RIKON Power Tools 20-100 User Manual

6” Jointer with Center Mount Fence

Model: 20-100

Part #20-100M1

Owner’s Manual

Record the serial number and date of purchase

in your manual for future reference.

Serial number:

Date of purchase:

For more information:

www.rikontools.com or info@rikontools.com

For Parts or Questions:

techsupport@rikontools.com or 877-884-5167

Operator Safety: Required Reading

IMPORTANT! Safety is the single most important consideration in the operation of this equipment. The following

instructions must be followed at all times.

There are certain applications for which this tool was designed. We strongly recommend that this tool not be modified and/or

used for any other application other than that for which it was designed. If you have any questions about its application, do

not use the tool until you have contacted us and we have advised you.

General Safety Warnings

KNOW YOUR POWER TOOL. Read the owner’s manual carefully. Learn the tool’s applications, work

capabilities, and its specific potential hazards.

ALWAYS GROUND ALL TOOLS.

If your tool is equipped with a three-pronged plug, you must plug it into a three-hole electric receptacle. If

you use an adapter to accommodate a two-pronged receptacle, you must attach the adapter plug to a

known ground. Never remove the third prong of the plug.

ALWAYS AVOID DANGEROUS ENVIRONMENTS.

Never use power tools in damp or wet locations. Keep your work area well lighted and clear of clutter.

ALWAYS REMOVE THE ADJUSTING KEYS AND WRENCHES FROM TOOLS AFTER USE.

Form the habit of checking to see that keys and adjusting wrenches are removed from the tool before

turning it on.

ALWAYS KEEP YOUR WORK AREA CLEAN. Cluttered areas and benches invite accidents.

ALWAYS KEEP VISITORS AWAY FROM RUNNING MACHINES.

All visitors should be kept a safe distance from the work area.

ALWAYS MAKE THE WORKSHOP CHILDPROOF.

Childproof with padlocks, master switches, or by removing starter keys.

NEVER OPERATE A TOOL WHILE UNDER THE INFLUENCE OF DRUGS, MEDICATION,

OR ALCOHOL.

ALWAYS WEAR PROPER APPAREL.

Never wear loose clothing or jewelry that might get caught in moving parts. Rubber-soled footwear is

recommended for the best footing.

ALWAYS USE SAFETY GLASSES AND WEAR HEARING PROTECTION.

Also use a face or dust mask if the cutting operation is dusty.

NEVER OVERREACH.

Keep your proper footing and balance at all times.

NEVER STAND ON TOOLS.

Serious injury could occur if the tool is tipped or if the cutting tool is accidentally contacted.

2

ALWAYS DISCONNECT TOOLS.

Disconnect tools before servicing and when changing accessories such as blades, bits, and cutters.

ALWAYS AVOID ACCIDENTAL STARTING.

Make sure switch is in “OFF” position before plugging in cord.

NEVER LEAVE TOOLS RUNNING UNATTENDED.

ALWAYS CHECK FOR DAMAGED PARTS.

Before initial or continual use of the tool, a guard or other part that is damaged should be checked to

assure that it will operate properly and perform its intended function. Check for alignment of moving parts,

binding of moving parts, breakage of parts, mounting, and any other conditions that may affect its

operation. A guard or other damaged parts should immediately be properly repaired or replaced.

Special Safety Rules For Jointers

Always keep cutter head and drive guards in place and in proper operating

condition.

NEVER make a jointing, planning, or rabbeting cut deeper than 1/8"

Do not perform jointing operations on material shorter than 10", narrower than 3/4", or

less than 1/2" thick.

Support the work piece adequately at all times during operation; maintain control

of the work at all times.

Do not back the work toward the in-feed table.

Do not attempt to perform an abnormal or little-used operation without study and

the use of adequate hold downs/push blocks jigs, fixtures, stops, and the like.

SAVE THESE INSTRUCTIONS.

Refer to them often.

