RIKON Power Tools 70-300 User Manual

16”x42” Heavy Duty Wood Lathe

Model: 70-300

Part # 70-300M1

Owner’s Manual

Record the serial number and date of purchase

in your manual for future reference.

Serial number:

Date of purchase:

For more information:

www.rikontools.com or info@rikontools.com

For Parts or Questions:

techsupport@rikontools.com or 877-884-5167

Safety Warning

IMPORTANT! Safety is the single most important consideration in the operation of this equipment. The following

instructions must be followed at all times.

There are certain applications for which this tool was designed. We strongly recommend that this tool not be modied and/

or used for any other application other than that for which it was designed. If you have any questions about its application,

do not use the tool until you have contacted us and we have advised you.

General Safety Warnings

KNOW YOUR POWER TOOL. Read the owner’s manual carefully. Learn the tool’s applications, work

capabilities, and its specic potential hazards.

ALWAYS GROUND ALL TOOLS.

If your tool is equipped with a three-pronged plug, you must plug it into a three-hole electric receptacle.

If you use an adapter to accommodate a two-pronged receptacle, you must attach the adapter plug to a

known ground. Never remove the third prong of the plug.

ALWAYS AVOID DANGEROUS ENVIRONMENTS.

Never use power tools in damp or wet locations. Keep your work area well lighted and clear of clutter.

ALWAYS REMOVE THE ADJUSTING KEYS AND WRENCHES FROM TOOLS AFTER USE.

Form the habit of checking to see that keys and adjusting wrenches are removed from the tool before

turning it on.

ALWAYS KEEP YOUR WORK AREA CLEAN. Cluttered areas and benches invite accidents.

ALWAYS KEEP VISITORS AWAY FROM RUNNING MACHINES.

All visitors should be kept a safe distance from the work area.

ALWAYS MAKE THE WORKSHOP CHILDPROOF.

Childproof with padlocks, master switches, or by removing starter keys.

NEVER OPERATE A TOOL WHILE UNDER THE INFLUENCE OF DRUGS,

MEDICATION, OR ALCOHOL.

ALWAYS WEAR PROPER APPAREL.

Never wear loose clothing or jewelry that might get caught in moving parts. Rubber-soled footwear is

recommended for the best footing.

ALWAYS USE SAFETY GLASSES AND WEAR HEARING PROTECTION.

Also use a face or dust mask if the cutting operation is dusty.

NEVER OVERREACH.

Keep your proper footing and balance at all times.

NEVER STAND ON TOOLS.

Serious injury could occur if the tool is tipped or if the cutting tool is accidentally

2

ALWAYS DISCONNECT TOOLS.

Disconnect tools before servicing and when changing accessories such as blades, bits, and cutters.

ALWAYS AVOID ACCIDENTAL STARTING.

Make sure switch is in “OFF” position before plugging in cord.

NEVER LEAVE TOOLS RUNNING UNATTENDED.

ALWAYS CHECK FOR DAMAGED PARTS.

Before initial or continual use of the tool, a guard or other part that is damaged should be checked to

assure that it will operate properly and perform its intended function. Check for alignment of moving

parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect its

operation. A guard or other damaged parts should immediately be properly repaired or replaced.

Special Safety Rules For Lathes

1. Do not operate this machine until you have read all of the following instructions.

2. Do not attempt to operate this machine until it is completely assembled.

3. Do not turn ON this machine if any pieces are missing.

4. If you are not familiar with the operation of the machine, obtain assistance from a qualied

person.

5. It is highly recommended that this machine be rmly mounted to a at and secure work

surface.

6. Always wear protective eyewear prior to operating this machine.

7. Do not operate this machine if you are under the inuence of drugs and/or alcohol.

8. Remove all jewelry prior to operating this machine.

9. Do not wear any gloves while operating this machine.

10. Always make sure the power switch is in the OFF position prior to plugging in the machine.

11. Always make sure the power switch is in the OFF position when doing any assembly or setup

operation.

