RIKON Power Tools 25-010H User Manual

25-010H

10” Planer / Jointer

with Helical Cutterhead

Operator’s Manual

Record the serial number and date of purchase in your manual for future reference.

Serial Number: _________________________ Date of purchase: _________________________

For technical support or parts questions, email techsupport@rikontools.com or call toll free at (877)884-5167

25-010HM2

www.rikontools.com

4001824

TABLE OF CONTENTS

Specications.....................................................................................................................2

Safety Instructions ........................................................................................................3 - 6

Getting To Know Your Machine ..............................................................................................7

Contents of Package .....................................................................................................7 - 8

Installation ......................................................................................................................8

Assembly .................................................................................................................... 9 - 11

Adjustments...............................................................................................................11 - 17

Operation ..................................................................................................................18 - 20

Maintenance ....................................................................................................................21

Electricals & Wiring Diagram .......................................................................................5 & 21

Troubleshooting .........................................................................................................22 - 23

Parts Diagrams & Parts Lists ..................................................................................24 - 29

Accessories ..........................................................................................................30

Notes ...............................................................................................................................30

Warranty ..........................................................................................................................31

SPECIFICATIONS

Motor .............................................................................................1-1/2 HP, TEFC

Motor Speed (no load).......................................................................... 3,400 RPM

Volts .................................................................................................... 110 / 220 V

Amps, Hertz ....................................................................................12 / 6 A, 60 Hz

Cutterhead Diameter .................................................................... 2-1/2" (63 mm)

Cutterhead Speed (RPM / CPM)....................................4,800 RPM / 19,200 CPM

Number of Carbide Inserts, 4-sided.................................................................... 44

Knife Insert Size (L x W x T) ...................................................0.59" x 0.59" x 0.10"

Maximum Depth of Cut (Planing & Jointing) .................................. 1/8" (3.18 mm)

Maximum Cutting Width (Planing & Jointing)....................................10" (255 mm)

Maximum Cutting Depth (Planing Height) ....................................6-1/4” (160 mm)

Planer Table Size ...............................................10-1/4" x 15-3/4" (260 x 400 mm)

Feed Speed Planing SF/min ......................................................24.6 (7.5 SM/min)

Jointer Table Size ...................................................11" x 40-1/2" (280 x 1003 mm)

Fence Size .......................................................................4" x 24" (100 x 610 mm)

Fence Tilting Degree ................................................................................... 0 - 45°

Dust Port ...............................................................................4” Diameter (95 mm)

Dust Collection Minimum CFM ........................................................................ 650

Overall Size (LxWxH).....................49-1/4" x 19" x 34" (1251 x 863.6 x 482.6 mm)

Base / Stand Size (approx.) .................................... 22” x 22-5/8” (560 x 575 mm)

Net Weight ......................................................................................147 lbs (67 kg)

NOTE: The specications, photographs, drawings and information in this manual represent the current model

when the manual was prepared. Changes and improvements may be made at any time, with no obligation on

the part of Rikon Power Tools, Inc. to modify previously delivered units. Reasonable care has been taken to

ensure that the information in this manual is correct, to provide you with the guidelines for the proper safety,

assembly and operation of this machine.

2

SAFETY INSTRUCTIONS

IMPORTANT! Safety is the single most important consideration in the operation of this equipment. The following

instructions must be followed at all times. Failure to follow all instructions listed below may result in electric shock,

re, and/or serious personal injury.

There are certain applications for which this tool was designed. We strongly recommend that this tool not be modied

and/or used for any other application other than that for which it was designed. If you have any questions about its

application, do not use the tool until you have contacted us and we have advised you.

SAFETY SYMBOLS

SAFETY ALERT SYMBOL: Indicates DANGER, WARNING, or CAUTION. This symbol may be used

in conjunction with other symbols or pictographs.

Indicates an imminently hazardous situation, which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation, which, if not avoided, could result in death or serious

injury.

Indicates a potentially hazardous situation, which, if not avoided, could result in minor or

moderate injury.

NOTICE: Shown without Safety Alert Symbol indicates a situation that may result in property damage.

GENERAL SAFETY

KNOW YOUR POWER TOOL. Read the owner’s manual

carefully. Learn the tool’s applications, work capabilities,

and its specic potential hazards.

4. AVOID A DANGEROUS WORKING ENVIRONMENT.

DO NOT use electrical tools in a damp environment or

expose them to rain.

BEFORE USING YOUR MACHINE

To avoid serious injury and damage to the tool, read and

follow all of the Safety and Operating Instructions before

operating the machine.

1. Some dust created by using power tools contains

chemicals known to the State of California to cause cancer,

birth defects, or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement, and other

• masonry products.

• Arsenic and chromium from chemically treated lumber.

Your risk from these exposures varies, depending on how

often you do this type of work. To reduce your exposure to

these chemicals: work in a well ventilated area and work

with approved safety equipment, such as those dust masks

that are specially designed to lter out microscopic

particles.

2. READ the entire Owner’s Manual. LEARN how to use

the tool for its intended applications.

3. GROUND ALL TOOLS. If the tool is supplied with a 3

prong plug, it must be plugged into a 3-contact electrical

receptacle. The 3rd prong is used to ground the tool and

provide protection against accidental electric shock. DO

NOT remove the 3rd prong. See Grounding Instructions

on the following pages.

5. DO NOT use electrical tools in the presence of

ammable liquids or gasses.

