6” Jointer with Micro-Adjustable Fence

Model: 20-110

Part #20-110M3

Owner’s Manual

Record the serial number and date of purchase

in your manual for future reference.

Serial number:

Date of purchase:

For more information:

www.rikontools.com or info@rikontools.com

For Parts or Questions:

techsupport@rikontools.com or 877-884-5167

Operator Safety: Required Reading

IMPORTANT! Safety is the single most important consideration in the operation of this equipment. The following

instructions must be followed at all times.

There are certain applications for which this tool was designed. We strongly recommend that this tool not be modified

and/or used for any other application other than that for which it was designed. If you have any questions about its

application, do not use the tool until you have contacted us and we have advised you.

General Safety Warnings

KNOW YOUR POWER TOOL. Read the owner’s manual carefully. Learn the tool’s applications, work

capabilities, and its specific potential hazards.

ALWAYS GROUND ALL TOOLS.

If your tool is equipped with a three-pronged plug, you must plug it into a three-hole electric

receptacle. If you use an adapter to accommodate a two-pronged receptacle, you must attach the

adapter plug to a known ground. Never remove the third prong of the plug.

ALWAYS AVOID DANGEROUS ENVIRONMENTS.

Never use power tools in damp or wet locations. Keep your work area well lighted and clear of clutter.

ALWAYS REMOVE THE ADJUSTING KEYS AND WRENCHES FROM TOOLS AFTER USE.

Form the habit of checking to see that keys and adjusting wrenches are removed from the tool before

turning it on.

ALWAYS KEEP YOUR WORK AREA CLEAN. Cluttered areas and benches invite accidents.

ALWAYS KEEP VISITORS AWAY FROM RUNNING MACHINES.

All visitors should be kept a safe distance from the work area.

ALWAYS MAKE THE WORKSHOP CHILDPROOF.

Childproof with padlocks, master switches, or by removing starter keys.

NEVER OPERATE A TOOL WHILE UNDER THE INFLUENCE OF DRUGS,

MEDICATION, OR ALCOHOL.

ALWAYS WEAR PROPER APPAREL.

Never wear loose clothing or jewelry that might get caught in moving parts. Rubber-soled footwear is

recommended for the best footing.

ALWAYS USE SAFETY GLASSES AND WEAR HEARING PROTECTION.

Also use a face or dust mask if the cutting operation is dusty.

NEVER OVERREACH.

Keep your proper footing and balance at all times.

NEVER STAND ON TOOLS.

Serious injury could occur if the tool is tipped or if the cutting tool is accidentally contacted.

2

ALWAYS DISCONNECT TOOLS.

Disconnect tools before servicing and when changing accessories such as blades, bits, and cutters.

ALWAYS AVOID ACCIDENTAL STARTING.

Make sure switch is in “OFF” position before plugging in cord.

NEVER LEAVE TOOLS RUNNING UNATTENDED.

ALWAYS CHECK FOR DAMAGED PARTS.

Before initial or continual use of the tool, a guard or other part that is damaged should be checked to

assure that it will operate properly and perform its intended function. Check for alignment of moving

parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect

its operation. A guard or other damaged parts should immediately be properly repaired or replaced.

Special Safety Rules For Jointers

Always keep cutter head and drive guards in place and in proper operating

condition.

NEVER make a jointing, planning, or rabbeting cut deeper than 1/8"

Do not perform jointing operations on material shorter than 10", narrower than 3/4", or

less than 1/2" thick.

Support the work piece adequately at all times during operation; maintain control

of the work at all times.

Do not back the work toward the in-feed table.

Do not attempt to perform an abnormal or little-used operation without study

and the use of adequate hold downs/push blocks jigs, fixtures, stops, and the

like.

SAVE THESE INSTRUCTIONS.

Refer to them often.

