RIKON Power Tools 25-200 User Manual

12" Planer/Jointer

Model: 25-200

Record the serial number and date of purchase

in your manual for future reference.

Serial number:

Date of purchase:

www.rikontools.com or info@rikontools.com

techsupport@rikontools.com or 877-884-5167

Part # 25-200M1

Owner’s Manual

For more information:

For Parts or Questions:

Index

1 GENERAL INFORMATION

1.1 Foreword

2 MACHINE DESCRIPTION

2.1 Machine identification

2.2 Getting to know your planer/jointer

2.3 Technical specification

2.4 Recommended protective clothing

2.5 Noise emission

2.6 Prescribed use of the machine

2.7 Hazards

2.8 Safety instructions for the planer/jointer

3 INSTALLATION

3.1 Lifting and unloading

3.2 Position of the machine

3.3 Identifying shipping boxes

3.4 Installation of loose parts

3.4.1 Fence rail installation

3.4.2 Fence installation

3.4.3 Switch installation

3.5 Electrical connection

3.6 Dust chute - installation

4 ADJUSTMENTS

4.1. Planer table height adjustment

4.2. Infeed table height adjustment

4.3. Jointer fence adjustment

5 OPERATING PROCEDURES

5.1 ON/OFF switch

5.2 Jointer mode

5.3 Planer mode

6 MAINTENANCE

6.1 Replacing cutter knives

6.2 Drive Belt Check

7 DIAGRAMS & COMPONENTS

8 NOTES

2

1. General Information

1.1 FOREWORD

This manual must be read and understood before operating the machine. This will provide a better working knowledge of the

machine, for increased safety and to obtain the best results.

2. Machine Description

2.1 MACHINE IDENTIFICATION

There is a identification plate attached to the rear of the machine, containing machine data and serial number.