12. Always turn the power switch to the OFF position and let the work piece come to a complete

stop prior to removal.

13. Use only sharp lathe tools.

14. The use of any accessories or attachments not recommended may cause injury to you and

damage your machine.

15. This machine must be properly grounded.

16. When turning between centers, make sure headstock and tailstock are snug against work

piece.

17. When face plate turning, rough-cut work piece close to the nished shape before screwing to

face plate.

California Proposition 65 Warning

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains

chemicals known to the State of California to cause cancer and birth defects or other reproductive harm.Your risk from

exposure to these chemicals varies, depending on how often you do this type of work. To reduce your exposure, work in

a well-ventilated area and with approved safety equipment, such as dust masks that are specially designed to lter out

microscopic particles.

For more detailed information about California Propostion 65 log onto rikontools.com.

SAVE THESE INSTRUCTIONS.

Refer to them often.

3

Table of Contents

Warnings .........……………………………………………………………………………………………………..........................2-3

Specications ....…………………………………………………………………………………………………..............................4

Contents of Package ...................................……..........................................................................................…....................5

Unpacking and Cleanup .......……………………………………………………………………………………..........…............5-6

Assembly .....…………………………………………………………………………………………………...….......……...............6

Controls and Features ..........……....................................................................................……............…..........................6-8

Speed Change ...…………………………………………………………………………………………………........…................8-9

Lathe Tools ...........................................................................................................................................................................9

Mounting Workpiece Between Centers ........……….................................................................................…..................9-10

Stock Selection ...................................................................................................................................................................10

Roughing Out ………………………………………………………………………………………….…….......….........................11

Coves, “V” Cuts, Parting and Beads............................................................................................................................12-13

Sanding & Finishing.....………………………………………………………………….…………….……….........…..................13

Face Plate or Bowl Turning...........................................................................................................................................13-14

Mounting Stock .………………………………………………………………..……………………………..........…....................14

Face Plate or Chuck .........................................................................………......................................................................14

Wood Selection .……………………………………………………………...……………………………......……..….................14

Checks and Cracks .……………………………………………………………………………………………........…..................15

Distortion ..........………………………………………………………………………………………………….............................15

Tools for Bowl Turning ...…………………………………………………………………………………….......…..…................15

To Shape Outside of Bowl ...........................................................................................................................................15-16

To Shape Interior of Bowl...................................................................................................................................................16

Sanding and Finishing .......................................................................................................................................................17

Adjusting Clamping Mechanism .......................................................................................................................................17

Electrical Requirements ....................................................................................................................................................18

Wiring Diagram.……………………………………………………………………………….………………….............................19

Troubleshooting.……………………………………………………………………………………………….........…...................20

Notes ...................................................................................................................................................................................21

Part Explosions and Part’s List....................................................................................................................................22-25

Warranty...............................................................................................................................................................................26

Specications

Stock Number .…….………………………..…..………………………………………………..........…………...................70-300

Over Bed .........…………………………………………………………………………….……….........……...............400mm(16")

Swing Over Tool Rest Base ..............................................................................................................................305mm(12")

Distance Between Centers ........................................................................................................................... 1092mm( 42")

Speeds (RPM) ...................................................................................................….........…..........................0-1200 & 0-3200

Spindle Nose ...............................................................................…..........................................…….................1-1/4”x8TPI

Drive Spindle Through Hole .......................................................................................................…...................15mm (5/8")

Tailstock Spindle Through Hole .......................................................................................................................10mm (3/8”)

Tailstock Spindle Travel ......................................................................................................................................100mm(4”)

Tool Rest .........…………………………………………………………………………………….........……...............355mm (14”)

Face Plate ......…………………………………………………………………………………….........….……...............152mm(6”)

Headstock Rotation ………………………………………………………...............…................45º, 90º, 135º, 180º, 270º 360º

Headstock Taper ....................................................................................................................................…….................MT-2

Tailstock Taper .………………………………………………………………………..........………….……………..................MT-2

Spindle Center to Floor (approx.) .............................................................................................................1130mm(44-1/2”)

Motor ..............................................................................................…...............…......….............................1.5HP, 3Ph, 230V

Input Power .............................................................................................................................................220v 240v 50/60Hz

Net Weight (approx.)..................................................................…..............................................................................386lbs

Shipping Weight (approx.) ......................................................................…................................................................440lbs

4

Contents of Package

Read and understand the entire contents of this manual before attempting assembly or operation!

