RIKON Power Tools 50-120 User Manual

6” X 48”Belt & 10”Disc Sander

Model: 50-120

Part # 50-120M2

Owner’s Manual

Record the serial number and date of purchase

in your manual for future reference.

Serial number:

Date of purchase:

For more information:

www.rikontools.com or info@rikontools.com

For Parts or Questions:

techsupport@rikontools.com or 877-884-5167

Operator Safety: Required Reading

IMPORTANT! Safety is the single most important consideration in the operation of this equipment. The

following instructions must be followed at all times.

There are certain applications for which this tool was designed. We strongly recommend that this tool not

be modified and/or used for any other application other than that for which it was designed. If you have

any questions about its application, do not use the tool until you have contacted us and we have advised

you.

General Safety Warnings

KNOW YOUR POWER TOOL. Read the owner’s manual carefully. Learn the tool’s

applications, work capabilities, and its specific potential hazards.

ALWAYS GROUND ALL TOOLS.

If your tool is equipped with a three-pronged plug, you must plug it into a three-hole electric

receptacle. If you use an adapter to accommodate a two-pronged receptacle, you must attach the

adapter plug to a known ground. Never remove the third prong of the plug.

ALWAYS AVOID DANGEROUS ENVIRONMENTS.

Never use power tools in damp or wet locations. Keep your work area well lighted and clear of clutter.

ALWAYS REMOVE THE ADJUSTING KEYS AND WRENCHES FROM TOOLS AFTER USE.

Form the habit of checking to see that keys and adjusting wrenches are removed from the tool before

turning it on.

ALWAYS KEEP YOUR WORK AREA CLEAN. Cluttered areas and benches invite accidents.

ALWAYS KEEP VISITORS AWAY FROM RUNNING MACHINES.

All visitors should be kept a safe distance from the work area.

ALWAYS MAKE THE WORKSHOP CHILDPROOF.

Childproof with padlocks, master switches, or by removing starter keys.

NEVER OPERATE A TOOL WHILE UNDER THE INFLUENCE OF DRUGS,

MEDICATION, OR ALCOHOL.

ALWAYS WEAR PROPER APPAREL.

Never wear loose clothing or jewelry that might get caught in moving parts. Rubber-soled footwear is

recommended for the best footing.

ALWAYS USE SAFETY GLASSES AND WEAR HEARING PROTECTION.

Also use a face or dust mask if the cutting operation is dusty.

NEVER OVERREACH.

Keep your proper footing and balance at all times.

NEVER STAND ON TOOLS.

Serious injury could occur if the tool is tipped or if the cutting tool is accidentally contacted.

2

ALWAYS DISCONNECT TOOLS.

Disconnect tools before servicing and when changing accessories such as blades, bits, and cutters.

ALWAYS AVOID ACCIDENTAL STARTING.

Make sure switch is in “OFF” position before plugging in cord.

NEVER LEAVE TOOLS RUNNING UNATTENDED.

ALWAYS CHECK FOR DAMAGED PARTS.

Before initial or continual use of the tool, a guard or other part that is damaged should be checked to

assure that it will operate properly and perform its intended function. Check for alignment of moving

parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect

its operation. A guard or other damaged parts should immediately be properly repaired or replaced.

Special Safety Rules For Belt & Disc Sanders

1. Do not operate this machine until you have read all of the following instructions.

2. Do not attempt to operate this machine until it is completely assembled.

3. Do not turn ON this machine if any pieces are missing.

4. If you are not familiar with the operation of the machine, obtain assistance from a qualified person.

5. It is highly recommended that this machine be firmly mounted to a flat and secure work surface or

stand.

6. Always wear protective eyewear prior to operating this machine.

7. Do not operate this machine if you are under the influence of drugs and/or alcohol.

8. Remove all jewelry prior to operating this machine.

9. Do not wear any gloves while operating this machine.

10.Always make sure the power switch is in the OFF position prior to plugging in the machine.

