4” X 36”Belt & 6”Disc Sander

Model: 50-110

Record the serial number and date of purchase

in your manual for future reference.

Serial number:

Date of purchase:

www.rikontools.com or info@rikontools.com

Part # 50-110M2

techsupport@rikontools.com or 877-884-5167

Owner’s Manual

For more information:

For Parts or Questions:

Operator Safety: Required Reading

IMPORTANT! Safety is the single most important consideration in the operation of this equipment.

The following instructions must be followed at all times.

There are certain applications for which this tool was designed. We strongly recommend that this tool

not be modied and/or used for any other application other than that for which it was designed. If you

have any questions about its application, do not use the tool until you have contacted us and we have

advised you.

General Safety Warnings

KNOW YOUR POWER TOOL. Read the owner’s manual carefully. Learn the tool’s

applications, work capabilities, and its specic potential hazards.

ALWAYS GROUND ALL TOOLS.

If your tool is equipped with a three-pronged plug, you must plug it into a three-hole electric receptacle.

If you use an adapter to accommodate a two-pronged receptacle, you must attach the adapter plug to a

known ground. Never remove the third prong of the plug.

ALWAYS AVOID DANGEROUS ENVIRONMENTS.

Never use power tools in damp or wet locations. Keep your work area well lighted and clear of clutter.

ALWAYS REMOVE THE ADJUSTING KEYS AND WRENCHES FROM TOOLS AFTER USE.

Form the habit of checking to see that keys and adjusting wrenches are removed from the tool before

turning it on.

ALWAYS KEEP YOUR WORK AREA CLEAN. Cluttered areas and benches invite accidents.

ALWAYS KEEP VISITORS AWAY FROM RUNNING MACHINES.

All visitors should be kept a safe distance from the work area.

ALWAYS MAKE THE WORKSHOP CHILDPROOF.

Childproof with padlocks, master switches, or by removing starter keys.

NEVER OPERATE A TOOL WHILE UNDER THE INFLUENCE OF DRUGS,

MEDICATION, OR ALCOHOL.

ALWAYS WEAR PROPER APPAREL.

Never wear loose clothing or jewelry that might get caught in moving parts. Rubber-soled footwear is

recommended for the best footing.

ALWAYS USE SAFETY GLASSES AND WEAR HEARING PROTECTION.

Also use a face or dust mask if the cutting operation is dusty.

NEVER OVERREACH.

Keep your proper footing and balance at all times.

NEVER STAND ON TOOLS.

Serious injury could occur if the tool is tipped or if the cutting tool is accidentally

2

ALWAYS DISCONNECT TOOLS.

Disconnect tools before servicing and when changing accessories such as blades, bits, and cutters.

ALWAYS AVOID ACCIDENTAL STARTING.

Make sure switch is in “OFF” position before plugging in cord.

NEVER LEAVE TOOLS RUNNING UNATTENDED.

ALWAYS CHECK FOR DAMAGED PARTS.

Before initial or continual use of the tool, a guard or other part that is damaged should be checked to

assure that it will operate properly and perform its intended function. Check for alignment of moving

parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect its

operation. A guard or other damaged parts should immediately be properly repaired or replaced.

Special Safety Rules For Belt & Disc Sanders

1. Do not operate this machine until you have read all of the following instructions.

2. Do not attempt to operate this machine until it is completely assembled.

3. Do not turn ON this machine if any pieces are missing.

4. If you are not familiar with the operation of the machine, obtain assistance from a

qualied person.

5. It is highly recommended that this machine be rmly mounted to a at and secure work surface

or stand.

6. Always wear protective eyewear prior to operating this machine.

7. Do not operate this machine if you are under the inuence of drugs and/or alcohol.

8. Remove all jewelry prior to operating this machine.

9. Do not wear any gloves while operating this machine.

10. Always make sure the power switch is in the OFF position prior to plugging in the machine.

11. Always make sure the power switch is in the OFF position when doing any assembly or setup

operation.

12. Always wear a dust mask and use adequate dust collection and proper ventilation. Use of

sanders can produce harmful particles while sanding certain types of woods.

13. The use of any accessories or attachments not recommended may cause injury to you and

damage your machine.