Failure to comply may cause serious injury!

Contents of Package:

1. Lathe

1. Tailstock

1. Headstock

1. Tool Rest Body

1. Tool Basket

1. Guard Assembly

1. Accessory Package

1. Owner’s Manual & Warranty Card

1. Leg Set

WARNING

Contents of Accessory Package

Accessory Package Box

1. Live Center

1. Rod for Live Center

1. Spur Center

1. Index Pin

1. Face Plate

1. Knockout Rod Headstock

1. Tool Rest

1. Tool Rest Extension

4. Adjustable Feet

Unpacking and Clean-Up

1. Remove the shipping container. Do not discard any shipping material until the lathe is set

up and running properly.

2. Remove hex cap bolts from skid bottom and move the lathe off the skid and into position.

3. Clean all rust protected surfaces with a cleaner degreaser. Clean thoroughly under the

headstock, tailstock and tool rest body.

5

Unpacking and Clean-up

1. Remove the shipping container. Do not discard any shipping material until the lathe is set up and

running properly.

2. Remove hex cap bolts from skid bottom and move the lathe off the skid and into position.

3. Clean all rust protected surfaces with a cleaner degreaser. Clean thoroughly under the headstock,

tailstock and tool rest body.

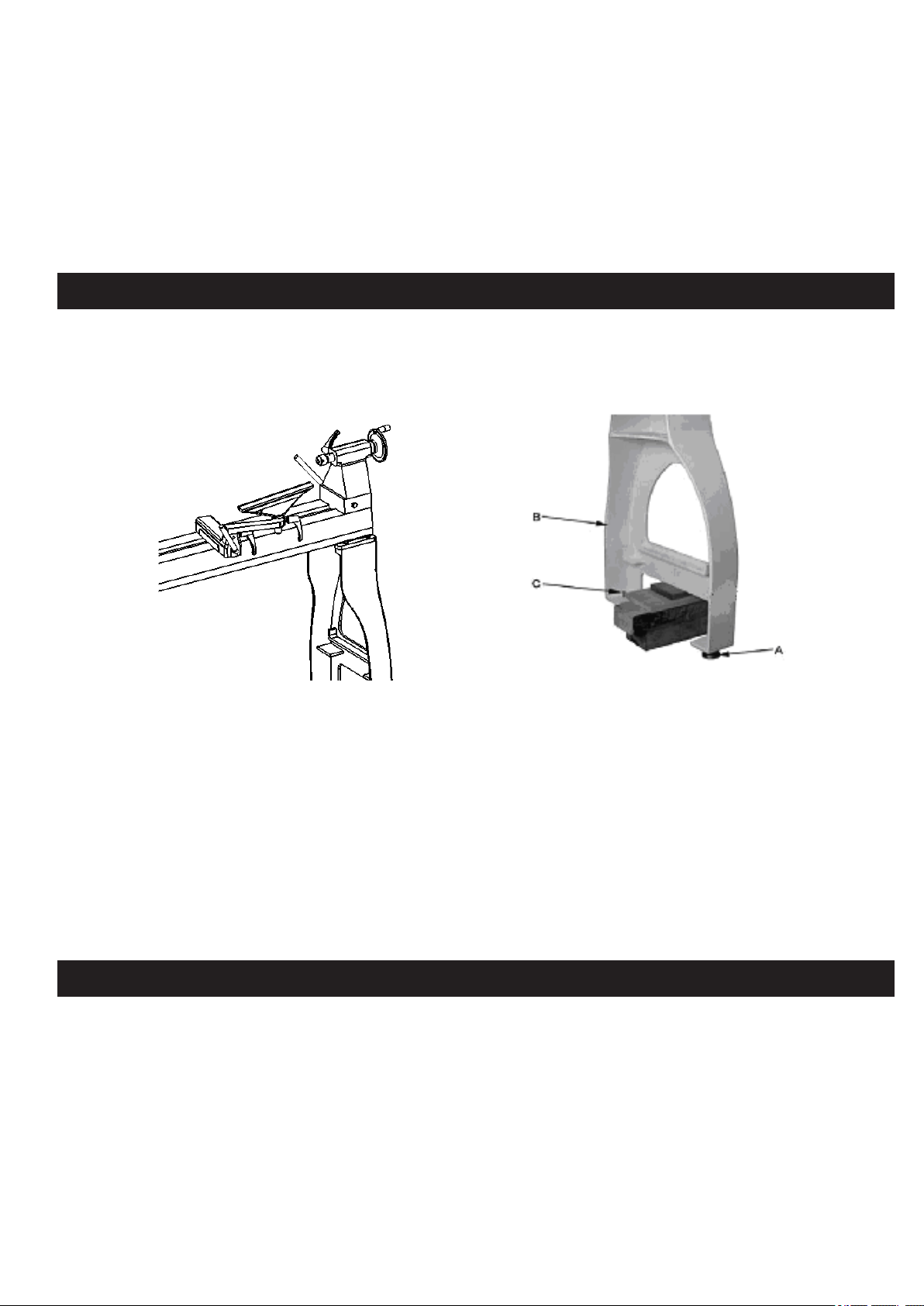

Assembly

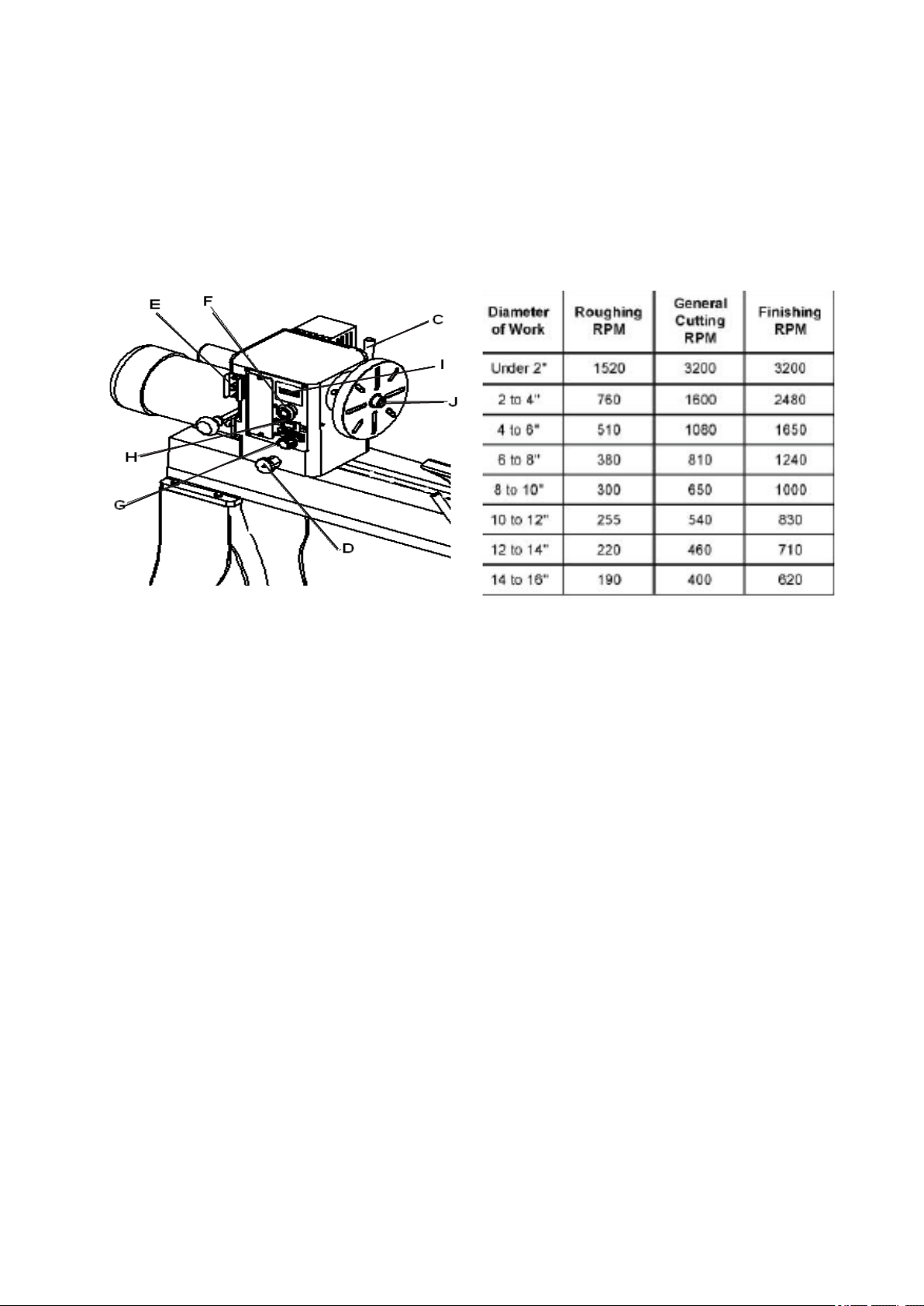

1. Secure tool rest (A, Fig. 1) to tool rest body (B, Fig. 1) by tightening handle (C, Fig.1).

2. Slide the tailstock and tool rest to the headstock end of the lathe bed. See “Controls and Features”

section of this manual on how to move the tailstock and tool rest.

Fig. 1 Fig. 2

3.Lift the tailstock end of the lathe up far enough to slide a few pieces of scrap wood under the leg,

see Figure 2.

4. Thread adjustable feet (A, Fig. 2) into stand leg (B, Fig. 2). There is a at spot on the shaft near the

foot that will accommodate a wrench. Thread a hex nut (C, Fig. 2) onto shaft and leave loose for now.

5. Remove the scrap pieces of wood and slide the tailstock, tool rest and headstock down to the tailstock end of the late bed.

6. Mount the two adjustable feet in the same manner as above and move the headstock, tool rest and

tailstock into their normal positions.

7. Adjust the feet so that the lathe rests evenly on the oor, and tighten the nuts.

Controls and Features

1. Headstock Lock Handle: (C, Fig. 3) Locks head in position. Unlock handle to position the head