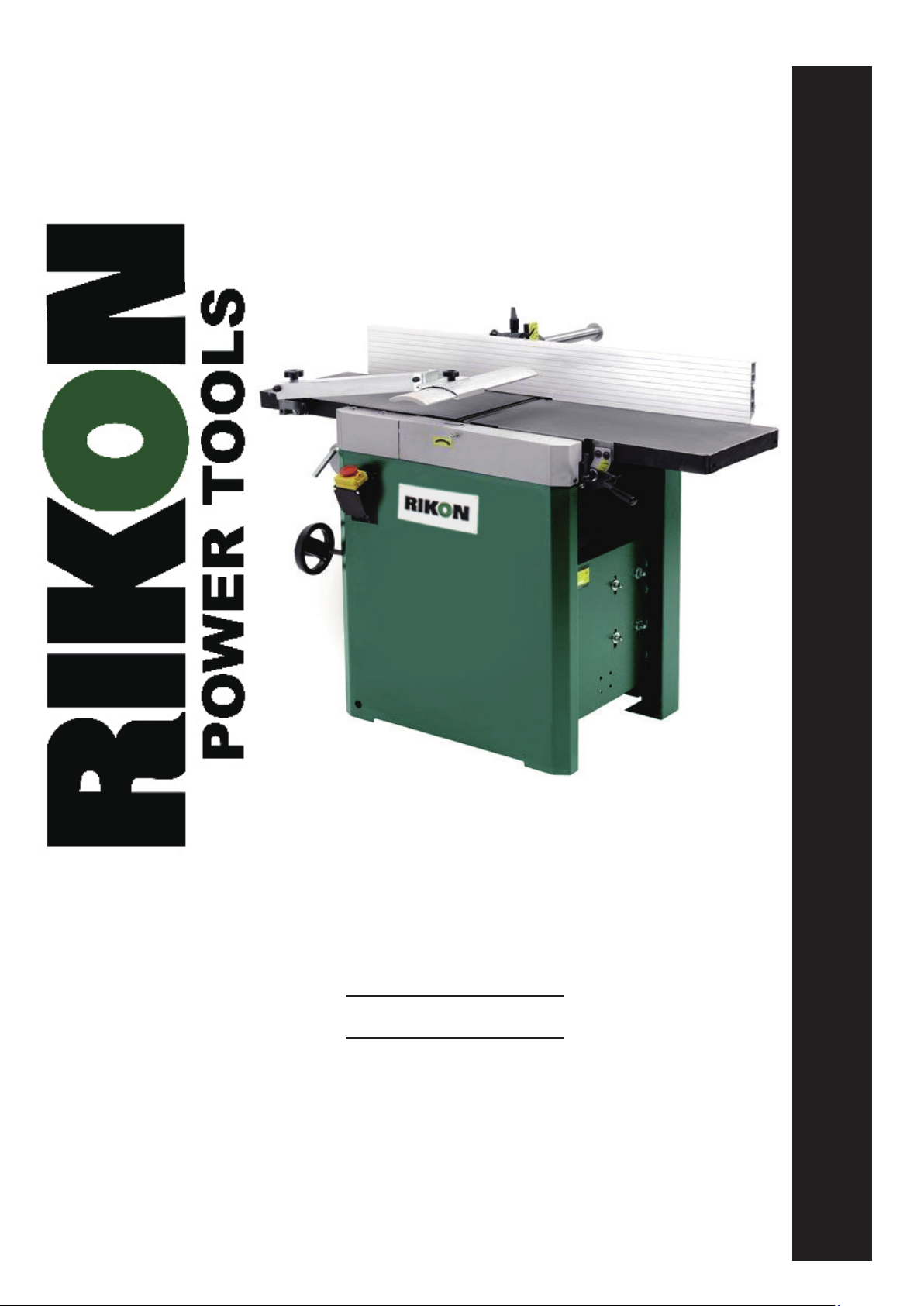

2.2 GETTING TO KNOW YOUR PLANER/JOINTER

2

8

1

6

10

5

9

3

4

7

1 Dust chute

2 Jointer fence

3 Infeed table

4 Height setting of infeed table

5 Cutterblock

6 On/off switch

7 Locking level

8 Outfeed table

9 Cutterhead guard

10 Height setting of the planer bed

3

2.3 TECHNICAL SPECIFICATION

SPECIFICATION 25-200

Feed speed sf/min 23

Cutterhead speed rpm 4700

Cutterhead diameter 2.75"

Max planer capacity 12" x 8"

Max planing width 12.20"

Max depth of cut jointer 1/8"

Max depth of cut planer 1/8"

Knives pcs 3

Fence tilting degree 0-45

Motor power output 3HP

Net Weight 386lbs

2.4 RECOMMENDED PROTECTIVE CLOTHING

• Non-slip footwear is recommended.

• Do not wear loose clothing, neckties or jewellery; they can be caught in moving parts.

• Roll up long sleeves above the elbow.

• Wear protective hair covering to contain long hair.

2.5 NOISE EMISSION

The measurements of noise, in the working position and during operation, were carried out under the standard ISO 7960 Annex B and C:

Instantaneous acoustic pressure:

Sound power level(no load) <98dB(A)

Sound power level(load) <107dB(A)

Sound Pressure level(no load) <89dB(A)

Sound Pressure level(load) <98dB(A)

Constant K=4 dB measured in accordance with EN ISO 3746:1995

The figures quoted are emission levels and are not necessarily safe working levels. Whilst there is a correlation between the emission

and exposure levels, this cannot be used reliably to determine whether or not further precautions are required. Factors that influence

the actual level of exposure of the workforce include the characteristics of the work room and the other sources of noise etc. i.e.

the number of machines and other adjacent processes. Also the permissible exposure level can vary from country to country. This

information, however, will enable the user of the machine to make a better evaluation of the hazard and risk.

2.6 PRESCRIBED USE OF THE MACHINE

This machine is intended for edge jointimg and thickness planing of solid woods. The permissible workpiece dimensions must be

observed (see Technical Specification).

Any other use is not as specified. Unspecified use, modification of the machine or use of parts not tested and approved by the

equipment manufacturer can cause unforeseen damage.

2.7 HAZARDS

ATTENTION Planing and jointing still present risks that cannot be eliminated by the manufacturer. Therefore the user must be aware

that wood working machines are dangerous if not used with care and all safety precautions adhered to.

4

2.8 SAFETY INSTRUCTIONS FOR PLANER/JOINTERS

A planer/jointer is a tool which can, due to operator carelessness, cause serious personal injury. It is therefore strongly recommended

you read and observe:

· these instructions, particularly the special safety information in the respective chapters;

· the relevant guidelines or regulations for the prevention of accidents pertaining to the use of planer/jointers, where applicable.