3

Table of Contents

Safety Warnings....................................................................................................................................2

Jointer Safety Rules ..........................................................................................................................3

Specifications ........................................................................................................................................4

Contents of Package ............................................................................................................................5

Unpacking and Setup ...........................................................................................................................5

Loose Parts ...........................................................................................................................................6

Getting To Know Your Jointer ............................................................................................................7

Assembly ..............................................................................................................................................8

Installing Bed to Stand .....................................................................................................................................8

Installing V Belt .............................................................................................................................8

Belt Guard.................................................................................................................................................9

Install Fence Bed Casting ...........................................................................................................................9

Installing Fence to Bed .....................................................................................................................................9

Installing Handwheels .......................................................................................................................10

Installing Depth Lock Handle ............................................................................................................10

Installing Depth Limiting Stop ............................................................................................................10

Installing Cutterhead Guard .......................................................................................................................10

Installing Access Cover ................................................................................................................................11

Installing Dust Chute ............................................................................................................................................11

90 Degree Fence Adjustment......................................................................................................................11

45 Degree Fence Adjustment.........................................................................................................................12

Setting Outfeed Table....................... ............................................................................................................13-14

Operation ...............................................................................................................................15-21

Maintenance..................................................................................................................22

Wiring Diagram ...................................................................................................................................22

Troubleshooting ..................................................................................................................................23

Parts Diagram ................................................................................................................................24-30

Parts List ........................................................................................................................................24-30

Warranty .............................................................................................................................................31

Cutting Capacity

Cutterhead Speed

Number of Knives

Cuts per Minute

Rabbeting Capacity

Rabbet Ledge

Infeed Table Length

Outfeed Table Length

Table Surface

Fence

Blade Size

Fence Tilts Right & Left

Positive Stops

Motor Input

1-1/2HP,1Ph, 115/230V, Prewired 115V

Net Weight

Specifications

7-1/4”W x 45-3/4”L x 31-1/2”H

4-3/4”H x 29-1/8”L

6-1/8”L x 5/8”H x 1/8”D

4

6”W x 1/2”D

4,800 RPM

14,400 CPM

1/2”

3-1/8” x 8-3/4”

22”

22-1/2”