along lathe bed. Tighten handle when properly positioned.

2. Headstock Indexing Pin: (D, Fig. 3) Turn the knurled knob counter-clockwise to unlock the plunger.

Pull the knob out to release the headstock. Unlock the headstock locking handle and rotate the headstock. Turn knurled knob clockwise until it stops to lock plunger.

3. Headstock Spindle Lock: (E, Fig. 3 Push pin in to keep the spindle from turning.

CAUTION! Never press the headstock spindle lock while the spindle is turning!

6

4. Headstock On/Off Button: (F, Fig.3) Pull the button out to turn “ON” the lathe. Push the button in to

turn the lathe “OFF”.

5. Headstock RPM Knob: (G, Fig. 3) Turn knob to desired RPM. There are two speed ranges offering

“speed” (0-3200) and “torque” (0-1200).

6. Headstock For/Rev Switch: (H, Fig. 3) Use the toggle switch to change the direction the spindle

turns. Only change direction when the spindle has stopped.

Fig. 3 Fig. 4

7. Headstock RPM Readout: (I, Fig. 3) Displays the spindles RPM, see Figure 4.

8. Headstock Spur Center: (J, Fig. 3) Used for turning between centers. Spindle taper is MT-2.

Remove spur center by inserting drift rod through the opposite end of the spindle and knocking spur

center out.

