OM SERIES

ASSEMBLING MANUAL

CAST BODY ASSEMBLING DETAILS

CABIN SHEETS ASSEMBLING DETAILS

Distribuitor: CALOR SRL

Str. Progresului nr. 30-40, sector 5, Bucuresti

tel: 021.411.44.44, fax: 021.411.36.14

www.calorserv.ro - www.calor.ro

00 REV. / 2010 - OM

OM SERIES CAST IRON BOILERS INSTALLATION SPECIFICATIONS :

This installation manual is prepared for licensed and certified installation and service technicians in domestic and

international markets and for perfect cast iron boiler installation.

Boiler room and boiler platform must be controlled before starting to installation process.If the conditions are inconvenient

do not start the installation process until all conditions are convenient.

Please read,study and understand this manual before starting the installation process.

Do not damage boiler body and cabins painting during and after installation process and during burner and system chimney connection process and warn other technicians for this matter.

Please ask for help from producer or sales company technical departments if any questions occur in your mind during

installation process.

Minimum 2 persons are required for OM series cast iron boilers installation.

Do not forget that correctly installed boiler will work properly for long time.

RIMA HEATING SYSTEMS

Sayfa - 2

It is obvious that technicians must provide safety and security conditions before and during installation process.

Technicians must pay attention while they are carrying heavy cast iron boiler sections before and during assembly and

installation process for preventing health injuries.

Installation components and equipments are provided with the boilers. Assembly silicone, silicone cartridge, nipple, gloves

and dust mask is provided with assembling equipments.

We thank you for reading these warnings and suggestions and wish you a successful installation.