11. Always make sure the power switch is in the OFF position when doing any assembly or setup

operation.

12. Always wear a dust mask and use adequate dust collection and proper ventilation. Use of sanders

can produce harmful particles while sanding certain types of woods.

13. The use of any accessories or attachments not recommended may cause injury to you and

damage your machine.

14. This machine must be properly grounded.

15. Abrasive discs and belts should be the recommended width and length of the manufacturer.

16. Always keep your face and hands clear of moving parts such as belts and pulleys.

17.Keep power supply cords free of moving parts of the sander. Damaged cords can result in electric

shock.

18. Maintain a 1/16” clearance between the sanding disc, sanding belt and tables.

19.Always support the workpiece with the table or backstop.

20.Remove material or debris from the work area. Keep work area neat and clean.

21.Keep these instructions for future reference.

SAVE THESE INSTRUCTIONS.

Refer to them often.

3

Table of Contents

Safety Warnings..................................................................................................................................2-3

Sander Safety Rules ..........................................................................................................................3

Specifications ........................................................................................................................................4

Contents of Package ............................................................................................................................................5

Assembly ...........................................................................................................................6-8

Electrical Requirements ...........................................................................................................................................9

Operation............................................................................................................10-11

Maintenance ...................................................................................................................................12

Changing the Motor Belt............................................................................................................................12

Trouble Shooting...............................................................................................................................................13

Wiring Diagram.................................................................................................................................13

Parts List .....................................................................................................................................14

Parts Explosion...........................................................................................................................................15

Notes .............................................................................................................................................16

Warranty .............................................................................................................................................17

Specifications

Belt Size

Belt Speed

Disc Size

Disc Speed

Table Size

Belt Table Tilt

Disc Table Tilt

Motor

Amps

Volts

Net weight

6”x48”

2030 SFPM

10”

1720 SFPM

4” x 8”

