Page 1

Rimoldr

SPARE

CATALOGO PEZZI

CATALOGUE RECHANGES

ERSA

PARTS CATALOGUE

01

RICAMBIO

lZTEILELISTE

227-00-01 AND

SUBCLASSES

n.

32/A

Page 2

MACHINE

HEAD

IDEN"(IFICATION

CONTENTS

INTRODUCTION

Page

5

II

TECHNICAL

Ill

TECHNICAL

INSTALLATION

-

a - Positioning

b -Assembly

c-

Filling lube oil sump

d -Assembly and adjustment

e

· Positioning

· Adjustment

f

g

·Adjustment

h-

Electric lubncauon control

II

a -Threading

b -Needle

c-

Positioning

· Tensioning

d

e · Stitch length adjustment

f -

Seam

g

· Trouble due

USE

-

width

of

of

and

of

of

change

and

discs

adjustment

transmission

to

DATA

DATA

head

adjustment

front

cover plate

Needle thread take-up

adjustment

adjustment

incorrect handling

BY MACHINE HEAD CLASS

BY

SUB-CLASS

I'NSTRUCTIONS

AND

TIMING

of

sewing parts

of

presserfoot arm

dev1ce

of

pressertoot

of

machine

5

"

6

"

Page

13

'

13

13

13

13

"

..

18

18

"

18

"

19

"

Page

21

21

"

27

"

27

"

27

"

"

27

27

"

28

"

-~

~

Ill

MAINTENANCE

-

a-

Daily

b -Weekly

c-

Quarterly

d-

Sharpening knives

e-

Instructions

a-

Introduction

-

II

-

a - All spare -parts

b ·Needles

Ill

IV

for

INSTRUCTIONS FOR

ofiDER

ILLUSTRATIONS

GENERAL

changing

PLACING PROCEDURE

LIST

Cam

OF

Shaft

(if

SPARE PARTS CATALOGUE

USE

PARTS

required)

Page

"

"

"

"

Page

"

"

..

"

..

..

29

29

29

29

29

29

33

33

33

33

33

35

113

Page 3

INTRODUCTION

.,

0-

.-

~-----·-

Page 4

a)

Identification

I. MACHINE HEAD IDENTIFICATION

numbers

1. Each machine head

· Class or sub-class number

·Serial number

2. The class

3.

The machine head serial number

or

sub-class number

is

identified by:

is

punched on

is

punched

the

name-plate bonded

on

a boss provided for the purpose

to

the machine base.

on

the

rear base.

II. TECHNICAL DATA

The

heads illustrated in this catalogue are

features:

1. RIM.27 straight needle

Differential can be adjusted while machine

2.,

3.

Stitch length adjustment by push·button control.

Stitdh length adjustment range: from 6

4.

5. Differential Feed Ratio: up

of

6. Width

7. Speed: from

8,

Lubrication: by two-stage

9. Drive motor:

10. Overall

11. Weight:

bight: from 3164"

5400

1/3

dimensions

about

46

system·

to

7000

HP

or

1/2

of

machine head:

1 bs.

size

55

to

to

3,5:

1 current use,

to

15/64".

r.p.m. according

oil

pump

HP

according to sub·class.

11

BY

MACHINE HEAD

the

single needle overlocking machines with

to 100.

is

running.

48 stitches per inch.

but

4 : 1 can be attained.

to

type of use.

4/5"

x 9 1/2".

CLASS

the

following general

Page 5

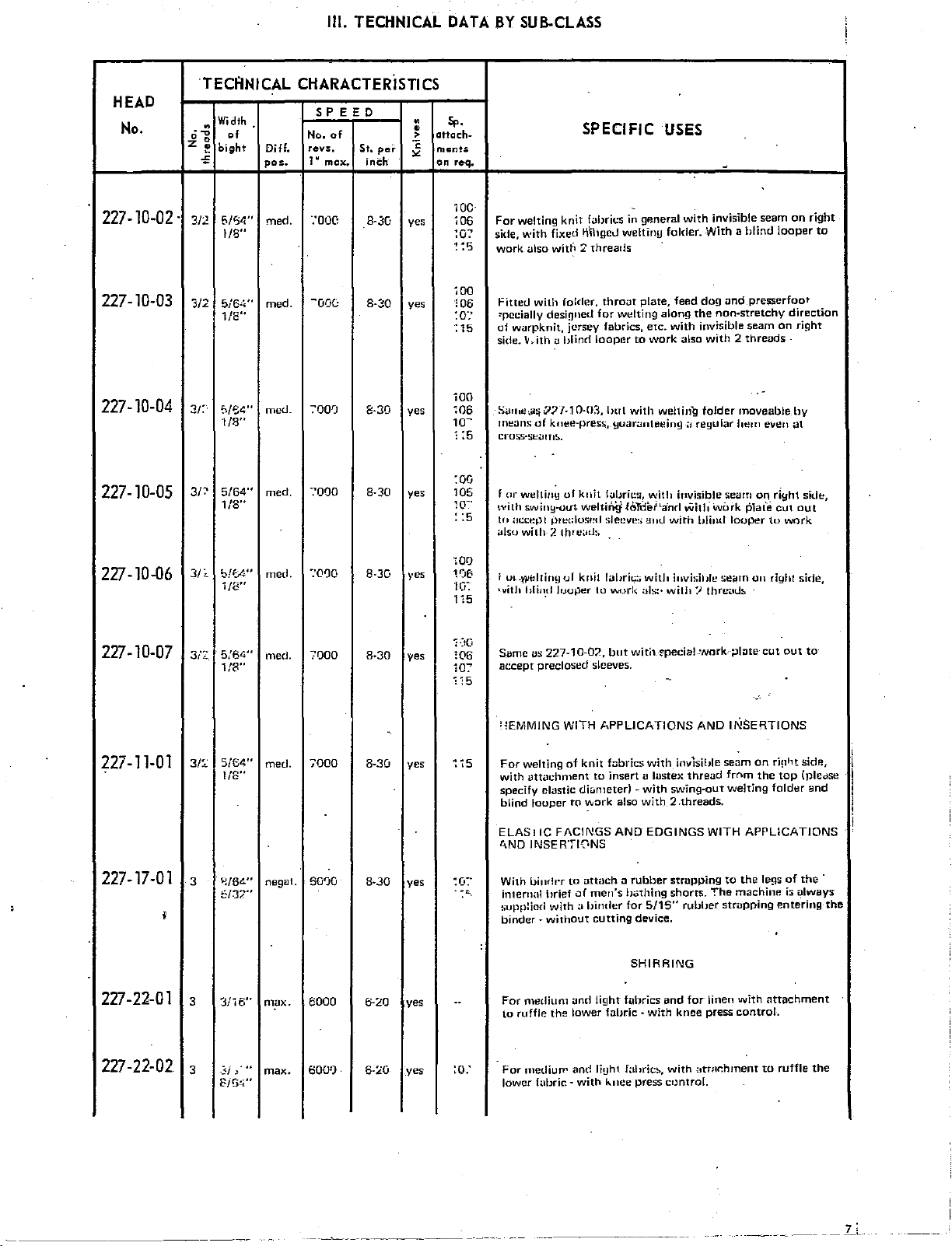

Ill.

TECHNICAL

DATA

BY

SUB-CLASS

HEAD

No.

227-10-02.

227-10-03

227-10-04

227-10-05

TECANICAL

Width

"

·~

of No.

0 0

z

~

bight

..,

5/S4''

3/2

1/8"

3/2

5i6•i"

1/8"

3/:

f>/f.4"

1/8"

5/64"

3r:'

1/8"

CHARACTERiSTICS

SPEED

of

Diff.

pos.

med.

med.

mec.L

med.

revs.

1 N

·:ooc

~00(;

700')

·:ooo

max,

St,

inCh-

B·3u ye:;

8<'":!0

8·30

8-30

pel'

"

•

>

·;;

"

yes

yes

yes

Sp.

attach-

ments

on

iOO

106

10-

':5

I

:oo

105

w~·

re-q,

100

For

i06

side,

~o:

~ ~

5

work

jQQ

fitted

'!06

~pm:ially

:o:·

of

:

15

side.

SarJ1e-.a~

means

crm;S·S!:!<IIIl!>.

fur

with

:

:5

to

also with- 2 threuLI:,

SPECIFIC

welting

knit

with

fixed li'illgcll weltin!J folder. With a

ulso

with 2 threads

with

folder.

desinned

warpknit,

wei tiny

;n;cept

jersey

lJ,

ith

i.l

blind

V/

/·1

0-03,

of

kne~·pres!;,

of

swiny·out

knit

welt-irllj f0ldet'a'nrl With wOrk Plale

~>ret:lusml

.

fabrics in gP.neral

throut

plate,

for

Wt!lting

fabrics,

looper

etc.

to

work

lml

with

yuaranteeing

l<a!Jril::;1 Vl.:ith

!>leeve:;

auLl

USES

with

feed

along

with

also

welting

01

iT•visible

with

~

invisible seam

blind

do~l

<Jnd.presserfoot

the

non-stretchy

invisible

reyular

blind

seam

with 2 threads

folder

moveable.

hem

seam

looper

looper

on

.

e\!en

011_

riyht sitlt!,

cut

to

on

right

to

direction

right

-

by

at

out

work

227-10-06

227-10-07

227-11-01

227-17-01

I

227-22-01

3/~

b!EA"

5.'64"

3/:~

1/8"

5i64"

3/~~

~/64"

3

f::/J2"

3

3/16''

1/8"

1/8"

med.

med.

med.

negat.

max.

''C%

7000

7000

6090

6000

8-3G

\•es

8-30

yes

.

8-30 yes

yes

8·30

yes

6-20

·:oo

10B

10:

115

i·)O

!06

10:'

ii5

~'iS

:o:-

...

..

f Ul-(lltdfiny

•vith

hli•~tl

Same

as

227-10-02,

accept

preclosed

'lEMMING

For

welting

with

uttm:hment

specify

clustic diLJmeterl

blind

looper

ELASIIC

t...,NQ

INSERTIONS

With Uind1·r

internal

brief

supplied

binder·

without

For

medium

to

ruffle

ul

knit

Juoper

FACINGS

with a hinder

the

fabril::; wit!• h•visil•fe

to

Vllf.)l'k

but

sleeves.

WITH

APPLICATIONS

of

knit

fnbrics

to

insert

to

work

to

uttach ~ rubber

of

men's

cutting

and

light

lower

fabric·

:.~Is:·

with.

~pecia!

with

u lastex

-with

also

with 2 .threads.

AND

EDGINGS

hothing

for

5/15"

device.

SHIRRING

fubrics

with

se4:1m

on

with/

threaU~

work--;:JI~te-cut

right

..

"

;,NO

INSERTIONS

invisible

swing-out

strapping

shorts.

and

knee

thread

WITH

rubber

for

linen

press

seam

on

frnm

welting

APPLICATIONS

to

the

The

machine

stwpping

with

control.

ri!1ht sidP.,

the

folder

legs

ilttachment

side,

out

to

top

(pledse

and

of

the

i:;

always

entering

the

·

.5/

J

227-22-02

3

...

Bi5-'i"

max.

6000

6-:iO

yes :o:

For

lower

mediull'

f;,1bric-

and

with

li!Jh1_

lo.nee

fabric!>,

press

with

<~tWr.hment

control.

.

to

ruffle

the

_______

___

Lc

Page 6

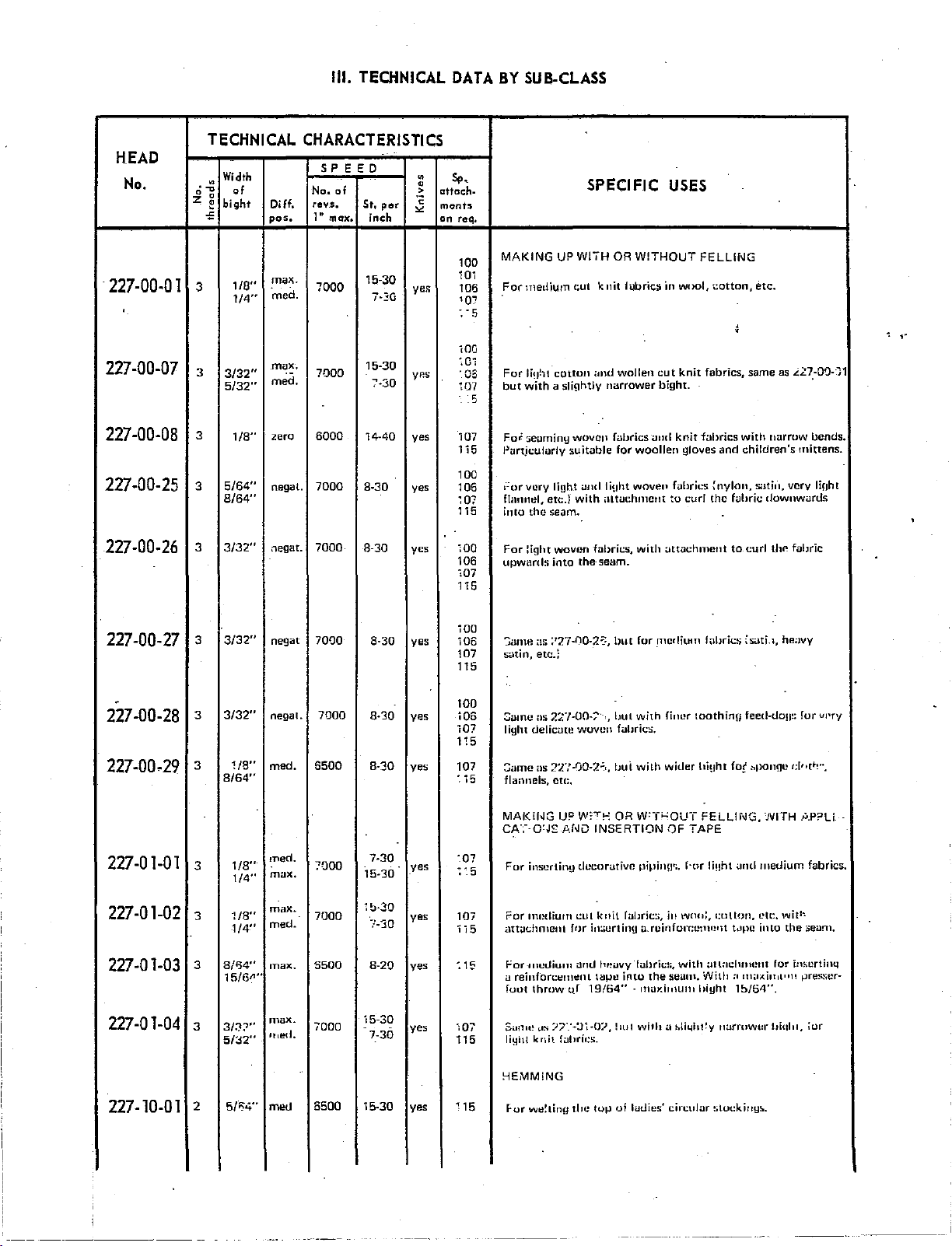

Ill.

TECHNICAL

DATA

BY

SUB-CLASS

HEAD

No.

227-00-01

227-00-07

227-00-08

227-00-25

227-00-26

TECHNICAL

Width

.

·~

of

0 0

:z;

~

bight

~

1/S''

3

1/4

..

3

3/32

..

5/32

..

3

1/8

..

5/64

8/64

3/32

..

..

..

3

3

CHARACTERISTICS

SP

EED

No.

of

revs.

Oiff.

pos.

max.

"med.

max.

med.

zero

negat.

negat.

1" max,

7000 ye;;

7000

6000

7000

7000

St,

inch

15-30

7-~G

15-30

:'·30

14-40

8-30

8-30

per

Sp

•

•

>

attach-

c

monts

"'

on req.

100

101

106

1Q7

:.

iOG

:01

yP.s

·cs

107

. 5

yes

107

1 i 5 Purt.iculorly

100

yes

106

107

115

;oo

yes

I

106

"t07

115

•

MAKING

For

medium cut

5

For

li!Jhl

but

with a slightly

Foi

:;eominy

1::ur Vl.!ry li!)ht

flmmtll,

into the seam.

For

light

upwards into the seam.

UP

cotton

suitable

etc.}

woven

SPECIFIC

WIIH

OR

knit

;md

wollen

narrower

woven

fubrics uml

for

and

liuht

with

illti.Jt:hmcnt

fol>rics,

USES

WITHOUT

fubric:i in wool, ;;otton, etc.

woollen

wovefl

with

FELLING

I

cut

knit

fabrics,

bight.

knit

fabrics

gloves

fabrics~

to

curl

<.~ttuchment

same

with

and

children's

nylon,

satin,

the

f<.~hric

to

curl

as

..!2:~-Q')-]1

nurrow

bends.

mittens.

very

downwurds

li!Jht

thP fabric

,,

227-00-27

-

227-00-28

227-00.29

227-01-01

227-01-02

227-01-03

227-01-04

3

3

3

3

3

3

3

3/32

..

3/32

..

1/8"

8/64

..

1/8

..

1/4

..

1/8"

1/4

..

8/134"

15/611"

3/3'}"

51o2'"

neg

at

7000

negat. 7000

med.

6500

med.

7000

ml..IX.

max.

7000

med.-

max.

5500

max.

7000

lh!!d.

8-30

yes

8-30

yes

8-30 yes

7-30 '.07

7-30

8-20

7-30

yes

yes

yes

yes

15-30

~0-30

15-30

-

iOO

':iame

106

107 satin, etc.;

115

100

i06

107

115

107

. 15

:

'5

107

ii5

:1!3

107

115

il:i ;'27-{)0-2.:::,

Same

ns

light

delicum

:::ame as 2:t.'·'i0-7.,;,, tJut

flannels,

1\tlAI<ii>JG

CA::·-o:J£

For

inserting

For

nmdiurn

att<Jc.;hment

ror

-mullium

a reinfon:to"lllto"nt

fout

throw-

Si.l!llt!

,..:;

liyhl

knit_ fLJhril:s.

!-tEMMlNG

hut

for

2:.:"1-00-;'·--,

cu:.

UP

_.c,_f.JiJ

o_r

/7".'-:11-0/,

hut

woven

W:-T~

decorative

cut

ft>r

anll

19/64" -ITlUY.illlUlHIIiyht

whh

fi.JIJrics.

wilh

OR w:T;....:OUT FELLif>JG, '.IVITH

INSERTION

pipinw;.

knit

f<.~hric:;,

in:;crtinH

bt!i.JVY

Iabrie!;,

tape

into

!llll

with

_rncrlilHH

u.rcinfon:cnw•lt

the

h11>rics

firmr

tooth

wkler

hi~Jht

QF

TAPE

f·or

li!lht

in weHr:,

with

;lltadum!nt

seum.

With

:.1

~li4ht!y

isati.1,

inn

feed-UO!I~:

fo!' :.pongc

and

medium

t:ulton,

L'll:.

t.tpc

into

for

a

m;MilhL••n

lb/64".

nurwwtlr

lliqlll,

heilvy

fur

d"t•!

.U.P?U

with

the

seam.

in!.tlrtinq

tJre!:.'ier-

ior

vr•ry

..

,

fabrics.

5/13"4"

227-10-01

-------

2

m<!tl

6500

15-30

yes

115

F-or

we~ting

tlu!

tup

ol

h.Jt.lies'

cin;u]ur

!;tockiny!..

Page 7

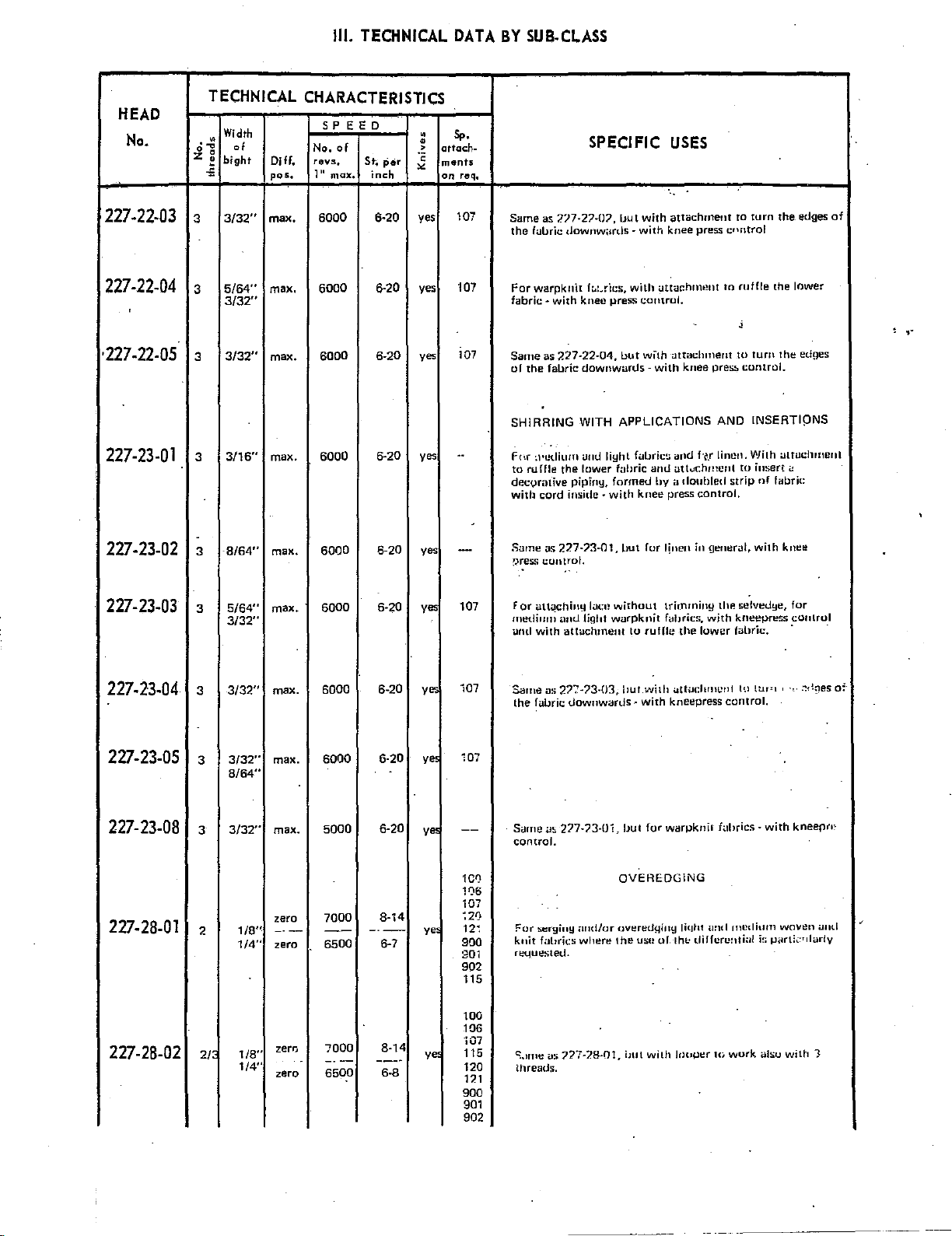

Ill.

TECHNICAL

DATA

BY

SUB-CLASS

HEAD

No.

