Rimoldi 063-46-01, 063-34-08, 063-34-09, 063-16-16 User Manual

PA

TS

CATALOGUE

..................

....

.·

.·.

lllll:

iii::

lii:l::l::

-··~

~----·

cia

ses

063·46·01

063·34·08

0

3·34·09

063·16

and

subclasses

·

16

n.3

N CAT 6526300Q3e11

t70

INDEX

INTRODUCTION

- MACHINE IDENTIFICATION

II

- TECHNICAL DATA

Ill - TECHNICAL SPECIFICATIONS

BY

MACHINE CLASS

INSTRUCTIONS

I

INSTALLATION AND TIMING

-

<l

-

b

c Lubric<Jtion

d

USE

II

-

a

-

b Changing

c

-

d

e -Stitch

f Problems

Ill-

MAINTENANCE

a

-

b c -

d

Positioning

Assembly

Assembling and adjusting

Threading

Setting

Setting

Every

Every week

Every

Assembling

of

head

of

tmnsmission

the

needle

the

presserfoot

the

tensions

length ad ju

due

to

day

three

months

the

ment

improper

oil basin

of

Sewing Parts

handling

of

machine

P<Jgc

P<Jgc

Page

Page

5

5

6

13

13

13

13

14

19

19

22

22

22

22

23

24

24

24

24

24

SPARE PARTS CATALOGUE

I -HOW

II

Ill-

IV-

TO USE THIS CATALOGUE

a -

Introduction

HOWTOORDER

-

All

-

All needles

parts

a

b

TABLES

NUMERICAL INDEX

OF

PARTS

Page

Page

Page

27

27

27

27

27

28

72

INTRODUCTION

3

a)

ldontilication numbtlrs

1.

Eac

h mat:hinll

- Class

or Subdass number

- Serial number

2.

Th•l

Clilss

or

is

idllntilied by:

Subclass number

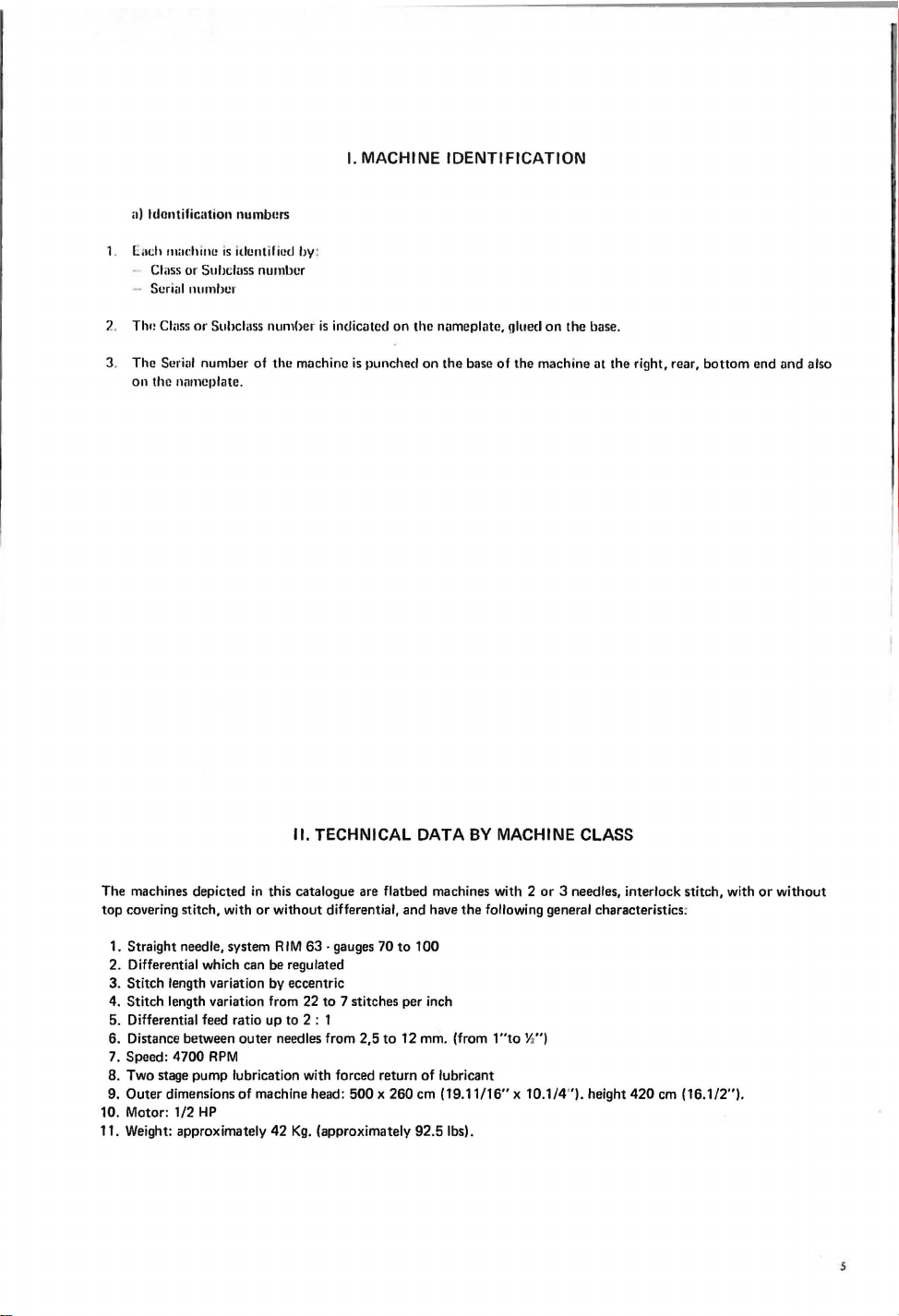

I. MACHINE IDENTIFICATION

is

indicated on the nameplate, glued

on

the base.

3. The Serial number

The machines depicted

top covering stitch, with

on the

nmncplate.

ol

the machine

II.

in

this catalogue are flatbed machines with 2

or

without differential, and have

is

punched on the base

TECHNICAL

DATA

BY MACHINE CLASS

the

following general characteristics:

ol

the machine at the right, rear, bottom end and also

or

3 needles, interlock stitch, with

or

without

1.

Straight needle, system

2. Differential which can be regulated

3. Stitch length variation by eccentric

4.

Stitch length variation from 22

5. Differential feed ratio up to 2 : 1

6. Distance between outer needles from

7.

Speed: 4700

B.

Two stage pump lubrication with forced return

9. Outer dimensions

10.

Motor: 1/2

11. Weight: approximately 42

RPM

HP

RIM

63 ·gauges 70

to

7 stitches per inch

of

machine head: 500 x 260 em (19.11/16" x 10.1/4" ). height

Kg.

(approximately 92.5 lbs).

2,5

to

to

100

12 mm. (from

of

lubricant

1"to

Y>

')

420

em (16.1/2").

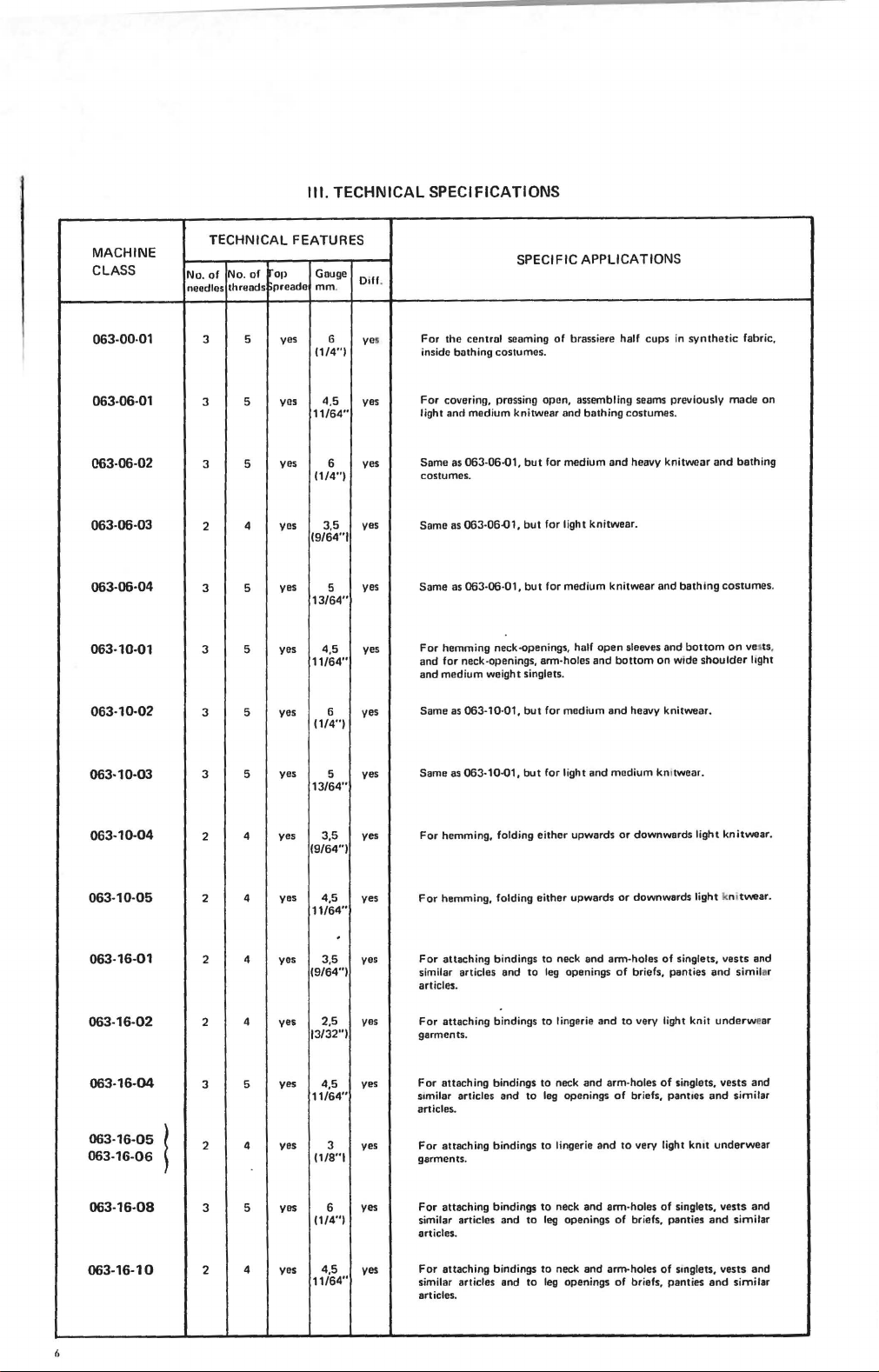

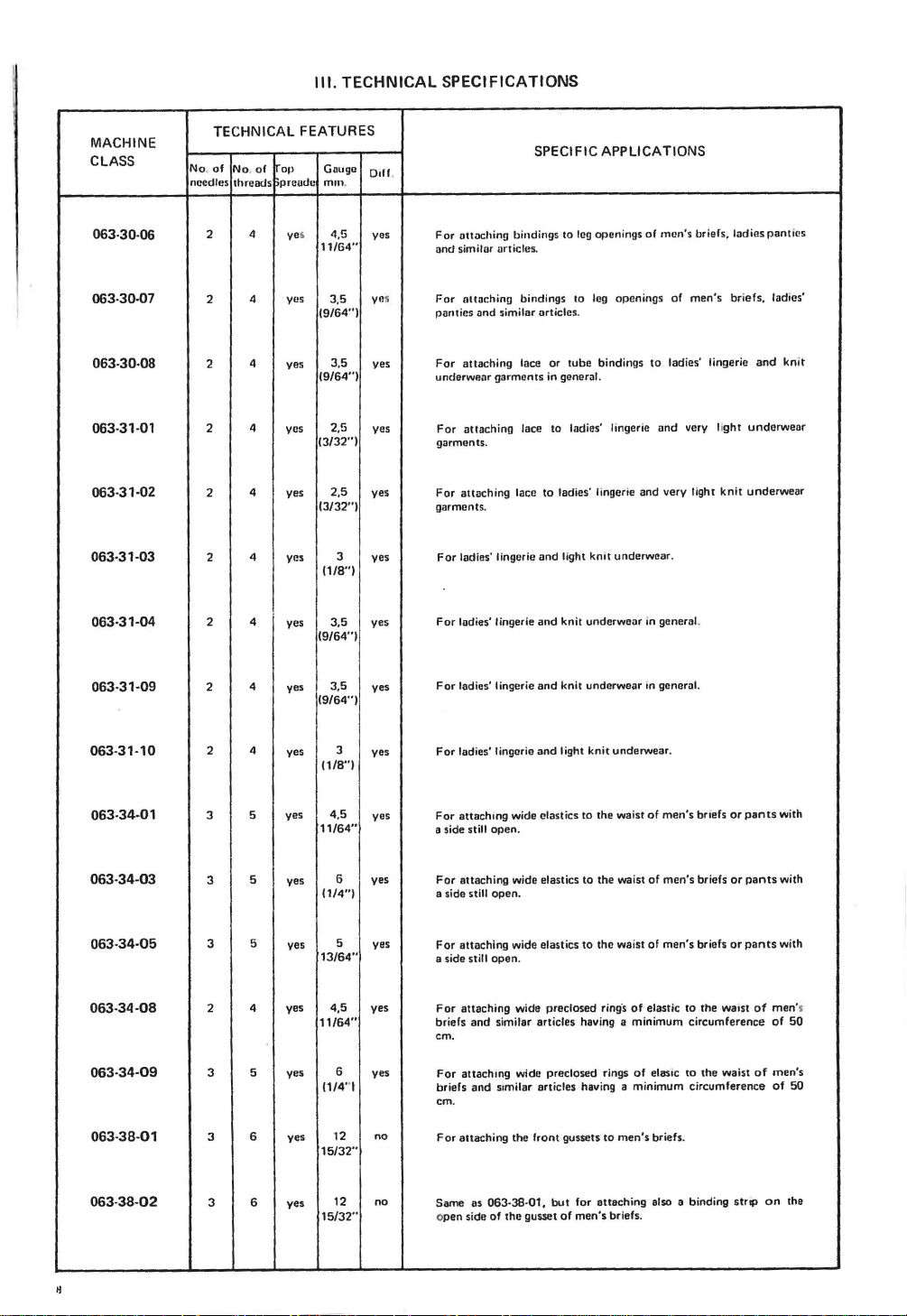

Ill. TECHNICAL SPECIFICATIONS

MACHINE

CLASS

No.

needles

063-00-01 3

063-06-01

063-06-02

063-06-03

063-06-04

063-10-01

063-10-02

TECHNICAL FEATURES

O(l

No.

of

threads

3 5

3 5

2

3 5

3 5

3 5

of

5

4

Gouge

prcado mm.

yes

G yes

(1/4")

4,5

yes

11/64"

yes

6

(1/4")

yes 3,5

(9/64"1

yes

5

13/64"

yes 4,5 yes

11/64"

yes 6 yes

(1/4")

Diff.

yes

yes

vas

yes

SPECIFIC APPLICATIONS

For

the central roaming

inside bathing costumes.

For

covering, prossing open, assembling seams previously mode

light

and

medium knitwear and bathing costumes.

Some as 063-06-01,

costumes.

Some as 063-06.01,

Same as 063-06-

For

hemming neck-openings, half

and for neck-openings, arm-holes and

and medium weight singlets.

Same

as

063-10·01,

of

brassiere half

but

for medium

but

for light knitwear.

01,

but

for medium knitwear and bathing

but

for medium

and

open

and

sleeves and

bottom

cups

in

synthetic

heavy knitwear

bottom

on

wide

heavy knitwear.

and

costumes

on veot

shoulder

fabric,

on

bathing

l1ght

.

s,

063·10-03

063-10-04

063-10-

05

3 5

2

2 4

063-16-01 2 4

063-16-02

063-16-04

063-16-05

063-16-06

2

3

2 4

~

063-16-08 3 5

063-16-10

2

4

4

5

4

yes

yes

yes

yes 3,5

yes 2,5

yes

yes

yes

yes

yes

5

13/64"

yes

3,5

(9/64")

yes

4,5

11/64"

yes

(9/64") similar articles and

yes

13/32")

yes

4,5

11/64"

yes

3

(1/8"1

yes

6

(1/4") similar articles and to

4,5 yes

11/64"

Same as 063-10.01,

For hemming, folding either upwards

For

hemming, folding either upwards

For

attaching bindings to neck and arm-holes of singlets, vests and

articles.

For

attaching bindings to lingerie and

garments.

For

attaching bindings to neck

s1milar articles and to

articles.

For

attaching bindings to lingerie

garments.

For

attaching bindings

articles.