45

45o, 90

215 lbs

3

o

o

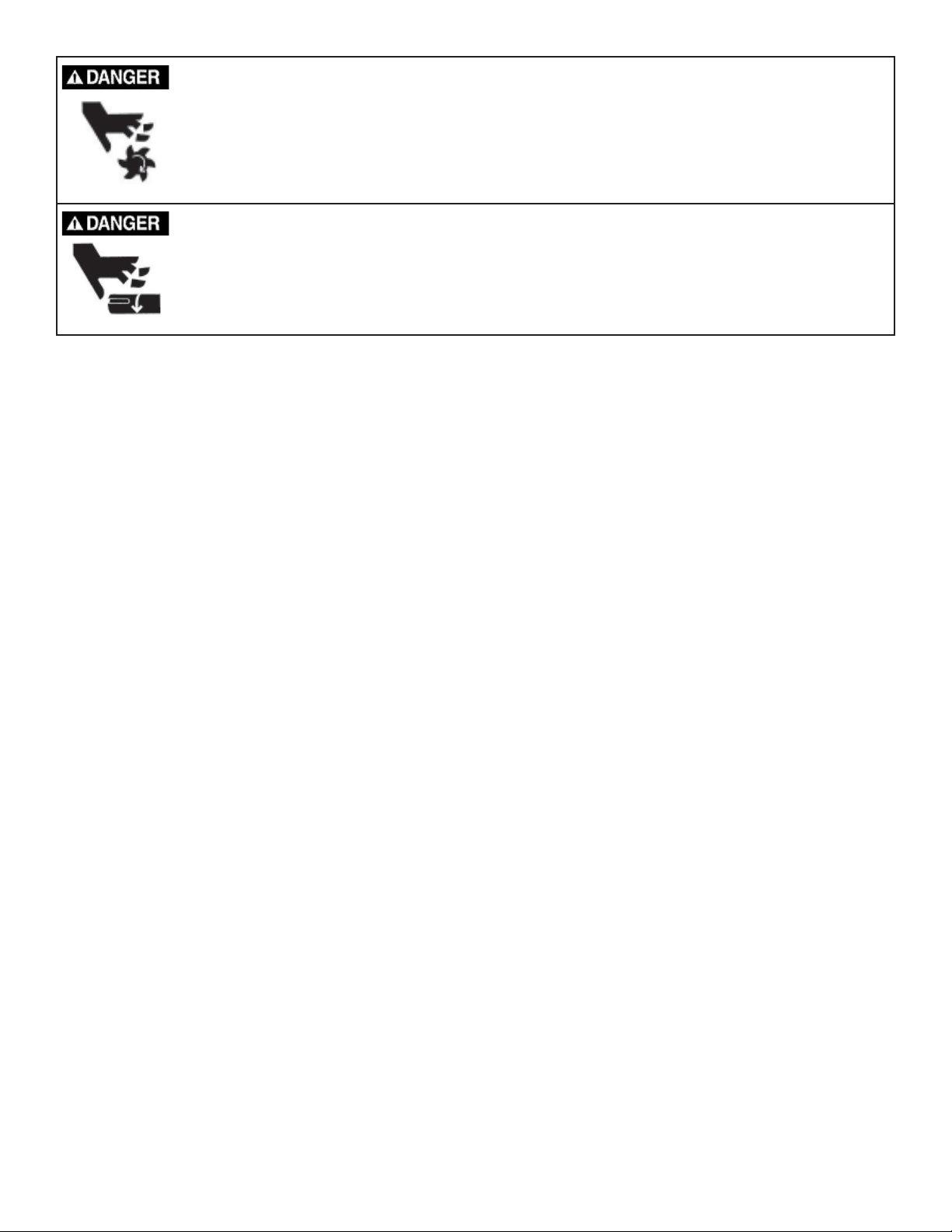

Unpacking and Checking Contents

The 20-100 RIKON 6” Jointer is shipped in two cartons.

Stand Carton

1 Stand with Motor

1 Stand Door

1 Dust Chute

1 “V-Belt”

1 Belt Guard

Main Unit Carton

1 Bed Assembly

1 Fence Assembly

1 Switch Assembly w/support

1 Cutter Guard

2 Push Blocks

1 Owner’s Manual w/ Warranty Card

1 Fence Base Casting

2 Hand Wheels

2 Fence Handles

2 Loose Bags

Loose Parts in Bag 1

1 Fence Lock Handle Assembly

1 Depth Limiting Stop

5

Loose Parts in Bag 2

3 3/8” Flat Washers

3 3/8” Lock Washers

3 Mounting Bolts

1 3mm Hex Wrench

1 5mm Hex Wrench

1 8/10mm Open End Wrench

1 12/14mm Open End Wrench

2 1/8” Flat Washers

6 1/8”x3/8” Pan Head Screws

1 Blade Adjust Tool

Tools Required for Assembly

Philips Head Screwdriver, Adjustable Wrench, 14mm Open End Wrench and a metric socket set.

Unpacking Carton and Cleaning

1. Carefully remove all contents from both shipping cartons. Compare contents of the shipping cartons

with the list of contents in this manual. Place parts on a protected surface.

2. Report any shipping damage to your local distributor.

3. Clean all rust protected surfaces (bed, fence, etc.) with a parts cleaning solvent or WD40.

Do not use; gasoline, paint thinner, mineral spirits, etc. as these may damage painted surfaces.

Caution: Cutterhead blades are extremely sharp! Use care when cleaning!

4. Apply a thin layer of paste wax to the milled surfaces of the fence and tables to prevent rust.

5. Set packing material and shipping cartons to the side. Do not discard until machine has been set

up and is running properly.

