RIKON Power Tools 30-251 User Manual

34” Floor Radial Drill Press

Model: 30-251

Part # 30-251M2

Record the serial number and date of purchase

in your manual for future reference.

Serial number:

Date of purchase:

For more information:

www.rikontools.com

or

info@rikontools.com

For Parts or Questions:

techsupport@rikontools.com or 877-884-5167

Owner’s Manual

Operator Safety: Required Reading

IMPORTANT!

instructions must be followed at all times.

There are certain applications for which this tool was designed. We strongly recommend that this tool not be modified

and/or used for any other application other than that for which it was designed. If you hav e any questions about its

application, do not use the tool until you have contacted us and we have advised you.

Safety is the single most important consideration in the operation of this equipment. The following

General Safety Warnings

KNOW YOUR POWER TOOL. Read the owner’s manual carefully. Learn the tool’s applications, work

capabilities, and its specific potential hazards.

ALWAYS GROUND ALL TOOLS.

If your tool is equipped with a three-pronged plug, you must plug it into a three-hole electric

receptacle. If you use an adapter to accommodate a two-pronged receptacle, you must attach the

adapter plug to a known ground. Never remove the third prong of the plug.

ALWAYS AVOID DANGEROUS ENVIRONMENTS.

Never use power tools in damp or wet locations. Keep your work area well lighted and clear of clutter.

ALWAYS REMOVE THE ADJUSTING KEYS AND WRENCHES FROM TOOLS AFTER USE.

Form the habit of checking to see that keys and adjusting wrenches are removed from the tool before

turning it on.

ALWAYS KEEP YOUR WORK AREA CLEAN. Cluttered areas and benches invite accidents.

ALWAYS KEEP VISITORS AWAY FROM RUNNING MACHINES.

All visitors should be kept a safe distance from the work area.

ALWAYS MAKE T HE WORKSHOP CHILDPROOF.

Childproof with padlocks, master switches, or by removing starter keys.

NEVER OPERATE A TOOL WHILE UNDER THE INFLUENCE OF DRUGS,

MEDICATION, OR ALCOHOL.

ALWAYS WEAR PROPER APPAREL.

Never wear loose clothing or jewelry that might get caught in moving parts. Rubber-soled footwear is

recommended for the best footing.

ALWAYS USE SAFETY GLASSES AND WEAR HEARING PROTECTION.

Also use a face or dust mask if the cutting operation is dusty.

NEVER OVERREACH.

Keep your proper f ooting and balance at all times.

NEVER STAND ON TOOLS.

Serious injury could occur if the tool is tipped or if the cutting tool is accidentally contacted.

2

ALWAYS DISCONNECT TOOLS.

Disconnect tools before servicing and when changing accessories such as blades, bits, and cutters.

ALWAYS AVOID ACCIDENTAL STARTING.

Make sure switch is in “OFF” position before plugging in cord.

NEVER LEAVE TOOLS RUNNING UNATTENDED.

ALWAYS CHECK FOR DAMAGED PARTS.

Before initial or continual use of the tool, a guard or other part that is damaged should be checked to

assure that it will operate properly and perform its intended function. Check f or alignment of moving

parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect

its operation. A guard or other damaged parts should immediately be properly repaired or replaced.

Special Safety Rules For Drill Press

1. Do Not operate the Drill Press until it is

assembled and you have read the instructions.

2. Do not operate the Drill Press unless you are

familiar with its safe operation. If you are not

familiar with the operation of a Drill Press seek

advice from your supervisor, instructor or other

qualified individual.

3. If you are using a bench top Drill Press, it must

be securely fastened to a stand or bench.

4. If you are operating a floor Drill Press it must

be securely fastened to the floor.

5. Always clear the table and work area before

turning on the Drill Press.

6. Always use drill bits, cutting tools and

accessories with a 1/2” shank or less.

7. Never place hands near the drill bit, cutting tool

or accessory.

8. Never wear loose clothing, gloves or ties while

operating the Drill Press.

9. Always have a firm footing while operating the

Drill Press.

10. Always keep work surface and work areas clear

of debris.