For

attaching bindings

similar articles end

articles.

but

for light

to

leg

openings

leg

openings

to

neck

leg

openings

to

neck and arm-holes

to

leg

openings

and

medium kn 1twear.

or

downwards light

or

downwards light kn•

of

briefs, panties

to

very light knit

and

arm-holes

of

briefs, pant1es

and

to

very light k01t

and

arm-holes

of

briefs, panties

of

briefs, panties

knitwear

and

underw

of

singlets, vests and

and

underwear

of

singlets, vests and

and

of

Singlets, vests and

and

twear

similar

ear

similar

similar

similar

.

.

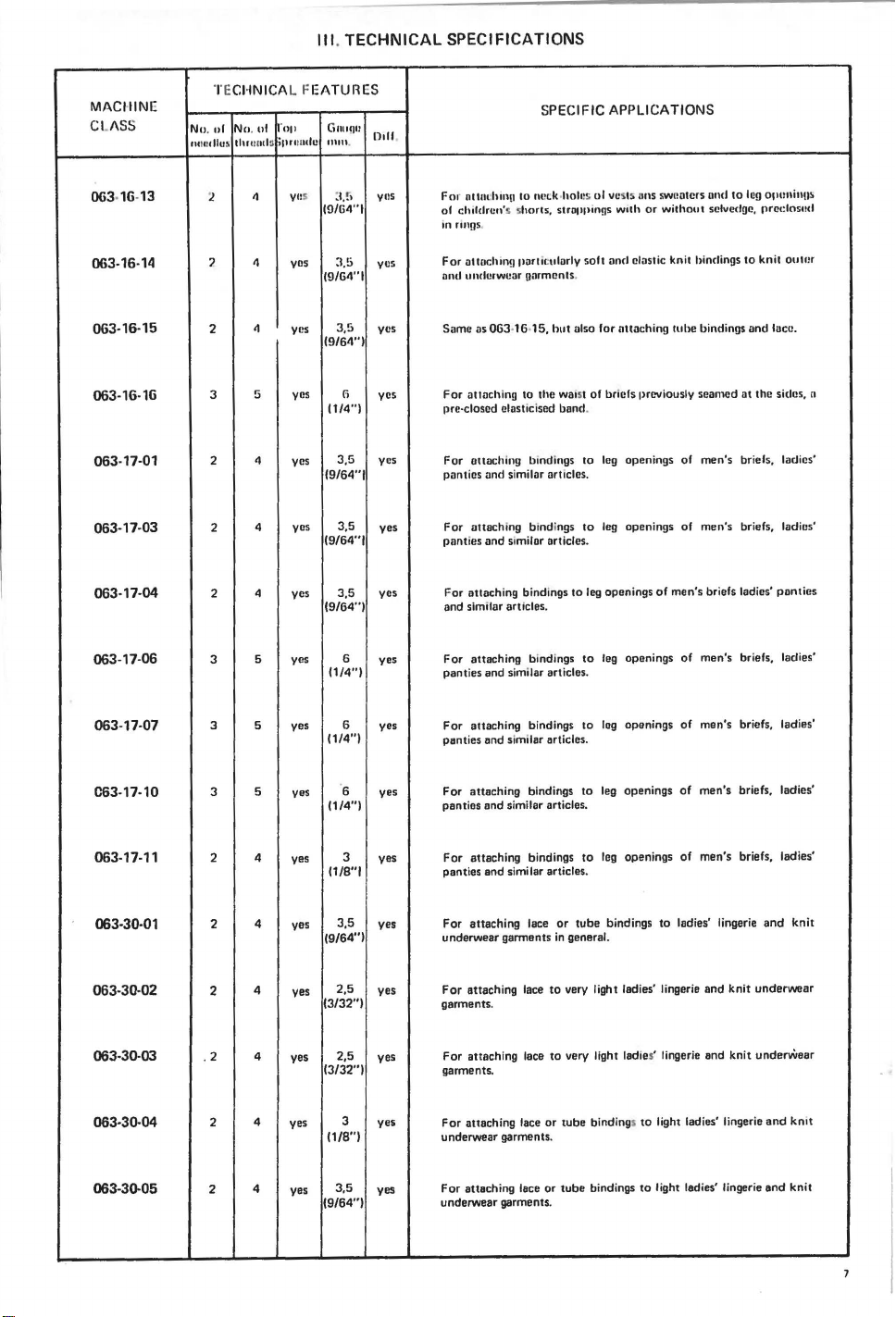

Ill

. TECHNICAL SPECIFICATIONS

MACI-IINE

CLASS

003-16-

13

Nu. ul

tlUt!

003-16-14

003-16-15 2

063-16-16

063-17-01

063-17-03

063-17-04

TECHNICAL FEATURES

np

Nu. nl

tht

uiU

tllu

2

7 4 yos

I5

s

4

4 yes

5

3

2 4 yes

4

2

2 4

Gnugu

tnm

>

,

~·.fi

19/134''1

3,5

(9/64"1

3,5

(9/64"1

fi yes

(1/4")

"prmuh:

yn

yes

3,5

(9/64"1 panties

3,5

yes

(9/64"1

yes

3,5

(9/64")

Dtll

Fol'

yns

yus

nttudunu

of

children's shorts, stropllings

in rings.

For

ouoching

ont.l

underwear garments.

yes Same as

For

pre-closed elasttcised band.

yes

yes

yes

For

For

panties and similar articles.

For attaching bindings to

and similar articles.

SPECIFIC APPLICATIONS

to

nt~ck·

hoh!s

ol

vc, ,:.

uns

063

-16-15,

portu::ulorly

hut

sw.,otcrs und

wllh

or

salt

oncl clastic knit bindings

also for attaching

without

tube

to

leg opuninU!t

sctvcclgc, prcdosucl

to

knit

bindings and lucc.

ouwr

attaching to the waist of briefs previously seamed at the sides, n

briels, ladies'

attaching bind ings to

and

similar

ort1cles.

attaching bindings

to

leg

leg

openings of

leg

openings

openings

men's

men's briefs, ladies'

ol

of

men's briefs ladies'

panties

063-17-06

063-17-07

C63-17-10

063-17-11

063-30-01

063-30-02 2

063-30-03

.2

063-30-04

063-30-05 2

yes 6

5

3

3

yes 6 yes

5

3 5 yes

2 4

2

2

yes

4

yes

4

yes

4

yes

4

yes

4

yes

For

yes

(1/4")

(1/4")

6 yes

(1/4")

3

yes

(1/8"1 panties and similar articles.

3,5

yes

(9/64") underwear garmants

2,5

yes

(3/32")

2,5

yes

(3/32")

3

yes

(1/8") underwear garments.

3,5

yes

(9/64")

attaching bindings

panties and similar articlas.

For

attaching bindings to

panties and similar articles.

For

attaching bindings

pantias and similar articlas.

For

attaching bindings

For attaching

For

attaching lace

garments.

For

attaching lace to very light ladies' lingerie and knit underWear

lace

or

in

to

very light ladies' lingerie and

garments.

For

attaching lace

For

attaching lace or

underwear garments.

or

tube

tube

to

to

to

tube

general.

bindings

bindings

leg

openings

log

openings

leg

openings

leg

openings

bindings

of

men's briefs,

of

man's briefs, ladies'

of

men's briefs, ladies'

of

men's briefs, ladies'

to

ladies' lingerie

to

light ladies' lingerie

to

light ladies' lingerie

knit

ladies'

and

knit

underwear

and knit

and

knit

Ill.

TECHNICAL SPECIFICATIONS

MACHINE

CLASS

063-30-06

063·30-07

063-30-08

063·31-01

063-31·02

063·31-03

063·31-04

TECHNICAL FEATURES

No. of No.

needles

of

op

threads

prcudc mm.

4 yes

2

yes

4

2

4 yes 3,5

2

4 yes 2,5

2

4

2

4

2

2 4 yes 3,5

19/64")

19/64")

13/32"1

yes 2,5

13/32"1

yes

19/64"1

Gauge Doll

4,5

11164"

3,5 yos

yes

3

1118")

yes

yes

yes

yes

yes

SPECIFIC APPLICATIONS

For

attaching

and simi lor articles.

For

panties and similar articles.

For

underwear

For

garments.

For

garments.

For

For

ladies' lingerie

bindings to leg

attaching

attaching

attaching

attaching

ladies' lingerie

bindings to leg

lace

garments

lace to ladies' lingerie

lace

or

tube

in general.

to

ladies' lingerie

and

light knot

and

knit

openings

openings

bindings

underwear

underwear

of

men's

of

to

ladies' lingerie

and

and

very

.

on

general.

briefs,

men's

very light

light

knit

ladies

briefs,

and

underwear

underwear

pant

ladi

ies

es'

knit

063·31·09

063·31·10

063·34-01

063-34-03

063-34-05

063-34-08

063-34-09

063-38-01

063-38-02

4 yes 3,5

2

4

2

5

3

5

3

5

3

4

2

3 5

6

3

6

3

11/8"1

4,5

11/64"

6

11/4"1

13/64"

4,5

yes

yes

yes

yes

yes

19/64"1

yes 3

yes

yes

yes 5 yes

yes

11/64"

yes

6

yes

1114

"1

yes

12

15/32"

yes

12

15/32"

no

no

For

ladies' lingerie

For

ladies' lingerie

For

attachmg

still

a side

For

attaching

still

a side

For

attaching

a

side

still

For

attaching

briefs

and

em.

For

attachong

briefs and srmilar articles having a minimum circumference

em

.

For

attaching

Same

as

pen

side

o

and

knit

underwear

and

light

knit

wide

clastics

to

open.

wide

elastics

open.

wide

elastics

open.

wide

similar articles having a

wide

the

front

063-38·01,

of

the

gusset

the

to

the

to

the

preclosed ring·s

preclosed rings

gussets

but

for

attaching

of

men's

underwear

waist

waist

waist

of

minimum

of

to

men's

briefs.

on

of

of

elastic

general.

.

men's

broefs

or

of

men's

briefs

or

men's

briefs

or

to

the

waost

circumference

elasoc

to

the

waist

briefs.

also a binding strop

pants

pants

pants

of

of

on

men'

of

of

with

with

with

50

men's

50

the

s

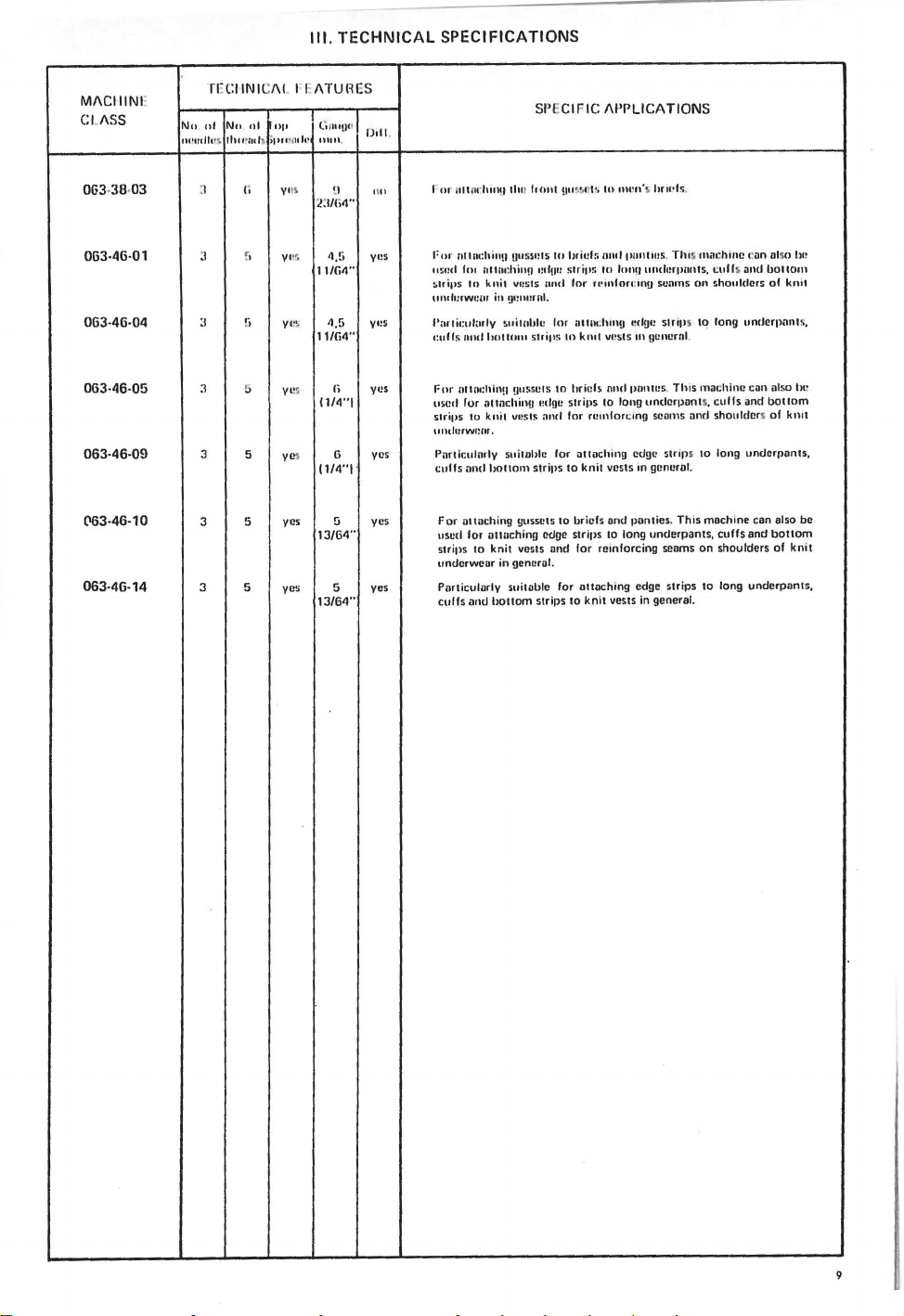

M/\CIIINI

CL/\SS

Ill. TECHNICAL SPECIFICATIONS

TE

CIINIC

/\1

ol

muh, ip

I L/\TUHES

op

ruiUIP

Gnuun

111111

Doll

SP

ECIFIC /\PPUCATIONS

.

·

No

of

Nu

IIPHIJIU!t

llu

063-38-03

063-46·01

063-46-04

05

063-46-

063·46-09

(163-46-10

063·46-14

3

3

3

3 5

3 5

(\

VIIS.

VII!.

!i

ro

VI

'!.

yt~s

5

5

ye

• G

yes

yes 5 yes

tl

2:1/(jl\"'

11,ti

11164''

11,5 yt!S

11/64"

f)

11/4"1

( 1/4"1 ·

G

13/64"

13/64"

l

yt!5

yes

yes

yes

lll

I~

ur

ntiiH:

hinu

u~ml

:arips In

undt:rwt!Uf

Pnnic:

c:uffs

F

nr

usml

slrips

t11ulurwnnr.

P;1rticutorly

cuHs

For

used for attnching edge

strips

underwear

Particularly suitallle for attnchong edge

cuff

uussms 10

fm n11u1:hh1!1

knit

v1:sts

in

umuunl.

ulmly

suilnhh: lor

nod

hultcun

nlln•:hhl!l

!IWiStHS to

for

au

aching mlge

to

knit

v1:sts ancl

suitable

and

bottom

nttnching gussets

to

knit vests

in

general.

s n

ncJ

bottom

mtur: srripr.

und

stri11

r.

