 12

.-

a::.·-6

227-00-32

REf.

H'

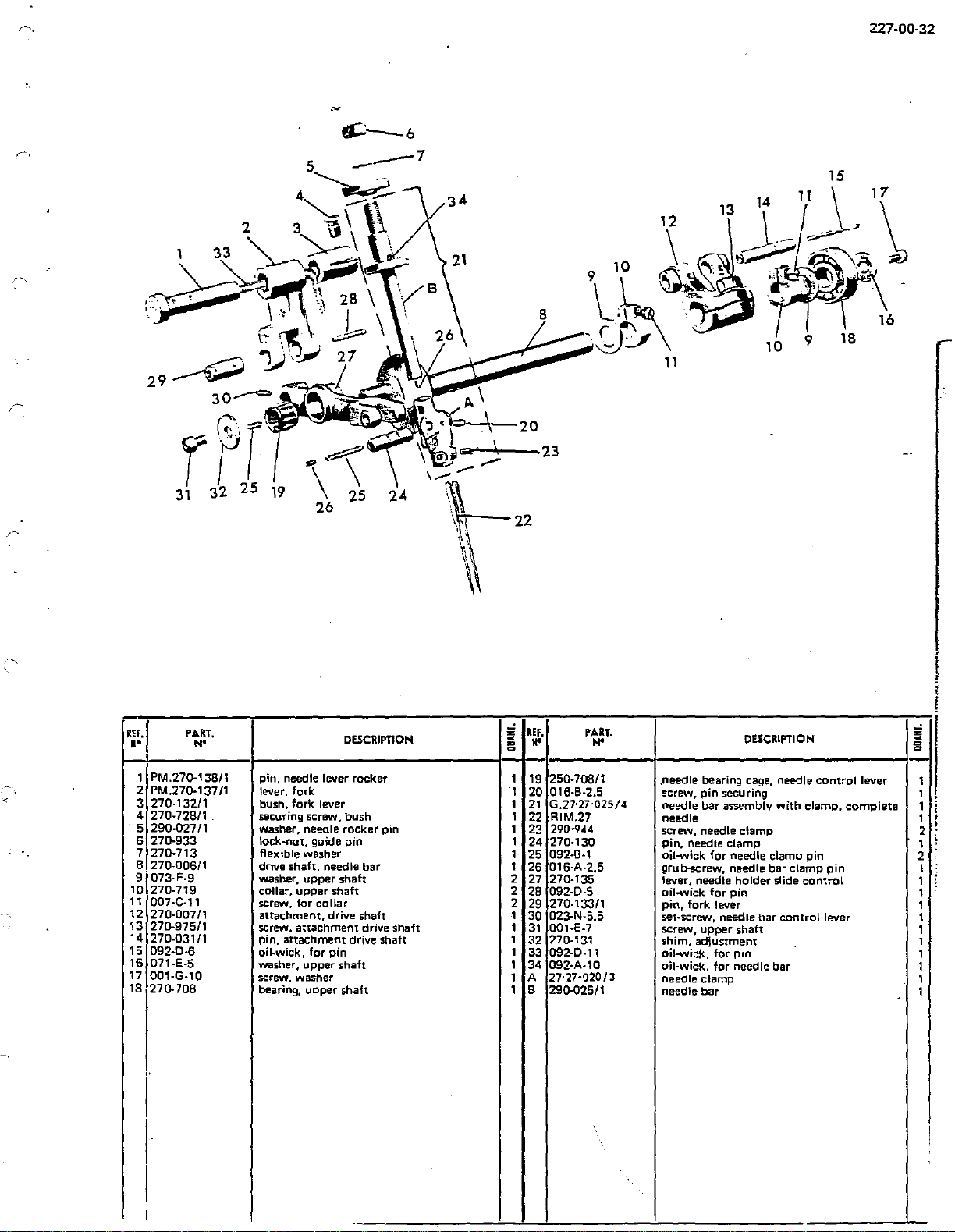

1 PM.27Q-138/1

2 PM.270-137/1

3 270-132/1

4 270-728/1

5

6 270-933

7 270-713

8

9 073-F-9

10

11

12

13

14

15 092-D-6

16

17

18

PA.kT.

N"

290-027/1

270-006/1

270-719

007-C-11

270-007/1

270-975/1

270-031/1

071-E-5

001-G-10

270-708

DESCRIPTION

pin, needle lever rocker

lever, fork

bush. fork lever 1

securing screw. bush 1

washer, needle rocker pin

lock·nut, guide pin

flexible washer

drive shaft, needle bar 1

washer, upper

collar, upper shaft

screw. for

attachment, drive shaft 1

screw. attachment drive shaft 1

pin, attachment drive shaft

oil-wick,

washer,

screw, washer

bearing,

collar

for

upper

upper

pin

shah

shaft

shaft

~

a

=

'1

lEF.

II'

1

19 250-708/1

20 016-B-2.5

21

G.27·27-025/4

22 RIM.27

290-944

1

23

1

24 270-130

1

25 092-B-1

26

016-A-2,5

2

27

270-135

2

28 092-D-5

2

29 270-133/1

30

023-N-5,5

31

001-E-7

,

270-131

32

1

33 092-D-11

1

34

092·A-10

27·27-020/3

1

A

1

B 290-025/1

PART.

N'

DESCRIPTION

.needle bearing cage, needle

screw,

pin

needle bar assembly with clamp,

needle

screw, needle clamp

pin, needle clamp

oil-wick for needle clamp pin

grub-screw,

lever, needle

oil-wick for pin

pin, fork lever

set-screw, needle bar control lever

screw. upper shaft

shim,

oil-wick,

oil-wick,

needle clamp

needle

securing

needle

holder

adjustment

for

pm

for

needle bar

bar

bar

clamp pin

slide

control

control

lever

complete

I

!

!