o

0-90

o

0-45

3/4 HP

10A

110V

104 lbs

4

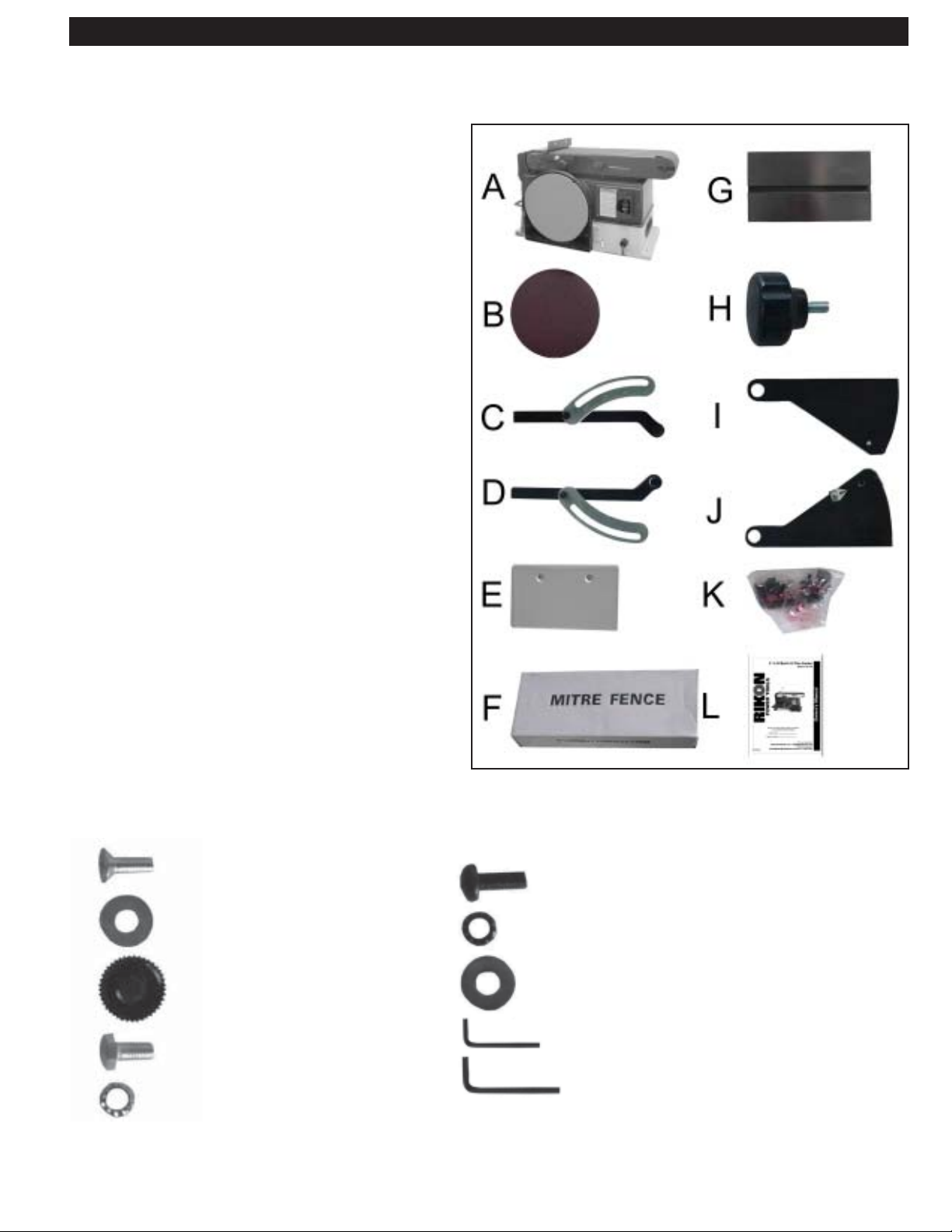

Contents of Package

When unpacking, check to make sure the following parts are included. If any parts are missing or broken,

please call RIKON Power Tools at the number on the cover of this manual as soon as possible.