111

slrips

for

for

striJ>S to

to

and

strips

hrit:fr.

nml

10

lonH

lor

n••nforemu

iUtiM:

hmo

kmt ves

ts

hriefs nne I

to

long

rctnfon.mg

nttoch

ing

knil

vests

llriefs ond

strips

to long

for

reinforcing scnms

to

knit

vests in general.

puntuts. Tlu

umfmpunts

senms

•~I!Jt!

slrrps to

111

gcncrnl

pnnws. Thts

undcrpon

scorns

edge

stnps to

1n

general.

panties

. Th1s mochi

underpants,

strips

s: mnr.

hmc

, c

uff

s

omd

on

shoulders

long

undcrpnnt~.

machin

e

u ,

cuffs and

and

shoulde

long

ne

cuffs

on

shoulders of knit

to

long

c·nn al

so h•:

bouom

of

knll

can

aloo ht•

bottom

rs

of

kmt

underpants,

can

also

and

bottom

underpants,

be

9

INTRODUCTION

INSTRUCTIONS:

_

INSTALLATION

_ USE ·

_

MAINTENANCE

FOR

AND

TIMING

l1

;~)

Positioning of

h!!ad

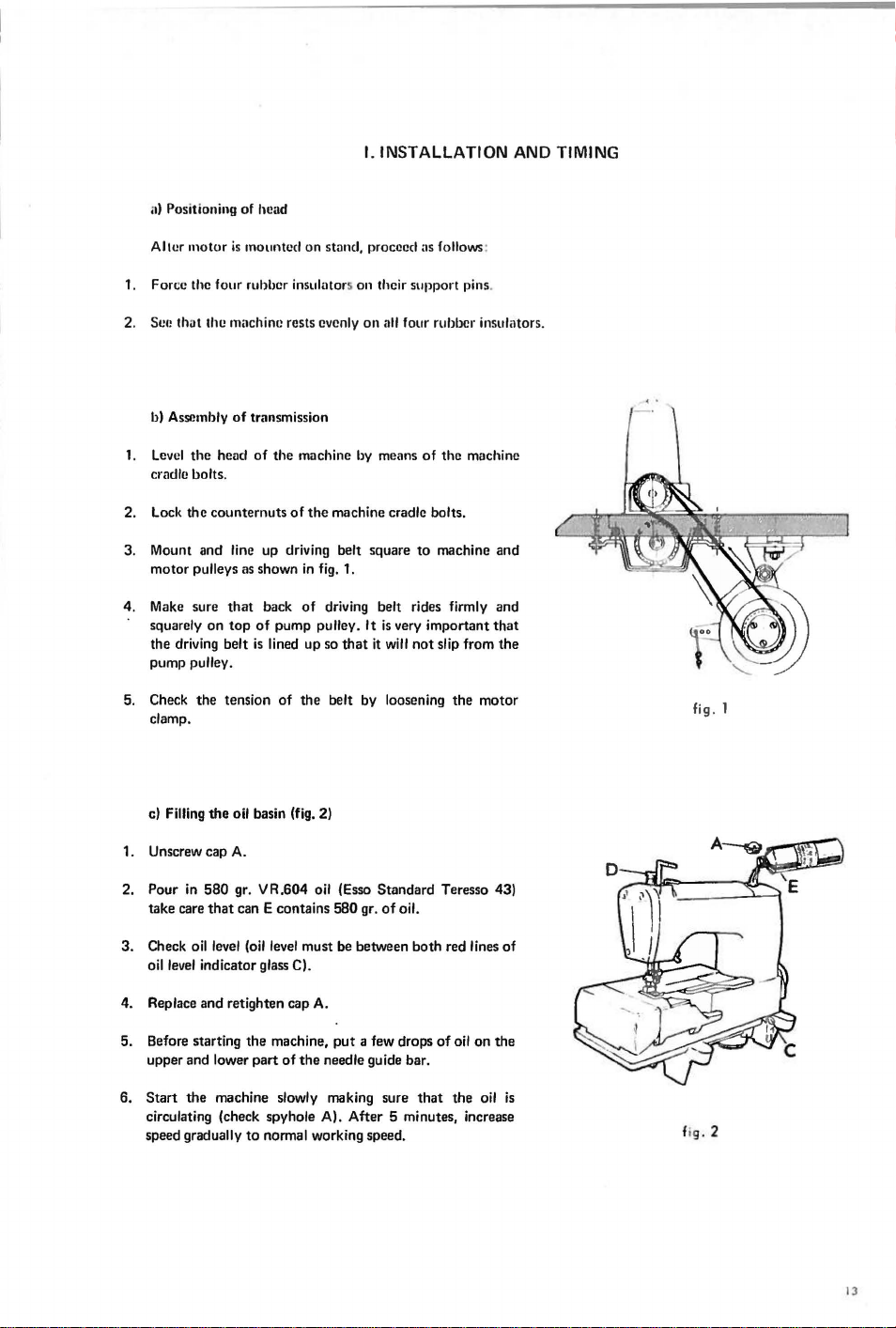

I.

INSTALLATION

AND TIMING

Alter motor

1. Force the four rubber

Sec~

2.

b) Assembly

1.

Level

is

mounted on stmul, proceed

insulntors on their support pins.

that the milchine rests evenly

of

transmission

the

head

of

the machine by means

on

all four rubber insulators .

cradle bolts.

of

the

2. Lock the counternuts

machine cradle bolts.

3. Mount and line up driving belt square

pulleys

as

shown

in

fig.

motor

4. Make sure

squarely

the driving belt

on

that

top

back

of

is

pump pulley. It

I ined up so

1.

of

driving belt rides firmly and

that

it

is

very important

will

pump pulley.

5. Check

the

tension

of

the belt by loosening the motor

clamp.

ilS

follows :

of

the machine

to

machine and

not

slip from

that

the

fig

. 1

Filling

the

c)

1.

Unscrew cap A.

2.

Pour in 580 gr. VR.604 oil (Esso Standard Teressa 43)

take care

Check oil level (oil level must be between both red lines

3.

oil basin (fig.

that

can E contains 580 gr.

2}

of

oil.

of

oil level indicator glass C).

4. Replace and retighten cap A.

5. Before starting the machine,

upper and lower

Start

6.

the

part

machine slowly making sure

circulating (check spyhole A).

speed

gradually

to

normal working speed.

put

of

the

needle guide bar.

a few drops

that

After

5 minutes, increase

of

oil

the oil

on

the

is

fig. 2

13

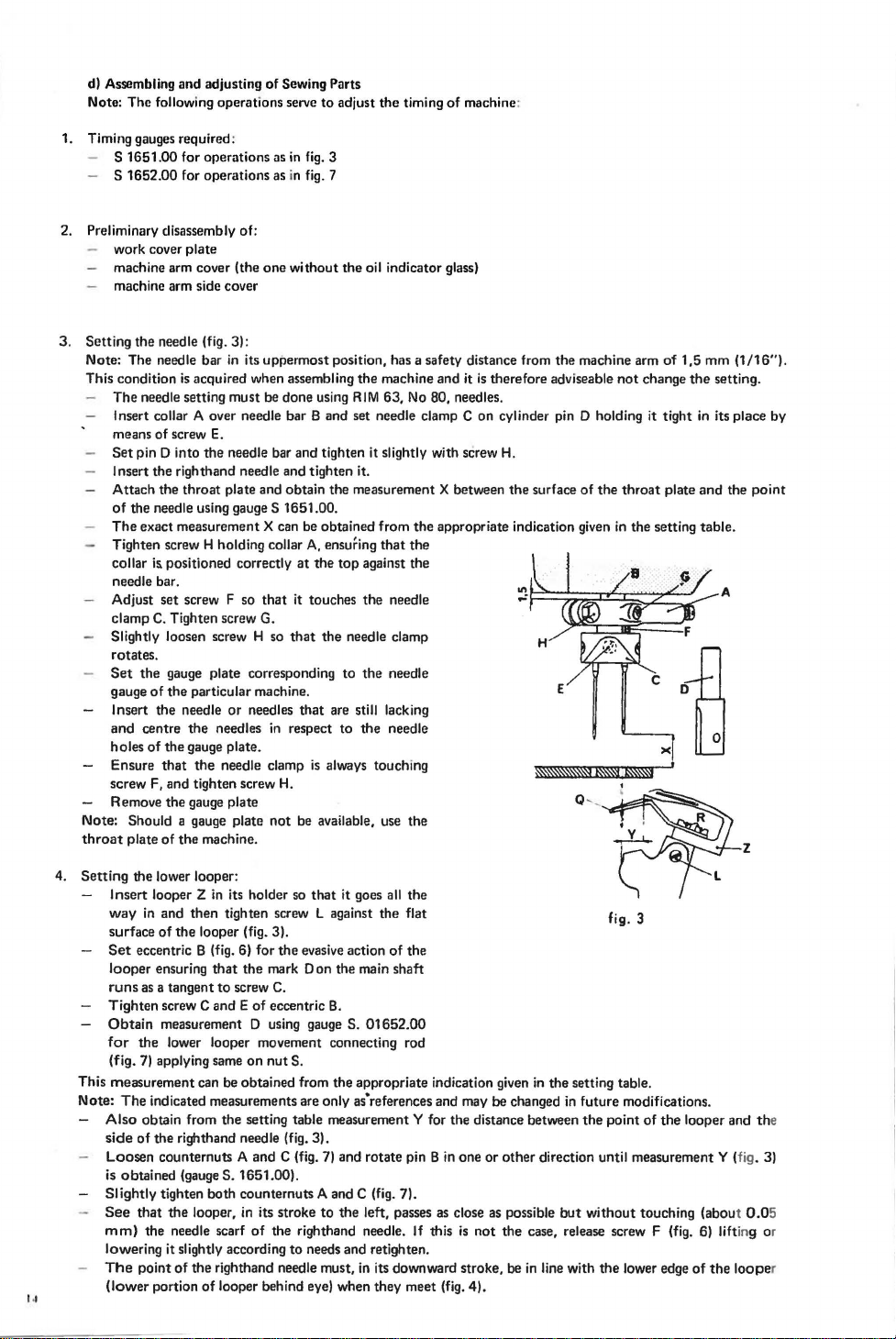

d) Assembling and adjusting

Note: The

1. Timing gauges required:

following operations serve

S 1651.00 for

S 1652.00 for operations as in fig. 7

operations

2. Preliminary disassembly of:

work cover plate

machine arm cover (the

machine arm side cover

3.

Setting

the

needle (fig . 3):

Note:

The needle

This condition

The

needle setting

Insert

means

Set

pin D into

Insert the righthand needle and tighten it.

Attach

of

the

The

exact measurement X can be obtained

Tighten screw H holding collar A, ensuring

collar

needle bar.

Adjust

clamp

Slightly loosen screw H so

rotates.

Set

the

gauge

Insert

and

centre

holes

of

Ensure

screw

Remove

Note:

Should a gauge plate

throat

plate

bar

in

its uppermost position, has a safety distance from

is

acquired when assembling

collar A over needle bar 8 and set needle clamp C on cylinder pin D holding it tight in its

of

screw

the

needle using

is.

positioned correctly

set

C.

Tighten screw

gauge plate corresponding

of

the

the

the

that

F, and tighten screw

the

of

must

E.

the

needle bar and tighten it slightly with screw H.

throat

plate and

gaugeS

screw F so

G.

particular machine.

needle

or

needles

the

needles

gauge plate.

the

needle clamp

gauge plate

the

machine.

of

Sewing Parts

as

in

fig. 3

one

without

be

done

using

obtain

1651.00.

at

the

that

it touches

that

that

in

respect

is

H.

not

be available, use

to

adjust

the

timing

the

oil indicator glass)

the

machine and it

RIM

63, No 80, needles.

the

measurement X between

from

the

that

against

the

needle

the

needle

the

needle

touch

the

the

ing

the

top

the

needle clamp

to

are still lacking

to

always

of

machine:

the

machine arm

is

therefore adviseable

the

surface

of

the

appropriate indication given

E

not

change

throat

in

the setting

of

plate

1,5

the

mm

setting

and

table.

A

(1/16").

.

place

the

point

by

4.

Setting

the lower looper:

Insert

1.1

looper Z in its holder so

way

in

and

surface

of

Set

eccentric 8 (fig. 6) for

looper

ensuring

runs

as a tangent

Tighten

screw C and E

Obtain

measurement D using gauge S.

for

the

(fig. 7) applying same

This

measurement

Note:

Also

side

Loosen

is

Slightly

See

mm)

lowering

The

(lower

lower looper movement connecting rod

The

indicated measurements are only as·references and may

obtain from

of

the righthand needle (fig. 3).

counternuts

obtained

tighten

that

the

the

it

point

portion

then

tighten screw L against the flat

the

looper (fig. 3).

that

the

to

screw C.

of

on

can be obtained from the appropriate indication given

the

setting table measurement Y for the distance between

A and C (fig. 7) and

(gaugeS. 1651.00).

both

counternuts

looper,

needle scarf

slightly according

of

in

of

the

righthand needle must, in its downward stroke,

of

looper behind eye) when

that

it goes all

the

evasive action

mark

Don

the main

eccentric

nutS

its stroke

the

B.

.

A and C (fig. 7).

to

the

righthand needle. If this

to

needs and retighten.

the

of

the

shaft

01652.00

rotate

pin B

left, passes

they

meet

be

in

one

or

other

as

close as possible

is

not

the

(fig.

be

4).

fig. 3

in

the setting table.

changed

in

future

modifications.

the

point

direction until measurement Y (fig. 3)

but

line with

without

the

lower edge

case, release screw F (fig. 6) lifting or

in

of

the

looper and the

touching (about

of

the

0.0

loope

5

r

It

thu r.troku

rod 0 (li!f. 7) must bu looscnml mnl, holdin!J

tin:

p1

Ofll'l'

ot

tht: loopur is rutunlud

position

is

obt<tincd. •

fig

. 4

or

utlvanccd,

lxlth

thu

cct:tmtrit: N

innt:r st:ttin!J

in

plan

r.cn:ws

M ul

:, rotall: tlu: pulh:y

ccwntric N of

t

fig

. 5

of

r.nnncctin!l

the

mm:hinn till

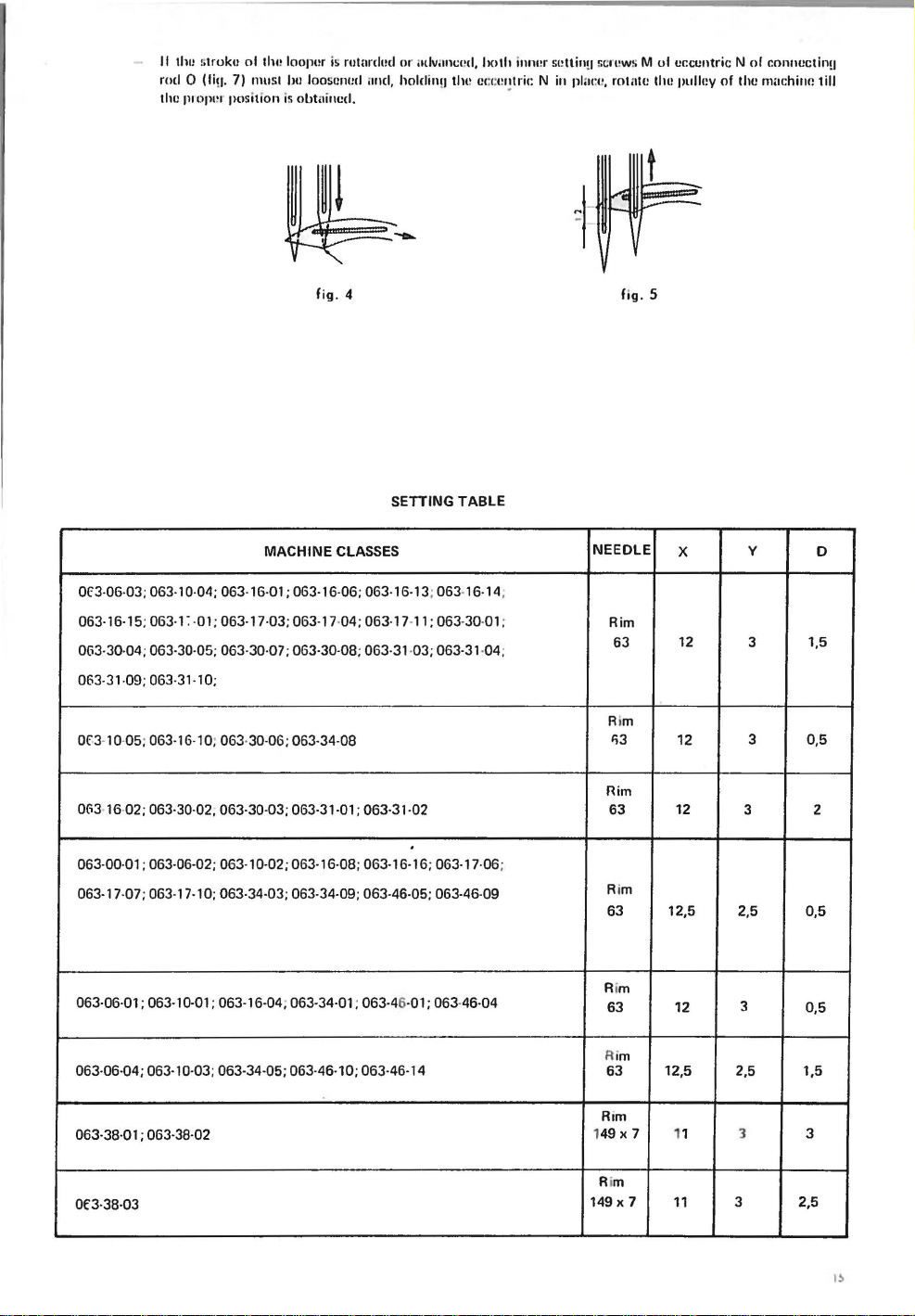

SETTING

MACHINE CLASSES

TABLE

0(3-06·03; 063·10-04; 063·16·01; 063·16-06; 063-16·13 ; 063-16·14,

063-16·15; 063·1: -01; 063-17-03; 063-17-04; 063-17-11; 063-

30·01

063-30·04; 063-30-05; 063·30·07 ; 063-30-08; 063-31 -03; 063-31-04;

063-31·09; 063-31-10;