6. ALWAYS keep the work area clean, well lit, and

organized. DO NOT work in an environment with oor

surfaces that are slippery from debris, grease, and wax.

7. KEEP VISITORS AND CHILDREN AWAY. DO NOT

permit people to be in the immediate work area,

especially when the electrical tool is operating.

8. DO NOT FORCE THE TOOL to perform an operation

for which it was not designed. It will do a safer and

higher quality job by only performing operations for

which the tool was intended.

9. WEAR PROPER CLOTHING. DO NOT wear loose

clothing, gloves, neckties, or jewelry. These items can

get caught in the machine during operations and pull the

operator into the moving parts. The user must wear a

protective cover on their hair, if the hair is long, to

prevent it from contacting any moving parts.

10. CHILDPROOF THE WORKSHOP AREA by

removing switch keys, unplugging tools from the

electrical receptacles, and using padlocks.

11. ALWAYS UNPLUG THE TOOL FROM THE

ELECTRICAL RECEPTACLE when making adjustments, changing parts or performing any maintenance.

3

SAFETY INSTRUCTIONS

12. KEEP PROTECTIVE GUARDS IN PLACE AND IN

WORKING ORDER.

13. AVOID ACCIDENTAL STARTING. Make sure that

the power switch is in the “OFF” position before plugging

in the power cord to the electrical receptacle.

14. REMOVE ALL MAINTENANCE TOOLS from the

immediate area prior to turning “ON” the machine.

15. USE ONLY RECOMMENDED ACCESSORIES. Use

of incorrect or improper accessories could cause serious

injury to the operator and cause damage to the tool. If in

doubt, check the instruction manual that comes with that

particular accessory.

16. NEVER LEAVE A RUNNING TOOL UNATTENDED.

Turn the power switch to the “OFF” position. DO NOT

leave the tool until it has come to a complete stop.

17. DO NOT STAND ON A TOOL. Serious injury could

result if the tool tips over, or you accidentally contact the

tool.

18. DO NOT store anything above or near the tool where

anyone might try to stand on the tool to reach it.

19. MAINTAIN YOUR BALANCE. DO NOT extend

yourself over the tool. Wear oil resistant rubber soled

shoes. Keep oor clear of debris, grease, and wax.

25. ALWAYS WEAR A DUST MASK TO PREVENT

INHALING DANGEROUS DUST OR AIRBORNE

PARTICLES, including wood dust, crystalline silica dust

and asbestos dust. Direct particles away from face and

body. Always operate tool in well ventilated area and

provide for proper dust removal. Use dust collection

system wherever possible. Exposure to the dust may

cause serious and permanent respiratory or other injury,

including silicosis (a serious lung disease), cancer, and

death. Avoid breathing the dust, and avoid prolonged

contact with dust. Allowing dust to get into your mouth

or eyes, or lay on your skin may promote absorption of

harmful material. Always use properly tting NIOSH/OSHA

approved respiratory protection appropriate for the dust

exposure, and wash exposed areas with soap and water.

26. USE A PROPER EXTENSION CORD IN GOOD

CONDITION. When using an extension cord, be sure to

use one heavy enough to carry the current your product

will draw. The table on the following page shows the correct size to use depending on cord length and nameplate

amperage rating. If in doubt, use the next heavier gauge.

The smaller the gauge number, the larger diameter of the

extension cord. If in doubt of the proper size of an extension cord, use a shorter and thicker cord. An undersized

cord will cause a drop in line voltage resulting in a loss of

power and overheating.

USE ONLY A 3-WIRE EXTENSION CORD THAT HAS

A 3-PRONG GROUNDING PLUG AND A 3-POLE

RECEPTACLE THAT ACCEPTS THE TOOL’S PLUG.

20. MAINTAIN TOOLS WITH CARE. Always keep tools

clean and in good working order. Keep all blades and tool

bits sharp, dress grinding wheels and change other

abrasive accessories when worn.

21. EACH AND EVERY TIME, CHECK FOR DAMAGED

PARTS PRIOR TO USING THE TOOL. Carefully check

all guards to see that they operate properly, are not damaged, and perform their intended functions. Check for

alignment, binding or breaking of moving parts. A guard

or other part that is damaged should be immediately

repaired or replaced.

22. DO NOT OPERATE TOOL WHILE TIRED, OR

UNDER THE INFLUENCE OF DRUGS, MEDICATION

OR ALCOHOL.

23. SECURE ALL WORK. Use clamps or jigs to secure

the workpiece. This is safer than attempting to hold the

workpiece with your hands.

24. STAY ALERT, WATCH WHAT YOU ARE DOING,

AND USE COMMON SENSE WHEN OPERATING A

POWER TOOL.

A moment of inattention while operating power tools may

result in serious personal injury.

27. ADDITIONAL INFORMATION regarding the safe and

proper operation of this product is available from:

• Power Tool Institute

1300 Summer Avenue

Cleveland, OH 44115-2851

www.powertoolinstitute.org

• National Safety Council

1121 Spring Lake Drive

Itasca, IL 60143-3201

www.nsc.org

• American National Standards Institute

25 West 43rd Street, 4th Floor

New York, NY 10036

www.ansi.org

• ANSI 01.1 Safety Requirements for

Woodworking Machines and the

U.S. Department of Labor regulations

www.osha.gov

28. SAVE THESE INSTRUCTIONS. Refer to them

frequently and use them to instruct others.