Keep all documents, supplied with the machine, for future reference.

The planer/jointer shall only be started and operated by persons familiar with planer/jointers and who are at any time aware of the

dangers associated with the operation of such tool. Persons under 18 years of age shall use this planer/thicknesser only under the

supervision of an instructor in the course of their vocational training.

The following residual risks do principally exist with planer/jointers and can not, even by employing safety devices, completely

eliminated:

- Hazard generated by environmental conditions:

do not operate the planer/jointer in rain or damp environment. Ensure sufficient lighting. Do not

operate the planer/jointer near inflammable liquids or gases.

- Hazard to other persons in the work area:

Keep bystanders, particularly children, out of the danger zone.

- Risk of injury by machine faults:

check the planer/jointer for damage before any use. Do not operate the machine with a damaged part. Replace blunt cutter knives at

once. Risk of injury by kickback if a blunt knife gets caught in the workpiece's surface.

- Risk of injury by an unstable stand of the planer/jointer:

when working long stock use suitable supports on both sides of the machine. Avoid adverse body positions. Ensure firm footing, and

keep your balance at all times.

- Risk of injury by foreign objects in the machine:

prior to any starting of the machine ensure that there are no objects (e.g. tools) in the machine.

- Risk of injury by workpiece kickback (workpiece is caught by the rotating cutterhead and thrown back against the

operator):

operate machine only with a fully functional anti-kickback lock. Always use sharp cutter knives. If in doubt check workpiece for

inclusion of foreign objects (e.g. nails, screws, lose knots).

- Risk of injury by touching the rotating cutterhead:

always keep your hands well clear of the cutterhead. Switch machine off and plug out if it is not used.

- Danger! Drawing-in/trapping hazard!

Take care that no parts of the body or clothing can get caught and drawn in by the rotating cutterblock (do not wear neck ties and

garments with wide sleeves; contain long hair with a hairnet).

- Risk of injury by cuts with cutterblock at standstill: Wear gloves when changing cutter knives.

- Risk of injury by inhaling wood dust: dust of certain timber species (e.g. oak, beech, ash) can cause cancer when inhaled. Use a

suitable dust collector:

Risk of injury by inadequate personal protection: when planing, wear:

- dust respirator;

- hearing protection;

- safety goggles.

California Propsition 65 Warning

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains

chemicals known to the State of California to cause cancer and birth defects or other reproductive harm.Your risk from

exposure to these chemicals varies, depending on how often you do this type of work. To reduce your exposure, work in

a well-ventilated area and with approved safety equipment, such as dust masks that are specially designed to lter out

microscopic particles.

For more detailed information about California Propostion 65 log onto rikontools.com.