3

Table of Contents

Safety Warnings....................................................................................................................................2

Jointer Safety Rules ..........................................................................................................................3

Specifications ........................................................................................................................................4

Contents of Package ............................................................................................................................5

Unpacking and Setup ...........................................................................................................................5

Loose Parts ...........................................................................................................................................6

Getting To Know Your Jointer ............................................................................................................7

Assembly ..............................................................................................................................................8

Installing Bed to Stand .....................................................................................................................................8

Installing Polly “V” Belt .............................................................................................................................8

Belt Guard.................................................................................................................................................9

Install Fence Bed Casting ...........................................................................................................................9

Installing Fence to Bed .....................................................................................................................................9

Mounting On/Off Switch ......................................................................................................................................10

Installing Handwheels .......................................................................................................................10

90 Degree Fence Adjustment......................................................................................................................10

45 Degree Fence Adjustment.........................................................................................................................11

Installing Depth Lock Handle ............................................................................................................11

Installing Depth Limiting Stop ............................................................................................................11

Setting Outfeed Table....................... ..................................................................................................................12

Installing Cutterhead Guard .......................................................................................................................13

Installing Access Cover ................................................................................................................................14

Installing Dust Chute ............................................................................................................................................14

Operation / Maintenance............................................................................................................15

Wiring Diagram ...................................................................................................................................15

Troubleshooting ..................................................................................................................................16

Parts Diagram ................................................................................................................................17-23

Parts List ........................................................................................................................................17-23

Notes ..................................................................................................................................................24

Warranty .............................................................................................................................................25

Cutting Capacity

Cutterhead Speed

Number of Knives

Cuts per Minute

Rabbeting Capacity

Rabbet Ledge

Infeed Table Length

Outfeed Table Length

Table Surface

Fence

Blade Size

Fence Tilts Right & Left

Positive Stops

Motor

1-1/2HP,1Ph, 115/230V, Prewired 115V

Net Weight

Specifications

4,500 & 5,500 RPM

13,500 & 16,500 CPM

7”W x 45-3/4”L x 31-1/2”H

4-3/4”H x 29-1/8”L

6”L x 5/8”H x 1/8”D

4

6” x 1/2”

1/2”

3-1/8” x 8-3/4”

22”

22-1/2”

45

45o, 90

258 lbs

3

o

o

Unpacking and Checking Contents

The RIKON 6” Jointer is shipped in two cartons.