14. This machine must be properly grounded.

15. Abrasive discs and belts should be the recommended width and lenght of the manufacturer.

16. Always keep your face and hands clear of moving parts such as belts and pulleys.

17.Keep power supply cords free of moving parts of the sander. Damaged cords can result in

electric shock.

18. Maintain a 1/16” clearance between the sanding disc, sanding belt and tables

19.Always support the workpiece with the table or backstop.

20. Remove material or debris from the work area. Keep work area neat and clean.

21.Keep these instructions for future reference.

SAVE THESE INSTRUCTIONS.

Refer to them often.

Note: This owner’s manual is not a teaching aid. Use of this owner’s manual is intended to

show assembly, adjustments, and general use.

3

Table of Contents

Safety Warnings..................................................................................................................................2-3

Sander Safety Rules ..........................................................................................................................3

Specications ........................................................................................................................................4

Unpacking ............................................................................................................................4

Assembly ...........................................................................................................................5

Installing the Table Assembly....................................................................................................................6

Assembling the Work Support Fence..........................................................................................6

Leveling the Table Assembly ............................................................................................................7

Intalling the Sanding Belt ..........................................................................................................................7

Operation ...........................................................................................................................................7

On/Off Switch ............................................................................................................................................8

Electrical Requirements.......................................................................................................................9

Maintenance ...................................................................................................................................10

Timing Belt Replacement............................................................................................................................10

Trouble Shooting................................................................................................................................11

Wiring Diagram.................................................................................................................................11

Parts List .....................................................................................................................................12

Parts Explosion...........................................................................................................................................13

Notes .............................................................................................................................................14

Warranty .............................................................................................................................................15

Specications

Belt Size

Belt Speed

Disc Size

Disc Speed

Table Size

Belt Table Tilt

Disc Table Tilt

Motor

Amps

Volts

Net weight

4”x36”

1930 SFPM

6”

3420 SFPM

9” x 6-1/4”

o

0-90

o

45

1/3 HP

4

110

37 lbs

Unpacking

When unpacking, check to make sure the following parts are included. If any parts are missing

or broken, please call RIKON Power Tools at the number on the cover of this manual as soon as

possible.

Item # Description Qty

42 Base 1

35 Table 1

27 Pad 6” Sandpaper 1

36 Table Support 1

32 Guard, Disc 1

9 Support Work 1

70 Miter Gauge 1

Plastic bag contains 1

assembly hardware.