11. Never attempt to do set-up work, assembly or

layout work on the Drill Press while it is in

operation.

12.Never start the Drill Press with the drill bit,

cutting tool or accessory in contact with the

work-piece.

13.Always lock all table, column and head locks

before turning on the Drill Press.

14.Never operate the Drill Press with a damaged

drill bit, cutting tool or accessory.

15.Always check the drill bit, cutting tool or

accessory in tight in the chuck.

16.Never operate the Drill Press with the chuck

key in the chuck.

17.Always adjust the depth stop to avoid drilling

into the table surface.

18.Never drill material unless it is properly

supported. Non flat work-pieces require

additional support.

19.Always clamp the work piece to the table.

20. Always support large work-pieces at the same

height as the table.

21.Never remove the work-piece or clear the

table until the Drill Press comes to a complete

stop.

22.Always wear a face shield and safety glasses

while operating the Drill Press.

23.Never operate the Drill Press with missing,

damaged, worn, loose or defective parts.

24.Never adjust, change speeds or perform

maintenance on the Drill Press while it is

operating.

25. Always clean the work surface and work area

when finished operating the Drill Press.

26. Always disconnect the power when adjusting

or performing maintenance on the Drill Press.

27.Always disconnect the power when finished

using the Drill Press to prevent accidental

operation.

SAVE THESE INSTRUCTIONS.

Refer to them often.

3

Table of Contents

Safety Warnings....................................................................................................................................2

Drill Press Safety Rules ..........................................................................................................................3

Specifications ........................................................................................................................................4

Contents of Package...................................................................................................................5

Unpacking and Cleaning the Drill Press........................................................................................................5

Getting To Know Your Drill Press...........................................................................................................6

Assembly ..............................................................................................................................................7

Head Assembly.................................................................................................................................8

Installing/Removing the Chuck and Arbor...........................................................................................9-10

Installing the Table.......................................................................................................................................10

Adjustment and Operation..........................................................................................................................11

Head Adjustments ..................................................................................................................................11

Table Adjustments.......................................................................................................................................12

Changing Spindle Speeds.................................................................................................................12-13

Setting the Spindle Lock...............................................................................................................................13

Setting the Drill Depth...............................................................................................................................13

Maintenance.......................................................................................................................................14

Wiring Diagram.......................................................................................................................................14

Electrical Requirements..........................................................................................................................15

Troubleshooting ..................................................................................................................................16

Parts Explosion ................................................................................................................................17

Parts List ........................................................................................................................................18

Notes ..................................................................................................................................................19

Warranty .............................................................................................................................................20