-'

;!;

= 0

1

1

1

1

2

1

2

I

1

1

1

1

1

,

1

1

1

1

Page 13

.-

6

7

9

. -

15

~

3

/33

A

1_/-

-~

13

·~~ia

"

32

----

-~::--·;

,·:~

I

---

--

-''SII,'

'29

-

'

I

,/'Y

'

fl

\ y·

~'I

.

,\

""._

20

',

9~1

25

~

26

IEF.

"'

1 27!l-102

2

270·096/1

3 27'77·112

4

092·0·5

5 128·111

6 271l-987

7

270.099

8 271l-103

9

073·F·9

10

270·719

11

007·C·11

12

270·108/1

13

270.098

14

092-C-2

15

092·0·9

16 250-471

PART.

N'

DESCRIPTION

pin,

upper

knife

upper

knife holder

upper

knife. serrated

oil.-wick

trimming guard,

securing screw,

block,

upper

lock-pawl,

washer, upper knife holder

collar,

upper

screw,

upper

pin,

yoke

yoke

attachment

oil•wick

oil-wick

upper

screw,

holder

upper

upper

knife

holder

upper

knife

knife holder

knife holder collar

attachment

for

yoke

for

attachment

knife holder

knife lever

knife

knife

pin

!2

kEf.

~

..

=

a

1 17

1 18

19

1

1

20 270·105

1

21

1

22

1

23

1 24

1 25

1 25

1 27

1

28

1 29 04-A-5

2

30

1 31 27.77·228

1

32 PM.271l-104/1

33

PART.

N•

007·P·10

064L•5

271l-104

277·113

271l-100

271l-106

003-L·12

wo-101

70-F-4

~;0~77

28·8·5

27.77·227

128·110

3

276

6·112

DESCRIPTION

set-screw, lower knife

washer,

fbr

lower

pin,

lower

spring, lower knife

pressure pin, lower knife

securing screw, lower knife holder

bushing, lower knife guide

washer,

screw, bushing

screw, upper knife holder

securing screw, angle

brace-plate, rear needle guard

angle stop, front needle guard_

knife

trimming

for

upper

pin

knife

holder

lower

knife

knife

for

bushing

holder. lower

guard

227-0il-32

knife

holder

upper

stop

knife

;;'

~

=

a

. '

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

I

1

-

Page 14

·.·:

r--------

I

1

,

23

~28

13

----

27

~~-

---

---

--

---

--

--

6

--

r-------,.

I I

I I

I

J-

I

I I

--:----

~------------------,

:

21

:

tJ~IB

I

I I

I I

------------J

12

lJ--16

,----......._19

l

~~25

L------------------~

I I

I I

I I

1

~~s:

I I

I I

' '

5

r-----··--------,

I I

:

I I

I I

I

\

~·.:

·~:

:

35

L--------------~

7

8

I

141

~37

~361

:

r·

I

REF.

••

10

1 1

12 G 27-778-076/1

13

14

15

16

17

34

35

36

37

38

PART.

N"

I

270.077

2.

270.081/1

3

270.083

092-C-2

4

5

PM270-085/1

6

270.087/1

7

270-985

8

2/0-08911

270-714

9

270-701 snap-ring 1

27-778·076/1

PM27.

778-076/1

270.085/1

270.091

004-L·B

001-~-4.3

G27.26·181/1

27.26-184/1

27.77-183

004-L-9 screw.

27.26-114/1

pin,

pressertoot

shaft,

presserfoot

bushing,

oil-wick

stop-pin,

lever,

presserfoot

screw,

spring,

snap-ring,

presserfoot

presserfoot

coupling,

stop-pin,

lock-ring, for

screw,

screw

for

227-00-32

presserfoot

shoe

presserfoot

chaming

needle

DESCRIPTION

presserfoot

lever

stroke

presserfoot

presserfoot

presserfoot

arm

arm

presserfoot

presserfoot

item

presserfoot

assembly

plate

presserfoot

plate

arm

lifter

lever

lifter

lever

shaft

adjustment

lifter

lifter

lever

lifter

lever 1

lifter lever

assembly

lifter lever 1

lifter lever travel

14

chaining

chaining finger

shaft

finger

-'

REf.

=

<

..

= =

0

1

18

1

19

1

20

4

21

1

22

1

23

1

24

25 G 27.277-181

1

26

27

1

28

1

29

30

1

31

1

32

1

33

1

1

1

1

1

1

PART.

N"

27.77-196

212

68-191

27-277-109/1

27.26·184

270-188

27.01 P-40311

27.26-186

27.277-114

27.277-10711

270-936/2

270-934/2

092-D-11 oil-wick 1

032-L·1C,5

CM

270-081,'1

270-073

bracket,

chaining

needle

shoe, presserfoot

chain

screw,

angle stop presserfoot 1

presserfoot

needle

needle

screw,

screw,

screw,

shaft,

tube,

protection

DESCRIPTION

presserfoot

finger,

guard, rear 1

cutter

angle

plate

guard.

front

rear

needle

presserfoot

pressertoot

mounting

assembly

for

narrow

front

needle

needle

plate

arm,

bight

guard

guard

securing

complete

~

0

1

1

1

1

1

1

1

1

1

1

2

1

1

---

Page 15

.-

er-·9

so_..!

'\\'-'

~6~-J~.

\

67

'

J\18

!\

\

~

~·

~·

5 f"""""

3

r6

64

......-r

70

. 8

·\·

30----

REF.

·"'

2 007-H-25 screw;

3 PM.27-27•205/3 cover, with

4 270-241/2 oil-cap,

5 270-965/2

6 270-983

7 PM.270-218/2 hinge assembly with guide tubes

8 007-R-7,5 screw. securing oil-cap plate

9

10 270-246

11

12

13

14 270-094 lever, presserfoot locking

15 270-701

16 270-086

17

18

19 270-993 set-screw

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

PART.