227-22-03

227-22-04

·227-22-05

227-23-01

227-23-02

TECHNICAL

Width

-~

of

0 0

z.

bight

.£

3/32"

3

5/64''

3

3/32"

3/32"

3

3/16"

3

8/64"

3

CHARACTERISTICS

S P E

ED

No.

of

revs

Dill.

pos.

max.

max.

max.

max.

max.

•

1" max.

6000

6000

6000

6000

6000

St.

inch

6·20

•

•

>

·c

per

"'

yes 107

yes

6·20

6-20 yes

yes

6·20

6-20 yes

s,.

attach-

ment.s

on

req.

107

107

..

-

.

SPECIFIC

Same

as ?.'77-27-07, Uut

the

fui.Jric

downw;1rds-

For

warpknit fuLdcs, with utmc:hment to ruffle the tower

fabric-

with

knee

press

with

with

knee

comrul.

USES

attachment

press

ro

turn

cnntrol

'

Same

as

2:?.7-22-04,

of

the

fabric

SHiRRING

fc,r

:l•cdium

to

ruffle

decvrative

with

Sarne

~res.<>

the

cord

as

227-?3-01,

control.

pipiny,

inside-

but

downwards-

WITH

APPLICATIONS

unt.l

lighl

lower

fuhric

formet.l

with

but

wllh

attachment

with

knee

preS!>

AND

fubric~

and

f·~.r

and

hy a doubled

knee

press

for linen in f)eneral,

linen.

att...r.hnnmt

control.

tu

tum

control.

INSERTI!)NS

1/'Jith Llttuchrl!erll

to

insert<:

strip

nf

with

the

the

fabric

kne~

edges

edges

of

,.

227-23-03

I

227-23-04

227-23-05

227-23-08

227-28-01

227-28-02

for

att~chinylacn

mediurn

and

Same

the

with

as

fa!Jric

antllight

i.ittadunent

27>73-03,

Y"'

ye

107

i07

107

5/64"

3/32"

3/32"

3/32"

max.

max.

max.

3

3

3

6000

6000

6000

6-20 yes

6-20

6·20

without

warpknit

to

ruHie

!Jut

UownwartJs~

with

with

trir_nminy

fabrics,

kneepress

thP.

!it:!lvedye,

with

the

<.~ttm:lummt

kne~press

lower

fabric. · ·

to

control.

UJI'I

for

control

-,.

~,!ges

•

of

8/64"

Sgme

a!.

217-?3·01,

For

:.erginy ;u1d/ur nvered{.liny lilJhl uml

fultrks

----

6-20

8·14

6-7

Y"'

ye>

--

1CQ

11)6

i07

~21

12,

900

901

902

115

control.

knit

requestell.

max.

3/32"

3

zero

1/8"

1/4"

-·-

zero

2

5000

7000

--

6500

where

!Jut

for

warpknit

OVEREOGiNG

the

ust! of.thl<

f;:thrics

·with

kneeprF

medium

diffurc~,ti:1l

woven

i~

1-l<~rll<:•dar!y

uml

100

106

2/

1/8"

1/4"

zero

zero

7000

----

6500

8·14

---·

6·8

ye

"i07

115

120

121

900

901

C::.nm~

as

??7-7.8-01,

threads.

but

with

hluper W work

alsu

with

1

902

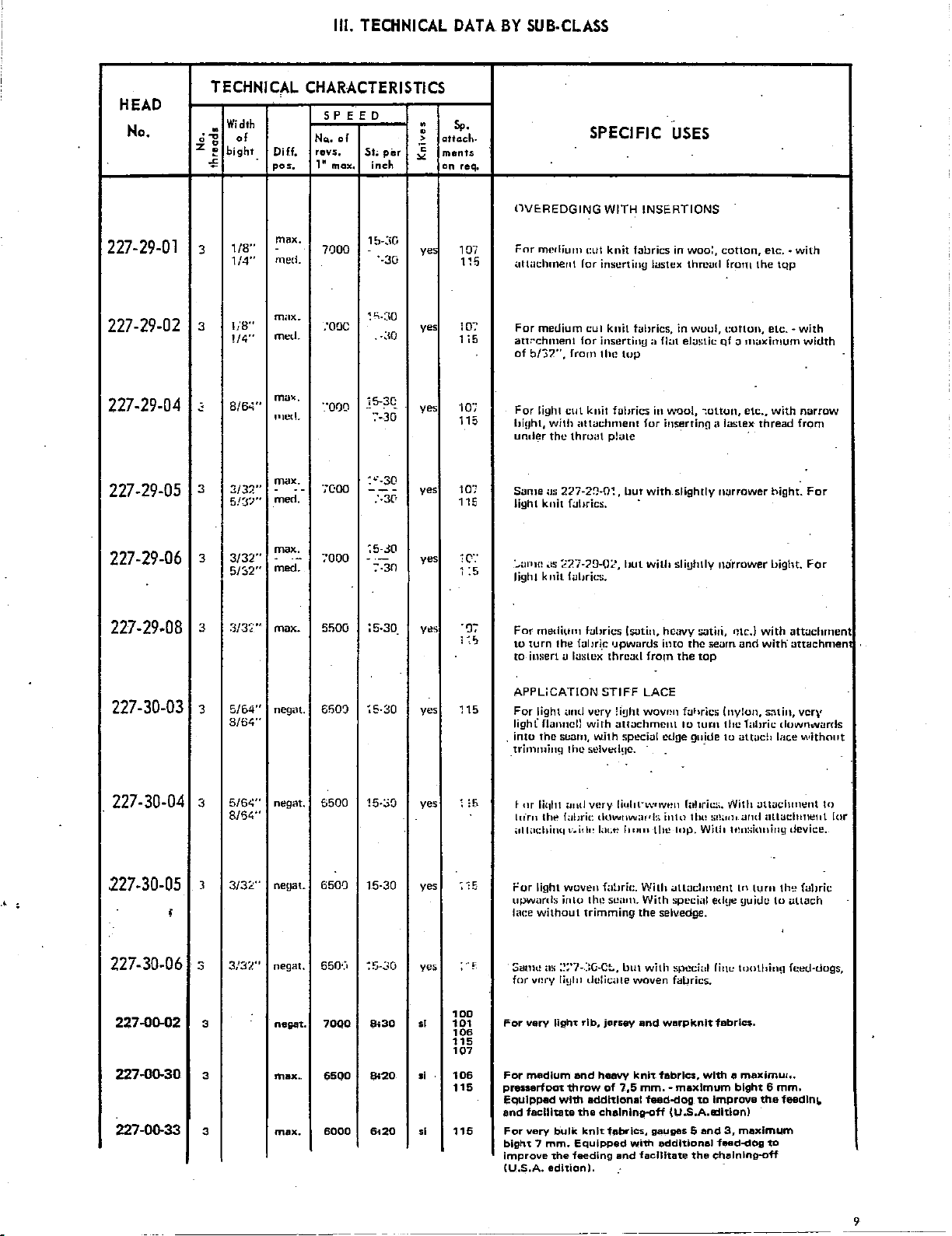

Page 8

Ill.

TECHNICAL

DATA

BY

SUB-CLASS

HEAD

No.

227-29-01

227-29-02

227-29-04

227-29-05

TECHNICAL

Width

.

·~

of

0 0

z

~

bight

.;;

1/8"

3

1/4"

1/8"

3

!/4"

8/6<i"

2

3

3/32"

5/3?"

CHARACTERISTICS

5 P E

ED

No..

of

fOV-5,

Oiff.

pos.

max.

-

mecl.

motx.

med.

max,

PlCtL

max.

merl.

1~

I

--

max,

7000

:ooc

·:ooo

-:coo

Sto

inch

1~<\G

"-30

~

C.-:JO

.<m

15-30

·:-30

:'"--30

---

:-3[•

per

Sp.

•

•

>

attach-

ments

"

"'

on

req,

ye

107

115

yes 10:'

1 i 5

yes

'107

i 15

yes

107

1 15

DVEoREDGING

For

nwllium

<ttl<Jclunent for

For

att;·chment

of

b/"37",

For

light

hi!Jht,

under

Same

light

t:ut

medium cut

for

frorn

cut

knit fabrics

with

itt

the

throat

iJ~;

227-2~-0~,

knit

f<~hrics.

SPECIFIC

WITH

INSERTIONS

knit

fabrics

inserting

inserting

llu~

tachment

lastcx

knit

h.tbrics, in wuul,

:1

top

for

p!<.~te

llut

with

·

USES

in

woo:,

cotton,

thrcml

rroTH

fiLII

in

waul, -:ottun,

ins~rtin!l

slightly

cotton,

el:.~~:tic

Qf o

a

laste_x

narrower

etc.·

the

tqp

etc.-

maximum

etc

..

with

thread

hight.

with

with

width

narrow

from

For

...

7000

5500

6!;0~

6500

6500

550·)

:5-JO

--

:'·30

:5-30

~6·30

15·:.>0

15-30

~5-.:m

yes

Yt!S

yes

yes

yes

yes

;c

1

:5

-~~

I;;

115

;

:5

: 15

:

"f,

:.,;,Hill!

.ts

lighl

For

to

to

APPLiCATION

For

ligh(

.

into

trhnrning

illlilchimt 1·.id•!

For

upwomb;

l<tce

Samt!

for

~27-79-o~·.

knit

fuiJries .

medium

turn

!he

insert

u

light

ami

flanncll

the

suarn, w.ith speciul

the

~

nr

liql11

ltlrn

omtl

th~

Iabrie

light

woven

inlo

without

m;

:~~·7-.::G-C::.,

v•!ry

liHIII

f-uhrics

f<11lri.c

Ia:,;

lex

very

with

selvt:tl!JC.

very

tluwnwaJ'!::.

lat;t~

th1~

trimming

tlciic<tte

!Jut

with

lsutin,

•Jpwan.ls

thrc<~tl

fro1n

STIFF

LACE

!iuht

wovr!n faf1rics

attachment

liullt·w•JVt!IJ

1111111

the

fahri1:.

Wilh

scam.

With

the

selv.edge.

but

wilb

woven

slightly

heavy

satili,

into

the

the

top

to

tum

ctlge

gu~de

ro:t!Jrit::;.

into

lht! st!;uJ•

top.

Wilh

all:Jchment

speci<tl

special

fai.Jrics.

narrower

ntc.l

iie<~rn

edye

rint:

with

and

with

(nylon,

satin,

the

Iabrie

to

<~ttucb

vVith

attaclunent

;md

illluchment

lt!n:>iuning

tn

turn

yuiUc

toothill!l

Uight.

For

attachment

attachmen

vcr\'

dowrhflfi!rds

lac.e

without

device.

the

fahric

to

utl:Jch

fceU-tlogs,

In

lt~r

227-29-06

227-29-08

227-30-03

227-30-04

227-30-05

;

3

3

3

3

3

5/~2"

~1/3·~·

5/6.4"

3/64"

5/6~"

8/64"'

3/3L"

..

mecl.

max.

negat.

negat.

negat.

-

.

max.

3/32'"

'

227-30.06

3/32"

3

negat.

227.00-02

227.00-30

227-0D-33

100

3

3

3

negat.

max.

max.

7000

6500

6000

!!i30

Bi20

6i20

10·1

ol

106

115

107

106

•I

116

ol

115

For

verv

For

medium

presaerfoot

l;::qulppad

end

facilitate

For

vary

bigh't 7

mm.

improve

(U.S.A.

editiOn).

llgh't

with

b'ulk knl't

the

rib,

and

throw

additional

the

Equipped

"feeding

jersey

and

heavy

knit

of

7,5

mm.-

fabrics,

with

and

feed-dog

gauges 5 and

facilitate

cholnlng-off

warpknlt

fabrics,

additional

fabriC$.

with

maximum

to

Improve

(U.S.A.a:Ution)

f..-d~og

the

c~alnlng-off

a

max.imu~o.

bight 6 mm.

the

3,

maximum

to

feadlnl.

9

Page 9

Ill.

TECHNICAL

DATA

BY

SUB-CLASS

HEAD

No.

227-00-04

'

227-00-05

227-00-06

227-00-09

227-00-10

TECHNICAL

Width

•

·~

of

0 0

z

~

bight

"'

3

5/64"

9/64"

5/64"

3

9/64"

3

1/8"

15/64"

3

3/64"

1/16"

.

2

1/16"

5/64"

CHARACTERISTICS

S P E

ED

No.

of

revs.

Diff.

pos.

negat.

negaE.

max.

Lero

zero

1"

max.

7000

7000

6500

6200

6200

St.

inch

8-30

8-30

8-20

2'J-.t;.Q

20-40

pel'

•

•

>

.

.,

"'

si

,;

si

,;

,;

s,.

•

attach·

ments

on

req,

100

101

106

107

1 1 b

100

101

106

107

115.

106

115

100

106

115

100·

106

115

SPECIFIC

ASSEM3LING OF FABRICS

CUR

LEO EDGES.

For

perfectly

fabrics

machine

-

Same

cutting

For

medium

throw

For

closing

For

closing the toes

straight

etc.

With

is

in

as

22/-00-04,

device

ond heavy fabrics,cwith o

of

19/64"

the

hanging

cutting

operation.

but

while

the

·maximum

toes

of

of

device

without

mactiine

nylon

helomca and

USES

WITH

OR

seams

on

adjustable

possibility

is

in

bight

ibt64".

stockings

cotton

WITHOUT

warpknit

while

of

operation.

maximum

socks.

nylon

the

;

adjusting

presserfoot

,.

the

227-00-11

227-00-22

227-2ll-07

227-28-08

227-29-07

227-30-01

100

3/64"

1

/16''

5i64"

9/64"

3/32"

9/64"

3/64"

1i16"

3/64"

1/16''

5/64"

1

/16''

negat.

negat.

negat.

negat.

mj)X.

negat.

3

3

3

3

3

3

5200

7000

6000

6500

6500

6500

14-40

8-30

14-40

14-40

15-40

15-30

,;

106

115

si

115

iOO

si

106

HP

115 turning

100

s;

106

107

115

,;

107 · Particulurly

115

,;

115

For

very light

very fine seam.

For

perfectly

etc.

With

unU

execution.

OVERl

For

made

Particularly

handkerchiefs,

.

OVEREDGING

and

of

lastex

A."'

For

With tensioning

kneepress

securing

DGING

serging

from

the

children's

the

fabric

thread

IACI-!tiJG

<Htachiny

and/or

lightweight fabrics such

edge

nylon

warpknit

straight

operated

the

seam

overedginy

of

the

suitable

for serging

head

scarves.

WITH

suitable

for seaming

knit

underwear

downwurds

into

the

:>T!H

wide

lace

(,!e..,.ice.

f<d>rics,

hanging

seams-on-warpknit

device for closing-up

at

the

begi~ning

headsquares,

fabric

into

;md!or

INSERTIONS

the

garments

and

simultaneously

seam

so as

to

LACE~

from

the

top

etc.

and

as

nylon,

the

seam.

overedging

bottom

avoid

on

£15

deniers).

at

the

veHs, scarves,

silk,

edge

turning

insertting

the

linking

wurpknit

nylon

the

ea1d

juponette,

on

ladies

the

edge

operation.

fabrics.

with

fabrics

stitches

of

the

etc.

a

..!

227-30-02

5/64"

9/64"

negat.

2

5500

15-30

115

si

For

<Jttaching

tensioning

~evit!e,

wide

lace fed

on

wan.Jknit

from

below

nylon

by

a lace rack

fabrics.

etc.

Page 10

INSTRUCTIONS

_

INSTALLATION

_ USE

_

MAINTENANCE

:FOR

AND

TIMING

--~-----'---~

--

-

-~-----~---~

------····-

-u

i

Page 11

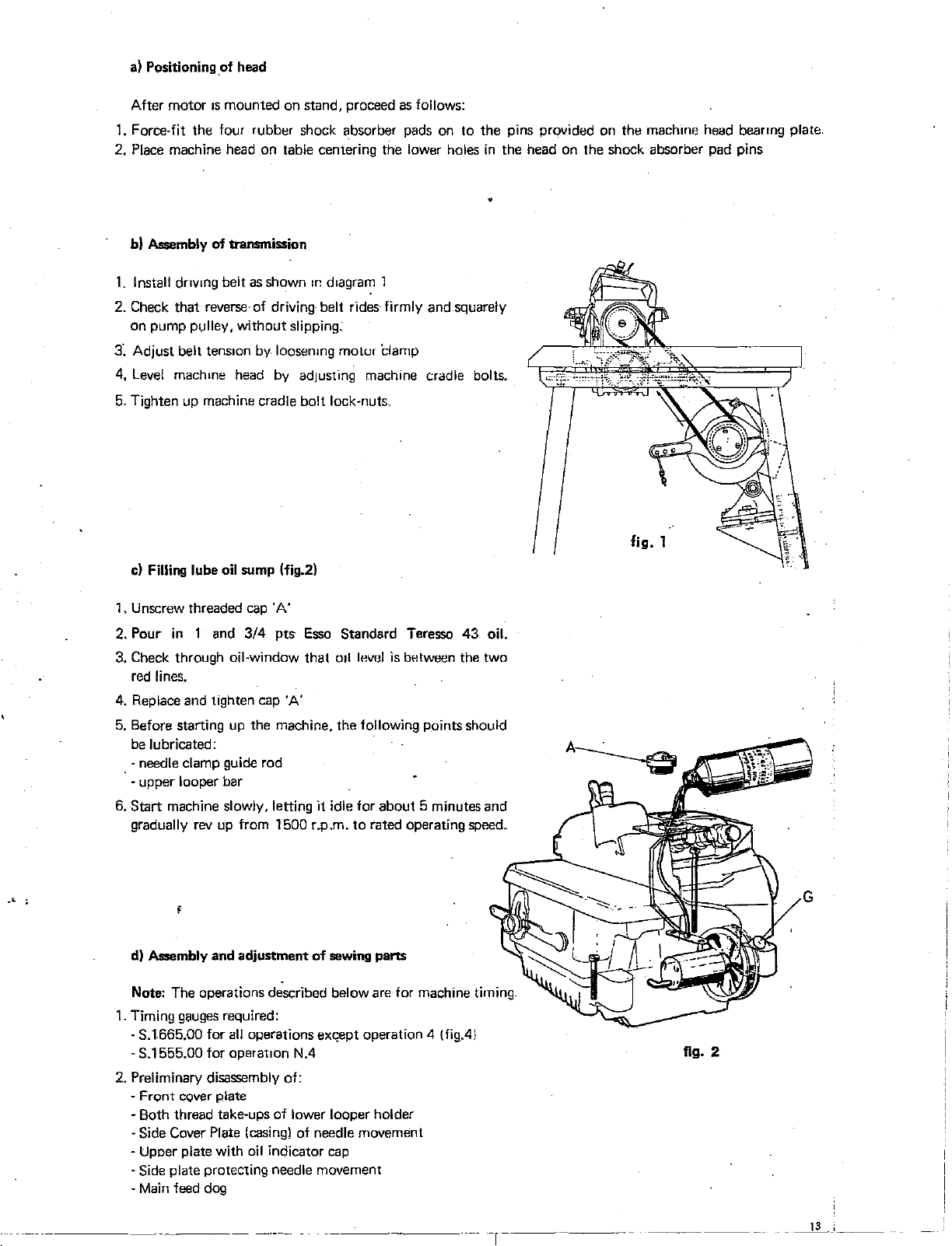

a)

Positioning of head

1s

After motor

1.

Force-fit the four rubber shock absorber pads on to the pins provided on the mach1ne head bearmg plate

2. Place machine head on table centering the lower holes

b)

As$embly of transmission

1.

Install dnvmg belt as shown

mounted on stand, proceed as follows:

1c

d1agram

1

in

the head on the shock absorber pad pins

2. Check that reverse of driving belt rides firmly and squarely

on pump pulley, without slipping:

3:

Adjust belt

4,

Level

tenSIOn

machme

by loosenmg motul clamp

head

by

adjusting

machine

cradle

bolts.

5. Tighten up machine cradle bolt lock-nuts.

c)

Filling lube oil sump (fig.2)

1. Unscrew threaded cap 'A'

2. Pour

3. Check through oil-window that

in

1 and

3/4

pts

Esso

Standard Teressa

011

lev"l

red lines.

4. Replace and tighten cap 'A'

5. Before starting up the machine, the

following points should

be lubricated:

· needle clamp guide rod

· upper looper bar

6.

Start

machine slowly, letting it idle for about 5 minutes and

gradually

rev

up from 1500 r.p.m.

to

rated operating speed.

'

d)

As$embly and adjustment

Note: The operations described below

1. Timing gauges required:

- S.1665.00 for

all

operations

- S.1555.00 for operat10n N.4

2. Preliminary disassembly of:

- Front cover plate

· Both thread take-ups of lower looper holder

·Side

Cover Plate

- Upoer plate with oil indicator

-Side

plate protecting needle movement

-

Main

feed dog

(casing}

of

sewing parts

are

ex~ept

operation 4 (

of needle movement

cap

43

oil.

is

between the two

for machine timing.

fig.41

fig. 2

r-----~-

-------

- -

_____li_

_

_;~~~

Page 12

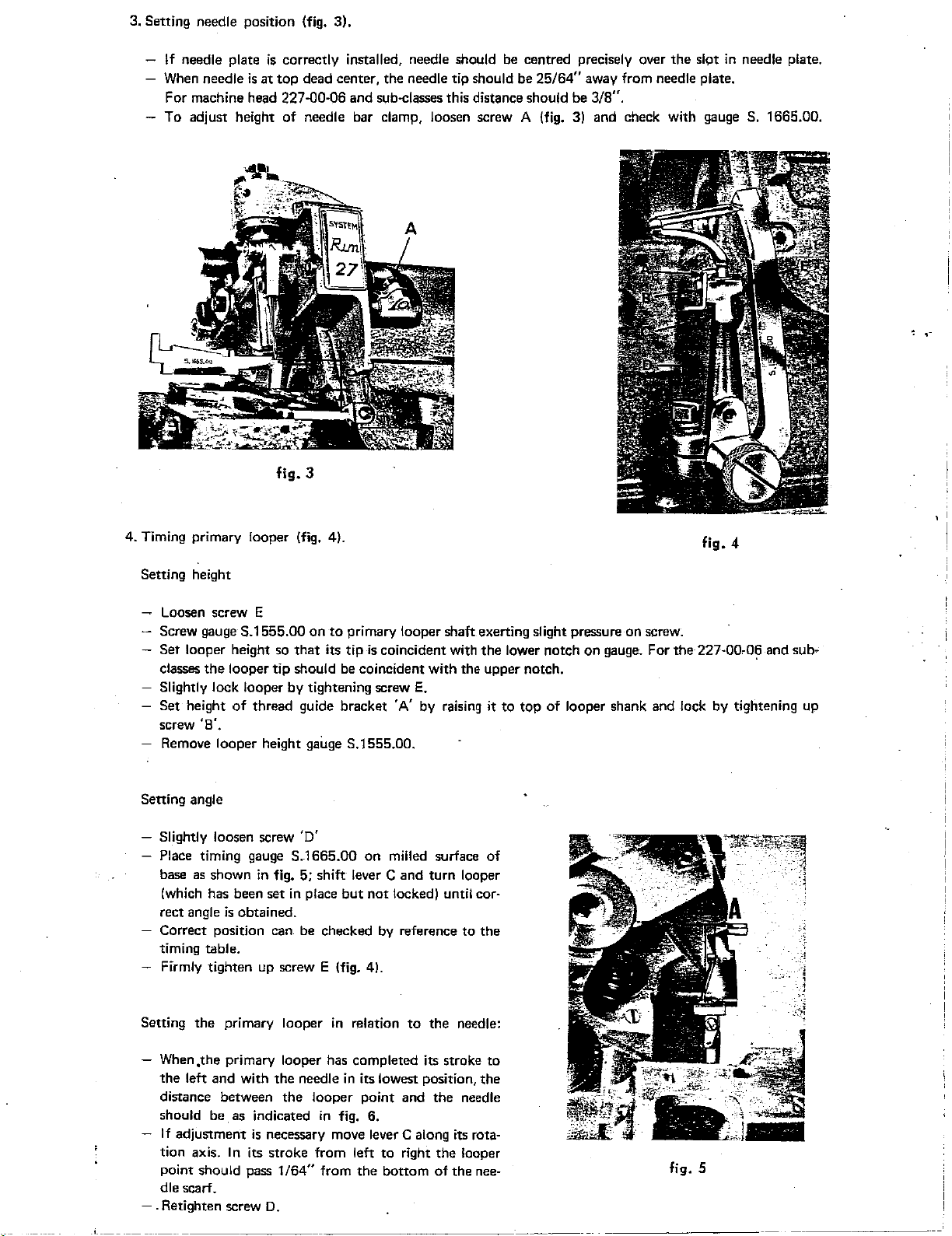

3. Setting needle position (fig. 3).

If

needle plate

When

needle

For machine head

To adjust height

is

correctly installed, needle should be centred precisely over

is

at

top

dead center, the needle tip should

227.00·06 and sub-classes this distance should be 3/8".

of

needle bar clamp, loosen screw A (fig. 3) and check with gauge S. 1665.00.

be

25/64"

the

slot

in

away from needle plate.

needle plate.