5

3. Installation

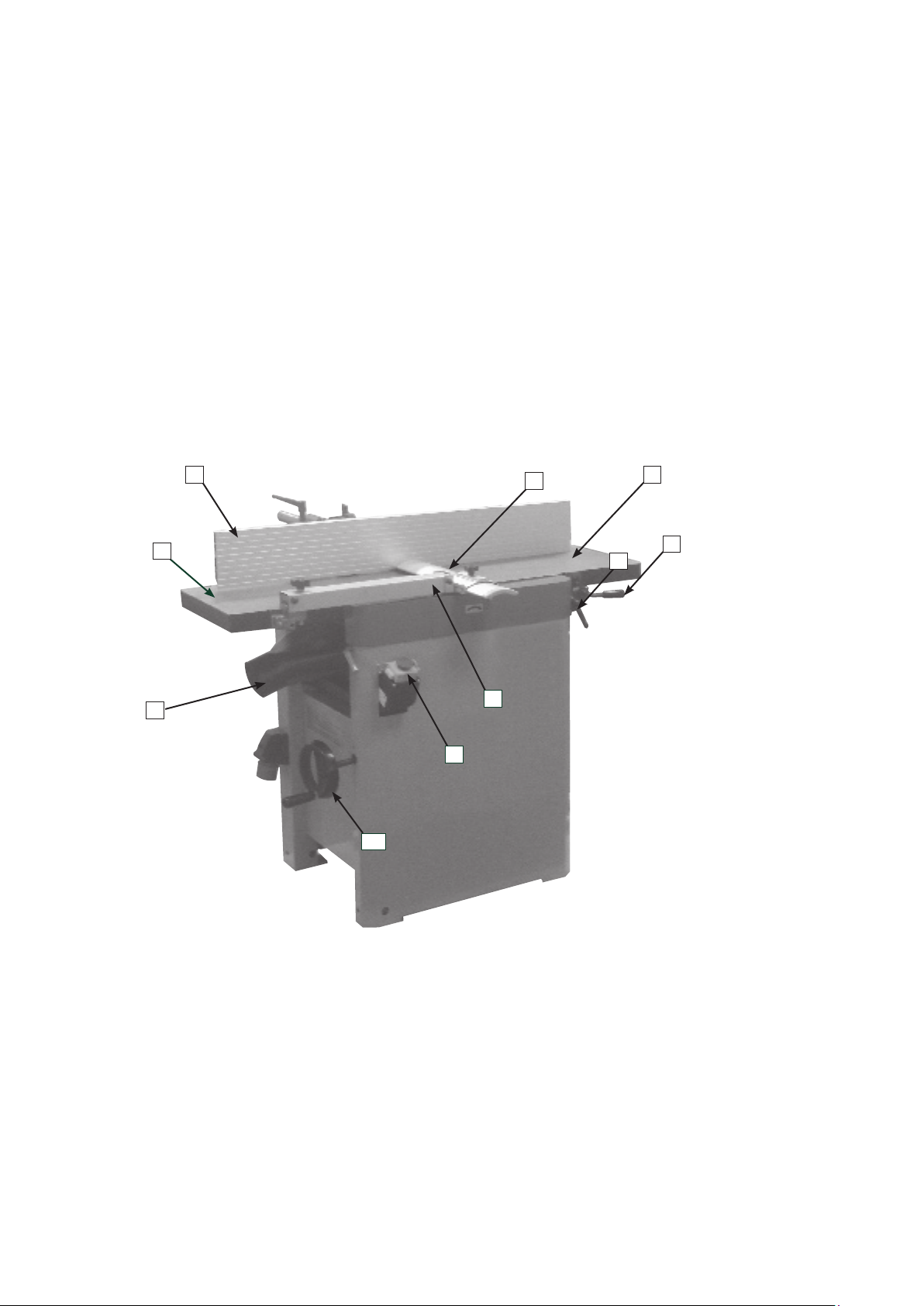

3.1. LIFTING AND UNLOADING

The machine can be transported by two means:

1. With a forklift truck. To do so, the machine is secured on a

pallet with four hex bolts.

2. With help. Here, the machine is carried by means of carrying

straps or two battens (A, Fig.1) placed underneath the planer

bed.

CAUTION

Do not move the machine by the infeed and outfeed tables,

these are not designed to withstand the tensile load by the

machine weight.

A

3.2 POSITION OF THE MACHINE

CAUTION

It is prohibited to install the machine in explosive environments.

Ensure that the floor area around the machine is level, well

maintained and free from loose material e.g. chips;

1. Remove four mounting bolts from the machine base.

2. Lift machine off the pallet and set down on the floor.

3. Fix the machine to the floor. Fix the machine feet and fix on

ground by means of expansion bolts (not supplied).

3.3 IDENTIFYING SHIPPING BOXES

BEFORE ASSEMBLY

It is advisable that before unpacking to have plenty of paper

towels or cloths available to clean off the rust preservative.