N•

I PM.270-208/3 side cover, with bushing

.270-245/4 oil-cap plate

G

270-Q93/1 cap, spring adjustment

032-F-9,5

605-412

270-078

2701·P·092

270-995

270-066/2

270-303

026-E-10 screw, seal

026·C-7

270-247/1

PM.270-095/3 shaft, pressurefoot pressure

G.270080/1 release

270-248/1

270-940

PM.270-210/3

270-972

270-730/2 screw,

270-220/1

PM.270-217/2 cover,

'\

\..~:_

packing ring, oil-cap

screw, cover securing

oil-cap plate gaSket ·

set·screw, stop cam

stOp cam

snap-ring

spring, presserfoot release rod

Pin,

spring. presserfoot pressure

screw,

plug,

nipple,

screw, splash guard securing

splash quard

plug,

plug,

work-plate

screw-bolt,

pin,

~.

... ) 26

'4\

DESCRIPTION.

top

cover

thread

With

presserfoot release lever

top

looper

cover

rod,

seal

screw

plug

front

looper

take-up bushing

window

cover securing

bushing

plug

securing

pressertoot

assembly

machine

cover

assembly

plate

and take•up

;i

REF.

~

K'

=

0

1

35

1

36

37

1

1

36

1

39

40

1

41

1

42

7

43

1

44

1

45

1

1

46

47

1

48

1

49

1

1

so

51

1

52 01205/A

1

53

1

54

2

55

2

1

56

57 270-619

1

58 270-624

2

59

1

60

1

61

1

1

52

63

1

64

1

1

65

1

66

1

67

1

68

69

\0

25

PART.

N•

007-F-14

270-221

054-0-4

270-226

G.270-242/3

028-E-10

270-212

001-0-6

001-0·4,5

270-718

017-E-4,5

270-030

270-973

270-715

270-129/1

270-73111

270-231

270-913

270-214

057-E-4

005-M-10

270-623/1

001-0-10

G.270-216/2

270-030/2

270-175

270-174

290-923

270-090/1

270-110

PM.270-301

016E

5.5

~;gm

31

_____

:~

............

_

'

'

DESCRIPTION

screw,

cover

spring, front cover

nut, retaining

screw, front cover securing

plate, complete with filters,

screw, bqttom plate securing

spring, workplate latch

screw, spring securing

screw, spring securing

collar, workplate pin

screw, collar

plug, differential shaft seal

screw-bolt,

set-screw

cap,

plug,

gasket

screw,

pin,

set-screw, side cover

nut,

screw,.side flange,

flange,

gasket, sealing disc

sealing disc

screw,

cover

screw, plug

nameplate,

nameplate,

set-screw, tie-rod

block,

tie-rod

splashguard assembly

screw

~:oo

OSit~T

machine assembly, short

for

guide

front

adjustment

pin

attachment

front

set-screw

left

sealing disc

plate

tie-rod

braclcet

WI

cover

plate

cover

plate

side

assembly,

front

cover

tensioning disc housing

left

cap

seal

securing

plate

front

plate

tubes

270-093/1

cover

-

~

~

a

1

1

1

1

1

4'

1 :

·1

1

1

2

1

1

1

1

2

1

3

1

1

1

3

1

1

1

2

1

1

1

1

1

1

1

1

I

l

;

Page 16

f1P

31

~t'1

30-.··?-

._p

25

26

<

---.C.

~

e:;;:..

~

·~.-

:.;..~

-

..

;·1

i

REF.

••

1 270-941

2 PM270-263/1

3 270-27413

4

5

6 270-265/1

7

8 270-268

9 780220-0-00

10

11

12

13

14

15

16

9

29

PART.

N•

270-264

270-265

270-266

270-26912

004

L-8

270.270/2

004

A-3.2

270.276/1

27.277-2751

032-A-6

780232-0-00

270-271

screw,

tube.

take-up,

needle

bush,

bush,

bush.

tube.

machme

take-up,

screw,

take-up,

screw.

bracket,

thread

screw,

for

227-00-32

machine

thread

thread

needle

needle

thread

upper

upper

lower

lower

type

pnmary

take-up

secondary

bracket

looper

guide,

thread

type

guide

DESCRIPTlON

guide

thread

thread

guide

thread

guide

thread

guide

thread

guide

thread

guide

nameplate

looper

securing

looper

securing

secondary

guide

nameplate

tube

securing

guide

looper

secunng

REF.

~

,.

=

~

1 17

18 270-233

1

1 19

1

20

21

2

2

22

23

2

24

2

1

25

1

26

27 27

28

29

30

31

PART.

N•

272-232:1

202558-2-00

603-031

270-230

270-232/2

004

\J-5.5

202556-0-00

270-232"1

250-031

27-253

016

E-2,5

27

00-2714

:;

:u

.27-262

004

P-4,5

"2

spring,

primary

bushing,

nut,

d1sc,

pm,

sprrng,

screw,needle

cup,

~rmg

disc

thread

,;ccew

thread

needle

screw

upper

tension

tension

tens1on

needle

tension

needle

tens10n

gUide

gu1de

thread

DESCRIPTION

looper

tenSIOn

adjustmg

screw

take-up

diSC

take-up

securing

assembly

2

4

4

6

4

1

2

4

1

2

1

1

1

1

1

I

l

!

!

:

Page 17

-----------------------

-----------

·-

-------~~:::::::::;:3:::::\l

i~\

1

------

------

12

...

~J

--

...

""

...

,"

-,

1

1

I

I i I I A E

I I 6 I - - •

l

L---------1~:

___

F:

_.J

2..

_______

-ll

___

\'~\

3 c H M

----~=:;;:.

1}~1'\/~::::~

_':.-::= / ,'

·:::---

, 45

[ :

--

"

..,.,.