6

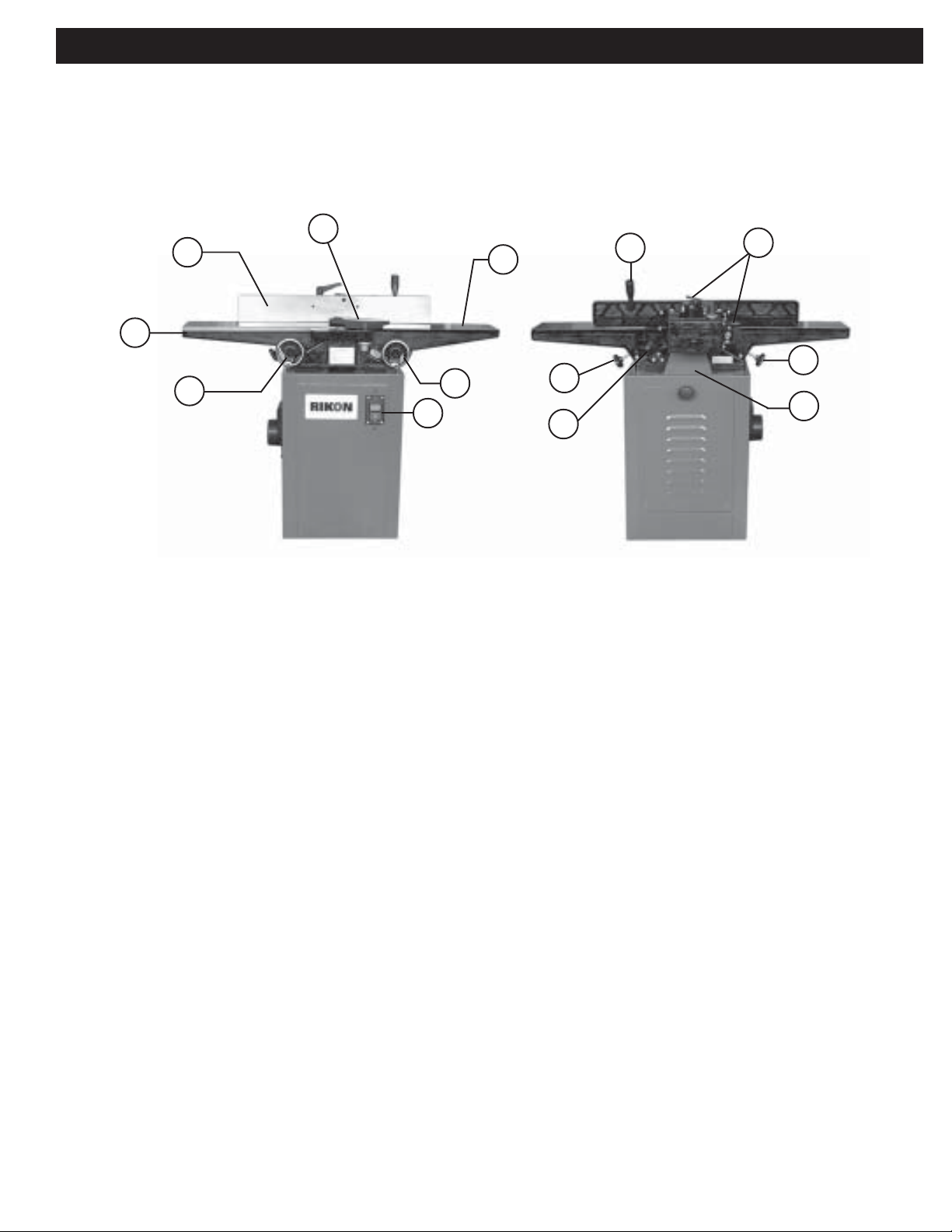

Getting to Know Your Jointer

5

3

2

1

1. Hand Wheel for Out-feed Table

2. Out-feed Table

3. Fence

4. Fence Adjustment Handle

5. Cutter Guard

6. In-feed Table

7. Hand Wheel for In-feed Table

7

8

6

13

12

8. On/Off Switch

9. Out-feed Table Lock Knob