,-

fig.

3

4.

Timing primary looper (fig. 4).

Setting height

Loosen

Screw gauge S.1555.00

Set looper height so

classes

screw E

the

looper

on

to

primary looper shaft exerting slight pressure on screw.

that

its

tip

is

coincident with

tip

should be coincident with the upper notch.

Slightly lock looper by tightening screw

Set height

screw

'8'.

of

thread guide bracket 'A' by raising it

Remove looper height gauge S.1555.00.

Setting

angle

Slightly

loosen screw

'D'

Place timing gauge S.1665.00 on milled surface

base

as

shown

(which

rect angle

has

Correct position

timing table.

in

fig. 5; shift lever C and turn looper

been set in place

is

obtained.

can

be

but

not

locked) until cor-

checked by reference to the

Firmly tighten up screw E (fig. 4).

E.

the

lower notch on gauge. For

to

top

of

looper shank and lock by tightening up

of

4

fig.

the

227·00.06 and sub-

Setting the primary looper

When .the primary looper

the left and with the needle

in

relation to the

has

completed its stroke

in

its lowest position, the

needle:

to

distance between the looper point and the needle

should be

If

adjustment

tion axis. In its stroke from left to right the looper

point should

as

indicated

is

necessary move lever C along its rota-

pass 1 /64"

in

fig.

6.

from the bottom

of

the

nee-

dle scarf .

. Retighten screw

D.

fig. 5

Page 13

D.

1111!111!;;1

.:>~L;UfLUdiY

LUUf.J~I

Note: To set

this the dimensions

the

dimenSion

in·

Figs. 7 and 8

Slightly loosen screw 8

Slightly loosen screw A

Adjust crossing

the

tlllg

secondary so that its tip passes behmd the pri-

of

secondary and primary looper rota-

mary looper barely skimming it.

Check distances gtven

tn

le).

During

should barely

If

push

1ts

left

adjustment

the

complete looper assembly inwards or out-

to

riqht motion the secondary looper

sk1m

the needle.

IS

required, slightly loosen Screw 0 and

wards. avoiding any change

ed, Make

Luck screw

Recheck

smoothly and verify

sure

all

parts move smoothly

LJ.

to

make sure the two loopers are crossing

all

Tiqhten up screws A and

- Finally, make sure

all

smoothly

11/32"

figures 7-8-9

in

Fig. 9, rotate

will

be increased or decreased.

(see

in

the distance already

tno1i.1g

the other settings.

B.

the assembly are moving

lever

tab-

fix-

E upwards

or

downwards: remember

fig. 6

that

by doing

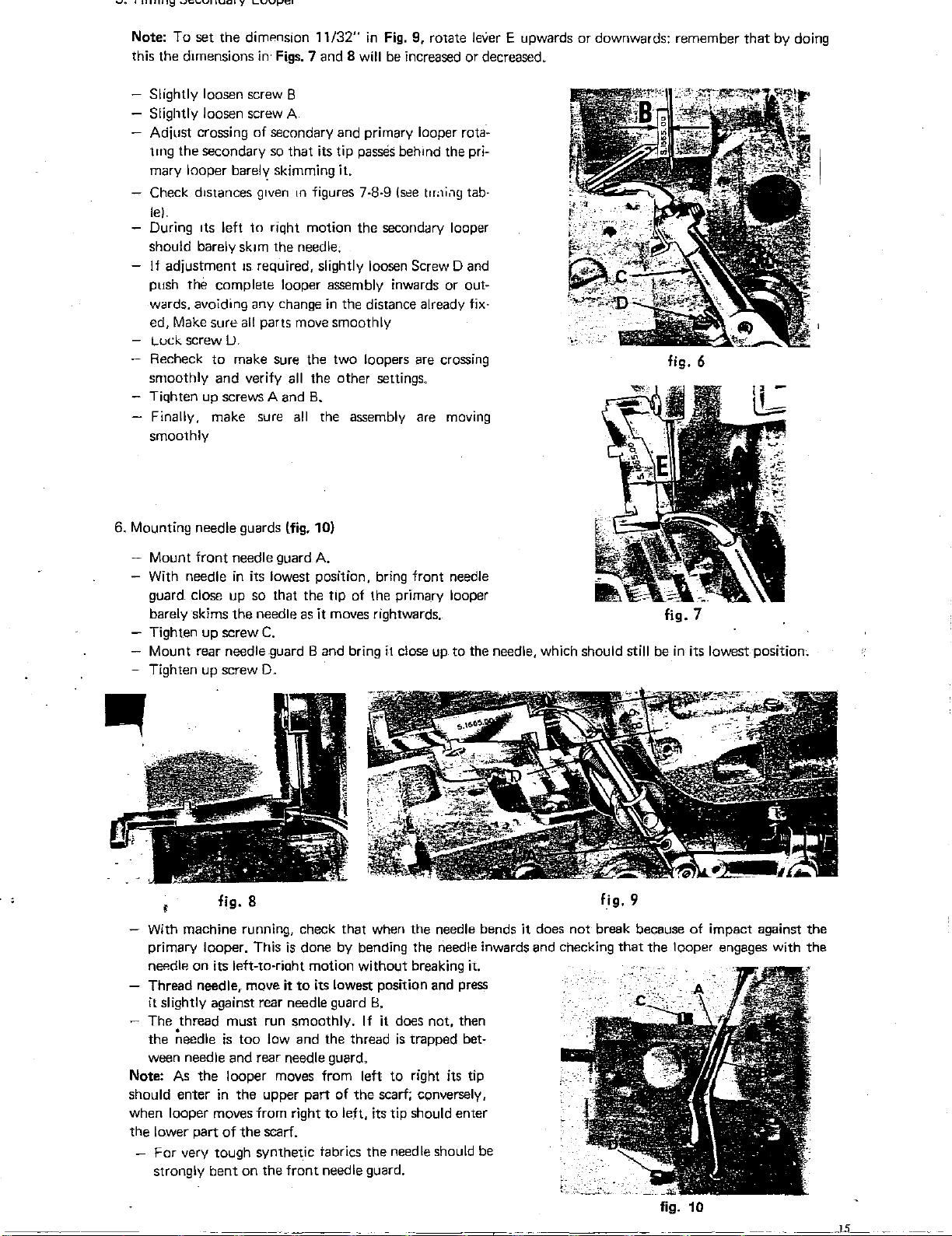

6. Mounting needle guards lfig.

- Mount front needle guard

With needle

in

its lowest position, bring front needle

10)

A.

guard close up so that the tip of the primary looper

barely skims the needle as it moves rightwards. fig. 7

- Tighten up screw

Mount rear needle guard 8 and bring

Tighten up screw 0

-

With machine running, check that when

primary looper. This

neP.dle

on its left-to-rioht motion without breaking it.

Thread needier move it

it slightly against rear needle guard

The thread must run smoothly.

~eedle

the

C.

..

fig. 8

is

done by bending the needle inwards and checking

to

its lowest position and press

is

too low and the thread

it

close up

the

needle bends it does not break because

B.

If

it does not, then

is

trapped bet-

to

the needle, which should still be

lig.9

that

ween needle and rear needle guard.

As

the

Note:

should enter

looper moves from left

in

the upper part of

when looper moves from right

part

of

the

the lower

scarf.

For very tough synthetic tabrics

strongly

bent

on the front needle guard.

to

left, its tip should enter

to

right its tip

the

scarf; conversely,

the

needle should be

in

its lowest positionc

of

impact against

the

looper engages with

the

the

fig. 10

___

,_1.5_

Page 14

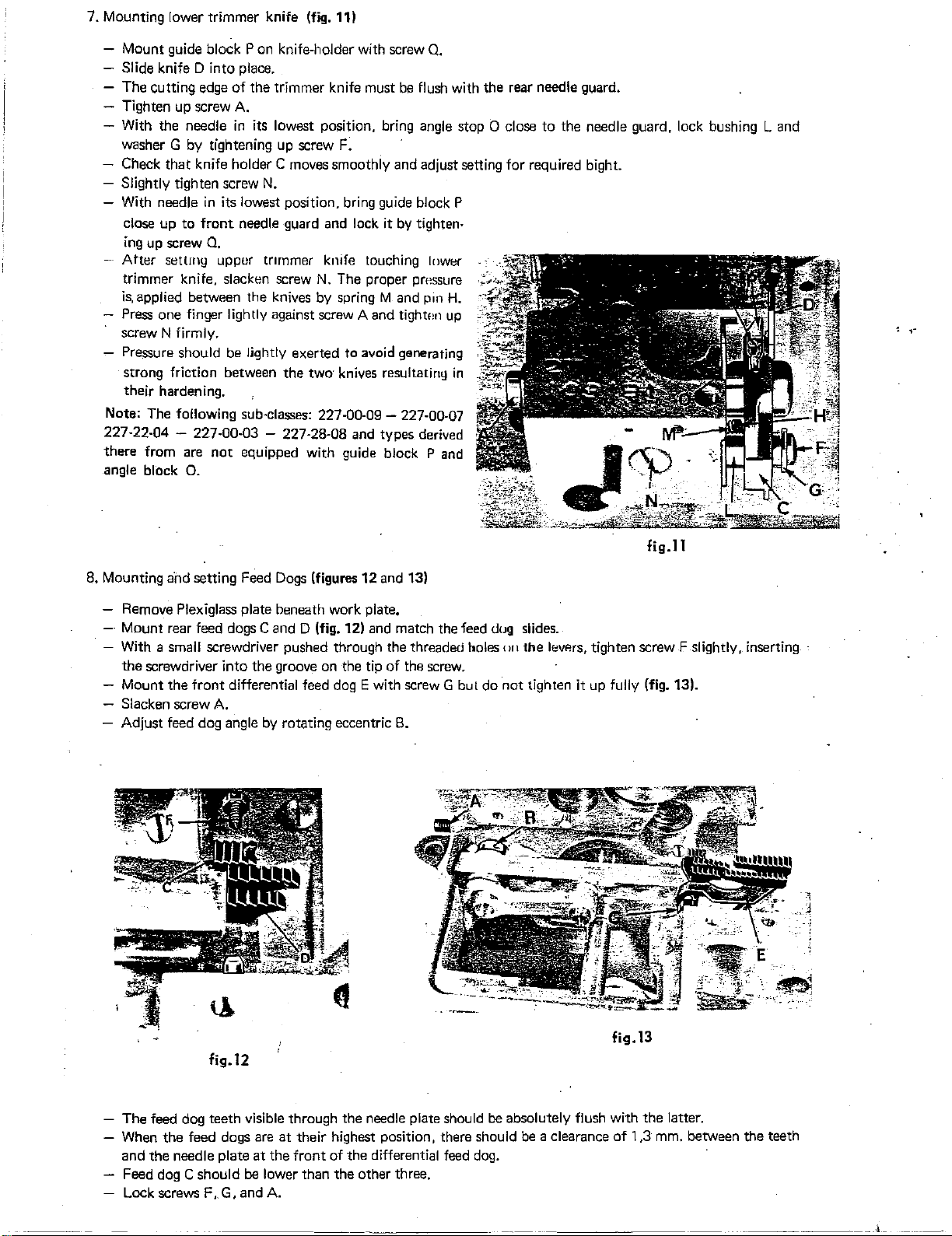

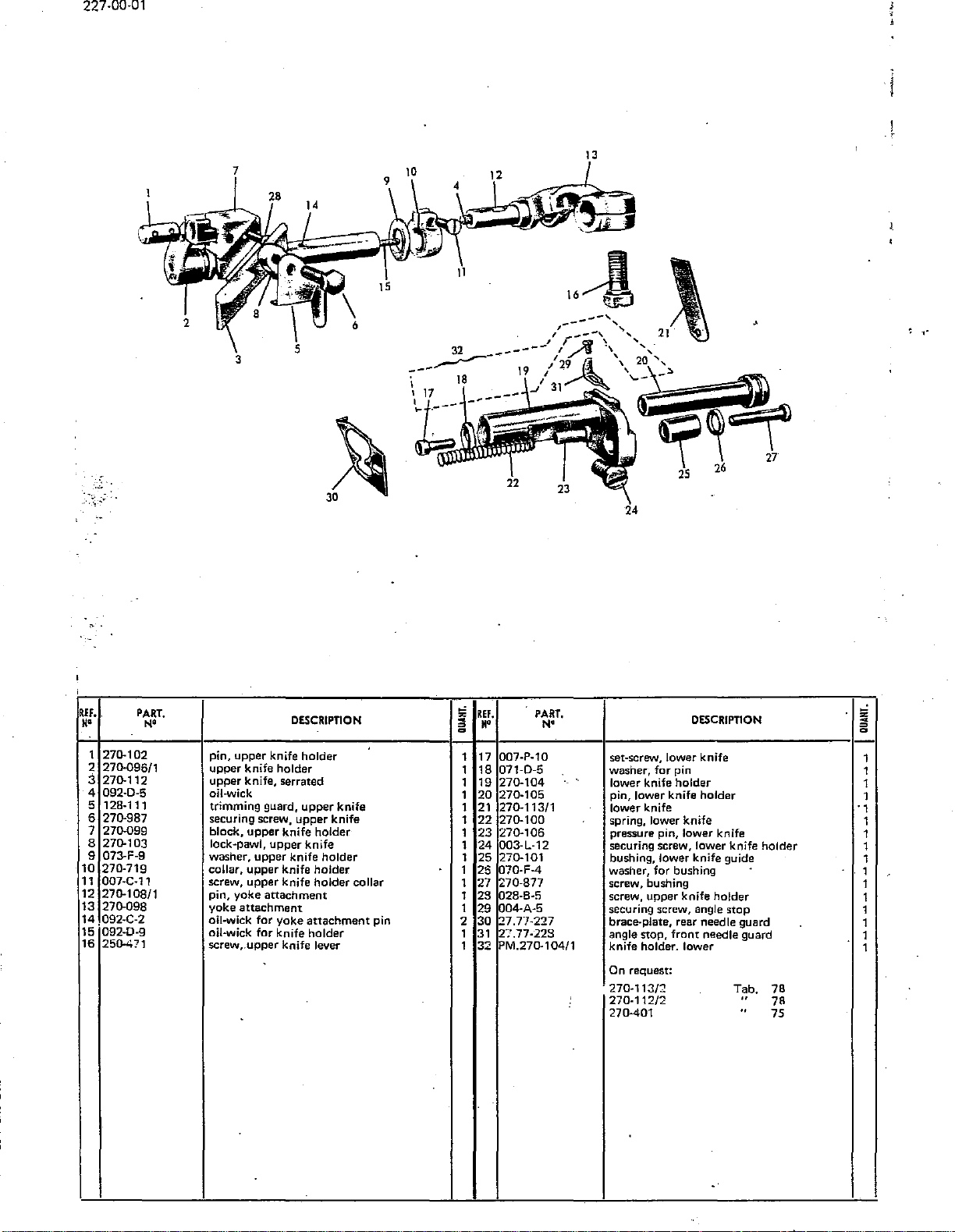

7. Mounting lower trimmer knife (fig. 11)

- Mount guide block P on knife-holder with screw

- Slide knife D into place.

- The cutting edge

- Tighten up screw

- With the needle

of

the trimmer knife must

be

A.

in

its lowest position. bring angle stop 0 close to the needle guard, lock bushing L and

washer G by tightening up screw F.

- Check

- Slightly tighten screw

-

that

knife holder C moves smoothly and adjust setting for required bight.

N.

With needle

close up to

ing

up screw

Atter

trimmer knife. slacken screw

is,

applied between the knives

Press

in

its lowest position. bring guide block P

front

needle guard and lock it

0.

settmy upper tnrnmer knife touching lower

N.

The proper pressure

by

spring M and

one

finger lightly against screw A and

by

tightt~n

screw N firmly.

Pressure

strong friction between the two· knives resultatiny

should

be

lightly exerted to avoid generating

their hardening.

Note: The following sub-classes:

227·22-04 - 227-00-03 - 227·28·08

not

there from are

angle block

0.

equipped with guide block P and

227·00·09-

and types derived

227·00·07

0.

flush with the rear needle guard.

tighten·

pin H.

up

in

8. Mounting and setting Feed

Dogs

(figures

12

and 13)

- Remove Plexiglass plate beneath work plate.

- Mount rear feed dogs C and D (fig. 12) and match the feed

- With a small screwdriver pushed through the threaded

the

screwdriver into the groove on the tip of the screw.

- Mount the front differential feed

- Slacken screw

- Adjust feed dog angle

A.

by

rotating eccentric

dogE

with screw G but do not tighten it up fully (fig. 13).

B.

dug

boles'"'

slides.

the

levP.rs,

lig.ll

tighten screw F slightly, inserting

fig.l2

- The feed dog teeth visible through the needle plate should be absolutely flush with the latter.

- When

the

feed dogs are

and the needle plate

at

their highest position, there should

at

the front of the differential feed

dog.

be

a clearance of 1,3

Feed dog C should be lower than the other three.

- Lock screws F, G, and A.

lig.l3

mm.

between the teeth

--L

--------·

Page 15

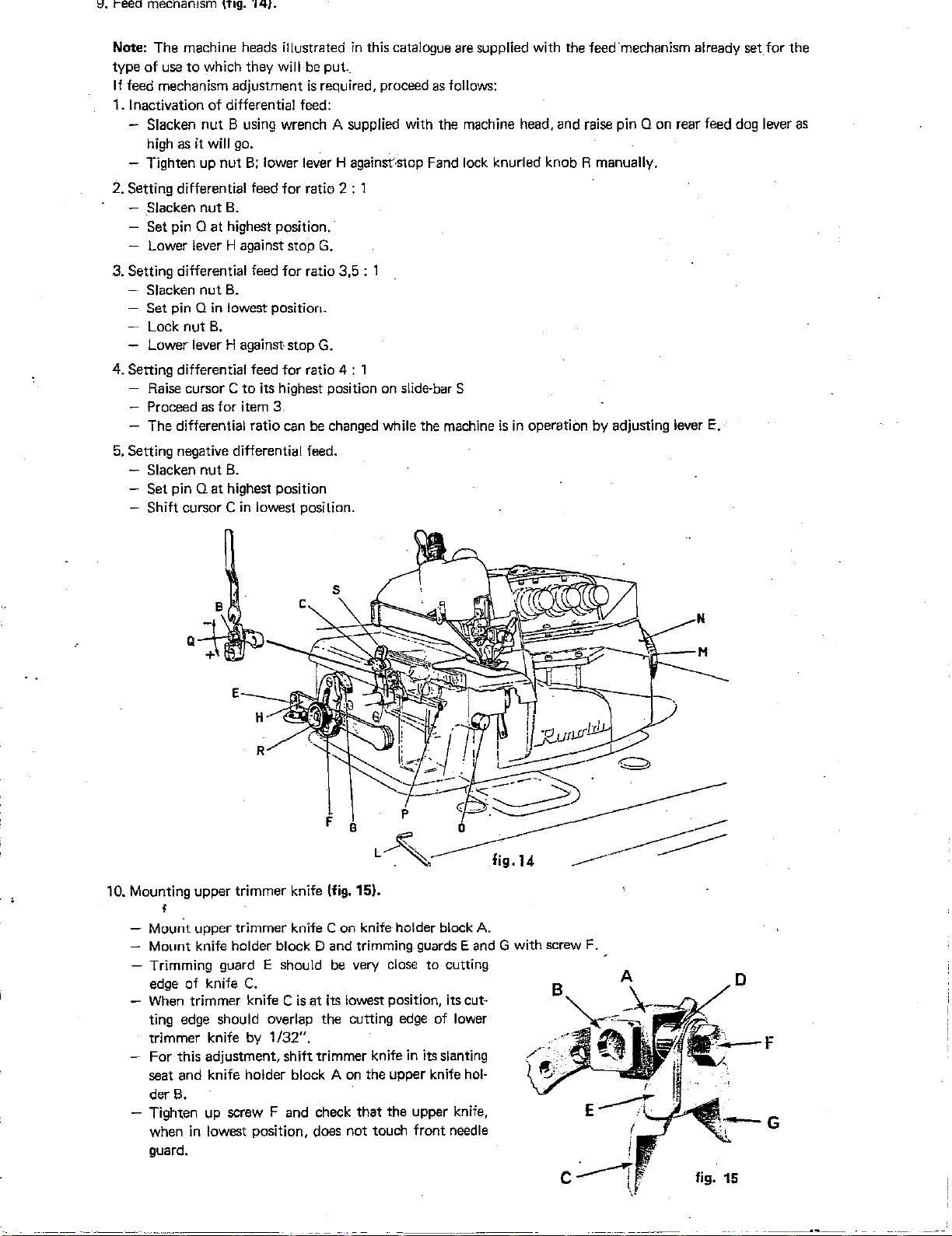

8.

1-eed

mechamsm \fig.

14).

Note: The machine heads illustrated

to

type of use

If

feed mechanism adjustment

Inactivation of differential feed:

1.

- Slacken

high as it

- Tighten up nut

which they will

nut

B using wrench A supplied with the machine head, and raise pin Q on rear feed dog lever as

will

go.

B;

lower lever H against-stop Fand

in

this catalogue are supplied with the feed·mechanism already

be

put

..

is

required, proceed

as

follows:

2. Setting differential feed for ratio 2 : 1

- Slacken nut

- Set pin Q

- Lower lever H against stop

B.

at

highest position.