4

SAFETY INSTRUCTIONS

ELECTRICAL SAFETY

THIS TOOL MUST BE GROUNDED

WHILE IN USE TO PROTECT THE OPERATOR FROM

ELECTRIC SHOCK.

IN THE EVENT OF A MALFUNCTION OR BREAKDOWN,

grounding provides the path of least resistance for electric

current and reduces the risk of electric shock. This tool

is equipped with an electric cord that has an equipment

grounding conductor and requires a grounding plug (not

included). The plug MUST be plugged into a matching electrical receptacle that is properly installed and grounded in

accordance with ALL local codes and ordinances.

DO NOT MODIFY ANY PLUG. If it will not t the electrical

receptacle, have the proper electrical receptacle installed

by a qualied electrician.

IMPROPER ELECTRICAL CONNECTION of the

equipment grounding conductor can result in risk of

electric shock. The conductor with the green insulation

(with or without yellow stripes) is the equipment grounding conductor. DO NOT connect the equipment grounding

conductor to a live terminal if repair or replacement

of the electric cord or plug is necessary.

EXTENSION CORDS

THE USE OF AN EXTENSION CORD

WITH THIS MACHINE IS NOT RECOMMENDED. For

best power and safety, plug the machine directly into a

dedicated, grounded electrical outlet that is within the

supplied cord length of the machine.

If and extension cord needs to be used, it should only

be for a limited operation of the machine. The extension cord should be as short as possible in length, and

have a minimum gauge size of 14AWG.

Check extension cords before each

use. If damaged replace immediately. Never use a tool

with a damaged cord, since touching the damaged

area could cause electrical shock, resulting in serious

injury.

Use a proper extension cord. Only use cords listed by

Underwriters Laboratories (UL). Other extension cords can

cause a drop in line voltage, resulting in a loss of power

and overheating of tool. When operating a power tool outdoors, use an outdoor extension cord marked “W-A” or “W”.

These cords are rated for outdoor use and reduce the risk

of electric shock.

CHECK with a qualied electrician or service personnel if

you do not completely understand the grounding

instructions, or if you are not sure the tool is properly

grounded when installing or replacing a plug.

USE ONLY A 3-WIRE EXTENSION CORD THAT HAS

THE PROPER TYPE OF A 3-PRONG GROUNDING PLUG

THAT MATCHES THE MACHINE’S 3-PRONG PLUG AND

ALSO THE 3-POLE RECEPTACLE THAT ACCEPTS THE

TOOL’S PLUG. *

REPLACE A DAMAGED OR WORN CORD

IMMEDIATELY.

This tool is intended for use on a circuit that has a 120

volt electrical receptacle. FIGURE A shows the type of the

220v, 3-wire electrical plug and electrical receptacle that

has a grounding conductor that is required if the motor

wiring is changed. See page 21.

Sample of 220 volt plug required for this machine.

Consult a qualied electrician

if the distance of the

machine from the electrical

panel is greater than 30 feet.

FIG. A

Keep the extension cord clear of

the working area. Position the cord so that it will not

get caught on lumber, tools or other obstructions while

you are working with your power tool.

* Canadian electrical codes require extension cords to

be certied SJT type or better.

** The use of an adapter in Canada is not acceptable.

THIS SYMBOL DESIGNATES

THAT THIS TOOL IS LISTED BY

THE INTERTEK TESTING

SERVICES, TO UNITED STATES

AND CANADIAN STANDARDS.

5

SAFETY INSTRUCTIONS

SPECIFIC SAFETY INSTRUCTIONS FOR PLANER / JOINTERS

This machine is intended for the surfacing of natural, solid woods. The permissible workpiece dimensions must be

observed (see Technical Specification). Any other use not as specified, including modification of the machine or use of

parts not tested and approved by the equipment manufacturer can cause unforeseen damage.

ATTENTION:

the user must be aware that wood working machines are dangerous if not used with care and all safety precautions are

adhered to.

1. Do not operate this machine until you have read all of the following instructions.

2. Do not attempt to operate this machine until it is completely assembled.

3. Do not turn ON this machine if any pieces are damaged or missing.

4. This machine must be properly grounded.

5. If you are not familiar with the operation of the machine, obtain assistance from a qualied person.

6. Always wear approved, safety protective eyewear and hearing protection when operating this machine.

7. Always wear a dust mask and use adequate dust collection and proper ventilation.

8. Do not wear loose clothing or jewelry when operating this machine. Keep long hair tied back.

9. Always make sure the power switch is in the OFF position prior to plugging in the machine.

10. Always make sure the power switch is in the OFF position and the machine is unplugged when doing any cleaning,

assembly, setup operation, or when not in use.

11. Make sure all safety guards and hardware are securely tightened before operating the machine.

12. Regularly check that the blades are locked tight in the cutterhead.

13. Always keep hands and fingers away from the cutterhead, chip exhaust opening, feed rollers, belts and pulleys to

prevent injury. Use push blocks when jointing wood shorter than 12" long, plus any narrow or thin stock.

14. Never joint wood less than 8" long, widths under 3/4", or material less than 1/4" thick.

15. Never make cuts deeper than 1/8”. Multiple cuts, 1/16" or less, produce better finish results.

16. Make sure there are no loose knots, nails, staples, dirt or foreign objects in the workpiece to be surfaced.

17. Use extra caution with large, warped, very small or awkward workpieces. Joint warped boards flat before planing.

18. Use extra supports (roller stands, saw horses, tables etc, for any workpieces large enough to tip when not held

down to the table top surfaces.