FIG. 1

FIG. 2

FIG. 3

6

3.4. INSTALLATIONS OF LOOSE PARTS

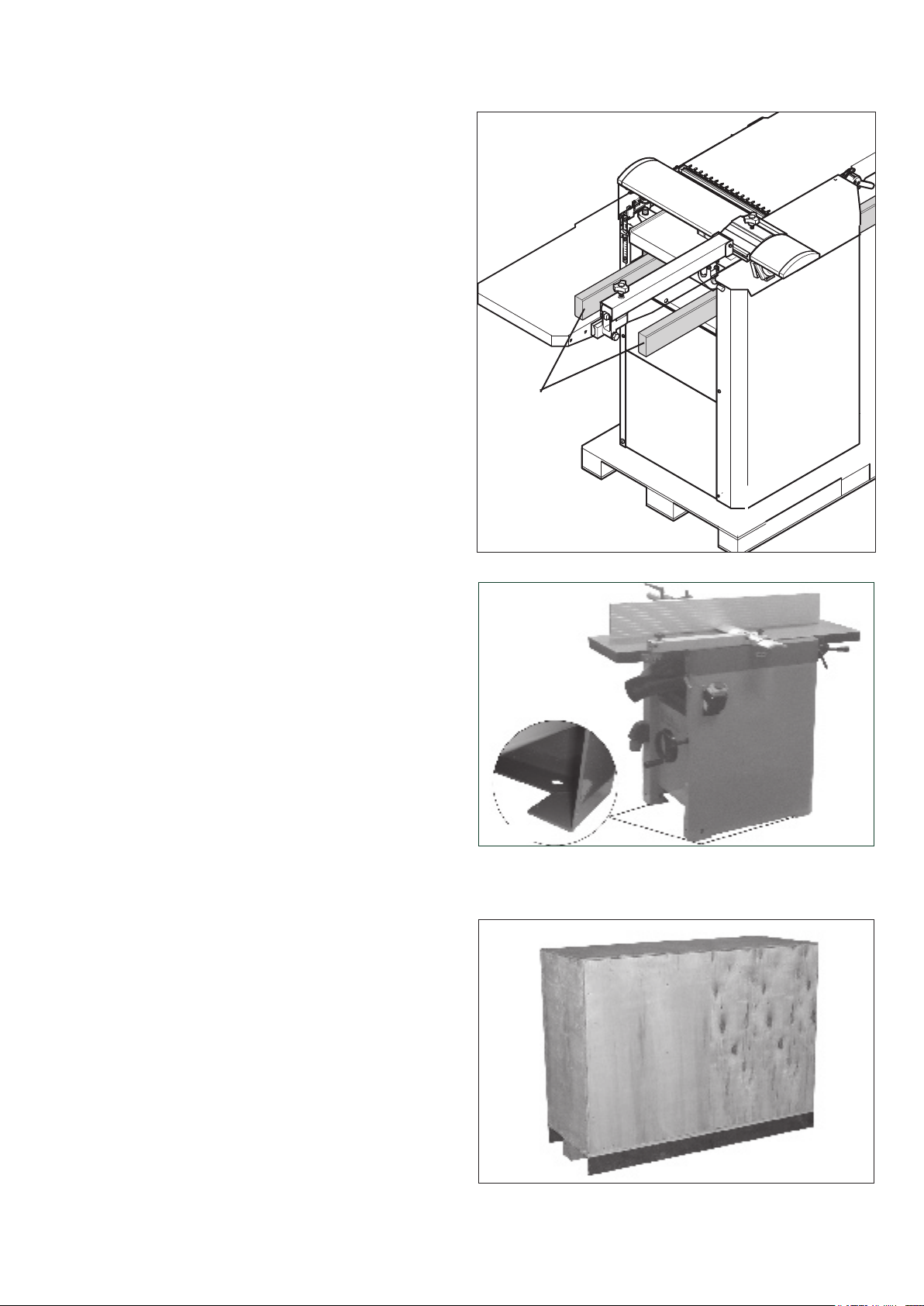

3.4.1 FENCE INSTALLATION

- To packaging, the fence seat (A, Fig. 4) is installed incorrectly

before shipment. Before installing the fence, taking off both of

the hex bolts (B, Fig. 4) and turn the fence seat 180 degrees.

- Locate the lock level (C. Fig.5) from the loose bag and install it

onto the fence seat as Fig.5.

A

B

FIG. 4

C

- Slide the fence guide bar (D, Fig.6) into the fence seat and

locking through the level (C, Fig.6)

3.4.2 SWITCH - INSTALLATION

- Fit the switch (G, Fig.7) onto the bracket with two hex nuts (H,

Fig.7)