4

Assembly

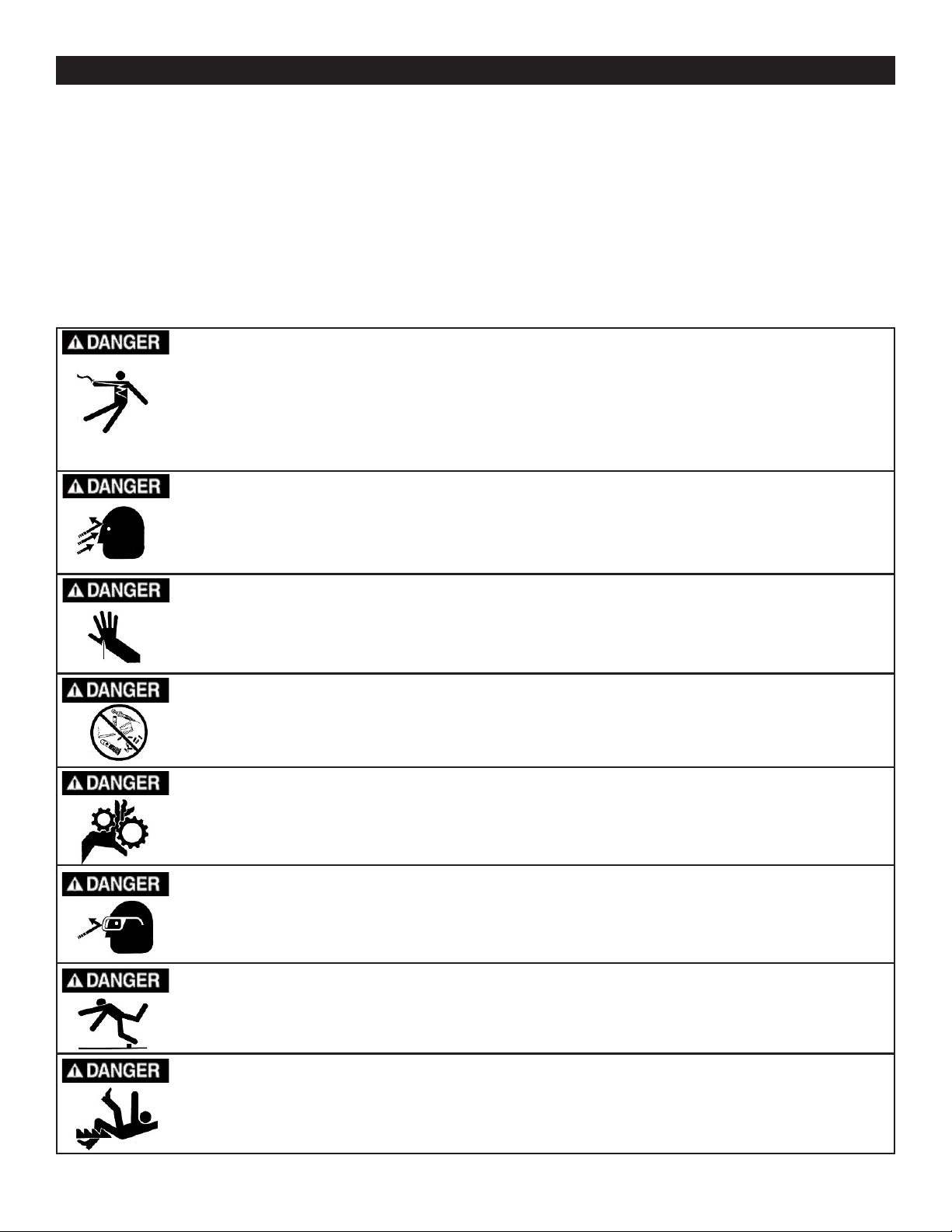

Securing Sander Base Assembly to

Workbench

The Sander Base must be secured before

using. Attach a large C-Clamp to each side of

the sander and the workbench. Or, permanently

mount following the instructions below:

1. Place the sander on the workbench in its

proper operating position.

2. Place a pencil through the mountong holes of

the sander base (42) and mark the hole locations

on workbench.

3. Remove sander and drill two 3/8 inch holes

through the workbench.

4. Align sander base over holes and secure using

two 5/16 inch screws (or larger) and hex nuts.

(See Fig. 01)