19. Surface wood in the same direction of the grain, not across the grain. Never plane end cuts or end grain.

20. Joint and plane only one workpiece at a time. Vary the feeding of the workpieces along the cutterhead,

center/left/right, so that all of the knives get used and thus remain sharp, longer.

21. Never reach inside of a running machine, and avoid awkward operations and hand positions where a sudden slip

could cause ngers or a hand to move into the cutterhead.

22. Do not clear a jammed workpiece while the machine is running. Stop the machine, unplug it from the power

scource, and then remove the jammed workpiece. Lowering the table may be necessary to dislodge the workpiece.

23. Keep your face and body to one side of the machine during use, out of line with a possible 'kick back' (lumber

caught in by the rotating cutterehead and thrown back towards the operator).

24. The use of any accessories or attachments not recommended may cause injury to you and damage your machine.

25. Sharpen or replace dull or chipped knives immediately, as injury to the user, or the machine, may result.

26. Replacement knives/inserts should be from, or through a source recommended by the manufacturer.

27. Remove material or debris from the work area. Keep work area neat and clean.

Use of this planer/jointer still presents risks that cannot be eliminated by the manufacturer. Therefore,

This owner’s manual is not a teaching aid and is intended to show

assembly, adjustments, and general use.

CALFORNIA PROPOSITION 65 WARNING: Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to the State of California to cause cancer and birth defects or

other reproductive harm.Your risk from exposure to these chemicals varies, depending on how often you do this type

of work. To reduce your exposure, work in a well-ventilated area and with approved safety equipment, such as dust

masks that are specially designed to lter out microscopic particles.

For more detailed information about California Proposition 65 log onto rikontools.com.