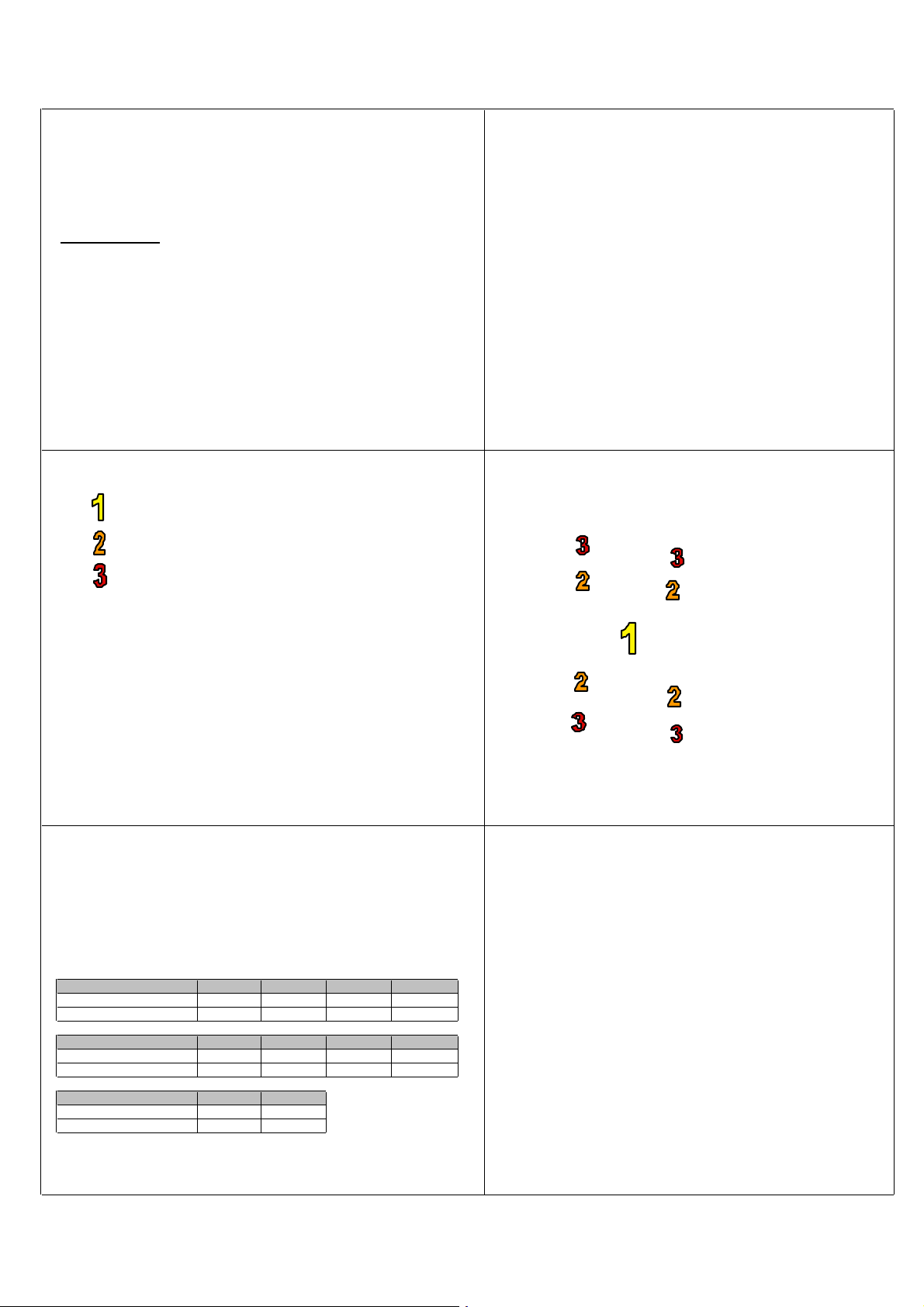

Boiler assembly chassis ( as tooled side looking at back and

top ) must be installed on to the concrete platform.

Concrete platform must be flat for keeping the boiler in balance.

Back section of the boiler must be positioned on to the chassis

in upright position. Holes on the chassis must be positioned as

opposite to the assembling holes on the back section, then

must be screwed with 4 pcs of M12x50 mm nuts for stabilizing

on back section.

Leakproof gaskets must be installed on axis nipple and axis

nipple must be installed to nipple axis hole.

*** For easier assembly, stick leakproof isolation ropes

on to the channels on cast iron sections before

starting section assembly process.

*** Leakproof isolation ropes must be installed exactly

in the channels.

*** There must not be any empty spaces in the connec tion points of leakproof isolation ropes.

Sayfa - 3

*** For easy assembly nuts head must be at bottom and

bolt pins must be at top side.

