RIKON Power Tools 23-400 User Manual

16" Planer

Model: 23-400

Part # 23-400M1

Owner’s Manual

Record the serial number and date of purchase

in your manual for future reference.

Serial number:

Date of purchase:

For more information:

www.rikontools.com or info@rikontools.com

For Parts or Questions:

techsupport@rikontools.com or 877-884-5167

Index

1 GENERAL INFORMATION

1.1 Foreword

2 MACHINE DESCRIPTION

2.1 Machine identification

2.2 Getting to know your machine

2.3 Technical specification

2.4 Recommended protective clothing

2.5 Noise emission

2.6 Prescribed use of the machine

2.7 Hazards

2.8 Safety instructions for planer

3 INSTALLATION

3.1 Lifting and unloading

3.2 Position of the machine

3.3 Identifying shipping boxes

3.4 Installations of loose parts

3.5 Electrical connection

3.6 Dust chute - Installation

4 INSTALLATION AND ADJUSTMENT

4.1. Planer table height adjustment

5 OPERATING PROCEDURES

5.1 ON/OFF switch

5.3 Thicknessing

6 MAINTENANCE

6.1 Replacing cutter knives

6.2 Drive Belt Check

7 DIAGRAMS & COMPONENTS

8 NOTES

9 WARRANTY

2

1. General Information

1.1 FOREWORD

This manual must be read and understood before operating the machine. This will provide a better working knowledge of the

machine, for increased safety and to obtain the best results.

2. Machine Description

2.1 MACHINE IDENTIFICATION

There is a metallic identification plate fixed to the machine, containing the manufacturer's data, year of construction, serial number.