Stand Carton

1 Stand with Motor

1 Stand Door

1 Dust Chute

1 Multi “V-Belt”

1 Belt Guard

Main Unit Carton

1 Bed Assembly

1 Fence Assembly

1 Switch Assembly w/support

1 Cutter Guard

2 Push Blocks

1 Owner’s Manual w/ Warranty Card

1 Fence Base Casting

2 Hand Wheels

2 Fence Handles

2 Loose Bags

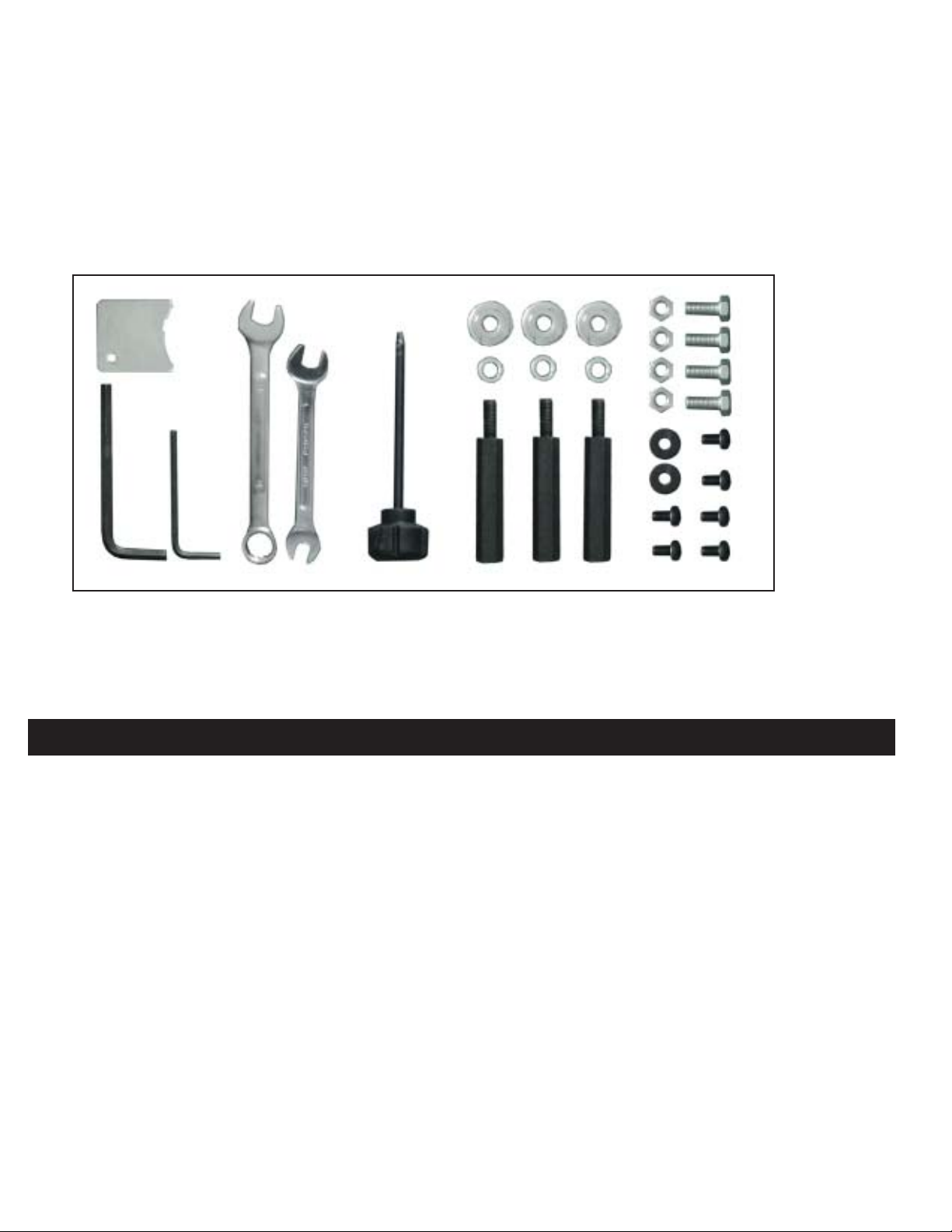

Loose Parts in Loose Bag 1

1 Fence Lock Handle Assembly

1 Depth Limiting Stop

1 Lock Handle

5

Loose Parts in Loose Bag 2

3 3/8” Flat Washers

3 3/8” Lock Washers

3 Mounting Bolts

1 3mm Hex Wrench

1 5mm Hex Wrench

1 8/10mm Open End Wrench

1 12/14mm Open End Wrench

4 Hex Head Screw M8

4 Hex Nut M8

2 1/8” Flat Washers

6 1/8”x3/8” Pan Head Screws

1 Blade Lock Tool

1 Blade Adjust Tool

Tools Required for Assembly

Philips Head Screwdriver, Adjustable Wrench, 14mm Open End Wrench and a metric socket set.

Unpacking Carton and Cleaning

1. Carefully remove all contents from both shipping cartons. Compare contents of the shipping

cartons with the list of contents in this manual. Place parts on a protected surface.

2. Report any shipping damage to your local distributor.

3. Clean all rust protected surfaces (bed, fence, etc.) with a parts cleaning solvent or WD40.

Do not use; gasoline, paint thinner, mineral spirits, etc. as these may damage painted surfaces.

Caution: Cutterhead blades are extremely sharp! Use care when cleaning!

4. Apply a thin layer of paste wax to the milled surfaces of the fence and tables to prevent rust.

5. Set packing material and shipping cartons to the side. Do not discard until machine has been

set up and is running properly.

6

Getting to Know Your Jointer

Note: Jointer top shown in white for clarity.