G.

3. Setting differential feed for ratio 3,5 : 1

Slacken

-

-

Set

- Lock

- Lower lever H against stop

pin Q

nut

nut

B.

in

lowest position.

B.

G.

4. Setting differential feed for ratio 4 : 1

Raise

cursor

C to

its

highest-

- Proceed as for item 3

position

on

slide-barS

- The differential ratio can be changed while the machine

5. Setting negative differential feed.

Slacken nut

Set pin

Shift cursor C

B.

Qat

highest position

in

lowest position.

lock

knurled knob R manually.

is

in

operation by adjusting lever

E.

set

for the

Q

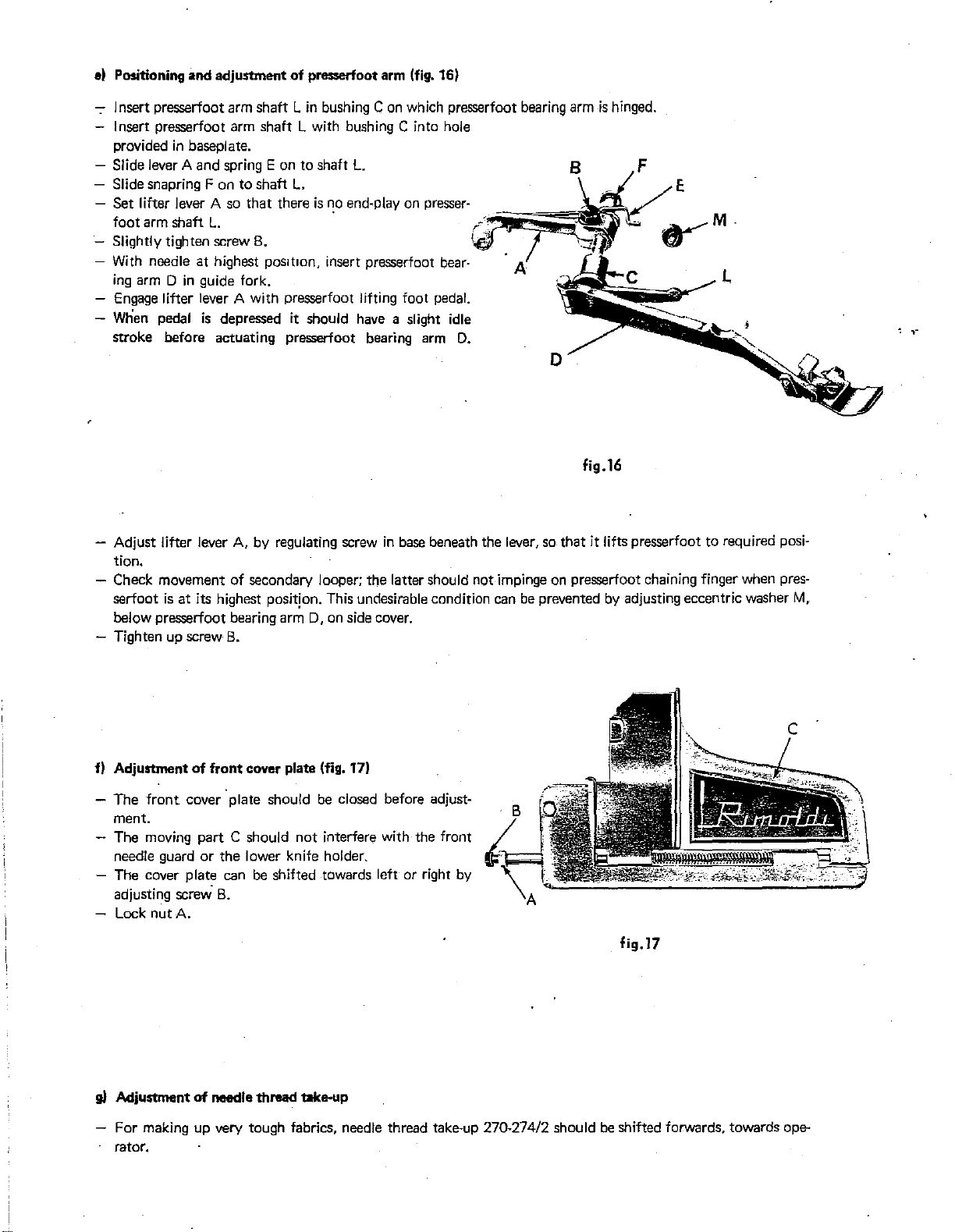

10. Mounting upper trimmer knife (fig. 15).

I

- Mount upper trimmer knife

-

Mount

- Trimming

edge of knife

When

knife holder block D and trimming

guard E should

C.

trimmer knife C

Con

knife holder block

be

very

close

is

at

its lowest position, its cut-

guards E and

to cutting

ting edge should overlap the cutting edge of lower

trimmer knife by 1

For this adjustment, shift trimmer knife

seat and knife holder block A

der

8.

/32".

in

on

the upper knife

its slanting

- Tighten up screw F and check that the upper knife,

in

when

lowest position, does not touch front needle

guard.

A.

G with screw

hol-

F.

A

D

G

Page 16

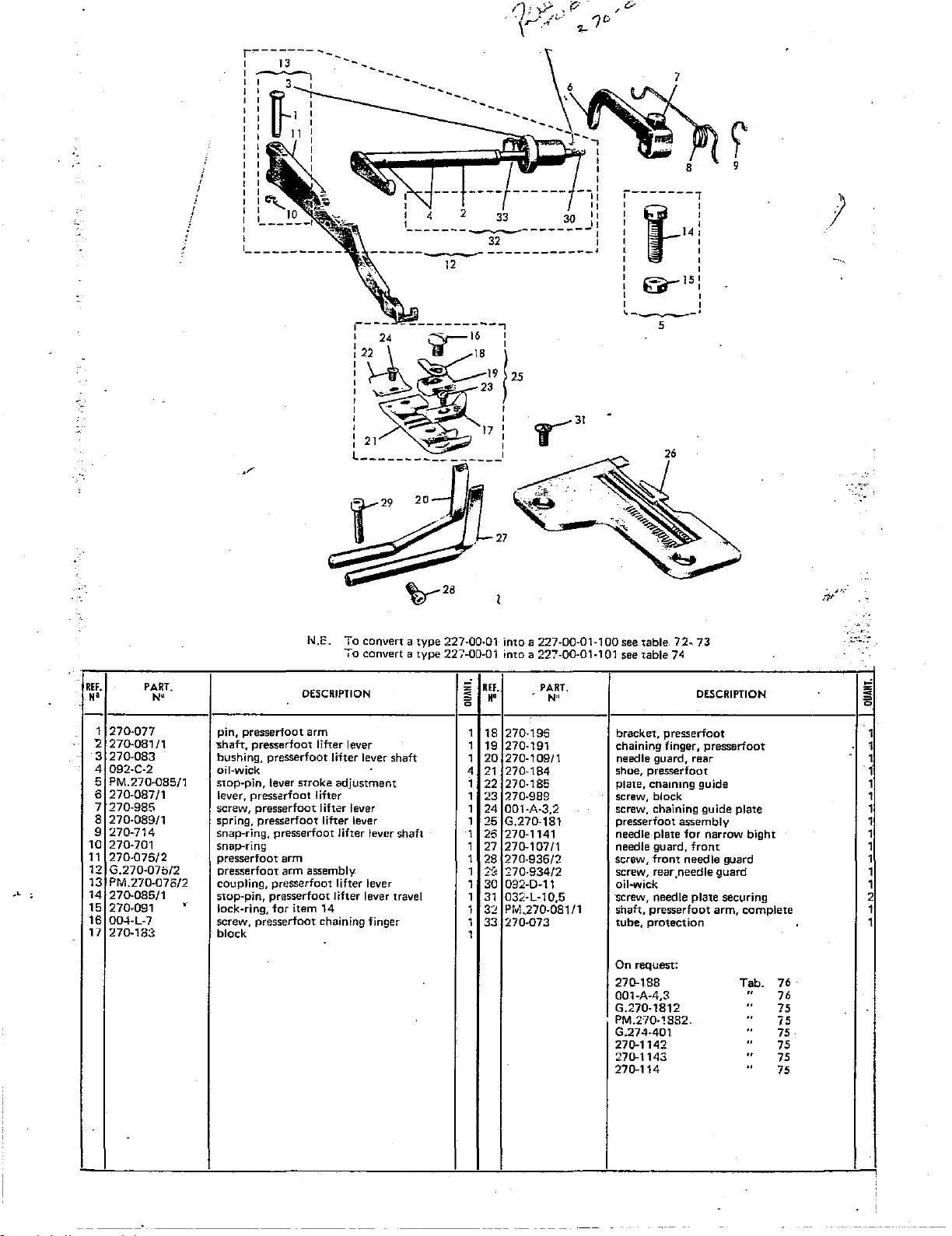

el Positioning and adjuotment

of

presserfoot

arm

(fig. 16)

- Insert presserfoot arm shaft

Lin

bushing

Con

which presserfoot bearing arm

Insert presserfoot arm shaft L with bushing C into hole

in

provided

- Slide lever A and spring E on to shaft

- Slide snapring F on to shaft

- Set lifter lever A so that there

foot arm shaft

- Slightly tighten screw

-

With

ing

arm 0

-

Engage

-

When

stroke before actuating presserfoot bearing

- Adjust lifter lever

tion.

baseplate.

L.

L.

is

no

end-play on presser-

L.

B.

needle at highest

in

guide fork.

pos1t1on,

insert presserfoot bear·

lifter lever A with presserfoot lifting foot pedal.

pedal

is

depressed it should

have

a slight idle

arm

A,

by regulating screw

in

base beneath the lever, so that it lifts presserfoot to required posi-

- Check movement of secondary looper; the latter should

serfoot

below presserfoot bearing arm

- Tighten up screw

is

at

its highest positjon. This undesirable condition can

0,

on side cover.

B.

is

hinged.

B F

E

-~~r;;;;;;?

:_

D,

fig.16

not

impinge on presserfoot chaining finger when pres-

be

prevented

by

adjusting eccentric washer

M,

f)

Adjustment

- The

ment.

- The moving part C should

of

front cover plate (fig. 17)

front

cover plate should

be

closed before adjust-

not

interfere with the front

needle guard or the lower knife holder.

- The cover plate can

adjusting screw.

B.

be

shifted towards left or right

by

- Lock nut A.

g)

Adjustment

of

needle thread take-up

For making up very tough fabrics, needle thread take-up 270-274/2 should

rator.

fig.l7

be

shifted forwards, towards ope-

Page 17

h)

Disassembly

ELECTRIC

and

replacement of

LUBRICATION

pressure

switch

CONTROL

DEVICE

(PRESSURE

SWITCH)

- Take down oil cup from baseplate and drain

Remove screw

by

which pressure switch bracket

- Slacken the two screws on the electric wire terminal

-

Slip

plastic tube connecting pressure switch

- Remove bracket and fix it

to

new pressure switch.

out

oil.

is

mounted on

oil

cup.

lugs.

to

rubber connection off the pressure switch.

Screw down electric wire lugs, slip plastic tube into pressure switch and mount switch on

screws

previously

Re-install

Replacement

Proceed

oil

of

as

Remove rubber tube, remove lamp (bayonet

Re-install rubber tube, replace pressure switch

Re-install

Electrical

oil

connection

removed.

cup and

pressure

fill

with

switch

oil

as

instructed on

lamp

page

11, par

c.

described under items l and 2 for replacement of pressure switch.

cap)

and replace with new lamo.

in

position and fasten firmly to

cup and

fill

of

pressure

with oil

switch

as

instructed on

on

Zefir

page

motors

11, par. c

..

oil

wrth screw

oil

cup using

the

-

Plug

cable

to

current socket and insert

Note:

If

with

no light socket

12

V.

connections, proceed

is

provided on the motor to be connected, but the voltage connection box

Mount a Mignon socket pitch 13

light terminal

Plug

cable

-

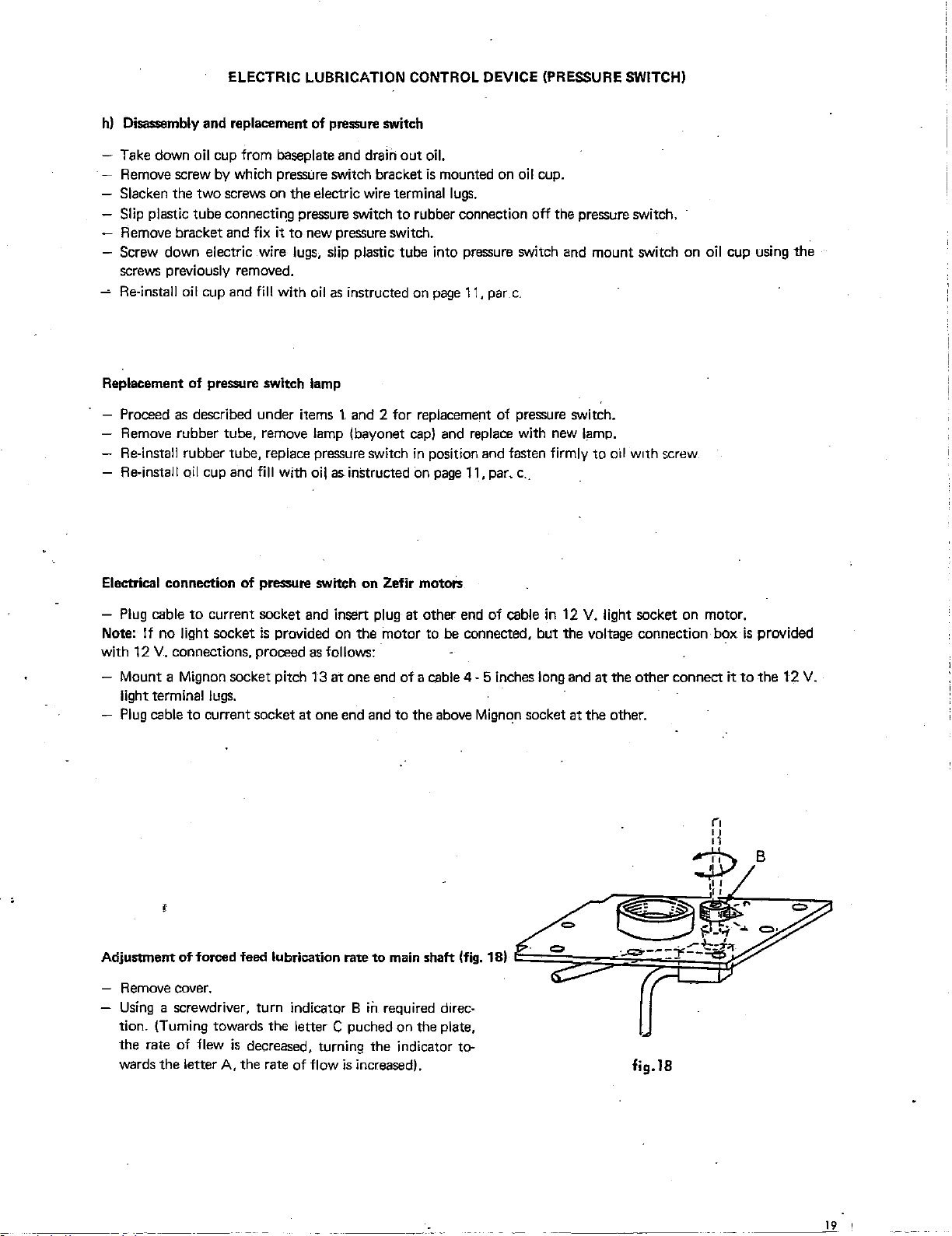

Remove

Using

a screwdriver, turn indicator B

lugs.

to

current socket

cover.

as

follows:

at

one end and

at

one end

plug

at other end of cable

of

a cable 4-5 inches long and

to

the above

ih

required direc-

tion. (Turning towards the letter C puched on the plate,

the

rate

of

flew

is

decreased,

wards the letter A, the rate

of

turning

flow

the indicator to-

is

increased).

Mign"!n

in

socket

12

V.

light socket on motor.

at

the other connect it

at

the other.

fig.lB

is

provided

to

the

B

12

V.

----~1~9

'

Page 18

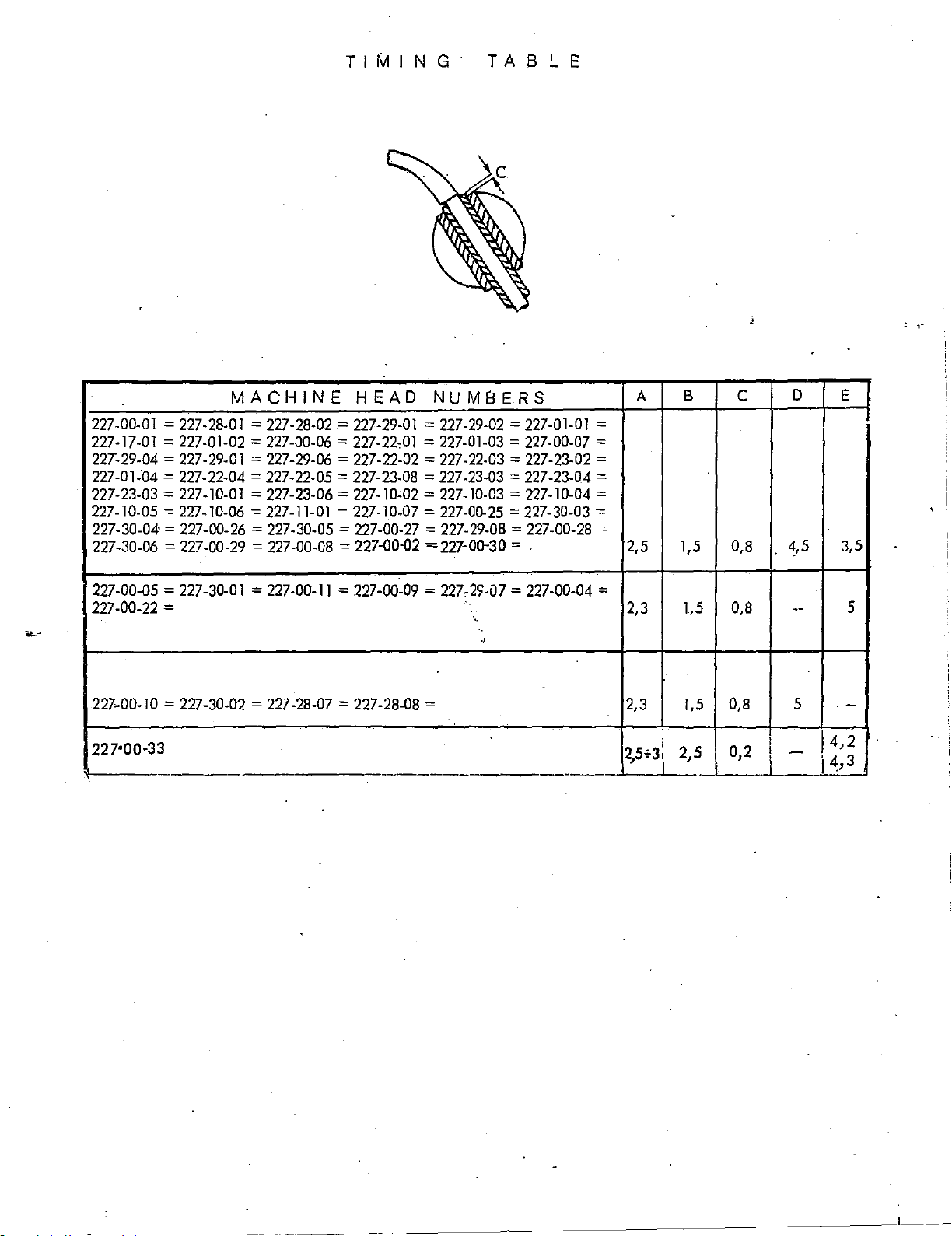

TIM

I N G T A 8 L E

MACHINE

227-00-01 = 227-28-01 = 227-28-02 = 227-29-01 = 227-29-02 = 227-01-01

227-17-01 = 227-01-02 = 227-00-06 = 227-22,01 = 227-01-03 = 227-00-07

227-29-04 =

227-01-04

227-23-03 = 227-10-01

227-10-05 = 227-10-06 = 227-11-01 = 227-10-07 = 227-00-25 = 227-30-03

227-30-04· = 227-00-26

227-30-06 = 227-00-29 = 227-00-08

227-00-05 = 227-30-01 = 227:00-11 = 227-00-09

227-00-22

227-00-10 = 227-30-02 = 227-28-07 = 227-28-08

227'00·33

227-29-01 = 227-29-06 = 227-22-02 = 227-22-03 = 227-23-02

= 227-22-04 = 227-22-05 =

= 227-23-06 = 227-10,02 =

= 227-30-05 =

= 2,3 1,5

HEAD

227-23-08 = 227-23-03

227-00-27 = 227-29-08 = 227-00-28

=

227-00-Q2

NUMBERS

= 227-23-04 =

227-10-03 = 227-10-04

=227-00-30 = . 2,5 1,5 0,8

= 227,29-07 = 227-00-04 =

'·

'·

..

= 2,3 1,5

.

-

-·

A B c

=

=

=

=

=

=

2,5f3

2,5

0,8

0,8

0,2

D

4,5

--

5

-

\

E

3,5

J4,2

\

4,3

I .