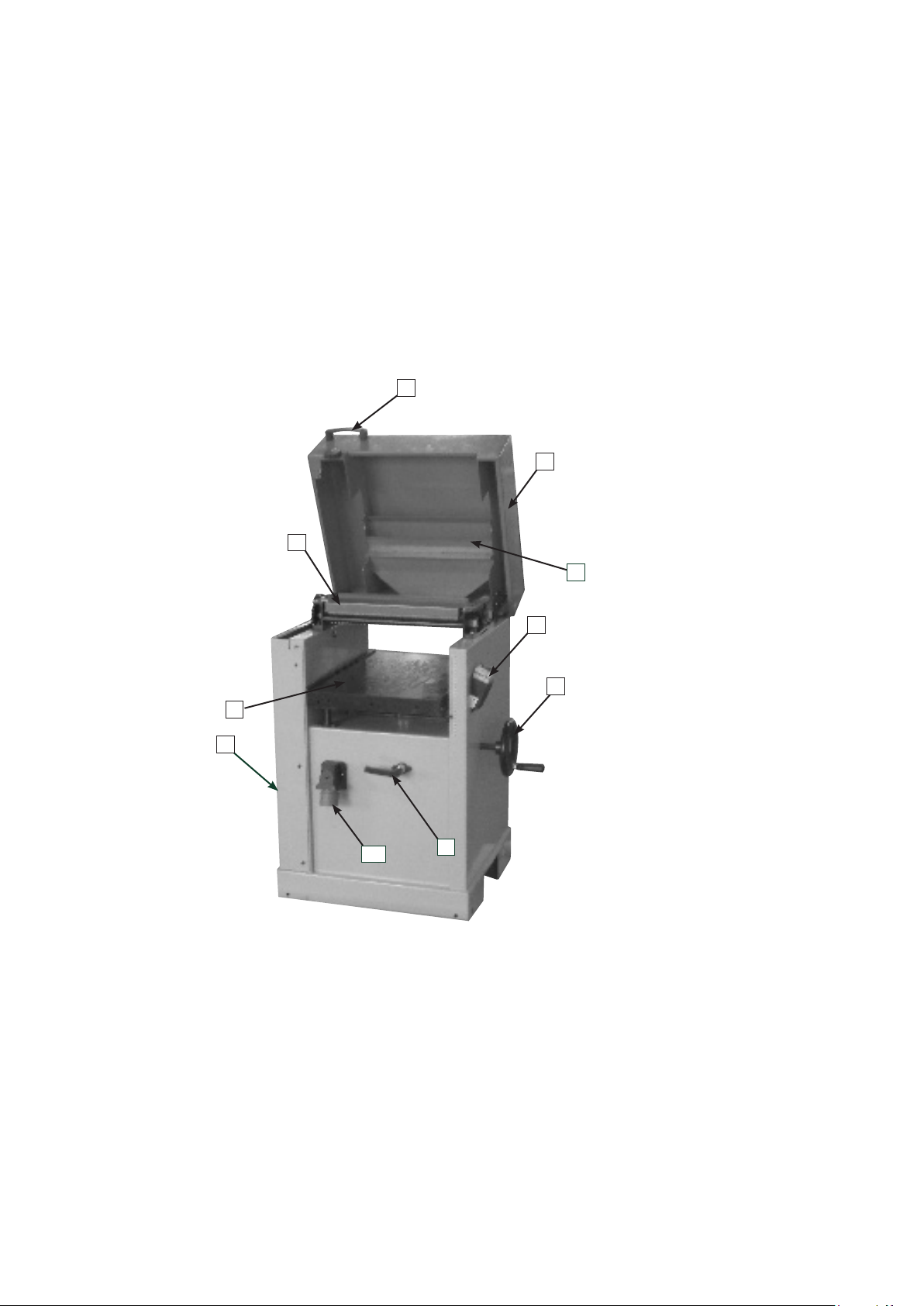

2.2 GETTING TO KNOW YOUR MACHINE

3

5

1

8

1 Planer table

2 Cutterhead guard

3 Opening handle

4 On/off switch

5 Cover

2

9

4

7

10

6

6 Locking level

7 Height setting of thickness table

8 Adjustment handle for feed speed

9 Dust chute

10 Plug

3

2.3 TECHNICAL SPECIFICATION

SPECIFICATION 23-400

Feed speed SF/min 16 to 23

Cutterhead speed rpm 5100

Cutterhead diameter 2-3/4"

Max planer capacity 8-13/16" x 16"

Max depth of cut 1/8"

Knives pcs 3

Motor power input 3HP

Net Weight 375lbs

2.4 RECOMMENDED PROTECTIVE CLOTHING

• Non-slip footwear is recommended.

• Do not wear loose clothing, neckties or jewellery; they can be caught in moving parts.

• Roll up long sleeves above the elbow.

• Wear protective hair covering to contain long hair.

2.5 NOISE EMISSION

The measurements of noise, in the working position and during operation, were carried out under the standard ISO 7960 Annex B and C:

Instantaneous acoustic pressure:

Sound power level(no load) <98dB(A)

Sound power level(load) <107dB(A)

Sound Pressure level(no load) <89dB(A)

Sound Pressure level(load) <98dB(A)

Constant K=4 dB measured in accordance with EN ISO 3746:1995

The figures quoted are emission levels and are not necessarily safe working levels. Whilst there is a correlation between the emission

and exposure levels, this cannot be used reliably to determine whether or not further precautions are required. Factors that influence

the actual level of exposure of the workforce include the characteristics of the work room and the other sources of noise etc. i.e.

the number of machines and other adjacent processes. Also the permissible exposure level can vary from country to country. This

information, however, will enable the user of the machine to make a better evaluation of the hazard and risk.

2.6 PRESCRIBED USE OF THE MACHINE

This machine is intended for surface thickness planing of solid woods. The permissible workpiece dimensions must be observed (see

Technical Specification).

Any other use is not as specified. Unspecified use, modification of the machine or use of parts not tested and approved by the

equipment manufacturer can cause unforeseen damage.

2.7 HAZARDS

ATTENTION Planer still present risks that cannot be eliminated by the manufacturer. Therefore the user must be aware that wood

working machines are dangerous if not used with care and all safety precautions adhered to.

4

2.8 SAFETY INSTRUCTIONS FOR PLANERS

A planer is a tool which can, due to operator carelessness, cause serious personal injury. It is therefore strongly recommended you

read and observe:

· these instructions, particularly the special safety information in the respective chapters;

· the relevant guidelines or regulations for the prevention of accidents pertaining to the use of planers, where applicable.

Keep all documents, supplied with the machine, for future reference.

The planer shall only be started and operated by persons familiar with planers and who are at any time aware of the dangers

associated with the operation of such tool. Persons under 18 years of age shall use this planer only under the supervision of an

instructor in the course of their vocational training.