10. Belt Guard

11. Fence Adjustment Lock Handle

12. Depth Limiter

13. In-feed Table Lock Knob

4

11

9

10

7

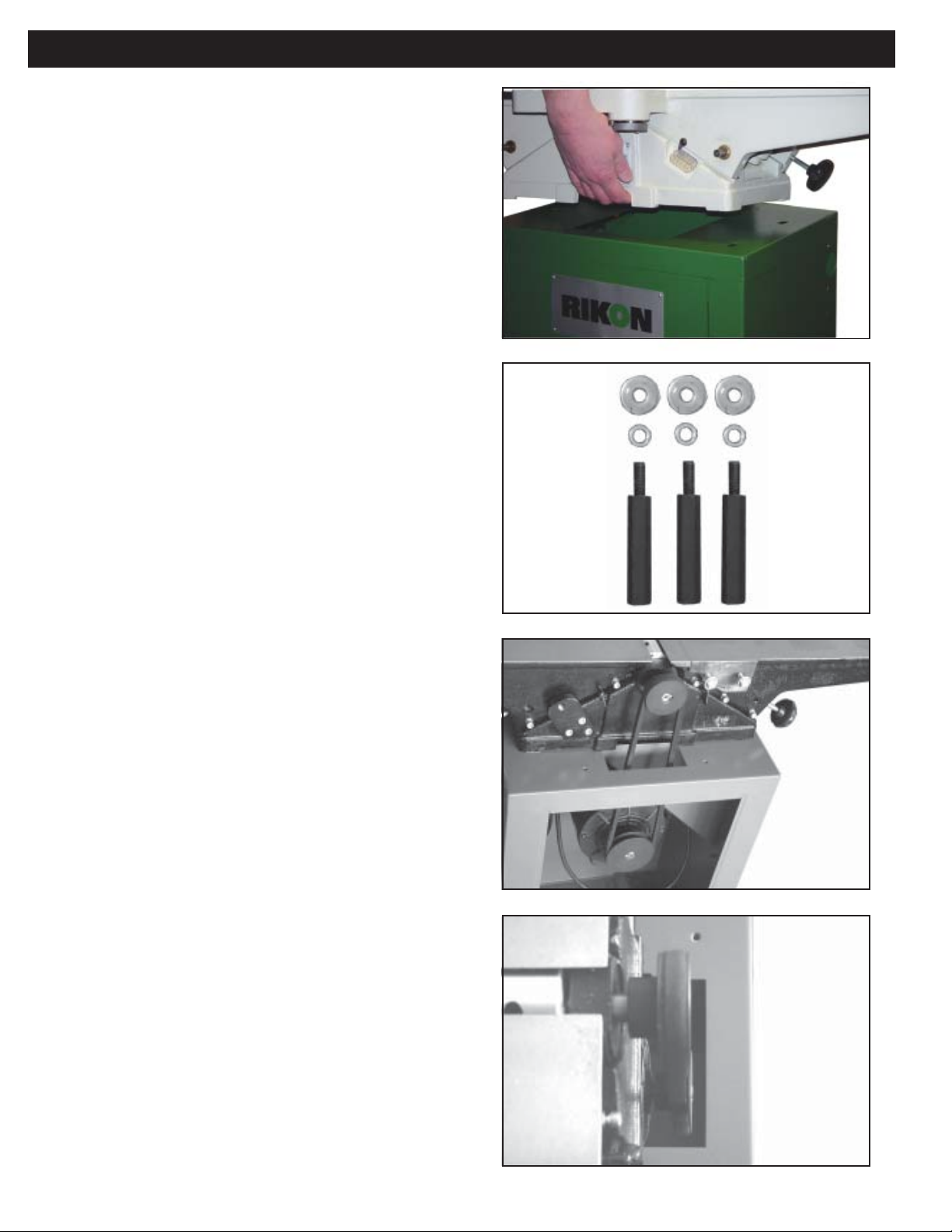

Installing Bed to Stand

1. Remove rear door on cabinet.

2. Place bed assembly on top of stand, making

sure the pulleys face the rear of the cabinet.