9~

10

KEF.

••

I

I

I I 1 I

\

I

I 1

I

\

I

I 1 1

I

\ I I

1 1 I

I

17

_.@)

18

I

I : : 1

I 1 I I

I 1

\ I < 1

I 1 1 1

I

43

M('/23

;'

22 I I

16

-Q

= 24__..(l 1

,.

II

~

,..

I ,

\::::::,

\ A I l

\ \ :

PART.

N'

\

1 1 ,

\ l

I 1

\

I 1

I 1

I I 1

1 " ,

\ ___________

26

1 54

1\

31

~:.-::.·:::::.=.--~-=-·::::.~-:::.~-----~

;i

DESCRIPTION

Rtf.

~

~

••

g

PART.

I I

1

i

1

3

38

14:

41

,

1 I

1 I

! I 1

1

1 1 :

'"--~35~-

/33

.

I

N•

-t

_41

T

46

DESCRiPTION

I

;;

~

=

g

1

34

1 G.270·816/1 oil

2 G.633·833/1

3

PM

.270-816/1

4 633-812 screw

5 PM.633-817/1 cover

6 633-818/1 washer

7 633-71111 gasket 2

.;.

8 270-82411

9 270-823/1

10

633-708

633-707

11

12

039-G-10

13

270-810/2

14

633-959/1 oil level

270-808/1

15

633-842

16

17

270-81111

18

270-946

19

270-947

20

065·L·5

21

059-G-6

270-83111

22

23

270-836

017-H-12

24

007-l·

25

26

27

28

29

30

31

32

33

20

633-966

270-82811 disc

270-996/2

270-827/1

633·925

G.270·996/2

270-00112

205520·5-00

pump

gear assembly

pump

worm

shaft

flexible

cup

screw,

pulley, oil pump 1 46 028-E-10

gasket

tube

pin

gasket

gasket

washer

nut

tube

felt

grub..screw 1 a 633-822/2

screw 1 c 533·819

gasket

plug

felt

spacer

plug,

oil

oil

assembly

unit

pin

spring

pulley

securing 1

window

pad

disc

oil

sump

sump

pump

and sump assembly

complete

270:966/1

1

35

G.270·646 oil

1

36

PM.27Q-645/1

4

37

057-A-3

1

38

270-650

1

270-551

39

40

270·73411

41

1

270-652

1

1 43

533·82611

1 44

270·645

45

016·8·2.5

1

1

1

2

2

2

2

2

54

270-432/1

1

270-430

55

1 A 633-82112

1

D 633-833

1

E

633-81811

F

533-834/1

1'

1

G 270-816/1

1 H

633·814

1

L 533·813

1 M

670-702

1

gasket

distributor

oil distributor

nut

valve

gasket

flexible

junction tube

coupling

pointer, oil disttibutor

grub-screw,

screw

current

rubber

gear

wheel

gear

wheel

gear

plate,

gear

plate,

washer,

drive

shaft

housing,

roller

roller

seal ring

washer

tube,

pointer

plug

gasket

pin

side

inner

inner

pump

housing

housil"'g

assembly

oil

pump

1

1

1

2

1

1

1

1

2

1

1

2

1

1

4

1

1

1

1

1

1

1

1

2

Page 18

.-

,-

1

22

\\

-~--~

18

227-00-32

16

'

I

'

'

24

REF.

••

1

2

3 059-A-5

4

5

6

7 270-701

8

9

10

,

12

13

14

15

16

17

18 G .270-005/3

19

20

21

22

PART.

N'

G.270·583

270.585

270-583

270-459

270·557

270·558

270-552

270-004

PM.270-005/3

270-588

058-M·10

067-H·10

270·971

051-L-10

PM.1159

270-58611

270·584

065·L·6

059-H-6

17'-......~

z

DESCRIPTION

tie-rod assembly, presserfoot lifter lever 1

coupling,

lock-nut,

rod,

loc::k·screw,

coupling, presserfoot lifter lever 1

snap-rings

pin,

bushing,

rubber

bearing

guard,

nut,

washer. machine bearing plate

screw, machine bearing plate

nut,

chain

machine

lever, presserfoot

pivot, presserfoot

washer 3

nut,

presserfoot

lifter

presserfoot

flywheel

for

coupling

upper

mounts,

plate,

flywheel

machine bearing screw

machine

with

hook

bearing

presserfoot lifter lever pivot

lever

lifter

plate

machine

with

plate

plate

lifter lever

tie·rod

lever 1

guard

pins

mounting

lifter

lifter lever

bolt

upper

~

-

=

a

tl

;.

'

~~

lEF.

..

1

23

270.558

2

24

270.590/1

270.590/2

7

001-G-10

25

270.589/1

26

3

2

,

4

1

1

8

4

4

4

1

1

1

1

1

PART.

N•

25

ON REQUEST

pin

waste

chute

chute

chute

liang·

(left)

chute

-short

waste

screw, waste

waste

DESCRIPTION

right)

securing

~

=

a

,

1

,

3

,

I

I

I

'

Page 19

r

::=-=..:..

1

;__-=---=-:

117 - • "-

I

I

1s

13

19

11

==

;aj-

16

14 I

20\J

-l

i

'

40

42

41

12

37

3

j"~~~

9

7

rr,-

1

22

19

i1

-----

23

~

rs

:----::;--,

,

/~

6

2

25

I

3

29{;~;

__

_]_a___

26 1

---

39

33

n~

~

••

RIF.