Of3·1 0·05 ; 063·16-1 0; 063-30-06; 063-34-08

063 16·02; 063·30-02; 063-30-03; 063-31-01; 063-31-02

063-00·01; 063·06-02; 063-10-02; 063-16-08; 063-16-16; 063·17·06;

063-17-07; 063·17-1

0;

063-34-03; 063-34-09; 063-46-05; 063-46-09

063-06·01; 063·10-01; 063-16-04 ; 063-34-01; 063-4 6-01; 063·46-04

NEEDLE

:

Rim

63

X

12 3

y

D

1,5

Rim

1\3

12

3

0,5

Rim

63

12

3 2

Rim

63 12,5

2,5

0,5

Rim

63 12

3

0,5

R

063-06-04; 063·1 0·03; 063-34-05 ; 063-46-10; 063-46-14

im

63

Rim

063-38·01: 063·38·02

149 K 7 11 l 3

Rim

Of3·38·03

149 X 7

12,5

11

2,5

1,5

3 2,5

1

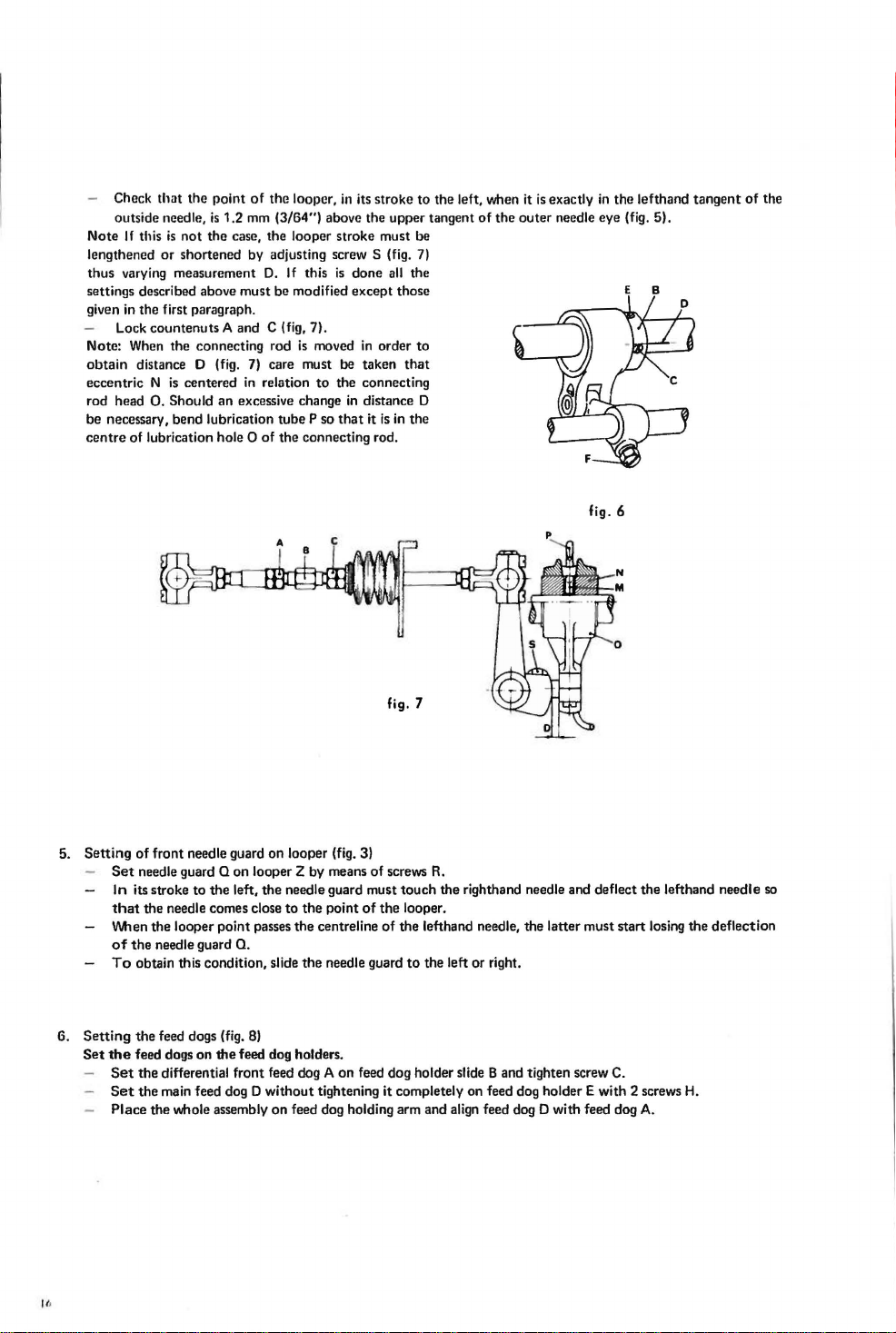

~

Check

that

the

point

of

the

looper,

in

outside needle,

Note

If

this

lengthened

thus

varying measurement

settings described above

given in the first paragraph.

Lock

countenuts

Note: When the connecting rod is moved

obtain

distance 0 (fig.

eccentric N is centered

rod

head

0.

be

necessary, bend lubrication

centre

of lubrication hole 0

is

not

or

shortened

Should

is

1.2 mm

(3/64")

the

case,

the

by

adjusting screw S (fig. 7)

D.

must

be modified except those

A and C (fig, 7) .

7)

care must be taken

in

relation

an

excessive change

tube

of

the

above

looper stroke must be

If this

is

to

the

P so

that

connecting rod.

its

stroke

the

upper tangent of

done

all

in

order

connecting

in

distance D

it

is

in

to

the left, when it

the

to

that

the

the

is

exactly

outer

needle eye (fig. 5).

in

fig . 6

the

E B

lefthand

tangent

of

the

Setting

of

5.

6.

front needle guard

Set

needle guard Q

In

its stroke

that

the

needle comes close

IMlen

the

looper

of

the

needle guard

To

obtain this condition, slide

Setting

the

feed dogs (fig. 8)

Set

the

feed dogs on

Set

the

differenti

Set

the

main feed dog D

Place

the

whole assembly

to

the

on

looper (fig. 3)

on

looper Z by means of screws

left,

the

needle guard must

to

the

point

point

passes

the

centreline

0.

the

needle guard

the

feed dog holders.

al

front feed dog A

without

on

on

tightening it completely

feed dog holding arm and align feed dog D with feed dog A.

R.

touch

the righthand needle and deflect

of

the

looper.

of

the

lefthand needle,

to

the left or right.

feed dog holder slide B and tighten screw C.

on

the

latter must

feed dog holder E with 2 screws

start

the

lefthand needle

losing

the

H.

so

deflection

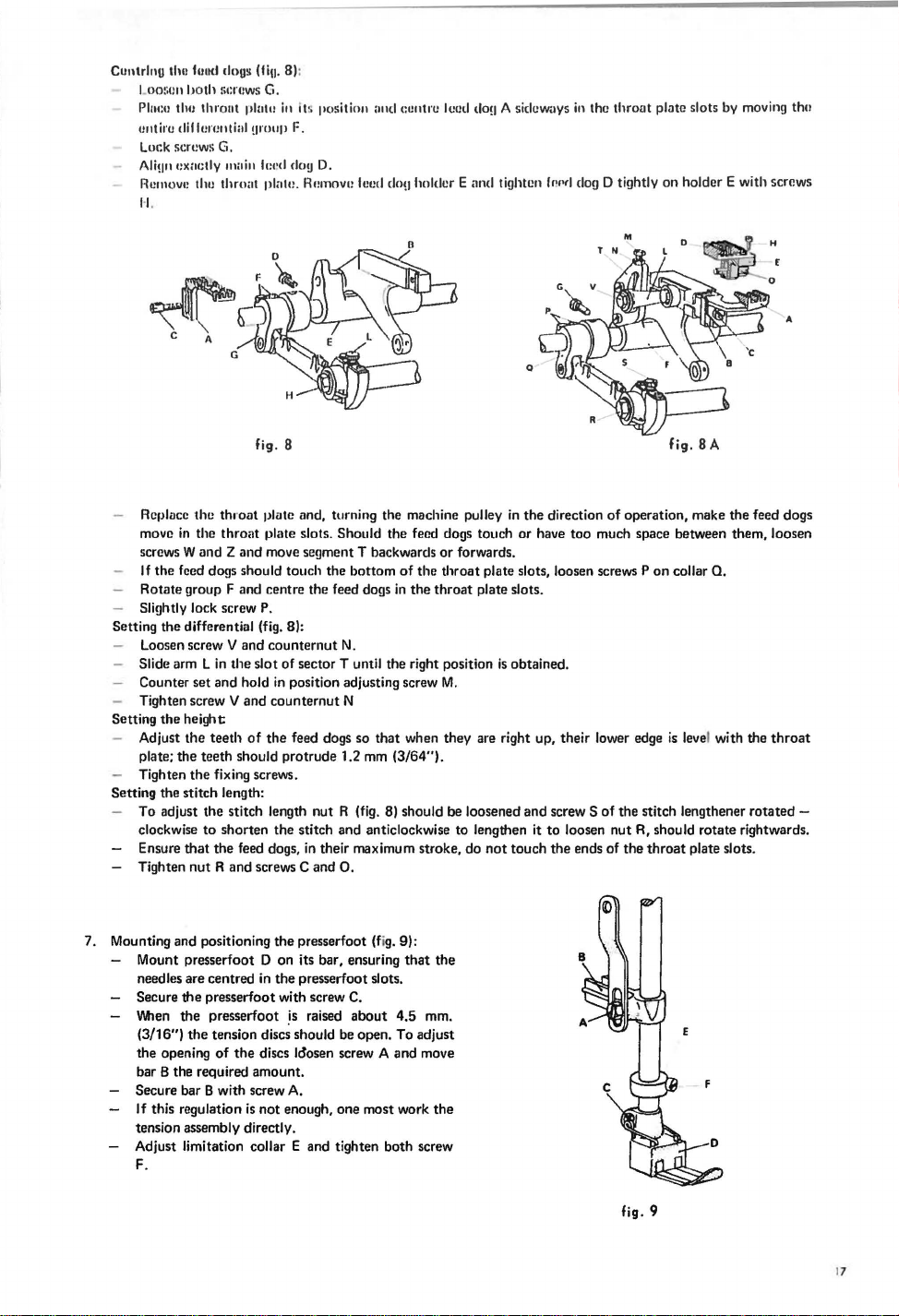

Cuntrlnu tim lund dous (liu. 8):

Loo:;un

both

:;~:mws

G.

Plm:u

tim throut plulll

tmtiru dilltmmtial

Lock scn:ws

Ali!JII

Rmnovu thu throat plait:. Rmnovt: lt:cd

G.

t:x:u:tly maiu h:t'tl

!JI'tlllfl

i11 it::

F.

clo!J

H.

positinu

D.

aucl

t:tmtrc Iced

do!J

holder E nnd tighten

do!J

A sidew.1ys

in

the throat plate slots by moving thu

lr:Prl

dog D tightly on holder E with screws

0

A

fig. 8

Rc(Jiacc

the

thr

oat

move

in

the

throat

W and Z and move segment T backwards

screws

If

the

feed dogs should touch

Rotate group F and centre the feed dogs

Slightly lock screw P.

Setting

the

differential (fig. 8):

Loosen screw V and

Slide arm L in

Counter

Tighten screw V

Setting

the

Adjust

plate;

Tighten

Setting the stitch length:

To adjust

clockwise

Ensure

Tighten

7. Mounting and positioning

Mount presserfoot D on its

needles are centred in

Secure

Wlen

(3/16")

the

opening

bar B the required amount.

Secure

If this regulation

tension assembly directly.

Adjust limitation

the

slot

set

and hold

height

the

the

that

the

the

the

barB

and

teeth

of

teeth should protrude 1.2

the

fixing screws.

the

stitch length

to

shorten

the

feed dogs,

nut

R and screws C and

presserfoot with screw

presserfoot

tension discs should be open. To adjust

of

the

with screw A.

is

not

collar E and tighten both screw

F.

fig.

BA

plate and, turning the machine pulley in

plate slots. Should the feed dogs touch or have too much space between them, loosen

or

forwards.

the

bottom

of

the

throat

in

the

throat

counternut

of sector T until the right position

in

counternut

the

the

N.

position adjusting screw

M.

N

feed dogs so

nut

stitch and anticlockwise to lengthen it

in

that

when they are right up, their lower edge is level with the

mm

(3/64").

R (fig.

8)

should be loosened and

their maximum stroke,

do

the

direction of operation, make

plate slots, loosen screws P

plate slots.

is

obtained.

screwS

of

the stitch lengthener

loosen

nut

ends of

the

not

touch

to

the

on

collar

R, should

throat

the

0.

rotate

rightwards.

plate slots.

feed dogs

throat

rotated-

0.

the

presserfoot (fi

bar, ensuring

the

presserfoot slots.

g.

9):

that

the

C.

!s

raised

about

4.5 mm.

discs ldosen screw A and move

enough, one most work

the

fig. 9

17

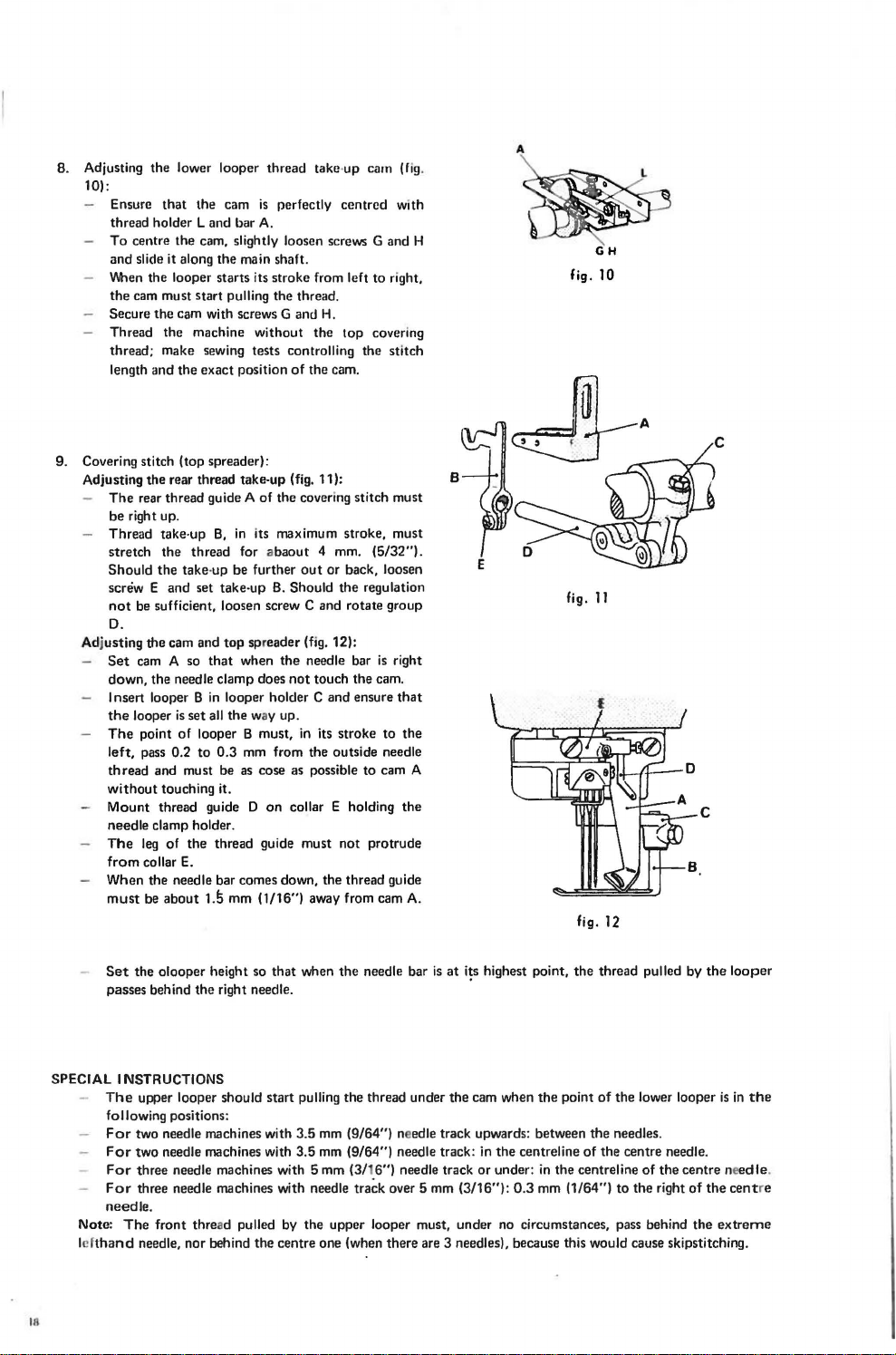

8. Adjusting the lower looper thread take-

10):

Ensure that the cam

thread holder

To

centre the cam, slightly loosen screws G and H

and slide it along the main shaft .