9. Headstock Faceplate: (K, Fig. 3) Used for turning bowls and plates. There are a number of screw

holes for mounting the work piece. Thread the faceplate onto the spindle in a clockwise direction, and

tighten two set screws. Remove the faceplate by loosening two set screws. Push in headstock spindle

lock and use the provided rod in faceplate holes to unthread the faceplate.

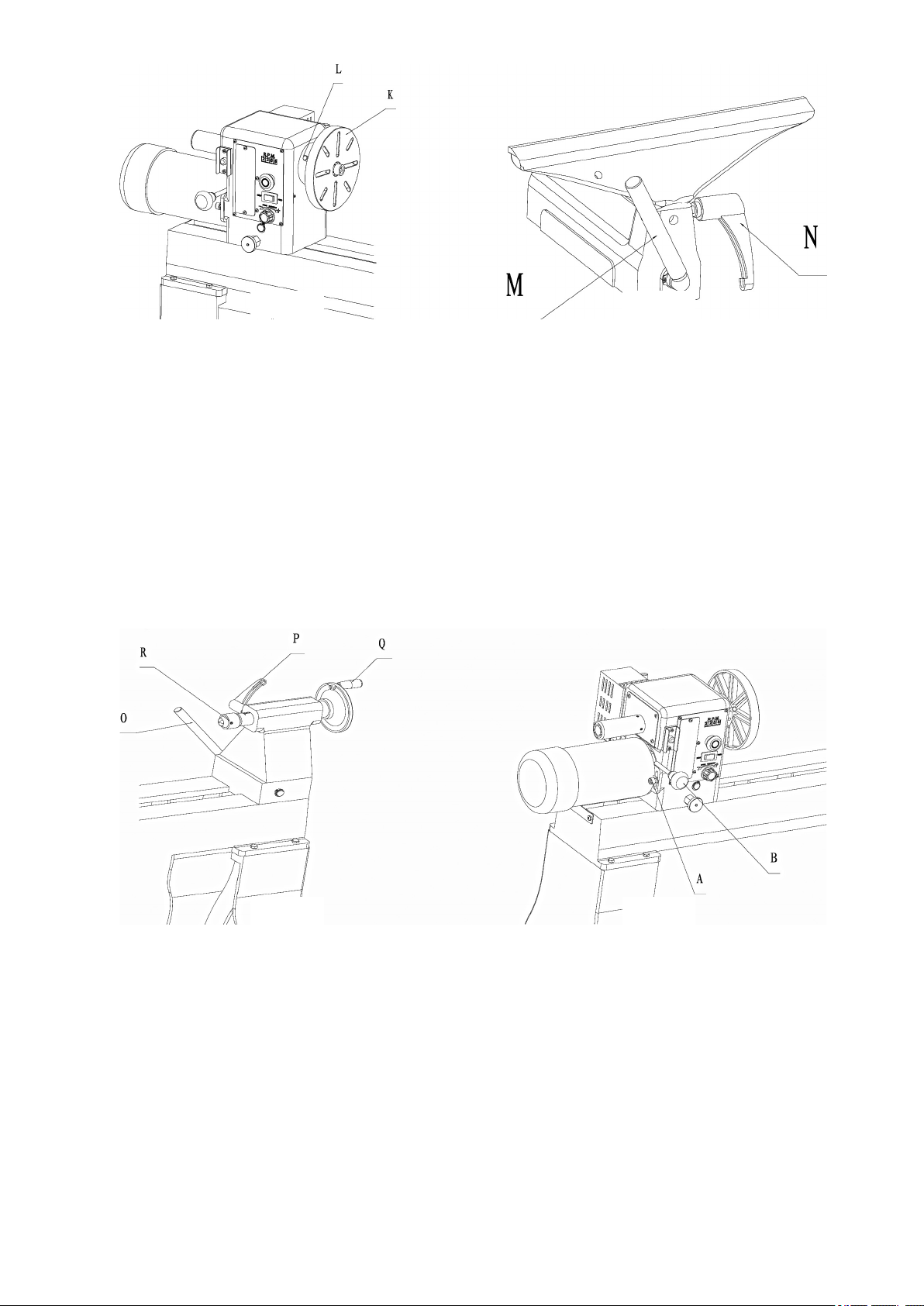

10. Headstock Indexing Hole: (L, Fig. 5) Thread indexing pin into the indexing hole making sure that

it locates in the spindle hole. There are 12 holes in the spindle 30° apart. There are three holes in the