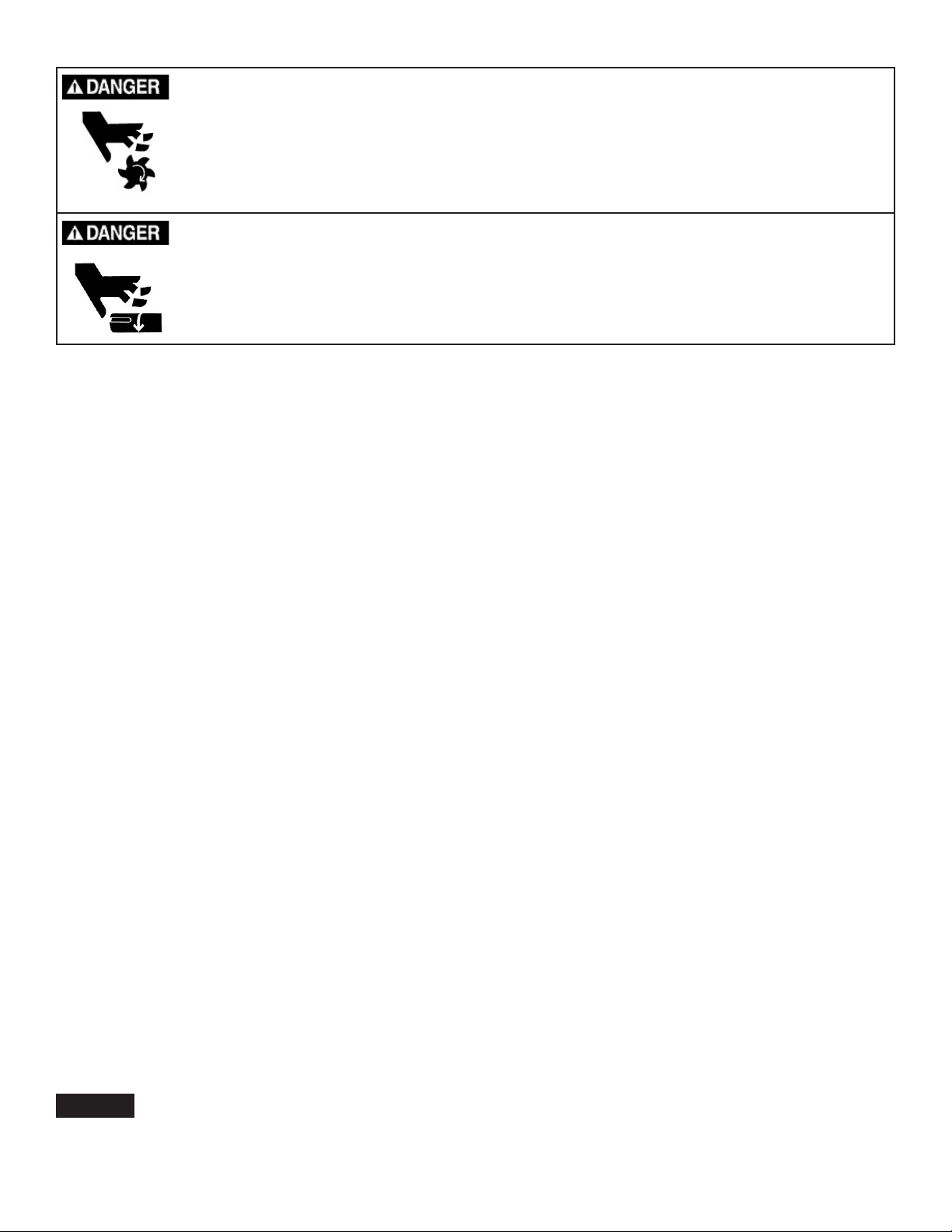

Mounting Sanding Disc and Guard

1. Locate sanding disc (27) and peel backing off

disc.

2. Align perimeter of sanding disc over plate.

When aligned, press disc rmly onto disc.

Fig. 01

Fig. 02

3. Position disc guard (32) onto lower portion of

sanding disc so that the mounting holes align.

4. Using a Phillips screwdriver, fasten two pan

head screws (found in parts bag) through disc

guard. (See Fig. 02)