2

3

1

4

7

8

5

15

6

14

13

10

12

9

11

1. Hand Wheel for Out-feed Table

2. Out-feed Table

3. Fence

4. Fence Adjustment Handle

5. Cutterhead Guard

6. In-feed Table

7. Hand Wheel for In-feed Table

8. On/Off Switch

9. Out-feed Table Lock Knob

10. Fence Tilt Lock Handle

11. Belt Guard

12. Fence Adjustment Lock Handle

13. Depth Limiter

14. In-feed Table Lock Knob

15. Telescoping Height Knob

7

Assembly

Installing Bed to Stand

1. Remove rear door on cabinet.

2. Place bed assembly on top of stand, making sure the

pulleys face the rear of the cabinet. Ask a friend for

assistance with this step. (DO NOT LIFT BY TABLE

ENDS, LIFT FROM CENTER OF CASTING) (Fig. 1)

3. Line up the two holes in stand top with holes in the

bed assembly by viewing through rear access door in

stand.

4. Attach stand to bed assembly by using two 3/8" lock

bolts and washers. (See Fig. 2) Hand tighten only at

this time.

5. Line up third hole in stand with hole in bed assembly

by viewing through dust chute.

Figure 1

6. Install third 3/8" lock bolt and washer through dust

chute to secure bed to stand. DO NOT tighten at this

time.

Installing the Poly V-Belt

1. Place the Multi “V-Belt” on the cutter-head pulley and

through the opening in the cabinet and onto the

motor pulley. (Fig. 3)

2. If necessary loosen the motor turn-buckle to raise the

motor. Verify that the Multi “V-Belt” is positioned

properly in the center of the pulleys. (Fig. 4)

3. Check to verify the motor pulley and the cutter-head

pulley are aligned vertically, and the Multi “V-Belt” does

not touch the cabinet. To adjust the pulleys, loosen the

motor mounts and slide the motor in or out or loosen

the three 3/8” lock bolts and move the jointer top.

(Fig. 5)

4. Tighten all three lock bolts (from Assembly Section #4

& #6 above) using 14mm or 9/16” wrench.

Figure 2

INCORRECT

Figure 3

CORRECT

Figure 4

5. Tension the Multi “V-Belt” using the motor plate turnbuckle. A properly tensioned belt should have 1/2"

deflection when finger pressure is applied half way

between the two pulleys.

6. Re-check the Mult “V-Belt” tension after 2 hours

of use. Re-tension as needed.

8

Figure 5

Installing Belt Guard

1. Place the belt guard (A, Figure 6) over the belt

opening in the stand.

2. Line up the holes in the stand with the holes in the

guard.

3. Attach the guard to the stand using two 1/4-20x1/2"

pan head screws and two 1/4" lock washers.

(B, Figure 6)

Install Fence Bed Casting

1. Use two 3/8" x 1-1/2" hex socket bolts and

washers (A, Fig. 7) to attach the fence bed casting

(B, Fig. 7) to the outfeed table bed using 13mm

socket/wrench.

2. Align top of the fence base casting flush with the

table surface and tighten.

A

B

Figure 6

A

B

Figure 7

Installing Fence to Bed

1. Remove the lock handle (A, Figure 8), flat washer,

and lock nut from the fence assembly.

2. Place the fence assembly onto the table. Be sure

key stock (B, Figure 8) on the bed lines up with

channel in the fence casting.

3. Place the flat washer and insert the lock handle

through the fence casting and the table casting.

4. Thread the special nut onto the lock handle. Make

sure the tab on the nut faces up and engages the

slot in the table casting. (Fig. 9)

A

B

Figure 8

Figure 9

9

Mounting the On / Off Switch

1. Decide where you want to mount the on / off

switch. It can be mounted on the in-feed side of

the cabinet or the out-feed side.

2. Feed the two power cords through the cabinet

(Fig. 10).

Mounting

Hardware

3. Mount the power switch column to the cabinet using

(4) 3/8” x 3/4” bolts, (4) washers and (4) 3/8” nuts

using a 14mm socket/wrench and tighten.

4. Plug the motor cords together (Green cords).

5. Plug the power cords together (Black cords).

6. Adjust the height of the switch to your desired

height by loosening the adjustment knob

(A, Fig. 11) on the power switch column.