When the looper starts its stroke from left to right,

the cam must start pulling the thread.

Secure the cam with screws G and H.

Thread the machine without the top covering

thread; make sewing tests controlling the stitch

length and the exact position

Land

is

perfectly centred with

bar A.

of

the cam.

9. Covering stitch (top spreader):

Adjusting the rear thread take-up (fig.

The

rear thread guide A of the coveri

be right up .

Thread take-up

stretch the thread for abaout

Should the take-up be further

screw E and set take-up B. Should the regulation

not

be sufficient, loosen screw C and rotate group

B,

in

its maximum stroke, must

11

4 mm. (5/32").

out

or back, loosen

D.

Adjusting the cam and

Set

cam A so

down,

the needle clamp does

Insert looper B

the

looper

The

point of looper B must,

left,

pass 0.2

thread

and must be

without

touching it.

Mount

thread guide D

needle clamp holder.

The

leg

of the thread guide must

from

collar

When the needle bar comes down, the thread guide

must

be about

top

spreader (fig. 12):

that

when the needle bar

not

in

looper holder C and ensure

is

set all the way up.

in

to

0.3

mm

from the outside needle

as

case as possible to cam A

on

collar E holding the

E.

1.S

mm (1/16") away from cam A.

touch the cam.

its stroke to the

up

cam (fig.

):

ng

stitch must

not

protrude

is

right

that

A

GH

fig. 10

fig.

II

c

fig. 12

Set

the olooper height so that when

passes behind the right needle.

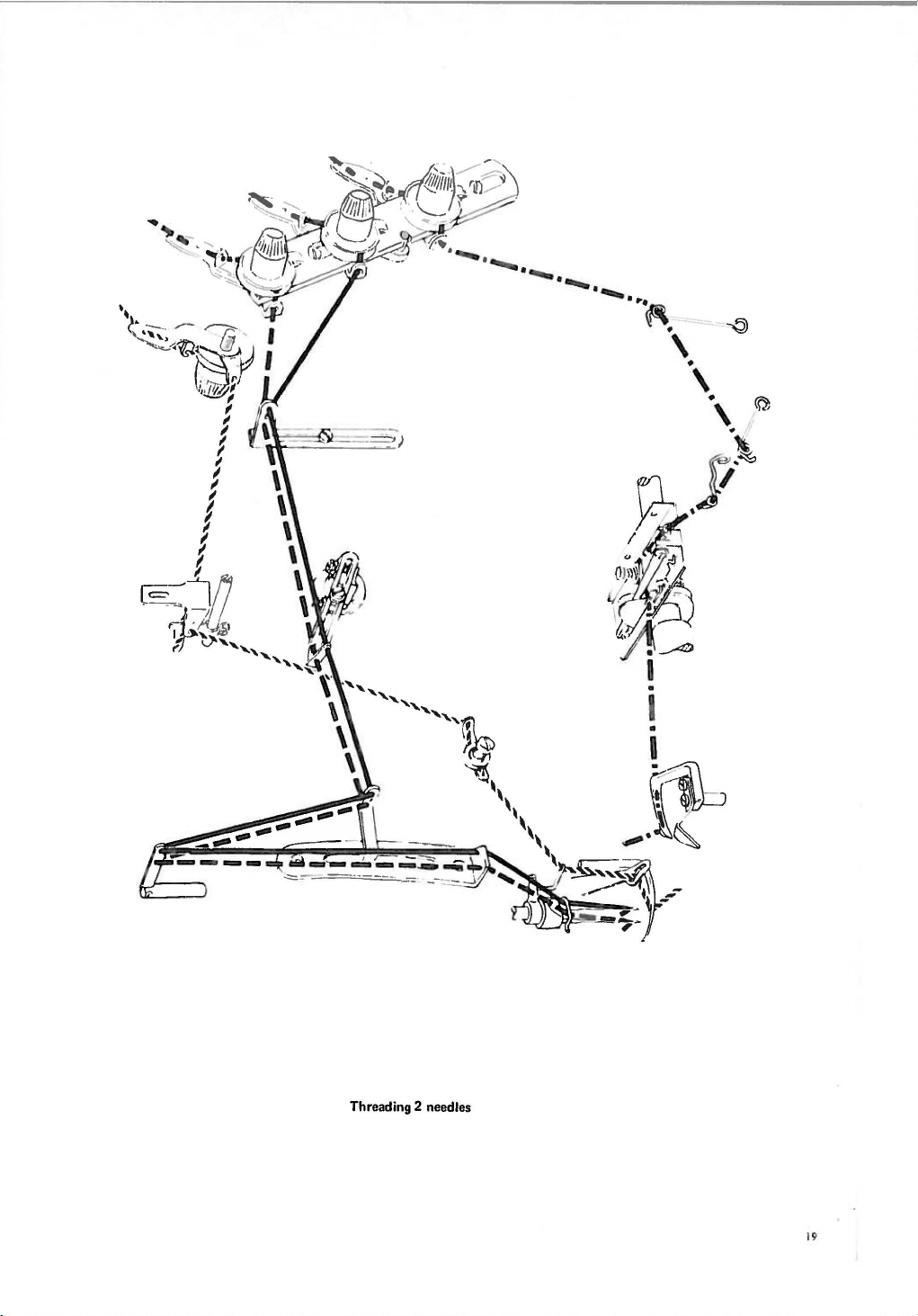

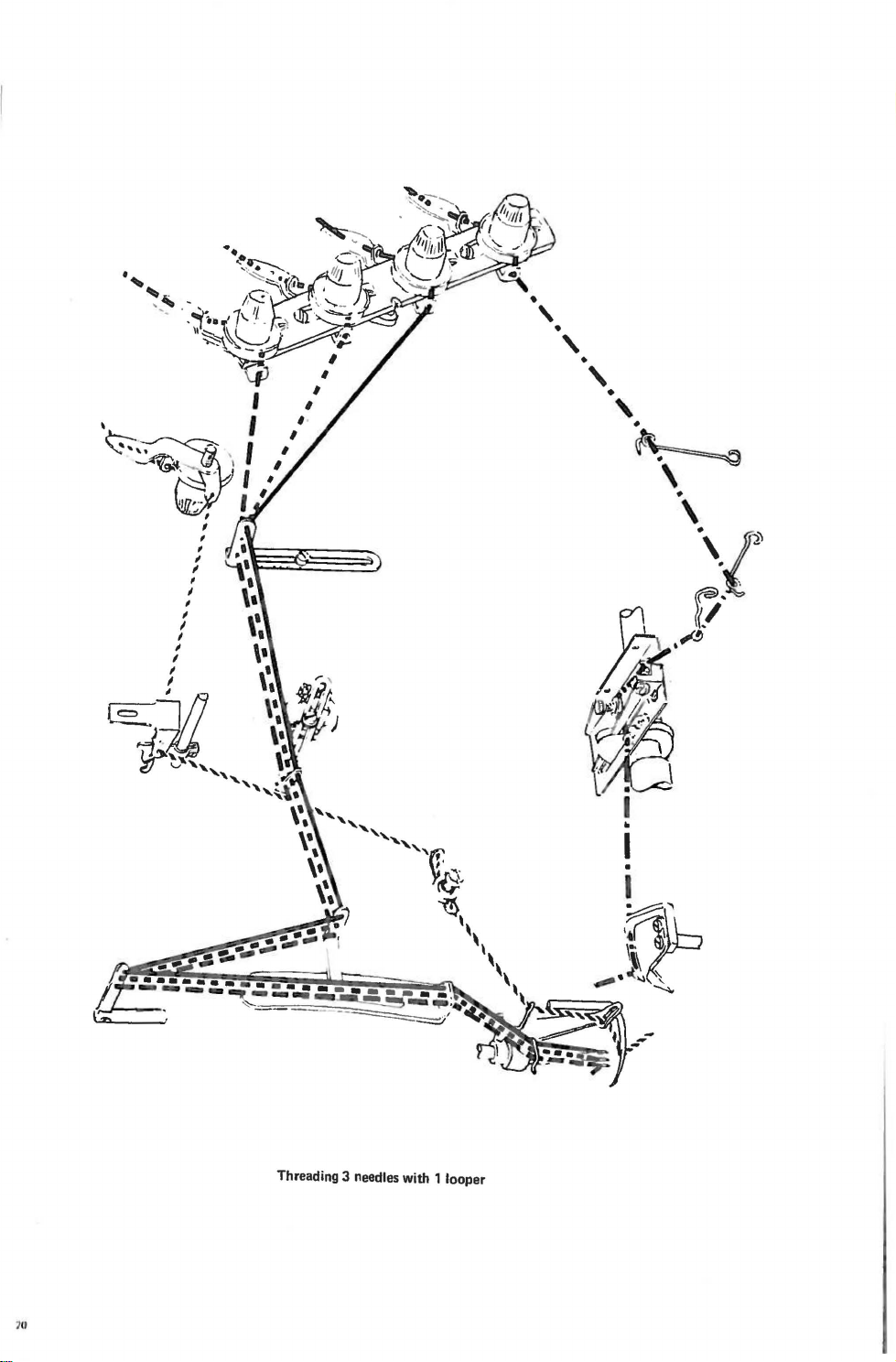

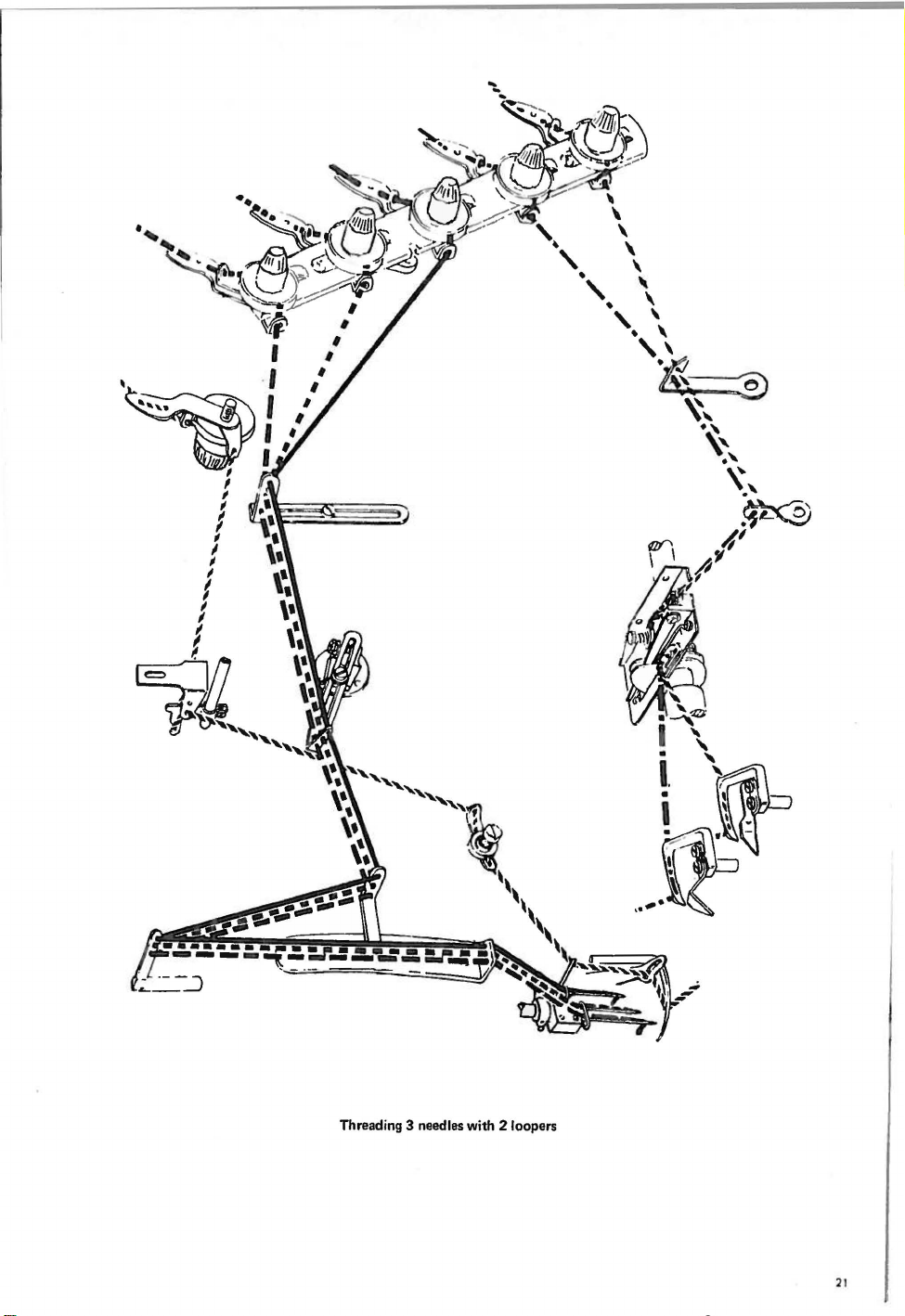

SPECIAL INSTRUCTIONS

The

upper looper should start pulling the thread under the cam when the point

following positions:

For

two needle machines with 3.5 mm (9/64") needle track upwards: between

For

two needle machines with 3.5

For

three needle machines with 5 mm

For

three needle machines with needle

needle.

Note:

The

front thread pulled by the upper looper must, under no circumstances, pass behind the

lch

hand

needle, nor behind the centre one (when there are 3 needles), because this would cause skipstitching.

In

the

needle bar

mm

(9/64") needle track: in

(3/

6") needle track or under :

tra~k

over 5 mm (3/16"): 0.3 mm (1/64") to the right

is

at

i~s

highest point,

the

centreline

the

the

of

in

the centreline

thread pulled by

of

the lower looper

needles.

the centre needle.

of

the

the

is

centre nee

of

the

extreme

looper

in

the

dle

cent

re

.

Threading 2 needles

19

,

I

I

,

I

Threading 3 needles with 1 looper

lO

..

....

Threading 3 needles with 21oopers

'

.--"~

"

I \

. '

i.

"lt

Iff\:

'

, . .,.

21

b) Changing the needle:

1.

Turn

off the motor.

2. Depress the

Take

3.

4.

loosen

5. Remove the needle.

6. Insert the new needle.

7.

The

8. Using the tweezers

9.

Tighten the needle holding screw taking care

Do

10.

motor

pedal to ensure

the needle to its highest point.

the needle holding screw by

needle scarf for the passage of the looper must be towards

not

exert too much pressure when tightening

supplied, ensure

that

the machine

1/2

a turn with screwdriver 990182·0·10 .

that

the needle rests against

not

is

completely stopped.

to move

the

the

screw.

the

rear of the machine.

the

bottom

needle.

of

the hole.

c) Adjusting

1.

Check

2.

The

3.

To

increase or lessen

d) Adjusting the tensions:

Tighten

1.

lower looper

the

presserfoot pressure:

the correct setting

needles must pass through che centre

othe

the tensions sufficiently to give a regular stitch formation.

is

left entirely loose, and only

of

the

pressure

presserfoot.

of

the

slots

in

the

presserfoot.

of

the presserfoot, turn knob D (fig. 2).

the

small tension,

In

on

the

take-up cam plate,

most cases,

the

thread tension for

is

tightened as requi

the

red

.

e)

1.

loosen

2.

Rotate

it.

Retighten

3.