6

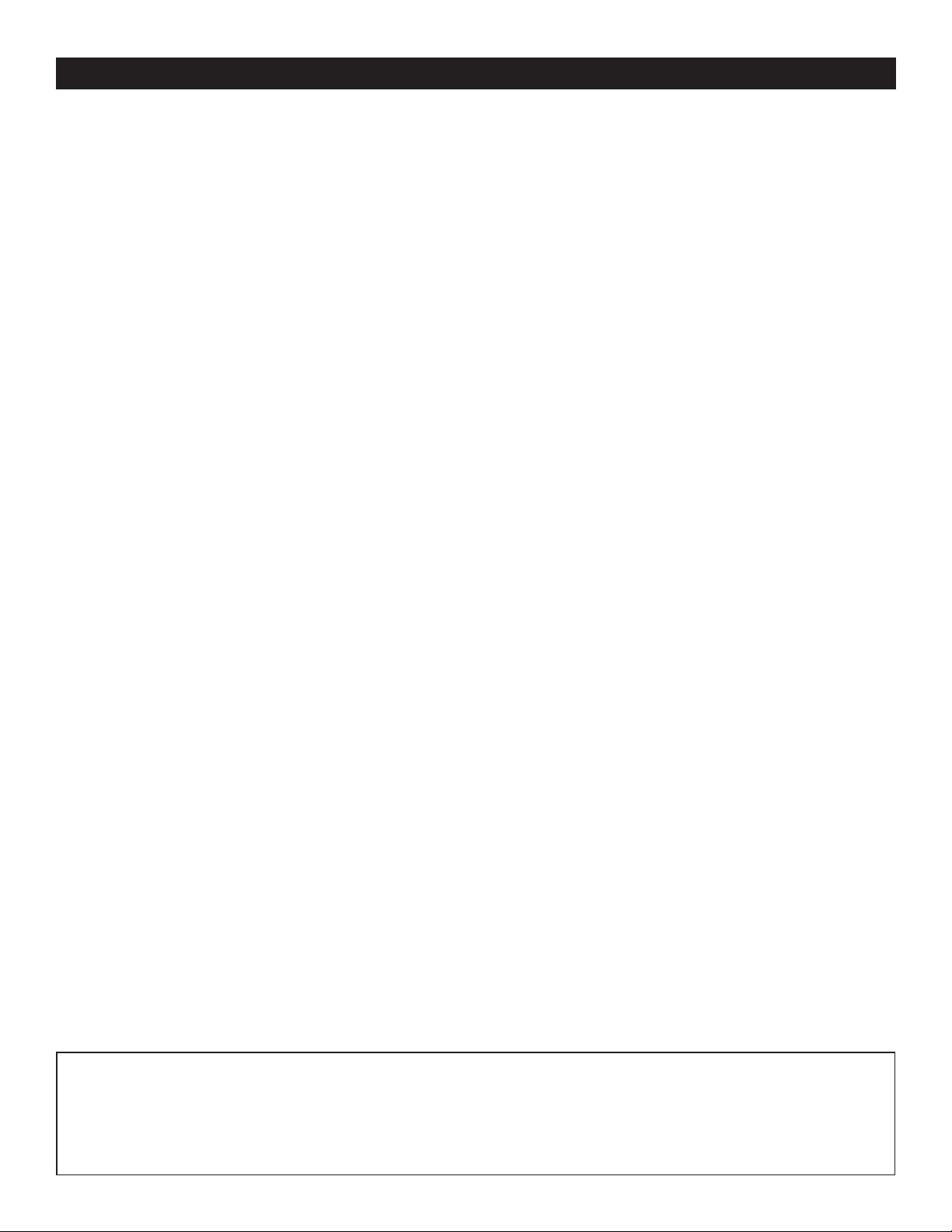

GETTING TO KNOW YOUR MACHINE

D

C

I

B

H

A

FRONT VIEW - JOINTER SETTING

E

L

B

F

M

J

K

G

O

REAR VIEW - PLANER SETTING

N

P

H

A On / Off Safety Switch

B Cutterhead Guard

C Jointer Dust Port - Work Position

D Outfeed Table

E Jointer Fence

F Infeed Table

G Jointer Depth of Cut Adjustment Knob

H Cutterhead Guard Height Adjustment Lever

I Jointer Depth of Cut Scale

J Planer Table Height Adjustment Handle

K Jointer Fence Support

L Planer Dust Port - Work Postion

M Outfeed Table Lock Handles

N Planer Table

O Planer Depth Gauge

P Power Cord

CONTENTS OF PACKAGE

Model 25-010H Planer/Jointer is shipped complete in one box.

Unpacking and Clean-up

1. Carefully remove all contents from the shipping carton. Compare the contents with the list of contents to make sure

that all of the items are accounted for, before discarding any packing material. Place parts on a protected surface

for easy identication and assembly. If any parts are missing or broken, please call RIKON Customer Service (877-

884-5167) as soon as possible for replacements. DO NOT turn your machine ON if any of these items are missing.

You may cause injury to yourself or damage to the machine.

2. Report any shipping damage to your local distributor.

3. Clean all rust protected surfaces with ordinary house hold type grease or spot remover. Do not use; gasoline, paint

thinner, mineral spirits, etc. These may damage painted surfaces.

4. Apply a coat of paste wax to the table to prevent rust. Wipe all parts thoroughly with a clean dry cloth. Be careful

when reaching inside of the planer as the knives are sharp and may cause injury if touched.