1

2

3

4

5

6

7 001-G-.12

8 001-G-10

9

10

11

12

13

14

15

16 PM 260·13411

17 PM 26(). 133/1

18 PM

19

20

21

22

23

24

25

26

27

28

29

N'

DISEGNO

AS.2727-140

AS.260-140

605-937

605-980

32727-157

01141

26().142

1146

:3260-137

25().143

25().130

250-137

260·140

260·13511

016-=-5

PM

250·148/1

270.158/1

2727-137

569

·;s

20 x 3o

PM

91().914

053-H-8

910-964

910-93411

3

910-914/1

OENOMINAZIONE

SUPPLIED

thread

thread

bracket

locl<·sctew.

bar

base, thread

screw, rod securing

screw,

plate,

pin.

frame.

upright,

upright,

rod,

connector·piece,

rod,

rod,

rod,

grub-screw

sustaining

bar.

rod,

pad,

screw,

pedal

mit,

screw,

hase.

pedal

WITH

stand assembly

stand

assembly

sustaining

rhreud

thread

threml

thre<ld gu•de

thread

thread

threud

thread

pedal

with

smnd

plate

securing

thret:~d

spool

spool

thread

guide

main

lower

main

upper

guide

rod

guide

gu•de

rod.

thread

guide

guide

spool

thread

swntl

sh<~rp

oedal

iJSsemhly comJJiete

HEAD

ONLY

complete

thread

assembly

guide

susmining

securing

guilfe

rod

rod

~lowed

upuen

~

~

=

Q

1

1 31

1

2

1

.1

1

1 37

1

4

1

1 41

1

1

1

1

1

1

10

1

1

1

4

2

1

2

2

1

1

llf.

"'

30

49012

910·143

32

569

1146

33

34

001·:3·10

270·157

35

016·F·5

36

270·158/1

605·937

38

605-980

39

40

1145

910·144

42 G 497

N

DISEGNO

'

DENOMINAZIONE

SUPPLIED

thread

upright,

pad,

pin,

cap-screw

rod,

grub·Ererew 1

h~u.

h•·acket,

lock-screw

lock·nut,

upnght,

thread

WITH

STAND

spool

main

thread

spool

thread

spool

thread

guide

thre::td

guide

rod

threllll

thread

top

sec lion

gu•de assembly 1

suslilining

guide

rod

sus.twning

guide

suswinrng 4

bur

~

=

"

Q

I

I

i

'

'

'

1

2

5

5

5

1

1

1

2

2

I

I

'

-·-~

I

Page 20

a

0

\

15.

\

6

1A

i.e

·-----=\1

'

10

I

----·

'

13

227-00-32

)

~--~

~111

-

IEF.

••

1

VR.504

2

1175

3

280-155

4

R1M.27

5

115112

6

533-742

7

8

641-LY-743

9

1156/1

1158

PART.

N'

-

-

o~l.

1

quart

machine

vee·belt

needle,

RIM.27

screwdriver

hex.

wrench.

pincers,

threadmg

hex.

wrench

wrench,

double-ended

)""'t

19

can

cover

-

1/8''.

3/32"

-

...........

8

,17

DESCRIPTION

for

270-715

(

4

/

12

1

!

~

~

1

1

1

5 13

1

1 15

1

1

1

IEF.

••

10

11

12

14

16

17

18

19

PART.

"'

270-741

539-M-745

277-113

27

77·112

01160/2

270·745

0116112

270-743

2i0·431

290-746

pipe-wrench,

wrench

for

kn1fe.

lower

kn:.'e,

upper

screwdriver

hex. wrench,

screwdriver

hex.

wrench,

power

cable

h@l{,

wrenc:h

On

reQuest:

270-SiS/1

DESCRIPTION

9/32"

oil

sump

9/32"

5/64"

and

plug

1/16"

plug

fo•

nl!'edles

Tab.

75

z

c

~

~

1

1

1

1

1

1

1

1

1

1

-

'

;

Page 21

t227-0!J.20'

14

B

~

6

·-

7

5

(21

16-

I

s~'LRLI1UrlJ£ac-~

····'

· ... : .

.~.....;·~-

-------~2

'

I

:1?

I~

[

_____

i--

1

I

I

19

I

oi''

c::r-:

.-

11

~-r

::__j

----;4--

---,

I

I

I

I

I

I

I

I

I

15

20

----··

REf.

·--

I-A

••

605-144

1

2 011

-lT

3

Q01G-12

4

605-143

5 605-723

6 605-937

7

605-380

8 G250 R-937"3

9

057

.C..-'3

27.77

w

11

001

C·5,5

,,

...

R-267

-----·

DESCRIPTION

ba;.

toP.

base

sc:-ew

uupnght

tapered

sieeve

bracket

knurled

head

e/a:;ric reel ::.ttmd

nut

gUide, ,.e,:;f':>rcing

screw

!>Crew

tape

·-

i·

=

~

1

1

1

1

2

1

4

1

1

1

1

REF.

H'

PM::7.-.7

1<

13

2.".7.77 F:.-134

14

2.'

.

15

;.7.'lG B-1?1

16

·:a.1256·0·G·J

1:

0~4

18

: .

.'.~

13

:104

:a

G?.7.:.7J

.,..S

21

PART.

N•

.'7-136

L-8

..,; P-0.11

G-3

F-181

2:Jx30

F-267

gur<fe.

remfcrc:ng

shce

lug,

ch:uning

!in!JP.I',

m<.~c!Hne,

screw

plate

•;crew

presserfoot,

M:rew.

pl.rle

c!mining

type

c..:omplete

~r,nne

securing

DESCRIPTION

t.Jpe,

complete

n.1mepline

~

• i

'

'

I

'

1

i

~

-

1

;

?.

--

Page 22

-----------~----

..

.-

a)

Identification numbers

1.

Every head

- class or sub-class number

- serial number

2. The class

3.

The

head serial

is

identified by:

and

sub-class

number

num~r

is

are engraved on the name-plate, on

engraved on a

HEAD IDENTIFICATION

I.

boss

on the

bottom

of

the

the

base

base

.

of

the machine.

II.

The machines depicted

following

1.