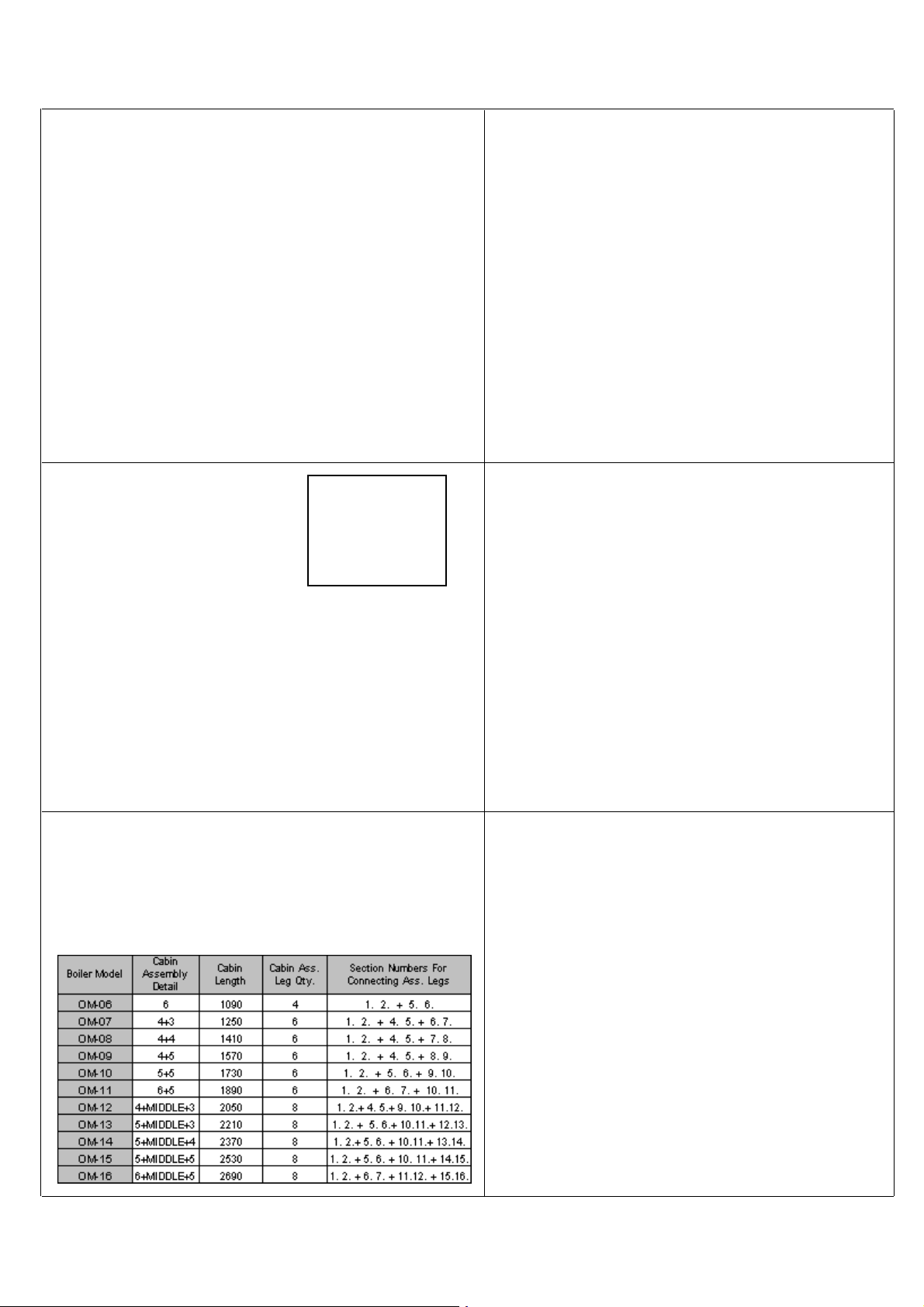

Back section smoke leakage proof channels must be cleared

with a brush or with a piece of clothe and silicone must be filled

in it afterwards.

Prepared smoke leakproof isolation rope must be sticked in

that channel like in the picture with the help of silicone which is

already filled.

*** For easier assembly , silicone can be used for

preventing o-ring and nipple to fall down .

After installing leakproof isolation rope, axis nipple, o ring to

back section it must be installed by sliding the middle section

on the chassis.

*** The middle section which has thermostat hole must

be used as the second middle section before the

front section. ( Section number 3 )

M10 x 240 section assembling rods must be connected to

assembling ears and foot in balance and middle section must

be connected to back section.

*** Section assembling rods are for the assembling of

the sections. They are not for preventing leakages.

Same process must be replied according to the capacity

( middle section quantity ) of the boiler. Middle section

assemblies must be done in the same way.

After middle sections assembling same process must be

applied to front section for front section assembly.

Sayfa - 4

*** The rope which is installed to last middle section

smoke leakproof channel ( the middle section before

the front section) can not be installed to the channel

between 2nd and 3rd passes.

Boiler assembly rods must be connected after all sections

assembly process is finished.

4 pcs of assembling rods must be connected to the boiler,

stabilization holes which are on front and back sections of

the boilers. Nuts and bolts must be installed in cross ways

Screwing torque : 6 kgm

*** Section assembly rods must not be taken off .

These rods will be used on cabin assembly.

Expansion Springs Assembly :

4 pcs of boiler assembly rods in the front and nuts must be

taken off one by one and expansion springs must be connected in cross way. Than nuts and bolts must be screwed again.

For screwing torque control : 3 kgm

*** Expansion springs assembly must be done one by

one and in cross ways.

Boiler assembly expansion springs assembly must be done

as seen in the figure on top ; with nuts and bolts.

Spring joints distance must be approximately 0,5 mm.

After section assembly and boiler assembly rods assembly

boiler back chimney door and water input - output adaptors

must be installed.

Boiler back cihmney door must be installed and must be

screwed with 4 pcs of M12 x 95 rods for preventing the

leakage.

Water input- output adaptors must be installed by connecting

washers and, must be screwed with 4 pieces of bolts for

preventing leakage.

*** Water input adaptor must be installed (adaptor at

bottom ) as 1 1/2'' releasing valve shows bottom or

side ways.

*** Water input adaptor must be installed with connect ing washer, pipe with flange,washer and adaptor in

a raw.