Carton Contents

Item Description Qty

A Belt & disc sander assembly 1

B Sanding disc 1

C Table support w/scale 1

D Table support 1

E Work table for belt 1

F Miter Gauge 1

G Work table for disc 1

H Locking knob for table support 2

I Mount, support table 1

J Mount, support table w/indicator 1

K Bag of loose parts 1

H Owner’s manual 1

List of loose parts in bag

Description Qty Description Qty

Sunk head screw M6x16 2

Washer 6mm 2

Pan head screw M6x16 4

Lock washer 6mm 4

Knurled nut M6 2

Hex. bolt 4

Lock washer 4

Washer 6mm 2

Hex “L” wrench 3mm 1

Hex “L” wrench 6mm 1

5

Assembly

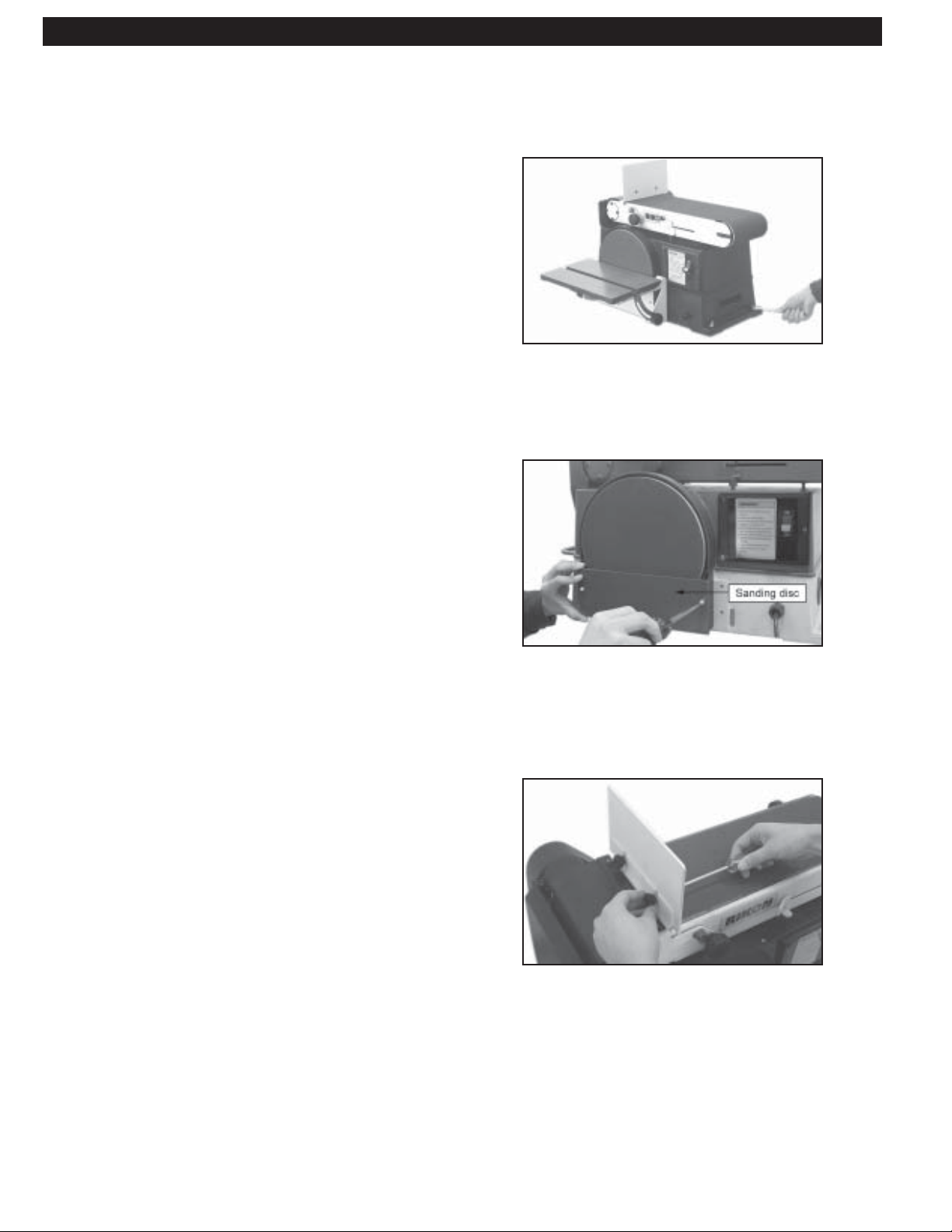

Securing Sander Base Assembly to Workbench

The sander base must be secured before using.

Attach a large C-Clamp to each side of the sander

and the workbench. Or, permanently mount following

the instructions below:

1. Place the sander on the workbench in its final

operating location.

2. Place a pencil through the mountong holes of the

sander base (42) and mark the hole locations on

workbench.

3. Remove sander and drill four 3/8 inch holes through

the workbench.

4. Align sander base over holes and secure using four

5/16 inch screws (or larger) and hex nuts.

(See Fig. 01)

Mounting Sanding Disc and Guard

1. Locate sanding disc (22) and peel backing off

disc.

2. Align perimeter of sanding disc over plate. When

aligned, press disc firmly onto disc.

3. Position disc guard (27) onto lower portion of

sanding disc so that the mounting holes align.

4. Using a Phillips screwdriver, fasten two pan head

screws (found in parts bag) through disc guard.

(See Fig. 02)

Fig. 01

Fig. 02

Installing the Belt Table

1. Place the work table for belt on the work support.

2. Insert two countersink head screws through work

table and the work support slot.

3. Put a 6mm washer and a wing nut on the screw

and tighten. (See Fig. 03)

Fig. 03

6

Loading...

Loading...