5

-

~~-

-~~~~--~~~~~~~~~~~~~~~·~-··-

. '

Page 19

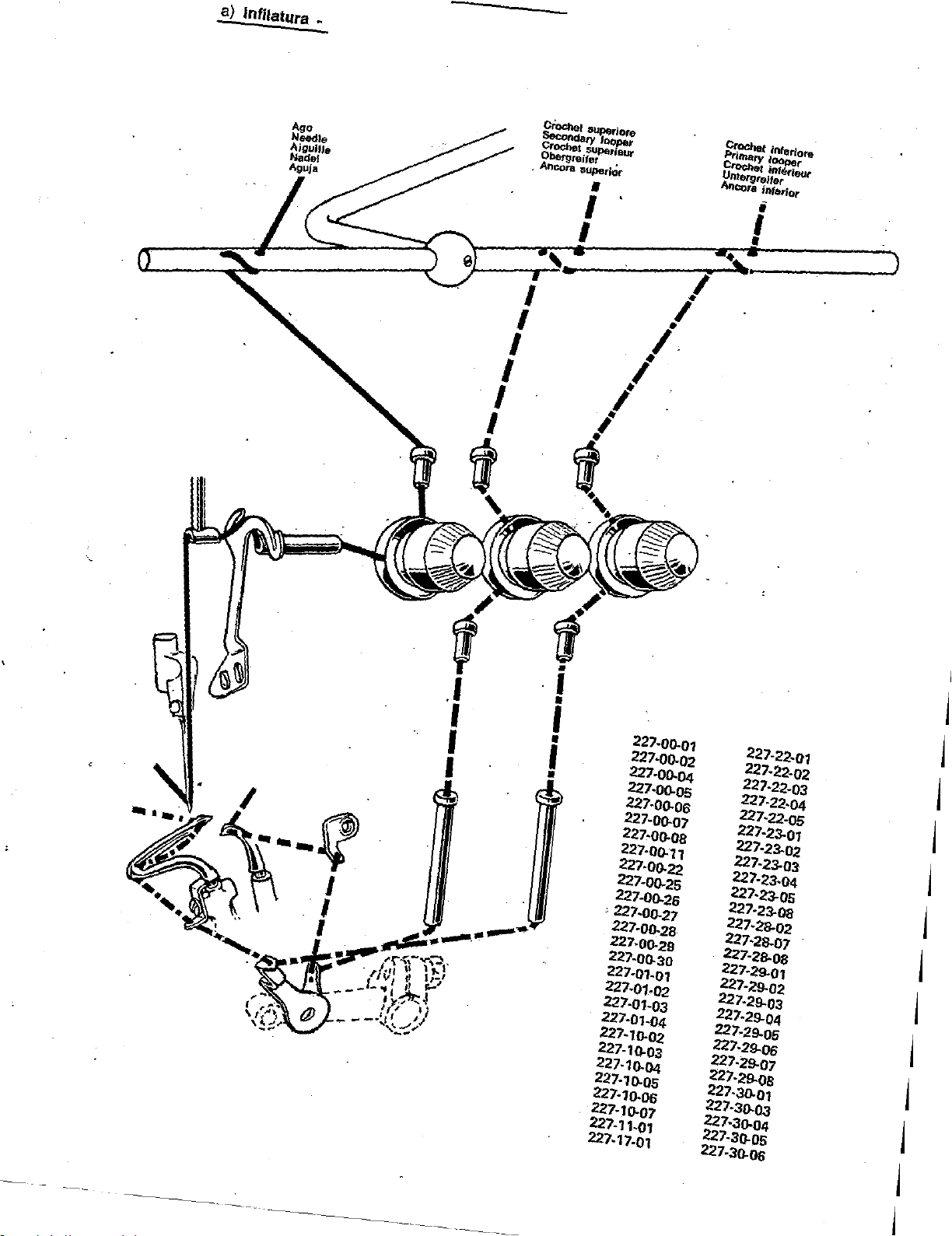

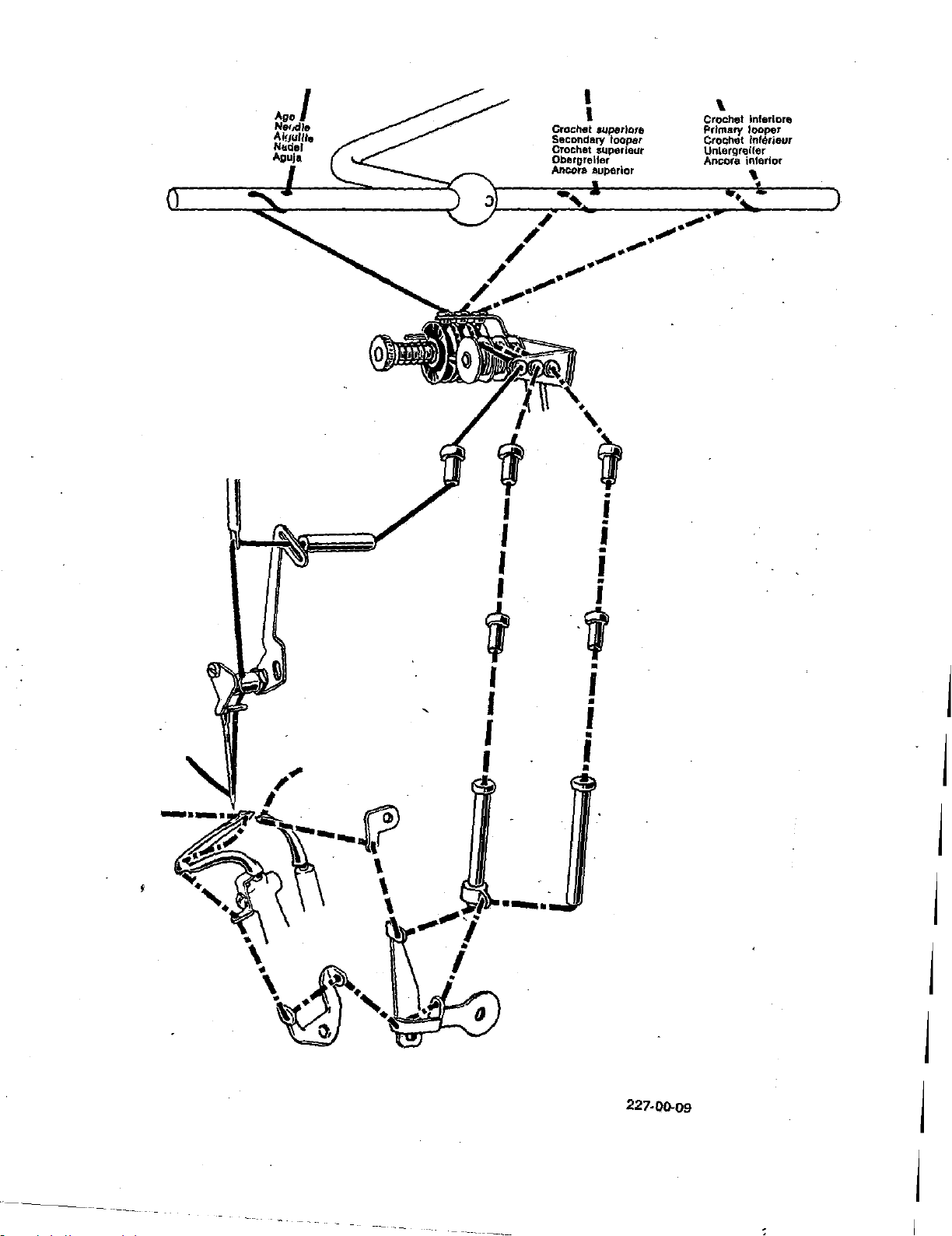

a)

lnfilat11ra

:.

crOCher

~ry

Crochet

Obef'!llreifer

Ancora

IJUJlerior

I

superio,e

,,.,.,

SUJ>eneur

•

•

C~t

inletiore

Primary

lOOPer

~t

Untergreifer

Aneora

inf~Kteur

interior

.I

I

I

I

I

---~

I

I

I

•

I

•

I

•

I

•

227-00-01

221-oo.o2

227-00-04

227-oo.os

227-oo.os

227·00-07

227·00-08

227·00-11

227-00-22

227-00-25

227-D0-26

'227-00-27

227-00-28

227-00-29

227-oo.ao

227-01-01

227-01·02

227-01-03

227-01-04

227-10.02

227-10-03

227-10-04

227·10-0S

227-10-0G

227-10.07

227-11-01

227-17-01

227-22-07

227-22-02

227·22-03

227-22-04

227-22-05

227-23-01

227-23-02

227-23-03

227-23-04

227·23-0S

227-23-0a

227·28-02

227·28-07

227-2a.oa

227-29-01

227-29-02

227-29-03

227-29-04

227-29-os

227-29-0G

227-29-07

227-29-0S

227-30-01

227-30.03

227·30.04

227-30-0S

227-30-06

j

j

j

j

j

j

j

j

j

j

j

j

-

--

----

j

j

Page 20

f'.•nrh111l

PtlmJ!t)'

C•<l(:lnol

\I.,IPI(jf<'IIN

4•u·o'"'

\

\

\

\

\

It

J

J

'

. '

I

•

I

'"'~•or•

lnnper

'"""'II"U

'"""''O'

\

•

;

j

j

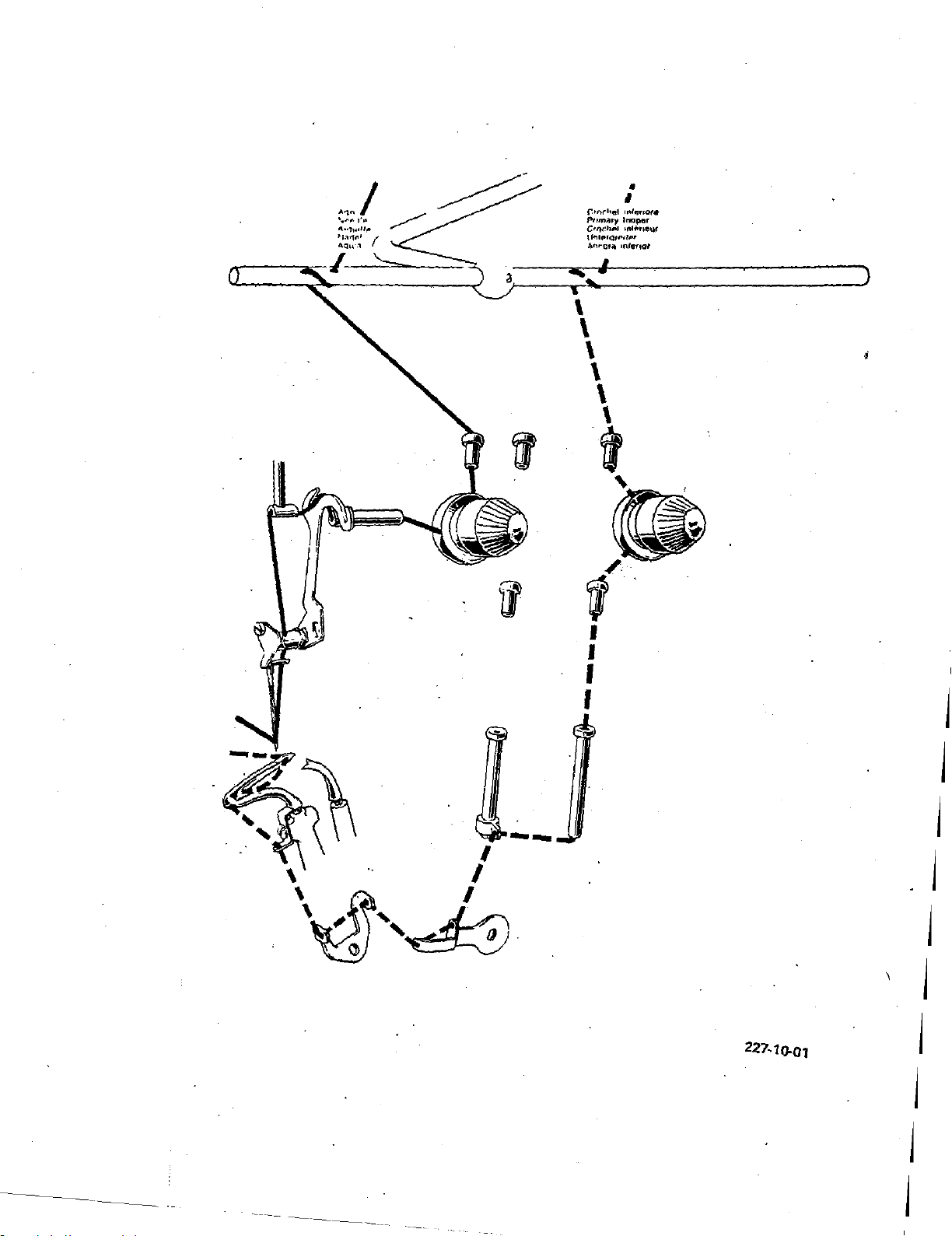

227-10.01

j

j

. j

j

\ j

j

j

j

j

Page 21

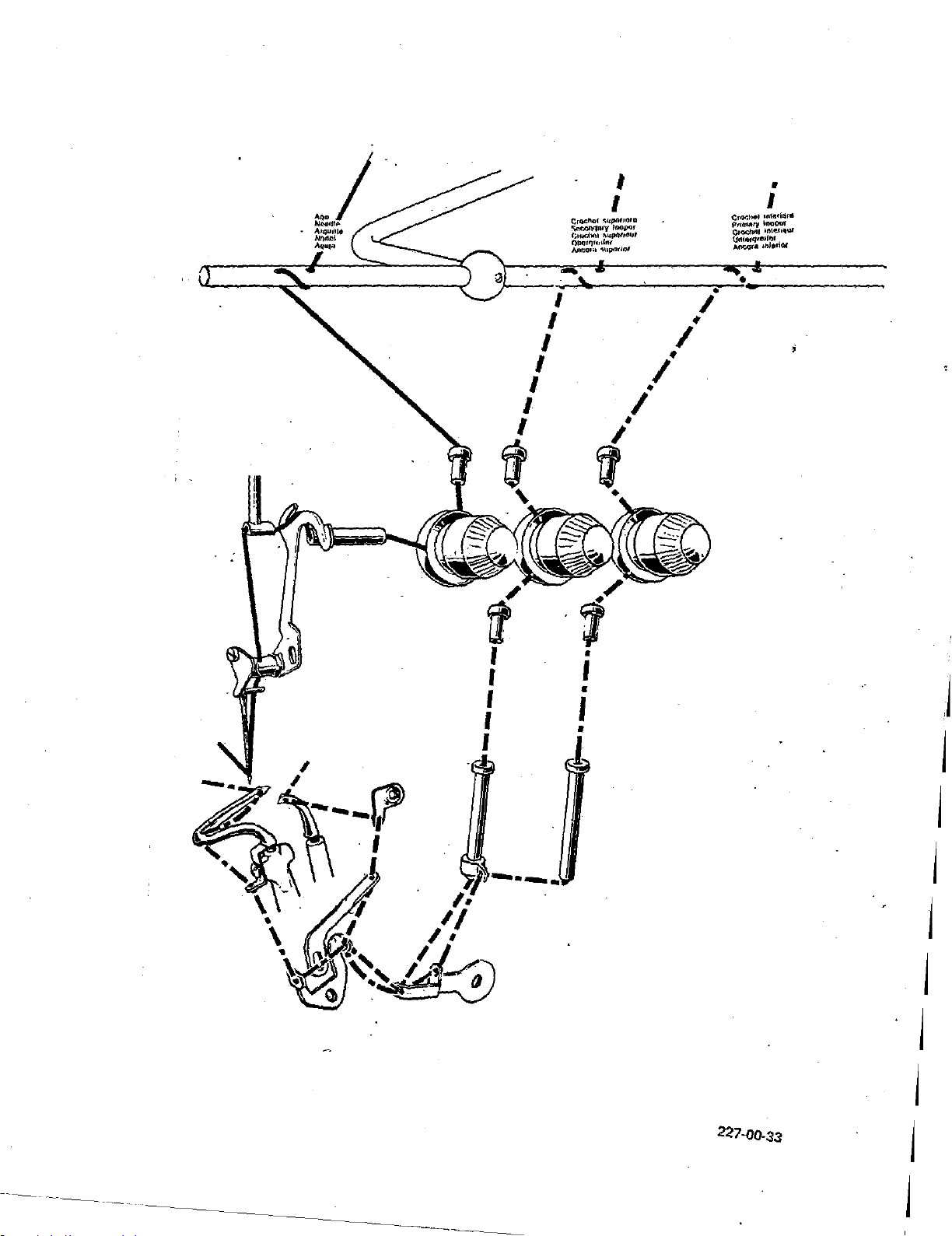

I

'

I

I

I

Crochet superior&

Secondary looper

Crochet superieur

Obergreller

Ancora auperlor

\

Crochet lnterlore

Primary looper

Crot;het inf6rieur

UnlergreUer

Ancora inferior

I

I

'

I

'

I

·-·

I

•

I

•

I

•

•

j

j

j

j

j

227-00-09

j

j

j

Page 22

I

I

I

I

I

I

I

~

'

(

I

I

#

I

•

•

I

(:r<Yo!Mtl

u•te•i'llr•

fl'n!l'tltl~

lnal)af

Cl'~

ln\~1...-

tJntowve>IOJr

AIIIOO;If.

11>1111«

! ,

I

•

I

I

I

'

I

•

l

I

•

•

j I

j

j

j

j

j

j

j

------

227-00-33

j

j

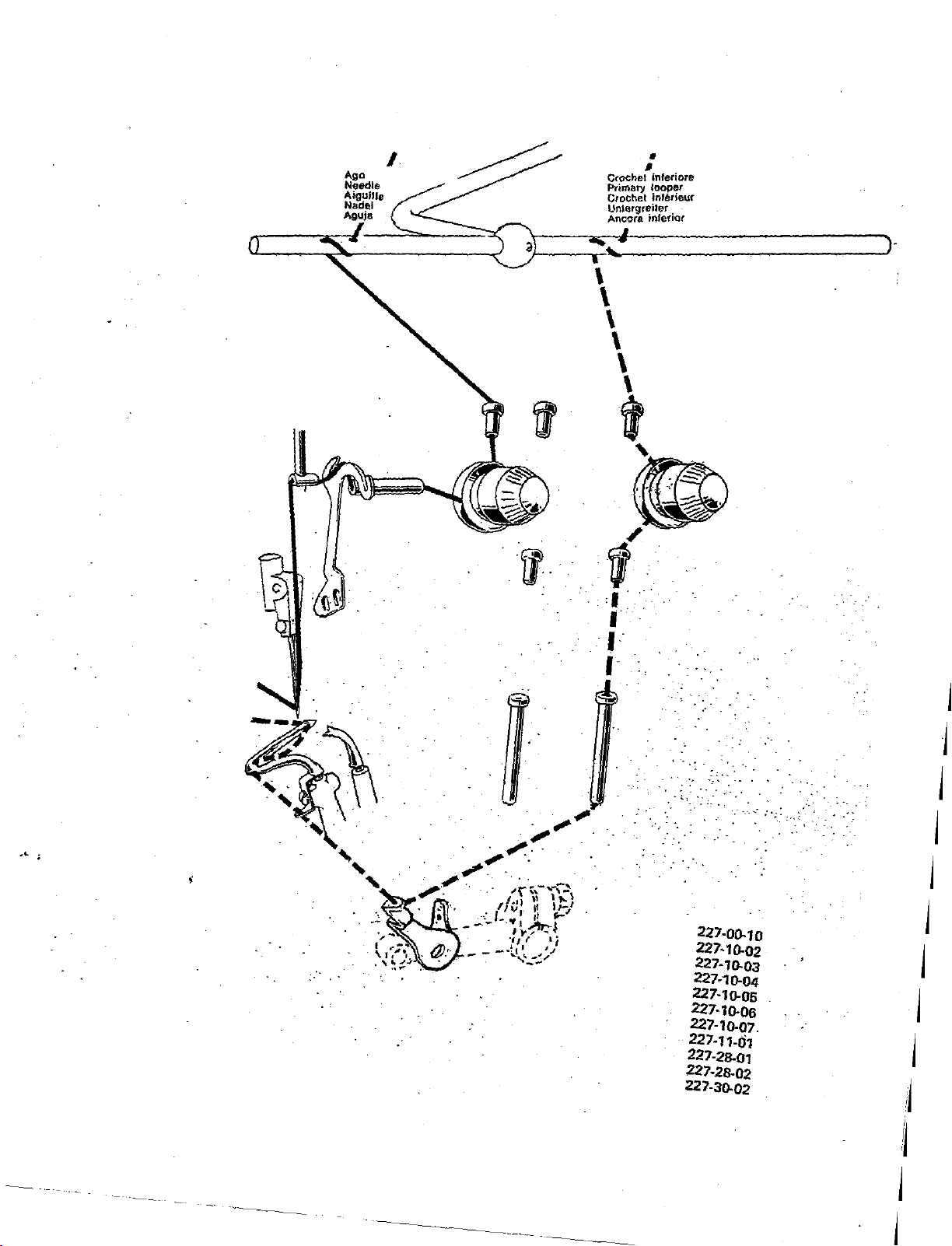

Page 23

I

~~

..

~

AigUille .

Nadel

Aguja

--he!

C

r:-z...

Pnmary • IE!tieur

Crochet

Unlergreiler .

Ancora infenor

\

\

\

\

\

\

t

/

·.

I

•

• •

infer1ore

looper

m

'··

--~

'

....

-,

---

...

.~

~

'

' I

I

. ~.

227-00.TO

227·10.02

227-10.03

227-10.04

227·10.05

227-10.06

227-10-07.

227-11-01

227-28-01

227-28-02

227-30.02

j

j

j

·---

~

:.

:.

j

j

j

j

j

j

:j

---

------

- - ---

--~

1

j

j

Page 24

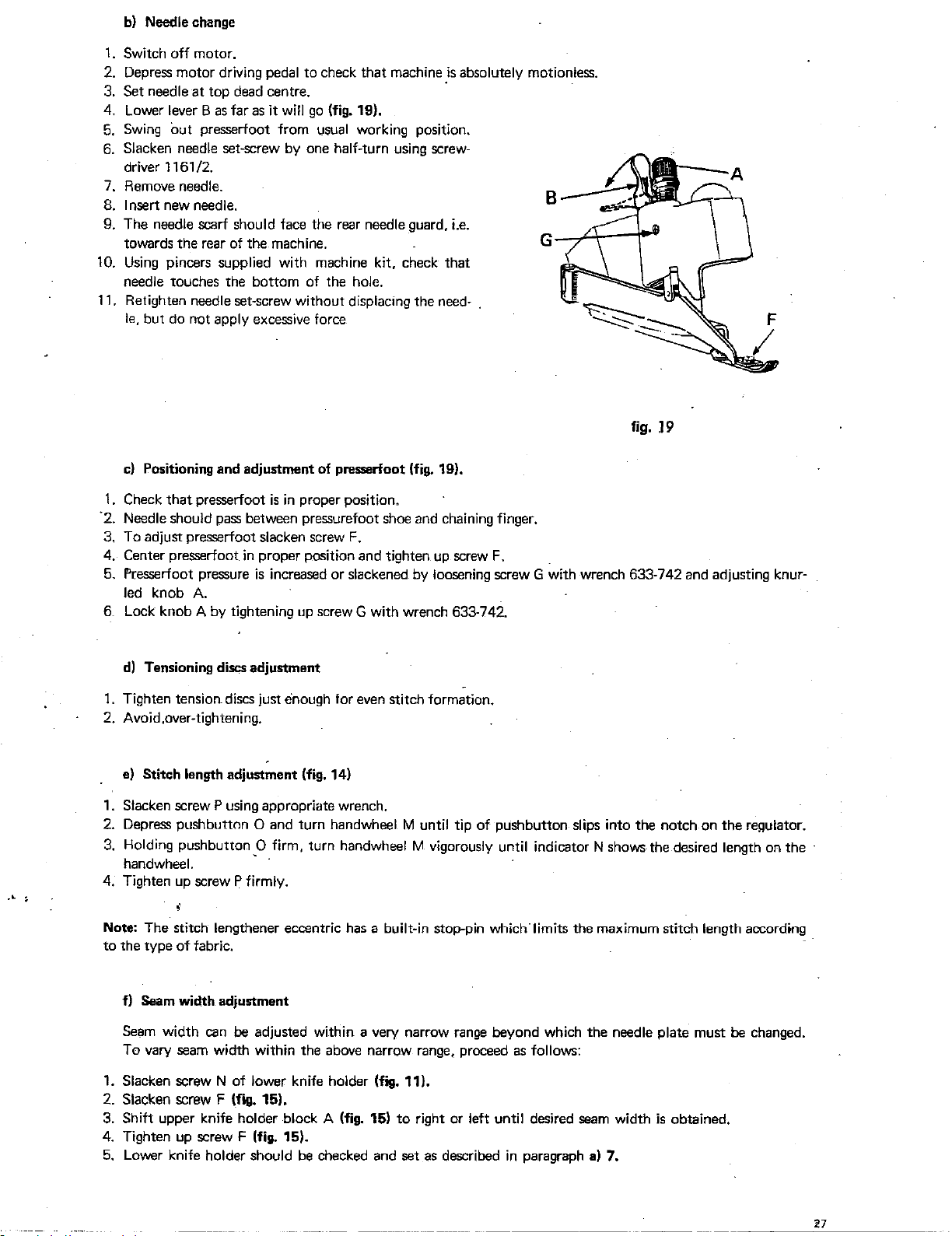

b)

Needle change

1.