Ask a friend for assistance with this step. (DO

NOT LIFT BY TABLE ENDS, LIFT FROM

CENTER OF CASTING) (Fig. 1)

3. Line up the two holes in stand top with holes

in the bed assembly by viewing through rear

access door in stand.

4. Attach stand to bed assembly by using two

3/8" lock bolts spring washers and washers.

(See Fig. 2) Hand tighten only at this time.

5. Line up third hole in stand with hole in bed

assembly by viewing through dust chute.

6. Install third 3/8" lock bolt and washer through

dust chute to secure bed to stand. DO NOT

tighten at this time.

Assembly

Figure 1

Installing the V-Belt

1. Place the “V-Belt” on the cutter-head pulley

and through the opening in the cabinet and

onto the motor pulley. (Fig. 3)

2. If necessary loosen the motor mounting

screws to raise the motor.

3. Check to verify the motor pulley and the cutterhead pulley are aligned vertically, and the “VBelt” does not touch the cabinet. To adjust the

pulleys, loosen the motor mounts and slide the

motor in or out or loosen the three 3/8” lock

bolts and move the jointer top.

(Fig. 4)

4. Tighten all three lock bolts (from Assembly

Section #4 & #6 above) using 14mm or 9/16”

wrench.

5. Tension the “V-Belt”. A properly tensioned belt

should have 1/2" deflection when finger

pressure is applied half way between the two

pulleys.

Figure 2

Figure 3

6. Re-check the “V-Belt” tension after 2

hours of use. Re-tension as needed.

Figure 4

8

Installing Belt Guard

1. Place the belt guard (A-Fig. 6) over the belt

opening in the stand.

2. Line up the holes in the stand with the holes in

the guard.

3. Attach the guard to the stand using two 1/4-

20x1/2" pan head screws and two 1/4" lock

washers. (B-Fig. 6) Make sure belt is clear of

the guard.