FIG. 5

C

D

FIG. 6

H

7

FIG. 7

G

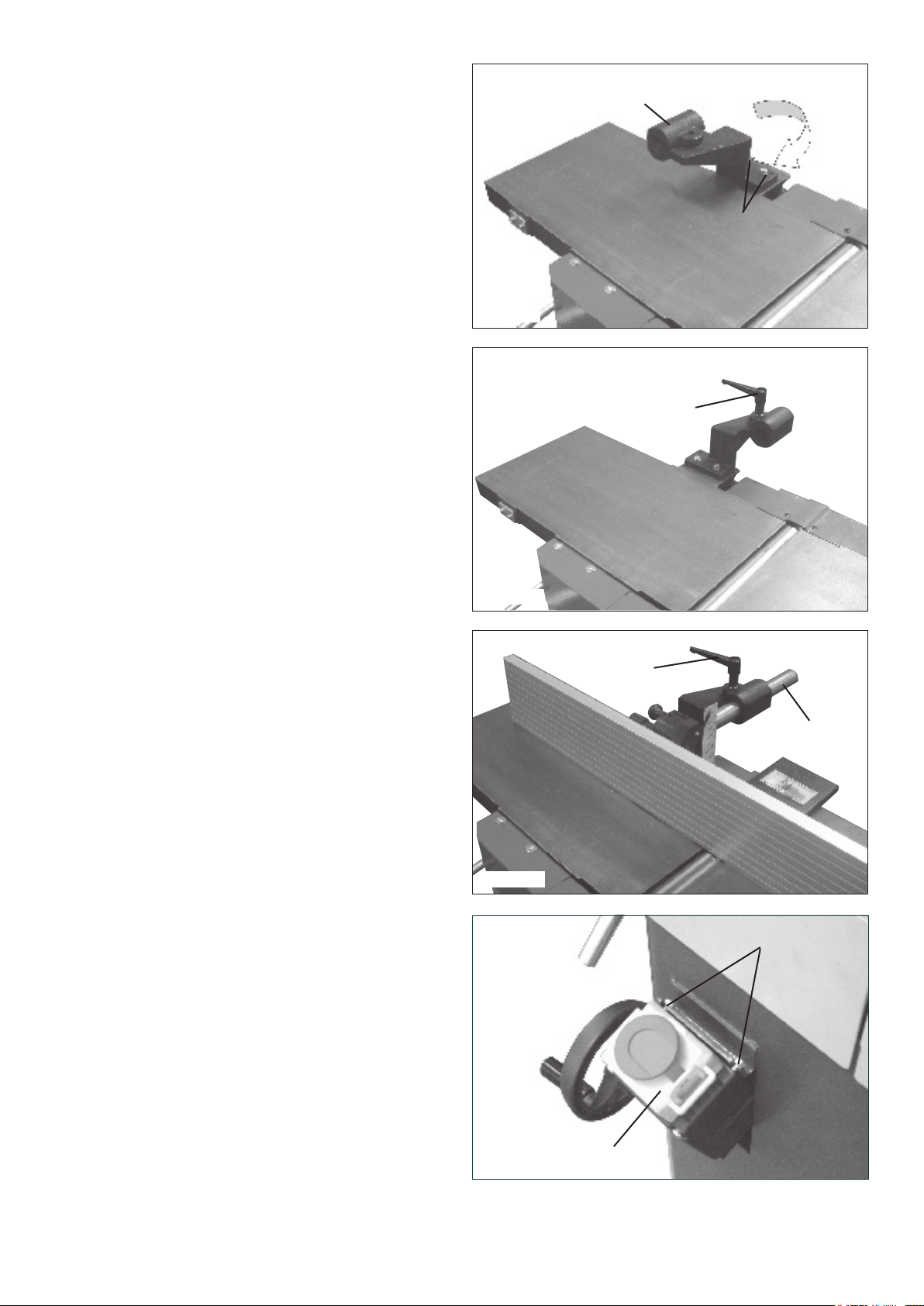

3.4.3 Cutterhead guard - INSTALLATION

- Take off both of the hex socket screws (A, Fig.8). Install the

cutterhead guard assembly (B, Fig.8) using two of hex socket

screws. Make sure the square washer (C, Fig. 8) stay between

the table and cutterhead guard.