Variation

of

stitch length (fig. 8):

nut

R using the proper spanner.

screw S

of

the stitch lengthener; rotating it clockwise

nut

R.

to

shorten

the

stitch and anticlockwise

to

lengthen

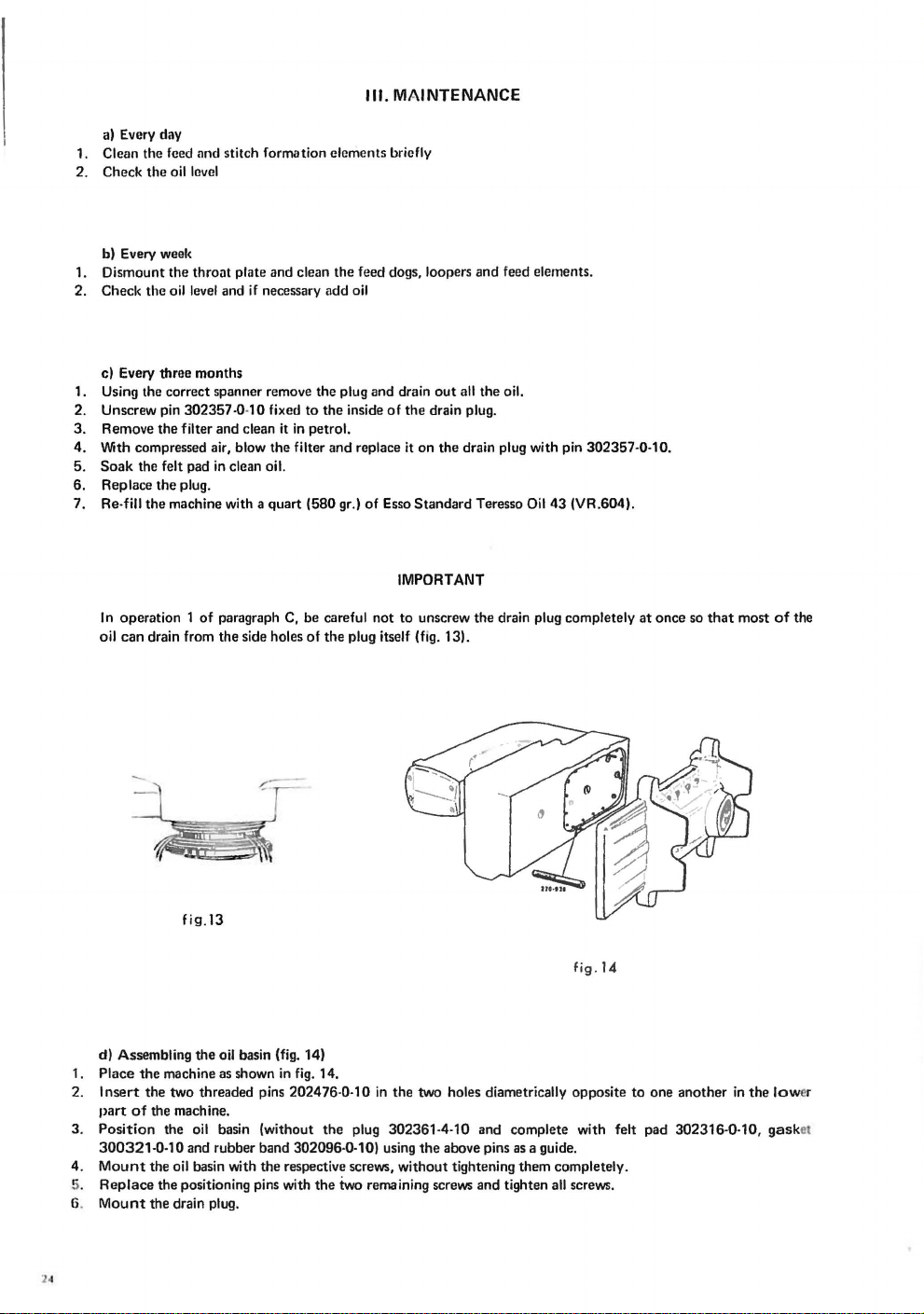

f)

lrruuularitios

due

to

improper handlinu

of

machine

N.

1

2

3

4

IRr!EGULARITY

Jrrenulnr stitc:h

Feed and Iabrie slipping Insufficient prusscrfoot pressure

sideways

Skipstitching Lower

Thread break age Tensions

Tensions hadly adjusted

Thrc;ul

takc·ups haclly adjusted

Incorrect threading

not

Yarns

Feed dogs badly adjusted in height and slant

Differential

Front

Needle badly positioned

Lower

Yarn irregularly

gauged

hadly adjusted

or

upper looper badly adjusted in respect

needle guard

looper take-up cam badly adjusted

too

taut

too

wound

PROBABLE CAUSES

far away

on

cone

from

needles

to

needle

Needle breakage

5

Puncturing

6

of

fabric

Oil leakage

7

8

Lack of I ubrication Oil level

Needle

bent

Needle badly mounted

Blunt needle

Needle gauge

Needle with unsuitable

- Screws joining base and

- Oil recovery gasket in oil pump,

- Side cover

V-

belt

-

Lubrication

not

on

machine arm

too

low

incorrectly

pump

suitable for

point

pump

not

mounted

filter clogged

throat

bot

not

tight

plate

tight

centred

enough

23

a)

Every day

1. Clean the feed

2. Check the

oil

Ill. MAINTENANCE

and stitch formation clements briefly

level

b) Every

1. Dismount the throat plate and clean the feed dogs, loopers and feed elements.

2. Check the oil

c) Every three months

1.

Using the correct spanner remove the plug and drain

2. Unscrew pin

3. Remove the filter and clean it

4. With compressed air, blow the filter and replace it on the drain plug with pin 302357-0-10.

5. Soak the felt pad

6. Replace the plug.

Re-fill the machine with a quart (580 gr.) of Esso Standard Teressa Oil 43 (VR.604).

7.

In

oil can drain from the side holes of the plug itself (fi

weel<

level

and

if

necessary add oil

302357-0·10 fixed

in

clean oil.

operation 1 of paragraph

to

the inside

in

petrol.

C,

be careful not

out

all

the oil.

of

the drain plug.

IMPORTANT

to

unscrew the drain plug completely at once so

g.

13).

that

most

of

the

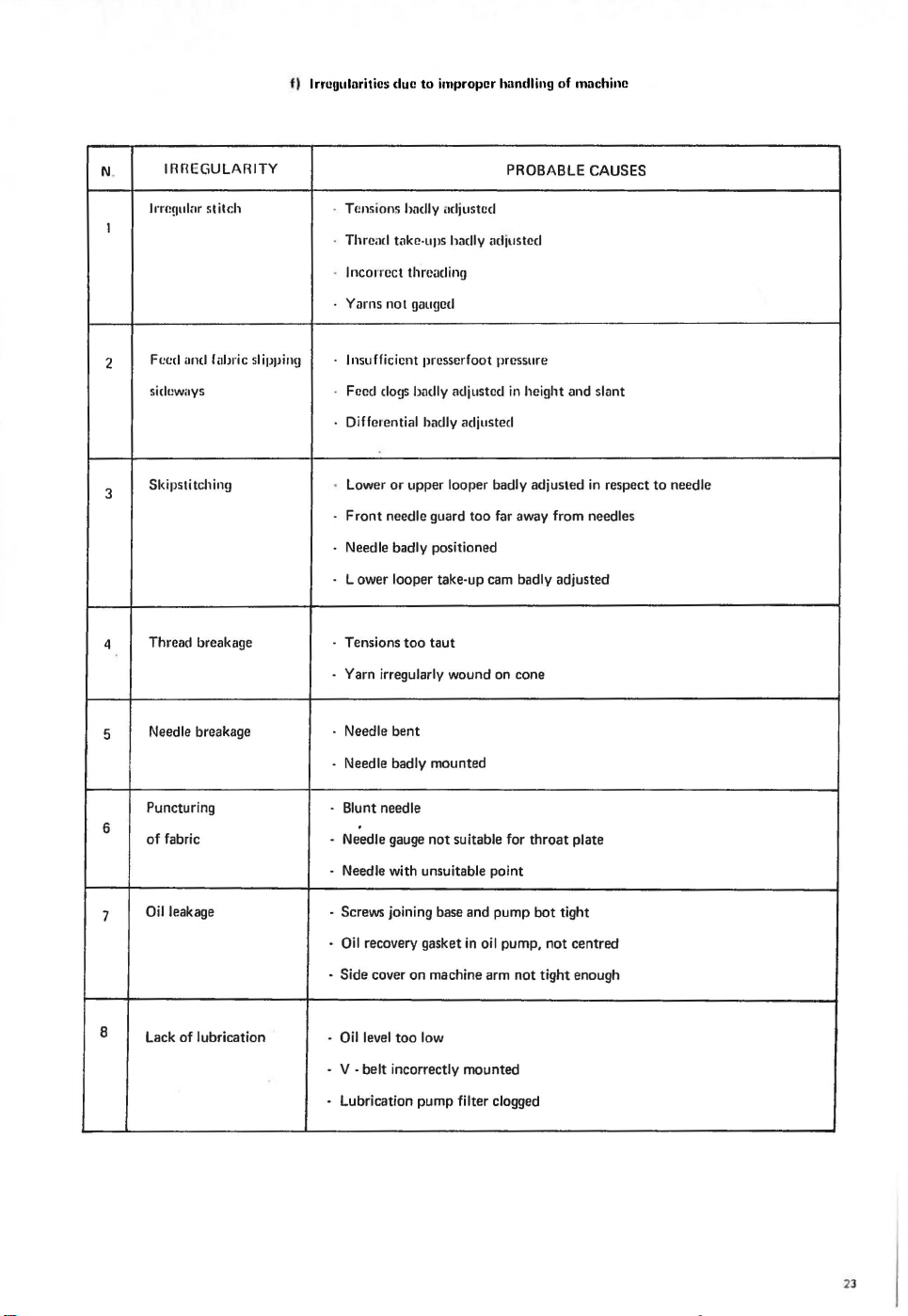

fig.13

fig.

14

d) Assembling the

1. Place

2.

3.

4.

5. Replace the positioning pins with the

6.

the

machine

Insert

the two threaded pins 202476-0-10

part

of

the machine.

Position

300321-0-10 and rubber band 302096-0-10) using

Mount

the oil basin with the respective screws, without tightening them completely.

Mount

the drain plug.

oil

basin (fig. 14)

as

shown

in

fig.

14.

in

the two holes diametrically opposite

the oil basin (without the plug 302361-4-10 and complete with felt pad 302316-0·10,

two

the

above pins

remaining screws and tighten

as

a guide.

all

screws.

to

one another

in

the

low

er

gask

et

SPARE

PARTS

CATALOGUE

2S

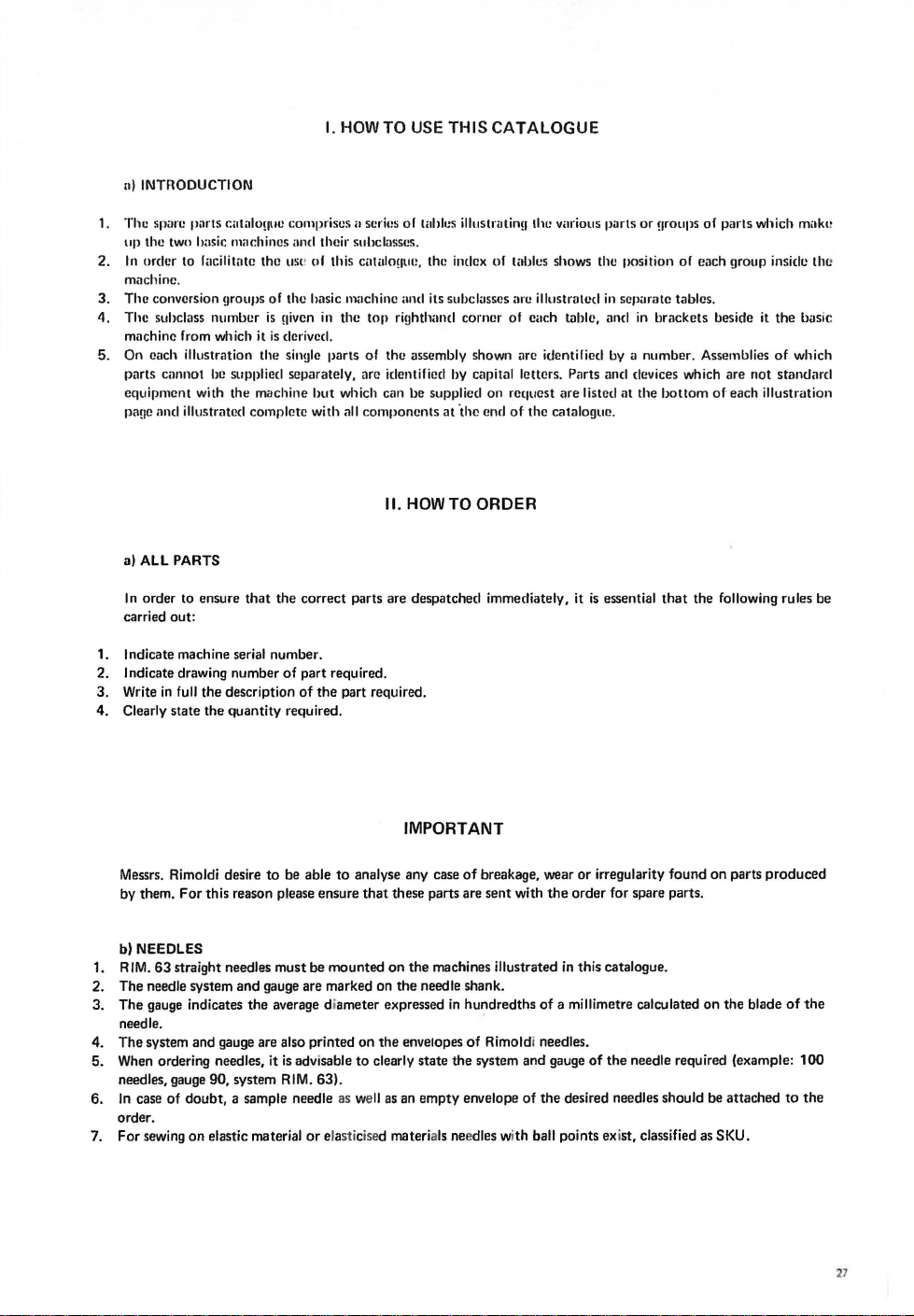

I. HOWTO

11)

INTRODUCTION

1.

The

spare pnrts catalo!lue comprises a series of tables illustratin!l the various parts

up

the two hasic machines and their subclasses.

2.

In

order to facilitate the us!'

machine.

3.

The

conversion !lroups of the hasic machine and its subclasses

4. The subclass

machine from which it

5.

On each illustration the single parts of the assembly shown arc identified by a number. Assemblies

parts cannot he SliPIJiied separately, are identified hy capital letters. Parts and devices which are not

equipment with the machine

page and illustrated

a) ALL PARTS

In

order to ensure

carried

1.

Indicate machine serial number.

Indicate drawing number

2.

3.

Write

Clearly state the

4.

number

complete with all

:

the

that

description

quantity

out

in

full

uf this

is

!liven in the

is

derived.

hut

the

correct

of

part

of

the

required.

which can

parts are despatched immediately, it

required.

part required.

USE

THIS CATALOGUE

cataiO!IUU,

top

components

the index

righthand corner of each table, and

be

supplied on request are listed

II.

HOW

uf

at 'the end

TO

ORDER

wbles shows tlw position

aw

illustrated

of

the catalogue.

or

in

separate tables.

in

at

the

is

essential

nroups

of

of

each group inside the

brackets beside it

bottom

that

the following rules be

parts which maku

the

basic

of

which

standard

of

each illustration

IMPORTANT

Messrs. Rimoldi desire

by them.

b)

1. RIM.

2. The needle system and gauge are marked on

The

3.

needle.

The

4.

5.

When ordering needles,

needles, gauge

6.

In

order

For

7.