2. Differential

general characteristics:

Straight needle, system

can

be

TECHNICAL DATA

in

this catalogue are overedging machines with 2 needles, needle gauge

RIM

27/Fmb ·Thickness

regulated while machine

is

80

· 100.

running.

BY

MACHINE CLASS

3. Push-button stitch length adjustment.

Stitch length variable from 6

4.

5. Differential feed ratio: up

6. Width of bight: from

7. Speed: from 6000

to

3/16"

6500

to

30

stitches per inch.

to

3,5:1 and also up

to

5/16".

RPM,

depending on the tYpe of application and manufacture.

to

4:1.

8. Lubrication: by pump.

9. Motor: 1/3

HP

or 1/2

HP,

according

to

subclasses.

10. Outer dimensions of machine head: 12" x 9.3/4".

11. "''eight: approx. 45 lbs.

3/32",

with the

Page 23

a}

Positioning

After

motor

1.

Force-fit

2. Place machine head

the

of

head

is

mounted

four

INSTALLATION

I.

on stand, proceed as follows:

rubber

shock

absorber

on

table centering

the

pads

lower

on

to

holes in

the

the

AND

pins

head

TIMING

provided

on

the

on

the

machine

shock absorber pad pins.

head

bearing

plate

f'.

.•

b) Assembly

1.

Install driving belt as shown

2.

Check

on

pump

3.

Adjust

that

pulley,

belt

of

transmission

reverse

without

tension

of

driving

by

loosening

in

diagram

belt

slipping.

1.

rides firmly

motor

clamp

and

squarely

4. Level machine head by adjusting machine cradle bolts.

5. Tighten up machine cradle bolt lock·nuts.

c)

Filling lube oil sump (fig. 2)

Unscrew threaded cap

1.

Pour

in

2.

Check

3.

,

red lines .

Replace and tighten cap 'A'.

4.

Before starting

5.

1 and

through

'A:

3/4

pts Esso Standard Teressa

oil-window

up

the machine, the following

that

oil level

is

between

points

43

the

should

oil.

two

be lubricated:

- needle clamp guide rod

-

upper

looper bar

6.

Start

machine slowly. letting it idle for

gradually rev up from 1500 r.p.m.

about

5 minutes and

to

rated operating speed.

d)

Assembly and adjustment of sewing parts

Note: The operations described below are for machine timing

1.

Timing gauges required:

·

S.

.··-.

1686.00

·

S.

1555.00 for operation

2. Preliminary disassembly of:

·-Front

for

all

cover plate

operations

N.

except

4

operation 4 (fig. 4).

· Both thread take·ups of lower looper holder

·

Side Cover Plate (casing) of needle movement

· Upper plate with oil indicator cap

· Side plate protecting needle movement

· Main feed dog

Hg.

2

Page 24

3.

Setting

of needle (fig.

3).

-~

•

if

the

needle plate

be

centred

..

holes

of

the

the

distance between

surface of the needle plate

is

at

its highest point.

if

adjustment

move needle bar clamp up

S.1686.00

setting. Retighten screw A .

is

in

proper position,

for passage through

needle plate .

the

is

necessary, loosen screw A (fig.

as

indicated in

the

.-

needle _points and

is

11/32 inch when

or

down,

fig. 3 to

the

needles

resPective needle

using_

needle gauge

obtain the correct

the

must

the

needle

3}

top

and

~-~

·..--;

__

"""""

-~

i::

A

i

f

-.--·-·;.":":···.--

__

4. Setting primary looper (fig. 4

SETTING OF

fig. 4

Setting

angle

Slightly loosen screw 'D'

Place timing gauge S.1686.00 on milled surface

as

shown

in

fig.

5;

shift

lever C

has been

is

obtained.

Correct

timing table.

Firmly tighten up screw E

set

in

place

but

position can be checked by reference

and

turn

not

locked) until correct angle

(fig.

41.

loosen

mount looper height gauge 5.1555.00 on the primary looper shaft wi:

special

raise

5.1555.00.

slightly tighten screw E (fig. 4).

set thread guide bracket A by raising thread guide bracket to the

primary

retighten screws 8 and

remove looper height gauge 5.1555.00.

looper (which

HEIGHT

screw

E.

screw supplied with gauge as shown in

or

lower looper so

looper

shank.

that

its

point

contacts

E.

of

base

to

the

fig. 3

fig.

the

4.

upper

line

on

timing gaur-

top

of

th

...

Setting

the primary

When the primary

the

left and with

distance

be

If

tion axis. ln its

point

dle scarf.

Retighten

'between

as

indicated

adjustment

should pass 1

scr~w

in

IS

necessa;-y move lever C along its rota·

D

looper

looper

the

the

looper

fig. 6.

stroke

64"

in

has

needle

point

from left

from

relation

completed

in

its lowest position,

the

and

to

bottom

to

the

its stroke

the

needle should

right

of

the

needle:

looper

the

to

the

"·

A

nee-

llg. 5

" .

...

c

----

....

f

Page 25

---------

5.

Timing

Secondary Looper

fig. 6

If

adjustment

is

required, slightly loosen Screw 0 and push

wards, avoiding any change

Lock-screw

Recheck

Tighten up screws A and

Finally, make sure

D.

to

make sure the two loopers are crossing

B.

all

the assembly are moving

Note: To

~ownwards:

mcreased

Slightly

Slightly loosen screw

Adjust crossing

looper

tip

barely

set

the

remember

or

decreased.

loosen screw B.

rotating

passes

behind the

skimming

dimension 1

that

A.

of

secondary

the

secondary

primary

it.

Check distances given in figures 7-8 {see

timing

table).

Durin£ its left

ary looper should barely

in

the distance already fixed. Make sure

to

right

smoothly

motion

skim

and

smoothly.