*** 1 1/2'' output of output adaptor must show top or

side ways.

Sayfa - 5

and must be screwed in balance.

After installation of boiler input and output adaptors, boiler

Boiler Burning Gas ( 1. Pass )

Boiler Burning Gas ( 2. Pass )

Boiler Burning Gas ( 3. Pass )

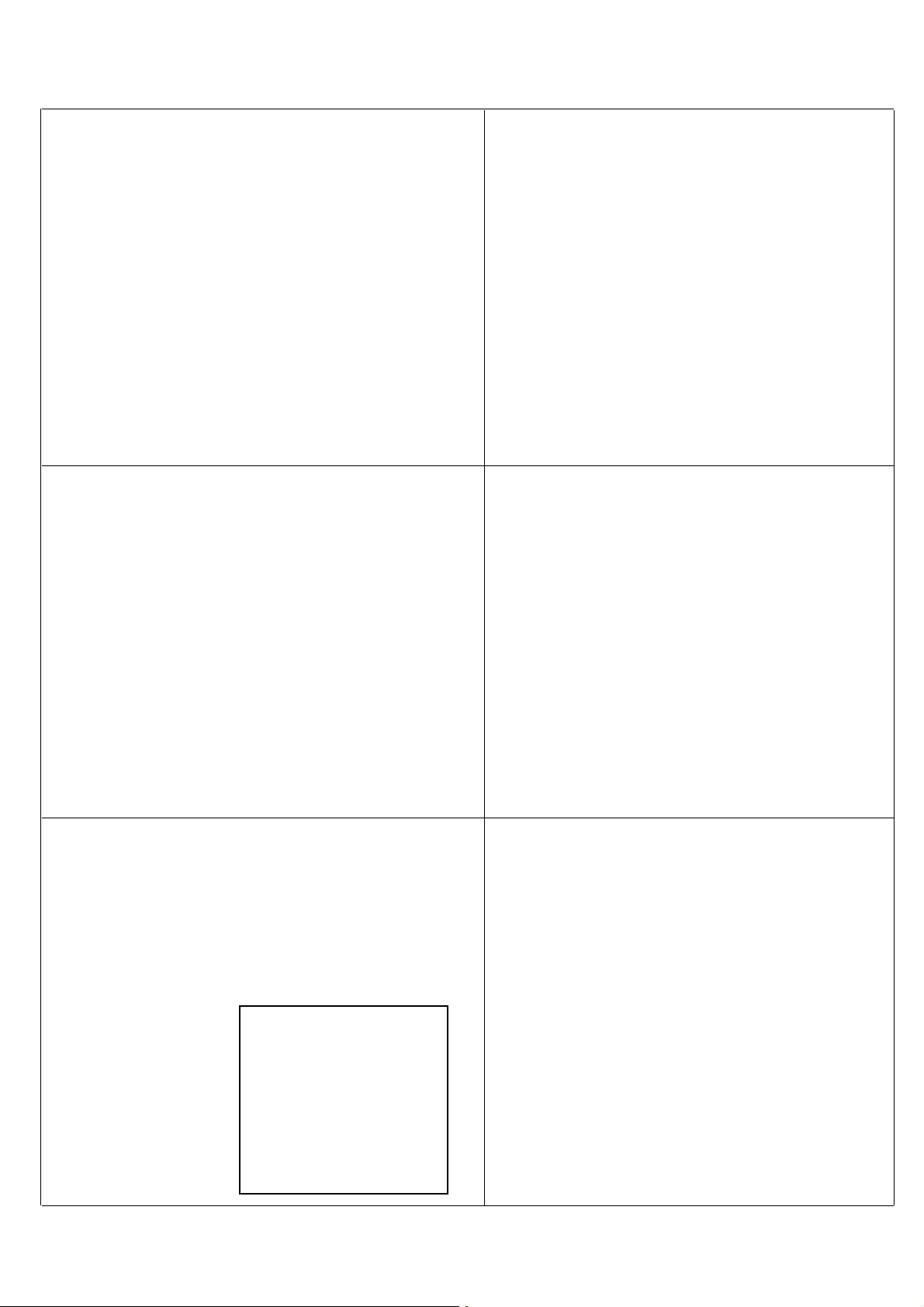

1. Install the flame delayer turbulators to the channels as seen

on table.