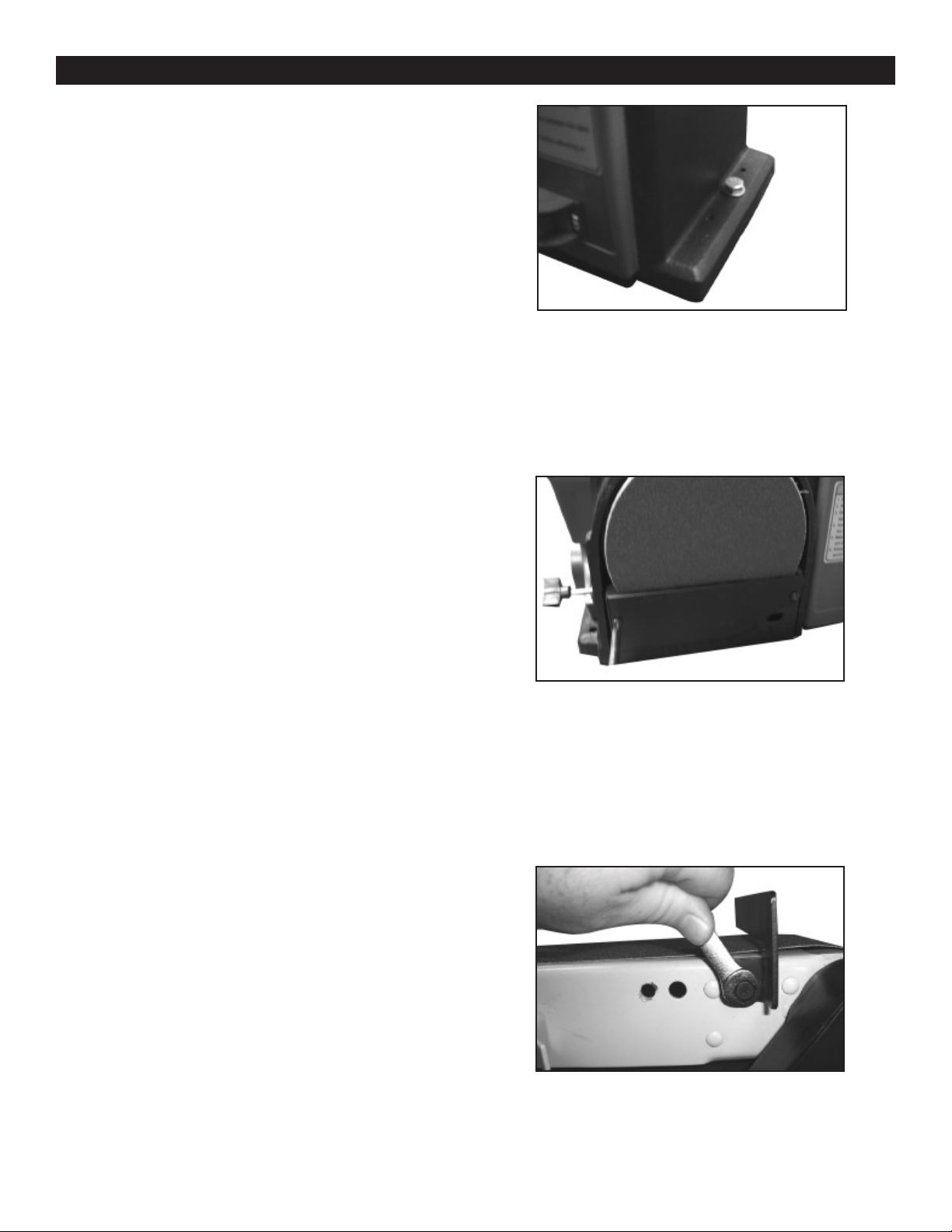

Installing the Work Support

1. Place Work Support (9) over sanding belt.

2. Place the hex screw (6) through the lock

washer and at washer (7 and 8) and fasten.

(See Fig. 03)

