RIKON Power Tools 70-100 User Manual

Mini Lathe

Model: 70-100

Part # 70-100M2

Owner’s Manual

Record the serial number and date of purchase

in your manual for future reference.

Serial number:

Date of purchase:

For more information:

www.rikontools.com or info@rikontools.com

For Parts or Questions:

techsupport@rikontools.com or 877-884-5167

Safety Warning

IMPORTANT! Safety is the single most important consideration in the operation of this equipment. The following

instructions must be followed at all times.

There are certain applications for which this tool was designed. We strongly recommend that this tool not be modified

and/or used for any other application other than that for which it was designed. If you have any questions about its

application, do not use the tool until you have contacted us and we have advised you.

General Safety Warnings

KNOW YOUR POWER TOOL. Read the owner’s manual carefully . Learn the tool’s applications, work

capabilities, and its specific potential hazards.

ALWAYS GROUND ALL TOOLS.

If your tool is equipped with a three-pronged plug, you must plug it into a three-hole electric

receptacle. If you use an adapter to accommodate a two-pronged receptacle, you must attach the

adapter plug to a known ground. Never remove the third prong of the plug.

ALWAYS AVOID DANGEROUS ENVIRONMENTS.

Never use power tools in damp or wet locations. Keep your work area well lighted and clear of clutter.

ALWAYS REMOVE THE ADJUSTING KEYS AND WRENCHES FROM TOOLS AFTER USE.

Form the habit of checking to see that keys and adjusting wrenches are removed from the tool before

turning it on.

ALWAYS KEEP YOUR WORK AREA CLEAN. Cluttered areas and benches invite accidents.

ALWAYS KEEP VISITORS AWAY FROM RUNNING MACHINES.

All visitors should be kept a safe distance from the work area.

ALWAYS MAKE THE WORKSHOP CHILDPROOF.

Childproof with padlocks, master switches, or by removing starter keys.

NEVER OPERATE A TOOL WHILE UNDER THE INFLUENCE OF DRUGS,

MEDICATION, OR ALCOHOL.

ALWAYS WEAR PROPER APPAREL.

Never wear loose clothing or jewelry that might get caught in moving parts. Rubber-soled footwear is

recommended for the best footing.

ALWAYS USE SAFETY GLASSES AND WEAR HEARING PROTECTION.

Also use a face or dust mask if the cutting operation is dusty.

NEVER OVERREACH.

Keep your proper footing and balance at all times.

NEVER STAND ON TOOLS.

Serious injury could occur if the tool is tipped or if the cutting tool is accidentally contacted.

2

ALWAYS DISCONNECT TOOLS.

Disconnect tools before servicing and when changing accessories such as blades, bits, and cutters.

ALW A YS A VOID ACCIDENT AL STARTING.

Make sure switch is in “OFF” position before plugging in cord.

NEVER LEAVE TOOLS RUNNING UNATTENDED.

ALWAYS CHECK FOR DAMAGED PARTS.

Before initial or continual use of the tool, a guard or other part that is damaged should be checked to

assure that it will operate properly and perform its intended function. Check for alignment of moving

parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect

its operation. A guard or other damaged parts should immediately be properly repaired or replaced.

Special Safety Rules For Lathes

1. Do not operate this machine until you have read all of the following instructions.

2. Do not attempt to operate this machine until it is completely assembled.

3. Do not turn ON this machine if any pieces are missing.

4. If you are not familiar with the operation of the machine, obtain assistance from a qualified person.

5. It is highly recommended that this machine be firmly mounted to a flat and secure work surface.

6. Always wear protective eyewear prior to operating this machine.

7. Do not operate this machine if you are under the influence of drugs and/or alcohol.

8. Remove all jewelry prior to operating this machine.

9. Do not wear any gloves while operating this machine.

10.Always make sure the power switch is in the OFF position prior to plugging in the machine.

1 1.Always make sure the power switch is in the OFF position when doing any assembly or setup

operation.

12.Always turn the power switch to the OFF position and let the work piece come to a complete stop

prior to removal.

13.Use only sharp lathe tools.

14.The use of any accessories or attachments not recommended may cause injury to you and

damage your machine.