*** Small turbulators must be installed to 2nd passes and

2 pieces for each .Big turbulators must be installed to

3rd passes.

Turbulators must be installed to passage channels from front

section.

Boiler Model ОМ-06 ОМ-07 ОМ-08 ОМ-09

Second pass 1+1+1+1 1+1+1+1 1+1+1+1 1+1+1+1

Third pass 1+1+1+1 1+1+1+1 1+1+1+1 1+1+1+1

*** Turbulators must be connected through the middle of

the front section.

Sayfa - 6

must be tested for leakage by filling water inside without

connecting the front burner door ,for 10 minutes under

9 bars pressure .

Test Result :

If any leakage is spotted boiler must be repaired by exploring

the spot. If there are no leakages,flame delayer turbulators

assembly process must be started.

Table - 1 Flame Delayer Turbulator Installation Table :

Boiler Model ОМ -10 ОМ-11 ОМ-12 ОМ-13

Second pass 1+1+1+1 1+1+1+1 1+1+1+1 1+1+1+1

Third pass 1+1+1+1 1+1+1+1 1+1+1+1 None

Boiler Model ОМ-14 OМ 15-16

Second pass 1+1+1+1 None

Third pass None None

After the installation of the turbulators to the passes boiler

burner door must be connected to front section.

4 hinges which are conneced to front section, must be

connected to the hinge arms on the burner door.

Connect M10 x 80 mm hinge bolts according to your desire

for opening side according to plumbing connections and

boiler room.

After connecting bolts 4 pcs M16 nuts and pins must be

connected and screwed in balance.

*** There must be no gap between the burner door and

front section for preventing smoke leakage.

After body assembly and leakage tests blakite® - which is

given with assembling parts - must be applied between the

sections for preventing smoke leakage.