7. Adjust the switch (B, Fig. 11) to the desired angle.

8. Re-tighten the adjustment knob (A, Fig. 11) on the

power switch column.

Installing Handwheels

1. Press handwheels (A, Fig. 12) onto shaft, aligning

the slot in the handle with the pin on the shaft. If

necessary, use a hammer with a block of wood to

tap the handwheel completely onto the shaft.

Power Cords

Figure 10

B

A

Figure 11

B

A

2. Tighten set screw, (B, Fig. 12).

Adjustments and Operation

90º Fence Adjustment

1. Set in-feed table to the same height as the out-feed

table.

2. Move the fence by releasing lock handle (A,

Figure 13) and pushing the fence assembly until it

overlaps the tables.

3. Adjust the fence to a 90º angle by releasing lock

handle (B, Figure 13).

Figure 12

B

A

Figure 13

10

4. Place a combination square on the in-feed table to check

that the fence is 90º to the table.

5. If fence is not square to table, release lock handle (D,

Figure 14) and turn handle (C, Figure 14) until the fence is

90º.

6. Now that the fence is 90º to the table, adjust the positive

stop screw assembly (E, Figure 14) to maintain the 90º

position.

7. Retighten lock handle (D, Figure 14).

45º Fence Adjustment

1. Loosen lock handle (B, Figure 14). Move the stop plate

(F, Figure 14) out of the way and position the fence at the

45º angle. Make sure the fence sits against the stop bolt

(G, Figure 14).

Figure 14

2. Place a combination square on the fence and table to

confirm a 45º angle setting.

3. To adjust, loosen lock nut and bolt (G, Figure 14), until a

45º angle is obtained, and tighten lock nut (G, Figure 14).

4. Tighten lock handle (B, Figure 14).

Depth Lock Handle

1. Install the depth lock handle. (A, Figure 15). The depth

lock handle helps lock the infeed bed in place for

rabbeting cuts.This should be attached before Depth

Limiting Stop (B, Figure 15) for easier installation.

Depth Limiting Stop

A

B

D

C

Figure 15

1. Attach depth limiting stop. (B, Figure 15).

11

Setting Out-feed Table to Cutter-head

Knives

WARNING

DO NOT connect machine to power source

at this time!

Cutter-head blades are extremely sharp!

Use Caution when hands are near the cutter-head!

Failure to comply may cause serious injury!

1. Unplug the Jointer from the power source.

2. Remove the blade guard by turning knob. (Figure

16) clockwise while lift up on the blade guard.

Caution: Blades are sharp! Use care while

working around the blades.

3. Open the rear door and move the motor belt until

the blade lock hole is lined up (Figure 17).

Figure 16

4. Insert blade lock tool. This locks the head in the

proper position for replacing the first blade.

5. Loosen table lock screw (C, Figure 15) and gib

lock screw (D, Figure 15) and raise the out-feed

table to the height of blade number one by turning

hand wheel. Counter-clockwise will cause the outfeed table to rise. Clockwise will cause the outfeed table to lower. Set a straight edge on the outfeed table (Figure 18). Position of the table and

Straight edge should look like Figure 19. Use care

when handling the straight edge near the blades

so as not to damage them.

6. When the out-feed table and blade number one

are the same height, tighten gib and table lock

screws.

Do not change the setting for the out-feed table

again. This will only change if the blades

are replaced or sharpened.

Figure 17

Figure 18

7. Bring the straight edge toward the left of the jointer

and confirm that blade number one is at the same

height at the left of the table as it is at the right

side of the table.

12

Figure 19

8. If blade is higher or lower at the right of the table

than it is at the left, slightly loosen four screws

(Figure 20) by turning clockwise as viewed from

the in-feed table. To lower, turn the screw

clockwise. To raise, turn the screw counterclockwise. Blades are set at the proper height

when the top of the blades are1/16" above the

cutter-head. Alternately tighten four screws to

hold each blade in place.

9. Repeat this process with blades two and three.

The out-feed table and cutter-head knives are

correctly adjusted when all three blades are

parallel to the out-feed table and all three

blades are set at the same height in the cutterhead.