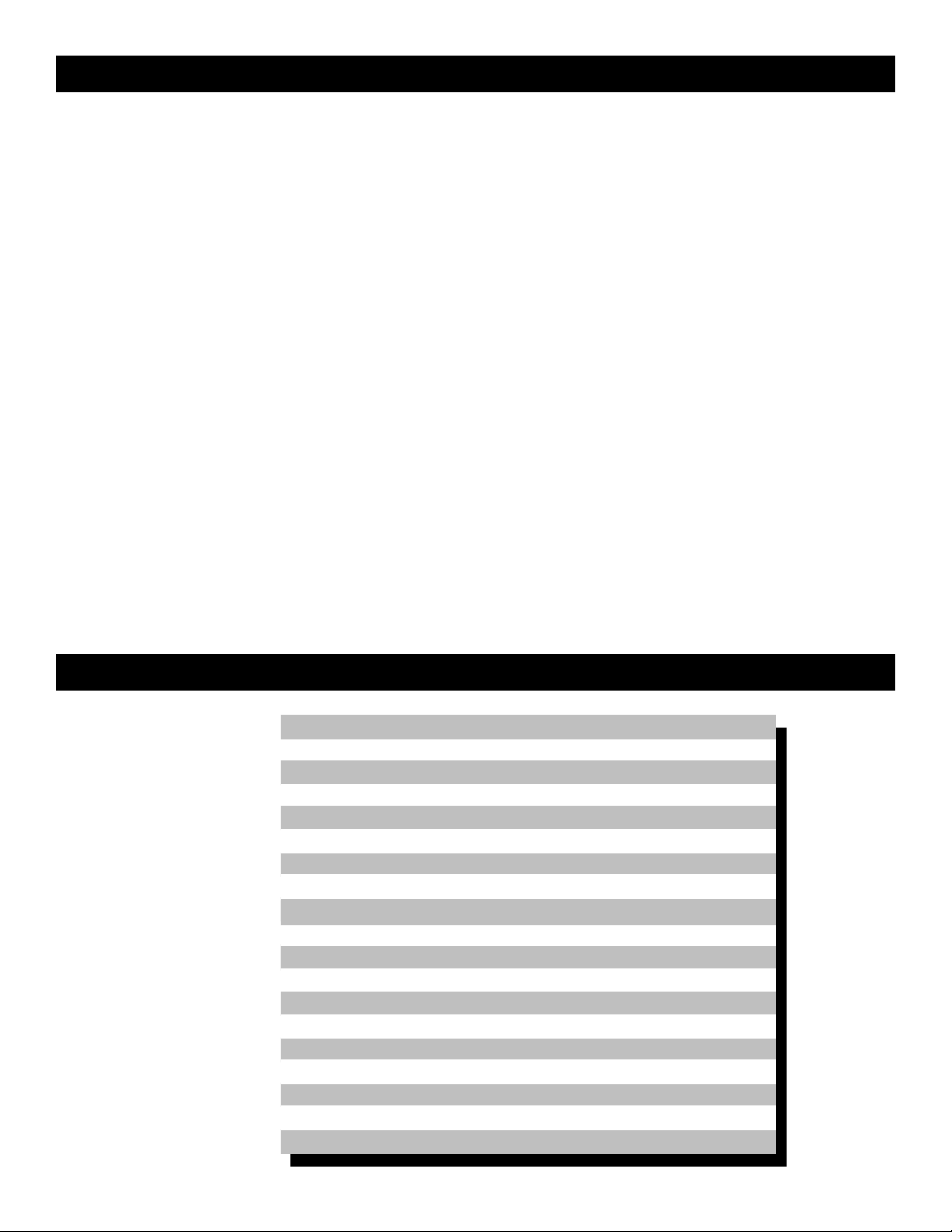

Specifications

Type

Swing

Motor

Chuck Size

Drilling Capacity

Spindle Travel

Spindle Taper

Head Rotates

Amps

Head Tilt

Volts

Number of Speeds

Net weight

Speed Range

Quill Diameter

Tab le

Table Tilt

Table Rotates

Base Size

Column Diameter

Overall Height

Net weight

Floor

34”

1/3 HP, 110V, 4.5A

5/8”

5/8”

3-1/8”

MT2

o

360

11

Left-90o Right-45

220

5

240 lbs

620-3,100RPM

2-3/16”

11-13/16” Round

o

45

o

360

18” x 10-5/8”

2-7/8”

64”