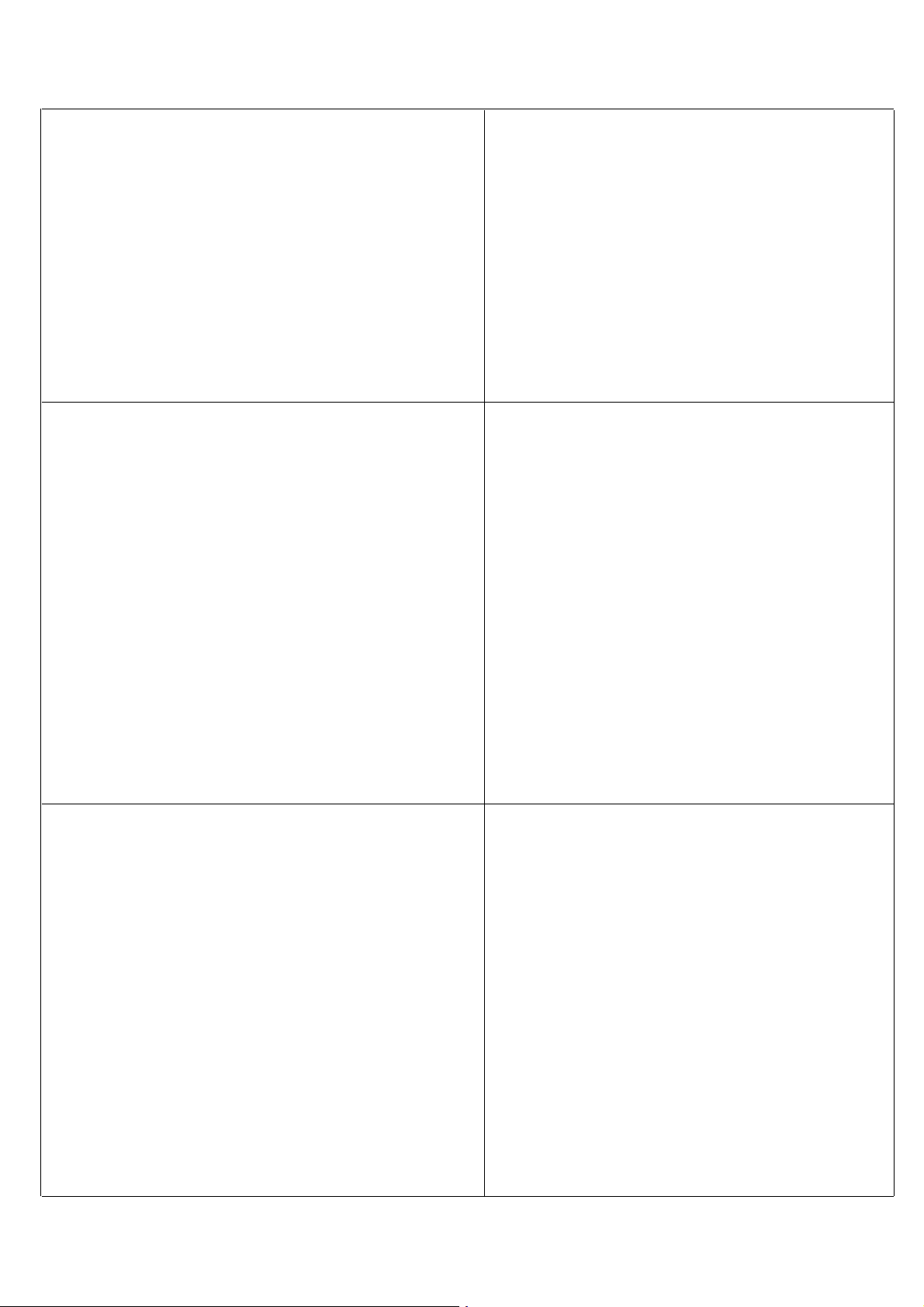

For cabin sheets installation cabin assembly legs must be

connected to rods on the boiler legs.

Cabin sheet assembly legs must be connected to the rods

which we have used for sections connections,as shown in

the picture. Than the rods must be screwed.

Table - 2 Assembling Leg Table :

Sayfa - 7

*** Selection of section legs and cabin sheet assembly

legs is shown in table 2.

After connection of cabin sheet assembly legs in both sides of

the boiler body, cabin sheet assembly ears on top of the boiler

body must be connected to their places.

*** If there are no assembling rods on the section which

assembly legs and ears

will be connected, these

rods can be taken from

other sections .

Cabin sheet assembly ears must be

connected to the assembly rods on top

side as seen in the picture. Than, nuts

must be screwed with a light force for

holding the piece.

Table - 3 Assembly Ear Table :

Sayfa - 8

After the installation of the cabin sheet assembling legs

and ears , body insulation and cabin sheets must be installed

on the body.

8 cm body isolation must be prepared according to boiler

dimensions and installed on the boiler body.

Body insulation must be cut for opening thermostat socket.

Same process must be applied to additional right and left

cabin sheets for their installation to the boiler body.

Sayfa - 9

Isolation must be cut around assembling ears connection

points.

Isolation must be connected with a stainless steel wire from 2

points to the body for stabilization.

First the holes on the side cabin sheets must be connected to

the pins on the assembly legs and than must be connected to

cabin sheet assembly ears with M8 x 20 bolts as seen in the

picture.

After installation of side cabins control panel must be connected

on to the front top cabin sheet.

Sayfa - 10

There are three holes on the front cabin sheet. Thermocouples

( sensors) of the control panel ( thermostat,safety thermostat,

thermometer ) must be passed through the middle hole.

Control panel must be stabilized to the holes on right and left.

After installing sensors edges inside the socket segment

must be plugged for preventing the sensor edges to move out.

After these processes pins on the top cabin must be connected

to segments on side cabins.

Extra top cabin must be installed by connecting to the segments

on side cabins.

After side and top cabin sheet assembly, back cabin sheet

must be installed.

Sayfa - 11

*** Oil which is given with the assembling parts,must be

filled to thermostat hole for increasing the sensitivity

of the sensors.

Back cabin sheet isolation must be installed and back sheet

Than the boiler is ready for burner installation, system and

chimney connections.

*** Burner installation, chimney and system connec tions must be done according to the standards and

in attention with specifications in operation and

maintenance manuals and by authorized technicians.

Sayfa - 12

must be connected to the side cabins ( as the open side

shows upside ) with cabin connection screws as shown in the

picture. ( 4 pcs. for right , 4 pcs. for left and 3 pcs. for the

middle connection point. )

As back cabin sheet installation completes, all cabin parts

installation is finishes.

Loading...

Loading...