If the out-feed table is set too high, a curved finished

surface results.

Figure 20

If the out-feed table is set too low, gouging will result at

the end of the cut.

Installing Cutter-Head Guard

1. Turn spring knob (A, Figure 21) approximately one

and one half revolutions counter-clockwise and

hold.

2. Insert guard post into hole in table. Make sure

spring engages slot in guard post.

3. Check for proper operation. Guard must return

fully to fence when released. If guard does not

return fully, remove pull guard, apply more tension

to spring knob by turning it another half turn

counter-clockwise, and re-insert guard. If guard

closes too quickly and strikes fence too hard,

release some tension on the spring.

A

Figure 21

13

Installing Access Cover

1. Install access cover by placing bottom of panel

into access in stand and fasten by turning latch

knob. (Figure 22)

Installing Dust Chute

Figure 22

1. Attach the dust chute (See Figure 23) to the base

with four 1/4"-10x1/2"pan head screws and four

washers.

Figure 23

14

Operation

Maintenance

CA CA

UTION!UTION!

CA

UTION! BEFORE CLEANING OR CARRYING OUT MAINTENANCE WORK, DISCONNECT

CA CA

UTION!UTION!

THE MACHINE FROM THE POWER SOURCE (WALL SOCKET). NEVER USE WATER OR OTHER

LIQUIDS TO CLEAN THE MACHINE. USE A BRUSH. REGULAR MAINTENANCE OF THE

MACHINE WILL PREVENT UNNECESSARY PROBLEMS.

Keep the table clean to ensure accurate cutting.

Keep the outside of the machine clean to ensure accurate operation of all moving parts and prevent

excessive wear.

Keep the ventilation slots of the motor clean to prevent it from overheating.

Keep the inside (near the saw blade, etc.) clean to prevent accumulation of dust.

Wiring Diagram

This machine must be grounded.

Replacement of the power supply cable should only be done by a qualified electrician.

15

A

y

A

djust belt tension

A

g

p

y

y

j

y

Have a licensed electrician install proper size breakers

Low Voltage Check for proper voltage

ir flow restricted on motor Clean out motor to obtain normal air flow

Loose connection or open circuit in motor Inspect motor for loose connections

Pulley set screw loose Tighten set screw

Circuit too long or undersized wires Reduce the length of the wire or Increase the wire size

Voltage too low Have the voltage checked by an electrician

Circuit breakers do not have sufficient capacit

Use of extension cord Use heavier gauge extension cord or no extension cord

Drive belt tension too high

djust outfeed table level with the knives

Feed rate too high Feed workpiece slower

Knives dull Replace knives or sharpen

Knives are set higher than the outfeed table or not

level with the table Readjust the knives

Knives are dull Sharpen or replace knives

*********Warning*********

ur

Broken tension spring Install new tension spring

Troubleshooting

WARNING!

FOR YOUR OWN SAFETY, ALWAYS TURN OFF AND UNPLUG THE MACHINE BEFORE CARRYING OUT ANY

TROUBLESHOOTING.

Symptom Possible Cause Solution

Motor will not start Machine not plugged in Plug the machine in

Motor Overheats Motor overloaded Reduce load on motor. Feed work slower

Excessive motor noise Bad motor Have motor checked

Motor will not develop full power or stalls Circuit overloaded with lights or other tools Decrease the load on the circuit

Loose in feed or outfeed tables Loose gibs Tighten the gibs

Finish stock is concave on the end Knives are set higher than the outfeed table Raise outfeed table level with knives

Back side of finish stock is thicker than the front Outfeed table set too high

16

Stock is concave in the middle Table out of level Raise the table ends

Ripples on planed surface One blade set higher than the others Readjust blades

Kickback

Workpiece strikes the outfeed table Outfeed table set too high or blades to low Readjust knives level with outfeed table

Fence not accurate at 90 or 45 degrees Fence stop not properly adjusted Readjust the fence stops

Machine bogs down in the cut Excessive depth of cut Decrease depth of cut

Safety guard won't return to the fence No tension on the spring Retension saftey guard spring

result in serious in

ma

l

. Failure to com

Do not make adjustments while the Jointer is running. Ensure the switch is off, power is disconected and all moving parts have stopped before

servicin

Cutterhead Assembly

Index

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Part

No.