134 lbs

o

4

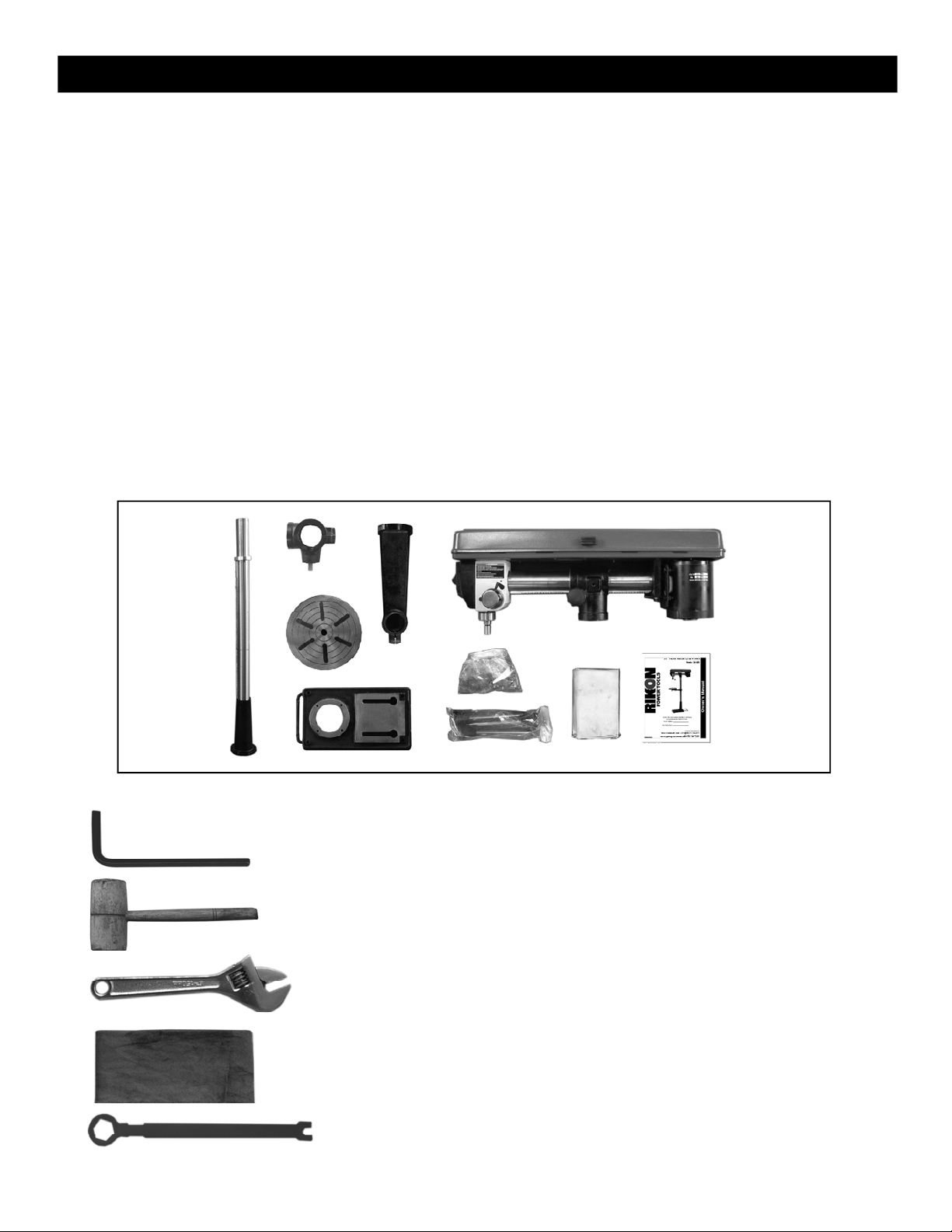

Contents of Package

Model 30-251 34” Floor Radial Drill Press

is shipped complete in one box.

1. Unpacking and Checking Contents

a. Separate all “loose parts” from packaging

materials and check each item with “Table of

Loose Parts” to make sure all items are

accounted for, before discarding any packaging

materi al.

b. With the help of another person, carefully lift the

Drill Press head out of the box.

c. Remove protective oil that is applied to the table

and column before assembly. Use any ordinary

house hold type grease or spot remover.

d. Apply a coat of paste wax to the table and

column to prevent rust. Wipe all parts thoroughly

with a clean dry cloth.