headstock casting that accept the indexing pin. These holes are 20° apart. The combination of holes

will allow you to mark your workpiece for evenly spaced features. CAUTION! Never start the lathe

with the index pin engaged in the spindle!

11. Tool Rest Body Lock Handle: (M, Fig. 6) Locks the tool rest body in position. Unlock handle to

position the tool rest in any location along lathe bed. Tighten handle when properly positioned.

12. Tool Rest Lock Handle: (N, Fig. 6) Locks the tool rest in position. Unlock the handle to position

tool rest at a specic angle, or height. Tighten handle when properly positioned.

7

Fig. 5 Fig. 6

13. Tailstock Lock Handle: (O, Fig. 7) Locks the tailstock in position. Unlock handle to position the tool

rest in any location along lathe bed. Tighten handle when properly positioned.

14. Tailstock Quill Lock Handle: (P, Fig. 7) Locks the tailstock quill in position. Unlock handle to position the quill. Tighten handle when properly positioned.

15. Tailstock Quill Handwheel: (Q, Fig. 7) Turn the handwheel to position the quill. The tailstock quill

lock handle must be loose to position quill.

16. Tailstock Live Center: (R, Fig. 7) Used for turning between centers. Quill taper is MT-2. Remove

live center by retracting the quill until live center loosens. Remove, or add different tips to the live center by inserting the provided rod through the holes in the center’s shaft. Unscrew the tip and change

as needed.

Fig. 7 Fig. 8

Speed Change

1. Disconnect the machine from the power source!

2. Loosen the locking Screw (A, Fig. 8).

3. Lift up on the tensioning handle (B, Fig. 8) to remove tension from the poly v-belt. You can now

position the belt in the desired speed range. It is pictured in the low speed pulley range. Note: The

“High” speed range (0-3200) provides maximum speed, where as the “Low” speed range (0-1200) will

provide maximum torque.

4. Lower the tensioning handle so that the weight of the motor provides the needed tension and

tighten the locking handle.

8

AC Inverter does not require any programming. It is pre-programmed from the factory. The

buttons and knob on the face of inverter should not be changed. Use only controls on the

front of headstock. Refer to Inverter manual.