For

this reason please ensure

NEEDLES

63

straight needles

gauge indicates

system and gauge are also printed on

90,

case

of

doubt,

.

sewing

on

elastic material

to

be able

to

analyse any case

must

be

mounted

the

average diameter expressed

it

is

advisable

system RIM.

a sample needle as we

to

63).

or

elasticised materia

that

these parts are

on

the

the

the

envelopes

clearly state

ll

as

an

of

breakage, wear

sent

with

machines illustrated in this catalogue.

needle shank.

in

hundredths

of

Rimoldi needles.

the

system and gauge

empty

envelope

ls

needles wi

th

or

irregularity

the

order

for spare parts.

of

a millimetre calculated

of

the

of

the

desired needles should be

ball points exi

st,

needle required {example:

found

on

parts

on

the

attached

classified as SKU.

produced

blade

of

to

the

100

the

27

INDEX

OF

TABLES

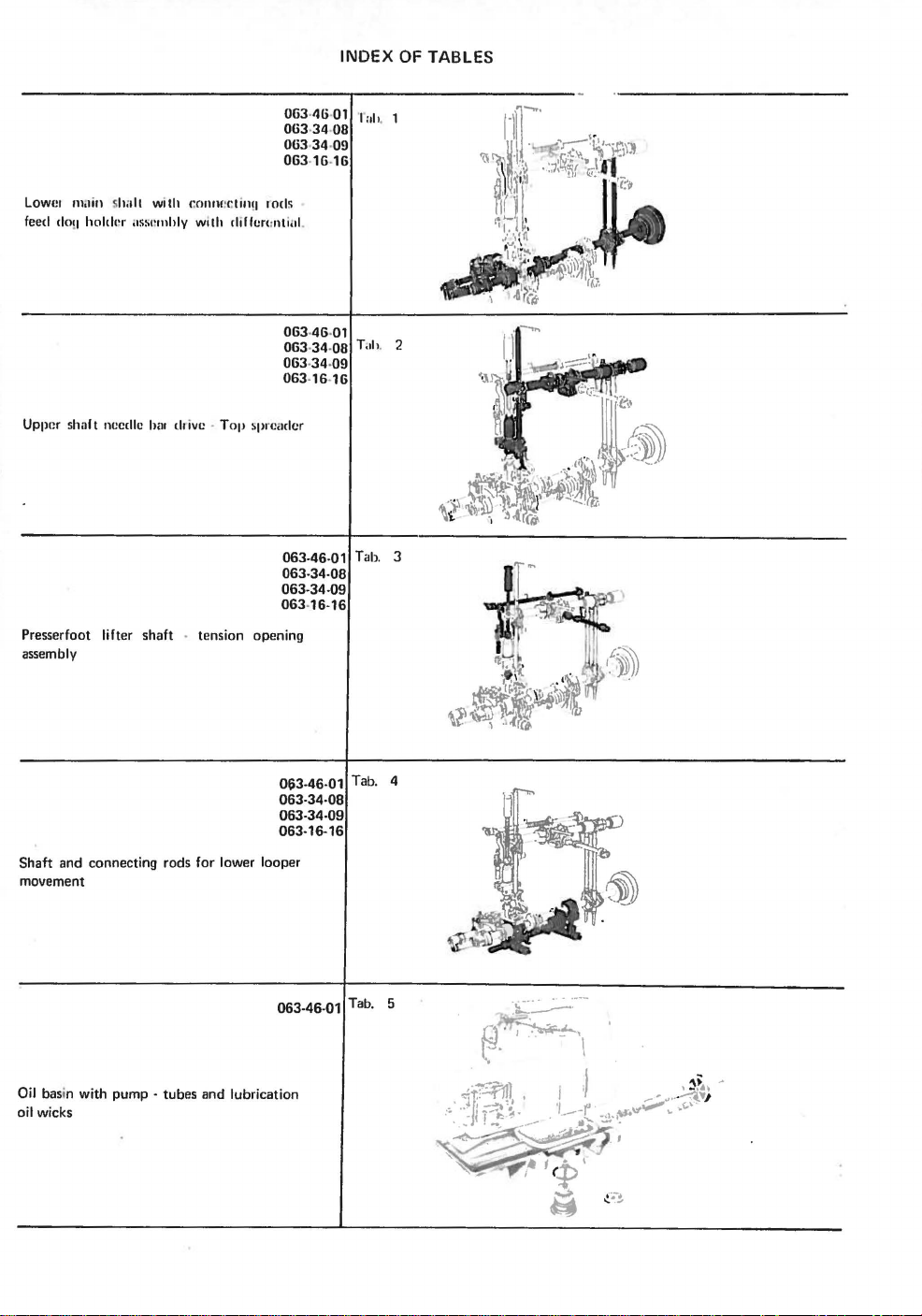

Lowm main s

feed

ciO

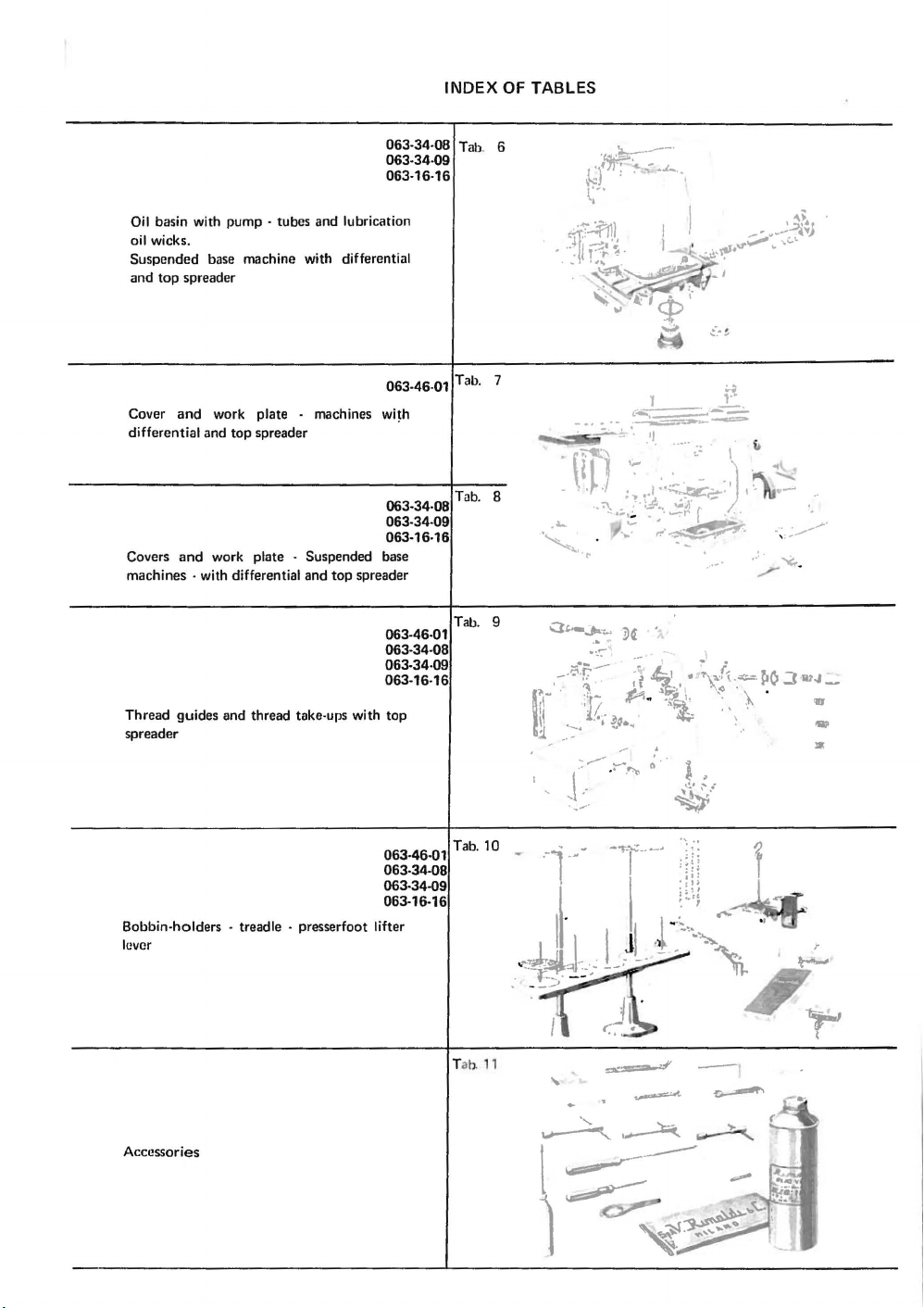

Uppur shaft needle

Presserfoot lifter

assembly

halt

!J holcll'r

with r.nnrlf'r.tinu rods

iiSSll

rnhly with

har

shaft

dr

ive ·

· tension

!lifhm

Top

063-46·01

063-34-08

063-34

063-16-16

:ntiill.

063-46

34-08

063063-34063-16·16

sprea

der

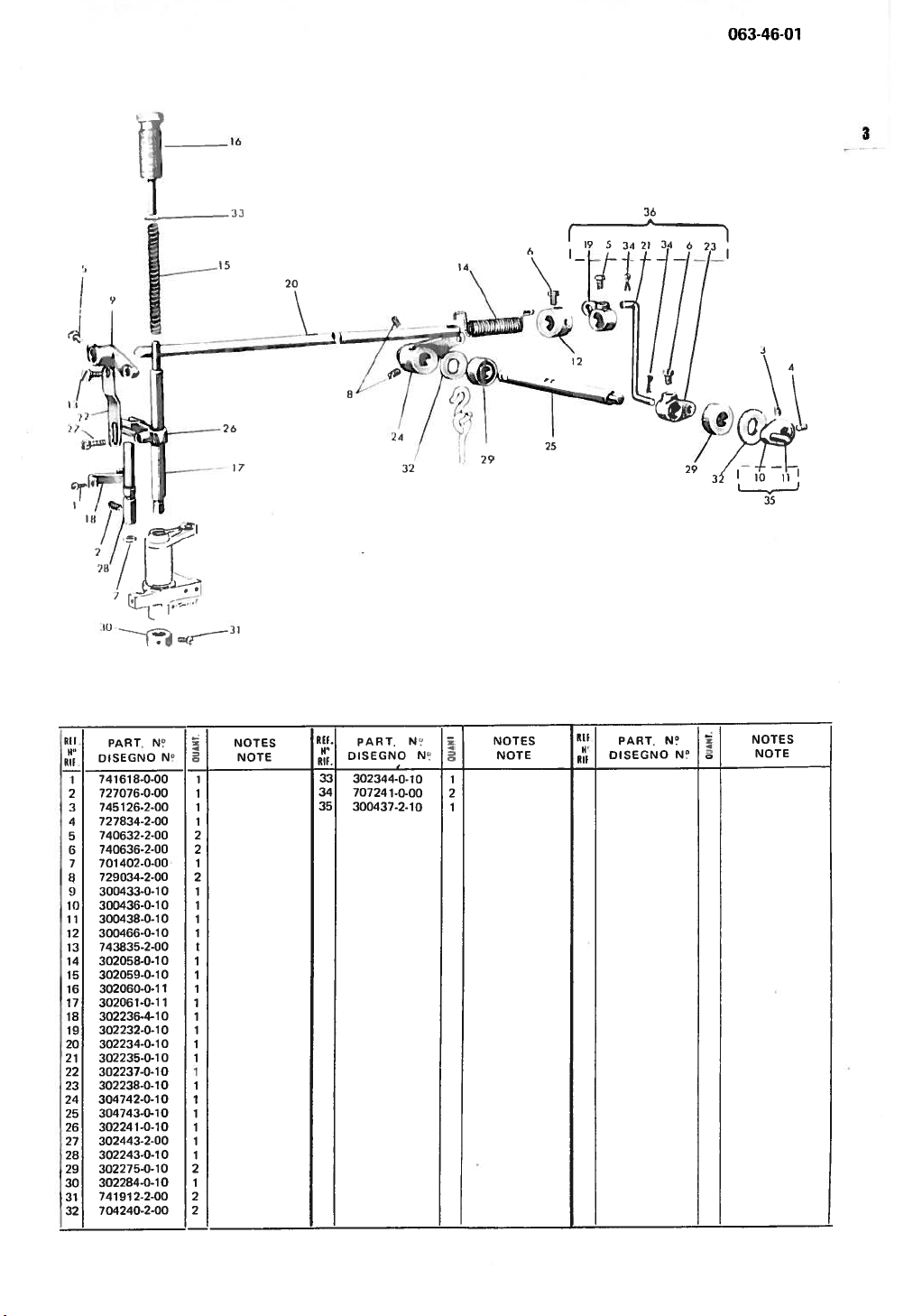

063-46-01 Tab. 3

063-34-08

063-34-

063

-16-16

opening

-09

-01

09

09

'f"

ilh

. 1

Tah. 2

OG3-46-01

063

Tab. 4

-34-08

063-34-09

063-16-16

Shaft

and

connecting rods

movement

Oil basin with

oil wicks

pump · tubes

for

lower looper

and

lubrication

063-46-01 Tab.

5

Oil

basin with pump · tubes and lubrication

wicks.

oil

Suspended

and

top

base

spreader

machine

with

differential

INDEX

063-34-08 Tab. 6

063-34-09

063-16-16

OF TABLES

Cover and work

differential

Covers and

machines · with differential and

Thread guides and thread take-ups

spreader

Bobbin-holders · treadle ·

lever

plate · machines

and

top spreader

work

plate · Suspended

presserfoot

top

spreader

with

063-46-01 Tab.

wi~h

063-34-08

063-34-09

063-16-16

base

063-46-01

063-34-08

063-34-09

063-16-16

top

063-46-01 Tab.

063-34-08

063-34-09

063-16-16

lifter

Tab.

Tab. 9

10

7

8

..

._~

·

...

~·

-

.-,-~ ~ -~r--

.

,JJ)

__

_,

_,

J

·~

T

ab.

11

Accessories

063·00

-

--

063·06·

063·06·02

063·06·03

063·06·04

063·10·

063·10·

063·10·03

063·10·04

063·10·

063·16·01

063·16·

063·16·04

063·16·06

063·16·08

063

063-16-13

063-16-14

063-

063-16-16

063-17-01

063-17-03

063-17-04

063-17-06

063-17-07

063-17-10

063-17-11

063-30·01

063-30-02

063-30-03

063-30-04

063-30-05

063063-30-07

063·31-01

063-31-02

·01

01

01

02

05

02

·16·10

16-15;

30..()6

063-30-08

12

Tal•

13

Tnh.

14

Tab.

15

Tah.

16

Tab.

17

Ta

b.

18

Tab.

19

Tab.

20

Tab.

21

Tab.

Tab. 22

23

Tab.

24

Tab.

25

Tab.

Tab.

26

Tab. 27

Tab.

28

Tab. 29

30

Tab.

Tab.

31

Tab. 32

Tab.

33

Tab. 34

Tab. 35

36

Tab.

37 133

Tab.

38

Tab.

Tab.

39

Tab.

40

Tab.

41

Tab. 42

Tab.

43

Tab. 44

Ta

b.

45

Tab.

46

Tab. 47

063

·31·03

063·31·04

063·31 ·

09

063·31 ·

10

063·34·

01

063·34·

03

063·34·

05

063·34·

08

34·09

063·

063·38·

01

063·38·02

063·38·

03

063·46·01

063·46·04

063·46·

05

063

-46·

09

063-46-10

063-46·

14

K DEVICE

KNEE

PRESS FOR K

DEVICE

COLLARET FOLDER

TABLES

PIECES

(illuminated cover plate)

OF GUIDES

ON

DEVICE

FOR

REQUEST

SHIFTING

FromTab.

Tnh.

Tah.

Tab. 50

Tab.

Tall. 52

Tah.

Tab.

Tab. 55

Tab.

Tab.

Tah. 58

Tab. 59

Ta

Tab.

Tab. 62

Tab. 63

Tab.

Tab. 65

Tab. 66

Tab.

Tab.

Tab.

To

Tab. 77

b.

"

..

4!1

49

51

53

54

56

57

60

61

64

67

68

69

70

71

72

77

30

70

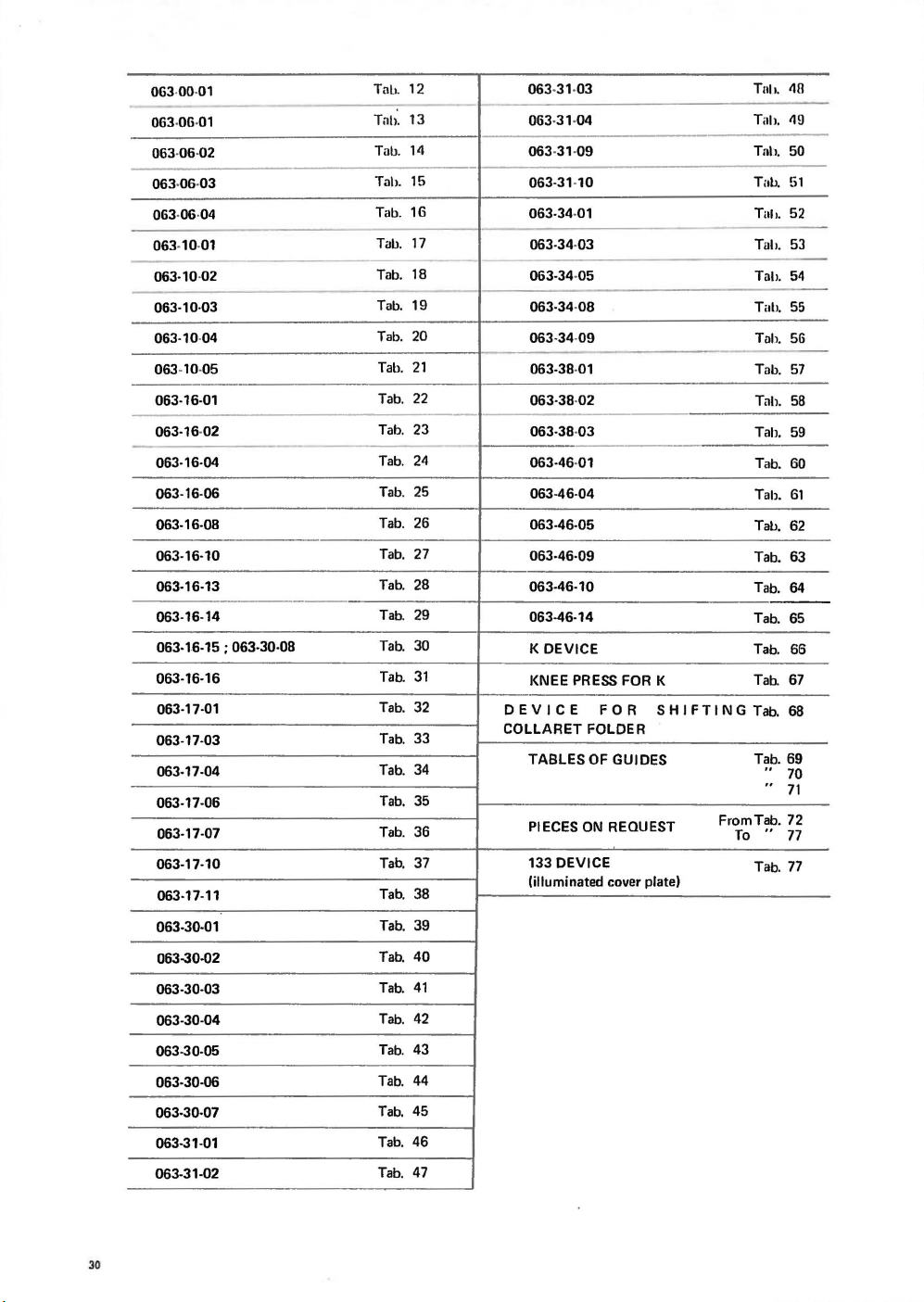

063-46-01

1

49

71

---

11

:18

I

I

I

I

I

I

Rll

PART

H

All

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24 300230-0-10 1

25

26

27

28

29

30

31

32

N'