Fig. 03

5

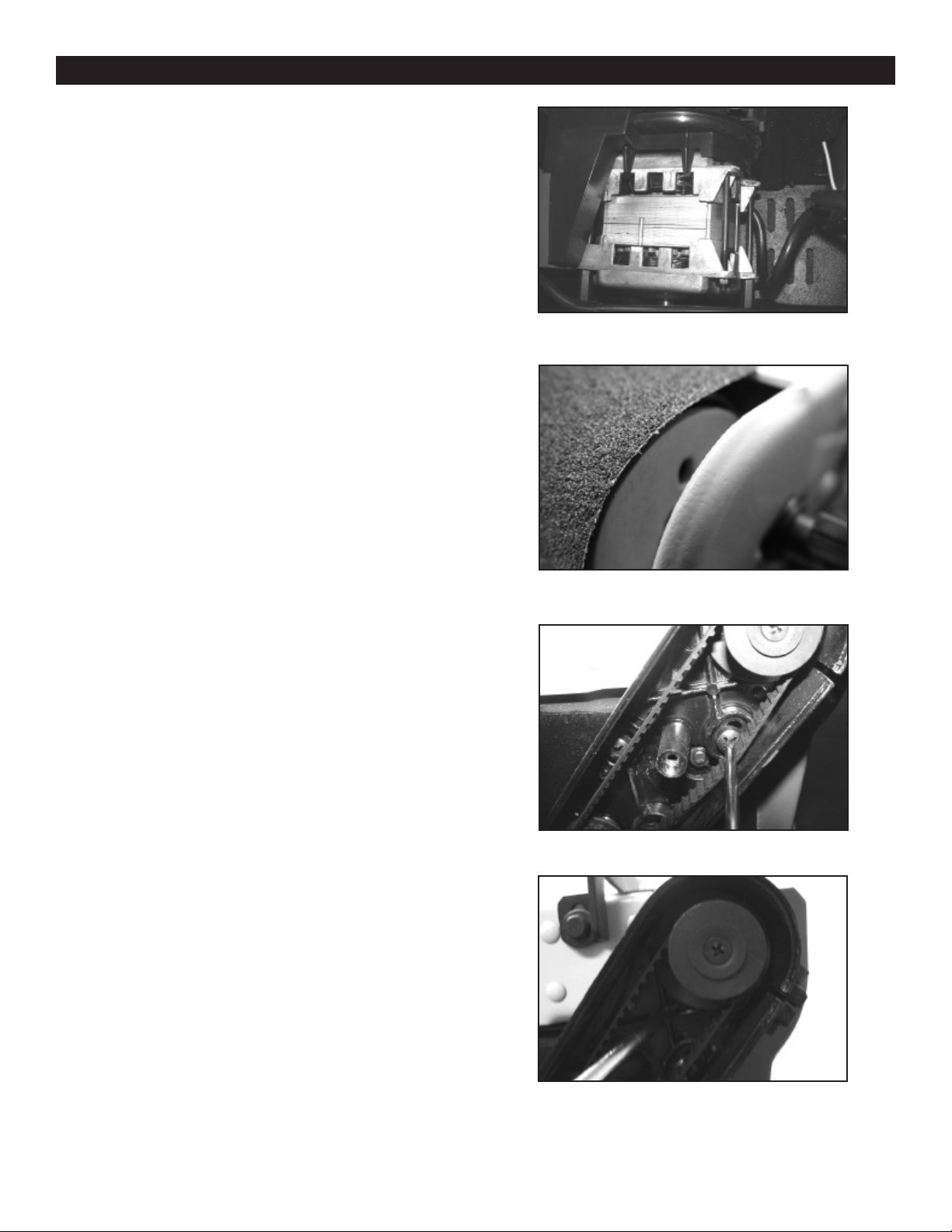

Installing the Table Assembly

1. Locate the Table Support (36) and mounting

hex screws (6) and washers (7 and 8).

2. Stand Table (35) on its side, align holes.

3. Fasten Table Support to Table. Do not over

tighten screws.

4. Position Table Support (36) in corresponding

holes on side of base. (See Fig. 04)

5. Place Washer (8) on Knob (1) shaft and insert

through slot into threaded holes in base.

6. Loosen the three Hex screws (6) and adjust

table so that there is a maximum of 1/16 inch

space between the sanding disc and the table.

Tighten screws. (See Fig. 05)

Fig. 04

Fig. 05

6

Leveling Table Assembly

1. Place a combination square on the Table (35)

so that it also touches the sanding Disc (27).

(See Fig. 08)

If the Table is 90 degrees to the Disc, no

adjustments are needed.

2. If the Table is not 90 degrees with the Disc,

loosen the table lock Knob (1) and tilt the Table

until the square is ush with the Disc.

3. Retighten the Knob to secure the table.

4. Attach the scale label (37) to the “0” degrees

mark on the dust guard (34).

Installing and Adjusting the Sanding Belt

Fig. 08

*Belt table must be in the vertical position.

1. Move Tension Lever (66) to the right to release

the Sanding Belt (10) tension. (See Fig. 09)

2. Place the Sanding Belt over the Drive and Idler

Drums (13 and 65). (See Fig. 10)

Make sure that the inside direction arrows point

down, towards the Drive Drum (13). (See Fig. 11)

3. Center Belt on both drums.

4. Slide Tension Lever (66) to the left to tighten

belt

tension.

5. Tighten Hex Socket Screw (56) when Bed (4)

is

in desired working position.

6. Plug the Power Cord (38) into the wall outlet.

Turn the power Locking Switch (22) On, and the

off

while viewing the belt movement. If the belt looks

like it was going to slide off either drum, the belt

racking needs to be adjusted (described in the

next

step).