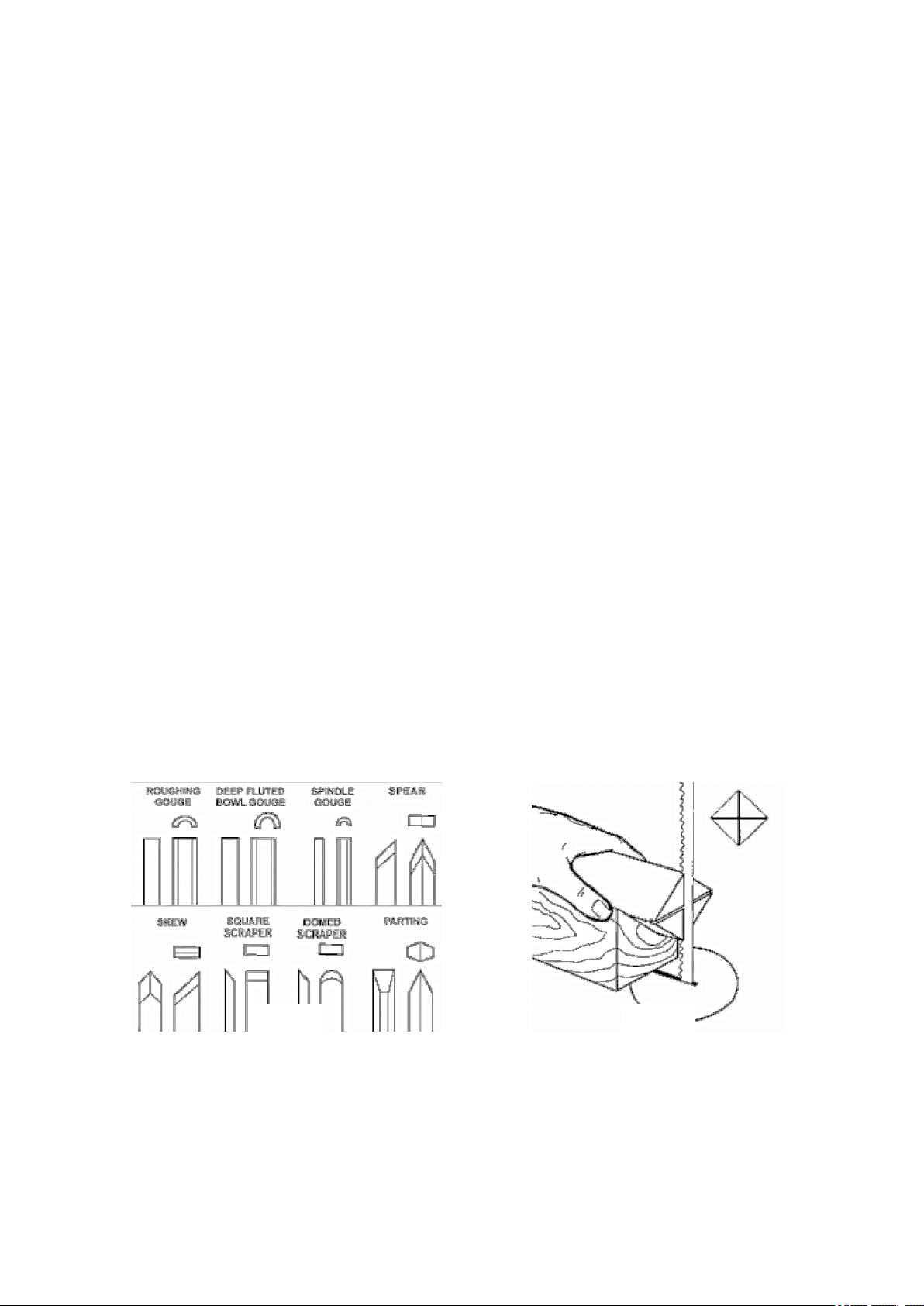

Lathe Tools

If possible, select only high quality, high speed steel turning tools with long handles. As one becomes

procient in turning, a variety of specialty tools for specic applications can be acquired. The following

tools provide the basics for most woodturning projects.

Roughing Gouge - used for rapidly cut raw wood into round stock, see Figure 9.

Deep Fluted Bowl Gouge - used for turning bowls and plates, see Figure 9.

Spindle Gouge - used for turning beads, coves and other details, see Figure 9.

Spear - ne scraping and delicate operations, such as the forming of beads, parallel grooves and

shallow vees, etc, see Figure 9.

Skew - used to make vees, beads, etc., see Figure 9.

Square Scraper - used for diameter scraping and featureless scraping, etc, see Figure 9.

Large Domed Scraper - used to reduce ridges on the interior of bowls, round edges of bowls, etc,

see Figure 9.

Parting Tool - used to cut directly into the material, or to make a cut off. Also used for scraping and to

set diameters, see Figure 9.

For safety and best performance, keep tools sharp. If a tool stops cutting, or requires excessive

pressure to make a cut, it needs to be sharpened. A number of brand name sharpening jigs and xtures are available, however, a woodturner should learn to sharpen tools freehand.

Fig. 9 Fig. 10

Mounting Work piece Between Centers

Spindle turning takes place between the centers of the lathe. It requires a spur center in the headstock and a live center in the tailstock.

9

Loading...

Loading...