The following residual risks do principally exist with planers and can not, even by employing safety devices, completely eliminated:

- Hazard generated by environmental conditions:

do not operate the planer in rain or damp environment. Ensure sufficient lighting. Do not

operate the planer near inflammable liquids or gases.

- Hazard to other persons in the work area:

Keep bystanders, particularly children, out of the danger zone.

- Risk of injury by machine faults:

check the planer for damage before any use. Do not operate the machine with a damaged part. Replace blunt cutter knives at once.

Risk of injury by kickback if a blunt knife gets caught in the workpiece's surface.

- Risk of injury by an unstable stand of the planer:

when working long stock use suitable supports on both sides of the machine. Avoid adverse body positions. Ensure firm footing, and

keep your balance at all times.

- Risk of injury by foreign objects in the machine:

prior to any starting of the machine ensure that there are no objects (e.g. tools) in the machine.

- Risk of injury by workpiece kickback (workpiece is caught by the rotating cutterhead and thrown back against the

operator):

operate machine only with a fully functional anti-kickback lock. Always use sharp cutter knives. If in doubt check workpiece for

inclusion of foreign objects (e.g. nails, screws, lose knots).

- Risk of injury by touching the rotating cutterhead:

always keep your hands well clear of the cutterhead. Switch machine off and plug out if it is not used.

- Danger! Drawing-in/trapping hazard!

Take care that no parts of the body or clothing can get caught and drawn in by the rotating cutterhead (do not wear neck ties and

garments with wide sleeves; contain long hair with a hairnet).

- Risk of injury by cuts with cutterhead at standstill: Wear gloves when changing cutter knives.

- Risk of injury by inhaling wood dust: dust of certain timber species (e.g. oak, beech, ash) can cause cancer when inhaled. Use a

suitable dust collector:

- fitting the outer diameter of the suction port (100 mm)

- air volume >= 815 m3/h;

- vacuum at suction port of machine >= 740 Pa;

- air speed at suction port of machine >= 20 m/s;

- Risk of injury by inadequate personal protection: when planing, wear:

- dust respirator;

- hearing protection;

- safety goggles.

5

3. Installation

3.1. LIFTING AND UNLOADING

The machine can be transported by two means:

- with a forklift truck. To do so, the machine is secured on a

pallet with four hex bolts.

- by several persons slide the machine from the pallet.

CAUTION

Do not carry the machine holding it at the infeed and outfeed

tables, these are not designed to withstand the tensile load by

the machine weight.

3.2 POSITION OF THE MACHINE

CAUTION

It is prohibited to install the machine in explosive environments.

Ensure that the floor area around the machine is level, well

maintained and free from loose material such as saw dust or

other wood waste.

1. Remove four mounting bolts from the machine base.

2. Lift machine off the pallet and set down on the floor.

3. Fix the machine to the floor. Fix the machine feet and fix on

ground by means of expansion bolts (not supplied).

3.3 IDENTIFYING SHIPPING BOXES

BEFORE ASSEMBLY

It is advisable that before unpacking to have plenty of paper

towels or cloths available to clean off the rust preservative.

FIG. 1

FIG. 2

3.4. INSTALLATIONS OF LOOSE PARTS

The machine is supplied almost assembled. Prior to use, the

handwheel must be fitted.

Install the handwheel (A, Fig.4) with set screw (B, Fig.4)