1/32''

by doing

in Fig. 8,

this

rotate

the

dimensions

fever E

in

upwards

Fig. 7 will

and primary

so

that

its

looper

the

second-

the needle.·

fig. 1

the

complete looper assembly inwards or out-

all

parts move smoothly.

verify

all

the

other

settings.

or

be

6. Setting the needle guards (fig.

To

set

front

needle guard

With needles

Retighten screw

To

set

a~

their lowest position,

C.

rear needle guard

With needles in their lowest position,

Retighten screw

It

must

be checked

D.

break through impact with the primary looper.

of

the

machine and check

breaking

them.

If

this

slightly just above the shanks, where the

9)

A,

loosen screw

B.

loosen screw

that

when working,

that

is

not

fig.B

C.

set

front

needle guard so

D.

set

rear needle guard so

any

eventual slight bending

To

do

this, bend the needles slightly

the

primary looper. during its stroke from left

the case, the needle guards need

part

is

not

so hard. Check

that

that

to

it

touches

it

touches

of

the

be

positioned

that

the

needles.

needles

needles does

correctly

each needle

sponding plane of the front and rear needle guards.

Thread the needles, bringing them

pushing them slightly against rear needle guard

The thread

the

needle

must

run freely.

is

too

low and the thread

to

their lowest position and

B.

If

this

is

not

the

is

trapped

case it means

between needle

that

and needle guard.

~JOTE:

The

point

of

the

looper,

enter

the needle scarf

in

the lower portion.

left,

For very hard synthetic fabrics the needle

on the

front

needle guard.

in

its stroke from left to right,

in

its upper portion

and

must

must

in its

stroke

to

flex considerably

the

D

without

not

towards

to

right, passes

hv

operates

lia.

deflection.

cause

the

bending

in

9

them

inner

without

the

to

part

them

corre-

Page 26

7.

Mounting lower

trimmer

knife (fig. 10)

Mount guide block P on knife-holder with screw

Slide knife D into place.

The

cutting edge

Tighten.

With the needles in its lowest position, bring angle stop 0 close

washer G by tightening

Check

51

- With needles in its lowest position, bring guide block

P close up

tightening

After setting

trimmer

is applied between

Press

screw N firmly.

Pressure should be lightly

strong friction between

their

up

that

ightly tighten screw

knife, slacken screw

one

hardening.

of_

the

trimmer

screw

A.

up

knife holder C moves

N.

to

front

needle guard and lock it by

up

screw

a.

upper

trimmer

the

knives by spring M and pin

finger lightly against screw A and tighten up

the

knife

must

_

screw

F.

smoothly

knife touching lOwer

N.

The proper pressure

exerted

to

avoid generating

two knives resultating

Q.

be

flUsh

with

the

and adjust setting for required bight.

H.

in

·rear needle guard.

to

the needle guard, lock bushing L and

i

'I

i

~-~

;;

__

ie·

'~

«:""

\

N

.

:-.·

··.-:·

---~

8. Mounting and setting Feed Dogs (figures

Remove Plexiglass plate beneath work plate.

Mount rear feed dogs C and D (fig. 11) and match

With a small screwdriver pushed through the threaded holes on

the

screwdriver into

Mount the

Slacken screw

Adjust feed dog angle by rotating eccentric

.---~···

~

front

'

.~

-~'-

the

differential feed

A.

..

""

\;:_

..

~,

groove

on

the

dogE

tip of

11

and 12)

the

screw.

with screw G

B.

c ;

. ! D

--~s

~a"·-~-~-

~

.

•,

fig.

11

I

,,.

the

feed dog slides.

the

but

do not tigh;en it up fully

fig.

10

levers, tighten screw F slightly, inserting

(fig.

12).

fig.

12

The feed dog teeth visible through the needle plate should be absolutely flush with

When

the

feed dogs are

and

the

needle plate.

Feed dog C should

Lock

screw_s

F,

G,

9. Feed mechanism (fig.

Note: The machine heads illustrated in this catalogue are supplied with the feed mechanism already

type

of use to which they

If

feed mechanism adiustm8!"7

at

their highest position, there should be a clearance of 1,3 mm. between

at

the

front

be

lower than the

and

A.

131.

will

be

is

of

the

differential feed dog.

other

two.

put.

r~quired.

proceed

as

follows:

the_

latter.

set

the

for

teeth

the

Page 27

--------

------

1.

Inactivation

Slacken

of

differential

nut

high as it will

up

Tighten

nut

2. Setting differentiaTfeed

Slacken

Set

Lock

pin Q

nut

nut

at

B.

B.

Lower lever H against

3. Setting

differential feed for retia 3.5 : 1

Slacken

Set

Lock

nut

B.

pin Q in lowest positio·n.

nut

B.

Lower lever H against

4. Setting differential feed

Raise cursor C

------

feed:

8 using wrench A supplied

go.

B:

lower lever H against

_

for

ratio 2 : 1

highest position.

stop

G.

stop

G.

for

ratio 4 : 1

to

its highest position

- Proceed as for item 3

- The differential ratio can be changed

5. Setting negative differential feed·

Slacken

Set

Shift

nut

B.

pin

Qat

highest position.

cursor C in lowest position.

with

stop

F and lock knurled knob R manually.

on

slide-barS

w~ile

the

the

machine head, and

machine

is

in

operation

raise

pin

by

adjusting lever

Q on rear feed

E.

dog

lever

as

fig.

13

10.

Mounting

upper

Mount

upper

trimmer

trimmer

knife

knife

(fig. 14).

C on

knife

holder

block

Mount knife holder block D and trimming guards E and G with screw

F.

Trimming guard E should be very close to cutting

,'of knife

edge

When

trimmer

cutting

·trimmer knife by

For

this

slanting seat and

knife holder

Tighten

when

in

guard.