1A

2A

3A

4A

5A

6A

7A

8A

9A

10A

11A

12A

13A

14A

15A

16A

17A

18A

Description

Cutterhead

Knife

Knife Lock Bar

Bearing Housing

Bearing Housing

Cutterhead Pulley

Hex Screw/Cutterhead Locking

Flat Washer 6mm

Key

Stud Bolt 10mm

Lock Washer 10mm

Screw/Cutterhead Set

Ball Bearing 62032

Ball Bearing 62022

Pin Stop

Spring

Flat Washer 10mm

Hex Bolt M6x12

Q’ty

1

3

3

1

1

1

12

1

1

2

2

6

1

1

1

6

2

1

17

Fence Assembly

18

Fence Assembly

Index

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

Part

No.

1B

2B

3B

4B

5B

6B

7B

8B

9B

10B

11B

12B

13B

14B

15B

16B

17B

18B

19B

20B

21B

22B

23B

24B

25B

26B

27B

28B

29B

30B

31B

32B

33B

34B

35B

36B

37B

38B

39B

40B

41B

42B

43B

44B

45B

46B

47B

48B

49B

50B

51B

52B

53B

54B

55B

56B

57B

Description

Fence Body

Handle

Hex Nut 10mm

Hex Socket Bolt M8-1.25x33

Pin Roll

Block

Hex Nut M8-1.25

Hex Bolt M8-1.25x25

Plastic Bar

Handle

Pin Roll

Cam Wheel

Hex Socket Bolt M8-1.25x25

Hex Socket Bolt M8-1.25x25

Tilt Shaft

Worm Gear

Hex Bolt M8-1.25x20

Tube

Pin Roll

Tilt Plate

Hex Bolt M6-1.0x12

Hex Nut

Flat Washer 13mm

Handle Hex Nut/Small

Spring

Handle

Screw Handle

Nut Quill

Casting

Quill

Bracket

Bolt M8-1.25x10

Pin Roll

Pin Roll

Gear

Plate

Screw/Phip M6-1.0x15

Handle

Screw Handle

Screw Adjusting

Casting

Set Screw

Shaft

Thread Shaft

Flange

Hex Socket

Gear Shaft

Key

Lock Tube

Tube

Thread Rod

Flat Washer 11mm

Handle Hex Nut/Large

Handle Wheel

Flat Washer 6mm

Hex Bolt M6-1.0x12

Special Lock Nut

Q’ty

1

2

2

1

1

1

4

1

1

1

4

1

1

1

1

1

2

2

1

1

1

2

2

2

3

3

3

1

1

1

1

1

2

1

1

1

3

1

1

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

1

19

Stand and Motor Assembly

20

Stand and Motor Assembly

Index

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

Part

No.

1C

2C

3C

4C

5C

6C

7C

8C

9C

10C

11C

12C

13C

14C

15C

16C

17C

18C

19C

20C

21C

22C

23C

24C

25C

26C

27C

28C

29C

30C

31C

32C

33C

34C

35C

36C

37C

38C

39C

40C

41C

42C

43C

44C

45C

46C

47C

48C

49C

50C

51C

52C

Description

Tapping Screw

Switch

Switch Box

Stain Relief Bushing

Cable

Cable

Switch Support (Upper)

Lock Knob

Switch Support (Lower)