15.This machine must be properly grounded.

16.When turning between centers, make sure headstock and tailstock are snug against work piece.

17.When face plate turning, rough-cut work piece close to the finished shape before screwing to face

plate.

18.Never jam tools into work piece or take too big a cut.

19.Do not operate this machine without following all these instructions.

20.Keep these instructions for future reference.

SAVE THESE INSTRUCTIONS.

Refer to them often.

3

T able of Contents

Safety Warnings.....................................................................................................................................................2

Lathe Safety Rules................................................................................................................................ ............... 3

Specifications.........................................................................................................................................................4

Unpacking and Contents..................................................................................................................................... .5

Getting to Know Y our Lathe...................................................................................................................................6

Assembly ....................................................................................................................... ......................................... 6

Installing the T ool Rest and Base........................................................................................................................ .6

Installing Spindle Lock...........................................................................................................................................7

Attaching the Spur Center...................................................................................................... ...............................7

Attaching the Live Center ......................................................................................................................................7

Installing the Faceplate..........................................................................................................................................8

Installing the T ool Holder ........................................................................................................................................8

Securing the Lathe to a Work Surface or Stand..................................................................................................8

Adjustments............................................................................................................................................................8

Adjusting the T ool Rest..........................................................................................................................................8

Adjusting the Tailstock...........................................................................................................................................9

Changing Spindle Speeds....................................................................................................................................9

T ypical Operations.................................................................................................................................................9

Indexing /Spindle Lock........................................................................................................................................10

Maintenance.........................................................................................................................................................10

Electrical Requirements...............................................................................................................................................11

Wiring Diagram......................................................................................................................................12

Troubleshooting................................................................................................................ ....................................13

Explosion Diagram..............................................................................................................................................14

Parts List...............................................................................................................................................................15

Warranty.................................................................................................................................................................16

Notes......................................................................................................................................................................17

Specifications

Model Number

Swing Over Bed

Swing Over T ool Rest Base

Working Distance Between Centers

Motor

Speeds

Speed Ranges

Spindle Nose in x TPI

Headstock T aper

T ailstock T aper

Hole Through Spindle

Ram Travel

Overall Dimensions

Net Weight

70-100

12”

9-1/2”

16”

1/2HP , 1Ph, 1 15V only

6

430,810,1230,1810,2670,3900 RPM

1”x 8

MT2

MT2

3/8”

2-1/2”

31-3/4”(L)x18”(W)x11-1/2”(H)