OISEGNO

727215-0721444-2-00 1

740237-0-00

742811-0-00 1

741559-2-00

741546-2-00 2

742232-2-00

742068-2-00

742036-0-00 2

745136-2727245-2-00

727216-0-00 2

727834-2-00

740243-0-00 1

746612-2-00 1

704406-0-00

202486-0-10 2

303494-0·1 0 1

300208-0-10 1

300209-0-1 0

302026-0-1 0

300222-0-10

300228-0-1 0 1

300231-0-1 0 1

741928-0-00

300356-0-1 0

300359-0-1 0 1

300361-0-10

300362-0-1 0

300364-0-10 1

741055-0-00 1

N:

00

00

s

l;

2

4

2

1

1

4

1

1

1

31

16

64

NOTES

NOTE

2

1

2

3

4

1

1

I

Rll.

w

DISEGNO

Rll

300367-0-1 0

33

300371-0-10

34

300467-0-10

35

300468-0-1 0

36

704805-0-00

37

740475-2-00

38

39

706434-0-00

302371-3-10

40

301406-0-10

41

42

301420-0-10

43

301519-0-10

44

302271-0-1 0

45

301578-0-10

46

302010-0-10

302115-0-10

47

48

745827-2-00

49

30160350 301604-0-10

51

301650-0-1 0

52

302007-0-10

302027-

53

54

302026-0-11

302152-0-10

55

302163-0-10

56

303458-

57

58

304686-0-10

302267-0-1 0

59

302272-0-10

60

704855-0-00

61

704814-0-

62

63

729044-2301459-4-10

64

PART

0-1

0-1

0-1

N

00

00

N

0

0

0

!5

s

30

1

1

2

1

2

NOTES

NOTE

1

2

2

1

2

1

2

1

1

2

1

1

1

1

4

2

2

1

1

1

1

1

1

1

1

I

Kll

Rlf

65

66

67

68

69

70

71

72

H

OISEGNO

N.

PART

303400-3-00

302116-2-10

302269-2-10

302366-4-10

303401-4-1 0 1

302029-4-11 1

302270-4-10

742813-0-00 2

N?

s

0

"'

44

1

1

1

1

1

63

,---

I

• 1

-.---...

NOTES

NOTE

46

66

47

I

7

I

LO9t7E9O

II

t

01

/1

L

/

\

I

‘

I

(i

\

‘

‘

\

I

A

9i;

•)

I

I,

I

II

1-1

•iL

/

IC

C

C

I’

9

L

8

6

LI

91

LI

81

61

06

16

ii

Li

176

96

96

Li

86

66

02

6$

$2

178

jj

01

61

CI

171

91

LC17L

It’L

690L

1090L

68LL

1602

1060$

lNVd

ONtJ3SIG

668LL

0

N

I’

oN

00-0-itDIt’L

00-0-L0091’L

00-6-60

00-6-CEI’LiL

00-0-069

I’

00689911’L

6

00-0-8I081’L

00-6-Cit’91’L

0069C90I’L

9

00-i-80t’91’L

00-0-91

1’

00-0-C

6

00-0-91

00-0-O668LL

00-0-1

00-0-9668LL

0006668LL

6

00-0-CO6OLL

01-0-881602

00-0-IL

01-0-861106

6

01-0-680606

00-0-8O6IDOL

6

00-0-80690L

00-6-t’61716L

6

00-0-0617606

01-0-182002

6

01-0-882008

6

01-0-2817002

01-0-810602

0

16L

00O-2281’OL

01-0-1790602

OLOILI6OC

I,

I

310N

1£

—J

I

SOlON

-[

It’

917

LI’

81’

61’

09

19

69

$9

‘9

99

99

L9

89

69

09

19

69

$9

‘9

99

99

L9

89

_I,——8

f-,-

::_rJ,

•jpj

92

92

LC

88

68

01’

61’

CI’

171’

917

1,1

-

-

-

i

S3ION

OION

•;N

lHVd

69

OL

IL

CL

t’L

1602

9L

LL

8L

6L

08

18

68

28

1’O

600L

99

98

8

0

a

3

9

I-I

1

98

N

d

0

Ii

S

C

ONDOSIG

N

01-2-160608

01-6-680602

01-17-610608

01-2-881602

01-17-ILI6O$

0

I-1’-IJL

0

-17-606602

01-17-896602

01-17-286602

01-0-066008

I-1’-096602

0

O0-6-I’2066L

6

01-0-060608

01-0-666602

I-t’-0L720C

0

00-0-01

000-8IOIOL

01-2-081602

o

L-0-6L0602

o

1-0-099902

01-0-610606

01-0-810608

01-0-981602

01-0-181602

010-291608

01-6-1791602

01-0-822602

qqx17

o

1-0-060602

o

I-C-9L990C

0L-0-8LI60$

o

1-0-996606

OL-0--I’LI6OC

S]ION

OION

I9t’L

11’L

llfI’d

1602

IS8IL

oN

0ND]SI0

N

OI-0-6LLI’OC

0

1-C-CLO6OC

OI-0-t’O

01-0-861602

01-0-t’CIiOC

OI-0-91’LiOC

0I-0-91’IiOC

01-0-991608

01-0-691608

01-0-091608

01-0-691608

01-6-681608

0I-0-9LI602

0L-0-LLL6OC

OI-1’-YSIiOC

01-0-106602

01-0-196602

0-69660C

01

01-0-896608

-0-CL66OC

01

01

-0-I’LiiOC

00-0-800202

01-0-686608

01-0-t’8I602

01-0-868608

01

-0-Ot’CiOE

00-6-96

00-i-I

00-0-898t’OL

00-0-698t’OL

00-0--1’6L

01-0-158608

01-0-698608

0

-0-698608

C

6

6

6

6

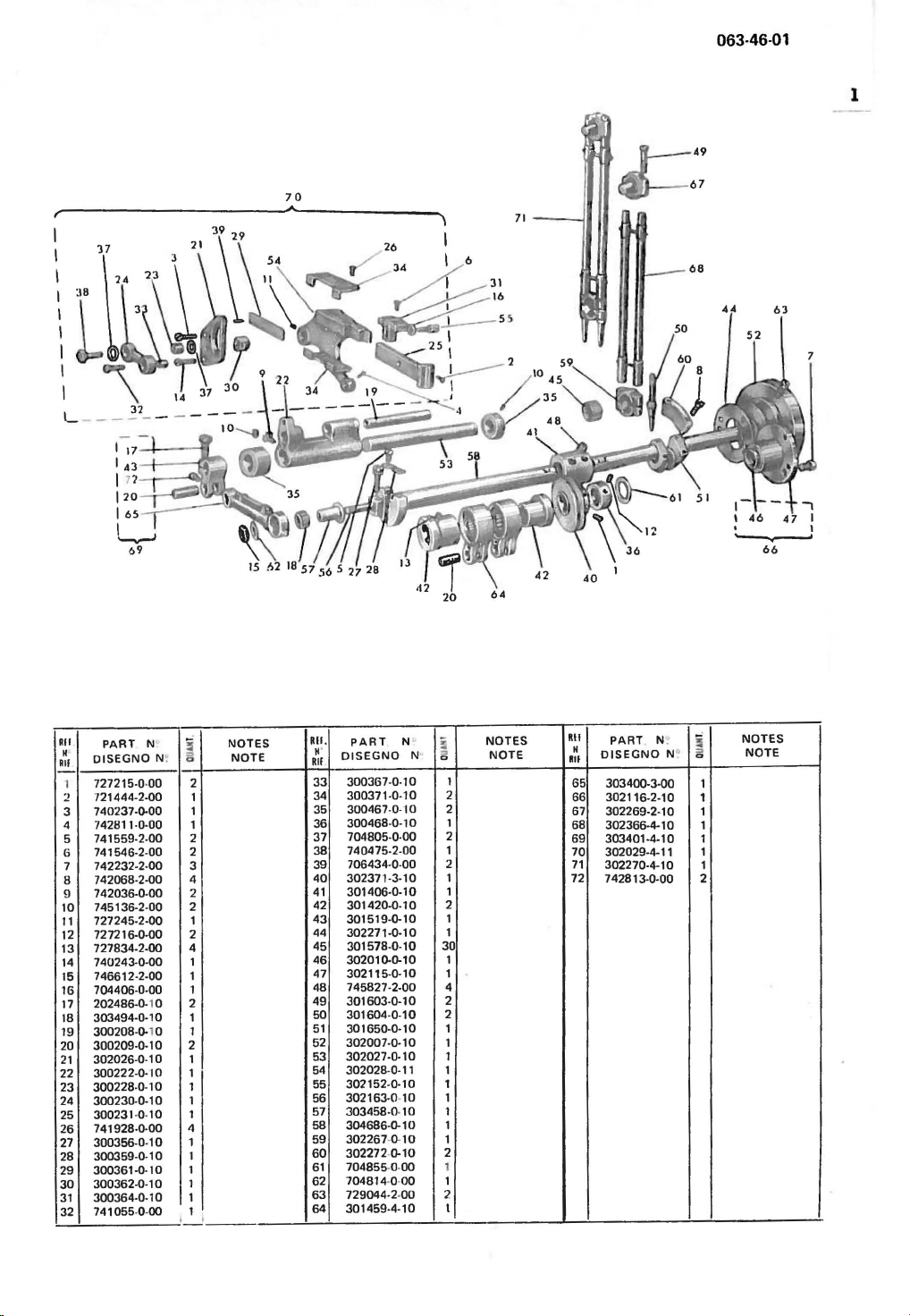

063-46-01

3

I)

FE

?3

6

/1

LLV///’

2o

a,

IH//

Eli

2

:3

4

5

0

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

PART

IJISEGNO

741513-0-00

727076-0-00

145126-2-00

727234-2-00

740632-2-00

740636-2-00

701402-0-00

729034-2-00

300433-0-10

300436-0-10

300438-0-10

300466-0-10

743835-2-00

302058-0-10

302059-0-10

302060-0-11

302061-0-11

302236-4-10

302232-0-10

302234-0-10

302235-0-10

302237-0-10

302238-0-10

304742-0-10

304743-0-10

302241-0-10

302443-2-00

302243-0-10

302275-0-10

302284-0-10

741012-2-00

704240-2-00

II

REF.

33

34

35

PART

DISEGNO

302344-0-10

707241-0-00

300437-2-10

N

N

NOTES

NOTE

3

1

1

1

1

2

2

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

2

2

2

N’

N

NOTES

NOTE

3

2

REF

—

PART.

DISEGNO

N°

N

NOTES

NOTE

3

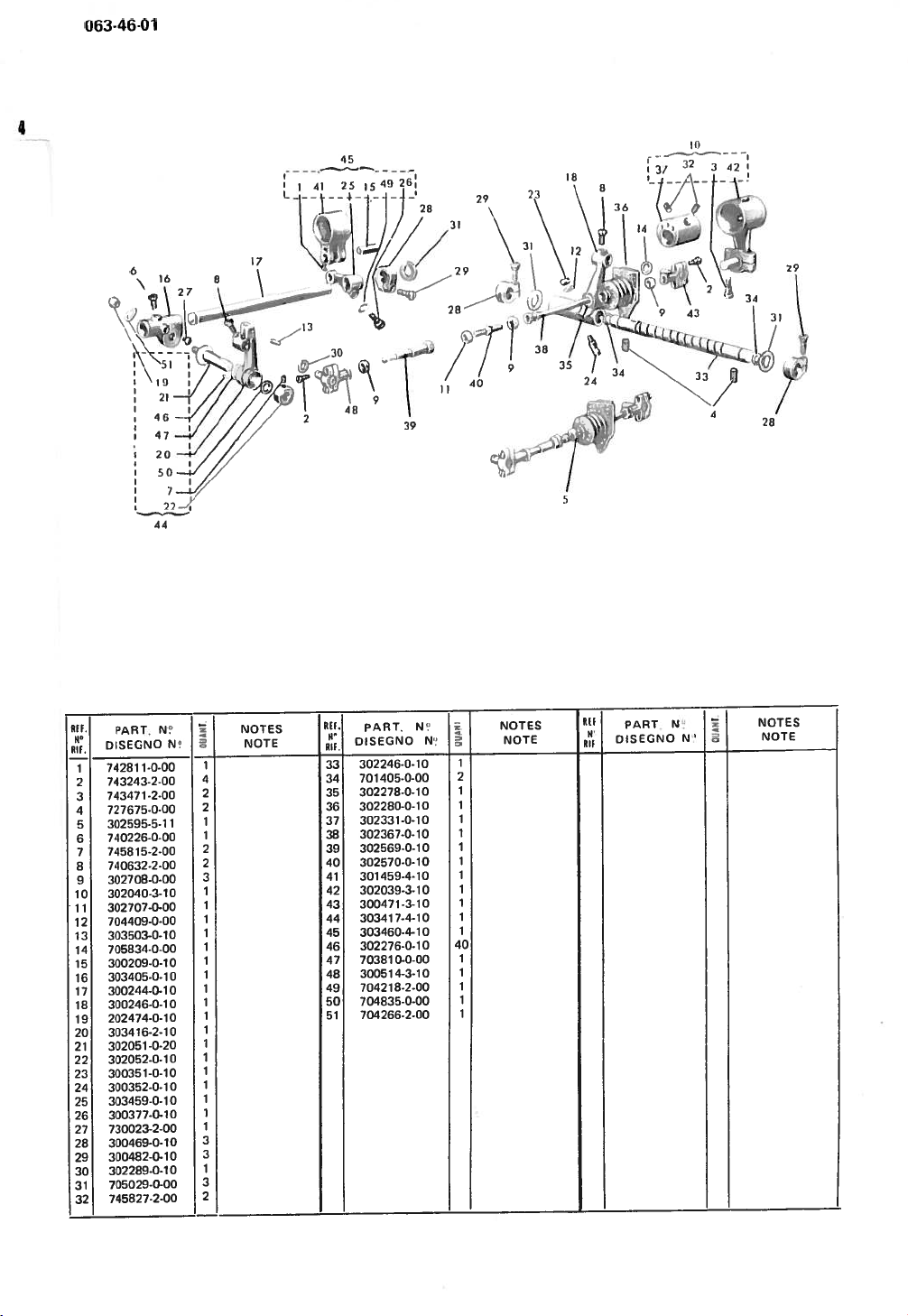

063-46-01

•

6

:c

4?

77/

‘

\9

32

\

K’

\2

-/

I,

7’

28

15

1128

\31

‘I

‘

39

29

\3\\2\ç

/1

40

2’

41

I

-

48

/

21

“1

3835

l

16

)J

:

:

/

\

RU.

/

22

25

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

1$

19

20

21

23

24

26

27

28

29

30

31

32

PART.

DISEGNO

1-0-00

74281

743243-2-00

743471-2-00

727675-0-00

302595-5-11

740226-0-00

7451115-2-00

740632-2-00

302708-0-00

302040-3-10

302707-0-00

704409-0-00

303503-0-10

70111134-0-00

300209-0-10

303406-0-10

300244-0-10

300246-0-10

202474-0-10

303416-2-10

3020151-0-20

302052-0-10

3003151-0-10

300352-0-10

303460-0-10

300377-0-10

730023-2-00

300469-0-10

300482-0-10

302289-0-10

705029-0-00

745827-2-00

N

N•

NOTES

NOTE

1

4

2

2

1

1

2

2

3

1

1

1

1

1

1

1

1

1

1

-

1

1

1

1

1

1

1

1

3

3

1

3

2

RU.

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

DISEGNO

302246-0-10

701405-0-00

302278-0-10

302260-0-10

302331-0.10

302367-0-10

302569-0-10

302570-0-10

301459-4-10

302039-3-10

300471-3-10

303417-4-10

303460-4-10

302276-0-10

703810-0-00

300514-3-10

704218-2-00

704835-0-00

704266

PART.

2-00

N

N

NOTES

NOTE

1

2

1

1

1

1

1

1

1

1

1

1

1

40

1

1

1

1

1

R11

Rif

—

DISEGNO

PART

N

N

NOTES

NOTE

—

Loading...

Loading...