7. If the Sanding Belt (10) moves towards the

Fig. 09

Fig. 10

Fig. 11

7

8. If the Sanding Belt (10) moves away from the

Sanding Disc (27) when it was turned on, turn

the tracking Knob (1) counter clockwise Ľ turn,

and test again. (See Fig. 12)

Operation

Operation

Warning: Disconnect machine from power supply

before making any adjustments.

Remounting Table for Vertical Sanding

1. Remove backstop lock bolt and remove work

support. (See Fig. 13)

2. Unscrew Knob (1) and remove.

3. Pull Table Support (36) index pins out of

mounting holes.

4. Loosen hex socket screw and raise sanding

bed to the desired sanding position.

5. Insert the Table index pins into the auxiliary

(upper) holes in the sanding position.

6. Tighten Hex Socket Screw (56). Make sure

table is not touching sanding belt.

Fig. 12

Fig. 13

On/Off Switch

The On/Off Locking Switch (22) needs to have

the switch key inserted before the switch can

be used (key located in parts bag). This feature

prevents unauthorized use of the sander. (See

Fig. 14)

CAUTION: Never walk away from sander when

machine is running. Always lock the switch in the

Off position and unplug from the power supply

when not in use.

(See Fig. 15)

Fig. 14

Fig. 15

8

Electrical Requirements

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric

current to reduce the risk of electric shock. This tool is equipped with an electric cord having an

equipment-grounding conductor and a grounding plug. The plug must be plugged into a matching

outlet that is properly installed and grounded in accordance with all local codes and ordinances.

Do not modify the plug provided. If it will not t the outlet, have the proper outlet installed by a

qualied electrician.

Improper connection of the equipment-grounding conductor can result in a risk of electric shock. The

conductor, with insulation having an outer surface that is green with or without yellow stripes, is the

equipment-grounding conductor. If repair or replacement of the electric cord or plug is necessary, do

not connect the equipment-grounding conductor to a live terminal.

Check with a qualied electrician or service personnel if the grounding instructions are not completely

understood, or if in doubt as to whether the tool is properly grounded.

Use only three wire extension cords that have three-prong grounding plugs and three-pole

receptacles that accept the tool’s plug.*

Repair or replace a damaged or worn cord immediately.

This tool is intended for use on a circuit that has an outlet that looks the one illustrated in Figure

A below. The tool has a grounding plug that looks like the grounding plug as illustrated in Figure A

below. A temporary adapter, which locks like the adapter as illustrated in Figure B below, may be

used to connect this plug to a two-pole receptacle, as shown in Figure B if a properly grounded outlet

is not available.** The temporary adapter should only be used until a properly grounded outlet can

be installed by a qualied electrician. The green colored rigid ear or tab, extending from the adapter,

must be connected to a permanent ground such as a properly grounded outlet box.

* Canadian electrical codes require extension cords to be certied SJT type or better.

** Use of an adapter in Canada is not acceptable.

9

Maintenance

1. Apply a light coat of paste wax to the worktable

to make feeding stock easier.

2. Use compressed air to blow out dust and

debris from sander and motor. (See Fig. 16)

Oil Sleeve Bearings

Oil sleeve bearings after each 10 hours of use

with 30 weight oil. (See Fig. 17)

1. Release belt tension by sliding the Tension

Lever (66) to the right.

2. Move the Sanding Belt (10) slightly to the right

or left of the Idler Drum (65) to expose the oval

shaped oiling hole.

3. Apply only two or three drops of oil in the left

and right oiling holes.

4. Adjust belt tracking – previously described.

Timing Drive Belt Replacement

Fig. 16

1. Using a Phillips screwdriver, remove the Screw

(44) from Belt Cover (52), and remove cover.

2. Loosen three screws to allow Drive Pulley (46

and 49) to shift enough to place Drive Belt (42)

around them. (See Fig. 18)

3. Place Drive Belt around Drive Pulley (46), then

Drive Pulley (49).

4. Tighten the three screws slightly.

5. Adjust tension of Drive Belt by placing a

standard screwdriver in the adjusting hole by

pushing up on the screwdriver to apply tension to

the Drive Belt. (See Fig. 19)

6. Tighten the three screws again.

7. Grab the Drive belt with two ngers on the

outside-center and squeeze. There should be

about Ľ inch give to the Drive Belt fro proper

tension.