Assembly

A

B

Figure 6

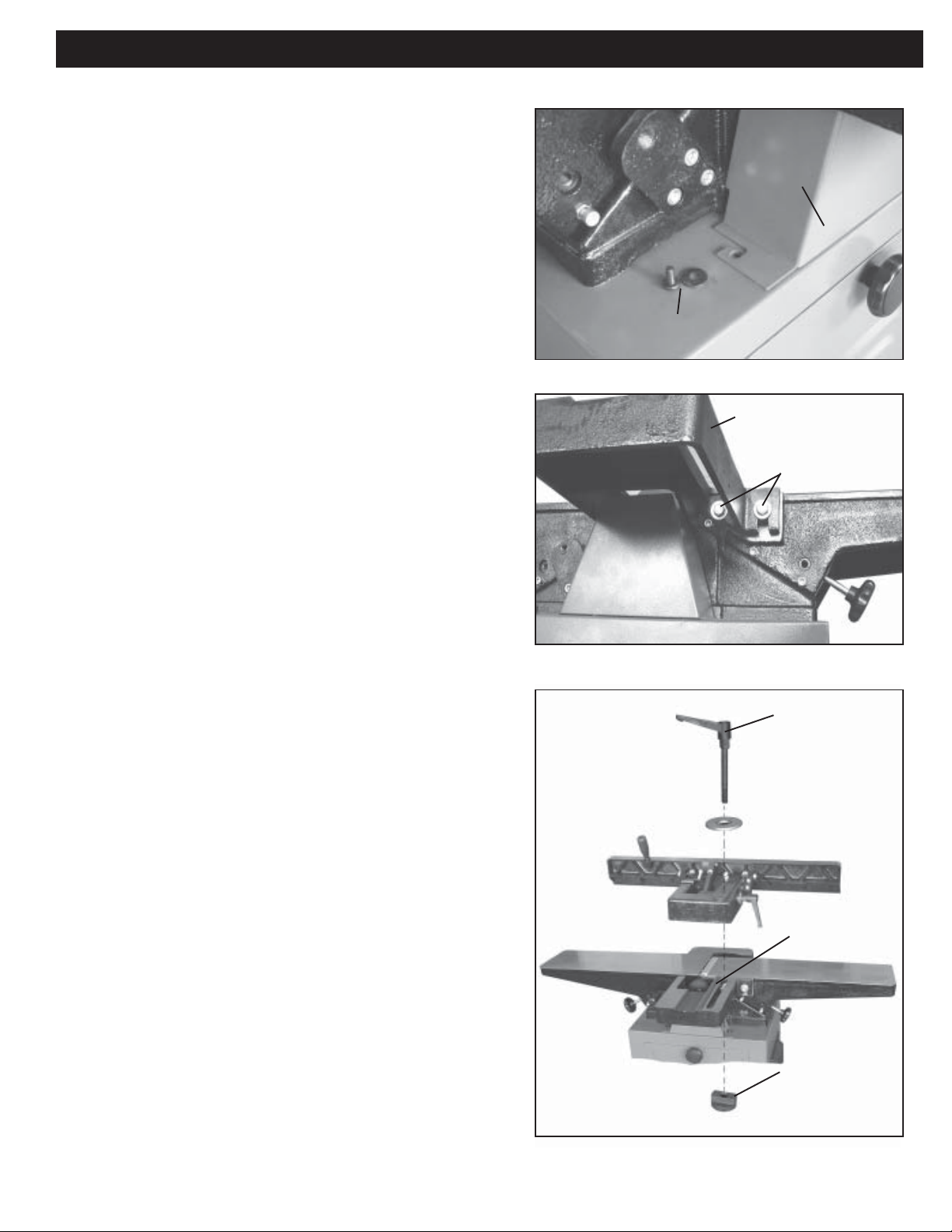

Install Fence Bed Casting

1. Use two 3/8" x 1-1/2" hex socket bolts and

washers (A-Fig. 7) to attach the fence bed

casting (B-Fig. 7) to the outfeed table bed

using 13mm socket wrench.

2. Align top of the fence base casting flush with

the table surface and tighten.

Installing Fence to Bed

1. Remove the lock handle (A- Fig. 8), flat

washer, and lock nut from the carton.

2. Place the fence assembly onto the table. Be

sure key stock (B- Fig. 8) on the bed lines up

with channel in the fence casting.

B

A

Figure 7

A

3. Place the flat washer and insert the lock

handle through the fence casting and the table

casting.

4. Thread the special nut onto the lock handle.

Make sure the tab on the nut faces up and

engages the slot in the table casting. (C-Fig.

8)