Switch off motor.

2. Depress motor driving

3.

Set neadle

4. Lower

5.

Swing

6. Slacken neadle set-screw

driver 1161 /2.

7. Remove needle.

8. Insert new neadle.

9. The neadle scarf should face the rear neadle guard, i.e.

towards

10.

Using

needle touches the bottom of the hole.

11. Retighten needle

but do not apply excessive force

le,

c)

Positioning and adjustment of presserfoot (fig. 19).

at

top dead centre.

lever B

pincers supplied with machine kit, check that

as

out

presserfoot from usual working

the

rear of the machine.

pedal to check that machine

far

as

it

will

go

(fig. 19),

by

one half-turn using screw·

set~screw

without

displacing the need·

_is

pOSitiOn.

absolutely motionless.

fig.

F

19

...

.

1.

Check

that

presserfoot

·2. Neadle should pass between pressurefoot shoa and chaining finger.

3. To adjust presserfoot

4. Center presserfoot

5. Fresserfoot pressure

led

knob A.

6 Lock knob A

d)

Tensioning discs adjustment

1.

Tighten tension discs just enough for even stitch formation.

2. Avoid,over-tightening,

e) Stitch length adjustment (fig. 14)

1.

Slacken screw P using appropriate wrench.

2. Depress pushbutton 0 and turn handwheal M until tip

3.

Holding pushbutton

handwheal.

4. Tighten

Note: The stitch lengthener eccentric

to

the type

by

up

screw P firmly .

of

fabric.

is

in

proper position.

slacken screw

in

proper position and tighten

is

increased or slackened

tightening

up

_0

firm, turn handwheal M vigorously until indicator N shows the desired length on the

F.

up

screw

F.

by

loosening screw G with wrench 633-742 and adjusting knur-

screw G with wrench 633-742.

of

pushbutton slips into the notch on

has

a built-in stop-pin which"limits the maximum stitch length according.

the

regulator.

f) Seam width adjustment

Seam width can

To vary seam width within the above narrow range, procead

1.

Slacken screw N of lower knife holder (fig. 11).

2. Slacken screw F (fig. 15).

3. Shift upper knife holder block A (fig. 15)

4.

Tighten

5.

Lower knife holder should

up

be

adjusted within a very narrow range beyond which the neadle plate must be changed.

screw F (fig. 15).

be

to

checked and set

as

follows:

right or left until desired seam width

as

described

in

paragraph a) 7.

is

obtained.

Page 25

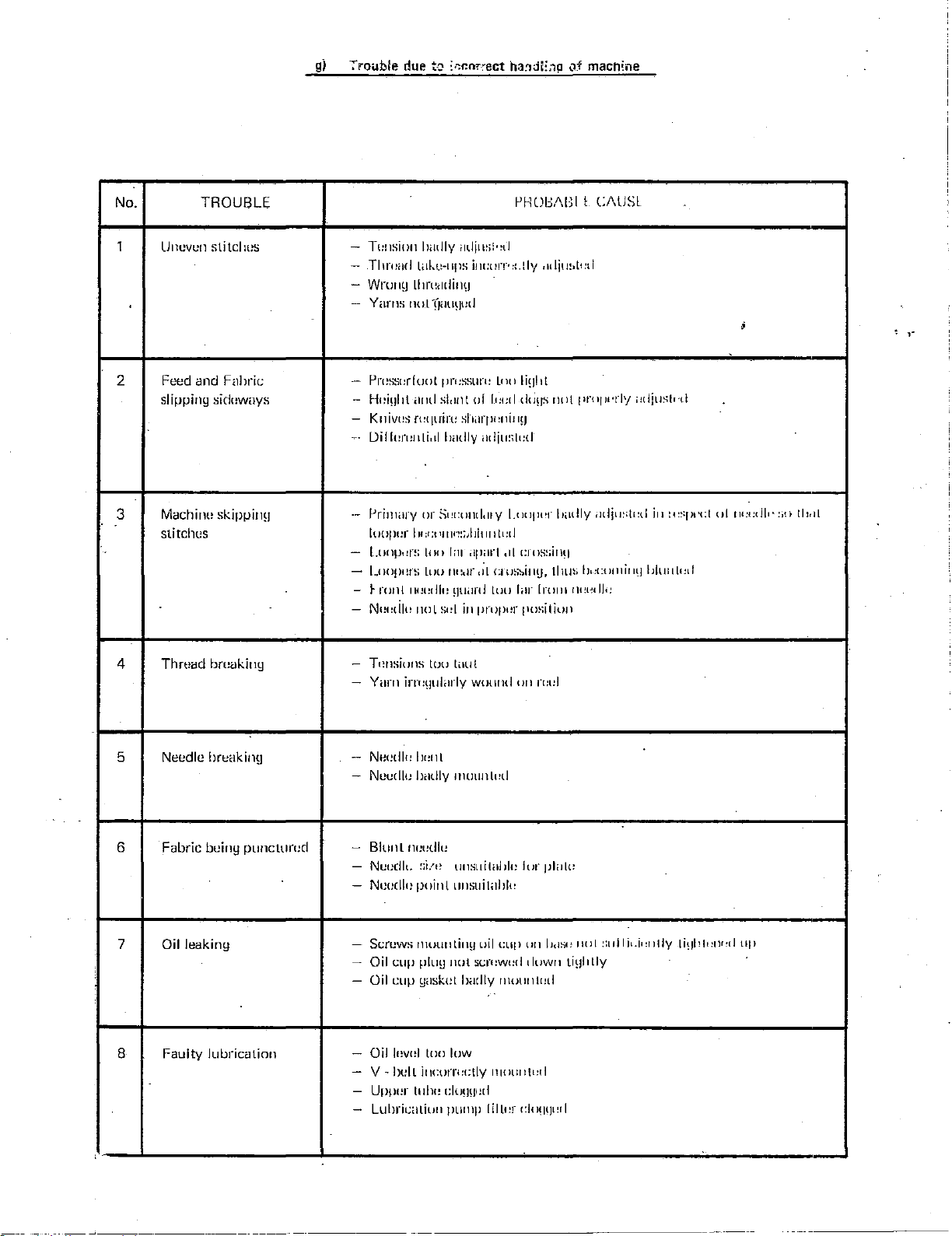

g)

irou:ble

due

t·:J

~r.r.n;-:-ect

ha!ldE;'l!J

of

mach~ne

No.

TROUBLE

1 Uneven

2 Feed and

slipping

3

Machine

stitches

Thmad bwekiny

4

sli

tcllus

Ftlhril:

sidt:ways

skippinu

-

Tw1sion lJiidly

-

Tl Jn:iJcl

-

Wruny

-

Yarns

no

Pn!S.':it:rfuol pn:ssun: l(Jo

-

-

H1:inllt

-

Knivus

..

L)iflufi!Jlli,d

PrilllilfY

·-

IH:t;t

llJOjlt:r

-

l.tHl!J•:n; too l;u .tpart til

I . .IHljlt!I'S LtJO IU:.Jr,it

-

-

~ron!

IJtJI:dlt:

-

Nt:t:dll: tJo\

Tnnsions too

-

-

Yarn

irn:~Julilrfy

rJdjJJ~>i·~tl

lHkt.H

lp!i

llln~e~dill~J

l

TJilli~Jud

<I!Jti

slc~nt

n:quiru

:-illdrpl:lliJIH

hmlly

or

St:t:und,uy

'IIJn:;AJhi!Jit:tl

~JlltJnl

Sid

in

lo•u

int:uiT'

of lt:l:cl

adju:;lt:d

ctw;:-.iJJV,

tuo

prupt:r

l

wound

f'HUll/\lll

::.tly

li~Jht

d<ius

l.tnljH'f

cro:-i~iillq

filr

position

on

n:t!l

t C!\USL

.uljw,lt

:d

not

prnru·rly

[Jadly ildjtJ::tr·d

!Inn;

IJ,:t:tltlliii~J

!nun

ru:t~tiJ;:

.

<Jdjusb·d

i11

!•,.:pt•t:\

!Jillltlt:tl

;

.

oltu·l:tilt·:;n

, .

!ltd!

5 Needle

6

Fabric

Oilleakiny

7

8

Faulty

breaking

being

punctun:d

lubrication

--

NP.1!dl1:

Neudlu

-

-

Blunt

-

Neudlc

-

Nu!:cll1:

- Scn:ws

-

Oil cup pluu

-

Oil

cup

-

Oil

h!vtd too

V

~bell

-

-

Upp1!r

Lubrit.:aliun

-

lu:nl

badly

lllUUlllt!tl

m:t:dlt:

!ii/~!

un~ltilii!Jh:

pointunsuililhlt:

lllutu

1Li11H

nol

scn:wt:d

ym;kutl>aclly 11\ounl!:d

low

im:orn:ctly

Ulill!

clomJI!d

pulllp

lor

uil

cup

tllllllll!t:!l

lillt:r

dn!J!Jt~r[

pltllt!

on

lJdS!!

tluwn

1

HJ

l !ad I

ti~JII

tly

i1.i•

:nlly

li

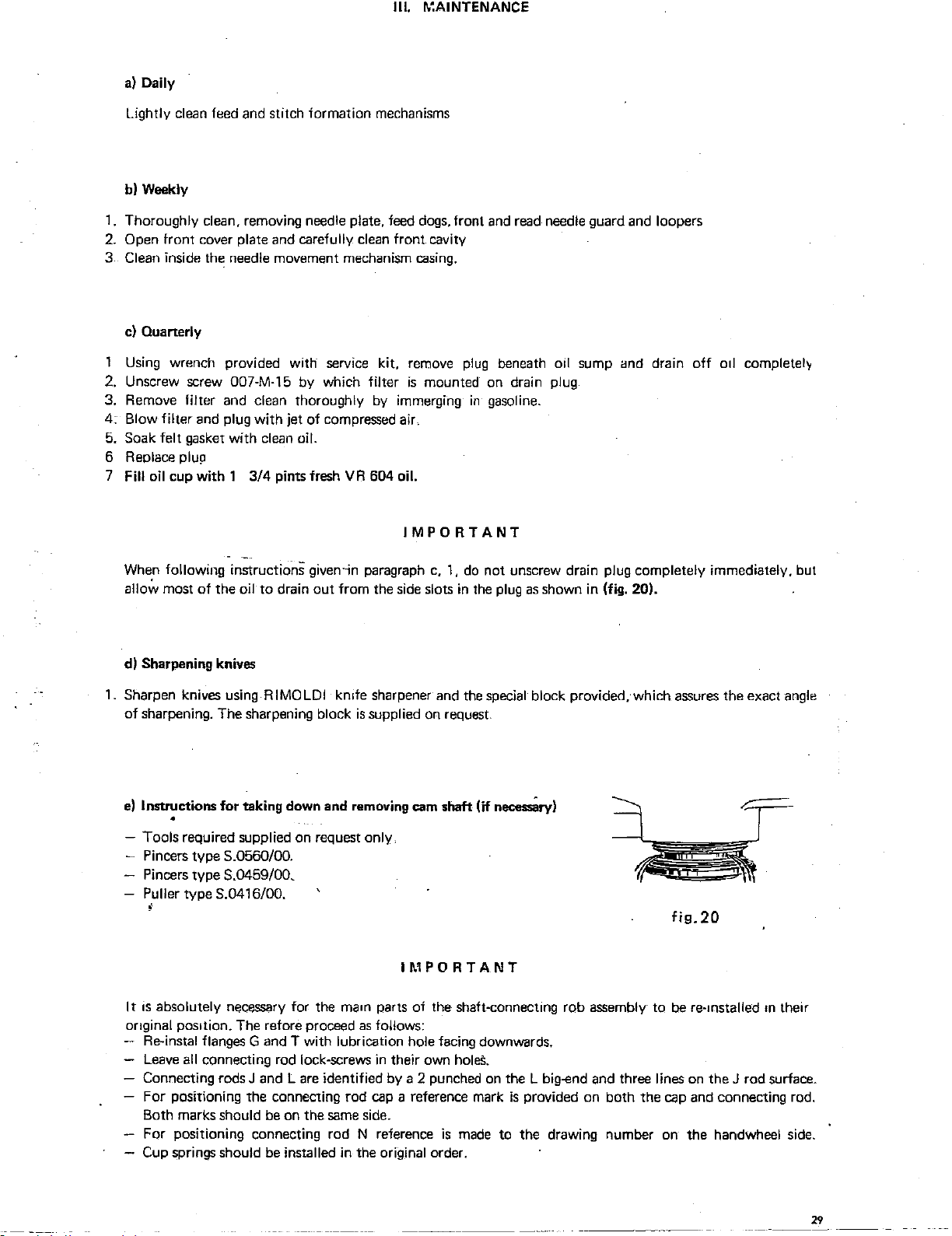

a)

Daily

Ill.

~~AINTENANCE

Lightly

clean

feed

and

stitch formation

mechanisms

b) Weekly

1.

Thoroughly clean, removing needle plate,

2.

Open front cover plate and carefully

3 Clean inside

c)

Ouanerly

1 Using wrench provided

th~

needle movement mechanism

with

service kit, remove

feed

clean

2. Unscrew screw 007-M-15 by which filter

3. Remove filter

4: Blow

5.

filter

Soak felt

6 Replace plup

7 Fill oil cup

and

and

plug

gasket

with

with 1 3/4

clean thoroughly by immerging

with

jet

of

compressed

clean

oil.

pints fresh VR 604 oil.

dogs,

front

front cavity

casing.

plug

is

mounted

in

air.

IMPORTANT

and

read

needle guard

beneath oil sump imd drain

on

drain plug

and

gasoline.

loopers

off

o1l

completel\'

When

following instructions

allo,;,_,

most

of

the oil

to

drain

given

out

d) Sharpening knives

1.

Sharpen knives using R IMOLDI kmfe

of

sharpening. The sharpening block

e)

Instructions

for

taking down and removing cam shaft

•

-Tools

It

anginal pos1tion.

required supplied on request only.

Pincers type S.0560/00.

Pincers type S.0459/00.

Puller type S.0416/00.

IS

absolutely

Re-instal flanges G

Leave

Connecting rods J

necessary

The

for the

retore proceed

and

T with lubrication hole facing downwards.

all connecting rod lock-screws in their own

and L are

For positioning the connecting rod

Both marks should

For positioning

Cup springs should

be

on the

connecting

be

installed in the original order.

in

from

is

paragraph

the

sharpener

supplied

side

c,

1,

slots in

and

on

request.

do

the

IMPORTANT

maon

parts

of

the shaft-connecting rob assembly

as

follows:

holes.

identified by a 2 punched

cap

a reference mark

same

side.

rod N reference

is

made

not unscrew drain plug completely immediately, but

the

plug

as

shown in (fig. 20).

special

(if

necessiiry)

block provided, which

assures

the exact

angle

fig.20

to

be

on

the L big-end and three lines

is

provided on both the

to

the

drawing

number

re-mstalled

on

the J rod surface.

cap

and

on

the

handwheel

connecting rod.

on

their

side.

29

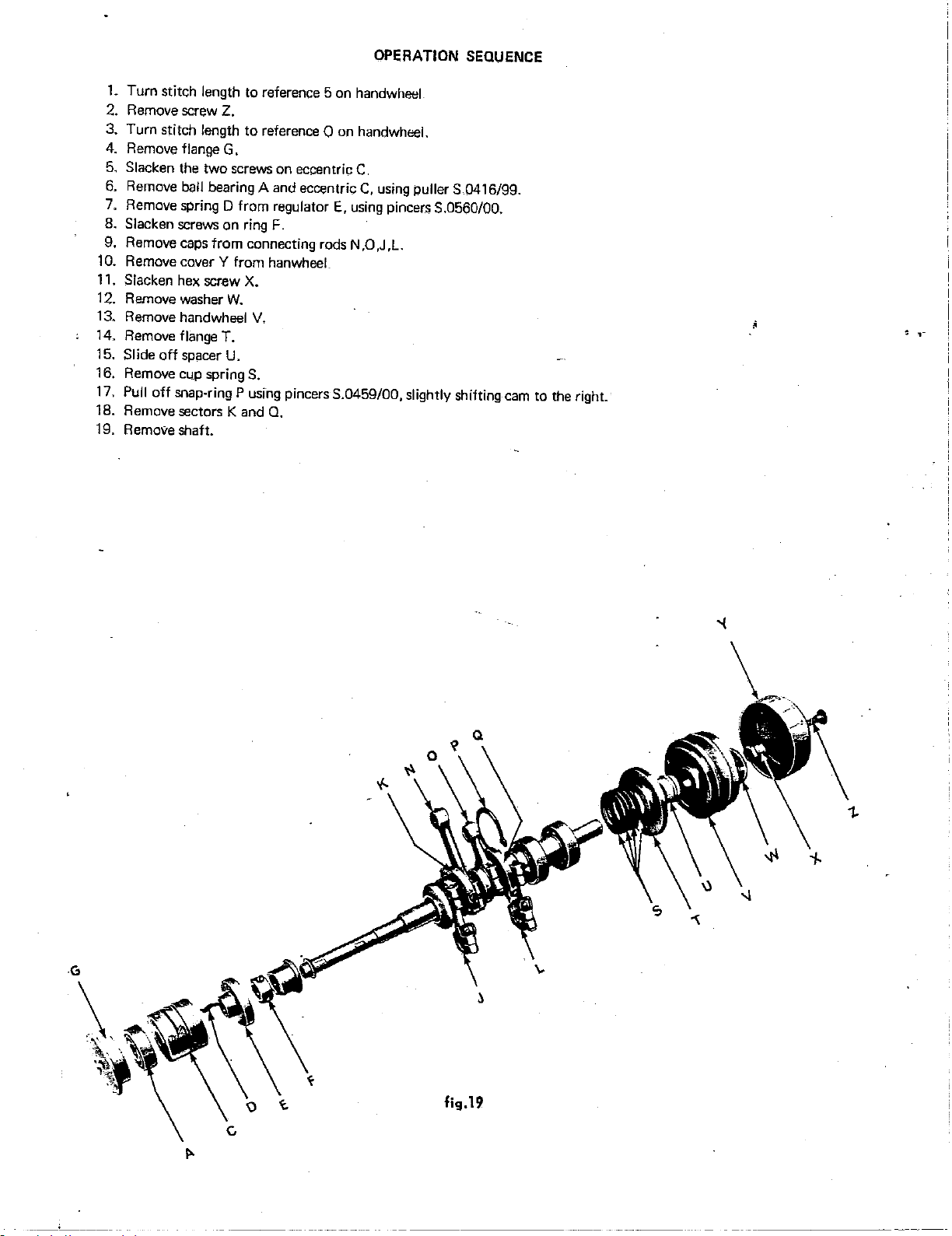

Page 27

OPERATION

1. Turn stitch length to reference 5 on handwheel

2.

Remove screw Z.

3. Turn stitch length

4.

Remove flange G.

5.

Slacken the

6.

Remove ball bearing A and eccentric

7.

Remove spring D from regulator

8. Slacken screws on ring

9.

Remove

1

0.

Remove cover Y from hanwheeL

Slacken hex screw X.

11.

12. Remove washer

13. Remove handwheel

14. Remove flange

15. Slide

16. Remove cup spring

17.

Pull

18. Remove sectors K and

19. Remove shaft.

caps

off

spacer U.

off

snap-ring P using pincers S.0459/00, slightly shifting

to

reference 0 on handwheel.

two

screws

from

connecting rods N

W.

V,

T.

S.

on eccentric

F.

Q.

C.

C,

using puller S .0416/99.

E,

using pincers S.0560/00.

,0

,J

,L.

SEQUENCE

cam

to the right.

!

,-

fig.19

--···

·-·----·

-----------

---~-

Page 28

-:-··

..=_;;.-_

--~.::

:;~

.

SPARE

PARTS

CATALOGUE

~

~~

-

~-----~---~~

~-~

31

Page 29

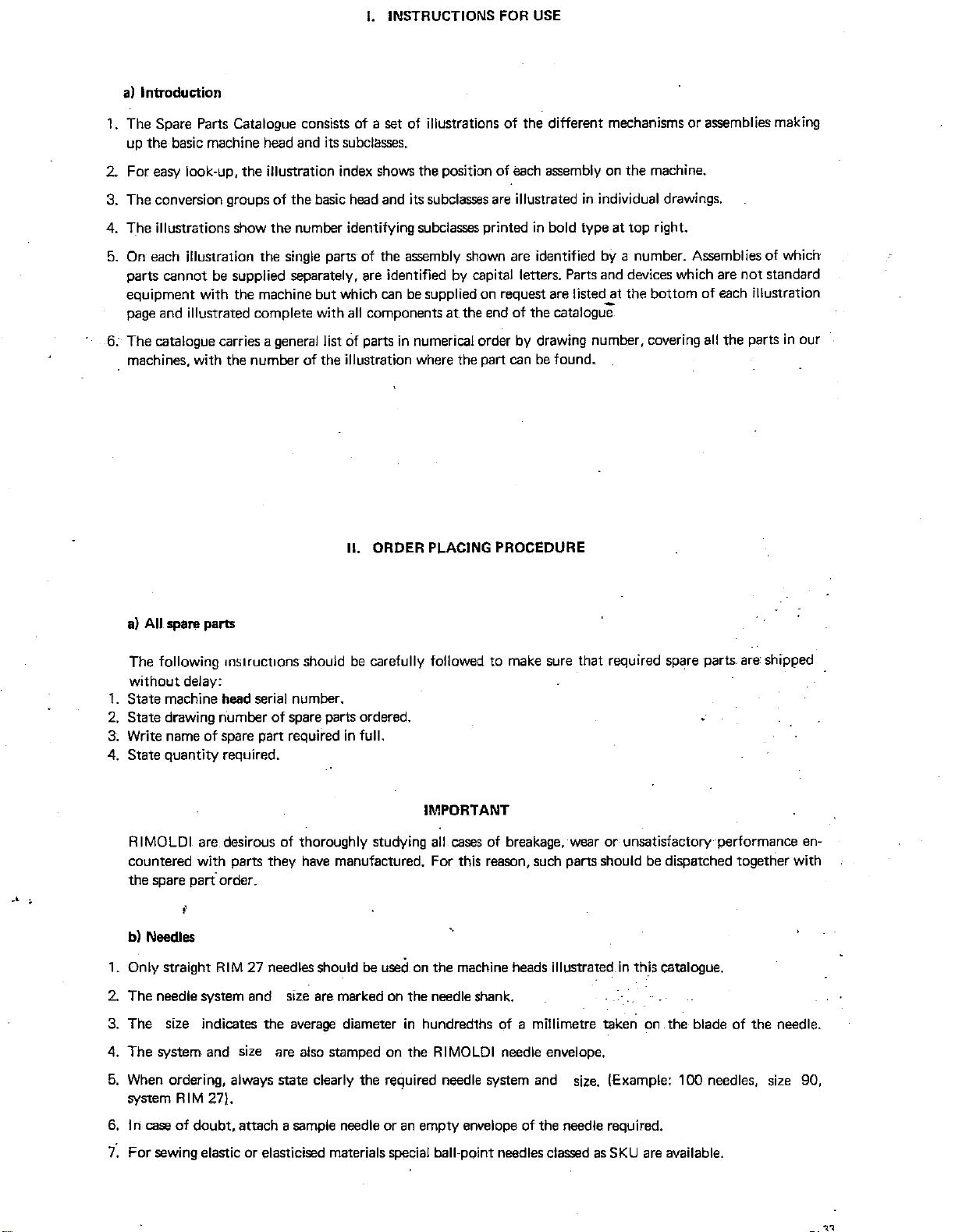

a)

Introduction

I. INSTRUCTIONS FOR

USE

1. The Spare Parts Catalogue consists

the

basic machine head and its subclasses.

up

2. For easy

look-up,

3. The conversion groups

4. The

5.

illustrations show

On each illustration the single parts

parts cannot

equipment with the machine but which

the

illustration index shows the position

ot

the basic head and its subclasses are illustrated

the

number identifying subclasses printed

be

supplied separately, are identified

page and illustrated complete with

6. The catalogue carries a general list

machines, with the number of the

ot

a set

of

illustrations

at

the assembly shown are identified

by

can

be

supplied

all

components

of parts

in

at

numerical order

ot

ot

each assembly on

capital letters. Parts and devices which are not standard

on

request are listed at the bottom

the end

ot

by

illustration where the part can

II.