NOTE: Too much tension on the Drive Belt can

load-down motor and cause possible damage. If

the Drive Belt is loose, it may fail prematurely.

Fig. 17

Fig. 18

8. Replace Belt Cover (52).

Fig. 19

10

Troubleshooting

Wiring Diagram

11

Parts List

Item #

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21*

22*

23

24

25

26

27

28

29

30

31

32

33

34

35

36

Description

Knob

Washer, Rubber

Washer, Notched

Bed

Screw, Flat Cross, M5x0.8-35

Screw, Hex M6x1.0-14

Lockwasher, Helical M5

Washer, 6.5x17.8x1.6

Support, Work

Belt, Sanding 4”x36”

Lockwasher, Helical M5

Screw, Pan Hd M5x0.8-8

Drum, Drive

Screw, Socket Set M8x1.25-10

Cap, Bearing

Bearing w/ Flat Washer

Spacer, Bearing

Housing Switch

Lockwasher, Ext. M5

Screw, Pan Hd. M5x0.8-16

Key Switch

Switch Locking

Lead

Screw, Pan Cross, type “AB” M4.2x1.4-30

Cover, Switch Box

Relay

Pad, 6” Sandpaper

Screw, Pan Cross M6x1.0-12

Lockwasher, Helical M6

Disc

Screw, Pan Hd type “AB” M4.2x1.4-12

Guard, Disc

Shroud, Disc

Collector, Dust

Table

Support, Table

Item #

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

Description

Label, Scale

Cord w/ Plug

Motor (1/3 HP)

Connector, Wire

Nut, Hex M6x1.0

Base

Belt, Timing Drive

Screw, Flat Cross M5x0.8-10

Washer, Countersink

Pulley, Drive

Screw, Pan Hd. M6x1.0-25

Washer, M6x12x1.6

Pulley, Drive

Screw, Flat Hd. M5x0.8-25

Support, Bearing

Cover, Belt

Support, Belt

Nut, Square M8x1.25

Bumper, Rubber

Screw, Hex Soc. Cap M8x1.25-25

Bearing, Ball

Ring, Retaining M12

Shaft, Drive

Nut, Hex Flange M5x0.8

Spacer, Guide

Spring, Index

Guide, Drum

Shaft, Idler

Drum, Idler

Lever, Tension

Spring, Tension

Spacer, Lever

Washer, M5x15x1.2

Miter Gauge

Manual

Warranty Card

12

Parts Explosion

13

Notes

14

Warranty

2-Year Limited Warranty

RIKON Power Tools Inc. (“Seller”) warrants to only the original retail consumer/purchaser of our

products that each product be free from defects in materials and workmanship for a period of two

(2) years from the date the product was purchased at retail. This warranty may not be transferred.

This warranty does not apply to defects due directly or indirectly to misuse, abuse, negligence,

accidents, repairs, alterations, lack of maintenance or normal wear and tear. Under no

circumstances will Seller be liable for incidental or consequential damages resulting from

defective products. All other warranties, expressed or implied, whether of merchantability,

tness for purpose, or otherwise are expressly disclaimed by Seller. This warranty does not cover

products used for commercial, industrial or educational purposes.

This limited warranty does not apply to accessory items such as blades, drill bits, sanding discs or

belts and other related items.

Seller shall in no event be liable for death, injuries to persons or property, or for incidental,

contingent, special, or consequential damages arising from the use of our products.

To take advantage of this warranty proof of purchase documentation, which includes date of

purchase and an explanation of the complaint, must be provided.

The Seller reserves the right to effect at any time, without prior notice, those alterations to parts,

ttings, and accessory equipment which they may deem necessary for any reason whatsoever.

To take advantage of this warranty, please ll out the enclosed warranty card and send it to:

RIKON Warranty

16 Progress Rd.

Billerica, MA 01821

The card must be entirely completed in order for it to be valid. If you have any questions

please contact us at 877-884-5167 or warranty@rikontools.com.

15

For more information:

16 Progress Rd.

Billerica, MA 01821

877-884-5167/978-528-5380

Loading...

Loading...