C.

knife

C is

edge should overlap

1/32".

adjustment,

knife

shift

holder

B.

up

screw F and check

lowest

position,

does

at

the

its

I owest

cutting

trimmer

block

that

not

touch

position,

edge

of

knife

A on

th~

the up-per

front

its

lower

in

its

upper

knife,

needle

fig.

F

14

Page 28

e)

Positioning and adjustment

of

presserfoot arm

{fig.

15).

Insert presserfaot

arm

shaft L

in

bus,b.ing

Con

which

Insert presserfoot arm shaft L with bushing C into hole

provided

Slide lever

Slide snapring F on

Set lifter

foot

Slightly tighten screw

With needle

ing

- Engage

When pedal

in

baseplate.

A and spring E on

lever A so

arm shaft L.

arm D

in

guide fork.

lifter lever A

to

shaft

L.

to

shaft

L.

that there

is

no

end·play

on

B.

at

highest position, insert presserfoot bear·

with

presserfoot lifting

is

depressed it should have a slight idle

foot

stroke before actuating presserfoot bearing arm

Adjust lifter lever

tion.

Check

movement

serfoot

below presserfoot

is

at

Tighten up screw

its

A,

by regulating screw

of

secondary

highest

bearing

position.

arm

B.

in

looper; the latter

This

undesirable

0,

on

side

cover.

base beneath

presserfoot

presser-

pedal.

D.

should

condition

the

not

bearing

lever, so

impinge

can

be

arm

that

on

presserfoot

prevented

is

hinged.

E.

~M

L

it lifts presserfoot to required posi·

chaining finger

by

adjusting eccentric

when

washer

pres-·

M,

f)

Adjustment

The

ment.

The moving part C should

needle guard

The cover plate can be shifted towards left

adjusting screw

Lock

g)

Adjustment

of

front

cover plate

front

cover plate should be closed before adjust·

or

the

lower knife holder.

{fig.

16).

not

interfere with the front

B.

nut

A.

of

needle thread takiHip

or

right

by

For making up very tough fabrics, needle thread take·up 270·274/2 should be shifted forwards, towards ope·

rater.

Page 29

ELECTRIC LUBRICATION CONTROL DEVICE (PRESSURE SWITCH)

.-

h) Disasoombly

-·

Take

down

- Remove screw

Slacken

Slip plastic

Remove

Screw

scrAINS previously removed.

Re-install

and

replacement

oil cup from baseplate and drain

by

which pressure switch bracket is

the

two

screws

tube

connecting pressure switch to rubber

bracket

down

and fix it

electric wire lugs, slip plastic

011

cup and

on

fill

of

pressu"'

the

electric wire terminal lugs.

to

new pressure switch.

with oil

as

switch

tube

instructed

out

oil.

mounted

into pressure switch and

on

page 11,

on

connection

par

c.

oil

cup_

off

the

pressure switch.

mount

switch on oil

cup

using

the

Replacement

Proceed as described under items 1 and 2 for replacement

Remove

Re-install rubber

Re-install oil

Electrical

- Plug cable

Nota: If

with

12

Mount

light terminal lugs.

Plug cable

of

pressu"'

rubber

cup

connection

to

current

no

light socket

V. connections, proceed as follows:

a Mignon

to

current

switch lamp

tube, remove lamp (bayonet cap)

tube.

replace pressure switch in position and fasten firmly to

and

fill

of

pressu"'

socket

is

socket

socket

with oil

provided on

pitch 13

as

instructed

switch

on

and insert plug

the

at

one

at

one

end

and

on

page 11, par c

Zafir

moton

at

other

motor

to

be

end

of a cable 4 • 5 inches long

and

to

the

above Mignon

of

pressure switch.

replace with new lamo.

end

of

cable in 12

connected,

but

socket

the

and

at

V.

voltage

the

light

at

011

the

other.

wah

~cr~w

socket

on

connection

other

connect

motor.

box

it

is provided

to

the

12 V.

~

.

Remove cover.

Using a screwdriver, turn indicator 8 in required direc-

tion !Turning towards

the rate

wards

of

flew

the

letter A, the rate of flow

the

letter C puched on

is

decreased, turning the indicator to-

is

increased).

the

plate,

fig.

IS

B

Page 30

.-

TIMING

T A B L E

MACHINE HEAD NUMBERS

227 .()().32

227-00-20

227.()1.()7

227-00-21

----

A

2,5<2,8

2,5<3

2,5<3

8

1,5 3,3<3,5

1,5

1,5

-

c

8,5

3,5

D

0,5

0,3

0,3 8,8

F

-

8,8

Page 31

,

a ·

Thre~umg

.-

II

- USE

I

(~

I

'

•

I

i

\

·~

..

'

\

'

\

\

'

~·

I

I

I

I

~

'\

I

I

I

I

~

~

'

\

-

/

I

'

I

I

I

I

227-o0-32

Page 32

b)

Needle change

1.

Switch

off

motor.

Depress motor'driving pedal

2.

3.

Set needle at

4.

Lower lever

Swing

5.

Slacken

6.

top

dea~

8 as far as it

·out presserfoot from

needle set-screw by

centre.

will

to

check

that machine

go

(fig. 19).

usual

working position.

one

half-turn using screw-

is

absolutely motionless.

driver 290-7 46.

7.

Remove

8.

Insert new needle.

The needle scarf should face

9.

r·

10.

towards

Using

needle touches

Retighten needle set-screw without· displacing

11.

le,

needle.

the

rear

needle guard. i.e.

the

rear

of

the

machine.

pincers supplied with machine kit, check

the

bonom

but do not apply excessive force.

of

the

hole.

the

that

need-

F

c)

Positioning and adJustment

1.

Check

that

presserfoot

Needle should pass between pressurefoot

r

2.

To

adjust presserfoot slacken screw

3.

Center presserfoot

4.

Presserfoot pressure

5.

led

knob

A.