ORDER PLACING PROCEDURE

the different mechanisms or assemblies making

the

machine.

in

individual drawings.

in

bold type

at

top right.

by

a number. Assemblies of which

of

each

illustration

the catalogue

drawing number, covering

be

found.

all

the parts

in

our

a)

All

spare

parts

The following mstruct1ons should be carefully followed to make sure that required spare parts. are shipped

without delay:

1.

State machine

2. State drawing number

3. Write name

head

serial number.

of

spare parts ordered.

of

spare part required

in

full.

4. State quantity required.

IMPORTANT

RlMOLDl are desirous of thoroughly studying

countered with parts they

the spare

b)

1. Only straight

Needles

part· order.

RIM

27 needles should

have

manufactured. For this reason, such parts should

be

used on the machine heads illustrated

all

cases of breakage, wear or unsatisfactory performance en-

be

dispatched together with

in

this catalogue.

2. The needle system and size are marked on the needle shank.

3. The size indicates the average diameter

4. The system and size are also stamped on the

in

hundredths of a millimetre taken on the blade of the needle.

RIMOLDI

needle envelope.

5. When ordering, always state clearly the required needle system and size. (Example:

6.

system

In

case

RIM

27).

of

doubt, attach a sample needle or

an

empty envelope of the needle required.

i. For sewing elastic or elasticised materials special ball-point needles classed as

SKU

are available.

100 needles, size 90,

Page 30

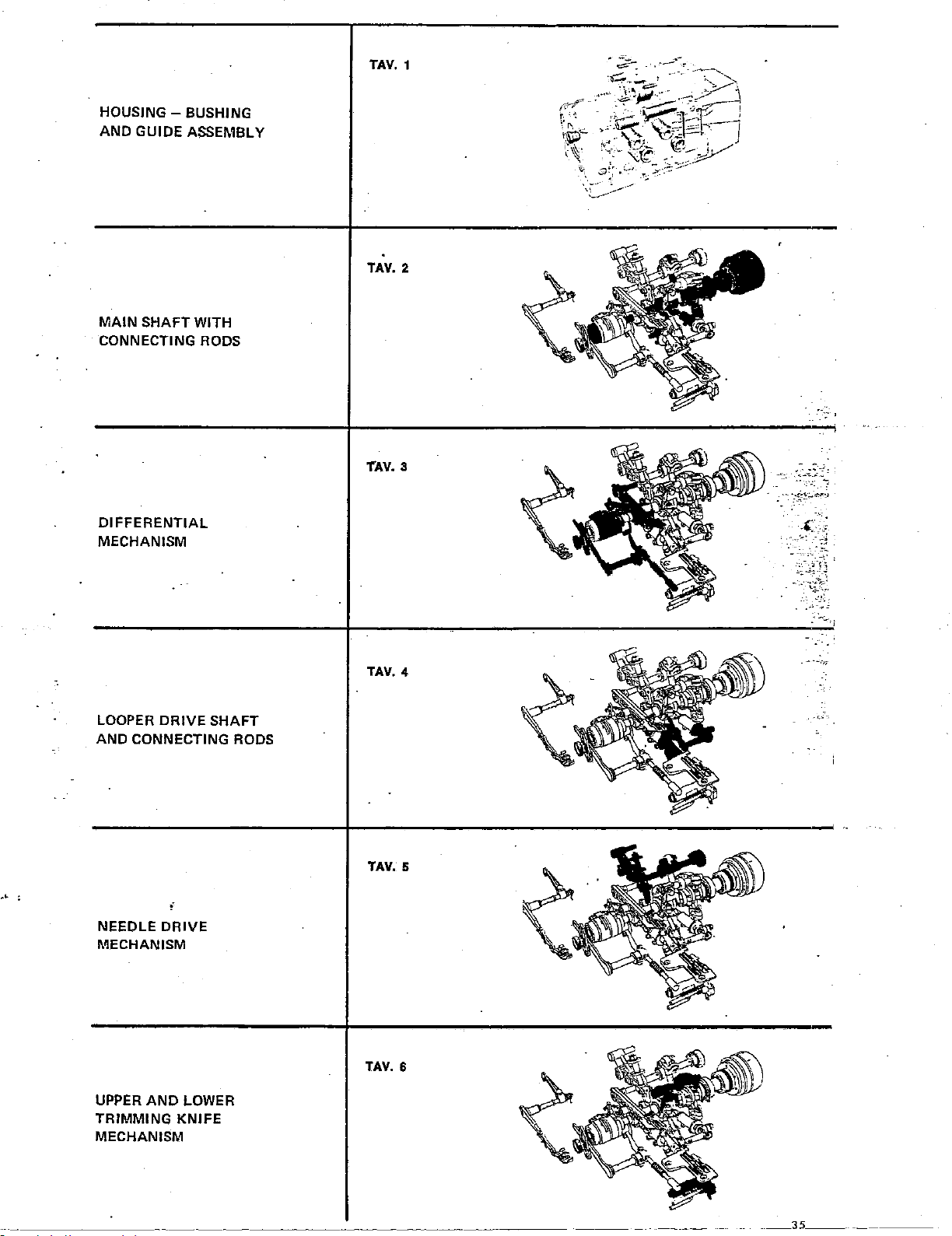

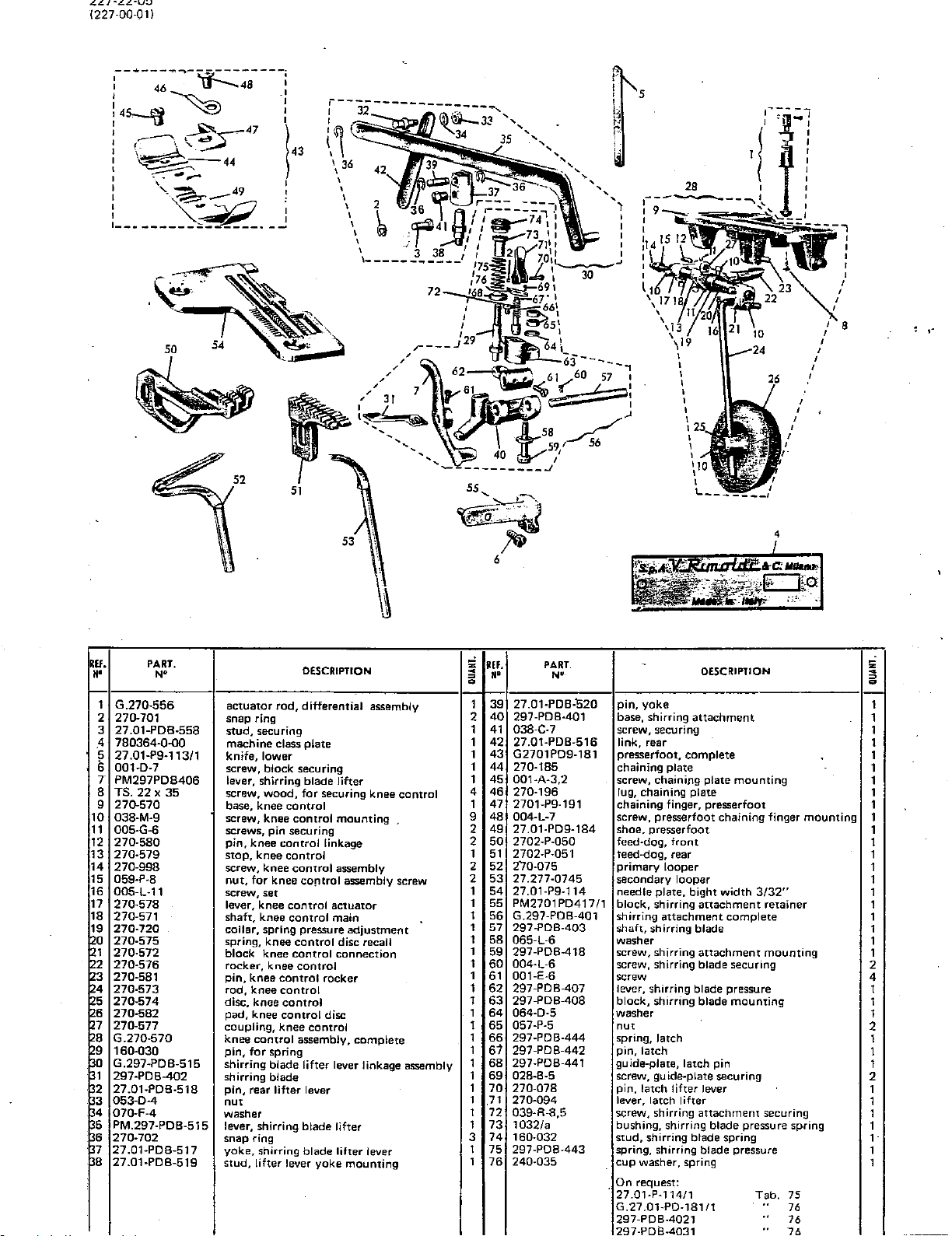

TAV.

1

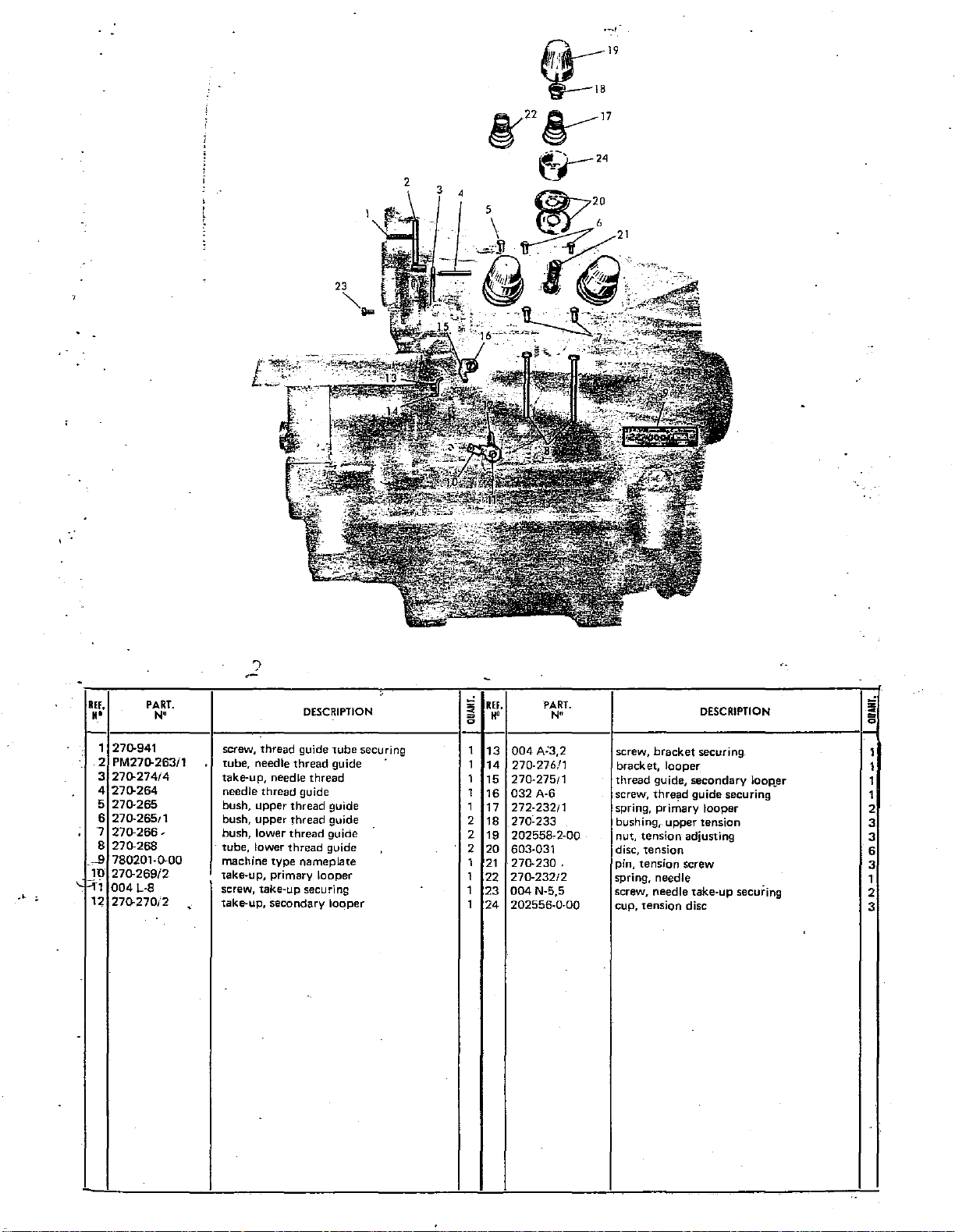

HOUSINGAND

GUIDE ASSEMBLY

MAIN

SHAFT

BUSHING

WITH

CONNECTING RODS

DIFFERENTIAL

MECHANISM

TAV.

TAV.

,

__

_

'i

___

'

-~

-

---

2

3

.:(

:;

--

->:

.

~~~':}j

..

:<r~~

~;;c-~--

LOOPER

DRIVE

SHAFT

AND CONNECTING RODS

;

NEEDLE

DRIVE

MECHANISM

UPPER

TRIMMING

AND

LOWER

KNIFE

MECHANISM

TAV.

TAV.

TAV.

4

5

6

---

------·--

._35

__

Page 31

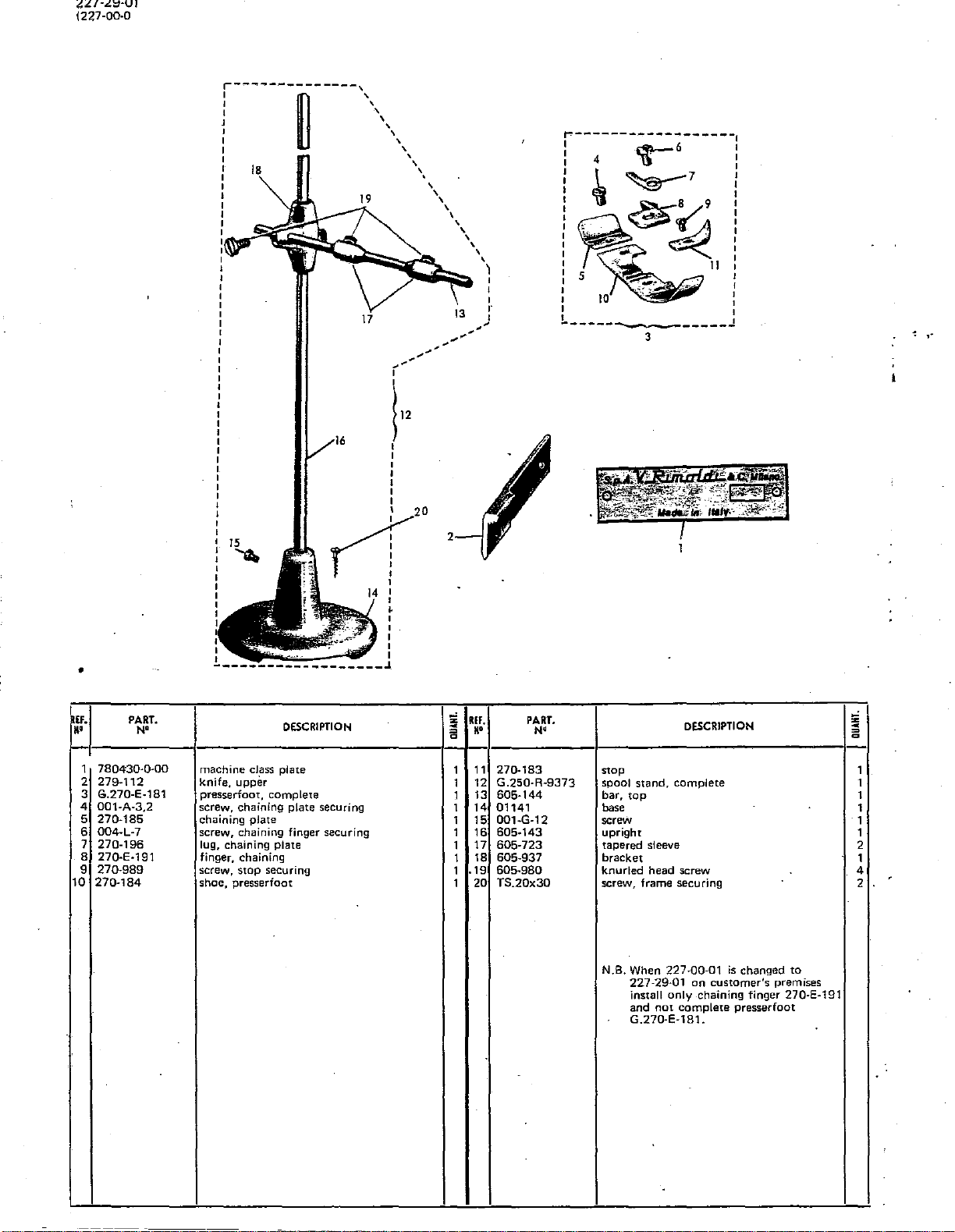

Tav. 7

PRESSER

LINKAGE

NEEDLE PLATE

MACHINE COVER

AND WORK PLATE

THREAD

AND TENSION DISCS

OIL

LUBRICATION

SUMP

FOOT

AND

TAKE-UP

AND

PUMP

Tav. 8

Tav. 9

Tav.lO

MACHINE MOUNTING

BRACKET

KNEE CONTROL

REEL STANDS

AND

STANDARD SERVICE

KIT

AND

FOOT PEDAL

Tav.ll

Tav

.12

Tav. 13

;

~

·~1~

lf

1

-

-

-~

-;:::;'

...-:>

e

I

~·

~

'),:·----~-=------

•

..

"'~

~

=¢"

=-~

..

.~-

--

,--

-~-·--

_.._

-.~.

-

"

!

~

,:

""

~

•.

,

~"

'~

~

.1l,.J

I

.

-·

.t~

~

Page 32

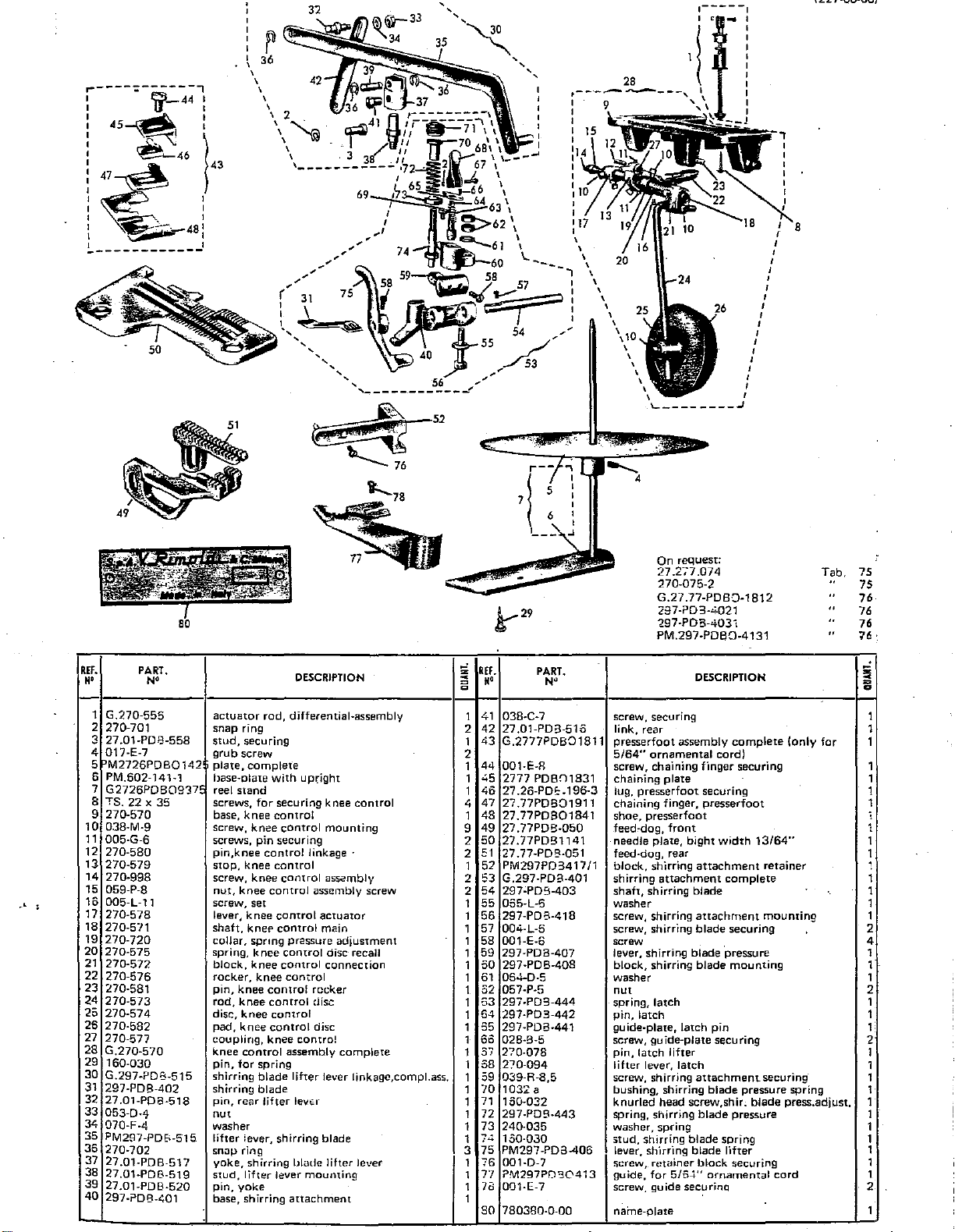

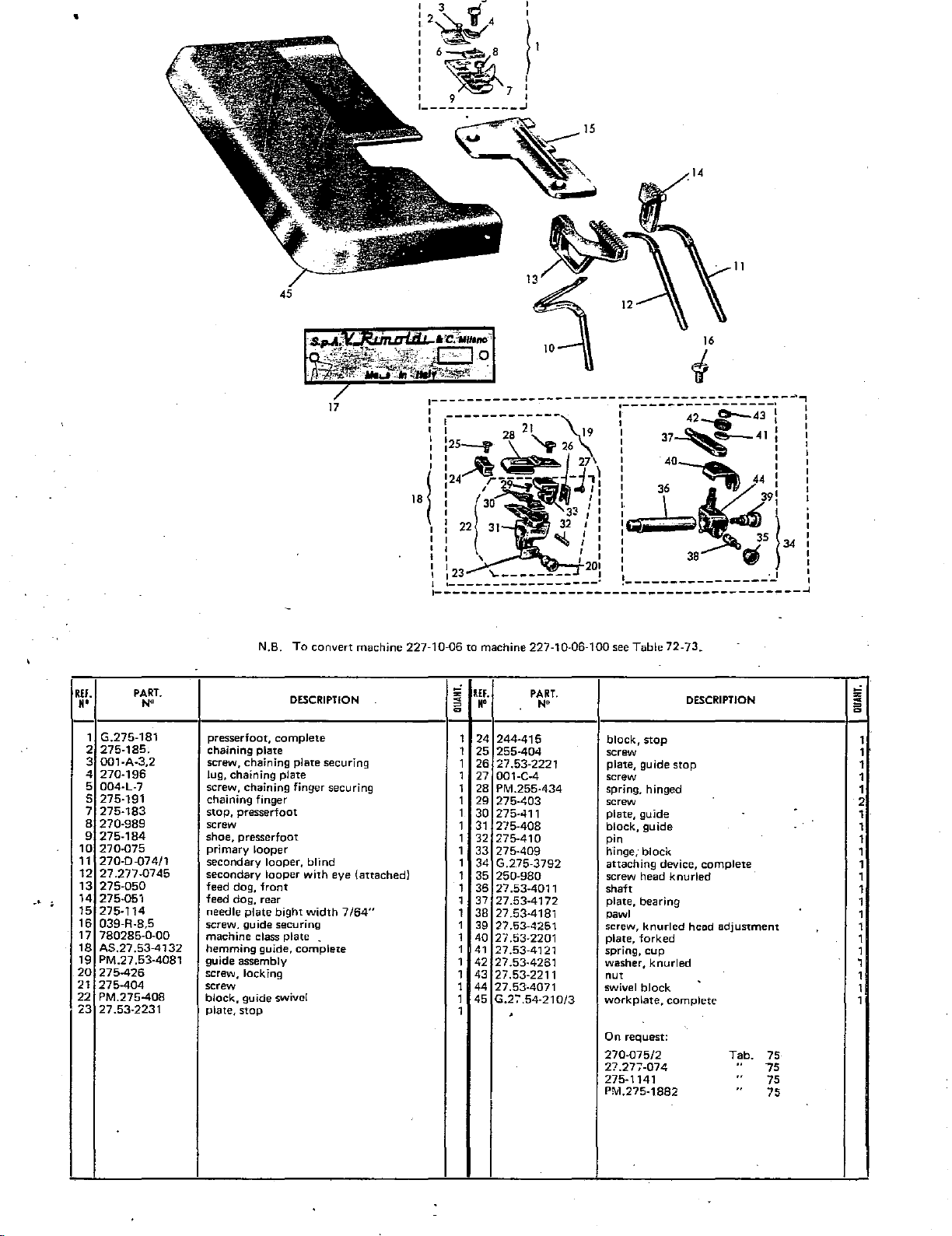

HEAD 227-28-01

Tab

14

HEAD 227-10-02

Tab.

45

HEAD

HEAD

HEAD

HEAD

HEAD

HEAD 227-01-02

HEAD 227-00-06

HEAD

HEAD

HEAD

HEAD

HEAD

HEAD

227-28-02. Tab.

227-29-01

227-29-02

227-01-01

227-17-01

227-22-01

227-23-01

227-01-03

227-00-07

227-29-04

227·29-05

15

Tab.

16

Tab.

17

Tab.

18

Tab

19

Tab.

20

Tab.

21

Tab

22 HEAD 227-30-03 Tab. 53

23

Tab

Tab 24

Tab. 25

Tab.

26

Tab 27

HEAD 227-10-03 Tab. 46

HEAD

HEAD 227-10-05

HEAD 227-10-06

HEAD 227-11-01 Tab. 50

HEAD 227-10-07

HEAD 227-00-25

HEAD

HEAD

HEAD

HEAD

HEAD

227-10-04

227-30-04

227-00-26

227-30-05

227-00-27

227-29-08

Tab. 47

Tab.

48

Tab. 49

Tab.

51

Tab.

52

Tab. 54

Tab. 55

56

Tab

57

Tab.

Tab.

58

~~

.

HEAD

HEAD 227-22-02

HEAD 227-22-03

HEAD 227-23-02

HEAD

HEAD

HEAD

HEAD

HEAD

HEAD 227-23-04

HEAD 227-23-05

HEAD

HEAD 227-30-01

227-29-06

227-01-04

227-22-04

227-22-05

227-23-08

227-23-03

227-00-05

Tab.

28

Tab

29

Tab 30

Tab.

31

Tab. 32

Tab. 33

Tab. 34

Tab 35

Tab.

36 HEAD 227-28-08

Tab.

37

Tab. 38

Tab.

39

Tab 40

HEAD 227-00-28

HEAD 227-30-06

HEAD 227-00-29

HEAD 227-00-11

HEAD

HEAD

HEAD

HEAD

HEAD 227-00-08

HEAD

HEAD

HEAD 227-00-33

227-29-07

227-00-09

227-00-10

227·28-07

227-00-02

227-00-30

Tab. 59

Tab. 60

Tab. 61·

Tab. 62

Tab. 63

Tab. 64

Tab. 65

Tab.

66

Tab.

67

Tab. 68

Tab. 69

Tab. 70

Tab.

71

HEAD 227-30-02

HEAD 227-00-04

HEAD 227-10-01

HEAD

227-00-22

Tab.

41

Tab. 42

Tab.

43

Tab.

44

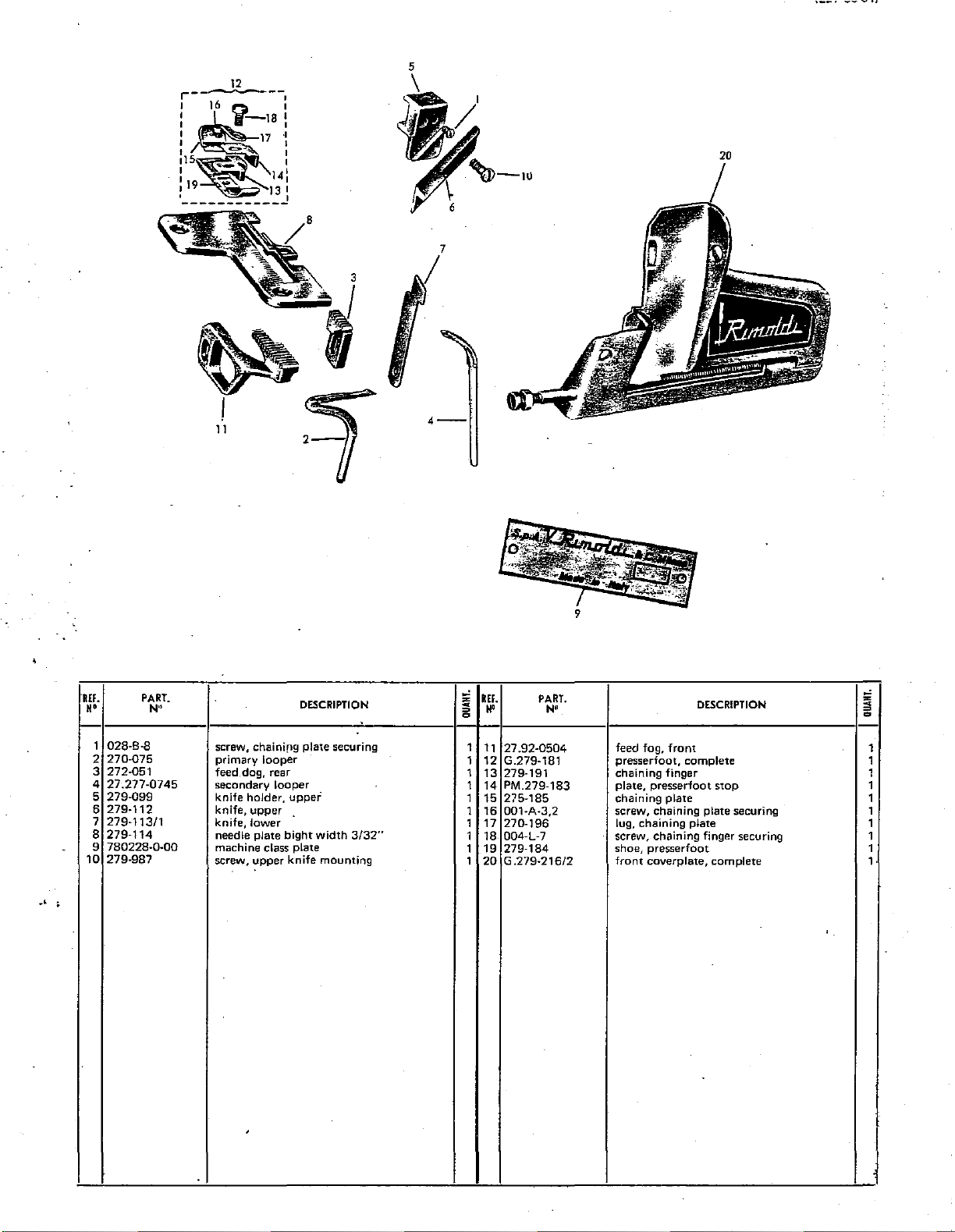

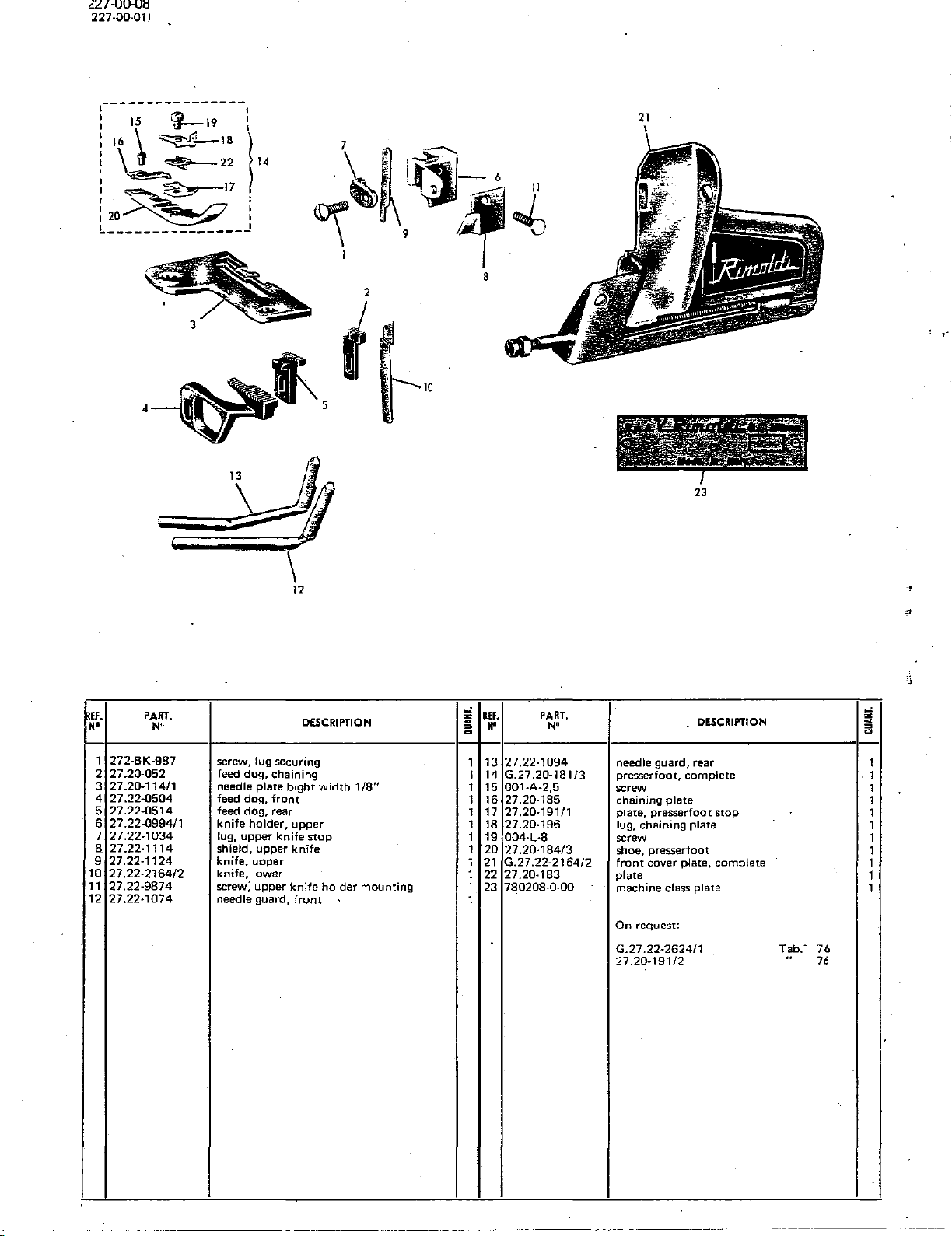

TABLE DEL

PARTS

PARTS

TABLE

ON

FOR

FOR

OF

REQUEST

(100)

W1

(100)

W1

(101)

X1

PARTS SUPPLIED

Tab.

Tab.

Tab.

Tab.

Tab.

Tab.

Tab.

72

73.

74

75

76

77

78

Page 33

,---------------------,

-----~----

1'

I

I

I

I

I

I

·'

REf.

••

1

270-016

2

270-097/1

3

270-058/2

4 270-057{1

5

270-268

5

270-002/1

7

G.270-002/1

PART.

N"

bushiny, needle

bushing,

rear bushing,

front

guide

base,

base

'

DESCRIPTION

bar

knife

looper

looper

looper

~;hi.ifl

holder

shaft

shaft

thread

upper

bushing,

tube.

machine

with

bushings and thread guides

REf.

~

••

0

1

1 9

10

2

11

2

2

12

1

13

1

8 270-912

270-044/2

270-042/3

270-542

270-082/1

270-264

PART.

N''

Jatc:h

pin,

bushing,

bushing

pin,

coverplatfbushing,

thread

work

differential

Oeh),

prt!s•.;erfout

uuitle,

needle

DESCRIPTION

plate

shaft

differential

c:enteriny

lifter

shaft

lever

5i

~

·=

0

.

1

1

1

2

1

1

\

Page 34

227-00-01

20

,.

33

..

lEf.

·N'

1

PM.270-009/4

i2

280-012/3

3

270·116/2

4

270-061/2

270-060/1

.5

,6

270-05911

270-009/4

'7

270-707

8

9

270-613

10

270-709

270-062

11

270-704

12

13

270·705

14

$-620

270-614

15

16

270-008/1

17

270-612/1

18

270-981

19

270-608/5

PART.

N•

----------

DESCRIPTION·

main

shaft,

with

control

rod,

control

rod,

control

rod,

sleeve, secondary looper control rod

sleeve,

primary

main

shaft

ball

bearing,

spacer,

bearing

ball

bearing,

guide,

connecting

snap-ring,

spring,

cup

flange,

right

spacer,

main

handwheel

washer

with

set-screw,

cover

with

connecting

needle

bar

knife

secondary

looper

right 2

left

rod 2

right

ball

shaft

right 1

guide

hanwheel

handwheel

looper

control

bearing

rods

rod

~

~

=

REF.

N'

PART.

N'

"

1

270-310

20

1

21

2:'0-517/2

·no-999

1 22

OlO-H-13,7

2 n

1

24

270-975

1

290-944

1

25

092-D-14

25

1 27 092-C-2 wick

1

28

270-010/2

074-A-12

29

2?'0-722

1

30

290-726

1 31

1

3?

016-D-5 screw,

270-938

33

02.3-!';-5,5

34

1

001-E-10

1

35

1

36

010·0·11,5

PM.270-059/1

1

37

PM.270-060/J

38

pivot,

rockers

screws,

screw

and

screw, sleeve

lock-screw,

oil

bush,

waSher,

ring,

cap,

lock-screw,

grub-screw,

screw,

screw,

sleeve

sleeve

22

DESCRIPTION

lwm.lwheel 1

rocker

for

control

rods

270-115/2

wick,

main

intermediate

differential

odjustment

main

shaft

adjustment

right flonge

looper

assembly

assembly

connecting

intermediate

pin

control

280-012/3

rod

shaft

ring 2

guide

bush

rod

!5

=

"

2

4

4

·-

2

1

2

1

1

1

1

1

2

.:

a

'

..

1

N. B.

Be<JrinHS

supplietl

it

is

indispensable

order

sheet

pearing

moved

reference

us

on

bearing.

number

sep;lrute spares, hOwever

to

Roman

outer

specify

numeral

race

of

the

the

8

1:1.m

on

there-

he

the

ap-

.

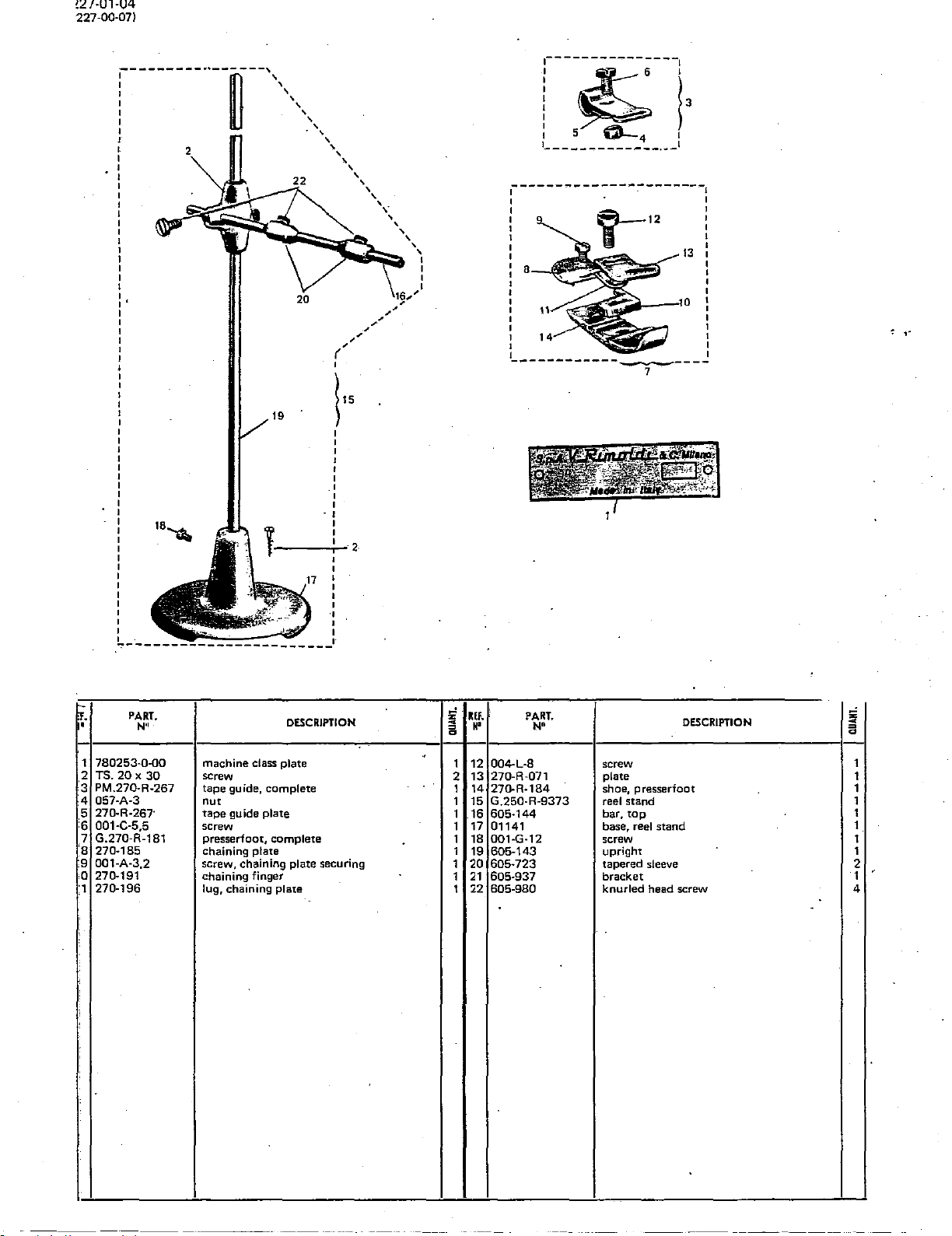

Page 35

REf.

H'

PART.

N"

DESCRIPTION

;i

~

0

ltEF.

H'

PART.

N"

--c

1

PM.270-049/1

270-051

2

270-977

3

'

..

-4

270-640/3

5

092-8-1

6

270-937/1

7

270-052

8

270-611/1

'

270-979

9

10

070-M-4,5

11

270-035

12

~030-06

13

270-048

14

073-C-8

15

270-054

16

071-M-5,5

17

279-047/2

18

070-F-4

19

057-F-4

20

270-975

·'

21

22

23

24

25

26

27

28

29

30

31

32

33

34

"5

.·-6

:.7

·.a

::s

·10

41

42

43

44

45

45

--

-

---

270-039

270-7391

071-H-5

270-036/1

270-935

026-C-7

PM.270-038/3

270-040

270-031/1

092-D-6

092-D-12

270-041/1

250-471

017-E-11,5

039-H-9

064-F-5

270·992

270-287/1

07:,3-A-8

PM.270-562.'2

270-288/1

270-567

065-D-6

270-568

270-702

270-703

------·

'

-----------·--

ass~rnbly,

feed

screw,

guide

oil wick

securing

feed

eccentric,

securing

washer,

bush,

collar

link,

washer,

pin,

washer,

guide

washer,

nut

screw,

shaft,

.

sec4ring

washer,

sliding

counter-washer

screw,

complete

yoke,

pin,

oil

oil

rear

screw,

securing

screw,

washer,

screw.

upper

·wilsher,

lever,

stop

sector

washer,

knurled

snap

needle

differentiul

dog,

rear

attach

block,

screw,

dog,

chaining

feed

screw,

differential

differential