88.5 lbs

4

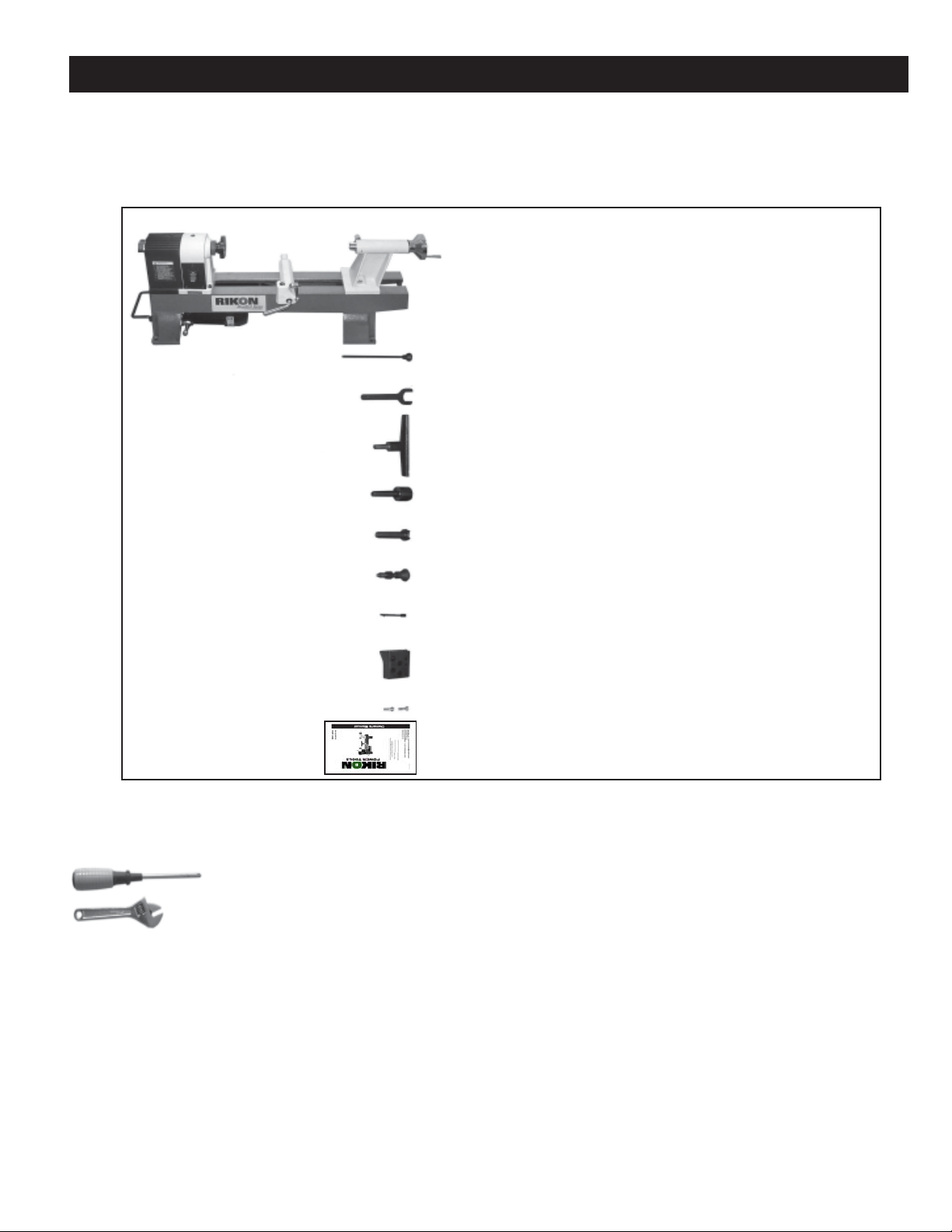

Contents of Package

Unpacking and Checking Contents

Unpack your lathe from its carton and check to see that you have all of the following items. Do not turn

your machine ON if any of these items are missing. Y ou may cause injury to yourself or damage to your

machine.

Item Description Q’ty

A Lathe.........................................................1

B Knokout Bar ..............................................1

C Wrench.....................................................1

D T ool Rest....................................................1

E Live Center ................................................1

Tools Required for Assembly

Item Description

Phillips Screwdriver

Adjustable Wrench

Unpacking and Clean-up

F Spur Center ...............................................1

G Spindle Lock Assembly ..............................1

H Knokout Bar for Live Center pointer ..........1

I Tool Holder................................................1

J Pan head screw.......................................2

K Manual/Warranty Card................................1

1. Carefully finish removing all contents from shipping cartons. Compare contents of the shipping

cartons with the list of contents above. Place parts on a protected surface.

2. Report any shipping damage to your local distributor.

3. Clean all rust protected surfaces with kerosene or diesel oil. Do not use; gasoline, paint thinner,

mineral spirits, etc. These may damage painted surfaces.

4. Set packing material and shipping cartons to the side. Do not discard until machine has been

set up and is running properly.