7

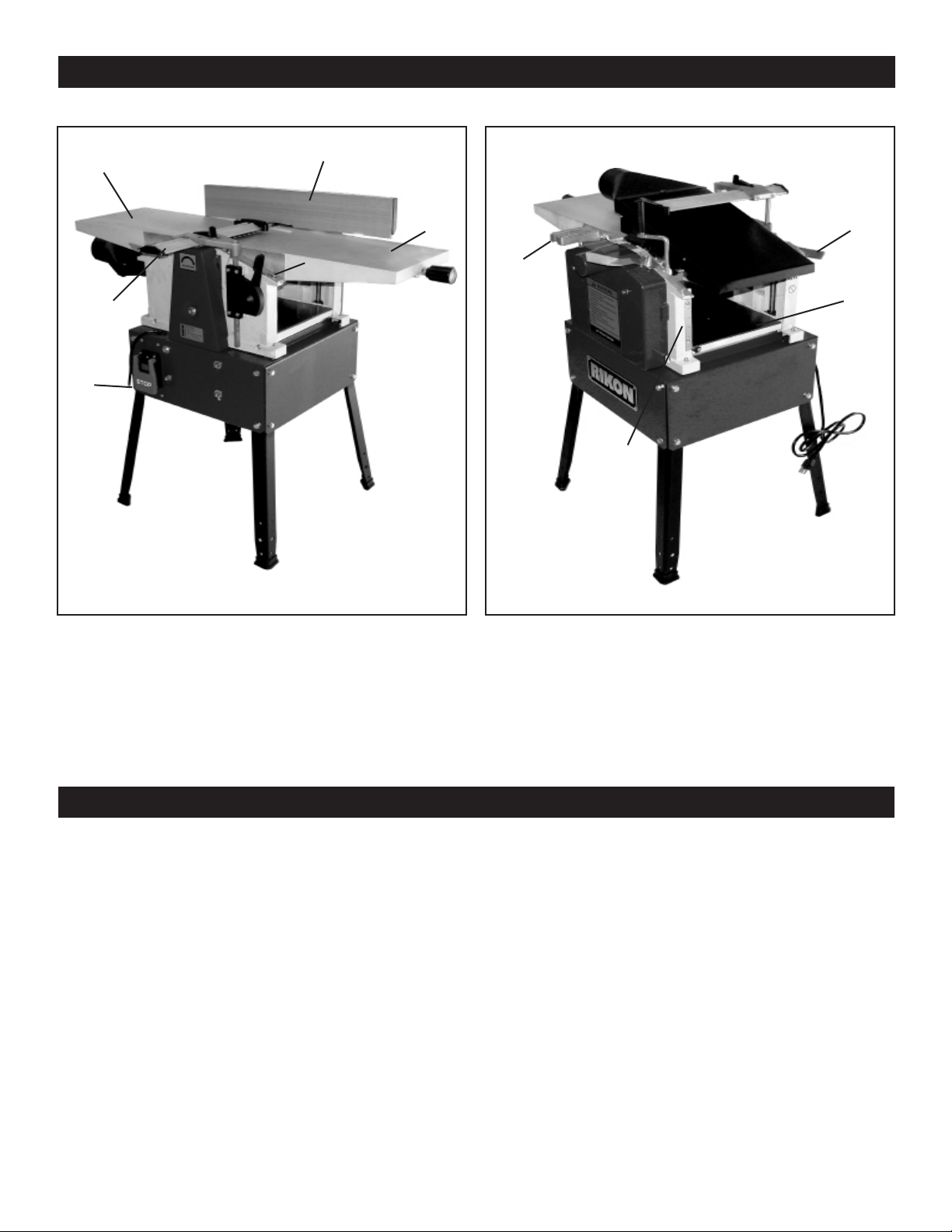

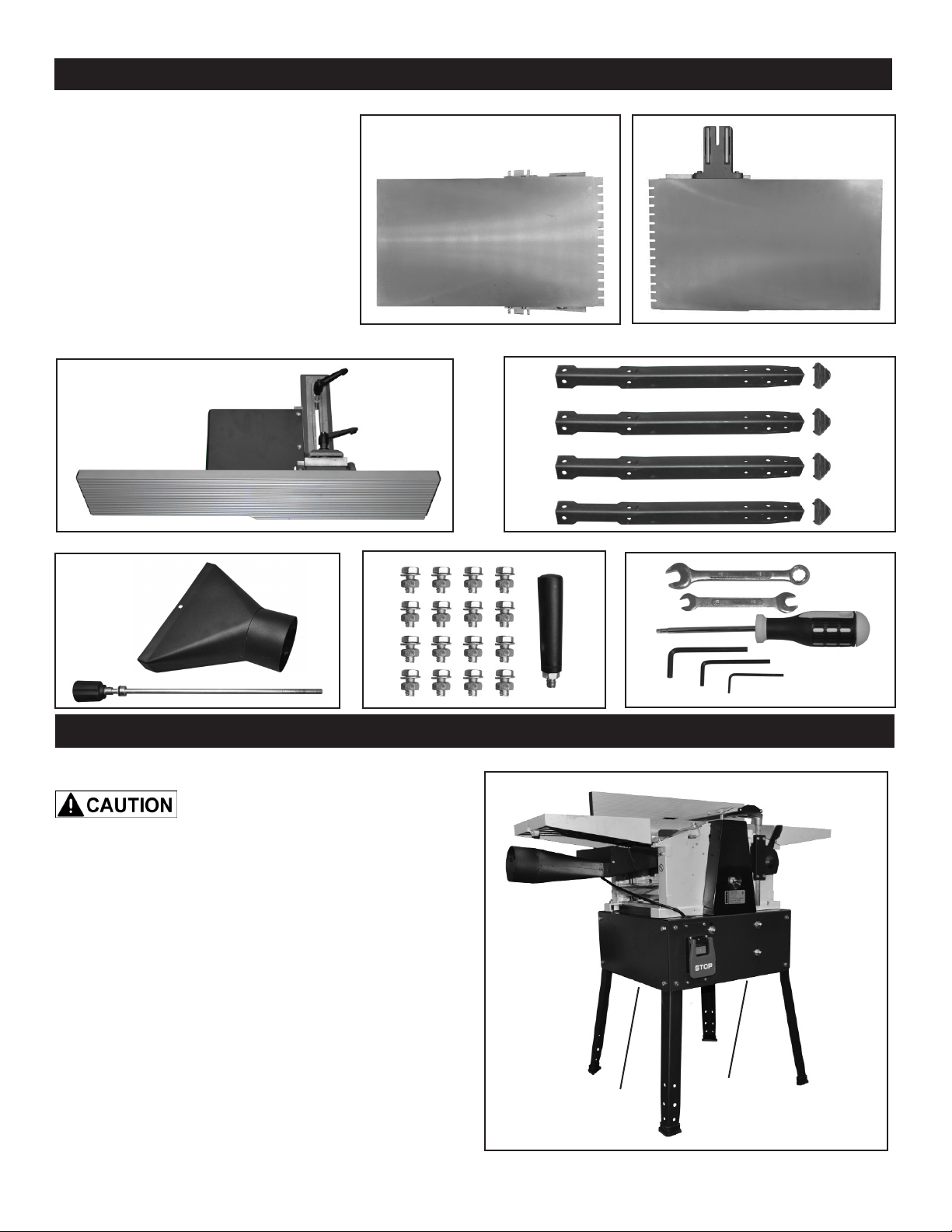

CONTENTS OF PACKAGE

LIST OF LOOSE PARTS

A. Outfeed Table

B. Infeed Table

C. Fence Assembly

D. Legs & Floor Pads

E. Dust Hood

F. Depth of Cut Control Bar

G. Nuts & Bolts for Leg Assembly

H. Handle

I. Tools a. - Wrenches - 10 & 13mm

b. - Star T25 Screwdriver

c. - Hex Wrenches - 3, 4 & 5mm

C

A

B

D

E

G

F

INSTALLATION

MOVING & INSTALLING THE PLANER

When moving the planer/jointer, lift

and move the machine with your hands holding the

undersides of the machine’s body. FIG. 1, A. DO NOT

move or carry the palner/jointer with the infeed and

outfeed tables, as this may damage the machine.

1. Position the machine on a solid, level foundation that

is located in an area that ample space in front and in back

of the planer/jointer for the moving of lumber to be milled.

Align the machine so that during use, any kickback will not

face aisles, doorways, or other work areas that bystanders

may be in. Do not locate or use the machine in damp or

wet conditions.

H

a

b

c

I

2. For best operation, the Planer/Jointer should be

directly plugged into a power source, without the use of

extensions.

3. The use of a industrial Dust Collector with a minimum

of 650 CFM suction is recommended for chip removal.

A

A

FIG. 1

8

ASSEMBLY

THE MACHINE MUST NOT BE PLUGGED IN AND THE POWER SWITCH

MUST BE IN THE 'OFF' POSITION UNTIL ASSEMBLY IS COMPLETE.