TABLE OF LOOSE PARTS

Item Part Name Qty

A Drill Press Head 1

BArm 1

C Table Support 1

DTable 1

E Column Assembly 1

FBase 1

G Loose Beg 2

H Chuck 1

I Owner’s manual 1

C

B

E

D

F

Tools required for assembly

1. Allen wrenches (provided).

2. Rubber mallet or block of wood and hammer.

3. Adjustable wrench or open end wrench.

G

G

H

A

I

4. Household grease remover.

5. Hex. Wrench (provided)

5

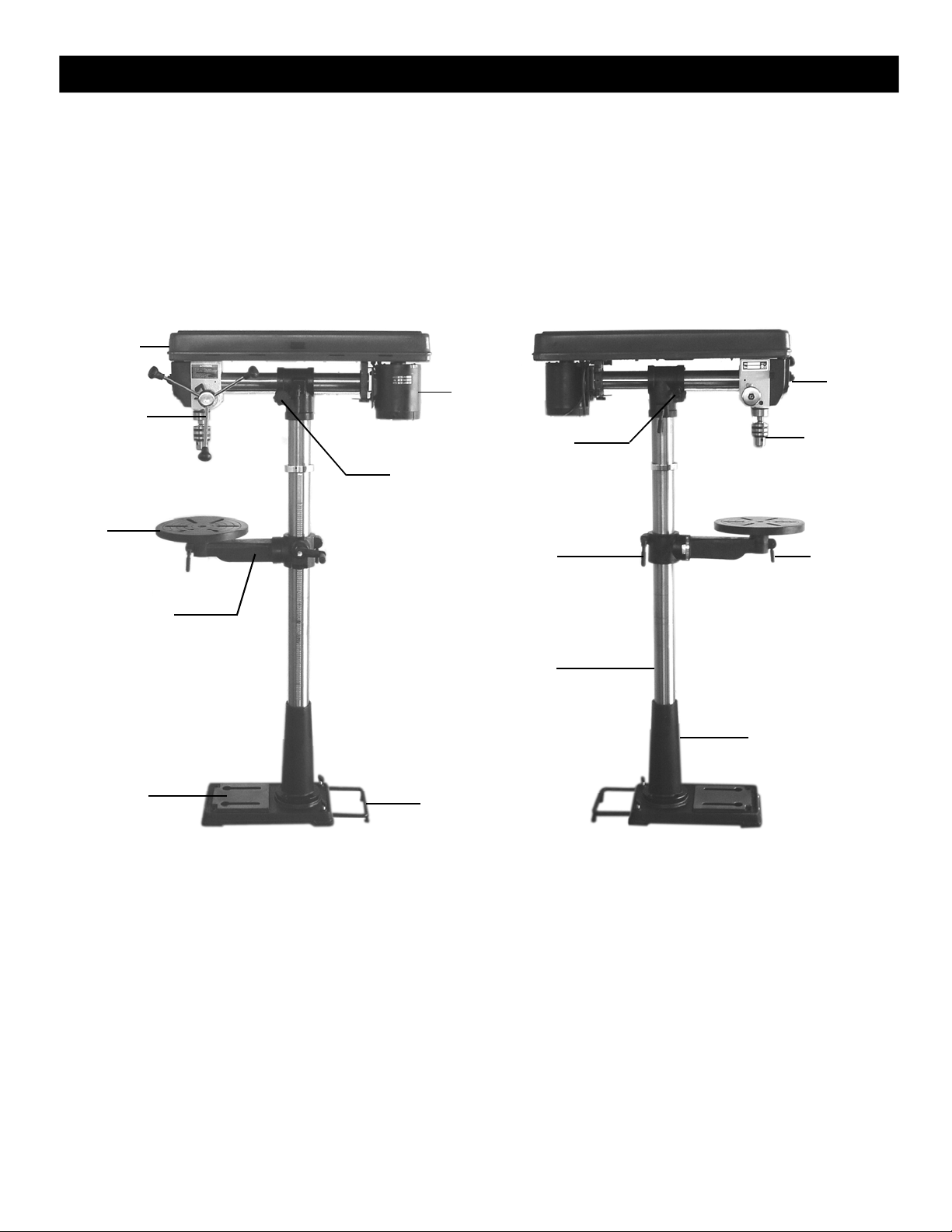

Belt Cover

Getting to Know Your Drill Press

Feed Handle

Ta b l e

Table support

Base

Motor

Crank Handle

Lock Handle Lock Handle

Extension

Support

Lock Handle

Column

Switch

Chuck

Column

Support

6

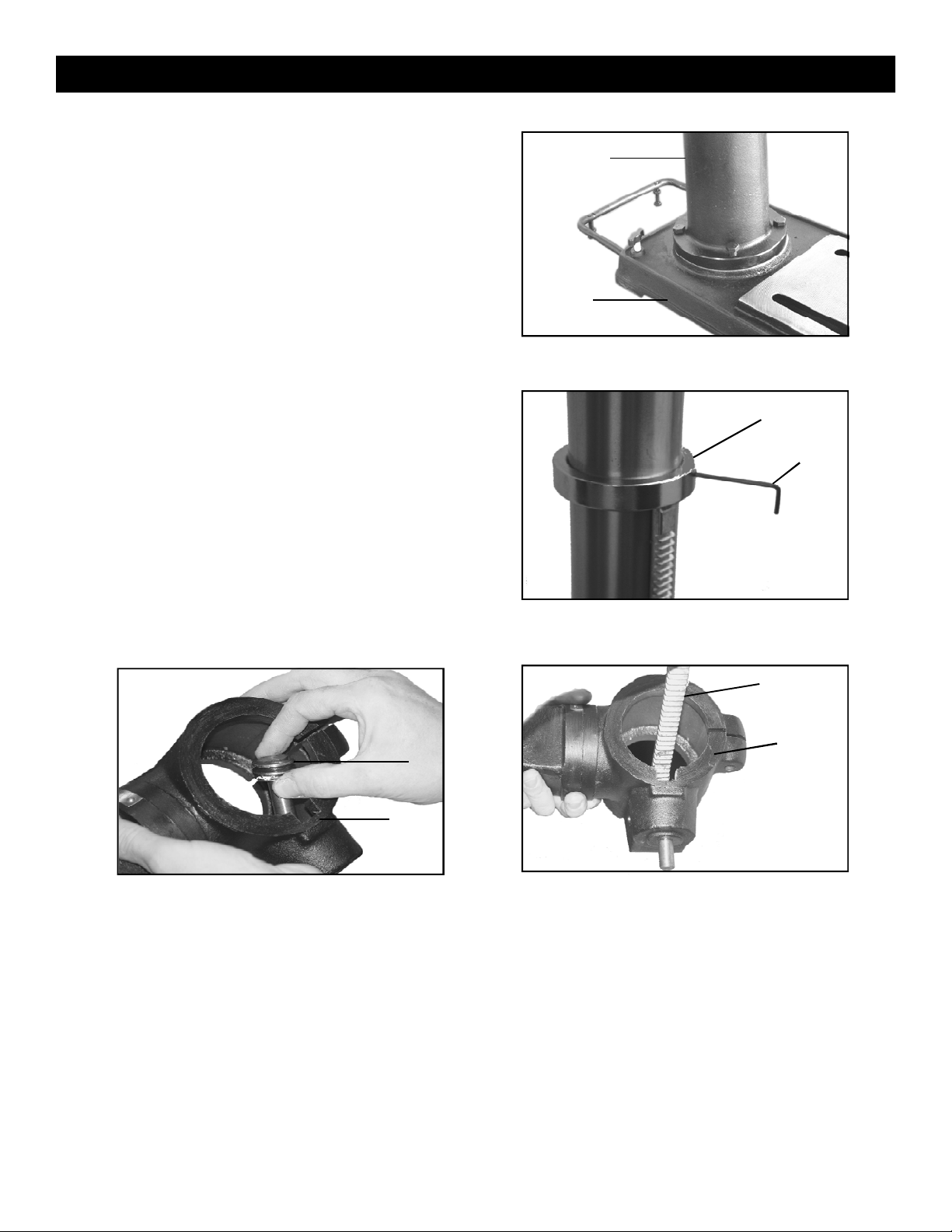

Base and Column Assembly

Assembly

1. Place the base (A-Fig. 1) on a level floor where

the machine will be used.

2. Attach the column (B-Fig.1) to the base (A-Fig.

1) using four M8x20 hex bolts. Tighten all four bolts.

3. Using an allen wrench (C-Fig. 2) remove the

column collar (D-Fig. 2) as shown.

4. Insert the worm elevation gear (E-Fig. 3) into the

table support bracket (F-Fig. 3) as shown.

5. Place rack (G-Fig. 4) inside the table support

bracket (F-Fig. 4) lining up the teeth as shown.

6. Slide the table support and rack assembly over

the column and replace the column collar.

B

A

Figure 1

D

C

Figure 3

Figure 2

G

F

E

F

Figure 4

7

Loading...

Loading...