5

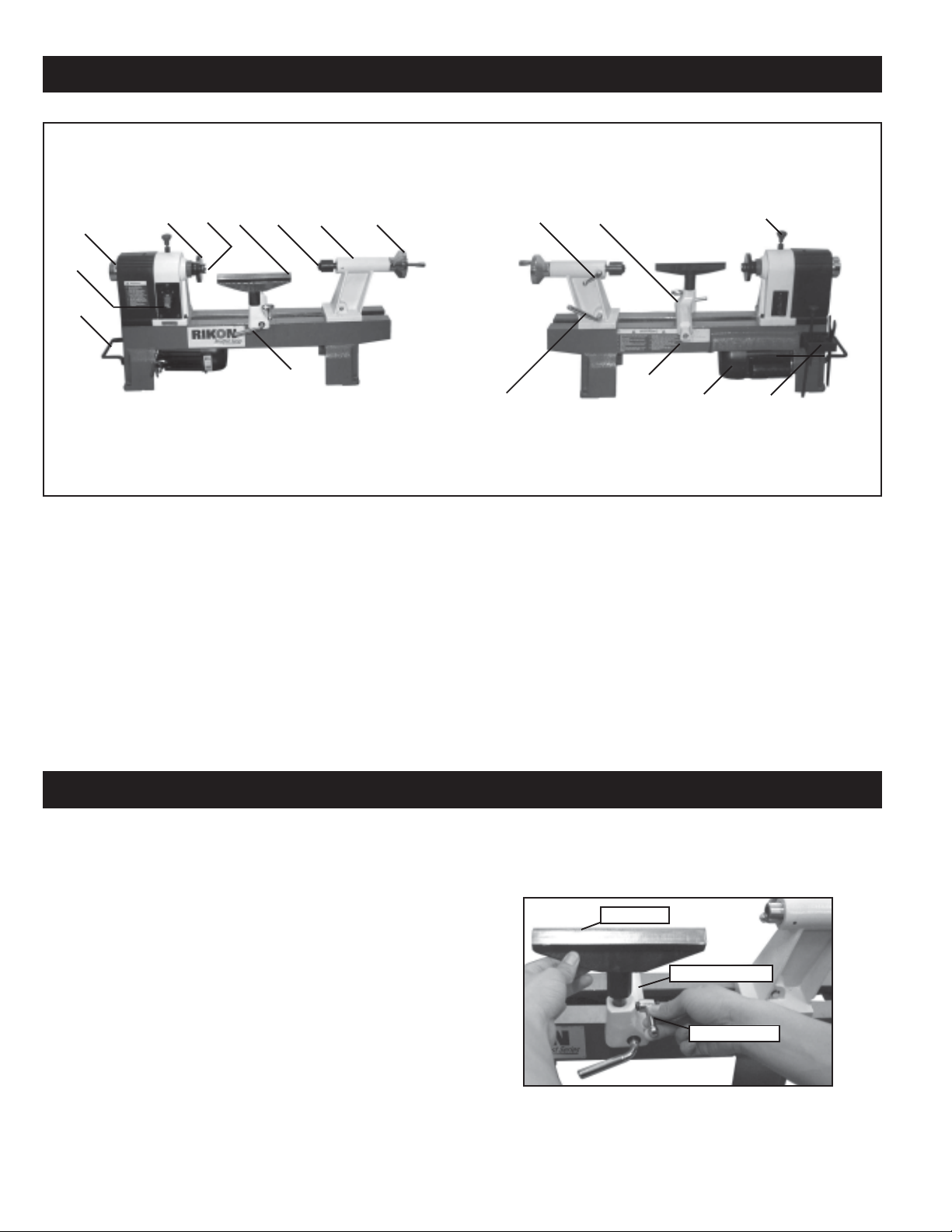

Getting to Know Your Lathe

4

5

3

6

2

1

Item Description

1 Lifting handle

2 Switch

3 Handwheel

4 Face plate

5 Spur center

6 T ool rest

7 Live center

8 T ail stock

9 T ailstock handwheel

7

17

8

9

10

11

15

16

Item Description

10 T ailstock spindle locking arm

11 T ool rest base

12 Spindle lock

13 T ool holder

14 Motor

15 Lathe bed

16 T ailstock locking lever

17 T ool rest seat locking lever

14 13

12

9

Assembly

The machine must not be plugged in and the power switch must be in the OFF position until assembly is

complete.

Installing Tool Rest and Base On

Lathe Bed

Remove the tailstock assembly by releasing the

locking handle and sliding the assembly off the end

of the lathe bed.

Slide the tool rest base onto the lathe bed and

reinstall the tailstock assembly .

Loosen locking arm and insert tool rest into tool

rest base, adjust height up or down and tighten

locking arm. (See Fig.01)

Fig.01

6

T ool rest

T ool rest base

Locking arm

Loading...

Loading...