B

C

Figure 8

9

Assembly

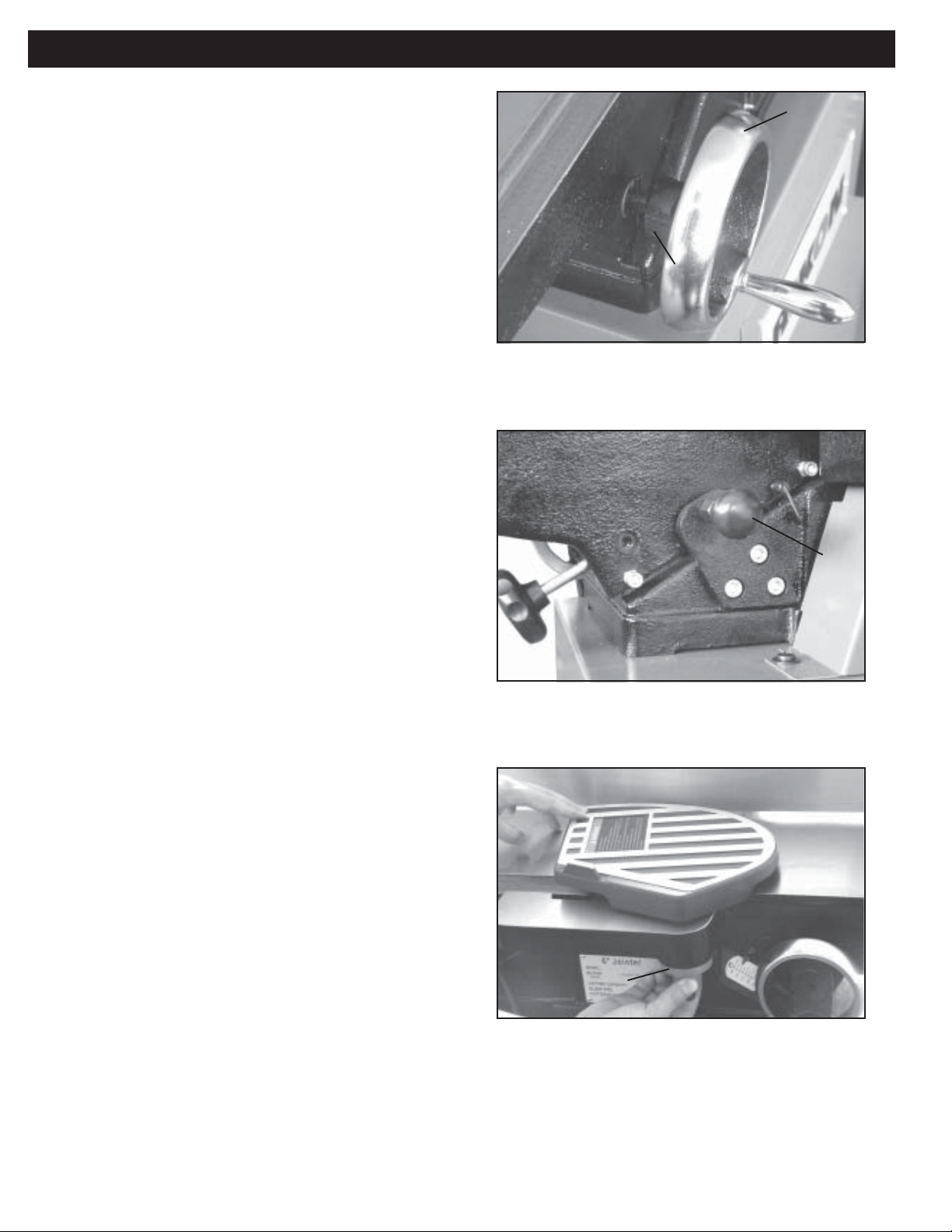

Installing Handwheels

1. Press handwheels (A-Fig. 9) onto shaft,

aligning the slot in the handle with the pin on

the shaft. If necessary, use a hammer with a

block of wood to tap the handwheel

completely onto the shaft.

2. Tighten set screw, (B-Fig. 9).

Depth Limiting Stop

1. Attach depth limiting stop. Thread stop into

steel plate at the rear of the infeed table.

(A- Fig. 10)

A

B

Figure 9

A

Installing Cutter-Head Guard

1. Turn spring knob (A-Fig. 11) approximately

one and one half revolutions counterclockwise and hold.

2. Insert guard post into hole in table. Make sure

spring engages slot in guard post.

3. Check for proper operation. Guard must

return fully to fence when released. If guard

does not return fully, remove guard, apply

more tension to spring knob by turning it

another half turn counter-clockwise, and reinsert guard. If guard closes too quickly and

strikes fence too hard, release some tension

on the spring.

Figure 10

A

Figure 11

10

Loading...

Loading...