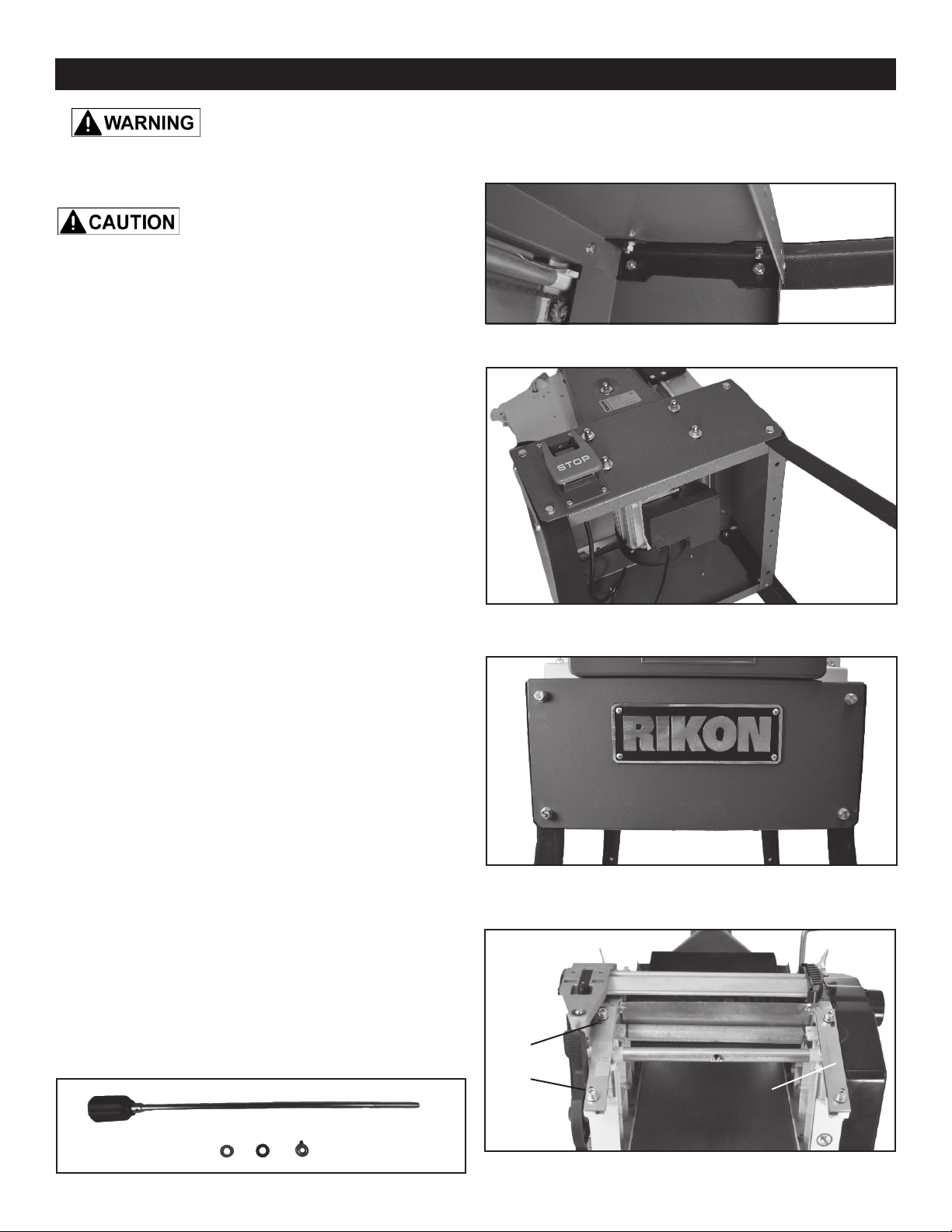

LEG INSTALLATION

To install the legs, the machine must

be placed onto its side to gain access to the underside

to secure the nuts and washers. The machine is heavy.

Additional help, or a suitable lifting device or support, will

be required for lifting the machine onto the stand once the

legs are installed.

NOTE: When assembling this Planer/Jointer, DO NOT fully

tighten the nuts and bolts until the assembly is complete.

1. Before laying the machine down on its side, lay down

some soft padding to protect the machine parts.

NOTE: The waste packaging may be utilized to support the

machine, preventing damage. This is especially needed if

the machine is laid on the side which has a plastic cover or

the On/Off switch.

FIG. 2

2. Gently lay the machine onto it's side. Ensuring that the

weight of the machine is distributed equally across the

main frame.

3. Fasten the four Legs to the main frame of the machine,

using the Bolts, Washers and Nuts provided. FIG. 2, 3.

4. Once the four legs have been secured to the main

frame, it may not be possible to fully tighten the lower bolts

until the machine is in the upright position.

5. With assistance, or with a suitable lifting device, return

the machine to an upright position. All four legs should be

stable, secure and on a level footing before final tightening the bolts. If machine does not sit on the legs properly,

loosen all of the leg bolts and allow the machine’s weight

to settle onto the egs evenly. Then fully tighen the bolts to

secure the legs in position. FIG. 4.

INFEED TABLE INSTALLATION

1. Remove the four socket head cap screws (#123) from

the infeed table’s Cover Rails (#125) that have been preinstalled on the sides of the machine’s frame. FIG. 5.