FIG. 8

B

C

A

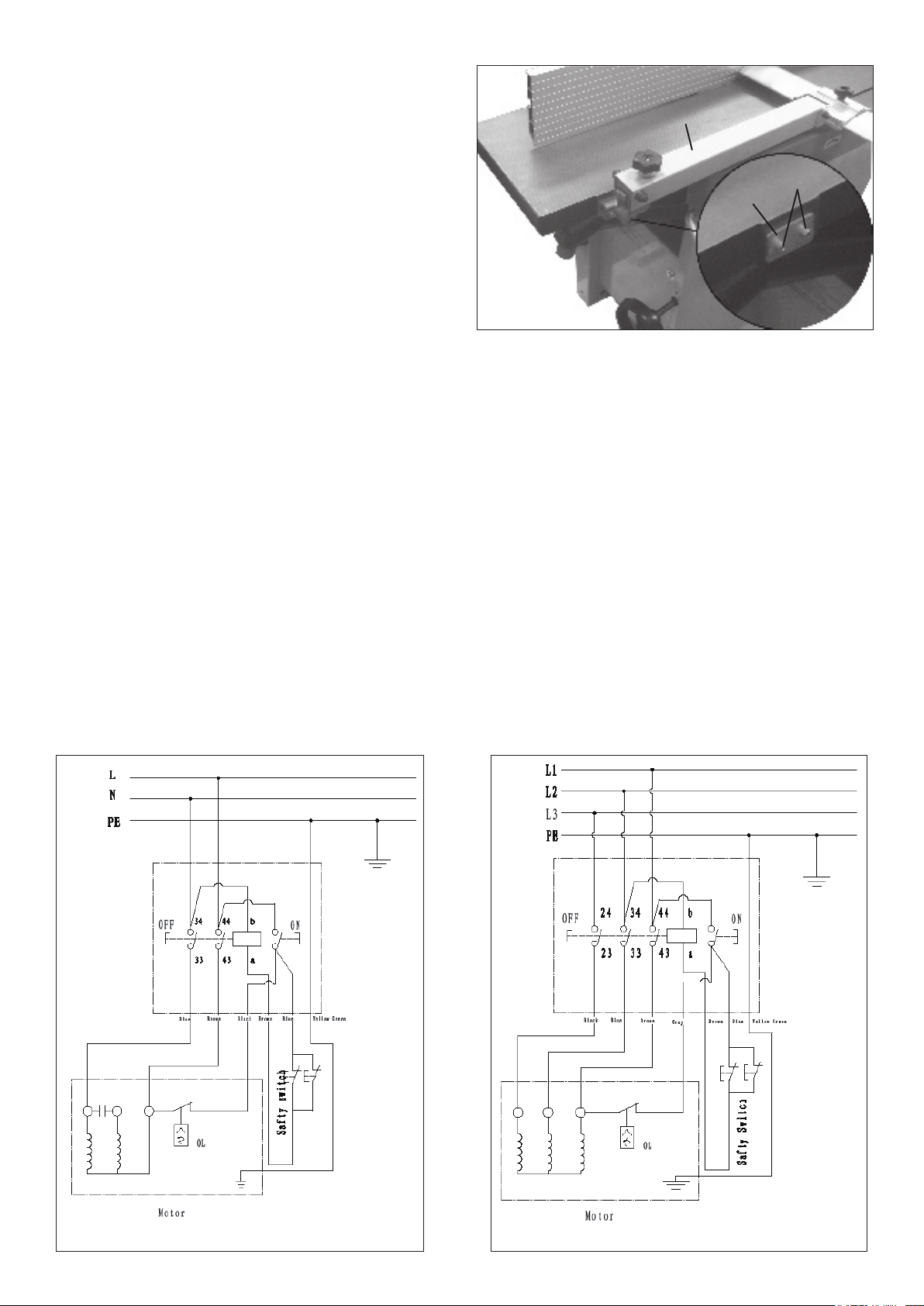

3.5 ELECTRICAL CONNECTION

Electrical installation should be carried out by competent, qualified personnel.

The connection should be made using the terminal box.

Ensure that the electrical supply corresponds with that of the machine, use cables of a section suitable for the power of the motor. For

an electrical supply of 230 V or a power rating greater than 15 A it will be necessary to increase the section of the connecting cables .

Connect the phase wires to the terminals R- S - T (L1 - L2 - L3) and the earth wire to the earth terminal.

On initial start-up check the direction of rotation, if it is incorrect then invert the two phase wires (for machines with 3 phase supply).

Direction of rotation of machines with single-phase supply is pre-determined during production .

On completion of the installation check that the terminal box is closed correctly and that the plug points are locked.

PT310 Single phase

PT310 Three phase

8

Loading...

Loading...