B

A

FIG. 4

6

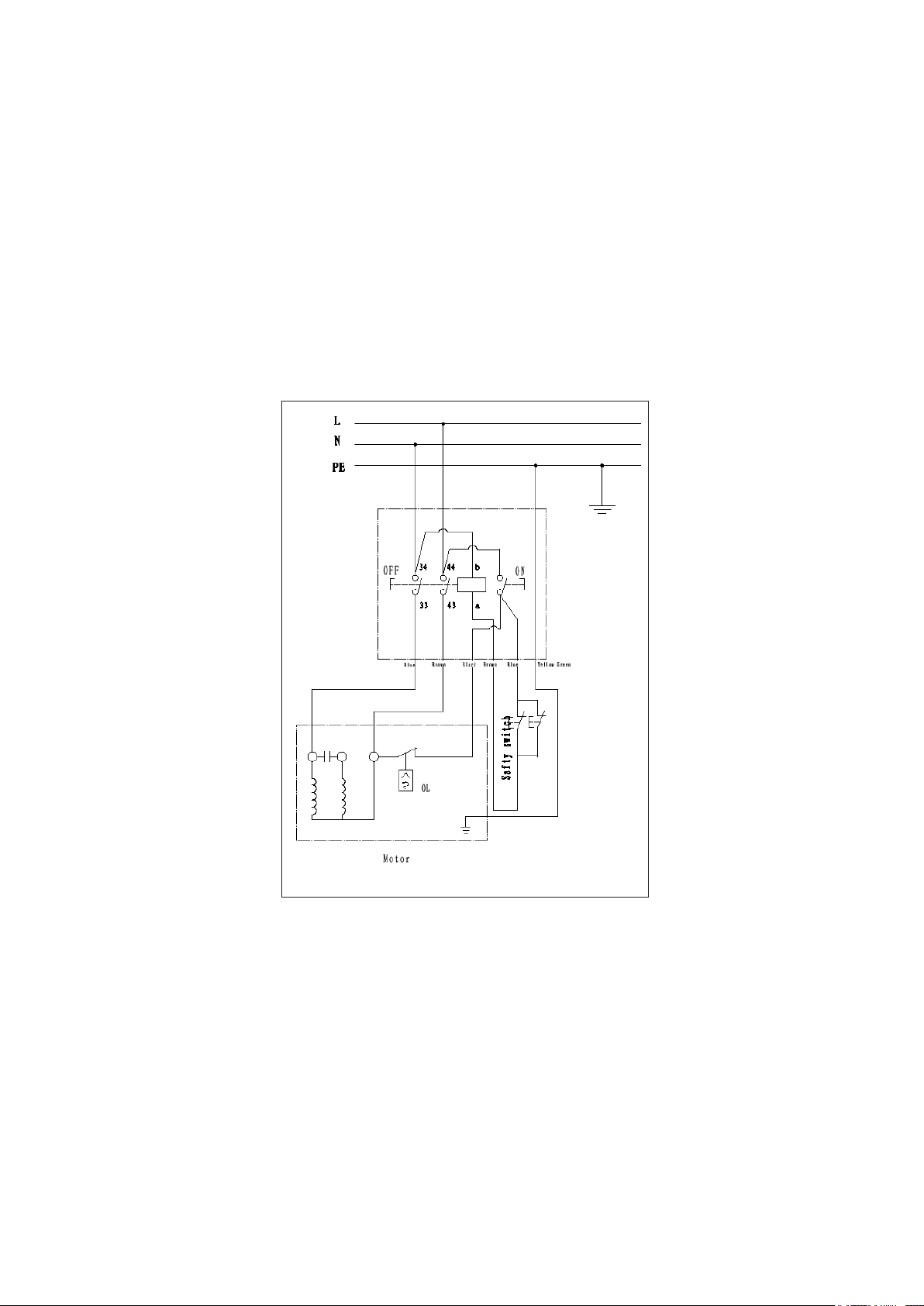

3.5. WIRING DIAGRAM

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the risk of electric shock. This tool is equipped with an electric cord having an equipment-grounding conductor and a grounding plug. The plug must

be plugged into a matching outlet that is properly installed and grounded in accordance with all local codes and ordinances.

Do not modify the plug provided. If it will not t the outlet, have the proper outlet installed by a qualied electrician.

Improper connection of the equipment-grounding conductor can result in a risk of electric shock. The conductor, with insulation having

an outer surface that is green with or without yellow stripes, is the equipment-grounding conductor. If repair or replacement of the

electric cord or plug is necessary, do not connect the equipment-grounding conductor to a live terminal.

Check with a qualied electrician or service personnel if the grounding instructions are not completely understood, or if in doubt as to

whether the tool is properly grounded.

Use only three wire extension cords that have three-prong grounding plugs and three-pole receptacles that accept the tool's plug.

Repair or replace a damaged or worn cord immediately.

TH410 Single phase

3.6. DUST CHUTE - INSTALLATION

The dust chute complete with suction connector must be

installed before planing.

Connect a suitable dust collector to the suction connector of the

planer.

7

Loading...

Loading...