Hex Bolt M8-1.25x12

Flat Washer 8mm

Pan Head Screw M5-0.08x16

J-Belt 5940

Hex Bolt M6-1.0x12

Flat Washer 6mm

Motor Pulley

Key

Motor

Carriage Bolt M8-1.25x16

Hex Nut M5-0.08

Pan Head Screw

Motor Mounting Plate

Pin Roll

Shaft

Bracket

Rubber Tube

Lock Washer 8mm

Hex Nut M8-1.25

Pan Head Screw

Screw Shaft

Nut

Screw Shaft

Bracket

Cable

Knob Screw

Washer

Door Latch

Lock Nut

Rubber Feet

Door

Lock Bolt

Stand Body

Belt Cover

Plastic Cap

Plate

Pan Head Screw

Relief

Plug Cable

Bracket

Dust Chute

Pan Head Screw

Tool Holder

Q’ty

4

1

1

1

1

1

1

1

1

5

12

4

1

7

7

1

1

1

4

4

6

1

4

4

2

1

7

5

1

1

1

1

1

1

1

1

1

1

4

1

3

1

1

1

1

2

2

1

1

1

2

1

21

Bed Assembly

22

Bed Assembly

Index

No.

1

2

3

4

5

6

7

8

9

10

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

43

44

45

46

47

48

49

50

Part

No.

1D

2D

3D

4D

5D

6D

7D

8D

9D

10D

12D

13D

14D

15D

16D

17D

18D

19D

20D

21D

22D

23D

24D

25D

26D

27D

28D

29D

30D

31D

32D

33D

34D

35D

36D

37D

38D

39D

40D

41D

43D

44D

45D

46D

47D

48D

49D

50D

Description

Rear Table

Lock Knob

Adjust Nut

Flat Washer 10mm

Bushing

Adjusting Screw

Ball Crank

Pivot Pin

Set Screw

Lock Screw

Hand Wheel

Handle

Handle Shaft Bolt

Front Table

Retaining Washer

Spring

Spring Knob

Retainer

Pointer

Ball Crank

Base

Gib

Depth Scale

Shoudler Pin

Brass Washer 10mm

Set Screw

Set Screw

Hen Nut

Screw

Rivet

Washer

Hex Nut

Rivet

Fence Base Casting

Key

Flat Washer 8mm

Hex Bolt M8-1.25x35

Spring Pin

1/8" Set Block

Hex Socket Bolt M8-1.25x16

Stud

Spring

Stud

Knob

Lock Handle

Cutterhead Guard

Guard Post

Manual

Q’ty

1

2

2

4

2

2

1

2

6

2

2

2

2

1

1

1

1

1

1

1

1

2

1

2

2

2

2

6

3

1

2

2

2

1

1

2

2

1

1

3

1

1

1

1

1

1

1

1

23

NOTES:

24

WARRANTY

RIKON Power Tools/Richen Enterprise, Inc. (“Seller”) warrants to only the original retail consumer/

purchaser of our products that each product be free from defects in materials and workmanship for a

period of two (2) years from the date the product was purchased at retail. This warranty may not be

transferred.

This warranty does not apply to defects due directly or indirectly to misuse, abuse, negligence,

accidents, repairs, alterations, lack of maintenance or normal wear and tear. Under no

circumstances will Seller be liable for incidental or consequential damages resulting from defective

products. All other warranties, expressed or implied, whether of merchantability, fitness for

purpose, or otherwise are expressly disclaimed by Seller. This warranty does not cover products

used for commercial, industrial or educational purposes.

2-Year Limited Warranty

This limited warranty does not apply to accessory items such as blades, drill bits, sanding discs or

belts and other related items.

Seller shall in no event be liable for death, injuries to persons or property, or for incidental,

contingent, special, or consequential damages arising from the use of our products.

To take advantage of this warranty proof of purchase documentation, which includes date of

purchase and an explanation of the complaint, must be provided.

The Seller reserves the right to effect at any time, without prior notice, those alterations to parts,

fittings, and accessory equipment which they may deem necessary for any reason whatsoever.

To take advantage of this warranty, please fill out the enclosed warranty card and send it to:

RIKON Warranty

110Cummings Park

Woburn, MA 01801

The card must be entirely completed in order for it to be valid. If you have any questions

please contact us at 877-884-5167 or warranty@rikontools.com.

25

For more information:

110 Cummings Park

Woburn, MA 01801

877-884-5167 / 781-933-8400

techsupport@rikontools.com

www.rikontools.com

Copyright Richen Enterprise, Inc. 2006

Printed in China 5/06

Loading...

Loading...