FIG. 3

FIG. 4

2. Remove the Collar and Spring Washer from the infeed

tables’s depth of cut adjustment Bar (#119). FIG. 6.

Continued on page 10

FIG. 6

CAP

SCREWS

COVER

RAILS

FIG. 5

9

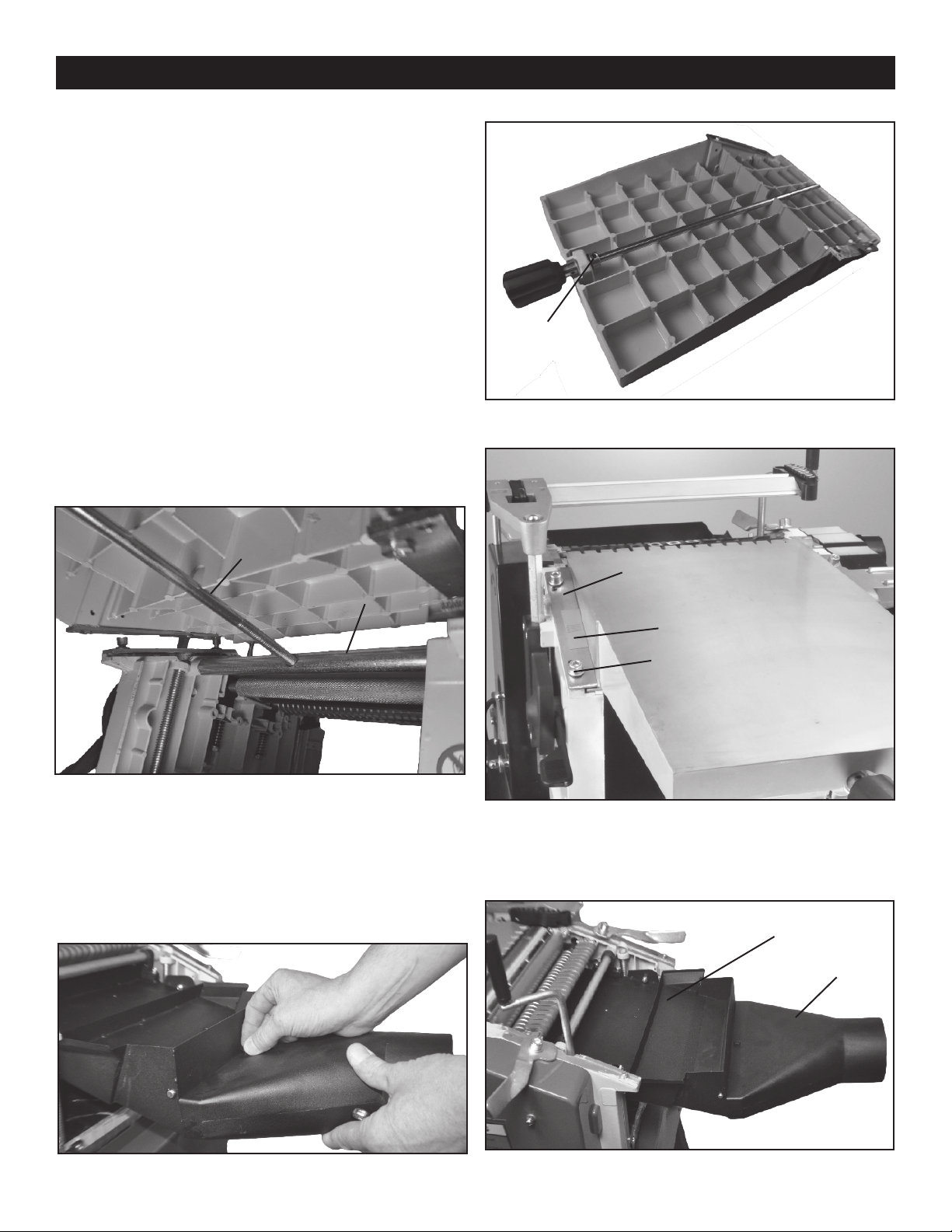

ASSEMBLY

Installing the Infeed Table - Continued from page 9

3. Insert the bar through the table’s end hole and underside of the table. Then re-attach the Spring Washer and

Collar onto the Bar to secure it in place. FIG. 7.

4. Hold the infeed table up to the machine while threading

the depth of cut control bar into the Spacer Shaft (#137).

FIG. 8.

5. Install the infeed table by positioning it under the table

cover rails and wind the depth of cut bar until the uppermost line on the depth Scale is registered. FIG. 15. Re-fit

and secure the table cover rails, FIG. 9.

NOTE: These rails should not be fully tightened, as the

table needs to slide up and down in order to adjust the

depth of cut. As a guide, fully tighten the socket head cap

screws and then back them off a 1/4 turn.

6. See page 12 for instructions on adjusting the table.

DEPTH OF CUT

CONTROL BAR

SPACER SHAFT

BAR

WASHER

& COLLAR

INFEED

TABLE

underside

view

FIG. 7

COVER RAIL

DEPTH SCALE

CAP SCREW

FIG. 8

DUST OUTLET INSTALLATION

1. At the opposite, outfeed end of the machine, locate the

Chip Ejector Hood (#194). FIG. 10. Attach the Dust Port

(#195) to the outlet with the two hex Bolts provided. FIG. 11

FIG. 10

FIG. 9

CHIP EJECTOR HOOD

DUST PORT

FIG. 11

10

Loading...

Loading...